Output Solutions 650 User Manual

User's Manual

C-650 Plus

p

p

A

Acknowledgements

EPSON is a Trademark of Seiko Epson Corporation.

IBM is a Trademark of International Business Machines Cor

ProPrinter is a Trademark of International Business Machines Cor

oration.

oration.

Publication of

Output Solutions GmbH

Talstraße 25

D 51399 Burscheid

Federal Republic of Germany

Pub. No. 602 650

Great care has been taken to ensure that the information in this publication is accurate and

complete. However, should any errors or omissions be discovered or should any user

wish to make suggestions for improving this manual, please feel encouraged to send us the

relevant details.

The contents of this manual are subject to change without notice.

Copyright © by Output Solutions GmbH.

All rights strictly reserved. Reproduction or

permitted without written authorization from the publisher.

February 2006

issue to third parties in any form is not

Safety Regulations

The printer C-650 Plus

computer systems.

fulfill the safety regulations according to DIN EN 60950-1 for

The mains cable must be connected to a ground protected wall-socket. The selected

voltage of the printer needs to fit to the local voltage.

The power plug must be easily accessible at any time so that it can be disconnected

immediately in case of danger or for maintenance purposes.

Comme le câble de secteur sert de dipositif d'arrêt-urgence, sa connexion à l'imprimante

doit être tout le temps accessible.

Before installing the printer, check the surrounding conditions in which the printer will be

placed (see next page, Operating Environment).

During a thunderstorm you should never attempt to connect or disconnect any data

transfer cables.

The power supply should only be opened and checked by authorized personnel. Repairs

and maintenance may only be attempted by authorized personnel as well. Repairs done

inappropriately may cause damage and severe danger for the user.

General Installation Precautions

To ensure optimum printer functionality and to avoid making service calls for problems

that are not directly caused by the product itself, bear in mind the information provided in

the following sections.

Electrical Power Supply

Make sure that the electrical wall outlet to which the printer is connected has a valid

ground and that it is able to supply the power needed by the machine. A wall outlet

without ground can cause functional problems and can be a safety hazard.

Do not plug the printer to electrical wall outlets that are already being used by equipment

that could cause electrical noise and excessive voltage fluctuations (fans and air

conditioners, large photocopiers, lift motors, TV radio transmitters and signal generators,

high frequency safety devices, and so on).

Common office equipment (calculating machines, typewriters, small photocopiers,

terminals and personal computers) can share the same outlet as long as they do not

cause excessive electrical noise.

Environmental Conditions

The environmental conditions in which the product can work properly referring to a normal

air-conditioned office environment (environmental temperature of 15 up to 35 °C, relative

humidity of between 15 and 85%).

During machine storage and operation, make sure that condensation does not form as the

result of extreme environmental variations.

Dust, dirt and smoke can cause the parts in

motion to wear excessively, short circuits (in the presence of a high degree of humidity).

High temperatures and low humidity can cause problems due to static electricity.

I

Safety Regulations

Locating the Machine

-

The printer must be installed on a flat, vibration free surface.

-

Do not position the machine near air conditioning systems, heat sources or in direct

sunlight.

-

Do not obstruct the printer's ventilation slots.

-

If the printer is installed in a cabinet, make sure that it has good ventilation so as to

avoid overheating.

-

Install the printer in a position so that paper jams can be cleared easily.

Work Environment

An environment that is too cold, hot or humid could be the cause of certain malfunctions.

The machine must not be positioned near air conditioning system vents or exposed to

direct sun light. Make sure that the machine's internal ventilation slots are not blocked,

especially if the printer is installed in furniture.

Printer Operating Condition

Check that the internal parts of the machine have no dirt deposited or residue of paper or

ink that could interfere with the performance of the printer's different components. Make

sure there is no internal damage caused by the insertion of documents with metal clips,

staples, pins or similar. Ensure that the parts specified are correctly lubricated.

II

TABLE OF CONTENTS

Preface ............................................................................................................................. VII

About this manual ............................................................................................................. VII

1. Getting Started ............................................................................................................1-1

1.1 Unpacking ..................................................................................................................1-1

1.1.1 Delivery contents Printer C-650 PLus .......................................................1-1

1.2 Requirements to the Location of the Printer...............................................................1-2

1.3 A first Look at the Printer............................................................................................1-3

1.3.1Front View ...................................................................................................1-3

1.3.2Rear View....................................................................................................1-3

1.4 Remove Transport Lock.............................................................................................1-4

1.5 Ribbon Installation......................................................................................................1-5

1.6 Mains Connection and Power On ..............................................................................1-7

1.7 Print Test....................................................................................................................1-9

1.7.1 Selftest ....................................................................................................1-9

1.7.1 Selftest Printing Contents......................................................................1-10

1.7.3 Dr. Grauert (print a letter) ......................................................................1-11

1.8 Connection to the System........................................................................................1-12

1.8.1 Parallel / Serial Interface .......................................................................1-12

1.9 Installing the Printer Drivers .....................................................................................1-12

2. Printer Operation........................................................................................................2-1

2.1 Operator Panel...........................................................................................................2-1

2.2 Function Keys ............................................................................................................2-2

2.3 Liquid Crystal Display (LCD) ......................................................................................2-4

2.4 Load Print Medium.....................................................................................................2-5

2.5 Menu Mode ................................................................................................................2-5

2.5.1 To Confirm a Macro Selection and Save the Settings.............................2-6

2.6 The Use of C-650 Plus Emulation .............................................................................2-6

3. Configuring the Printer..............................................................................................3-1

Main Functions and Entry Points into the Menu................................................................3-1

3.1 What is Configuration..............................................................................................3-2

3.2 Standard Configuration ...........................................................................................3-3

3.2.1 Explanation of the Printout on the Previous Page...................................3-4

3.3 Menu Structure.........................................................................................................3-4

3.3.1 How to use the Key in the Menu Mode ...................................................3-5

3.3.2 The Emulations of C-650 PLus...............................................................3-5

3.4 Menu Setup Description ..........................................................................................3-5

3.4.1 Select Current Macro ..............................................................................3-6

3.4.2 Select User to Setup ...............................................................................3-6

3.4.3 Configure.................................................................................................3-6

3.4.4 IBM Configure .......................................................................................3-10

3.4.5 LQ Configure.........................................................................................3-13

3.4.6 Save Parameters...................................................................................3-16

3.5 Print Test ................................................................................................................3-17

3.5.1 Users Guide ...................................................................................... 3-17

3.5.2 ASCII Character Set............................................................................. 3-17

3.5.3 Character Attributes ............................................................................. 3-17

3.5.4 Dr. Grauert (print a letter) ..................................................................... 3-17

3.6 Adjustment ............................................................................................................. 3-18

3.6.1 Photo Sensor Value .............................................................................. 3-18

3.6.2 Left Margin ............................................................................................ 3-19

3.6.3 Top Margin ............................................................................................ 3-20

3.6.4 Run-in Test............................................................................................ 3-20

3.6.5 Bidirectional Alignment Adjustment....................................................... 3-21

3.6.6 Print Photo Values................................................................................. 3-22

3.6.7 Inquire Photo Values ............................................................................. 3-23

3.6.8 Resume Hardware Parameters............................................................. 3-24

3.7 Debug / Test ........................................................................................................... 3-24

3.7.1 Data Backup Mode................................................................................ 3-25

3.7.2 Printing Saved Data .............................................................................. 3-25

3.7.3 Printing Last Data.................................................................................. 3-26

3.7.4 Printing Flash Data................................................................................ 3-26

3.7.5 Directly Dump........................................................................................ 3-27

3.8 Info Inquiring .......................................................................................................... 3-28

3.8.1 FW Version............................................................................................ 3-28

3.8.2 HW Configuration .................................................................................. 3-28

3.8.3 Printer ID ............................................................................................... 3-28

4. Maintenance ............................................................................................................... 4-1

4.1 Cleaning Surrounding Areas...................................................................................... 4-1

4.1.1 Remove the Ribbon................................................................................. 4-2

4.1.2 Remove the Alignment Unit..................................................................... 4-3

4.1.3 Cleaning Procedure................................................................................. 4-4

4.1.4 Install the Alignment Unit ........................................................................ 4-4

4.1.5 Install the Ribbon Cassette ..................................................................... 4-4

5. Options........................................................................................................................ 5-1

5.1 Optional Devices........................................................................................................ 5-1

IV

6. Technical Data............................................................................................................ 6-1

6.1 Technical Specification ............................................................................................ 6-1

6.2 Document Specification and Technical Instructions ................................................ 6-3

7. Interface Description ................................................................................................. 7-1

7.1 Serial Interface......................................................................................................... 7-1

7.2 Parallel Interface...................................................................................................... 7-2

7.3 USB Interface .......................................................................................................... 7-2

8. Firmware Update........................................................................................................ 8-1

9. Troubleshooting......................................................................................................... 9-1

How to Use This Section................................................................................................... 9-1

9.1 Power-related Problems............................................................................................. 9-1

9.2 Uncompleted Power On............................................................................................. 9-1

9.3 Ribbon or Carriage-related Problems ........................................................................ 9-2

9.4 Paper-related Problems ............................................................................................. 9-2

9.5 Print-related Problems ............................................................................................... 9-3

9.6 No Printout ................................................................................................................. 9-4

V

Table of Contents

3

Appendix A Code Pages .............................................................................................. A-1

A.1 PC Character Sets ................................................................................................... A-2

A.2 ISO Character Sets ................................................................................................. A-25

A.3 OCR-A Character Sets............................................................................................ A-34

A.4 OCR-B Character Sets............................................................................................ A-36

Appendix B IBM ProPrinter X24 and IBM ProPrinter II Emulation ........................... B-1

B.1 Command Index .................................................................................................... B-2

B.2 Command Description........................................................................................... B-4

B.2.1 Basic Operations............................................................................ B-4

B.2.2 Margins ............................................................................... B-6

B.2.3 Line Feed ............................................................................... B-8

B.2.4 Print Pitches ............................................................................. B-11

B.2.5 Print Attributes ............................................................................. B-13

B.2.6 Tabulation ............................................................................. B-19

B.2.7 Graphics ............................................................................. B-21

B.2.7.1 The IBM Graphic Commands .......................................... B-22

B.2.7.2 Alternate Graphic Mode (AGM) .......................................... B-24

B.2.8 Downloading Customized Characters (DLL)................................ B-26

B.2.9 Other Functions ........................................................................... B-31

B.

Hex - Decimal Conversion Table............................................................................. B-34

Appendix C Epson LQ Emulation................................................................................. C-1

C.1 Command Index .................................................................................................... C-2

C.2 Command Description............................................................................................... C-6

C.2.1 Basic Operations............................................................................C-6

C.2.2 Margins ...............................................................................C-8

C.2.3 Line Feed ............................................................................. C-10

C.2.4 Print Position ............................................................................. C-12

C.2.5 Print Pitches ............................................................................. C-14

C.2.6 Print Attributes .............................................................................C-16

C.2.7 Tabulation .............................................................................C-23

C.2.8 Graphics .............................................................................C-25

C.2.9 Other Functions ...........................................................................C-27

C.2.10 Ignored Commands ..................................................................... C-29

C.3 Hex - Decimal Conversion Table ............................................................................C-33

VI

p

p

A

Preface

About this Manual

This manual covers the printer in combination with an interface module.

The interface is an integral part of the printer, and the type of interface used significantly

influences the behaviour or o

The structure of this manual is such that the operator is led step-by-step through the

various procedures. It starts with the unpacking and setting-up, moves on to detailed

instructions for o

The manual is divided into the following chapters:

1. Getting Started

This chapter covers the unpacking and setting-up of the printer and the installation of the

ribbon cassette. By the end of this chapter the printer should be fully functional and

tested in its primary form. It is not yet connected to the host computer system and no

options are mounted.

eration of the printer.

erating the printer and ends with the mounting of options.

2. Operating the Printer

This chapter discusses in great detail the operation of the operator panel, all menu

functions, and the general operation of the menu.

3. Configuring the Printer

This chapter explains how to configure the printer so that it can communicate with the

corresponding system environment. Then this chapter thoroughly describes the

printer's operating controls. In the last part you will find tables with the possible values

of the menu items.

In this chapter you will also find a detail explanations of individual menu items.

4. Maintenance

This chapter shows how to clean the printer and how to remove the Alignment Unit.

5. Options

This is a description of the available options, the Tractor Unit and the USB Port.

6. Technical Data

ll technical details or data about the printer can be found here.

7. Interface Description

This chapter gives hints about possibilities to connect the printer to the various

computer systems and explains particularities depending on the version of the

operating system. Additionally, cable connection is illustrated.

8. Firmware Update

Output Solutions will advise users to update the printer’s firmware irregularly to

strengthen C-650 PLUS’s functions.

VII

Preface

A

9. Trouble Shooting and Diagnostics

Suggests how to identify and correct simple problems.

Appendix

A. Character Set Table

ll printer supported character sets are listed in this chapter.

B. IBM ProPrinter Emulation Commands

Quick reference for IBM ProPrinter X24 and IBM ProPrinter II

C. EPSON LQ Emulation Commands

Quick reference for EPSOM LQ Emulation.

Conventions Used in this Guide

The following conventions are used:

Bold

Note:

Caution:

[STOP ]

Headlines and important information.

Contains special advice to facilitate handling.

Contains important information to prevent damage of the

equipment.

Key functions are always depicted in brackets.

Abbreviations and Acronyms

DRAFT

HSD

LCD

LED

LQ

MACRO

NLQ

PH

VIII

Draft

High S

Liquid C

Light E

Letter Q

User defined group (1 up to 3) of stored parameter

Near L

Print H

Quality

peed D

rystal D

mitting D

uality

etter Q

ead

raft

isplay

iode

uality

r

y

1.

Getting Started

1.1 Unpacking

Check each item against the check list detailed below. Contact your supplier immediately if

any item is missing or damaged.

1.1.1 Delive

Check each item against the check list detailed below. Contact your supplier immediately if

any item is missing or damaged.

•

Printer

•

Power Cord (2)

•

C-650 PLUS Cartridge (Ribbon Cassette) (3)

•

Printout of the User's Manual (4)

Printout of the default menu configuration (5)

•

•

CD-ROM with a PDF format of the User's Manual and additional information (6)

Contents Printer C-650 Plus

C-650 Plus (1)

1-1

Getting Started

r

y

1.2

Requirements to the Location of the Printe

Environmental Conditions

This printer is designed to be installed in a typical office environment. We claim that

customer must follow these operation explanation as below for printer’s well working

status and safet

Install the printer in an area away from any heat source, air conditioner, or strong

•

airflow.

Avoid installing the printer where it is exposed to moisture or heat (eg. direct sunlight).

•

•

Avoid installing the printer in a dusty or humid environment.

•

Do not put printer to the high temperature, shake or wet environment. And no exposure

to direct sunlight. For example boiler, humidifier or fridge.

of operator:

•

Preconditions for Installation

•

Place the printer on the stand or a table.

•

When processing fanfold paper always place the printer with its front edge slightly off

the edge of the table.

Power Requirements

•

No special wiring is required. A typical office wall outlet is sufficient. Make sure that the

electrical wall outlet to which the printer is connected has a valid ground and that it is

able to supply the power needed by the machine.

•

Do not plug into the same wall outlet other equipment besides the printer such as

1-2

r

1.3

A First Look at the Printe

1.3.1 Front View

•

Top Cover (1)

•

Operator Panel (2)

•

Display (3)

•

Front Paper Feeding Platform (4)

•

Power Switch (5)

•

Bottom Frame (6)

Getting Started

1.3.2

Rear View

•

Serial Interface Connector (7)

•

Option Interface Board Slot (8) for detail see chapter 5

•

Rear Paper Feeding Path (9)

•

Power Cord Socket (10)

•

Electrical Label (11)

Options

1-3

Getting Started

p

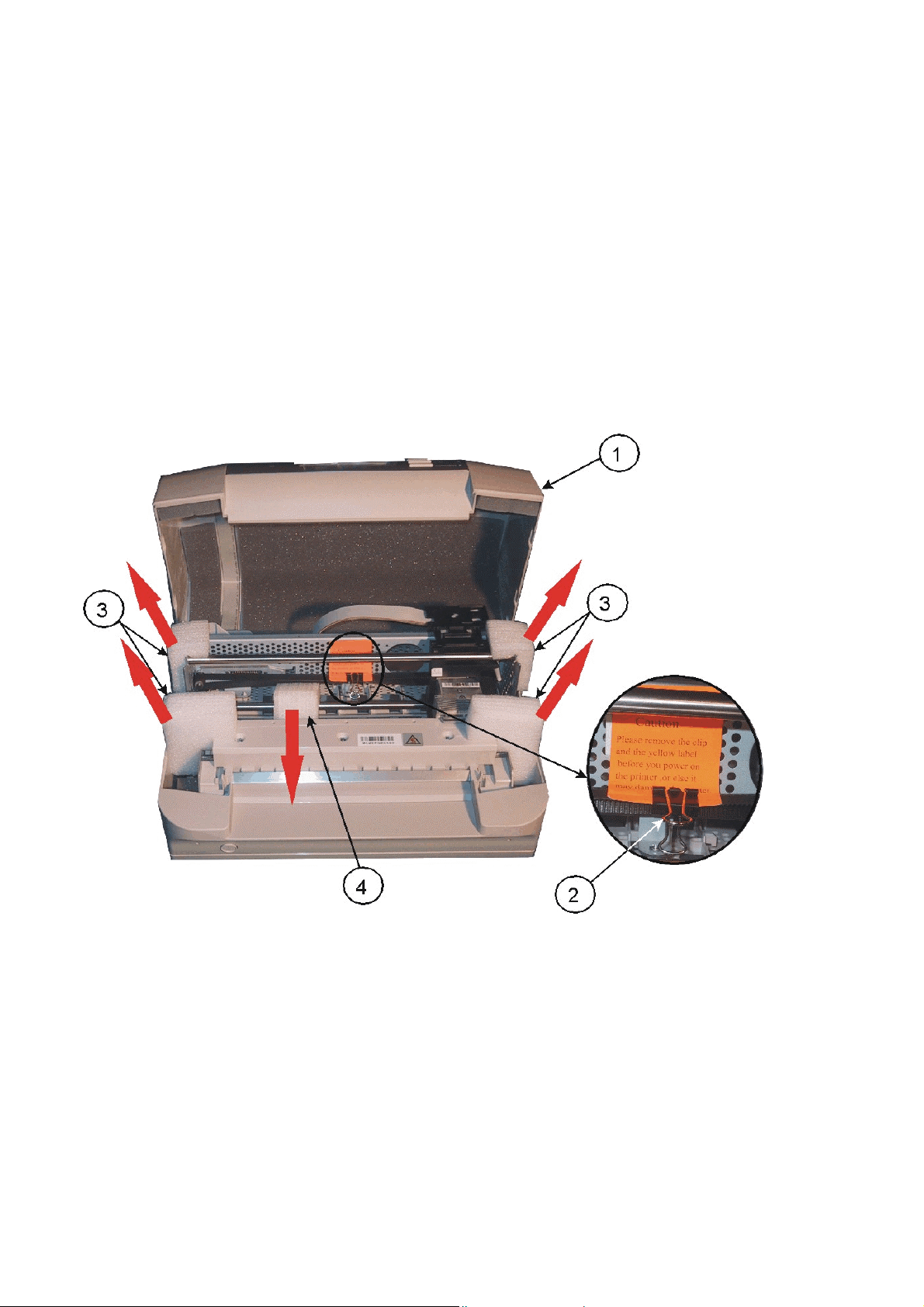

1.4 Remove Transport Lock

Note:

Please do not connect the printer's power cord at this moment, otherwise the

printer may be damaged permanently.

Open the top cover (1) first.

•

•

Remove the black iron clip (2) and yellow label, from the print head carriage.

•

Take out the four foam-rubber cushions (3) which on the both sides of carriage.

•

Remove the foam-rubber cushions (4) to the front by lifting up.

Remove all trans

ort

Re-packing Information

To ensure maximum protection when transporting the printer, always:

•

Remove the mains cable.

•

Remove the ribbon cassette.

•

Reposition the transport lock.

•

Pack the printer in its original packing material and ship in its original package.

1-4

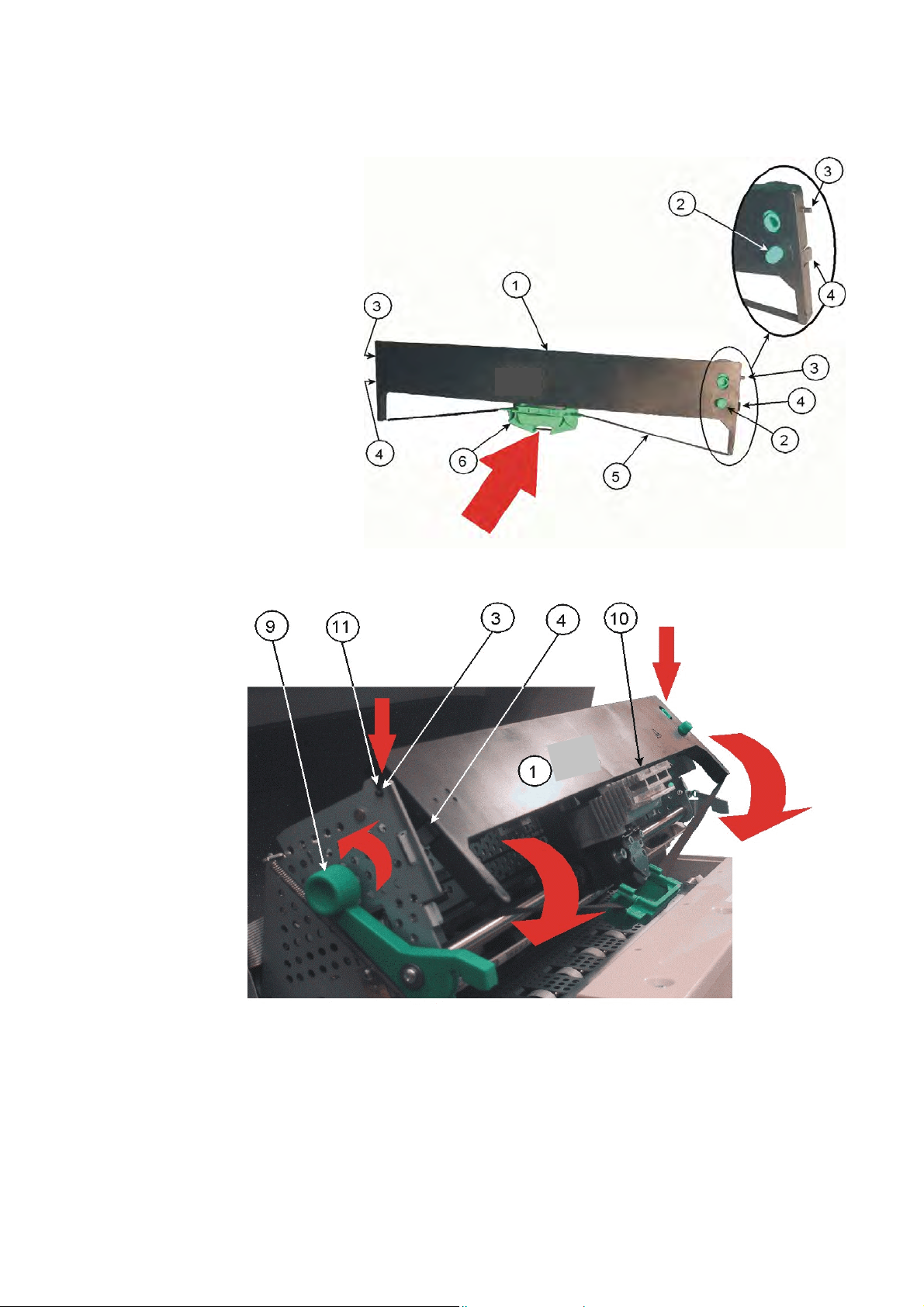

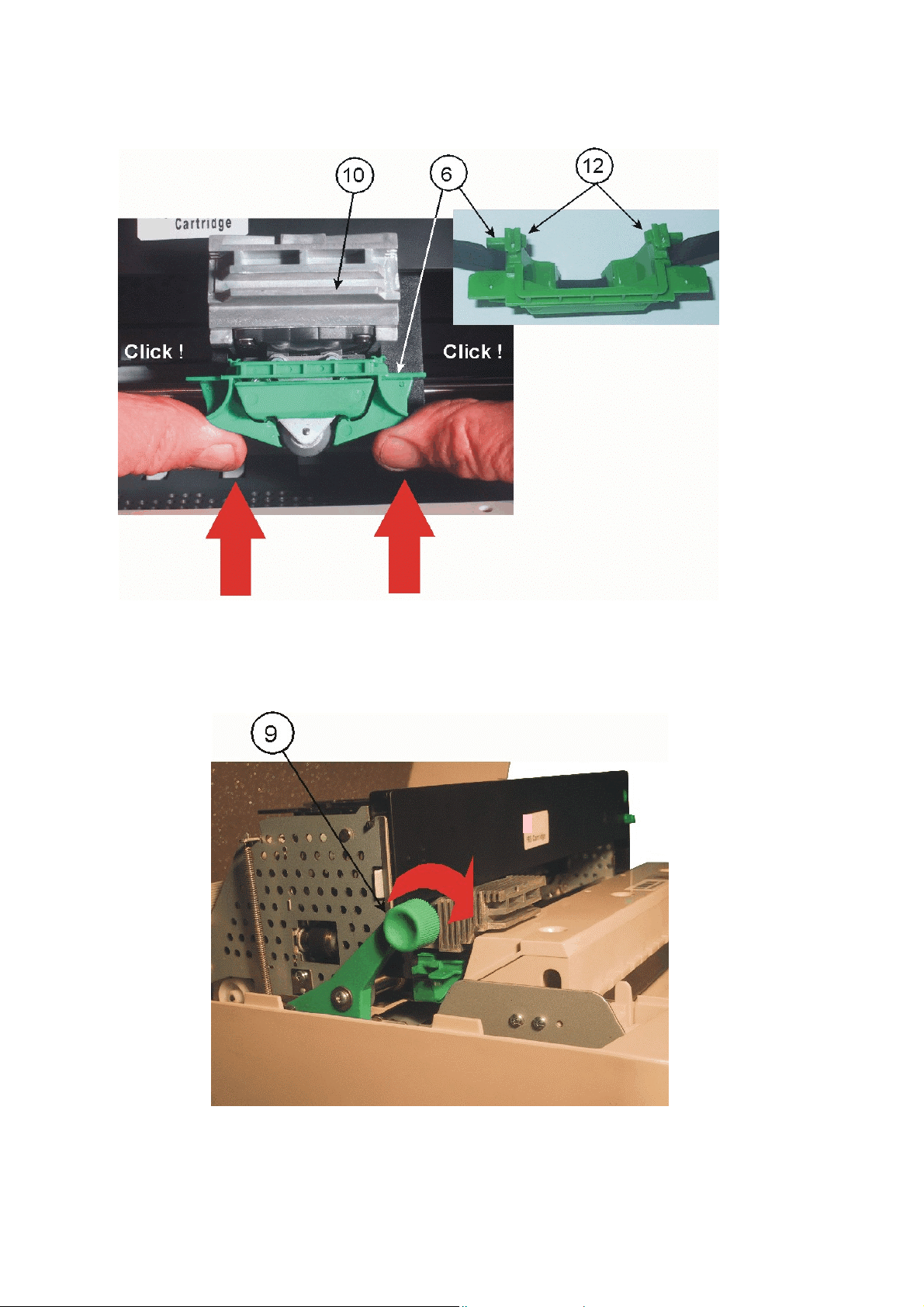

1.5

Ribbon Installation

•

Take out the Ribbon Cassette (1) from plastic wrapping

Details of the Ribbon Cassette (1):

•

Active Wheel (2)

•

Fixation Pin (3)

•

Fixation Block (4)

•

Ribbon (5)

•

Ribbon Guide (6)

Getting Started

Installing:

Power the printer on.

•

•

Remove the Ribbon Guide (6) by sliding down from the Ribbon Cassette (1).

•

Open top cover.

•

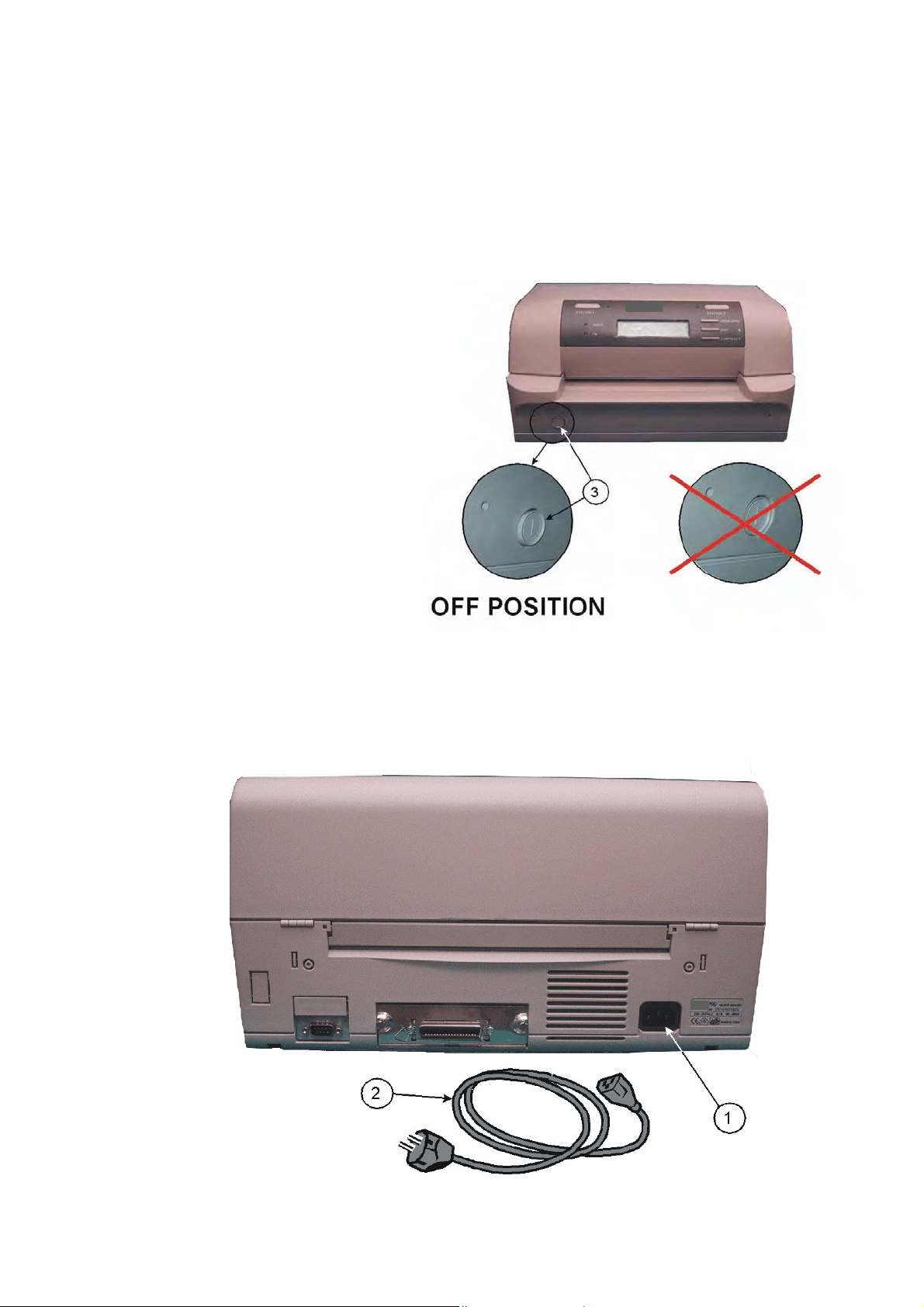

Swivel the green print unit lift handle (9) backwards to lift the print unit entirely.

•

Move print head (10) to the centre.

•

Insert the fixation pins (3) at the both ends of ribbon cassette (1) into the slots (11) at

both ends of print unit frame.

•

Try to push ribbon cassette (1) by rotation as shown in the picture above.

Press the ribbon cassette fixation block (4) into both ends slot of print unit until you

•

hear a “

CLICK”.

1-5

Getting Started

•

Insert ribbon guide (6) into print head (10) and press it up to make sure that the two

taps (12) on the ribbon guide (6) have been fixed.

•

Move the print head (10) to the right and left side until the ribbon is tight.

Swivel the green print unit lift handle (9) to let print unit back to its normal Position.

•

•

Close top cover.

1-6

p

1.6

Mains Connection and Power On

Getting Started

WARNING:

Before plug the power cord into the electrical wall outlet and power on the

printer, voltage rating indicated on the electrical data plate must be checked to

corres

Note:

Power switch (3) must be in off position.

•

Connect the printer to the mains using the power cord (2).

•

First connect the cable to the power cord socket (1) and then to the mains.

•

Do not plug into the same wall outlet other equipment besides the printer such as

coffee machines, copy machines, or air conditioners.

ond to the local mains.

1-7

Getting Started

A

Any p

The operator can press down front power switch (3 in figure before) to power on printer

now.

fter power on:

The ON

•

•

After a short delay the READY

be all lighted.

•

Several seconds later the print head start initialization action. You hear a sound of the

movement.

•

Only ON indicator will be light after initialization has been finished.

Note:

The display shows the message:

(1) indicator will be light up

(2), STATION 1

(3), and STATION 2

rinting medium in the printer paper path will be ejected.

CX LQ

(4) indicator will

ON-LINE

The informations shown by the LCD are either factory default or related to the selected

micro.

1-8

;

(sy

A

1.7

Print Test

1.7.1

Selftest

The following steps show which keys to use to start a test printout.

KEY

/ or action

DISPLAY

[STATION 2] and [COMPRESS –]

(synchronously)

OFF-LINE MODE

MENU SETUP

[COMPRESS –]

OFF-LINE MODE

MENU PRINTING

Getting Started

[STOP #]

After feeding an A4 paper the printer will start

process automatically if the operator put the

print medium into the paper feeding path.

MENU PRINTING

MENU PRINTING

PRINTING; WAITING...

The user needn’t align the print medium with

the left or right border of the printer.

The printer itself will look after the alignment.

If printing finished, printer will eject paper.

PRINTING

[STATION 2]

[STATION 2]

MENU PRINTING

WAITING...

MENU PRINTING

FINISH; PRESS STAT2

OFF-LINE MODE

MENU PRINTING

[STATION 2] and [COMPRESS –]

nchronously)

CX LQ1600K

ON-LINE

Note:

sample of the Menu Printing you will find on the next page.

1-9

Getting Started

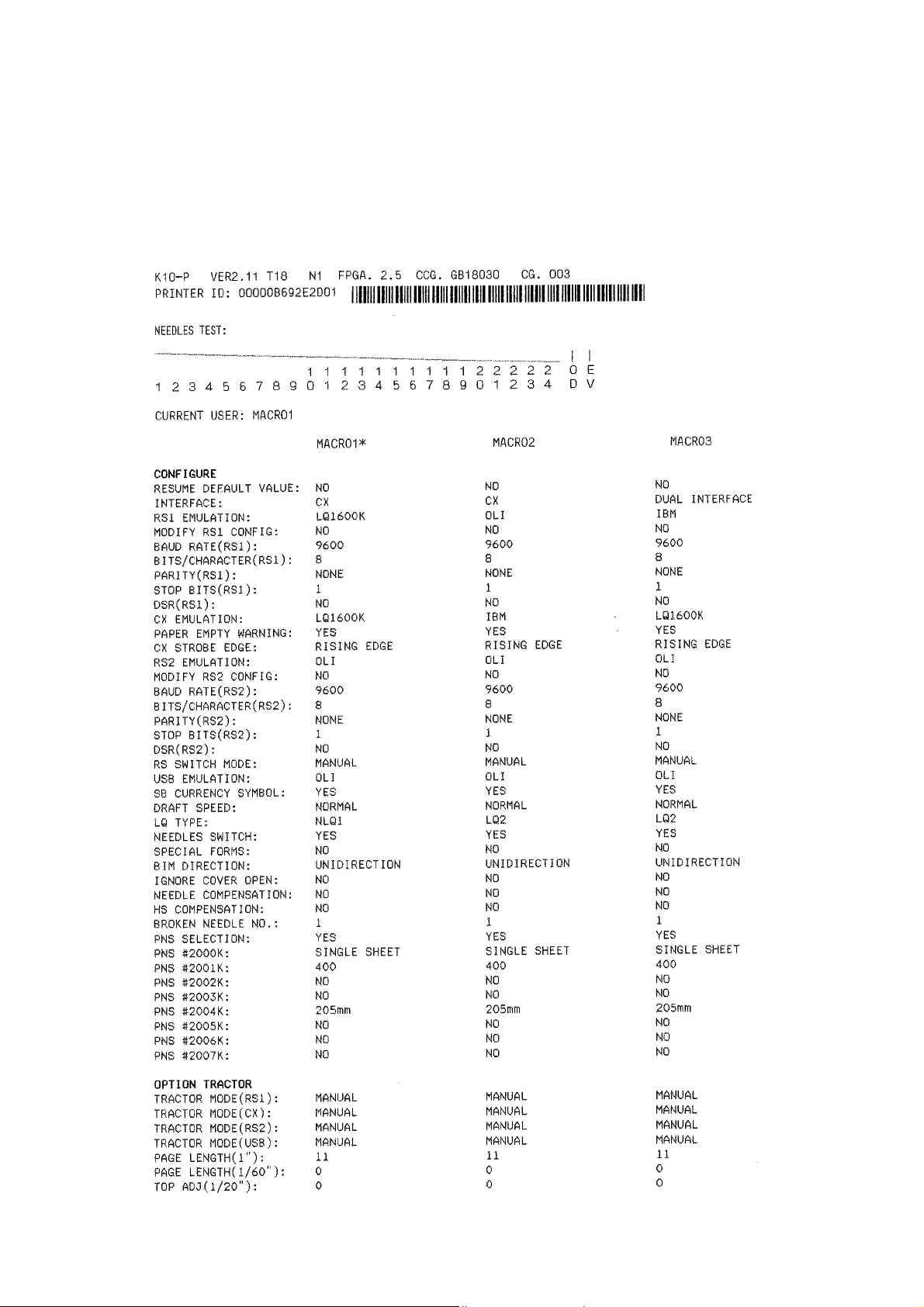

1.7.2 Selftest Printing Contents

For different menu setup configuration, there will be different printed out selftest printing

contents. Concerning your printer’s menu configuration please refer to printer packing

enclosed sheet.

1-10

V

V

V

N

M

N

A

Getting Started

1.7.3 Dr. Grauert

The following steps show which keys to use to start a test printout.

(print a letter)

KEY

/ or action

[STATION 2] and [COMPRESS –]

(synchronously)

[COMPRESS –]

[COMPRESS –]

[STOP #]

[COMPRESS –]

up to the message Y

[STOP #]

DISPLAY

OFF-LINE MODE

MENU SETUP

OFF-LINE MODE

MENU PRINTING

OFF-LINE MODE

PRINTING TEST

PRINTING TEST

USER'S GUIDE

PRINTING TEST

Dr. Grauert

Dr. Grauert

INSERT A4 SHEET

After feeding an A4 paper the printer

processes the printing.

If printing finished, printer will eject paper.

PRINTING TEST

PRINTING; WAITING...

PRINTING TEST

FINISH, PRESS STAT2

[STATION 2]

PRINTING TEST

Dr. Grauert

[STATION 2] and [COMPRESS –]

(synchronously)

Eilzustellung Norddeutsche

Farbwerke KG Herrn Dr.

Grauert

Große Elbstraße 64

2000 Hamburg 4

Org. III 5/37

17.04.75

ordruckgestaltung für den allgemeinen Schrift-

verkehr, für das Bestell- und Rechnungswesen

Sehr geehrter Herr Dr. Grauert,

Sie können das Schreiben der Briefe, Bestellungen, Rechnungen usw.

sowie das Bearbeiten des Schriftguts rationalisieren, wenn die

ordrucke Ihres Unternehmens den folgenden Normen entsprechen:

DIN 676 Geschäftsbrief; Vordrucke A4

DIN 677 -; Vordruck A5

DIN 679 Geschäftspostkarte; Vordrucke A6

DIN 4991 Vordrucke im Lieferantenverkehr; Rechnung

DIN 4992 -; Bestellung (Auftrag)

DIN 4993 -; Bestellungsannahme (Auftragsbestätigung)

DIN 4994 -; Lieferschein/Lieferanzeige

DIN 4998 Entwurfsblätter für Vordrucke

Diese Normen enthalten alle Einzelheiten für den sinnvollen und

zweckmäßigen Aufdruck. Wenn dazu bei der Beschriftung genormter

ordrucke DIN 5008 'Regel für Maschinenschreiben' beachtet wird,

entstehen übersichtliche und werbewirksame Schriftstücke.

Die beifgefügten 6 Mustervordrucke zeigen, daß das Beachten der

ormen die künstlerische und werbewirksame Gestaltung der Vor-

drucke nicht ausschließt.

Da wir uns auf die Herstellung genormter Vordrucke spezialisiert

haben, können wir besonders billig liefern. Eine Probestellung

wird Sie und Ihre Geschäftsfreunde von den Vorteilen überzeugen.

it bester Empfehlung

ORAG

Druckerei und Verlagshaus KG

Herrmann

nlagen

6 Mustervordrucke

H-A

Volkmann

4 34

22.04.75

E i l t

ON-LINE

CX LQ1600K

1-11

Getting Started

g

A

y

1.8

Connection to the System

1.8.1 Serial/Parallel Interface

Switch the printer and the computer OFF.

•

Connect the interface cable coming from the computer to the printer's standard

•

RS232 C serial (1) port or to the optional Centronics Parallel (2) port.

•

The followin

•

Interface

•

Baud-Rate (RS1)

•

Bits/Characters (RS1)

•

Parity (RS1)

•

Stop Bits (RS1)

•

DSR (RS1)

values are default settings, see chapter1.7.2 Selftest Printing Contents.

1

Dual Interface

9600 BPS

8 bit

None

No

fter powering the printer ON both interfaces, serial and parallel, are available for data

transfer due to the shared mode. The port to which data is sent becomes active

.

automaticall

For detail information to the ports see Chapter7 Interface Description

1.9

Installing the Printer Drivers

You will find the printer drivers on the CD-ROM.

•

.

1-12

g

y

(2)

2.

Printer Operation

2.1

Operator Panel

The Operator Panel

•

controls the setup for communication with the host computer;

•

controls various parameter settings;

•

allows manual control of the paper handling;

•

ives information about the printer's status.

Two lines L

1

The LCD Display (1) indicates the current status of the Printer. If any error occurs (e.g.

PLEASE CLOSE COVER

LED

L

ight E

lights only if the Printer is powered on and in the

mitting D

2

Online LED

3

Ready LED

4

Station 1 LED

5

Station 2 LED

iquid C

iode (LED)

rystal D

(flashing if receiving data)

(user 1 active; only lighting up if a second serial Interface is

installed and a special software is working)

(user 2 active; only lighting up if a second serial Interface is

installed and a special software is working)

isplay (LCD) Displa

) the corresponding error message will be displayed. The green

On-line Mode.

2-1

Printer Operation

g

g

•

p

•

•

2.2

Function Keys

The five function keys operate differently in the on line or off line mode. Please refer to the

followin

table for details when pressing the function keys.

If the Printer is powered on, the display shows in line two

lights. The Printer is in the

On-line Mode / Off-line Mode

On-line Mode

and ready to receive and print data.

ON-LINE

and the green LED (2)

In this mode only the [STOP ] key is active and the green LED (2) lights. By pressing the

key the Printer changes into the

Menu-Mode

To set the Printer into the Menu-Mode

Off-line Mode

, press the [STATION 2] and [COMPRESS –

or back into the On-line Mode .

]

together. Depending on the state of the Printer the four right hand keys have multiple

functions. For further information see paragraph

Function Key

[FEED/EJECT •

Menu-Mode = UP

or LEFT

depending

On-line

•

]

Feed or eject

paper depending

on the printin

on the actual menu

level

2.5 Menu-Mode

Off-line

.

Menu- Mode the

previous item in the

highest menu level

•

item in a selected

Menu-Mode

select in the

go up to the next

[STOP ]

Menu-Mode =

ACCEPT

[COMPRESS

–]

Menu-Mode =

DOWN

or RIGHT

depending on the

actual menu level

2-2

•

stop printing and

change to Offline Mode

•

activates or

cancels

compression

rinting

change to On-line

Mode and

continue printing

O.k. or confirm

the actual item

•

select the

following item in

the highest menu

level

•

go down to the

next item in a

selected group

Printer Operation

Function Key

•

[STATION 2]

together with

[COMPRESS –]

[STATION 2]

together with

[STOP ]

[FEED/EJECT •]

together with

[COMPRESS –]

change into the

Menu- Mode

•

in “Data backup”

mode of HEX

PRINTING, the

Printer will save the

8K data which it

received lately in

flash memory

•

in “Data backup”

mode of HEX

PRINTING, the

Printer will clear all

received data

which it backs up.

On-line

Off-line

•

On-line Mode

Menu-Mode

go back into the

2-3

Printer Operation

r

y

g

p

y

2.3

Liquid C

stal Display (LCD)

The LCD indicator gives information about the status of the printer. In general it can be

distin

uished between:

ONLINE messages

•

•

OFFLINE messages

Menu Information

•

The LCD has two lines with 20 characters per line. After power on the display shows for

le:

exam

•

emulation

•

in the upper line:

in the second line:

the head line with the printer name, the actual interface, and the

the status.

CX LQ1600K

-

After pressing the [STOP ] key you get the OFF-LINE

message.

CX LQ1600K

-

After entering the MENU MODE

together the printer displays:

by pressing the [STATION 2] and [COMPRESS –] keys

OFF-LINE MODE

MENU SETUP

You can enter the Menu Mode from the

On-line

orOff-line Mode

.

In this state it is possible to use all four keys at the right hand side of the Operator Panel

in the wa

as described in the table in paragraph

2.2 Function Keys

.

2-4

g

A

r

2.4

Load Print Medium

Printer Operation

The Printer can deal with single sheet, cheque,multi copy carbon paper and carton. The

printer will start inserting the sheet automatically when the operator puts the print medium

into paper feeding path. Users needn’t bother aligning the print medium with the left or

ri

ht border of the printer. The printer itself aligns automatically.

Note:

As soon as the auto alignment process starts after you put in a medium, please

release the medium.

2.5

Menu Mode

ll selectable features are accessible via the operator panel and combined in the Printe

MENU.

This feature provides:

•

•

•

easy configuration (language, etc.)

quick parameter changes

activation of test functions

There are six entry points in the highest level:

•

MENU SETUP

Set up the Menu parameters for various modules (common

configuration and different emulation) and the important save

function is included.

•

MENU PRINTING

Printout of the Menu which is in use.

•

PRINTING TEST

character attributes is possible.

ADJUSTMENT

•

setting up the photoelectric sensor and printing the new settings,

setting up the left margin, setting up the top margin, alignment

adjusting for bi-direction print, and run-in printing etc.

•

DEBUG TEST

magnetic stripe.

•

INFO INQUIRY

including the version (version number, nonstandard issue tag,

special simulation etc.), a hardware configuration (characters

generators, optional interface connections, a scanner, the sprocket),

A printout of the user's guide, the ASCII character sets and

Include printing the current settings of the photoelectric sensor, re-

A Hexdump-function is available and a soft test for reading a

Inquire current parameters settings of both software and hardware,

2-5

2.5.1 To Confirm a Macro Selection and Save the Settings

,

•

Press [STOP ] key; the confirmed value will now be shown in the head line.

MENU SETUP

SELECT CURRENT MACRO

•

Press [STOP ] key again.

SELECT CURRENT MACRO

MACRO1

•

Now it is possible to scroll up or down with the [FEED/EJECT •] or [COMPRESS –]

key.

•

Save the selected item immediately by pressing the [STOP ] key again.

•

SELECT CURRENT MACRO

SAVING

PLEASE WAIT

• After the saving procedure the printer changed to the On-line Mode.

2.6 The C-650 Plus Emulations

The printer

•

EPSON LQ1600K Emulation

IBM ProPrinter X24 Emulation

•

C-650 Plus

will be delivered with two different

Note:

Depending on the selected emulation you must also select the corresponding

Printer Driver.

2-6

r

r

y

3.

Configuring the Printe

Main Functions and Ent

The following Main Functions are available:

•

Menu Setup

With this function you are able to modify the parameters of the printer configuration.

For a detail information look at

Menu Printing

•

Printout of the Printer ID, a Needle Test and the parameter setting of the three Macros.

For a detail information look at

•

Printing Test

The printing of User’s Guide, ASCII character set, character attributes, Dr. Grauert

(print a letter). For a detail information look at

Adjustment

•

Printing current photosensor parameters, reset photosensor parameters and printing;

adjust left margin, top margin and bi-direction printing, run-in printing, inquire

photosensor value, reset hardware parameters. For a detail information look at

paragraph

•

Debug / Test

Hex printing (include: data backup, printing backup data, directly dump), magnetic stripe

operation (include read and write). For a detail information look at

3.6.

Points into the Menu

paragraph 3.4.

paragraph 3.2.

paragraph 3.5.

paragraph 3.7.

Info Inquiring

•

Inquiry the current setting parameters of software or hardware, including a version

(version number, special version tag, special emulation, FPGA Version, etc.), hardware

configuration (character’s generators, optional interface, scanner, sprockets), printer

ID. For a detail information look at paragraph 3.8.

3-1

Configuring the Printer

;

3.1

What is Configuration?

This chapter describes how to use the operator panel and menu settings to set up or

configure your printer, so that the printer and your computer system can communicate

correctly with each other.

Communication between the two requires that both, the computer operating system and

the printer have the same communication settings or features. The most important of

those are:

•

•

•

•

•

bit/character

baud rate

parity

stop bits

DSR

You may also need to change some of the printer's other features depending on your

hardware and application requirements, for example:

•

special forms

•

paper handling

The MENU MODE allows you to access the configuration memory. All settings of the

printer are stored in this memory and can be printed. The possible settings are described

in detail on the following pages. A detail description of all Menu settings you will find in

paragraph

The standard parameter setting can be printed by using the function PRINT MENU

following steps show which keys to use to start this printout.

3.4 Menu Setup Description.

. The

KEY

/ or action

[STATION 2] and [COMPRESS –]

(synchronously)

2 Line DISPLAY

OFF-LINE MODE

MENU SETUP

[COMPRESS –]

MENU PRINTING

[STOP #]

Insert the paper

PRINTING

[STATION 2]

[STATION 2]

MENU PRINTING

[STATION 2] and [COMPRESS –]

(synchronously)

OFF-LINE MODE

MENU PRINTING

MENU PRINTING

WAITING...

MENU PRINTING

FINISH; PRESS STAT2

OFF-LINE MODE

C-650P SERIAL1 Epson

ON-LINE

3-2

Loading...

Loading...