Orion VII EPA10 Owner's Manual

OPERATOR’S MANUAL

ACADEMY EXPRESS HYBRID 1368A

Printed: December 21, 2010

ORION VII HYBRID VEHICLE

CONTACT INFORMATION:

Daimler Buses North America

350 Hazelhurst Road

Mississauga, Ont ari o

Canada L5J 4T8

Telephone (905) 403-1111

Daimler Buses North America

165 Base Road, PO Box 748

Oriskany, New York

USA 13424

Telephone (315) 223-5100

© 2010 DAIMLER BUSES NORTH AMERICA

Table of Contents

INTRODUCTION ...............................................................................................................................1

GENERAL ......................................................................................................................................... 2

HYBRID ELECTRIC VEHICLE (H.E.V.) SAFETY INFORMATION ...................... ...... ..... ...... ...... ..... .3

Hybrid Electric Vehicle Propulsion System ................................................................................ 3

High Voltage Hazards ................................................................................................................3

OPERATOR’S COMPARTMENT ......................................................................................................4

FRONT INSTRUMENT PANEL .........................................................................................................9

WARNING LIGHTS AND INDICATORS .........................................................................................13

DRIVER’S SIDE CONTROL PANEL ...............................................................................................19

MASTER SWITCH ..........................................................................................................................25

Engine Stop Position ................................................................................................................25

Day Run Position .....................................................................................................................25

Night Run Position ...................................................................................................................25

Park Position ............................................................................................................................25

DESTINATION SIGNS ....................................................................................................................26

Electronic Destination Sign .......................................... ..... ...... ..... ...... ......................................26

Operator’s Display and Keyboard (ODK) .................................................................................26

Destination Sign Dimming Feature .......................................................................................... 28

DRIVER’S SEAT .............................................................................................................................29

USSC™ Q91 Driver’s Seat ......................................................................................................30

Driver’s Seat Belt .....................................................................................................................31

AIR BRAKE SYSTEM OPERATION ...............................................................................................32

Loss of Air Pressure .................................................................................................................32

Wet Weather Operation ...........................................................................................................33

Emergency/Parking Brake Control Valve ................................................................................. 33

Brake Interlock ......................................................................................................................... 34

Page 1

Table of Contents

Rear Axle Brakes Safety Circuit ........................................ ...... ..... ............................................34

Anti-Lock Braking System (ABS) .............................................................................................35

ABS Warning Light ...................................................................................................................35

ENGINE OPERATION ....................................................................................................................36

Pre Start-Up Inspection ............................................................................................................ 36

Starting an Electronically Controlled Engine ............................................................................ 36

Engine Warm Up ...................................................................................................................... 37

Operating the Engine ........................................................ ...... ..... ...... ......................................37

High Idle ................................................................................................................................... 37

Stopping the Engine .................................................................................................................38

Starting Engine From Rear Control Panel ...............................................................................38

Stopping Engine From Rear Control Panel ..............................................................................39

Engine Protection System - Electronically Controlled Engines (Cummins ISB™) ................... 39

B.A.E.™ HYBRID PROPULSION SYSTEM ....................................................................................41

Hybrid Electric Vehicle (HEV) Propulsion System Operation ................................................... 41

Propulsion Control System (PCS) ............................................................................................41

Alternating Current Traction Generator (ACTG) ......................................................................41

Alternating Current Traction Motor (ACTM) .............................................................................42

Motor Speed Warning Indicator ...............................................................................................42

Electric Alternator System (EAS) .............................................................................................42

Propulsion Control System (Emergency) Override Switch ....................................................... 43

Throttle and Brake Pedals .......................................................................................................43

Gear Range Selector Position .................................................................................................43

Stop HEV Indicator ..................................................................................................................44

DRIVER’S PRE-SERVICE INSPECTION ....................................................................................... 45

Driver Walk Around Test ..........................................................................................................45

Page 2

Table of Contents

Exterior Inspection ...................................................................................................................45

Interior Inspection ....................................................................................................................45

LIGHTING AND ELECTRICAL ........................................................................................................47

Lighting Operation .................................................................................................................... 47

Interior Lighting ........................................................................................................................ 47

Exterior Lighting ....................................................................................................................... 48

Batteries ...................................................................................................................................49

Disconnection of Electrical System .......................................................................................... 49

HEATING, AIR CONDITIONING, AND VENTILATION ...................................................................51

Front Heat/Defrost Blower Switch ................................ ..... ...... .................................................51

Climate Control System ......................................... ...... ............................................................52

Climate Control System Switch ................................................................................................ 52

Driver’s Booster Blower Switch ................................................................................................52

Fresh Air Ventilation .................................................................................................................53

Driver’s Fan .............................................................................................................. ................53

IntelligAIRE™ Climate Control System ....................................................................................54

PASSENGER ENTRANCE AND EXIT DOORS .............................................................................56

Accelerator Interlock ................................... ..... ...... ...... ..... .......................................................56

Door System Operation ...........................................................................................................56

Pull Cord Stop Request ................................... ...... ...... ............................................................57

Speed Sensing Interlock ..........................................................................................................57

Malfunction in Opening and Closing Front Door ......................................................................57

Door Master Switch ..................................................................................................................58

Malfunction in Opening and Closing Rear Doors .....................................................................58

External Front Door Access Switch .........................................................................................59

EMERGENCY ESCAPE EXITS ......................................................................................................60

Page 3

Table of Contents

Push Out Egress Windows ......................................................................................................60

Rear Roof Hatch ...................................................................................................................... 60

KNEELING SYSTEM .......................................................... ..... ...... ..... ...... ......................................61

Kneeling System Operating Procedure ....................................................................................61

WHEELCHAIR RAMP SYSTEM .....................................................................................................63

Ramp Malfunction .................................................. ...... ..... ...... ..... ............................................63

Operation .................................................................................................................................63

WHEELCHAIR RESTRAINT SYSTEM ...........................................................................................65

Mobility Device Securement Instructions .................................................................................65

ENGINE COOLING SYSTEM ......................................................................................................... 67

Checking and Replenishing Engine Coolant ............................................................................67

High Coolant Temperature .......................................................................................................68

Low Engine Coolant Level .......................................................................................................68

Modular Traction System (MTS) Coolant ................................................................................. 69

AMEREX™ FIRE SUPPRESSION SYSTEM ..................................................................................70

Fire Suppression System .........................................................................................................71

Automatic Operation ................................................................................................................72

Manual Operation ....................................................................................................................72

EXTERIOR COMPARTMENT AND SERVICE ACCESS DOORS .................................................74

GENERAL DATA AND TECHNICAL INFORMATION .................................................................... 77

Reporting Safety Defects .........................................................................................................78

Page 4

Introduction

INTRODUCTION

This manual describes the operating features and safety equipment of the Orion VII EPA10 Hybrid Vehicle. All

personnel involved in the operation of this vehicle should read this manual before providing any public service.

For additional information or assistance, refer to the contact information located at the back of this manual.

Page 1

General

GENERAL

The Orion VII EPA10 hybrid vehicle incorporates specia lly des igned features that provi de transp orta tion to the mobili ty

impaired and physically challenged. It is the operator’s responsibility to assist each passenger in boarding, seating,

attaching and securing restraining belts, and to provide assistance when leaving the vehicle.

Special features of the vehicle fulfill passenger needs in the following areas:

• Kneeling and wheelchair ramp

features allow coach floor to

street level access for the

wheelchair bound individual.

• Restraining belts and

securement devices are

located at all wheelchair

positions.

• Pull cords and push buttons

alert the operator of the NEXT

STOP request, are easily

accessible.

Page 2

Hybrid Electric Vehicle (H.E.V.) Safety Information

DANGER

DANGER

DANGER

HYBRID ELECTRIC VEHICLE (H.E.V.) SAFETY INFORMATION

Hybrid Electric Vehicle Propulsion System

Due to extremely high voltage

supplied by the energy storage

system (ESS), the propulsion

system contains a battery isolator

switch which allows the operator to

cut off propulsion system power in

special circumstances such as a

vehicle accident. This switch is

located in the curbside battery

compartment.

of Electrical System” on page 49.

See “Disconnection

High Voltage Hazards

Use extreme caution if any work

has to be performed on the

engine while it is running. High

voltage is present at the

generator terminals, traction

motor terminals, and all high

voltage cabling connecting the

generator and traction motor to

the Propulsion Control System

(PCS).

Use of the Battery Isolator

Switch is mandatory during

propulsion system maintenance.

If the vehicle was running just

prior to conducting

main99tenance, allow four

minutes for propulsion system

components to discharge

electricity before proceeding.

Even with the Battery Isolator

Switch in the OFF position, the

traction battery system remains

a severe shock hazard because

the battery modules themselves

are not disconnected by the use

of this switch. Always use

extreme caution when working

around the rooftop tub.

Although the operator would rarely

have access to any of the

propulsion system components,

he/she must be made aware of the

potential hazards.

Should a problem exist which

requires attention to the propulsion

system, the matter should

immediately be brought to the

attention of qualified service

personnel. For further information

on the HEV system, refer to BAE

Systems™ maintenance manual.

Page 3

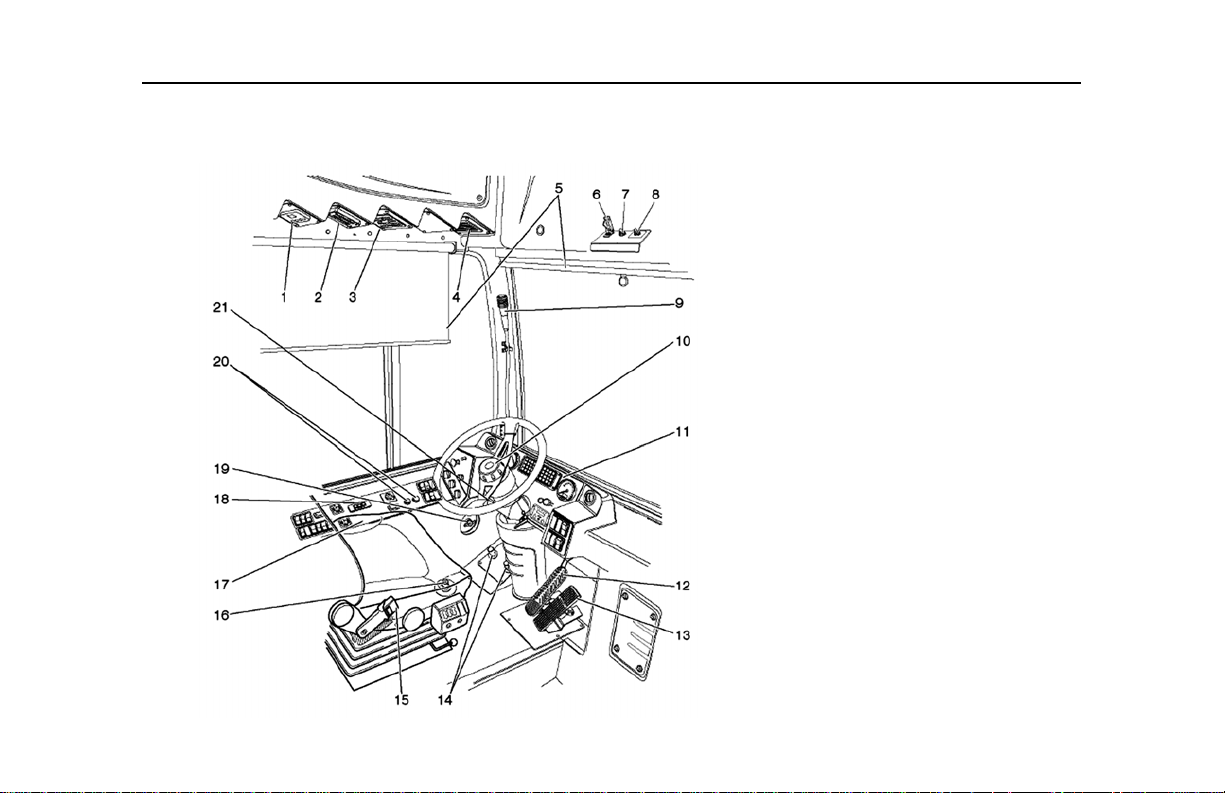

Operator’s C ompartment

OPERATOR’S COMPARTMENT

LEGEND

1. IntelligAIRE III™ Display Panel

2. Passenger Stop Request Chime

Unit

3. Destination Sign Keypad

4. Driver’s Booster Blower Vent

5. Driver’s Pull Down Sunvisors

6. Door Master Switch

7. Exhaust Regeneration Override

Switch

8. Regenerative Braking Switch

9. Gooseneck Microphone

10. Horn Button

11. Front Instrument Panel

12. Brake Pedal

13. Accelerator Pedal

14. Directional Signal Foot Control

Switches

15. Driver’s Seat

16. Headlight Dimmer Foot Control

Switch

17. Side Control Panel

Page 4

Operator’s C ompartment

CAUTION !

LEGEND

18. Alternating Current Traction

Motor (ACTM) Gear Selector

19. Door Emergency Release Valve

20. Driver’s Door Control Push

Buttons

21. Tilt/Telescopic Steering Column

Lever

The following features and special

equipment are used for normal

vehicle operation.

1. IntelligAIRE™ Display Panel

This display panel includes 4

touch keys, a 3 digi t display and

various display indicators. The

panel provides outside and

inside temperature readouts

and setpoint adjustments only.

See “IntelligAIRE™ Climate

Control System” on page 54.

2. Passenger Stop Request

Chime Unit

A single chime will be heard

from this unit when a

passenger, requesting a stop,

activates the touch tape. A

double chime notifies the

operator that a wheelc hair

passenger is requesting a stop.

3. Destination Sign Keypad

This keypad is used for

destination sign message

selection and programming.

See “Operator’s Display and

Keyboard (ODK)” on page 26.

4. Driver’s Booster Blower Vent

An auxiliary blower and vent

located inside the overhead

panel, above the operato r’s

roadside window, provides the

operator’s area with additional

climate control.

See “Fresh Air

Ventilation” on page 53.

5. Driver’s Pull Down Sunvisors

These adjustable pull down

mechanisms, loca ted above the

operator windshield and

operator’s side window,

prevents eye exposure to

sunlight. A scissor type

reinforcement retain s the

shades rigidity a nd prevents the

shade from excessive swaying.

6. Door Master Switch

Apply the parking or service

brakes before removing the door

master switch from its normally

guarded position to prevent the

vehicle from rolling.

The Door Master switch is a

guarded two position (NORM,

DISABLE) toggle switch used

to override a door malfunction

that is activating the door

interlock system a nd preventing

the service brakes and

accelerator interlocks from

releasing.

7. Exhaust Regeneration

Override Switch

The Exhaust Regeneration

Override swi tch is used in

situations where the front dash

HEST lamp is illuminated and

Page 5

Operator’s C ompartment

NOTE

the vehicles exhaust outlet is

near an area that could be

effected by high temperatures.

8. Regenerative Braking

Disable Switch

This two position (ON, OFF)

toggle switch enables the

operator to deactivate

regenerative braking in the

hybrid propulsion system. The

Regenerative disable switch

should be used only during

slippery, hazardous road

conditions.

9. Gooseneck Microphone

This microphone allows for

flexible operation of the

vehicles’ public address

system. A switch on the

microphone allows the operator

to activate the Public Address

system.

10. Horn Button

Pressing the disk in the center

of the steering wheel activates

two electrical horns.

11. Front Instrument Panel

This panel, located in front of

the operator, contains gauges,

indicator lights , and contro ls for

operating and monitoring

various vehicle systems. See

“Front Instrument Panel” on

page 9.

12. Brake Pedal

A "creep forward" mode is

present in all EPA10 hybrid

vehicles; as a result, the vehicle

will creep forward when the gear

range selector is in the D (drive)

position and the brake pedal is

released.

This foot-operated treadle

valve, located on the

compartment floor to the

immediate right of the steering

wheel, applies the vehicle

service brakes.

13. Accelerator Pedal

This foot operated pedal,

remotely controls the engine

fuel governor control, which in

turn controls the speed of the

vehicle.

This pedal is located on the

compartment floor to the right

of the brake pedal.

14. Directional Signal Foot

Control Switches

These two foot switches,

located on the floor to the lef t of

the steering wheel, ac tiv ate the

left and right turn signal lights.

Each switch must be pres se d

and held for the duration of the

signal.

15. Driver's Seat

The driver’s seat is equipped

with comfort options to

accommodate most operators.

See “Driver’s Seat” on

page 29.

Page 6

Operator’s C ompartment

WARNING

16. Headlight Dimmer Foot

Control Switch

This foot switch, when

activated, selects the headlight

high or low beam settings.

17. Side Control Panel

This panel, located on the left

hand side of the operator,

contains controls and switches

necessary for various vehicle

systems operations.

These systems include climate

control, front and rear door

control, master control of the

vehicle electrical system,

lighting, etc. See “D river’s

Side Control Panel” on

page 19.

18. Alternating Current Traction

Motor (ACTM) Gear Selector

Drive modes available on this

selector are Drive (D), Neutral

(N), and Reverse (R).

“Gear Range Selector

Position” on page 43.

See

19. Door Emergency Release

Valve

This rotary air valve overrides

the air system to allow front

doors to be opened manually.

See “Malfunction in Opening

and Closing Front Door” on

page 57.

20. Driver’s Door Control Push

Buttons

The rear and front door

controller push buttons allow

the operator to activate the

front and/or rear door s. Press

once to open and press again

to close the doors.

21. Tilt/Telescopic Steering

Column Lever

Stop the vehicle and apply the

parking brake before adjusting

the steering column. Failure to

do so could result in loss of

vehicle control, causing perso nal

injury and/or vehicle damage.

The steering column is

equipped with adjustment

features that accom modate the

size and height of most

operators. Tilt and height

features are adjusted using a

lever on the left hand side of

the steering column.

To adjust the tilt angle:

a. Pull back on the lever.

b. Grasp the steering wheel

and adjust the angl e forward

and aft until the desired

angle is reached.

Page 7

Operator’s C ompartment

c. Push down slightly on the

lever and gently articulate

the wheel until the column

locks in place.

Page 8

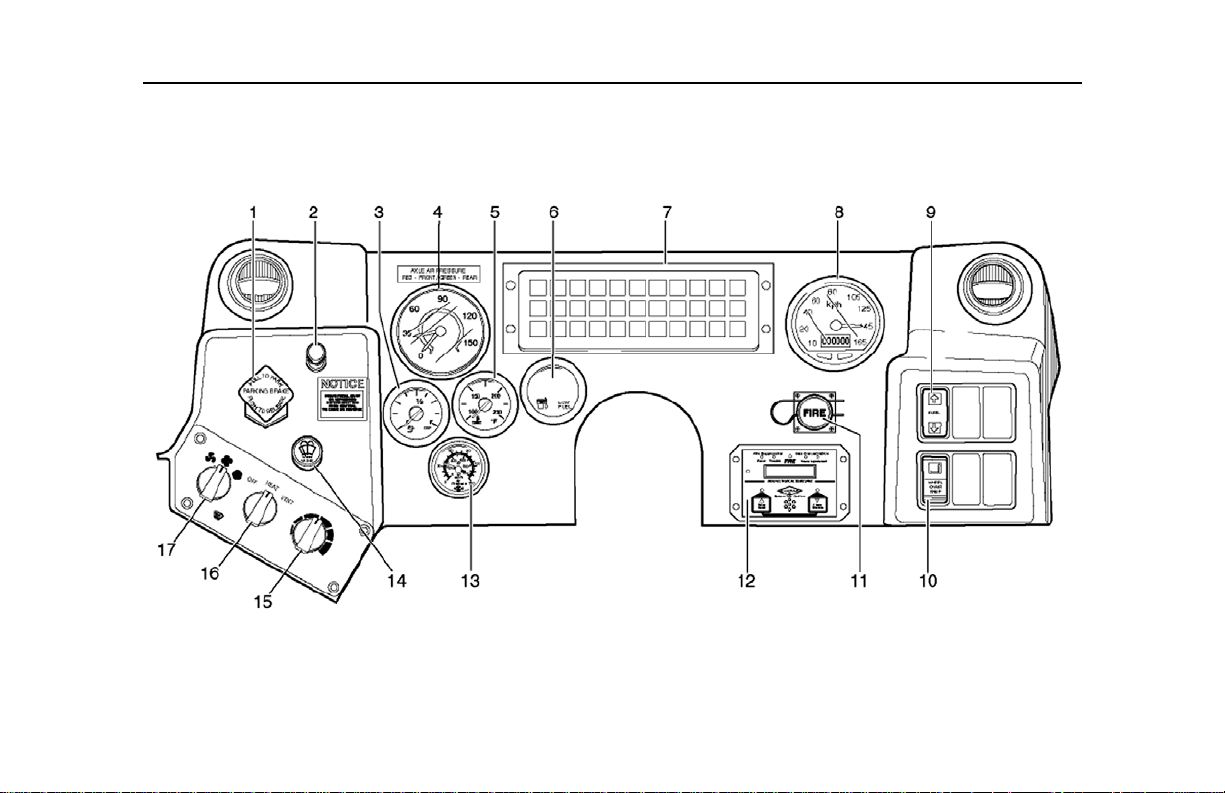

FRONT INSTRUMENT PANEL

Front Instrument Panel

Page 9

Front Instrument Panel

LEGEND

1. Parking/Emergency Brake

Control

2. Wiper Control Lamp

3. Diesel Emission Fluid (DEF)

Gauge

4. Air System Pressure Gauge

5. Engine Coolant Tem perat ure

Gauge

6. Diesel Fuel Gauge

7. LED Warning Lights and Indicator

Panel

8. Speedometer/Odometer Gauge

9. Kneeling System Switch

10. Wheelchair Ramp Switch

11. Manual Fire Suppression Button

12. Automatic Fire Suppression

System (AFSS) Display Panel

13. Accessory Tank Air Pressure

Gauge

14. Windshield Wiper/Washer Control

Valve

15. Driver’s Temperature Control

16. Driver’s Heat/Ventilation Control

17. Driver’s Heater/Defroster Control

The front instrument panel is a

collection of gauges, controls, and

warning indicators used to operate

and monitor various vehicle

systems.

1. Parking/Emergency Brake

Control

This Push/Pull valv e applies the

rear wheel spring brakes when

parking. It may also be used to

stop the vehicle in an

emergency situation.

PULL on the valve knob to

apply brakes, and PUSH to

release br akes.

See

“Emergency/Parking Brake

Control Valve” on page 33.

2. Wiper Control Lamp

This fixture illuminates the

wiper controls.

3. Diesel Emission Fluid (DEF)

Gauge

This gauge measures the

amount of DEF in the 10.6

gallon reservoir tank. Diesel

emission fluid is mixed with hot

exhaust, resulting in an

alteration of the chemical

composition of the ex haust to

make it EPA10 compliant.

A solid red light indicates an

initial warning level of 16.6%;

under such conditions,

removed the vehicle from

service immediately.

A flashing red light indicates a

critical warning level of 11%;

under such conditions,

immediately move the vehicle

to a safe location and shutdow n

the engine.

4. Air System Pressure Gauge

This dual indicator gauge

monitors brake circuit air

pressure for both primary and

secondary air circuits.

Normal air system pressure

should not register below

70 psi.

The spring brakes w ill gradually

apply automatically if pressure

Page 10

Front Instrument Panel

NOTE

is lost, and will be fully app lied if

pressure drops to 40 psi.

“Air Brake System

Operation” on page 32.

5. Engine Coolant Temperature

Gauge

This gauge registers the engine

coolant temperature. The

gauge is designed to register a

temperature range from 100° 260°F (38° - 127°C). The

normal operating temperature

is between 180° - 200°F (82° 93°C). If the temperature

continues to rise above this

range, the excessive high

temperature will trigger an

audible alarm and il luminate the

CHECK ENGINE indicator on

the front instrument pa nel. If the

engine temperature continues

to rise above 212°F (100°C),

the engine control unit (ECU)

will commence shutdown

sequence.

See

6. Diesel Fuel Gauge

This gauge indicator monitors

the amount of diesel fuel in the

125 gallon fuel tank.

Approximately 18 gallons of

fuel remains in the fuel tank

when the low fuel light on the

gauge illuminates. An EMPTY

reading indicates 11.7 gallons

of fuel remaining in the fuel

tank.

The vehicle will run out of fuel

with 5.37 gallons remaining in

the fuel tank.

7. LED Warning Lights and

Indicator Panel

The vehicle is equipped with a

visual and audible signal

system that is designed to

indicate the various warnings

and normal operating

conditions during vehicle

operation.

See “Warning

Lights and Indicators” on

page 13.

8. Speedometer/Odometer

Gauge

This combination needle

indicator and digital counter

registers vehicle speed and

records distance travelled. In

addition, the speedometer is

equipped with and audible text

messaging feature which will

notify the operator if a Low

Coolant, or Low Oil Pressure

situation exists.

9. Kneeling System Switch

Kneeling is controlled by this

momentary switch which lowers

the front of the vehicle

approximately 3 1/2 inches, to

enable easier access when

boarding the vehicle.

“Kneeling System” on

page 61.

10. Wheelchair Ramp Switch

This rocker switch controls the

operation of the front door

See

Page 11

Front Instrument Panel

NOTE

ramp, allowing wheelchair

access.

When activated, the green

warning light flashes and an

audible alarm sounds.

“Wheelchair Ramp System”

on page 63.

11. Manual Fire Button

This button allows the operator

to manually activate the fire

bottle. To operate, break the

seal, pull out the ring and pres s

the FIRE button.

12. Automatic Fire Suppression

System (AFSS) Display Panel

This display panel includes

basic to read LED’s and audio

alarm indication. Detailed

EVENTS are documented on

See

the Vacuum Fluorescent

Display (VFD) panel.

The methane functions are not

applicable to this vehicle.

13. Accessory Tank Air Pressure

Gauge

This gauge monitors the

amount of air remaining in the

front accessory air tank.

14. Windshield Wiper/Washer

Control Valve

This rotary knob controls the

left and right windshield wiper

and has a bui lt in washer

control.

Push in and hold to dispense

washer fluid.

15. Driver's Temperature Control

This rotary control knob

enables the operator to

regulate the temperature in the

operator’s area compartment.

See “Heating, Air

Conditioning, and

Ventilation” on page 51.

16. Driver's Heat/Ventilation

Control

This three positi on (OFF, HEAT ,

VENTILATION) rotary control

knob allows the operator to

select either heat or air flow

ventilation mode.

17. Driver’s Heater/Defroster

Control

This three position (LOW,

MEDIUM, HIGH) control knob

allows air to flow to the front

windshield, and the front

operator’s area.

Page 12

WARNING LIGHTS AND INDICATORS

Warning Lights and Indicators

Page 13

Warning Lights and Indicators

LEGEND

1. Stop Engine Indicator

2. Left Turn Signal Indicator

3. Alternator Indicator

4. Low Air Pressure Indicator

5. Brake ON Indicator

6. Parking Brake Applied Indicator

7. Check Hybrid Electric Vehicle

(HEV) Indicator

8. High Beam Indicator

9. Kneeling Indicator

10. Next Stop Indicator

11. Wheelchair Stop Indicator

12. Rear Door Indicator

13. Right Turn Signal Indicator

14. Wheelchair Ramp Indicator

15. Warning Interlock Deactivated

Indicator

16. Door Alarm Indicator

17. Air Conditioning (A/C) Fail

Indicator

18. Motor Over-Speed Warning

Indicator

19. Low Steering Fluid Indicator

20. Stop Hybrid Electric Vehicle

(HEV) Indicator

LEGEND

21. Class Door Indicator

22. Regenerative Braking Applied

Indicator

23. Regenerative Braking OFF

Indicator

24. High Exhaust System

Temperature (HE ST ) Indicator

25. Exhaust Regeneration Inhibit

Indicator

26. Wait to Start Indicator

27. Anti-Lock Braking System (ABS)

ON Indicator

28. Check Engine Indicator

29. Hybrid Coolant Low Indicator

These LED warning lights and

status indicators illuminate to alert

the operator to normal operating

conditions, as well as conditions

that may affect normal vehicle

operation.

All lights illuminate briefly at

start-up, when the Master Switch is

placed in the DAY RUN position.

The operator should verify all LED

illuminations on a daily basis and

report any dimmed or failed units to

service/maintenance personnel.

Distinct audible alarms and

illuminated indicators indicate

conditions that requ ire an immediate

response.

1. Stop Engine Indicator

This red indicator illuminates

when a serious malfunction is

detected in the engine system.

This malfunction could

potentially prohibit safe

operation of the engine and

vehicle.

If this condition occurs,

immediately remov e the vehicle

from service to a safe location,

and shutdown the engine.

Report the fault to

service/maintenanc e personnel

immediately.

Page 14

Warning Lights and Indicators

NOTE

2. Left Turn Signal Indicator

This green indicator flashes

ON/OFF when the roadside

directional signals are

operating.

3. Alternator Indicator

This red indicator illuminates

when a fault occurs in the

Electric Alternator System

(EAS).

4. Low Air Pressure Indicator

This red indicator illuminates,

accompanied by an audible

alarm, when the a ir pressure, in

the primary and/or secondary

reserve tanks, is low.

Minimum primary air system

pressure should be 70 psi, as

indicated on the air system

pressure gauge. The brake

system automatically starts to

apply as pressure drops below

40 psi.

If this condition occurs,

immediately remove th e vehicle

from service to a safe location

and shutdown the engine. Do

not operate the vehic le unti l the

fault has been corrected.

Report the fault to

service/maintenanc e personnel

immediately.

5. Brake ON Indicator

This red indicator illuminates

when a serv ice brake

application is made due to an

application of the brake treadle

valve, an application of the

parking brake, or the activation

of the brake interlock system.

A firm brake application must be

made after a door cycle in order

to shift out of neutral, release the

brakes and enable the throttle.

6. Parking Brake Applied

Indicator

This red indicator illuminates

when parking brakes are

applied.

7. Check Hybrid Electric V ehicle

(HEV) Indicator

This amber indicato r illuminates

when a fault has been detected

in the HEV propulsion system.

The vehicle may be driven

safely but should be taken in to

service for diagnosis as soon

as possible to avoid serious

damage to the system.

8. High Beam Indicator

This blue indicator illuminates

when headlight high beam s are

applied.

9. Kneeling Indicator

This red indicator illuminates

and an audible alarm is

activated, when the kneeling

system is activated.

Page 15

Warning Lights and Indicators

This indicator remains

illuminated until proper ride

height has been attained. See

“Kneeling System” on

page 61.

10. Next Stop Indicator

This amber indicator

illuminates, accompanied by a

sounding chime, when a

passenger, requesting the next

stop, has activated the touch

tape.

In addition, a STOP REQUEST

sign, located on the ceiling at

the standee line, will illuminate.

11. Wheelchair Stop Indicator

This amber indicator

illuminates, accompanied by a

sounding chime (double

chime), when a passenger,

requesting the next stop, has

activated the touch tape at a

wheelchair position.

In addition, a STOP REQUEST

sign, located on the ceiling at

the standee line, will illuminate.

12. Rear Door Indicator

This red indicator illuminates

when the rear exit door is open

or authorized by the operator

under normal operation. In

addition, this indicator will also

illuminate if the rear door

sensitive edge detects an

obstruction which is p reventing

the door panels from closing

completely.

13. Right Turn Signal Indicator

This green indicator flashes

ON/OFF when the curbside

directional signals are

operating.

14. Wheelchair Ramp Indicator

This red indicator illuminates

and an exterior audible alarm

and amber flashing light is

activated when the ramp is

deployed. See “Wheelc hai r

Ramp System” on page 63.

15. Warning Interlock

Deactiva ted Indicator

This red indicator will illuminate

when the door master switch

has been activated and the

interlocks have been bypassed.

16. Door Alarm Indicator

This red indicator flashes and

an audible alarm sounds when

the rear door emergency

handle is pulled. In ad dit ion t he

rear door overhead light will

flash continuously.

17. Air Conditioning (A/C) Fail

Indicator

This red indicator illuminates

when the air conditioning (A/C)

system operation is interrupted

due to a system fault.

Possible faults inc lude hi gh/ low

pressure and loss of refriger ant

or condenser fan failure. The

A/C system will switch

automatically to ventilation

mode.

Page 16

Warning Lights and Indicators

CAUTION !

Report the fault to

service/maintenance

personnel.

18. Motor Over-Speed Warning

Indicator

This red indicator illuminates

when the vehicle’s speed

exceeds the maximum limits of

the hybrid propulsion system.

Speed must be reduced by

activating the vehicle brakes,

failure to do so may result in

damage to the hybrid

propulsion system.

19. Low Steering Fluid Indicator

This red indicator illuminates

when the fluid level in the

steering pump reservoir is low.

Report the fault to

service/maintenance p ersonnel

immediately.

20. Stop Hybrid Electric Vehicle

(HEV) Indicator

This red indicator illuminates

and an audible alarm is

activated when a severe fa ult is

detected within the hybrid

propulsion system.

Immediately move the vehicle

to a safe location and shutdo wn

engine.

Indicator” on page 44.

21. Class Door Error Indicator

This red indicator illuminates

when a fault has been detected

with the rear door Contact-less

Acoustic Sensing System.

The class error fault will not

prohibit operation of the rear

doors.

22. Regen erative Braking

Applied Indicator

This red indicator illuminates

when regenerative braking is

occurring in the hybrid

propulsion system.

23. Regenerative Bra king OFF

Indicator

This red indicator illuminates

when regenerative braking

See “Stop HEV

switch, located in the front

destination sign compartment,

is placed in the OFF position.

24. High Exhaust System

Temperature (HEST)

Indicator

Exhaust heat can reach 812°F

(433.3° C). Ensure that the

exhaust outlet is away from

areas that could potentially be

damaged by severe heat.

This amber indicato r illuminates

to notify the operator of a high

heat hazard caused by the

exhaust system entering the

process of active regeneration.

When the vehicle is engaged in

active regeneration, the

exhaust will produce

temperatures in excess of

812°F (433.3°C) and caution

must be taken to ensure a two

foot minimum clearance of the

Page 17

Warning Lights and Indicators

exhaust outlet from ot her items

that can be effected by high

temperatures. In such

situations, activat e the Exh aus t

Regeneration OFF switch,

located on the front instrument

panel.

25. Exhaust Regeneration Inhibi t

Indicator

This amber indicato r illuminates

to notify the operator that the

EXHAUST REGENERATION

OVERRIDE switch is activated

and no active regeneration is

possible . This may force the

necessity of a Stationary

Regeneration.

26. Wait to Start Indicator

This amber indicator will

illuminate when the Master

Switch is placed in the DAY

RUN position, prior to activating

the ENGINE START button.

This allows the Cummi ns ISB™

intake air grid heater to warm

up the air intake manifold to a

sufficient temperature 4.4°C

(40°F) for start up.

Once the operating

temperature has be en reached,

the indicator lamp will turn OFF

and the engine will be re ady for

start up.

27. Anti-Lock Braking System

(ABS) ON Indicator

This amber indicato r illuminates

momentarily, for a bulb check

only, when the ABS is initially

activated.

The indicator illuminates, and

remains illuminated, when a

fault is detected in the ABS

system.

Light” on page 35.

28. Check Engine Indicator

This amber indicato r illuminates

when the engine electronic

control unit detects a

malfunction in the engine

system. This cond ition will NOT

prohibit safe operation of the

engine or vehicle.

See “ABS Warning

Report the fault to

service/maintenanc e personnel

as soon as possible.

29. Hybrid Coolant Low Indicator

This red indicator illuminates

and an audible alarm sounds

when the fluid level in the MTS

coolant reservoir is low.

Report the fault to

service/maintenanc e personnel

immediately.

Page 18

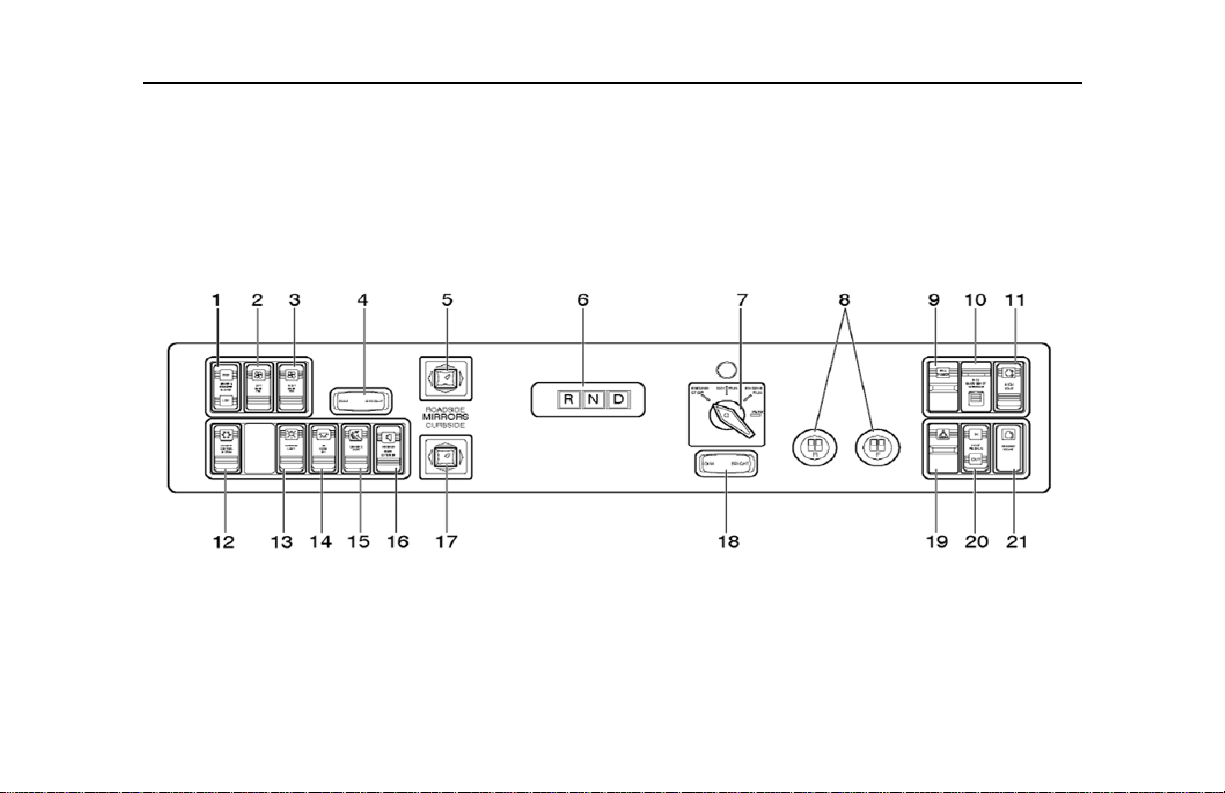

DRIVER’S SIDE CONTROL PANEL

Driver’s Side Control Panel

Page 19

Driver’s Side Control Panel

LEGEND

1. Driver’s Booster Blower Switch

2. Left Dash Fan Switch

3. Right Dash Fan Switch

4. Driver’s Light Dimmer Switch

5. Roadside Mirror Control

6. Alternating Current Traction

Motor (ACTM) Gear Selector

7. Master Switch

8. Driver’s Push Button Door

Controller

9. Hill Holder Switch

10. Propulsion Control System (PCS)

Emergency Override Switch

11. High Idle Switch

12. Climate Control System Switch

13. Farebox Light Switch

14. Interior Light Switch

15. Driver’s Light Switch

16. Speakers Switch

17. Curbside Mirror Control

18. Instrument Panel Dimmer Switch

19. Hazard Switch

20. Foot Pedals Switch

21. Engine Start Switch

The driver’s side control panel is

equipped with controls for

activating, deactivating, and

overriding vehicle co ntrol syst em s.

Systems include interior and

exterior lighting, engine control,

door control, suspension kneeling,

climate control, and P.A. systems.

All are enabled/dis abled, depen ding

on the position of the Master Switch.

See “Master Switch” on page 25.

1. Driver’s Booster Blower

Switch

This three position (HIGH, O FF,

LOW) rocker switch allows the

operator to activate the

overhead blower unit in the

operator’s compartment, for

increased circulati on.

2. Left Dash Fan Switch

This three position (HIGH, O FF,

LOW) rocker switch allows the

operator to activate the lef t front

dash mounted fan.

3. Right Dash Fan Switch

This three position (HIGH, O FF,

LOW) rocker switch allows the

operator to activate the right

front dash mounted fan.

4. Driver’s Light Dimmer Switch

This momentary rocker switch

allows the operator to increase

or decrease the intensity of the

operator’s light; loca ted di rec t ly

above the operator.

5. Roadside Mirror Control

This four-way push button

control remotely adjust s the

exterior roadside mirror to the

operator’s individual needs.

The operator can adjust the

position of the mirror by

pushing the knob either UP,

DOWN, LEFT or RIGHT.

6. Alternating Current Traction

Motor (ACTM) Gear Selector

The drive modes available on

this selector are Drive (D),

Neutral (N), and Reverse (R).

For gear transition, Neutral

Page 20

must always be activated first.

NOTE

NOTE

NOTE

See “Gear Range Selector

Position” on page 43.

7. Master Switch

This four position rotary switch

enables various electrical

systems under the following

selected positions: ENGINE

STOP, DAY RUN, NIGHT RUN,

or PARK.

Switch” on page 25.

8. Driver’s Door Control Push

Buttons

The rear and front door

controller push buttons

provides the operator with

complete control over the front

and rear doors. Press once to

open and press again to close

the doors.

See “Master

When the front or rear door is

opened, the activated button will

remain illuminated until the door

is closed.

9. Hill Holder Switch

This two position momentary

(ON, OFF) rocker switch

manually activates the brake

interlock circuit to prevent the

vehicle from rolling w hen on an

inclined surface.

The throttle will still be active

while the Hill Holder switch is

activated. Releasing the Hill

Holder switch will release the

brake interlocks.

Driver’s Side Control Panel

Releasing the brake pedal while

the Hill Holder switch is in the

ON position and the doors are

closed, will cause the vehicle to

slowly creep forward.

10. PCS Emergency Override

Switch

This rocker switch will override

the HybriDrive™ protection

system. This will allow the

propulsion system to operate

with known faults for as long as

the switch is depressed.

T o activate the PC S Emergency

Override switch, release the

locking tab by pushing and

Page 21

Loading...

Loading...