Page 1

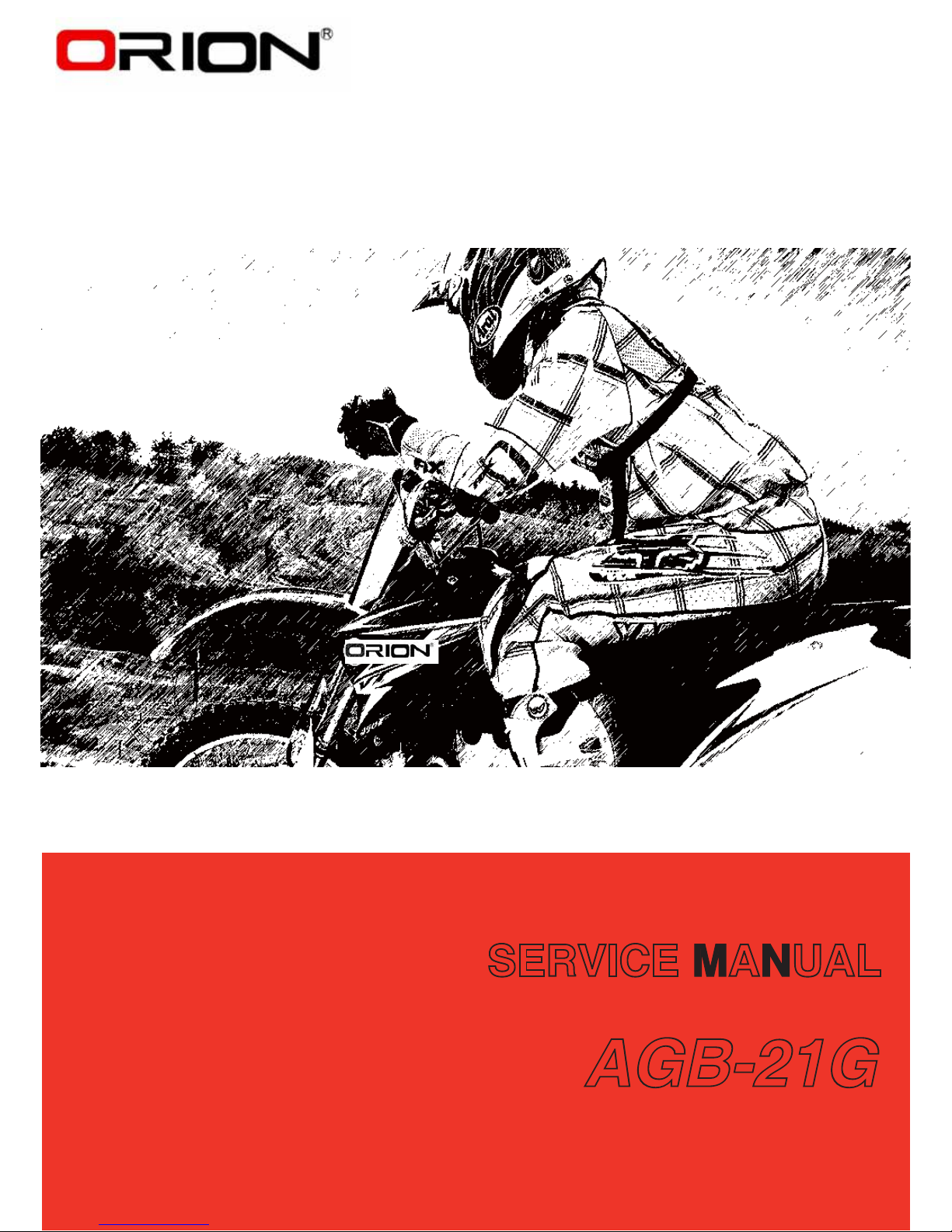

AGB-21G

SERVICE MANUAL

Page 2

Page 3

Congratulations on your purchase of an

Apollo AGB-21G.

127(

As improvements are made on this model,

some data in this manual may become out-

dated. If you have any questions, please con-

sult your dealer.

WARNING

PLEASE READ THIS MANUAL CAREFULLY

AND COMPLETELY BEFORE OPERATING

THIS MACHINE. DO NOT ATTEMPT TO

OPERATE THIS MACHINE UNTIL YOU

HAVE ATTAINED A SATISFACTORY

KNOWLEDGE OF ITS CONTROLS AND

OPERATING FEATURES AND UNTIL YOU

HAVE BEEN TRAINED IN SAFE AND

PROPER RIDING TECHNIQUES. REGULAR

INSPECTIONS AND CAREFUL MAINTENANCE, ALONG WITH GOOD RIDING

SKILLS, WILL ENSURE THAT YOU SAFETY

ENJOY THE CAPABILITIES AND THE RELIABILITY OF THIS MACHINE.

IMPORTANT NOTICE

THIS MACHINE IS DESIGNED STRICTLY

FOR COMPETITION USE, ONLY ON A

CLOSED COURSE. It is illegal for this

machine to be operated on any public street,

road, or highway. Off-road use on public lands

may also be illegal. Please check local regulations before riding.

1. THIS MACHINE IS TO BE OPERATED

BY AN EXPERIENCED RIDER ONLY.

Do not attempt to operate this

machine at maximum power until you

are totally familiar with its characteristics.

2. THIS MACHINE IS DESIGNED TO BE

RIDDEN BY THE OPERATOR ONLY.

Do not carry passengers on this

machine.

3. ALWAYS WEAR PROTECTIVE

APPAREL.

When operating this machine, always

wear an approved helmet with goggles or a face shield. Also wear heavy

boots, gloves, and protective clothing. Always wear proper fitting clothing that will not be caught in any of

the moving parts or controls of the

machine.

4. ALWAYS MAINTAIN YOUR MACHINE

IN PROPER WORKING ORDER.

For safety and reliability, the machine

must be properly maintained. Always

perform the pre-operation checks

indicated in this manual. Correcting a

mechanical problem before you ride

may prevent an accident.

5. GASOLINE IS HIGHLY FLAMMABLE.

Always turn off the engine while refueling. Take care to not spill any gasoline on the engine or exhaust system.

Never refuel in the vicinity of an open

flame, or while smoking.

SAFETY INFORMATION

II

INTRODUCTION

Page 4

6. GASOLINE CAN CAUSE INJURY.

If you should swallow some gasoline,

inhale excess gasoline vapors, or

allow any gasoline to get into your

eyes, contact a doctor immediately. If

any gasoline spills onto your skin or

clothing, immediately wash skin areas

with soap and water, and change your

clothes.

7. ONLY OPERATE THE MACHINE IN AN

AREA WITH ADEQUATE VENTILATION.

Never start the engine or let it run for

any length of time in an enclosed area.

Exhaust fumes are poisonous. These

fumes contain carbon monoxide,

which by itself is odorless and colorless. Carbon monoxide is a dangerous

gas which can cause unconsciousness or can be lethal.

8. PARK THE MACHINE CAREFULLY;

TURN OFF THE ENGINE.

Always turn off the engine if you are

going to leave the machine. Do not

park the machine on a slope or soft

ground as it may fall over.

9. THE ENGINE, EXHAUST PIPE, MUFFLER, AND OIL TANK WILL BE VERY

HOT AFTER THE ENGINE HAS BEEN

RUN.

Be careful not to touch them or to

allow any clothing item to contact

them during inspection or repair.

10. PROPERLY SECURE THE MACHINE

BEFORE TRANSPORTING IT.

When transporting the machine in

another vehicle, always be sure it is

properly secured and in an upright

position and that the fuel cock is in

the “ OFF ” position. Otherwise, fuel

may leak out of the carburetor or fuel

tank.

Page 5

TO THE NEW OWNER

This manual will provide you with a good basic

understanding of features, operation, and

basic maintenance and inspection items of this

machine. Please read this manual carefully

and completely before operating your new

machine. If you have any questions regarding

the operation or maintenance of your machine,

please consult your dealer.

NOTE:

This manual should be considered a permanent part of this machine and should remain

with it even if the machine is subsequently

sold.

NOTICE

Some data in this manual may become outdated due to improvements made to this

model in the future. If there is any question

you have regarding this manual or your

machine, please consult your dealer.

F.I.M. MACHINE WEIGHTS:

Weights of machines without fuel

The minimum weights for motocross

machines are:

for the class 125cc.......................minimum

64 kg

In modifying your machine (e.g., for weight

reduction), take note of the above limits of

weight.

HOW TO USE

THIS MANUAL

PARTICULARLY IMPORTANT

INFORMATION

The Safety Alert Symbol means ATTENTION!

BECOME ALERT! YOUR SAFETY IS

INVOLVED!

Failure to follow WARNING instructions could

result in severe injury or death to the machine

operator, a bystander, or a person inspecting

or repairing the machine.

A CAUTION indicates special precautions that

must be taken to avoid damage to the

machine.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

WARNING

CAUTION:

MANUAL FORMAT

All of the procedures in this manual are organized

in a sequential, step-by-step format. The information has been complied to provide the mechanic

with an easy to read, handy reference that contains

comprehensive explanations of all disassembly,

repair, assembly, and inspection operations.

In this revised format, the condition of a faulty

component will precede an arrow symbol and the

course of action required will follow the symbol, e.g.,

Bearings

Pitting/damage → Replace.

Page 6

INDEX

GENERAL INFORMATION

1

SPECIFICATIONS

2

REGULAR INSPECTION AND ADJUSTMENTS

ENGINE

CHASSIS

ELECTRICAL

3

4

5

6

7

Page 7

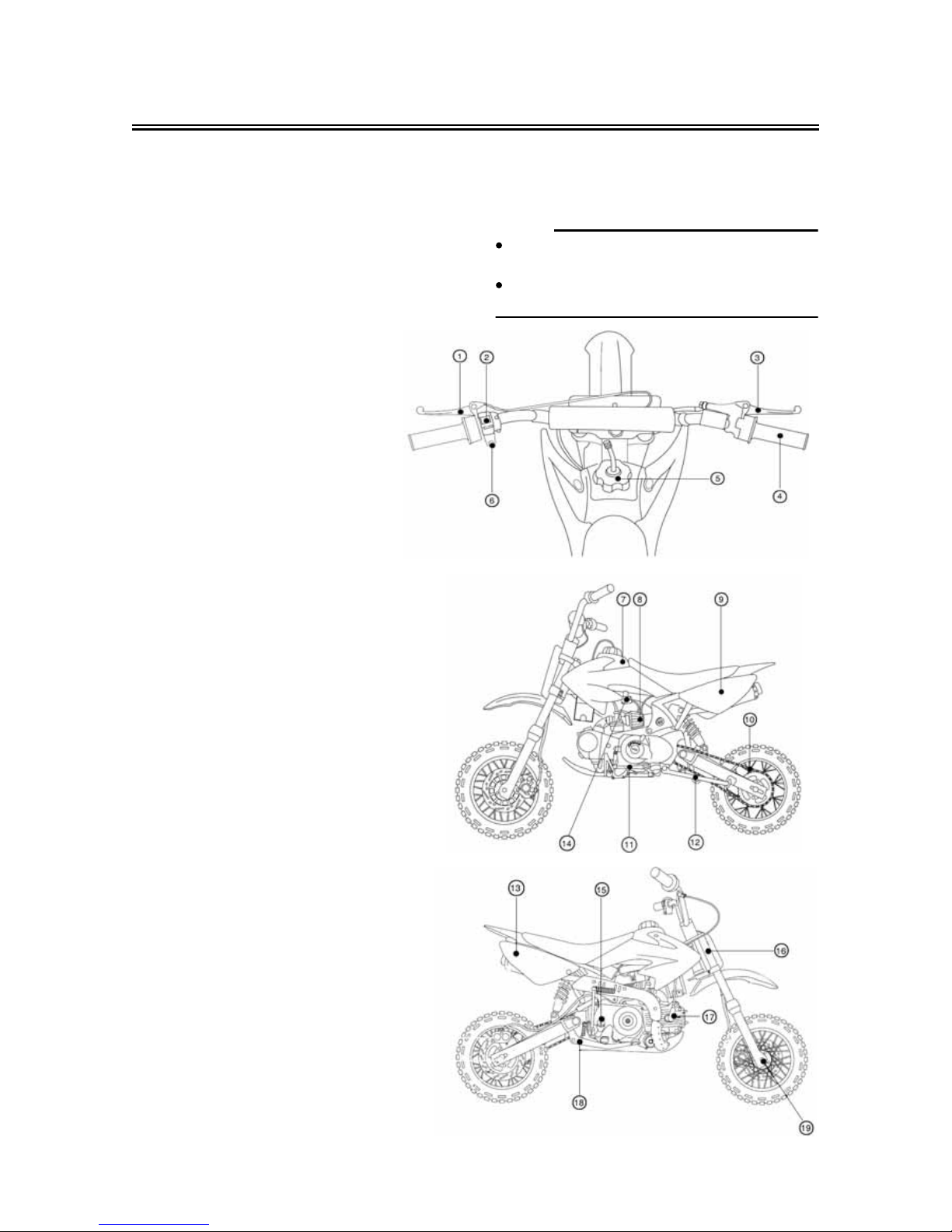

1 - 1

DESCRIPTION

GENERAL INFORMATION

DESCRIPTION

2 Clutch lever

3 Engine stop switch

4 Front brake lever

5 Throttle grip

6 Fuel tank cap

7 Engine start switch

8

9

:

Fuel tank

21

Air filter

22

Left side cover

23

Drive chain

24

Shift pedal

25

Side stand

26

Fuel cock

27

Spark plug

28

Right side cover

29

Kick starter cank

2:

Front fork

NOTE:

The machine you have purchased may differ

slightly from those shown in the following.

Designs and specifications are subject to

change without notice.

Rear brake pedal

Front axle

Page 8

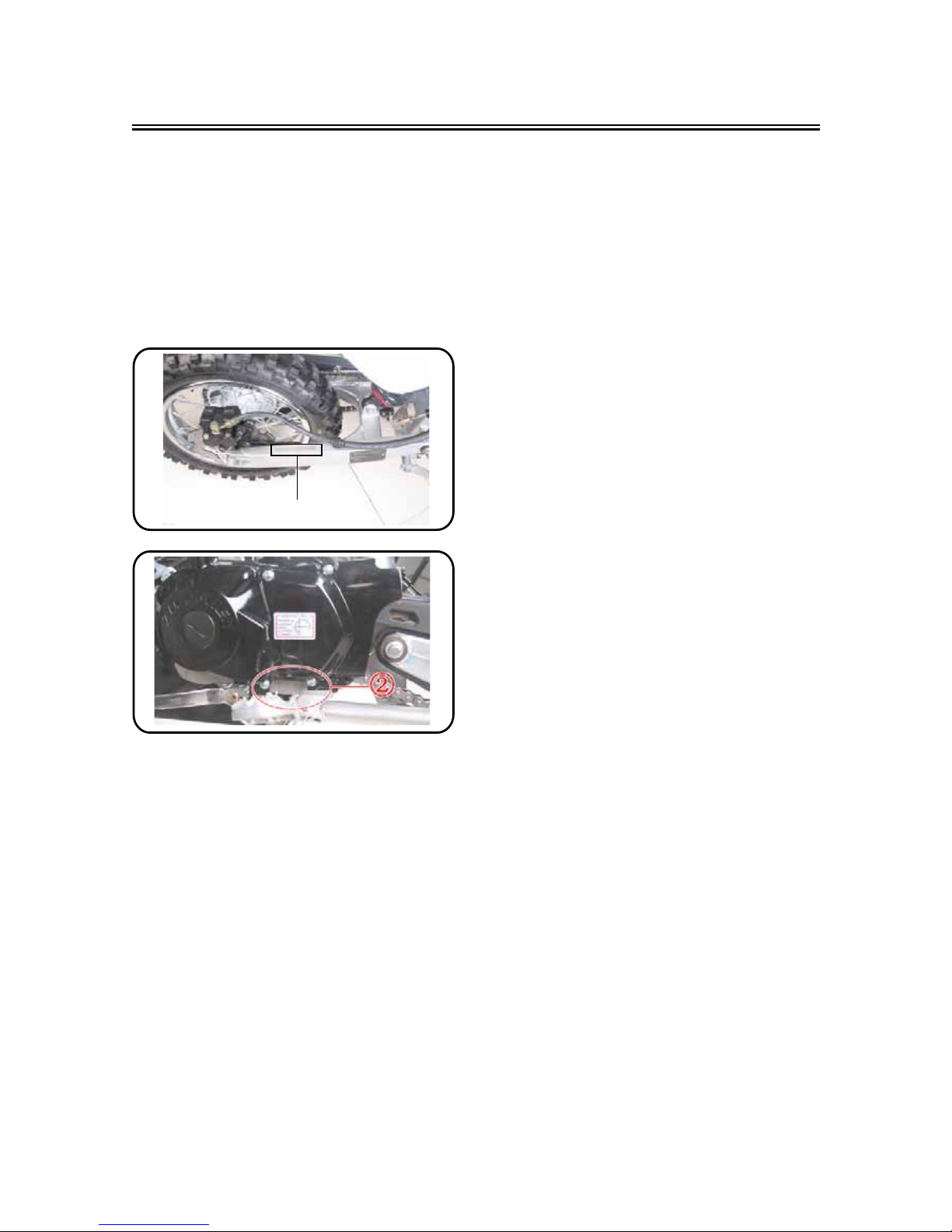

1 - 2

MACHINE IDENTIFICATION

MACHINE IDENTIFICATION

There are two significant reasons for knowing

the serial number of your machine:

1. When ordering parts, you can give the

number to your dealer for positive

identification of the model you own.

2. If your machine is stolen, the authorities

will need the number to search for and

identify your machine.

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number ① is

stamped on the right of the steering head pipe.

ENGINE SERIAL NUMBER

The engine serial number ② is stamped into

the elevated part of the right-side of the

engine.

ķ

Page 9

1 - 3

IMPORTANT INFORMATION

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND

DISASSEMBLY

1. Remove all dirt, mud, dust, and foreign

material before removal and disassembly.

When washing the machine with high

pressured water, cover the parts follows.

Silencer exhaust port

Side cover air intake port

2. Use proper tools and cleaning equipment. Refer to “SPECIAL TOOLS” section.

3. When disassembling the machine, keep

mated parts together. They include

gears, cylinders, pistons, and other

mated parts that have been “mated”

through normal wear. Mated parts must

be reused as an assembly or replaced.

4. During the machine disassembly, clean

all parts and place them in trays in the

order of disassembly. This will speed up

assembly time and help assure that all

parts are correctly reinstalled.

5. Keep away from fire.

Page 10

1 - 4

IMPORTANT INFORMATION

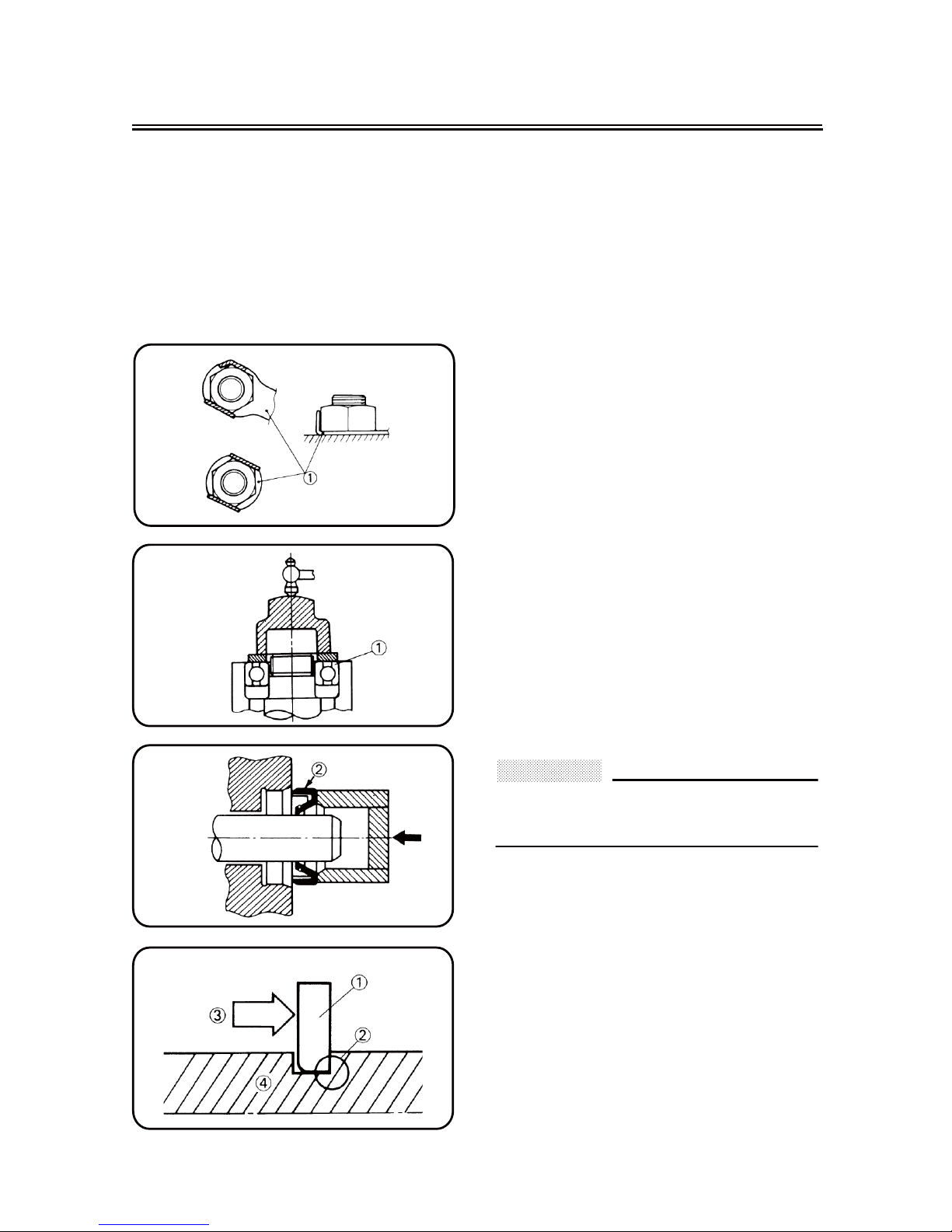

GASKETS, OIL SEALS AND O-RINGS

1. All gaskets, oil seals, and O-rings should

be replaced when an engine is overhauled. All gasket surfaces, oil seal lips,

and O-rings must be cleaned.

2. Properly oil all mating parts and bearings

during reassembly. Apply grease to the

oil seal lips.

LOCK WASHERS/PLATES AND COTTER

PINS

1. All lock washers/plates ① and cotter pins

must be replaced when they are

removed. Lock tab(s) should be bent

along the bolt or nut flat(s) after the bolt

or nut has been properly tightened.

BEARINGS AND OIL SEALS

1. Install the bearing(s) ① and oil seal(s) ②

with their manufacturer’s marks or numbers facing outward. (In other words, the

stamped letters must be on the side

exposed to view.) When installing oil

seal(s), apply a light coating of lightweight lithium base grease to the seal

lip(s). Oil the bearings liberally when

installing.

CAUTION:

Do not use compressed air to spin the

bearings dry. This causes damage to the

bearing surfaces.

CIRCLIPS

1. All circlips should be inspected carefully

before reassembly. Always replace piston pin clips after one use. Replace distorted circlips. When installing a circlip

①, make sure that the sharp-edged cor-

ner ② is positioned opposite to the thrust

③ it receives. See the sectional view.

④ Shaft

Page 11

1 - 5

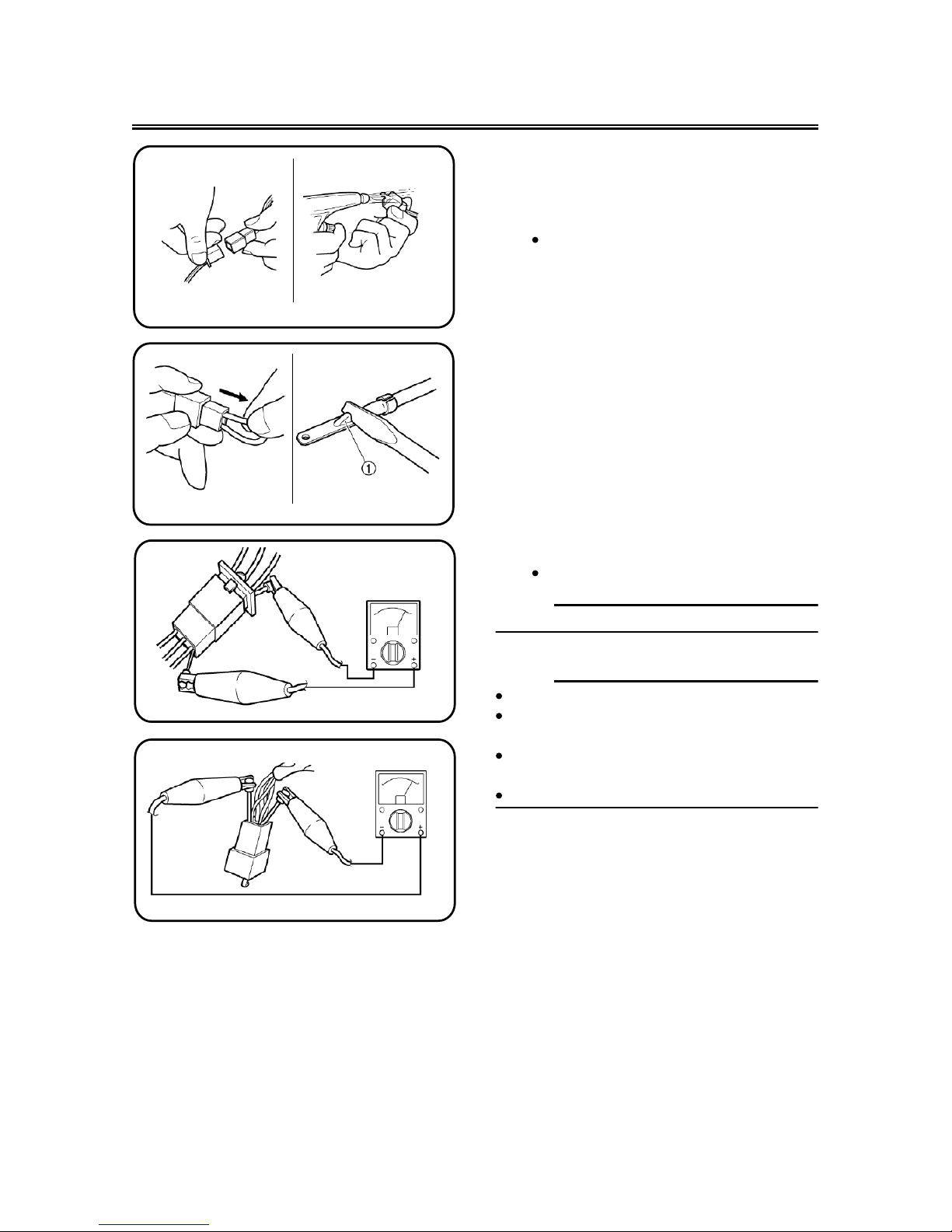

CHECKING OF CONNECTION

CHECKING OF CONNECTION

Dealing with stains, rust, moisture, etc. on the

connector.

1. Disconnect:

Connector

2. Dry each terminal with an air blower.

3. Connect and disconnect the connector

two or three times.

4. Pull the lead to check that it will not come

off.

5. If the terminal comes off, bend up the pin

① and reinsert the terminal into the con-

nector.

6. Connect:

Connector

NOTE:

The two connectors “click” together.

7. Check for continuity with a tester.

NOTE:

If there in no continuity, clean the terminals.

Be sure to perform the steps 1 to 7 listed

above when checking the wireharness.

For a field remedy, use a contact revitalizer

available on the market.

Use the tester on the connector as shown.

Page 12

1 - 6

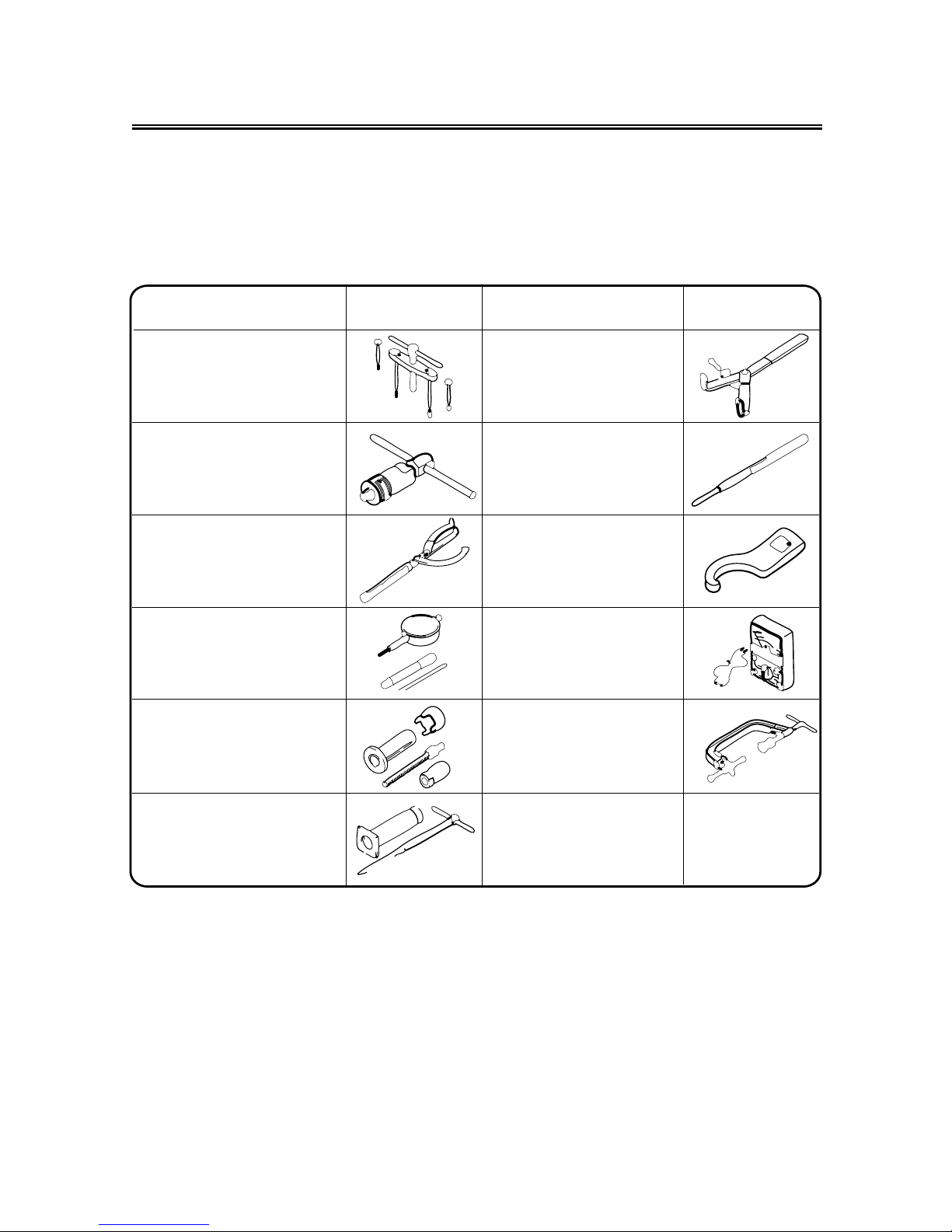

SPECIAL TOOLS

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the

correct special tool will help prevent damage caused by the use of improper tools or improvised

techniques. The shape and part number used for the special tool differ by country, so two types are

provided. Refer to the list provided to avoid errors when placing an order.

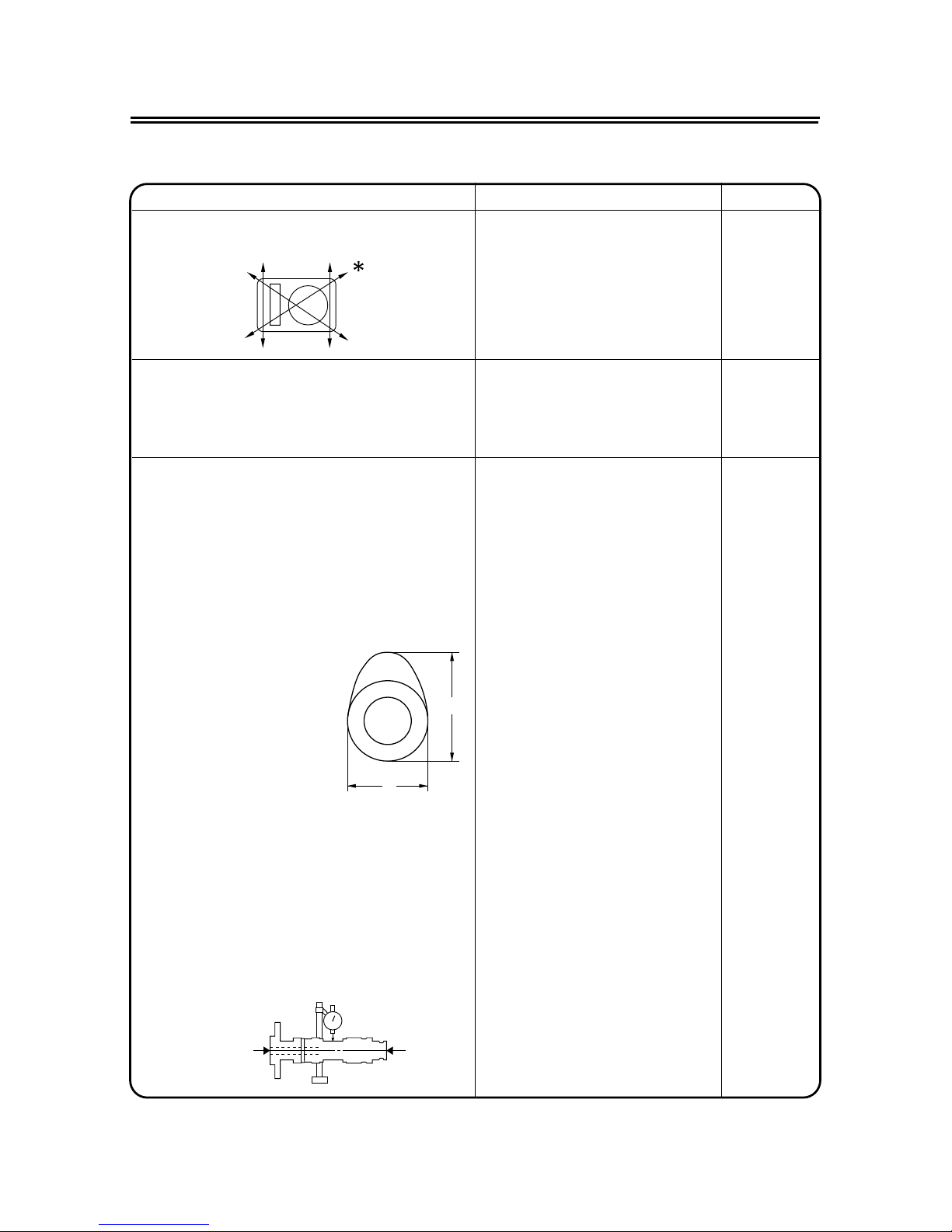

Tool name/How to us Illustration Tool name/How to us Illustration

Crankcase separating tool

These tool is used to remove the

crankshaft from either case.

Flywheel puller

This tool is used to remove the flywheel

magneto.

Rotor holding tool

This tool is used when loosening or

tightening the fly-wheel magneto

securing nut

Dial gauge and stand

Stand

These tools are used to check each part

for runout or bent.

Crankshaft installing tool/pot/bolt

Spacer (crankshaft installer)

Adapter (M12)

These tools are used to install the

crankshaft.

Piston pin puller set

This tool is used to remove the piston

pin.

Steering nut wrench

This tool is used when tighten the

steering ring nut to specification.

Pocket tester

Use this tool to inspect the coil

resistance, output voltage and amperage.

Valve spring compressor

This tool is needed to remove and

install the valve assemblies.

Clutch holding tool

This tool is used to hold the clutch

when removing or installing the clutch

boss securing nut.

Valve guide remover

This tool is needed to remove and

install the valve guide.

Page 13

1 - 7

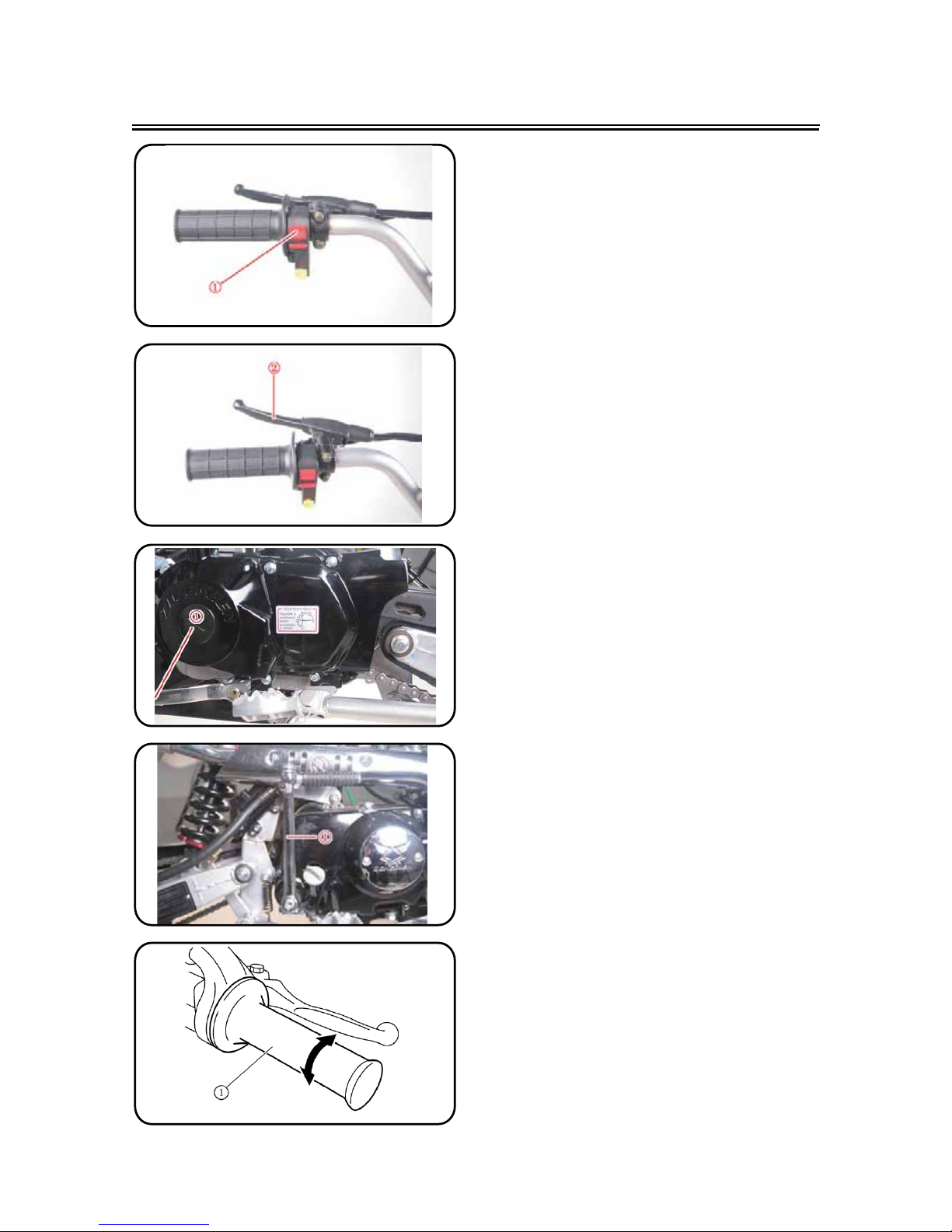

CONTROL FUNCTIONS

CONTROL FUNCTIONS

ENGINE STOP SWITCH

The engine stop switch ① is located on the left

handlebar. Continue pushing the engine stop

switch till the engine comes to a stop.

CLUTCH LEVER

The clutch lever ② is located on the left han-

dlebar; it disengages or engages the clutch.

Pull the clutch lever to the handlebar to disengage the clutch, and release the lever to

engage the clutch. The lever should be pulled

rapidly and released slowly for smooth starts.

SHIFT PEDAL

The gear ratios of the constant-mesh 4 speed

transmission are ideally spaced. The gears

can be shifted by using the shift pedal ① on

the left side of the engine.

KICKSTARTER CRANK

Rotate the kickstarter crank ① away from the

engine. Push the starter down lightly with your

foot until the gears engage, then kick smoothly

and forcefully to start the engine. This model

has a primary kickstarter crank so the engine

can be started in any gear if the clutch is disengaged. In normal practices, however, shift to

neutral before starting.

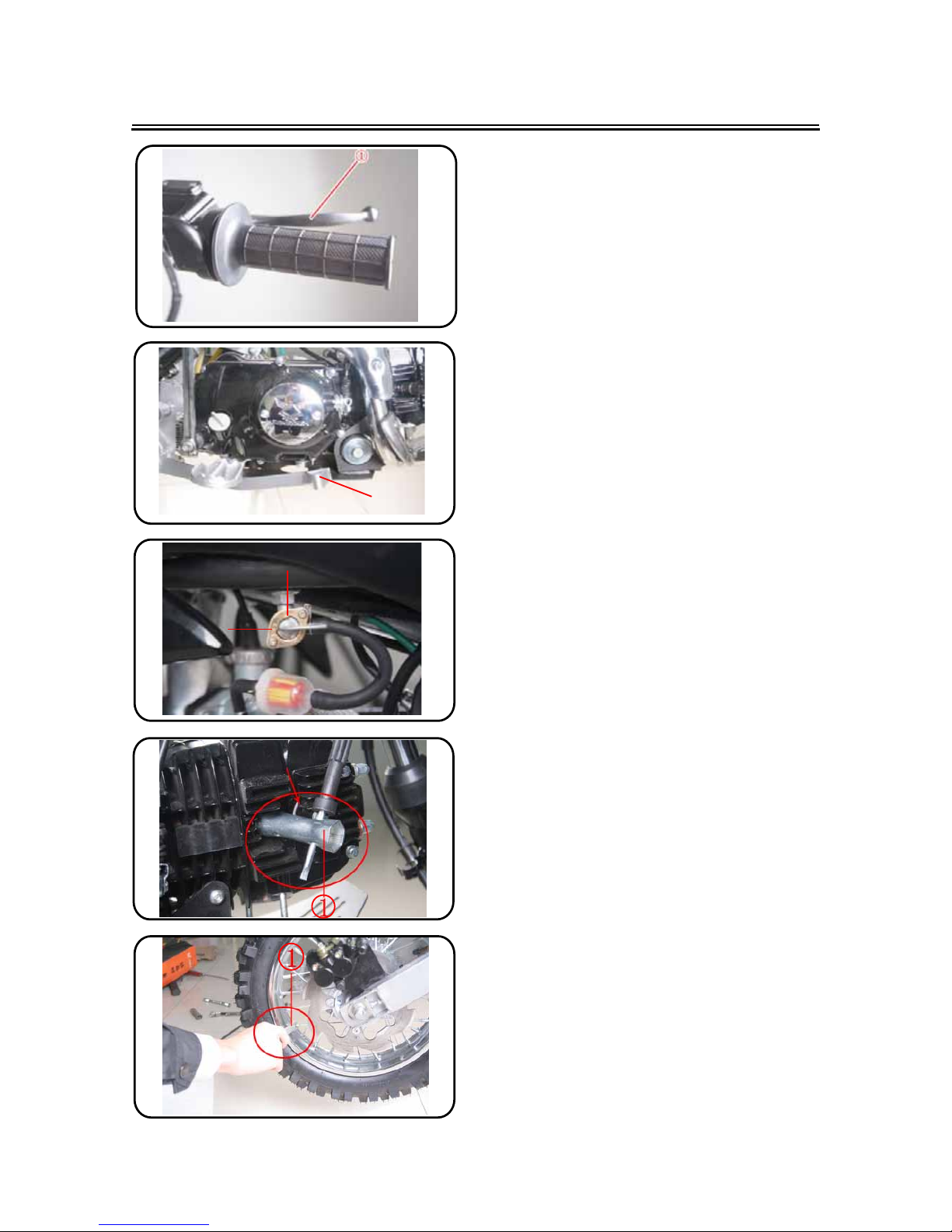

THROTTLE GRIP

The throttle grip ① is located on the right han-

dlebar; it accelerates or decelerates the

engine. For acceleration, turn the grip toward

you; for deceleration, turn it away from you.

Page 14

1 - 8

CONTROL FUNCTIONS

FRONT BRAKE LEVER

The front brake lever ① is located on the right

handlebar. Pull it toward the handlebar to activate the front brake.

REAR BRAKE PEDAL

The rear brake pedal ① is located on the right

side of the machine. Press down on the brake

pedal to activate the rear brake.

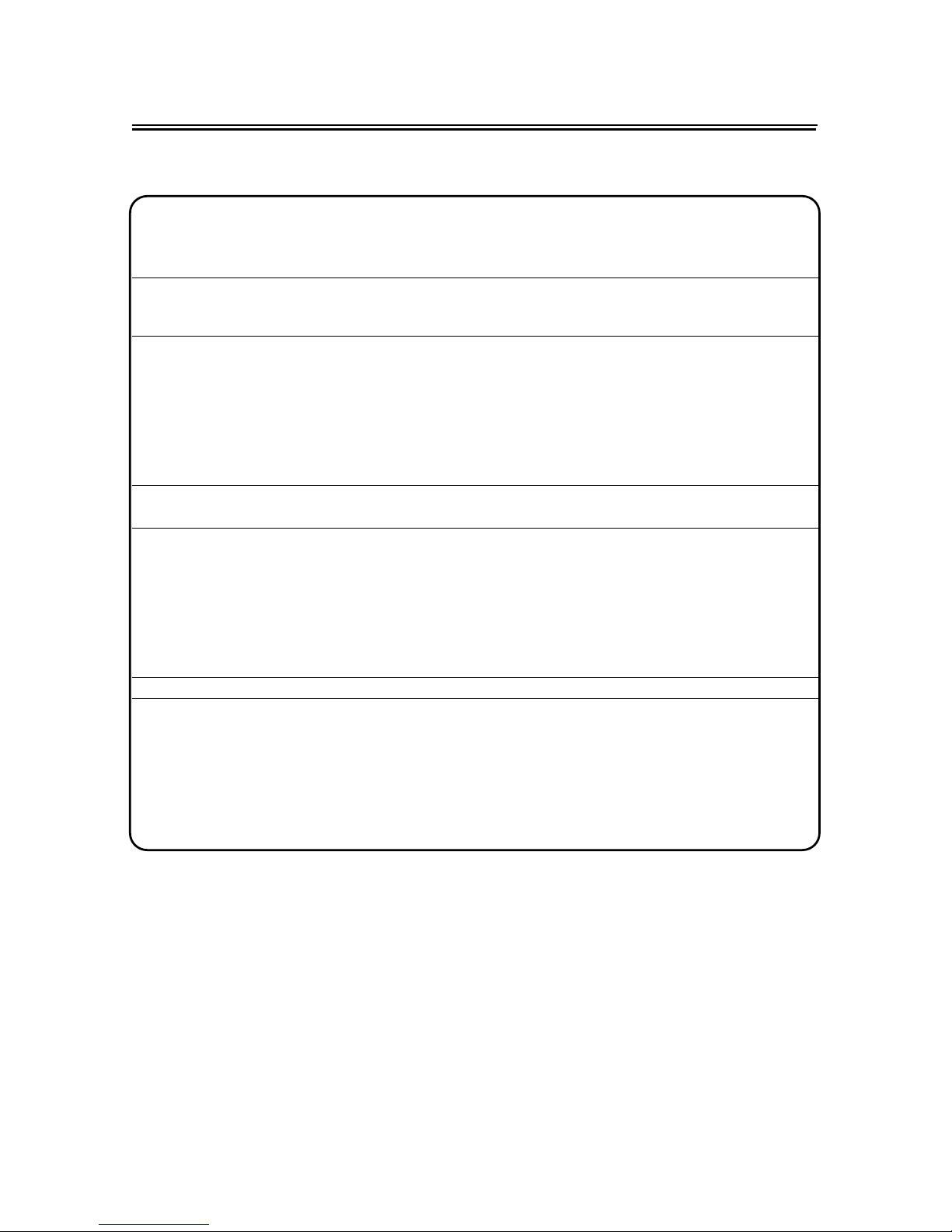

FUEL COCK

The fuel cock supplies fuel from the tank to

carburetor while filtering the fuel. The fuel cock

has the two positions:

OFF:With the lever in this position, fuel will not

flow. Always return the lever to this position when the engine is not running.

ON: With the lever in this position, fuel flows

to the carburetor. Normal riding is done

with the lever in this position

SPARK PLUG WRENCH

This spark plug wrench ① is used to remove

and install the spark plug.

NIPPLE WRENCH

This nipple wrench ① is used to tighten the

spoke.

①

NO

OFF

Page 15

2 - 1

SPECIFICATIONS

21G:emanledoM

:rebmunedocledoM

AGB-21G

Dimensions:

mm550,1,htgnelllarevO

mm006htdiwllarevO

mm038thgiehllarevO

mm096thgiehtaeS

mm501

,1esableehW

Minimum ground clearance 260 mm

Basic weight:

knatleufllufdnaliohtiW

Engine:

Air cooled 4-stroke epytenignE

denilcnidrawrof,rednilycelgniStnemegnarrarednilyC

m c3.6712t

nemecalpsiD

3

Bore s 0.54ekorts s 54 mm

1: 9oitarnoisserpmoC

retratskciKmetsysgnitratS

pmusyrD:metsysnoitacirbuL

Oil type or grade:

At 5 ˚C (40 ˚F) or higher

SF15W/40 type

SG motor oil

(Non-Friction modified)

At 15 ˚C (60 ˚F) or lower

2

2

GENERAL SPECIFICATIONS

66kg

and Electrical Starting

Page 16

2 - 2

GENERAL SPECIFICATIONS

Oil capacity:

Engine oil

L8.0egnahcliocidoireP

With oil filter replacement 0.85 L

L9.0tnuomalatoT

tnemeleepytteW:retlifriA

Fuel:

ahtiwylnoenilosagdedaelnumuimerPepyT

research octane number of 90 or higher.

Premium gasoline

L5.3yticapacknaT

Carburetor:

Z26-5KPepyT

rerutcafunaM

Spark plug:

A7RTC/NGK

rerutcafunam/epyT

mm7.0~6.0paG

csid-elpitlum,teW:epythctulC

Transmission:

Primary reduction system Gear

)277

.3(81/76oitarnoitcuderyramirP

Secondary reduction system Chain drive

Secondary reduction ratio 43/15 (2.867)

deeps-4,hsemtnatsnoCepytnoissimsnarT

noitarepotooftfeLnoitarepO

)818.2(11

/63ts1:oitarraeG

)839.1(61/13dn2

)053.1(02/72dr3

)340.1

(32/42ht4

Chassis:

eldarcelbuodimeSepytemarF

3.72elgnarets

aC˚

Tire:

ebuthtiWepyT

)tnorf(eziS

)raer(eziS

Tire pressure (front and rear) 130 kPa (1.3 kgf/cm

2

)

JINGKE

60/100-14 30M

80/100-12 41M

Page 17

2 - 3

GENERAL SPECIFICATIONS

Brake:

ekarbcsidelgniSepytekarbtnorF

noitarepodnahthgiRnoitarepO

ekarbcsidelgniSepytekarbraeR

noitarepotoofthg

iRnoitarepO

Suspension:

krofcipocseleTnoisnepsustnorF

)noisnepsusssorconomepytknil(mragniwSnoisnepsusraeR

Shock absorber:

repmadli

o/gnirpslioCrebrosbakcohstnorF

re

pm

a

dlio

/gnirpslioCrebrosbakcohsraeR

Wheel travel:

mm002levartleehwtnorF

mm002levartl

eehwraeR

Electrical:

otengamIDCmetsysnoitingI

Page 18

2 - 4

MAINTENANCE SPECIFICATIONS

ENGINE

timiLdradnatSmetI

Cylinder head:

mm30.0----timilpraW

Cylinder:

mm150.45~00.45eziseroB ----

mm50.0----timildnuorfotuO

Camshaft:

----)tfeL(evirdn

iahCdohtemevirD

Camshaft cap inside diameter

31.963 ~ 31.979 mm

----

Camshaft outside diameter

32.009 ~ 32.034 mm

----

mm071.0~030.0ecnaraelcpac-ot-tfahS

Cam dimensions

Intake “A” 26.555 ~ 26.675 mm 26.30 mm

“B” 20.99 ~ 21.01 mm 20.95 mm

Exhaust “A” 26.316 ~ 26.436 mm 26.00 mm

“B” 20.99 ~ 21.01 mm 20.95 mm

mm30.0----timiltuonurtfahsmaC

A

B

Page 19

2 - 5

MAINTENANCE SPECIFICATIONS

Timing chain:

Timing chain type / No. of links 90T/90 ----

----citamotuAdohtemtnemtsujdaniahcgnimiT

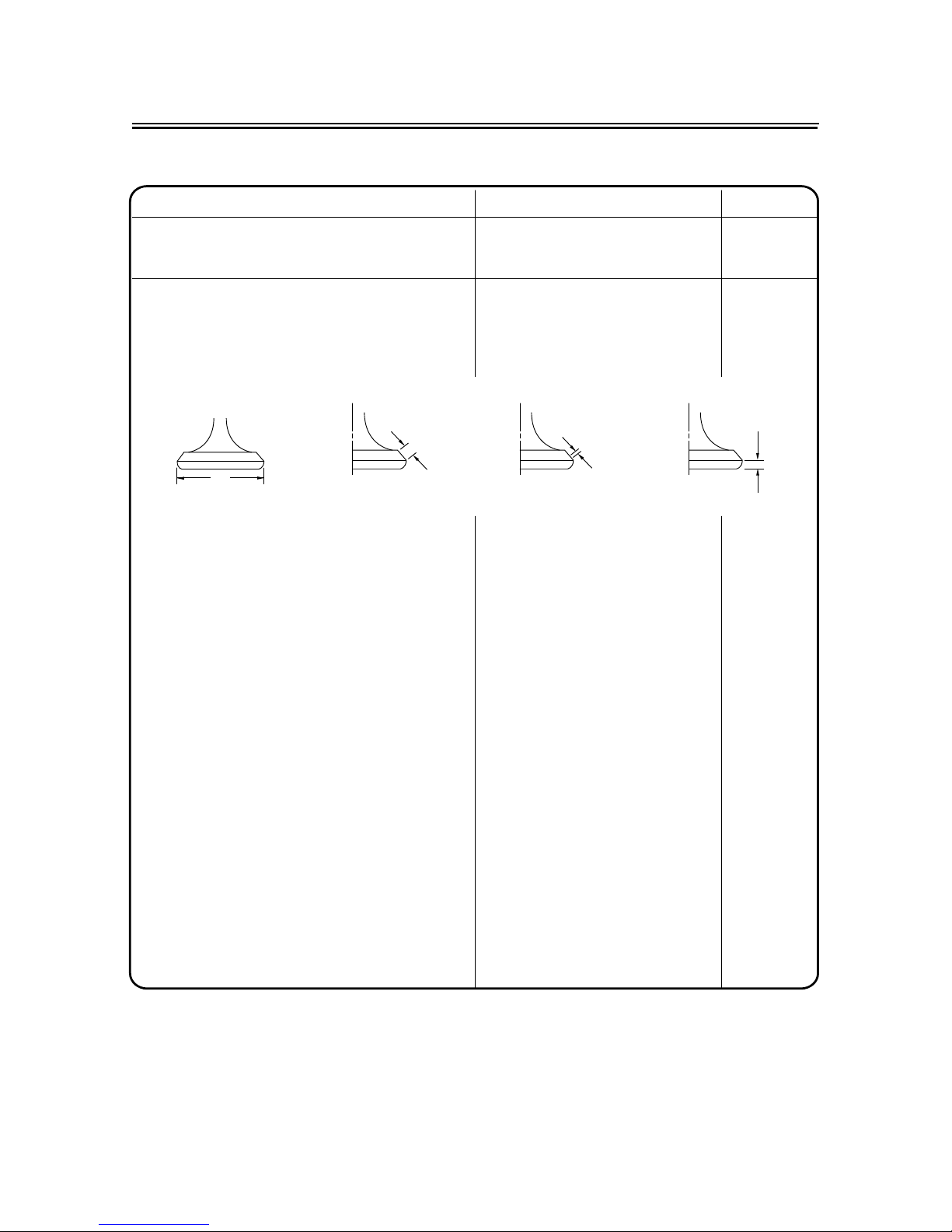

Valve, valve seat, valve guide:

Valve clearance (cold) IN 0.02 ~ 0.04 mm ----

EX 0.02 ~ 0.04 mm ----

Valve dimensions:

“A” head diameter IN 26.9 ~ 27.1 mm ----

EX 22.9 ~ 23.1 mm ----

“B” face width IN 1.1~1.5 mm ----

EX 1.1~1.5 mm ----

“C” seat width IN 0.9 ~ 1.1 mm 1.6 mm

EX 0.8 ~ 1.0 mm 1.6 mm

“D” margin thickness IN 0.65~0.95 mm ----

EX 0.65~0.95 mm ----

Stem outside diameter IN 4.97~4.985 mm 4.94 mm

EX 4.955 ~ 4.97 mm 4.925 mm

Guide inside diameter IN 5.000 ~ 5.012 mm 5.050 mm

EX 5.500 ~ 5.512 mm 5.550 mm

Stem-to-guide clearance IN 0.015 ~ 0.042 mm 0.08 mm

EX 0.030 ~ 0.057 mm 0.10 mm

timiLdradnatSmetI

Head Diameter

B

Face Width

C

Seat Width

D

Margin Thickness

A

Page 20

2 - 6

MAINTENANCE SPECIFICATIONS

mm30.0----timiltuonurmetS

Valve seat width IN 0.8 ~ 1.2 mm 1.6 mm

EX 0.8 ~ 1.2 mm 1.6 mm

Valve spring:

mm5.23mm87.33NIhtgneleerF

EX 35.55 mm 34.0 mm

Set length (valve closed) IN 22.45 mm ----

EX 25.45 mm ----

Compressed force

mm54.22taN46~52NI)dellatsni( ----

EX 105 ~ 129 N at 25.45 mm ----

3.1----NItimilt

liT ˚/ 0.8 mm

35.1----XE ˚/0.8 mm

Direction of winding

----esiwkcolCNI)weivpot(

----esiwkcolCXE

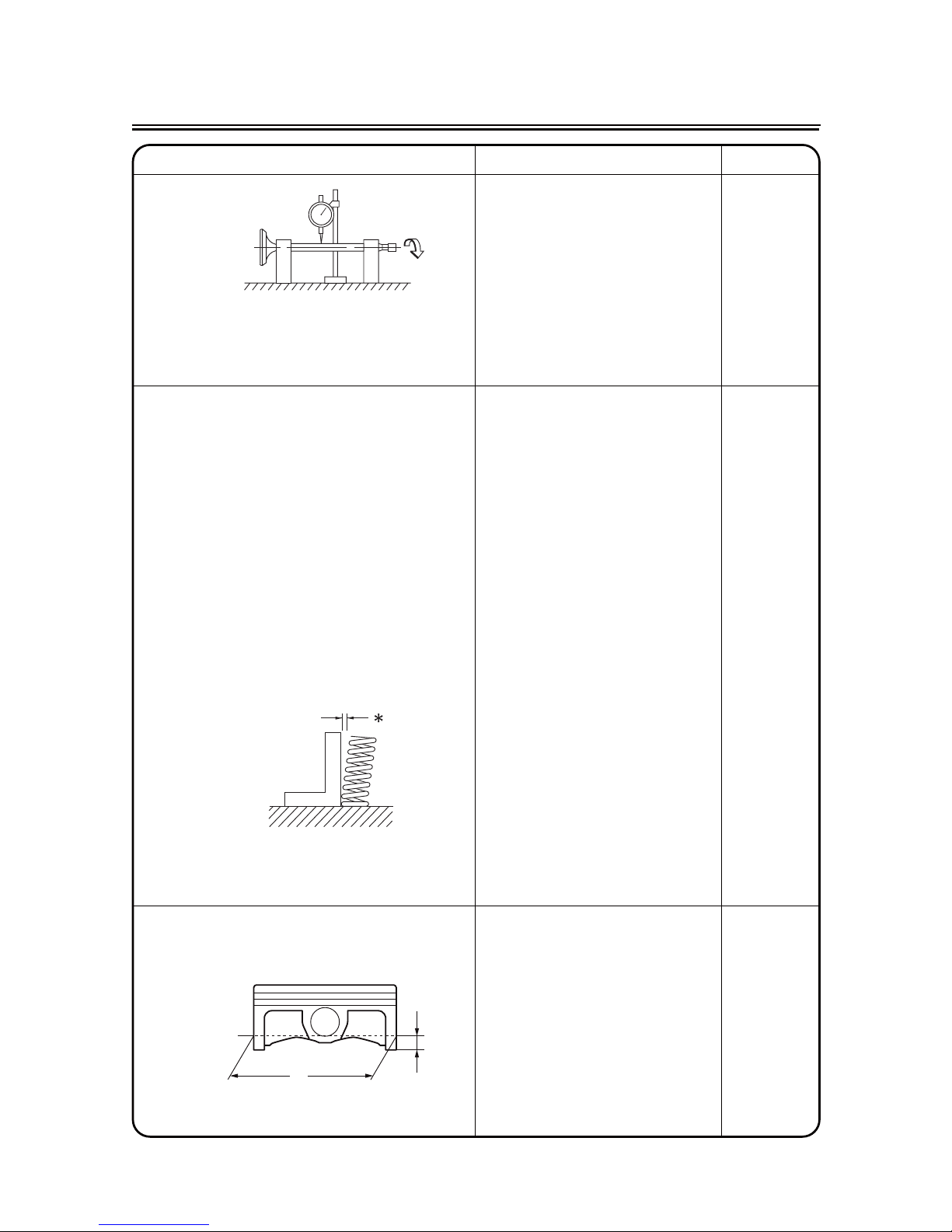

Piston:

Piston to cylinder clearance 0.025 ~ 0.05 mm 0.1 mm

Piston size “D” 53.965 ~ 53.975 mm ----

Measuring point “H” 10 mm ----

----

edis-NI/

mm4.0tes-ffonotsiP

timiLdradnatSm

etI

H

D

Page 21

2 - 7

MAINTENANCE SPECIFICATIONS

Piston pin bore inside diameter 14.002 ~ 14.013 mm 14.04 mm

Piston pin outside diameter 13.994 ~ 14.000 mm 13.98 mm

Piston rings:

Top ring:

----lerraBepyT

Dimensions (B s .980)T s 2.00mm ----

mm52.0~01.0)dellatsni(pagdnE 0.60 mm

Side clearance (installed) 0.040 ~ 0.080 mm 0.12 mm

2nd ring:

----repaTepyT

Dimensions (B s 98.0)T s 2.20 mm ----

mm03.0~51.0)dellatsni(

pagdnE 0.60 mm

mm080.0~040.0ecnaraelcediS 0.12 mm

Oil ring:

Dimensions (B s 29.1)T s 2.45 mm ----

mm05.0~02.0)dellatsni(pagdnE ----

Crankshaft:

Crank width “A” 40.15~ 40.20 mm ----

Runout limit “C” 0.03 mm 0.05 mm

Big end side clearance “D” 0.15 ~ 0.35mm 0.60 mm

Small end free play “F” 0.4 ~ 1.0 mm 2.0 mm

timiLdradnatSmetI

7

%

B

T

B

T

Page 22

2 - 8

MAINTENANCE SPECIFICATIONS

Clutch:

mm95.2~85.2ssenkcihtetalpnoitcirF 2.7 mm

----3ytitnauQ

----mm6.1~4.1ssenkcihtetalphctulC

----3ytitnauQ

mm1.0----t

imilpraW

mm5.91mm5.02htgneleerfgnirpshctulC

----4ytitnauQ

----

----

----hsupmac,hsuprennIdohtemesaelerhctulC

Shifter:

---

-rabediugdnamurdmaCepytretfihS

mm50.0----timilgnidnebrabediuG

Kickstarter:

----epyttehctardnakciKepyT

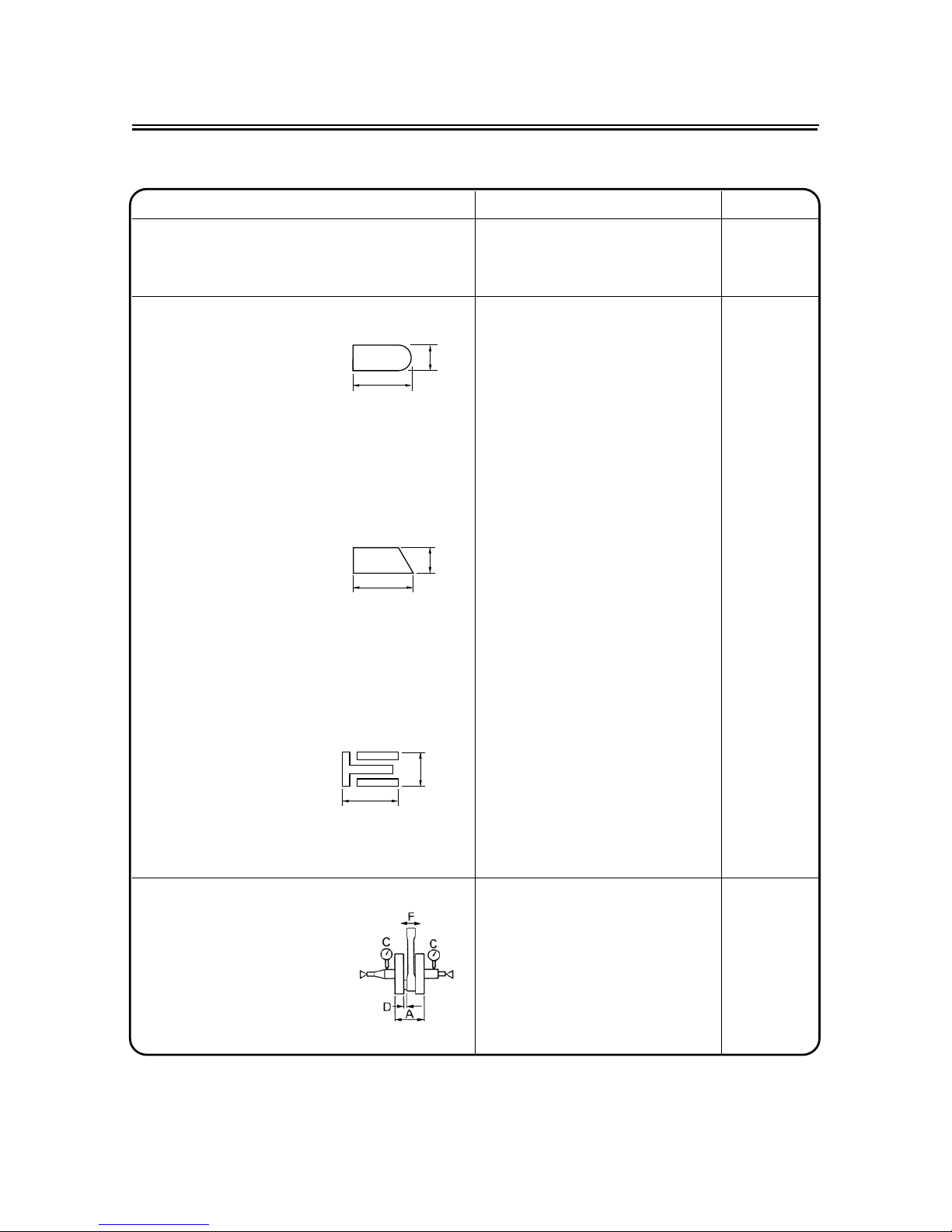

:roterubraC

/Z26-5KP

rerutcafunam/epyT

JINGKE

¾

----KJkram.D.I

#58)J.M(tejniaM ¾ ----

)J.A.M(tejrianiaM ø1.0 ¾

¾

----

----26-5

38#

ø2.0

8 g

2.0 ~ 3.0 mm

)N.J(eldeenteJ

)

I.J(Idle jet

Float needle valve size (F.N.A)

Float weight (F.W)

Float height (F.H)

¾ ---¾ ---¾ ---¾ ----

Air throttle (A.T) B6L ¾ ----

timiLdradnatSmetI

Page 23

3 - 1

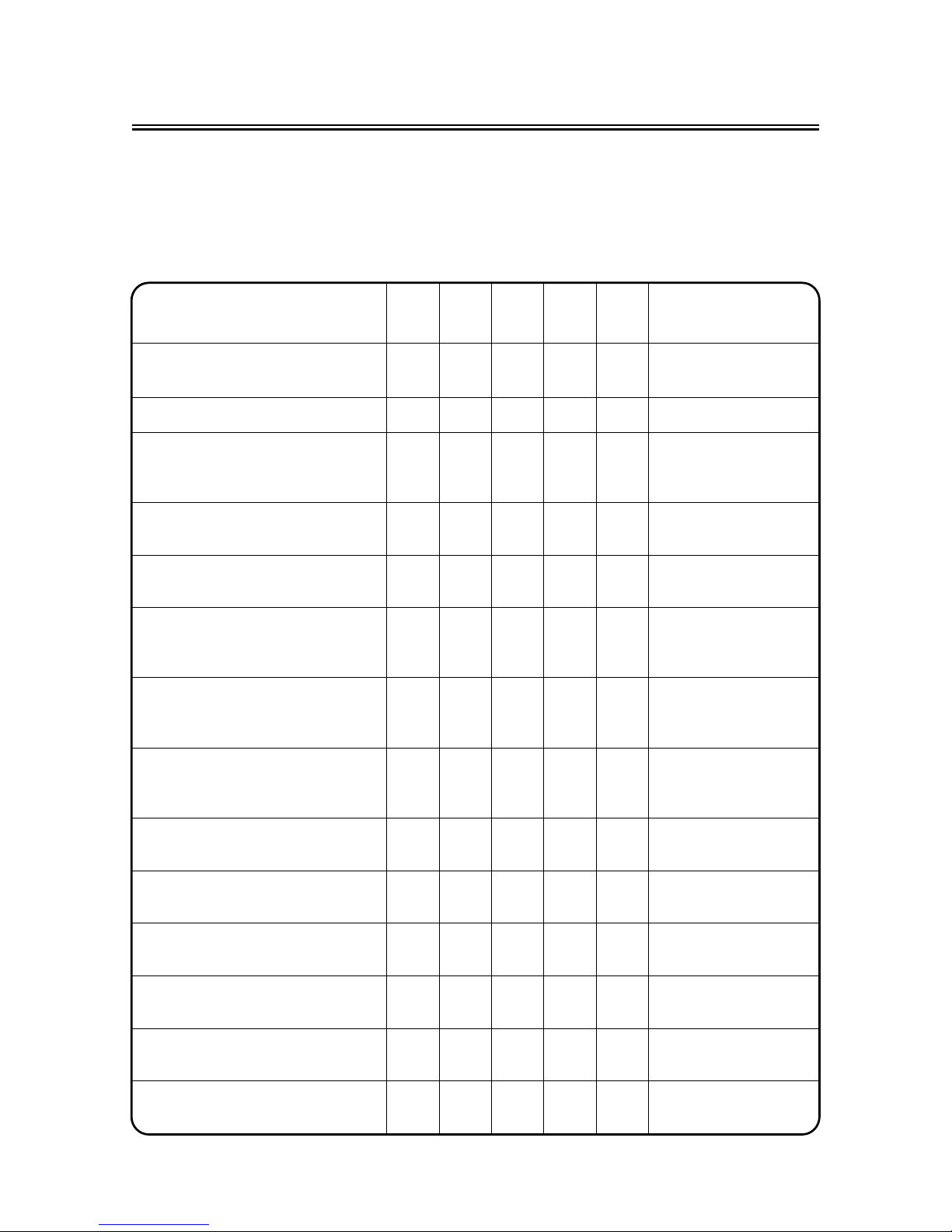

MAINTENANCE INTERVALS

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your dealer.

Item

After

break-in

Every

race

Every

third

(or

500 km)

Every

fifth

(or

1,000 km)

As required

Remarks

ENGINE OIL

Replace

Inspect

ƽ

ƽ

ƽ

ƽ

OIL FILTER ELEMENT, OIL STRAINER

Clean

ƽ

VALVES

Check the valve clearances

Inspect

Replace

ƽ

ƽ

ƽ

ƽ

The engine must be cold.

Check the valve seats

and valve stems for wear.

VALVE SPRINGS

Inspect

Replace

ƽ

ƽ

Check the free length and

the tilt.

VALVE LIFTERS

Inspect

Replace

ƽ

ƽ

Check for scratches and

wear.

CAMSHAFTS

Inspect

Replace

ƽ

ƽ

Inspect the camshaft surface.

Inspect the decompres-

sion system.

TIMING CHAIN SPROCKETS, TIMING

CHAIN

Inspect

Replace

ƽ

ƽ

Check for wear on the

teeth and for damage.

PISTON

Inspect

Clean

Replace

ƽ

ƽ

ƽ

ƽ

Inspect crack

Inspect carbon deposits

and eliminate them.

PISTON RING

Inspect

Replace

ƽ

ƽ

ƽ

Check ring end gap

PISTON PIN

Inspect

Replace

ƽ

ƽ

CYLINDER HEAD

Inspect and clean

ƽ

Inspect carbon deposits

and eliminate them.

Change gasket

CYLINDER

Inspect and clean

Replace

ƽ

ƽ

Inspect score marks

Inspect wear

CLUTCH

Inspect and adjust

Replace

ƽ

ƽ

ƽ

Inspect housing, friction

plate, clutch plate and

spring

TRANSMISSION

Inspect

Replace bearing

ƽ

ƽ

Page 24

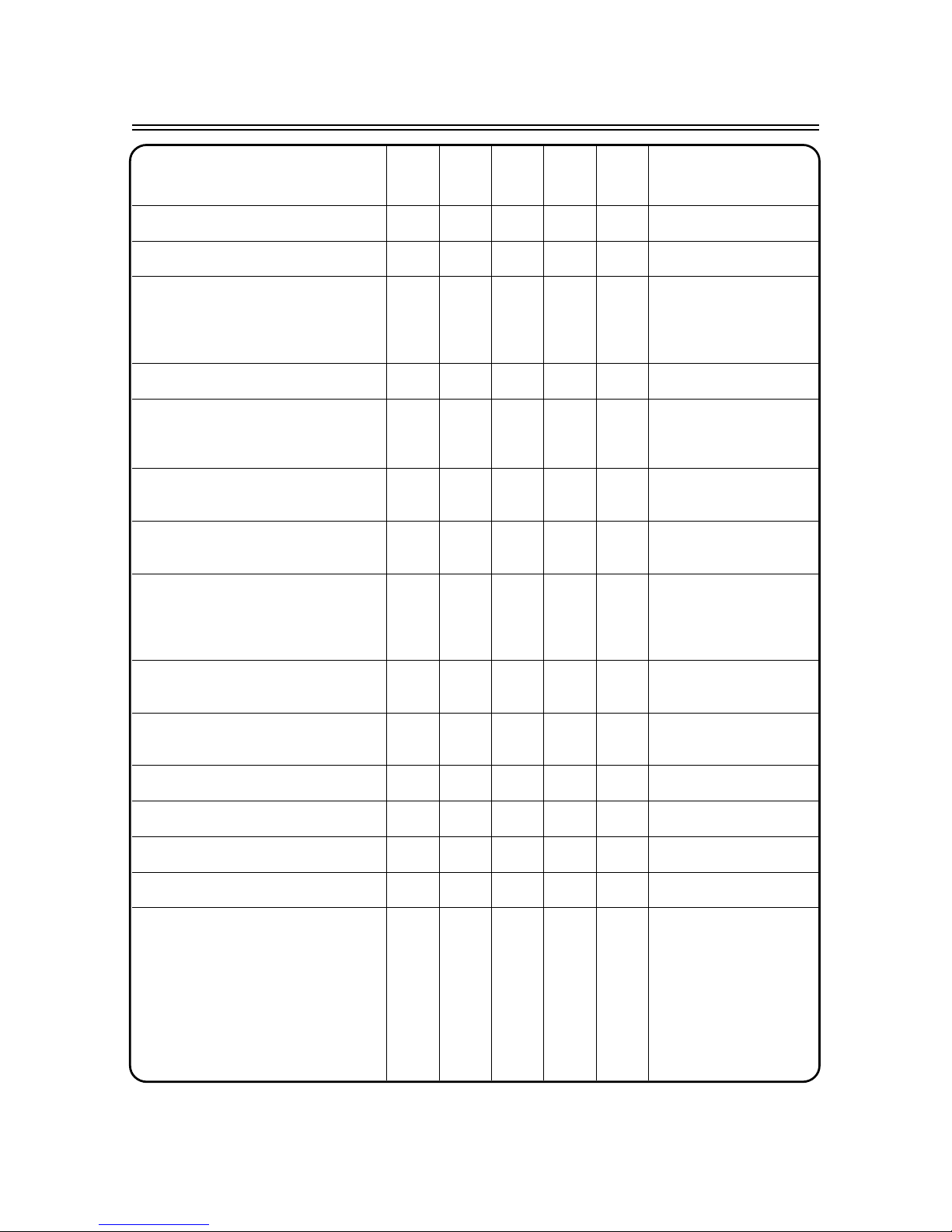

3 - 2

MAINTENANCE INTERVALS

SHIFT FORK, SHIFT CAM, GUIDE BAR

Inspect

ƽ

Inspect wear

ROTOR NUT

Retighten

ƽ

ƽ

EXHAUST PIPE, SILENCER, PROTECTOR

Inspect and retighten

Clean

Replace

ƽ

ƽ

ƽ

ƽ

* Whichever comes first

CRANK

Inspect and clean

ƽ

ƽ

CARBURETOR

Inspect, adjust and clean

ƽ

ƽ

When using a high-pres-

sure washer, make sure

that water does not enter

the accelerator pump.

SPARK PLUG

Inspect and clean

Replace

ƽ

ƽ

ƽ

DRIVE CHAIN

Lubricate, slack, alignment

Replace

ƽ

ƽ

ƽ

Use chain lube

Chain slack: 30 ~ 40 mm

OUTSIDE NUTS AND BOLTS

Retighten

ƽ

ƽ

Refer to “STARTING

AND BREAK-IN” section

in the CHAPTER 1.

AIR FILTER

Clean and lubricate

Replace

ƽ

ƽ

ƽ

Use foam air-filter oil or

equivalent oil

OIL FILTER

Replace

ƽƽ

OIL STRAINER (frame)

Clean

ƽ

FRAME

Clean and inspect

ƽ

ƽ

FUEL TANK, COCK

Clean and inspect

ƽ

ƽ

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper

bolts, master cylinder bolts and union

bolts

Replace pads

Replace brake fluid

ƽ

ƽ

ƽ

ƽ

ƽ

ƽ

ƽ

ƽ

ƽ

ƽ

ƽ

ƽ

Every one year

Item

After

break-in

Every

race

Every

third

(or

500 km)

Every

fifth

(or

1,000 km)

As required

Remarks

Page 25

3 - 3

MAINTENANCE INTERVALS

FRONT FORKS

Inspect and adjust

Replace oil

Replace oil seal

ƽ

ƽ

ƽ

ƽ

ƽ

FRONT FORK OIL SEAL AND DUST

SEAL

Clean and lube

ƽ

ƽ

esaerg esab muihtiL

REAR SHOCK ABSORBER

Inspect and adjust

Lube

Retighten

ƽ

ƽ

ƽ

ƽ

ƽ

(After

rain ride)

ƽ

Molybdenum disulfide

grease

DRIVE CHAIN GUIDE AND ROLLERS

Inspect

ƽ

ƽ

SWINGARM

Inspect, lube and retighten

ƽ ƽ

Molybdenum disulfide

grease

RELAY ARM, CONNECTING ROD

Inspect, lube and retighten

ƽ ƽ

Molybdenum disulfide

grease

STEERING HEAD

Inspect free play and retighten

Clean and lube

Replace bearing

ƽ ƽ

ƽ

ƽ

Lithium base grease

TIRE, WHEELS

Inspect air pressure, wheel run-out,

tire wear and spoke looseness

Retighten sprocket bolt

Inspect bearings

Replace bearings

Lubricate

ƽ

ƽ

ƽ

ƽ

ƽ

ƽ

ƽ

Lithium base grease

THROTTLE, CONTROL CABLE

Check routing and connection

Lubricate

Inspect and clean (throttle cable)

ƽ

ƽ

ƽ

ƽ

ƽ

ƽ

SAE 10W-30 motor oil

Inspect dirt and wear on

the throttle cable on the

carburetor side.

Item

After

break-in

Every

race

Every

third

(or

500 km)

Every

fifth

(or

1,000 km)

As required

Remarks

Page 26

3 - 4

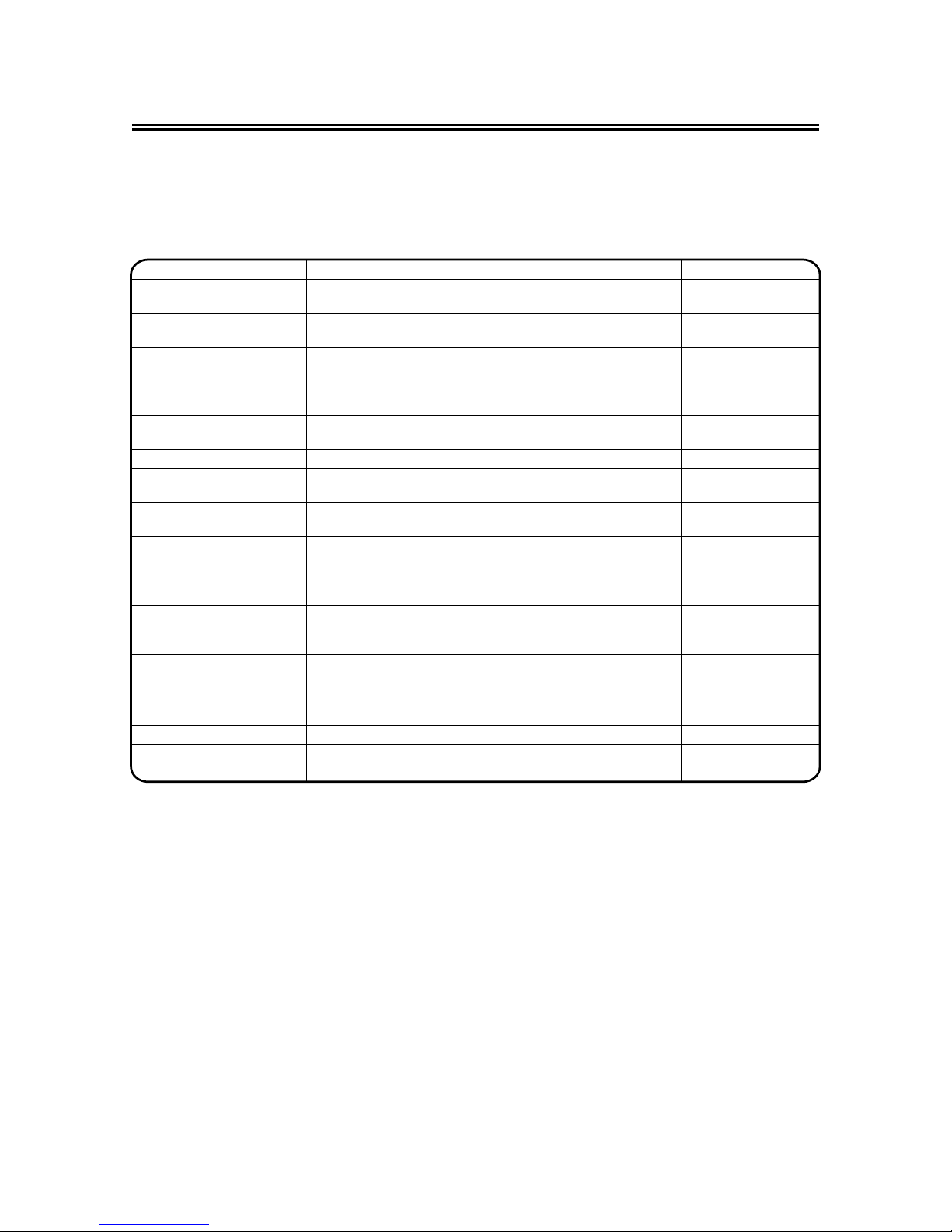

PRE-OPERATION INSPECTION AND MAINTENANCE

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

enituoRmetI

Fuel

Check that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.

Engine oil

Check that the oil level is correct. Check the crankcase and

frame oil line for leakage.

Gear shifter and clutch

Check that gears can be shifted correctly in order and that the

clutch operates smoothly.

Throttle grip/Housing

Check that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.

.ekarb raer dna tnorf fo tceffe dna ekarb tnorf fo yalp eht kcehCsekarB

Drive chain

Check drive chain slack and alignment. Check that the drive

chain is lubricated properly.

Wheels

Check for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.

Steering

Check that the handlebar can be turned smoothly and have no

excessive play.

Front forks and rear shock

absorber

Check that they operate smoothly and there is no oil leakage.

Cables (wires)

Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or

when the front forks travel up and down.

Exhaust pipe

Check that the exhaust pipe is tightly mounted and has no

cracks.

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose.

Lubrication Check for smooth operation. Lubricate if necessary.

Bolts and nuts Check the chassis and engine for loose bolts and nuts.

Lead connectors

Check that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.

Page 27

3 - 5

CLUTCH ADJUSTMENT

CLUTCH ADJUSTMENT

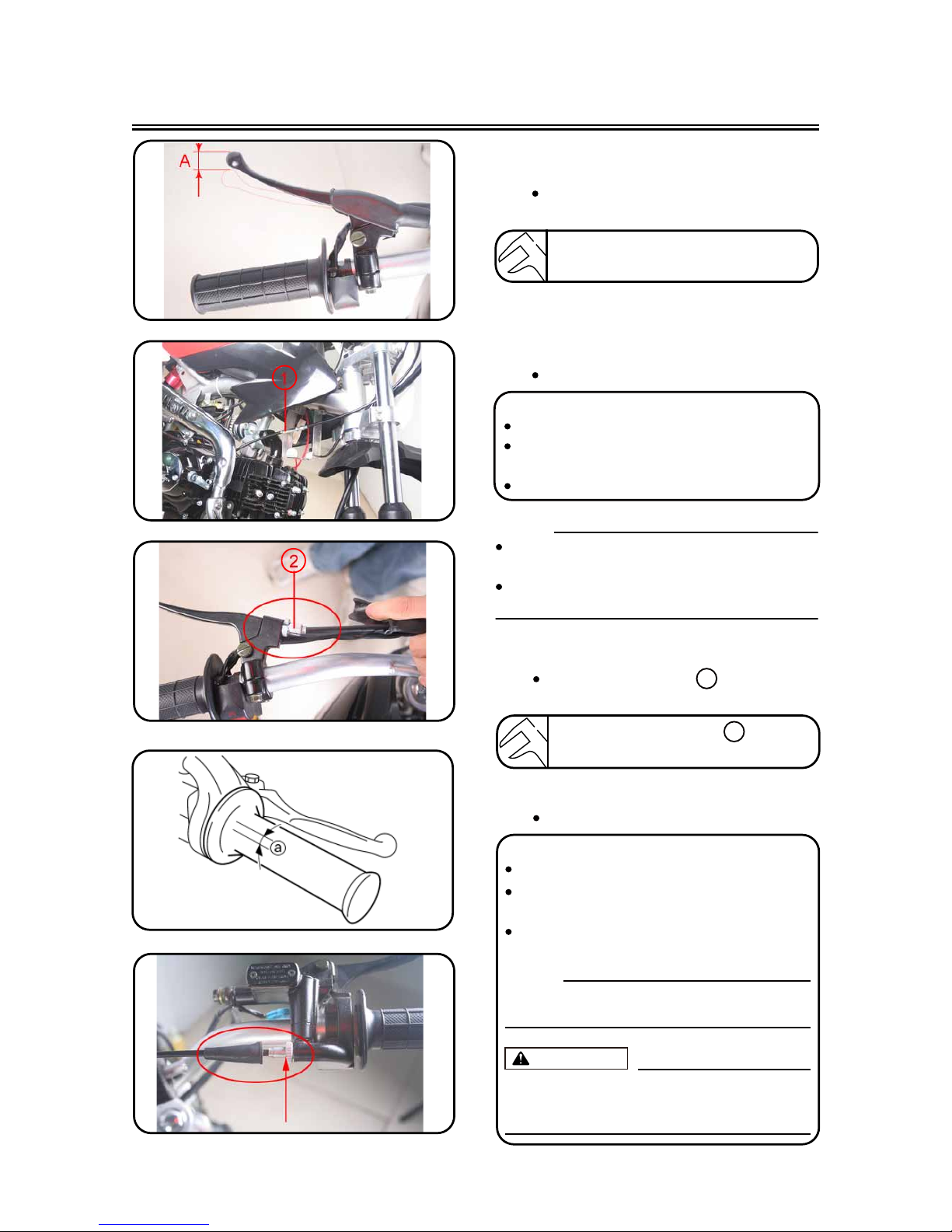

1. Check:

Clutch lever free play $

Out of specification m Adjust.

Clutch lever free play $ :

5 ~ 10 mm

2. Adjust:

Clutch lever free play

NOTE:

Make minute adjustment on the lever side

using the adjuster ② .

After adjustment, check proper operation of

clutch lever.

Clutch lever free play adjustment steps:

Loosen the locknuts ① .

Adjust the free play by changing their

tightening position.

Tighten the locknuts.

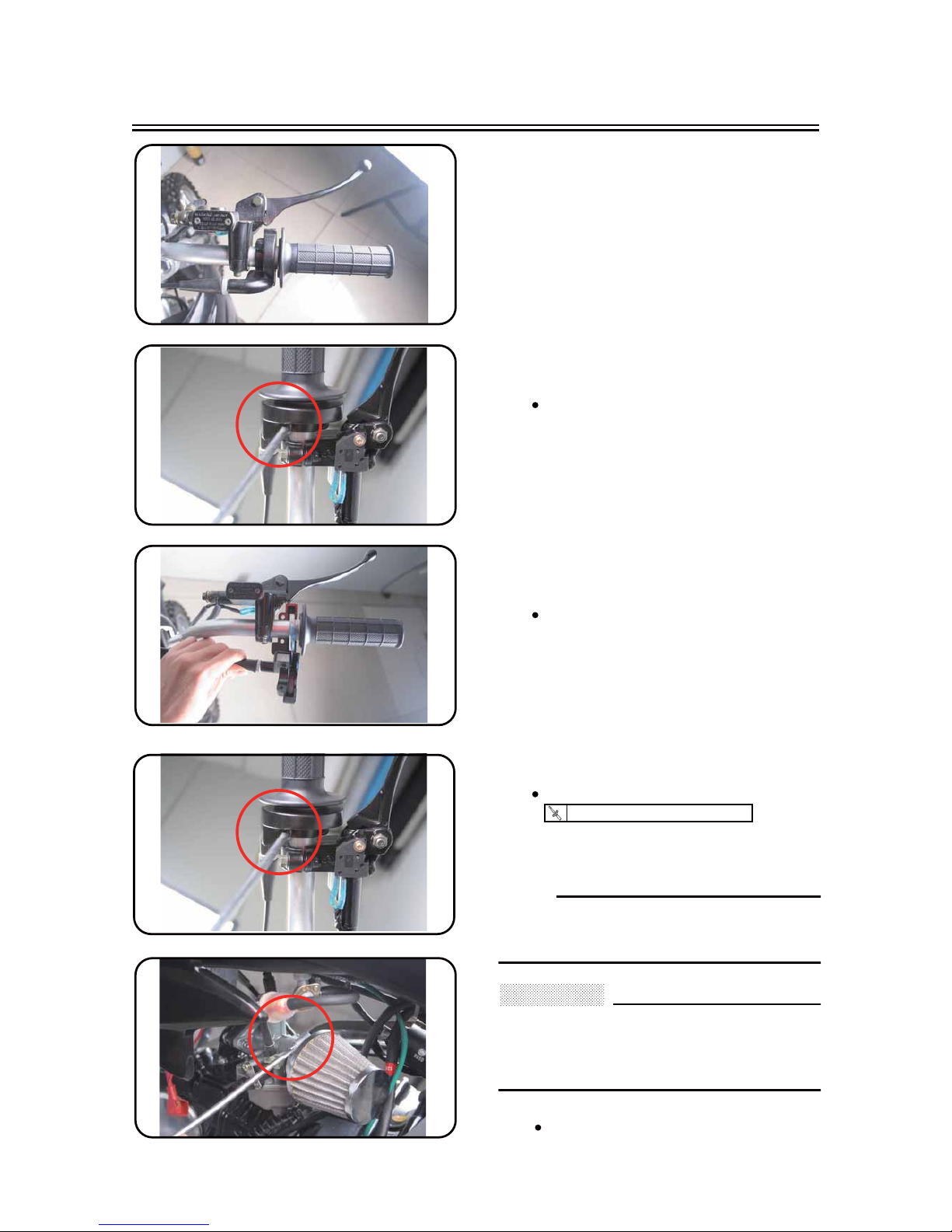

THROTTLE CABLE ADJUSTMENT

1. Check:

Throttle grip free play a

Out of specification m Adjust.

Throttle grip free play a :

3 ~ 5 mm

2. Adjust:

Throttle grip free play

Throttle grip free play adjustment steps:

Slide the adjuster cover.

Turn the adjuster ① until the specified free

play is obtained.

Tighten the locknut.

NOTE:

Before adjusting the throttle cable free play,

the engine idle speed should be adjusted.

WARNING

After adjusting, turn the handlebar to

right and left and make sure that the

engine idling does not run faster.

①

Page 28

3 - 6

THROTTLE CABLE ADJUSTMENT/

THROTTLE LUBRICATION

THROTTLE LUBRICATION

1. Remove:

Screw (throttle grip cap)

2. Apply:

Lithium soap base grease

On the throttle cable end

3. Install:

Screw (throttle grip cap)

T

R

.

.

4 Nm (0.4 m · kg)

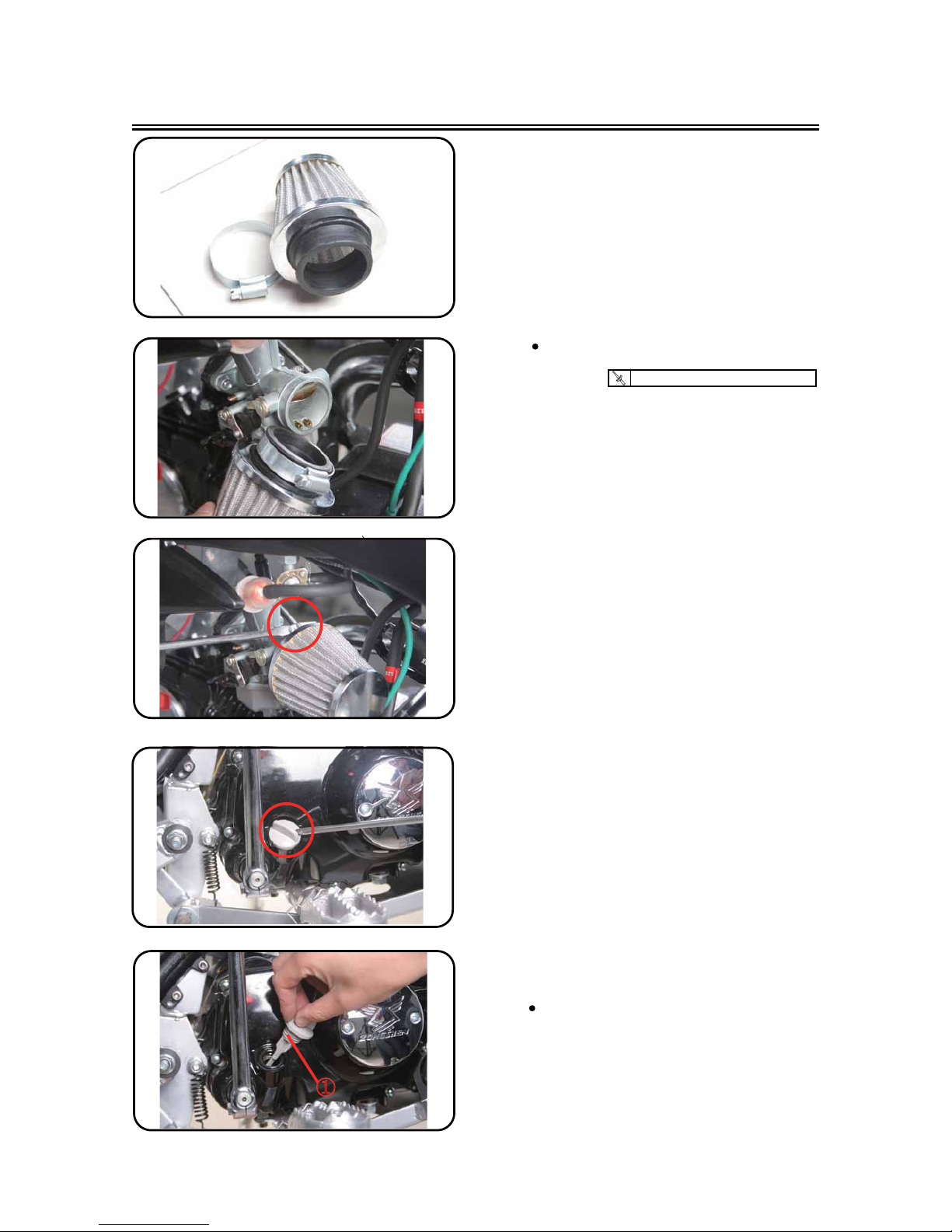

AIR FILTER REPLACE

NOTE:

Proper air filter maintenance is the biggest key

to preventing premature engine wear and

damage.

CAUTION:

Never run the engine without the air filter

element in place; this would allow dirt and

dust to enter the engine and cause rapid

wear and possible engine damage.

1. Remove:

Screw

Page 29

3 - 7

2. Install:

T

R

.

.

5 Nm (0.5 m · kg)

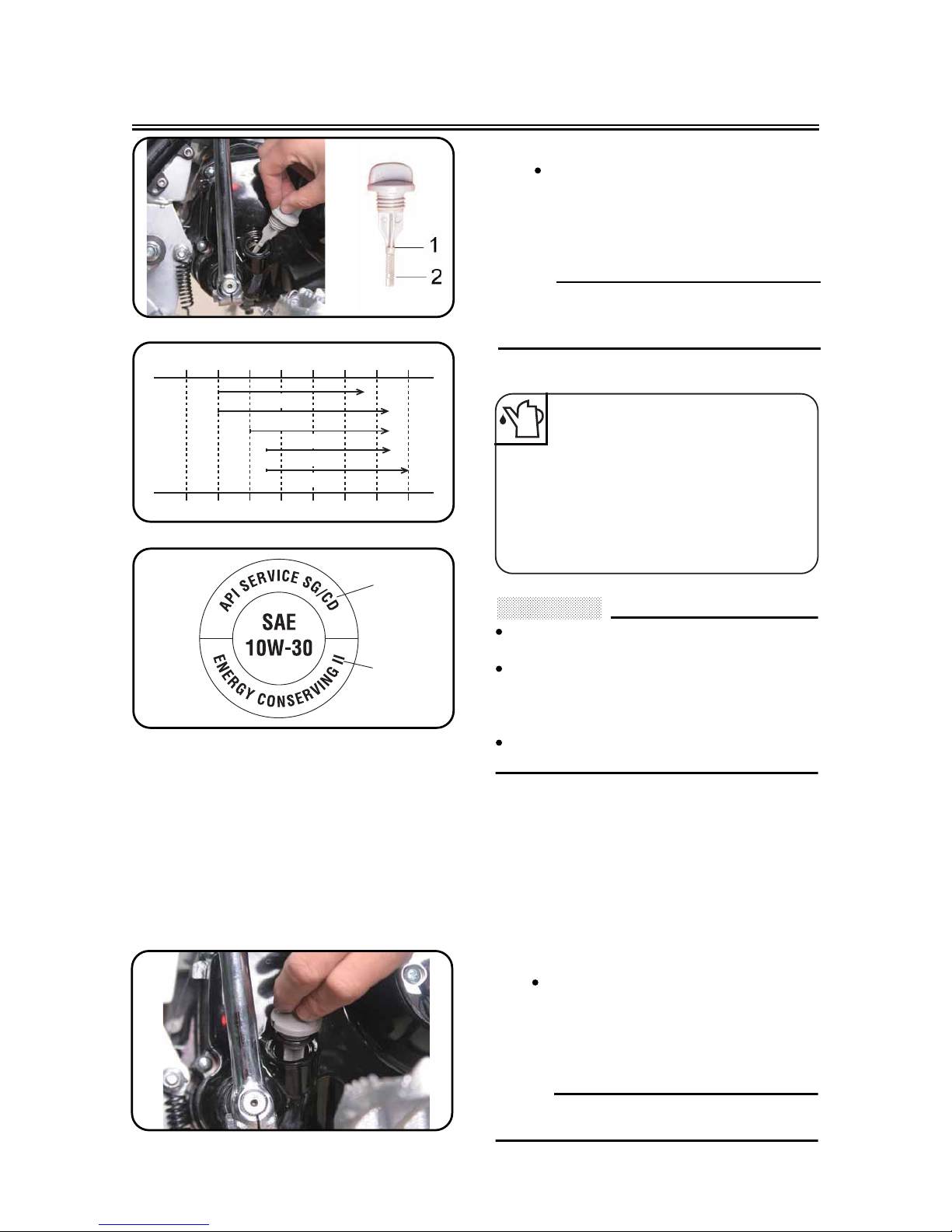

ENGINE OIL LEVEL INSPECTION

1. Start the engine, warm it up for several

minutes, and then turn off the engine and

wait for five minutes.

2. Place the machine on a level place and

hold it up on upright position by placing

the suitable stand under the engine.

3. Remove:

Oil tank cap ①

ENGINE OIL LEVEL INSPECTION

Fitting Screw

Page 30

3 - 8

ENGINE OIL LEVEL INSPECTION

CAUTION:

Do not add any chemical additives or use

oils with a grade of CD D or higher.

Do not use oils labeled “ENERGY CONSERVING II” E or higher. Engine oil also

lubricates the clutch and additives could

cause clutch slippage.

Do not allow foreign materials to enter the

crankcase.

5. Install:

Oil tank cap

6. Start the engine and let it warm up for

several minutes.

7. Turn off the engine and inspect the oil

level once again.

NOTE:

Wait a few minutes until the oil settles before

inspecting the oil level.

Recommended oil:

Refer to the following chart for

selection of oils which are suited

to the atmospheric temperatures.

Recommended engine oil classification:

API STANDARD:

API “SG” or higher grade

(Designed primarily for motor-

cycles)

4. Inspect:

Oil level

Oil level should be between maximum

and minimum marks.

Oil level is low m Add oil to proper

level.

NOTE:

When inspecting the oil level, do not screw the

oil tank cap into the oil tank. Insert the gauge

lightly.

-20-4-101403010502068308640 50

104

122

oCTemp.

oF

10W-30

10W-40

20W-40

20W-50

15W-40

D

E

Page 31

3 - 9

ENGINE OIL REPLACEMENT

ENGINE OIL REPLACEMENT

1. Start the engine and warm it up for several minutes, and then turn off the engine

and wait for five minute.

2. Place the machine on a level place and

hold it on upright position by placing the

suitable stand under the engine.

3. Place a suitable container under the

engine.

4. Remove:

Oil cap

5. Fill:

Engine oil

6. Check:

Oil leakage

7. Check:

Engine oil level

Oil quantity:

Total amount:

0.9 L

Periodic oil change:

0.8 L

With oil filter replacement:

0.85 L

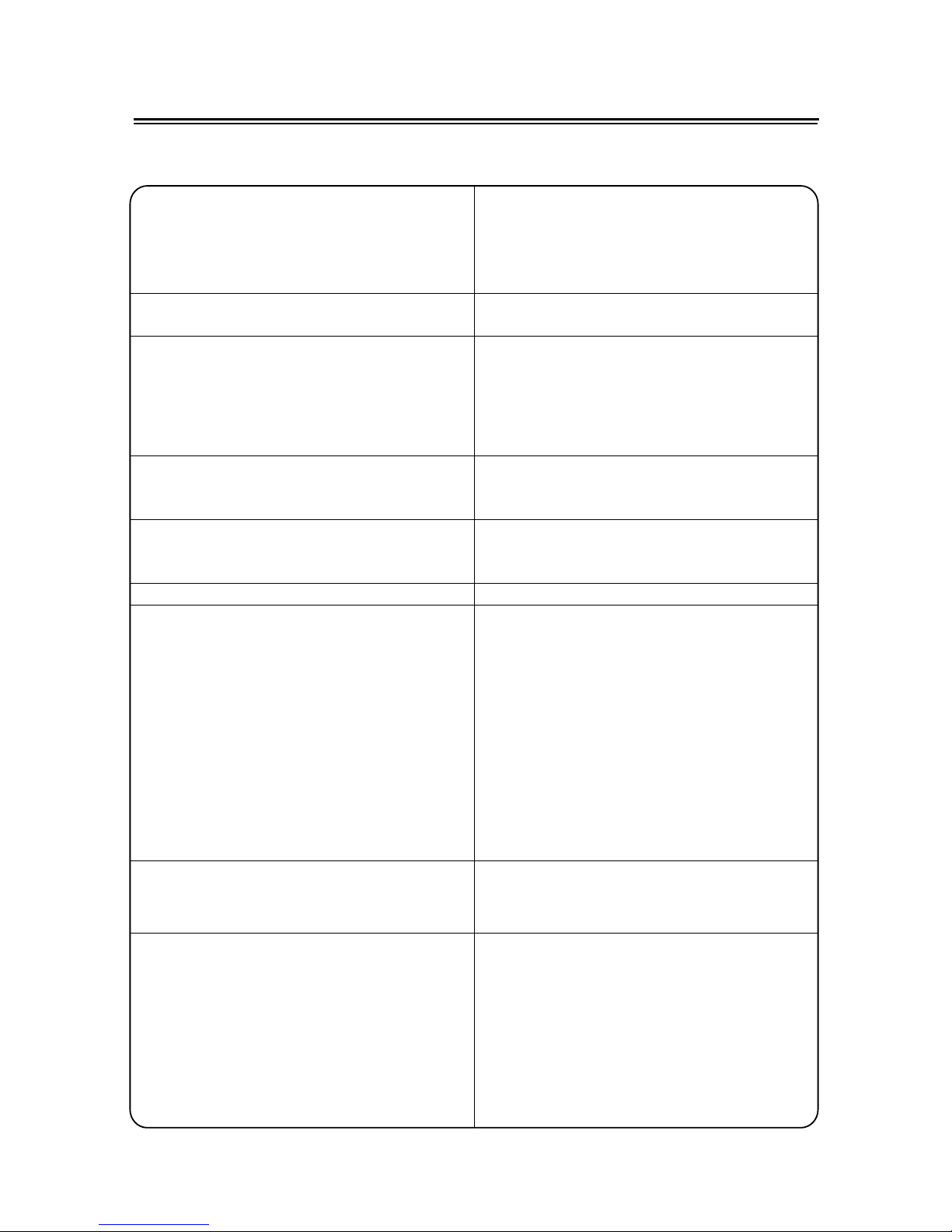

OIL PRESSURE INSPECTION

1. Check:

Oil pressure

Checking steps:

Slightly loosen the oil pressure check bolt

.

Start the engine and keep it idling until oil

starts to seep from the oil pressure check

bolt. If no oil comes out after one minute,

turn the engine off so it will not seize.

Check oil passages and oil pump for damage or leakage.

Start the engine after solving the problem(s) and recheck the oil pressure.

Tighten the oil pressure check bolt.

T

R

.

.

Oil pressure check bolt:

10 Nm (1.0 m • kg)

①

①

a

Page 32

3 - 10

PILOT SCREW ADJUSTMENT

1. Adjust:

Pilot screw ①

Adjustment steps:

NOTE:

To optimize the fuel flow at a smaller throttle

opening, each machine’s pilot screw has

been individually set at the factory. Before

adjusting the pilot screw, turn it in fully and

count the number of turns. Record this number as the factory-set number of turns out.

Turn in the pilot screw until it is lightly

seated.

Turn out the pilot screw by the factory-set

number of turns.

Pilot screw:

1-5/8 turns out (example)

PILOT SCREW ADJUSTMENT

ENGINE IDLING SPEED ADJUSTMENT

1. Start the engine and thoroughly warm it

up.

2. Attach:

Inductive tachometer

To spark plug lead.

3. Adjust:

Engine idling speed

Adjustment steps:

Adjust the pilot screw.

Refer to “PILOT SCREW ADJUSTMENT”

section.

Turn the throttle stop screw ① until the

engine runs at the lowest possible speed.

To increase idle speed m Turn the throt-

tle stop screw ① in .

To decrease idle speed m Turn the throt-

tle stop screw ① out B .

Engine idling speed:

1,400 ~ 1,600 r/min

A

ENGINE IDLING SPEED ADJUSTMENT

Page 33

3 - 11

CHASSIS/BRAKE SYSTEM AIR BLEEDING

CHASSIS

BRAKE SYSTEM AIR BLEEDING

Bleed the brake system if:

The system has been disassembled.

A brake hose has been loosened or

removed.

The brake fluid is very low.

The brake operation is faulty.

A dangerous loss of braking performance

may occur if the brake system is not properly bleed.

1. Remove:

Reservoir cap

Diaphragm

2. Bleed:

Brake fluid

Front

Rear

Air bleeding steps:

a. Add proper brake fluid to the reservoir.

b. Install the diaphragm. Be careful not to

spill any fluid or allow the reservoir to

overflow.

c. Connect the clear plastic tube ② tightly

to the caliper bleed screw ① .

d. Place the other end of the tube into a

container.

e. Slowly apply the brake lever or pedal

several times.

f. Pull the lever in or push down on the

pedal. Hold the lever or pedal in position.

g. Loosen the bleed screw and allow the

lever or pedal to travel towards its limit.

h. Tighten the bleed screw when the lever

or pedal limit has been reached; then

release the lever or pedal.

T

R

.

.

Bleed screw:

6 Nm (0.6 m • kg)

i. Repeat steps (e) to (h) until of the air

bubbles have been removed from the

system.

B

A

B

A

WARNING

①

②

①

②

Page 34

3 - 12

FRONT BRAKE ADJUSTMENT

3. Install:

Diaphragm

Reservoir cap

If bleeding is difficult, it may be necessary to

let the brake fluid system stabilize for a few

hours. Repeat the bleeding procedure when

the tiny bubbles in the system have disappeared.

j. Add brake fluid to the level line on the

reservoir.

Check the operation of the brake after

bleeding the brake system.

FRONT BRAKE

1. Check:

Brake lever position A

Brake lever position A :

Standard position Extent of adjustment

100 mm

Unavailable

REAR BRAKE ADJUSTMENT

REAR BRAKE ADJUSTMENT

1. Check:

Brake pedal height A

Out of specification m Adjust.

Brake pedal height A :

10 mm

2. Adjust:

Brake pedal height

Pedal height adjustment steps:

Loosen the locknut ① .

Turn the adjusting nut ② until the pedal

height D is within specified height.

Tighten the locknut.

Adjust the pedal height between the

maximum and the minimum

After the pedal height adjustment, make

sure that the rear brake does not drag.

WARNING

NOTE:

WARNING

Page 35

3 - 13

FRONT BRAKE PAD INSPECTION AND REPLACEMENT

FRONT BRAKE PAD INSPECTION AND

REPLACEMENT

1. Inspect:

Brake pad thickness A

Out of specification m Replace as a

set.

2. Replace:

Brake pad

Brake pad thickness:

4.0 mm

<Limit>: 1.0 mm

Brake pad replacement steps:

Remove Bolt 1 and 2

Loosen the Caliper

CAUTION:

Do not reuse the drained brake fluid.

Tighten the bleed screw.

T

R

.

.

Bleed screw 3 and 4 :

18 Nm (1.8 m • kg)

Install the Caliper Bolt 1 and 2

T

R

.

.

Bolt (brake caliper):

25 Nm (2.5 m • kg)

Remove Bolt 3 and 4

Replace the Brake pad

3. Inspect:

Brake fluid level

Refer to “BRAKE FLUID LEVEL

INSPECTION” section.

4. Check:

Brake lever operation

A softy or spongy feeling m Bleed

brake system.

Refer to “BRAKE SYSTEM AIR

BLEEDING” section.

Page 36

3 - 14

REAR BRAKE PAD INSPECTION AND REPLACEMENT

REAR BRAKE PAD INSPECTION AND

REPLACEMENT

1. Inspect:

Brake pad thickness A

Out of specification m Replace as a

set.

2. Replace:

Brake pad

Brake pad thickness:

4 mm

<Limit>: 1.0 mm

Brake pad replacement steps:

Remove the Screw 1 and 2.

Loosen the Caliper

Remove the Nut 3.

.

Reeplace the Brake pad.

Page 37

3 - 15

REAR BRAKE PAD INSPECTION AND REPLACEMENT

CAUTION:

Do not reuse the drained brake fluid.

Tighten the bleed screw 1 and 2.

T

R

.

.

Bleed screw 1 and 2:

18 Nm (1.8m kg)

T

R

.

.

Nut 3 (brake caliper):

20 Nm (2.0m kg)

3. Inspect:

Brake fluid level

Refer to “BRAKE FLUID LEVEL

INSPECTION” section.

4. Check:

Brake pedal operation

A softy or spongy feeling m Bleed

brake system.

Refer to “BRAKE SYSTEM AIR

BLEEDING” section.

BRAKE FLUID LEVEL INSPECTION

1. Place the brake master cylinder so that

its top is in a horizontal position.

2. Inspect:

Brake fluid level

Fluid at lower level m Fill up.

D Lower level

A Front

B Rear

Use only designated quality brake fluid to

avoid poor brake performance.

Refill with same type and brand of brake

fluid; mixing fluids could result in poor

brake performance.

Be sure that water or other contaminants

do not enter master cylinder when refilling.

Clean up spilled fluid immediately to

avoid erosion of painted surfaces or plastic parts.

Recommended brake fluid:

DOT #3 or DOT #4

A

B

WARNING

Page 38

3 - 16

SPROCKETS INSPECTION/DRIVE CHAIN INSPECTION

SPROCKETS INSPECTION

1. Inspect:

Sprocket teeth a

Excessive wear m Replace.

NOTE:

Replace the drive sprocket, rear wheel

sprocket and drive chain as a set.

DRIVE CHAIN INSPECTION

1. Remove:

Master link clip

Joint

Drive chain

2. Clean:

Drive chain

Place it in kerosene, and brush off as

much dirt as possible. Then remove the

drive chain from the kerosene and dry

the drive chain.

3. Measure:

Drive chain length (10 links) a

Out of specification m Replace.

Drive chain length (10 links):

<Limit>: 144.4 mm

4. Check:

Drive chain stiffness a

Clean and oil the drive chain and hold

as illustrated.

Stiff m Replace drive chain.

Page 39

3 - 17

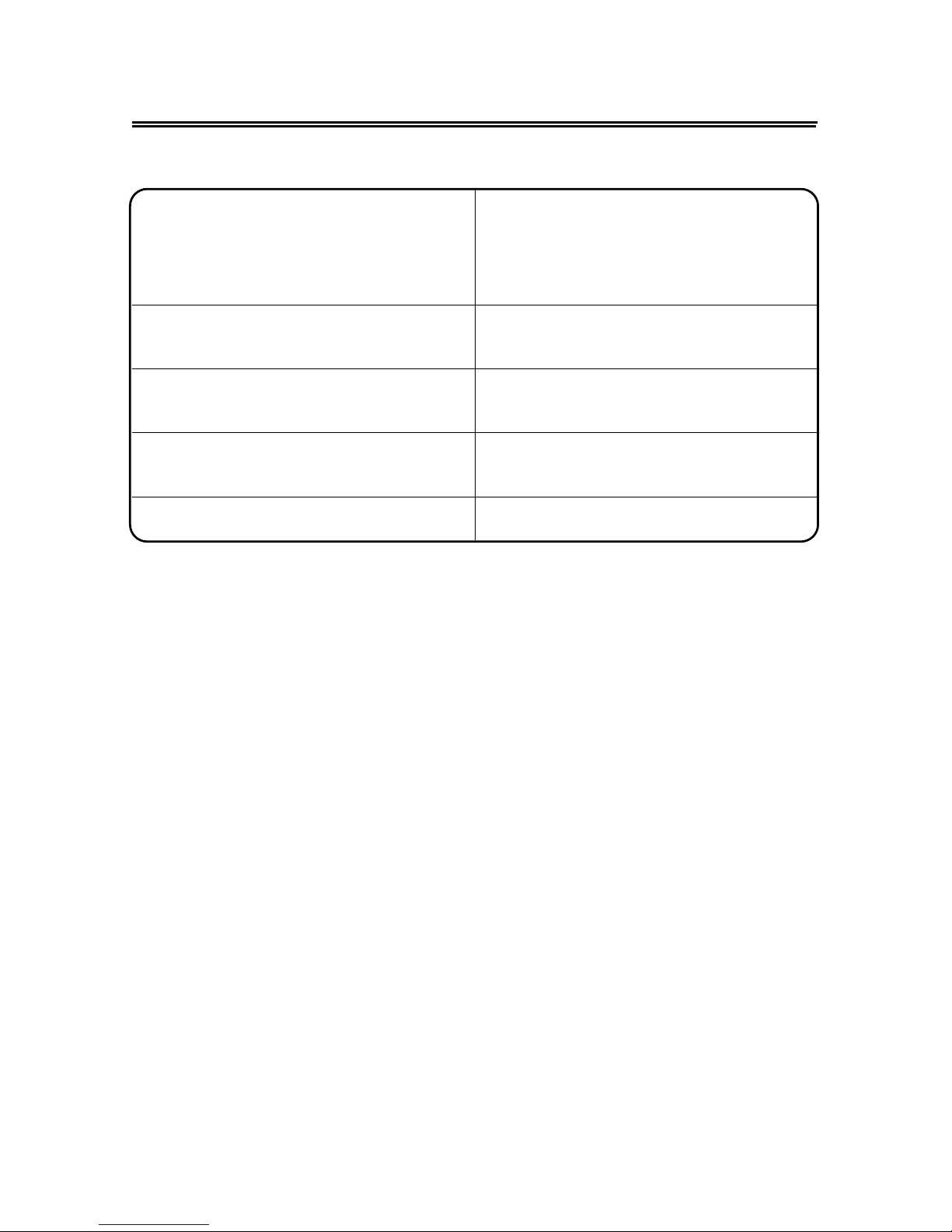

DRIVE CHAIN SLACK ADJUSTMENT

5. Install:

Drive chain

Joint

Master link clip

CAUTION:

Be sure to install the master link clip to the

direction as shown.

Turning direction

6. Lubricate:

Drive chain

Drive chain lubricant:

SAE 10W-30 motor oil or suitable chain lubricants

DRIVE CHAIN SLACK ADJUSTMENT

1. Elevate the rear wheel by placing the

suitable stand under the engine.

2. Check:

Drive chain slack A

Above the seal guard installation bolt.

Out of specification m Adjust.

NOTE:

Before checking or adjusting, rotate the

rear wheel through several revolutions and

check the slack several times to find the tightest point. Check and/or adjust the drive chain

slack with the rear wheel in this “tight chain”

position.

Drive chain slack:

30 ~ 50 mm

ķ

ĸ

Ĺ

A

A

Page 40

3 - 18

FRONT FORK INSPECTION

3. Adjust:

Drive chain slack

Drive chain slack adjustment steps:

Loosen the axle nut ① and locknuts ② .

Adjust the drive chain slack by turning the

adjusters ③ .

To tighten m Turn the adjuster ③ coun-

terclockwise.

To loosen m Turn the adjuster ③ clock-

wise and push wheel forward.

Turn each adjuster exactly the same

amount to maintain correct axle alignment.

NOTE:

Turn the adjuster so that the drive chain is in

line with the sprocket, as viewed from the

rear.

CAUTION:

Too small drive chain slack will overload

the engine and other vital parts; keep the

slack within the specified limits.

Tighten the axle nut while pushing down

the drive chain.

T

R

.

.

Axle nut:

65 Nm (6.5 m • kg)

Tighten the locknuts.

T

R

.

.

Locknut:

12 Nm (1.2 m

FRONT FORK INSPECTION

1. Inspect:

Front fork smooth action

Operate the front brake and stroke the

front fork.

Unsmooth action/oil leakage m Repair

or replace.

• kg)

Page 41

3-19

CHECKING THE BATTERY

CAUTION:

ELECTRICAL SYSTEM

CHECKING THE BATTERY

Batteries generate explosive hydrogen gas

and contain electrolyte which is made of

poisonous and highly caustic sulfuric acid.

Therefore, always follow these preventive

measures:

Wear protective eye gear when handling or

working near batteries.

Charge batteries in a well-ventilated area.

Keep batteries away from fire, sparks or

open flames (e.g., welding equipment,

lighted cigarettes).

DO NOT SMOKE when charging or handling batteries.

KEEP BATTERIES AND ELECTROLYTE

OUT OF REACH OF CHILDREN.

Avoid bodily contact with electrolyte as it

can cause severe burns or permanent eye

injury.

First aid in case of bodily contact:

External

SKIN – Wash with water.

EYES – Flush with water for 15 minutes and

get immediate medical attention.

Internal

Drink large quantities of water or milk fol-

lowed with milk of magnesia, beaten egg or

vegetable oil. Get immediate medical

attention.

1. Disconnect:

battery leads

(from the battery terminals)

First, disconnect the negative lead

1

, then

the positive lead

2

.

2. Remove:

Screw (Battery bracket ) :

WARNING

Page 42

3-20

CHECKING THE BATTERY

CAUTION:

CAUTION:

Add only distilled water. Tap water contains

minerals which are harmful to the battery.

3. Charge:

battery

Battery charging amperage and time

0.4 amps/10 hrs

Do not quick charge a battery.

To ensure maximum performance, always

charge a new battery before using it.

Do not use a high-rate battery charger.

They force a high-amperage current into

the battery quickly and can cause battery

overheating and battery plate damage.

If it is impossible to regulate the charging

current on the battery charger, be careful

not to overcharge the battery.

When charging a battery, be sure to re-

move it from the motorcycle. (If charging

has to be done with the battery mounted on

the motorcycle, disconnect the negative

lead from the battery terminal.)

To reduce the chance of sparks, do not

plug in the battery charger until the battery

charger leads are connected to the battery.

NOTE:

Before removing the battery charger lead

clips from the battery terminals, be sure to

turn off the battery charger.

Make sure that the battery charger lead

clips are in full contact with the battery terminal and that they are not shorted. A corroded battery charger lead clip may generate heat in the contact area and a weak clip

spring may cause sparks.

If the battery becomes hot to the touch at

any time during the charging process, disconnect the battery charger and let the battery cool before reconnecting it. Hot batteries can explode!

Replace the battery whenever:

battery voltage does not rise to specification or

bubbles fail to rise during charging,

sulphation of one or more battery cells occurs

(as indicated by the battery plates turning

white or material accumulating in the bottom of

the battery cell),

specific gravity readings after a long, slow

charge indicate that one battery cell’s charge

is lower than the rest,

warpage or buckling of the battery plates or insulators is evident.

WARNING

Page 43

3-21

CHECKING THE FUSES

CAUTION:

NOTE:

CHECKING THE FUSE

The following procedure applies to all of the

fuses.

To avoid a short circuit, always turn the main

switch to “OFF” when checking or replacing

a fuse.

Check:

fuse

a. Connect the pocket tester to the fuse and

check it for continuity.

Set the pocket tester selector to “7

1”.

b. If the pocket tester indicates “d”, replace the

fuse.

REAR SHOCK ABSORBER INSPECTION

1. Inspect:

Swingarm smooth action

Abnormal noise/unsmooth action m

Grease the pivoting points or repair the

pivoting points.

Damage/oil leakage m Replace.

REAR SHOCK ABSORBER INSPECTION

Page 44

3 - 22

REAR SHOCK ABSORBER SPRING PRELOAD

ADJUSTMENT

REAR SHOCK ABSORBER SPRING

PRELOAD ADJUSTMENT

1. Elevate the rear wheel by placing the

suitable stand under the engine.

2. Remove:

Rear frame

3. Loosen:

Locknut

4. Adjust:

Spring preload

By turning the adjuster .

* For EUROPE

NOTE:

Be sure to remove all dirt and mud from

around the locknut and adjuster before

adjustment.

The length of the spring (installed) changes

1.5 mm (0.06 in) per turn of the adjuster.

CAUTION:

Never attempt to turn the adjuster beyond

the maximum or minimum setting.

5. Tighten:

Locknut

6. Install:

Rear frame (upper)

Rear frame (lower)

Stiffer m Increase the spring preload.

(Turn the adjuster in.)

Softer m Decrease the spring preload.

(Turn the adjuster out.)

Spring length (installed) A :

Standard length Extent of adjustment

140 mm 135 ~ 140 mm

T

R

.

.

40 Nm

T

R

.

.

①

②

②

②

( 4 m • kg )

40 Nm

( 4 m • kg )

Page 45

3 - 23

TIRE PRESSURE CHECK/SPOKES INSPECTION AND

TIGHTENING/WHEEL INSPECTION

TIRE PRESSURE CHECK

1. Measure:

Tire pressure

Out of specification m Adjust.

NOTE:

Check the tire while it is cold.

Loose bead stoppers allow the tire to slip off

its position on the rim when the tire pressure

is low.

A tilted tire valve stem indicates that the tire

slips off its position on the rim.

If the tire valve stem is found tilted, the tire is

considered to be slipping off its position. Correct the tire position.

Standard tire pressure:

130 kPa ( 1.3 kgf/cm )

SPOKES INSPECTION AND TIGHTENING

1. Inspect:

Spokes

Bend/damagem Replace.

Loose spoke m Retighten.

2. Tighten:

Spokes

NOTE:

Be sure to retighten these spokes before and

after break-in. After a practice or a race check

spokes for looseness.

T

R

.

.

3 Nm (0.3 m · kg)

WHEEL INSPECTION

1. Inspect:

Wheel runout

Elevate the wheel and turn it.

Abnormal runout m Replace.

①

2

Page 46

3 - 24

STEERING HEAD INSPECTION AND ADJUSTMENT

2. Inspect:

Bearing free play

Exist play m Replace.

STEERING HEAD INSPECTION AND

ADJUSTMENT

1. Elevate the front wheel by placing a suitable stand under the engine.

2. Check:

Steering stem

Grasp the bottom of the forks and gently rock the fork assembly back and

forth.

Free play m Adjust steering head.

3. Check:

Steering smooth action

Turn the handlebar lock to lock.

Unsmooth action m Adjust steering ring

nut.

4. Adjust:

Steering ring nut

Steering ring nut adjustment steps:

Remove the number plate.

Remove the handlebar and handlebar

upper bracket.

Loosen the steering ring nut using the

steering nut wrench .

①

ĸ

Page 47

3 - 25

STEERING HEAD INSPECTION AND ADJUSTMENT

Tighten the steering ring nut using

steering nut wrench .

NOTE:

Apply the lithium soap base grease on the

thread of the steering stem.

Set the torque wrench to the steering nut

wrench so that they form a right angle.

T

R

.

.

Steering ring nut (initial tightening):

30 Nm ( 3 m • kg )

Loosen the steering ring nut one turn.

Retighten the steering ring nut using the

steering nut wrench.

Avoid over-tightening.

Check the steering stem by turning it lock

to lock. If there is any binding, remove the

steering stem assembly and inspect the

steering bearings.

Install the upper bracket ⑤ , washer, steer-

ing stem nut ⑥ , handlebar ⑦ , handlebar

upper holder ⑧

.

CAUTION:

First tighten the bolts on the front side of

the handlebar holder, and then tighten

the bolts on the rear side.

T

R

.

.

Steering stem nut:

70 Nm ( 7 m • kg )

Handlebar upper holder:

25 Nm ( 2.5 m • kg )

③

ĺ

WARNING

Page 48

3 - 26

ELECTRICAL/SPARK PLUG INSPECTION

ELECTRICAL

SPARK PLUG INSPECTION

1. Remove:

Spark plug

2. Inspect:

Electrode ①

Wear/damage m Replace.

Insulator color ②

Normal condition is a medium to light

tan color.

Distinctly different color m Check the

engine condition.

NOTE:

When the engine runs for many hours at low

speeds, the spark plug insulator will become

sooty, even if the engine and carburetor are in

good operating condition.

3. Measure:

Plug gap D

Use a wire gauge or thickness gauge.

Out of specification m Regap.

4. Clean the plug with a spark plug cleaner

if necessary.

Spark plug gap:

0.6 ~ 0.7 mm

5. Tighten:

Spark plug

NOTE:

Before installing a spark plug, clean the gasket surface and plug surface.

Finger-tighten D the spark plug before

torquing to specification E .

T

R

.

.

15 Nm (1.5 m • kg)

Page 49

3 - 27

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

Timing mark accessing screw

2. Check:

Ignition timing

Checking steps:

Start the engine and let it warm up. Let the

engine run at the specified speed.

Engine speed:

1,400 ~ 1,600 r/min

Visually check the stationary pointer D is

within the firing range E on the rotor.

Incorrect firing range m Check rotor and

pickup assembly.

3. Install:

Timing mark accessing screw

Page 50

4 - 1

! ! ! !

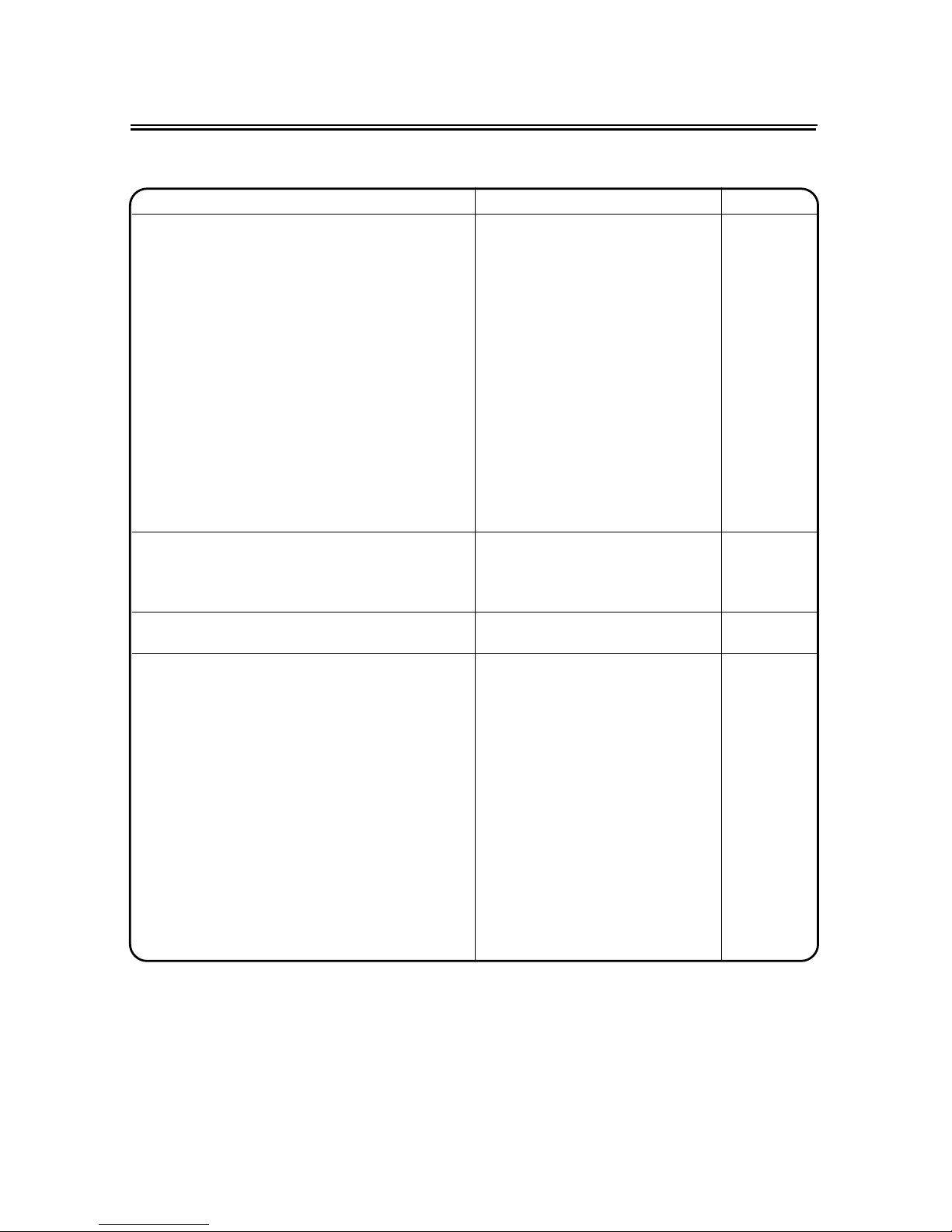

Order Job / Part name Q’ty Remarks

1 LEFT TANK COVER

2 RIGHT TANK COVER

3 SEAT

4 LEFT FENDER PLATE

5 RIGHT FENDER PLATE

6 TAIL FENDER

7 FUEL TANK

8 FUEL CAP

9 PET-COCK

Remove the parts in the order listed.

For installation, reverse the removal procedure.

1

1

1

1

1

1

1

1

1

ENGINE

SEAT, FUEL TANK AND SIDE COVERS

2

5

3

6

1

4

7

8

9

SEAT, FUEL TANK AND SIDE COVERS

Page 51

4 - 2

REMOVAL POINTS

Fuel Tank , Side covers and Seat

Remove:

! ! !

SEAT, FUEL TANK AND SIDE COVERS

Bolt for Tank Cover

Right Tank Cover

Seat Bolt

Bolt for Fuel Tank

Fuel Tank

Screw for Tank Cover and Seat

Left Tank Cover

Screw for Fender plate

Left Fender plate

Right Fender plate

Screw for Fender plate

Seat

Page 52

4 - 3

Order Job / Part name Q’ty Remarks

1 BOLT

2 HOOP

3 RUBBER MAT

4 NUT M6×14

5 EXHAUST MUFFLER

6 EXHAUST PIPE SEAL

Remove the parts in the order listed.

For installation, reverse the removal procedure.

1

1

1

2

1

1

5

3

2

4

6

1

NEW

EXHAUST PIPE AND SILENCER

EXHAUST PIPE AND SILENCER

Page 53

4 - 4

EXHAUST PIPE AND SILENCER

INSPECTION

Silencer and exhaust pipe

1. Inspect:

Gasket ①

Damage

Replace.

ASSEMBLY AND INSTALLATION

Silencer and exhaust pipe

1. Install:

Gasket ①

Exhaust muffler

Nut (exhaust pipe)

NOTE:

First, temporarily tighten the Nut ķ (exhaust

pipe), then tighten

the bolt ĸ

T

R

.

.

15 Nm (1.5 m • kg)

2. Install:

Washer

Bolt (silencer)

T

R

.

.

25 Nm (2.5 m • kg)

m

Page 54

4 - 5

Order Job / Part name Q’ty Remarks

1 SCREW FOR AIR-FITER CLAMP

2 AIR-FITER

3 CRBURETOR

4 GASKET,HEAT INSULATING,

CRBURETOR

5 O-RING

6 INLET PIPE

7 O-RING

8 GASKET

Remove the parts in the order listed.

For installation, reverse the removal procedure.

CRBURETOR & AIR-FITER

CRBURETOR & AIR-FITER

1

1

1

2

1

1

1

1

NEW

NEW

NEW

Page 55

4 - 6

CARBURETOR DISASSEMBLY

! ! ! !

Order Job / Part name Q’ty Remarks

1 UPPER COVER

2 GASKET,UPPER COVER

3 RETURN SPRING,AIR THROTTLE

4 V-CLIP

5 E-CIRCLIP

6 NEEDLE,JET

7 AIR THROTTLE

8 O-RING

9 ADJUSTING SCREW,AIR THROTTLE

Remove the parts in the order listed.

For installation, reverse the removal procedure.

10 SPRING,ADJUSTING SCREW

11 O-RING

12 WASHER

13 ADJUSTING SCREW SPRING

14 IDLE FOAM JET

15 MAIN JET,OIL

16 MAIN JET,FOAM

17 MAIN MEASURING HOLE

18 IDLE JET

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

NEW

NEW

CARBURETOR DISASSEMBLY

Page 56

4 - 7

CARBURETOR DISASSEMBLY

Order Job / Part name Q’ty Remarks

Remove the parts in the order listed.

For installation, reverse the removal procedure.

19 FLOAT COMP

20 NEEDLE VALVE,CARBURETOR

FLOAT

21 HOOK,NEEDLE VALVE

22 FLOAT PIN

23 GASKET,FLOAT CHAMBER

24 DRAIN SCREW

25 O-RING

27 SCREW UNIT,FLOAT CHAMPER

28 PIPE CLIP

29 HOSE

1

1

1

1

1

1

3

1

1

1

NEW

NEW

CARBURETOR DISASSEMBLY

Page 57

4 - 8

CARBURETOR

INSPECTION

Carburetor

1. Inspect:

Carburetor body

Contamination → Clean.

NOTE:

Use a petroleum based solvent for cleaning.

Blow out all passages and jets with compressed air.

Never use a wire.

2. Inspect:

Adjust Screw,Mixture ①

Idle Jet ②

Main Measuring Hole and Main Nozzi ③

Main Jet ④

Drain Screw ⑤

Damage → Replace.

Contamination → Clean.

NOTE:

Use a petroleum based solvent for cleaning.

Blow out all passages and jets with compressed air.

Never use a wire.

Needle valve

1. Inspect:

Needle valve ①

Valve seat ②

Grooved wear b → Replace.

Dust c → Clean.

Jet needle

1. Inspect:

Jet needle ①

Bends/wear → Replace.

Clip groove

Free play exists/wear → Replace.

Clip position

Standard clip position:

No.4 Groove

Page 58

4 - 9

! ! ! !

Order Job / Part name Q’ty Remarks

1 COVER,L.RR.CRANKCASE

2 INITIATIVE CHAIN DRIVER RIVET

PLANK

3 DRIVING GEAR

4 SHIFT PEDAL

5 GUAGE OIL LEVER

6 KICK STARTER

7 SPARK PLUG CAP

8 ENGINE SKID PLATE

Remove the parts in the order listed.

For installation, reverse the removal procedure.

1

1

1

1

1

1

1

1

1

1

1

1

2

SPROCKET REPLACEMENT

1

12

2

3

4

6

7

13

13

10

11

9

9 SIDE STAND

10 RIGHT FOOT PAGS

11 LEFT FOOT PEGS

12 BRACKET FOR PEDAL

13 AXLE

SPROCKET REPLACEMENT

8

5

Page 59

4 - 10

CYLINDER HEAD

CYLINDER HEAD

6

3

2

8

9

7

1

4

5

10

11

Order Job / Part name Q’ty Remarks

1 Spark plug

2 Bolt M6 x 110

3 Cylinder cover L / Gasket

4 Timing driven sprocket

5 Valve cover / O-ring

6 Valve cover / O-ring

7 Cylinder cover

8 Gasket,cylinder cover

9 Cylinder head

Remove the parts in the order listed.

For installation, reverse the removal procedure.

10 Gasket,cylinder head

11 Rectangle ring

1

1

1

1

1

1

1

1

1

1

1

NEW

NEW

NEW

NEW

NEW

NEW

Page 60

4 - 11

CYLINDER HEAD

REMOVING THE CYLINDER HEAD

2. Align:

“I” mark

a

on the generator rotor (with the

stationary pointer

b

on the crankcase cov-

er)

a. Turn the primary pulley counterclockwise.

b. When the piston is at TDC on the compres-

sion stroke, align the “I” mark

c

on the cam-

shaft sprocket with the mark

d

on the cylin-

der head.

3. Loosen:

Bolt

1

1. Remove:

Long Bolt A

4. Remove:

Bolt

2

Nut B

Page 61

4 - 12

CYLINDER HEAD

Bolt

1

Washer

2

Spring Chain Tensioner Push Road ③

NOTE:

To prevent the timing chain from falling into the

crankcase, fasten it with a wire

a

.

While holding the generator rotor bolt with a

wrench, remove the bolt.

Chain Tensioner Push Road Assembly④

5 Remove Chain Tensioner

Page 62

4 - 13

CYLINDER HEAD

NOTE:

NOTE:

NOTE:

6. Remove:

cylinder head

Loosen the

nuts ķĸĹĺĻ

in the proper sequence.

Loosen each nut 1/2 of a turn at a time.

After all of the nuts are fully loosened, remove

them.

CHECKING THE CYLINDER HEAD

1. Eliminate:

combustion chamber carbon deposits

(with a rounded scraper)

Do not use a sharp instrument to avoid damaging or scratching:

spark plug threads

valve seats

2. Check:

cylinder head

Damage/scratches

Replace.

3. Measure:

cylinder head warpage

Out of specification

Resurface the cylin-

der head.

Cylinder head warpage

Less than 0.03 mm

a. Place a straightedge

1

and a thickness

gauge

2

across the cylinder head.

b. Measure the warpage.

c. If the limited isexceeded, resurface the cylin-

der head as follows.

d. Place a 400

600 grit wet abrasive paper

on the surface plate and resurface the cylinder head using a figure-eight sanding pattern.

To ensure an even surface, rotate the cylinder

head several times.

Page 63

4 - 14

CYLINDER HEAD

NOTE:

CHECKING THE TIMING CHAIN TENSIONER

1. Check:

timing chain tensioner

Cracks/damage

Replace.

CHECKING THE TAPPET COVERS AND

CAMSHAFT SPROCKET COVER

The following procedure applies to both of the

tappet covers and O-rings.

1. Check:

tappet cover

camshaft sprocket cover

O-ring

Damage/wear

Replace the defective

part(-s).

INSTALLING THE CYLINDER HEAD

1. Install:

dowel pins

1

O-ring (New)

2

gasket (New)

3

2. Install:

cylinder head

Apply engine oil onto the threads of the cylinder head nuts.

Tighten the cylinder head nuts in the proper

tightening sequence as shown and torque

them in two stages.

Cylinder head nut and bolt

M7 (

1 4

) 15Nm

M6 (

5

) 10Nm

M6 (

6

) 10Nm

M6 (

7

) 10Nm

M30(

8

) 20Nm

1

1

Page 64

4 - 15

CYLINDER HEAD

NOTE:

NOTE:

CAUTION:

6 Nm (0.6 m kg)

INSTALLING THE CAMSHAFT SPROCKET

1. Align:

“I” mark on the generator rotor

(with the mark on the generator rotor cover)

a. Turn the crankshaft counterclockwise.

b. When the piston is at TDC on the compres-

sion stroke, align the “I” mark

a

on the gen-

erator rotor with the mark

b

on the genera-

tor rotor cover.

Be sure to keep the timing chain as tight as possible.

2. Install:

timing chain

(onto the camshaft sprocket)

camshaft sprocket

(onto the camshaft)

The notch

a

on the camshaft should face towards the intake side of the engine.

Align the camshaft marks

a

with the edge of

the cylinder head as shown.

Do not turn the crankshaft when installing

the camshaft to avoid damage or improper

valve timing.

3. Install:

Timing chain tensioner bolt and washer (New)

1

Camshaft sprocket bolts

2

12 Nm (1.2 m kg)

Page 65

4 - 16

Order Job / Part name Q’ty Remarks

1 RIGHT COVER,CYLINDER HEAD

2 GASKET

3 SHAFT,VALVE RROCKER ARM

4 ADJUSTING NUT

5 ADJUSTING SCREW

6 VALVE RROCKER ARM

7 CAM SHAFT

8 VALVE COTTER

9 PETAINER,VALVE SPRING

Remove the parts in the order listed.

For installation, reverse the removal procedure.

1

1

2

2

2

2

1

4

2

2

2

2

1

1

10 VALVE INNER SPRING

11 VALVE OUTER SPRING

12 VALVE STEM SEAL

13 INTAKE VALVE

14 EXHAUST VALVE

CAMSHAFT /VALVES AND VALVE SPRINGS

CAMSHAFT /VALVES AND VALVE SPRINGS

4

3

6

8

9

7

1

2

5

10

11

12

13

14

NEW

NEW

Page 66

4 - 17

CAMSHAFT /VALVES AND VALVE SPRINGS

REMOVING THE ROCKER ARMS AND CAMSHAFT

1. Loosen:

locknuts

1

adjusting screws

2

2. Remove:

3. Remove:

camshaft

1

intake rocker arm shaft ①

exhaust rocker arm shaft ②

intake rocker arm

exhaust rocker arm

CHECKING THE CAMSHAFTS

1. Check:

camshaft bushings

Damage/wear

Replace.

camshaft lobes

Blue discoloration/pitting/ scratches

Replace the camshaft.

3

4

4

3

Page 67

4 - 18

CAMSHAFT /VALVES AND VALVE SPRINGS

A

2 Measure:

camshaft lobe dimensions

A

Out of specification Replace the camshaft.

Camshaft lobe dimension limit

Intake

26.30 mm

Exhaust

26.00 mm

3. Check:

camshaft oil passage

Obstruction

Blow out with compressed air.

CHECKING THE ROCKER ARMS AND

ROCKER ARM SHAFTS

The following procedure applies to all of the

rocker arms and rocker arm shafts.

1. Check:

rocker arm

Damage/wear

Replace.

2. Check:

rocker arm shaft

Blue discoloration / excessive wear/pitting/scratches

Replace or check the lu-

brication system.

3. Check:

camshaft lobe

Excessive wear

Replace the camshaft.

4. Measure:

rocker arm inside diameter

Out of specification

Replace.

Rocker arm inside diameter

10.000

10.015 mm

Limit 10.1 mm

5. Measure:

rocker arm shaft outside diameter

Out of specification

Replace.

Rocker arm shaft outside

diameter

9.98 9.995 mm

Limit 9.910

mm

Page 68

4 - 19

CAMSHAFT /VALVES AND VALVE SPRINGS

NOTE:

NOTE:

NOTE:

6. Calculate:

rocker-arm-to-rocker-arm-shaft clearance

Calculate the clearance by subtracting the rocker arm shaft outside diameter from the rocker

arm inside diameter.

Out of specification

Replace the defective

part(-s).

Rocker-arm-to-rocker-arm-shaft

clearance

0.005

0.035 mm

INSTALLING THE CAMSHAFT AND ROCKER ARMS

1. Lubricate:

rocker arm shaft

Recommended lubricant

Molybdenum disulfide oil

2. Install:

exhaust rocker arm

exhaust rocker arm shaft

Make sure that the exhaust rocker arm shaft is

completely pushed into the cylinder head.

3. Install:

intake rocker arm

intake rocker arm shaft

1

Insert the camshaft into the hole in the cylinder

head and the intake rockerarm shaft as shown .

4. Lubricate:

Camshaft

Recommended lubricant

Camshaft

Molybdenum disulfide oil

Camshaft bearing

Engine oil

3

2

4

Page 69

4 - 20

CAMSHAFT /VALVES AND VALVE SPRINGS

NOTE:

NOTE:

NOTE:

REMOVING THE VALVES

The following procedure applies to all of the

valves and related components.

Before removing the internal parts of the cylinder head (e.g., valves, valve springs, valve

seats), make sure that the valves properly seal.

1. Check:

valve sealing

Leakage at the valve seat

Check the valve

face, valve seat, and valve seat width.

Refer to “CHECKING THE VALVE SEATS”.

a. Pour a clean solvent

a

into the intake and

exhaust ports.

b. Check that the valves properly seal.

There should be no leakage at the valve seat

1

.

2. Remove:

valve cotters

1

Remove the valve cotters by compressing the

valve springs with the valve spring compressor

2

and attachment 3.

3. Remove:

upper spring seat

1

valve springs

2

oil seal

3

4

valve

Identify the position of each part very carefully

so that it can be reinstalled in its original place.

Page 70

4 - 21

CAMSHAFT /VALVES AND VALVE SPRINGS

NOTE:

NOTE:

CHECKING THE VALVES AND VALVE GUIDES

The following procedure applies to all of the

valves and valve guides.

1. Measure:

valve-stem-to-valve-guide clearance

Valve-stem-to-valve-guide clearance =

Valve guide inside diameter

a

–

Valve stem diameter

b

Out of specification Replace the valve

guide.

Valve-stem-to-valve-guide clearance

Intake

0.015

0.042 mm

Limit: 0.08 mm

Exhaust

0.030

0.057 mm

Limit: 0.10 mm

2. Replace:

valve guide

To ease valve guide removal and installation,

and to maintain the correct fit, heat the cylinder

head to 100

C in an oven.

a. Remove the valve guide with a valve guide

remover

1

.

b. Install the new valve guide with a valve guide

installer

2

and valve guide remover 1.

c. After installing the valve guide, bore the

valve guide with a valve guide reamer

3

to

obtain the proper valve-stem-to-valve-guide

clearance.

After replacing the valve guide, reface the valve

seat.

Page 71

4 - 22

CAMSHAFT /VALVES AND VALVE SPRINGS

NOTE:

3. Eliminate:

carbon deposits

(from the valve face and valve seat)

4. Check:

valve face

Pitting/wear

Grind the valve face.

valve stem end

Mushroom shape or diameter larger than the

body of the valve stem

Replace the valve.

5. Measure:

valve margin thickness

a

Out of specification Replace the valve.

Valve margin thickness

0.65

0.95 mm

6. Measure:

valve stem runout

Out of specification

Replace the valve.

When installing a new valve, always replace

the valve guide.

If the valve is removed or replaced, always replace the oil seal.

Valve stem runout

Limit: 0.03 mm

CHECKING THE VALVE SEATS

The following procedure applies to all of the

valves and valve seats.

1. Eliminate:

carbon deposits

(from the valve face and valve seat)

2. Check:

valve seat

Pitting/wear

Replace the cylinder head.

3. Measure:

valve seat width

a

Out of specification Replace the cylinder

head.

Valve seat width

Intake: 0.8

1.2mm

Limit: 1.6 mm

Exhaust: 0.8

1.2mm

Limit: 1.6 mm

Page 72

4 - 23

CAMSHAFT /VALVES AND VALVE SPRINGS

NOTE:

CAUTION:

NOTE:

a. Apply Mechanic’s blueing dye (Dykem)

1

onto the valve face.

b. Install the valve into the cylinder head.

c. Press the valve through the valve guide and

onto the valve seat to make a clear pattern.

d. Measure the valve seat width. Where the

valve seat and valve face contacted one

another, the blueing will have been removed.

4. Lap:

valve face

valve seat

After replacing the cylinder head or replacing

the valve and valve guide, the valve seat and

valve face should be lapped.

a. Apply a coarse lapping compound

a

to the

valve face.

Do not let the lapping compound enter the

gap between the valve stem and the valve

guide.

b. Apply molybdenum disulfide oil onto the

valve stem.

c. Install the valve into the cylinder head.

d. Turn the valve until the valve face and valve

seat are evenly polished, then clean off all of

the lapping compound.

For the best lapping results, lightly tap the valve

seat while rotating the valve back and forth between your hand.

Page 73

4 - 24

CAMSHAFT /VALVES AND VALVE SPRINGS

e. Apply a fine lapping compound to the valve

face and repeat the above steps.

f. After every lapping procedure, be sure to

clean off all of the lapping compound from

the valve face and valve seat.

g. Apply Mechanic’s blueing dye (Dykem)

b

onto the valve face.

h. Install the valve into the cylinder head.

i. Press the valve through the valve guide and

onto the valve seat to make a clear impres-

sion.

j. Measure the valve seat width

c

again. If the

valve seat width is out of specification,reface

and lap the valve seat.

CHECKING THE VALVE SPRINGS

The following procedure applies to all of the

valve springs.

1. Measure:

valve spring free length

a

Out of specification Replace the valve

spring.

Valve spring free length (intake

and exhaust)

Inner spring

33.78 mm Limit: 32.5 mm

Outer spring

35.55 mm Limit: 34.0 mm

2. Measure:

compressed spring force

a

Out of specification Replace the valve

spring.

b

Installed length

Compressed spring force

Intake and exhaust inner

spring

52

64 Nm at 22.45 mm

Intake and exhaust outer

spring

105

129

Nm

at

25.45 mm

3. Measure:

valve spring tilt

a

Out of specification Replace the valve

spring.

Spring tilt limit

Intake and exhaust inner spring

1.3

/0.8 mm

Intake and exhaust outer spring

1.35

/0.8 mm

Page 74

4 - 25

CAMSHAFT /VALVES AND VALVE SPRINGS

NOTE:

NOTE:

CAUTION:

INSTALLING THE VALVES

The following procedure applies to all of the

valves and related components.

1. Deburr:

valve stem end

(with an oil stone)

2. Lubricate:

valve stem

oil seal

(with the recommended lubricant)

Recommended lubricant

Molybdenum disulfide oil

3. Install:

valve

1

oil seal

2

valve springs

3

upper spring seat