Osburn OB01601 User Manual

OWNER’S MANUAL

1600 INSERT

Manufactured by: STOVE BUILDER INTERNATIONAL INC

250, rue de Copenhague, Saint-Augustin-de-Desmaures (Quebec) G3A 2H3

After-sale service: 418-908-8002 E-mail: tech@sbi-international.com

www.osburn-mfg.com

(OB01601 model)

US ENVIRONMENTAL PROTECTION

AGENCY PHASE II CERTIFIED WOOD

INSERT

OREGON DEPARTEMENT

ENVIRONMENTAL QUALITY

Verified and tested following

ULC S628, UL 907, UL 1482 Standards by an

accredited laboratory

.

This manual is available for free download on the manufacturer’s web site. It is a copyrighted

document. Re-sale is strictly prohibited. The manufacturer may update this manual from time to

time and cannot be responsible for problems, injuries, or damages arising out of the use of

information contained in any manual obtained from unauthorized sources.

READ AND KEEP THIS MANUAL FOR REFERENCE

Printed in Canada 12-06-2015

45084A

TABLE OF CONTENTS

REGISTER YOU WARRANTY ONLINE

TECHNICAL SPECIFICATIONS ......................................................................................... 4

INSTALLATION ................................................................................................................... 5

DOOR OVERLAY INSTALLATION ............................................................................................ 6

DOOR ADJUSTMENT ................................................................................................................... 7

PRE-INSTALLATION REQUIREMENTS.................................................................................... 8

MINIMUM MASONRY OPENING, CLEARANCES TO COMBUSTIBLES, AND FLOOR

PROTECTOR ................................................................................................................................ 10

VENTING REQUIREMENTS ..................................................................................................... 12

INSTALLATION INSTRUCTIONS ............................................................................................ 13

OPERATION ..................................................................................................................... 18

TESTING YOUR WOOD ............................................................................................................. 19

THE FIRST FIRES ........................................................................................................................ 19

IGNITION ..................................................................................................................................... 19

HEATING ..................................................................................................................................... 20

RELOADING ................................................................................................................................ 20

CREOSOTE FORMATION AND NEED FOR REMOVAL ....................................................... 21

ASH DISPOSAL ........................................................................................................................... 21

MAINTENANCE ................................................................................................................ 22

GLASS .......................................................................................................................................... 22

GASKETING ................................................................................................................................ 22

PAINT ........................................................................................................................................... 22

BAFFLE INSTALLATION .......................................................................................................... 23

SECONDARY AIR TUBE REPLACEMENT ............................................................................. 24

OSBURN LIMITED LIFETIME WARRANTY ..................................................................... 25

To receive full warranty coverage, you will need to

show evidence of the date you purchased your insert.

Keep your sales invoice. We also recommend that

Registering your warranty online will help us track

rapidly the information we need on your insert.

2

you register your warranty online at

http://www.osburn-mfg.com/warranty-

registration.aspx

INTRODUCTION

SBI INC., one of the most important wood stove and fireplace manufacturers in Canada,

congratulates you on your purchase and wishes to help you get maximum satisfaction

from your wood insert. In the pages that follow, we will give you advice on wood heating

and controlled combustion as well as technical specifications regarding installation,

operation and maintenance of the model you have chosen.

The instructions pertaining to the installation of your wood insert comply with ULC-S628

and UL-1482 standards.

Read this entire manual before you install and use your new insert. If this insert is

not properly installed, a house fire may result. To reduce the risk of fire, follow the

installation instructions. Failure to follow instructions may result in property

damage, bodily injury, or even death.

Consult your municipal building department or fire officials about restrictions and

installations requirements in your area and the need to obtain a permit.

Keep this instructions manual for future references.

CAUTIONS:

•

HOT WHILE IN OPERATION. KEEP CHILDREN, CLOTHING AND FURNITURE AWAY. CONTACT MAY

CAUSE SKIN BURNS

•

DO NOT USE CHEMICALS OR FLUIDS TO IGNITE THE FIRE

•

DO NOT LEAVE THE INSERT UNATTENDED WHEN THE DOOR IS SLIGHTLY OPENED

•

DO NOT BURN WASTES, FLAMMABLE FLUID SUCH AS GASOLINE, NAPHTHA OR MOTOR OIL

•

DO NOT CONNECT TO ANY AIR DISTRIBUTION DUCT OR SYSTEM

•

ALWAYS CLOSE THE DOOR AFTER THE IGNITION

.

.

.

.

.

.

3

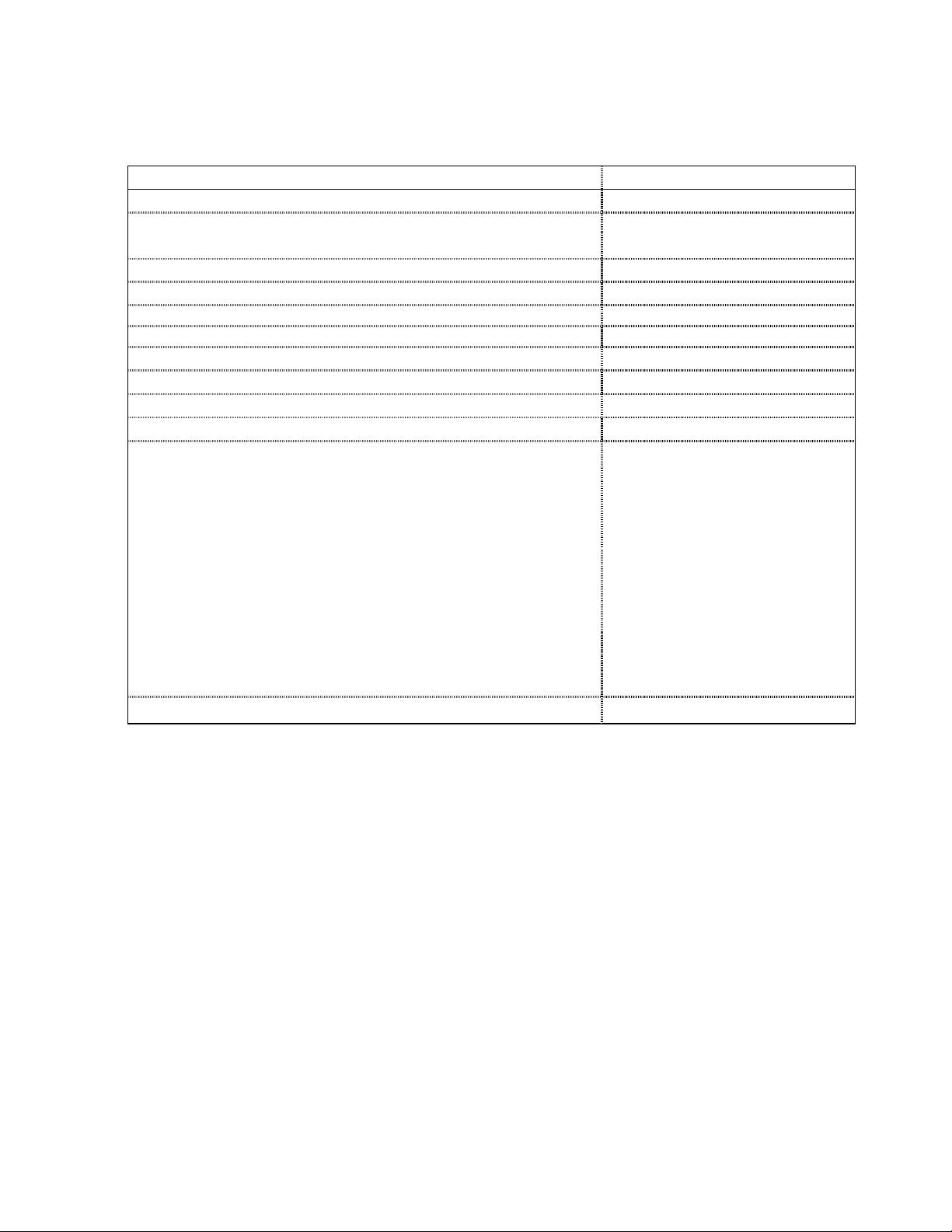

TECHNICAL SPECIFICATIONS

Combustible:

Recommended surface:

Heating Capacity

* :

Optimum efficiency:

Average emissions, EPA:

Color

:

Flue Pipe

Diameter

:

Minimum Vertical Flue Height :

Maximum Log Length

:

Overall:

Combustion Chamber

:

Door Opening:

Weight:

Wood

Up to 1800 square feet

E.P.A :

Seasoned cordwood:

42,600 BTU/h

65,000 BTU/h

80%

4.4 g/h

Type de cheminée : Maximum:

Continuous: :

Metallic Black

6’’ (152 mm)

2100°F (1150 °C)

1200°F (650 °C)

12’ (3,66 m)

Dimensions

17 ’’ (432 mm)

W x D x H

25 7/8’’ x 25 5/8’’ x 22 5/8"

(657 x 651 x 575 mm)

Width x Depth :

Volume :

1.85 ft3 (0,052 m3)

*Why is the BTU indicated on the EPA label smaller than the one advertised?

You will notice a difference between the BTU output as indicated on the unit’s white EPA label affixed to the glass and

the BTU as advertised on our web site and/or product literature. The maximum BTU output we advertise for this unit is

what will be obtained with a full load of seasoned cordwood inserted inside the firebox. The EPA output, on the other

hand, is what has been obtained during emissions testing. The EPA test procedure requires that a special type of wood

be used and positioned inside the firebox in a manner that does not represent the way the firebox volume would

normally be utilized using seasoned cordwood. The EPA test load is typically much smaller. Hence, the BTU as per the

EPA label is reduced. The BTU output that should be considered by a normal user is the one we advertise for seasoned

cordwood.

W x D

18 1/8’’ x 14 3/4 ’’

(460 x 375 mm)

W x H

15 5/8’’ x 8 1/2’’

(397 x 216 mm)

368 lb ( 167 Kg)

4

INSTALLATION

SAFETY NOTICE

• I

F THIS INSERT IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT. TO REDUCE THE RISK

OF FIRE, FOLLOW THE INSTALLATION INSTRUCTIONS. FAILURE TO FOLLOW INSTRUCTIONS MAY

RESULT IN PROPERTY DAMAGE, BODILY INJURY, OR EVEN DEATH

• C

ONSULT YOUR MUNICIPAL BUILDING DEPARTMENT OR FIRE OFFICIALS ABOUT RESTRICTIONS

AND INSTALLATIONS REQUIREMENTS IN YOUR AREA

• U

SE SMOKE DETECTORS IN THE ROOM WHERE YOUR INSERT IS INSTALLED

• K

EEP FURNITURE AND DRAPES WELL AWAY FROM THE INSERT

• N

EVER USE GASOLINE, GASOLINE-TYPE LANTERN FUEL, KEROSENE, CHARCOAL LIGHTER FLUID,

OR SIMILAR LIQUIDS TO START OR "FRESHEN UP" A FIRE. KEEP ALL SUCH LIQUIDS WELL AWAY

FROM THE INSERT

• I

N THE EVENT OF A CHIMNEY FIRE, PUSH THE AIR CONTROL FULL CLOSED TO DEPRIVE THE FIRE

OF OXYGEN. CALL THE FIRE DEPARTMENT

• D

O NOT CONNECT TO ANY AIR DISTRIBUTION DUCT OR SYSTEM

• A

SOURCE OF FRESH AIR INTO THE ROOM OR SPACE HEATED SHALL BE PROVIDED WHEN

REQUIRED

• A

WOOD INSERT MUST NEVER BE INSTALLED IN A HALLWAY OR NEAR A STAIRCASE, SINCE IT MAY

BLOCK THE WAY IN CASE OF FIRE OR FALL TO RESPECT REQUIRED CLEARANCES

•

DO NOT INSTALL IN A SLEEPING ROOM

.

.

.

.

.

.

.

.

.

.

5

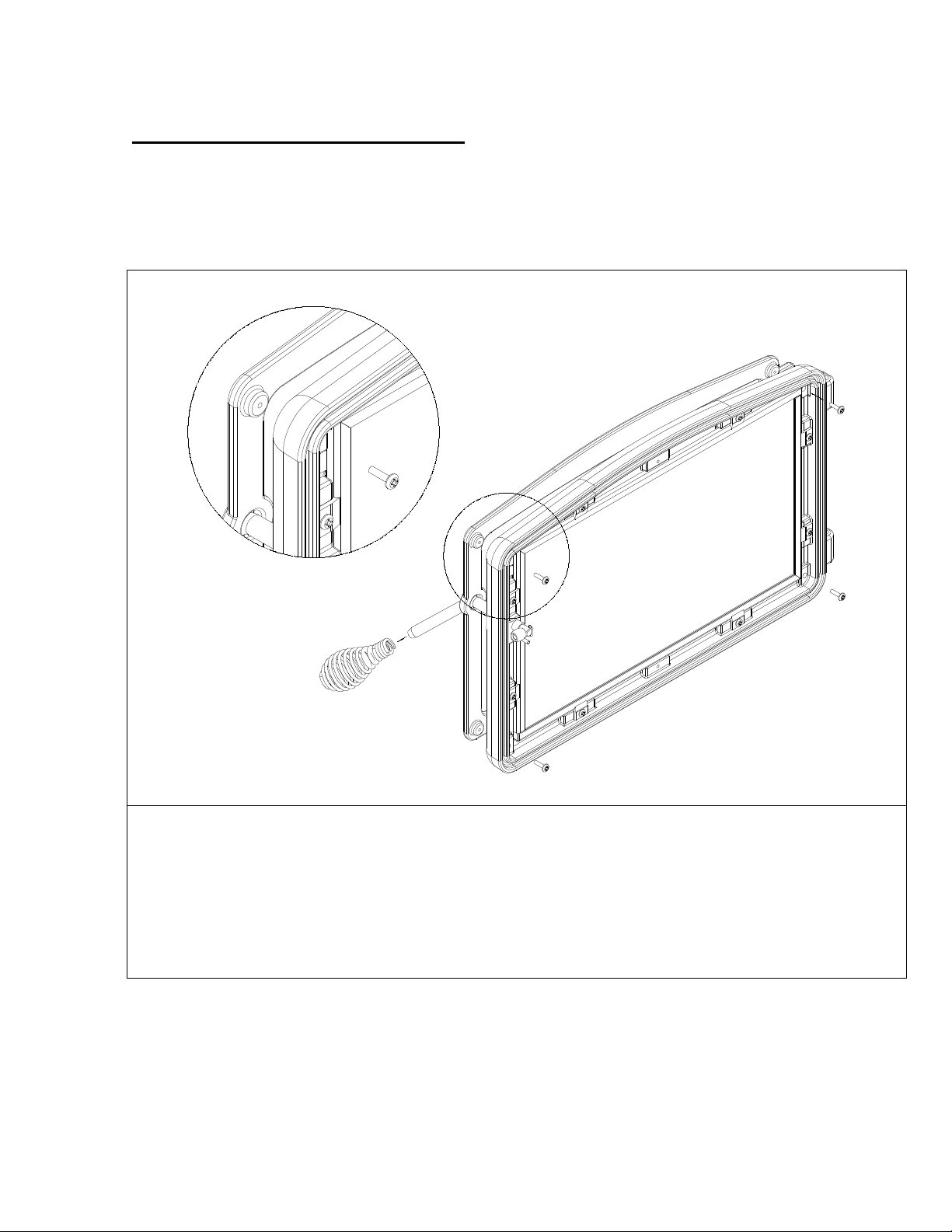

DOOR OVERLAY INSTALLATION

In order to complete the assembly of your Osburn 1600 wood insert, you need to install the door

overlay. See figure 1 below for installation instructions :

1- Position the overlay on the door frame and fix it in place from behind using the

4 screws.

Note: It is not necessary to remove the glass or any other component to install the overlay.

Figure 1 : Door overlay installation

6

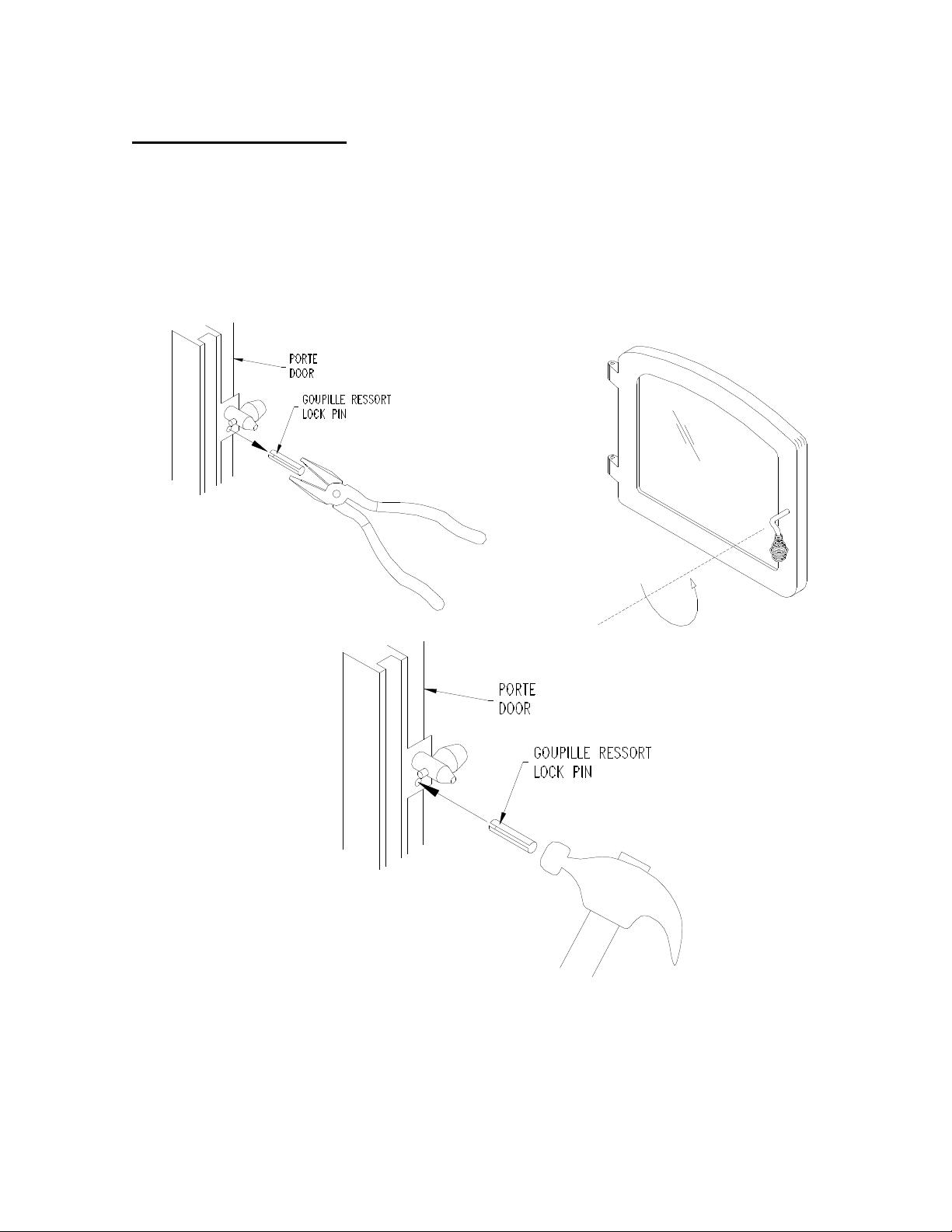

DOOR ADJUSTMENT

In order for your insert to operate properly, the door should be adjusted periodically to

provide an air tight fit. To adjust:

• Remove the lock pin (spring pin) by pulling and turning it using pliers ("wise grip")

• Turn the handle counter clock wise one turn to increase pressure

• Re-install the lock pin (spring pin) with a small hammer

Figure 2: Door Adjustment

7

PRE-INSTALLATION REQUIREMENTS

MASONRY & ZERO CLEARANCE REQUIREMENTS

The masonry fireplace must meet the minimum code requirements, or NFPA 21,1 or the

equivalent for a safe installation. Contact your local Building Inspector for requirements in

your area. An inspection of the fireplace should include the following:

1. CONDITION OF THE FIREPLACE AND CHIMNEY: Examine the masonry fireplace

and chimney prior to installation, to determine that they are free from cracks, loose

mortar, creosote deposits, blockage, or other signs of deterioration. If evidence of

deterioration is noted, the fireplace or chimney should be upgraded prior to installation.

2. INSTALLATION INTO AN EXISTING FACTORY-BUILT ZERO-CLEARANCE

FIREPLACE: It is possible to install a wood insert into an existing factory-built zero-

clearance fireplace. However, there currently exists no UL or ULC standard specific to

that type of installation. The first thing that must be verified is that the factory-built

zero clearance fireplace is listed (it must be certified by a competent certification body

such as Omni or Warnock Hersey). It must be suitable for use with solid fuel and

nothing in the owner’s manual must specifically prohibit the installation of a fireplace

insert. When in doubt, check with the fireplace manufacturer. The installation of the

zero-clearance fireplace MUST be thoroughly inspected by a professional in order to

ensure that it still meets the manufacturer’s specs and code conformity. The chimney

must be of at least 1" (25 mm) larger in diameter to accommodate a required

continuous stainless steel liner running from the flue collar to the top of the chimney

termination.

Never remove parts that serve to insulate the zero-clearance fireplace from

combustible material. Only readily detachable parts that are easily replaced, such as

damper parts, screens, and doors, are to be removed from the fireplace. These parts

must be stored nearby and available for retrofit if the insert is ever removed. Removal

of any parts which render the fireplace unfit for use with solid fuel requires the fireplace

to be permanently labelled by the installer as being no longer suitable for solid fuel

until the removed parts are replaced and the fireplace is restored to its original certified

condition. Furthermore, any air vents, grilles, or louvers that serve to create an air

circulation pattern around and outside the zero-clearance fireplace shall never be

removed.

3. HEARTH EXTENSION: Verify that there is a non-combustible hearth extending at

least 16" in front of the fireplace (18” for Canada, or 457 mm) and at least 8" (203mm)

to the side of the fireplace. Fireplaces without this hearth extension will not meet the

minimum requirements, and will require additional protection.

8

Loading...

Loading...