Page 1

FW-X240

AUTO TRANSFORMER

Installation Manual

Page 2

FW-X240 Auto Transformer

1

Page 3

About OutBack Power Systems

OutBack Power Systems is a leader in advanced energy conversion technology. Our products include

true sine wave inverter/chargers, maximum power point charge controllers, system communication

components, as well as breaker panels, breakers, accessories, and assembled systems.

Notice of Copyright

FW-X240 Auto Transformer Installation Manual © 2007 All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, OUTBACK POWER SYSTEMS:

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR

OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION.

THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision - July, 2008

Contact Information:

OutBack Power Systems

19009 62nd Ave. NE

Arlington, WA 98223

Phone: 360.435.6030

Fax: 360.435.6019

www.outbackpower.com

2

Page 4

Welcome to the OutBack Power Systems FW-X240 Auto Transformer

The FW-X240 Auto Transformer can be used for step-up, step-down, generator and split phase output

balancing or with series-stacked FX or VFX Series Inverter/Chargers for inverter balancing.

OutBack Power Systems does everything possible to assure the components you purchase will func-

tion properly and safely when installed as instructed according to local and national electrical codes

(NEC). Please read all of the following instructions and the instructions that come with any other

OutBack components that make up your power system.

The FW-X240 Auto Transformer Speci cations:

• 120 volt/25 amp primary and secondary side

• 120 or 240 VAC 60 Hz systems only

• Allows powering 240 volt items ( e.g., a deep well pump) with a single 120 volt AC source

• Step-down feature allows battery charging with both legs of a 240 volt generator through a single

120 volt FX Series Inverter/Charger

Two identical windings:

• Winding one is between leads #1 and #2

• Winding two is between leads #3 and #4

• The start for each winding are on lead #1 and on lead #3

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Please read all instructions and cautionary markings on the FW-X240 and other system components

and their instructional manuals.

To reduce risk of electric shock:

• Disconnect all DC and AC power sources before attempting any maintenance or repair.

• The input side of the AC and DC breakers may be live even though the breakers are o .

• Be sure to test all terminals with a voltmeter before touching or using any tools.

• Always use caution when using metal tools to prevent contact with live parts or terminals.

• All installations must be in compliance with all local and national electrical codes and standards.

3

Page 5

Grounding Instructions

• The FW-X240’s metal mounting bracket must be connected to a permanently grounded

system. System grounding as required by the National Electric Code, ANSI /NFPA 70-1996, is the

responsibility of the system installer.

• The FW-X240 hardware kit includes grounding washers to penetrate a powder-coated nish,

assuring a proper ground connection to any FLEXware enclosure or mounting plate.

• An installation might call for an optional grounding wire between the FW-X240 and the FLEXware

enclosure or mounting plate to which it’s attached depending on local code requirements or the

nature of the installation itself.

Connections

• No additional terminals or lugs are required for hook-up of the AC wiring.

• AC wiring must be no less than 10 AWG gauge copper wire, rated for 75 degrees C or higher and

must be sized appropriately to the circuit breaker.

Hardware Kit

The FW-X240 comes with four M6 X 20 mm screws, four at washers, and four grounding washers for

mounting to a FLEXware Mounting Plate from inside a FLEXware AC enclosure.

4

Page 6

)

r

a

b

)

r

e

k

a

e

r

b

(

d

e

R

1

#

s

u

b

l

a

r

t

u

e

n

(

e

t

i

h

W

2

#

)

r

a

b

s

u

b

l

a

r

t

u

e

n

(

e

t

i

h

W

3

#

)

r

e

k

a

e

r

b

(

k

c

a

l

B

4

#

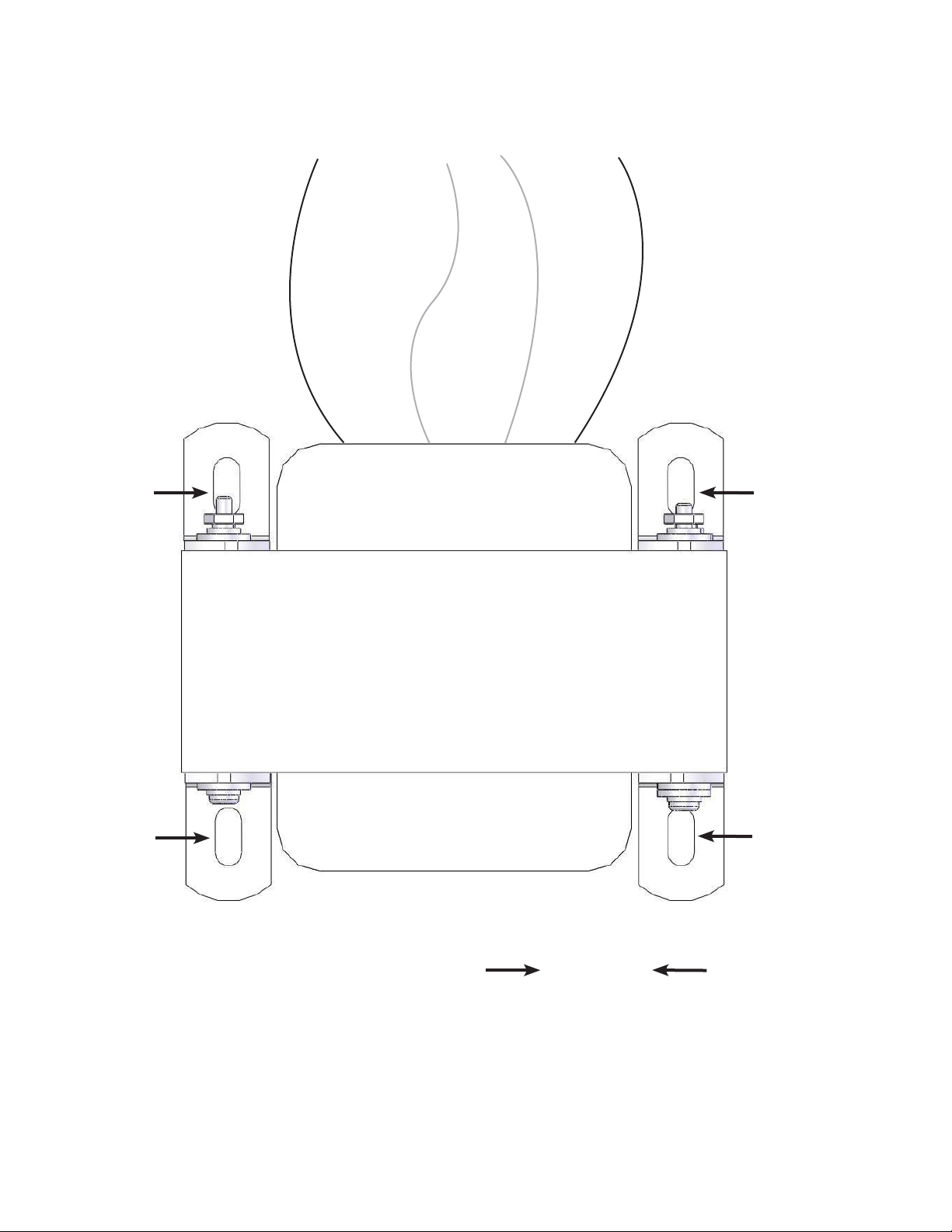

Figure 1: FW-X240 Auto Transformer, top view Mounting Slots

The FW-X240 is installed inside a FLEXware enclosure which is designed for attachment to a FLEXware

Mounting Plate.

5

Page 7

MOUNTING SLOTS

(HARDWARE

INCLUDED)

Figure 2: FW500 AC Chassis

Note: The FW-X240 should be installed inside the FW500 after the FW500 is secured to the FLEXware

Mounting Plate.

6

Page 8

Notes:

• The FW-X240 should be installed inside the FW1000

after the FW1000 is secured to the FLEXware

Mounting Plate.

• The FW-X240 can be fastened to other surfaces

providing the surface and fasteners used can safely

sustain a weight in excess of 25 lbs.

MOUNTING SLOTS

(HARDWARE

INCLUDED)

Figure 3 FW1000 AC Chassis

7

Page 9

Figure 4: Step-Down Wiring

Diagram

• L1: Black

• L2: Red

• Neutral: White

• TBB: Terminal Bus Bar

8

Page 10

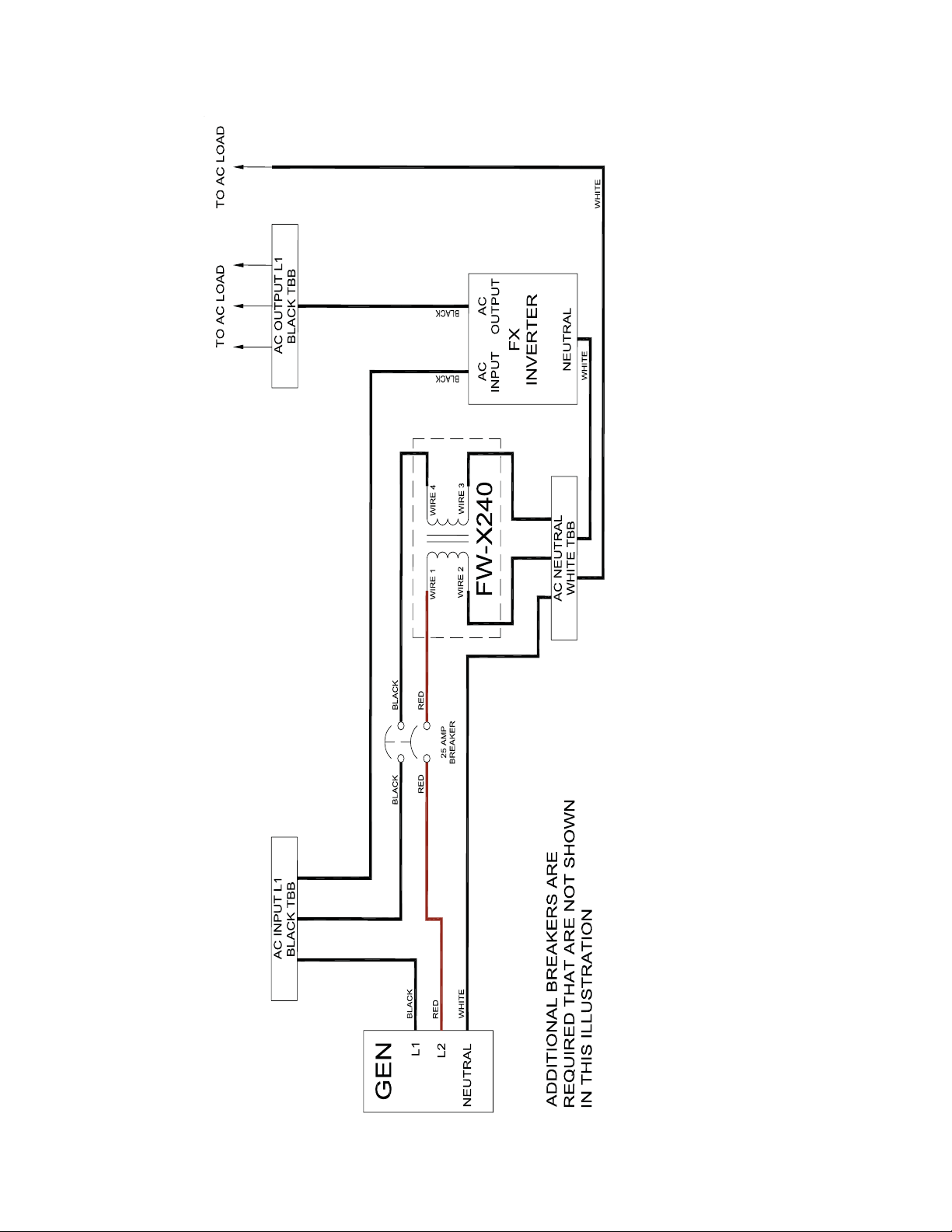

Figure 5: Generator Step-

Up Wiring Diagram

• L1: Black

• L2: Red

• Neutral: White

• TBB: Terminal Bus Bar

9

Page 11

Figure 6: OutBack

Stacking Wiring Diagram

• L1: Black

• L2: Red

• Neutral: White

• TBB: Terminal Bus Bar

10

Page 12

LOAD L1 120VAC

500

WATTS

LOAD L2 120VAC

4500

WATTS

TO LOADS

500W

25 AMP

25 AMP

2500W 2500W

120 V 120 V

X240

BLACK

AC NEUTRAL BUS

RED

WHITEWHITE

TO LOADS

4500W

25 AMP

2000W2000W

Figure 7: FW-X240 Installation Balancing Two FX Series Inverter/Chargers (OutBack Stacking)*

* Figure 9 shows current owing from the L1 FX through the FW-X240 to run in parallel with the L2 FX

output. The L1 inverter is producing almost half of the power required to power the load on L2 and

at the same time is supplying power to its own L1 load.

• When both FXs are awake and producing power, a 240 Volt load will be powered by both inverters

equally.

• If there is less than 1000 watts on L1, then the L2 FX will go to sleep. The FW-X240 is still active and

producing 240VAC.

• A small 240VAC load would be powered from the L1 inverter and the FW-X240.

• A large load turning on will wake up the L2 FX. The L2 inverter will go back to sleep as soon as the

large load on L2 goes away.

Note: Systems with more than four FXs might require two FW-X240s in parallel and require 35 amp

breakers as well.

11

Page 13

12

Page 14

TM

Product Registration

us with some important information

Outback Power Systems Inc.

19009 62nd Ave. NE

Arlington, WA 98223

Please take a moment to register and provide

and return it to:

NOTE: Please complete one form for all installed FLEXware product.

FLEXware Product Registration

System Owner

Name: _______________________________________ Address: ________________________________________

City, State, Zip Code: ____________________________ Country: ________________________________________

Telephone Number: _____________________________ E-mail: _________________________________________

Installer

Company: ____________________________________ Contractor Number: _______________________________

Installer Address: _______________________________ Installer City, State, Zip: ____________________________

Installer E-mail: _________________________________

System

System Install/Commission Date: __________________

Sold by: ______________________________________ Purchase Date: ___________________________________

Please circle type of application:

O -Grid Grid-Interactive AC Coupled Backup Mobile

Please circle installed components:

FLEXware Enclosures and Mounting Components IOB Kits

FLEXware 250 FLEXware MP

FLEXware 500 AC FLEXware PV 8

FLEXware 500 DC FLEXware PV 12

FLEXware 1000 AC

FLEXware 1000 DC

The system is equipped with (circle one):

FW-X240 PSX-240 PSX-240-Relay

Please circle the three most important factors a ecting your purchase decision:

• Price • Product Reputation • Product Features • Reputation of OutBack Power Systems • Value

I am interested in receiving information concerning OutBack Power Systems products and

events (circle one):

Yes No

FW-IOB-S-120VAC

FW-IOB-S-230VAC

FW-IOB-D-120/240VAC

FW-IOB-D-120VC

FW-IOB-D-230VAC

FW-IOB-T-120/208VAC

FW-IOB-T-230/400VAC

FW-IOB-Q-120/240VAC

FW-IOB-Q-230VAC

13

Page 15

14

Page 16

Corporate O ce

19009 62nd Avenue NE

Arlington, WA USA

(+1) 360-435-6030

European Sales O ce

C/ Castelló, 17

08830 - Sant Boi de Llobregat

BARCELONA, España

+34.93.654.9568

www.outbackpower.com

900-0076-01-00 REV C

Loading...

Loading...