TubeHead

Model 9305

Assembly and Using Manual

If you love vacuum tubes, here’s a device that’s

got your name on it. The TubeHead is a low-cost,

two-channel vacuum tube pre-amplifier with a

twist. The twist is that this circuit is designed

to be adjustable from crisp solid-state

transparency to an exaggerated caricature of tube

amp warmth. In between these extremes, you’ll

find tonal coloring options than you’ve never had

before and sounds that mimic every tube amp you

ever heard. This circuit is so versatile that you

may use it in place of compressors, limiters and

sustainers even though, technically, it is none of

these.

(c) 1993 PAiA Electronics, Inc.

Portions of this document are excerpted from

an article in the December 1993 issue of

Electronic Musician magazine, copyright 1993,

and are reprinted by permission of the Publisher.

TubeHead 1

ASSEMBLING THE TubeHead

Before beginning assembly, go through the manual.

Look at the drawings. Feel the parts. You’re

naturally eager to plunge right in, but take a few

deep breaths first.

Notice that each step in the manual is marked with

a checkoff box like this:

DESIGNATION VALUE COLOR CODE

( ) R27 100 ohm brown-black-brown

Checking off each step as you do it may seem

silly and ritualistic, but it greatly decreases the

chance of omitting a step and also provides

some gratification and reward as each step is

completed.

Numbered figures are printed in the Illustrations

Supplement in the center of this manual. These pages

may be removed for easy reference during assembly.

THE CIRCUIT BOARD

The TubeHead is built on a single-sided circuit

board. Before beginning assembly, clean oxidation

from the copper side of the circuit board using

scouring cleanser and water. The copper should be

bright and shiny before beginning assembly.

Once you begin putting parts on the circuit board,

it’s a good idea to continue until all the parts

are mounted. Stopping overnight may allow the

copper to oxidize and make soldering more difficult.

TOOLS

You’ll need a minimum of tools to assemble the kit

- a small pair of diagonal wire cutters and pliers,

screwdriver, sharp knife, ruler, soldering iron and

solder.

Modern electronic components are small (in case you

hadn’t noticed) and values marked on the part are

often difficult to see. Another handy tool for

your bench will be a good magnifying glass. Also

2 TubeHead

use the magnifier to examine each solder joint as

it is made to make sure that it doesn’t have any of

the problems described in the SOLDERING section

which follows.

SOLDERING

Select a soldering iron with a small tip and a

power rating not more than 35 watts. Soldering

guns are completely unacceptable for assembling

solid state equipment because the large magnetic

field they generate can damage components.

Use only rosin core solder (acid core solder is for

plumbing, not electronics work). A proper solder

joint has just enough solder to cover the soldering

pad and about 1/16-inch of lead passing through it.

There are two improper connections to beware of:

Using too little solder will sometimes result in a

connection which appears to be soldered when

actually there is a layer of flux insulating the

component lead from the solder bead. This

situation can be cured by reheating the joint and

applying more solder. If too much solder is used

on a joint there is the danger that a conducting

bridge of excess solder will flow between adjacent

circuit board conductors forming a short circuit.

Accidental bridges can be cleaned off by holding

the board upside down and flowing the excess solder

off onto a clean, hot soldering iron.

Use care when mounting all components. Never force

a component into place.

TubeHead 3

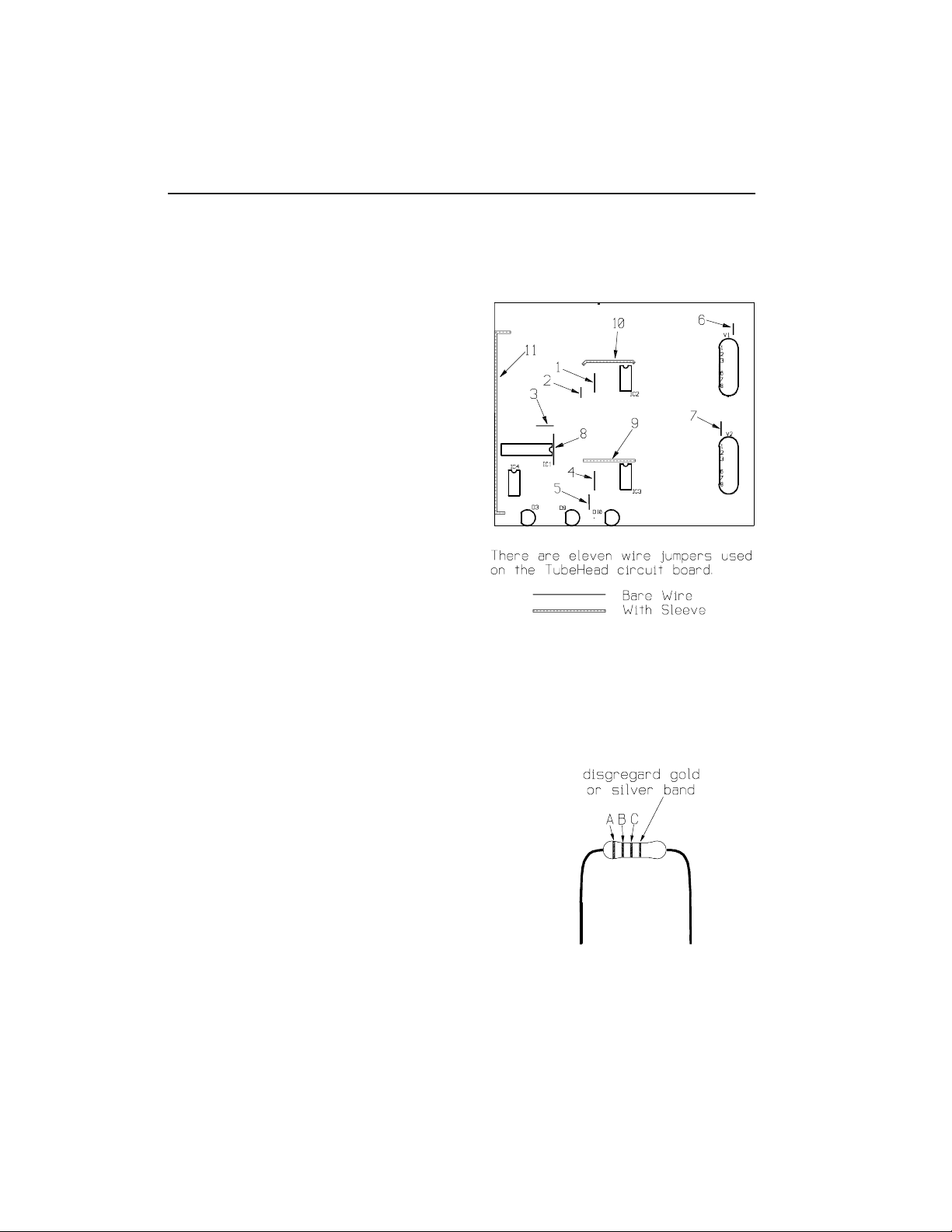

WIRE JUMPERS

Assembly begins by forming and installing the

eleven wire jumpers indicated by bold lines on the

circuit board parts placement designators and the

illustration to the right. For each jumper,

cut a length of the bare wire supplied by

measuring it against the distance between the

circuit board holes and adding about 1/2". Bend

1/4" of each end down and push through the circuit

board holes. Press the jumper fully against the

board and solder both ends. Trim off excess wire

flush with the solder joint.

Notice that three of the jumpers will be covered

with the insulating sleeving provided. Cut a

piece of sleeving slightly shorter than the

distance between the holes and slip it over the

jumper before bending the wire ends down and

placing.

( ) As outlined above, form and install the

eleven wire jumpers used on the circuit

board.

RESISTORS

Solder each resistor in place following the

parts placement designators printed on the circuit

board and the assembly drawing Fig 1. Note that

resistors are nonpolarized and may be mounted with

either lead in either of the corresponding holes.

Before mounting each resistor, bend its leads so

that they are at a right angle to the body of the

part. Put the leads through the holes and then

push the resistor firmly into place. Cinch the

resistor in place by bending the leads on the

solder side of the board out to an angle of about

45 degrees. Solder both ends of each resistor in

place as you install it. Clip each lead flush

with the solder joint as the joint is made.

4 TubeHead

DESIGNATION VALUE COLOR CODE A-B-C

( ) R1 100 ohm brown-black-brown

( ) R3 100 ohm brown-black-brown

( ) R4 33K orange-orange-orange

( ) R5 33K orange-orange-orange

( ) R12 22K red-red-orange

( ) R22 330 ohm orange-orange-brown

( ) R27 150K brown-green-yellow

( ) R28 8200 grey-red-red

( ) R29 1K brown-black-red

( ) R40 22K red-red-orange

( ) R50 330 orange-orange-brown

( ) R55 150K brown-green-yellow

( ) R56 8200 grey-red-red

listed below: 10K brown-black-orange

( ) R6 ( ) R30 ( ) R33

( ) R34 ( ) R61

listed below: 100K brown-black-yellow

( ) R9 ( ) R37 ( ) R62

( ) R63

listed below: 270K red-violet-yellow

( ) R10 ( ) R11 ( ) R38

( ) R39

listed below: 82K grey-red-orange

( ) R13 ( ) R14 ( ) R41

( ) R42

listed below: 470K yellow-violet-yellow

( ) R17 ( ) R25 ( ) R45

( ) R53

listed below: 47K yellow-violet-orange

( ) R19 ( ) R21 ( ) R26

( ) R47 ( ) R49 ( ) R54

TubeHead 5

DESIGNATION VALUE COLOR CODE A-B-C

listed below: 2700 red-violet-red

( ) R31 ( ) R32 ( ) R59

( ) R60

The following resistors are installed vertically

on the circuit board.

( ) R2 330 ohm orange-orange-brown

( ) R57 100 ohm brown-black-brown

( ) R58 100 ohm brown-black-brown

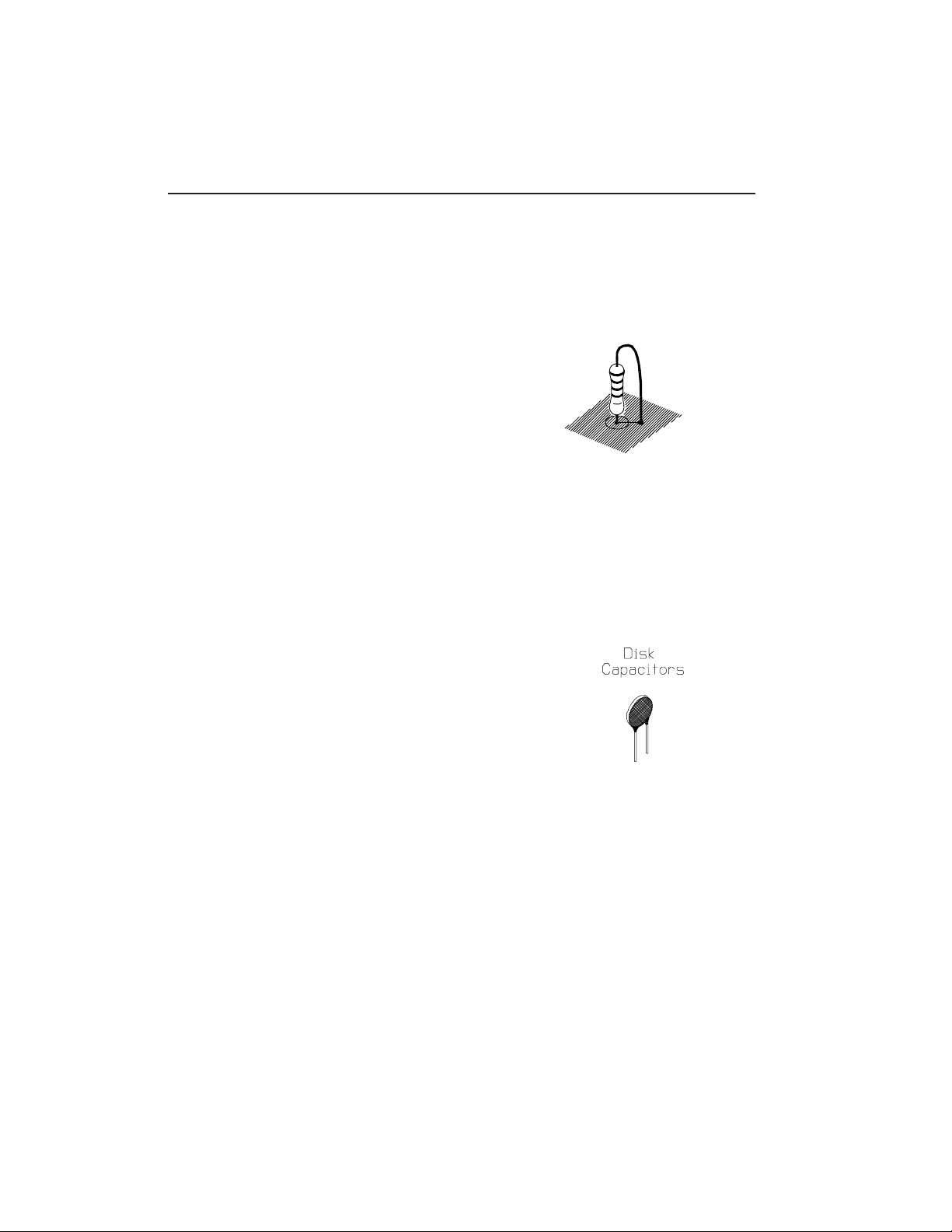

CERAMIC DISK CAPACITORS

Some of the capacitors used in the TubeHead are

non-polarized ceramic disks, either lead can go in

either of the holes on the circuit board. Leads

are already parallel to one another but still may

need to be bent slightly to match the spacing of

the circuit board holes. Like the resistors, push

the leads through the holes in the board and push

the part against the circuit board as far as it

wants to go. Don’t force it, it’s OK if it sits a

little off the board.

Capacitors are often marked with obscure codes

that indicate their values. The 1, 2 or 3 digit

number that specifies value may be preceded or

followed by letters indicating such things as

tolerance. If you get confused about which

capacitors are which, it may help to group them by

same type and check them against quantities on the

packing list at the end of this manual.

DESIGNATION VALUE MARKING

( ) C7 220 pF 221

( ) C11 .01 uF 103

( ) C14 20 pF 20

( ) C16 5 pF 5

( ) C20 .05 uF 503

( ) C21 .01 uF 103

( ) C24 20 pF 20

( ) C26 5 pF 5

6 TubeHead

TRIMMER POTENTIOMETERS

Mount the two trimmer potentiometers by inserting

their three pins into the holes provided. Press

them down until the “shoulders” of the solder pins

are resting on the surface of the circuit board.

Solder all three pins on each part

DESIGNATION VALUE

( ) R23 100K

( ) R51 100K

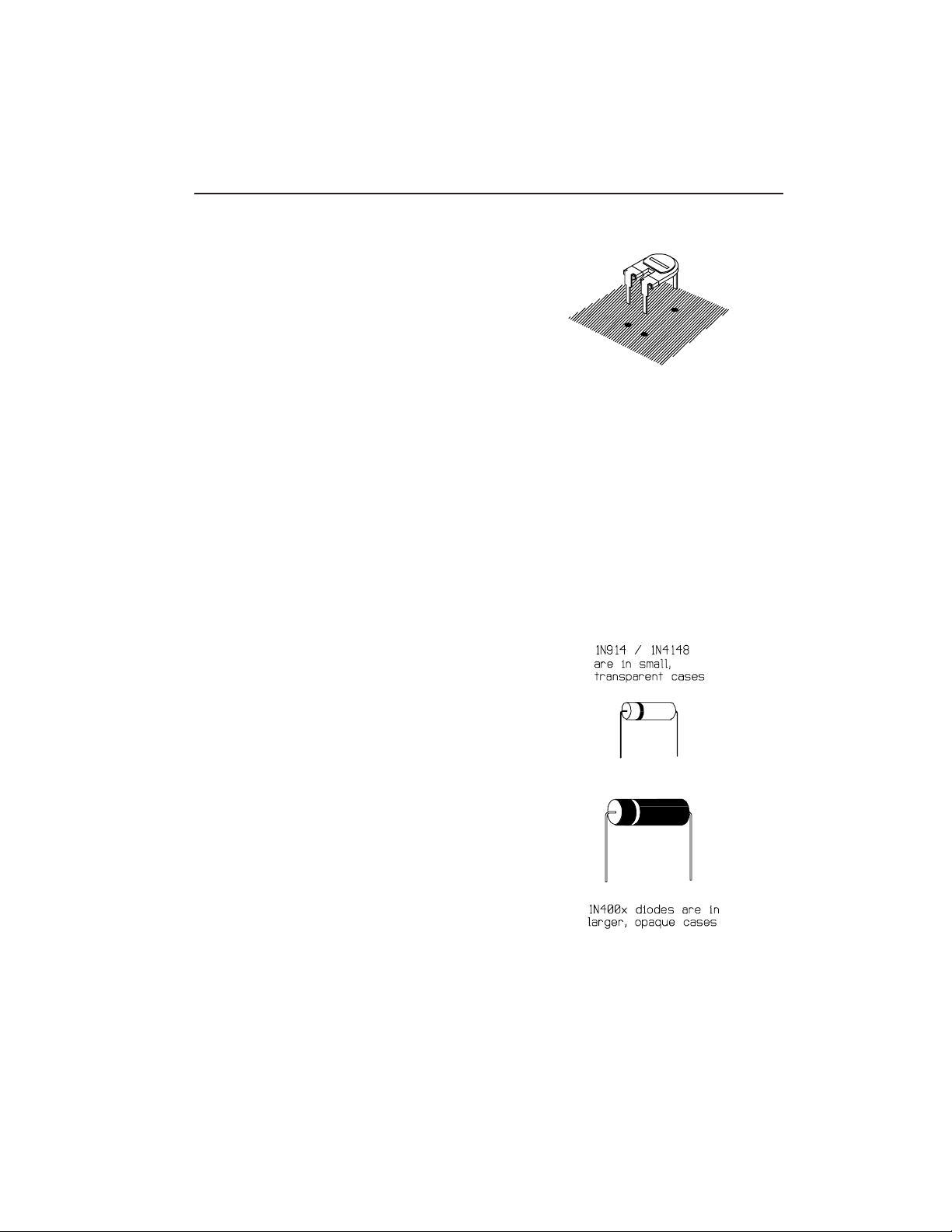

DIODES

Two types of diodes are used in the TubeHead, five

1N4148 silicon signal diodes in small transparent

glass cases and two 1N400x power diodes in larger

opaque cases.

Unlike the previous components, diodes are

polarized and must be installed so that the lead

on the banded end of the part corresponds to the

banded end of the designator on the circuit board.

Bend the leads so they are at right angles to the

body of the part and insert them through the holes

provided in the circuit board.

Diodes are also somewhat heat sensitive so the

soldering operation should be done as quickly as

possible.

DESIGNATION VALUE

( ) D1 1N4001, 1N4002 or 1N4003

( ) D2 “ “ “

listed below: 1N4148 or 1N914

( ) D4 ( ) D5 ( ) D6

( ) D7 ( ) D8

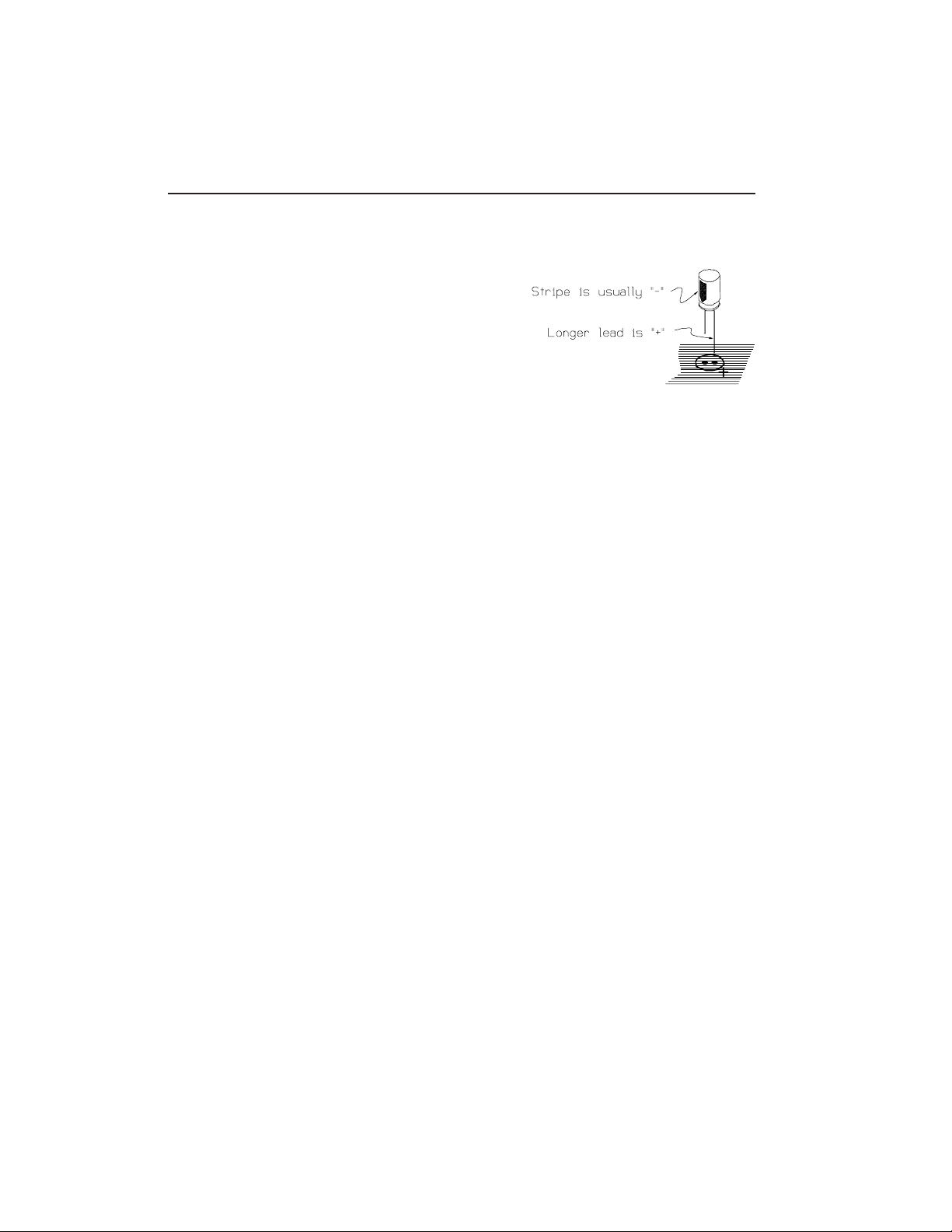

ELECTROLYTIC CAPACITORS

TubeHead 7

The remaining capacitors are electrolytic types.

Like the diodes, electrolytic capacitors are

polarized and the leads are not interchangeable.

Leads are marked “+” and/or “-” and the “+” lead

must go through the “+” hole in the circuit board.

Frequently the positive lead of the capacitor is

significantly longer than the negative lead.

Usually the Negative lead of the capacitor is

marked rather than the positive. It naturally goes

through the hole not marked “+”.

Capacitors supplied with specific kits may have a

higher Voltage (V) rating than the minimum

specified below.

DESIGNATION VALUE

( ) C1 100 uF /25v.

( ) C2 1000 uF /16v.

( ) C3 100 uF /25v.

( ) C4 1000 uF /16v.

( ) C17 2.2 uF /25v.

( ) C27 2.2 uF /25v.

listed below: 33 uF /25v.

( ) C5 ( ) C6 ( ) C8

( ) C9 ( ) C10 ( ) C19

( ) C29

listed below: 1 uF /50v.

( ) C12 ( ) C13 ( ) C15

( ) C18 ( ) C22 ( ) C23

( ) C25 ( ) C28

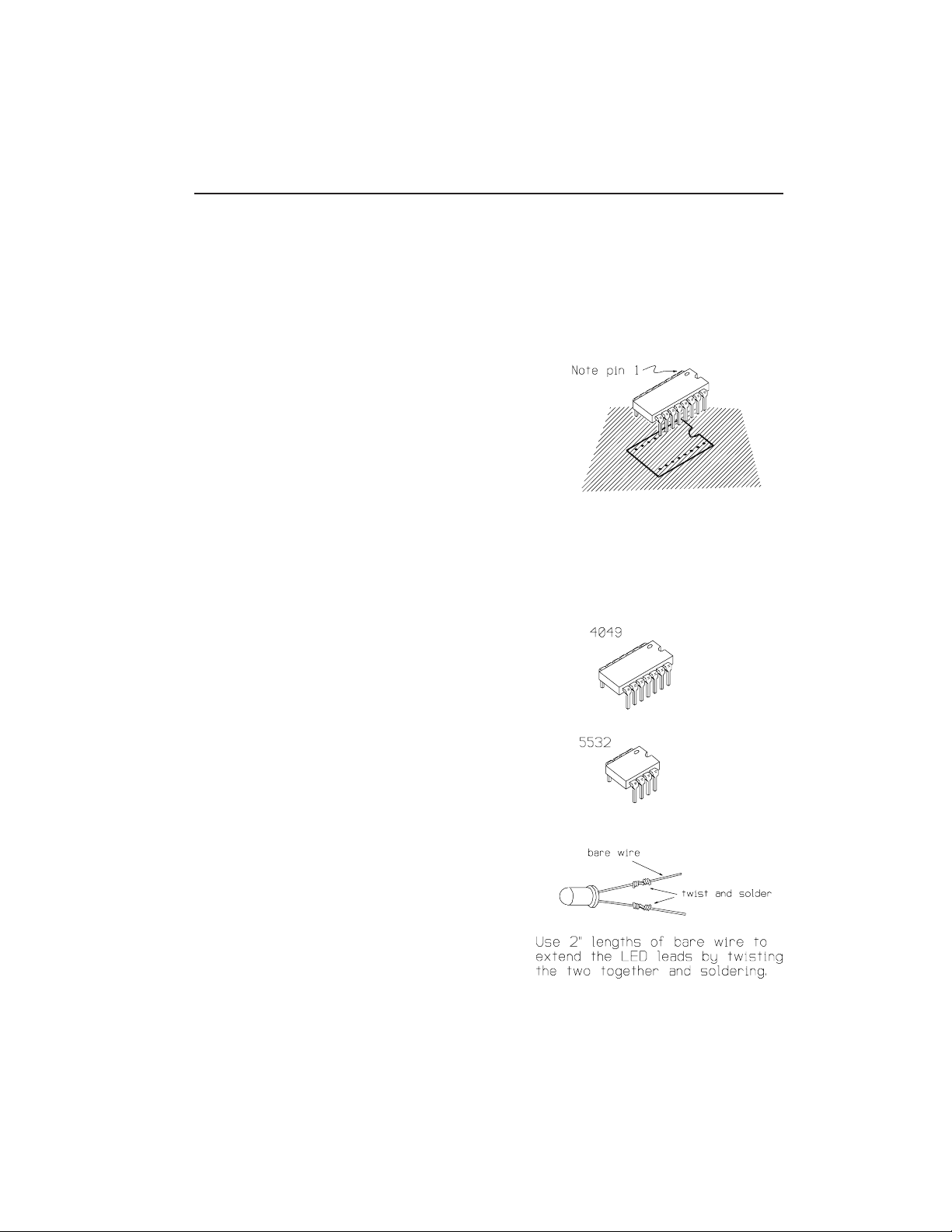

INTEGRATED CIRCUITS

Of all the parts, the ICs are the most easily

damaged and should be treated with some respect.

In particular, they may be destroyed by discharges

of static electricity. Modern ICs are not nearly

as sensitive to this kind of damage as were

8 TubeHead

earlier versions, but it is still good practice to

handle these parts as little as possible. Also

good practice: don’t wear nylon during assembly.

Don’t shuffle around on the carpet immediately

before assembly (or if you do, touch a lamp or

something to make sure you’re discharged). Don’t

be intimidated. It’s rare for parts to be damaged

this way.

ICs are polarized in one or both of two ways; A

dot formed into the case of the IC corresponding

to pin 1 or a semicircular notch that indicates

the end of the package with pin 1. Take care that

this polarizing indicator corresponds to the

similar indicator on the circuit board graphics.

The pins of the ICs may be splayed somewhat and

not match the holes in the circuit board exactly.

Carefully re-form the leads if necessary

so that they are at right angles to the part.

Solder each IC in place as it is installed by

initially soldering two pins in diagonal corners

of the pattern. Make sure that the part is seated

firmly against the pc board by pressing it down

while remelting the solder joint at first one

corner, then the other. Finally, solder the

remaining connections.

DESIGNATION PART NO. DESCRIPTION

( ) IC1 4049 Hex inverting buffer

( ) IC2 5532 Dual low noise op amp

( ) IC3 5532 “

( ) IC4 5532 “

LEDs

When the TubeHead is installed in its case, the

three LEDs will engage the holes in the front

panel and be supported by their leads. Using six

2" lengths of the bare wire, extend the leads of

the LEDs as shown.

TubeHead 9

Loading...

Loading...