Page 1

O.S.

2D

OPERATIONAL INSTRUCTIONS FOR O.S. TYPE 2D CARBURETTOR

This carburettor

has

been

designed

expressly

for

21

class

racing

engines

and

releases

the full potential of the

O.S.

MAX-21 SE-M marine engine. It has a large throat area for high peak power output, but provides for the positive throttle

response and rapid acceleration demanded of high performance racing boat engines, via an automatic mixture control

system which also ensures ease of handling for the less experienced.

FUEL SYSTEM

The

somewhat

violent

changes

in

hull

attitude that

may

occur in rough water means that the fuel 'head' at the

carburettor can vary considerably. Therefore, it is

recommended that a muffler (silencer) pressurized fuel

feed system be used.

ADJUSTMENT

WARNING: Running the engine needlessly with the boat out of

the water, without load and without cooling water, may

damage the engine due to overheating. Therefore, always

lower the boat into the water immediately after the engine

has been started, so as to prevent over-speeding and to allow

cooling water to be forced up to the cylinder-head.

Having carried out the initial running-in ("breaking-in")

procedure as described in the engine instructions, complete

the running-in as follows:

1) Open the throttle slightly from the idling position and start

the engine, following the procedure described in the engine

instruction leaflet.

2) Lower the boat into the water, open the throttle fully and

run the boat straight ahead for 20 to 30 metres. Now return

the model and close the needle-valve 20° to 30°. Repeat the

run, taking note of the improvement in speed.

3) Continue with further runs, gradually closing the needle-valve

(20° to 30° at a time) until no further increase in speed is

obtained.

4) If the needle-valve is closed beyond the optimum setting, the

model will slow down, accompanied by visibly diminished

exhaust smoke. In this case, immediately throttle down and

return the model to shore. Re-open the needle-valve approximately one-half turn and repeat the runs until the optimum

needle setting is found.

5) Aim to have the model achieving its highest performance

after the engine has consumed about one litre of fuel. Having

found the optimum needle-valve setting, make a note of the

number of turns necessary to re-establish this from the closed

position.

6)

With the engine run-in and the optimum needle-valve setting

determined, the mixture control valve (idle valve) should be

checked as follows:

7) Run the boat in the normal way, then close the throttle.

Allow it to idle for about five seconds, then abruptly re-open

the throttle fully. If, at this point, the engine puffs out a

good deal of smoke and does not accelerate smoothly and

rapidly, it is a sign that the idling mixture is too rich.

Therefore, turn the mixture control valve clockwise 1/8 to

1/4 turn (45° to 90°). Repeat the run and recheck the result.

8) If, on the other hand, the idling mixture is too lean, the

engine is likely to speed up momentarily, then cut out

abruptly when the throttle is re-opened. In this case, turn

the mixture control valve counter-clockwise 1/8 to 1/4 turn.

Carry out these adjustments patiently under actual running

conditions until the engine responds quickly and positively to

the throttle control. (Use a small screwdriver to adjust the

mixture control valve via its slotted screwhead in the centre

of the outer end of the throttle rotor.)

Note: Mixture adjustments must not be attempted under 'no-

load' conditions. Please refer to the warning at the

beginning of this section.

9) With the optimum mixture control valve position, light

smoke is visible during high speed running, and the engine

revolutions increase smoothly during acceleration.

Remember that, if the engine is operated with the fuel/air

mixture slightly too lean, it will overheat and run unevenly.

Page 2

As

with

all engines,

it

is

advisable

to

set

both

valves

slightly

on the rich side of the best rpm setting, as a safety measure.

10) When the mixture has been corrected, the idling speed will

probably increase. Readjust the throttle opening by means

of the throttle trim on the transmitter, or by screwing out

the throttle-stop screw, so that the lowest possible idling

speed, without stopping the engine, may be obtained. Adjust

the throttle-stop screw so that the engine stops (the throttle

fully closed) when the throttle trim is at the lowest position.

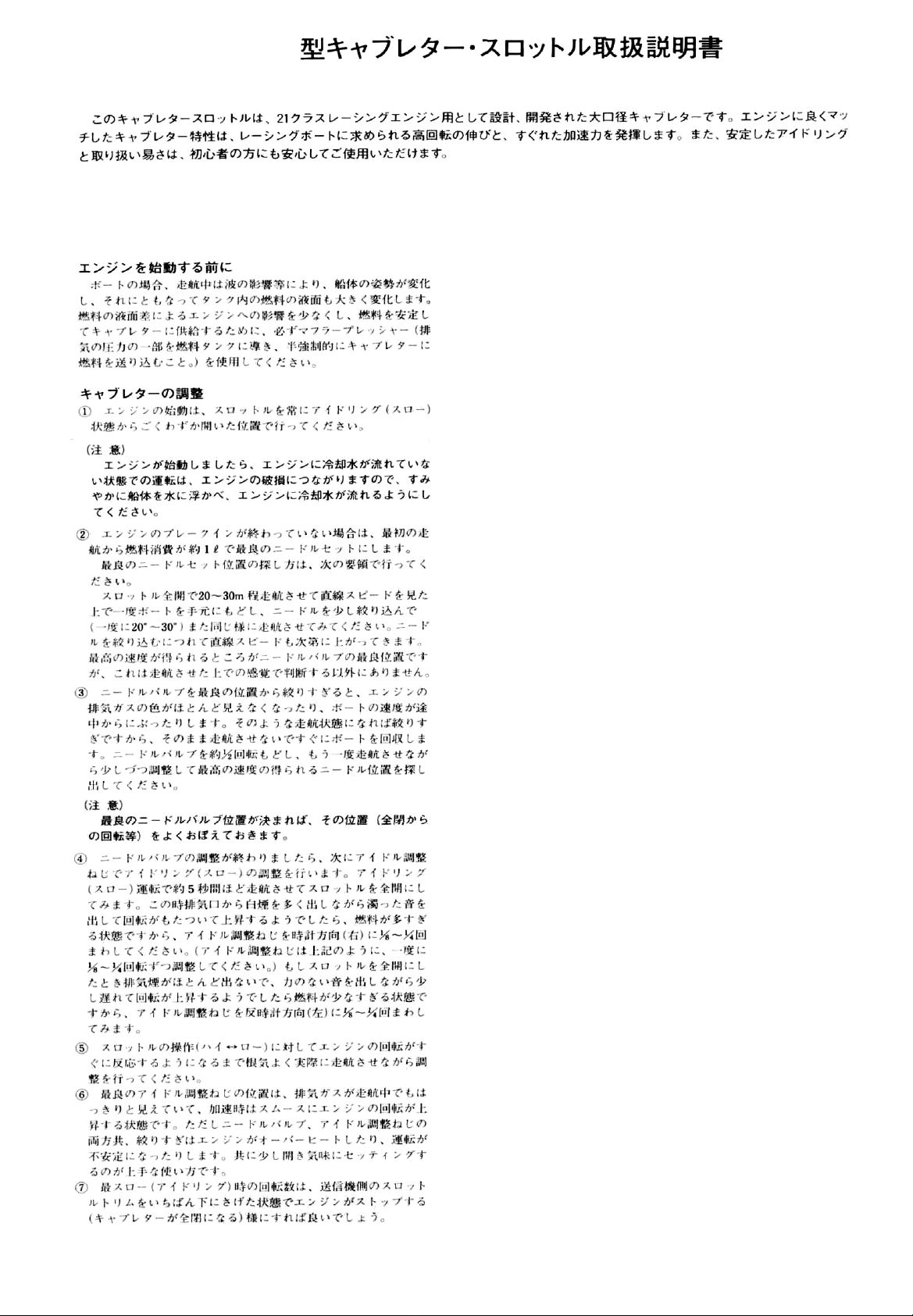

Remove this with

an 8mm spanner

Photograph (1)

Dirt and fibrous matter

mostly accumulate here

Photograph (2)

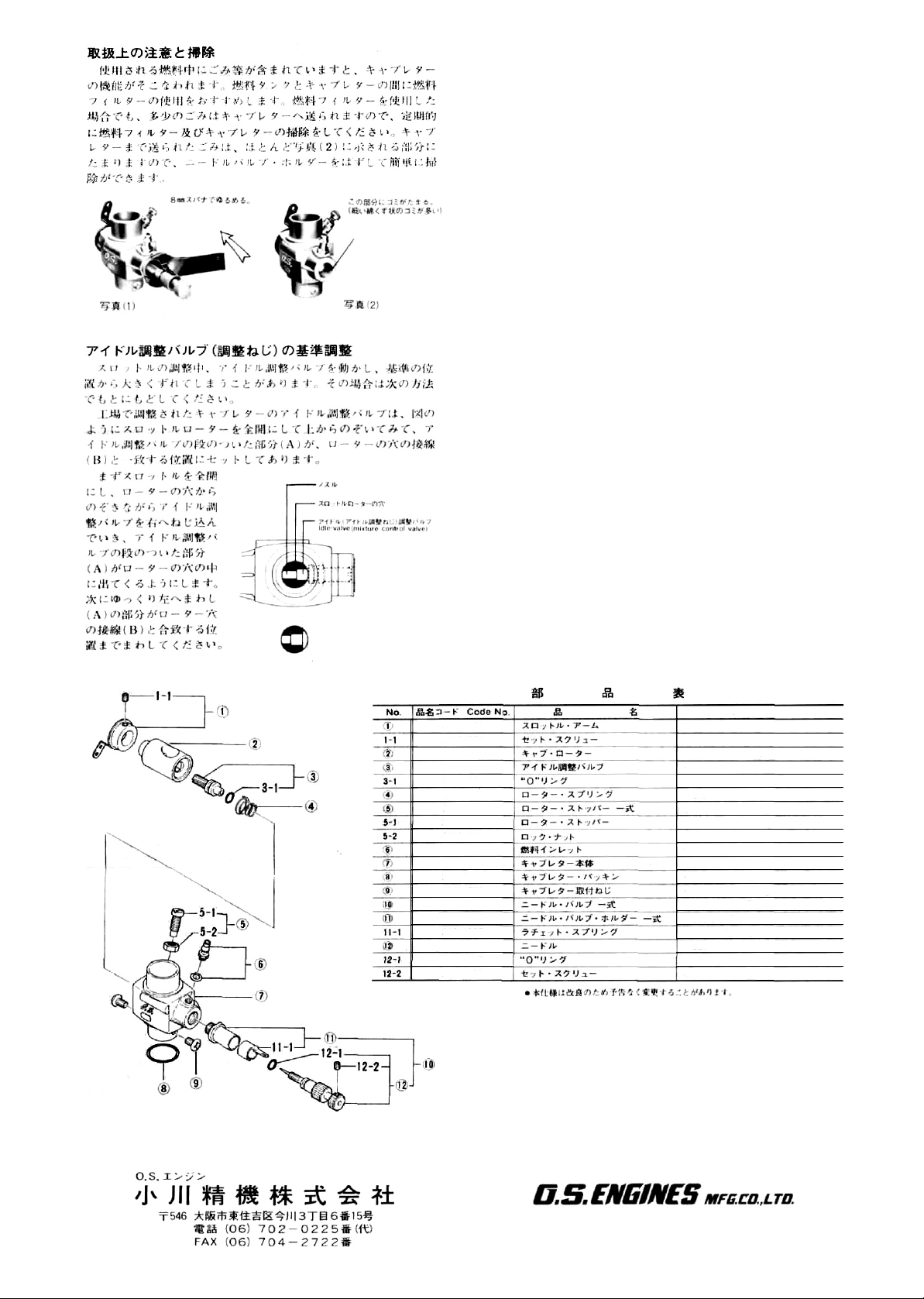

Nozzle

Throttle rotor hole

A

CARBURETTOR CLEANLINESS

The correct functioning of the carburettor depends on its small

fuel orifices remaining clear. The minute particles of foreign

matter that are present in any fuel can easily partially obstruct

these orifices and upset mixture strength so that engine performance becomes erratic and unreliable.

It is recommended that fuel is passed through a filter when the

tank is filled and that a good in-line filter is installed between the

fuel tank and carburettor and, furthermore, that this filter is

frequently cleaned to remove dirt and lint that accumulates on

the filter screen. Finally, occasionally remove the needle-valve

holder from the carburettor as shown in Photo (1) and extract

any remaining foreign matter that may have lodged in the location shown in Photo (2).

REALIGNMENT OF IDLE VALVE

(MIXTURE CONTROL VALVE)

In the course of making carburettor

possible that the idle valve may be inadvertently screwed in or

out too far and thereby moved beyond its effective adjustment

range. Its basic setting can be re-established as follows:

With the throttle fully open, the position of the idle valve can be

seen by looking into the intake. The basic (factory) setting is as

shown in the main sketch, i.e. with the shoulder portion 'A'

exactly at a tangent to the throttle rotor hole.

To return the idle valve to its original position, first screw in the

idle valve, while looking into the rotor hole, until the shouldered

portion comes into view — see small sketch. Then gradually un-

screw the idle valve until 'A' is precisely tangential to the rotor

hole (i.e. so that 'A' and 'B' are superimposed) as in the main

sketch.

adjustments, it is just

B

22481400

26381501

26781200

26781309

24881824

26781506

22481300

22481310

22481320

22681953

24481150

22615000

23081706

24981930

26781965

26711305

24981959

24981837

26381501

Throttle Lever

Set-screw

Carburettor Rotor

Mixture Control Valve

"0" Ring

Rotor Spring

Rotor Stop Set Screw Assembly

Rotor Stop

Rock Nut

Fuel Inlet

Carburettor Body

Carburettor Rubber Gasket

Carburettor Fixing Screw

Needle Valve Assembly

Needle Valve Holder Assembly

Ratchet Spring

Needle

"0" Ring

Set-screw

• The above specifications are subject to change without notice for improvement.

Description

6-15 3-chome Imagawa Higashisumiyoshi-ku

Osaka 546, Japan. TEL. (06) 702-0225

© Copyright 1988 by O.S. Engines Mfg. CO., Ltd. All rights reserved. Printed in Japan.

FAX.

(06)

704-2722

38909

Loading...

Loading...