Page 1

OPERATIONAL INSTRUCTIONS FOR O.S. TYPE 2S & 2SB CARBURETTORS

These slide-throttle type carburettors have been designed especially for 3.5 cc class racing car engines. They

release

the

full

potential of the

rapid acceleration and high peak power output. The Type 2S carburettor is for track racing, while Type

2SB is for 'off-road' or 'buggy' racing.

The carburettors are intended for operation with a muffler-pressurized fuel system. Make sure that the fueltank is sealed to prevent loss of pressure.

O.S.

MAX-21

series

racing

car

engines,

providing instant throttle

response,

INSTALLATION OF THE CARBURETTOR

Installation procedure is as follows.

1. Remove the protective plug from the engine's intake boss.

Make sure that the carburettor retainer (cotter-pin) does

not obstruct the boss.

2. Carefully insert the carburettor, with its rubber gasket,

into the boss.

3.

Press

down carburettor

and secure as follows:

(a) for MAX-21 RF-B — gently rotate cotter-pin screw

until it stops, then tighten with a further one-third

turn (approx. 120°); or

(b)for MAX-21 SE and MAX-21 VF engines — gently

rotate cotter-pin nut until it stops, then rotate it a

further 30 ~ 40° to tighten.

to

lightly

compress rubber gasket

ADJUSTMENT

1) Set the needle-valve at the optimum setting as described

in the RUNNING-IN paragraph of the engine instructions

sheet.

2) With the engine running, close the throttle and allow it to

idle for about five seconds, then open the throttle fully

and abruptly. If, at this point, the engine puffs out a

good deal of smoke and the car does not accelerate

smoothly and rapidly, it is a sign that the idling mixture

is too rich. If it is found difficult to judge this response,

allow the engine to idle for a longer period, say 10~15

seconds, then again apply full throttle. If the mixture is

too rich, the engine will either emit a large quantity of

smoke or lose speed and stop. Turn the mixture control

valve (located in the side of the carburettor body opposite

the slide valve) clockwise to correct over-rich setting.

(Use a small screw-driver and adjust in increments of 30

to 45°.) If, on the other hand, the idling mixture is too

lean, the engine is likely to speed up momentarily and

then cut out abruptly when the throttle is fully opened.

In this case, turn the mixture control valve counter-clock-

wise 30 to 45°.

3) Carry out adjustments patiently, under actual running

conditions, until the engine responds quickly and positively to the throttle control.

Note: Mixture adjustments cannot be made accurately under

'no load' running conditions which, in any case, are

not advised since such running carries a risk of damaging the engine through over-revving.

4) With the optimum mixture control valve position, light

smoke is visible during high speed running, and the engine

revolutions increase smoothly during acceleration.

Remember that, if the engine is operated with the fuel/air

mixture slightly too lean, it will overheat and run unevenly. As with all engines, it is advisable to set both valves

very slightly on the rich side of the best rpm setting, as a

safety measure.

5) If the engine runs too fast with the throttle closed, the

throttle stop screw should be turned counter-clockwise to

allow the throttle opening to be reduced.

Note: If the fuel, gear ratio or clutch engagement point are

altered, it may be necessary to re-adjust the carburettor.

Page 2

CARBURETTOR CLEANLINESS

Minute particles of foreign matter (present, to some extent,

in all fuels) will cause problems if not removed before they

reach the carburettor jet. Use high quality fuel filters and

make sure that the fuel tank and your refuelling container

are clean. The use of an O.S. Super-Filter (Type S or Type L),

with its special double-filter system, is recommended. Installed

inside the refuelling can at its outiet, it will prevent the

passage of foreign matter into the fuel tank, and a good

inline filter, between tank and carburettor, will give added

protection.

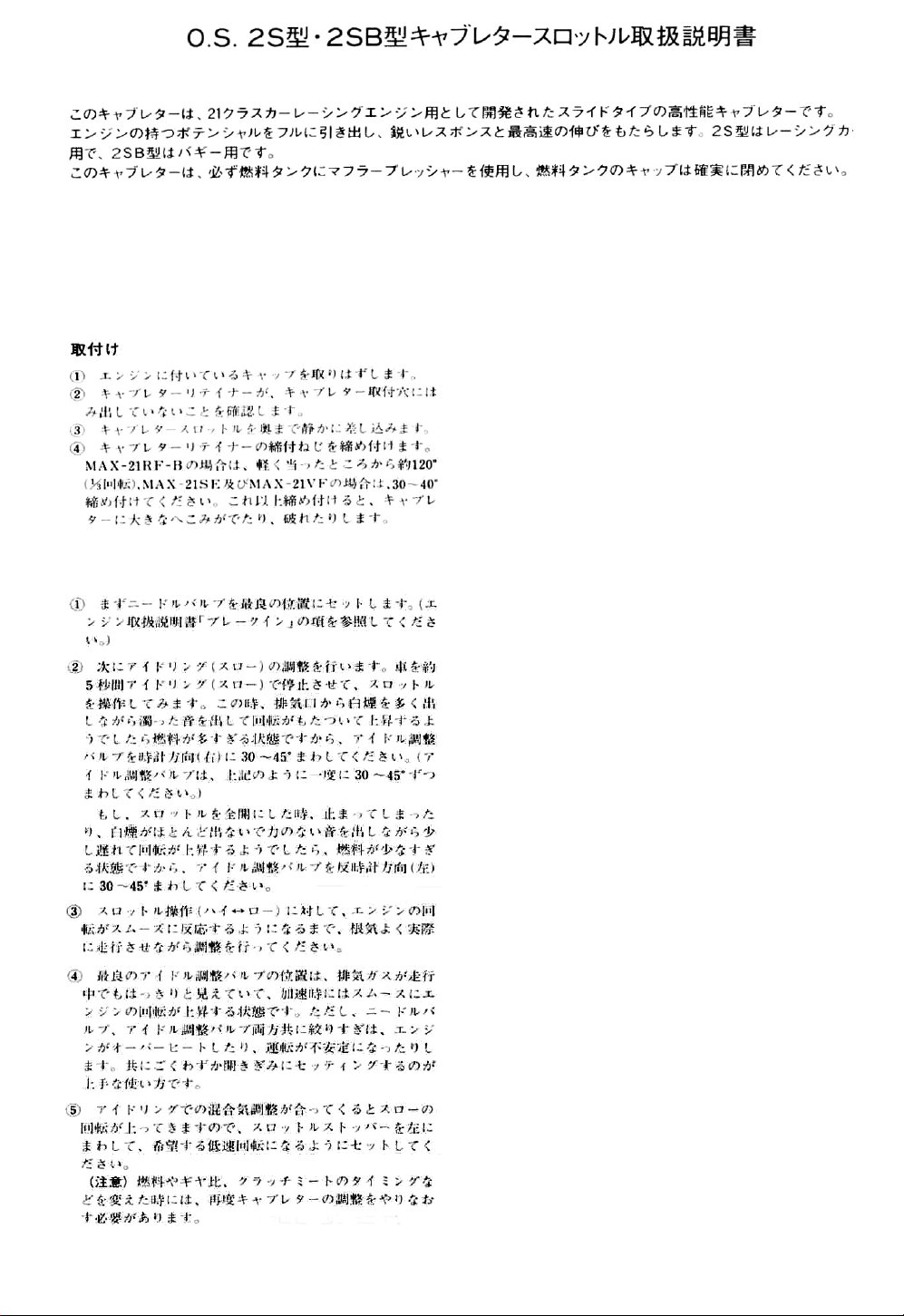

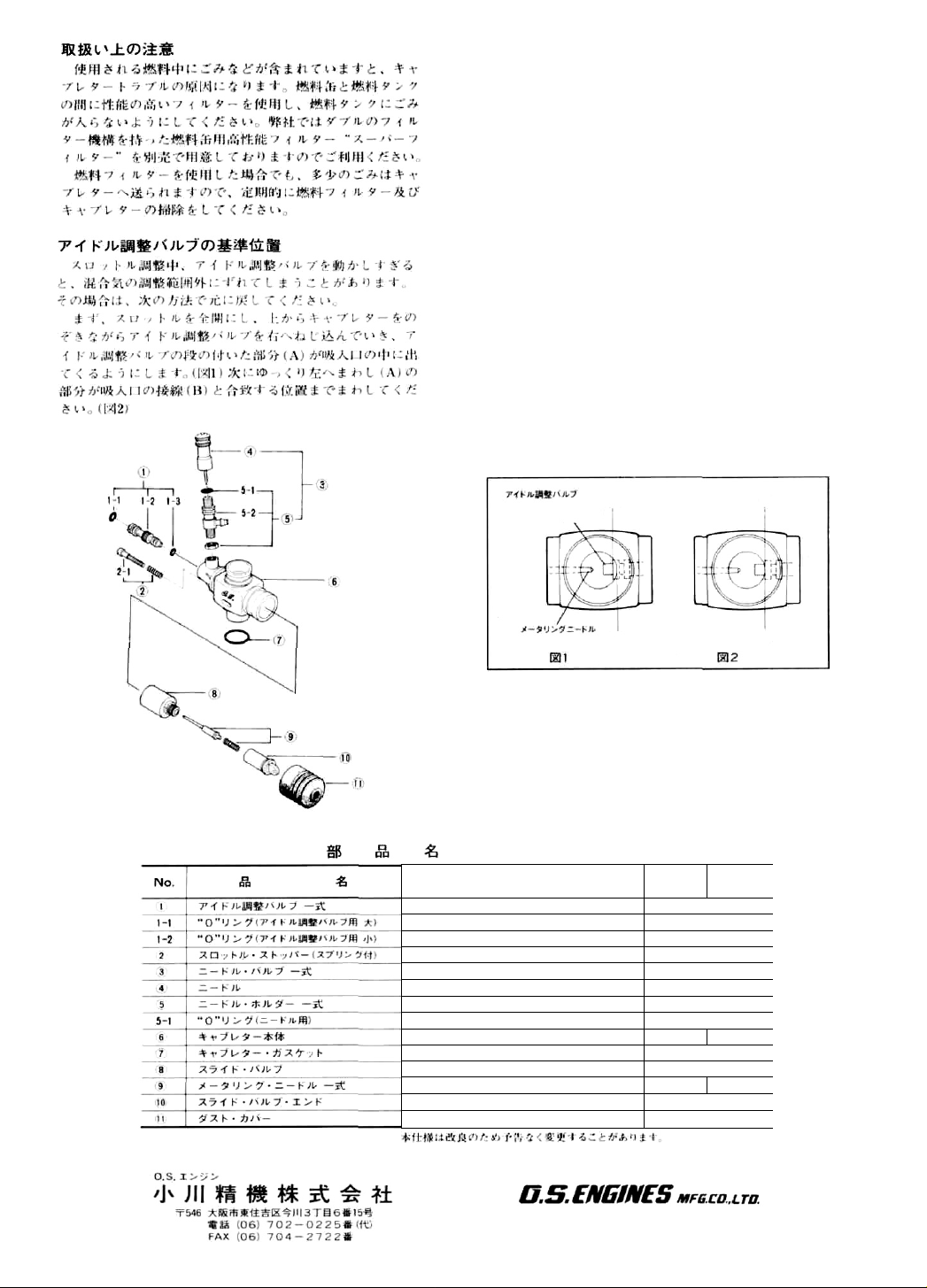

REALIGNMENT OF MIXTURE CONTROL VALVE

In the course of making carburettor adjustments, it is just

possible that the mixture control valve may be inadvertently

screwed in or out too far and thereby moved beyond its

effective adjustment range. Its factory setting, as indicated in

Fig. 2, can be re-established as follows:

When seen from above, with the throttle fully open, the

shouldered portion 'A' should be exactly at a tangent to the

throttle rotor hole. Therefore, to return the mixture control

valve to its original position, first screw-in the mixture

control valve while looking into the rotor hole until the

shouldered portion comes into view. (Fig. 1). Then, gradually

unscrew the mixture control valve until 'A' is precisely

tangential to the rotor hole (i.e. so that 'A' and 'B' are

superimposed) as in Fig. 2.

Idle-valve

(mixture control valve)

Metering needle

Fig.1

PARTS LIST

Description

Mixture Control Valve Ass'y

"0"ring(L) for Mixture Control Valve

"0"ring(S) for Mixture Control Valve

Throttle Stop Screw Ass'y

Needle Valve Assembly

Needle

Needle Valve Holder Assembly

"0"ring for needle

Carburettor Body

Carburettor Rubber Gasket

Slide Valve

Metering Needle Assembly

Slide Valve Hook

Dust Cover

(A)

(A)

(B)

2

S

22884600

46066319

22781800

22884300

22884900

22884970

22884940

22881800

22884100

22615000

22884201

22884401

22884411

22884210

(B)

Fig.2

2SB

22884110

22884430

The specifications are subject to alteration for improvement without notice.

6-15 3-chome Irnagawa Higashisumiyoshi-ku

Osaka 546. Japan. TEL (06) 702-0225

Copyright 1992 by O.S. Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan.

FAX (06)704-2722

109203

Loading...

Loading...