Page 1

www.orioncontrols.com

LED BLINK CODES

LED NAME STATUS1 STATUS2

NORMALOPERATION 0 1

SATFAIL 1 2

OATFAIL 2 2

SPCFAIL 3 2

MODULEALARM 4 2

MECHCOOL FAIL 1 3

MECHHEAT FAIL 2 3

FANPROOF FAIL 3 3

DIRTYFILTER 4 3

EMERGENCYSHUTDOWN 5 3

LOWSAT 1 4

HIGHSAT 2 4

CONT.TEMP COOL FAIL 3 4

CONT.TEMP HEAT FAIL 4 4

PUSHBUTTON OVR 1 5

ZONEOVR 2 5

OUTPUTFORCE ACTIVE 0 6

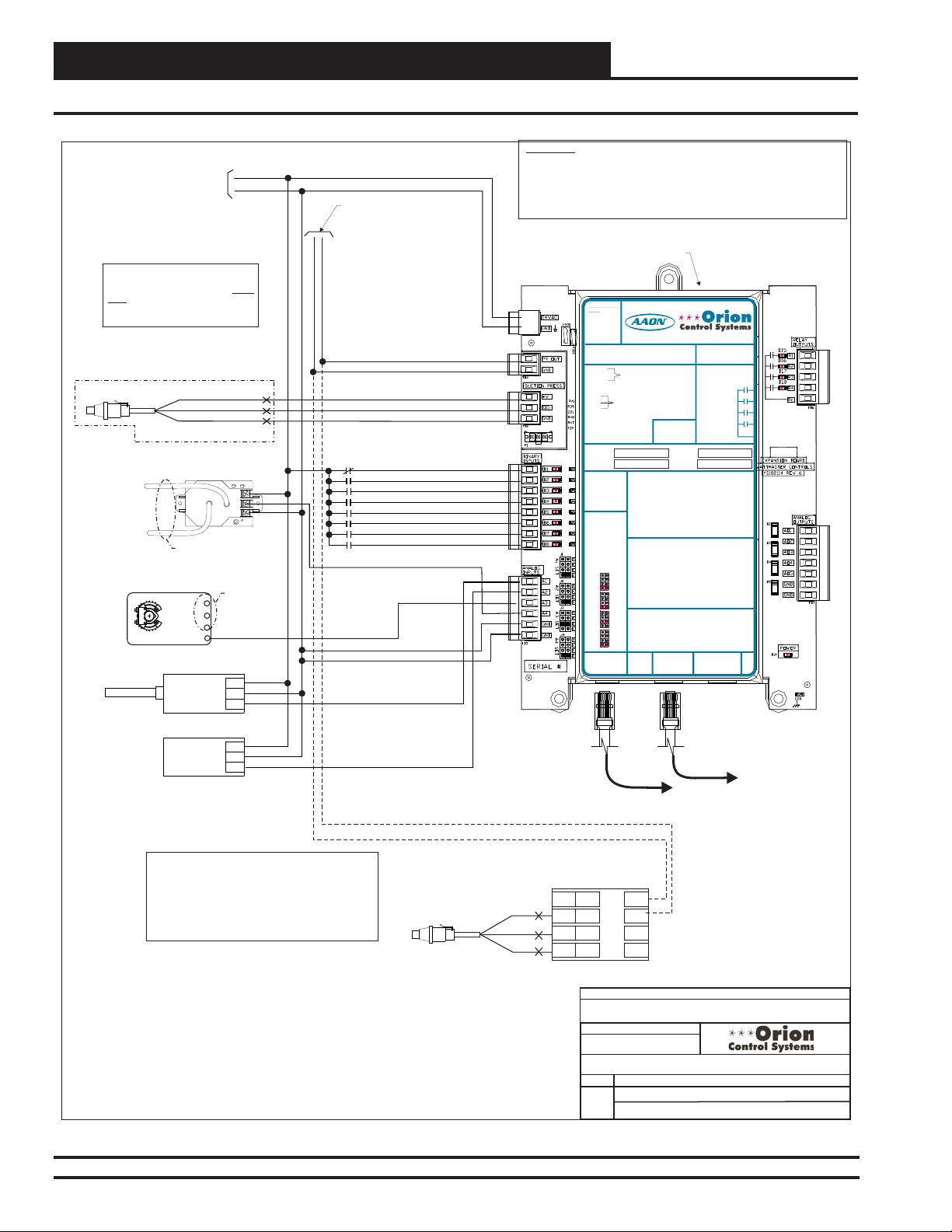

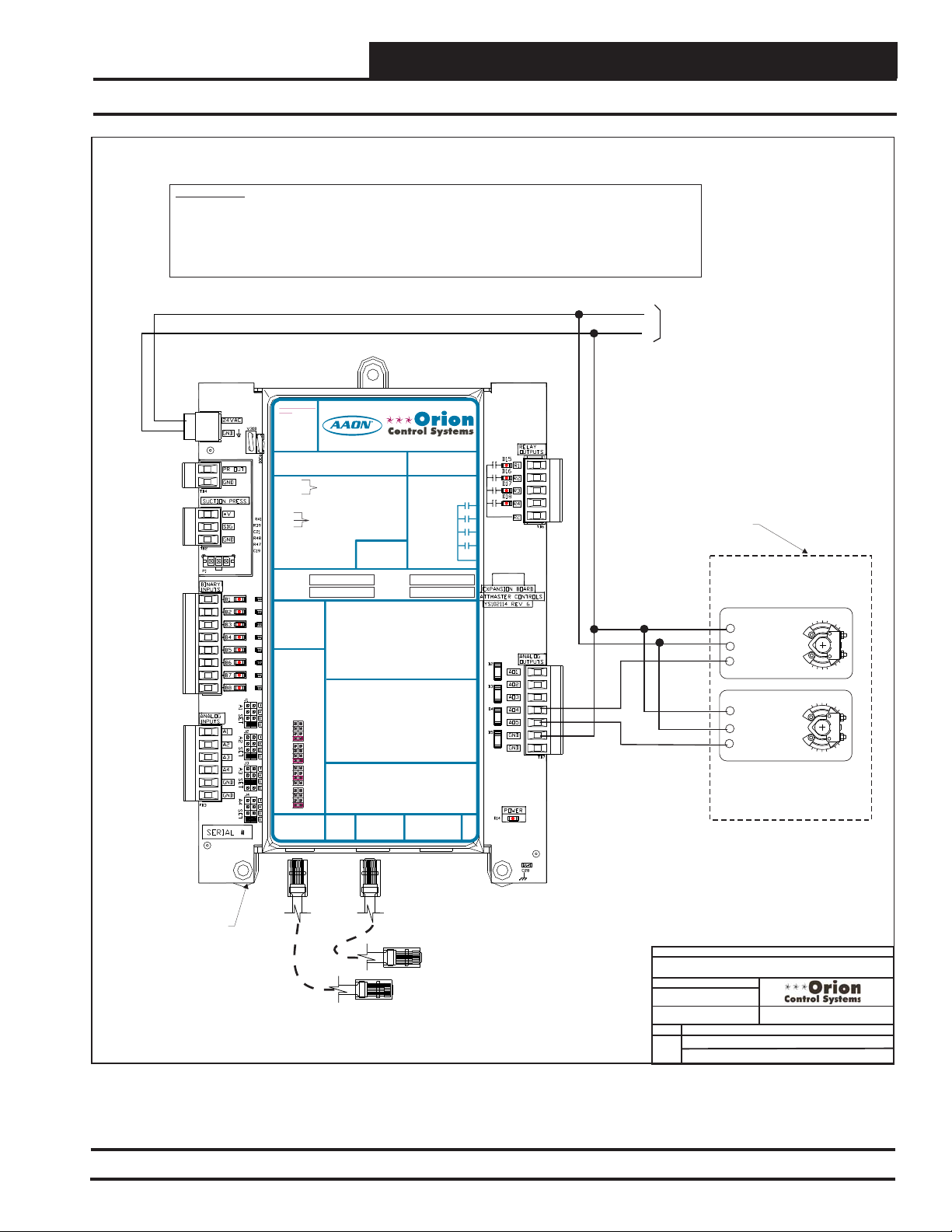

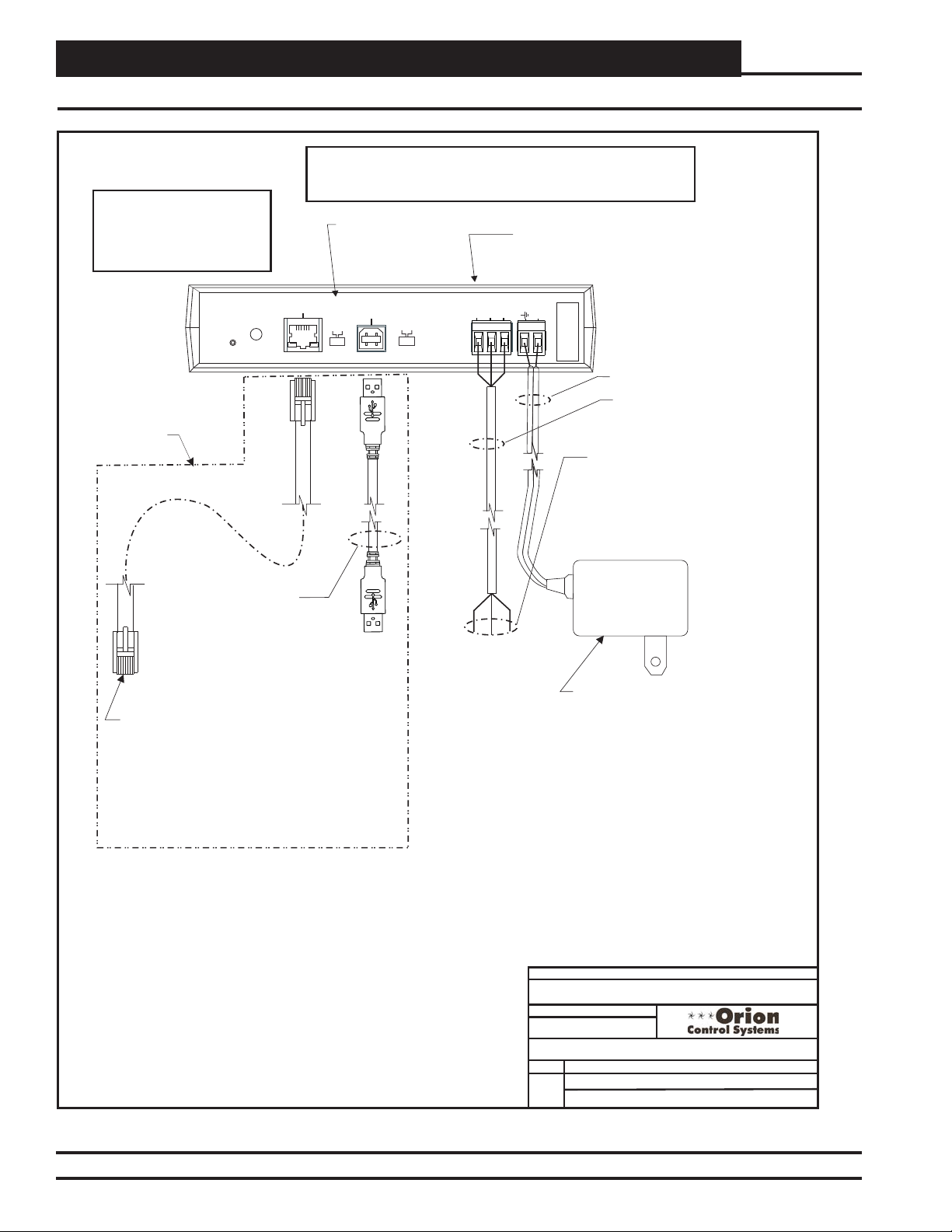

VCM-X E-BUS Component &

System Wiring Technical Guide

Use For VCM-X E-BUS Controller Code: SS1030 and later

For VCM Wiring Information, See Component & System Wiring

Technical Guide - Form: OR-VCMWIRE-TGD

RS-485 COMMUNICATION LOOP. WIRE

“R” TO“R”, “T” TO “T” “SHLD” TO “SHLD”

www.aaon.com

www.orioncontrols.com

VCM-X MODULAR E-BUS CONTROLLER

Orion No.:OE332-23E-VCMX-MOD-A

AI1 = SPC (SPACETEMPERATURE SENSOR)

= SAT(SUPPLY AIR TEMPERATURE SENSOR)

AI2

= RAT(RETURN AIR TEMPERATURE SENSOR)

AI3

AI4

= OAT(OUTDOOR AIR TEMPERATURE SENSOR)

AI5

= SUCTION PRESSURE SENSOR (FROM EXP. MODULE)

AI7

= SPACETEMPERATURE SENSOR SLIDE ADJUST

OR VOLTAGE RESETSOURCE

A01

= ECONOMIZER (2-10 VDC OUTPUT)

A02

= SUPPLYFAN VFD (0-10 VDC OUTPUT)

E-BUS

CONNECTOR

ANALOG INPUT

JUMPER

SETTINGS

THERM

4-20mA

AI1

0-10V

0-5V

THERM

4-20mA

AI2

0-10V

0-5V

THERM

4-20mA

AI3

0-10V

0-5V

THERM

4-20mA

AI4

0-10V

0-5V

THERM

4-20mA

AI5

0-10V

0-5V

THERM

4-20mA

AI7

0-10V

0-5V

ANALOG INPUTJUMPER SETTINGS

MUSTBE SET AS SHOWN FOR

PROPER OPERATION

STATIC

PRESSURE

WattMaster Label

#LB102073-01-A

Rev.: 1A

WARNING!POLARITY MUST BE OBSERVED

OR THE CONTROLLER WILLBE DAMAGED

2

IC

EXPANSION

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

RELAY

COMMON

FAN

RELAY2

RELAY3

RELAY4

RELAY5

AAON No.:

V07150

24 VAC POWER ONLY

2

I C DIGITAL

SENSOR

Page 2

Table of Contents

SYSTEM OVERVIEW, INSTALLATION & COMMISSIONING ...............................................................5

Systems Overview ..................................................................................................................................................6

System Installation ..................................................................................................................................................8

Transformer Sizing & Cabling - Devices Without Modular Connectors ............................................................9

Transformer & Wire Sizing - Devices With Modular Connectors ....................................................................10

System Commissioning .......................................................................................................................................20

SYSTEM CONFIGURATIONS ............................................................................................................21

Stand Alone System Wiring ..................................................................................................................................22

Interconnected System Wiring ..............................................................................................................................23

Networked Single Loop System With CommLink Only .........................................................................................24

Networked Single Loop System With MiniLink PD & Modular VAV/Zone Controllers ...........................................25

Networked Single Loop System With MiniLink PD & Non-Modular VAV/Zone Controllers ...................................26

Networked Single Loop System With CommLink, MiniLink PD & Modular VAV/Zone Controllers ........................27

Networked Single Loop System With CommLink, MiniLink PD & Non-Modular VAV/Zone Controllers ................28

Networked Multiple Loop System Wiring With Modular VAV/Zone Controllers .....................................................29

Networked Multiple Loop System Wiring With Non-Modular VAV/Zone Controllers .............................................30

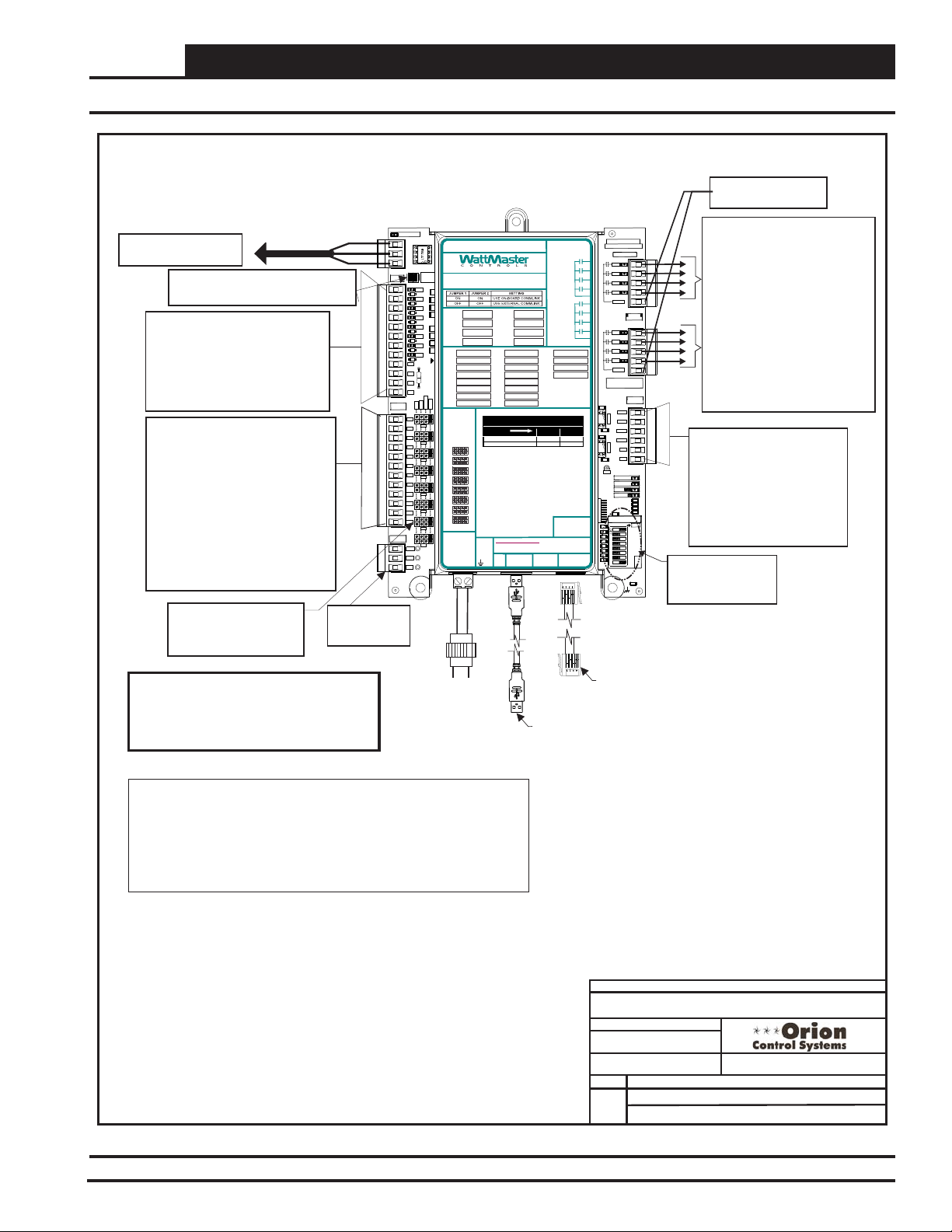

VCM-X E-BUS CONTROLLER WIRING .............................................................................................31

Main Controller Wiring ..........................................................................................................................................32

Main Controller Addressing ...................................................................................................................................33

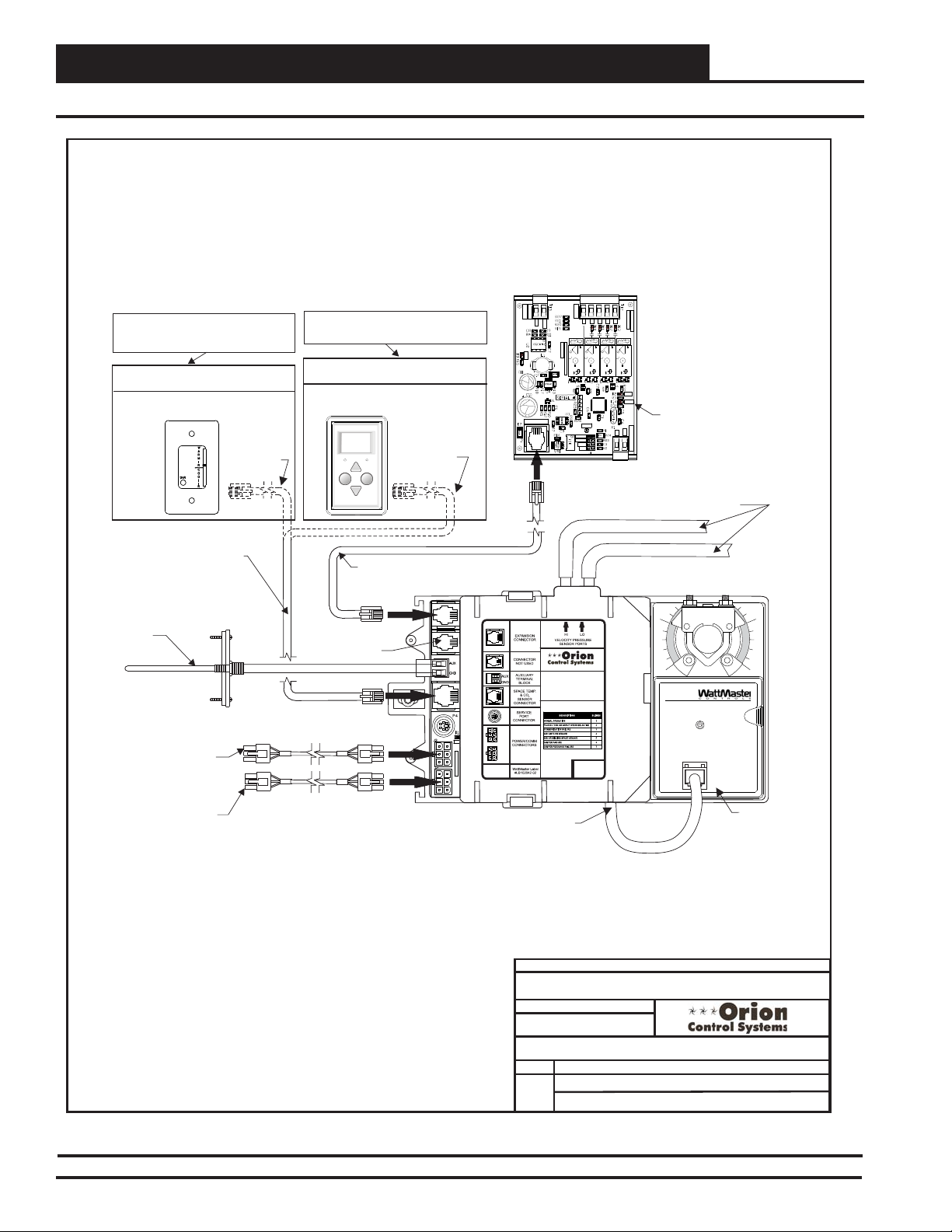

Digital Room Sensor Wiring ..................................................................................................................................34

Wall-Mounted CO

Sensor Wiring .........................................................................................................................34

2

Duct-Mounted CO2 Sensor Wiring ........................................................................................................................35

Space Temperature Sensor Wiring .......................................................................................................................36

Remote Supply Air Reset Wiring ...........................................................................................................................36

Supply Air, Return Air, and Outdoor Air Temperature Sensor Wiring ....................................................................37

Economizer Damper Actuator Wiring ....................................................................................................................38

Supply Fan VFD & Bypass Damper Actuator Wiring ............................................................................................39

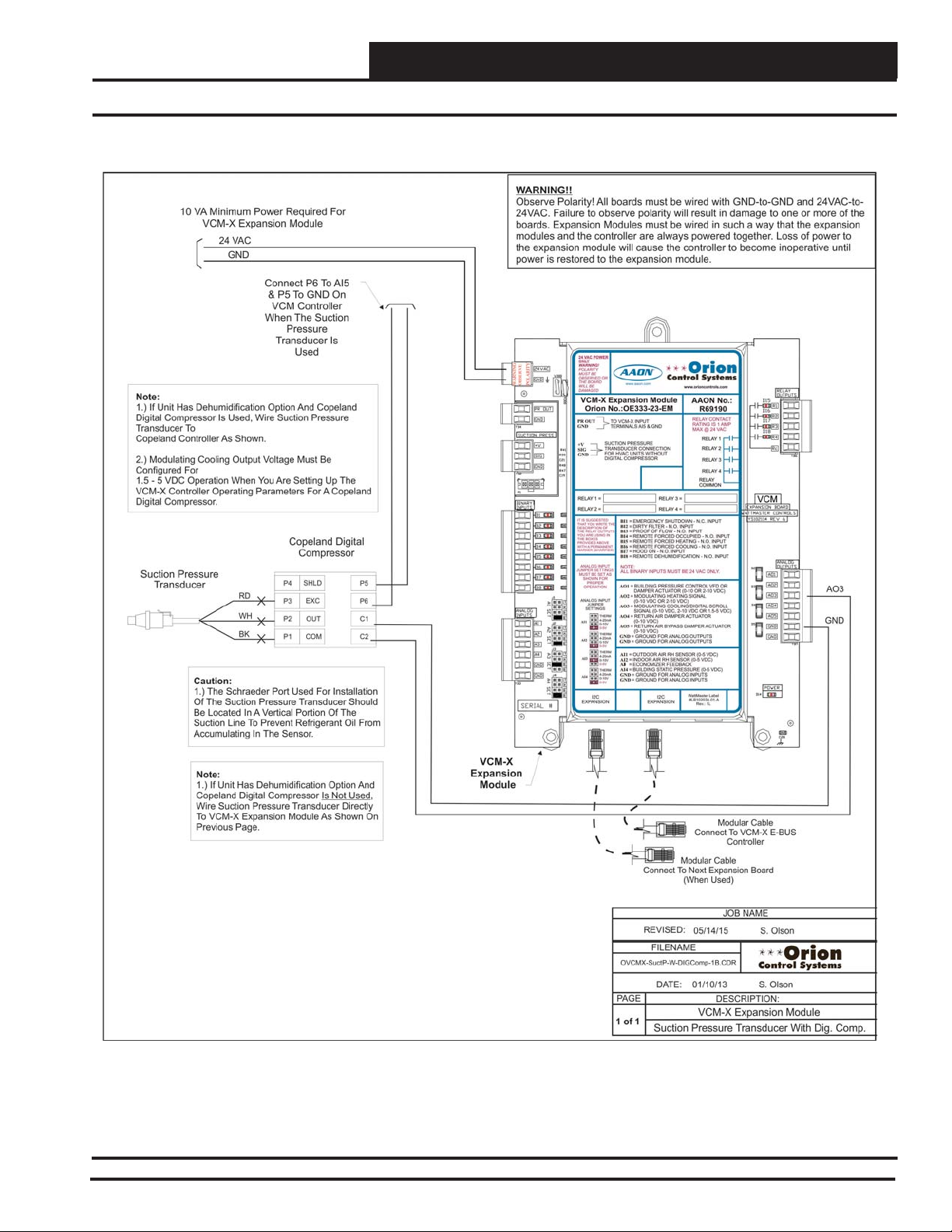

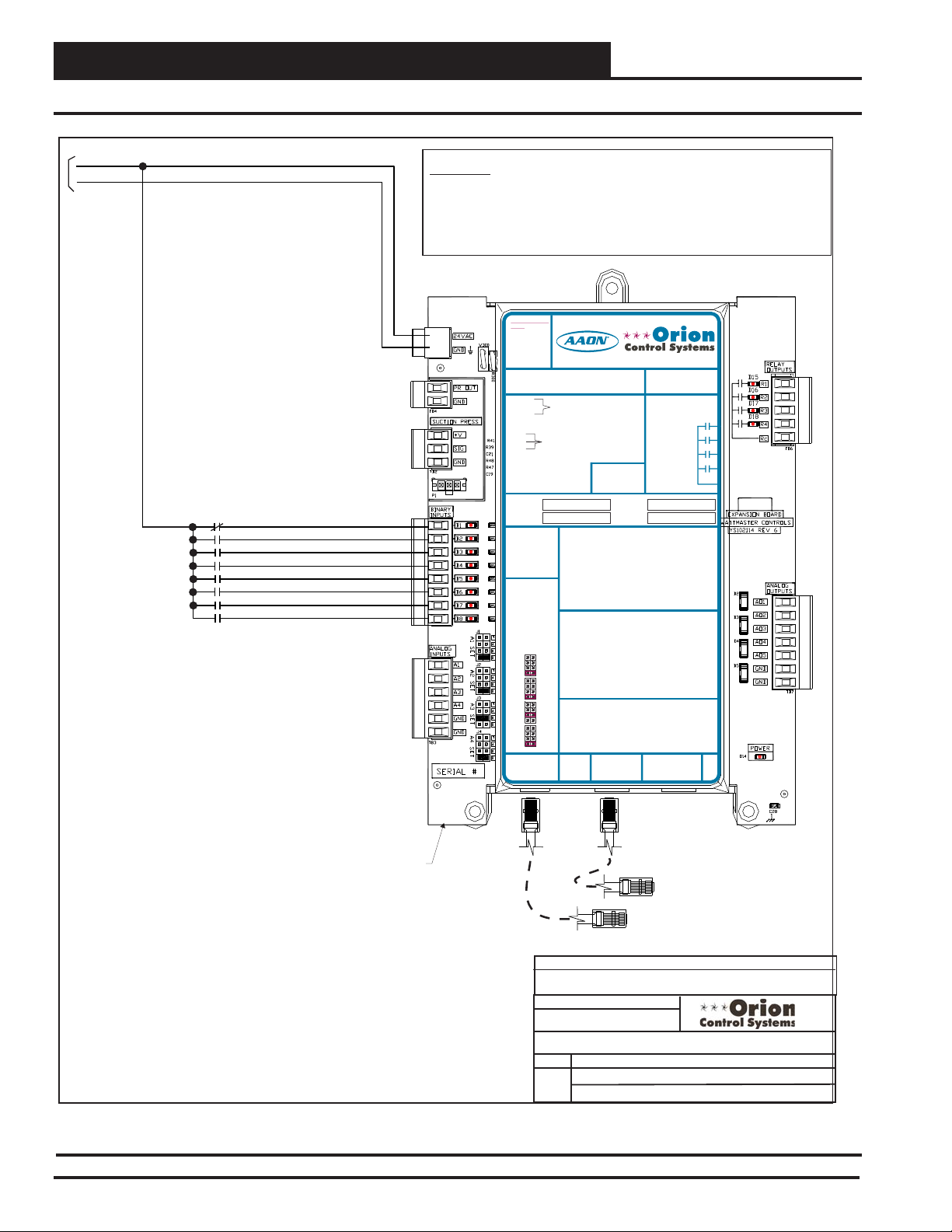

VCM-X EXPANSION, 4 BINARY INPUT, & 12 RELAY EXPANSION MODULE WIRING .....................41

VCM-X Expansion Module Input Wiring ................................................................................................................42

VCM-X Expansion Module Output Wiring .............................................................................................................43

Suction Pressure Transducer Without Digital Compressor Wiring ........................................................................44

Suction Pressure Transducer With Digital Compressor Wiring .............................................................................45

Expansion Module Binary Input Wiring .................................................................................................................46

4 Binary Input Expansion Module Wiring ..............................................................................................................47

Outdoor Air Humidity Sensor Wiring .....................................................................................................................48

2

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

Form: OR-VCMXWIRE-TGD-01B Copyright June 2015 W attMaster Controls, Inc.

AAON

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

This document is subject to change without notice.

is a registered trademark of AAON, Inc., Tulsa, OK.

VCM-X Component & Systems Wiring

Page 3

Table of Contents

Indoor Wall Mounted Humidity Sensor Wiring ......................................................................................................49

Return Air Humidity Sensor Wiring .......................................................................................................................50

Title 24 Economizer Actuator Feedback Wiring ....................................................................................................51

Building Pressure Sensor, Actuator & VFD Wiring ................................................................................................52

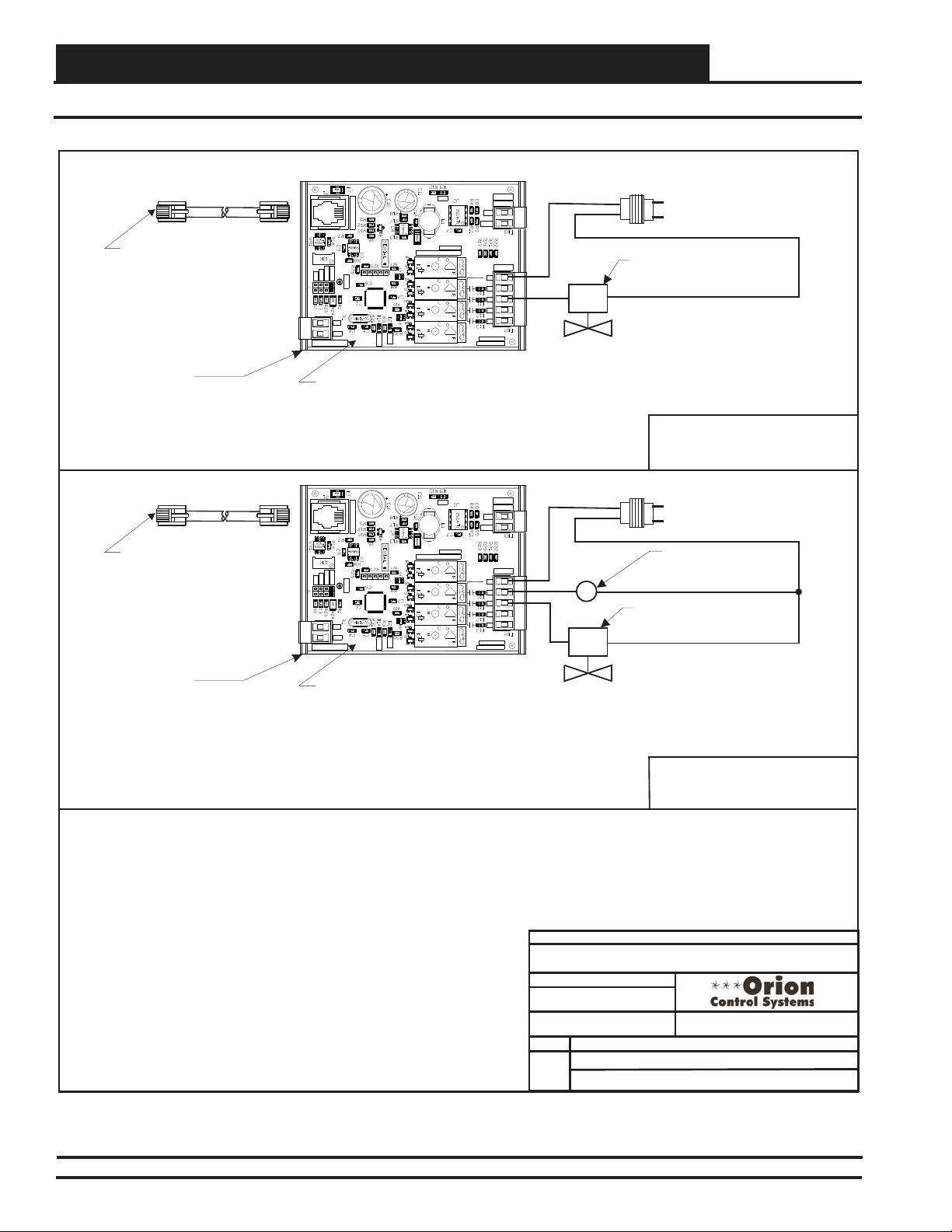

Modulating Heating Wiring ....................................................................................................................................53

Modulating Cooling Wiring ....................................................................................................................................54

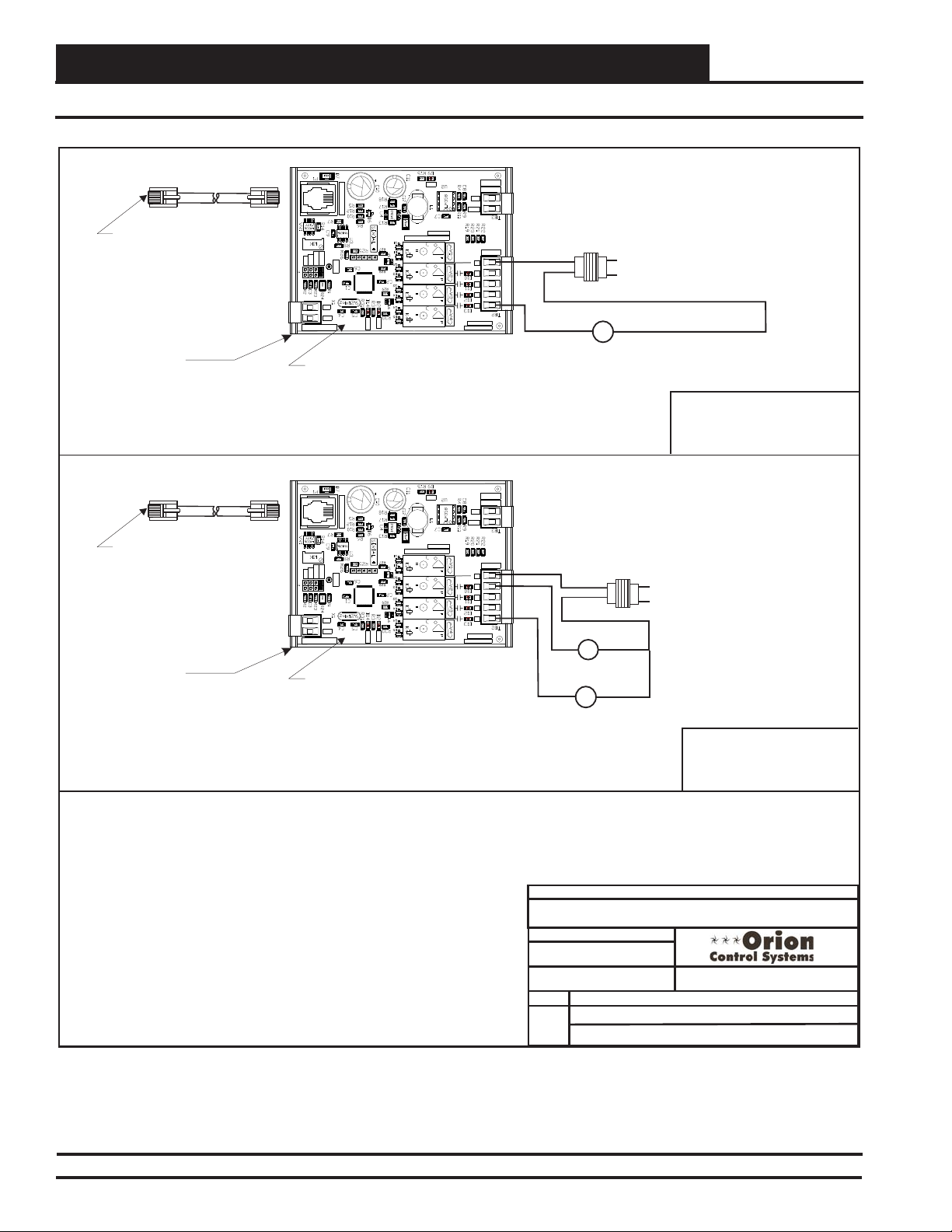

Return Air Bypass Wiring ......................................................................................................................................55

12 Relay Expansion Module Wiring ......................................................................................................................56

Airfl ow Monitoring Station Wiring ..........................................................................................................................57

MODULAR & NON-MODULAR VAV/ZONE CONTROLLER DIAGRAMS .............................................. 59

Modular VAV/Zone Controller Actuator Package Wiring .......................................................................................60

Non-Modular VAV/Zone Controller Actuator Package Wiring ...............................................................................61

Expansion Module Wiring .....................................................................................................................................62

Slaved Zone Wiring ...............................................................................................................................................68

COMMUNICATION DEVICES DIAGRAMS ........................................................................................69

System Manager SD Modular Cable Connections ...............................................................................................70

System Manager SD Cable Pigtail - Wiring Detail ................................................................................................71

System Manager SD Networked Wiring ...............................................................................................................72

Modular Service SD Tool Connections..................................................................................................................73

System Manager Touch Screen II to VCM-X E-BUS Controller Wiring.................................................................74

System Manager Touch Screen II to VAV/Zone Controller Wiring ........................................................................75

CommLink 5 Connections & Wiring ......................................................................................................................76

IP Module Installation Instructions ........................................................................................................................77

On-Site Computer Connection ..............................................................................................................................78

Remote Site Computer Connection ......................................................................................................................79

USB-Link 2 Connections & Wiring ........................................................................................................................80

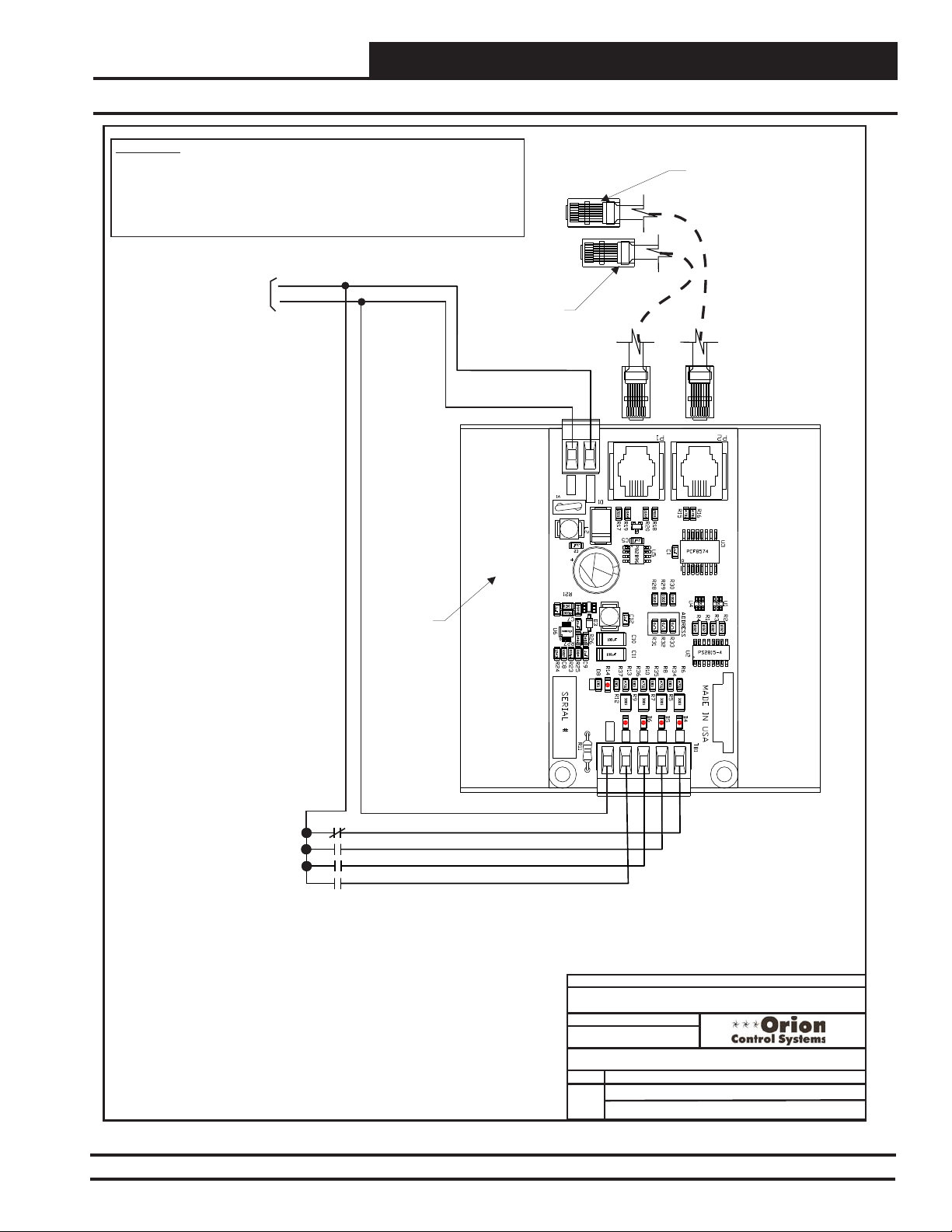

MiniLink Polling Device Wiring Using Modular Connectors ..................................................................................81

MiniLink Polling Device Wiring Using Wire Terminals ...........................................................................................82

Power/Comm Board Wiring - When Used For Local Loop Devices ......................................................................83

Power/Comm Board Wiring - When Used For Network Loop Devices .................................................................84

ADD-ON DEVICES DIAGRAMS .........................................................................................................85

Lighting Panel Wiring For Standard Lighting Contactors ......................................................................................86

GPC-X Controller Wiring .......................................................................................................................................87

GPC-X Controller - Address Switch Setting ..........................................................................................................88

GPC-XP Controller Wiring.....................................................................................................................................89

GPC-XP Controller Addressing & Baud Rate Setting ...........................................................................................90

GPC-XP Controller On-Board CommLink 5 Setting ..............................................................................................91

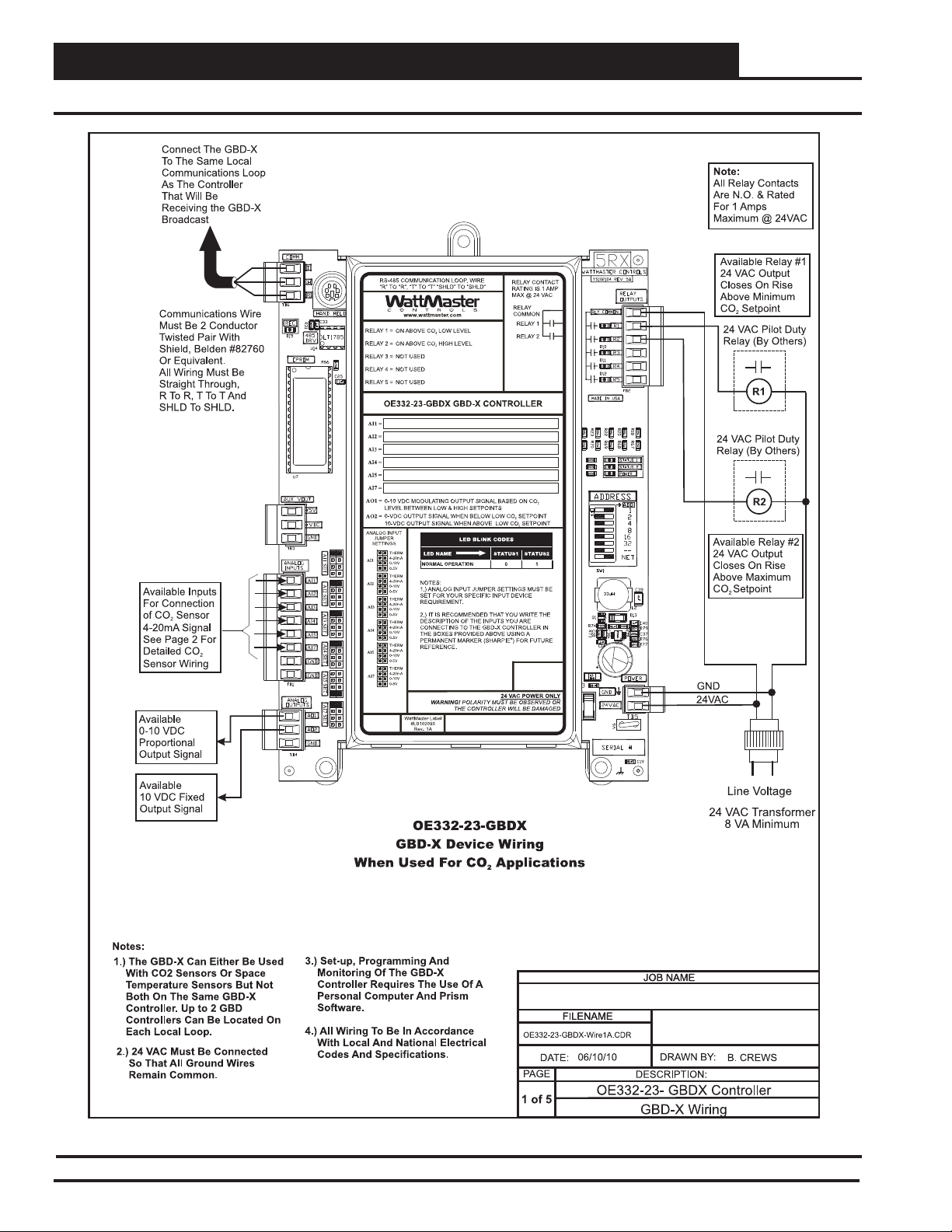

GBD-X Controller - CO

GBD-X Controller - Space Temp. Sensor Averaging Wiring .................................................................................94

GBD-X Controller Address Switch Setting ............................................................................................................96

Applications Wiring .........................................................................................................92

2

VCM-X Component & Systems Wiring

3

Page 4

Table of Contents

MODULE WIRING & CONNECTIONS ...............................................................................................97

HP1C Module Wiring ............................................................................................................................................98

HP2C2 Module Wiring ..........................................................................................................................................99

Full Digital Module Wiring ...................................................................................................................................100

Dual Digital Module Wiring ..................................................................................................................................101

MODGAS-X Controller Wiring - Single Modulating Valve - No Staging ..............................................................102

MODGAS-X Controller Wiring - Two Modulating Staged Valves ........................................................................103

MODGAS-XWR Controller Wiring - Single Modulating Valve - No Staging ........................................................104

MODGAS-XWR Controller Wiring - Single Modulating Valve & 1 Fixed Stage...................................................105

MODGAS-XWR Controller Wiring - Two Modulating Staged Valves ..................................................................106

MHGRV-X Controller Wiring................................................................................................................................107

WSHP-X2 Controller Wiring - Single Circuit .......................................................................................................108

WSHP-X2 Controller Wiring - Dual Circuit ..........................................................................................................109

PREHEAT-X Controller Wiring ............................................................................................................................110

MODGAS II Controller Wiring ..............................................................................................................................111

MHGRV II Controller Wiring ................................................................................................................................112

MHGRV III Controller Wiring ...............................................................................................................................113

MISCELLANEOUS DIAGRAMS & TECHNICAL INFORMATION .......................................................115

Modular Room Sensor Wiring .............................................................................................................................116

EPROM Chip Locations ......................................................................................................................................117

EPROM Chip Installation Procedures .................................................................................................................120

Updating Modules with the Service Tool SD .......................................................................................................121

Temperature & Humidity Sensor Voltage-Resistance Tables ..............................................................................123

Pressure Sensors Voltage-Resistance Tables ....................................................................................................124

Suction Pressure Transducer Testing ........................................................................................... ......................125

4

VCM-X Component & Systems Wiring

Page 5

Systems Overview

System Overview,

Installation &

Commissioning

VCM-X Component & System Wiring

5

Page 6

Systems Overview

System Types

Overview

The Orion system components can be confi gured into several types

of systems. It is a good idea to become familiar with the different

types of systems and their architecture by reading the information in

this section and looking at the confi guration diagrams in the System

Confi gurations section of this manual. The information below is de-

signed to help you understand how the system components integrate

with each other and the available confi guration options.

System Types

Four different system confi gurations are available depending on

the type and number of controllers that you have on your system.

1. Stand Alone

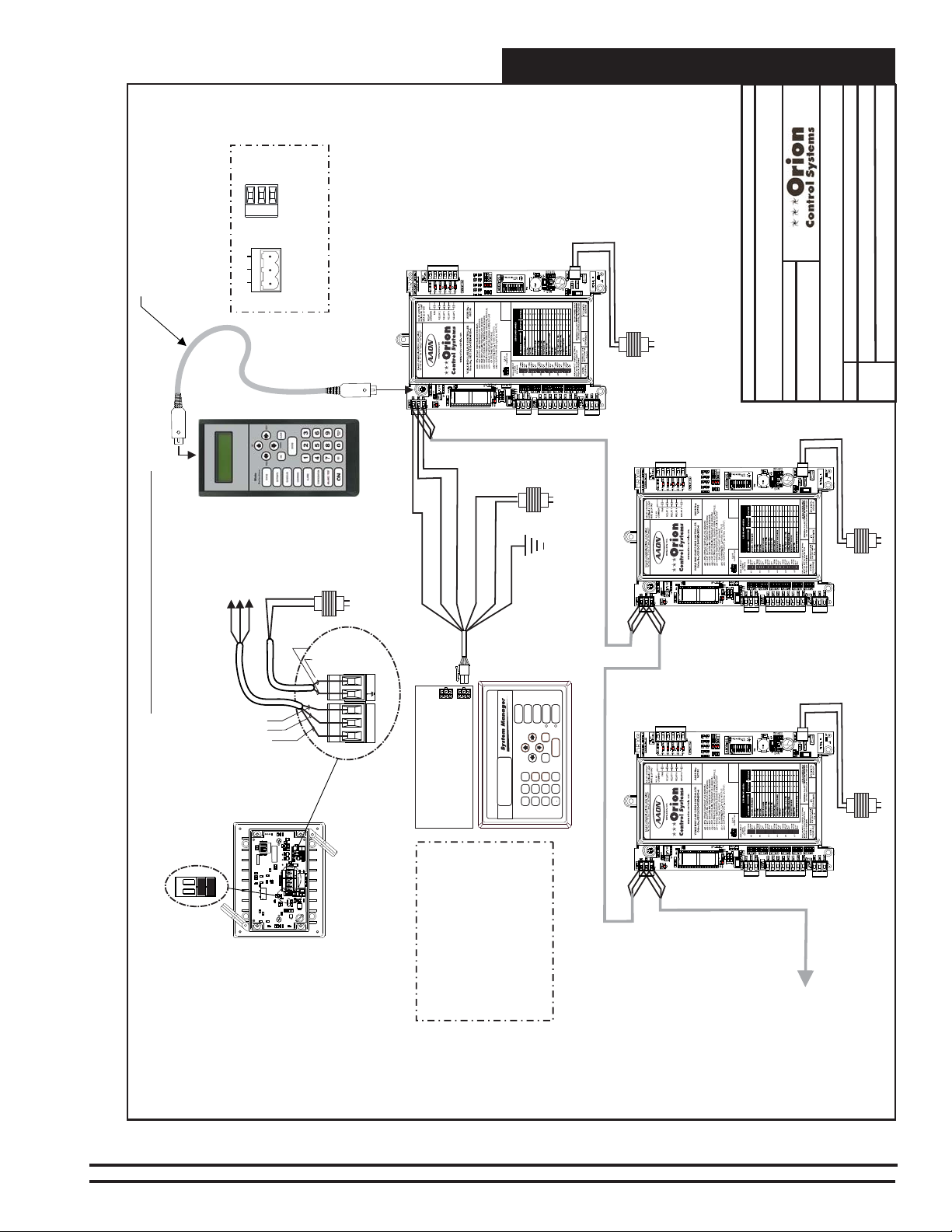

(See Figure 3, page 22 for Connection Diagram)

Interconnected

This system consists of a group of VCM-X E-BUS Controllers

interconnected with communication cable to allow programming

from one central location. Broadcasting between controllers is not

available. Programming and status monitoring are accomplished by

one or more of the following methods.

1. By using an operator interface. This can be a Modular

System Manager, a System Manager TS II, a Modular

Service Tool, or all 3 devices.

2. A computer interface can also be used in conjunction

with the other operator interfaces listed above, or by

itself. This requires a CommLink 5 or USB-Link 2 and a

personal computer with the Prism 2 computer front end

software installed.

2. Interconnected

(See Figure 4, page 23 for Connection Diagram)

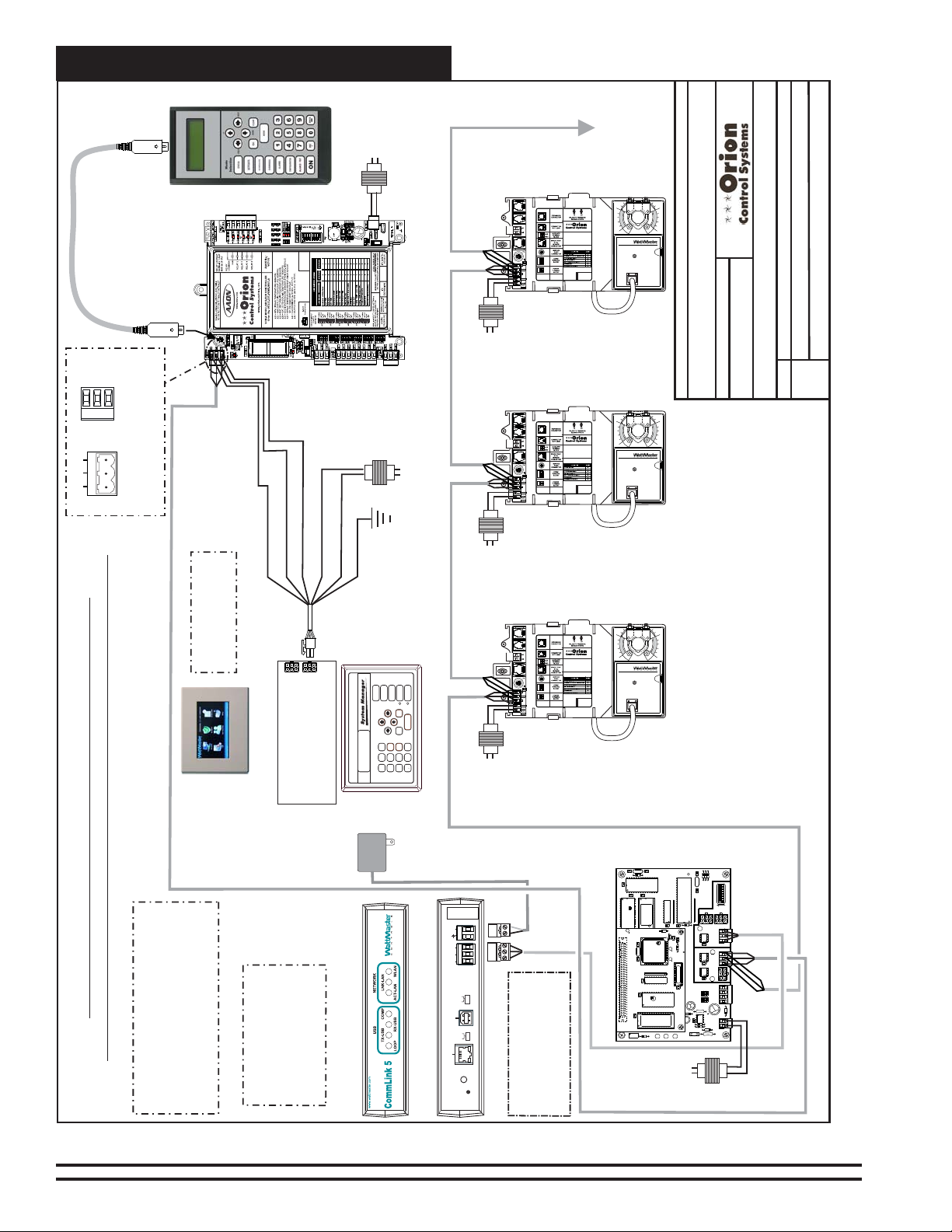

3. Networked Single Loop

(See Figures 5-9, pages 24-28 for Connection

Diagrams)

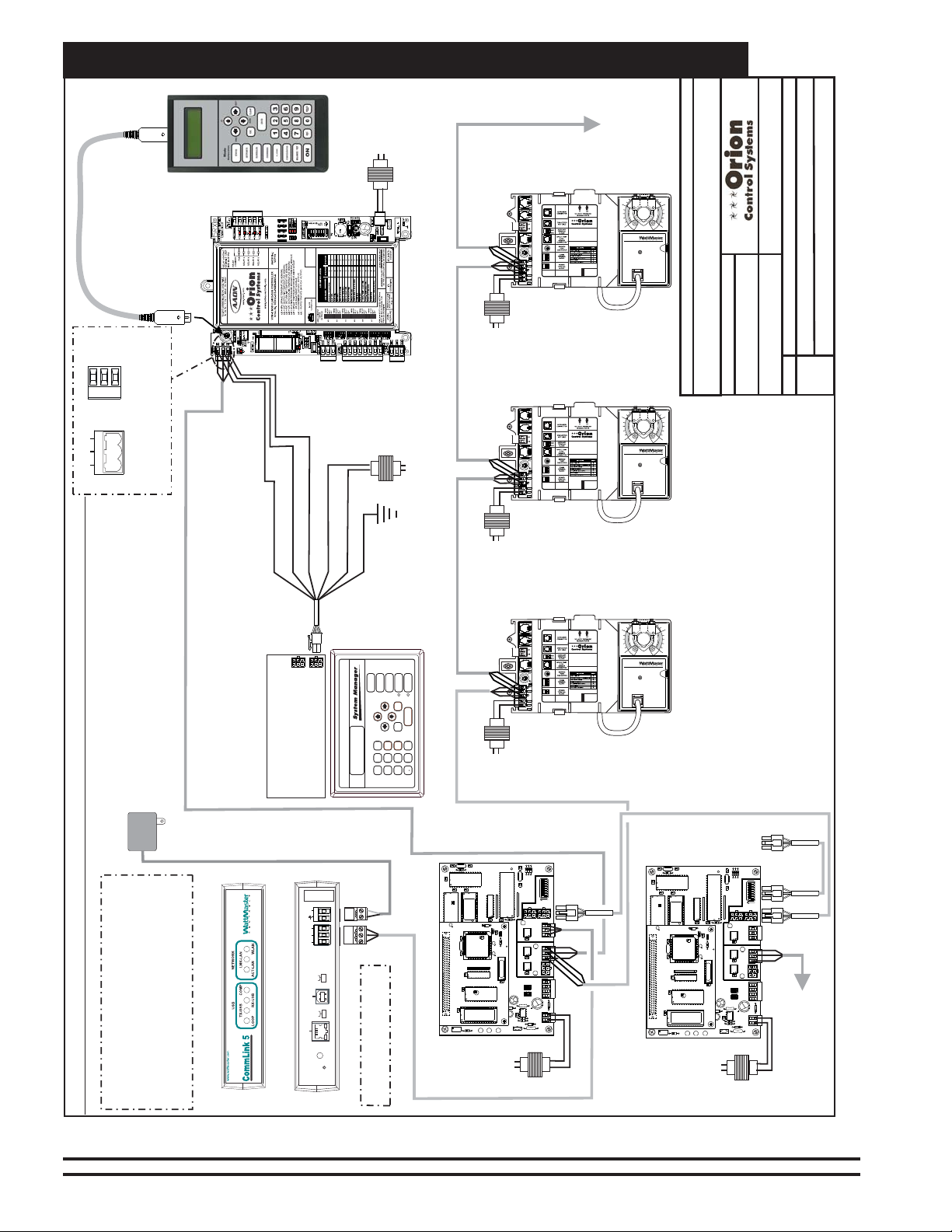

4. Networked Multiple Loop

(See Figures 10-11, pages 29-30 for Connection

Diagrams)

5. Computer, CommLink 5, IP Module, USB-Link 2

(See Figures 54-58, pages 76-80 for Connection

Diagrams)

System Type Definitions

Stand Alone

This system consists of a single VCM-X E-BUS Controller. Programming and status monitoring are accomplished by one or more

of the following methods.

1. By using an operator interface. This can be a Modular

System Manager, a System Manager TS II, a Modular

Service Tool, or all 3 devices.

2. A computer interface can also be used in conjunction

with the other operator interfaces listed above, or

by itself. This requires a CommLink 5 or USB-Link 2

and a personal computer with the Prism 2 computer

front end software installed.

Networked Single Loop

The Networked Single Loop system, as its name implies, consists of

a single communications loop. This loop utilizes a network device to

share information that is broadcast from one controller to all controllers on the loop. The system can consist of the following devices.

1. A series of VCM-X E-BUS Controllers that utilizes

a network device to share information that is broadcast

from one controller to all controllers on the loop.

2. A single VCM-X E-BUS Controller and a series of VAV/

Zone Controllers. These VAV/Zone Controllers can

either be of the Modular type or Non-modular type.

The Modular type use Power/Comm Boards and

prefabricated cables and the Non-Modular type utilize

terminals and 2 conductor twisted pair with shield wire.

A network device is used to share information which is

broadcast back and forth between all controllers on the

loop.

These systems require a network device in the form of either a

CommLink 5 communications interface or a MiniLink Polling Device. Both network devices may also be used together. Programming

and status monitoring are accomplished by the following methods:

1. By using an operator interface. This can be a Modular

System Manager, a System Manager TS II, a Modular

Service Tool, or all 3 devices.

2. A computer interface can also be used in conjunction

with the other operator interfaces listed above, or

by itself. This requires a CommLink 5 or USB-Link 2

and a personal computer with the Prism 2 computer

front end software installed.

6

When using the MiniLink Polling Device alone, only the System

Manager, System Manager TS II, and Modular Service Tool can be

used to program and monitor the system. With the addition of the

CommLink 5, the Prism 2 computer front end software and a PC

can be used to program and monitor the system in addition to the

Modular Service Tool, Modular System Manager, and the System

Manager TS II.

VCM-X Component & System Wiring

Page 7

Systems Overview

Communication Devices

Networked Multiple Loop

The Networked Multiple Loop System consists of two or more loops,

each being called a “Local Loop”, with one “Network Loop” that

ties the “Local Loops” together. Each of these loops can consist of

one of the following groups of controllers:

1. A series of VCM-X E-BUS Controllers.

2. A single VCM-X E-BUS Controller and a series of VAV/

Zone Controllers. These VAV/Zone Controllers can

either be of the Modular type or Non-modular type.

The Modular type use Power/Comm Boards and

prefabricated cables and the Non-Modular type utilize

terminals and 2 conductor twisted pair with shield wire.

A network device is used to share information which is

broadcast back and forth between all controllers on the

loop.

To form the Networked Multiple Loop System, the following network

devices are required:

1. A MiniLink Polling Device is required per loop

(Local Loop). This allows the controllers to share

information that is broadcast from one controller to all

controllers on that local loop.

2. One CommLink 5 is required for the entire system.

It resides on the Network Loop and allows for

communications between all the local loops and

provides for global broadcasts to all controllers on the

entire system.

Programming and status monitoring are accomplished by one or

more of the following methods:

1. By using an operator interface. This can be a Modular

System Manager, a System Manager TS II, a Modular

Service Tool, or all 3 devices. The Modular System

Manager, System Manager TS II, or Modular Service

Tool connect to any “Local Loop” on the system.

2. A computer interface can also be used in conjunction

with the other operator interfaces listed above, or by

itself. This requires a personal computer with the Prism

II computer front end software installed connected to

the CommLink 5.

Network Communications Devices

MiniLink Polling Device

The MiniLink Polling device is used in the following applications:

1. This device is required on all Zoning applications. It is

optional on single loop VAV systems.

2. This device is required on each local loop of all

Networked Multiple Loop systems.

3.

This device is responsible for local loop broadcasts only.

It always resides on the local loop.

For a Networked Single Loop VCM-X E-BUS system, this device

can be used for tenant logging and alarm reporting to a Modular System Manager or System Manager TS II. It can be used to broadcast

information such as outside air temperature or outside air humidity

to all devices on the local loop. It can also be used to broadcast space

temperature from a GPC-X or GPC-XP Controller to any controllers

on this loop that do not have their own Space Temperature Sensor.

For a Networked Single Loop VAV system, the MiniLink Polling

Device can be used for tenant logging and alarm reporting to a

Modular System Manager or System Manager TS II. It must be used

to broadcast information such as, internal schedule, supply air temperature, fan and heat status, unoccupied calls for heating and cooling

from the VAV/Zone Controllers, and forced modes of operation.

For a Networked Single Loop Zoning system, this device must be

used for zone voting, because it calculates the heating and cooling

totals on the loop and broadcasts cooling, venting, and heating

modes to the VCM-X E-BUS Controller. It can also be used for

tenant logging and alarm reporting to the Modular System Manager

or System Manager TS II.

CommLink 5

The CommLink 5 device is used in the following applications.

1. A CommLink 5 is required on all Networked Multiple

Loop Systems.

2. A CommLink 5 is optional on all Networked Single

Loop Systems.

3. A CommLink 5 is required on any system when a

permanent computer interface is desired. The USB-Link

2 can be used for temporary computer connection for

setting up or servicing the system, but does not have the

complete functionality that the CommLink 5 provides.

The CommLink 5 is responsible for local loop broadcasts on a Networked Single Loop system, and on this type of system, the Loop

switch on the back of the CommLink must be set to “Single.” This

device is responsible for network broadcasts on Networked Multiple

Loop systems. On this type of system, the Loop switch on the back

of the CommLink must be set to “Multiple.”

For a Networked Single Loop VCM-X E-BUS system, this device

can be used for tenant logging and alarm reporting to a Modular

System Manager or System Manager TS II. It can also be used to

broadcast information like outside air temperature or outside air humidity to all local loops on the entire networked system. It may also

be used to broadcast space temperature from a GPC-X or GPC-XP

Controller to any controllers on the local loop that do not contain

their own Space Temperature Sensor.

On a Networked Single Loop VAV/Zone system, the CommLink

5 can be used to broadcast information such as internal schedule,

supply air temperature, fan and heat status, unoccupied calls for

heating and cooling, and forced modes of operation to and from the

VAV/Zone Controllers.

VCM-X Component & System Wiring

7

Page 8

System Installation

Wiring Considerations

Wiring Considerations

Before beginning installation, please study the wiring diagrams

for the controllers you are using with your particular application.

These diagrams appear in this manual and can also be found in the

technical guides supplied with your specifi c controllers. Wire and

transformer sizing instructions and examples are found in Figures

1 & 2, pages 9-10 of this manual.

The Modular VAV/Zone Controllers are equipped with modular connections. Non-Modular VAV/Zone Controllers have wiring terminals

instead of modular connectors. The VCM-X E-BUS Controller

is supplied with modular connectors. The Power/Comm board is

supplied with both terminals and a modular connector on the input

side. All of its outputs use modular connectors. The Minlink Polling

Device is equipped with both modular and wiring terminal blocks.

W e recommend (when possible) using modular cables instead of hard

wiring to wire terminal blocks to save installation time and eliminate

wiring errors. In some cases, however, hard wiring is unavoidable.

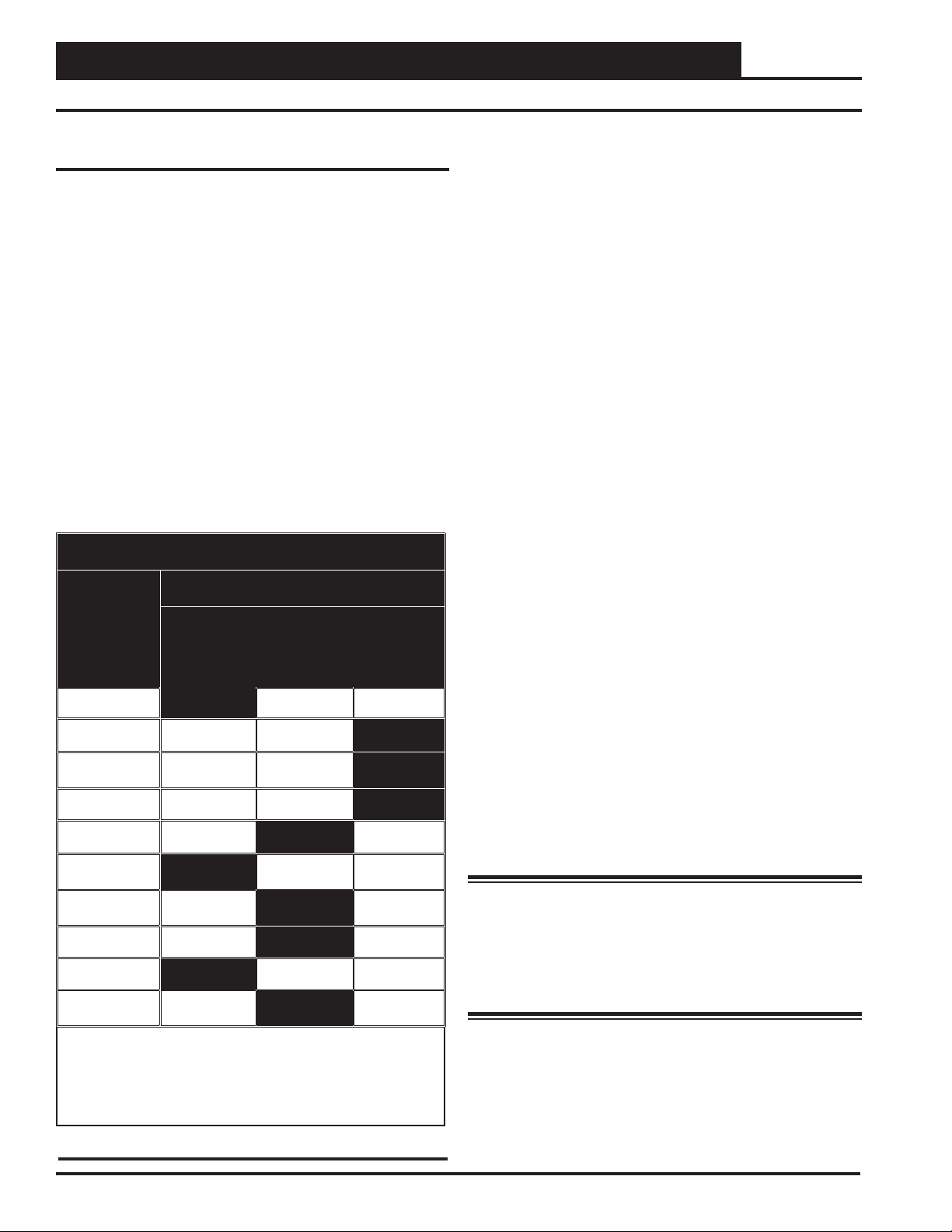

The table below lists the various Orion devices/controllers and their

available termination type(s) for communications and power wiring.

Communications And Power Wiring

Terminations For Orion Products

Available Power And Communications

Orion

Controller Or

Device

VCM-X E-BUS X

VAV/Zone •X

Power/Comm

Board

MiniLink PD X

CommLink 5 X

*Modular System

Manager

System Manager

TS II

GPC-X X

GPC-XP X

Lighting

Controller

* The System Manager is supplied with a pigtail connector that has a

modular plug on one end and stripped wires on the other end. The pigtail is

used to allow wiring connection to the HVAC unit controller wire terminals

and to a 24 VAC power transformer on systems that do not use Power/

Comm boards.

Modular

Connectors

Only

X

Connections

Wire

Terminals

Only

X

X

Both

Modular

Connectors

And Wire

Terminals

X

Power/Comm Board Requirements

Standard Connection Confi gurations and Use

Power/Comm boards are typically used on Networked, Single, and

Multiple Loop systems to transfer 24 VAC power and “Local Loop”

communications to Modular VAV/Zone Controllers, Modular System

Managers, or other Power/Comm boards.

The Power/Comm board must always be powered by its own dedicated 24 VAC transformer connected to its 2-wire, 24 VAC input

terminals (TB1).

Local Loop communications can be transferred to the Power/Comm

Board via a modular cable connected to its “Comm In” modular

connector input terminal (P2). This modular cable connection can

originate from the “Local Loop” modular connector of the MiniLink PD for this loop, another Power/Comm board output on the

same loop, or a Modular VAV/Zone Controller or Modular System

Manager output on the same loop. A Power/Comm board can also

be connected if desired to the “Local Loop” by hard wiring a 2-wire

shielded cable connected between its 3-wire communications input

terminal (TB1) and a Power/Comm board, or the MiniLink PD

“Local Loop”, 3-wire communications terminal.

For detailed wiring diagrams, see the Power/Comm board wiring

diagrams in the “Communication Devices Diagrams” section of this

manual. For Power/Comm board transformer sizing, see Figures 1

& 2, pages 9-10 of this manual.

Alternative Connection Confi guration and Use

If desired, the Power/Comm board can also be used to transfer both

24 VAC power and “Network Loop” communications to multiple

MiniLink PDs. Connection between the MiniLink PD(s) and Power/

Comm board(s) is accomplished by using modular cables between

the Power/Comm board’s modular output connectors and the MiniLink PD(s)’s “Network Loop” modular input connectors. When a

Power/Comm board is used to connect power and communications

to MiniLink PDs in this manner, that particular Power/Comm board

cannot also be used to share communications and/or power with

Modular VAV/Zone Controllers or Modular System Manager(s).

Warning: Do not ground the 24 VAC transformer that

is to be used with the Power/Comm board. Grounding of

the transformer will damage the Power/Comm board and

all boards connected to it. A separate transformer must be

used for each Power/Comm board. No exceptions. Do not

connect any other devices to the transformer used for the

Power/Comm board!

For detailed wiring diagrams, see the Power/Comm board wiring

diagrams in the “Communication Devices Diagrams” section of

this manual.

For Power/Comm board transformer sizing, see Figures 1 & 2,

pages 9-10 of this manual.

Table 1: Communications and Power Terminations

8

VCM-X Component & Systems Wiring

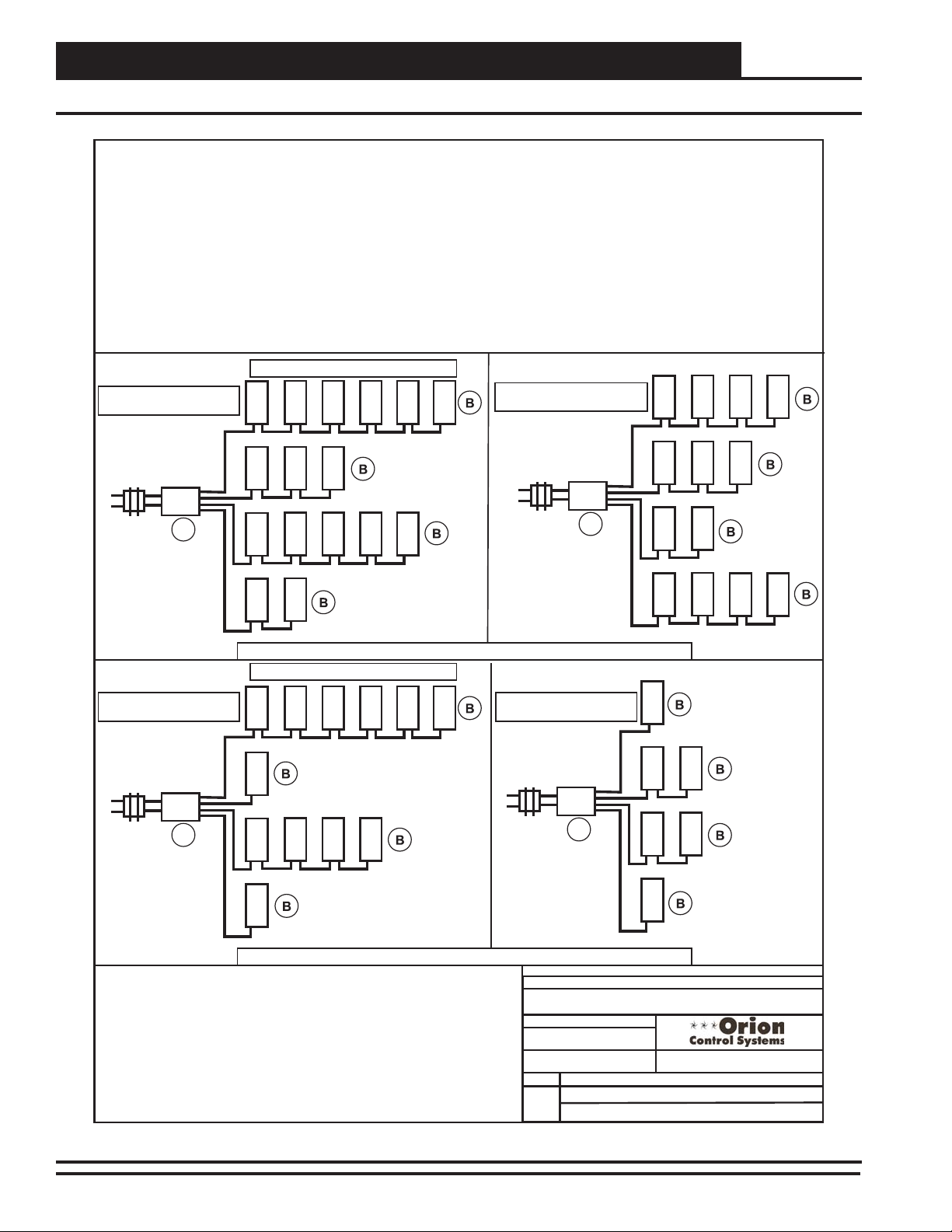

Page 9

System Installation

FILENAME

DATE:

DESCRIPTION:

PAGE

Wire & Transformer Sizing

JOB NAME

O-VCMXWRSIZ1A.CDR

Orion VCM-X System

24 VAC Power - Transformer & Wire Sizing Considerations for Devices Without Modular Connectors

Component Power Requirements

120 / 24VAC

120 / 24VAC

Distance A to B cannot exceed 57.80 Ft.

Distance from A to B cannot exceed 115.60 Ft.

Distance from A to C cannot exceed 115.60 Ft.

Distance from A to B cannot exceed 230.40 Ft.

Distance from A to C cannot exceed Ft.

Distance from A to D cannot exceed Ft.

Distance from A to E cannot exceed Ft.

230.40

230.40

230.40

120 / 24VAC

Some installers like to use one large 24 VAC transformer to power several devices. This is allowable as long as polarity is maintained to each device

on the transformer circuit.

Using

separate transformers also allows redundancy in case of a transformer failure. Instead of having 8 controllers inoperative because of a malfunctioning

transformer you have only 1 controller off line. If the installer does decide to use a large transformer to supply power to several devices, the following

transformer and wire sizing information is presented to help the installer correctly supply 24 VAC power to the devices.

Following is a typical example to help the installer to correctly evaluate transformer and wiring designs.

Each GPC-XP Controller requires 8 VA @ 24VAC power. In the examples below we have a total of 8 GPC-XP Controllers.

8 GPC-XP Controllers @ 8 VA each................ 8 x 8 VA = 64 VA.

The above calculation determines that our transformer will need to be sized for a minimum of 64 VA if we are to use one transformer to power all the

controllers.

Next we must determine the maximum length of run allowable for the wire gauge we wish to use in the installation. Each wire gauge below has a

voltage drop per foot value we use to calculate total voltage drop.

18ga wire.................................0.00054 = voltage drop per 1’ length of wire

16ga wire.................................0.00034 = voltage drop per 1’ length of wire

14ga wire.................................0.00021 = voltage drop per 1’ length of wire

For our example we will use 18 gauge wire. WattMaster recommends 18 gauge as a minimum wire size for all power wiring.

Next use the voltage drop per foot value for 18 gauge wire from the list above and multiply by the total VA load of the 8 controllers to be installed.

0.00054 (Voltage drop per foot for 18 gauge wire) x 64VA controller load = Volts/Ft.

WattMaster controllers will operate efficiently with a voltage drop no greater than 2 Volts. Divide the total allowable voltage drop of 2 Volts by the

number you arrived at above and you have the maximum number of feet you can run the 18 gauge wire with an 75 VA transformer with no more than a

2 Volt drop at the farthest controller from the transformer..

2 (Volts total allowable voltage drop)

= 57.80

0.0346 (Voltage drop per 1 ft. @ 64VA load)

Parallel circuiting of the wiring instead of wiring all 8 controllers in series allows for longer wire runs to be used with the same size wire (as shown in

our examples below).

Warning: If polarity is not maintained, severe damage to the devices may result. WattMaster Controls recommends

using a separate transformer for each device in order to eliminate the potential for damaging controllers due to incorrect polarity.

0.0346

feet

It is often necessary for the installer to calculate and weigh the cost and installation advantages and disadvantages of wire size,

transformer size, multiple transformers, circuiting, etc., when laying out an installation. No matter what layout scheme is decided upon, it is mandatory

that the farthest controller on the circuit is supplied with a minimum of 22 Volts.

GPC-X Controller ............................8 VA

VCM-X E-BUS Controller ................8 VA

GPC-XP Controller ..........................8 VA

Lighting Panel Controller .....10 VA

MiniLink Polling Device..........6 VA

A

A

A

BCDE

B

BC

1 of 2

01/07/13

VAV/Zone Controller.........................6 VA

Transformer Sizing & Wiring For Devices W/Out Modular Connectors

Figure 1: Transformer & Wire Sizing - Devices without Modular Connectors

VCM-X Component & Systems Wiring

9

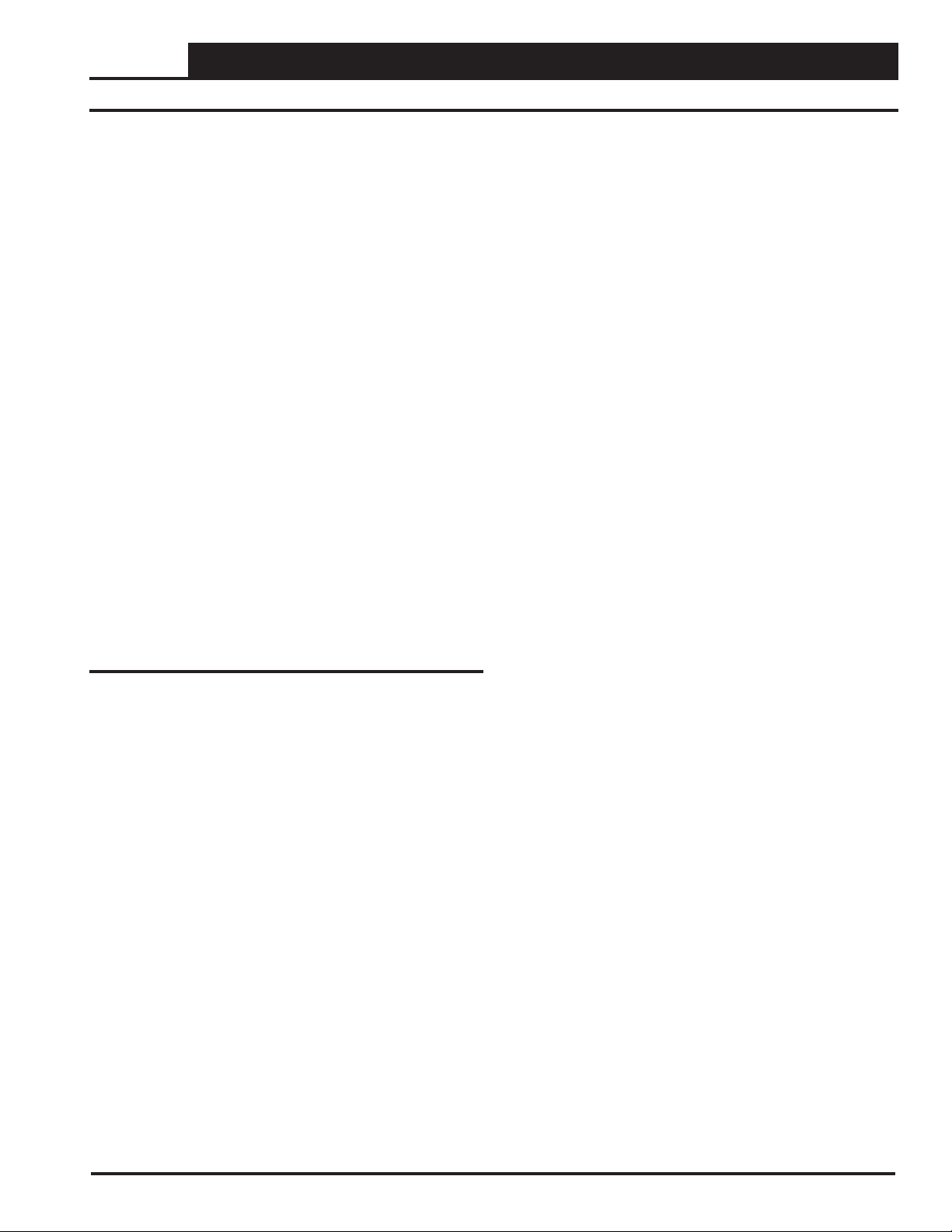

Page 10

System Installation

FILENAME

DATE:

B. CREWS

DESCRIPTION:

PAGE

DRAWN BY:

Wire & Transformer Sizing

JOB NAME

2 of 22 of 2

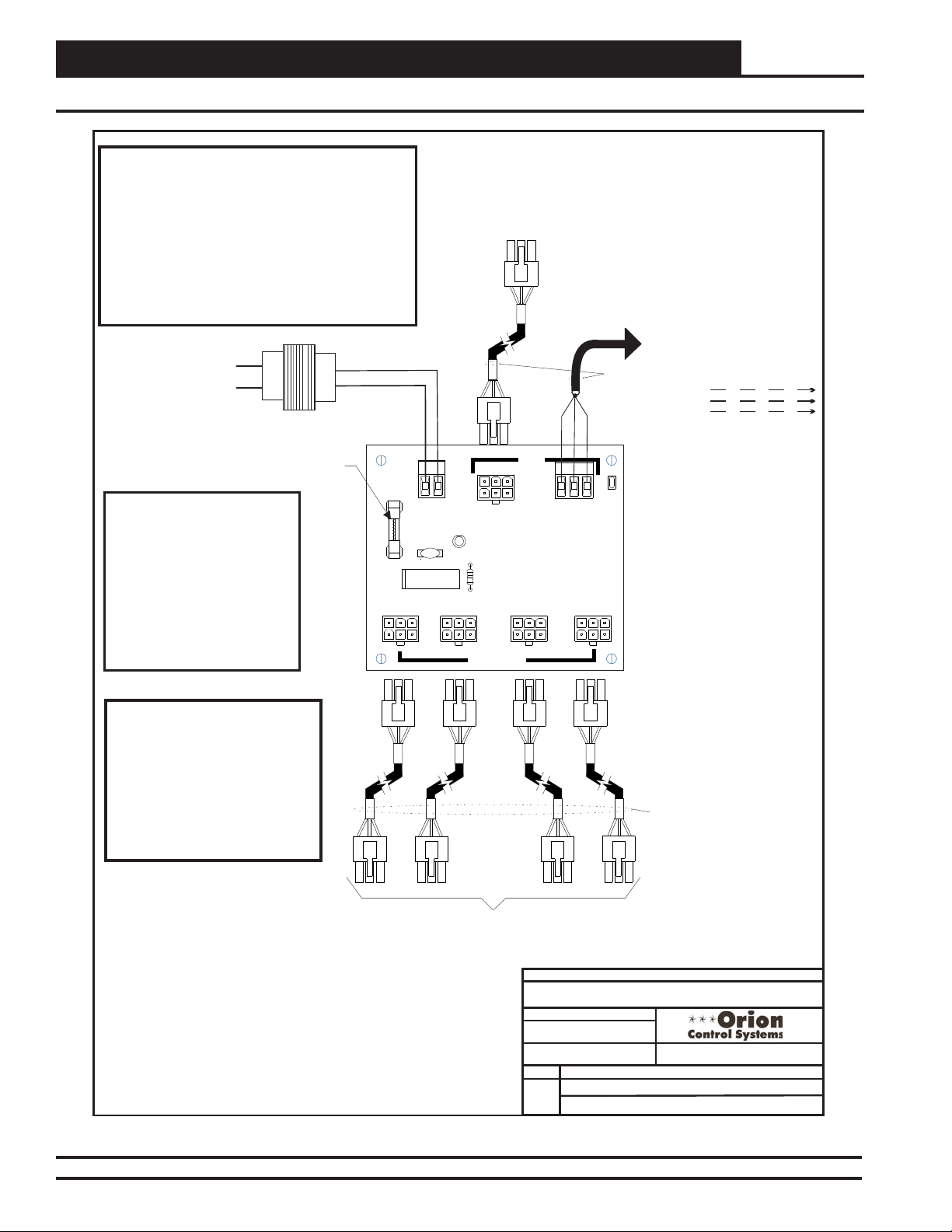

24VAC Power - Transformer & Cabling Considerations for Devices With Modular Connectors

Modular devices include the VAV/Zone Controller, Modular

System Manager & MiniLink Polling Device. When sizing

transformers for the devices it is important to design your

layout so that the fewest number of Power/Comm distribution

boards and the least number of transformers can be used.

The polarity problem discussed in regards to other devices

that do not have modular connections is not an issue with the

modular devices as they cannot be connected with reversed

polarity because of the modular board connectors and cable.

Also the prefabricated cable is always 16 gauge. Wire size

selection is therefore not an issue with the modular devices.

However, the same minimum voltage rules apply to modular

devices as with other non-modular devices. In order to

simplify wiring design and layout with modular devices the

following rules apply:

Power/Comm Board maximum transformer size = 100VA.

This is due to the board circuitry and fusing. Each modular

device is to be calculated at 6VA. This allows for a maximum

of 16 devices per Power/Commboard. If more than 16

devices are required, multiple Power/Comm boards must be

used.

No more than 6 modular devices allowed per branch circuit.

(The Power/Comm board has a total of 4 branch circuits)

The longest total run per branch circuit is 240 Ft. This is due

to voltage drop on the prefabricated cable.

Below are some examples of transformer sizing and branch

circuit design.

120 / 24VAC

120 / 24VAC

120 / 24VAC

120 / 24VAC

80 VA

Transformer

Minimum

See Warning

Note Below

40 VA

Transformer

Minimum

See Warning

Note Below

100 VA

Transformer

Minimum

See Warning

Note Below

75 VA

Transformer

Minimum

See Warning

Note Below

Power/Comm

Board

Power/Comm

Board

Power/Comm

Board

Power/Comm

Board

Total length of all modular cables used on each branch ( A to B) cannot exceed 240 Ft.

Total length of all modular cables used on each branch ( A to B) cannot exceed 240 Ft.

A

A

A

A

12 Devices At 6 VA = 72 VA

Use 75 VA Transformer

WARNING!

DO NOT GROUND THE 24V TRANSFORMER THAT IS TO BE USED

WITH THE POWER/COMM BOARDS. GROUNDING OF THE

TRANSFORMER WILL DAMAGE THE POWER/COMM BOARD AND

ALL BOARDS CONNECTED TO IT. A SEPARATE TRANSFORMER

MUST BE USED FOR EACH POWER/COMMBOARD. NO

EXCEPTIONS. DO NOT CONNECT ANY OTHER DEVICES TO THE

TRANSFORMER USED FOR THE POWER/COMM BOARD!

6 Devices At 6 VA = 36 VA

Use 40 VA Transformer

16 Devices At 6 VA = 96 VA

Use 100 VA Transformer

13 Devices At 6 VA = 78 VA

Use 80 VA Transformer

6 Devices Maximum Per Branch Circuit

6 Devices Maximum Per Branch Circuit

O-VCMXWRSIZ1A.CDR

Orion VCM-X System

03/09/06

Transformer Sizing & Cabling For Devices With Modular Connectors

Figure 2: Transformer & Wire Sizing - Devices with Modular Connectors

10

VCM-X Component & Systems Wiring

Page 11

System Installation

Stand-Alone

MiniLink Polling Device (MiniLink PD)

Standard Connection Confi gurations and Use

The MiniLink PD is used on Networked Single and Multiple Loop

systems to provide two-way communication between all devices on

it’s “Local Loop” and to all the other “Network Loop” devices on

the entire system. The MiniLink PD is equipped with both modular

connectors and hard wiring terminal blocks for connection of 24

VAC power “Local Loop” and “Network Loop” communications.

Each MiniLink PD is normally hard wired to a 24 VAC power

source connected to its 24 VAC input terminal (TB1). “Network

Loop” communications are transferred between multiple MiniLink

PDs by modular cables connected to their “Network Loop” modular connectors (P3 and P5). A CommLink 5 must be connected to

one of the MiniLink PDs on the system by using a 2-wire shielded

cable connected between its 3-wire “Network Loop” communications terminal block (TB4) and to the CommLink’s “485 Loop”

terminal block. Transfer of “Local Loop” communication from the

MiniLink PD to a Power/Comm board is made by using a modular

cable connected between the MiniLink PD “Local Loop” modular

connector (P4) and the Power/Comm board modular “Comm In”

connector (P2). If desired as an alternative, transfer of “Local Loop”

communication from the MiniLink PD to a Power/Comm board can

be made by hard wiring a 2-wire shielded cable connected between

the MiniLink PD’s 3-wire communications terminal (TB1) and the

3-wire communications input (TB1) on the Power/Comm board.

Installation Procedures

The installation procedures that follow are based on recommended

methods of wiring connection and controller installation. Installation

procedures vary depending on the type of system you are installing.

The system you are installing could be a Stand Alone, Interconnected,

Networked Single Loop, or Networked Multiple Loop system. The

Networked System also has installation variations based on the type

of components you are installing for that system. The following

information explains the procedures for all of these systems. Please

fi nd the system and components that closely match your system and

follow the outlined procedures.

Stand Alone Systems

See Figure 3, page 22 of this manual for a detailed Stand Alone

System wiring diagram. Also see pages 9-10 for wire and transformer

sizing information. Y ou should review these diagrams before attempting connections or powering up the controller or interface devices.

1. Install a 24 VAC, 8 VA minimum, transformer for the

VCM-X E-BUS Controller and wire from transformer

to the controller using 18 gauge minimum, 2 conductor

cable for power. Observe polarity on all power wiring.

2. The Modular Service Tool SD connects to the controllers

using the supplied cable with DIN connectors on both

ends. The connection point on the controller is located

near the communications connector. The Comm unications setting must be set to Lo Speed Stand

Alone.

3. The Modular System Manager SD comes supplied with

a 12 foot modular cable with a modular connector on

one end and stripped wires on the other. If the Modular

System Manager is to be mounted in a remote location,

run 18 gauge, 2 conductor shielded cable for

communications from the controller’s 3 wire

communications terminal to a junction box. Run 18

gauge minimum, 2-wire, power wires from a separate

24 VAC, 6 VA minimum transformer into the

junction box. Splice the modular cable to the

communications and power wire inside of the junction

box by making solid connections, using wire nuts or butt

splice connectors. The Communications setting must be

set to Lo Speed Stand Alone.

4. The System Manager TS II utilizes a 3-wire

communication terminal block for connection to any

controller on the communications local loop that has

communication wire terminals. A separate transformer

is required for the System Manager TS II. It has a 2-wire

24 VAC terminal block for connection to a 24 VAC

transformer. The transformer should be sized to provide

6 VA minimum power and should be connected using

using 18 gauge minimum 2 conductor wire. In the

Settings Menu, enter

Address.

5. If a CommLink 5 is used for a computer interface,

connect communications using 18 gauge, 2 conductor

with shield cable. Connect from the controller’s 3-wire

communications connector to the CommLink’s 3-wire

communications connector. For this type of system, the

Loop switch located on the back of the CommLink 5

must be set to “Single”.

6. Use 18 gauge minimum, 2-wire cable for all 24 VAC

power wiring. Be sure to maintain polarity on all boards.

If a CommLink is connected, use the 110 VAC/24 VAC

power supply furnished with the CommLink for its

power source.

7. Before powering up the controller, set the desired board

address on the controller (usually 1).

<0> for the System Manager

VCM-X Component & Systems Wiring

11

Page 12

System Installation

Interconnected & Networked Single Loop

Interconnected Systems

See Figure 4, page 23 for a detailed Interconnected System wir-

ing diagram. Also see pages 9-10 for wire and transformer sizing

information. You should review these diagrams before attempting

connections or powering up the controller or interface devices.

1. Connect all VCM-X E-BUS Controllers in a daisy chain

format using 18 gauge, 2 conductor shielded cable for

communications. Install a separate 24 VAC, 8 VA

minimum transformer for each VCM-X E-BUS

Controller and wire the transformers to each

controller using 18 gauge minimum, 2 conductor cable.

Observe polarity on all boards.

2. The Modular Service Tool SD will connect to any of

the controllers using the supplied cable with DIN

connectors on both ends. The connection point on the

controller is located near the communications connector.

The Communications setting must be set to Lo Speed

Stand Alone.

3. The Modular System Manager SD comes supplied with

a 12 foot modular cable with a modular connector on

one end and stripped wires on the other. If the Modular

System Manager is to be mounted in a remote location,

run 18 gauge, 2 conductor shielded cable for

communications from the controller’s 3-wire

communications terminal to a junction box. Run 18

gauge minimum, 2-wire power wires from a separate

24 VAC, 6 VA minimum transformer into the junction

box. Splice the modular cable to the communications

and power wire inside of the junction box by making

solid connections, using wire nuts or butt splice

connectors. The Communications setting must be set

to Lo Speed Stand Alone. .

4. The System Manager TS II utilizes a 3-wire

communication terminal block for connection to any

controller on the communications local loop that has

communication wire terminals. A separate transformer

is required for the System Manager TS II. It has a 2-wire

24 VAC terminal block for connection to a 24 VAC

transformer. The transformer should be sized to provide

6 VA minimum power and should be connected using 18

gauge minimum 2 conductor wire. In the Settings Menu,

enter

sure One to One Unit Connection is not selected.

5. If a CommLink 5 is used to provide for connection to a

computer interface, connect communications using 18

gauge, 2 conductor shielded cable. Connect from one

of the controller’s 3-wire communications connectors

to the CommLink’s 3-wire communications connector.

For this type of system, the Loop switch on the back of

the CommLink needs to be set to “Single”.

<0> for the System Manager Address and make

6. Use 18 gauge minimum, 2-wire cable for all 24 VAC

power wiring. Be sure to maintain polarity on all boards.

If a CommLink 5 is installed, use the 110 VAC/24 VAC

power supply furnished with the CommLink for its

power source.

7. Before powering up the controllers, set each controller’s

board address to a unique number from 1 through 60.

Networked Single Loop Systems

See Figures 5-9, pages 24-28 for detailed Networked Single Loop

System wiring diagrams. Also see pages 9-10 for wire and transformer sizing information. Y ou should review these diagrams before

attempting connections or powering up the controller or interface

devices.

Loop Containing VCM-X E-BUS Controllers Only

(Using CommLink 5)

1. Connect all VCM-X E-BUS Controllers on the loop in a

daisy chain format using 18 gauge, 2 conductor shielded

cable wiring from each controller’s communication

terminals to the next controller’s communication

terminals. Install a separate 24 VAC, 8 VA minimum

transformer for each controller and wire from controllers

to the transformers using 18 gauge minimum, 2 wire

cable. Be sure to observe polarity on all boards.

2. Connect 18 gauge minimum 2 conductor shielded cable

from one of the VCM-X E-BUS Controller’s 3 wire

communication terminals to the CommLink5’s 3 wire

communications terminal. The Loop switch on the

back of the CommLink must be set to “Single” for this

installation. Use the 110 VAC/24 VAC power supply

furnished with the CommLink for its power source.

3. The Modular Service Tool SD will connect to any of the

controllers using the supplied cable with DIN connectors

on both ends. The connection point on the controller

is located near the communications connector. The

Communications setting must be set to Lo Speed

Network Mode.

4. The Modular System Manager SD comes supplied with

a 12 foot long modular cable with a modular connector

on one end and stripped wires on the other. If the System

Manager is to be mounted in a remote location, run 18

gauge, 2 conductor shielded cable for communications

from one of the controller’s 3 wire communications

terminals to a junction box. Run 18 gauge, 2 wire, 24

VAC power wires supplied by a separate transformer

into the junction box. Splice modular cable to the

communications and power wire inside of the junction

box using solid connections from wire nuts or buttsplice connectors. The Modular System Manager MUST

always be connected on the “Local Loop”, never the

“Network Loop”. The Communications setting must be

set to Lo Speed Network Mode.

12

VCM-X Component & Systems Wiring

Page 13

System Installation

Networked Single Loop

5. The System Manager TS II utilizes a 3 wire

communication terminal block for connection to any

controller on the communications local loop that has

communication wire terminals. A separate transformer

is required for the System Manager TS II. It has a 2

wire 24 VAC terminal block for connection to a 24 VAC

transformer. The transformer should be sized to provide

6 VA minimum power and should be connected using

18 gauge minimum, 2 conductor wire. In the Settings

Menu, enter

6. Before powering up the controllers, set each controller’s

board address to a unique number from 1 through 59.

Loop Containing VCM-X E-BUS Controller with Modular

VAV/Zone Controllers and MiniLink PD Only

1. Connect all controllers in a daisy chain format

using 18 gauge, 2 conductor shielded cable for

communications. Using 18 gauge minimum, 2 wire

cable for power, install a 24 VAC, 8 VA minimum,

transformer for the VCM-X E-BUS Controller and

wire from the transformer to the VCM-X E-BUS

Controller. Using 18 gauge minimum, 2 wire cable

for power, install a separate 24 VAC transformer sized

for the required VA load for each Power/Comm board on

the loop and wire from each transformer to its Power/

Comm board. Observe polarity on all boards.

2. Connect 2 conductor shielded cable from the VCM-X

E-BUS Controller’s 3 wire communications connector

to the MiniLink PD’s 3 wire communications connector

marked “Local Loop”. Use 18 gauge minimum, 2 wire

cable for all power wiring and be sure to maintain

polarity on all boards.

3. Using a modular cable, connect from the MiniLink PD’s

modular connector marked “Local Loop” to a

Power/Comm board’s modular input connector.

4. Using modular cables, connect from the Power/Comm

board’s modular output connectors to the Modular VAV/

Zone Controllers. The VAV/Zone Controllers connect

together using modular cables from each VAV/Zone

Controller to the next controller and/or to a Power/

Comm board. A maximum of 16 VAV/Zone Controllers

are allowed per Power/Comm board. If you have more

than 16 VAV/Zone Controllers, you will need multiple

Power/Comm boards. Each Power/Comm board must

have its own 24 VAC transformer sized for the total

number of VAV/Zone Controllers connected to it.

<63> for the System Manager Address.

6. The Modular System Manager SD can connect to any

VAV/Zone Controller or directly to one of the Power/

Comm board’s modular output connectors. The

Communications setting must be set to Lo Speed

Network Mode.

7. The System Manager TS II utilizes a 3 wire

communication terminal block for connection to any

controller on the communications local loop that has

communication wire terminals. Since you are using

Modular VAV/Zone Controllers, you can use a modular

pigtail connector that has a modular connector on one

end and stripped wires on the other to connect the

System Manager TS II to the Power/Comm board or

one of the Modular VAV/Zone Controllers. A separate

transformer is required for the System Manager

TS II. It has a 2 wire 24 VAC terminal block

for connection to a 24 VAC transformer. The

transformer should be sized to provide 6 VA minimum

power and should be connected using 18 gauge

minimum wire. In the Settings Menu, enter <63> for the

System Manager Address.

8. Before powering up the controllers, set each VAV/

Zone Controller’s board address to a unique number

from 1 through 58. Address the VCM-X E-BUS

Controller at 59. Set MiniLink PD’s address at 1.

Note: Only communications, not power, are transferred

from the MiniLink Polling Device to the Power/

Comm board via the modular cable. A separate

transformer is required for the MiniLink Polling

Device. Both power and communications are

transferred from the Power/Comm board to the

VAV/Zone Controllers and the Modular System

Manager.

Warning: Each Power/Comm board must have its own

24 VAC transformer for its power source. This

transformer cannot be shared with any other

board. Do not ground the transformer that is

connected to the Power/Comm board. The

transformer should be sized for the required

VA by using the information found on pages

9-10 of this manual.

5. The Modular Service Tool SD will connect to any of the

controllers using the supplied cable with DIN

connectors on both ends. The connection point on the

controller is located near the communications connector.

The Communications setting must be set to Lo Speed

Network Mode.

VCM-X Component & Systems Wiring

13

Page 14

System Installation

Networked Single Loop

Loop Containing VCM-X E-BUS Controller with

Non-Modular VAV/Zone Controllers and MiniLink PD Only

1. Connect 2 conductor shielded cable from the VCM-X

E-BUS Controller’s 3 wire communications connector to

the MiniLink PD’s 3 wire communications connector

marked “Local Loop”. Using 18 gauge minimum, 2

wire cable for power, install a 24 VAC, 8 VA minimum,

transformer for the VCM-X E-BUS Controller and wire

from the transformer to the VCM-X E-BUS Controller.

Also connect a 24 VAC 6 VA minimum transformer

to the MiniLink PD power terminals using 18 gauge

minimum, 2 wire cable. Then wire from the VCM-X

E-BUS Controller’s 3 wire communications connector

or the MiniLink PD’s 3 wire communications connector

marked ”Local Loop” to the fi rst VAV/Zone Controller’s

3 wire communications terminals. Using 18 gauge

minimum, 2 wire cable, connect all of the associated

Non-Modular VAV/Zone Controllers in a daisy chain

format using 18 gauge, 2 conductor shielded cable for

communications. Using 18 gauge minimum, 2 wire

cable for power, install a 24 VAC, 6 VA minimum,

transformer for each Non-Modular VAV/Zone Controller

and wire from each transformer to its VAV/Zone

Controller. WattMaster recommends you use a separate

transformer for each VAV/Zone Controller as stated.

As an alternative, it is allowable to have several NonModular VAV/Zone Controllers share one properly sized

transformer (6 VA per VAV/Zone Controller). Warning:

Polarity must be observed on all of the VAV/Zone

Controllers or damage to the controllers will result. Use

18 gauge minimum, 2 wire cable for all power wiring

and be sure to maintain polarity on all boards.

2. The Modular System Manager can connect to any VAV/

Zone Controller or to the VCM-X E-BUS Controller.

Use the supplied pigtail cable which has a modular

connector for connection to the back of the Modular

System Manager and wire to any controller on the

communications local loop with communication wire

terminals. A separate transformer is required for the

Modular System Manager. Connect the 2 power wires

from the pigtail connector to a 24 VAC transformer. The

transformer should be sized to provide 6 VA minimum

power. The Communications setting must be set to Lo

Speed Network Mode.

3. The Modular Service Tool SD will connect to any of the

controllers using the supplied cable with DIN connectors

on both ends. The connection point on the controller

is located near the communications connector. The

Communications setting must be set to Lo Speed

Network Mode.

4. The System Manager TS II utilizes a 3 wire

communication terminal block for connection to any

controller on the communications local loop that has

communication wire terminals. A separate transformer

is required for the System Manager TS II. It has a 2

wire 24 VAC terminal block for connection to a 24 VAC

transformer. The transformer should be sized to provide

6 VA minimum power and should be connected using 18

gauge minimum wire. In the Settings Menu, enter

for the System Manager Address.

5. Before powering up the controllers, set each VAV/

Zone Controller’s board address to a unique number

from 1 through 58. Address the VCM-X E-BUS

Controller at 59. Set MiniLink PD’s address at 1.

Loop Containing VCM-X E-BUS Controller with Modular

VAV/Zone Controllers and CommLink 5 Only

1. Connect all controllers in a daisy chain format

using 18 gauge, 2 conductor shielded cable for

communications. Using 18 gauge minimum, 2 wire

cable for power, install a 24 VAC, 8 VA minimum,

transformer for the VCM-X E-BUS Controller and

wire from transformer to the VCM-X E-BUS

Controller. Using 18 gauge minimum, 2 wire cable

for power, install a separate 24 VAC, transformer sized

for the required VA load for each Power/Comm board on

the loop and wire from each transformer to its Power/

Comm board. Observe polarity on all boards.

2. Use 18 gauge minimum, 2 wire cable for all 24 VAC

power wiring. Be sure to maintain polarity on all boards.

Use the 110 VAC/24 VAC power supply furnished with

the CommLink for its power source.

3. Using 2 conductor shielded cable, connect from the

CommLink 5’s 3 wire communications connector to the

Power/Comm board’s or VCM-X E-BUS Controller’s 3

wire communications input connector. The Loop switch

on the back of the CommLink 5 should be set to

“Single”.

4. Using modular cables, connect from the Power/Comm

board’s modular output connectors to the VAV/

Zone Controllers. The VAV/Zone Controllers connect

together using modular cables from each VAV/Zone

Controller to the next controller and/or to a Power/

Comm board. A maximum of 16 VAV/Zone Controllers

are allowed per Power/Comm board. If you have more

than 16 VAV/Zone Controllers, you will need multiple

Power/Comm boards. Each Power/Comm board must

have its own 24 VAC transformer sized for the total

number of VAV/Zone Controllers connected to it.

<63>

14

5. The Modular System Manager can connect to any VAV/

Zone Controller or directly to one of the Power/Comm

board’s modular output connectors. The

Communications setting must be set to Lo Speed

Network Mode.

VCM-X Component & Systems Wiring

Page 15

System Installation

Networked Single Loop

6. The Modular Service Tool SD will connect to any

of the controllers using the supplied cable with DIN

connectors on both ends. The connection point on the

controller is located near the communications connector.

The Communications setting must be set to Lo Speed

Network Mode.

7. The System Manager TS II utilizes a 3 wire

communication terminal block for connection to

any controller on the communications local loop that

has communication wire terminals. A separate

transformer is required for the System Manager TS II.

It has a 2 wire 24 VAC terminal block for connection to

a 24 VAC transformer. The transformer should be sized

to provide 6 VA minimum power and should be

connected using 18 gauge minimum wire. In the

Settings Menu, enter

Address.

8. Before powering up the controllers, set each VAV/

Zone Controller’s board address to a unique number

from 1 through 58. Address the VCM-X E-BUS

Controller at 59.

Note: Both power and communications are transferred

from the Power/Comm board to the VAV/Zone

Controllers and the Modular System Manager. Only

communications are transferred from Power/Comm

board to Power/Comm board.

<63> for the System Manager

the fi rst VAV/Zone Controller’s 3 wire communications

terminal. Connect all of the associated Non-Modular

VAV/Zone Controllers in a daisy chain format using 18

gauge, 2 conductor shielded cable for communications.

Using 18 gauge minimum, 2 wire cable for power,

install a 24 VAC, 6 VA minimum, transformer for each

Non-Modular VAV/Zone Controller and wire from each

transformer to its VAV/Zone Controller. WattMaster

recommends you use a separate transformer for each

VAV/Zone Controller as stated. As an alternative, it

is allowable to have several Non-Modular VAV/Zone

Controllers share one properly sized transformer (6 VA

per VAV/Zone Controller). Warning: Polarity must be

observed on all of the VAV/Zone Controllers or damage

to the controllers will result. Use 18 gauge minimum,

2 wire cable for all 24 VAC power wiring. Be sure to

maintain polarity on all boards.

3. The Modular System Manager can connect to any VAV/

Zone Controller or to the VCM-X E-BUS Controller.

Use the supplied pigtail cable which has a modular

connector for connection to the back of the Modular

System Manager and wire to any controller on the

communications local loop with communication wire

terminals. A separate transformer is required for the

Modular System Manager. Connect the 2 power wires

from the pigtail connector to a 24 VAC transformer. The

transformer should be sized to provide 6 VA minimum

power. The Communications setting must be set to Lo

Speed Network Mode.

Warning: Each Power/Comm board must have its own

24 VAC transformer for its power source. This

transformer cannot be shared with any other

board. Do not ground the transformer that is

connected to the Power/Comm board. The trans former should be sized for the required VA by

using the information found on pages 9-10

of this manual.

Loop Containing VCM-X E-BUS Controller with Non-Modular VAV/Zone Controllers and CommLink 5 Only

1. Connect 2 conductor shielded cable from the VCM-X

E-BUS Controller’s 3 wire communications connector

to the CommLink 5’s 3 wire communications connector.

Use the 110 VAC/24 VAC power supply furnished with

the CommLink for its power source. Be sure to maintain

polarity on all boards. The Loop switch on the back of

the CommLink 5 should be set to “Single”.

2. Using 18 gauge minimum, 2 wire cable for power, install

a 24 VAC, 8 VA minimum, transformer for the VCM-X

E-BUS Controller and wire from the transformer to the

VCM-X E-BUS Controller. Then wire from the VCM-X

E-BUS Controller’s 3 wire communications connector or

the CommLink 5’s 3 wire communications connector to

4. The Modular Service Tool SD will connect to any

of the controllers using the supplied cable with DIN

connectors on both ends. The connection point on the

controller is located near the communications connector.

The Communications setting must be set to Lo Speed

Network Mode.

5. The System Manager TS II utilizes a 3 wire

communication terminal block for connection to

any controller on the communications local loop that

has communication wire terminals. A separate

transformer is required for the System Manager TS II.

It has a 2 wire 24 VAC terminal block for connection to

a 24 VAC transformer. The transformer should be sized

to provide 6 VA minimum power and should be

connected using using 18 gauge minimum wire. In the

Settings Menu, enter

Address.

6. Before powering up the controllers, set each VAV/

Zone Controller’s board address to a unique number

from 1 through 58. Address the VCM-X E-BUS

Controller at 59.

<63> for the System Manager

VCM-X Component & Systems Wiring

15

Page 16

System Installation

Networked Single Loop

Loop Containing VCM-X E-BUS Controller with Modular V A V/

Zone Controllers, MiniLink PD, and CommLink 5

1. Connect the CommLink 5 to the MiniLink PD by

using 2 conductor shielded cable to connect from the

CommLink 5’s 3 wire communications connector to

the MiniLink PD’s 3 wire communications connector

marked “Network Loop”. Use the 110 VAC/24 VAC

power supply furnished with the CommLink for its

power source. Be sure to maintain polarity on all boards.

The Loop switch on the back of the CommLink 5

should be set to “Multiple”. Also connect a 24 VAC 6

VA minimum transformer to the MiniLink PD power

terminals using 18 gauge minimum, 2 wire cable.

2. Connect all controllers in a daisy chain format

using 18 gauge, 2 conductor shielded cable for

communications. Using 18 gauge minimum, 2 wire

cable for power, install a 24 VAC, 8 VA minimum,

transformer for the VCM-X E-BUS Controller and wire

from the transformer to the VCM-X E-BUS Controller.

Using 18 gauge minimum, 2 wire cable for power, install

a separate 24 VAC transformer sized for the required

VA load for each Power/Comm Board on the loop and

wire from each transformer to its Power/Comm board.

Observe polarity on all boards.

3. Using 2 conductor shielded cable, connect from the

VCM-X E-BUS Controller’s 3 wire communications

connector to the MiniLink PD’s 3 wire communications

connector marked “Local Loop”. Use 18 gauge

minimum wire for power and observe polarity on

all boards.

4. Using a modular cable, connect from the MiniLink PD’s

modular connector marked “Local Loop” to a

Power/Comm board’s modular input connector.

5. Using modular cables, connect from the Power/Comm

board’s modular output connectors to the VAV/Zone

Controllers. The VAV/Zone Controllers connect together

using modular cables from each VAV/Zone Controller

to the next controller and/or to a Power/Comm board. A

maximum of 16 VAV/Zone Controllers are allowed per

Power/Comm board. If you have more than 16 VAV/

Zone Controllers, you will need multiple Power/Comm

boards. Each Power/Comm board must have its own

24 VAC transformer sized for the total number of VAV/

Zone Controllers connected to it.

6. The Modular System Manager can connect to any

VAV/Zone Controller or directly to one of the Power/

Comm board’s modular output connectors. The

Communications setting must be set to Lo Speed

Network Mode.

7. The System Manager TS II utilizes a 3 wire

communication terminal block for connection to any

controller on the communications local loop that has

communication wire terminals. Since you are using

Modular VAV/Zone Controllers, you can use a modular

pigtail connector that has a modular connector on one

end and stripped wires on the other to connect the

System Manger TS II to the Power/Comm board or

one of the Modular VAV/Zone Controllers. A separate

transformer is required for the System Manager TS II. It

has a 2 wire 24 VAC terminal block for connection to a

24 VAC transformer. The transformer should be sized to

provide 6 VA minimum power and should be connected

using 18 gauge minimum wire. In the Settings Menu,

enter <63> for the System Manager Address.

8. The Modular Service Tool SD will connect to any of the

controllers using the supplied cable with DIN connectors

on both ends. The connection point on the controller

is located near the communications connector. The

Communications setting must be set to Lo Speed

Network Mode.

9. Before powering up the controllers, set each VAV/

Zone Controller’s board address to a unique number

from 1 through 58. Address the VCM-X E-BUS

Controller at 59. Set MiniLink PD’s address at 1.

Note: Only communications, not power, is transferred

from the MiniLink Polling Device to the Power/

Comm board via the modular cable. Both power and

communications are transferred from the Power/

Comm board to the VAV/Zone Controllers and the

Modular System Manager.

Warning: Each Power/Comm board must have its own

24 VAC transformer for its power source.

This transformer cannot be shared with any

other board. Do not ground the transformer

that is connected to the Power/Comm board.

The transformer should be sized for the

required VA by using the information found

on pages 9-10 of this manual.

Loop Containing VCM-X E-BUS Controller with Non-Modular VAV/Zone Controllers, MiniLink PD, and CommLink 5

1. Connect the CommLink 5 to the MiniLink PD by

using 2 conductor shielded cable to connect from the

CommLink’s 3 wire communications connector to

the MiniLink PD’s 3 wire communications connector

marked “Network Loop”. Use the 110 VAC/24 VAC

power supply furnished with the CommLink for its

power source. Be sure to maintain polarity on all boards.

The Loop switch on the back of the CommLink 5

should be set to “Multiple”. Also connect a 24 VAC 6

VA minimum transformer to the MiniLink PD power

terminal using 18 gauge minimum, 2 wire cable.

16

VCM-X Component & Systems Wiring

Page 17

System Installation

Networked Multiple Loop

2. Connect all controllers in a daisy chain format using 2

conductor shielded cable to connect from the controller’s

3 wire communications connector to the MiniLink PD’s

3 wire communications connector marked “Local Loop”.

Using 18 gauge minimum, 2 wire cable for power, install

a 24 VAC, 8 VA minimum, transformer for the VCM-X

E-BUS Controller and wire from the transformer to the

VCM-X E-BUS Controller. Then wire from the VCM-X

E-BUS Controller’s 3 wire communications connector

to the MiniLink PD’s 3 wire communications connector

marked “Local Loop”. From either the MiniLink PD

connector marked “Local Loop” or the VCM-X E-BUS

Controller’s 3 wire communications connector, wire to

the fi rst VAV/Zone Controller’s 3 wire communications

terminal. Using 18 gauge minimum, 2 wire cable,

connect all of the associated Non-Modular VAV/Zone

Controllers in a daisy chain format using 18 gauge, 2

conductor shielded cable for communications.

3. Using 18 gauge minimum, 2 wire cable for power,

install a 24 VAC, 6 VA minimum, transformer for each

Non-Modular VAV/Zone Controller and wire from each

transformer to its VAV/Zone Controller. WattMaster

recommends you use a separate transformer for each

VAV/Zone Controller as stated. As an alternative, it

is allowable to have several Non-Modular VAV/Zone

Controllers share one properly sized transformer (6 VA

per VAV/Zone Controller). Warning: Polarity must be

observed on all of the VAV/Zone Controllers or damage

to the controllers will result. Use 18 gauge minimum, 2

wire cable for all power wiring and be sure to maintain

polarity on all boards.

4. The Modular System Manager can connect to any VAV/

Zone Controller or to the VCM-X E-BUS Controller.

Use the supplied pigtail cable which has a modular

connector for connection to the back of the Modular

System Manager and wire to any controller on the

communications local loop with communication wire

terminals. A separate transformer is required for the

Modular System Manager. Connect the 2 power wires

from the pigtail connector to a 24 VAC transformer. The

transformer should be sized to provide 6 VA minimum

power. The Communications setting must be set to Lo

Speed Network Mode.

5. The System Manager TS II utilizes a 3 wire

communication terminal block for connection to any

controller on the communications local loop that has

communication wire terminals. Since you are using

Modular VAV/Zone Controllers, you can use a modular

pigtail connector that has a modular connector on one

end and stripped wires on the other to connect the

System Manager TS II to the Power/Comm board or

one of the Modular VAV/Zone Controllers. A separate

transformer is required for the System Manager TS II. It

has a 2 wire 24 VAC terminal block for connection to a

24 VAC transformer. The transformer should be sized to

provide 6 VA minimum power and should be connected

using 18 gauge minimum wire. In the Settings Menu,

enter <63> for the System Manager Address.

6. The Modular Service Tool SD will connect to any of the

controllers using the supplied cable with DIN connectors

on both ends. The connection point on the controller

is located near the communications connector. The

Communications setting must be set to Lo Speed

Network Mode.

7. Before powering up the controllers, set each VAV/

Zone Controller’s board address to a unique number

from 1 through 58. Address the VCM-X E-BUS

Controller at 59. Set MiniLink PD’s address at 1.

Networked Multiple Loop Systems

See Figures 10-11, pages 29-30 of this manual for detailed Networked Multiple Loop System wiring diagrams. Also see pages

9-10 for wire and transformer sizing information. You should review

these diagrams before attempting connections or powering up the

controller or interface devices.

Local Loops containing VCM-X E-BUS Controllers with

Modular VAV/Zone Controllers