Ozito LFG-4100 Instruction Manual

WHAT’S IN THE BOX

CORDLESS

FINISHING

GRINDER

18V Li-ion

INSTRUCTION MANUAL

SPECIFICATIONS

Input: 18V

No Load Speed: 6000 / min

Disc Diameter: 100mm (4”)

Spindle Size: M10

Battery Power: 1.3Ah Li-ion

Charge Time: 3 - 5 Hours

Weight: 2 kg

ozito.com.au

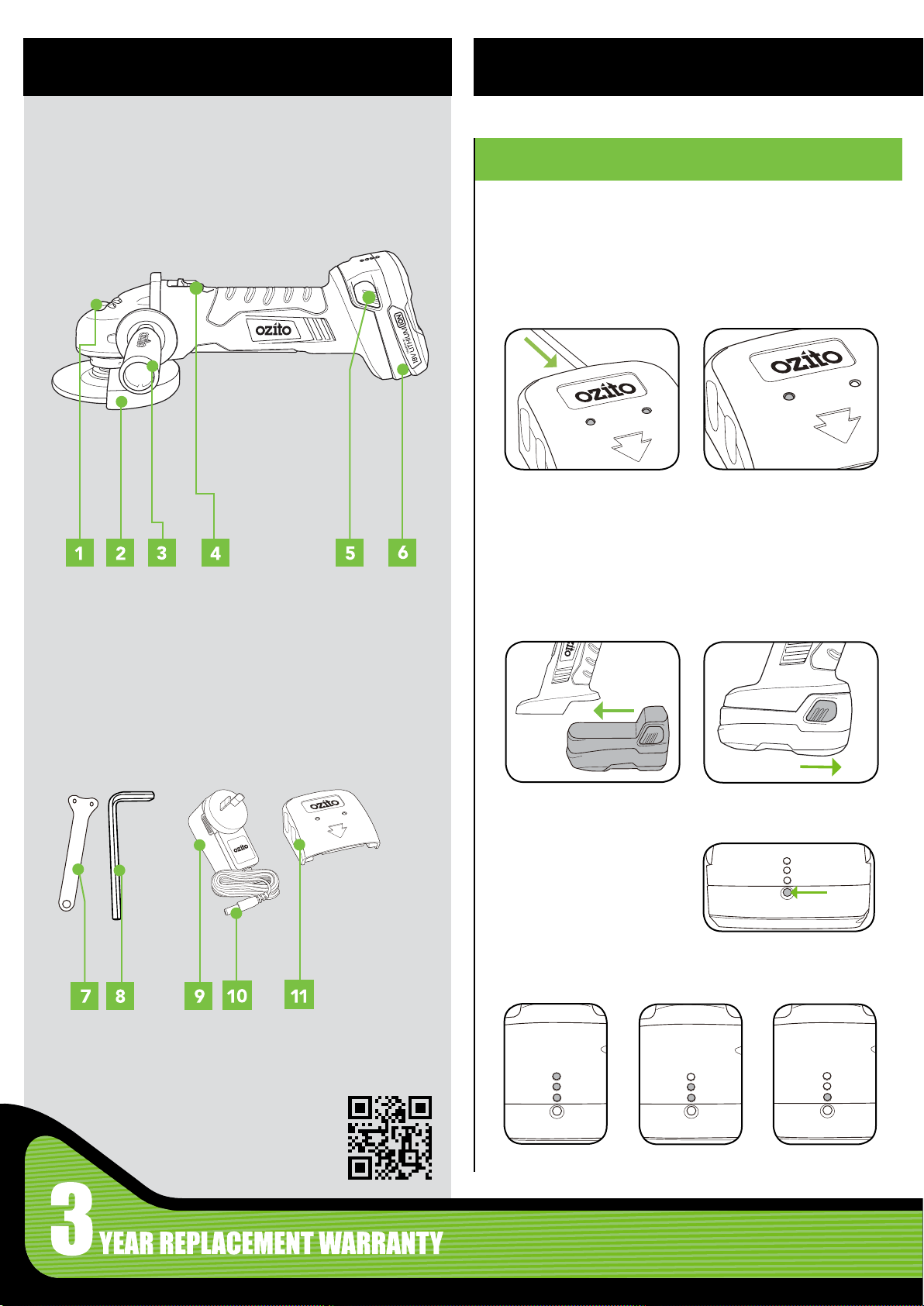

Angle Grinder

18V Battery x 2

Pin Spanner

Allen Key

Charging Cradle

Charging Adaptor

LFG-4100

KNOW YOUR PRODUCT

SETUP & PREPARATION

CORDLESS FINISHING GRINDER

1. Spindle Lock

2. Adjustable Safety Guard

3. Side Handle

4 Lock On Slide Switch

5 Battery Release Button

6 18V Battery

1. BATTERY

This charger is recommended for use with a residual current

device with a rated residual current of 30mA or less.

Charging

1. Plug charging jack into

charging cradle. Both

lights will illuminate when

connected.

Note: Once fully charged, both the red and green lights will

illuminate.

Installing and Removing

Slide the battery into the

grinder base until it clicks into

place.

2. Slide cradle onto the battery.

Only the red light will be

illuminated when properly

connected and charging.

Hold down the battery release

buttons and slide the battery

out.

ACCESSORIES

7 Pin Wrench

8 Hex Key

9 Charging Adaptor

10 Charging Jack

11 Charging Cradle

Battery Indicator

1. Depress the battery

indicator button.

2. Observe which lights illuminate for a reading on your battery’s

charge.

ONLINE MANUAL

Scan this QR Code with your

mobile device to take you to

the online manual.

Charged

Low Charge

Flat

2. SIDE HANDLE & GUARD

Side Handle

The side handle can be tted on either side of your grinder. The

correct position will be determined by your preferred hand and the

operation being performed.

Attaching

1. Firmly attach the

side handle in the

desired position on

the grinder.

Removing

2. Remove the side

handle.

3. GRINDING DISC

Inspect the grinding disc before tment to ensure it is not cracked

or deformed. The grinding disc is suitable for grinding tasks only.

Only use grinding discs with a diameter of 100mm.

1. Depress and hold

spindle lock button.

2. Rotate spindle to locate

the lock position.

Safety Guard

The safety guard should be used at all times whilst operating the

nishing grinder.

Attaching

1. Loosen guard bolt, align tabs and

rotate guard to the required position.

Removing

3. Loosen guard bolt.

2. Tighten guard

bolt.

3. Use pin spanner to

loosen the outer ange.

5. Screw the outer ange onto the spindle.

Note: the ring on the ange must locate within the hole on the

grinding disc.

6. Depress and hold spindle

lock button. Firmly tighten

the outer ange with the

pin spanner.

4. Insert the disc with the

label facing up.

4. Align tabs on the guard with slots on the guard collar. Remove

guard.

7. Use the above operation in reverse to remove grinding disc.

CAUTION: REGULARLY CHECK THAT THE OUTER

FLANGE HAS NOT BECOME LOOSE DURING

OPERATION.

Loading...

Loading...