Page 1

www.orioncontrols.com

BACnet® Link

Technical Guide

Revision- 02B - August 2005

Page 2

Table Of Contents

General Information ........................................................................................................................................ 3

Data Sharing............................................................................................................................................................................... 3

Scheduling .................................................................................................................................................................................. 3

Hardware Specifications ............................................................................................................................................................. 3

Connection and Wiring Information ................................................................................................................ 4

Troubleshooting Information .......................................................................................................................... 5

General Information .................................................................................................................................................................... 5

Using LED’s To Verify Operation ................................................................................................................................................ 5

Programming- General Information ................................................................................................................ 6

BACnet® Link Overview ............................................................................................................................................................. 6

BACnet® Link Device Object...................................................................................................................................................... 6

WattBacObjectTypes .................................................................................................................................................................. 6

Local Address (MAC address).................................................................................................................................................... 6

BACnet® Services Supported ................................................................................................................................................... 6

MS/TP LAN Baud Rate............................................................................................................................................................... 6

Programming - Standard Objects ................................................................................................................... 7

General Information .................................................................................................................................................................... 7

Parameters ................................................................................................................................................................................. 7

Instance Number Base ............................................................................................................................................................... 7

MUA II Instance Number Base ................................................................................................................................................... 7

MUA II BACnet® Property Identifier ........................................................................................................................................... 8

VAV/CAV Instance Number Base ............................................................................................................................................... 9

VAV/CAV BACnet® Property Identifier ....................................................................................................................................... 9

CW/HW Instance Number Base............................................................................................................................................... 10

CW/HW BACnet® Property Identifier........................................................................................................................................11

Parameter Instance Numbers................................................................................................................................................... 12

Programming - Proprietary Objects .............................................................................................................. 13

BACnet® Link Overview .......................................................................................................... ................................................. 13

MUA II Object............................................................................................................................................................................ 13

MUA II Property Identifier ......................................................................................................................................................... 14

VAV/CAV Object ....................................................................................................................................................................... 15

VAV/CAV Property Identifier ..................................................................................................................................................... 16

CW/HW Object ......................................................................................................................................................................... 17

CW/HW Property Identifier ....................................................................................................................................................... 18

Proprietary Object Instance Numbers ....................................................................................................................................... 19

Appendix 1 ..................................................................................................................................................... 20

BACnet® Link Protocol Implementation Conformance Statement........................................................................................... 20

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

Form: OR-BACNET-TGD-02B Copyright 2005 WattMaster Controls, Inc.

AAON® is a registered trademark of AAON, Inc., Tulsa, OK.

®

BACnet

is a registered trademark of ASHRAE Inc., Atlanta, GA.

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

This document is subject to change without notice.

Page 3

General Information

Technical Guide

The OE367-22 BACnet® Link provides bi-directional translation of

data and information between BACnet® devices and Orion VAV/CAV,

CW/HW and MUA II unit controllers.

Up to 16 total, Orion VAV/CAV, CH/HW, MUA II or any combination

of these controllers may be connected to each BACnet® Link. Up to 4

BACnet® Links can be used on a Orion Controls system allowing for

a maximum of 64 total controllers to be used.

Data Sharing

The BACnet® Link interface provides the following data sharing capabilities:

• Provides values from points on the Orion side of the

gateway to BACnet

originating from BACnet

• Allows BACnet

Orion controller side of the BACnet

standard BACnet® write services

®

devices as if the values were

®

objects.

®

devices to modify point values on the

®

Link by using

Scheduling

®

services

®

devices to send Schedule events

• Ability to allow BACnet

to the Orion controller side of the gateway by using

standard BACnet

Hardware Specifications

Table 1 below contains the hardware specifications for the BACnet

Link interface.

Technical Data

BACnet Loop

Controller Loop

Protocol (BACn et Loop)

Protocol

(Wa ttMa ster L o o p)

Power Input Voltage

Power Consumption

Operating Temp

Operating Humidity

Weight

Table 1: BACnet® Link Interface Technical Data

RS-485, Auto Detect Host

Matching - 9600, 19200, 38400,

76800 Baud Rates

RS-485, 9600 Baud

MS/TP Lan

HSI Open Protocol

Token Passing

24 VAC

10 VA Maximum

10°F to 149°F

90% RH N on-Condensing

8 oz

®

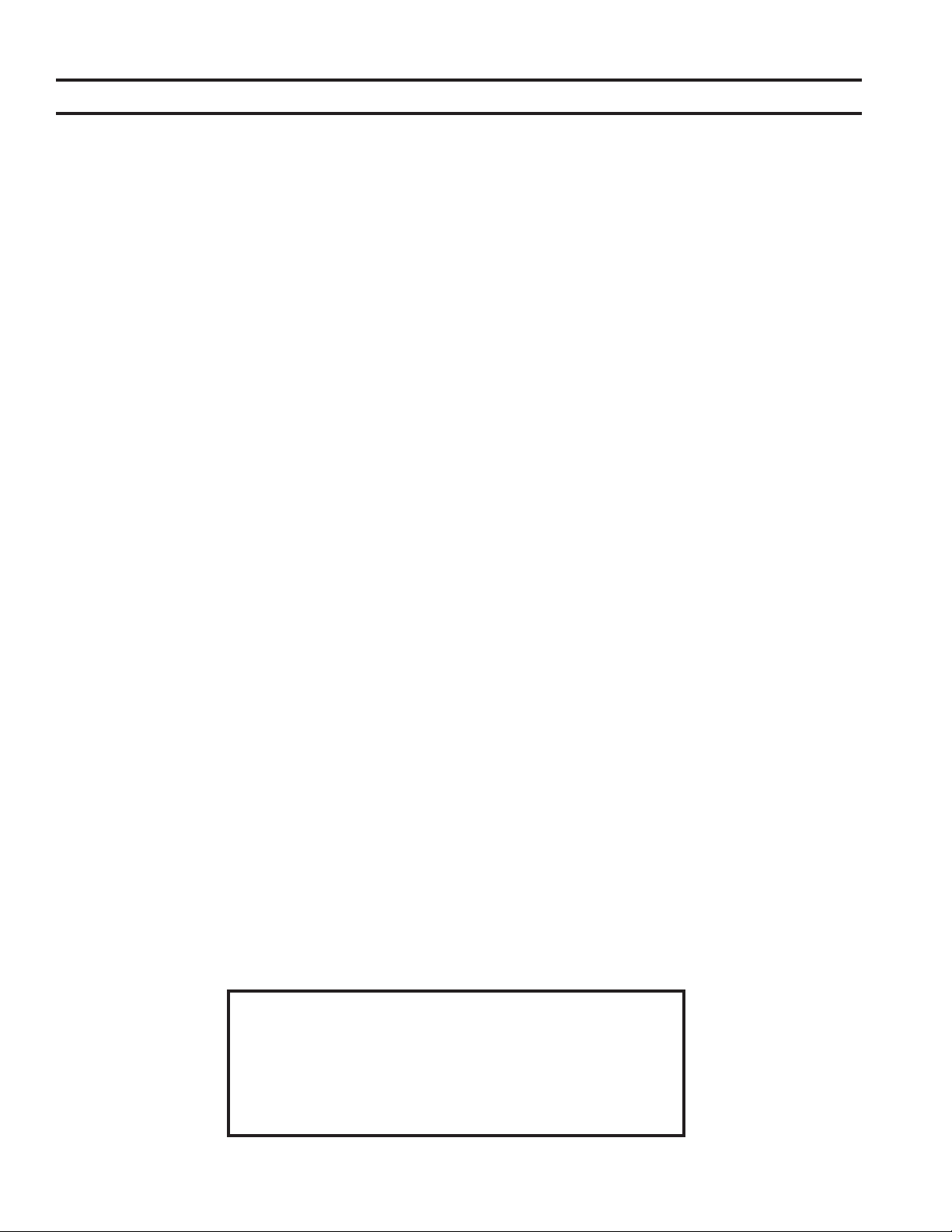

4.50"

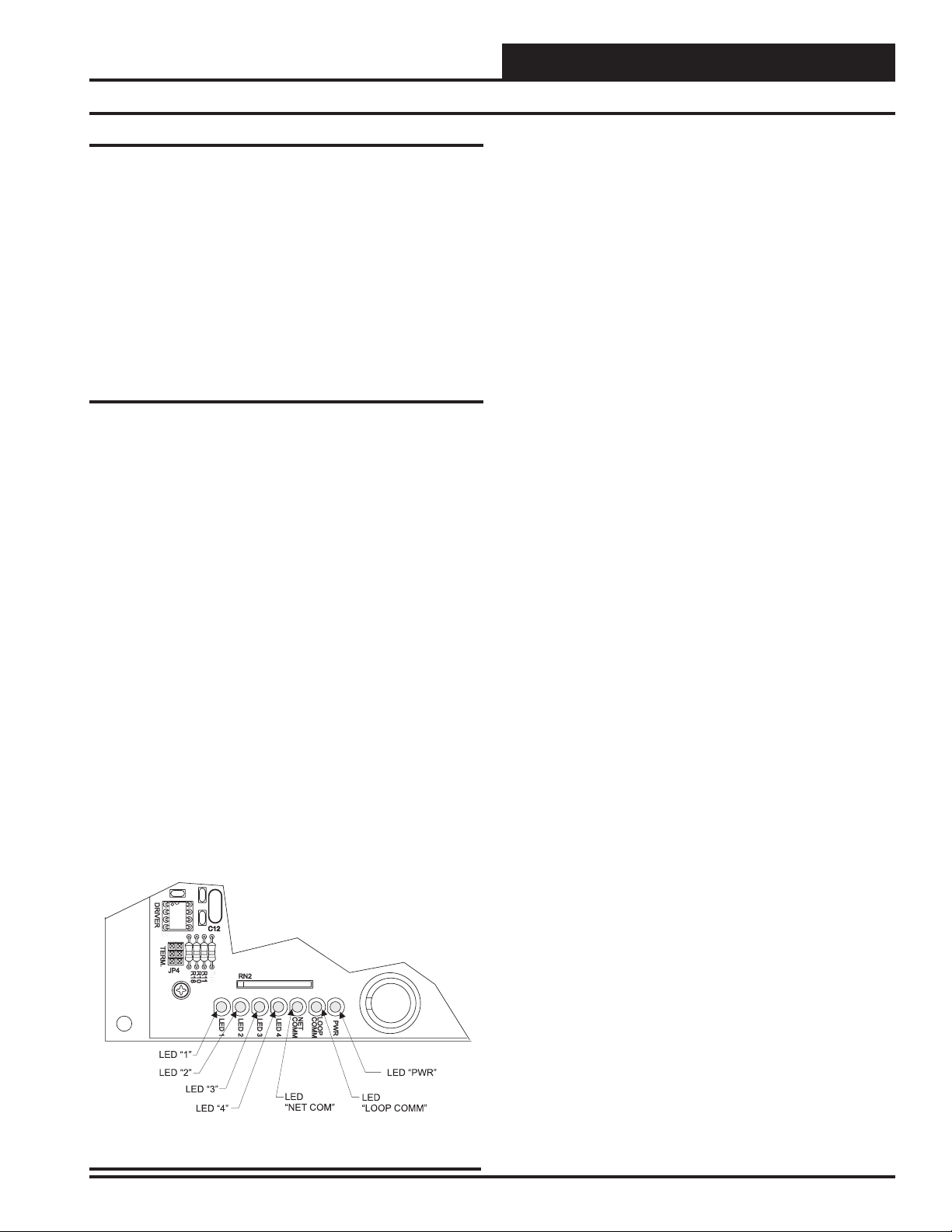

0.25”

4.00”

Network (MSTP)

Communications

Wiring Terminal

Network

Driver Chip

0.20 Dia.

Mounting Hole

Typ. 4 P L.

NET-

WORK

LOOP R4

C9

DRIVER

U7

TERM.

Mounting

Backplate

ADDR.

2

C4

U1

EEPROM

T

SHLD

R

C10

C12

R15

R11

R10

R18

JP4

Network

Communications

LED

R1

R3

JP1

1

U6

X2

RN2

LED 1

LED 2

LED 3

Local Loop

Communications

LED

Address Switch

EPROM Chip

Pin 1 Indicator

TRANSLATOR BOARD

YS101928

REV 0

C2

U2

RN1

U9

NET

COMM

LED 4

C3

C7

LOOP

COMM

PWR

7.00"

U3

C8

EPROM

Q1

R13

Power

LED

RAM Chip

Pin 1 Indicator

RAM

JP2

VCC VBAT

R16

R2

C11

WDOG

U10

JP3

C14

R14

R17

D2

R20

SERIAL #

U5

R12

C17

C1

U4

R19

R21

R5

X1

C5

LOCAL

C6

LOOP

R

SHLD

T

L1

R6

R7

R8

R9

D1

GND

C16

+24VAC

R22

U11

D3

R23

(+)

(-)

U8

DRIVER

C13

TB3

C19

Local Loop

Communications

Wiring Terminal

Local Loop

Communications

Driver Chip

24 VAC Power

Terminals

0.25”

7.50"

Figure 1: BACnet® Link Board Components and Dimensions

BACnet® Link Interface 3

Page 4

Technical Guide

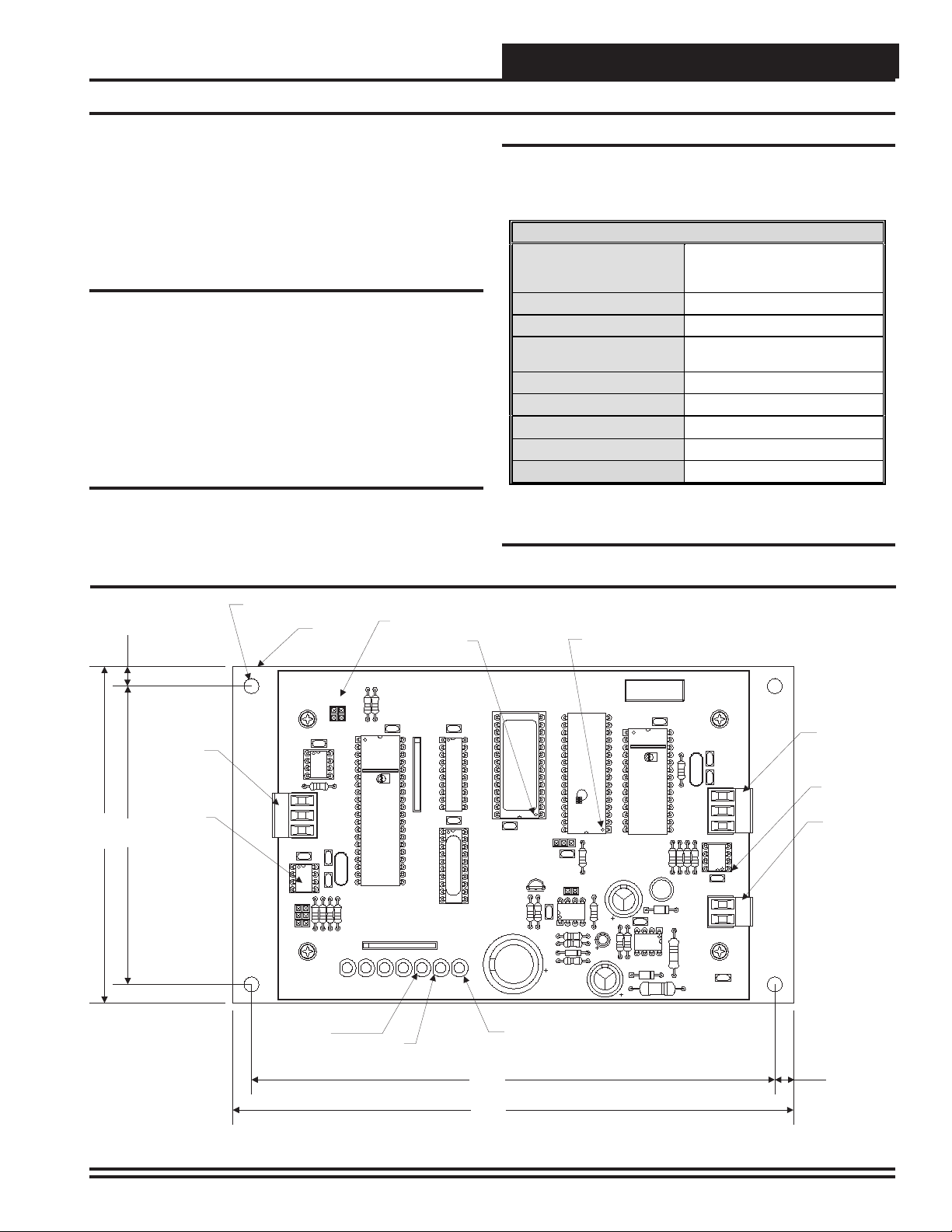

Connection and Wiring Information

BACnet Link Interface

BACnet MS/TP

LAN Connection

To BACnet

Network

Line Voltage

VAV/CAV or MUA II Unit Controller

24 VAC

(10 VA)

VAV/CAV or MUA II Unit Controller

VAV/CAV or MUA II Unit Controller

T

SHLD

R

Mode

Selection

STATUS

SETPOINTS

SCHEDULES

OVERRIDES

ALARMS

CONFIGURATION

BALANCE-TEST

ON

UP

PREV

DOWN

ESC

ENTER

13

2

708

DEC

Typical Terminal Blocks. All

Wiring To Be T To T, SHLD

(G) To SHLD (G)&RToR

NEXT

CLEAR

654

9

MINUS

-

Modular Service Tool

All Programming Of Unit Controllers

Must Be Done With The Modular Service Tool

Figure 2: BACnet® Link Interface Wiring

24 VAC

(8 VA)

Line Voltage

VAV/CAV or MUA II Unit Controller

24 VAC

(8 VA)

Line Voltage

24 VAC

(8 VA)

Line Voltage

VAV/CAV or MUA II Unit Controller

24 VAC

(8 VA)

Line Voltage

To Next VAV/CAV or MUA II

Controller On Loop

Up To 16 Controllers

Can Be Interconnected

24 VAC

(8 VA)

Line Voltage

VAV/CAV or MUA II Unit Controller

24 VAC

(8 VA)

Line Voltage

Figure 3: BACnet® Link Interface Address Switch Setting

4

BACnet® Link Interface

Page 5

Troubleshooting Information

Technical Guide

General Information

The BACnet® Link is designed to only work with the following Orion

controllers.

VAV/CAV Controller (SS1003, SS1012, Y200235, Y200301)

MUA II Controller (SS1004, Y200231, Y200306, Y200405)

CW/HW Controller (Y200311)

To determine what controller you have you must look at the label located on the controller E-prom. If the controller label does not match

any of the SS or Y numbers listed above, your controller will not work

with the BACnet® Link.

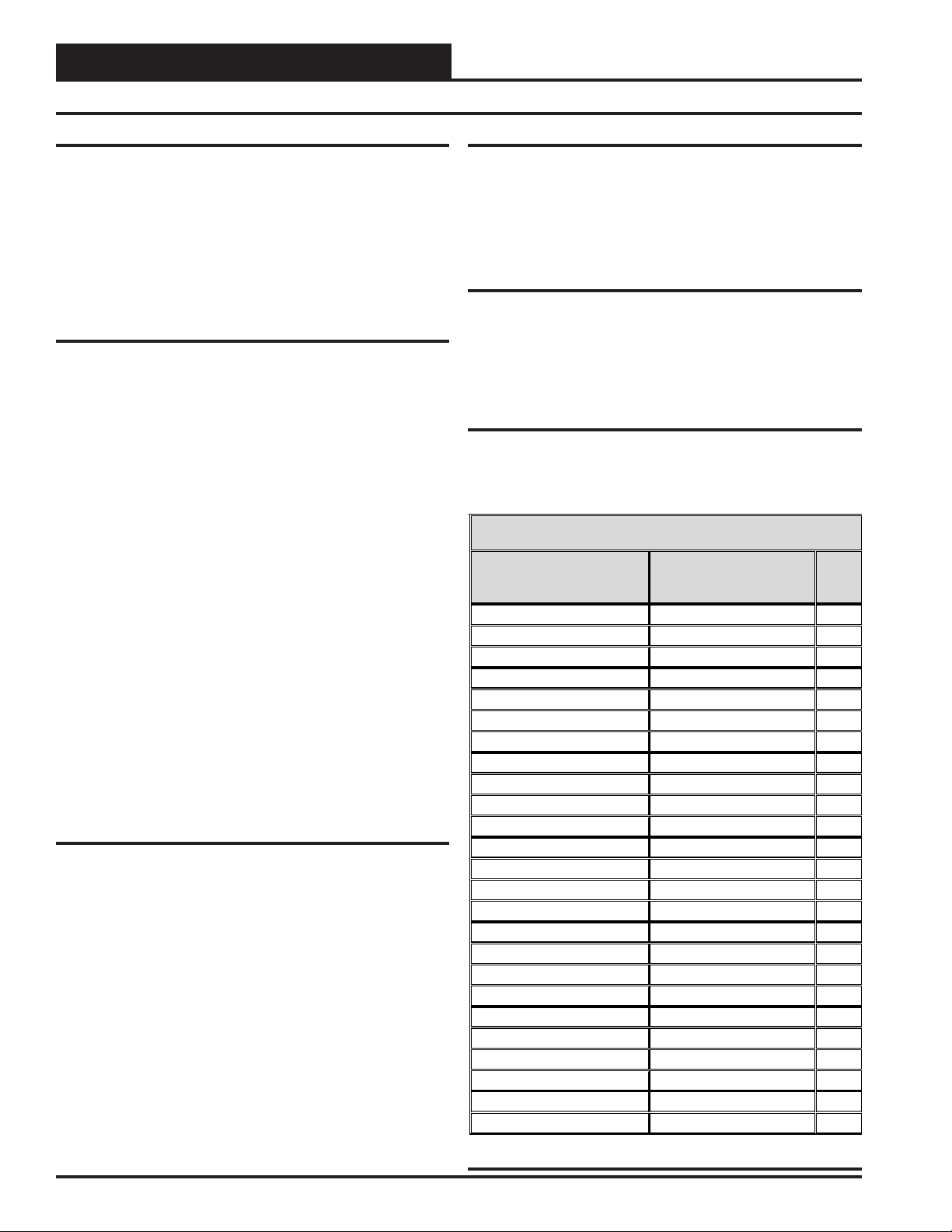

Using LED’s To Verify Operation

The BACnet® Link is equipped with LED’s that can be used for troubleshooting. There are seven LED’s on the BACnet® Link. Five of these

LED’s are used in troubleshooting. The LED’s and their uses are as

follows:

PWR

This LED will light up to indicate that 24 VAC power has been applied to the controller.

LOOP COMM

This LED will light up to indicate communication with the controllers

on the loop.

NET COMM

This LED will light up to indicate communication with the BACnet®

router.

LED 4

This LED is not currently used.

LED 3

This LED is also used to indicate communication with the BACnet®

router.

LED 2

This LED is used to indicate the number of controllers the BACnet®

Link is communicating with.

LED 1

This LED is not currently used.

PWR LED Operations

When the BACnet® Link is powered up, the “PWR” LED should light

up and stay on continuously. If it does not light up, check to be sure

that you have 24 VAC connected to the board, that the wiring connections are tight and that they are wired for correct polarity. The 24

VAC power must be connected so that all ground wires remain common. If after making all these checks the PWR LED does not light up,

please contact WattMaster technical support for assistance.

LOOP COMM LED Operations

When power is applied to the BACnet® Link the “LOOP COMM”

LED will also light up. The LED should flicker rapidly indicating

that the BACnet® Link is trying to communicate with the controllers

on the loop. A “flicker” is defined as a brief moment when the LED

turns off then back on. If the LOOP COMM LED does not operate as

indicated above, first power down the unit and then reapply power. If

this does not work, then contact WattMaster technical support for assistance.

LED 2 Operations

When power is first applied, “LED 2” will be off temporarily then will

blink one time for each controller it is communicating with. For example, if you have 10 controllers on the loop connected to the BACnet® Link then LED 2 will blink 10 times. If the amount of blinks

does not match the number of controllers connected to the loop, it

indicates there is a communications problem. The best way to find

out which board is not communicating is to go to each controller and

look at its COMM LED. The LED should be solid and will flicker

occasionally indicating communication with the BACnet® Link. If

the COMM LED does not flicker, there is no communication with that

controller.

NET COMM LED Operations

The “NET COMM” LED works the same way as the LOOP COMM

LED but it indicates that the BACnet® Link is trying to communicate

with the BACnet® router.

Figure 4 BACnet® Link LED Locations

BACnet® Link Interface

LED 3 Operations

When power is first applied , “LED 3” will be off temporarily and

then will blink slowly indicating communication with the BACnet®

router. If LED 3 does not blink, this means it is not communicating

with the BACnet® router. The first thing to check is the wiring between the BACnet® Link and the BACnet® router. Make sure that T

is wired to the (-) terminal of the router and R is wired to the (+)

terminal of the router.

If all of these tests are made and the controller still doesn’t operate,

please contact W attMaster Controls Technical Support at our T oll Free

number, 866-918-1100 for assistance.

5

Page 6

Technical Guide

Read

Programming- General Information

BACnet® Link Overview

The BACnet® Link provides the communications interface between the

Orion system and a BACnet® network. One BACnet® Link can support

up to sixteen controllers. The BACnet

network using Master-Slave/Token Passing (MS/TP) LAN data link

protocol.

The BACnet® Link supports 3 different controller types (device objects). These are the Orion MUA II, VAV/CAV and the CW/HW controllers.

®

Link connects to the BACnet

BACnet® Link Device Object

The information that follows describes the characteristics of the BACnet

Link Device Object. The properties for the BACnet® Link Device Object are listed in Table 2.

Object Name

The Object Name is a 15 byte character string that can be set through

the BACnet® front end.

Instance Number

The Instance Number of the Device Object is determined by the address jumper setting on the BACnet® Link. The BACnet® Link has two

address jumpers which allows the addressing number range to be from

0 to 3. The Instance Number of the Device Object would be the jumper

number plus 600192. This means there can be only four BACnet® Links

(Device Objects) on the entire local BACnet® system installation.

Location and Description

The Location and Description are 15 bytes character strings that can

be set through BACnet®.

Local Time and Date

The BACnet® Link (Device Object) does not have a hardware real time

clock. It does however keep a software timer running once the time and

date has been set through the BACnet® front end (by others). Since this

is a software timer, if the BACnet® Link loses power, the time will be

lost or incorrect and will need to be reset.

WattBacObjectTypes

The BACnet® Link (Device Object) amends the following object type

to BACnet®’s object type, BACnetObjectType.

WattBacObjectTypes := Enumerated {

CwHw (259)

MuaII (258)

VavCav (257)

}

If any of these W attBacObjectT ypes conflict with other custom BACnet

object types on your BACnet® system, please contact WattMaster controls.

Local Address (MAC address)

The BACnet® Link’s Local Address (MAC address) on the MS/TP

LAN is determined by the address jumper on the device. The Local

®

Address is always the address jumper plus 32. Therefore, the

BacnetOrionInterface device’s Local Address (MAC address) can be

set to address 32, 33, 34 or 35. See Figure 3 for address switch setting

information.

BACnet® Services Supported

The BACnet® Link supports the following BACnet® services:

®

ReadProperty Service ReadPropertyMultiple Service

WriteProperty Service Who-Has and I-Have Service

Who-Is and I-Am Service

MS/TP LAN Baud Rate

The OE367-22 BACnet® Link (Device Object) is able to detect the Baud

rate of the host BACnet® MS/TP LAN and automatically adjust its Baud

rate to match the host. The BACnet® Link will then operate at the host’s

Baud rate of 9600, 19200, 38400 or 76800 Baud as required.

BACnet® Link De vice Object Pr oper ties

Pr oper ty Identifie r Property Data Type

APD U _Timeout Unsigned R/O

Application_Software_Version CharacterSting R/O

Data_Base_R evision Unsigned R/O

Description CharacterSting R/W

Firmware_R evision CharacterSting R/O

Lo c a l _ Date Da te R/ W

Local_Time Time R/W

Location CharacterSting R/W

Max_ APD U _Length_A ccepted Unsigned R/O

Max_ M aster Unsigned R/O

Max-Info_Fram es Unsigned R/O

Mod el_Nam e CharacterSting R/O

Num ber_Of_A PD U_R etried Unsigned R/O

Object_Identifier BACnetO bjectIdentifier R/O

Object_List BACnetA RR AY [N] R/O

Object_Nam e C haracterString R/W

Object_Type BAC netObjectType R/O

Protocol_Conformance_C lass Unsigned(1..6) R/O

Protocol_Object_Types_Supported BAC netObjectTypesSupported R/O

®

Protocol_Services_Supported BAC netServicesSupported R/O

Protocol_Version Unsigned R/O

Segm entation_Supported BACnetSegm entation R/O

System_Status BAC netDeviceStatus R/O

Vendor_Identifier Unsigned16 R /O

Vendor_N ame CharacterString R/O

or

Write

6

Table 2: BACnet® Link Device Object Properties

BACnet® Link Interface

Page 7

Programming - Standard Objects

Technical Guide

General Information

The BACnet® Link provides additional shadowing Analog Input Objects and Analog V alue Objects for read/write parameters of the MUA

II, VAV/CAV and CW/HW controllers.

Note: The BACnet® Link does not implement any operational

function for the Analog Input Object or the Analog Value

Object but only uses the Current Value property of the

Analog Input/Value Object as a vehicle to convey one

specified parameter of the MUA II, VAV/CAV or CW/

HW controller.

Read Only Parameters are represented by Analog Input Objects and

Setpoint Parameters are represented by Analog Value Objects.

Parameters

Parameters for (1) MUA II controller are represented by 36 Analog

Input/Value Objects.

Parameters for (1) VAV/CAV controller are represented by 52 Analog

Input/Value Objects.

Parameters for (1) CW/HW controller are represented by 54 Analog

Input/Value Objects.

Instance Number Base

Each Analog Input/Value Object has an unique Object Instance Number Base that can be used to identify which parameter the object represents. The unique Object Instance Numbers are calculated from formula based on the Instance Number Base which are defined in the tables

that follow.

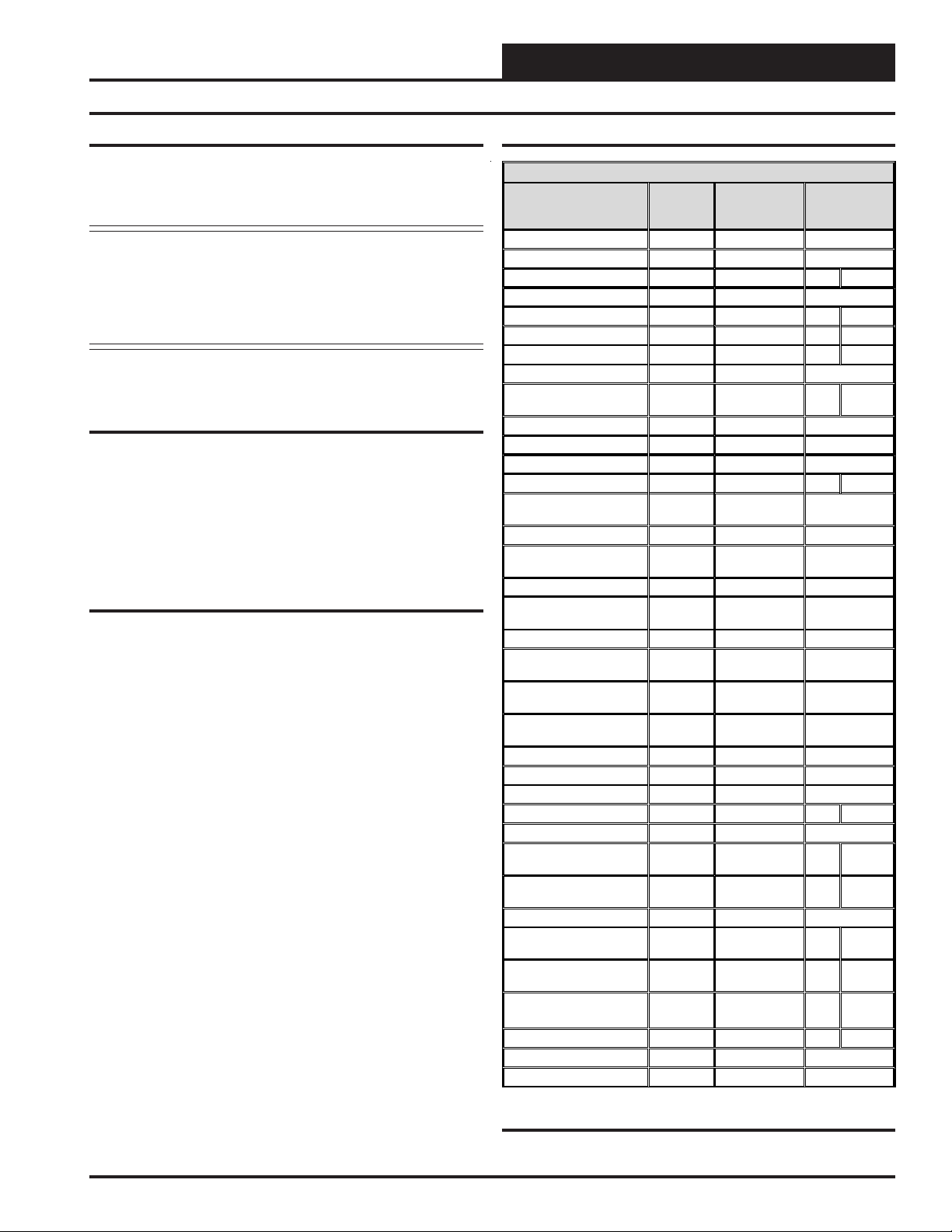

MUA II Instance Number Base

Instance Number Base For MUA II Controller

Spt.

Limits

SA Spt.

+ 50

Parameter

Alarm Status 14 Analog Input

Control Status 12 Analog Input

Cooling Deadband 20 Analog Value 2 20

Current Mode 11 Analog Input

Dew Point Reset Limit 27 Analog Value 40 DP Spt.

Dewpoint Setpoint 22 Analog Value 40 80

Enthalpy Deadband 23 Analog Value 3 20

External Heat Position 15 Analog Input

External Heat Proportion

Band

External Relay Group #1 34 Analog Input

External Relay Group #2 35 Analog Input

External Relay Group #3 36 Analog Input

Heating Deadband 21 Analog Value 2 20

Modulate Gas Valve

Position

On Board Relay Group 33 Analog Input

Outdoor Air Cooling

Setpoint

Outdoor Air Dew Point 5 Analog Input

Outdoor Air Dew Point

Setpoint

Outdoor Air Enthalpy 8 Analog Input

Outdoor Air Enthalpy

Deadband

Outdoor Air Enthalpy

Setpoint

Outdoor Air Heating

Setpoint

Outdoor Air Humidity 7 Analog Input

Outdoor Air Temperature 2 Analog Input

Reheat Value Position 18 Analog Input

Schedule Force 32 Analog Value 0 2

Space Humidity 13 Analog Input

Space Humidity At Max

Supply

Space Humidity At Min

Supply

Space Temperature 16 Analog Input

Space Temperature At

Max Supply

Space Temperature At Min

Supply

Supply Air Reset Limit 24 Analog Value SA

Supply Air Setpoint 31 Analog Value 50 90

Supply Air Setpoint Mirror 1 Analog Input

Supply Air Temperature 19 Analog Input

Instance

Number

Base

30 Analog Value 1 30

17 Analog Input

10 Analog Input

28 Analog Value 0 100

29 Analog Value 0 100

25 Analog Value 40 100

26 Analog Value 40 100

Represented

By

Object

3 Analog Input

6 Analog Input

9 Analog Input

4 Analog Input

BACnet® Link Interface

Table 3: Instance Number Base Data For MUA II

7

Page 8

Technical Guide

Programming - Standard Objects

MUA II BACnet® Property Identifier

The BACnet® Link amends the following property identity to BACnet®’s

property identifier.

BACnetPropertyIdentifier :

WattBacScheduleState ::= ENUMERATED {

NormalOperation (0),

ForceOccupied (1),

ForceUnoccupied (2)

}

MuaIIControlMode ::= ENUMERATE {

Unoccupied (0),

RemoteContactOccupied (1),

NormalScheduleOccupied (2),

HolidayModeActive (3),

ScheduleForceOccupied (4),

ScheduleForceUnoccupied (5),

CurrentOutputForceMode (6),

PushButtonOverride (7)

}

MuaIIControlStatusBits ::= BIT STRING {

CoolingDemand (0),

HeatingDemand (1),

DehumidificationDemand (2),

FanInStartUpDelay (3),

ProofOfFlow (4),

SpaceHumiditySensorInstalled (5),

SpaceTemperatureSensorInstalled (6),

ExternalHeatConfig (7),

ReheatRelayConfig (8),

ModGasIIConnected (9),

ReheatIIConnected (10),

}

MuaIIOnBoardRelayBits ::= BIT STRING {

OnBoardRelay1 (0),

OnBoardRelay2 (1),

OnBoardRelay3 (2),

OnBoardRelay4 (3),

OnBoardRelqy5 (4),

}

MuaIIExRelayGroup1Bits ::= BIT STRING {

ExpansionBoard1Relay1 (0),

ExpansionBoard1Relay2 (1),

ExpansionBoard1Relay3 (2),

ExpansionBoard1Relay4 (3),

}

MuaIIExRelayGroup2Bits ::= BIT STRING {

ExpansionBoard2Relay1 (0),

ExpansionBoard2Relay2 (1),

ExpansionBoard2Relay3 (2),

ExpansionBoard2Relay4 (3),

}

MuaIIExRelayGroup3Bits ::= BIT STRING {

ExpansionBoard3Relay1 (0),

ExpansionBoard3Relay2 (1),

ExpansionBoard3Relay3 (2),

ExpansionBoard3Relay4 (3),

}

MuaIIAlarmBits ::= BIT STRING {

BadSupplyAirTemperatureSensor (0),

NoOutdoorAirTemperatureAvailable (1),

MissingHumiditySensor (2),

FanProvingAlarm (3),

LowSupplyAirTemperature (4),

HighSupplyAirTemperature (5),

}

8

BACnet® Link Interface

Page 9

Technical Guide

Instance

VAV/CAV Instance Number Base VAV/CAV BACnet® Property Identifier

Instance Number B ase For VAV/CAV Controller

Parameter

Alarm Status 17 Analog Input

CO2 Setpoint 42 Analog Value 0 8000

Configuration 13 Analog Input

Control Mode 11 Analog Input

Control Status 12 Analog Input

Control Temperature 19 Analog Input

Cooling Setpoint 1 Analog Input

Duct Static Pressure 9 Analog Input

Duct Static Setpoint 38 Analog Value 0.01 3

Economizer Position 14 Analog Input

External Relay Group #1 35 Analog Input

External Relay Group #2 36 Analog Input

External Relay Group #3 37 Analog Input

Heating Setpoint 2 Analog Input

Minimum Outside Air

Setpoint

Occupied Cooling Setpoi nt 32 Analog Value 0 90

Occupied Heating Setpoint 20 Analog Value 0 90

On Board Relay Group 34 Analog Input

Outdoor Air Humidity 10 Analog Input

Outdoor Air Sensor Offset 31 Analog Value -10 10

Outdoor Air Temperature 8 Analog Input

Outdoor Air Wetbulb 3 Analog Input

Relief Pressure 18 Analog Input

Relief Pressure Setpoint 40 Analog Value -0.3 0.3

Return Air CO2 Level 41 Analog Input

Return Air Sensor Offset 30 Analog Value -10 10

Return Air Temperature 7 Analog Input

Schedule Force 33 Analog Value 0 2

Space Sensor Offset 28 Analog Value -10 10

Space Temperature 5 Analog Input

Staging Deadband 23 Analog Value 0 10

Supply Air Cooling Setpoint 25 Analog Value 50 70

Supply Air Heating Setpoint 26 Analog Value 0 300

Supply Air Sensor Offset 29 Analog Value -10 10

Supply Air Temperature 6 Analog Input

Temperature Demand 4 Analog Input

Unoccupied Cooling Setpoint 21 Analog Value 0 30

Unoccupied Heating Setpoint 22 Analog Value -30 0

VFD Blower Fan 15 Analog Input

VFD Exhaust Fan 16 Analog Input

Warm Up Setpoint 27 Analog Value 50 90

Wetbulb Setpoint 24 Analog Value 0 80

Number

Base

39 Analog Value 1 99

Represented

By

Object

Limits

Table 4: Instance Number Base Data For VAV/CAV

The BACnet® Link amends the following property identity to BACnet®’s

property identifier.

BACnetPropertyIdentifier :

WattBacScheduleState ::= ENUMERATED {

NormalOperation (0),

ForceOccupied (1),

ForceUnoccupied (2)

}

VavCavControlMode ::= ENUMERATE {

Unoccupied (0),

RemoteContactOccupied (1),

NormalScheduleOccupied (2),

PushButtonOrZoneOverride (3),

HolidayModeActive (4),

UnoccupiedZoneDemand (5),

RemoteScheduleOverride (6),

CurrentOutputForceMode (7),

SATHighOrLowCutOff (8),

CO2OverrideInProgress (9),

PurgeModeActive (10)

}

VavCavControlStatusBits ::= BIT STRING {

AhuControlEconomizer (0),

NoOutdoorAirTempSensor (1),

CarbonDioxiodeSensorPresent (2),

HeatCoolStagingDisabled (3),

DehumidificationMode (4),

ModGasIIConnected (5),

ReheatIIConnected (6),

}

VavCavConfigurationBits ::= BIT STRING {

CoolingDemand (0),

HeatingDemand (1),

CoolingEnabled (2),

HeatingEnabled (3),

EconomizerEnabled (4),

FanInStartUpDelay (5),

WarmUpModeActive (6),

ProofOfFlow (7),

HumidistatContact (8),

ProofOfFlowConfig (9),

ConstantVolumeConfig (10),

HeatWheelConfig (11),

HumiditySensorConfig (12),

WetBulbSensorConfig (13),

ReliefPressureConfig (14)

}

BACnet® Link Interface

9

Page 10

Technical Guide

Instance

Programming - Standard Objects

VavCavOnBoardRelayBits ::= BIT STRING {

OnBoardRelay1 (0),

OnBoardRelay2 (1),

OnBoardRelay3 (2),

OnBoardRelay4 (3),

OnBoardRelqy5 (4),

}

VavCavExRelayGroup1Bits ::= BIT STRING {

ExpansionBoard1Relay1 (0),

ExpansionBoard1Relay2 (1),

ExpansionBoard1Relay3 (2),

ExpansionBoard1Relay4 (3),

ExpansionBoard2Relay1 (4),

ExpansionBoard2Relay2 (5),

ExpansionBoard2Relay3 (6),

ExpansionBoard2Relay4 (7),

}

VavCavExRelayGroup2Bits ::= BIT STRING {

ExpansionBoard3Relay1 (0),

ExpansionBoard3Relay2 (1),

ExpansionBoard3Relay3 (2),

ExpansionBoard3Relay4 (3),

}

VavCavExRelayGroup3Bits ::= BIT STRING {

ExpansionBoard4Relay1 (0),

ExpansionBoard4Relay2 (1),

ExpansionBoard4Relay3 (2),

ExpansionBoard4Relay4 (3),

}

VavCavAlarmBits ::= BIT STRING {

BadSpaceTempSensor (0),

FanProvingAlarm (1),

MechanicalCoolingAlarm (2),

MechanicalHeatingAlarm (3),

DirtyFilterDetected (4),

HighSpaceTempAlarm (5),

LowSpaceTempAlarm (6),

}

CW/HW Instance Number Base

Instance Number B ase For CW/HW Controller

Parameter

Alarm Status 17 Analog Input

CO2 Setpoint 42 Analog Value 0 8000

Cold Water Position 44 Analog Input

Configurati on 13 A nal og Inp ut

Control Mode 11 Analog Input

Control Status 12 Analog Input

Control Temperature 19 Analog Input

Cooling Setpoint 1 Analog Input

Duct Static Pressure 9 Analog Input

Duct Static Setpoint 38 Analog Value

Economizer Position 14 Analog Input

External Relay Group #1 35 Analog Input

External Relay Group #2 36 Analog Input

HCW Configuration 45 Analog Value 0 31

Heating Setpoint 2 Analog Input

Hot Water P o sition 43 Analog Input

Minimum Outside Air

Setpoint

Occupied Cooling Setpoint 32 Analog Value 0 90

Occupied Heating Setpoint 20 Analog Value 0 90

On Board Relay Group 34 Analog Input

Outdo o r Ai r Humidit y 10 Anal o g In put

Outdoor Air Sensor Offset 31 Analog Value -10 10

Outdoor Air Temperatur e 8 A nal og Inp ut

Outdoor Air Wetbulb 3 Analog Input

Relief Pressure 18 Analog Input

Relief Pressure Setpoint 40 Analog Value 1 99

Return Air CO2 Level 41 Analog Input -0.3 0.3

Return Air Sensor Offset 30 Analog Value -10 10

Return Air Temperature 7 Analog Input

Schedule Force 33 Analog Value 0 2

Space Sensor Offset 28 Analog Value -10 10

Space Temperature 5 Analog Input

Staging Deadband 23 Analog Value 0 10

Supply Air Cooling Setpoint 25 Analog Value 50 70

Supply Air Heating Setpoint 26 Analog Value 0 300

Supply Air Sensor Offset 29 Analog Value -10 10

Supply Air Temperature 6 Analog Input

Temperature Demand 4 Analog Input

Unoccupied Cooling Setpoint 21 Analog Value 0 30

Unoccupied Heating Setpoint 22 Analog Value -30 0

Vfd Blower Fan 15 Analog Input

Vfd Exhaust Fan 16 Analog Input

Warm Up Setpoint 27 Analog Value 50 90

Wetbulb Setpoint 24 Analog Value 0 80

Number

Base

39 Analog Value 0.01 3

Represented

By

Object

Limits

10

Table 5: Instance Number Base Data For CW/HW

BACnet® Link Interface

Page 11

Technical Guide

CW/HW BACnet® Property Identifier

The BACnet® Link amends the following property identity to BACnet®’s

property identifier.

BACnetPropertyIdentifier :

WattBacScheduleState ::= ENUMERATED {

NormalOperation (0),

ForceOccupied (1),

ForceUnoccupied (2)

}

CwHwControlMode ::= ENUMERATE {

Unoccupied (0),

RemoteContactOccupied (1),

NormalScheduleOccupied (2),

PushButtonOrZoneOverride (3),

HolidayModeActive (4),

UnoccupiedZoneDemand (5),

RemoteScheduleOverride (6),

CurrentOutputForceMode (7),

SATHighOrLowCutOff (8),

CO2OverrideInProgress (9),

PurgeModeActive (10)

}

CwHwControlStatusBits ::= BIT STRING {

AhuControlEconomizer (0),

NoOutdoorAirTempSensor (1),

CarbonDioxiodeSensorPresent (2),

HeatCoolStagingDisabled (3),

DehumidificationMode (4),

ModGasIIConnected (5),

ReheatIIConnected (6),

}

CwHwConfigurationBits ::= BIT STRING {

CoolingDemand (0),

HeatingDemand (1),

CoolingEnabled (2),

HeatingEnabled (3),

EconomizedEnabled (4),

FanInStartUpDelay (5),

WarmUpModeActive (6),

ProofOfFlow (7),

HumidistatContact (8),

ProofOfFlowConfig (9),

ConstantVolumeConfig (10),

HeatWheelConfig (11),

HumiditySensorConfig (12),

WetBulbSensorConfig (13),

ReliefPressureConfig (14)

}

CwHwOnBoardRelayBits ::= BIT STRING {

OnBoardRelay1 (0),

OnBoardRelay2 (1),

OnBoardRelay3 (2),

OnBoardRelay4 (3),

OnBoardRelqy5 (4),

}

CwHwExRelayGroup1Bits ::= BIT STRING {

ExpansionBoard1Relay1 (0),

ExpansionBoard1Relay2 (1),

ExpansionBoard1Relay3 (2),

ExpansionBoard1Relay4 (3),

ExpansionBoard2Relay1 (4),

ExpansionBoard2Relay2 (5),

ExpansionBoard2Relay3 (6),

ExpansionBoard2Relay4 (7),

}

CwHwExRelayGroup3Bits ::= BIT STRING {

ExpansionBoard3Relay1 (0),

ExpansionBoard3Relay2 (1),

ExpansionBoard3Relay3 (2),

ExpansionBoard3Relay4 (3),

}

CwHwAlarmBits ::= BIT STRING {

BadSpaceTempSensor (0),

FanProvingAlarm (1),

MechanicalCoolingAlarm (2),

MechanicalHeatingAlarm (3),

DirtyFilterDetected (4),

HighSpaceTempAlarm (5),

LowSpaceTempAlarm (6),

}

CwHwConfigBits ::= BIT STRING {

EnableChillerWater (0),

ChillerWaterReverseActing (1),

EnableHotWater (2),

HotWaterReverseActing (3),

EnableHotWaterOnDehumidification (4),

}

BACnet® Link Interface

11

Page 12

Technical Guide

Instance

Programming - Standard Objects

Parameter Instance Numbers

Instance Number Calculation

The Instance Number for a controller parameter is determined by using

the BACnet® Link Loop Address for the controller, the MUA II, VAV/

CAV or CW/HW controllers address switch setting and the Instance

Number Base of the desired Parameter you wish to calculate for that

controller..

®

mation. Be sure to use the BACnet

Link Loop Address not the “MAC”

address. Possible valid BACnet® Link Loop Address addresses are 0

through 3.

Proceed by determining the address switch setting of the controller you

wish to calculate. This is accomplished by verifying the address switch

setting for the desired controller. Possible valid controller addresses are

1 through 32.

In order to calculate the Instance Number for the desired Parameter you

must use the WattMaster base address (600191) as a starting point.

®

Next you must determine the BACnet

troller you wish to calculate. This is determined by looking at the BAC-

®

net

Link Loop Address switch setting for the loop the desired control-

Link Loop Address for the con-

ler is installed on. See Figure 3 for Loop Address switch setting infor-

Look up the Instance Number Base for the controller and specific parameter you desire from the Instance Number Base Table for that controller. See Table 3 through Table 5.

Use the numbers that you just determined to calculate the Instance Number for the desired parameter using the formula below. Please see the

examples that follow the formula.

Parameter Instance Number Calculation Examples

Co ntrolle r

Type &

Parameter

MUA II

Current Mode

MUA II

Alarm Status

VAV/CAV

Control Mode

VAV/CAV

Alarm Status

BACnet

Link

Loop

Addres s

0 1 11 60 0 19 1 +((0 * 16 + 1-1) * 64 ) + 11 ) = 60 0202 600202

3 3 14 6001 91 + ((3 * 16 + 3-1) * 64) + 14 ) = 6 03 405 603405

1 14 11 600191 + ((1 * 16 + 1 4-1) * 64) + 11 ) = 60 20 58 6020 58

2 15 17 600191 + ((2 * 16 + 1 5-1) * 64) + 17 ) = 60 31 25 6031 25

Controller

Addre ss

Parameter

Number

Table 6: Parameter Instance Number Calculations

12

Base

Parameter Instance N umber

Calculation

BACnet® Link Interface

Parameter

Instance

Number

Page 13

Programming - Proprietary Objects

Technical Guide

BACnet® Link Overview

The BACnet® Link provides the communications interface between the

Orion system and a BACnet® network. One BACnet® Link can support

up to sixteen controllers. The BACnet

®

Link connects to the BACnet

network using Master-Slave/Token Passing (MS/TP) LAN data link

protocol. Complete information regarding the BACnet® Link device

object can be found on pages 3 through 5 of this manual.

®

The BACnet

Link supports 3 different controller types (objects). These

are the Orion MUA II, VAV/CAV and the CW/HW controllers. The

sections that follow describe the properties for each controller (device

object).

MUA II Object

The information that follows describes the characteristics of the MUA

II Object. The properties for the MUA II Object are listed in Table 7.

Object Name

The Object Name for the MUA II controller is a 15 byte character string

that can be set through the BACnet® front end.

Object Type

The Object Type of the MUA II controller is MuaII or 258.

Object Instance Number

The Instance Number of the MUA II Object is determined by two variable values. The first variable is the loop address setting on the BACnet® Link for the specific loop the MUA II controller resides on and the

second is the MUA II controller address. The BACnet® Link loop address can be either 0, 1, 2 or 3. See Figure 3 at the front of this manual

for detailed information on the BACnet® Link loop address jumper settings.

The second variable value used to calculate the Object Instance number

is the MUA II controller address and is determined by the address switch

settings on the MUA II controller. Valid address settings are 1 through

16.

See Table 10 at the end of this chapter for complete Object Instance

Number calculation information

Object Properties

The information and tables that follow detail the properties and property identifiers for the MUA II Object.

Properties For The MUA II Controller

Property Name Property Data Type

®

Alarm_Status MuaIIAlarmBits 1024 R/O

Application_Software_Version Unsigned 11 R/O

Control_Status MuaControlBits 1025 R/O

Cooling_Deadband Unsigned 1026 R/W

Dew_Point_Reset_Limit Unsigned 1029 R/W

Dew_Point_Setpoint Unsigned 1030 R/W

Enthalpy_Deadband U nsigned 1033 R/W

Enth alpy _U n it BAC ne tE ng ineer ingUnits 1082 R/O

Exter nal _ He at_P ositi on Rea l 103 5 R/O

External_Heat_Proportion_Band Unsigned 1034 R/W

Heating_Deadband Unsigned 1036 R/W

Humidity_Unit BACnetEngineeringUnits 1084 R/O

Modulate_Gas_Valve_Position Unsigned 1038 R/O

Object_Identifier BA CnetObjectIdentifier 75 R/O

Object_Name CharacterString 77 R/W

Object_Type W attBacObjectTypes 79 R/O

Outdoor_Air_Cooling_Setpoint Real 1041 R/O

Outdoor_Air_Dew_Point Real 1045 R/O

Outdoor_Air_Dew_Point_Setpoint Real 1046 R/O

Outdoor_Air_Enthalpy R eal 1047 R/O

Outdoor_Air_Enthalpy_Deadband Real 1049 R/O

Outdoor_Air_Enthalpy_Setpoint Real 1048 R/O

Outdoor_Air_Heating_Setpoint Real 1042 R/O

Outdoor_Air_Humidity Real 1050 R/O

Outdoor_Air_Temperature Real 1052 R/O

Position_Unit BAC netEngineeringUnits 1085 R/O

Reheat_Value_Position Unsigned 1054 R/O

Relays MuaIIRelayBits 1055 R/O

Schedule_Force WattBacScheduleState 1059 R/W

Space_Humidity Real 1060 R/O

Space_Humidity_At_Max_Supply Unsigned 1061 R/W

Space_Humidity_At_Min_Supply U nsigned 1062 R/W

Space _Temperature Real 1064 R /O

Space_Temperature_At_Max_Supply Unsigned 1065 R/W

Space_Temperature_At_Min_Supply Unsigned 1066 R/W

Supp ly _A ir_R e set_L imit U nsig ned 1070 R/W

Supply_Air_Setpoint Unsigned 1072 R/W

Supply_Air_Setpoint_Mirror R eal 1081 R/O

Supp ly _A ir_T emeratu re Real 1073 R/O

Temperature_Unit BACnetEngineeringUnits 1086 R/O

Property

Iden tifie r

Read

Or

Write

BACnet® Link Interface

Table 7: MUA II Object Properties

13

Page 14

Technical Guide

Programming - Proprietary Objects

MUA II Property Identifier

BacnetOrionInterface device amends the following property identity to

BACnet®’s property identifier BACnetPropertyIdentifier:

WattBacScheduleState ::= ENUMERATED {

NormalOperation (0),

ForceOccupied (1),

ForceUnoccupied (2)

}

MuaIIControlMode ::= ENUMERATE {

Unoccupied (0),

RemoteContactOccupied (1),

NormalScheduleOccupied (2),

HolidayModeActive (3),

ScheduleForceOccupied (4),

ScheduleForceUnoccupied (5),

CurrentOutputForceMode (6),

PushButtonOverride (7)

MuaIIControlBits ::= BIT STRING {

MuaIIControlModeBit0 (0),

MuaControlModeBit0 (1),

MuaControlModeBit0 (2),

CoolingDemand (3),

HeatingDemand (4),

DehumidificationDemand (5),

FanInStartUpDelay (6),

ProofOfFlow (7),

SpaceHumiditySensorInstalled (8),

SpaceTemperatureSensorInstalled (9),

ExternalHeatConfig (10),

ReheatRelayConfig (11),

ModGasIIConnected (12),

ReheatIIConnected (13),

}

MuaIIRelayBits ::= BIT STRING {

OnBoardRelay1 (0),

OnBoardRelay2 (1),

OnBoardRelay3 (2),

OnBoardRelay4 (3),

OnBoardRelqy5 (4),

ExpansionBoard1Relay1 (8),

ExpansionBoard1Relay2 (9),

ExpansionBoard1Relay3 (10),

ExpansionBoard1Relay4 (11),

ExpansionBoard2Relay1 (16),

ExpansionBoard2Relay2 (17),

ExpansionBoard2Relay3 (18),

ExpansionBoard2Relay4 (19),

ExpansionBoard3Relay1 (24),

ExpansionBoard3Relay2 (25),

ExpansionBoard3Relay3 (26),

ExpansionBoard3Relay4 (27),

}

MuaIIAlarmBits ::= BIT STRING {

BadSupplyAirTemperatureSensor (0),

NoOutdoorAirTemperatureAvailable (1),

MissingHumiditySensor (2),

FanProvingAlarm (3),

LowSupplyAirTemperature (4),

HighSupplyAirTemperature (5),

}

14

BACnet® Link Interface

Page 15

Technical Guide

VAV/CAV Object

The information that follows describes the characteristics of the VAV/

CA V Object. The properties for the VAV/CAV Object are listed in Table

8.

Object Name

The Object Name for the VAV/CAV controller is a 15 byte character

string that can be set through the BACnet

Object Type

The Object Type of the VAV/CAV controller is VavCav or 257.

Object Instance Number

The Instance Number of the VAV/CAV Object is determined by two

variable values. The first variable is the loop address setting on the

BACnet® Link for the specific loop the VAV/CAV controller resides on

and the second is the VAV/CAV controller address. The BACnet® Link

loop address can be either 0, 1, 2 or 3. See Figure 3 at the front of this

manual for detailed information on the BACnet® Link loop address

jumper settings.

The second variable value used to calculate the Object Instance number

is the VAV/CAV controller address and is determined by the address

switch settings on the VAV/CAV controller. Valid address settings are 1

through 16.

See Table 10 at the end of this chapter for complete Object Instance

Number calculation information

Object Properties

The information and tables that follow detail the properties and property identifiers for the VAV/CAV Object.

®

front end.

Object Properties For The VAV/CAV Controller

Property Name Property Data Type

Alarm _Status V avA larmBits 1024 R/O

Ap plication_Software_V ersion Unsigned 11 R/O

CO 2_Setpoint Real 1094 R/O

Control_Status V avCon trolBits 1025 R/O

Control_Temperature Real 1028 R/O

Cooling_Setpoint Real 1027 R/O

Duct_Static_Pressure R eal 1090 R/O

Duct_Static_Setpoint Real 1031 R/W

Econom izer_Position Real 1032 R/O

Fan_Speed_Unit BA CnetEngineeringUnits 1083 R/O

Heating_Setpoint Real 1037 R/O

Humidity_Unit BA CnetEngineeringUnits 1084 R/O

Min_Outside_Air_Setpoint Real 1091 R/W

Object_Identifier BACnetObjectIdentifier 75 R/O

Object_Name CharacterString 77 R/W

Object_Type WattBacObjectTypes 79 R/O

Occu pied_Cooling_Setpoint Unsigned 1039 R/W

Occu pied_Heating_Setpoint Unsigned 1040 R/W

Outdoor_Air_Humidity Real 1050 R/O

Outdoor_A ir_Sensor_Offset Real 1051 R/W

Outdoor_A ir_Tem perature Real 1052 R/O

Outdoor_A ir_W etbulb Real 1053 R/O

Position_Unit BACnetEngineeringUnits 1085 R/O

Relays VavRelayBits 1055 R/O

Relief_Pressure Real 1056 R/O

Relief_Pressure_Setpoint Real 1092 R/W

Return_A ir_CO2_L evel Real 1093 R/O

R eturn _ Air_S e n sor_ O ffs et R ea l 105 8 R/W

Return_A ir_Temperature Real 1057 R/O

Schedule_Force W attBacSch eduleState 1059 R/W

Space_Sen sor_Offset Real 1063 R/W

Space_T emp erature Real 1064 R/O

Staging_Dea dband Integer 1067 R/W

Supply_A ir_Cooling_Setpoint Unsigned 1068 R/W

Supply_A ir_Heating_Setpoint Unsigned 1069 R/W

Supply_A ir_Sensor_Offset Real 1071 R/W

Supply_A ir_Temp erature R eal 1073 R/O

Tem perature_Dem and Real 1074 R/O

Tem perature_Unit BA Cn etEngineeringUnits 1086 R/O

Un occupied_Coolting_Setpoint Unsigned 1075 R/W

Un occupied_Heating_Setpoint Unsigned 1076 R/W

Vfd_B lower_Fan Real 1077 R/O

Vfd_E xhaust_Fan Real 1078 R/O

W arm_ Up_S etpoint Unsigned 1079 R/W

W etbulb_Setpoint U nsigned 1080 R/W

Property

Ide n tifier

Read

Or

Write

BACnet® Link Interface

Table 8: VAV/CAV Object Properties

15

Page 16

Technical Guide

Programming - Proprietary Objects

VAV/CAV Property Identifier

BacnetOrionInterface device amends the following property identity to

BACnet®’s property identifier BACnetPropertyIdentifier:

WattBacScheduleState ::= ENUMERATED {

NormalOperation (0),

ForceOccupied (1),

ForceUnoccupied (2)

}

VavCavControlMode ::= ENUMERATE {

Unoccupied (0),

RemoteContactOccupied (1),

NormalScheduleOccupied (2),

PushButtonOrZoneOverride (3),

HolidayModeActive (4),

UnoccupiedZoneDemand (5),

RemoteScheduleOverride (6),

CurrentOutputForceMode (7),

SATHighOrLowCutOff (8),

CO2OverrideInProgress (9),

PurgeModeActive (10)

}

VavCavRelayBits ::= BIT STRING {

OnBoardRelay1 (0),

OnBoardRelay2 (1),

OnBoardRelay3 (2),

OnBoardRelay4 (3),

OnBoardRelqy5 (4),

ExpansionBoard1Relay1 (8),

ExpansionBoard1Relay2 (9),

ExpansionBoard1Relay3 (10),

ExpansionBoard1Relay4 (11),

ExpansionBoard2Relay1 (12),

ExpansionBoard2Relay2 (13),

ExpansionBoard2Relay3 (14),

ExpansionBoard2Relay4 (15),

ExpansionBoard3Relay1 (16),

ExpansionBoard3Relay2 (17),

ExpansionBoard3Relay3 (18),

ExpansionBoard3Relay4 (19),

ExpansionBoard4Relay1 (24),

ExpansionBoard4Relay2 (25),

ExpansionBoard4Relay3 (26),

ExpansionBoard4Relay4 (27),

}

VavCavControlBits ::= BIT STRING {

VavControlModeBit0 (0),

VavControlModeBit0 (1),

VavControlModeBit0 (2),

VavControlModeBit0 (3),

AhuControlEconomizer (4),

NoOutdoorAirTempSensor (6),

CarbonDioxiodeSensorPresent (7),

HeatCoolStagingDisabled (11),

DehumidificationMode (12),

ModGasIIConnected (13),

ReheatIIConnected (14),

CoolingDemand (16),

HeatingDemand (17),

CoolingEnabled (18),

HeatingEnabled (19),

EconomizedEnabled (20),

FanInStartUpDelay (21),

WarmUpModeActive (22),

ProofOfFlow (23),

HumidistatContact (24),

ProofOfFlowConfig (25),

ConstantVolumeConfig (26),

HeatWheelConfig (27),

HumiditySensorConfig (28),

WetBulbSensorConfig (29),

ReliefPressureConfig (30)

}

VavCavAlarmBits::= BIT STRING {

BadSpaceTempSensor (0),

FanProvingAlarm (1),

MechanicalCoolingAlarm (2),

MechanicalHeatingAlarm (3),

DirtyFilterDetected (4),

HighSpaceTempAlarm (5),

LowSpaceTempAlarm (6),

}

16

BACnet® Link Interface

Page 17

Technical Guide

CW/HW Object

The information that follows describes the characteristics of the CW/

HW Object. Properties for the CW/HW Object are listed in Table 9.

Object Name

The Object Name for the CW/HW controller is a 15 byte character

string that can be set through the BACnet® front end.

Object Type

The Object Type of the CW/HW controller is CwHw or 259.

Object Instance Number

The Instance Number of the CW/HW Object is determined by two variable values. The first variable is the loop address setting on the BAC-

®

net

Link for the specific loop the CW/HW controller resides on and

the second is the CW/HW controller address. The BACnet® Link loop

address can be either 0, 1, 2 or 3. See Figure 3 at the front of this

manual for detailed information on the BACnet® Link loop address

jumper settings.

The second variable value used to calculate the Object Instance number

is the CW/HW controller address and is determined by the address switch

settings on the CW/HW controller. Valid address settings are 1 through

16.

See Table 10 at the end of this chapter for complete Object Instance

Number calculation information

Object Properties

The information and tables that follow detail the properties and property identifiers for the CW/HW Object.

Object Prop erties Fo r The C W /HW Controller

Property Name Property Data Type

Alarm_Status CwHwAlarmBits 1024 R/O

Applilcation_Software_V ersion Unsigned 11 R /O

CO 2_Setpoin t Real 1094 R/O

Cold_W a ter_Position Real 1088 R/O

Control_Status CwHwControlBits 1025 R/O

Control_Tem perature Real 1028 R/O

Cooling_Setpoint Real 1027 R/O

Duct_Static_Pressure Real 1031 R/O

Duct_Static_S etpoint Real 1090 R/W

Econom izer_P osition Real 1032 R/O

Fan_Spe ed_ Unit BACn e tEngineeringU ni ts 1083 R/O

Hcw_Configuration HcwConfigBits 1089 R./W

Heating_S etpoint Real 1037 R/O

Hot_W ater_Position Real 1087 R/O

Humidity_Unit BACnetEngineeringUnits 1084 R/O

Min_ O utside_Air_Setpoin t Real 1091 R/W

Object_Identifier BACn etObj ectIdentifier 75 R/O

Object_Nam e CharacterString 77 R/W

Object_Type WattBacObjec tTypes 79 R/O

Occupied _Coolin g_Setpoin t Unsigne d 1039 R/W

Occupied_H eating_S etpoint Unsigned 1040 R/W

Outdoor_Ai r_H um idity Real 1050 R/O

Outdoor_Ai r_Sens or_Off set Real 1051 R/W

Outdoor_Ai r_Temperature Real 1052 R/O

Outdoor_Ai r_Wetbulb Real 1053 R/O

Position_Uni t BACne tEngine eringUn its 1 085 R/O

Relays CwHwRelayBits 1055 R/O

Relief_Pressure Real 1056 R/O

Relief_Pressure_Setpoint Real 1092 R/W

Return_Ai r_CO 2_Lev el Real 1093 R/O

Return_Ai r_Sensor_Of fset Real 1058 R/W

Return_Ai r_Tem perature Real 1057 R/O

Schedule_F orce W attBacSched uleState 1059 R/W

Space_Sensor_ Offset Real 1063 R/W

Space_Temperature Real 1064 R/O

Staging_D eadband Integer 1067 R/W

Supply_A i r_Cooling_ Setpoint Unsigned 1068 R/W

Supply_A i r_Heating_Se tpoint Unsigned 1069 R/W

Supply_A ir_Sens or_Offset Real 1071 R/W

Supply_A ir_Tem p erature Real 1073 R/O

Tem perature_Dem an d Real 1074 R/O

Tem perature_Un it BACne tEngineeringUn its 1 086 R/O

Unoccupied_Coolting_Setpoint Unsigned 1075 R/W

Unoccu pied_H eating_Setpoint Unsigned 1076 R/W

Vfd_B low er_Fan Real 1077 R/O

Vfd_Ex haus t_Fan Real 1078 R/O

Wa rm _Up _S etpoint Unsigned 1079 R/W

We tbulb_ Setpoint Unsigne d 1080 R/W

Property

Iden ti fie r

Read

Or

Write

BACnet® Link Interface

Table 9: CW/HW Object Properties

17

Page 18

Technical Guide

Programming- Proprietary Objects

CW/HW Property Identifier

BacnetOrionInterface device amends the following property identity to

BACnet®’s property identifier BACnetPropertyIdentifier:

WattBacScheduleState ::= ENUMERATED {

NormalOperation (0),

ForceOccupied (1),

ForceUnoccupied (2)

}

CwHwControlMode ::= ENUMERATE {

Unoccupied (0),

RemoteContactOccupied (1),

NormalScheduleOccupied (2),

PushButtonOrZoneOverride (3),

HolidayModeActive (4),

UnoccupiedZoneDemand (5),

RemoteScheduleOverride (6),

CurrentOutputForceMode (7),

SATHighOrLowCutOff (8),

CO2OverrideInProgress (9),

PurgeModeActive (10)

}

CwHwRelayBits := BIT STRING {

OnBoardRelay1 (0),

OnBoardRelay2 (1),

OnBoardRelay3 (2),

OnBoardRelay4 (3),

OnBoardRelqy5 (4),

ExpansionBoard1Relay1 (8),

ExpansionBoard1Relay2 (9),

ExpansionBoard1Relay3 (10),

ExpansionBoard1Relay4 (11),

ExpansionBoard2Relay1 (12),

ExpansionBoard2Relay2 (13),

ExpansionBoard2Relay3 (14),

ExpansionBoard2Relay4 (15),

ExpansionBoard3Relay1 (16),

ExpansionBoard3Relay2 (17),

ExpansionBoard3Relay3 (18),

ExpansionBoard3Relay4 (19),

ExpansionBoard4Relay1 (24),

ExpansionBoard4Relay2 (25),

ExpansionBoard4Relay3 (26),

ExpansionBoard4Relay4 (27),

}

CwHwControlBits ::= BIT STRING {

VavControlModeBit0 (0),

VavControlModeBit0 (1),

VavControlModeBit0 (2),

VavControlModeBit0 (3),

AhuControlEconomizer (4),

NoOutdoorAirTempSensor (6),

CarbonDioxiodeSensorPresent (7),

HeatCoolStagingDisabled (11),

DehumidificationMode (12),

ModGasIIConnected (13),

ReheatIIConnected (14),

CoolingDemand (16),

HeatingDemand (17),

CoolingEnabled (18),

HeatingEnabled (19),

EconomizedEnabled (20),

FanInStartUpDelay (21),

WarmUpModeActive (22),

ProofOfFlow (23),

HumidistatContact (24),

ProofOfFlowConfig (25),

ConstantVolumnConfig (26),

HeatWheelConfig (27),

HumiditySensorConfig (28),

WetBulbSensorConfig (29),

ReliefPressureConfig (30)

}

CwHwAlarmBits ::= BIT STRING {

BadSpaceTempSensor (0),

FanProvingAlarm (1),

MechanicalCoolingAlarm (2),

MechanicalHeatingAlarm (3),

DirtyFilterDetected (4),

HighSpaceTempAlarm (5),

LowSpaceTempAlarm (6),

}

CwHwConfigBits ::= BIT STRING {

EnableChillerWater (0),

ChillerWaterReverseActing (1),

EnableHotWater (2),

HotWaterReverseActing (3),

EnableHotWaterOnDehumidification (4),

}

18

BACnet® Link Interface

Page 19

Proprietary Object Instance Numbers

BACnet Link

Proprietary Object

Instance Number Calculation

The Instance Number for a Proprietary Object is determined by using

the BACnet® Link Loop Address for the controller and the MUA II,

VAV/CAV or CW/HW controllers address switch setting.

In order to calculate the Instance Number for the Proprietary Object

you must use the W attMaster base address (600191) as a starting point.

Next you must determine the BACnet® Link Loop Address for the controller you wish to calculate. This is determined by looking at the

®

BACnet

controller is installed on. See Figure 3 for Loop Address switch setting

information. Be sure to use the BACnet

Link Loop Address switch setting for the loop the desired

®

Link Loop Address not the

Technical Guide

®

“MAC” address. Possible valid BACnet

are 0 through 3.

Proceed by determining the address switch setting of the controller you

wish to calculate. This is accomplished by verifying the address switch

setting for the desired controller. Possible valid controller addresses are

1 through 16.

Use the numbers that you just determined to calculate the Instance Number for the Proprietary Object using the formula below. Please see the

examples that follow the formula.

Link Loop Address addresses

Prop rieta ry O bje ct Insta n ce N um b er Ca lcu lation Ex am ple s

Controller

Type

MUA II 0 1 600191 + (0 * 16) + 1 = 600192 600192

CW/HW 3 4 600191 + (3 * 16) + 4 = 600243 600243

VAV/CAV 1 12 600191 + (1* 16) + 12 = 600219 600219

MUA II 2 7 60 0191 + (2* 16) + 7 = 600230 600230

Loop

Address

Controller

Addres s

Proprie tary Obj e ct

Instance N umber

Calculation

Table 10: Proprietary Instance Number Calculation Examples

Instance N umber

BACnet® Link Interface

19

Page 20

Technical Guide

Appendix 1

BACnet® Link Protocol Implementation

Conformance Statement

BACnet® Link Basic Information

BACnet® Link is a device which provides an interface between the

WattMaster Controls Orion System and the BACnet® network. One

®

BACnet

CW/HW controllers. The BACnet® Link connects to the BACnet® network through MS/TP as data link/physical layer.

BACnet

BACnet® Link supports the following BACnet® interoperability Building Blocks

Link can connect up to sixteen Orion VAV/CAV, MUA II or

®

Interoperability Building Blocks

• Data Sharing-ReadProperty-B (DS-RP-B)

Tested with Cimetric’s BACnet

®

Explorer

• Data Sharing-ReadPropertyMultiple-B (DS-RPM-B)

Not tested

• Data Sharing-WriteProperty-B (DS-WP-B)

Tested with Cimetric’s BACnet

BACnet® Device Profile

BACnet® Link conforms to the following device profile.

• BACnet

Tested with Cimetric’s BACnet

®

Application Specific Controller (B-ASC)

Non Standard Application Services

BACnet® Link does not support any non-standard application services..

BACnet® Link Objects

BACnet® Link provides the following objects.

®

Explorer

®

Explorer

• Standard Objects

• Device object

• Analog Input object

• Analog Value object

• Proprietary object

• VAV/CAV object

• MUA II object

• CW/HW object

Standard Object Details

BACnet® Link has the following properties available.

BACnet® Link Object Properties

Property Read or

APDU Timeout R/O

Application Software

Version

Data Base Revision R/O

Description R/W 15

Firmware Revision R/O

Loca l Date R/W Software Timer

Loca l Time R/W S o ftware T imer

Location R/W 15

Max APDU Length

Accepted

Max Info Frames R/O

Max Master R/O

Model Name R/O

Number Of APDU

Retried

Object Identifier R/O 6 00192 P lus Sw itch

Object List R/O

Object Nam e R /W 15

Object Type R/O 8

Protocol Conformance

Class

Protocol Object Types

Supported

Protocol Services

Supported

Protocol Version R/O

Segmentation

Supported

System Status R/O

Vendo r Ident ifier R/O

Vendor Name R/O WattMaster

Write

R/O

R/O 204

R/O

R/O 2

R/O

R/O

R/O No

Lim its , Va lu e , C o m me nt

Table 11: BACnet® Link Device Object Properties

20

BACnet® Link Interface

Page 21

Technical Guide

Analog Valu e Ob jec t Prop erties

Property Read or

Write

Event State R/O Not Implemented

Object Identifier R/O

Object Name R/W 15

Object Type R/O 2

Out of Service R/O Not Implemented

Present Value R /O

Status Flags R/W No t Implemen ted

Units R/O

Limits, Value, Comment

Table 12: Analog Value Object Properties

Analog Input Object Properties

Property Read or

Write

Event State R/O N ot Imp lemen ted

Ob ject Id e n tifie r R/O

Object Name R/W 15

Object Type R/O 0

Ou t of S erv ice R/O N o t Im p lem e n ted

Present Va lue R/O

Status Flags R/W N o t Implem en ted

Units R/O

Limits, Valu e , Com men t

Table 13: Analog Input Object Properties

Proprietary Object Details

BACnet® Link has the following proprietary object properties available.

MUA II Object Properties

Prope rty Read

Write

Alarm Status R/O

Application Software Version R/O

Control Status R/O

Cooling Deadband R/W 2 20

De w P o i nt R e s et L i mit R/W

Dew Point Setpoint R/W 40 80

Enthalpy Deadband R/W 3 20

Enthalpy Unit R/O 24

External Heat Position R/O

External H eat Prop or tion B an d R/W 1 30

Heating D ead ban d R/W 2 2 0

Humidity Unit R/O 29

Modu late G as V a lve Po sition R/O

Object Identifier R/O

Object Name R/W 15

Object Type R/O 258

Outdoor Air Cooling Setpoint R/O

Outdoor Air Dew Point R/O

Outdoor Air Dew Point Setpoint R/O

Outdoor Air Enthalpy R/O

Outdoo r A ir Enth alpy D e adb and R/O

Outdoor Air Enthalpy Setpoint R/O

Outdoo r A ir Hea ting Se tpoin t R/O

Outdoor Air Humidity R/O

Outdoor Air Temperature R/O

Position Un it R/O 98

Reheat Value Position R/O

Relays R/O

Schedule Force R/W 0 2

Space H um idity R/O

Space H um idity A t M a x S upp ly R/W 0 1 00

Space H um idity A t M in Su pp ly R/W 0 100

Space Te mp era ture R/O

Space Te mp era ture A t M ax Supp ly R/W 40 100

Space Te mp era ture A t M in Sup ply R /W 40 100

Supply A ir R eset L imit R/W

Supply Air Setpoint R/W 50 90

Supply A ir Setpo int M irro r R/O

Supply A ir Te m per ature R/O

Temperature Unit R/O 64

or

Limits, V alu e ,

Comment

BACnet® Link Interface

Table 14: MUA II Object Properties

21

Page 22

Technical Guide

Appendix 1

VAV/CAV Object Properties

Property Read

Write

Alarm Status R/O

Application Software Version R/O

CO2 Setpoint R/O 0 8000

Control Status R/O

Control Tem per at ure R/O

Cooling Setpoint R/O

Duct Static Pressure R/O

Duct Static Setpoint R/W 0.01 3

Economiz e r Position R/ O

Fan Speed Unit R/O 98

Heating Setpoint R/O

Humidity Unit R/O 29

Min Outside Air Setpoint R/W 1 99

Object Identifier R/O

Object Name R/W 15

Object Type R/O 257

Occupied Cooling Setpoint R/W 0 90

Occupied Heating Setpoint R/W 0 90

Outdoor Air Humidity R/O

Outdoor Air Sensor Offset R/W -10 10

Outdoor Air Temperature R/O

Outdoor Air Wetbulb R/O

Position Unit R/O 98

Relays R/O

Relief Pressure R/O

Relief Pressure Setpoint R/W -0.3 0 .3

Return Air CO2 Level R/O

Return Air Sensor Offset R/W -10 10

Return Air Temperature R/O

Schedule Force R/W 0 2

Space Sensor Offset R/ W -10 10

Space Temperature R/O

Stagint Deadband R/W 0 10

Supply Air Cooling Setpoint R/W 50 70

Supply Air Heating Setpoint R/W 0 300

Supply Air Sensor Offset R/W -10 10

Supply Air Tem per at ure R/O

Temp erature D emand R/O

Temp erature U n i t R/O 64

Unoccupied Cooling Setpoint R/W 0 30

Unoccup ied H eat ing Setpoint R/W -30 0

VFD Blower Fan R/O

VFD Exhaust Fan R/O

Warm Up Setpoint R/W 50 90

Wetbulb Setpoint R/W 0 80

or

Limits, Value,

Comment

Table 15: VAV/CAV Object Properties

CW/H W Objec t P r op e rties

Property Read

Write

Alarm Status R/O

Application Software Version R/O

CO2 Setpoin t R/W 0 8000

Cold Water Po sition R/O

Control Status R/O

Control Temperature R/O

Cooling Se tpoint R/O

Duct Static Pressure R/O

Duct Static Setpoint R/W 0.01 3

Economizer P osition R /O

Fan Speed Un it R/O 98

HCW Configuration R/W

Heating Setpoint R/O

Hot Water Pos ition R /O

Humidity Unit R/O 29

Min Outside Air Setpoint R/W 1 99

Object Identifier R /O

Object Name R/W 15

Object Type R/O 259

Occupied Cooling Setpoint R/W 0 90

Occupied Heating Setpoint R/W 0 90

Outdoor Air Humidity R/O

Outdoor Air Sensor Offset R/W -10 10

Outdoor Air Temperature R/O

Outdoor Air Wetbulb R/O

Position Unit R/O 98

Relays R/O

Relief Pressure R/O

Relief Pressure Setpoint R/W -0.3 0.3

Return Air CO 2 L eve l R/O

Return Air Sensor Offset R/W -10 10

Return Air Temperature R/O

Schedule F orce R/W 0 2

Space Sensor Offset R/W -10 10

Space Temperature R/O

Stagint Deadban d R/W 0 10

Supply Air Coo l ing S etpoin t R/W 50 7 0

Supply Air Heating Setpoint R/W 0 300

Supply Air Sensor Offset R/W -10 10

Supply Air Tem p erature R/O

Temperature D em an d R/O

Temperature U n it R/O 64

Unoccupied Cooling Setpoint R/W 0 30

Unoccupied Heating Setpoint R/W -30 0

Vfd Blower F an R/O

Vfd Exhaust Fan R/O

Warm Up Setpoint R/W 50 90

Wetbu lb Setpoint R/W 0 80

or

Li m its, Valu e,

Comment

22

Table 16: CW/HW Object Properties

BACnet® Link Interface

Page 23

Technical Guide

List Of All Property Identifiers For Proprietary Objects

Property

Identifier

1024 Alarm_Status R /O

1025 Control_Status R/O

1026 Cooling_Dea dband R/W

1027 Cooling_Setpoint R/O

1028 Control_Temperature R/O

10 29 De w_P oint_Re set_L imit R/W

1030 Dew_Point_Setpoint R/W

1031 Duct_Static_Setpoint R/W

1032 Econom izer_P osition R /O

1033 Enthalpy_De adban d R/W

1034 External_Heat_Proportion_Band R/W

10 35 Externa l _ Hea t_ Pos iti o n R /O

1036 Heating_Deadband R/W

1037 Heating_Setpoint R/O

1038 Modulate_Gas_Valve_Position R/O

1039 Occupied_Cooling_Setpoint R/W

1040 Occupied_Heating_Setpoint R/W

1041 Outdoor_Air_Cooling_Setpoint R/O

1042 Outdoor_Air_Heating_Setpoint R/O

1043 Not Used -----

1044 Not Used -----

1045 Outdoor_Air_Dew_Point R/O

1046 Outdoor_Air_Dew_Point_Setpoint R/O

1047 Outdoor_Air_Enthalpy R/O

1048 Outdoor_Air_Enthalpy_Setpoint R/O

1049 Outdoor_Air_Enthalpy_Deadband R/O

1050 Outdoor_Air_Humidity R/O

1051 Outdoor_Air_Sensor_Offset R/W

1052 Outdoor_Air_Temperature R/O

1053 Outdoor_Air_Wetbulb R/O

1054 Reheat_Value_ Position R/O

1055 Relays R/O

1056 Relief_Pressure R/O

1057 Return_A ir_Tem pe rature R/O

1058 Return_A ir_Senso r_Offset R/W

1059 Schedule_Force R/W

Property Name Read O r Write

List Of All Property Identifiers For Proprietary Objects

Property

Identifier

1060 Space_Humidity R/O

1061 Space_Hum idity_At_Ma x_Su pply R/W

1062 Space_Humidity_At_Min_Supply R/W

1063 Space_Sensor_Offset R/W

1064 Space_Temperature R /O

1065 Space_Temperature_At_Max_Supply R/W

1066 Space_Temperature_At_Min_Supply R/W

1067 Staging_Deadband R/W

1068 Supply_A ir_Co oling_ Setpo int R/W

1069 Supply_Air_Heating_Setpoint R/W

1070 Supply_Air_Reset_Limit R/W

1071 Supply_A ir_Sen sor_O ffset R/W

1072 Supply_Air_Setpoint R/W

1073 Supply_Air_Temerature R/O

1074 Temperature_Demand R/O

1075 Unoccu pied_C oo lting_Se tpoint R/W

1076 Unoccupied_Heating_Setpoint R/W

1077 Vfd_Blower_Fan R/O

1078 Vfd_Exhaust_Fan R/O

1079 Warm_Up_Setpoint R/W

1080 Wetbulb_Setpoint R/W

1081 Supply_Air_Setpoint_Mirror R/O

1082 Enthalpy_Un it R/O

1083 Fan_Speed_Unit R/O

1084 Humidity_U n it R/O

1085 Position_Unit R/O

1086 Temperature_Unit R /O

1087 Hot_Water_Position R/O

1088 Cold_Water_Position R/O

1089 Hcw_Configuration R./W

1090 Duct_Static_Pressure R/O

10 91 Min_Outs id e_Air_Setp o i n t R/W

1092 Relief_Pressure_Se tpoint R/W

1093 Return_A ir_CO 2_L eve l R/O

1094 CO2_Se tpoint R/O

Property Name Read O r Write

Table 17: List Of All Property Identifiers

BACnet® Services

Objects cannot be dynamically created or deleted by using BACnet

Services with the BACnet® Link .

BACnet® Segmented Requests

BACnet® Link does not support segmented requests.

BACnet® Segmented Responses

BACnet® Link does not support segmented responses.

BACnet® Link Interface

BACnet® Data Link Layer

®

BACnet® Link supports the following data link layer.

• Master-Slave/Token Passing (MS/TP) LAN

Data Link Protocol

• Tested with Allertons BACtalk

®

Router 200

23

Page 24

Form: OR-BACNET-TGD-02B Printed in the USA August 2005

All rights reserved Copyright 2005

WattMaster Controls Inc. • 8500 NW River Park Drive • Parkville, Mo. • 64152

Phone (816) 505-1100 www.orioncontrols.com Fax (816) 505-1101

Loading...

Loading...