Page 1

Operating Manual

OPTIMOD-FM

8300

Digital Audio Processor

Version 2.1 Software

Page 2

IMPORTANT NOTE: Refer to the unit’s rear panel for your Model Number.

Model Number: Description:

8300 OPTIMOD 8300, Stereo Encoder, Digital I/O, Protec-

tion Structure, Two-Band Structure, Multi-Band

Structure, 115V (for 90-130V operation) or 230V (for

200-250V operation), switchable to 50µs or 75µs.

8300J As above, but for 90-117V operation.

MANUAL:

Part Number: Description:

96116.210.03 8300 Operating Manual

CAUTION:

NO USER SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT REMOVE COVER (OR BACK).

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRICAL SHOCK,

DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

This symbol, wherever it appears, alerts you to

the presence of uninsulated dangerous voltage

inside the enclosure voltage that may be

sufficient to constitute a risk of shock.

This symbol, wherever it appears, alerts you to important

operating and maintenance instructions in the accompa-

nying literature. Read the manual.

In accordance to the WEEE (waste electrical and electronic equipment) directive of the European Parliament, this product must not be discarded into the

municipal waste stream in any of the Member States. This product may be

sent back to your Orban dealer at end of life where it will be reused or recycled

at no cost to you.

If this product is discarded into an approved municipal WEEE collection site or

turned over to an approved WEEE recycler at end of life, your Orban dealer

must be notified and supplied with model, serial number and the name and

location of site/facility.

Please contact your Orban dealer for further assistance.

www.orban.com

Page 3

IMPORTANT SAFETY INSTRUCTIONS

All the safety and operating instructions should be read before the appliance is operated.

Retain Instructions: The safety and operation instructions should be retained for future reference.

Heed Warnings: All warnings on the appliance and in the operating instructions should be adhered to.

Follow Instructions: All operation and user instructions should be followed.

Water and Moisture: The appliance should not be used near water (e.g., near a bathtub, washbowl, kitchen sink, laundry tub, in a wet base-

ment, or near a swimming pool, etc.).

Ventilation: The appliance should be situated so that its location or position does not interfere with its proper ventilation. For example, the appli-

ance should not be situated on a bed, sofa, rug, or similar surface that may block the ventilation openings; or, placed in a built-in installation, such as a

bookcase or cabinet that may impede the flow of air through the ventilation openings.

Heat: The appliance should be situated away from heat sources such as radiators, heat registers, stoves, or other appliances (including amplifiers)

that produce heat.

Power Sources: The appliance should be connected to a power supply only of the type described in the operating instructions or as marked on

the appliance.

Grounding or Polarization: Precautions should be taken so that the grounding or polarization means of an appliance is not defeated.

Power-Cord Protection: Power-supply cords should be routed so that they are not likely to be walked on or pinched by items placed upon or

against them, paying particular attention to cords at plugs, convenience receptacles, and the point where they exit from the appliance.

Cleaning: The appliance should be cleaned only as recommended by the manufacturer.

Non-Use Periods: The power cord of the appliance should be unplugged from the outlet when left unused for a long period of time.

Object and Liquid Entry: Care should be taken so that objects do not fall and liquids are not spilled into the enclosure through openings.

Damage Requiring Service: The appliance should be serviced by qualified service personnel when: The power supply cord or the plug has

been damaged; or Objects have fallen, or liquid has been spilled into the appliance; or The appliance has been exposed to rain; or The appliance

does not appear to operate normally or exhibits a marked change in performance; or The appliance has been dropped, or the enclosure damaged.

Servicing: The user should not attempt to service the appliance beyond that described in the operating instructions. All other servicing should be

referred to qualified service personnel.

The Appliance should be used only with a cart or stand that is recommended by the manufacturer.

Safety Instructions (European)

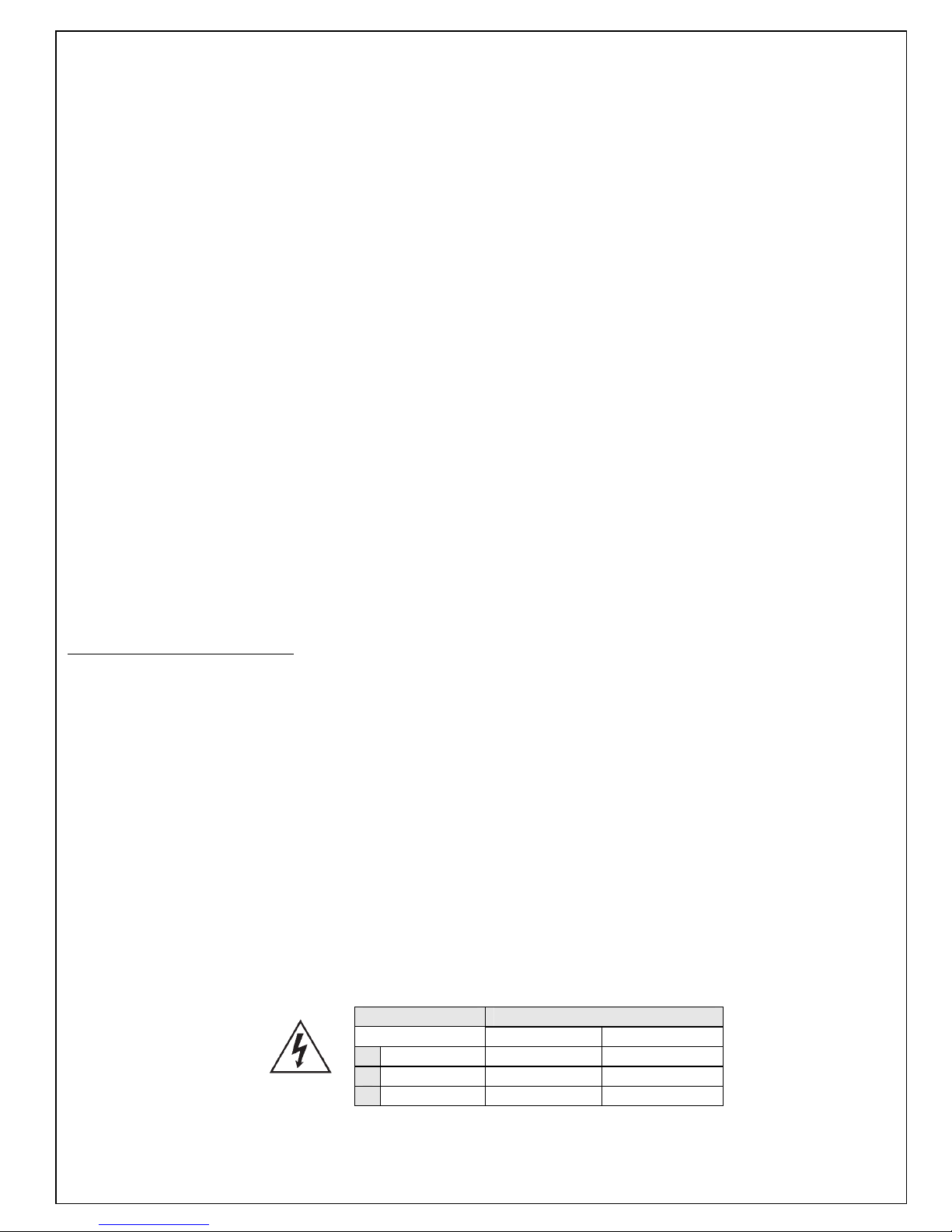

Notice For U.K. Customers If Your Unit Is Equipped With A Power Cord.

WARNING: THIS APPLIANCE MUST BE EARTHED.

The cores in the mains lead are coloured in accordance with the following code:

GREEN and YELLOW - Earth BLUE - Neutral BROWN - Live

As colours of the cores in the mains lead of this appliance may not correspond with the coloured markings identifying the terminals in your plug, proceed as follows:

The core which is coloured green and yellow must be connected to the terminal in the plug marked with the letter E, or with the earth symbol, or coloured green, or green and yellow.

The core which is coloured blue must be connected to the terminal marked N or coloured black.

The core which is coloured brown must be connected to the terminal marked L or coloured red.

The power cord is terminated in a CEE7 / 7 plug (Continental Europe). The green / yellow wire is connected directly to the unit's chassis. If you need to

change the plug and if you are qualified to do so, refer to the table below.

WARNING: If the ground is defeated, certain fault conditions in the unit or in the system to which it is connected can result in full line voltage between

chassis and earth ground. Severe injury or death can then result if the chassis and earth ground are touched simultaneously.

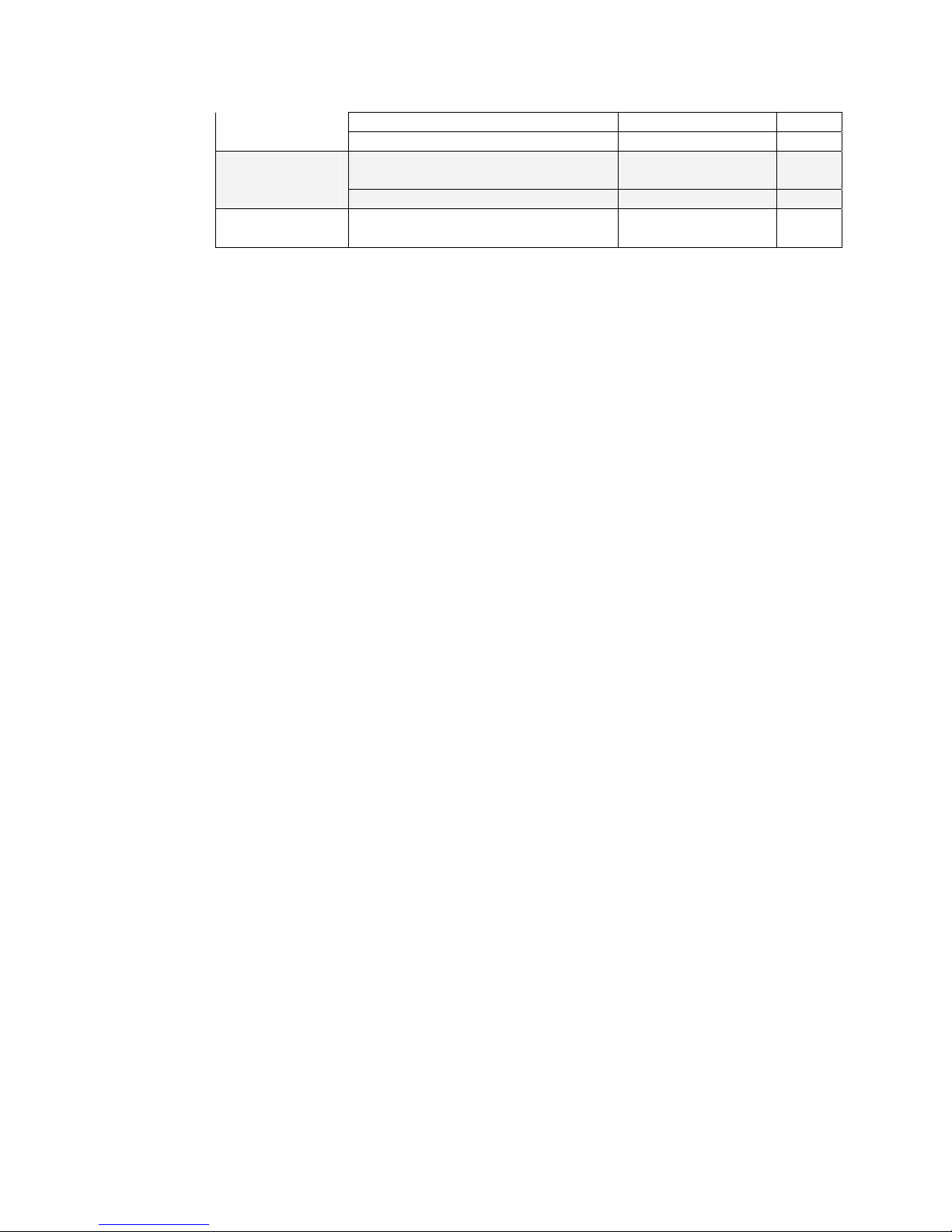

Conductor WIRE COLOR

Normal Alt

L LIVE BROWN BLACK

N NEUTRAL BLUE WHITE

E EARTH GND GREEN-YELLOW GREEN

AC Power Cord Color Coding

Page 4

Safety Instructions (German)

Gerät nur an der am Leistungsschild vermerkten Spannung und Stromart betreiben.

Sicherungen nur durch solche, gleicher Stromstärke und gleichen Abschaltverhaltens ersetzen. Sicherungen nie überbrücken.

Jedwede Beschädigung des Netzkabels vermeiden. Netzkabel nicht knicken oder quetschen. Beim Abziehen des Netzkabels den

Stecker und nicht das Kabel enfassen. Beschädigte Netzkabel sofort auswechseln.

Gerät und Netzkabel keinen übertriebenen mechanischen Beaspruchungen aussetzen.

Um Berührung gefährlicher elektrischer Spannungen zu vermeiden, darf das Gerät nicht geöffnet werden. Im Fall von Betriebsstörungen darf das Gerät nur Von befugten Servicestellen instandgesetzt werden. Im Gerät befinden sich keine, durch den Benutzer

reparierbare Teile.

Zur Vermeidung von elektrischen Schlägen und Feuer ist das Gerät vor Nässe zu schützen. Eindringen von Feuchtigkeit und

Flüssigkeiten in das Gerät vermeiden.

Bei Betriebsstörungen bzw. nach Eindringen von Flüssigkeiten oder anderen Gegenständen, das Gerät sofort vom Netz trennen und

eine qualifizierte Servicestelle kontaktieren.

Safety Instructions (French)

On s'assurera toujours que la tension et la nature du courant utilisé correspondent bien à ceux indiqués sur la plaque de l'appareil.

N'utiliser que des fusibles de même intensité et du même principe de mise hors circuit que les fusibles d'origine. Ne jamais

shunter les fusibles.

Eviter tout ce qui risque d'endommager le câble seceur. On ne devra ni le plier, ni l'aplatir. Lorsqu'on débranche l'appareil,

tirer la fiche et non le câble. Si un câble est endommagé, le remplacer immédiatement.

Ne jamais exposer l'appareil ou le câble ä une contrainte mécanique excessive.

Pour éviter tout contact averc une tension électrique dangereuse, on n'oouvrira jamais l'appareil. En cas de dysfonctionnement,

l'appareil ne peut être réparé que dans un atelier autorisé. Aucun élément de cet appareil ne peut être réparé par l'utilisateur.

Pour éviter les risques de décharge électrique et d'incendie, protéger l'appareil de l'humidité. Eviter toute pénétration

d'humidité ou fr liquide dans l'appareil.

En cas de dysfonctionnement ou si un liquide ou tout autre objet a pénétré dans l'appareil couper aussitôt l'appareil

de son alimentation et s'adresser à un point de service aprésvente autorisé.

Safety Instructions (Spanish)

Hacer funcionar el aparato sólo con la tensión y clase de corriente señaladas en la placa indicadora de características.

Reemplazar los fusibles sólo por otros de la misma intensidad de corriente y sistema de desconexión. No poner nunca los fusibles en

puente.

Proteger el cable de alimentación contra toda clase de daños. No doblar o apretar el cable. Al desenchufar, asir el enchufe y no el

cable. Sustituir inmediatamente cables dañados.

No someter el aparato y el cable de alimentación a esfuerzo mecánico excesivo.

Para evitar el contacto con tensiones eléctricas peligrosas, el aparato no debe abrirse. En caso de producirse fallos de funcionamiento,

debe ser reparado sólo por talleres de servicio autorizados. En el aparato no se encuentra ninguna pieza que pudiera ser reparada por

el usuario.

Para evitar descargas eléctricas e incendios, el aparato debe protegerse contra la humedad, impidiendo que penetren ésta o líquidos

en el mismo.

En caso de producirse fallas de funcionamiento como consecuencia de la penetración de líquidos u otros objetos en el aparato,

hay que desconectarlo inmediatamente de la red y ponerse en contacto con un taller de servicio autorizado.

Safety Instructions (Italian)

Far funzionare l'apparecchio solo con la tensione e il tipo di corrente indicati sulla targa riportante i dati sulle prestazioni.

Sostituire i dispositivi di protezione (valvole, fusibili ecc.) solo con dispositivi aventi lo stesso amperaggio e lo stesso comportamento

di interruzione. Non cavallottare mai i dispositivi di protezione.

Evitare qualsiasi danno al cavo di collegamento alla rete. Non piegare o schiacciare il cavo. Per staccare il cavo, tirare la presa e mai

il cavo. Sostituire subito i cavi danneggiati.

Non esporre l'apparecchio e il cavo ad esagerate sollecitazioni meccaniche.

Per evitare il contatto con le tensioni elettriche pericolose, l'apparecchio non deve venir aperto. In caso di anomalie di funzionamento

l'apparecchio deve venir riparato solo da centri di servizio autorizzati. Nell'apparecchio non si trovano parti che possano essere riparate

dall'utente.

Per evitare scosse elettriche o incendi, l'apparecchio va protetto dall'umidità. Evitare che umidità o liquidi entrino nell'apparecchio.

In caso di anomalie di funzionamento rispettivamente dopo la penetrazione di liquidi o oggetti nell'apparecchio, staccare immediatamente

l'apparecchio dalla rete e contattare un centro di servizio qualificato.

Page 5

PLEASE READ BEFORE PROCEEDING!

Manual

The Operating Manual contains instructions to verify the proper operation of this unit and initialization of certain options.

You will find these operations are most conveniently performed on the bench before you install the unit in the rack.

Please review the Manual, especially the installation section, before unpacking the unit.

Trial Period Precautions

If your unit has been provided on a trial basis:

You should observe the following precautions to avoid reconditioning charges in case you later wish to return the unit to

your dealer.

(1) Note the packing technique and save all packing materials. It is not wise to ship in other than the factory carton. (Re-

placements cost $35.00).

(2) Avoid scratching the paint or plating. Set the unit on soft, clean surfaces.

(3) Do not cut the grounding pin from the line cord.

(4) Use care and proper tools in removing and tightening screws to avoid burring the heads.

(5) Use the nylon-washered rack screws supplied, if possible, to avoid damaging the panel. Support the unit when tighten-

ing the screws so that the threads do not scrape the paint inside the slotted holes.

Packing

When you pack the unit for shipping:

(1) Tighten all screws on any barrier strip(s) so the screws do not fall out from vibration.

(2) Wrap the unit in its original plastic bag to avoid abrading the paint.

(3) Seal the inner and outer cartons with tape.

If you are returning the unit permanently (for credit), be sure to enclose:

The Manual(s)

The Registration / Warranty Card

The Line Cord

All Miscellaneous Hardware (including the Rack Screws and Keys)

The Extender Card (if applicable)

The Monitor Rolloff Filter(s) (OPTIMOD-AM only)

The COAX Connecting Cable (OPTIMOD-FM and OPTIMOD-TV only)

Your dealer may charge you for any missing items.

If you are returning a unit for repair, do not enclose any of the above items.

Further advice on proper packing and shipping is included in the Manual (see Table of Contents).

Trouble

If you have problems with installation or operation:

(1) Check everything you have done so far against the instructions in the Manual. The information contained therein is

based on our years of experience with OPTIMOD and broadcast stations.

(2) Check the other sections of the Manual (consult the Table of Contents and Index) to see if there might be some sug-

gestions regarding your problem.

(3) After reading the section on Factory Assistance, you may call Orban Customer Service for advice during normal Cali-

fornia business hours. The number is (1) 510 / 351-3500.

Page 6

This equipment generates, uses, and can radiate radio-frequency energy. If it is not installed

and used as directed by this manual, it may cause interference to radio communication. This

equipment complies with the limits for a Class A computing device, as specified by FCC

Rules, Part 15, subject J, which are designed to provide reasonable protection against such

interference when this type of equipment is operated in a commercial environment. Operation

of this equipment in a residential area is likely to cause interference. If it does, the user will be

required to eliminate the interference at the user’s expense.

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the radio Interference Regulations of the Canadian Department of

Communications. (Le present appareil numerique n’emet pas de bruits radioelectriques depassant les limites applicables aux appareils numeriques [de las class A] prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le ministere des Communications du

Canada.)

Perform the installation under static control conditions. Simply walking across a rug can generate a static charge of 20,000 volts. This is the spark or shock you may have felt when

touching a doorknob or some other conductive surface. A much smaller static discharge is

likely to destroy one or more of the CMOS semiconductors employed in OPTIMOD-FM. Static

damage will not be covered under warranty.

There are many common sources of static. Most involve some type of friction between two

dissimilar materials. Some examples are combing your hair, sliding across a seat cover or

rolling a cart across the floor. Since the threshold of human perception for a static discharge

is 3000 volts, you will not even notice many damaging discharges.

Basic damage prevention consists of minimizing generation, discharging any accumulated

static charge on your body or workstation, and preventing that discharge from being sent to or

through an electronic component. You should use a static grounding strap (grounded through

a protective resistor) and a static safe workbench with a conductive surface. This will prevent

any buildup of damaging static.

WARNING

WARNING

IMPORTANT

U.S. patents 208,548, 4,460,871, 5,737,434, 6,337,999, 6,434,241, 6,618,486, and 6,937,912

protect OPTIMOD 8300. Other patents pending.

Orban and Optimod are registered trademarks.

All trademarks are property of their respective companies.

This manual is part number 96116.210.03. Published April 2009.

© Copyright Orban

8350 East Evans Suite C4, Scottsdale, AZ 85260 USA

Phone: (1) (480) 403-8300; Fax: (1) (480) 403-8301; E-Mail: custserv@orban.com; Site: www.orban.com

Page 7

Operating Manual

OPTIMOD-FM

8300

Digital Audio Processor

Version 2.1 Software

Page 8

Table of Contents

Index.........................................................................................................................0-9

Section 1 Introduction

.........................................................................................................................................1-1

ABOUT THIS MANUAL.......................................................................................................1-1

THE OPTIMOD-FM 8300 DIGITAL AUDIO PROCESSOR .......................................................1-1

User-Friendly Interface............................................................................................1-2

Absolute Control of Peak Modulation...................................................................1-2

Flexible Configuration ............................................................................................1-3

Adaptability through Multiple Audio Processing Structures ...............................1-4

Controllable .............................................................................................................1-5

PRESETS IN OPTIMOD-FM ..............................................................................................1-5

Factory Presets .........................................................................................................1-5

User Presets..............................................................................................................1-6

INPUT/OUTPUT CONFIGURATION ........................................................................................1-6

Digital AES3 Left/Right Input/Output ....................................................................1-7

Analog Left/Right Input/Output.............................................................................1-7

Stereo Analog Baseband Composite Output ........................................................1-7

Subcarriers................................................................................................................1-8

Remote Control Interface .......................................................................................1-8

Computer Interface .................................................................................................1-9

RS-232 Serial Port ............................................................................................................. 1-9

RJ45 Ethernet Connector ................................................................................................. 1-9

LOCATION OF OPTIMOD-FM.........................................................................................1-10

Optimal Control of Peak Modulation Levels.......................................................1-10

Best Location for OPTIMOD-FM ...........................................................................1-11

If the transmitter is not accessible:................................................................................ 1-11

If the transmitter is accessible: ...................................................................................... 1-11

STUDIO-TRANSMITTER LINK.............................................................................................1-13

Transmission from Studio to Transmitter.............................................................1-13

Digital Links .................................................................................................................... 1-13

Composite Baseband Microwave STLs........................................................................... 1-14

Dual Microwave STLs...................................................................................................... 1-14

Analog Landline (PTT / Post Office Line)....................................................................... 1-16

Using the Orban 8100AST (or 8100A/ST) External AGC with the 8300 .............1-16

STL and Exciter Overshoot ....................................................................................1-16

USING LOSSY DATA REDUCTION IN THE STUDIO..................................................................1-17

ABOUT TRANSMISSION LEVELS AND METERING ..................................................................1-17

Meters ....................................................................................................................1-17

Studio Line-up Levels and Headroom ..................................................................1-18

Fig. 1-1: Absolute Peak Level, VU and PPM Reading.................................................... 1-18

Transmission Levels................................................................................................1-19

LINE-UP FACILITIES .........................................................................................................1-19

Metering of Levels.................................................................................................1-19

Composite Output Level ................................................................................................ 1-19

Built-in Calibrated Line-up Tones.................................................................................. 1-20

Built-in Calibrated Bypass Test Mode............................................................................ 1-20

MONITORING ON LOUDSPEAKERS AND HEADPHONES..........................................................1-20

EAS TEST......................................................................................................................1-21

Page 9

PC CONTROL AND SECURITY PASSCODE.............................................................................1-22

WARRANTY, USER FEEDBACK...........................................................................................1-23

User Feedback........................................................................................................1-23

LIMITED WARRANTY .............................................................................................1-23

INTERNATIONAL WARRANTY...............................................................................1-23

EXTENDED WARRANTY ........................................................................................1-24

Section 2 Installation

.........................................................................................................................................2-1

INSTALLING THE 8300.......................................................................................................2-1

Figure 2-1: AC Line Cord Wire Standard.......................................................................... 2-2

Figure 2-2: Wiring the 25-pin Remote Interface Connector........................................... 2-4

8300 REAR PANEL ...........................................................................................................2-5

INPUT AND OUTPUT CONNECTIONS.....................................................................................2-6

Cable.........................................................................................................................2-6

Connectors ...............................................................................................................2-6

Analog Audio Input.................................................................................................2-6

Analog Audio Output .............................................................................................2-7

AES3 Digital Input and Output...............................................................................2-7

Composite Output and Subcarrier Input ...............................................................2-8

Figure 2-3: Separation vs. load capacitance ....................................................................2-9

Grounding..............................................................................................................2-10

Power Ground........................................................................................................2-11

Circuit Ground .......................................................................................................2-11

8300 FRONT PANEL .......................................................................................................2-11

STUDIO LEVEL CONTROLLER INSTALLATION (OPTIONAL) .......................................................2-13

If you are using Orban 8200ST external AGC......................................................2-13

Figure 2-4: 8200ST Jumper Settings (*Factory Configuration) .....................................2-14

QUICK SETUP.................................................................................................................2-16

ANALOG AND DIGITAL I/O SETUP.....................................................................................2-24

AUTOMATION USING THE 8300’S INTERNAL CLOCK............................................................2-30

SECURITY AND PASSCODE PROGRAMMING.........................................................................2-32

To Create a Passcode: ............................................................................................2-33

To Edit a Passcode:.................................................................................................2-33

To Delete a Passcode: ............................................................................................2-34

To Lock the Front Panel Immediately:..................................................................2-34

To Program local lockout: .....................................................................................2-34

To Unlock the Front Panel: ...................................................................................2-35

Dial-up Networking and the Passcode.................................................................2-35

If You Have Forgotten Your Passcode..................................................................2-35

REMOTE CONTROL INTERFACE PROGRAMMING ..................................................................2-36

NETWORKING AND REMOTE CONTROL..............................................................................2-37

SYNCHRONIZING OPTIMOD TO A NETWORK TIME SERVER....................................................2-39

Table 2-1: NIST-referenced timeservers .........................................................................2-40

INSTALLING 8300 PC REMOTE CONTROL SOFTWARE ..........................................................2-43

Installing the Necessary Windows Services..........................................................2-43

Check Hardware Requirements ............................................................................2-43

Running the Orban Installer Program..................................................................2-44

Setting Up Ethernet, LAN, and VPN Connections ...............................................2-45

Conclusion..............................................................................................................2-45

APPENDIX: SETTING UP SERIAL COMMUNICATIONS .............................................................2-47

Preparing for Communication through Null Modem Cable ..............................2-47

Connecting Using Windows 2000 Direct Serial Connection:..............................2-47

Page 10

Connecting Using Windows XP Direct Serial Connection ..................................2-52

Preparing for Communication through Modems ...............................................2-57

Connecting Using Windows 2000 Modem Connection ......................................2-57

Connecting using Windows XP Modem Connection ..........................................2-63

UPDATING YOUR 8300’S SOFTWARE.................................................................................2-69

Section 3 Operation

.........................................................................................................................................3-1

8300 FRONT PANEL .........................................................................................................3-1

INTRODUCTION TO PROCESSING..........................................................................................3-3

Some Audio Processing Concepts.................................................................................... 3-3

Distortion in Processing ................................................................................................... 3-3

Loudness and Distortion .................................................................................................. 3-3

OPTIMOD-FM — from Bach to Rock ......................................................................3-4

Fundamental Requirements: High-Quality Source Material and Accurate

Monitoring...............................................................................................................3-4

ABOUT THE 8300’S SIGNAL PROCESSING FEATURES ..............................................................3-5

Signal Flow...............................................................................................................3-5

ITU-R 412 Compliance .............................................................................................3-9

Two-Band Purist Processing ....................................................................................3-9

Input/Output Delay ...............................................................................................3-10

CUSTOMIZING THE 8300’S SOUND ...................................................................................3-10

Basic Modify...........................................................................................................3-11

Full Modify .............................................................................................................3-11

Advanced Modify ..................................................................................................3-12

Gain Reduction Metering .....................................................................................3-12

To Create or Save a User Preset ............................................................................3-13

ABOUT THE PROCESSING STRUCTURES ...............................................................................3-14

FACTORY PROGRAMMING PRESETS ...................................................................................3-16

Table 3-1: Factory Programming Presets....................................................................... 3-17

EQUALIZER CONTROLS ....................................................................................................3-21

Table 3-2: Five-Band Equalization Controls .................................................................. 3-22

STEREO ENHANCER CONTROLS .........................................................................................3-26

Table 3-3: Stereo Enhancer Controls ............................................................................. 3-26

AGC CONTROLS ............................................................................................................3-27

Table 3-4: AGC Controls................................................................................................. 3-27

Advanced AGC Controls........................................................................................3-30

CLIPPER CONTROLS.........................................................................................................3-33

Table 3-5: Clipper Controls ............................................................................................ 3-34

Advanced Clipper Controls ...................................................................................3-37

THE TWO-BAND STRUCTURE ...........................................................................................3-37

The Protection Presets...........................................................................................3-38

Setting Up the Two-Band Structure for Classical Music......................................3-38

Customizing the Settings ......................................................................................3-39

The Two-Band Structure’s Full and Advanced Setup Controls ...........................3-39

Table 3-6: Two-Band Controls ....................................................................................... 3-40

Advanced Two-Band Controls ..............................................................................3-44

THE FIVE-BAND STRUCTURE ............................................................................................3-45

Putting the Five-Band Structure on the Air.........................................................3-45

Customizing the Settings ......................................................................................3-45

Table 3-7: Multiband Controls....................................................................................... 3-46

The Five-Band Structure’s Full and Advanced Setup Controls ...........................3-46

Page 11

Table 3-8: MB Attack / Release Controls........................................................................ 3-47

Table 3-9: MB Band Mix Controls...................................................................................3-48

Advanced Multiband Controls..............................................................................3-53

ABOUT THE 8300’S HD / DIGITAL RADIO PROCESSING........................................................3-55

Delay Difference between Digital-Channel and FM Outputs ............................3-56

Table 3-10: HD Audio Controls....................................................................................... 3-56

HD I/O Setup Controls ...........................................................................................3-56

HD Audio Controls.................................................................................................3-56

ITU-R MULTIPLEX POWER CONTROLLER............................................................................3-57

Multiplex Power Threshold ............................................................................................3-57

Figure 3-1: Multiplex Power over 15 Minute Observation Interval with MPX Power

Controller Active, measured at Optimod’s Composite Output ....................................3-58

Audio Processing and the Multiplex Power Threshold Control ...................................3-59

Table 3-11: Test Modes................................................................................................... 3-59

TEST MODES .................................................................................................................3-59

GETTING THE BASS SOUND YOU WANT ............................................................................3-60

USING THE 8300 PC REMOTE CONTROL SOFTWARE ...........................................................3-62

To set up a new connection: .................................................................................3-63

To initiate communication: ...................................................................................3-63

To modify a control setting:..................................................................................3-64

To recall a preset:...................................................................................................3-64

To save a user preset you have created: ..............................................................3-65

To back up User Presets, system files, and automation files onto your computer’s

hard drive:..............................................................................................................3-65

To restore archived presets, system files, and automation files:........................3-66

To share an archived User Preset between 8300s: ........................................................3-67

To modify INPUT/OUTPUT and SYSTEM SETUP: ...........................................................3-67

To modify AUTOMATION: .........................................................................................3-67

To group multiple 8300s: ......................................................................................3-68

Operation Using the Keyboard ............................................................................3-68

To Quit the Program..............................................................................................3-68

About Aliases created by Optimod 8300 PC Remote Software .........................3-68

Multiple Installations of Optimod 8300 PC Remote ...........................................3-69

To Import Archived 8400 and 8500 Presets into Your 8300................................3-70

Section 4 Maintenance

.........................................................................................................................................4-1

ROUTINE MAINTENANCE ...................................................................................................4-1

SUBASSEMBLY REMOVAL AND REPLACEMENT.......................................................................4-2

FIELD AUDIT OF PERFORMANCE..........................................................................................4-6

Table 4-1: Decoder Chart for Power Supervisor .............................................................. 4-8

Table 4-2: Layout Diagram of J7, with expected voltages on each pin .........................4-9

Table 4-3: Typical Power Supply Voltages and AC Ripple ..............................................4-9

Section 5 Troubleshooting

.........................................................................................................................................5-1

PROBLEMS AND POTENTIAL SOLUTIONS...............................................................................5-1

RFI, Hum, Clicks, or Buzzes ...............................................................................................5-1

Unexpectedly Quiet On-Air Levels ................................................................................... 5-1

Poor Peak Modulation Control ........................................................................................5-1

Audible Distortion On-Air ................................................................................................5-2

Page 12

Audible Noise on Air........................................................................................................ 5-2

Whistle on Air, Perhaps Only in Stereo Reception ......................................................... 5-3

Interference from stereo into SCA .................................................................................. 5-4

Fig. 5-1: Typical 8300 baseband spectrum with heavy processing, 0-100 kHz. ............. 5-4

Shrill, Harsh Sound ........................................................................................................... 5-4

Dull Sound ........................................................................................................................ 5-5

System Will Not Pass Line-Up Tones at 100% Modulation ............................................ 5-5

System Will Not Pass Emergency Alert System (“EAS” USA Standard) Tones at the

Legally Required Modulation Level ................................................................................ 5-5

System Receiving 8300’s Digital Output Will Not Lock .................................................. 5-5

19 kHz Frequency Out-of-Tolerance................................................................................ 5-5

L–R (Stereo Difference Channel) Will Not Null With Monophonic Input...................... 5-6

General Dissatisfaction with Subjective Sound Quality.................................................. 5-6

Security Passcode Lost (When Unit is Locked Out) ......................................................... 5-6

Connection Issues between the 8300 and a PC, Modem, or Network ................5-6

Troubleshooting Connections.................................................................................5-7

You Cannot Access the Internet After Making a Direct or Modem Connection to

the 8300: ..................................................................................................................5-7

OS-SPECIFIC TROUBLESHOOTING ADVICE ............................................................................5-8

Troubleshooting Windows 2000 Direct Connect:..................................................5-8

Troubleshooting Windows 2000 Modem Connect:.............................................5-10

Troubleshooting Windows XP Direct Connect: ...................................................5-11

Troubleshooting Windows XP Modem Connect: ................................................5-11

TROUBLESHOOTING IC OPAMPS .......................................................................................5-12

TECHNICAL SUPPORT.......................................................................................................5-13

FACTORY SERVICE...........................................................................................................5-13

SHIPPING INSTRUCTIONS ..................................................................................................5-14

Section 6 Technical Data

.........................................................................................................................................6-1

SPECIFICATIONS................................................................................................................6-1

Performance.............................................................................................................6-1

Installation ...............................................................................................................6-2

CIRCUIT DESCRIPTION .......................................................................................................6-5

Overview ..................................................................................................................6-5

Control Circuits ........................................................................................................6-6

User Control Interface and LCD Display Circuits ...................................................6-7

Input Circuits............................................................................................................6-8

Output Circuits.........................................................................................................6-9

DSP Circuit..............................................................................................................6-12

Power Supply .........................................................................................................6-12

ABBREVIATIONS .............................................................................................................6-13

PARTS LIST ....................................................................................................................6-14

Obtaining Spare Parts ...........................................................................................6-15

Base Board .............................................................................................................6-15

CPU Module ...........................................................................................................6-17

RS-232 Board..........................................................................................................6-18

Power Supply .........................................................................................................6-19

Input/Output (I/O) Board ......................................................................................6-20

DSP Board...............................................................................................................6-23

Display Board.........................................................................................................6-25

SCHEMATICS AND PARTS LOCATOR DRAWINGS...................................................................6-25

Page 13

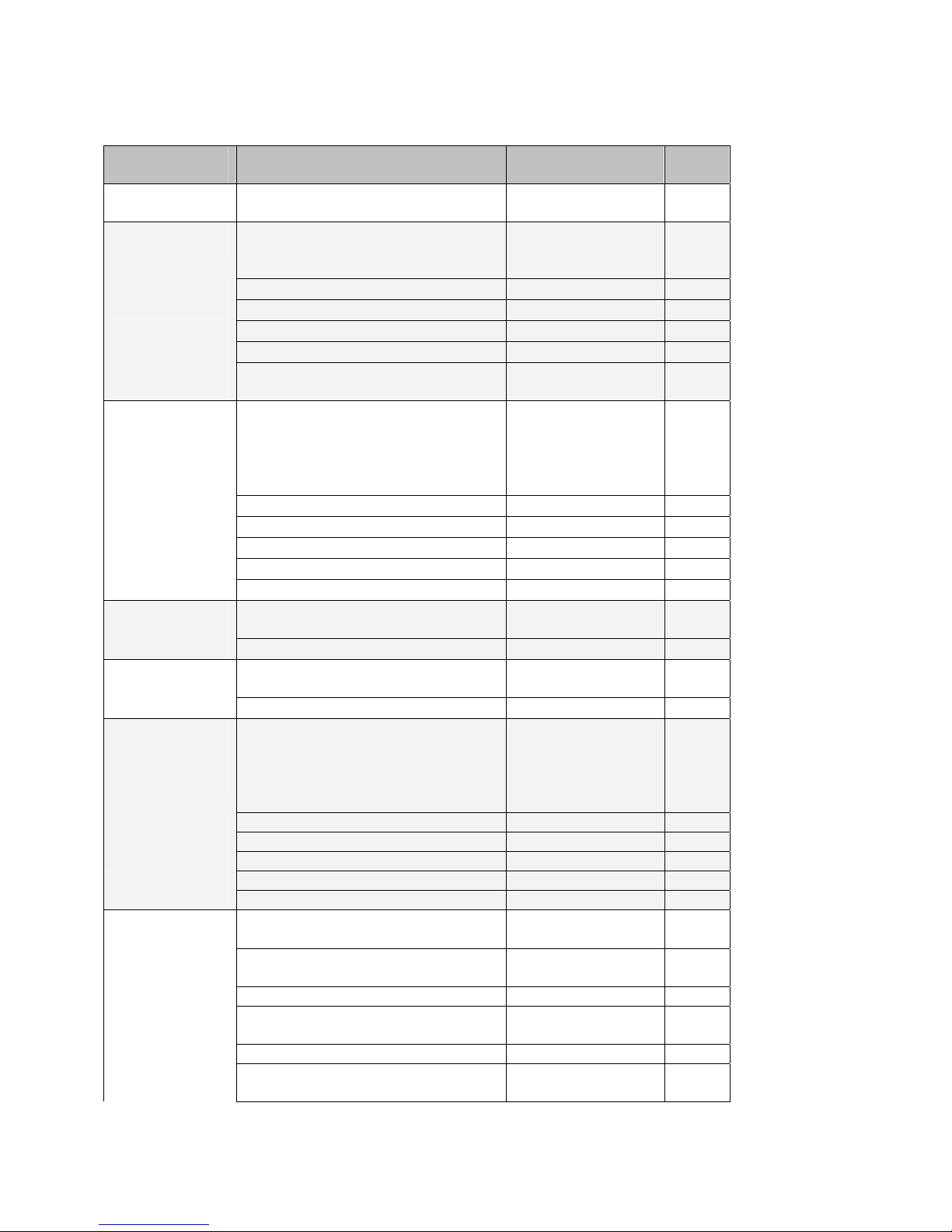

Function Description Drawing Page

Chassis

Base Board

CPU Module

RS-232 Board

Power Supply

I/O Board

DSP Board

Circuit Board Locator and Basic Interconnections

Glue logic; supports CPU module

and RS-232 daughterboard.

Top view

(not to scale)

Parts Locator

Drawing

6-29

6-30

Contains:

System Connections Schematic 1 of 4

CPU module interface Schematic 2 of 4

CPU module interface (ver. .06) Schematic 2 of 4

Power Supply Monitor Schematic 3 of 4

CPLD, General Purpose Interface,

Schematic 4 of 4

6-31

6-32

6-33

6-34

6-35

and Remotes

Control microprocessor. Services

front panel, serial port, Ethernet,

Parts Locator

Drawing

6-36

DSP board, and control board. Resides on base board.

Contains:

Ethernet Schematic 1 of 5

General Purpose Bus Schematic 2 of 5

Memory Schematic 3 of 5

Miscellaneous Functions Schematic 4 of 5

Power and Ground Distribution Schematic 5 of 5

Supports Serial Port Parts Locator

6-37

6-38

6-39

6-40

6-41

6-42

Drawing

Schematic 1 of 1

±15V analog supply; ±5V analog

supply; +5V digital supply

Parts Locator

Drawing

Schematic 1 of 1

Analog Input/Output

AES3 Input/Output

Parts Locator

Drawing

6-43

6-44

6-45

6-46

Composite Output

SCA Input.

Contains:

L and R Analog Inputs Schematic 1 of 5 6-47

L and R Analog Outputs Schematic 2 of 5 6-48

Composite / SCA Schematic 3 of 5 6-49

Control and Digital I/O Schematic 4 of 5 6-50

Interface and Power Distribution Schematic 5 of 5 6-51

DSP Chips; Local +3.3V regulator.

Contains:

DSP Extended Serial Audio Inter-

Parts Locator

6-52

Drawing

Schematic 1 of 7 6-53

face (ESAI)

DSP Host Interface Schematic 2 of 7 6-54

DSP Serial Peripheral Interface,

Schematic 3 of 7 6-55

Power, and Ground

ISA Bus 8-bit I/O Schematic 4 of 7 6-56

Serial Audio Interface and Clock

Schematic 5 of 7 6-57

Generation

Page 14

Display Board

DSP Block

Diagram

Power Distribution Schematic 6 of 7 6-58

No-Connects Schematic 7 of 7 6-59

Front-Panel LCD, LEDs, Buttons,

and Rotary Encoder

Parts Locator

Drawing

6-60

Schematic 1 of 1 6-61

Shows signal processing 6-62

Page 15

Index

1

19 K Ref control 2- · 10

8

8100A/ST 1- · 16

8100A1 1- · 16

8100AST 1- · 16

8100AXT2 1- · 16

8200ST 2- · 13

8300 HD 3- · 55

8300 OPTIMOD-FM 1- · 1

8400

comparison with 8300 3- · 70

importing 8400 presets 3- · 4, 70

A

A/D converter

circuit description 5- · 9

specification 6- · 2

Abbreviations 6- · 13

AC Line Cord Standard 2- · 2

Advanced Modify 3- · 12

AES/EBU I/O 2- · 7

AGC

bass attack control 3- · 31

bass coupling control 3- · 29

bass delta threshold control 3- · 32

bass release control 3- · 31

bass threshold control 3- · 31

control list 3- · 27

crossover control 3- · 32

defeating 3- · 18, 27

drive control 3- · 28

external AGC setup 2- · 13

gate threshold control 3- · 28

idle gain control 3- · 31

master attack control 3- · 31

master delta threshold control 3- · 31

master release control 3- · 28

matrix 3- · 30

Maximum Delta Gain Reduction control 3- ·

30

meter 2- · 12, 2

ratio control 3- · 30

window release control 3- · 30

window size control 3- · 30

AGC 3- · 6

allpass crossover 3- · 32

analog baseband outputs 1- · 7

analog I/O 1- · 7

analog input

circuit description 6- · 8

ref level, I/O setup 2- · 24

analog input 2- · 6

analog landline 1- · 16

analog output

circuit description 6- · 10

analog output 2- · 7

anti-aliased 3- · 37, 53

archiving presets 3- · 65

attack 3- · 31

attack time controls 3- · 53

audio

connections 2- · 6

input, connecting 2- · 6

output 2- · 7

output, connecting 2- · 7

Audio Precision 4- · 6

auditing performance 4- · 6

automation

add event 2- · 31

delete event 2- · 32

edit event 2- · 32

automation 2- · 30

automation 3- · 67

B

B4>B5 coupling 3- · 7

B5 down expand 3- · 51

backing up presets 3- · 65

balance adjust 2- · 26

balanced

inputs 2- · 6

output, simulates transformer 2- · 7

band coupling 3- · 51

base board

removing 4- · 3

replacing 4- · 5

Page 16

baseband spectrum

control 3- · 6

baseband spectrum 5- · 4

Basic Modify 3- · 11

Bass

equalizer 3- · 61

Getting sound you want 3- · 60

bass clip threshold 3- · 33

bass punch

and the bass clipper 3- · 33

bass threshold 3- · 31

battery

replacing 6- · 6

Beatles 3- · 31

bit depth of internal processing 6- · 1

block diagram 6- · 62

bone-conduction comb filtering 3- · 10

Brilliance control 3- · 24

buttons

escape 2- · 12

escape 3- · 2

modify 2- · 12

modify 3- · 1

next 2- · 11

NEXT 3- · 1

previous 2- · 11

PREVIOUS 3- · 1

RECALL 2- · 12

RECALL 3- · 1

setup 2- · 12

setup 3- · 1

soft buttons 2- · 11

buzz 5- · 1

bypass

local 1- · 21

PC remote 1- · 22

remote interface 1- · 22

test mode 1- · 20

C

cable

shielding 2- · 10

type recommended for analog I/O 2- · 6

CD mastering, overprocessing in 3- · 5

chassis

getting inside 4 · 2

ground 2- · 11

circuit board locator drawing 6- · 29

circuit description

control 6- · 6

LCD display 6- · 7

user control interface 6- · 7

circuit description 6- · 5

CIT25 2- · 8

classical 3- · 18, 38

cleaning front panel 4- · 1

clipper

bass clip threshold control 3- · 33

clipper shape control 3- · 33

control list 3- · 33

final clip drive control 3- · 33

clipper, bass 3- · 7

clock

battery 6- · 6

reset to hour 2- · 37

reset to midnight 2- · 37

resetting via remote control 2- · 37

setting 2- · 30

common-mode rejection 2- · 10

components

obtaining 6- · 15

composite

circuit description 6- · 11

isolation transformer 2- · 8

limiter 3- · 8

peak level control 1- · 19

composite baseband microwave STL 1- ·

14

composite limiter

drive 3- · 34

pilot tone protection 2- · 9

composite output

cable specification 2- · 8

I/O setup 2- · 20, 26

impedance 2- · 8

level adjustment range 2- · 8

level control 2- · 8

setting output impedance 2- · 8

specifications 6- · 3

termination 2- · 8

composite output 2- · 8

composite outputs 1- · 7

compression

defined 3- · 3

compressor gate 3- · 29

Compressor look-ahead

and bass clipper mode 3- · 36

computer

connecting to 2- · 4

troubleshooting connections 5- · 7

Windows 2000 5- · 8

Windows XP 5- · 11

Page 17

computer interface

RS-232 2- · 5

serial 2- · 5

computer interface 1- · 9

connecting

through Win XP direct serial 2- · 52

connection to PC

troubleshooting 5- · 6

connectors

audio 2- · 6

input and output 2- · 6

contrast 2- · 11

contrast control 3- · 1

control knob 2- · 12

control knob 3- · 1

controls

contrast 2- · 11

contrast 3- · 1

description 3- · 1

soft buttons 3- · 1

corrosion 4- · 1

CPU board

replacing 4- · 5

CPU module

removing 4- · 3

crossover

allpass 3- · 32

linear phase 3- · 32

modes 3- · 32

D

D/A converter

circuit description 6- · 10

specification 6- · 2

Delay

Analog vs. HD 3- · 56

delay 3- · 10

delta release control 3- · 54

digital I/O 1- · 7

digital input

circuit description 6- · 9

digital links 1- · 13

digital output

circuit description 6- · 11

digital radio

setup controls 3- · 56

display assembly

removing 4 · 2

display board

parts list 6- · 25

replacing 4 · 5

distortion

aliasing 3- · 8

caused by poor source material 3- · 4

excessive 5- · 6

on material with strong HF content 3- · 37

specification 6- · 1

testing 4- · 10

troubleshooting 5- · 2

dither 2- · 29

DJ Bass control 3- · 25

downward expander 3- · 50

DSP

block diagram 6- · 62

circuit description 6- · 12

DSP board

removing 3- · 4

replacing 4- · 5

dual microwave STLs 1- · 14

dull sound

troubleshooting 5- · 5

E

EAS

modulation low 5- · 5

test tones 1- · 21

easy setup 2- · 16

echo fusion threshold 3- · 10

EQ Frequency control

HD 3- · 57

equalizer

bass shelf 3- · 21

control list 3- · 21

parametric 3- · 23

equalizer 3- · 7

escape button 2- · 12

escape button 3- · 2

Ethernet 2- · 37, 45, 63

exciter overshoot 1- · 16

Exit Test 2- · 36

F

factory presets

selecting 2- · 21

factory presets 1- · 5

factory service 5- · 13

final clip drive 3- · 33

Firewall 2- · 45, 63

Page 18

Firmware

updating 8500 2- · 69

five-band

attack time controls 3- · 53

band coupling controls 3- · 51

band on/off switch 3- · 53

band threshold control 3- · 49

delta release control 3- · 54

downward expander thresold control 3- · 50

full modify control list 3- · 46

HF clipper threshold 3- · 52

high frequency limiter control 3- · 43, 54

limiter attack control 3- · 54

maximum distortion control 3- · 44, 54

multiband drive control 3- · 46

multiband gate threshold control 3- · 49

multiband limit threshold control 3- · 50

multiband limiter drive control 3- · 50

mutiband release control 3- · 47

output mix controls 3- · 52

five-band 3- · 45

frequency response

specification 6- · 1

testing 4- · 9

front panel 3- · 1

Full Modify 3- · 11

fuse 2- · 5

G

gain reduction

meters 2- · 12

meters 3- · 2

gate

threshold control 3- · 49

gate 3- · 29

gate LED 2- · 12, 2

Gateway 2- · 45, 63

gateway address 2- · 38

getting inside the unit 4 · 2

gold (format) 3- · 19

GPI

specifications 6- · 4

GPI interface

testing 4- · 13

ground

chassis 2- · 11

ground lift switch 2- · 3, 5

grounding

circuit 2- · 11

loss of 4- · 1

power 2- · 11

grounding 2- · 10

grouping 8300s 3- · 68

H

Haas threshold 3- · 10

half-cosine interpolation limiter 3- · 8

HD

EQ frequency control 3- · 57

EQ Gain control 3- · 57

Limiter Drive control 3- · 57

HD Radio

GR meter 2- · 13

setup controls 3- · 56

HD Radio 1- · 3

headphones

low delay monitoring 1- · 21

low-delay monitoring 2- · 18, 27

headphones 1- · 20

HF enhancer 3- · 7

high frequency

excessive energy in source material 3- · 5

High Frequency Enhancer 3- · 25

high frequency limiter

threshold 3- · 52

high frequency limiter 3- · 7, 43, 52, 54

high-pass filter

30 Hz 3- · 6, 25

hum 5- · 1

I

I/O

AES/EBU 2- · 7

connections 2- · 3

I/O board

replacing 4- · 5

IC opamps

troubleshooting 5- · 12

idle gain 3- · 31

import

8400 presets 3- · 4, 70

input

analog, connecting 2- · 6

analog, specifications 6- · 2

digital, specifications 6- · 2

meters 2- · 12

SCA, specifications 6- · 4

subcarrier 2- · 8

Page 19

input level

line-up 1- · 18

input meters 1- · 19

input meters 3- · 2

input selector

I/O setup 2- · 24

input/output board

removing 4- · 3

inspection of package contents 2- · 1

installation procedure 2- · 1

Internet

cannot access 5- · 7

IP address 2- · 37

IP port 2- · 38

ITU412

setting up controller 2- · 22

ITU412 3- · 9, 57

J

J.17

and 8300 digital I/O 1- · 7

and NICAM 1- · 14

deemphasis applied to digital audio input 6-

· 3

defined 1- · 7

preemphasis applied to digital audio output

6- · 3

line-up tones

system will not pass at 100% modulation 5- ·

5

line-up tones 1- · 20

LLHard mode 3- · 36

location 1- · 10

lock

driven equipment cannot lock to 8300 output

5- · 5

lockout

immediate 2- · 34

programming local 2- · 34

unlocking front panel 2- · 35

look-ahead

limiting 3- · 3

Lookahead

Multiband Control 3- · 53

Lookahead 3- · 44

lossy data reduction

in studio 1- · 17

NICAM 1- · 14

used in STLs · 13

loudness

and distortion 3- · 3

insufficient 5- · 6

insufficient due to poor peak control 5- · 1

loudness/distortion tradeoff 3- · 33

L–R will not null 5- · 6

L

latency

low delay presets 2- · 18

low delay presets 3- · 10, 15, 18, 71

latency 3- · 10

LEDs

gate 2- · 12, 2

Less-More

index 3- · 43

Less-More 3- · 27

level

metering 1- · 19

setup 2- · 18

transmission 1- · 19

limiter

attack 3- · 54

limiting

defined 3- · 3

line voltage 2- · 2

linear-phase crossover 3- · 32

M

MAC address 5- · 7

main board

reattaching 4 · 5

master delta threshold 3- · 31

matrix, AGC 3- · 30

maximum distortion control 3- · 44, 54

measuring performance 4- · 6

meter

circuit description 6- · 7

composite 1- · 19

gain reduction 3- · 12

meters

AGC 2- · 12, 2

circuit description 6- · 7

composite 3- · 2

gain reduction 2- · 12

gain reduction 3- · 2

input 2- · 12

input 3- · 2

studio 1- · 17

Page 20

Mod Reduction control 2- · 36

modem

preparing for connection 2- · 57

recommended baud rate 2- · 58

setting up 2- · 38

specification for 2- · 44

Windows 2000 configuration 2- · 57

Windows XP configuration 2- · 63

modify button 2- · 12

modify button 3- · 1

modulation control

troubleshooting poor 5- · 1

monitoring 1- · 20

Mono mode 2- · 36

MPX Power Offset 3- · 35

multiband drive 3- · 46

multiband limit threshold 3- · 50

multiband llimiter drive 3- · 50

multipath distortion 3- · 26

multiplex power

meter 2- · 13

multiplex power 3- · 57

N

NAB Broadcast and Audio System Test CD

4- · 6

network

timeserver 2- · 39

networking 2- · 37

NEWS preset 3- · 19

NEXT button 2- · 11

NEXT button 3- · 1

NICAM 1- · 14

noise

troubleshooting 5- · 2

null modem cable

communicating through 2- · 47

null modem cable 2- · 43

O

oldies 3- · 19

Orban 222 stereo enhancer 3- · 26

output

analog output level trim adjustment 4- · 9

analog, connecting 2- · 7

analog, specifications 6- · 2

composite 2- · 8

composite, specifications 6- · 3

digital, setting dither 2- · 29

digital, setting sample rate 2- · 28

digital, setting sync 2- · 28

digital, setting word length · 28

digital, specifications 6- · 3

headphone monitoring, setup 2- · 18, 27

output level

I/O setup 2- · 27, 28

quick setup 2- · 20

output mix controls 3- · 52

overshoot

in exciter 1- · 16

overshoot

reduction 1- · 17

overshoot

excessive 5- · 1

overshoot 3- · 58

overshoot compensator drive 3- · 37

P

parametric equalizer 3- · 7

parent preset 3- · 43

parts

obtaining 6- · 15

parts list

base board 6- · 15

CPU module 6- · 17

display board 6- · 25

DSP board 6- · 23

I/O board 6- · 20

power supply 6- · 19

RS-232 board 6- · 18

parts list 6- · 14

passcode

and dial-up networking 2- · 35

creating 2- · 33

deleting 2- · 34

editing 2- · 33

programming 2- · 32

recovering from lost 2- · 35

PC

Orban installer program 2- · 44

PC board locator diagram 6- · 29

PC control

security 1- · 22

PC hardware requirements 2- · 43

PC Remote

aliases 3- · 68

moving alias folders 3- · 70

Page 21

multiple coexisting versions 3- · 69

upgrading versions 3- · 69

PC Remote Software 3- · 62

peak control criteria 1- · 10

peak-to-average ratio 3- · 3

performance

measuring 4- · 6

phase rotator 3- · 6, 25

phase-linear

system group delay spec · 10

two-band purist processing 3- · 9

phase-linear 1- · 4

phase-linear 3- · 39

pilot tone

frequency out of tolerance 5- · 5

reference output 1- · 8

reference output 2- · 9

port, IP 2- · 38

Ports 2- · 45, 63

power

cord 2- · 2, 5

power 2- · 2

power supply

circuit description 6- · 12

parts list 6- · 19

testing 4- · 8

power supply board

reattaching 4 · 5

removing 4 · 4

prcocessing

styles 3- · 4

pre-emphasis

defeating 2- · 19

quick setup 2- · 17

preset

restoring archived 3- · 66

presets

backup 3- · 65

classical 3- · 18

customizing 3- · 10

factory 1- · 5

factory programming 3- · 16

five-band 3- · 14, 19

protection 3- · 38

saving user 3- · 6, 13

sharing between 8300s 3- · 67

two-band 3- · 14

UL (ultra-low latency) 3- · 10, 15

user presets 1- · 6

PREVIOUS button 2- · 11

PREVIOUS button 3- · 1

processing

AGC 3- · 6

block diagram 6- · 62

distortion in 3- · 3

equalization 3- · 7

input conditioning 3- · 6

intelligent clipping 3- · 8

introduction to 3- · 3

multiband compression 3- · 7

signal flow 3- · 5

stereo enhancement 3- · 6

structures 1- · 4

structures 3- · 14

two-band purist 30 · 9

Proof of Performance 1- · 5

Proof of Performance 3- · 59

protect preset 3- · 18

punch

increasing 3- · 54

Q

quick setup 2- · 16

R

rack-mounting unit 2- · 3

ratio

AGC 3- · 30

control 3- · 7

limit 3- · 26

rear panel 2- · 5

RECALL button 2- · 12

RECALL button 3- · 1

registration card 2- · 1

release

fast 3- · 48

medium-fast 3- · 48

medium-slow 3- · 48

slow 3- · 47

remote

PC Remote software 3- · 62

remote control

bypass 1- · 22

connecting 2- · 3

GPI, specifications 6- · 4

wiring 2- · 4

remote control 2- · 5

remote interface

functions controllable by 2- · 36

GPI 1- · 8

programming GPI 2- · 36

Page 22

testing 4- · 13

wiring 2- · 4

remote interface connector 2- · 5

Remote Software 2- · 39, 43, 69

resolution

specification 6- · 1

RFI 5- · 1

right channel balance

I/O setup 2- · 26

RJ45 jack 2- · 38

routine maintenance 4- · 1

RS232

testing 4- · 13

RS232 board

replacing 4- · 5

RS-232 connector 2- · 5

RS-232 interface

circuit description 6- · 7

removing board 4- · 2

S

sample rate

at digital output 6- · 3

internal, specification 6- · 1

setting output 2- · 20

sample rate converter

testing 4- · 11

saving user presets 3- · 6, 13

SCA

composite meter does not indicate 1- · 19

input, specifications 6- · 4

inputs 1- · 8

interference from stereo 5- · 4

modulation reduction 2- · 23

screen display 2- · 11

screen display 3- · 1

screens

System Setup 2- · 16

Security

lock immediately 2- · 34

security 1- · 22

security 2- · 32

Serial Communications

setting up 2- · 47

serial connection

setting up direct 2- · 39

serial connector 2- · 5

service 5- · 13

setup

I/O 2- · 24

quick 2- · 16

setup button 2- · 12

setup button 3- · 1

shelving equalizer

bass, slope of 3- · 7

shipping instructions 5- · 14

shrill sound

troubleshooting 5- · 4

signal flow diagram 6- · 62

soft buttons 2- · 11

soft buttons 3- · 1

Software

updating 8500 2- · 69

software updates 1- · 5

Sound Technology 4- · 6

source material

poor-quality, adjusting processing for 3- · 5

requirements for 3- · 4

spare parts

obtaining 6- · 15

specifications 6- · 1

spectrum analyzer 4- · 6

Speech/music detector 3- · 36, 53

sports 3- · 48

sports preset 3- · 20

Stanford Research Systems 4- · 6

station ID

setting 2- · 22

stereo encoder

testing 4- · 11

stereo encoder 3- · 8

stereo enhancer 3- · 26

Stereo mode 2- · 36

STL

compatibility with 32 kHz sample rate 2- · 8

overshoot in uncomressed digital 2- · 8

systems 1- · 13, 14

studio chassis mode 2- · 17

studio-transmitter link 1- · 13

subassembly removal and replacement 4- ·

2

subcarrier

input, specifications 6- · 4

inputs 2- · 9

modulation reduction 2- · 23

subcarrier input 2- · 8

subcarrier inputs 1- · 8

subnet mask 2- · 37

switches

ground lift 2- · 3, 5

voltage select 2- · 2, 5

Page 23

system setup

quick setup 2- · 16

System Setup screen 2- · 16

T

talk 3- · 48

TALK preset 3- · 19

TCP/IP

setting parameters 2- · 37

technical support 5- · 23, 13

telephone support 5- · 23, 13

test modes 3- · 59

Threshold

Multiband Speech 3- · 44

threshold control 3- · 49

time

daylight saving 2- · 17

summer 2- · 17

time & date 2- · 16

timeserver 2- · 39

top cover

reattaching 4 · 6

removing 4 · 2

transformer

composite isolation 2- · 8

troubleshooting

installation 5- · 1

two-band

bass attack control 3- · 44

bass coupling control 3- · 42

bass threshold control 3- · 44

clipping control 3- · 43

crossover control 3- · 44

drive control 3- · 40

full modify controls 3- · 39

gate control 3- · 42

high frequency clip threshold control 3- · 44

high frequency limiting control 3- · 43

master attack control 3- · 44

master compression threshold 3- · 44

release control 3- · 41

two-band structure 3- · 37

unpacking 2- · 1

Updating software 2- · 69

upgrading software 1- · 5

user presets

archiving 3- · 14

creating 3- · 6, 11, 13

user presets 1- · 6

V

voltage select switch 2- · 2, 5

VPN, setting up 2- · 45, 63

W

warranty 1- · 23

Warranty 1- · 23

warranty 6- · 5

whistle on-air

troubleshooting 5- · 3

window

release control 3- · 30

window size control 3- · 30

Windows

installing services 2- · 43

Windows 2000

adding direct serial connection 2- · 48, 52,

58, 65

Direct Connect 5- · 8

direct serial connection 2- · 47

modem connect 5- · 10

modem connection 2- · 57

Windows XP

direct connect 5- · 11

modem configuration 2- · 63

modem connect 5- · 11

word length

at output, specification 6- · 3

setting output 2- · 28

X

U

unlock front panel 2- · 35

XLR connector

wiring standard 2- · 7

Page 24

Page 25

OPTIMOD-FM DIGITAL INTRODUCTION

Section 1

Introduction

About this Manual

The Adobe pdf form of this manual contains numerous hyperlinks and bookmarks. A

reference to a numbered step or a page number (except in the Index) is a live hyperlink; click on it to go immediately to that reference.

If the bookmarks are not visible, click the “Bookmarks” tab on the left

side of the Acrobat Reader window.

1-1

This manual has a table of contents and index. To search for a specific word or

phrase, you can also use the Adobe Acrobat Reader’s text search function.

The OPTIMOD-FM 8300 Digital Audio Processor

Orban’s all-digital OPTIMOD-FM 8300 Audio Processor can help you achieve excellent audio quality in FM stereo broadcasting. Because all processing is performed by

high-speed mathematical calculations within Motorola DSP56362 Digital Signal

Processing chips, the processing has cleanliness, quality, and stability over time and

temperature that is unmatched by analog processors.

OPTIMOD-FM 8300 is descended from the industry-standard OPTIMOD-FM audio

processors. Thousands of these processors are on the air all over the world. They

have proven that the “OPTIMOD sound” attracts and keeps an audience even in the

most competitive commercial environment.

Because OPTIMOD-FM incorporates several audio processing innovations

exclusive to Orban products, you should not assume that it can be operated

in the same way as less sophisticated processors. If you do, you may get

disappointing results.

Take a little time now to familiarize yourself with OPTIMOD-FM. A small investment

of your time now will yield large dividends in audio quality.

The rest of Section 1 explains how OPTIMOD-FM fits into the FM broadcast facility.

Section 2 explains how to install it and set it up. Section 3 tells how to operate

OPTIMOD-FM. Sections 4 through 6 provide reference information.

Page 26

1-2

INTRODUCTION ORBAN MODEL 8300

OPTIMOD-FM was designed to deliver a high quality sound while simultaneously increasing the average modulation of the channel substantially beyond that achievable by “recording studio”-style compressors and limiters. Because such processing

can exaggerate flaws in the source material, it is very important that the source

audio be as clean as possible.

For best results, feed OPTIMOD-FM unprocessed audio. No other audio processing is necessary or desirable.

If you wish to place level protection prior to your studio / transmitter link (STL), use

an Orban studio level control system expressly designed for this purpose. (At the

time of this writing, this is the Orban 8200ST OPTIMOD-Studio Compressor / Limiter /

HF Limiter / Clipper.) The 8200ST can be adjusted so that it substitutes for the broadband AGC circuitry in OPTIMOD-FM, which is then defeated.

User-Friendly Interface

An LCD and full-time LED meters make setup, adjustment and programming

of OPTIMOD-FM easy — you can always see the metering while you’re adjusting

the processor. Navigation is by dedicated buttons, soft buttons (whose functions

are context-sensitive), and a large rotary knob. The LEDs show all metering functions of the processing structure (Two-Band or Five-Band) in use.

Absolute Control of Peak Modulation

The 8300 provides universal transmitter protection and audio processing

for FM broadcast. It can be configured to interface ideally with any commonly

found transmission system in the world.

The 8300 provides pre-emphasis limiting for the two standard pre-emphasis

curves of 50s and 75s. Its pre-emphasis control is seldom audibly apparent,

producing a clean, open sound with subjective brightness matching the original

program.

By integrating the stereo encoder with the audio processing, the 8300 elimi-

nates the overshoot problems that waste valuable modulation in traditional external encoders. The stereo encoder has two outputs with independent level

controls, each capable of driving 7in parallel with 47,000pF, (100ft / 30m of

coaxial cable).

The 8300 prevents aliasing distortion in subsequent stereo encoders or transmis-

sion links by providing bandwidth-limiting and overshoot-compensated 15

kHz low-pass filters ahead of the 8300’s audio outputs and stereo encoder.

Anti-aliased clippers running at 256 kHz sample rate prevent any trace of

“digital clipper” sound.

Page 27

OPTIMOD-FM DIGITAL INTRODUCTION

Flexible Configuration

The 8300 includes analog and AES3 digital inputs and outputs. Both digital in-

put and digital output are equipped with sample-rate converters and can operate at 32 kHz, 44.1 kHz, 48, 88.2, and 96 kHz sample rates. The pre-emphasis

status and output levels are separately adjustable for the analog and digital outputs.

The 8300 has an internal, DSP-based stereo encoder (with a patented “half-

cosine interpolation” composite limiter operating at 512 kHz sample rate)

to generate the pilot tone stereo baseband signal and control its peak level. The

composite limiter is a unique, “you can only do this in DSP” process that beats

composite clippers by preserving stereo imaging while fully protecting the

stereo pilot tone, RDS / RBDS, and subcarriers.

The 8300’s digital output can be switched to emit processed audio suitable for

HD Radio, digital radio, and netcasts. Meanwhile, the analog output and

composite output continue to emit audio processed for the analog FM channel.

To do this, the output of the multiband compressor (5-band or 2-band) splits into

two paths. The FM path feeds an advanced, distortion-canceling clipper and

overshoot compensator, while the HD path is de-emphasized and then feeds a

look-ahead limiter.

1-3

Note that the “UL” [ultra-low-latency] presets do not offer HD processing. If a UL preset is put on-air, the HD output will emit a de-emphasized,

FM-processed signal.

The analog inputs are transformerless, balanced 10k instrumentation-

amplifier circuits, and the analog outputs are transformerless balanced, and

floating (with 50 impedance) to ensure highest transparency and accurate

pulse response.

The 8300 has two independent composite baseband outputs with digitally

programmable output levels. Robust line drivers enable them to drive 100 feet

of RG-59 coaxial cable without audible performance degradation.

The 8300 has two subcarrier inputs that are mixed with the output of

OPTIMOD-FM’s stereo encoder before application to the composite output connectors. One input can be re-jumpered to provide a 19 kHz pilot reference output. The other input has an internal level trim to accommodate subcarrier generators with output levels as low as 220 mV.

The 8300 precisely controls the audio bandwidth to 15 kHz. This prevents

overshoots in uncompressed digital links operating at a 32 kHz-sample rate and