Page 1

Increase Quality Through Interaction with the Field

The Oreck Manufacturing Company

Compiled by Clark DeNoble

8143 Air Purifier Tune-Up & Service Guide

07/20/2005

Increase Quality Through Interaction with the Field

1

Page 2

Increase Quality Through Interaction with the Field

Table of Contents

Tune-Up Pages 3-13

Check Housing Aesthetics and Structural Integrity Page 3

If Equipped: Check that the Louver Functions Smoothly Page 3

Check Fan Speed Switch and Motor Function Pages 3-4

Check the Status Light Function Pages 4-6

If Equipped: Check the Ionizer Switch Function Page 6

Check For Unusual Noises Pages 6-10

Thorough Washing Instruction Pages 8-10

If Equipped: Check Scent Cartridge Holder Function Page 10

Check the Safety Interlock Switch Function Page 10

Check the Structural Integrity of the Cell Pages 10-11

Clean Pages 11-12

Finishing Up Pages 12-13

Other Troubleshooting & Service Pages 13-21

Status Light Dead Pages 6

Nothing Works Pages 13-14

Lights Work Motor Doesn’t Pages 14-15

Remove and Replace Motor Pages 15-19

Cell High Voltage Circuit Board Replacement Pages 9-20

Circuit Diagram (10/20/03) Page 21

If the conditions are dry

enough even a cell this dirty

may not set off the red status

LED continuously.

Increase Quality Through Interaction with the Field

2

Page 3

Increase Quality Through Interaction with the Field

Tune-Up

1. Check Housing Aesthetics and Structural Integrity

a. If you cannot see the blemish at arms length then it probably doesn’t matter

otherwise apply the following.

b. Hairline scratches:

i. Top & Sides-no more than 2, at ≤ ½”, on each surface.

ii. Rear & Bottom-no more than 3, at ≤ 1”, on each surface.

c. Gouges:

i. Top & Sides-none

ii. Rear & Bottom-no more than 2, at ≤ ¼”, on each surface.

d. Cracks:

i. No more than 2 total, at ≤ ¼”, per unit.

2. If Equipped: Check that the Louver Functions Smoothly

a. Operate the actuator back and forth.

b. Assure the louvers all move together at the same time.

3. Check the Fan Speed Switch and Motor Functions

a. Must function in all three positions.

b. Test whether the fan will bind in Silent. Unplug the unit and set the switch to silent.

Plug in the unit-the fan should start up.

c. If it doesn’t, first check for proper fan installation:

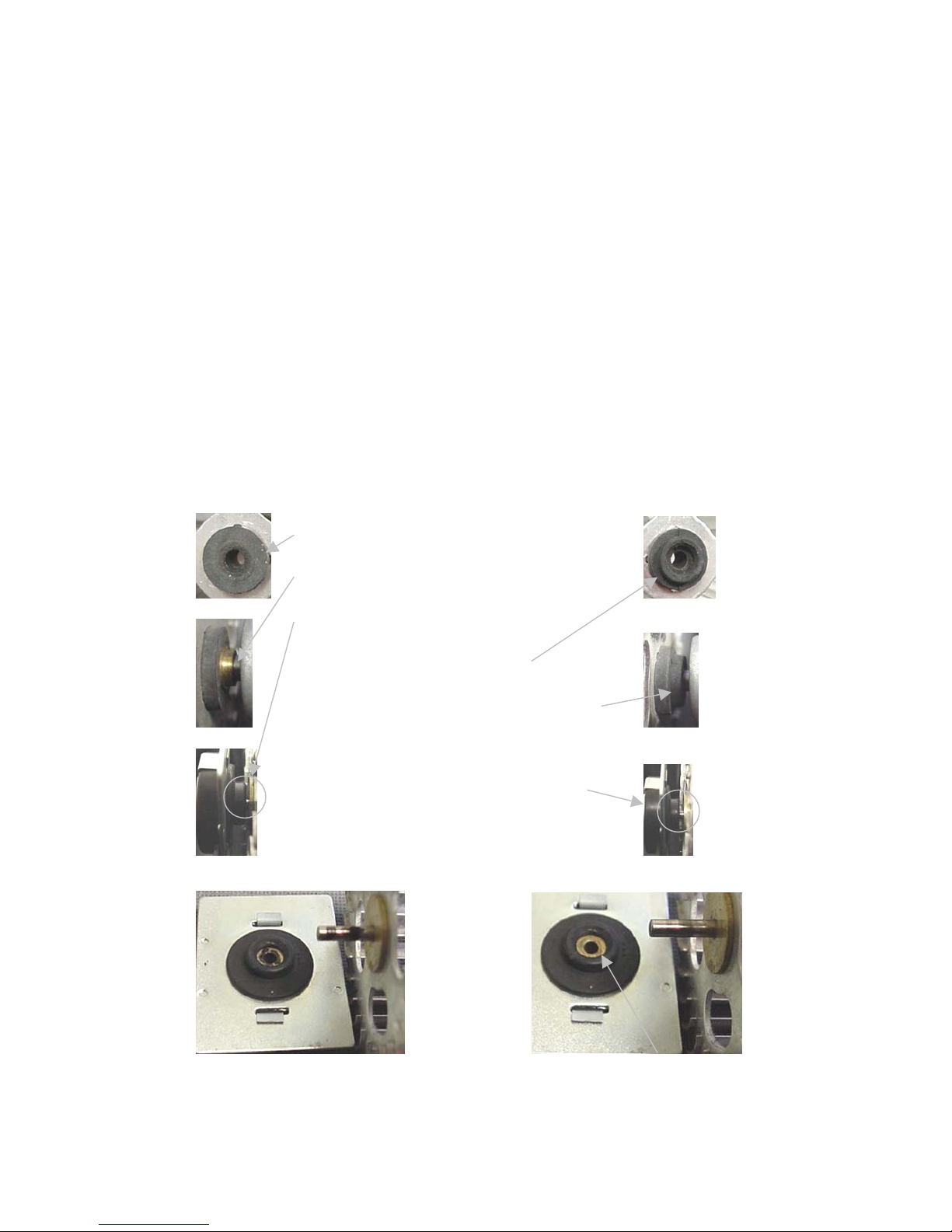

The fan grommet on the left is solid, has four

holding tabs, butts against the motor shaft’s

brass ring and must hold in this position to

provide clearance between the fan and fan

bushing grommet. This fan grommet must be

a tight fit to the motor shaft and free of

lubricants.

The grommet on the right is tiered, has four

holding tabs and envelops and holds onto the

motor shaft’s brass ring. As you can see if

this grommet is only butted against the brass

ring then the normal clearance between the

fan and fan bushing grommet shown in the

picture would be nonexistent. The reduced

clearance could cause screeching as the

d. Then check to see if the fan shaft and bearing are gummed up or worn:

Clean fan shaft and bearing. Apply oil to bearing assembly.

Increase Quality Through Interaction with the Field

3

Page 4

Increase Quality Through Interaction with the Field

FYI-There is a felt behind the bearing. When you apply oil to the bearing hole

allow time for it to soak into the felt.

Fan Bearing

Assembly-

Front

Bearing Assembly Bracket

4. Check Status OK Light Function

a. Changes from red to green when the unit is turned ON.

b. If it stays RED then remove the cell, activate the unit.

c. If the light turns green then the cell was the problem (Red Status Light Due to Cell-

Additional).

d. If the light stays red then either the circuit area is wet, poor electrical contact between

the cell and HV contacts or HV assembly is defective.

Felt Retainer

Oil Retention

Felt

You’ve washed, rinsed and dried the cell and the

Status light was still red.

1. Remove the cell and power up the unit. If the

Status light goes green then proceed to step

2.

Note: If the Status light stays red see 4c.

2. Carefully pry up and remove the front plate

support bar and return cell to unit.

Note: Be sure to remember how the bar was

positioned on the cell plates.

3. If the Status light turns green then skip to step 9.

4. If the Status light turns red go to step 5.

Increase Quality Through Interaction with the Field

5. Carefully pry up and remove the rear plate

support bar and return cell to unit.

Note: Be sure to remember how the bar was

positioned on the cell plates.

6. If the Status light turns green then remove

the cell from the unit and reinstall the first

support bar.

7. If the Status light stays green then that

support bar is good.

8. If the Status light turns red then remove the

support bar and proceed to step 9.

4

Page 5

Increase Quality Through Interaction with the Field

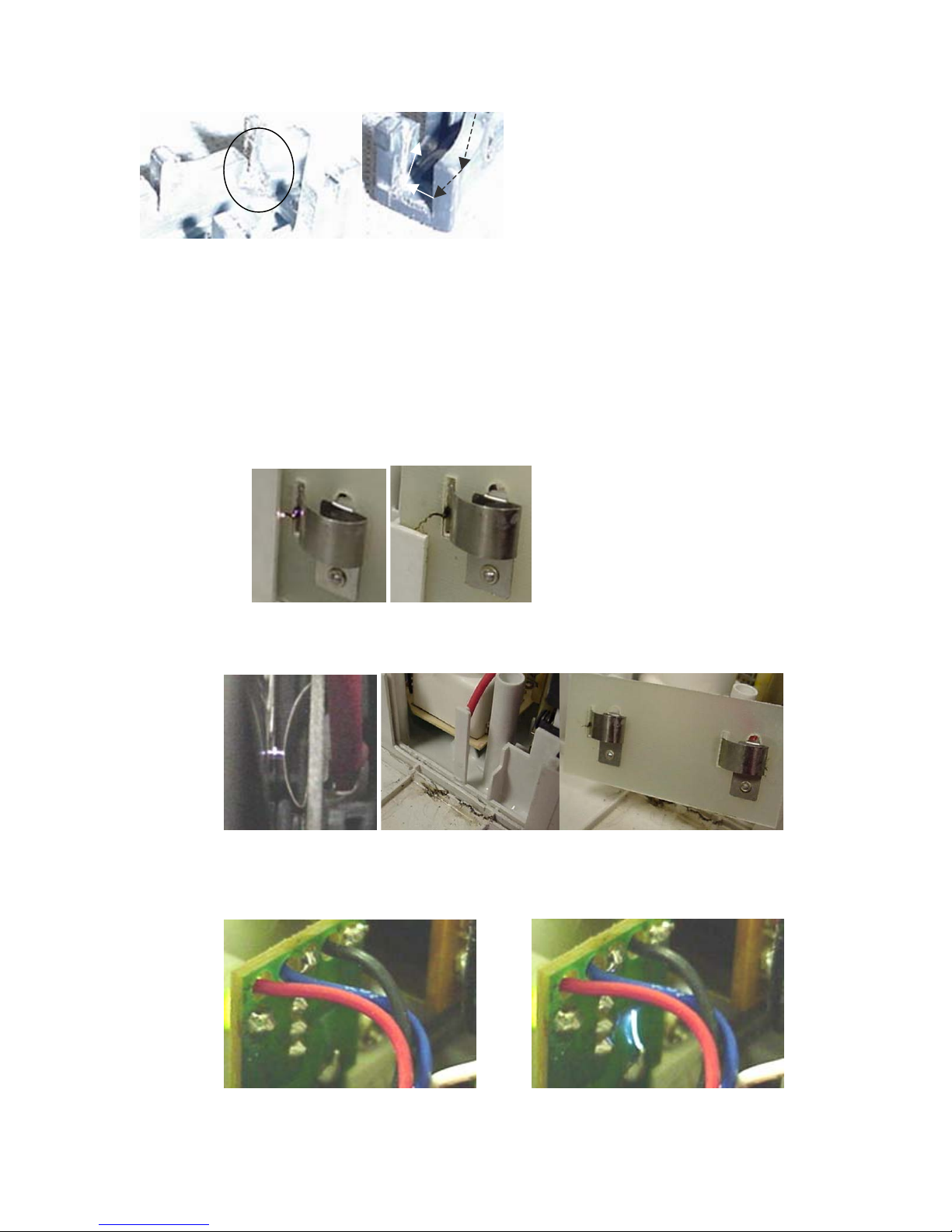

9. Take the bar/s and look for a carbon trail light

to dark brown or just discolored (circled).

This trail is often hard to see but it is

supplying an electrical path from a negative

plate to a positive plate (see arrows). This

electrical connection causes the Status light

to turn red.

10. Scrap off the carbon trail on one bar, reinstall

and test. If the Status light stays red then

remove the bar and scrap some more.

11. If the Status light turns green then go to work

on the other bar (if there is one) and repeat

step 10.

e. Some cells deeply burned/hidden carbon trails that cannot be scraped off or corona

wires that were stretched or broken. Replace the cell.

f. Red Light due to arcing or carbon trails at the cell contact board.

Picture 1 shows the arc in progress.

Picture 2 shows the carbon trail formed by the arc. The carbon trail makes later

failure much easier, scratch it off.

g. If with the cell in, the status light constantly changes from green to red and back:

Either the HV conductor is not making good contact with the cell. Bending it out

usually does the trick.

Dry the slot and cell contact board before buying a new HV circuit

board (See pictures on page 19)

or

h. There is arcing on the LED board due to post ionizer reaction with residue on the

housing. (See Thorough Washing Instruction).

Increase Quality Through Interaction with the Field

5

Page 6

Increase Quality Through Interaction with the Field

i. Status light function reversed:

Operates in reverse, when you turn the unit ON the Status light briefly shows green

then goes to red and when you turn the unit OFF the Status light fades from red to

green and goes out, then either the wiring is reversed or the LED board is defective.

j. Status light never comes on:

If the Status light doesn't light at all then either the LED board, transformer or HV

circuit board is defective (See Status Light Dead).

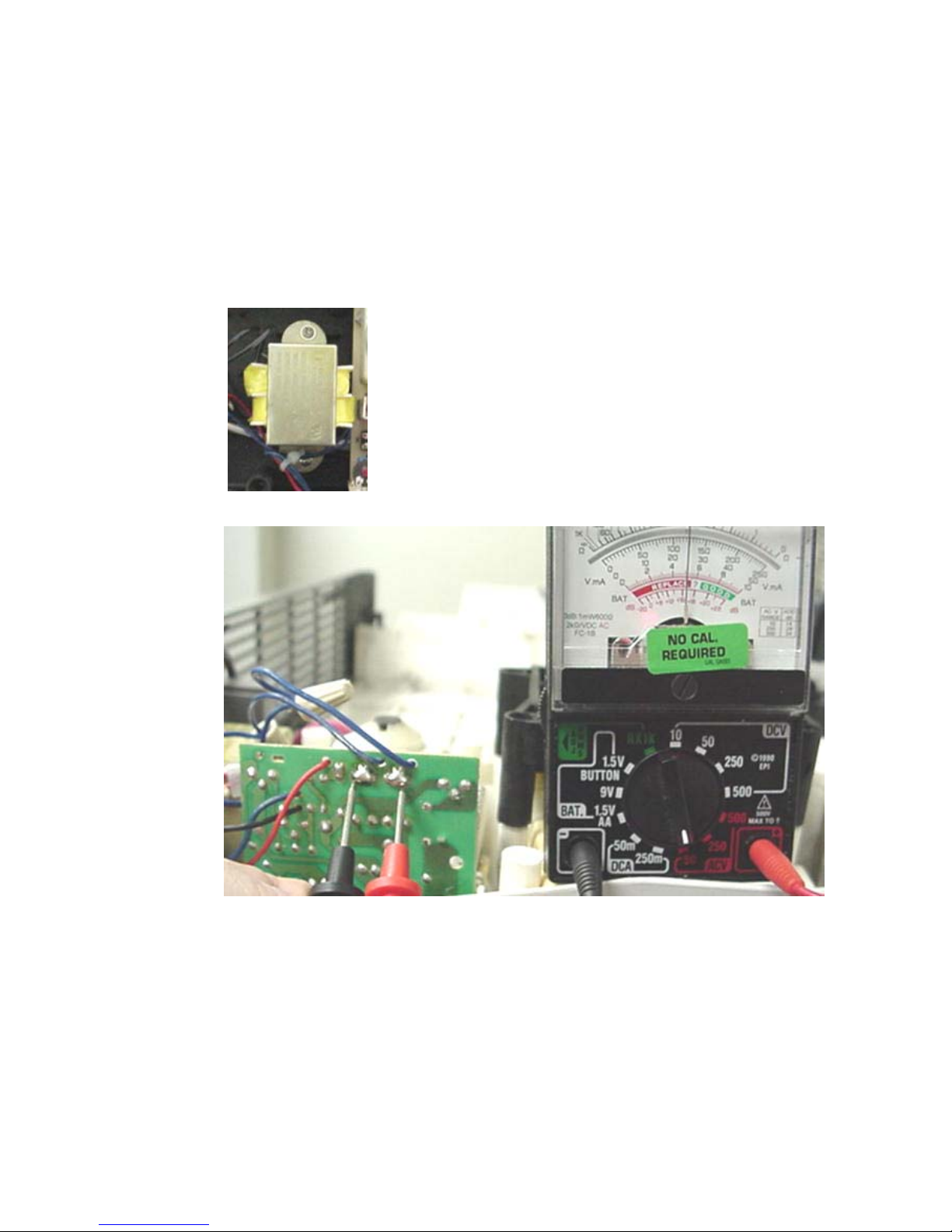

Status Light Dead

There may be a problem with the yellow step down transformer.

If the transformer passes this check then the problem is the LED board or the

whole LED HV circuit board assembly.

Select the 50 VAC scale on your Multimeter. Turn the unit ON.

Touch the meter leads to the two solder joints shown below. A good transformer will

put out 24VAC.

If you don’t see 24VAC, turn the unit OFF and scrape the solder joints to remove any

coating. Turn the unit ON and test again. If you still don’t measure 24VAC then the

transformer needs to be replaced

Important: If the transformer is bad the power to the cell will also

be OFF. Replace the bad transformer first and test before ordering

the LED or HV boards.

5. If Equipped: Check the Ionizer Switch Function

6. Check for Unusual Noises

a. Ticking

i. Unbalanced Fan-shaft tapping the brass bearing-). If you see a significant up

and down movement this may be the problem (replace the fan unless

twisted. (See Twisted Fan 6 a iv).

ii. Dry Felt/Bearing-no oil

iii. Cocked Bearing-straighten

Increase Quality Through Interaction with the Field

6

Page 7

Increase Quality Through Interaction with the Field

iv. Twisted Fan- Determine if the fan is twisted (the blades should be

horizontal). You can untwist the fan by gently turning the ends so the blades

straighten out (this has eliminated ticking

v. Bent Fan-some service fans get bowed from either shipping damage or

mishandling-replace the fan

vi. Dry Motor Ball Bearings

There are a couple of ways to determine if it's the motor bearing:

• Take a long shaft screwdriver, put the blade against the bearing

housing then put your ear against the handle and listen.

• Remove the fan and hear if the noise continues.

Indicators

• No noise (the bearing is packed (greased) well and probably on

a new unit).

• Some very sporadic non-rhythmic bearing ticking only heard

using the screwdriver (normal).

• Then there's the “shaking ball bearings in a cup” noise (bearing

is dry-this is probably the condition that gives you the noise of

concern).

• Finally, f it sounds like gravel then the bearings are already

damaged.

Although not recommended, if you choose to repack the bearings, use hightemperature grease, not automotive axle (stinky) grease.

b. Snapping behind the switch panel. Arcing at the LED board (may or may not cause

the Status light to flicker.

If the arcing stops when the ionizer is turned off then it is always due to

residue/moisture in the cell/fan portion of the housing including the ionizer needle

and bracket. This will require a thorough washing.

Increase Quality Through Interaction with the Field

7

Page 8

Increase Quality Through Interaction with the Field

THOROUGH WASHING INSTRUCTION

1. REMOVE UPPER HOUSING

Turn the unit onto its’ backside.

Remove 9 screws.

2. REMOVE UPPER HOUSING

Tilt the upper housing off the lower

housing.

You may need to hold the fan- bushing

bracket down while removing the upper

housing.

Remove the fan and bracket.

3. REMOVE THE SAFETY INTERLOCK SWITCH

Loosen the switch panel from the

housing.

Push in the safety interlock switch

button and pull out the switch.

Disconnect the power cord connector

from the switch terminal.

4. FREE THE POWER CORD NEUTRAL LEAD

Find the wire butt connector that

secures five (5) wires together.

Often you can squeeze the connector

and release the wires otherwise you’ll

need to cut the connector as shown

and pull it off the wires.

5. REMOVE THE TRANSFORMER

Increase Quality Through Interaction with the Field

Remove the two (2) screws that

fasten down the transformer

.

8

Page 9

Increase Quality Through Interaction with the Field

6. REMOVE THE POWER SUPPLY

Remove the two (2) screws that fasten down the

power supply.

7. REMOVE THE MOTOR HOLD DOWN BRACKET

Remove the four (4) screws from the bracket.

Remove the bracket.

Remove the two (2) upper motor mounts

8. REMOVE THE IONIZER NEEDLE AND BRACKET

Remove one (1) screw from the ionizer needle bracket.

Remove the needle and bracket.

9. REMOVE THE IONIZER POWER SUPPLY AND MOTOR

10. REMOVE THE LOWER MOTOR MOUNTS

Increase Quality Through Interaction with the Field

Remove one (1) screw from the ionizer power

supply.

Gently remove the switch panel, transformer, power

supply, motor and ionizer power supply with needle

from the lower housing.

9

Page 10

Increase Quality Through Interaction with the Field

11. REMOVE THE POWER CORD

Remove two (2) screws.

Remove the cord clamp.

Remove the cord.

12. CLEAN AND REASSEMBLE

CAUTION DO NOT USE:

Solvent Spot & Stain Remover: liquefies the plastic.

1. Cleaning may involve just rinsing the

housings, fan and cell parts with hot water.

2. If a cleanser is used be sure to thoroughly

rinse with water (excessive residue may

cause arcing on the LED board.

3. The cell must be thoroughly dried or the

Status light will stay red and the cell plastic

might be burned.

4. Reassemble the unit starting with M in reverse

order.

5. At step 4

a. Strip the five (5) leads to expose ≈

½” of bare metal.

b. Twist the exposed wires together

clockwise (important if using a wire

nut).

c. Crimp on a wire but (shown) or twist

on a wire nut. Check that all the

wires are securely captured.

6. Tie the three (3) bundles together.

c. Rumbling

i. Worn fan grommet

ii. Unbalanced fan – remove fan if noise goes away it’s the fan

iii. Unbalanced motor – remove the fan if the noise continues it’s the motor

iv. Unit on an uneven surface

d. Screeching/Seal Bark

i. The fan is rubbing against the rubber fan bearing

7. If Equipped: Check the Scent Cartridge Holder Function

8. Check the Safety Interlock Function and Begin Cleaning Process

a. Leave the unit turned on, loosen the grill retainer screw, push in the actuator and

remove the grill-the unit should turn off.

b. If it doesn’t, replace the interlock switch.

c. Place the grill and place in a soap bath. Gently clean, rinse and dry.

Increase Quality Through Interaction with the Field

10

Page 11

Increase Quality Through Interaction with the Field

9. Check the Structural Integrity of the Cell

a. Remove the cell from the unit

b. Remove the Pre-filter from the Precipitator cell and place in a soap bath. Gently

clean, rinse and dry.

c. Remove Odor (Carbon) Absorber and discard.

d. Pre-charge wires should be stretched tight (may have a slight wavy look if it doesn’t

cause arcing)

e. Plates should be flat and evenly spaced

f. End Cards and spacers should be free of burns and distortions.

g. Discard the precipitator cell if pre-charge wires are broken or plates are bent beyond

reasonable repair or end cards/spacers are burnt beyond repair.

Pre-charge wires

Spacer

End Card

e. Wash out the precipitator cell and fan. Gently clean with Assail-A-Cell or other

10. Clean

Skip the Thorough Washing Instruction (See 6b) and go to step g if the unit doesn’t

require a thorough washing.

Use a vacuum cleaner to remove dust and debris from the Precipitator Cell cavity, fan,

louvers and exhaust grill.

recommended cleanser, rinse with fresh water and dry.

Increase Quality Through Interaction with the Field

11

Page 12

Increase Quality Through Interaction with the Field

Gently clean the two metal contacts of the cell interconnect board with a plastic safe

contact cleaner/lubricant and soft cloth.

Use Zoom Spout or equivalent to lubricate the fan bearing.

11. Finishing Up

• Cell High Voltage function can be verified. Method can be performed with or without

the top cover installed. Safety First-If performed without the top cover installed

remove the fan.

• Neon Bulb Circuit Tester: Caution-the condition is a static charge. Manage the tester

lead so you don’t have to hold the tester. Touch the front cell contact with one leg of

the inexpensive circuit tester shown in Figure A1. Leave the other leg dangling. Turn

the unit on and enable the safety switch as shown in A2. If the neon bulb of the tester

doesn’t light up then the HV Power Supply is defective.

Fix tester lead to this

contact point.

A1 A2

• Negative HV Power Supply Test-Ionizer Generator function can be verified. Safety

First – Remove top cover and fan.

• Caution-the condition is a static charge. Manage the lead so you don’t have to hold

the tester.

• Rest the end of the test lead on the ionizer needle.

• Turn the unit ON and insure the IONIZER switch is in the IONIZER position.

• The bulb will glow if the ion generator is working.

Increase Quality Through Interaction with the Field

12

Page 13

Increase Quality Through Interaction with the Field

Located in the fan

chamber on a bracket on

the right side of the back

wall.

Ionizer Needle

Off

• Fit the pre-filter and new odor absorber to the precipitator cell.

• Install the cell.

• Fix the grill in place and tighten the retaining screw.

• Recheck all switch functions for proper unit operation.

• Clean the exterior using Oreck Foam Cleaner 32252 or equivalent. Don’t spray any

cleaning product into louver area (may result in stray static arcing).

Other Service Considerations

Nothing Works

1. Set the Multimeter to Ohms

On

2. Find the unit’s plug. Touch a probe to the large blade and the other to the small blade

(Polarity doesn’t matter here).

3. If the unit is off, you should get an ∞ reading.

Increase Quality Through Interaction with the Field

Touch the test probes together and adjust for a 0 indication.

13

Page 14

Increase Quality Through Interaction with the Field

4. You should get a 0 reading in each of the three On positions.

5. If you get an ∞ (infinite) reading the problem is either with the power switch, wiring including

cord, safety switch or safety switch actuator.

6. Check that the safety switch actuator on the grill (1/8” bump) isn’t missing

7. The actuator activates the switch safety interlock.

Lights Work but the Motor Doesn’t (Added 11/21/03):

1. Unplug the unit from the wall socket.

2. Remove the top cover (9 screws).

3. Turn the fan speed switch to OFF.

4. Touch a meter lead to the Neutral/Larger blade of the plug.

Increase Quality Through Interaction with the Field

14

Page 15

Increase Quality Through Interaction with the Field

5. Touch the other lead to the back of the power switch where the black, (brown or blue) and

red.

6. If you get a ∞ reading in any position then the motor is bad.

7. Check the Interlock/Safety switch by removing the two leads (Fig F).

8. Touch the Multimeter leads to the switch terminals and press in the switch button with a small

blunt object (Fig G). If the meter goes to 0 then the switch is good.

F G

Remove and Replace the Motor

1. Turn the unit over and remove nine (9) screws.

2. Turn the unit back over and carefully remove the top housing.

3. You may need to reach in and pull down the fan assembly if it’s caught in the top housing

(Fig H).

Increase Quality Through Interaction with the Field

15

Page 16

Increase Quality Through Interaction with the Field

4. Lift the fan out of the side shown in Fig H and pull it off the motor shaft (Fig I).

I

5. Remove the four (4) screws securing the motor to the lower housing (Fig J).

J

6. Remove the two (2) upper motor mounts.

7. Remove the ionizer mounting screw.

8. Lift up the ionizer and move it out of the way.

Increase Quality Through Interaction with the Field

16

Page 17

Increase Quality Through Interaction with the Field

9. Turn the defective motor on its’ side and remove the cable clamp screw.

.

10. Cut the four (4) wire leads from the motor. Remove motor.

11. Install the new motor and place the new harness with the old harness.

12. Cut off the excess wire from the new motor to match the total length of the old harness.

Increase Quality Through Interaction with the Field

17

Page 18

Increase Quality Through Interaction with the Field

13. Trim back the jacket (outer covering) for a convenient lead length on both harnesses so you

can strip (3/8”) the wires.

14. For stability cable tie both harnesses together before connecting leads.

15. Connect the leads together: white/white, blue/blue, red/red & black/black.

16. Bend the harnesses to fit under the ionizer generator.

17. Place the ionizer generator over the harnesses and fasten with one screw.

18. Place the motor mounts on the motor.

19. Fit the motor bracket over the motor and fasten with four screws.

Increase Quality Through Interaction with the Field

18

Page 19

Increase Quality Through Interaction with the Field

20. Fit the fan to the motor shaft. One fan grommet is made to butt up against the brass retainer

on the motor shaft and another fits over.

21. Reassemble and test operation: must work in all three “On” positions.

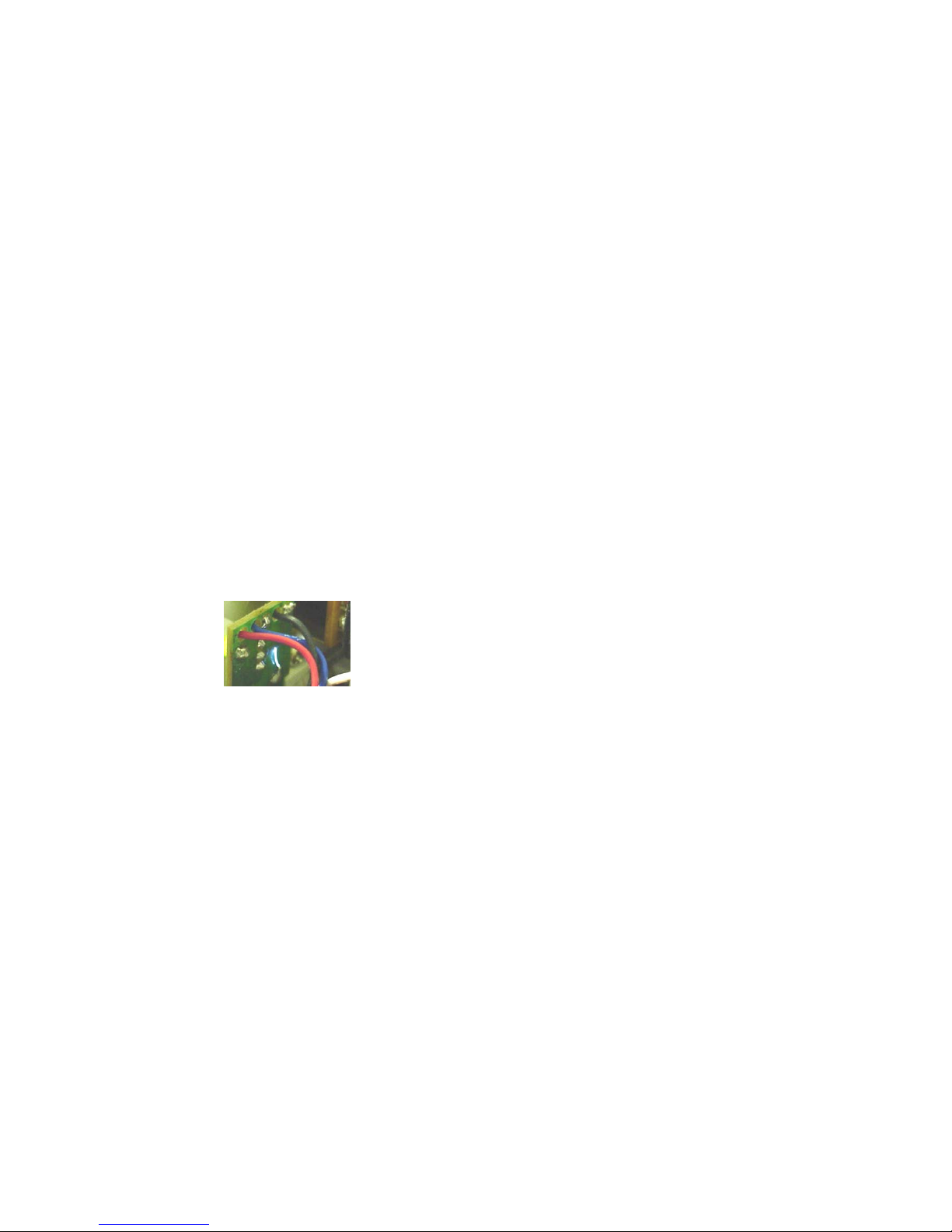

Cell High Voltage Circuit Board Replacement

1. On the HVPS circuit board remove two (2) screws. Cut the leads to the circuit board as

shown in Figure A, B & C. Remove the defective power supply.

A

2. Install the new circuit board and fasten with two screws (Fig A & B).

3. Strip 3/8” of insulation from each of the cut wires.

4. Splice the new circuit board leads to the stripped leads with wire nuts or butt terminals:

red/red, black/black and the blues as shown in Figure D. The circled blue leads are

connected to the leads from the yellow transformer.

B

C

Increase Quality Through Interaction with the Field

D

19

Page 20

Increase Quality Through Interaction with the Field

5. Tie-wrap all leads together and position the connectors so they will not contact the top

housing (Fig E).

E

6. Perform the tests in Tune-Up to assure successful repair.

7. Reassemble unit.

Increase Quality Through Interaction with the Field

20

Page 21

Increase Quality Through Interaction with the Field

Circuit Diagram

Red Blue Black

. .. … Off

Black Black Brown

Red

Blue

Black

Off On

Safety

Interlock

Switch

On/Off & Fan

Control Switch

Status

Ionizer On/Off

Switch

Black

Ionizer On

LED Board

Ionizer

Module

Side with writing on cord jacket

High Voltage

Power Supply

White

Red

White

Red to ionizer

plate on cell

Red Black

Transformer

Black

Motor

White w/needle

Green

Cord Neutral Lead

Cord Hot Lead

Increase Quality Through Interaction with the Field

21

Loading...

Loading...