Page 1

Two Condenser

LED BLINK CODES

LED NAME STAT

BLINKS QTY. OF SENSORS INSTALLED

LED NAME

ALARM

NO PROBLEMS 0

NO SENSORS DETECTED 1

HIGH HEAD PRESSURE DETECTED 2

LOW HEAD PRESSURE DETECTED 3

Head Pressure II Module

Technical Guide

COND. A ENABLE

RATING IS 1 AMP

RELAY CONTACT

2C2Orion No.:OE370-23-HP

E-BUS

Connector

MAX @ 24 VAC

REV. VLV. AENABLE

COND. B ENABLE

REV. VLV. B ENABLE

RELAY COMMON

COND. A SIGNAL

COND. B SIGNAL

www.aaon.com

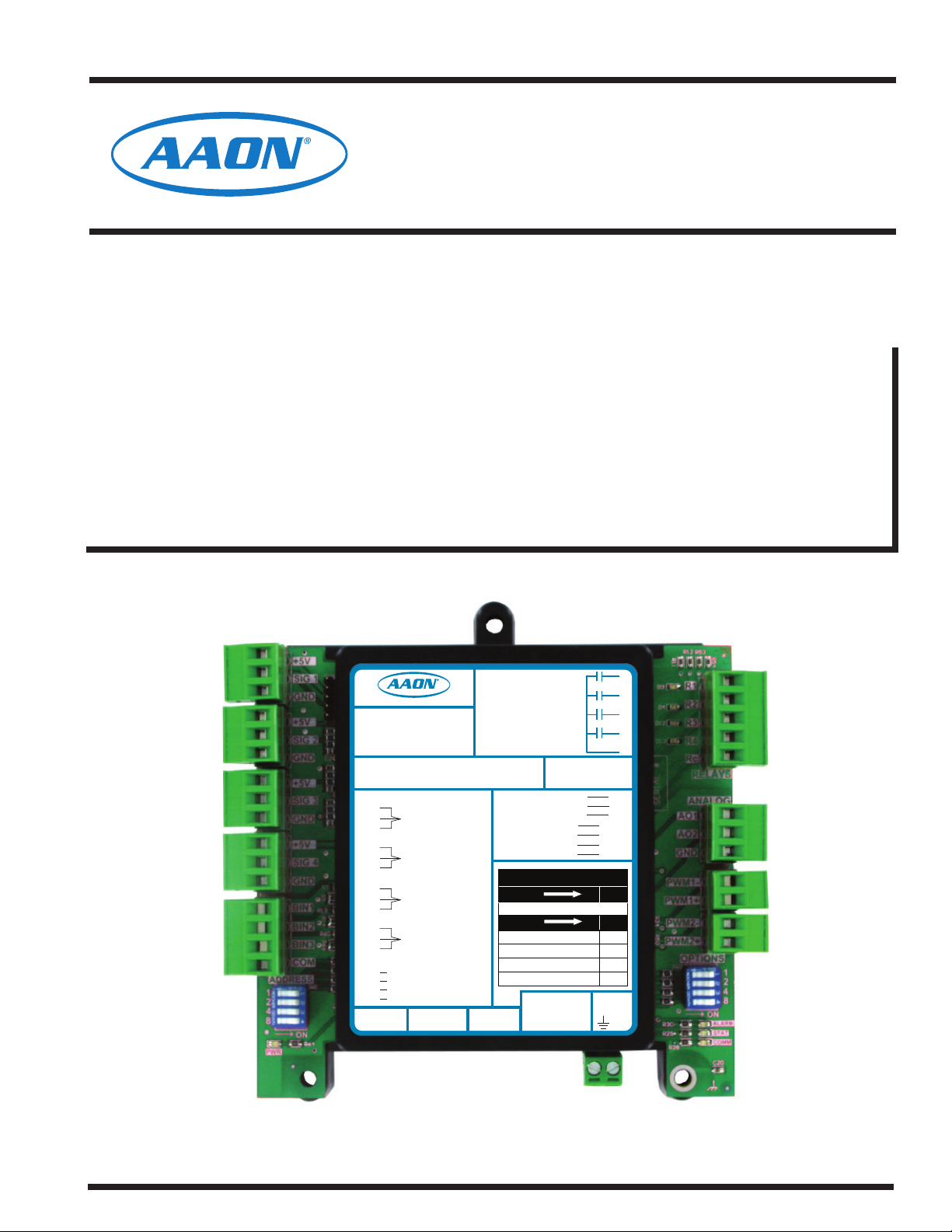

Two Condenser Head Pressure II Module

A1

+5V

HEAD

SIG 1

PRESSURE

GND

TRANSDUCER #1

A2

+5V

HEAD

SIG 2

PRESSURE

GND

TRANSDUCER #2

B1

+5V

HEAD

SIG 3

PRESSURE

GND

TRANSDUCER #3

B2

+5V

HEAD

SIG 4

PRESSURE

GND

TRANSDUCER #4

COND. A ENABLE INPUT

BIN 1

REV. VLV. ENABLE INPUT

BIN 2

COND. B ENABLE INPUT

BIN 3

COM

COMMON

WattMaster Label

E-BUS

Connector

#LB102110-A

Rev.: 1A

COND. FAN A

COND. FAN A

COND. FAN B

COND. FAN B

AAON No.:

V20660

GND

PWM1PWM1+

PWM2PWM2+

GND

AO1

AO2

GND

R1

R2

R3

R4

RC

+24 VAC

Page 2

Zone

TABLE OF CONTENTS

OVERVIEW ....................................................................................................................................... 3

Overview .................................................................................................................................................................. 3

Features ................................................................................................................................................................... 3

INSTALLATION AND WIRING .......................................................................................................... 4

Environmental Requirements ...................................................................................................................................4

Mounting .................................................................................................................................................................. 4

Power Supply ........................................................................................................................................................... 4

Important Wiring Considerations .............................................................................................................................. 4

Stand-Alone Wiring ..................................................................................................................................................5

Condenser Type Selection ....................................................................................................................................... 5

E-BUS Controller to Two Condenser Head Pressure II Module Wiring ...................................................................6

SEQUENCE OF OPERATION ............................................................................................................ 8

Inputs and Outputs ...................................................................................................................................................8

Stand-Alone Input Commands ................................................................................................................................ 8

Input Commands (VCM-X Connection) ................................................................................................................... 9

Modes of Operation ................................................................................................................................................. 9

TROUBLESHOOTING ..................................................................................................................... 12

Head Pressure Module Valve/Fan Position Troubleshooting ................................................................................. 12

Troubleshooting for Stand Alone Mode .................................................................................................................. 13

Pressure Transducer Troubleshooting .................................................................................................................. 14

Using LEDs to Verify Operation .............................................................................................................................14

LED Diagnostics .................................................................................................................................................... 15

Other Checks .........................................................................................................................................................15

Zone

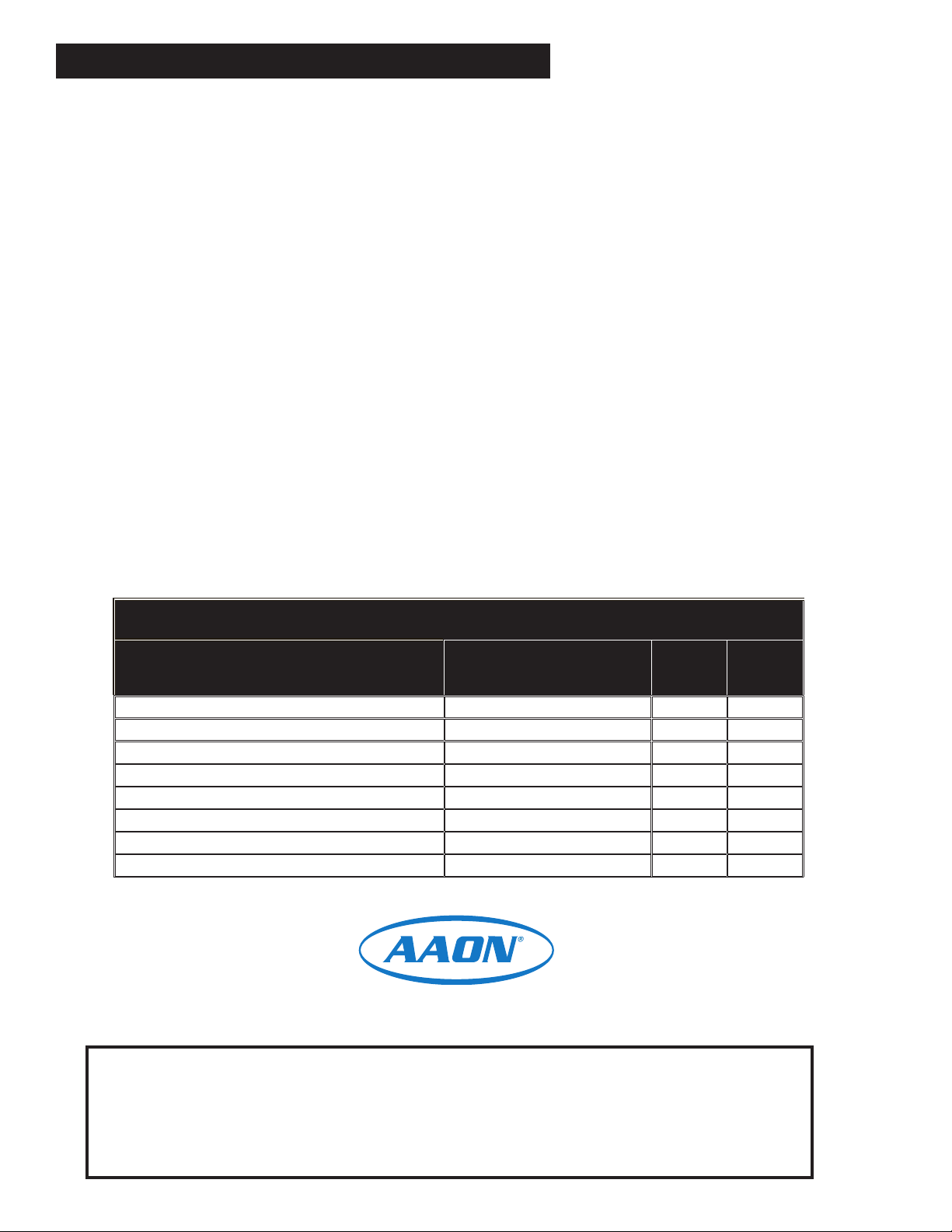

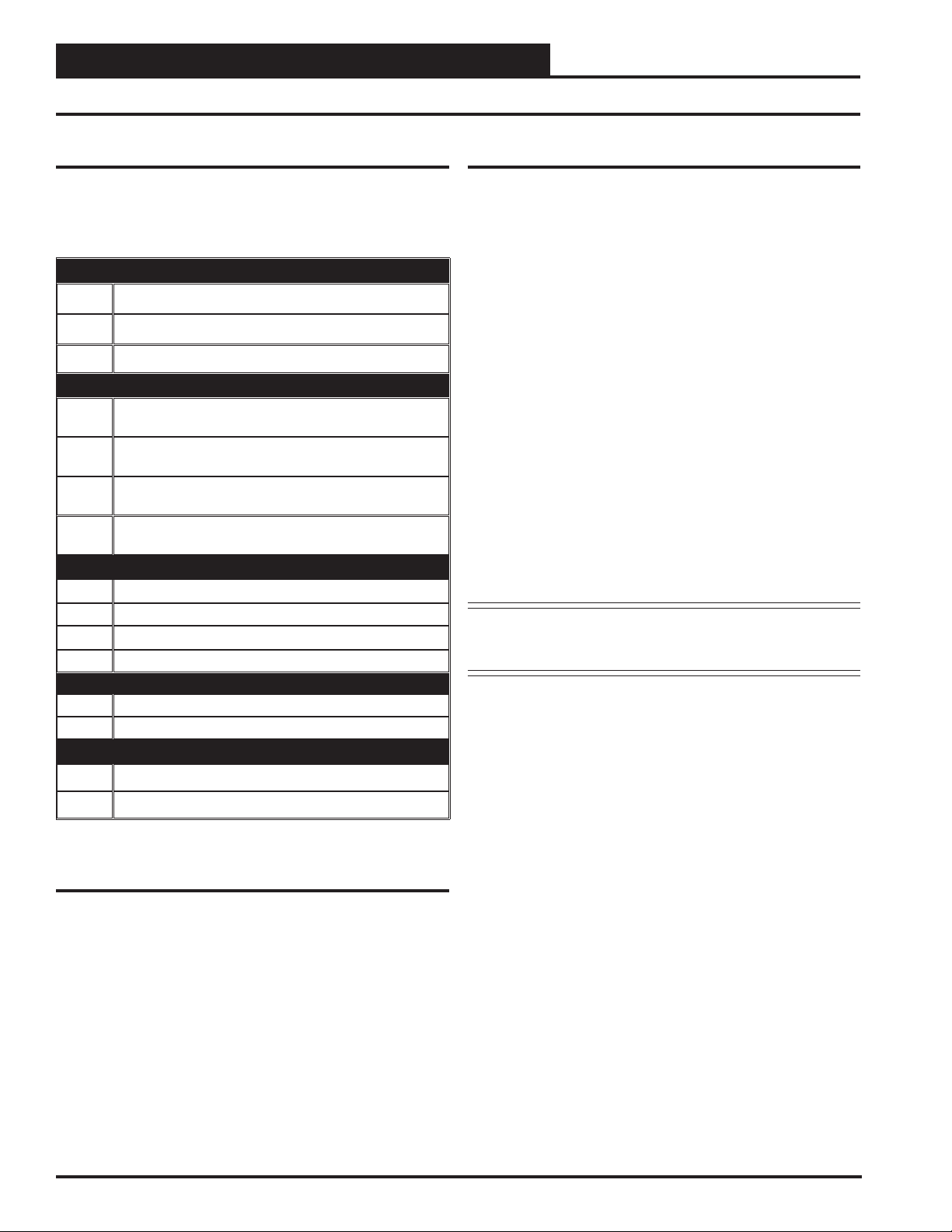

PART NUMBER CROSS REFERENCE TABLE

PART DESCRIPTION ORION AAON

TULSA

Two Condenser Head Pressure II Module - Tulsa OE370-23-HP2C2 V20660 N/A

Two Condenser Head Pressure II Module - Coil OE370-23-HP2C2-C N/A 31426

VCM-X Modular E-BUS Controller - Tulsa OE332-23E-VCMX-MOD-A V07150 N/A

VCM-X Modular E-BUS Controller - Coil OE332-23E-VCMX-MOD-C N/A 30553

VCM-X WSHP E-BUS Controller - Tulsa OE332-23E-VCMX-WSHP-A V07140 N/A

VCM-X WSHP E-BUS Controller - Coil OE332-23E-VCMX-WSHP-C N/A 30526

SA E-BUS Controller - Tulsa OE332-23E-SA-A V07160 N/A

SA Expansion Module - Tulsa OE333-23-SA-A R96180 N/A

www.aaon.com

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101

E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

Copyright April 2015 WattMaster Controls, Inc.

AAON Manual Part Number: V22100

AAON® is a registered trademark of AAON, Inc., Tulsa, OK.

WattMaster Form : AA-HP2C2-TGD-01E

Neither WattMaster Controls, Inc. nor AAON

assumes any responsibility for errors or omissions in this

document.

This document is subject to change without notice.

®

AAON

COIL

Page 3

INSTALLATION & WIRING

Module Overview

Overview

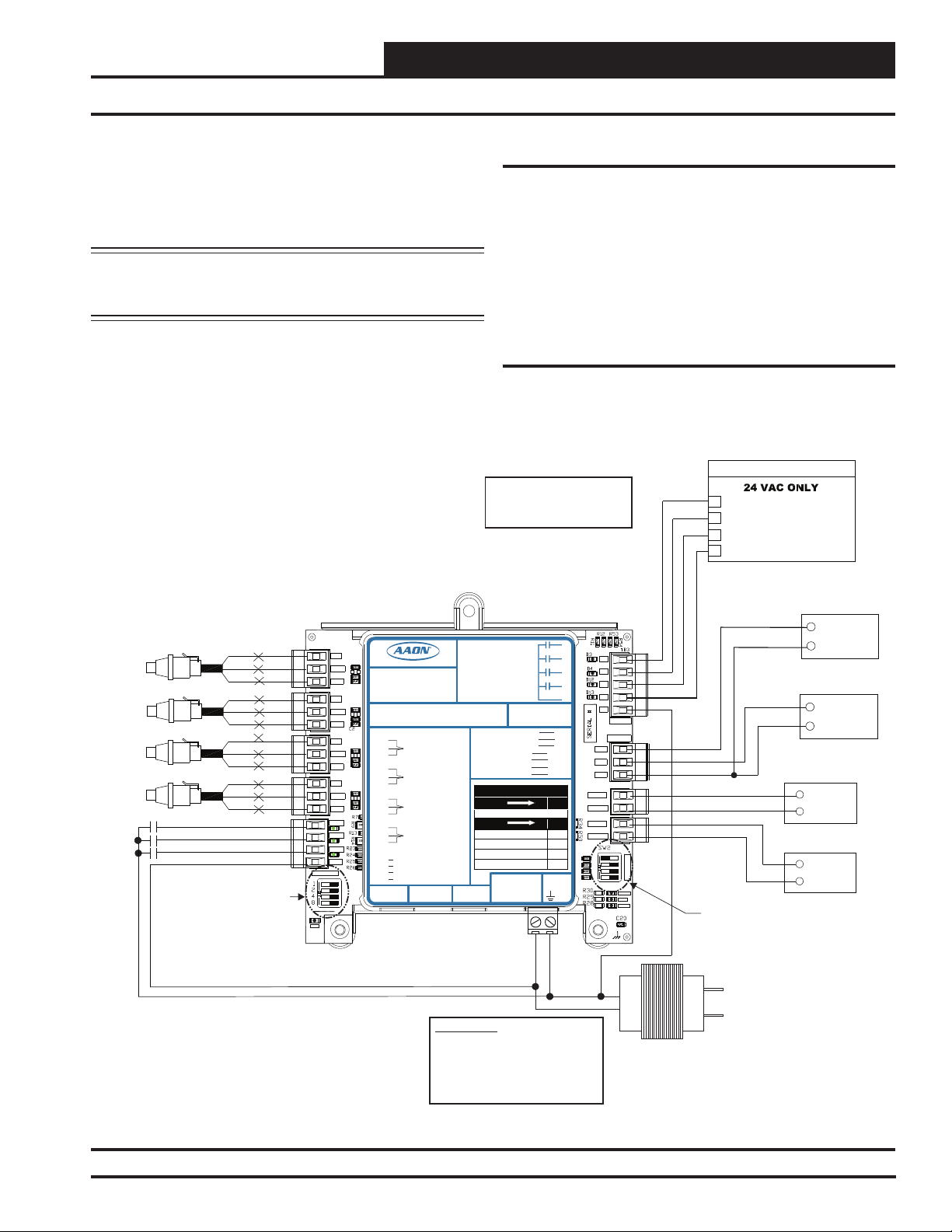

The Two Condenser Head Pressure II Module (OE370-23-HP2C2)

monitors four individual head pressure transducers and controls two

Condenser Fans or Water Valves on units with two physically separate

condenser sections. The highest reading of head pressure transducers 1

& 2 controls Condenser Signal A. The highest reading of head pressure

transducers 3 & 4 controls Condenser Signal B. If this is a heat pump unit,

the module is able to detect when the unit is in Heat Pump Heating mode

and will force the condenser signal to 100% until it leaves this mode.

The Two Condenser Head Pressure II Module is designed to work

stand-alone by using its OPTIONS dip switch to adjust the Head Pressure setpoint.

The Two Condenser Head Pressure II Module is directly connected to

the VCM-X Modular E-BUS, VCM-X WSHP E-BUS or SA E-BUS

Controller, allowing the Module(s) to receive setpoints from the Controller. See chart on page 2 for part numbers.

When using the Two Condenser Head Pressure II Module with the RNE

Controller, refer to the RNE Controller Technical Guide.

The Two Condenser Head Pressure II Module also provides a pulse

width modulation (PWM) signal or voltage output signal to control the

condenser fans.

The Two Condenser Head Pressure II Module requires a 24 VAC power

connection with an appropriate VA rating.

Features

The Two Condenser Head Pressure II Module provides the following:

Can be operated stand alone or up to (2) modules can be

daisy-chained together and connected to a VCM-X

Modular E-BUS, VCM-X WSHP E-BUS, or SA E-BUS

Controller

Monitors up to four individual head pressure transducers

Provides control of Condenser Output Signals based on the

highest reading of head pressure transducers

Capable of monitoring a Reverse Valve Signal

Forces Condenser Fans to 100% while in the Heat Pump

Heating Mode

NOTE: The Two Condenser Head Pressure II Module contains

no user-serviceable parts. Contact qualifi ed technical

personnel if your Module is not operating correctly.

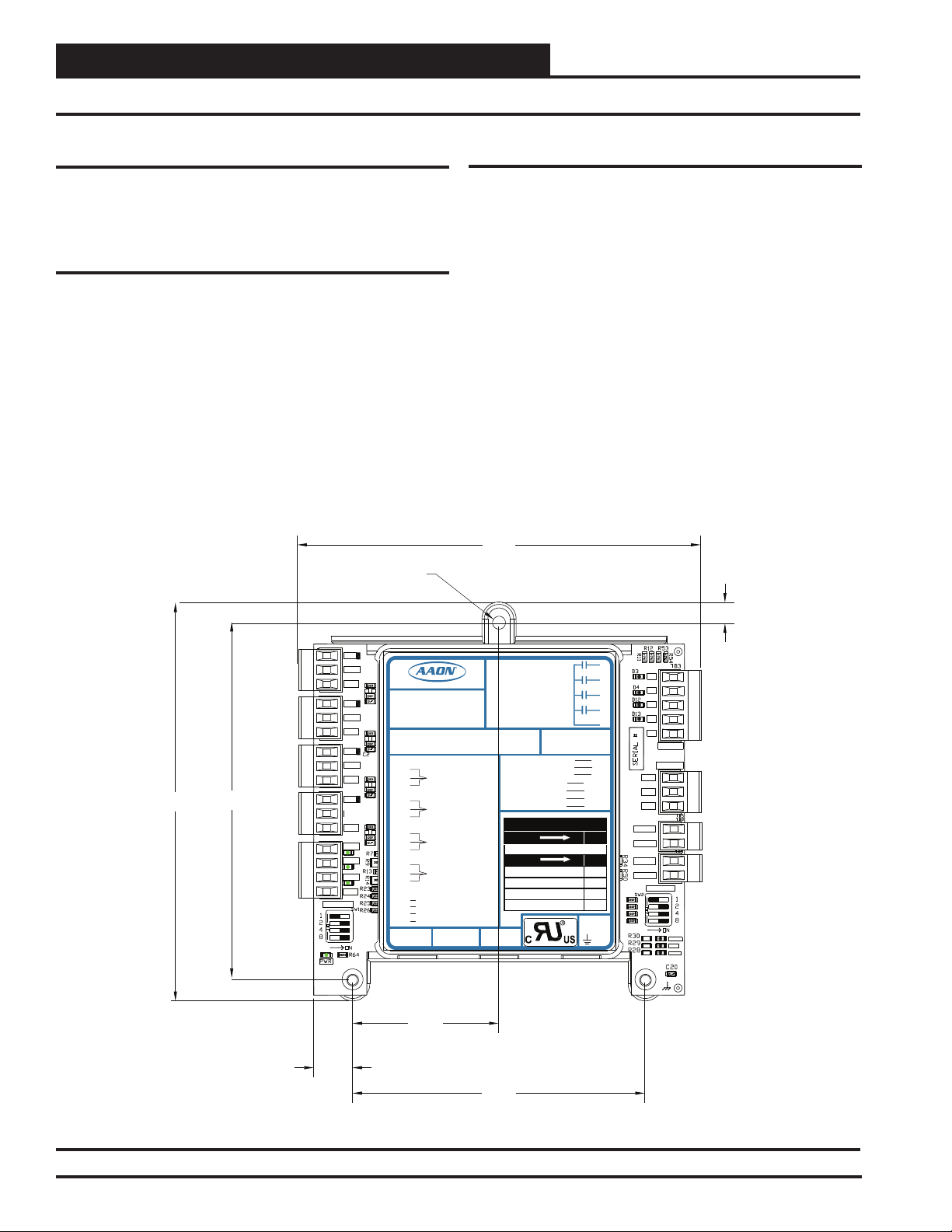

+5V

SIG 1

GND

+5V

SIG 2

GND

+5V

SIG 3

GND

+5V

SIG 4

GND

BIN 1

BIN 2

BIN 3

COM

ADDRESS

www.aaon.com

Two Condenser Head Pressure II Module

A1

+5V

HEAD

SIG 1

PRESSURE

GND

TRANSDUCER #1

A2

+5V

HEAD

SIG 2

PRESSURE

GND

TRANSDUCER #2

B1

+5V

HEAD

SIG 3

PRESSURE

GND

TRANSDUCER #3

B2

+5V

HEAD

SIG 4

PRESSURE

GND

TRANSDUCER #4

COND. A ENABLE INPUT

BIN 1

REV. VLV. ENABLE INPUT

BIN 2

COND. B ENABLE INPUT

BIN 3

COM

COMMON

WattMaster Label

E-BUS

Connector

#LB102110-A

Rev.: 1A

Figure 1: Two Condenser Head Pressure II Module

COND. A ENABLE

REV. VLV. AENABLE

COND. B ENABLE

REV. VLV. B ENABLE

MAX @ 24 VAC

RATING IS 1 AMP

RELAY CONTACT

RELAY COMMON

2C2Orion No.:OE370-23-HP

COND. A SIGNAL

COND. B SIGNAL

COND. FAN A

COND. FAN A

COND. FAN B

COND. FAN B

LED BLINK CODES

LED NAME STAT

BLINKS QTY. OF SENSORS INSTALLED

LED NAME

NO PROBLEMS 0

NO SENSORS DETECTED 1

HIGH HEAD PRESSURE DETECTED 2

LOW HEAD PRESSURE DETECTED 3

E-BUS

Connector

AAON No.:

V20660

GND

PWM2PWM2+

ALARM

AO1

AO2

GND

PWM1PWM1+

GND

R1

AO1

AO2

GND

PWM1-

PWM1+

PWM2-

PWM2+

R1

R2

R3

R4

Rc

RELAYS

ANALOG

OPTIONS

ALARM

STAT

COMM

R2

R3

R4

RC

+24 VAC

Two Condenser Head Pressure II Module Technical Guide

3

Page 4

INSTALLATION & WIRING

Mounting and Wiring Considerations

Zone

Zone

Environmental Requirements

The Two Condenser Head Pressure II Module needs to be installed in

an environment that can maintain a temperature range between -30°F

and 150°F and not exceed 90% RH levels (non-condensing).

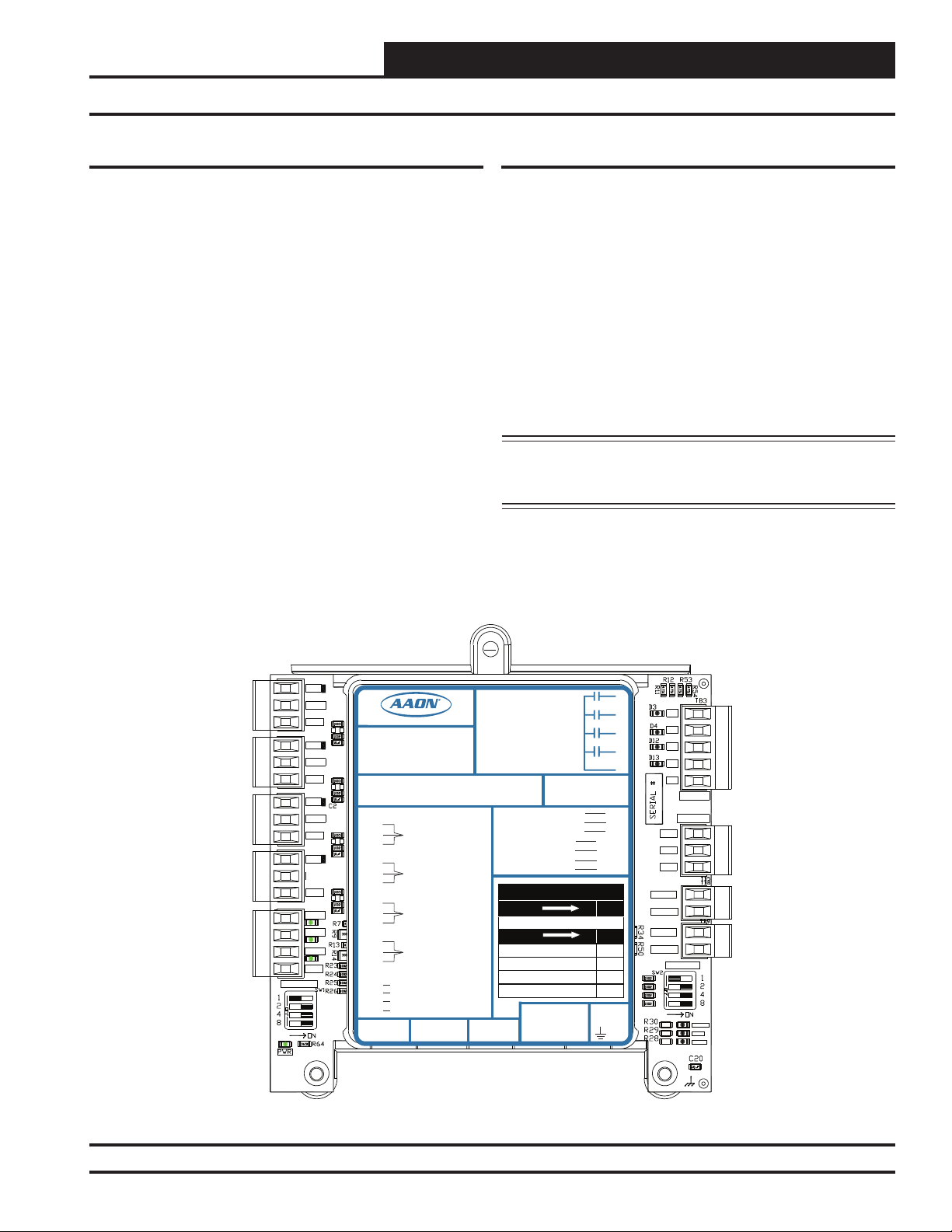

Mounting

The Two Condenser Head Pressure II Module is housed in a plastic

enclosure. It is designed to be mounted by using the 3 mounting holes

in the enclosure base. It is important to mount the module in a location

that is free from extreme high or low temperatures, moisture, dust, and

dirt. Be careful not to damage the electronic components when mounting the module.

See Figure 2 for Module dimensions (in inches).

0.18 DIA. TYP.

Important Wiring Considerations

Please read carefully and apply the following information when wiring

the Two Condenser Head Pressure II Module:

1. To operate the Two Condenser Head Pressure II Module, you

must connect power to the 24 VAC input terminal block.

2. Each Pressure Transducer must have its own 18-gauge

shielded twisted pair cable. The Drain Wire must be the “Gnd”

signal for the transducer.

3. When the Analog Output is being used to control the

Condenser Fan Speed or Water Valve Percentage, the cable

must be 18-gauge shielded wire, and the Drain Wire must be

the “Gnd” signal.

4. If the Pulse Width Modulation (PWM) Output is being used to

directly control the ECM 142 motor, the wires do not need to

be shielded and can be any 18-gauge wire.

5.71

5.64

5.04

ADDRESS

+5V

SIG 1

GND

+5V

SIG 2

GND

+5V

SIG 3

GND

+5V

SIG 4

GND

BIN 1

BIN 2

BIN 3

COM

www.aaon.com

Two Condenser Head Pressure II Module

A1

+5V

HEAD

SIG 1

PRESSURE

GND

TRANSDUCER #1

A2

+5V

HEAD

SIG 2

PRESSURE

GND

TRANSDUCER #2

B1

+5V

HEAD

SIG 3

PRESSURE

GND

TRANSDUCER #3

B2

+5V

HEAD

SIG 4

PRESSURE

GND

TRANSDUCER #4

COND. A ENABLE INPUT

BIN 1

REV. VLV. ENABLE INPUT

BIN 2

COND. B ENABLE INPUT

BIN 3

COM

COMMON

WattMaster Label

E-BUS

#LB102110-A

Connector

Rev.: 1A

REV. VLV. AENABLE

REV. VLV. B ENABLE

MAX @ 24 VAC

RATING IS 1AMP

RELAY CONTACT

2C2Orion No.:OE370-23-HP

LED NAME STAT

BLINKS QTY. OF SENSORS INSTALLED

LED NAME

NO PROBLEMS 0

NO SENSORS DETECTED 1

HIGH HEAD PRESSURE DETECTED 2

LOW HEAD PRESSURE DETECTED 3

E-BUS

Connector

2.07

COND. A ENABLE

COND. B ENABLE

RELAY COMMON

AAON No.:

COND. A SIGNAL

COND. B SIGNAL

GND

COND. FAN A

COND. FAN A

COND. FAN B

COND. FAN B

LED BLINK CODES

V20660

GND

PWM1PWM1+

PWM2PWM2+

ALARM

GND

AO1

AO2

0.29

R1

R1

R2

R2

R3

R3

R4

R4

RC

Rc

RELAYS

ANALOG

AO1

AO2

GND

PWM1-

PWM1+

PWM2-

PWM2+

OPTIONS

+24 VAC

ALARM

STAT

COMM

0.55

4.14

Figure 2: Two Condenser Head Pressure II Module Dimensions

4

Two Condenser Head Pressure II Module Technical Guide

Page 5

INSTALLATION & WIRING

Stand-Alone Wiring

5. Check all wiring leads at the terminal block for tightness.

Be sure that wire strands do not stick out and touch adjacent

terminals. Confi rm that all transducers required for your

system are mounted in the appropriate location and wired into

the correct terminals.

WARNING: Be sure all controllers and modules are

powered down before connecting or

disconnecting HSSC cables.

OE370-23-HP2C2

Two Condenser Head Pressure II Module

Head Pressure Transducers

0 - 667 PSI

(One Per Refrigerant Circuit)

+V

RD

SIG

WH

GND

BK

+V

RD

SIG

WH

GND

BK

+V

RD

SIG

WH

BK

GND

+V

RD

SIG

WH

BK

GND

CONDENSER A ON/OFF

REVERSING VALVE A/B ON/OFF

CONDENSER B ON/OFF

COM

Set ADDRESS Dip Switch 1 to ON

for Water Cooled or to OFF for Air

Cooled. Currently showing OFF for

Air Cooled.

ADDRESS Dip Switch 2 is not used

in this application..

Set ADDRESS Dip Switch 3 to ON

to disable Circuit B alarms when

only one Condenser is Used.

Currently showing OFF.

Set ADDRESS Dip Switch 4 to OFF

to make reversing valve "ON to

Heat / OFF to Cool.” Set to ON to

make reversing valve “ON to Cool /

OFF to Heat.” Currently showing

OFF.

ADDRESS

PWR

BIN 1

BIN 2

BIN 3

COM

+5V

SIG 1

GND

+5V

SIG 2

GND

+5V

SIG 3

GND

+5V

SIG 4

GND

www.aaon.com

Two Condenser Head Pressure II Module

+5V

SIG 1

GND

+5V

SIG 2

GND

+5V

SIG 3

GND

+5V

SIG 4

GND

COND. AENABLE INPUT

BIN 1

REV. VLV. ENABLE INPUT

BIN 2

COND. B ENABLE INPUT

BIN 3

COM

COMMON

E-BUS

Connector

A1

HEAD

PRESSURE

TRANSDUCER #1

A2

HEAD

PRESSURE

TRANSDUCER #2

B1

HEAD

PRESSURE

TRANSDUCER #3

B2

HEAD

PRESSURE

TRANSDUCER #4

WattMaster Label

#LB102110-A

Rev.: 1A

Stand-Alone Wiring

To operate the Two Condenser Head Pressure II Module as Stand Alone,

connect the Module to a 24 VAC connection with an appropriate VA

rating. See Figure 3 for wiring.

Check all wiring leads at the terminal block for tightness. Be sure that

wire strands do not stick out and touch adjacent terminals. Confi rm that

all transducers required for your system are mounted in the appropriate

location and wired into the correct terminals.

Condenser Type Selection

As shown in Figure 3, set ADDRESS Dip Switch 1 to ON for water

cooled or to OFF for air cooled. Refer to page 8 for further instructions.

NOTE:

ALL RELAY OUTPUTS

NORMALLY OPEN AND

ARE

RATED FOR 24 VAC POWER

- 1 AMP MAXIMUM LOAD

ONLY

AAON No.:

V20660

GND

GND

PWM1PWM1+

PWM2PWM2+

ALARM

GND

AO1

AO2

GND

R1

R2

R3

R4

RC

+24 VAC

24 VAC

COND. AENABLE

REV. VLV. AENABLE

COND. B ENABLE

REV. VLV. B ENABLE

MAX @ 24 VAC

RATING IS 1AMP

RELAY CONTACT

RELAY COMMON

2C2Orion No.:OE370-23-HP

COND. ASIGNAL

COND. B SIGNAL

COND. FANA

COND. FANA

COND. FAN B

COND. FAN B

LED BLINK CODES

LED NAME STAT

BLINKS QTY. OF SENSORS INSTALLED

LED NAME

NO PROBLEMS 0

NO SENSORS DETECTED 1

HIGH HEAD PRESSURE DETECTED 2

LOW HEAD PRESSURE DETECTED 3

E-BUS

Connector

WARNING!!

Observe Polarity! All boards

must be wired with GND-to-GND

and 24 VAC-to-24 VAC. Failure

to observe polarity could result in

damage to the boards.

R1

R2

R3

R4

Rc

AO1

AO2

GND

PWM1-

PWM1+

PWM2-

PWM2+

RELAYS

ANALOG

COMM

OPTIONS

ALARM

STAT

COMM

24 VAC Transformer

3 VA Minimum

R1

R2

R3

R4

YELLOW

BLUE +24 OUT

YELLOW

BLUE +24 OUT

HVAC UNIT CONNECTION

CONDENSER A ENABLE

REVERSING VALVE A ENABLE

CONDENSER B ENABLE

REVERSING VALVE B ENABLE

Condenser

Condenser

+

COM

Condenser Fan A

ECM Motor

Duty Cycle

+24 Volts

Condenser Fan B

ECM Motor

Duty Cycle

+24 Volts

OPTIONS Dip Switch is

Used for Setting the Head

Pressure Setpoint if Not

Using Default Setpoint.

Line Voltage

Signal A

+

COM

Signal B

Figure 3: Two Condenser Head Pressure II Module Wiring Diagram (Stand-Alone)

Two Condenser Head Pressure II Module Technical Guide

5

Page 6

Zone

INSTALLATION & WIRING

Zone

E-BUS Controller to Two Condenser Head Pressure II Module Wiring

VCM-X Modular E-BUS, VCM-X WSHP

E-BUS or SA E-BUS Controller to Two

Condenser Head Pressure II Module

Wiring

Up to (2) Two Condenser Head Pressure II Modules can be daisy-chained

together and connected to the E-BUS Controller using a modular HSSC

cable. The Two Condenser Head Pressure II Module requires a 24 VAC

power connection with an appropriate VA rating. See Figure 4 below

for wiring.

NOTE:

ALL RELAY OUTPUTS

NORMALLY OPEN AND

ARE

RATED FOR 24 VAC POWER

ONLY - 1 AMP MAXIMUM LOAD

OE370-23-HP2C2

www.aaon.com

Two Condenser Head Pressure II Module

A1

+5V

HEAD

SIG 1

PRESSURE

GND

TRANSDUCER #1

A2

+5V

HEAD

SIG 2

PRESSURE

GND

TRANSDUCER #2

B1

+5V

HEAD

SIG 3

PRESSURE

GND

TRANSDUCER #3

B2

+5V

HEAD

SIG 4

PRESSURE

GND

TRANSDUCER #4

COND. AENABLE INPUT

BIN 1

REV. VLV. ENABLE INPUT

BIN 2

COND. B ENABLE INPUT

BIN 3

COM

COMMON

WattMaster Label

E-BUS

#LB102110-A

Connector

Rev.: 1A

REV. VLV. A ENABLE

REV. VLV. B ENABLE

MAX @ 24 VAC

RATINGIS 1 AMP

RELAYCONTACT

2C2Orion No.:OE370-23-HP

LED NAME STAT

BLINKSQTY. OF SENSORS INSTALLED

LED NAME

NOPROBLEMS 0

NOSENSORS DETECTED 1

HIGHHEAD PRESSURE DETECTED 2

LOWHEAD PRESSURE DETECTED 3

E-BUS

Connector

COND. AENABLE

COND. B ENABLE

RELAYCOMMON

COND. ASIGNAL

COND. B SIGNAL

COND. FANA

COND. FANA

COND. FAN B

COND. FAN B

LED BLINKCODES

Head Pressure Transducers

0 - 667 PSI

(One Per Refrigerant Circuit)

RD

WH

BK

RD

WH

BK

RD

WH

BK

RD

WH

BK

Set ADDRESS Dip Switch 1 to ON for

Water Cooled or to OFF for Air Cooled.

Currently showing OFF for Air Cooled.

Set ADDRESS Dip Switch 2 to OFF

on all communicating applications

unless it is intended to be the Second

Head Pressure Module on a system. If

set to ON, it will not communicate.

Currently showing OFF.

Set ADDRESS Dip Switch 3 to ON to

disable Circuit B alarms when only one

Condenser is Used. Currently showing

Set ADDRESS Dip Switch 4 to OFF to

make reversing valve "ON to Heat /

OFF to Cool.” Set to ON to make

reversing valve “ON to Cool / OFF to

Heat.” Currently showing OFF.

OFF.

.

SIG

GND

SIG

GND

SIG

GND

SIG

GND

Two Condenser Head Pressure II Module

+V

+V

+V

+V

ADDRESS

PWR

+5V

SIG 1

GND

+5V

SIG 2

GND

+5V

SIG 3

GND

+5V

SIG 4

GND

BIN 1

BIN 2

BIN 3

COM

Any E-BUS Module can be connected to the E-BUS Controller’s E-BUS

port or can be daisy-chained together using HSSC cables.

NOTE: Contact Factory for the correct HSSC cable length for

your application. Cables are available in ¼, ½, 1, 2, 3,

4, and 5 Meter lengths and 100 and 150 Foot lengths.

HVAC UNIT CONNECTION

CONDENSER A ENABLE

REVERSING VALVE A ENABLE

CONDENSER B ENABLE

REVERSING VALVE B ENABLE

Condenser

Signal A

+

COM

Condenser

Signal B

+

COM

Condenser Fan A

ECM Motor

Duty Cycle

+24 Volts

Condenser Fan B

ECM Motor

Duty Cycle

+24 Volts

AAON No.:

V20660

GND

GND

PWM1PWM1+

PWM2PWM2+

ALARM

GND

R1

R2

R3

R4

RC

AO1

AO2

GND

AO1

AO2

GND

PWM1-

PWM1+

PWM2-

PWM2+

+24 VAC

24 VAC

R1

R2

R3

R4

Rc

RELAYS

ANALOG

OPTIONS

ALARM

STAT

COMM

24 VAC Transformer

R1

R2

R3

R4

COMM

YELLOW

BLUE +24 OUT

YELLOW

BLUE +24 OUT

OPTIONS Dip Switch Setting Not Required

When Connected To

VCM-X E-BUS Controller

Line Voltage

3 VA Minimum

or SA E-BUS Controller

Connect To Other

WattMaster-Approved

E-BUS Expansion Module(s)

WARNING!! Observe Polarity! All boards

must be wired with GND-to-GND and 24

VAC-to-24 VAC.

Failure to observe polarity could result in

damage to the boards.

HSSC Cable

HSSC Cable

Connect To VCM-X E-BUS

Controller or SA E-BUS Controller

Figure 4: VCM-X E-BUS Controller to Two Condenser Head Pressure II Module Wiring Diagram

6

Two Condenser Head Pressure II Module Technical Guide

Page 7

INSTALLATION & WIRING

E-BUS Controller to Two Condenser Head Pressure II Module Wiring

WARNING: Be sure all controllers and modules are

powered down before connecting or

disconnecting HSSC cables.

For Stand Alone Applications,

Connect To System Manager. For Network

Applications Connect To Next Controller

And/Or MiniLink PD On Local Loop.

Local Loop

RS-485

9600 Baud

All Comm Loop Wiring Is

Straight Thru

T to T, R to R & SHLD to SHLD

HSSC Cable Connect To

VCM-X E-BUS Port

See Individual

AI1 SET AI2 SET AI3 SET

AI4 SET AI5 SET AI7 SET

Component Wiring

Diagrams For

Detailed Wiring Of

Analog Inputs And

OE332-23E-VCMX-MOD-

VCM-X Modular

E-BUS Controller

RS-485 COMMUNICATION LOOP. WIRE

“R” TO “R”, “T”TO “T” “SHLD” TO “SHLD”

VCM-X MODULAR E-BUS CONTROLLER

Orion No.:OE332-23E-VCMX-MOD-A

AI1 = SPC (SPACETEMPERATURE SENSOR)

AI2

= SAT(SUPPLY AIR TEMPERATURE SENSOR)

AI3

= RAT(RETURN AIR TEMPERATURE SENSOR)

AI4

= OAT(OUTDOOR AIR TEMPERATURE SENSOR)

AI5

= SUCTION PRESSURE SENSOR (FROM EXP. MODULE)

AI7

= SPACETEMPERATURE SENSOR SLIDE ADJUST

OR VOLTAGE RESETSOURCE

A01

= ECONOMIZER (2-10 VDC OUTPUT)

A02

= SUPPLYFAN VFD (0-10 VDC OUTPUT)

E-BUS

CONNECTOR

ANALOG INPUT

JUMPER

SETTINGS

THERM

LED NAME STATUS1 STATUS2

4-20mA

AI1

0-10V

NORMALOPERATION 0 1

0-5V

SATFAIL 1 2

THERM

OATFAIL 2 2

4-20mA

AI2

SPCFAIL 3 2

0-10V

0-5V

MODULEALARM 4 2

THERM

MECHCOOL FA IL 1 3

4-20mA

AI3

MECHHEAT FAIL 2 3

0-10V

0-5V

FANPROOF FAIL 3 3

THERM

DIRTYFILTER 4 3

4-20mA

AI4

EMERGENCYSHUTDOWN 5 3

0-10V

0-5V

LOWSAT 1 4

THERM

HIGHSAT 2 4

4-20mA

AI5

CONT.TEMP COOL FAIL 3 4

0-10V

CONT.TEMP HEAT FAIL 4 4

0-5V

PUSHBUTTON OVR 1 5

THERM

4-20mA

ZONEOVR 2 5

AI7

0-10V

OUTPUTFORCE ACTIVE 0 6

0-5V

ANALOG INPUTJUMPER SETTINGS

MUSTBE SET AS SHOWN FOR

PROPER OPERATION

WattMasterLabel

STATIC

#LB102073-01-A

PRESSURE

Rev.: 1A

EXPANSION

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

RELAY

COMMON

RELAY2

RELAY3

RELAY4

RELAY5

LED BLINKCODES

24 VAC POWER ONLY

WARNING!POLARITY MUST BE OBSERVED

OR THE CONTROLLER WILLBE DAMAGED

2

IC

FAN

AAON No.:

V07150

2

IC DIGITAL

SENSOR

Note:

All Relay Outputs Are Normally Open And

Rated For 24 VAC Power Only.

1 Amp Maximum Load.

R - 24VAC

G - Fan ON/OFF Only

Relay Output Contacts

R2 Through R5 May Be User-Configured

For The Following:

1 - Heating Stages

2 - Cooling Stages

3 - Warm-up Mode Command (VAV Boxes)

4 - Reversing Valve (Air To Air Heat Pumps)

5 - Reheat Control (Dehumidification)

6 - Exhaust Fan Interlock

7 - Preheater For Low Ambient Protection

8 - Alarm

9 - Override

10 - Occupied

11 - OA Damper

12 - Heat Wheel

13 - Emergency Heat

Note: 1.) When Using the HP2C Module,

All Compressors Will Be Wired From the

Protection Module, Not the VCM-X Controller.

Note: A Total Of 20 Relays AreAvailable By

Adding Relay Expansion Modules. All

Expansion Module Relay Outputs Are User

Configurable As Listed Above.

GND

Line Voltage

24VAC

Size Transformer For Correct

Total Load.

VCM-X Controller = 8 VA

Jumpers

Splice If Required

OE271

Static Pressure

Transducer

Connect FRP Tubing To High Pressure

Port (Bottom Tube) and Route To Static

Pressure Pickup Probe Located In Unit

Discharge. Leave Port Marked “Lo” Open

To Atmosphere

Connect To

Expansion Module(s)

(When Used)

Connect To Digital Room Sensor And/Or

Digital CO Sensor

2

Warning:

24 VAC Must Be Connected So That All Ground

Wires Remain Common. Failure To Do So Will

Result In Damage To The Controllers.

Figure 4, cont.: VCM-X E-BUS Controller to Two Condenser Head Pressure Module II Wiring Diagram

Two Condenser Head Pressure II Module Technical Guide

7

Page 8

SEQUENCE OF OPERATION

Stand-Alone Input Commands

Zone

Zone

General

The following inputs and outputs are available on the Two Condenser

Head Pressure II Module. See Table 1 below to reference the Input/

Output Map.

Binary Inputs

1 Condenser Fan A On/Off (24 VAC Wet Input)

2 Reversing Valve On/Off (24 VAC Wet Input)

3 Condenser Fan B On/Off (24 VAC Wet Input)

Binary Outputs

Condenser A Enable Relay

1

(Dry Contact Output Rated for 24 VAC)

Reversing Valve A Enable

2

(Dry Contact Output Rated for 24 VAC)

Condenser B Enable Relay

3

(Dry Contact Output Rated for 24 VAC)

Reversing Valve B Enable

4

(Dry Contact Output Rated for 24 VAC)

Analog Inputs

1 Head Pressure #1 (0-667 PSI Sensor)

2 Head Pressure #2 (0-667 PSI Sensor)

3 Head Pressure #3 (0-667 PSI Sensor)

4 Head Pressure #4 (0-667 PSI Sensor)

Analog Outputs (0-10 or 2-10 VDC)

1 Condenser Signal A (AOUT 1)

2 Condenser Signal B (AOUT 2)

PWM Inputs

1 ECM 142 PWM Input (0-100% Duty Cycle)

2 ECM 142 PWM Input (0-100% Duty Cycle)

Table 1: Two Condenser Head Pressure II Module

Inputs & Outputs

Stand-Alone Input Commands

Condenser Fan A On/Off

A 24 volt signal to Binary Input #1 initiates the Condenser Fan A Enable

function. Typically, the source for this signal is the “Y” call from the

thermostat calling for a compressor to run.

Reversing Valve On/Off

A 24 volt signal to Binary Input #2 indicates the reversing valve has

been energized and initiates the Reversing Valve Enable On indication

function. Typically, the source for this signal is the “O” call from a

thermostat or other controller.

Condenser Fan B On/Off

A 24 volt signal to Binary Input #3 initiates the Condenser Fan B Enable

function. Typically, the source for this signal is the “Y” call from the

thermostat calling for a compressor to run.

Head Pressure Setpoint

The Head Pressure Setpoint is set using the OPTIONS Dip Switches. See

Table 2. The Default Setpoint for an Air Cooled Condenser is 340 for

410-A refrigerant. The Default Setpoint for a Water Cooled Condenser

is 235 for 410-A refrigerant. Set the OPTIONS Dip Switch to 0 if using

these Default Settings. See “ADDRESS Dip Switch” below. You must

cycle power after setting Dip Switch values.

NOTE: The only setpoint available for adjustment by the con-

tractor is the Head Pressure Setpoint. The rest of the

setpoints described can only be changed by the factory.

ADDRESS Dip Switch Settings for Condenser

Type Selection

When using the OPTIONS Dip Switch to set the Head Pressure Setpoint,

you must also set the ADDRESS Dip Switch to designate the type of

condenser you are using.

Set ADDRESS Dip Switch 1 to ON for a Water Cooled Condenser or

to OFF for an Air Cooled Condenser.

If set to ON for a Water Cooled Condenser, the Analog Condenser Output

Signal will be 2-10 VDC for the Water Valve. If set to OFF for an Air

Cooled Condenser, the Analog Condenser Output Signal will be 0-10

VDC for the Condenser Fan.

8

You must cycle power after setting Dip Switch values. See Figure

3 or 4 for ADDRESS Dip Switch location and Table 3 for Setting

information.

Two Condenser Head Pressure II Module Technical Guide

Page 9

SEQUENCE OF OPERATION

VCM-X Input Commands and Modes of Operation

Input Commands (VCM-X Connection)

Condenser A & B On/Off

Instead of a hard wired input signal to the Condenser Enable input,

the VCM-X Modular Controller, VCM-X WSHP Controller, or SA

Controller communicates to the Module via E-BUS communications.

This signal indicates the compressor(s) are called to run and drives the

condenser A & B On/Off function.

Reversing Valve Enable A & B On/Off

As with the Condenser Signal On/Off function, the VCM-X Modular

Controller, VCM-X WSHP Controller, or SA Controller communicates

to the Module via E-BUS communications and signals that the reversing

valve has been energized and that heating has been enabled.

NOTE: When the term “ON” is used, it means there is either 24

VAC on the appropriate Binary Input or a call-to-run

signal is being received from a VCM-X series or SA

series controller. When the term “OFF” is used, it means

there is either 0 VAC on the appropriate Binary Input or

the call-to-run signal from a VCM-X series or SA series

controller has been removed.

Sensor Reading Routine

The Two Condenser Head Pressure Module is used on units with two

physically separate condenser sections. Up to (2) Head Pressure Sensors

can be monitored in each section. The highest of the two readings in

each section will be used to control the condenser fan(s) in that section.

Air from the condenser fan(s) in each section fl ows through both con-

denser coils. As a result, if you modulate the fan(s) based on the highest

reading, you will have enough air fl ow for both coils.

The highest reading of Head Pressure Sensors 1 & 2 controls Condenser

Fan A. The highest reading of Head Pressure Sensors 3 & 4 controls

Condenser Fan B.

Modes of Operation

OFF Mode

The Head Pressure Control Board is in the OFF Mode when the Condenser Input Signals are “OFF.” In this mode, all relays are off, the

Analog Output is 0 VDC, and the PWM Output is 0% Duty Cycle.

Cooling Mode

If the Head Pressure Controller has been confi gured for the Reversing

Valve to be energized in the Cooling Mode and to Fail to the Heat Mode

(Dipswitch 4 is set ON), then the Head Pressure Controller will be in

the Cooling Mode when one or both of the Condenser Signal inputs is

“ON” and the Reversing Valve Enable Signal is “ON”. In this circumstance, the Reversing Valve Enable Relay Output(s) will energize for

indication purposes.

If the Head Pressure Controller has been confi gured for the Reversing

Valve to be energized in the Heating Mode and to Fail to the Cool Mode

(Dipswitch 4 is set OFF), then the Head Pressure Controller will be in

the Cooling Mode when one or both of the Condenser Signal inputs is

“ON” and the Reversing Valve Enable Signal is “OFF”.

The Condenser Enable Relays will energize to enable the Condenser

Fans or Water Valves. In a water system, the Water Flow Valve will

start at 75% for 3 minutes. The Condenser Output Signals will then

automatically adjust between 0 and 100% to maintain the desired Head

Pressure Setpoint. The Condenser Output Signals can be a 0-10 VDC,

2-10 VDC or 0-100% PWM signal provided by the appropriate output.

Both outputs mirror each other.

Heating Mode

If the Head Pressure Controller has been confi gured for the Reversing

Valve to be energized in the Cooling Mode and to Fail to the Heat Mode

(Dipswitch 4 is set ON), then the Head Pressure Controller will be in

the Heating Mode when one or both of the Condenser Signal inputs is

“ON” and the Reversing Valve Enable Signal is “OFF”.

If the Head Pressure Controller has been confi gured for the Reversing

Valve to be energized in the Heating Mode and to Fail to the Cool Mode

(Dipswitch 4 is set OFF), then the Head Pressure Controller will be in

the Cooling Mode when one or both of the Condenser Signal inputs is

“ON” and the Reversing Valve Enable Signal is “ON”. In this circumstance, the Reversing Valve Enable Relay Output(s) will energize for

indication purposes.

In this mode, the Condenser Output Signals will go to 100% and remain

there until it leaves the Heating Mode.

NOTE: The Reversing Valve Dipswitch 4 setting determines

whether the Reversing Valve Dipswitch 4 Relay is ON

to Heat / OFF to Cool or ON to Cool / OFF to Heat.

NOTE: The Reversing Valve Enable outputs are for indication

only and are not wired to anything.

Two Condenser Head Pressure II Module Technical Guide

9

Page 10

SEQUENCE OF OPERATION

OPTIONS Dip Switch Settings

Zone

Zone

OPTIONS Dip

Switch Settings

Binary Value R410-A R410-A

0 340 (DEFAULT) 235 (DEFAULT)

1 260 210

2 270 220

3 280 230

4 290 240

5 300 250

6 310 260

7 320 270

8 330 280

9 340 290

10 350 300

11 360 310

12 370 320

13 380 330

14 390 340

15 400 350

Air Cooled Condenser Water Cooled Condenser

Head Pressure Setpoint

Table 2: OPTIONS Dip Switch/Head Pressure Setpoint Settings for Stand-Alone Operation

ADDRESS Dip Switch 1 Settings

Switch 1 Default SP Description of Default Head Pressure Setpoint

OFF 340 Air Cooled Condenser using R410-A Refrigerant

ON 235 Water Cooled Condenser using R410-A Refrigerant

Switch 1 determines Air or Water Cooled Condenser

NOTE: You must cycle power after setting Dip Switch values.

Table 3: ADDRESS Dip Switch 1 Condenser Type Settings

10

Two Condenser Head Pressure II Module Technical Guide

Page 11

SEQUENCE OF OPERATION

OPTIONS Dip Switch Settings

ADDRESS Dip Switch 2 Settings

Switch 2 Description

Set to OFF if Using only (1) Head Pressure Module

OFF

ON

Table 4: ADDRESS Dip Switch 2 Address Settings When in Communicating Mode

or if this is Module 1 when Using (2) Head Pressure

Modules.

Set to ON if this is Module 2 when Using (2) Head

Pressure Modules.

ADDRESS Dip Switch 3 Settings

Switch 3 Description

OFF Enable Circuit B Alarm

ON

Disable Circuit B Alarm when only one condenser is

used.

Table 5: ADDRESS Dip Switch 3 Settings

ADDRESS Dip Switch 4 Settings

Switch 4 Description

OFF Reversing Valve On to Heat/ Off to Cool

ON Reversing Valve On to Cool/ Off to Heat

Table 6: ADDRESS Dip Switch 4 Settings for Reversing Valve

Two Condenser Head Pressure II Module Technical Guide

11

Page 12

Zone

TROUBLESHOOTING

Zone

Head Pressure Module Valve / Fan Position Troubleshooting

Head Pressure Module Valve/Fan

Position Troubleshooting

If confi gured for Water valve:

Aout Signal is 2 to 10 volts.

2 volts = 0% valve position or fully closed

10 volts = 100% valve position or fully open

PWM signal is not used for water valve but does modulate.

At Startup for cooling, valve will open to 75% or 8 volts for 3

minutes then will modulate to try to maintain head pressure

setpoint.

For heating, valve will open and stay at 100%.

If confi gured for Air Condenser Fan:

Aout Signal is 0 to 10 volts.

Minimum fan speed is 1 volt. (10%)

Maximum fan speed is 10 volts. (100%)

Anything less than 1.5 volts the fan will be off.

PWM 0 volts = 100% fan speed

6 volts = 75% fan speed

12 volts = 50% fan speed

18 volts = 25% fan speed

20.4 volts = 15% fan speed

Above 20.4 volts = 0% fan speed

At Startup for cooling, fan will start at 100% for 3 minutes

and then will modulate to try to maintain head pressure

setpoint.

For heating, fan will run and stay at 100%.

Safeties:

If the head pressure signal is above 500 PSIG, fan will go to

100% (high pressure safety).

If the head pressure signal is below 1 PSIG, fan will go to

100% (assuming bad sensor).

If the head pressure rises 50 PSI above setpoint, the condenser

signal will go to 100%.

PWM signal is 0 to 100%

PWM+ (to ground) will always read 24 vdc.

PWM- (to ground) can be measured for volts dc and this

formula will tell you the percentage signal: (24 – measured

value)/24 (measured value = PWM- to ground)

12

Two Condenser Head Pressure II Module Technical Guide

Page 13

TROUBLESHOOTING

Troubleshooting for Stand-Alone Mode

Troubleshooting for Stand-Alone Mode

If you suspect or encounter general problems during operation of the

Two Condenser Head Pressure II Module while in Stand Alone Mode,

follow the Troubleshooting Flowchart in Figure 5 below.

Head Pressure Control

Troubleshooting Flowchart

(Stand-Alone Mode)

Start Here

Yes

“STAT” LED

Blinking

No

Verify

Incoming

Power

No

Is

?

No

Is There

@ “PWR”

24VAC

Testpoint

Fan Speed

or Water Valve

Position Will

Be at

Is

Condenser

A or B Fan or

Water Valve

Operating?

No

Is

“ERROR”

LED Blinking

Yes

?

Call WattMaster

Technical

Support

100%

No

Yes

?

Yes

Yes

Heat

Inputs

Active

BIN 2

Are

Enable

A& B

High

Blinks

2

Is

“ERROR”

LED Blinking

Note: “STAT” LED

will blink the # of

Good sensors

connected

“STAT”

Yes

?

blinking correct

Check wiring

on all sensors

No

Is

# of

Sensors

No

?

LED

?

1 Blink =

None of the

Yes

Sensors are

Detected

Check wiring

on all sensors

Measure DC

Volts between

SIGx & GND for

all sensors

Compare readings

Call AAON

Technical

Support

to chart

=

Pressure on one

of the Sensors

(More than

500 PSI)

Check

Refrigerant

Charge on

All Circuits

3 Blinks =

Lo Pressure

On one of

the Sensors

Less than 35 PSI

Check

Refrigerant

Charge on

All Circuits

Measure DC

Volts between

&

Lower

Monitor DC

Volts on

A ut 1 & 2O

A ut 1 & 2 VoltageO

should Modulate

Down to a Min

voltage of 0VDC

(See Sequence)

Pressure is

than Setpoint

Same

There will

be No

Change on

A ut 1O& 2

??

?

Higher

Monitor DC

Volts on A ut 1O

& A ut 2O

A ut VoltageO 1 & 2

Should Modulate

Up to a Max

Voltage of 10VDC

(See Sequence)

GND for

SIGx

All sensors

Compare readings

Call AAON

Technical

to chart

Support

.

.

Figure 5: Two Condenser Head Pressure II Module Troubleshooting Diagram

Two Condenser Head Pressure II Module Technical Guide

13

Page 14

Zone

TROUBLESHOOTING

Zone

Pressure Transducer Troubleshooting and LEDs

Pressure Transducer Troubleshooting

If you suspect there is a problem with the Module related to pressure

transducer measurements, reference Table 7 below.

Pressure Sensor Chart

Voltage Pressure Voltage Pressure

0.5 0 2.6 350

0.6 17 2.7 367

0.7 33 2.8 384

0.8 50 2.9 400

0.9 67 3.0 417

1.0 83 3.1 434

1.1 100 3.2 450

1.2 117 3.3 467

1.3 133 3.4 484

1.4 150 3.5 500

1.5 167 3.6 517

1.6 183 3.7 534

1.7 200 3.8 550

1.8 217 3.9 567

1.9 233 4.0 584

2.0 250 4.1 600

2.1 267 4.2 617

2.2 283 4.3 634

2.3 300 4.4 650

2.4 317 4.5 667

2.5 334

Using LEDs to Verify Operation

The Two Condenser Head Pressure II Module is equipped with LEDs

that can be used to verify operation and perform troubleshooting. There

are LEDs for communication, operation modes, diagnostic codes, and

relays. The Two Condenser Head Pressure Module has eight LEDs—

one for power, one for operation status, one for communication, one

for alarms, and four for compressor relays. See Figure 6 for the LED

locations. The LEDs associated with these inputs and outputs allow you

to see what is active without using a voltmeter.

Status LEDs

“COMM” - This LED will light up to indicate Communications with

the VCM-X series or SA series controller. If Communications are established, the COMM LED will blink. You should not see this LED light

up in stand-alone mode, because there would be no communications

with the VCM-X series or SA series controller.

“ALARM” - This is the diagnostic blink code LED. It will light up and

blink out diagnostic codes. See Table 8 below for Diagnostic Blink

Code descriptions. The blink code descriptions are also located on the

Module’s front cover.

No. of

Blinks

0 No Problems

1 No Sensors Detected

2 High Head Pressure Detected

3 Low Head Pressure Detected

Table 8: ALARM LED Blink Codes

“STAT” - This is the status blink code LED. It will light up and fi rst

blink the address of the Module. It will then blink out the quantity of

sensors installed. See Table 9 below for Status Blink Code descriptions.

The blink code descriptions are also located on the Module’s front cover.

Alarm

Table 7: Two Condenser Head Pressure II Module

Transducer Chart

14

Two Condenser Head Pressure II Module Technical Guide

No. of

Blinks

Random Blinks Quantity of Sensors

Installed

Status

Table 9: STAT LED Blink Codes

Page 15

TROUBLESHOOTING

LED Diagnostics

Module LEDs

“R1” - This LED will light up whenever Condenser A Enable Relay is

enabled and will stay lit as long as the relay is active.

“R2” - This LED will light up when the Reversing Valve A Enable Relay

is enabled and will stay lit as long as the Reversing Valve A is active.

“R3” - This LED will light up whenever Condenser B Enable Relay is

enabled and will stay lit as long as the relay is active.

“R4” - This LED will light up when the Reversing Valve B Enable Relay

is enabled and will stay lit as long as the Reversing Valve B is active.

LED Diagnostics

“PWR” LED: When the Two Condenser Head Pressure II Module is

powered up, the PWR LED (located below the address switches) should

light up and stay on continuously. If it does not light up, check to be

sure that the power wiring is connected to the board, the connections are

tight, and the VCM-X series or SA series controller is powered. If after

making all these checks, the PWR LED does not light up, the module

is probably defective.

“COMM” LED: When the Two Condenser Head Pressure II Module

is powered up while in Stand Alone Mode, the COMM LED does not

light up. When the module is connected to a VCM-X series or SA series

controller, the COMM LED should light up, indicating Communications.

Each time Communications are detected, this LED should continuously

blink on and off, for a half second. This LED should never stop checking

for a Communications signal. If it does not light up, check to be sure that

the power wiring is connected to the board, the connections are tight,

and the VCM-X series or SA series controller is confi gured for Head

Pressure Control and is powered up. If after making all these checks,

the COMM LED does not light up, the board is probably defective.

“STAT” LED: As previously described, when the module is fi rst pow-

ered up, the STAT LED will b

“ALARM” LED: As previously described, this LED will blink on and

off to indicate alarms and diagnostics.

link out the number of installed sensors

Figure 6: LED Locations

Other Checks

NOTE: The Two Condenser Head Pressure II Module contains

no user-serviceable parts. Contact qualifi ed technical

personnel if your module is not operating correctly.

Two Condenser Head Pressure II Module Technical Guide

15

Page 16

www.aaon.com

2425 So. Yukon Ave • Tulsa, OK 74107-2728

Ph: (918) 583-2266 • Fax: (918) 583-6094

AAON® Manual Part No.: V22100

WattMaster Manual Form No: AA-HP2C2-TGD-01E

Loading...

Loading...