Page 1

PCS 3840

Operating Instructions Read operating instructions before use!

Manuel d’utilisation Lire attentivement le mode d‘emploi avant chaquemise en service !

EN

73701540

FR

Page 2

1

EN

1. For Safe Operation

Dear Customer,

Firstly, we wish to thank you for having chosen our products and hope that the use of this machine will

be extremely satisfying for you and fully meet your expectations. This manual has been drawn up to

allow your to get to know your machine well and use it in safe and efficient conditions; please do not

forget that it is an integral part of the machine and keep it to hand to be consulted at all times and consign it with the machine if you should sell or lend it to others.

Your new machine has been designed and manufactured to current standards and is safe and reliable

if used in full respect of the instructions contained in this manual (forecast use); any other use or failure to comply with the instructions for safe use, maintenance and repair shall be considered as

“improper use”, cause the warranty to become null and void and relieve the Manufacturer from all

responsibility, with the user becoming responsible for charges for damages or personal or third party

injury.

If any slight differences are found between the description herein and the machine you own, please

bear in mind that due to continual product improvement, the information contained in this manual is

subject to modification without prior notice or obligatory updating, although the essential features for

the purposes of safety and operation remain unchanged. In the event of doubt, please contact your

dealer. Enjoy your work!

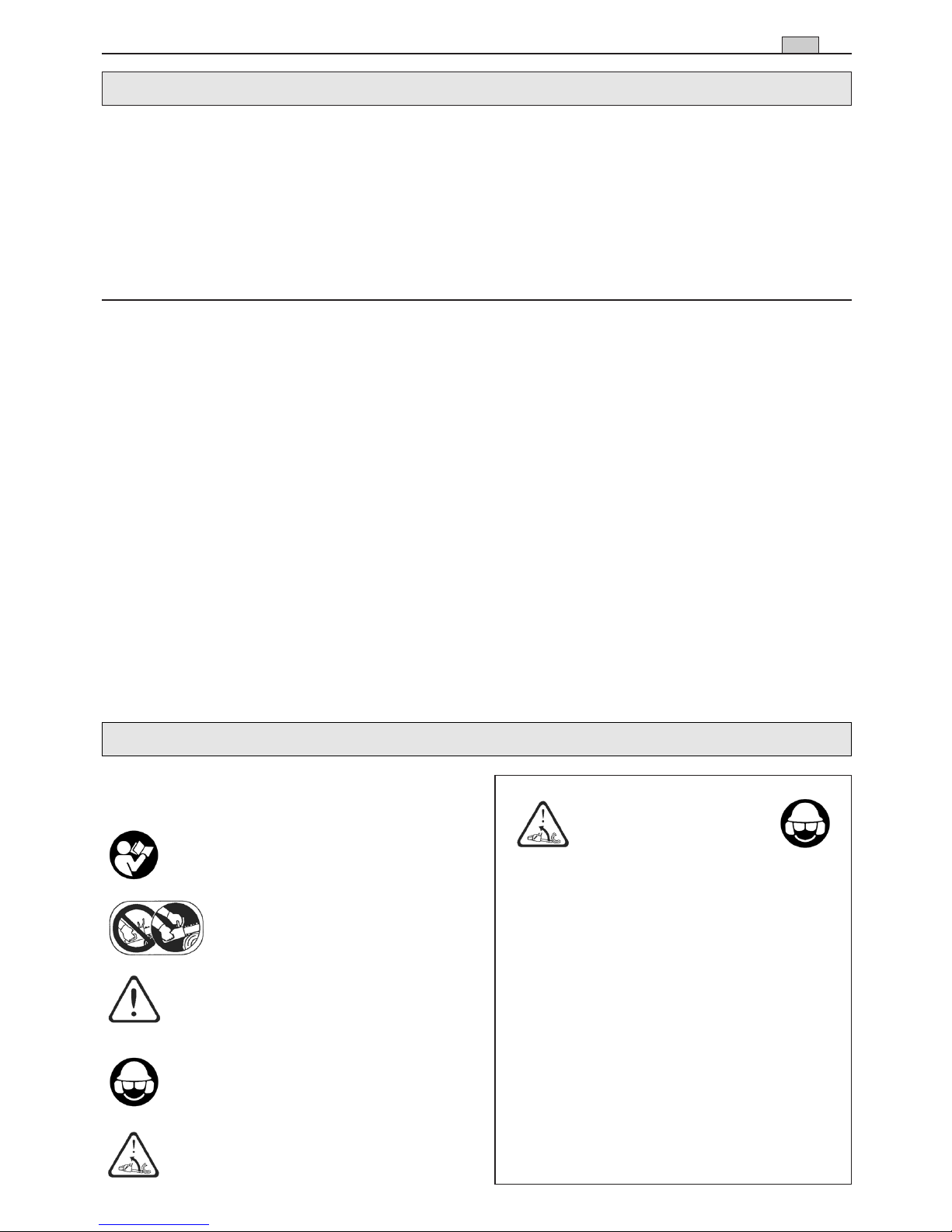

EXPLANATION OF SYMBOLS AND SAFETY

WARNINGS

Read operator's instruction

book before operating this

machine.

Use the chain saw with two

hands.

Read, understand and follow all

warnings.

Wear head, eye and ear protection.

Warning! Danger of kickback.

WARNING!!!

RISK OF DAMAGING HEARING

IN NORMAL CONDITIONS OF USE,

THIS MACHINE MAY INVOLVE A DAILY

LEVEL OF PERSONAL EXPOSURE TO

NOISE FOR THE OPERATOR EQUAL

TO OR GREATER THAN

85 dB(A)

1. For Safe Operation ...................................................................... 1

2. Explanation of Symbols on the Machine ................................... 4

3. Installing Guide Bar and Saw Chain .......................................... 5

4. Fuel and Chain Oil ...................................................................... 6

5. Operating the Engine .................................................................. 8

6. Sawing ....................................................................................... 11

7. Maintenance .............................................................................. 13

8. Maintenance of Saw Chain and Guide Bar .............................. 15

9. Troubleshooting Guide ............................................................. 16

Contents

1. For Safe Operation

Page 3

2MM2

EN

1. For Safe Operation

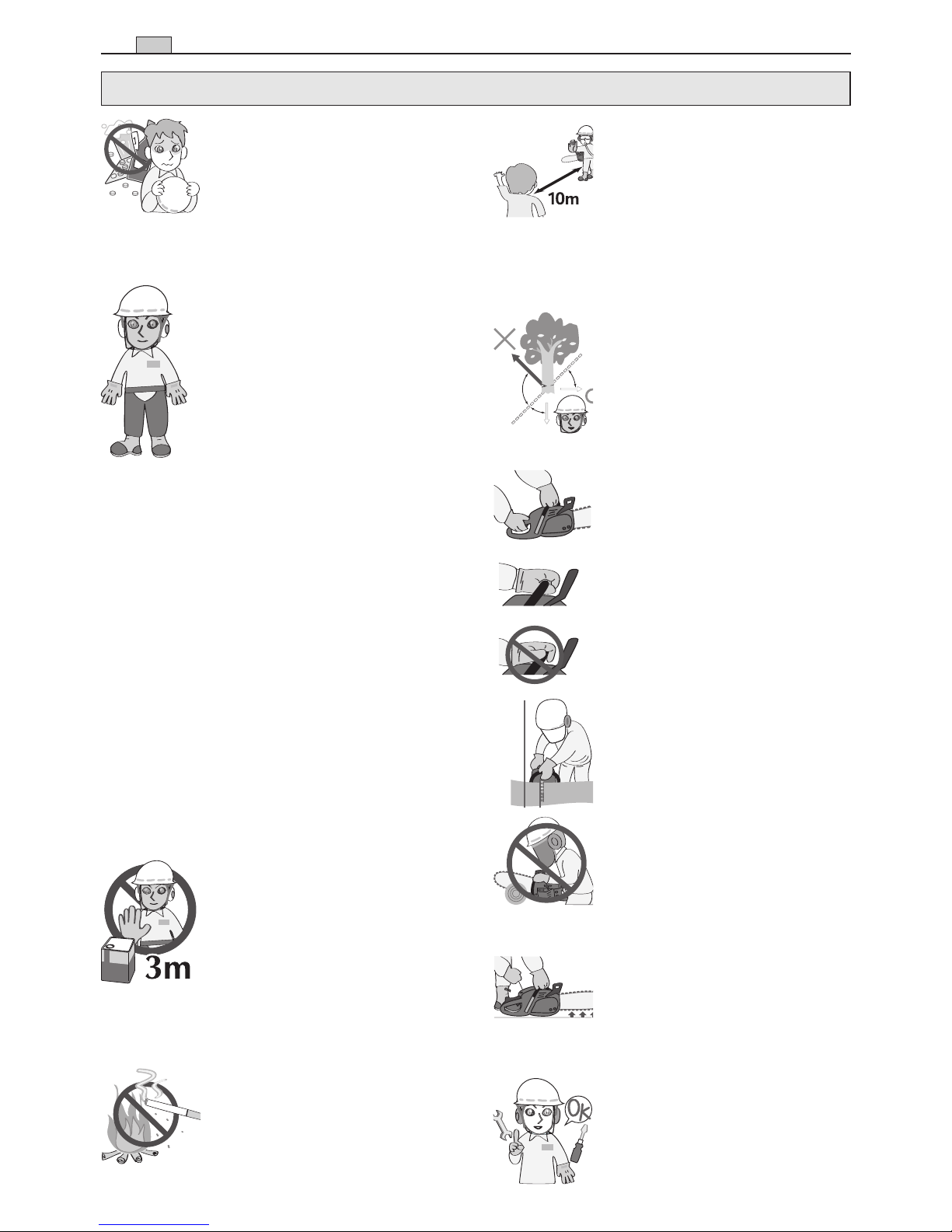

1. Never operate a chain saw

when you are fatigued, ill, or

upset, or under the influence of

medication that may make you

drowsy, or if you are under the

influence of alcohol or drugs.

2. Use safety footwear, snug fitting clothing and eye, hearing and

head protection devices.

Use the vibration-proof glove.

3. Keep the saw chain sharp and

the saw, including the AV system,

well maintained. A dull chain will

increase cutting time, and pressing a dull chain through wood will

increase the vibrations transmitted to your hands. A saw with

loose components or with damaged or worn AV buffers will also

tend to have higher vibration levels.

4. All the above mentioned precautions do not guarantee that

you will not sustain whitefinger

diseaseor carpal tunnel syndrome.

Therefore, continual and regular

users should monitor closely the

condition of their hands and fingers. If any of the above symptoms appear, seek medical advice

immediately.

5. Always use caution when handling fuel. Wipe up all spills and

then move the chain saw at least 3

m from the fueling point before

starting the engine.

6. Eliminate all sources of sparks

or flame (i.e. smoking, open

flames, or work that can cause

sparks) in the areas where fuel is

mixed, poured, or stored.

7. Do not smoke while handling

fuel or while operating the chain

saw.

8. Do not allow other persons to

be near the chain saw when starting or cutting. Keep bystanders

and animals out of the work area.

Children, pets and bystanders

should be a minimum of 10 m

away when you start or operate

the chain saw.

9. Never start cutting until you

have a clear work area, secure

footing, and a planned retreat

path from the falling tree.

10. Always hold the chain saw

firmly with both hands when the

engine is running. Use a firm grip

with thumb and fingers encircling

the chain saw handles.

11. Keep all parts of your body

away from the saw chain when the

engine is running.

12. Before you start the engine,

make sure the saw chain is not

contacting anything.

13. Always carry the chain saw

with the engine stopped, the

guide bar and saw chain to the

rear, and the muffler away from

your body.

14. Always carry the chain saw

with the engine stopped, the

guide bar and saw chain to the

rear, and the muffler away from

your body.

15. All chain saw service, other

than the items listed in the

Owner’s Manual, should be performed by competent chain saw

service personnel. (E.g., if improper tools are used to remove the

flywheel, or if an improper tool is

used to hold the flywheel in order

to remove the clutch, structural

1. For Safe Operation

Page 4

3

EN

1. For Safe Operation

damage to the flywheel could

occur which could subsequently

cause the flywheel to disintegrate.)

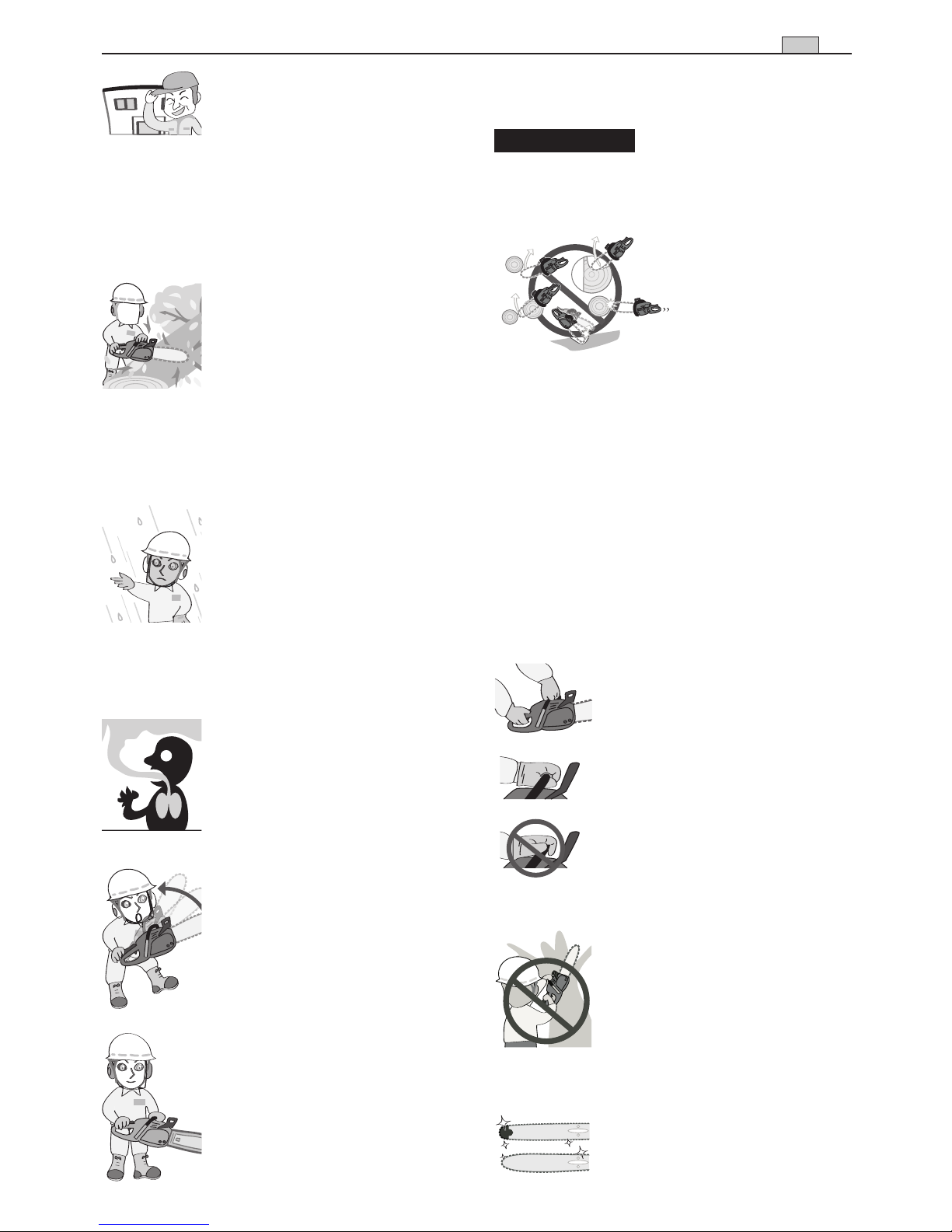

16. Always shut off the engine

before setting it down.

17. Use extreme caution when

cutting small size brush and

saplings because slender material

may catch the saw chain and be

whipped toward you or pull you

off balance.

18. When cutting a limb that is

under tension, be alert for springback so that you will not be struck

when the tension in the wood

fibers is released.

19. Never cut in high wind, bad

weather, when visibility is poor or

in very high or low temperatures.

Always check the tree for dead

branches which could fall during

the felling operation.

20. Keep the handles dry, clean

and free of oil or fuel mixture.

21. Operate the chain saw only in

well ventilated areas. Never start

or run the engine inside a closed

room or building. Exhaust fumes

contain dangerous carbon

monoxide.

22. Do not operate the chain saw

in a tree unless specially trained to

do so.

23. Guard against kickback.

Kickback is the upward motion of

the guide bar which occurs when

the saw chain at the nose of the

guide bar contacts an object.

Kickback can lead to dangerous

loss of control of the chain saw.

24. When transporting your chain

saw, make sure the appropriate

guide bar scabbard is in place.

KICKBACK SAFETY PRECAUTIONS FOR

CHAIN SAW USERS

Kickback may occur when

the nose or tip of the guide bar touches an

object, or when the wood closes in and

pinches the saw chain in the cut. Tip contact

in some cases may cause a lightning fast

reverse reaction, kicking the guide bar up

and back towards the

operator.

Pinching the saw

chain along the top of

the guide bar may

push the guide bar

rapidly back towards the operator. Either of

these reactions may cause you to lose control

of the saw, which could result in serious personal injury.

• Do not rely exclusively on the safety devices

built into your saw. As a chain saw user you

should take several steps to keep cutting

jobs free from accident or injury.

1. With a basic understanding of kickback you

can reduce or eliminate the element of surprise.

Sudden surprise contributes to accidents.

2. Keep a good grip on the saw

with both hands, the right hand on

the rear handle, and the left hand

on the front handle, when the

engine is running. Use a firm grip

with thumbs and fingers encircling

the chain saw handles. A firm grip

will help you reduce kickback and

maintain control of the saw.

3. Make certain that the area in

which you are cutting is free from

obstructions. Do not let the nose

of the guide bar contact a log,

branch, or any other obstruction

which could be hit while you are

operating the saw.

4. Cut at high engine speeds.

5. Do not overreach or cut above

shoulder height.

6. Follow the manufacturer’s

sharpening and maintenance

instructions for the saw chain.

7. Only use replacement bars and

chains specified by the manufacturer or the equivalent.

!

WARNING!

Page 5

4MM4

EN

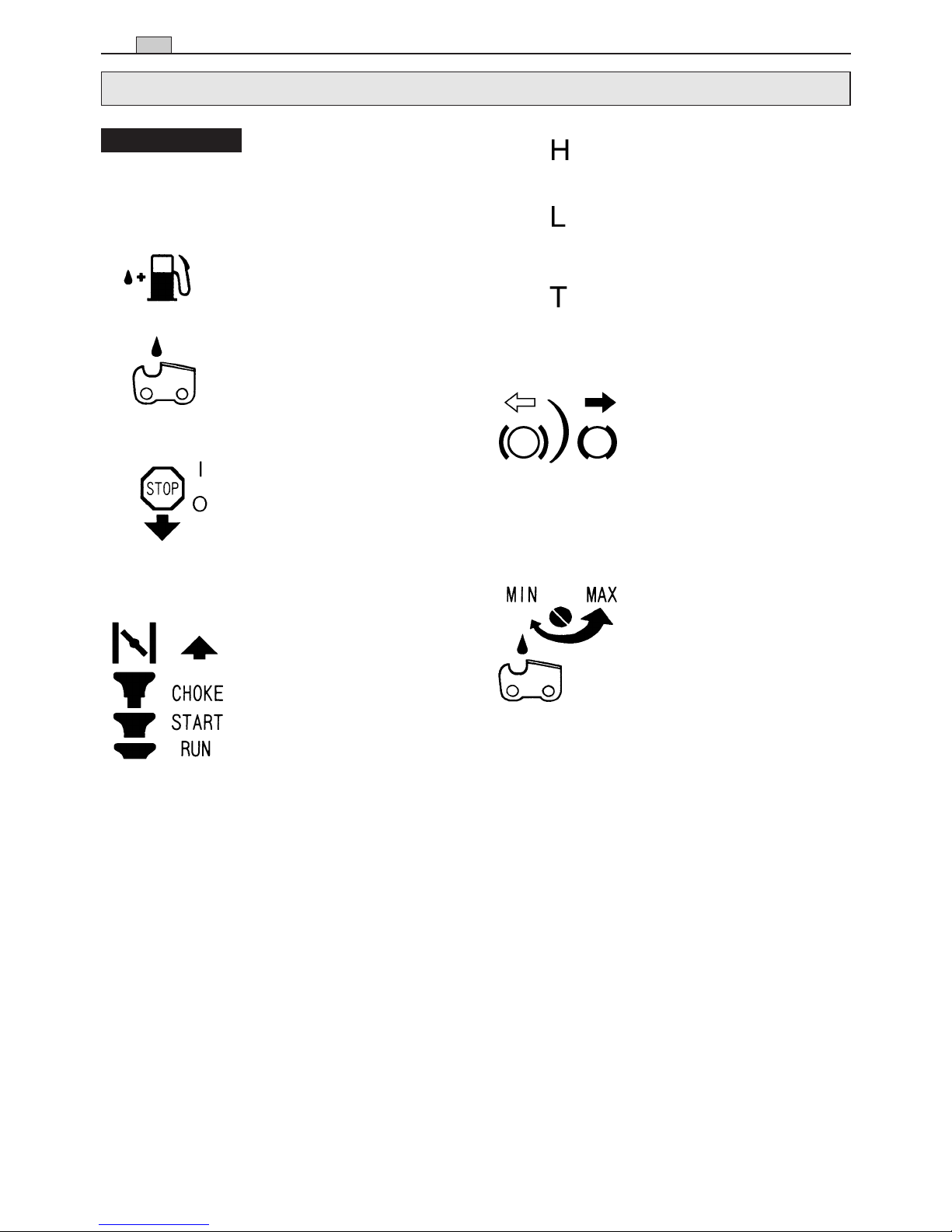

2. Explanation of Symbols on the Machine

For safe operation and

maintenance, symbols are carved in relief on

the machine.

According to these indications, please be

careful not to make any mistake.

The port to refuel “MIX GASOLINE”

Position: Fuel cap

The port to top up chain oil

Position: Oil cap

Setting the switch to the “I”

position, the engine starts.

Setting the switch to the “O”

position, the engine stops

immediately.

Position: Front at the top of

the rear handle

Starting the engine. If you pull

out the choke knob (at the

back-right of the rear handle)

to the point of the arrow, you

can set the starting mode as

follows:

• First-stage position – starting mode when the engine is

warm.

• Second-stage position –

starting mode when the

engine is cold.

Position: Upper-right of the

aircleaner cover

!

WARNING!

The screw under the “H”

stamp is The High-speed

adjustment screw.

The screw under the “L” stamp

is The Slow-speed adjustment

screw.

The screw at the left of the “T”

stamp is the Idle adjustment

screw.

Position: Left side of the rear

handle

Shows the directions that the

chain brake is released (white

arrow) and activated (black

arrow).

Position: Front of the chain

cover

If you turn the rod by screwdriver follow the arrow to the

"MAX" position, the chain oil

flow more, and if you turn to

the "MIN" position, less.

Position: Bottom of the

power unit

2. Explanation of Symbols on the Machine

Page 6

5

EN

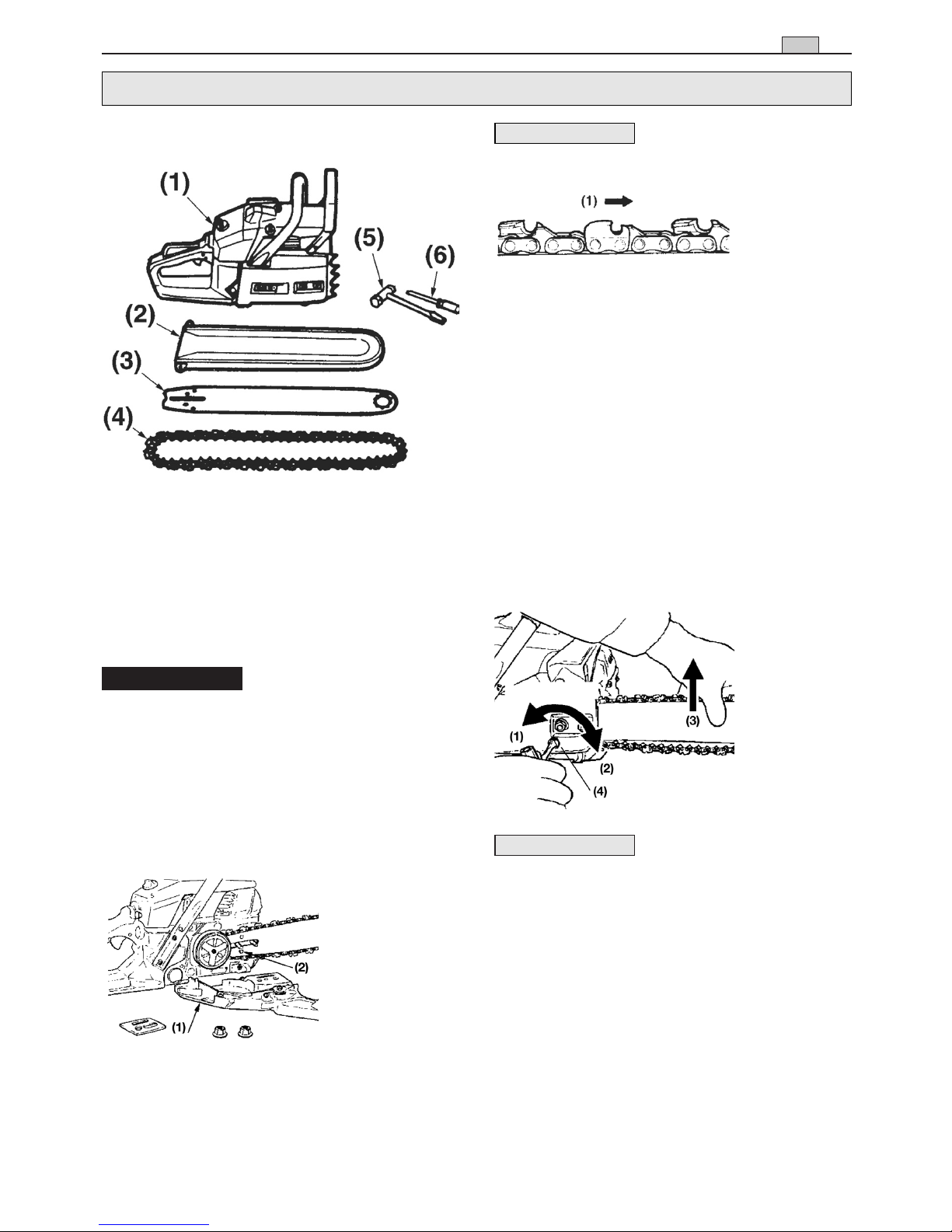

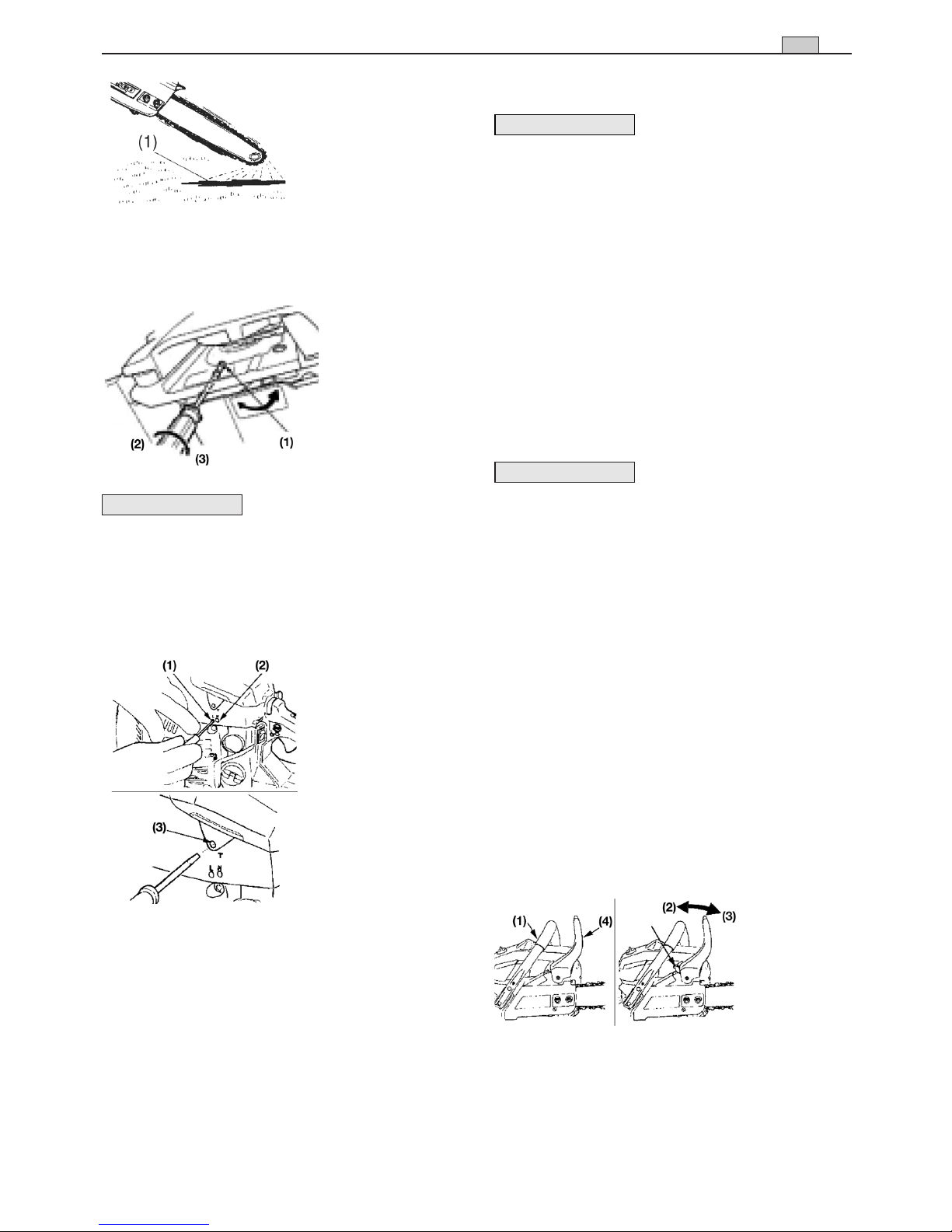

3. Installing Guide Bar and Saw Chain

A standard saw unit package contains the items

as illustrated.

Open the box and install the guide bar and the

saw chain on the power unit as follows:

The saw chain has very

sharp edges. Use thick protective gloves for

safety.

1. Pull the guard towards the front handle to

check that the chain brake is not engaged.

2. Loosen the nuts and remove the chain cover.

3. Gear the chain to the sprocket and, while fit-

ting the saw chain around the guide bar,

mount the guide bar to the power unit. Adjust

the position of chain tensioner nut.

!

WARNING!

Pay attention to the correct

direction of the saw chain.

4. Fit the chain cover to the power unit and fasten the nuts to finger tightness.

5. While holding up the tip of the bar, adjust the

chain tension by turning the tensioner screw

until the tie straps just touch the bottom side

of the bar rail.

6. Tighten the nuts securely with the bar tip held

up (12 ~ 15 Nm). Then check the chain for

smooth rotation and proper tension while

moving it by hand. If necessary, readjust with

the chain cover loose.

7. Tighten the tensioner screw.

A new chain will expand its

length in the beginning of use. Check and readjust the tension frequently as a loose chain can

easily derail or cause rapid wear of itself and the

guide bar.

NOTE

NOTE

3. Installing Guide Bar and Saw Chain

(1) Chain cover

(2) Chain Tensioner

nut

(1) Moving

direction

(1) Loosen

(2) Tighten

(3) Lift up

(4) Tensioner

screw

(1) Power unit

(2) Bar protector

(3) Guide bar

(4) Saw chain

(5) Plug wrench

(6) Screwdriver for carburetor adjustment

Page 7

6MM6

EN

4. Fuel and Chain Oil

• FUEL

Gasoline is very flammable. Avoid smoking or bringing any flame or

sparks near fuel.

Make sure to stop the engine and allow it cool

before refueling the unit.

Select outdoor bare ground for fueling and

move at least 3 m (10 ft) away from the fueling point before starting the engine.

• The engines are lubricated by oil specially for-

mulated for air-cooled 2-cycle gasoline engine

use. Use an anti-oxidant added quality oil

expressly labeled for air-cooled 2-cycle engine

use (JASO FC GRADE OIL or ISO EGC

GRADE).

• Do not use BIA or TCW (2-stroke water-cool-

ing type) mixed oil.

• RECOMMENDED MIXING RATIO GASO-

LINE 50: OIL 1

• Exhaust emission are controlled by the funda-

mental engine parameters and components

(eq., carburation, ignition timing and port timing) without addition of any major hardware or

the introduction of an inert material during

combustion.

• These engines are certified to operate on

unleaded gasoline.

• Make sure to use gasoline with a minimum

octane number of 89RON (USA/Canada:

87AL).

• If you use a gasoline of a lower octane value

!

WARNING!

than prescribed, there is a danger that the

engine temperature may rise and an engine

problem such as piston seizing may consequently occur.

• Unleaded gasoline is recommended to reduce

the contamination of the air for the sake of

your health and the environment.

• Poor quality gasolines or oils may damage

sealing rings, fuel lines or fuel tank of the

engine.

• HOW TO MIX FUEL

Pay attention to agitation.

1. Measure out the quantities of gasoline and oil

to be mixed.

2. Put some of the gasoline into a clean,

approved fuel container.

3. Pour in all of the oil and agitate well.

4. Pour in the rest of gasoline and agitate again

for at least one minute. As some oils may be

difficult to agitate depending on oil ingredients, sufficient agitation is necessary for the

engine to last long. Be careful that, if the agitation is insufficient, there is an increased

danger of early piston seizing due to abnormally lean mixture.

5. Put a clear indication on the outside of the

container to avoid mixing up with gasoline or

other containers.

6. Indicate the contents on outside of container

for easy identification.

• FUELING THE UNIT

1. Untwist and remove the fuel cap. Rest the

cap on a dustless place..

2. Put fuel into the fuel tank to 80% of the full

capacity.

3. Fasten the fuel cap securely and wipe up any

fuel spillage around the unit.

!

WARNING!

4. Fuel and Chain Oil

Page 8

7

EN

4. Fuel and Chain Oil

1. Select flat and bare ground for fueling.

2. Move at least 10 feet (3 meters) away from

the fueling point before starting the

engine.

3. Stop the engine before refueling the unit.

At that time, be sure to sufficiently agitate

the mixed gasoline in the container.

• FOR YOUR ENGINE LIFE, AVOID:

1. FUEL WITH NO OIL (RAW GASOLINE) – It will

cause severe damage to the internal engine

parts very quickly.

2. GASOHOL – It can cause deterioration of

rubber and/or plastic parts and disruption of

engine lubrication.

3. OIL FOR 4-CYCLE ENGINE USE – It can

cause spark plug fouling, exhaust port blocking, or piston ring sticking.

4.

Mixed fuels which have been left unused

for a period of one month or more may clog

the carburetor and result in the engine failing

to operate properly.

5. In the case of storing the product for a long

period of time, clean the fuel tank after rendering it empty. Next, activate the engine and

empty the carburetor of the composite fuel.

6. In the case of scrapping the used mixed oil

container, scrap it only at an authorized

repository site.

Moreover, normal wear and

change in product with no functional influence

are not covered by the warranty. Also, be careful

that, if the usage in the instruction manual is not

observed as to the mixed gasoline, etc.

described therein, it may not be covered by the

warranty.

• CHAIN OIL

Use motor oil SAE #10W-30 all year round or

SAE 30 ~ #40 in summer and SAE #20 in winter.

Do not use wasted or regenerated oil that can cause damage to the oil

pump.

NOTE

NOTE

!

WARNING!

Page 9

8MM8

EN

5. Operating the Engine

It is very dangerous to run

a chainsaw that mounts broken parts or lacks

any parts. Before starting engine, make sure

that all the parts including bar and chain are

installed properly.

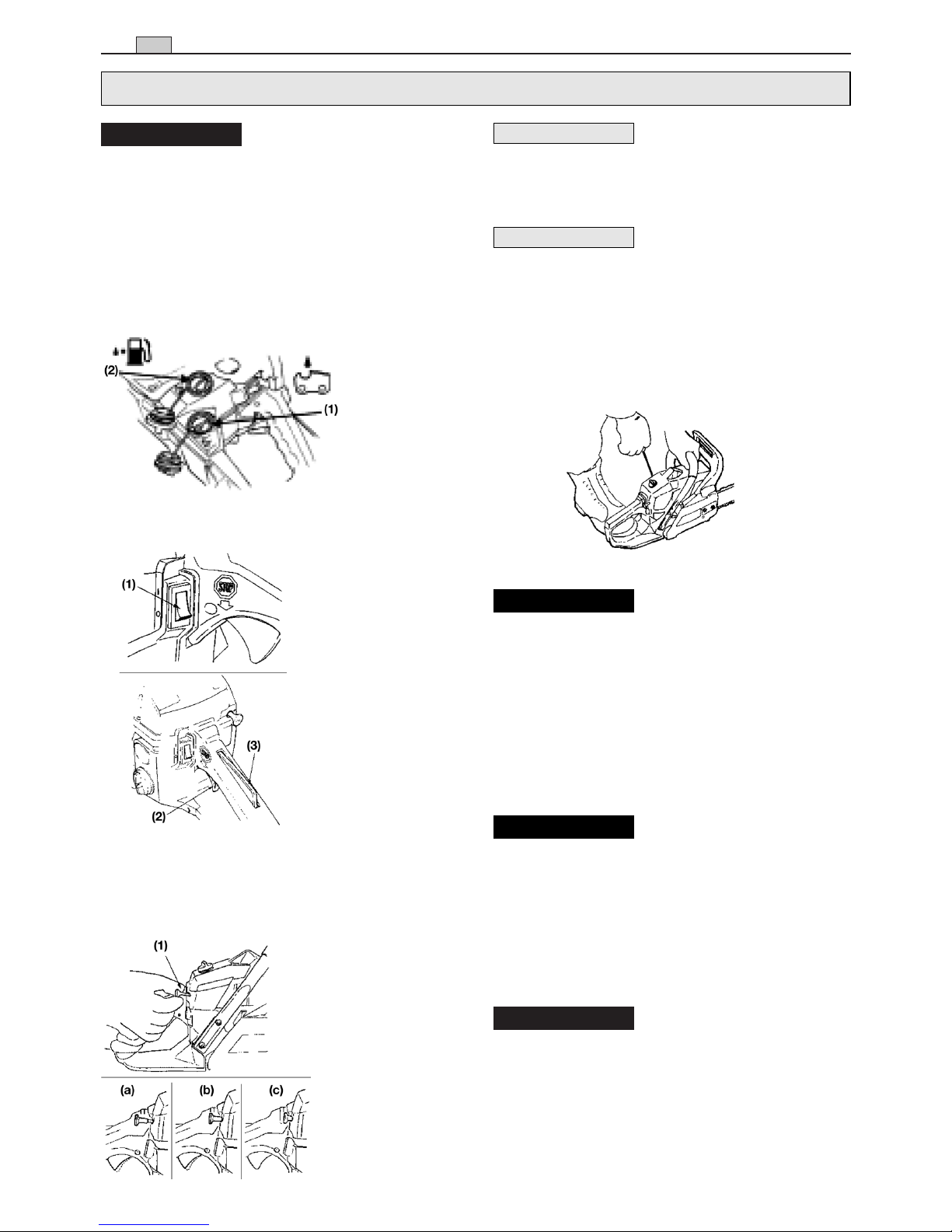

•STARTING THE ENGINE

1. Fill fuel and chain oil tanks respectively, and

tighten the caps securely.

2. Set the switch to “I” position.

3. While holding the throttle lever together with

the trigger safety, push in the side latch and

release the throttle lever to leave it at the

starting position.

!

WARNING!

When restarting immediately

after stopping the engine, set the Choke knob in

the first-stage position (choke open and throttle

lever in the starting position).

Once the choke knob has

been pulled out, it will not return to the operating

position even if you press down on it with your

finger. When you wish to return the choke knob

to the operating position, pull out the throttle

lever instead.

4. While holding the saw unit securely on the

ground, pull the starter rope vigorously.

Do not start the engine

while the chain saw hangs in one hand. The

saw chain may touch your body. This in very

dangerous.

5. When engine has ignited, first push in the

choke knob to the first-stage position and

then pull the starter again to start the engine.

6. Allow the engine to warm up with the throttle

lever pulled slightly.

Keep clear of the saw

chain as it will start rotating upon starting of

engine.

• CHECKING THE OIL SUPPLY

Make sure to set up the bar

and the chain when checking the oil supply.

If not, the rotating parts may be exposed. It is

very dangerous.

After starting the engine, run the chain at medium speed and see if chain oil is scattered off as

shown in the figure.

!

WARNING!

!

WARNING!

!

WARNING!

NOTE

NOTE

5. Operating the Engine

(1) Chain oil

(2) Fuel

(1) Switch

(2) Throttle lever

(3) Throttle interlock

(1) Choke knob:

(a) When the engine

is cool

(b) When the engine

is warm up

(c) After the engine

starts

Page 10

9

EN

5. Operating the Engine

The chain oil flow can be changed by inserting a

screwdriver in the hole on bottom of the clutch

side. Adjust according to your work conditions.

The oil tank should become

nearly empty by the time fuel is used up. Be sure

to refill the oil tank every time when refueling the

saw.

• ADJUSTING THE CARBURETOR

The carburetor has been adjusted at the factory.

Should your unit need readjustment due to the

changes in altitude or operating conditions,

please let your skillful dealer make the adjustment.

A wrong adjustment may cause damage to your

unit.

If you have to make the adjustment yourself,

please follow the procedure below carefully.

Before adjusting the carburetor, make sure that

the provided air/fuel filters are clean and fresh

and the fuel properly mixed.

NOTE

When adjusting, take the following steps:

Be sure to adjust the carbu-

retor with the bar chain attached.

1. “H” and “L” needles are restricted within the

number of turn as shown below.

“H” needle: -1/4

“L” needle: -1/4

2. Start the engine and allow it to warm up in

low speed for a few minutes.

3. Turn the idle adjusting screw (T) counterclockwise so that the saw chain does not

turn. If the idling speed is too slow, turn the

screw clockwise.

4. Make a test cut and adjust the “H” needle for

best cutting power, not for maximum speed.

Over revolution of “H” needle

causes a lack of power or a poor acceleration. In

such a case please turn the “H” needle a little

counterclockwise.

• CHAIN BRAKE

This machine is equipped with an automatic

brake tostop saw chain rotation upon occurrence of kickback during saw cutting.

The brake is automatically operated by inertial

force, which acts on the weight fitted inside the

front guard.

This brake can also be operated manually with

the front guard turned down to the guide bar.

To release the brake, pull up the front guard

toward the front handle till a “click” sound is

heard.

Caution

Be sure to confirm brake operation during daily

inspection.

How to confirm:

1. Turn off the engine.

NOTE

NOTE

(1) Front handle

(2) Released

(3) Braking

(4) Brake lever

(1) “L” needle

(2) “H” needle

(3) Idle adjusting

screw

(1) Chain oil

(1) Chain oil flow

adjusting shaft

(2) Rich

(3) Lean

Page 11

10MM10

EN

5. Operating the Engine

2. Holding the chain saw horizontally, release

your hand from the front handle, hit the tip of

the guide bar to a stump or a piece of wood,

and confirm brake operation. Operating level

varies by bar size.

In case the brake is not effective, ask our dealer

for inspection and repairs.

If the engine keeps rotating at high speed with

the brake engaged, the clutch will overheat

causing trouble.

When the brake engages during operation,

immediately release the throttle lever to stop the

engine.

• CARBURETOR ANTI-FREEZE MECHANISM

Operating chain saws in temperatures of 0 – 5°C

at times of high humidity may result in ice forming within the carburetor, and this in turn may

cause the output power of the engine to be

reduced or for the engine to fail to operate

smoothly.

This product has accordingly been designed

with a ventilation hatch on the right side of the

surface of the cylinder cover to allow warm air to

be supplied to the engine and to thereby prevent

icing from occurring.

Under normal circumstances the product should

be used in the normal operating mode, i.e., in the

mode which it is set at the time of shipment.

However when the possibility exists that icing

may occur, the unit should be set to operate in

the anti-freeze mode before use

Continuing to use the product in the anti-freeze mode even when temperatures have risen and returned to normal, may

result in the engine failing to start properly or in

the engine failing to operate at its normal speed,

and for this reason you should always be sure to

return the unit to the normal operating mode if

there is no danger of icing occurring.

HOW TO SWITCH BETWEEN OPERATING

MODES

1. Flip the engine switch to turn off the engine.

2. Remove the cover to the air filter, remove the

air filter, and then remove the choke knob from

the cylinder cover.

3. Loosen the screws holding the cylinder cover

in place (i.e., the three screws on the inside

and the one screw on the outside of the

cover), and then remove the cylinder cover.

4. Press with your finger down on the icing cap

located on the right-hand side of the cylinder

cover to remove the icing cap.

5. Adjust the icing cap so that the “snow” mark

faces upwards and then return it to its original

position in the cylinder cover.

6. Fix the cylinder cover back into its original

position, and then fix all other parts back into

their proper positions.

• STOPPING THE ENGINE

1. Release the throttle lever to allow the engine

to idle for a few minutes

2. Set the switch to the “O” (STOP) position.

NOTE

(1) Switch

(1) Cylinder cover

(2) “Sunshine” mark

(3) “Snow” mark

(a) Normal operating mode

(b) Anti-freeze mode

(1) Cylinder

cover

(2) Choke knob

(3) Icing cap

Page 12

11

EN

6. Sawing

• Before proceeding to

your job, read the section “For Safe Operation”. It is recommended to first practice sawing easy logs. This also

helps you get accustomed to your unit.

•Always follow the safety

regulations. The chain

saw must only be used

for cutting wood. It is

forbidden to cut other

types of material.

Vibrations and kickback

vary with different materials and the requirements of the safety regulations would not be

respected. Do not use

the chain saw as a lever

for lifting, moving or

splitting objects. Do not

lock it over fixed stands.

It is forbidden to hitch

tools or applications to

the PTO other than

those specified by the

manufacturer.

•

It is not necessary to force the saw into the

cut. Apply only light pressure while running the

engine at full throttle.

• When the saw chain is caught in the cut, do

not attempt to pull it out by force, but use a

wedge or a lever to open the way.

• GUARD AGAINST KICKBACK

!

WARNING!

•

This saw is equipped with

a chain brake that will

stop the chain in the

event of kickback if operating properly. You must

check the chain brake

operation before each

usage by running the saw

at full the throttle for 1-2

seconds and pushing the

front hand guard forward.

The chain should stop

immediately with the

engine at full speed. If the

chain is slow to stop or

does not stop, replace the

brake band and clutch

drum before use.

• It is extremely important

that the chain brake be

checked for proper operation before each use and

that the chain be sharp in

order to maintain the kickback safety level of this

saw. Removal of the safety devices, inadequate

maintenance, or incorrect

replacement of the bar or

chain may increase the

risk to serious personal

injury due to kickback.

• FELLING A TREE

1. Decide the felling direction considering the

wind, lean of the tree, location of heavy

branches, ease of completing the task after

felling and other factors.

2. While clearing the area around the tree,

arrange a good foothold and retreat path.

(1) Notch cut

(2) Felling cut

(3) Felling direction

6. Sawing

Page 13

12MM12

EN

6. Sawing

3. Make a notch cut one-third of the way into

the tree on the felling side.

4. Make a felling cut from the opposite side of

the notch and at a level slightly higher than

the bottom of the notch.

When you fell a tree, be

sure to warn neighboring workers of the danger.

Bucking and Limbing

•Always ensure your foothold. Do not stand

on the log.

• Be alert to the rolling over of a cut log.

Especially when working on a slope, stand

on the uphill side of the log.

• Follow the instructions in “For Safe

Operation” to avoid kickback of the saw.

Before starting work, check the direction of

bending force inside the log to be cut. Always

finish cutting from the opposite side of the bending direction to prevent the guide bar from being

caught in the cut.

A log lying on the ground

Saw down halfway, then roll the log over and cut

from the opposite side.

A log hanging off the ground

In area “A”, saw up from the bottom one-third

and finish by sawing down from the top. In area

“B”, saw down from the top one-third and finish

by sawing up from the bottom.

!

WARNING!

!

WARNING!

Cutting the limbs of Fallen Tree

First check to which side the limb is bent. Then

make the initial cut from the bent side and finish

by sawing from the opposite side.

Be alert to the springing

back of a cut limb.

Pruning of Standing Tree

Cut up from the bottom, finish down from the

top.

•Do not work standing on unstable bases or

rung ladders.

• Do not overreach.

• Do not cut above shoulder height.

• Always use both your hands to hold the

saw.

!

WARNING!

!

WARNING!

Page 14

13

EN

7. Maintenance

Before cleaning, the

inspecting or repairing the unit, make sure

that engine has stopped and is cool.

Disconnect the spark plug to prevent accidental starting.

• MAINTENANCE AFTER EACH USE

1. Air filter

Loosen the knob and remove the air cleaner

cover.

Take off the filter element and brush off attached

sawdust. When the filter is clogged with dust,

separate it in halves and shake-wash with gasoline.

When using compressed air, blow from the

inside.

To assemble the cleaner halves, press the rim

until it clicks.

When installing the main filter, make sure that the

grooves on the filter edge are correctly fit with

the projections on the cylinder cover.

2. Oiling port

Dismount the guide bar and check the oiling port

for clogging.

NOTE

!

WARNING!

3. Guide bar

When the guide bar is dismounted, remove sawdust in the bar groove and the oiling port.

Grease the nose sprocket from the feeding port

on the tip of the bar.

4. Others

Check for fuel leakage and loose fastenings and

damage to major parts, especially handle joints

and guide bar mounting.

If any defects are found, make sure to have them

repaired before operating the saw again.

• PERIODICAL SERVICE POINTS

1. Cylinder fins

Dust clogging between the cylinder fins will

cause overheating of the engine.

Periodically check and clean the cylinder fins

after removing the air cleaner and the cylinder

cover.

When installing the cylinder cover, make sure

that switch wires and grommets are positioned

correctly in place.

Be sure to block the air intake hole.

NOTE

7. Maintenance

(1) Oiling port

(2) Grease port

(3) Sprocket

(1) Oiling port

Page 15

14MM14

EN

7. Maintenance

2. Fuel filter

1. Using a wire hook, take out the filter from the

filler port.

2. Disassemble the filter and wash with gasoline, or replace with a new one if needed.

• After removing the filter, use a pinch to hold

the end of the suction pipe.

• When assembling the filter, take care not to

allow filter fibers or dust inside the suction

pipe.

3. Spark plug

Clean the electrodes with a wire brush and reset

the gap to 0.65 mm as necessary.

4. Sprocket

Check for cracks and for excessive wear interfering with the chain drive. If the wear is considerable, replace it with new one. Never fit a new

chain on a worn sprocket, or a worn chain on a

new sprocket.

NOTE

5. Front and Rear dampers

Replace if adhered part is peeled or crack is

observed on the rubber part. Replace if the

inside of the rear damper metal has been beaten

by the stopper bolt and the clearance of the

metal increased.

(1) Fuel filter

Page 16

15

EN

8. Maintenance of Saw Chain and Guide Bar

1. Saw Chain

It is very important for

smooth and safe operation to always keep

the cutters sharp.

The cutters need to be sharpened when:

• Sawdust becomes powder-like.

•You need extra force to saw in.

• The cut path does not go straight.

•Vibration increases.

• Fuel consumption increases.

Cutter setting standards

Be sure to wear safety

gloves.

Before filing:

• Make sure the saw chain is held securely.

• Make sure the engine is stopped.

• Use a round file of proper size for the chain

(see “Chain maintenance table”).

Place the file on the cutter and push straight forward.

Keep the file position as illustrated.

After each cutter has been filed, check the depth

gauge and file it to the proper level as illustrated.

Be sure to round off the

front edge to reduce the chance of kickback

or tie-strap breakage.

!

WARNING!

!

WARNING!

!

WARNING!

Make sure every cutter has the same length and

edge angles as illustrated.

2. Guide Bar

• Reverse the bar occasionally to prevent partial

wear.

• The bar rail should always be square.

Check for wear of the bar rail. Apply a ruler to the

bar and the outside of a cutter. If a gap is

observed between them, the rail is normal.

Otherwise, the bar rail is worn. Such a bar needs

to be corrected or replaced.

(1) Appropriate

gauge checker

(2) Depth gauge

standard

(3) Make the shoul-

der round: (see

“Chain maintenance table”)

(A) Cutter length

(30°) Filing angle

(85°) Side plate angle

(60°) Top plate cutting

angle

(1) Ruler

(2) Gap

(3) No gap

(4) Chain tilts

8. Maintenance of Saw Chain and Guide Bar

Page 17

16MM16

EN

8. Maintenance of Saw Chain and Guide Bar / 9. Troubleshooting Guide

9. Troubleshooting Guide

PROBLEME CAUSE REMEDY

1) Starting failure

WARNING

Make sure the

icing prevention

system is not

working.

2) Lack of

power/Poor acceleration/Rough

idling

3) Oil does not

come out

– Check fuel for water or substandard

mixture.

– Check for engine flooding.

– Check spark ignition.

– Check fuel for water or substandard

mixture.

– Check air filter and fuel filter for

clogging.

– Check carburetor for inadequate

adjustment.

– Check oil for substandard quality.

– Check oil passage and ports for

clogging.

– Replace with proper fuel.

– Remove and dry the spark plug.

– Then pull the starter again with no

choke.

– Replace with a new plug.

– Replace with proper fuel.

– Clean.

– Readjust speed needles.

– Replace.

– Clean.

If the unit seems to need further service, please consult with an authorized

service shop in your area.

3. Chain maintenance table

The characteristic data of the chain and bar homologated for this machine

are shown in the “EC Conformity Statement” that accompanies same machine. Do not use other

types of chain or bar for safety reasons.

The table gives the sharpening data for different types of chain, without this giving the possibility of using chains other than the homologated one.

!

WARNING!

Chain stroke Limiter tooth level (a) File diameter (d)

Inches mm Inches mm Inches mm

3/8 Mini 9,32 0,018 0,45 5/32 4,0

0,325 8,25 0,026 0,65 3/16 4,8

3/8 9,32 0,026 0,65 13/64 5,2

0,404 10,26 0,031 0,80 7/32 5,6

a

d

Page 18

1

FR

1. Pour la sécurité

Cher Client,

Nous désirons avant tout vous remercier de la préférence que vous avez accordée à nos produits et nous espérons que l’utilisation de cette machine vous réservera de grandes satisfactions et répondra pleinement à votre

attente. Ce manuel a été rédigé pour vous permettre de bien connaître votre machine et de l’utiliser dans les

meilleures conditions de sécurité et d’efficacité; n’oubliez pas qu’il est partie intégrante de la machine, gardez-le

à portée de la main pour pouvoir le consulter à tout moment et remettez-le avec la machine si vous deviez la céder

ou la prêter à d’autres personnes.

Votre nouvelle machine a été projetée et construite conformément aux normes en vigueur, elle résulte sûre et fiable si elle est utilisée dans le plein respect des indications contenues dans ce manuel (utilisation prévue); toute

autre utilisation ou le non-respect des normes de sécurité pour l’emploi, l’entretien et la réparation indiquées sont

considérés comme une “utilisation impropre” et entraîne la perte de la garantie et le déclin de toute responsabilité du Constructeur, en reversant sur l’utilisateur les frais dérivant de dommages ou lésions personnelles ou à

autrui.

Si vous deviez trouver de légères différences entre la description donnée et la machine en votre possession, tenez

compte du fait que, dans le cadre de l’amélioration continuelle du produit, les informations contenues dans ce

manuel sont sujettes à des modifications sans préavis ou obligation de mise à jour, sans remettre en cause toutefois les caractéristiques essentielles aux fins de la sécurité et du fonctionnement. En cas de doute, contactez

votre revendeur. Bon travail!

EXPLICATION DES SYMBOLES ET REGLES DE

SECURITE

Lire le manuel avant d’utiliser cette

machine.

Utiliser la tronçonneuse en se servant des deux mains.

Lisez, cherchez à comprendre et

suivez toutes les instructions.

Porter casque, lunettes de protection et protège-oreilles.

Avertissement! Phénomène de

rebond dangereux.

ATTENTION

!!!

DANGER D’ATTEINTE A L’OUIE

L’OPERATEUR UTILISANT NORMALE-

MENT CETTE MACHINE PEUT S’EXPOSER

QUOTIDIENNEMENT A UN BRUIT EGAL

OU DEPASSANT

85 dB(A)

1. Pour la sécurité ....................................................................................... 1

2. Explication des symboles figurant sur la machine ................................. 4

3. Montage du guide-chaîne et de la chaîne .............................................. 5

4. Carburant et huile de chaîne ................................................................... 6

5. Moteur ...................................................................................................... 8

6. Travail à la tronçonneuse ...................................................................... 11

7. Entretien ................................................................................................ 13

8. Entretien de la chaîne et du guide-chaîne ............................................ 15

9. Guide de dépannage ............................................................................ 16

Sommaire

1. Pour la sécurité

Page 19

2MM2

FR

1. Ne jamais utiliser une tronçonneuse

lorsqu’on est fatigué, malade, énervé,

sous l’influence de médicaments

entraînant vertige ou somnolence, ou

encore sous l’influence de l’alcool ou

de drogues.

2. Porter des chaussures de sécurité,

des vêtements moulants, des lunettes

de protection, un casque de sécurité

et un casque anti-bruit. Utiliser les

gants anti-vibrations.

3. Maintenir la chaîne de scie bien

tendue et la scie, y compris le système AV, bien entretenue. Une chaîne

lâche augmente le temps de coupe

ainsi que les vibrations dans les mains

lorsque la chaîne est appuyée contre

le bois. Le niveau de vibration augmente également sur les scies dont

les pièces sont desserrées, ou dont

les tampons AV sont endommagés ou

usés.

4. Toutes les précautions indiquées

cidessus ne constituent pas une

garantie de protection contre la maladie des mains blanches ou le syndrome du canal carpien. Les personnes qui utilisent régulièrement lascie

devront surveiller attentivement l’état

de leurs mains et de leurs doigts.

Dès que l’un de ces symptômes

apparaît, veuillez consulter votre

médecin.

5. Observer les précautions d’usage

avec le carburant. Essuyer immédiatement l’essence répandue et éloigner

le bidon d’essence d’au moins 3 mètres avant de mettre le moteur de la

tronçonneuse en marche.

6. Ne tolérer aucun flamme ou source

d’étincelles à proximité de l’endroit où

est entreposée l’essence et pendant

la préparation du mélange ou le remplissage du réservoir. (S’abstenir de

fumer, de faire du feu ou d’utiliser un

outil produisant des étincelles.)

7. Ne jamais fumer en manipulant l’essence ou en utilisant la tronçonneuse.

8. Ne pas mettre la tronçonneuse en

marche à proximité d’autres personnes. Ne pas tolérer la présence d’enfants ou d’animaux sur le lieu de travail. Faire éloigner toute personne ou

animal d’au moins 10 mètres avant de

mettre en marche et d’utiliser la tronçonneuse.

9. Avant de commencer à tronçonner,

dégager le lieu de travail, prévoir une

voie de retraite pour le moment où

l’arbre va choir et bien se caler les

pieds pour assurer sa posture.

10. Lorsque le moteur est en marche,

tenir fermement la tronçonneuse à

deux mains. Saisir la poignée et le

guidon à pleine main.

11. Ne jamais approcher la main ou

toute autre partie du corps de la chaîne lorsque le moteur est en marche.

12. Avant de mettre le moteur en marche, vérifier que rien ne touche la

chaîne.

13. Lorsqu’on se déplace avec la

tronçonneuse, le moteur doit être

arrêté. Porter la tronçonneuse par le

guidon avec la chaîne vers l’arrière.

Veiller à ne pas se brûler contre le pot

d’échappement.

14. Avant de se servir de la tronçonneuse, contrôler l’état de la chaîne

(usure, tension, etc.). Ne jamais utiliser une tronçonneuse endommagée,

mal réglée, mal remontée ou dépourvue de ses carters. Vérifier que la

chaîne s’immobilise lorsque qu’on

relâche la gâchette d’accélérateur.

15. Toute intervention d’entretien non

décrite dans le présent mode d’emploi doit être confiée à un personnel

d’entretien qualifié.

1. Pour la sécurité

1. Pour la sécurité

Page 20

3

FR

(En particulier, toute tentative de

démontage du volant ou de l’embrayage sans disposer des outils

appropriés risque de fissurer le volant

qui pourrait ensuite se désintégrer en

marche).

16. Toujours arrêter le moteur avant

de poser la tronçonneuse.

17. Observer la plus grande prudence

en coupant les broussailles. Une liane

ou un arbrisseau se prenant dans la

chaîne risquent de faire perdre l’équilibre ou de cingler le visage.

18. Lorsqu’on coupe une branche en

flexion, prendre garde à la détente au

moment où les fibres porteuses sont

sectionnées.

19. Ne coupez jamais si le temps est

mauvais, si la visibilité est insuffisante

ou si la température est trop basse ou

trop élevée. Assurez-vous qu’il n’y a

pas de branches sèches qui puissent

tomber pendant la coupe.

20. Maintenir la poignée et le guidon

toujours propres et secs; essuyer

immédiatement toute trace d’huile, de

graisse ou de carburant.

21. La tronçonneuse ne doit être utilisée qu’en plein air ou dans un local

bien ventilé. Ne jamais mettre en marche ou laisser tourner le moteur dans

un local fermé.

Les gaz d’échappement sont dangereux car ils contiennent du monoxyde

de carbone.

22. Sans entraînement spécial, s’abstenir d’utiliser la tronçonneuse juché

sur un arbre.

23. Prendre garde au rebond, particulièrement dangereux car la tronçonneuse risque d’échapper des mains.

On appelle rebond le brusque saut de

la tronçonneuse lorsque la chaîne à

l’extrémité du guide-chaîne bute

contre quelque chose.

24. Pour transporter la tronçonneuse,

recouvrir la chaîne de son fourreau.

PRECAUTIONS A OBSERVER POUR EVITER LE

REBOND DE LA TRONÇONNEUSE

Le phénomène de rebond de

la tronçonneuse se produit lorsque l’extrémité du

guide-chaÎne heurte quelque chose ou lorsque la

coupe se resserre et coince la chaîne. Si le guidechaîne bute contre un objet, il arrive que la tron-

çonneuse saute en l’air

et se retourne contre l’opérateur. Si la chaîne

coince dans la coupe se

resserrant vers le haut, la

tronçonneuse est brusquement refoulée en

arrière vers l’opérateur.

Dans les deux cas, la perte de contrôle de l’outil

peut résulter en un très grave accident corporel.

• Les dispositifs de sécurité dont est équipée la

tronçonneuse ne dispensent pas d’observer la

plus grande prudence. Pour éviter tout accident ou

blessure, observer scrupuleusement les consignes

de sécurité ci-après lors de l’emploi de la tronçonneuse.

1. Une bonne compréhension du phénomène de

rebond de la tronçonneuse permet de prévoir les

situations où il risque de se produire et d’éviter d’être

pris par surprise.

Cet effet de surprise peut favoriser les accidents.

2. Tenir fermement la tronçonneuse à

deux mains, main droite sur la poignée arrière et main gauche sur le guidon avant avec le pouce à l’opposé

des autres doigts pour affermir la

prise lorsque le moteur est en marche.

Une bonne prise aide à maîtriser la

tronçonneuse en cas de rebond.

3. Avant de commencer à couper,

vérifier que la zone à couper est dégagée, Eliminer au préalable toute branche ou tout obstacle sur lequel la

chaîne risquerait de buter.

4. Faire tourner le moteur à vitesse

élevée pendant la coupe.

5. Ne pas travailler en tenant la tronçonneuse à bout de bras ou plus haut

que les épaules.

6. Observer les recommandations du

fabricant en matière d’entretien ou

d’affûtage de la chaîne.

7. Comme rechange, n’utiliser que

des chaînes et guide-chaînes d’origine ou recommandés par le fabricant.

!

ATTENTION!

1. Pour la sécurité

Page 21

4MM4

FR

2. Explication des symboles figurant sur la machine

Pour une utilisation et un

entretien sûrs, les symboles sont gravés en relief

sur la machine.

Selon ces indications, faire attention de ne pas

commettre d’erreur.

Orifice de remplissage de

“MELANGE DEUX TEMPS”

Emplacement: Près du bouchon

de carburant

Orifice de remplissage d’huile de

chaîne

Emplacement: Près du bouchon

d’huile

Régler le commutateur sur la

position “O”, et le moteur s’arrête

immédiatement.

Emplacement: Partie avant audessus de la poignée arrière

Au démarrage du moteur, si on tire

le bouton du starter (à droite à

l’arrière du levier arrière) dans le

sens de la flèche, le mode de

démarrage peut être réglé comme

suit:

•Premier cran – mode démarrage à chaud.

• Second cran – mode démarrage à froid.

Emplacement: Partie supérieure

droite du cache de filtre à air

!

ATTENTION!

La vis sous la marque “H” est la

vis de réglage Grande vitesse.

La vis sous la marque “L” est la

vis de réglage Petite vitesse.

La vis à gauche de la marque “T”

est la vis de réglage Vitesse neutre.

Emplacement: Côté gauche de la

poignée arrière

Indique le sens dans lequel le

frein de chaîne est lâché (flèche

blanche) et engagé (flèche noire).

Emplacement: Partie avant du

cache de chaîne

Si on fait tourner la tige à l’aide

d’un tournevis, suivre la flèche

jusque la position “MAX” pour

faire arriver plus d’huile sur la

chaîne, et faire tourner la tige

vers la position “MIN” pour qu’il

en arrive moins.

Emplacement: Partie inférieure

de l’ensemble moteur

2. Explication des symboles figurant sur la machine

Page 22

5

FR

Contenu de l’emballage de la tronçonneuse.

Déballer et mettre en place le guide-chaîne et la chaîne sur le groupe moteur en procédant comme suite:

Travailler avec des gants

épais pour ne pas risquer de se blesser sur les

dents de la chaîne.

1. Tirez la protection en direction de la poignée avant

pour vérifier que le frein de chaîne n’est pas

enclenché.

2. Desserrer les écrous et déposer le carter de chaî-

ne.

3. Engager la chaîne autour de la roue dentée du

moteur et mettre en place la guide-chaîne en passant la chaîne tout autour. Amener l’écrou de tendeur de chaîne.

!

ATTENTION!

Respecter le sens de montage

de la chaîne.

4. Remettre le carter de chaîne contre le groupe

moteur en serrant les écrous à la main.

5. Tout en soulevant le guide-chaîne par le bout, tourner la vis du tendeur pour donner à la chaîne la tension correcte. A la partie inférieure du guide-chaîne, les patins des maillons de chaîne doivent juste

toucher la glissière.

6. Toujours en tenant le guide-chaîne soulevé, bloquer les écrous du carter (12 ~ 15 Nm). Tourner la

chaîne à la main pour vérifier qu’elle tourne sans

résistance excessive et qu’elle est convenablement tendue. Si nécessaire, redesserrer les écrous

du carter de chaîne et refaire le réglage de tension.

7. Serrer la vis du tendeur.

Lorsqu’elle est neuve, la chaîne

a tendance à s’allonger. Contrôler et régler fréquemment la tension de la chaîne. Si la chaîne est trop peu

tendue, elle risque de sauter et s’use rapidement,

ainsi que le guide-chaîne.

REMARQUE

REMARQUE

3. Montage du guide-chaîne et de la chaîne

3. Montage du guide-chaîne et de la chaîne

(1) Couvercle de

chaînette

(2) Ecrou de mise

sous tension de

chaînette

(1) Sens de

rotation

(1) Desserrer

(2) Serrer

(3) Soulever

(4) Vis du tendeur

(1) Groupe moteur

(2) Protège-chaîne

(3) Guide-chaîne

(4) Chaîne

(5) Clé pour obturateurs

(6) Tournevis de réglage du carburateur

Page 23

6MM6

FR

• CARBURANT

L’essence est un produit hautement inflammable. S’abstenir de fumer et ne

tolérer aucun flamme ou source d’étincelles à proximité de l’endroit où est entreposée l’essence.

Arrêter le moteur puis le laisser refroidir un peu

avant de remplir le réservoir.

Remplir le réservoir à l’extérieur sur une surface

nue et éloigner le bidon d’essence d’au moins 3

mètres avant de mettre le moteur de la tronçonneuse en marche.

• Les moteurs sont lubrifiés à l’aide d’une huile spé-

cialement conçue pour les moteurs 2 temps à

refroidissement par air. Utilisez une huile antioxydante de haute qualité spécialement destinée aux

moteurs 2 temps à refroidissement par air (HUILE

DE TYPE JASO FC ou DE TYPE ISO EGC).

• Ne jamais utiliser des huiles mélangées BIA ou TCW

(pour les moteurs 2 temps à refroidissement par

eau).

• RAPPORT DE MELANGE RECOMMANDE

ESSENCE 50: HUILE 1

• La composition des gaz d’échappement est contrô-

lée par les principaux paramètres et composants du

moteur (comme par ex., la carburation, le calage de

l’allumage et le calage du port) sans avoir besoin

d’effectuer des changements de matériel ou à introduire un matériel inerte durant la combustion.

• Ces moteurs sont certifiés pour fonctionner avec de

l’essence sans plomb.

•Utiliser toujours une essence à indice d’octane

minimal de 89RON (USA/Canada: 87AL).

• Si une essence à indice d’octane inférieur est utili-

!

ATTENTION!

sée, il y a un risque important d’augmentation dangereuse de la température du moteur, entraînant

des problèmes de moteur au niveau des cylindres

par exemple.

• Il est préférable d’utiliser de l’essence sans plomb

afin de réduire la pollution de l’atmosphère et de

participer ainsi à la protection de l’environnement et

de votre santé.

• De l’essence ou de l’huile de basse qualité risque

d’endommager les joints, les conduites d’essence

ou le réservoir d’essence du moteur.

• COMMENT OBTENIR UN BON MELANGE

Faire attention à ne pas trop

remuer le carburant.

1. Mesurez les volumes d’essence et d’huile à mélan-

ger.

2. Verser un peu d’essence dans un récipient à car-

burant propre.

3. Verser ensuite toute l’huile, puis bien remuer le

tout.

4. Verser enfin le reste de l’essence, puis bien mélan-

ger l’ensemble pendant une minute environ. Etant

donné que certains types d’huiles sont plus fluides

que d’autres en fonction de leur composition, un

brassage énergique est nécessaire afin de garantir

une bonne marche du moteur pendant longtemps.

En effet, en cas de mélange insuffisant, un risque

majeur de problèmes au niveau des cylindres peut

apparaître en raison d’un mélange hétérogène.

5. Placer une étiquette assez grande sur le récipient

afin d’éviter de le confondre avec de l’essence ou

avec d’autres récipients.

6. Indiquer les composants sur cette étiquette afin

d’en faciliter l’identification.

• REMPLISSAGE DU RESERVOIR

1. Dévisser puis retirer le bouchon de carburant.

Déposer ce bouchon sur une surface non poussiéreuse.

2. Remplir le réservoir de carburant à 80% de sa

capacité totale.

3. Visser fermement le bouchon du réservoir et

essuyer toute éventuelle éclaboussure d’essence

sur l’appareil.

!

ATTENTION!

4. Carburant et huile de chaîne

4. Carburant et huile de chaîne

Page 24

7

FR

1. Choisir une surface plane et nue pour effectuer

le remplissage.

2. S’éloigner d’au moins 3 mètres du point de remplissage avant de démarrer le moteur.

3. Arrêter le moteur avant de démarrer l’appareil.

Bien remuer à cet instant le mélange d’essence

dans le réservoir.

•A EVITER POUR PROLONGER LA DUREE DE VIE

DU MOTEUR:

1. ESSENCE SANS HUILE (ESSENCE PURE) –

L’essence pure est capable d’endommager très

rapidement les pièces du moteur.

2. ESSENCE-ALCOOL – Ce mélange risque de très

rapidement détruire les pièces en caoutchouc

et/ou en plastique et d’empêcher la lubrification du

moteur.

3. HUILE POUR MOTEURS 4 TEMPS – Elles risquent

d’encrasser les bougies, de bloquer l’échappement ou d’endommager les segments des pistons.

4.

Les mélanges d’huile et de carburants laissés

au repos pendant une période d’un mois ou

plus

risquent sérieusement d’encrasser le carburateur et d’entraîner par conséquent une défaillance

du moteur.

5. Dans l’éventualité d’une longue période d’inactivité, nettoyer le réservoir de carburant après l’avoir

vidangé. Allumer ensuite le moteur et vider le

mélange d’essence du carburateur.

6. En cas de mise au rebut du récipient contenant le

mélange d’huile, en disposer toujours dans une

décharge autorisée.

Il est également important de

rappeler que l’usure et les dégradations normales de

l’appareil ne sont en aucun cas couvertes par cette

garantie.

De plus, le non-respect des instructions relatives aux

proportions des mélanges d’essence, etc. décrites

dans ce mode d’emploi risque d’entraîner un refus de

couverture par la garantie.

REMARQUE

!

ATTENTION!

• HUILE POUR CHAÎNE

Utilisez une huile moteur SAE #10W-30 tout au long

de l’année ou de l’huile SAE #30 ~ #40 en été et SAE

#20 en hiver.

N’utilisez pas de l’huile usagée

ou recyclée, elle pourrait endommager la pompe à

huile.

REMARQUE

4. Carburant et huile de chaîne

Page 25

8MM8

FR

En cas de redémarrage immé-

diatement après l’arrêt du moteur. Bouton de starter

en première position (starter ouvert et levier de commande des gaz en position de démarrage).

Après avoir sorti le bouton de

starter, il ne retourne pas à la position de service,

même si vous l’enfoncez avec le doigt. Lorsque vous

voulez ramener le bouton de starter à la position d’ouverture, appuyer sur le levier de commande des gaz.

4Tenir la tronçonneuse plaquée au sol et tirer la cor-

delette du lanceur avec force.

Ne pas mettre le moteur en

marche en portant la tronçonneuse d’une main.

Cela est très dangereux car on risque de se blesser avec la chaîne.

5. Si le moteur démarre et cale, repousser le bouton

de starter à la première position et tirer à nouveau

la corde du lanceur pour remettre le moteur en

marche.

6. Laisser le moteur se réchauffer en accélérant légèrement.

Ne pas s’approcher de la

chaîne qui se met à tourner dès que le moteur

démarre.

• CONTRÔLE DU GRAISSAGE DE LA CHAÎNE

Avant de vérifier l’huile, s’assurer que la barre et la chaîne sont bien en place.

Si elles ne le sont pas les pièces rotatives exposées constituent un véritable danger.

Une fois que le moteur a démarré, le faire tourner à

régime moyen et vérifier que l’huile de chaîne est projetée et forme une trace sur le sol.

!

ATTENTION!

!

ATTENTION!

!

ATTENTION!

REMARQUE

REMARQUE

Il est dangereux d’utiliser une

scie avec des pièces cassées ou manquantes.

Avant de mettre le moteur en marche, toujours

vérifier que toutes les pièces sont posées correctement, notamment la barre et la chaîne.

• DÉMARRAGE DU MOTEUR

1. Remplir le réservoir de carburant et le réservoir

d’huile de chaîne et bien refermer les bouchons.

2. Mettre l’interrupteur en position “I”.

3. Tirer le bouton de starter à la seconde position. Le

starter se ferme et le levier de commande des gaz

est alors placé en position de démarrage.

!

ATTENTION!

5. Moteur

(1) Huile de

chaîne

(2) Carburant

(1) Interrupteur

(2) Levier accéléra-

teur

(3) Blocage accélé-

rateur

5. Moteur

(1) Bouton de star-

ter:

(a) lorsque le moteur

est froid

(s) lorsque le moteur

est chaud

(c) lorsque le moteur

est mis en marche

Page 26

Le débit d’huile peut varier en tournant le bouton de

réglage placé au sommet du couvercle du cylindre.

Effectuer les réglages nécessaires selon les circonstances des travaux.

Le réservoir d’huile doit être

presque vide quand le carburant est épuisé.

Veiller à remplir le réservoir d’huile à l’occasion du

plein en carburant de la tronçonneuse.

• RÉGLAGE DU CARBURATEUR

Le carburateur a été ajuste à la fabrique. Au cas où

cette machine nécessite un adjustage ultérieur à

cause de changement d’altitude ou de conditions de

service, prière de se mettre en contact avec ie distributeur qualifié.

Un ajustage erroné risque d’endommager cette

machine.

Au cas où l’on désire effectuer soi-même l’ajustage, il

est recommandé de procéder de la manière suivante.

Avant de refaire le réglage du carburateur, vérifier que

le filtre à air et le filtre à essence sont propres et que

la composition du carburant utilisé est correcte.

REMARQUE

Méthode de réglage:

Le réglage du carburateur doit

se faire avec le guide-chaîne et la chaîne en place.

1. Le nombre de tour des pointeaux “H” et “L “ est

limité de la manière suivante.

Pointeau “H”: -1/4

Pointeau “L”: -1/4

2. ettre le moteur en marche et le laisser se réchauffer à régime faible pendant quelques minutes.

3. Tourner la vis de réglage de ralenti (T) dans le sens

contraire des aiguilles d’une montre jusqu’à ce que

la chaîne ne tourne plus. À l’inverse, si le régime de

ralenti est trop bas, tourner la vis dans le sens des

aiguilles d’une montre.

4. Faire un essai de coupe et régler le pointeau “H”

pour obtenir le régime optimal de coupe qui n’est

pas nécessairement le régime maximum.

Une rotation excessive de l’aiguille “H” causera une perte de puissance ou une

mauvaise accélération. Dans ce cas il sera nécessaire

de tourner l’aiguille “H” légèrement dans le sens des

aiguilles d’une montre.

• FREIN DE LA CHAÎNE

La présente machine est munie d’un frein automatique qui arrête le mouvement de la chaîne de scie en

appliquant le frein automatiquement par l’action d’inertie qui sollicite au poids se trouvant dans l’intérieur

de la garde avant lorsqu’un recul s’est produit pendant le sciage.

Ce frein peut être appliqué manuellement aussi en faisant incliner la garde avant vers la barre de guidage à

la main. Pour dégager le frein, relever la garde avant

vers la manette jusqu’à ce que celle-ci fasse un clic.

Attention

Lors de l’inspection quotidienne, vérifier le bon fonctionnement du frein.

Méthode de vérification:

1. Arrêter le moteur.

REMARQUE

REMARQUE

5. Moteur 9

FR

(1) Huile de chaîne

(1) Levier avant

(2) Relâché

(3) Freinage

(4) Levier freina-

ge

(1) Pointeau “L”

(2) Pointeau “H”

(3) Vis de réglage de

ralenti

(1) Arbre de réglage

de l’arrivée d’huile de chaîne

2) Riche

3) Pauvre

Page 27

2. En maintenant la tronçonneuse horizontalement

avec les deux mains, enlever la main de la manette avant et appliquer l’extrémité de la barre de guidage à une souche pour vérifier le bon fonctionnement du frein. La hauteur d’opération sera différente selon la taille du guide de chaîne.

Lorsque le frein fonctionne mal, adressez-vous à votre

concessionnaire pour le faire réparer.

Si l’on laisse tourner le moteur à grande vitesse en

appliquant le frein, l’embrayage sera chauffé et cela

entraîne des causes de pannes.

Lorsque le frein s’applique accidentellement pendant

le fonctionnement, dégager le doigt du papillon immédiatement pour arrêter le moteur.

• MÉCANISME ANTIGEL DE CARBURATEUR

L’utilisation des tronçonneuses à des températures de

0 – 5 °C et avec une humidité élevée peut entraîner la

formation de glace dans le carburateur, et ceci à son

tour peut entraîner une réduction de la puissance du

moteur ou une opération non régulière du moteur.

Ce produit a en conséquence été conçu avec un volet

d’aération sur le côté droit de la surface du cache-culbuteurs pour laisser l’air chaud être fourni vers le

moteur et empêcher de la sorte la formation de glace.

Dans des circonstances normales, le produit doit être

utilisé en mode d’utilisation normale, c.-à-d., dans le

mode auquel il est réglé lors de l’expédition.

Cependant, lorsque la possibilité existe de formation

de glace, l’appareil doit être réglé pour agir en mode

antigel avant utilisation.

Le fait de continuer à utiliser le

produit en mode antigel, même lorsque les températures ont augmenté et sont revenues à la normale,

peut entraîner un démarrage incorrect du moteur ou

son impossibilité à fonctionner à sa vitesse normale,

et pour cette raison, vous devez toujours ramener

l’appareil au mode d’utilisation normale s’il n’y a pas

de risque de formation de glace.

COMMENT CHANGER ENTRE LES MODES D’UTILISATION

1. Désenclencher le commutateur de moteur pour

couper le moteur.

2. Déposer le capot au filtre à air, déposer le filtre à air,

puis déposer le bouton de starter du cache-culbuteurs.

3. Desserrer les vis en maintenant le cache-culbuteurs

en position (c.-à-d., les trois vis à l’intérieur et une

vis à l’extérieur du capot), puis déposer le cacheculbuteurs.

4. Appuyer avec le doigt sur le capuchon de gel situé

sur le côté droit du cache-culbuteurs pour le déposer.

5. Ajuster le capuchon de gel pour que la marque

“neige” soit dirigée vers le haut, puis le ramener à

sa position d’origine dans le cache-culbuteurs.

6. Refixer le cache-culbuteurs à sa position d’origine,

puis refixer toutes les autres pièces à leurs positions correctes.

• ARRET DU MOTEUR

1. Relâcher la gâchette d’accélérateur et laisser le

moteur tourner au ralenti pendant quelques minutes.

2. Régler l’interrupteur en position “O” (ARRET).

REMARQUE

5. Moteur10MM10

FR

(1) Interrupteur

(1) Couvercle du cylindre

(2) Marque “soleil”

(3) Marque “neige”

(a) Mode d’opération normal

(b) Mode antigel

(1) Cache-culbu-

teurs

(2) Bouton de

starter

(3) Capuchon de

gel

Page 28

•Avant de commencer à travailler, lire attentivement le

chapitre “Pour la sécurité”

au début de cette notice.

Commencer à se familiariser avec le fonctionnement

de la tronçonneuse en

sciant quelques bûches

dans de bonnes conditions

de travail à titre d’exercice

• Suivre les règles de sécurité. La tronçonneuse ne doit

être utilisée que pour scier

du bois. Il est interdit de

couper d’autres matériaux.

Les vibrations et le rebond

sont en effet différents et

les mesures de sécurité ne

seraient pas respectées.

N’utilisez pas la tronçonneuse comme levier pour

lever, déplacer ou casser

quoi que ce soit. Il est

interdit de brancher sur la

prise de force de la tronçonneuse des outils ou des

applications autres que

ceux que le constructeur a

indiqués.

•

Il n’est pas nécessaire d’appuyer dans la coupe. Si

le moteur tourne suffisamment vite, une légère

pression suffit.

• Si la chaîne reste coincée dans la coupe, ne pas for-

cer pour l’extraire. Ecarter la coupe en introduisant

un coin ou en faisant levier avec un pied-de-biche.

• MESURES DE PROTECTION CONTRE LES

REBONDS

!

ATTENTION!

• Cette tronçonneuse est équi-

pée d’un frein de chaîne qui,

si la machine est en bon état,

immobilise immédiatement la

chaîne en cas de rebond.

Avant chaque séance de travail, contrôler le fonctionnement du frein de chaîne en

accélérant à fond et en poussant le protège-main avant

vers l’avant au bout de 1 ou 2

secondes. La chaîne doit

s’immobiliser immédiatement même avec le moteur

tournant à plein régime. Si la

chaîne ne s’arrête pas ou ne

s’arrête que trop lentement,

remplacer immédiatement la

bande de frein et le tambour

d’embrayage.

• Pour la sécurité, il est extrê-

mement important de vérifier

avant d’utiliser la tronçonneuse que le frein de chaîne

fonctionne bien et que la

chaîne est bien affûtée, ce

qui limite le risque de rebond.

Un entretien négligé et l’utilisation de la tronçonneuse

sans ses dispositifs de sécurité, ou avec un guide-chaîne

en mauvais état et une chaîne mal affûtée, augmentent

le risque de rebond et de

grave accident corporel.

•ABATTAGE D’UN ARBRE

1. Déterminer le sens dans lequel l’arbre doit choir,

compte tenu du vent, de l’inclinaison du tronc, de

la disposition des branches les plus lourdes, de la

commodité des travaux après abattage, etc.

2. Nettoyer la zone de travail autour de l’arbre.

Prévoir une voie de retraite pour le moment où l’arbre va choir et bien se caler les pieds pour assurer

sa posture.

6. Travail à la tronçonneuse 11

FR

(1) Coupe

(2) Entaille d’abattage

(3) Sens d’abattage

6. Travail à la tronçonneuse

Page 29

3. Du côté où l’arbre doit choir, pratiquer une entaille

d’abattage d’une profondeur du tiers du diamètre

de l’arbre.

4. Faire ensuite une coupe horizontale de l’autre côté,

légèrement plus haut que le fond de l’entaille d’abattage.

Avant d’abattre un arbre, faire

évacuer toutes les personnes présentes et surveiller la zone de travail.

Débitage et ébranchage

•Toujours bien se caler les pieds. Ne pas monter

sur le tronc.

•Prendre garde au fait que le tronc risque de se

retourner ou de rouler. Si le terrain est en pente,

toujours se tenir plus haut que le tronc sur la

pente.

• Pour éviter le rebond de la tronçonneuse,

respecter les consignes du chapitre “Pour la

sécurité”.

Avant de couper une branche ou un tronc en flexion,

observer le sens de la flexion et finir la coupe à l’opposé du côté en flexion pour éviter que le guide-chaîne ne soit coincé dans la coupe.

Tronc reposant sur le sol

Couper à moitié, retourner le tronc et finir la coupe par

l’autre côté.

Tronc en surélévation

Commencer par couper au tiers par en dessous dans

la “A”et finir la coupe par-dessus. Dans la zone “B”,

couper au par-dessus et finir la coupe par en dessous.

!

ATTENTION!

!

ATTENTION!

Ebranchage d’un arbre abattu

Observer d’abord le sens de flexion de la branche.

Faire une première entaille du côté en flexion et finir la

coupe du côté opposé.

Attention au saut de la bran-

che au moment où elle se détache du tronc.

Elagage d’un arbre

Commencer par entailler par en dessous et finir la

coupe pardessus.

• Ne jamais travailler sur un échafaudage ou une

échelle instable.

• Ne pas travailler à bout de bras trop loin de soi.

•Ne pas couper plus haut que le niveau des épaules.

•Toujours tenir la tronçonneuse à deux mains.

!

ATTENTION!

!

ATTENTION!

6. Travail à la tronçonneuse

12MM12

FR

Page 30

Avant toute intervention de

nettoyage, d’inspection ou de démontage, arrêter

le moteur et attendre qu’il refroidisse.

Débrancher le fil de la bougie pour éviter que le

moteur ne démarre accidentellement.

• ENTRETIEN APRES CHAQUE UTILISATION

1. Filtre à air

Desserrer le bouton et déposer le couvercle du filtre à

air.

Retirer l’élément de filtre et enlever la sciure qui s’est

adhérée. Si le filtre est bouché, le séparer en deux

moités et le laver en secouant, avec de l’essence.

Si on utilise de l’air comprimé, souffler par l’intérieur.

Pour remonter le filtre, appuyer sur les bordures jusqu’à encliquetage.

En remettant le filtre principal, introduire les languettes

du bord du filtre dans les renfoncements du cache

culbuteur.

2. Orifice de sortie d’huile

Déposer le guide-chaîne et vérifier que l’orifice de sortie d’huile n’est pas obstrué.

REMARQUE

!

ATTENTION!

3. Guide-chaîne

Après la dépose du guide-chaîne, éliminer la sciure

dans la rainure et l’orifice de sortie d’huile.

Injecter de la graisse dans l’orifice de graissage de la

roue dentée à l’extrémité du guide-chaîne.

4. Divers

Vérifier que le carburant ne fuit pas et que la boulonnerie est bien serrée. En particulier, contrôler l’état et

le serrage de la poignée, du guidon et du guide-chaîne. En cas d’anomalie, ne pas réutiliser la tronçonneuse avant de l’avoir réparée.

• ENTRETIEN PERIODIQUE

1. Ailettes de refroidissement du cylindre

Si de la poussière reste entre les ailettes du cylindre,

le moteur va chauffer. Vérifier périodiquement les

ailettes du cylindre et les nettoyer en déposant le filtre à air et le couvre cylindre.

Lors de la remise en place du couvre-cylindre, s’assurer que les fils de la gâchettes et les passe-fils sont

bien positionnés.

Couvrir au préalable l’ouverture d’admission d’air.

REMARQUE

7. Entretien 13

FR

(1) Orifice de sortie d’huile

(2) Orifice de graissage

(3) Roue dentée

(1) Orifice de sortie

d’huile

7. Entretien

Page 31

2. Filtre à essence

1. A l’aide d’un fil de fer recourbé, sortir le filtre à

essence de l’orifice de remplissage.

2. Démonter le filtre et le laver avec de l’essence, ou

remplacer le filtre par un neuf si nécessaire.

• Après dépose du filtre, immobiliser le tuyau d’aspi-

ration à l’aide d’une pince.

• Au remontage, veiller à ne pas introduire de la

poussière ou des impuretés dans le tuyau d’aspiration.

3. Bougie

Nettoyer les électrodes et, si nécessaire, régler l’écartement à 0,65 mm.

4. Roue dentée

Vérifier que la roue dentée n’est pas ébréchée et que

la denture n’est pas usée au point de patiner sur la

chaîne. Remplacer la roue dentée si elle est endommagée ou très usée.

Ne pas utiliser une chaîne neuve avec une roue dentée usée ou bien une chaîne usée avec une roue dentée neuve.

REMARQUE

5. Silent-blocs avant et arrière

Remplacer si des parties d’adhèsion sont enlevées ou

si des fêlures sont observées sur les pièces en caoutchouc.

Remplacer si l’intérieur de la pièce métallique d’amortisseur arrière a été cogné par le boulon de la pièce

d’arrêt et si le jeu de la pièce métallique a augmenté.

7. Entretien14MM14

FR

(1) Filtre à essence

Page 32

1. Chaîne

Pour la sécurité et le rendement dans le travail, les dents de la chaîne doivent

toujours être bien affûtées.

Les dents de chaîne doivent être affûtées lorsque:

• La sciure produite est poudreuse.

• Il faut appuyer excessivement pour faire mordre la

chaîne dans le bois.

• La coupe n’est pas droite.

• La tronçonneuse vibre fortement.

• La consommation de carburant augmente.

Méthode et critères d’affûtage

Porter des gants de sécurité.

Avant l’affûtage:

•Immobiliser fermement la chaîne.

•Arrêter le moteur.

• Se procurer une lime ronde de taille appropriée

(voir le “Tableau d’entretien de la chaîne”)

Poser la lime sur la dent et pousser bien droit.

Maintenir l’orientation de la lime indiquée ci-contre.

Après affûtage de toutes les dents, vérifier la chaîne à

l’aide d’un gabarit d’affûtage en limant à la cote indiquée ci-dessous.

Arrondir le bord d’attaque des

dents pour réduire le risque de rebond ou de rupture des maillons.

!

ATTENTION!

!

ATTENTION!

!

ATTENTION!

Vérifier que toutes les dents présentent les longueurs

et angles de tranchant indiqués sur l’illustration.

2. Guide-chaîne

•Retourner le guide-chaîne de temps à autre pour

éviter l’usure inégale.

• Le rail du guide-chaîne doit maintenir la chaîne d’aplomb.

Poser une règle contre le rail et contre l’extérieur

d’une dent. Il doit subsister un interstice entre le

guide-chaîne et la règle. Si ce n’est pas le cas, cela

signifie que le rail est usé. Il faut alors réparer ou remplacer le guide-chaîne.

8. Entretien de la chaîne et du guide-chaîne 15

FR

(1) Gabarit d’affû-

tage

(2) Arrondir l’arête

(3) Voie standard:

(voir le “Tableau

d’entretien de la

chaîne”)

(A) Longueur de tran-

chant

(30°) Angle d’affûtage

(85°) Angle de tran-

chant latéral

(60°) Angle de tran-

chant supérieur

(1) Règle

(2) Interstice

(3) Pas d’interstice

(4) La chaîne est pen-

chée

8. Entretien de la chaîne et du guide-chaîne

Page 33

16MM16

FR

8. Entretien de la chaîne et du guide-chaîne / 9. Guide de dépannage

9. Guide de dépannage

1) Défaut de démar-

rage

AVERTISSEMENT