Page 1

SIMPLY AMAZING

Service Manual

®

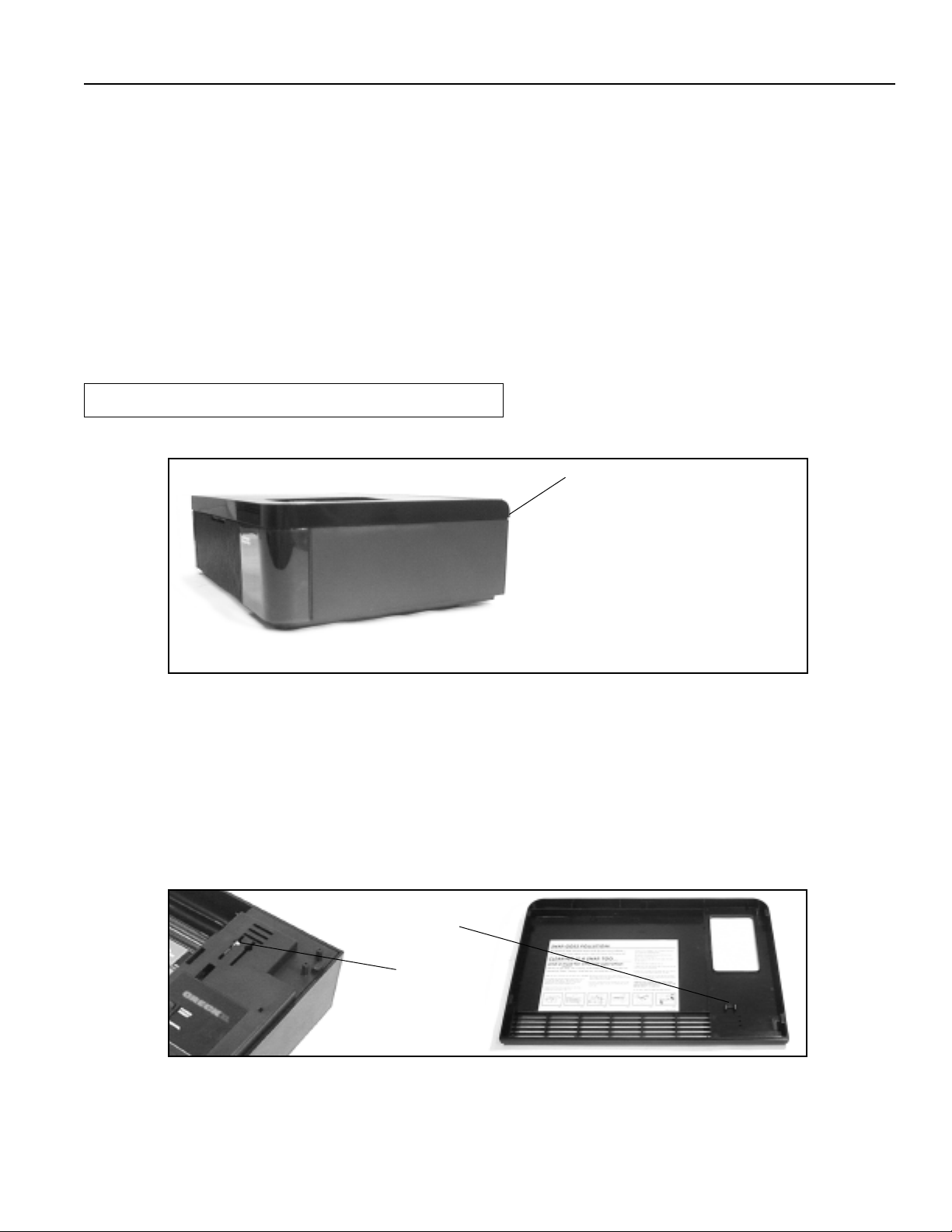

Table Top Air Cleaner

Super Air 5 / Air 6

REV I., Please disregard all earlier versions.

Model 447628 & 4478801

Page 2

Important Safeguards

When using electrical appliances consideration should be given to basic safety

precautions including:

1. Read all instructions.

2. Do not immerse appliance, cord or plug in water or other liquid and take care to ensure

that the control panel is kept clean and dry.

3. Do not use the appliance if there is any visible damage to the appliance or to the supply

cord.

4. Close supervision is necessary when any appliance is used by or near children.

5. Do not let the cord hang over the edge of the table or worktop or touch hot surfaces.

6. Do not use the appliance outdoors.

7. Do not use the appliance for other than its intended use.

WARNING: DO NOT USE THIS ELECTRONIC AIR CLEANER WHEN OXYGEN IS

8.

BEING USED OR WHEN COMBUSTIBLE GASES ARE PRESENT. HIGH VOLTAGE

SPARKS CAN CAUSE IGNITION AND SUBSEQUENT PERSONAL INJURY OR

PROPERTY DAMAGE.

NOTE: Care should be taken to avoid touching the sharp ionizer needle situated above

9.

the fan. Always disconnect the unit from power prior to cleaning or servicing.

General Knowledge Warning - The intent of this manual is to provide general

guidance to be used by a qualified service technician in servicing the Oreck tabletop electrostatic

air cleaner. The technician should have a good understanding relative to working with electrical

and mechanical equipment. A knowledge base to include basic electronics, basics of motors and

general mechanical knowledge is required to service this equipment. Attempting to service the

equipment without the above background could result in electric shock, personal injury or

property damage. Do not attempt to service equipment unless properly qualified.

Rotating Element Warning - Unit has a rotating blower wheel and cooling fan to

circulate air and keep the unit cool. When servicing the unit and repairing the unit always insure

that you keep objects and internal electrical wiring away from the rotating elements. Failure to

allow for proper clearance for rotating members can cause electric shock, personal injury or

property damage.

Tools Required

Multimeter Fluke Model 8024-B

High Voltage Probe Fluke Model 80K-40

#2 Flat Blade Screwdriver

#2 Phillips Drive Screwdriver

Diagonal Wire Cutters

Wire nuts

Needlenose Pliers

2

Page 3

Table of Contents

General Description and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Periodic Maintenance and Tune-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Trouble Shooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Parts Removal and Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Cross Section and Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

General Description and Operation

Airborne particles and odors are removed from

air passing through the unit by the process of

electrostatic precipitation and the revolutionary

post filter which combines antimicrobial

treatment and activated charcoal.

The air around you is filled with thousands of particles of air

pollution. Some of the pollutants - dust, pollen and lint are visible to the naked eye, but most of

the pollutants - smoke and bacteria, to name a few, are microscopic in size.

Polluted air enters the unit through the front of the air cleaner. The fan pulls in dirty air and the

pre-filter traps large particles (hair, lint, etc.). The smaller particles (dust, smoke, pollen) in the

dirty air receive a positive electrical charge as they pass through the ionizing section. The

positive charged particles then enter the collecting section which uses a series of alternately

charged aluminum plates to attract and retain the particles. It works like a powerful magnet

and the particles remain there through natural adhesion until removed by the washing process.

The air then passes through the post filter that helps control microorganisms and remove

household odors. Next, the negative ion generator freshens stale air. Finally, clean air passes

back into the room through the top grille.

3

Page 4

Periodic Maintenance Tune-Up

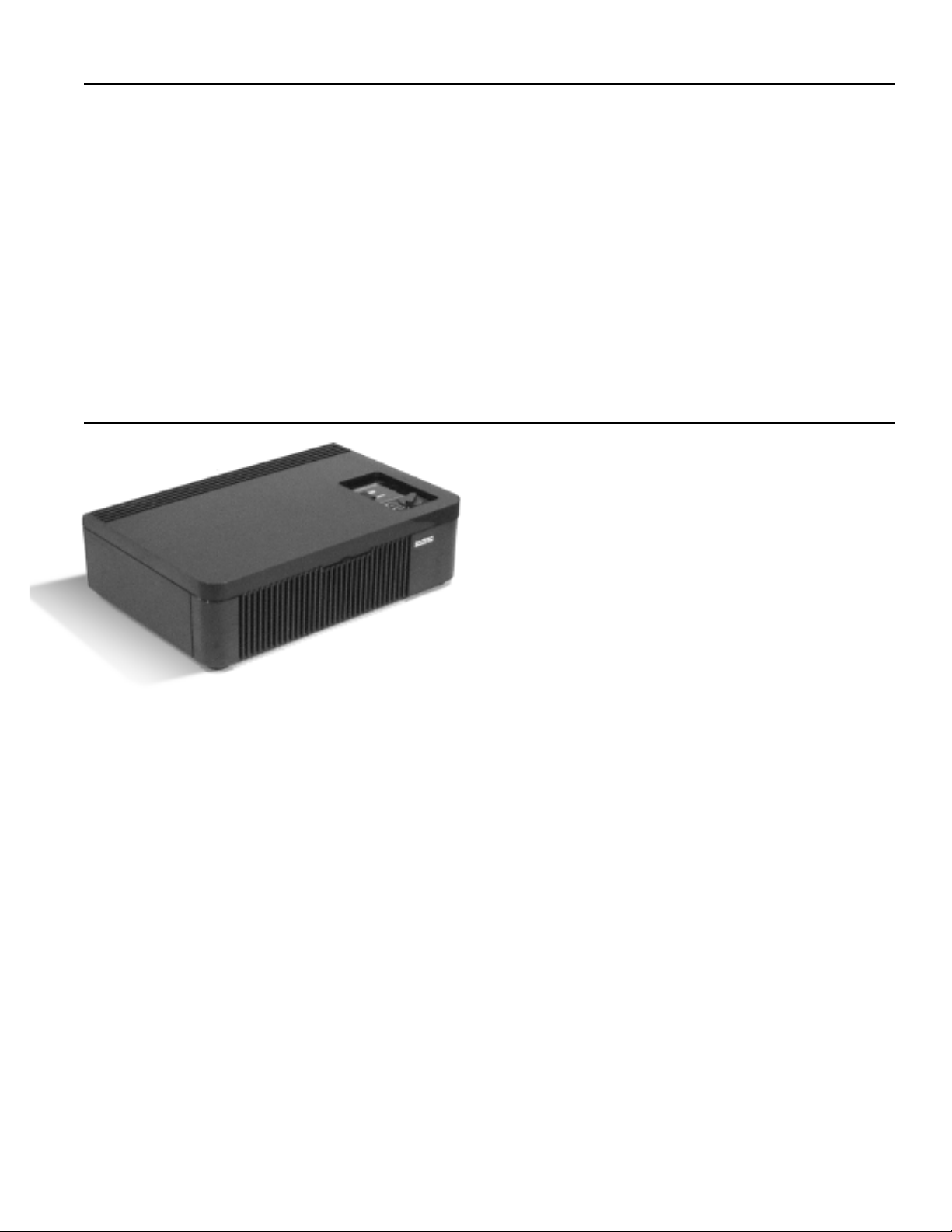

1. Remove collecting cell and pre/post filters.

2. Wipe down inside of unit with damp cloth.

3. Thoroughly Clean Collecting Cell with Oreck Assail-A-Cell Cleaner.

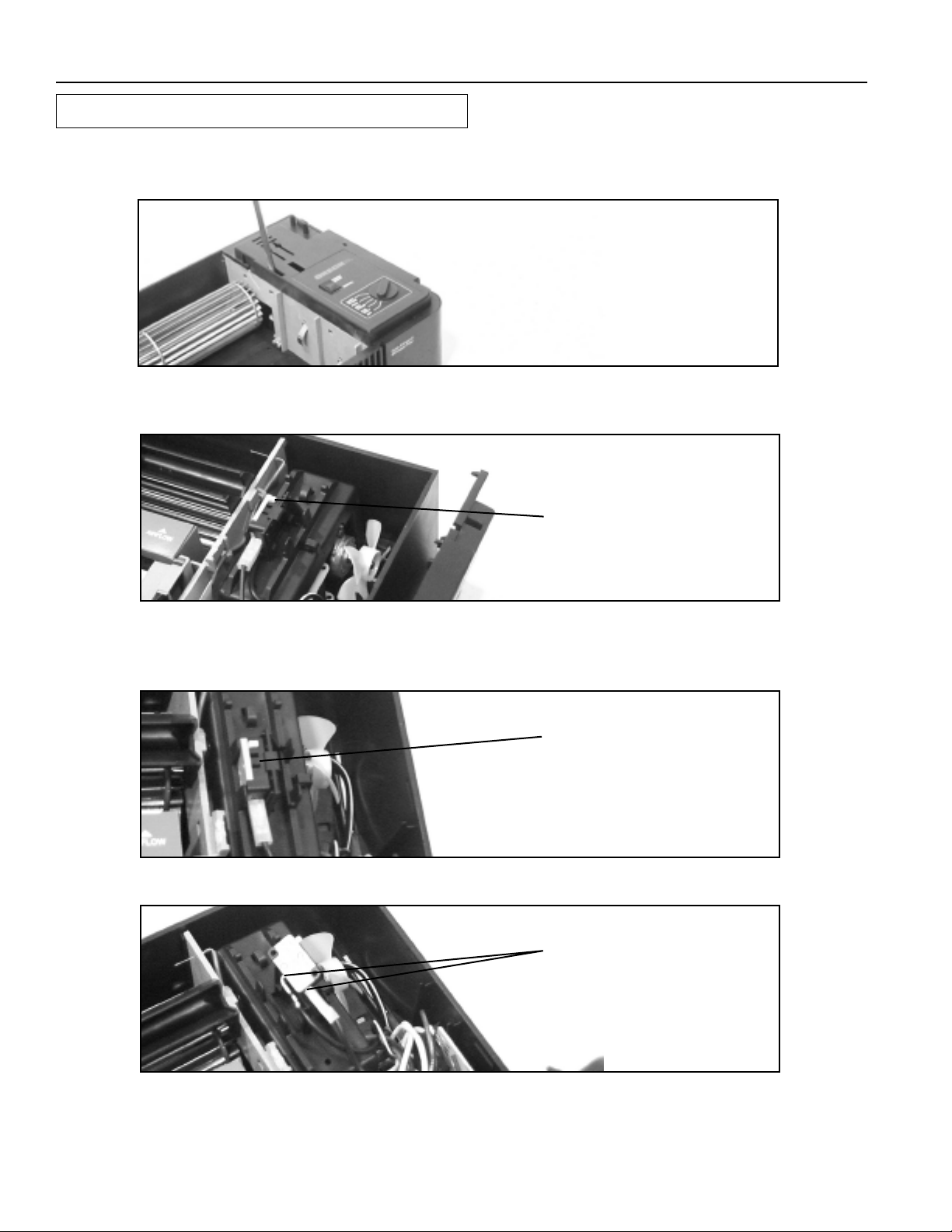

4. Check for any broken wires in the collecting cell, and ensure wires are securely seated

in the plastic spacer at the center of the cell. Check for any bent plates in collecting cell.

Replace if damaged.

wires

plastic spacer

plates

5. Thoroughly Clean pre-filter with warm soapy water.

6. Clean negative ion generator tip with a alcohol and a cotton swab.

7. Clean the dirt and grime from the motor shaft using a soft cloth.

8. Squirt a few drops of machine oil (“3 in 1” type oil, not

WD-40 type oil) in the slot on the

shaft to lubricate the bearing.

9. Check to ensure blower wheel rotates freely.

10. Check to ensure rubber grommet on motor shaft is not worn or loose. Replace if

necessary.

11. Check the bearing in the bearing wall (opposite end of motor) on other end of blower

wheel for excessive wear or damage. Replace if necessary.

12. Re-install collecting cell and pre-filter.

13. Install New Post Filter (Activated Charcoal Filter).

4

Page 5

Troubleshooting Guide

Warning: The troubleshooting portion of this manual requires that the unit power be “ON” for

much of the servicing portion of troubleshooting. When working on the unit under power, use all

of the standard precautions in working with any electro-mechanical device that contains line

voltage, high voltage, and rotating elements. Failure to follow standard safety procedures can

cause electrical shock, personal injury or property damage.

Initially:

1. Plug the unit into a proper outlet.

2. Check the unit on all speeds to see if the blower and motor are operating properly. The

power supply light should not operate on the “fan” selection mode.

Problem Being Checked:

1. If the motor and blower do not operate

:

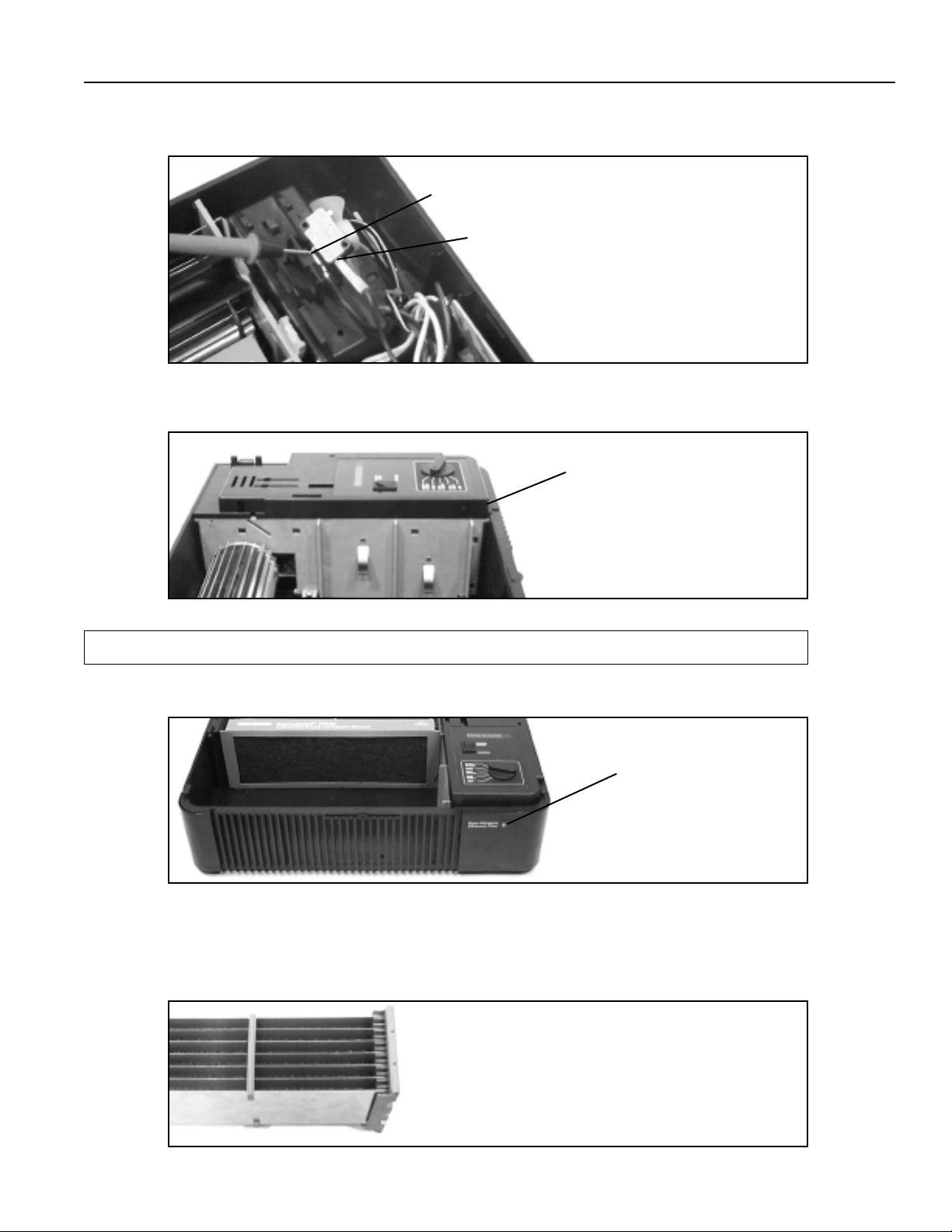

a. Check the top for proper positioning. The top must fit tightly on the unit.

Remove the top. Depress the

interlock switch with a plastic

handle screwdriver to test

operation. If the motor and

blower operate, then the

problem is that the interlock

switch is not gettting engaged

when the top is on. Reinstall

the top and ensure tight fit so

activator post can engage the

interlock switch.

b. With the top removed, depress the interlock switch with a plastic handle screwdriver to

test operation.

c. If the motor and blower operate, then the problem is that the interlock switch is not

engaged when the top is on.

d. Check the top to see if there is a broken activator post.

e. Check the top to determine if it is warped. If the top appears to be warped, try

a new top.

Activator Post

Interlock Switch

Turn the top over and examine it for a broken activator post. Lay the top on a smooth

surface. Check it for warpage that could keep the interlock switch from being engaged.

f. Check the interlock switch (item 3 of the parts diagram).

5

Page 6

Troubleshooting Guide

How to Remove the Power Supply Cover

1. Insert flathead screwdriver into slot on the interior edge of the power supply cover, and

push plastic clip away from contact wall so that the cover can be lifted up.

Gently pry the plastic clip

away from contact wall to

release the cover.

2. The switch wires will limit the movement of the power supply cover.

3. Is the switch actuator broken?

If the actuator is broken,

replace the switch.

4. Is the switch properly seated in the bracket, or is the bracket broken or distorted?

The switch is held in position by a bracket that allows the switch to be snapped

between two locator ribs on the bracket.

If the switch is out of

position, straighten and

secure it. If the bracket is

broken or distorted, replace

the motor bracket.

5. Are the wires connected to the switch?

Check both wires on the

interlock switch to ensure

that they are connected and

tight.

6

Page 7

Troubleshooting Guide

6. Check the voltage to and from the switch when activated. You should be able to

measure line voltage entering and leaving the switch when activated.

TO SWITCH, If voltage is

LINE SIDE

LOAD SIDE

7. Check the switch plate cover. The plate must sit squarely on the bearing wall

and the cabinet base.

present on line side of the

switch but not present on

load side, the switch is bad.

FROM SWITCH, If there is no

voltage on line side of the

switch, check the wall outlet.

If there is voltage at the

outlet, then the line cord is

bad.

If the switch plate cover is

not secure, it will prevent the

top from engaging the

interlock switch. Insure that

the cover is in position.

2. If the motor operates but the green “cleaning air” light does not operate:

a. Remove the cell and check to see if the “cleaning air” light comes on.

CLEANING

AIR LIGHT

b. If the light operates with the cell removed, check the cell for broken wires that

could cause a dead short. Check to see if the cell plates are bent or touching.

Check to see if there is a foreign object in the cell. Check for carbon paths or

tracks on the cell ends.

If the cell has loose or broken wires or bent plates,

replace the cell. If there are no loose or broken

wires present, hold the cell up to the light and look

for metal shavings or anything that may be causing

a short. If nothing is apparent, clear and retest the

cell. If the problem persists, replace the cell. If carbon

tracking is present on cell ends, replace the cell.

7

Page 8

Troubleshooting Guide

c. If the light does not operate with the cell removed, check the wires to the

light and confirm that they are properly connected. Check the voltage from

the light terminals on the power supply board. Set meter to appropriate scale.

You should have about 16 volts DC.

d. Option 1: Check the output of the power supply by using the recommended H.V.

probe and a multimeter. The unit must be "ON" with the operating switch in the

"Max Clean" position and the interlock switch must be depressed. The voltage

should measure from -5.5 KVDC to -7.0 KVDC. An alternate method to check

voltage is by using a plastic handled screwdriver to short the high voltage

contacts and observe a spark.

If the wire has voltage, the

light is bad and needs to be

replaced. If the wire does

not have voltage, go to

next step.

If the voltage is not present,

check the transformer output.

If the voltage is present and not

within range, replace the power

supply board and check the

transformer output. If the

voltage is present and within

range, the power supply is

operating properly.

Option 2: Using a plastic handle screwdriver, short the high voltage contacts

and observe a spark.

Short the HV contacts to

observe a spark.

8

Page 9

Troubleshooting Guide

e. Check the input voltage to the transformer using a standard lead and a multimeter.

Check the voltage from the black lead on the terminal L speed control switch and white

lead on power supply board labeled line neutral. Activate the interlock switch. The

meter should indicate line voltage. Check the voltage on the two yellow wires on the

power supply board from the transformer. The interlock switch must be activated. The

meter must indicate 24 vac.

BLACK LEAD

YELLOW WIRES

WHITE LEAD

If there is no power to the

transformer, recheck

section 1, the interlock

switch.

If there is power to the

transformer, but no output

voltage, replace the

transformer and power

supply board assembly.

3. If the green “cleaning air” light operates and the blower wheel does not turn.

a. Remove the top and check to see if the stripper is in place.

The stripper is held in

position by slots in the

contact wall and bearing

plate and alignment tabs on

the stripper plate. If the

stripper is not in position,

reposition the plate by

placing tabs into the slots.

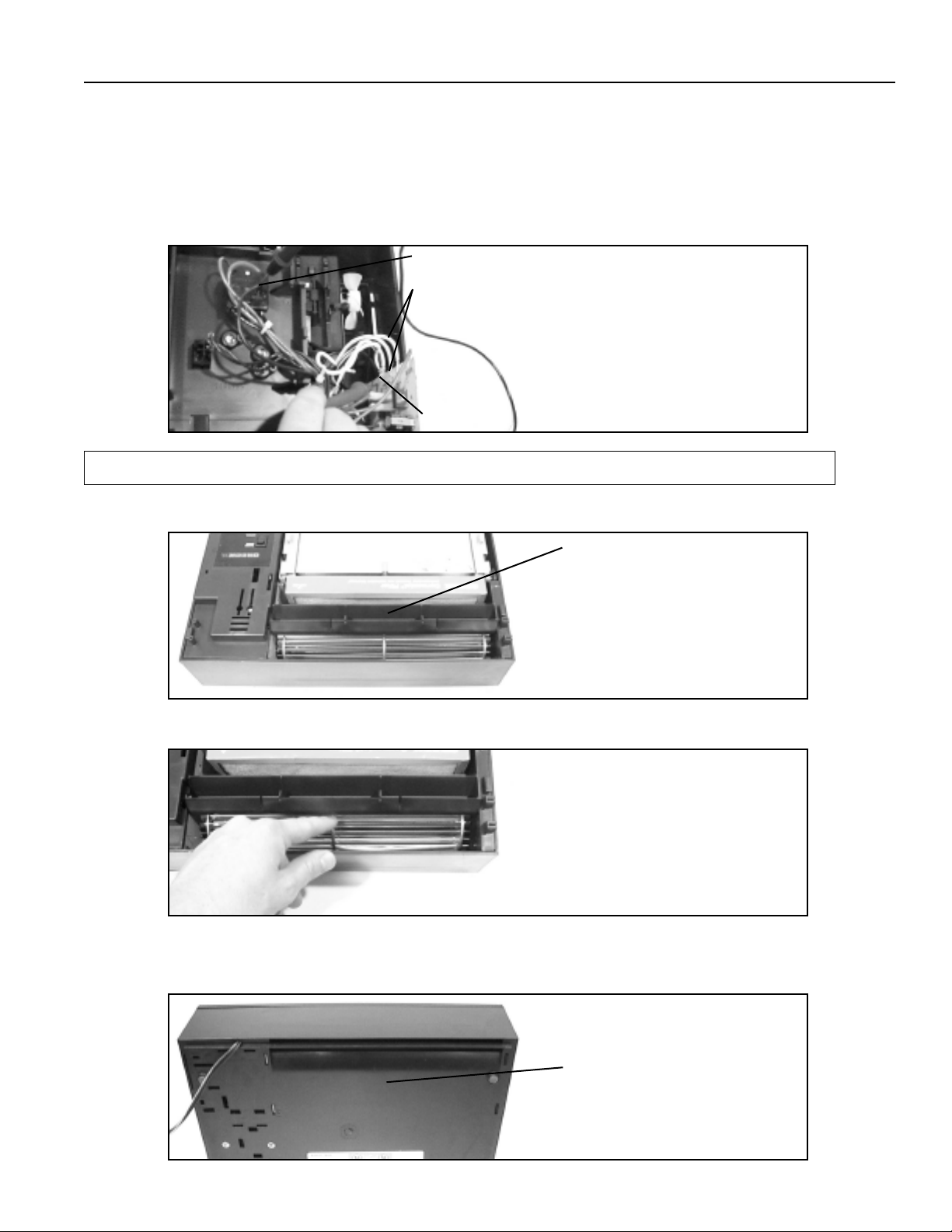

b. Use your hand to try to spin the blower wheel.

If the wheel does not spin

freely, check for anything

that may be blocking the

movement of the wheel and

remove the blockage. If no

blockage is apparent, see

3c and 3d

c. Turn the unit over and check for signs of distortion in the cabinet bottom beneath the

motor that might prevent the blower from spinning.

If the cabinet bottom is

distorted, replace the unit.

9

Page 10

Troubleshooting Guide

d. If there are no signs of distortion, remove the blower wheel (see: Blower Wheel

Removal

wheel. If the motor shaft operates, the problem is related to the blower wheel.

4. If the motor shaft does not turn on all speeds, or seems sluggish, it may be due to a

build-up of dirt and grime on the motor shaft. To remedy this.

a. Clean the dirt and grime from the motor shaft using a soft cloth.

) and activate the unit. Notice if the motor shaft rotates without the blower

If the motor shaft rotates

then replace the blower

wheel drive grommet and

bearing wall. If the motor

shaft does not rotate, replace

the motor.

Motor Shaft

b. Squirt a few drops of lubricating oil (“3 in 1” type oil, not WD-40 type oil) in the slot on

the shaft to lubricate the bearing.

5. If the blower wheel vibrates:

a. Check for bent or warped blades.

Replace the blower wheel if

blades appear warped or

bent.

b. Check for loose or worn drive grommet.

Replace the drive grommet.

10

Page 11

Troubleshooting Guide

c. Check to see if the blower wheel is adequately supported by the outside bearing

plate assembly.

d. Check to see if the motor mounting bracket snap tabs are in place or are loose.

Look into the four base slots to see the tabs.

The outboard end of the blower wheel should be

firmly supported, allowing no

rotation. If that end of the wheel can be moved front

to back and up and down, remove the bearing plate

assembly and check the bearing for damage or

excessive wear. Replace parts as needed. Use care

in handling the blower wheel. Do not distort the

wheel blades. On reassembly, insert the outboard

wheel shaft into the bearing plate then position the

plate into the cabinet. The blower wheel should be

positioned so that the clearance between the ends of

the wheel and the adjacent walls are approximately

equal on both sides. If the wheel is too close it may

drag on the wall. Too much clearance at the outboard

end may cause the wheel shaft to slip out of the

outboard bearing.

movement other than

If the tabs are not in position,

use a screwdriver inserted

into slots to push the tabs

out of the slot. You may

need to twist the screwdriver

slightly to disengage the

snaps. Inspect the mounting

bracket; replace it if

damaged. Check for broken

mounting tabs, distorted

bracket (because of

excessive heat). A distorted

motor bracket normally

indicates motor overheating.

The motor should be

replaced.

e. Check to see if the motor is loose in the support bracket by holding the bracket

and trying to move the motor. If the motor moves, remove the mounting bracket to

check the isolator pads

Insure that the isolator pads

are in position. Replace if the

motor moved while being

held in place with mounting

bracket.

11

Page 12

Troubleshooting Guide

6 If the cell is arcing, check the following:

a. If there are loose or broken ionizer wires.

b. If the cell is dirty. Remove the cell and wash with warm soapy water. Dry completely

before re-installing.

c. If there are bent cell plates.

Replace the cell.

Replace the cell by following

instructions on inside of

cabinet top.

d. If the cell is improperly installed in the unit.

e. If the cell contacts are broken or loose.

CELL CONTACTS

Reinstall the cell.

Replace the cell.

12

Page 13

Troubleshooting Guide

f. If the H.V. contacts are not properly aligned or the contact wall is not properly

aligned.

The H.V. contacts must make

good contact. Replace the

contact wall or straighten the

contacts, if possible.

7. Checking for ionizing needle operation. Using HV voltage probe check needle for

high voltage -5.5 KVDC to -7.0 KVDC.

a. If voltage is present, the ionizer is OK.

Clean needle with alcohol

and a cotton swab.

b. If voltage is not present, check HV power supply.

See above diagram.

c. If voltage is present at HV power supply but not the needle.

Replace the negative ionizer

assembly including wire,

with needle attached, and

terminal.

IMPORTANT: Replace using

wire routing on contact

board.

13

Page 14

Notes

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

14

Page 15

Super Air 5 Model 447628

Parts Removal and Replacement

General Parts Replacement

Motor Removal and Replacement page 16

Power Supply Removal and Replacement page 19

Transformer Removal and Replacement page 21

Bearing Wall Assembly and

Blower Wheel Removal and Replacement page 22

Led Assembly Removal and Replacement page 23

Cell Assembly Removal and Replacement page 23

Ionizer Needle Removal and Replacement page 23

Fan Blade Removal and Replacement page 24

Warning - All parts removal and replacement should

be performed with power disconnected from the unit.

15

Page 16

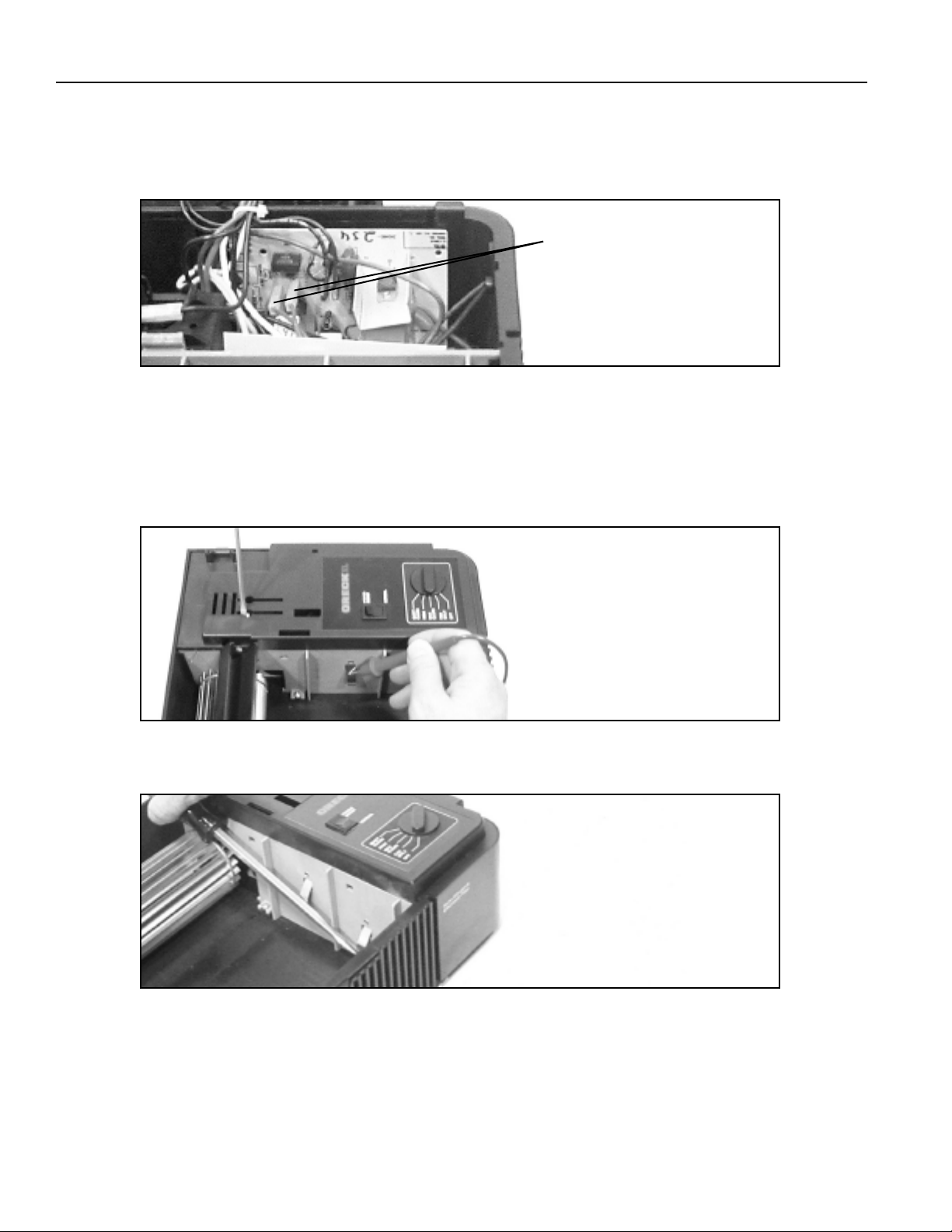

General Parts Replacement

Motor Removal and Replacement

1. Remove the cabinet top by pressing

down the thumb latch and sliding the

top forward.

2. Remove the cell assembly (see inside

of top for instructions).

3. Remove the stripper by pulling it

to the right and applying pressure to

the bearing wall. Lift the left hand side

of the stripper out of the bearing wall

locator seat and then remove the

stripper.

4. Flip the unit onto its side with the

bearing wall up and release the two

locking tabs for the bearing wall

assembly by using a regular

screwdriver from the bottom. Place

screwdriver blade into the slot on top

of the snap finger locking tab and twist

the blade slightly while pulling on the

bearing plate. Repeat for the second

tab. The bearing wall may now be

removed by moving the blower wheel

and bearing wall away from the cabinet

and lifting the bearing wall off of the

blower wheel.

16

Page 17

General Parts Replacement

ROTATING ELEMENT WARNING - Unit has a rotating blower wheel and cooling

fan to circulate air and keep the unit cool. When servicing the unit and repairing

the unit always insure that you keep objects and internal electrical wiring away

from the rotating elements. Failure to allow for proper clearance for rotating

members can cause electric shock, personal injury or property damage.

5. Remove the blower wheel by gently

grasping the outside of the wheel at the

center support rib and the rib closest

to the motor. Tilt the wheel up and pull

it away from the motor shaft. The blower

wheel rubber grommet is glued to the

shaft of the motor and will remain

attached to the motor.

6. Remove the power supply cover by

placing a screwdriver blade in the cover

slot with the blade inserted on the blower

wheel side of the slot. Catch the tan snap

tab and twist the screwdriver slightly while

lifting up on the cover and remove the

power supply cover assembly. Lay the

assembly aside out of the way.

7. Remove the interlock switch from the

mounting bracket by releasing the snap

lever and lifting the switch out of the

bracket. It is not necessary to disconnect

the switch wires.

8. Turn the unit over. Use a screwdriver to

release the motor mounting bracket

locking tabs by inserting the screwdriver

blade between the snap tab and the

housing. Twist the snap tab toward the

center of the four motor mounting slots.

You will need to pull the mounting bracket

away from the cabinet while releasing the

tabs. After releasing all four tabs, remove

the bracket.

SLOTS

17

Page 18

General Parts Replacement

HIGH VOLTAGE WARNING - This equipment is supplied with line voltage from a

standard wall socket. Use standard precautions in working on it with line voltage

applied. Failure to practice normal electrical safety precautions can cause

electrical shock, personal injury or property damage.

9. Unplug the red terminal (3), brown

terminal (2) and black terminal (1) wires

from the selector switch by pushing a

paper clip (straightened) under the wire

into the switch while pulling on the wire

lightly.

10. Remove the white motor wire from the

power supply board line neutral

connection.

11. Remove the motor and replace it with the

new motor.

12. Reverse the above steps to replace the

motor.

13. It is important that the motor isolators are

installed correctly and are seated as

designed. Contacts on side of insulator

should fit over motor bearing bracket.

Motor and isolators must fit securely.

MOTOR WIRE

ISOLATOR PAD

18

Page 19

General Parts Replacement

Power Supply Removal and Replacement

1. Follow steps 1, 3, and 6 of Motor Removal and Replacement.

EXTREME HIGH VOLTAGE WARNING - This equipment is supplied with line

voltage from a standard electrical wall socket. That voltage is transformed to a

24V signal that is then amplified to over 6000VDC. In working with the equipment

you must always know the voltage level for the equipment and wiring. Attempting

to measure or work with the 6000 VDC power without using the proper high

voltage probe can cause electrical shock, personal injury or property damage.

Probing a high voltage without the proper meter will potentially damage the volt meter.

EXTREME HIGH VOLTAGE WIRING WARNING - The unit has been designed

such that extremely high cell collector voltage wiring is isolated from all other

wiring. Special wiring routing holders have been designed into the unit. This

extremely high voltage wiring must be routed correctly. Failure to route and isolate

the wire can create a fire hazard, personal injury or property damage.

INSULATOR BOARD WARNING - The unit has been designed with special

insulator and isolator spacer boards that must be in position. These boards are

made of a special insulator material and must be in position to properly isolate

wiring and connectors from uninsulated parts. Failure to place the boards in the

proper location can create a fire hazard, cause personal injury, or property damage.

2. Before removing the HV power supply

board make note of the position of all

the wiring. You will note that all wiring is

bound and well away from the motor

fan. The HV power single red line

coming from the left hand side of the

board is routed in special built-in plastic

routing holders and isolated from all

other wires. Note that the routing and

isolation is critical and must not be

altered. In addition, the two insulator

sheets are preset and must be in

position. After carefully noting the

above, remove the HV power supply

board by first removing the HV red lead

from the bottom holder. You can now lift

the board up and rotate it into a position

to allow the connectors to be removed.

Reconnect the replacement board by

carefully removing one wire at a time

from the connected board and placing it

on the same location on the

replacement board.

19

Page 20

General Parts Replacement

All leads must be connected to the new board properly. The HV power line must be

isolated and properly routed. Two insulator sheets must be in position and all wiring must

be captured to prevent contact with rotating elements. A wiring diagram is included in the

service manual for your use.

3. The new board may now be reinstalled in

the housing by sliding it back into position.

The housing has two board reference ribs

molded in the bottom that hold the board

in position. Position the board between

the side wall and the reference ribs. You

may need to hold the board in place

before and during installation of the power

supply cover.

ROTATING ELEMENT WARNING - Unit has a rotating blower wheel and cooling

fan to circulate air and keep the unit cool. When servicing the unit and repairing

the unit always insure that you keep objects and internal electrical wiring away

from the rotating elements. Failure to allow for proper clearance for rotating

members can cause electric shock, personal injury or property damage.

4. The power supply cover may now be

reinstalled. Check wiring to insure it is

routed properly and cannot contact motor

fan and is properly isolated. Install the

power supply cover by placing the cover

locator tabs into the cabinet at an angle

while rotating it into place. The locking

snap should engage when in the final

position.

EXTREME HIGH VOLTAGE WARNING - This equipment is supplied with high

voltage from a standard electrical wall socket. That voltage is transformed to a 24V

signal that is then amplified to over 6000 VDC. In working with the equipment you

must always know the voltage level for the equipment and wiring. Attempting to

measure or work with the 6000 VDC power without using the proper high voltage

probe can cause electrical shock, personal injury or property damage. Measuring

high voltage without the proper meter and probe will potentially damage the volt meter.

20

Page 21

General Parts Replacement

5. To test the power supply, touch the metal

shaft of a screwdriver, with an insulated or

plastic handle, to one of the contacts while

keeping the screwdriver tip about 1/8"

away from the other contact. You should

see an arc and hear a snapping sound.

6. Reverse step 1.

Transformer Removal and Replacement

1. Follow steps 1, 2, 3, and 6 of Motor

Removal and Replacement

Remove two #6 screws and nuts that

secure the transformer to the cabinet

bottom. Save for installment of the new

transformer.

.

HIGH VOLTAGE WARNING - This equipment is supplied with line voltage from a

standard wall socket. Use standard precautions in working on it with line voltage

applied. Failure to practice normal electrical safety precautions can cause

electrical shock, personal injury or property damage.

ROTATING ELEMENT WARNING - Unit has a rotating blower wheel and cooling

fan to circulate air and keep the unit cool. When servicing the unit and repairing

the unit always insure that you keep objects and internal electrical wiring away

from the rotating elements. Failure to allow for proper clearance for rotating

members can cause electric shock, personal injury or property damage.

2. Remove the power supply and disconnect

the yellow low voltage leads and white line

voltage lead. Remove the black input line

to selector switch position 4 using a

straightened paper clip inserted into the

selector switch connection.

21

Page 22

General Parts Replacement

3. Remove the two #8/32 lockwasher nuts

and remove the transformer and replace it

with the new unit.

4. Reverse the above steps 1,2, and 3 to

replace the transformer.

Bearing Wall Assembly and Blower Wheel Removal and Replacement

1. Follow steps 1, 2, 3, 4 and 5 of Motor Removal and Replacement.

2. The rubber grommet will need to be

removed from the motor shaft. This can

be done by cutting it off using a sharp

razor knife and slitting the grommet along

the motor shaft axis. You can then peel

the grommet off of the shaft. The motor

shaft must be clean before installing the

new blower wheel and grommet. Using a

razor knife, carefully remove any sealant

on the shaft and wipe it with a clean cloth.

3. You are now ready to reinstall the new

lower wheel and grommet assembly.

Place one drop of adhesive (loctite 401 or

equivalent "super glue" type adhesive) on

the motor shaft in the small groove about

1/2" from the blower wheel attachment

end. Place the new bearing wall

assembly on the blower wheel shaft.

Slide the grommet on to the motor shaft

and rotate the bearing wall and blower into

position. Snap the wall into the cabinet.

Move the blower wheel so that the tips of

the blades are about 1/4" from the bearing

wall.

4. Reverse the above steps 1, 2 and 3 and to replace the bearing wall and blower wheel.

22

Page 23

General Parts Replacement

Led Assembly Removal and Replacement

1. Follow steps 1, 2, and 6 of Motor Removal and Replacement.

2. Disconnect the two red led leads from the

power supply board and remove the led

assembly by removing the led retaining

ring from the back of the front panel and

removing the led and the leads.

3. Replace with a new led assembly.

4. Reverse the above steps 1 and 2 to

replace the led assembly.

Cell Assembly Removal and Replacement

1. Follow steps 1and 2 of Motor Removal and Replacement.

LED LEADS

2. Replace with a new cell.

3. Reverse the above step 1 to replace the

cell.

Ionizer Needle Removal and Replacement

1. Follow steps 1, 3, and 6 of Motor Removal and Replacement.

EXTREME HIGH VOLTAGE WARNING - This equipment is supplied with line

voltage from a standard electrical wall socket. That voltage is transformed to a

24V signal that is then amplified to over 6000 VDC. In working with the equipment

you must always know the voltage level for the equipment and wiring. Attempting

to measure or work with the 6000 VDC power without using the proper high

voltage probe can cause electrical shock, personal injury or property damage.

Probing a high voltage without the proper meter will potentially damage the volt

meter.

23

Page 24

General Parts Replacement

EXTREME HIGH VOLTAGE WIRING WARNING - The unit has been designed

such that extremely high cell collector voltage wiring is isolated from all other

wiring. Special wiring routing holders have been designed into the unit. This

extremely high voltage wiring must be routed correctly. Failure to route and isolate

the wire can create a fire hazard, personal injury or property damage.

2. Carefully remove the ionizer needle

assembly that is the piece of red insulated

wire with fast on connection on one end

and the needle on the other end. Replace

with new needle assembly.

3. Reverse step 1 above to replace

assembly.

IONIZER NEEDLE

ASSEMBLY

Fan Blade Removal and Replacement

1. Follow steps 1, 2, 3, and 6 of Motor Removal and Replacement.

ROTATING ELEMENT WARNING - Unit has a rotating blower wheel and cooling

fan to circulate air and keep the unit cool. When servicing the unit and repairing

the unit always insure that you keep objects and internal electrical wiring away

from the rotating elements. Failure to allow for proper clearance for rotating

members can cause electric shock, personal injury or property damage.

2. Remove fan with flathead screwdriver by

lightly prying the fan off of the motor shaft.

3. Replace the fan with the new fan and

insure that the new fan is installed on the

motor shaft with the metal locking collar

closest to the motor body. Press the fan

onto the shaft and allow about 1/4"

distance between the motor end bracket

and the fan hub. Spin the fan to ensure it

is clear of all objects.

4. Reverse above step 1 above to replace

the fan.

24

Page 25

Parts List

QTY

ITEM # PART NO. DESCRIPTION

1

1

1

1 4 247135-001 FAN BLADE

2 5 AT2PK CHARCOAL COMBINATION FILTER

1 6 247667-001 CONTROL LABEL

1 7 342472-002 CONTACT WALL ASSEMBLY

1 8 342480-003 PLASTIC MESH PREFILTER

1 9 254682-001 BLOWER WHEEL KIT

1 10 254681-001 MOTOR KIT (BALL BEARING MOTOR DOES NOT REQUIRE COOLING FAN)

1 11 451686-003 CABINET TOP, GRAY

1 12 442415-101 COLLECTOR CELL

1 13 142475-001 ION NEEDLE ASSEMBLY

1 14 342228-001 STRIPPER

1 15 342227-001 MOTOR MOUNTING BRACKET

1 16 136483-001 DRIVE GROMMET

1 17 342402-251 HV POWER SUPPLY BOARD

1 342402-254 HV POWER SUPPLY BOARD “HUMP BACK”

1 18 442223-201 CABINET BOTTOM

2 19 242253-001 MOTOR ISOLATOR PAD

1 20 142581-001 SWITCH ASSEMBLY

1 21 145820-002 SWITCH ROCKER

1 40184-01 CARTON

1 442414-001 CARTON INSERT

2 NLA 20CFT CHARCOAL FILTERS (NO LONGER AVAILABLE)

3 30CFT CHARCOAL FILTERS

1 33358 CELL CLEANER

1 242809-015 OWNER’S MANUAL

1 242235-001 SWITCH KNOB, BLACK

2 242331-007 TRANSFORMER

3 242404-001 INTERLOCK SWITCH

12

11

5

8

14

1

6

18

21

20

9

7

25

13

16

2

17

3

15

19

10

4

19

Page 26

L

INE

CORD

INTERLOCK

S

WITCH

P

OWER SWITCH

BLK (HI)

B

LOWER

W

HT

B

LK

1

20V

WHT

2

4V

LED

R

ED

L

INE NEW

1 2

LED

FUSE

HV POWER SUPPLY

R

ED

Y

EL

YEL

R

ED (142475-001)

GRN (242477-027)

G

RN

RED

BLUE (242477-035)

ION./COLL. CELL

POWER BOOST

SWITCH

B

LUE (242477-035)

CONTACT WALL

GRN

GRN

BLACK (RIBBED)

B

RN (MED)

RED (LO)

B

LACK (RIBBED)

1

20V, 60HZ

P

OWER

SWITCH

O

UTPUT

POS 1 OFF

POS 2 L-1

POS 3 L-1,4

POS 4 L-2,4

P

OS 5 L-3,4

Wiring Diagram

2004 Oreck Holdings, LLC.

©

All rights reserved.

All trademarks are owned and used under the authority of Oreck Holdings, LLC.

75422-01

Page 27

Notes

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

27

Page 28

©2004 Oreck Holdings, LLC. All rights reserved. All trademarks are owned and used under the authority of Oreck Holdings, LLC.

75422-01 REV I 08/04

R-7693, R-7695

Loading...

Loading...