Page 1

Installation and Operating Manual

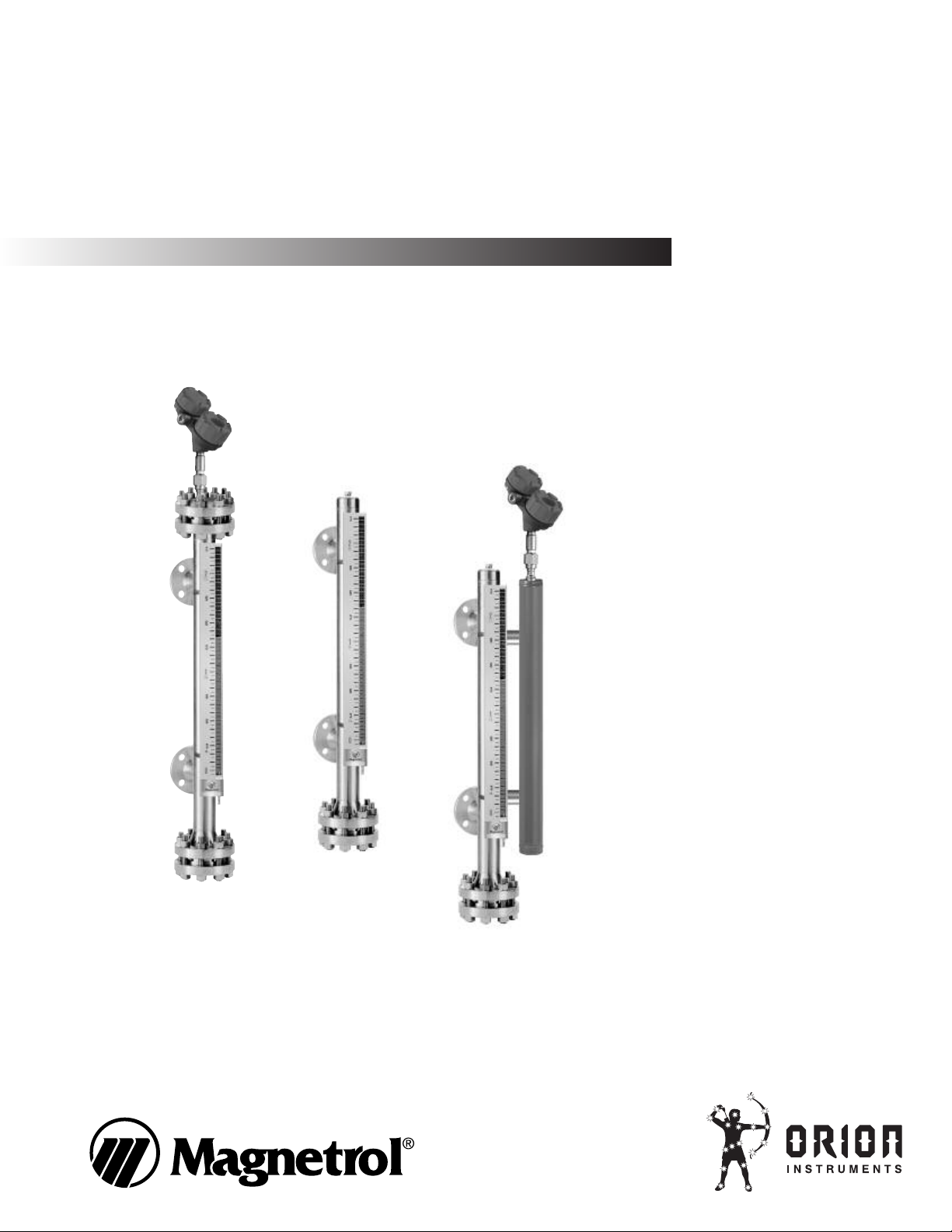

Magnetic Liquid

Level Indicators

Gauges

Switches

Transmitters

A Magnetrol Company

Page 2

Read this Manual Before Installing

his manual provides information on Magnetic Liquid

T

Level Indicators. It is important that all instructions are

read carefully and followed in sequence.

Notice of Trademark, Copyright, and Limitations

agnetrol & Magnetrol logotype, Orion Instruments,

M

Aurora, Eclipse, and Jupiter are trademarks of Magnetrol

International.

Conventions Used in this Manual

Certain conventions are used in this manual to convey

specific types of information. General technical material,

support data, and safety information are presented in

narrative form. The following styles are used for notes,

cautions, and warnings.

Notes

Notes contain information that augments or clarifies

an operating step. Notes do not normally contain

actions. They follow the procedural steps to which

they refer.

Cautions

Cautions alert the technician to special conditions that

could injure personnel, damage equipment, or reduce

a component’s mechanical integrity. Cautions are also

used to alert the technician to unsafe practices or the

need for special protective equipment or specific

materials. In this manual, a caution box indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Warnings

Warnings identify potentially dangerous situations or

serious hazards. In this manual, a warning indicates an

imminently hazardous situation which, if not avoided,

could result in serious injury or death.

Safety Messages

Follow all standard industry procedures for servicing

electrical equipment when working with or around high

voltage. Always shut off the power supply before touching any components.

WARNING! Explosion hazard. Do not connect or

disconnect equipment unless power has been switched off

or the area is known to be non-hazardous.

Low Voltage Directive

For use in Installation Category II, Pollution Degree 2.

If equipment is used in a manner not specified by the

manufacturer, protection provided by the equipment

may be impaired.

Copyright © 2010 Magnetrol International.

All rights reserved.

Performance specifications are effective with date of issue

and are subject to change without notice. Magnetrol

reserves the right to make changes to the product

described in this manual at any time without notice.

Magnetrol makes no warranty with respect to the accuracy

of the information in this manual.

Warranty

All Magnetrol/Orion mechanical level controls are

warranted free of defects in materials or workmanship for

five full years from the date of original factory shipment.

All Magnetrol/Orion electronic level controls are

warranted free of defects in materials or workmanship for

one full year from the date of original factory shipment.

If returned within the warranty period; and, upon factory

inspection of the control, the cause of the claim is

determined to be covered under the warranty; then,

Magnetrol/Orion will repair or replace the control at no

cost to the purchaser (or owner) other than transportation.

Magnetrol/Orion shall not be liable for misapplication,

labor claims, direct or consequential damage or expense

arising from the installation or use of equipment. There

are no other warranties expressed or implied, except special

written warranties covering some Magnetrol products.

Quality Assurance

The quality assurance system in place at Magnetrol guarantees the highest level of quality throughout the company. Magnetrol is committed to providing full customer

satisfaction both in quality products and quality service.

Magnetrol’s Corporate quality assurance system is registered to ISO 9001

affirming its commitment to known

international quality standards providing the strongest assurance of

product/service quality available.

Page 3

Table of Contents

Magnetic

Liquid Level Indicators

1.0 Installation

1.1 Unpacking.............................................................4

1.2 Pre-installation Checklist .......................................4

1.3 Equipment and Tools ............................................4

1.4 Side Mount Installation.........................................5

1.5 Top Mount Installation .........................................6

1.6 Top/Bottom Connection Installation.....................6

1.7 Start-up .................................................................6

1.8 Special Accessory Installation.................................7

1.8.1 Insulation or Blanket Installation................7

1.8.2 Steam Heat Tracing Installation..................8

1.8.3 Electric Heat Tracing Installation................8

1.8.3.1 Units with a fixed-point

thermostatic switch..............................8

1.8.3.2 Units with an adjustable “bulb-type”

thermostatic switch..............................9

1.9 Switch Installation ...............................................10

1.9.1 OES Cam Operated Switch......................10

1.9.1.1 Mounting to an

Atlas™or Gemini™MLI ....................10

1.9.1.2 Mounting to an Aurora®MLI ...........10

1.9.1.3 Wiring ...............................................11

1.9.2 ORS Electric Reed Switch ........................11

1.9.2.1 Mounting to an

Atlas or Gemini MLI.........................12

1.9.2.2 Mounting to an Aurora MLI .............12

1.9.2.3 Wiring ...............................................12

1.10 Analog Transmitter Installation............................13

1.10.1 OCT Reed Transmitter.............................13

1.11 Internal Electronic Transmitter Installation .........13

1.12 Internal Eclipse®Transmitter Installation.............14

2.0 Reference Information

2.1 Description..........................................................14

2.2 Theory of Operation ...........................................15

2.2.1 Side Mount...............................................15

2.2.2 Top Mount ...............................................15

2.3 Troubleshooting...................................................16

2.3.1 Side Mount...............................................16

2.3.2 Top Mount ...............................................17

2.4 Spare Parts...........................................................17

2.5 Maintenance........................................................17

2.6 Specifications.......................................................18

2.6.1 Magnetic Level Indicator ..........................18

2.6.2 Model OES Switch ...................................19

2.6.3 Model ORS Switch...................................19

2.6.4 Model OCT Analog Transmitter ..............19

2.6.5 Model 2XX Jupiter™ Magnetostrictive

Transmitter ...............................................19

2.6.6 Model 705 Eclipse Transmitter .................19

Page 4

1.0 Installation

Caution: If equipment is used in a manner not specified by manu-

acturer, protection provided by equipment may be

f

impaired.

1.1 Unpacking

Unpack the instrument carefully. Inspect all units for

damage. Report any concealed damage to carrier within

24 hours. Check the contents of the packing slip and

purchase order. Check and record the serial number for

future reference when ordering parts.

Caution: Do not discard the shipping container until all parts are

checked.

1.2 Pre-installation Checklist

1. Manually move the float from 0% to 100% to 0% prior

to start up/check out in order to reinitialize accessory

products, if so equipped. Accessories may inadvertently

change state due to rough handling in shipment.

2. Remove float prior to pressure testing tank.

Caution: Float damage will occur if not removed from chamber prior

to pressure testing the tank.

3. Verify the MLI’s center to center distance equals the

vessel’s center to center.

1.3 Equipment and Tools

• Open-end wrenches or adjustable wrench to fit the process

studs and nuts. A torque wrench is highly desirable.

• Flat-blade screwdriver

• Digital multimeter or digital volt/ammeter if transmitters

or switches are attached

• Level

• Gasket for mating flanges

• Teflon tape & “never seize” for threaded units

• Pipe wrench for threaded units

4

46-638 Magnetic Liquid Level Indicators

Page 5

1.4 Side Mount Installation

Caution: This instrument is intended for use in Installation

ategory II, Pollution Degree 2 locations.

C

NOTE: Top of gauge nameplates are available as an option.

The MLI nameplate can be used as bottom reference of

the external cage. Install the cage to the vessel with nameplate at bottom. Isolation valves are recommended for

installation between vessel and external cage. Check to

ensure the external cage is vertical. All piping should be

straight and free of “low spots” or “pockets” so that the

lower liquid connection will drain toward the external

cage. Adjust piping as required.

It is recommended a drain valve be installed in the bottom

flange to allow cleaning and checking level. Close the

isolation valves until start up.

Initial installation of the Magnetic Level Indicator is simple. Unless otherwise specified, MLIs will be shipped from

the factory fully assembled. All flanges will be torqued to

ANSI specifications. Make sure all process connections

attached to the vessel which the gauge will be mounted to

are vertically level, and flanges, if any are level.

Carefully unpack the MLI and stand it up vertically.

NOTE: Longer units require support of the entire length of the cham-

ber while being lifted in place vertically. This will prevent bowing of the chamber, that could result in glass breakage. Once

the gauge is mounted to the vessel and the liquid level rises

inside the vessel, the gauge will become operational

Isolation valves are recommended, but not required. If

isolation valves are used, care must be used when opening

the valves to prevent a surge of fluid or gases through the

chamber. A surge can cause the float to be propelled to the

far end of the chamber, and float damage could result.

Caution: If for any reason the MLI is pressurized higher than the

maximum pressure indicated on the name tag, the float

inside the chamber is subject to collapsing and causing

float failure.

NOTE: Float is shipped in chamber.

46-638 Magnetic Liquid Level Indicators

5

Page 6

1.5 Top Mount Installation

Caution: This instrument is intended for use in Installation

Category II, Pollution Degree 2 locations.

The top mount gauge can be installed as one complete

unit or disassembled to allow access from inside the tank.

Correct vertical installation is required to assure proper

float movement.

To disassemble you need only to unscrew the threaded cap

at the bottom mounting flange or connection.

Caution: Proper precautions should be taken to prevent the

bending of the guide rod.

1.6 Top/Bottom Connection Installation

Caution: This instrument is intended for use in Installation

Category II, Pollution Degree 2 locations.

Carefully unpack the MLI and stand the unit up vertically.

Note the float stop disc at the bottom flange. Note the

float stop bar (welded in place) at the top of the gauge.

This always indicates the top of gauge.

The float is shipped in the chamber.

Caution: Overall length should be ±1⁄16". Smooth float travel must be

assured by no bending of the chamber pipe.

1.7 Start-up

Increase system pressure slowly while commissioning the

instrument. Thoroughly check for leaks, and verify that

the local indicator device accurately tracks the liquid level.

Verify external accessory devices (switches, transmitter, etc.)

are functional and properly calibrated.

Caution: Do not open the bottom isolation valve quickly. Allow the

level to rise until the MLI displays the correct level in the

vessel.

6

46-638 Magnetic Liquid Level Indicators

Page 7

1.8 Special Accessory Installation

1.8.1 Insulation or Blanket Installation

Factory recommended high temperature insulation specifications:

Temperature Thickness Liner Jacket

0° to +250° F (-18° to +121° C)

+251° to +500° F (+122° to +260° C) 1" Weather resistant silicone cloth

+501° to +1000° F (+261° to +538° C) 2" Weather resistant aluminized silicone cloth

1

⁄2"

Weather resistant silicone cloth

• Thickness is1⁄2" when the MLI has switches or a transmitter.

• Insulation used is 8 lb. density ceramic blanket

• All removable insulated blankets are fastened to the MLI by

velcro and straps. Quilting pins available as an option.

• All removable insulation blankets are sewn with fire retardant

teflon thread.

• High temperature guide for the level flow gauge side mount:

Consult factory for specific temperature guide lines.

Figure 1

Low Temperature

Insulated Magnetic

Level Indicator

Factory recommended cryogenic insulation specifications:

Temperature Thickness Liner Jacket

+32° to -100° F (0° to -73° C) 2"

-101° to -320° F (-74° to -196° C) 4"

Outdoor .016 smooth aluminum Polyurethane with all

jacket with vapor barrier service jacket vapor barrier

• Purpose: To maintain the required low temperature of the

service fluid to be measured.

• All insulation joints will be staggered.

• All insulation joints will be sealed with a non-breathing

moisture resistant mastic.

• All weather resisting jacketing seams will be sealed with a

weather resistant caulk.

• The weather resistant jacket will be sealed to the 2" or 4"

plexiglass frost extension, with weather resistant caulk.

• The face of the frost extension must always be exposed.

• Cryogenic units will be flipper style indicators.

46-638 Magnetic Liquid Level Indicators

7

Page 8

Figure 2

1.8.2 Steam Heat Tracing Installation

Steam Heat Tracing is available as a factory installed

option. Steam traced units are generally supplied with a

factory installed insulation blanket (also optional).

3

Two steam connections (typically

⁄8" × 0.035" tubing)

protrude from the unit. See Figure 2. The following

installation procedure is suggested:

• Remove factory installed plastic caps from the tube ends.

• Inspect tube ends for dents and burrs. Tubing length may

be adjusted (cut), if required.

• Compressed air may be applied to either end to verify that

no foreign material exists in the tube tracing assembly.

• A suitable saturated steam source and drain should be connected. Do not exceed applicable pressure ratings for the

particular tubing size. Standard compression fittings may

be used to make the connections, and either connection

may be used as inlet or outlet.

• Apply steam to the unit and check for leaks.

Figure 3

• Contact factory or local representative for assistance, if

required.

1.8.3 Electric Heat Tracing Installation

Electric Heat Tracing is available as a factory installed

option. Electric traced units are generally supplied with a

factory installed insulation blanket (also optional).

Electrical connections are supplied, based on specific

customer requirements. Operating voltage and power

consumption will vary for each particular configuration.

More specific information is supplied with each unit,

and is also available from the factory (unit serial number

is required).

The two most common configurations are units with a

fixed-point thermostatic switch or units with an adjustable

“bulb-type” thermostatic switch.

1.8.3.1 Units with a fixed-point thermostatic switch

With a fixed-point thermostatic switch (customer specified

temperature set point), a wiring harness, or optional

junction box with terminal strip will be available to

accommodate field wiring. See Figure 3 (typical).

NOTE: It is the responsibility of the customer to comply with applica-

ble installation codes and practices. Installation should be

performed by qualified personnel.

8

46-638 Magnetic Liquid Level Indicators

Page 9

1. Locate specific power specification and wiring diagram

supplied with unit.

2. Provide appropriate conduit and wiring to the unit.

3. Apply sufficient operating power.

4. Verify that unit will generate sufficient heat and maintain

proper temperature.

NOTE: Wiring diagrams are supplied with units manufactured with

this option.

1.8.3.2 Units with an adjustable “bulb-type” thermostatic switch

With an adjustable “bulb-type” thermostatic switch, the

temperature may be preset at the factory, however field

personnel should verify this setting during installation. A

wiring harness, or optional junction box with terminal

strip will be available to accommodate field wiring.

NOTE: For supply connections, use wire with a minimum rating of

+167° F (+75° C) as required by process conditions. Use a

minimum of 14 AWG wire for power and ground field wires.

NOTE: Housing must be grounded via protective ground screw in the

base of the housing.

NOTE: It is the responsibility of the customer to comply with applica-

ble installation codes and practices. Class I, Division 1 locations may contain explosive gas mixtures. Appropriate

precautions must be taken. Installation should be performed

by qualified personnel.

1. Locate specific power specification and wiring diagram

supplied with unit.

2. Provide appropriate conduit and wiring to the unit.

3. Verify thermostat setting. Adjust, if necessary.

4. Apply sufficient operating power. Circuit breaker should

be a GFI (ground fault interrupter) type with maximum

30 mA ground leakage current trip setting. GFI should

be sized at 125% of rated load.

5. Verify that unit will generate sufficient heat and maintain

proper temperature.

NOTE: Wiring diagrams are supplied with units manufactured with

this option.

46-638 Magnetic Liquid Level Indicators

Caution: In hazardous areas, do not power the unit until the conduit

is sealed and the enclosure cover is screwed down securely.

9

Page 10

3.0 (76)

REF.

5.5 (139)

REF.

8.375 (212)

REF.

(2) 3/4" NPT

conduit connections

.5 (12)

REF.

INSTALL

THIS SIDE

UP

ORION INSTRUMENTS

FLOAT BELOW SWITCH

inches (mm)

1.9 Switch Installation

1.9.1 OES Cam Operated Switch

The Model OES snap switch is utilized to expand the control capabilities of Orion’s extensive line of magnetic level

indicators. This cam-operated double pole double throw

mechanism is clamp-mounted to the outside of the MLI.

This mounting style allows easy addition or repositioning

of switches without disruption of the process.

The OES switch(es) are pre-installed, calibrated, and

checked for proper orientation at the factory. Your unit

may be equipped with one or more switches for alarming

or control. To change the location of the switch in the

field, simply unscrew the clamp and slide the switch to a

new location. See Figure 4.

1.9.1.1 Mounting to an Atlas™or Gemini™MLI

Caution: If equipment is used in a manner not specified by the

manufacturer, protection provided by the equipment may

be impaired.

Figure 4

Contact closure is shown with the

magnetic float below the switch

Figure 5

Wiring of OES

cam operated switch

Remove the cover of the enclosure. Position the OES camoperated snap switch on the MLI body so that the centerline of the switch enclosure is at the desired switch point

level. Ensure that the switch is oriented so that the arrow

on the switch mechanism is pointing toward the top of the

MLI. Install the clamps around the MLI and over the

mounting brackets on the top and bottom of the switch

housing. Tighten the clamps so that the switch is secured

to the MLI. Replace housing cover. If required, place the

insulation between the MLI body and the switch before

tightening the clamps.

1.9.1.2 Mounting to an Aurora®MLI

The Aurora may be ordered with one or more OES clampon switches. During assembly Orion can ensure proper

function of the switches. Special care must be taken when

adding OES switches to an Aurora after initial purchase.

For proper function, the switch must be located as close to

the internal float magnet as possible. This is achieved by

marking the location of the indicator on the Aurora body.

The indicator must be rotated on the chamber so that the

switch can be positioned closest to the float. Loosen the

indicator clamps, rotate the indicator 90 degrees around the

chamber and retighten the clamps. Mount the OES switch

where the indicator was originally located. Move the float,

or move level, to verify proper operation of the switch.

10

46-638 Magnetic Liquid Level Indicators

Page 11

1.9.1.3 Wiring

The lower conduit opening is protected with a plastic

shipping plug. The upper opening is sealed with a steel

plug. If it is preferable to wire through the upper conduit

entry, the steel plug may be moved to the lower opening.

NOTE: For supply connections, use wire with a minimum rating of

+167˚ F (+75˚ C) as required by the process conditions. Use a

minimum of 14 AWG wire for power and ground field wires.

NOTE: Housing must be grounded via protective ground screw in

base of housing.

Caution: In hazardous areas, do not power the unit until the conduit

is sealed and the enclosure is screwed down securely.

The DPDT switch has two sets of contacts. See Figure 5

on page 7 and label on mechanism. To wire switch, strip

about

1

⁄2" of insulation from end of wire. Using a flat head

screwdriver or pliers, push orange tab away from the wire

opening on the terminal block. DO NOT pry up on the

orange tab as damage to the terminal block may result.

Insert wire into opening and release tab. Check that the

wire is securely fastened within the terminal block. Repeat

for balance of connections.

1.9.2 ORS Electric Reed Switch

The Model ORS reed switch is available to augment the

control capabilities of Orion’s extensive line of magnetic

level indicators. Housed in an explosion proof stainless

steel enclosure, the ORS mounts to the outside of the

MLI via clamps. This mounting style allows addition or

repositioning of switches at any time, without disruption

of the process.

The ORS switch(es) are pre-installed, calibrated, and

checked for proper orientation at the factory. Your unit

may be equipped with one or more switches for alarming

or control. To change the location of the switch in the

field, simply unscrew the clamp and slide the switch to a

new location.

46-638 Magnetic Liquid Level Indicators

11

Page 12

FLOAT ABOVE SWITCH

FLOAT BELOW SWITCH

1 (RED)

C

(WHITE)

C (WHITE)

2 (BLACK)

1 (RED)

2 (BLACK)

8-32 Ground Screw

3.00

(76.2)

3.00

(76.2)

1/2"

MNPT

1.00

(25.4)

0.84

(21.3)

inches (mm)

1.9.2.1 Mounting to an Atlas or Gemini MLI

aution: If equipment is used in a manner not specified by the

C

manufacturer, protection provided by the equipment may

be impaired.

With mounting clamps loosened, position ORS reed

switch on the MLI body so that the centerline of the stainless steel tube which houses the switch is at the desired

switch point level. The switch should be oriented so that

the green ground screw is closest to the top of the MLI.

See Figure 8. Tighten the clamps so that the switch is

secured to the MLI. If required, place the insulation

between the MLI body and the switch before tightening

the clamps.

Figure 8

Figure 9

Wiring of ORS

Reed Switch

Contact closure shown for

both conditions of the switch

relative to the magnetic float

1.9.2.2 Mounting to an Aurora MLI

Follow procedure for mounting to Atlas or Gemini, but

ensure that the switch is positioned on the circumference

of the Aurora body as close to the indicator as possible.

1.9.2.3 Wiring

The leads protruding from the potted end of the switch

housing are color coded as follows:

White = Common

Black = Normally Closed

Red = Normally Open

NOTE: For supply connections, use wire with a minimum rating of

+167° F (+75° C) as required by the process conditions. Use a

minimum of 14 AWG wire for power and ground field wires.

NOTE: Housing must be grounded via protective ground screw on

upper mounting tab.

12

46-638 Magnetic Liquid Level Indicators

Page 13

4.0 (102) REF.

Inactive length

XXX = Span

active length

3.8 (140)

REF.

3.5 (90)

REF.

4.5 (115)

REF.

0.4 (10) REF.

Label bracket

3/4" NPT

conduit

connection

red

yellow

black

Resistor

Chain

Reed

Switch

inches (mm)

Figure 10

1.10 Analog Transmitter Installation

1.10.1 OCT Reed Transmitter

The OCT analog transmitter mounts directly to the side

of the Atlas or Gemini chamber, providing a continuous

4–20 mA output signal proportional to liquid level. Using

simple and reliable reed switches surface mounted to a

printed circuit board, the unit provides level accuracy of

±0.50" (13 mm).

The OCT reed transmitter is shipped attached to the MLI

gauge and is precalibrated to the customer specified span.

See Figure 10. Refer to Figure 11 for wire terminations for

the OCT.

Installation is simplified by utilizing gear clamps that can

be repositioned with a screw driver.

Caution: If the MLI is insulated, the analog transmitter probe must be

located outside of the insulation blanket.

NOTE: For supply connections, use wire with a minimum rating of

+167° F (+75° C) as required by process conditions. Use a

minimum of 14 AWG wire for power and ground field wires.

black: common connection of reed contacts

yellow: upper end of the resistor chain

red: lower end of the resistor chain

46-638 Magnetic Liquid Level Indicators

Figure 11

NOTE: Housing must be grounded via protective ground screw in the

base of the housing.

NOTE: It is the responsibility of the customer to comply with applicable

installation codes and practices. Class I, Division 1 locations

may contain explosive gas mixtures. Appropriate precautions

must be taken. Installation should be performed by qualified

personnel.

Caution: In hazardous areas, do not power the unit until the conduit

is sealed and the enclosure cover is screwed down securely.

1.11 Internal Electronic Transmitter Installation

The Gemini Model enables the customer to install several

different types of either continuous measuring instruments

(transmitters) or point level control devices (switches). The

electronic instrument is installed in the 2" or 3" secondary

chamber of the Gemini MLI. The factory should be consulted for these applications to review operating parameters

and to ensure that the desired instrument is properly

applied.

As the electronic instrument is supplied separately from

the Gemini MLI, the instruction manual for the electronic

unit should be carefully reviewed prior to installation in

the chamber. The instruction manual will be shipped with

the instrument.

13

Page 14

1.12 Internal Eclipse Transmitter Installation

The Eclipse Guided Wave Radar Transmitter can be

mounted in either the Gemini or the Aurora MLIs. The

Aurora is designed to support operation of the Eclipse in

the same chamber as the float. Due to this, the coaxial

type probe must be used. With the dual chamber Gemini

design, either the twin rod, coaxial, or single rod types

may be used. Caution should be exercised in probe selection to take into account, media dielectric, viscosity, temperature, pressure, transition zone distances and overfill

requirements. Each Eclipse will be supplied complete with

an instruction manual. A review of the manual is recommended prior to installation of the Eclipse transmitter in

the Gemini or Aurora MLI.

NOTE: Flag or shuttle indicator can be designed for mounting at any

angle. Do not rotate indicator after gauge is manufactured,

due to inability to rotate baffle plate once welding has been

completed.

2.0 Reference Information

2.1 Description

Magnetic Level Indicators (MLIs) are suitable for installation on process applications that will not restrict float travel

in the piping column. It is a magnetic coupled, local level

indicator which is isolated from the process in a sealed

non-magnetic external cage. Bi-color flags provide visual

indication of level up to 100 feet. Field-adjustable level

switches and transmitters are available as options.

The Atlas is a magnetically coupled local level indicator

isolated from the process via a sealed non-magnetic external chamber. A fluorescent orange shuttle or series of bicolored flags provide visual indication of liquid level from

distances of up to 100 feet. Available switches for point

alarms include electronic DPDT, reed and pneumatic

technologies. Transmitter technologies for continuous

4–20 mA outputs include reed and guided wave radar.

Atlas is suitable for installation on process applications

including corrosive services that do not impede the movement of the float in the piping column.

14

Aurora and Gemini incorporate a combination of the

Atlas magnetic level gauge and Magnetrol’s Eclipse

Guided Wave Radar. This represents the industries first

totally redundant mag gauge/transmitter combination.

46-638 Magnetic Liquid Level Indicators

Page 15

Local indication, 4–20 mA output, HART and Fieldbus

Stainless steel

chamber wall

Float

magnets

Liquid

level

Float

Flux ring

Indicating

flags

Flux

ring

Magnet

spacer

protocols are available. Float damage will not result in loss

of the 4–20 mA signal

Aurora: The Eclipse Guided Wave Radar probe is mounted directly inside of the Gemini chamber. a minimum

3" chamber is utilized to accommodate the Eclipse probe

and allow unobstructed float travel. Patent pending.

Gemini: The dual chamber approach also accomplishes

total redundancy but increases the ease of gauge or transmitter isolation. The Atlas gauge provides local indication

while the Eclipse is mounted directly inside a connected

second chamber. The units perform independently of

each other.

2.2 Theory of Operation

2.2.1 Side Mount

A float equipped with a strong magnet assembly inside and

weighted to the specific gravity of the fluid to be measured,

moves up and down in a non-magnetic chamber, as the

fluid inside rises and falls with the level of the liquid in

the vessel.

Figure 12

Figure 13

Attached to the external wall of the non-magnetic chamber

is a non-porous glass tube. Inside this hermetically sealed

glass tube is a highly visible fluorescent orange indicator or

flags with a strong magnetic assembly inside. See Figures

12 and 13.

The indicator is always coupled to the float magnetically,

to indicate the exact measurement of the fluid.

2.2.2 Top Mount

A top mounted float assembly consisting of a magnet

assembly at the top, a guide rod in the middle, and a float

at the bottom. The float at the bottom is submerged in the

liquid inside the vessel. The entire guide rod assembly is

weighted to the specific gravity of the fluid to be measured.

Attached to the external wall of the non-magnetic chamber

is a non-porous glass tube. Inside this hermetically sealed

glass tube is a highly visible fluorescent orange indicator or

flags with a strong magnetic assembly inside. See Figures

12 and 13.

The indicator or flags are always coupled to the magnetic

assembly, to indicate the exact measurement of the fluid.

46-638 Magnetic Liquid Level Indicators

15

Page 16

2.3 Troubleshooting

2.3.1 Side Mount

Problem Solution

Flags do not rotate with level change. Test flags with a magnet from bottom to top (magnet not

ncluded). If flags test okay, check for float obstruction.

i

(See Section 2.5, Maintenance on page 16)

Flags rotate at different height than actual level. Float selected for different specific gravity. Replace float with

a float with correct specific gravity rating. Confirm correctness

of float orientation. Top is up.

Float inside the level gauge is moving Make sure the MLI is level vertically.

slow or not at all.

The process fluid being measured may be too viscous and

heat tracing may be required to make the material more fluid.

Heat tracing can be purchased from the factory.

The specific gravity of the process fluid and the float weight

may need to be reverified.

The liquid being measured may contain magnetic particles

collecting on the magnetic section of the float causing drag.

If this happens, magnetic trap assemblies can be purchased

from the factory.

Visual inspection of the float may be required to see if the float

has collapsed.

Switch does not actuate with level change. Check micro switch for continuity. Replace if damaged. If

okay, remove switch from piping column and test switch magnet assembly with re-alignment magnet, by moving magnet

over the housing face. If the switch magnet assembly fails to

respond, replace the switch. If the switch tests okay, check

float travel.

Reed transmitter does not track level. Remove transmitter assembly from piping column and test

with re-alignment magnet. Run magnet from bottom to top of

reed chain. Check zero and span calibration. If no change in

output, replace.

Scale is at zero to the center of the bottom The scale assembly is mounted to the chamber using stainless

process connection, but the indicator is above steel gear clamps. It can be easily adjusted in the field using a

or below zero. screwdriver. Make sure the scale zero is in line with the center

of the process connection.

The float stop spring at each end of the chamber is there to

cushion as well as position the float assembly to the center of

the process connection. Make sure top or bottom float stop

springs are not bent or broken.

Shuttle indicator has uncoupled and In some “flashing” applications, the float may rise or fall quickly.

fallen to the bottom of the glass tube. Consult factory for suggestions to help avoid this.

To re-couple the indicator to the float, simply use a small magnet and run it along the length of the chamber to locate the

float. Mark the location of the float on the outside chamber.

Use the small magnet to couple with the indicator and pull the

indicator up to meet and couple with the float.

16

Make sure all stainless steel gear clamps are tight. The scale

channel must be tight against the chamber.

NOTE: Ensure unit installation is level.

46-638 Magnetic Liquid Level Indicators

Page 17

2.3.2 Top Mount

Problem Solution

The float assembly or visual indicator is Make sure the vessel opening or flange connection that the to

moving slowly or not at all. mount flange connects to is level.

he top mount guide rod assembly may be bent. Visual inspec-

T

tion is required.

The process fluid in the vessel may be too viscous, Heating the

vessel to make the process fluid more liquid may be required.

The specific gravity of the process fluid and the float may need

to be reverified.

Visual inspection of the float inside the process fluid may be

required to see if the float has collapsed.

My scale is at the center of the zero mark on The scale assembly is mounted to the chamber using stainless

the outside of the top mount chamber but steel gear clamps. It can be easily adjusted in the field using a

the indicator is above or below zero. screwdriver. Make sure the scale zero is in line with the zero

mark on the outside of the top mount chamber.

The float stop spring at the top of the chamber is there to cushion the magnet assembly. Make sure the bottom float stop tube

is not bent or broken

The float stop tube is at the bottom inside the chamber. It is

there to stop the magnet assembly at the zero mark on the outside of the chamber

2.4 Spare Parts

Spare parts are available for Magnetrol/Orion MLIs and

certain switches and transmitters. Please consult the factory.

Have the unit model number and serial number available

for reference.

2.5 Maintenance

Periodic inspections are a necessary means to keep your

level control in good working order. This control is a safety

device to protect the valuable equipment it serves.

If the process liquid is clean (no solids or deposits), the

MLI should require minimum maintenance. If the process

liquid is dirty (solids and deposits), it is recommended the

external cage be isolated from the process and flushed periodically. For complete cleaning, after draining the unit,

remove the bottom flange and float, inspect cage and float

for buildup and clean if required.

46-638 Magnetic Liquid Level Indicators

Magnetic traps are available to prevent magnetic particulate travel from the vessel to the chamber.

17

Page 18

2.6 Specifications

2.6.1 Magnetic Level Indicator

Design Atlas and Aurora – single chamber

Gemini – dual chamber

Materials of construction – MLI Metal alloys 316/316L or 304/304L stainless steel,

321 stainless steel, 347 stainless steel,

Titanium, Monel, Hastelloy B,

Hastelloy C-276, Inconel 625, Inconel 825,

Alloy 20, Electropolished 316 stainless steel,

904L stainless steel and other non-magnetic alloys

Plastics Fiberglass, PVC, CPVC, kynar, polypropylene

Materials of construction – Float Same as chamber materials, 316 SS or titanium standard

Construction options Conformance to ASME B31.1, ASME B31.3 or NACE MR0175

available

Certified material test reports (CMTR) Available upon request

Pressure class ratings ANSI 150#, 300#, 600#, 900#, 1500#, 2500#

DIN PN16, PN25/40, PN64, PN100, PN160, PN250, PN320

Process connection sizes

Process connection types MNPT, FNPT, weldolet®, sockolet®, threaded couplings,

Measuring range 12 to 600 inch (30 to 1524 centimeters) standard

Temperature range -320° to +1000° F (-196° to +538° C)

Pressure range Full vacuum to 4500 psig (310 bar)

Specific gravity range As low as 0.35 S.G.U.

Indicators Magnetically actuated flag assembly in contrasting orange/black,

Flag assembly seal Inert gas filled and hermetically sealed with Insta-seal valve

Visual indication Easily visible from 75 to 100 feet (23 to 30 meters)

Scale options Etched stainless steel with either height, volume, or

Switch options Model OES electric cam operated snap action

Transmitter options Model 705 Eclipse Guided Wave Radar

High temperature options Electric or steam tracing with or without special high

Low temperature options Cryogenic insulation with special polymeric frost extension

1

⁄2" to 8"

DN 20 to DN 150

threaded nipples, buttweld nipples, plain-end nipples,

slip-on flanges, weldneck flanges, lap joint flanges,

tri-clamp fitting, Van Stone flanges

Consult factory for lengths over 600 inch (50 feet)

yellow/black, red/white colors, or high visibility shuttle follower

percentage units

Model ORS electric reed type

Model 2xx Jupiter Magnetostrictive

Model OCT analog reed chain

temperature insulation

18

46-638 Magnetic Liquid Level Indicators

Page 19

2.6.2 Model OES Switch

• Electric snap action switch

• 10 amp DPDT

• ±0.75" (19 mm) float travel

• -58° to +392° F (-50° to +200° C)

• Cast aluminum enclosure, (2)1⁄2" NPT conduit entries

See bulletin OES for further information

2.6.3 Model ORS Switch

• Electric reed switch, hermetically sealed

• 1 amp SPDT

• Stainless steel enclosure with mounting tabs

• ±0.5" (13 mm) float travel

• -58° to +482° F (-50° to +250° C)

• Stainless steel enclosure with mounting tabs

See bulletin ORS for further information

2.6.4 Model OCT Analog Transmitter

Power: 24 VDC

Maximum Range: Up to 20 feet standard

(Consult factory for longer lengths)

Accuracy: ±0.5" (13 mm)

Output: 4–20 mA

Temperature range: -40° to +500° F (-40° to +260°C)

See bulletin OCT for further information

2.6.5 Model 2XX Jupiter™Magnetostrictive Transmitter

Power: 24 VDC

Maximum Range: Up to 35 feet (10.67 meters)

Accuracy: ±0.015" (0.38 mm)

Output: 4–20 mA (HART optional)

Temperature range: -40° to +175° F (-40° to +79°C)

See bulletin ORI-148 for further information

2.6.6 Model 705 Eclipse Transmitter

See bulletin 57-101 for details

46-638 Magnetic Liquid Level Indicators

19

Page 20

ASSURED QUALITY & SERVICE COST LESS

5300 B elmont Roa d • D owners Grov e, Il linois 605 15-4499 • 6 30-969 -4000 • F ax 630 -969-9489 • www.ma gnetro l.com

145 Ja rdin Dr ive, Unit s 1 & 2 • Conc ord, O ntario Can ada L 4K 1X7 • 9 05-738-9600 • F ax 905-738- 1306

Heiken sstraa t 6 • B 9 240 Ze le, Belgium • 0 52 45. 11.11 • F ax 052 45. 09.93

Regent Bus iness Ctr., Ju bilee Rd. • Bu rgess Hil l, Sus sex RH15 9T L U.K. • 01444-8713 13 • F ax 01 444-87 1317

6646 C omplex Dri ve • Bato n Roug e, Louisian a 7080 9 • 2 25-906 -2343 • Fax 225 -906-2 344 • www.or ioninstrume nts.co m

Copyright © 2010 Magnetrol International, Incorporated. All rights reserved. Printed in the USA.

Service Policy

Owners of Magnetrol/Orion Instruments controls may

request the return of a or any part of an instrument for

complete rebuilding or replacement. They will be rebuilt

or replaced promptly. Instruments returned under our

service policy must be returned by prepaid transportation. Magnetrol will repair or replace the control at no

cost to the purchaser (or owner) other than transportation if:

1. Returned within the warranty period; and

2. The factory inspection finds the cause of the claim

to be covered under the warranty.

If the trouble is the result of conditions beyond our

control; or, is NOT covered by the warranty, there will

be charges for labor and the parts required to rebuild or

replace the equipment.

In some cases it may be expedient to ship replacement

parts; or, in extreme cases a complete new instrument,

to replace the original equipment before it is returned. If

this is desired, notify the factory of both the model and

serial numbers of the instrument to be replaced. In such

cases, credit for the materials returned will be determined on the basis of the applicability of our warranty.

Return Material Procedure

So that we may efficiently process any materials that are

returned, it is essential that a “Return Material

Authorization” (RMA) number be obtained from the

factory, prior to the material's return. This is available

through Magnetrol’s local representative or by contacting the factory. Please supply the following information:

1. Company Name

2. Description of Material

3. Serial Number

4. Reason for Return

5. Application

Any unit that was used in a process must be properly

cleaned in accordance with OSHA standards, before it is

returned to the factory.

A Material Safety Data Sheet (MSDS) must accompany

material that was used in any media.

All shipments returned to the factory must be by prepaid transportation.

All replacements will be shipped F.O.B. factory.

No claims for misapplication, labor, direct or consequential damage will be allowed.

Viton® is a registered trademark of DuPont Performance Elastomers.

BULLETIN: 46-638.5

EFFECTIVE: August 2010

SUPERSEDES: August 2004

Loading...

Loading...