Orban 6200, 6200S Service manual

Operating Manual

OPTIMOD

6200/6200S

Digital Audio Processor

IMPORTANT NOTE: Refer to the unit’s rear panel for your Model #.

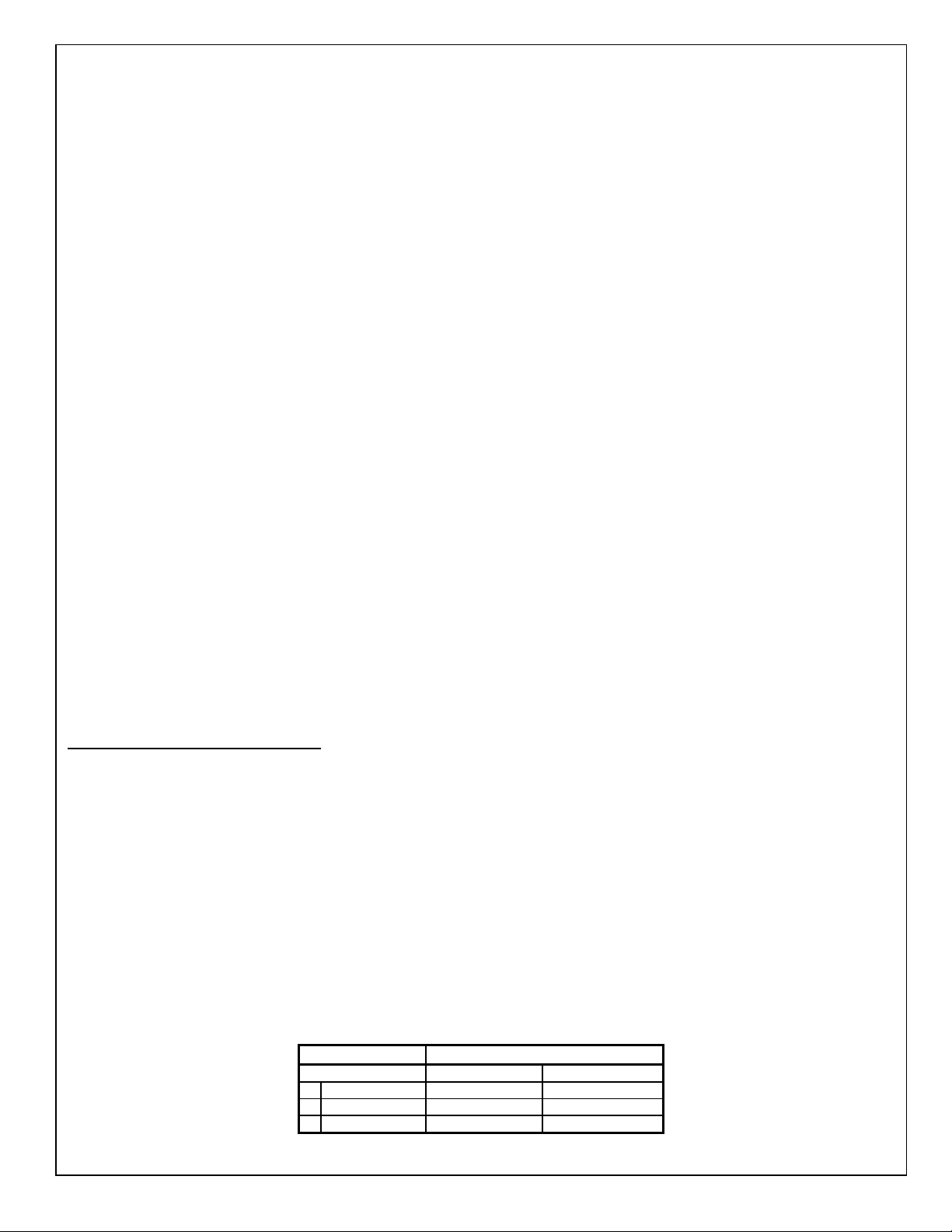

Model Number: Description:

6200/U OPTIMOD-DAB 6200, Stereo Encoder, Digital I/O

Protection Structure, Two-Band Structure

set to 115V (for 90-130V operation)

6200/E OPTIMOD-DAB 6200, Stereo Encoder, Digital I/O

Protection Structure, Two-Band Structure

set to 230V (for 200-250V operation)

6200/S OPTIMOD 6200S, Stereo Encoder, Digital I/O

Protection Structure, Two-Band Structure

(for 90-250V operation)

MANUAL:

Part Number: Description:

96104-000-04 6200 Operating Manual

CAUTION:

NO USER SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

WARNING:

DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT REMOVE COVER (OR BACK).

TO REDUCE THE RISK OF FIRE OR ELECTRICAL SHOCK,

This symbol, wherever it appears,

alerts you to the presence of uninsulated

dangerous voltage inside the enclosure voltage

that may be sufficient to constitute a risk of shock.

This symbol, wherever it appears,

alerts you to important operating and

maintenance instructions in the accompanying

literature. Read the manual.

IMPORTANT SAFETY INSTRUCTIONS

All the safety and operati ng i nstructions should be read before t he appl i ance is operated.

Retain Instructions:

The safety and operation instructions should be retained for fut ure reference.

Heed Warnings:

Follow Instructions:

Water and Moisture:

ment, or near a swimming pool, et c.).

Ventilation:

ance should not be s it uated on a bed, s ofa, rug, or s im ilar s urfac e that may bl ock the v enti lati on openings; or, pl aced i n a built-in installation, such as

a bookcase or cabinet that m ay impede the flow of air through the ventilation openings.

Heat:

The appliance should be situat ed away from heat sources such as radiators, heat regist ers, s toves, or other applianc es (incl uding amplif iers)

that produce heat.

Power Sources:

the appliance.

Grounding or Polarization:

Power-Cord Protection:

against them, paying parti cular attention to cords at pl ugs, convenience receptacl es, and the point where they exit from the appliance.

Cleaning:

Non-Use Periods:

Object and Liquid Entry:

Damage Requiring Service:

The power supply cord or the plug has been damaged; or

Objects have fallen, or liquid has been spilled into t he appliance; or

The appliance has been exposed to rain; or

The appliance does not appear to operate normally or exhibits a marked change in perf orm ance; or

The appliance has been dropped, or the enclosure dam aged.

All warnings on the appliance and in t he operating instructions shoul d be adhered t o.

All operation and user instruc tions should be followed.

The appliance should not be used near water (e.g. , near a bathtub, washbowl, k itchen sink, laundry tub, in a wet base-

The appliance should be situat ed so that its location or pos ition does not int erfere with its proper ventilati on. For example, t he appli-

The appliance should be connected to a power s upply only of the type described in the operating instructi ons or as marked on

Precautions should be tak en so that the grounding or polarization means of an appliance is not defeated.

Power-supply cords should be rout ed so that they are not likely to be walked on or pinched by items placed upon or

The appliance should be cleaned only as recommended by the manufacturer.

The power cord of the appliance should be unplugged f rom the outlet when left unused for a long period of time.

Care should be taken so that objects do not fall and liquids are not spilled into the enclosure through openings.

The appliance should be serviced by qualified service personnel when:

Servicing:

referred to qualified servic e personnel.

The Appliance should be used only with a cart or sta nd that is recommended by the manufacturer.

The user should not attempt to s ervice the appl iance beyond that des cribed in the operat ing instruct ions. All other serv icing should be

Safety Instructions (European)

Notice For U.K. Customers If Your Unit Is Equipped With A Power Cord.

WARNING: THIS APPLIANCE MUST BE EARTHED.

The cores in the mains lead are col oured i n accordance with the following c ode:

GREEN and Y E LLOW - Earth BLUE - Neutral BROWN - Live

As colours of the cores in the mains lead of this appl i ance may not correspond with the coloured markings identifyi ng the terminals in your plug, proceed as follows:

The core which is coloured green and yell ow must be connected to the term i nal i n the plug marked with the letter E, or with the earth symbol, or coloured green, or green and yellow.

The core which is coloured blue mus t be connected to the terminal m arked N or coloured black.

The core which is coloured brown must be connected to the terminal m arked L or coloured red.

The power cord is terminated in a CEE7/7 plug (Continental Europe). The green/yellow wire is connec ted directly to the unit's chas s is. If you need to change the plug and

if you are qualified to do so, refer to the table below.

!

WARNING: If the ground is defeated, certain fault c onditions in the unit or in the s ys te m to whic h it is conne c ted c a n re s ult i n full line voltage be twee n c has s is a nd ea rth

ground. Severe injury or death can then result if the chassis and earth ground are touched simultaneously.

Conductor

L LIVE BROWN BLACK

N NEUTRAL BLUE WHITE

E EARTH GND GREEN-YELLOW GREEN

Normal Alt

AC Power Cord Color Coding

WIRE COLOR

Safety Instructions (German)

Gerät nur an der am Leistungsschild vermerkten Spannung und Stromart betreiben.

Sicherungen nur durch solche, glei cher Stromstärke und gleichen A bschaltverhaltens erset zen. Sicherungen nie überbrücken.

Jedwede Beschädigung des Netzkabels vermeiden. Netzkabel ni cht knicken oder quetsc hen. Beim Abziehen des Netzkabel s den

Stecker und nicht das Kabel enfassen. Beschädigte Netzkabel sofort auswechseln.

Gerät und Netzkabel keinen übertriebenen m echanischen Beaspruchungen aussetzen.

Um Berührung gefährlicher elektrischer Spannungen zu vermeiden, darf das Gerät ni cht geöffnet werden. Im Fall v on Betriebsstörun-

gen darf das Gerät nur Von befugten Servi cestellen instandgesetz t werden. Im Gerät befinden sich keine, durch den Benutzer

reparierbare Teile.

Zur Vermeidung von elektrisc hen S chlägen und Feuer ist das Gerät vor Näss e zu schützen. Eindringen von Feuchtigkeit und

Flüssigkeiten in das Gerät vermeiden.

Bei Betriebsstörungen bzw. nach Eindringen von Flüssigk ei t en oder anderen Gegenständen, das Gerät sofort vom Netz trennen und

eine qualifizierte Servi cestelle kontaktieren.

Safety Instructions (French)

On s'assurera toujours que la tension et la nat ure du courant utilisé correspondent bien à ceux indiqués sur la plaque de l'appareil.

N'utiliser que des fusibles de même intensité et du même principe de mise hors circuit que les fus i bles d'origine. Ne jamais

shunter les fusibles.

Eviter tout ce qui risque d'endommager le câble seceur. On ne devra ni le plier, ni l'aplatir. Lorsqu'on débranche l'appareil,

tirer la fiche et non le câble. Si un câble est endommagé, le rem pl acer immédiatement.

Ne jamais exposer l'appareil ou le câble ä une contrainte mécanique excessive.

Pour éviter tout contac t averc une tension électrique dangereuse, on n'oouvrira jamais l'appareil . En cas de dysfoncti onnem ent,

l'appareil ne peut être réparé que dans un atelier autorisé. Aucun élément de cet appareil ne peut être réparé par l'utilisateur.

Pour éviter les risques de décharge électrique et d'incendie, protéger l'appareil de l'humidité. Eviter toute pénétration

d'humidité ou fr liquide dans l' apparei l .

En cas de dysfonct i onnem ent ou si un liquide ou tout autre objet a pénét ré dans l'appareil couper aussitôt l ' apparei l

de son alimentation et s'adresser à un point de service aprésvente autorisé.

Safety Instructions (Spanish)

Hacer funcionar el aparato sólo con l a tensión y clase de corrient e señaladas en la placa indicadora de características.

Reemplazar los fusibles sólo por otros de la misma intens i dad de corriente y sistema de des conexión. No poner nunca los fusibl es en

puente.

Proteger el cable de alimentaci ón contra toda clase de daños. No doblar o apretar el cable. Al desenchufar, as i r el enchufe y no el

cable. Sustituir inmediatamente cables dañados.

No someter el aparato y el cable de al i m entación a esfuerzo mecánico excesivo.

Para evitar el contacto con tensiones eléctricas peligrosas, el aparato no debe abrirse. E n caso de producirse fallos de funcionamiento,

debe ser reparado sólo por talleres de serv i cio autorizados. En el aparato no s e encuentra ninguna pieza que pudiera ser reparada por

el usuario.

Para evitar descargas eléc tricas e incendios, el aparat o debe protegerse contra la humedad, impidiendo que penet ren ésta o líquidos

en el mismo.

En caso de producirse fallas de funcionamiento como cons ecuencia de la penetración de líquidos u otros objetos en el aparato,

hay que desconectarlo inmediatamente de la red y ponerse en contacto con un taller de servicio autori zado.

Safety Instructions (Italian)

Far funzionare l'apparecchio sol o con la tensione e il tipo di corrent e i ndi cati sulla targa riportante i dat i sulle prestazioni.

Sostituire i dispositivi di protezione (valvole, fusibili ecc.) solo con dispos itivi aventi lo stesso amperaggio e lo stesso comportamento

di interruzione. Non cavall ot tare mai i dispositivi di protezione.

Evitare qualsiasi danno al cavo di collegamento alla rete. Non piegare o schiacciare il c avo. Per staccare il c avo, tirare la presa e mai

il cavo. Sostit ui re subito i cavi danneggiati.

Non esporre l'apparecchio e il cav o ad esagerate sollecitazioni meccaniche.

Per evitare il contatt o con le tensioni elettriche peri colose, l'apparecchio non deve venir aperto. In caso di anomalie di f unzionamento

l'apparecchio deve venir riparat o solo da centri di servizi o autorizzati. Nell'apparecchio non si trovano parti che possano essere riparate

dall'utente.

Per evitare scosse el ettriche o incendi, l'apparecchio va protetto dall'umidità. Evitare che umidità o l i quidi entrino nell'apparecchio.

In caso di anomalie di funz i onam ento rispettivamente dopo la penetrazione di liquidi o oggetti nell'apparecchio, staccare imm ed i at am ente

l'apparecchio dalla rete e cont at tare un centro di servizio qualificato.

PLEASE READ THIS FIRST!

Manual

The Operating Manual contains instructions to verify t he proper operation of this unit and initial i zation of certain

options. You will find these operations are most conveniently performed on the bench before you install the unit

in the rack.

Please review the Manual, es pecially the installat i on section, before unpacking the uni t.

Trial Period Precautions

If your unit has been provided on a t ri al basis:

You should observe the followi ng precautions to avoid reconditi oni ng charges in case you later wis h to return

the unit to your dealer.

Note the packing technique and s ave all packing materials. It is not wise to sh i p i n ot her than the factory car-

ton. (Replacements cos t $35.00).

(1) Avoid scratching the paint or plating. Set the unit on soft, clean surfaces.

(2) Do not cut the grounding pin from the l i ne cord.

(3) Use care and proper tools in removing and tightening screws to avoid burri ng the heads.

(4) Use the nylon-washered rack s crews supplied, if possi bl e, to avoid damaging the panel. Support the unit

when tightening the screws s o that the threads do not scrape the paint inside the slotted holes .

Packing

When you pack the unit for shi ppi ng:

(1) Tighten all screws on any barrier strip(s) so the screws do not fall out from vibration.

(2) Wrap the unit in its original plastic bag to avoid abrading the paint .

(3) Seal the inner and outer cartons with tape.

If you are returning the unit permanent l y (for credit), be sure to enclose:

Your dealer may charge you for any m i ssing items.

If you are returning a unit for repair, do not enclose any of the above items.

Further advice on proper packing and shi ppi ng i s included in the Manual (see Table of Contents).

Trouble

If you have problems with i nstallation or operation:

(1) Check everything you hav e done so far against the instructions in the Manual. The informat i on contained

therein is based on our years of ex peri ence with OPTIMOD and broadcast s t ations.

(2) Check the other sections of the Manual (consult the Tabl e of Contents and Index) to see if t here m i ght be

some suggestions regarding y our probl em .

(3) After reading the section on Factory Assistance, you may call Orban Custom er Service for advice during

normal California business hours. The number is (1) 510/351-3500.

• The Manual(s)

• The Registration/Warranty Card

• The Line Cord

• All Miscellaneous Hardware (i ncluding the Rack Screws and K eys)

• The Extender Card (if applicable)

• The Monitor Rolloff Filt er(s) (OPTIMOD-AM only)

• The COAX Connecting Cable (OPTIMOD-FM and OP TIMOD-TV only)

Operating Manual

OPTIMOD

6200/6200S

Digital Audio Processor

This digital apparatus does not exceed the Class A limits for radio noise emissions

from digital apparatus set out in the radio Interference Regulations of the Canadian

Department of Communications. (Le present appareil numerique n’emet pas de

bruits radioelectriques depassant les limites applicables aux appareils numeriques

(de las class A) prescrites dans le Reglement sur le brouillage radioelectrique

edicte par le ministere des Communications du Canada.)

WARNING

Perform the installation under static control conditions. Simply walking across a rug

can generate a static charge of 20,000 volts. This is the spark or shock you may

have felt when touching a doorknob or some other conductive item. A much

smaller static discharge is likely to completely destroy one or more of the CMOS

semiconductors employed in OPTIMOD-FM. Static damage will not be covered

under warranty.

There are many common sources of static. Most involve some type of friction

between two dissimilar materials. Some examples are combing your hair, sliding

across a seat cover or rolling a cart across the floor. Since the threshold of human

perception for a static discharge is 3000, many damaging discharges will not even

be noticed.

Basic damage prevention consists of minimizing generation, discharging any

accumulated static charge on your body or work station and preventing that

discharge from being sent to or through an electronic component. A static

grounding strap (grounded through a protective resistor) and a static safe

workbench with a conductive surface should be used. This will prevent any buildup

or damaging static.

IMPORTANT

The OPTIMOD 6200 is protected by U.S. patents 4,208,548; 4,460,871; and U.K. patent 2,001,495. Other

patents pending.

Orban is a registered trademark.

All trademarks are property of their respective companies.

This manual is part number 96104.000.04

© Copyright 2000-2001

Phone: (1) 510/351-3500; Fax: (1) 510/351-0500; E-Mail: custserv@orban.com; Site: www.orban.com

1525 ALVARADO STREET, SAN LEANDRO, CA 94577 USA

P/N: 96104.000.04

OPTIMOD

TABLE OF CONTENTS

Index ............................................................................................I-7

Reading this Manual.................................................................. 1-2

6200 OPTIMOD-DAB Digital Audio Processor.......................... 1-2

User-Friendly Interface......................................................................................... 1-3

Flexible Configuration .........................................................................................1-3

Adaptability through Multiple Audio Processing Structures .......................... 1-4

Controllable..........................................................................................................1-4

Presets in OPTIMOD-DAB ........................................................... 1-5

Factory Processing Presets .................................................................................1-5

User Presets ........................................................................................................... 1-5

Input/Output Configuration ..................................................... 1-6

Digital AES/EBU Left/Right Input/Output........................................................... 1-6

I-1

Analog Left/Right Input/Output ........................................................................ 1-6

Studio-Transmitter Link................................................................ 1-7

Transmission from Studio to Transmitter.............................................................1-7

Location of OPTIMOD-DAB..................................................... 1-10

At the Transmitter is Best....................................................................................1-10

Where Access to the Transmitter Plant is Not Possible.................................. 1-10

OPTIMOD-DAB at the Transmitter: Gain Control before the STL..................1-11

Using Lossy Data Reduction in the Studio............................. 1-11

Interfacing to the Transmitter ................................................. 1-12

Sync Input ........................................................................................................... 1-12

Sample Rate and Audio Bandwidth...............................................................1-12

Subframe Delay .................................................................................................1-13

Program-Associated Data (PAD) ....................................................................1-13

Setting Modulation Levels....................................................... 1-13

Monitoring on Loudspeakers and Headphones.................. 1-14

EAS Test...................................................................................... 1-15

Security Pascode for PC Control............................................ 1-16

ORBAN Model 6200

DTV Applications.......................................................................1-16

Using the 6200 in the United States DTV System.............................................1-16

Audio Processing for Consistency and Loudness Control............................1-18

A Hybrid Technique for DTV Processing..........................................................1-18

Advantages of Multiband Compression in DTV Audio.................................1-19

Using the 6200 in the 5.1 Channel Plant..........................................................1-20

Bypassing the Loudness Controller ..................................................................1-20

The 6200 in 2-Channel DTV Applications ........................................................1-20

Webcasting Applications.........................................................1-21

Using the 6200 in Streaming Applications.......................................................1-21

Using the 6200 in Non-Streaming Applications, to Prepare Audio

Files for Download...........................................................................................1-22

Decoder Headroom..........................................................................................1-22

Loudness..............................................................................................................1-22

Choosing your Encoder.....................................................................................1-23

MP3.......................................................................................................................1-23

W arranty, Feedback.................................................................1-23

User Feedback Form..........................................................................................1-23

Installing the 6200........................................................................2-2

Figure 2-1: Jumper Settings...............................................................................2-3

Figure 2-2: AC Line Cord Wire Standard.........................................................2-4

Figure 2-3: Wiring the 25-pin Remote Control Connector............................2-6

Figure 2-4: Wiring the RS-232 Computer Interface Connector....................2-7

6200 Rear Panel...........................................................................2-7

Audio Input and Output Connections.....................................2-8

Cable .....................................................................................................................2-8

Connectors............................................................................................................2-8

Analog Audio Input..............................................................................................2-8

Analog Audio Monitor Output............................................................................2-9

AES/EBU Digital Input and Output ..........................................2-10

OPTIMOD

Grounding................................................................................. 2-10

6200 Front Panel....................................................................... 2-11

Installation of Studio Level Controller (optional).................. 2-13

I-3

Power Ground....................................................................................................2-11

Circuit Ground.................................................................................................... 2-11

If you are using Orban 8200ST-Studio Chassis................................................2-13

Figure 2-5: 8200ST Jumper Settings (*Factory Configuration)....................2-14

Figure 2-6: 464A Jumper Settings................................................................... 2-16

If you are using Orban 464A Co-Operator.....................................................2-17

If you are using an Orban 4000 Transmission Limiter.....................................2-19

Figure 2-7: 4000 Jumper Locations................................................................2-19

Figure 2-8: 4000 HF Limiter Jumpers............................................................... 2-20

Figure 2-9: 4000 Pre-Emphasis Jumper..........................................................2-20

Figure 2-10: 4000 Pre-Emphasis Jumper........................................................2-21

Figure 2-11: 4000 Stereo Coupling Jumper..................................................2-21

System Setup............................................................................. 2-23

Analog I/O Setup ..................................................................... 2-24

Digital I/O Setup ....................................................................... 2-30

Security and Pascode Programming.................................... 2-35

Remote Control Interface Programming.............................. 2-36

6200 Front Panel......................................................................... 3-2

Introduction to Processing ........................................................ 3-3

Some Audio Processing Concepts.................................................................... 3-3

Distortion in Processing........................................................................................ 3-3

Loudness and Distortion......................................................................................3-4

OPTIMOD-DAB — from Bach to rock................................................................. 3-4

Customizing the 6200’s Sound.................................................. 3-5

Less-More ..............................................................................................................3-5

Full Control ............................................................................................................3-6

Fundamental Requirements: High-Quality Source Material

and Accurate Monitoring ............................................................................... 3-6

ORBAN Model 6200

About the Processing Structures...............................................3-6

Factory Programming Presets ...................................................3-7

Factory Programming Presets.............................................................................3-7

Table 3-1: Factory Programming Presets (Radio)..........................................3-9

Table 3-2: Factory Programming Presets (Television)..................................3-11

The Protection Limiter Structure ..............................................3-13

Setting Up the Protection Limiter......................................................................3-13

Protection Limiting: Orban’s Approach..........................................................3-14

Equalization Controls................................................................3-16

Table 3-3: Multi-Band Equalization Controls .................................................3-16

The Two-Band Structure ...........................................................3-20

Setting Up the Two-Band Structure..................................................................3-20

Gain Reduction Metering .................................................................................3-21

Using the Two-Band Structure for Classical Music .........................................3-21

The Two-Band Structure’s Full Setup Controls.................................................3-22

Table 3-4: Two-Band Controls.........................................................................3-22

The Multi-Band Structure ..........................................................3-26

Putting the Multi-Band Structure on the Air ....................................................3-27

Customizing the Settings ...................................................................................3-27

The Multi-Band Structure’s Full Setup Controls ...............................................3-28

Table 3-5: Multi-Band Controls .......................................................................3-28

Test Modes.................................................................................3-35

Table 3-6: Test Modes......................................................................................3-35

Using the 6200 for Mastering....................................................3-35

Limitations in Mastering Applications ..............................................................3-37

Routine Maintenance ................................................................4-2

Getting Inside the Chassis..........................................................4-2

Field Audit of Performance .......................................................4-8

OPTIMOD

Problems and Possible Causes................................................. 5-2

RFI, Hum, Clicks, Or Buzzes.................................................................................. 5-2

Poor Peak Modulation Control ..........................................................................5-2

Audible Distortion On-Air..................................................................................... 5-2

Audible Noise On-Air...........................................................................................5-3

Shrill, Harsh Sound ................................................................................................ 5-3

System Receiving 6200’s Output Will Not Lock................................................5-4

System Will Not Pass Line-Up Tones at 100% Modulation................................5-4

System Will Not Pass Emergency Alert System (“EAS” USA Standard)

Tones at the Legally-Required Modulation Level ........................................5-4

General Dissatisfaction with Subjective Sound Quality..................................5-4

Excessively Loud Commercials (DTV applications).........................................5-4

Inconsistent Levels (DTV applications).............................................................5-5

Incorrect Lip Sync (DTV Applications)............................................................... 5-5

I-5

Troubleshooting IC Opamps..................................................... 5-5

Technical Support ...................................................................... 5-6

Factory Service........................................................................... 5-6

Shipping Instructions .................................................................. 5-7

Specifications ............................................................................. 6-2

Circuit Description...................................................................... 6-6

Overview...............................................................................................................6-6

12.288MHz Oscillator and System Clocking ..................................................... 6-6

1 Microprocessor and Power Monitoring Circuit ................................... 6-8

2 RAM, ROM and EEPROM........................................................................6-9

3 Data Latches, Tri-State Data Buffers and Address Decoders........... 6-9

User Control Interface and LED Display Circuits..............................................6-9

1. Remote and RS-232 Interfaces............................................................6-10

2. Switch Matrix and LED Indicators ........................................................6-10

3. LED Meter Circuits..................................................................................6-10

ORBAN Model 6200

Input Circuits .......................................................................................................6-11

1. Analog Input Stages..............................................................................6-11

2. Stereo Analog-to-Digital (A/D) Converter..........................................6-12

3. Digital Input Receiver and Sample Rate Converter (SRC)..............6-12

4. Digital Sync Input Receiver...................................................................6-13

Output Circuits....................................................................................................6-14

1. Stereo Digital-to-Analog (D/A) Converter..........................................6-14

2. Analog Output Stages ..........................................................................6-15

3. Digital Sample Rate Converter (SRC) and Output Transmitter .......6-16

DSP Circuits..........................................................................................................6-17

Power Supply ......................................................................................................6-18

Parts List ......................................................................................6-20

Obtaining Spare Parts........................................................................................6-21

Vendor Codes ...........................................................................6-29

Schematics, Assembly Drawings.............................................6-30

Abbreviations ............................................................................6-50

OPTIMOD

INDEX

I-7

6

6200 OPTIMOD-DAB 1-2

6200S 1-2

A

abbreviations 6-49

AC Line Cord Wire Standard

2-4

AES/EBU I/O 2-10, 2-34

AGC

defeating 3-22, 3-28

meter 2-12, 3-2

AGC bass coupling 3-23, 29

AGC drive 3-28, 3-22

AGC on/off 3-22, 3-28

AGC release 3-23, 29

analog input 2-8

calibration 2-26

clip level 2-24

impedance 2-2

reference 2-26

analog i/o 1-6

setup 2-24

analog landline 1-9

analog monitor out 2-9

analog output 2-9, 6-3

source 2-28

assembly drawings 6-29

audio

analog input 2-8, 6-2

analog output 2-9, 6-3

bandwidth 1-12

connections 2-8

digital I/O 2-10, 6-3, 4

audio processing 3-3, 6

B

balance control 3-19

balanced

inputs 2-9

output transformer 2-9

band 2 to 1 coupling 3-32

band 3 to 4 coupling 3-32

band 4 to 5 coupling 3-33

band 5 threshold 3-33

bandwidth 2-23

bass

balance 3-24

clip control 3-25, 29

coupling 3-23, 24, 29

equalization 3-16

buttons

escape 2-12, 3-2

modify 2-11, 3-2

next 2-11, 3-2

previous 2-11, 3-2

recall 2-11, 3-2

setup 2-11, 2-23, 3-2

soft keys 2-11

buzzes 5-2

bypass

locally 1-15

PC remote 1-16

remote interface 1-15

C

cable 2-8

shielding 2-8

chassis

getting inside 4-2

circuit description 6-6

circuit ground 2-11

clicks 5-2

clipping 3-3

common mode rejection 2-9

compression 3-3

computer interface 2-6

connectors 2-8

contrast 2-11, 3-2

control knob 2-11, 3-2

controls

2B DRIVE 3-23

2B REL 3-23

AGC B CPL 3-23, 29

AGC DRIVE 3-22, 28

AGC ON/OFF 3-22, 3-28

AGC REL 3-23, 29

analog input clip 2-24

analog in reference 2-26

analog output source 2-28

band 2 to 1 coupling 3-32

band 3 to 4 coupling 3-32

band 4 to 5 coupling 3-33

band 5 threshold 3-33

BASS CLIP 3-25, 29

BASS CPL 3-24

contrast 2-11, 3-2

DI MODE 2-30

digital in reference 2-30

digital output 2-32

digital output rate 2-33

dither 2-34

DJ BASS 3-17, 30

DO RATE 2-33

DO SYNC 2-33

DWNEXP THR 3-33

eq 3-16

FINAL LIMT 3-25, 34

full control 3-6

GATE THR 3-23, 30

HF FREQ 3-19

HF GAIN 3-18

HF WIDTH 3-19

high frequency 3-18

input selector 2-24

LC THRESH 3-26

Less-More 3-5

LO PASS 3-19

LOW BASS 3-16

MAX LPF 2-23

MB DRIVE 3-30

MB REL 3-31

MF FREQ 3-18

MF GAIN 3-18

MF WIDTH 3-18

MID BASS 3-18

midrange eq 3-18

MODEM INIT 2-37

I-8

ORBAN Model 6200

MONO/ST 2-24

Multi-Band OUT 3-19

multi-band structure 3-28

R CH BAL 2-28, 32

soft keys 3-2

STAT BITS 2-34

SYNC DELAY 2-33

two-band 3-22

user bits 2-32

word length 2-33

D

decoder headroom 1-22

digital I/O 1-6, 2-10

level 2-32

setup 2-30

sync 2-33

digital input

calibration 2-30

mode 2-30

pre-emphasis 2-30

reference 2-30

sync 6-4

digital links 1-7

digital output

not locking 5-4

display board

reattaching 4-6, 4-7

removing 4-3, 4

distortion 5-2

dither 2-34

DJ bass boost 3-17, 30

downward expansion

threshold 3-33

DTV 1-16, 1-18, 5-4, 5-5

two-channel 1-20

5.1 applications 1-20

multiband compress 1-19

E

EAS test tones 1-15

not passing 5-4

enabling analog input 2-24

enabling digital input 2-30

environmental specs 6-5

eq controls 3-16

escape button 2-12, 3-2

exit test 2-36

F

factory presets 1-5, 3-7

radio 3-9

tv 3-11

factory service 5-6

field audit 4-8

final limiter control 3-25, 34

front panel 2-11, 3-2

full control 3-6

fuse 2-4

G

gain reduction

meters 2-12, 3-2

metering 3-21

gate LED 2-12, 3-2

GATE THR control 3-23, 30

getting inside the unit 4-2

grounding 2-5, 7, 10, 11

ground loops 2-10

H

harshness 5-3

headphones 1-14

HF Freq control 3-19

HF Gain control 3-18

HF parametric eq 3-18

HF Width control 3-19

hum 5-2

I

impedance 2-2

inconsistent levels 5-5

input

analog 2-8

balanced 2-9

impedance 2-2

meters 2-12, 3-2

overload point 2-9

reference level 2-26, 30

termination 2-2

unbalanced 2-9

inspection 2-2

installation 2-1

464A Co-Operator 2-17

8200ST 2-13

Orban 4000 Limiter 2-19

studio controller 2-13

internal clock 2-33

introduction 1-1

J

jumper settings 2-3

input termination 2-2

L

LEDs

gate 2-12, 3-2

Less-More control 3-5

limiter meter 2-12, 3-3

limiting 3-3

line voltage 2-4

line-up tones at 100%

modulation

not passing 5-4

lip sync problems 5-5

Lo Pass control 3-19

location 1-10

look-ahead limiting 3-3

lossy data reduction 1-11

loud commercials 5-4

loudness controller

bypassing 1-20

threshold 3-26

loudness vs. distortion 3-4

low bass control 3-16

M

main board

reattaching 4-6

removing 4-4

mastering applications 3-35

mastering presets 3-36

MB DRIVE control 3-30

OPTIMOD

I-9

meters

AGC 2-12, 3-2

gain reduciton 2-12, 3-2

input 2-12, 3-2

limiter 2-12, 3-3

ppm 2-27

vu 2-27

MF Freq control 3-18

MF Gain control 3-18

MF Width control 3-18

mid bass control 3-18

midrange parametric eq 3-18

modem initialization

setting 2-37

modify button 2-11, 3-2

modulation

switching 1-13

monitoring 1-14

analog 2-9

mono 2-24

MP3 1-22

multi-band structure 3-26

controls 3-28

customizing settings 3-27

output mix 3-19

release control 3-31

setup 3-27

N

next button 2-11, 3-2

NICAM 1-8

noise 5-3

non-streamng applications 1-

21

O

output

analog 2-9

balanced 2-9

not locking 5-4

P

packing list 2-2

PAD 1-13

parts list 6-20

passcode programming 2-35

PC control 1-16

peak modulation

cannot control 5-2

power

ground 2-11

power specificiations 6-5

power supply

circuit description 6-19

power supply board

reattaching 4-5

removing 4-5

ppm meter 2-27

prep files for download 1-21

presets

factory 1-5, 3-7

user presets 1-5

previous button 2-11, 3-2

problems 5-2

processing structures

protection 3-9, 13

two-band 3-9, 11, 20

multi-band 3-26

program associated data 1-

13

protection structure 3-9, 13

setup 3-13

R

radio presets 3-9

rackmounting unit 2-5

rear panel 2-7

recall button 2-11, 3-2

remote control 2-6

bypass 1-15

programming 2-36

remote interface 2-6, 6-4

programming 2-36

RFI 2-10, 5-2

right channel bal 2-28, 32

routine maintenance 4-2

RS-232 connector 2-6

S

sample rate 1-12, 2-33

schematics 6-29

screen display 2-11, 3-2

security 1-16, 2-35

setup

button 2-11, 2-23, 3-2

system 2-23

shipping

container 2-2

damage 2-2

intructions 5-7

shrillness 5-3

soft keys 2-11, 3-2

sound custimization 3-5

source material 3-6

spare parts

obtaining 6-21

SPDIF 2-34

specifications 6-2

ST CHASSIS mode 2-23

status bits 2-34

stereo 2-24

STL systems 1-7, 8, 11

streaming media 1-21

studio level controller

installation 2-13

subframe delay 1-13

sync delay 2-33

sync input 1-12

system setup 2-23

T

technical data 6-1

technical support 5-6

temperature 2-5

test tones 3-35

exiting 2-36

frequencies 2-33

modes 3-35

threshold

band five 3-33

downward expansion 3-

33

top cover

reattaching 4-7

removing 4-2

troubleshooting

IC opamps 5-5

I-10

ORBAN Model 6200

tv presets 3-11

two-band structure 3-9, 11,

3-20

controls 3-22

drive control 3-23

release control 3-23

setup 3-20

U

unbalanced

inputs 2-9

unpacking 2-2

user feedback 1-23

user presets 1-5

V

vendor codes 6-28

voltage selector 2-4

vu meter 2-27

W

warranty 1-22, 6-5

webcast applications 1-21

encoder 1-22

word length 2-33

X

XLR connectors 2-8

OPTIMOD INTRODUCTION

Section 1 Introduction

Reading this Manual.................................................................. 1-2

6200 OPTIMOD-DAB Digital Audio Processor.......................... 1-2

Presets in OPTIMOD-DAB ........................................................... 1-5

Input/Output Configuration ..................................................... 1-6

Studio-Transmitter Link................................................................ 1-7

1-1

Location of OPTIMOD-DAB..................................................... 1-10

Using Lossy Data Reduction in the Studio............................. 1-11

Interfacing to the Transmitter ................................................. 1-12

Setting Modulation Levels....................................................... 1-13

Monitoring on Loudspeakers and Headphones.................. 1-14

EAS Test...................................................................................... 1-15

Security Pascode for PC Control............................................ 1-16

DTV Applications...................................................................... 1-16

Webcasting Applications........................................................ 1-21

W arranty, Feedback................................................................ 1-23

1-2

INTRODUCTION ORBAN Model 6200

Reading this Manual

This manual supports both 6200 OPTIMOD-DAB and 6200S OPTIMOD digital audio

processors. In general, when text refers to 6200 OPTIMOD-DAB, the information also

applies to 6200S. Whenever there is a difference, it is noted. At the time of this writing,

6200S differs from 6200 in size and a few specifications (noted in Section 6), and has no

rear panel remote control interface connector.

6200 OPTIMOD-DAB Digital Audio Processor

Orban’s all-digital 6200 OPTIMOD-DAB Audio Processor can help you achieve the

highest possible quality digital audio broadcast processing. Because all processing is

performed by high-speed mathematical calculations within Motorola DSP56009 Digital

Signal Processing chips, the processing has cleanliness, quality, and stability over time

and temperature that is unmatched by analog processors.

OPTIMOD-DAB is descended from the industry-standard OPTIMOD audio processors

for radio and television. Thousands of these broadcast-specific processors are on the air

all over the world. They have proven that the “OPTIMOD sound” can attract and keep an

audience even in the most competitive commercial environment.

Because OPTIMOD-DAB incorporates several audio processing innovations exclusive to Orban products, you should not assume that it can be operated in the same

way as less sophisticated processors. If you do, you may get disappointing results.

Take a little time now to familiarize yourself with OPTIMOD-DAB. A small investment

of your time now will yield large dividends in audio quality.

The rest of Chapter 1 explains how OPTIMOD-DAB fits into the DAB and DTV broadcast plants, or can be used for webcasting. Chapter 2 explains how to install it. Chapter 3

tells how to properly operate OPTIMOD-DAB. Chapter 4 through Chapter 6 provides

reference information.

OPTIMOD-DAB was designed to deliver a high quality sound while simultaneously increasing the average modulation of the channel substantially beyond that achievable by

“recording studio”-style compressors and limiters. Because such processing can exaggerate flaws in the source material, it is very important that the source audio be as clean

as possible.

For best results, feed OPTIMOD-DAB unprocessed audio. No other audio processing

is necessary or desirable.

If you wish to place level protection prior to your studio/transmitter link (STL), use the

Orban 8200ST OPTIMOD-Studio Compressor/Limiter/HF Limiter/Clipper. The 8200ST

OPTIMOD INTRODUCTION

can be adjusted so that it substitutes for the broadband AGC circuitry in OPTIMODDAB, which is then defeated.

User-Friendly Interface

• A liquid crystal display (LCD) makes setup, adjustment and programming of

OPTIMOD-DAB easy. Dynamically labeled soft keys provide a context-sensitive interface. Dedicated LEDs show all metering functions of the processing structure in

use.

• Push one of the dedicated buttons to “Recall” a preset, to “Modify” processing, or to

access the system’s Setup controls.

Flexible Configuration

• OPTIMOD-DAB precisely controls peak levels to prevent overmodulation. The

maximum level of the digital samples is controlled to better than 1%.

• The OPTIMOD-DAB Audio Processor is supplied with analog and AES/EBU digi-

tal inputs and outputs. Both digital input and digital output are equipped with sam-

ple-rate converters and can operate at 32kHz, 44.1kHz, and 48kHz sample rates.

1-3

• The analog inputs are transformerless, balanced 10kΩ instrumentation-amplifier cir-

cuits, and the analog monitor outputs are transformerless balanced, and floating with

30Ω impedance to ensure highest transparency and accurate pulse response.

• All input, output, and power connections are rigorously RFI-suppressed to Orban’s

traditional exacting standards, ensuring trouble-free installation.

• OPTIMOD-DAB controls the audio bandwidth as necessary to accommodate the

transmitted sample frequency. OPTIMOD-DAB’s high frequency bandwidth can be

switched instantly (typically in 500Hz increments) between 4.0kHz and 20kHz.

20kHz is used for highest-quality systems. 15kHz meets the requirements of the proposed AM IBOC systems that use 32kHz sample frequency. 10kHz bandwidth meets

the requirements of auxiliary Eureka-147 transmissions using a 24kHz sample frequency. Lower audio bandwidths meet the requirements of auxiliary speech grade

services and the proposed digital shortwave systems.

• OPTIMOD-DAB is equipped with a second serial port to interface to a DAB trans-

mitter. This serial port is intended to support PAD (Program-Associated Data)

services. (This support is not available with Firmware Version 2.0 or lower.)

• OPTIMOD-DAB Audio Processor is designed to meet all applicable international

safety standards.

1-4

INTRODUCTION ORBAN Model 6200

Adaptability through Multiple Audio Processing Structures

• A processing structure is a program that operates as a complete audio processing

system. Only one processing structure can be active at a time. Just as there are many

possible ways of configuring a processing system using analog components (such as

equalizers, compressors, limiters, and clippers), there are many possible processing

structures achie vable by OPTIMOD-DAB. OPTIMOD-DAB realizes it s processing

structures as a series of high-speed mathematical computations made by Digital Signal Processing (DSP) chips.

• OPTIMOD-DAB features three processing structures: Five-Band (or Multi-Band)

for a consistent, “processed” sound, free from undesirable side effects; Two-Band

for a tastefully controlled sound that preserves the frequency balance of the original

program material; and Protect, which provides up to 25dB of safety limiting with

minimal side effects.

• OPTIMOD-DAB can increase the density and loudness of the program material by

multi-band compression and look-ahead limiting — improving the consistency of

the station’s sound and increasing loudness and definition remarkably, without producing unpleasant side effects.

• OPTIMOD-DAB rides gain over an adjustable range of up to 25dB, compressing

dynamic range and compensating for operator gain-riding errors and for gain inconsistencies in automated systems.

• OPTIMOD-DAB’s processing structures are all phase-linear to maximize audible

transparency.

• OPTIMOD-DAB can be changed from one processing structure to another with a

smooth cross-fade.

• OPTIMOD-DAB’s Two-Band structure includes the CBS Loudness Controller for

DTV applications. This system measures subjective loudness (as perceived by an average listener) and then closes a feedback loop to limit loudness to a preset level. It

effectively controls loud commercials, which are the primary irritant in broadcast

television audio.

Controllable

• All compression, limiting, and clipping can be defeated by remote control to permit

broadcast system test and alignment or “proof of performance” tests.

• Both 6200 and 6200S can be remote-controlled by an external computer running

Orban remote software (included) and connected directly or via modem to one of

OPTIMOD’s RS-232 serial ports. 6200 OPTIMOD-DAB (and not Model 6200S) can

also be remote-controlled by 5-12V pulses applied to eight programmable, optically

isolated ports.

OPTIMOD INTRODUCTION

• OPTIMOD-DAB Audio Processor contains a built-in line-up tone generator, facili-

tating quick and accurate level setting in any system.

Presets in OPTIMOD-DAB

There are two distinct kinds of presets in OPTIMOD-DAB: Factory Processing Presets

and User Presets.

Factory Processing Presets

There are 36 Factory Processing Presets — 26 for radio and 10 for television. These are

our “factory recommended settings” for various program formats or types. The description indicates the processing structure and the type of processing. Each Factory Processing Preset on the Recall Preset list is really a library of 20 separate presets, selected by

pressing the

for more or less processing.

Factory Processing Presets are stored in OPTIMOD-DAB’s non-volatile memory and

cannot be erased. You can change the settings of a Factory Processing Preset, but you

must then store those settings as a User Preset, which you are free to name as you wish.

The Factory Preset remains unchanged.

Modify

button and using the

LESS-MORE

control to adjus t OPTI M OD-DAB

1-5

User Presets

User Presets permit you to change a Factory Processing Preset to suit your requirements,

and store those changes.

You may store up to 32 User Presets. They are indicated on the Recall Preset list by a

number designation from 01 to 32, followed by a description.

You may enter in any description you wish, up to 16 characters. User Presets cannot be

created from “scratch.” Start by recalling a Factory Preset. You can then immediately

store this in a User Preset, give it whatever name you wish, then make changes to the

settings. Or you can recall a Factory Preset, make the changes first, and then store this in

a User Preset.

Either way, the Factory Preset remains for you to return to if you wish.

User Presets are backed up in EEPROM, which is a form of rewritable memory that does not require battery backup. So your presets are safer than they

would be if the memory required battery backup.

You can also modify an existing User Preset.

1-6

INTRODUCTION ORBAN Model 6200

Input/Output Configuration

OPTIMOD-DAB is designed to simultaneously accommodate:

•

Digital AES/EBU left/right inputs and outputs.

• Analog left/right inputs and outputs.

Digital AES/EBU Left/Right Input/Output

The digital input and output follow the professional AES/EBU standard. They are both

equipped with sample rate converters to allow operation at 32, 44.1, and 48kHz sample

frequency.

To ensure best control of peak modulation, operate the output at 48kHz. This

guarantees that the output samples are synchronous with the peak-controlled

samples produced by the processing.

The left/right digital input is on one XLR-type female connector on the rear panel; the

left/right digital output is on one XLR-type male connector on the rear panel. A second

digital input is available to genlock the 6200’s output sample frequency to house sync, if

required.

OPTIMOD-DAB is designed to simultaneously accommodate digital and analog inputs

and outputs. You select whether OPTIMOD-DAB uses the digital or analog input on the

System Setup I/O Calib screen or by remote interface. Both analog and digital outputs

are active continuously.

Level control of the AES/EBU input is via software control through System Setup.

Analog Left/Right Input/Output

The left and right analog inputs are on XLR-type female connectors on the rear panel.

Input impedance is greater than 10kΩ; balanced and floating. Inputs can accommodate

up to +27dBu (0dBu = 0.775Vrms).

The left and right analog outputs are on XLR-type male connectors on the rear panel.

Output impedance is 30Ω; balanced and floating.

The outputs are intended for monitoring. Their output level is fixed at +14dBu full scale.

They can drive 600Ω or higher impedances.

Level control of the analog inputs is via software control through System Setup. (See

step 2 on page 2-24 and step 3 on page 2-26.)

OPTIMOD INTRODUCTION

Studio-Transmitter Link

Transmission from Studio to Transmitter

1-7

There are five types of studio-transmitter links (STLs) in common use in broadcast service: uncompressed digital, digital with lossy compression (like MPEG, Dolby

®

x

), microwave, analog landline (telephone/post line), and audio subcarrier on a video

microwave STL.

STLs are used in two fundamentally different ways. They can either pass unprocessed

audio for application to the 6200’s input, or they can pass the 6200’s peak-controlled

output. The two applications have fundamentally different performance requirements. In

general, a link that passes unprocessed audio should have very low noise and low nonlinear distortion, but its transient response is not important. A link that passes processed

audio doesn’t need as low a noise floor as a link passing unprocessed audio. However, its

transient response is critical. In DAB applications such a link must be uncompressed

digital and must use digital inputs and outputs to achieve best results. We will elaborate

below.

Digital links

Digital links may pass audio as straightforward PCM encoding, or they may apply lossy

data reduction processing to the signal to reduce the number of bits per second required

for transmission through the digital link. Such processing will almost invariably distort

peak levels, and such links must therefore be carefully qualified before you use them to

carry the peak-controlled output of the 6200 to the transmitter. For example, the MPEG

Layer 2 algorithm can increase peak levels up to 4dB at 160kB/sec by adding large

amounts of quantization noise to the signal. While the desired program material may

psychoacoustically mask this noise, it is nevertheless large enough to affect peak levels

severely. For any lossy compression system the higher the data rate, the less the peak

levels will be corrupted by added noise, so use the highest data rate practical in your system.

®

, or APT-

It is practical (though not ideal) to use lossy data reduction to pass unprocessed audio to

the 6200’s input. The data rate should be at least of “contribution quality” — the higher,

the better. If any part of the studio chain is analog, we recommend using at least 20-bit

A/D conversion before encoding.

Because the 6200 uses multi-band limiting it can dynamically change the frequency response of the channel. This can violate the psychoacoustic masking assumptions made in

designing the lossy data reduction algorithm. Therefore, you need to leave “headroom”

in the algorithm so that the 6200’s multi-band processing will not unmask quantization

noise. This is also true of any lossy data reduction applied in the studio (such as hard

disk digital delivery systems).

For MPEG Layer 2 encoding, we recommend 384kB/second or higher.

Some links may use straightforward PCM (pulse-code modulation) without lossy data

reduction. If you connect to these through an AES/EBU digital interface, these can be

1-8

INTRODUCTION ORBAN Model 6200

very transparent provided they do not truncate the digital words produced by the devices

driving their inputs and they do not require downward sample rate conversion.

Downward sample rate conversion can cause overshoot due to spectral truncation and asynchronous re-sampling of the 48kHz peak-controlled samples.

If the link does not have an AES/EBU input, you must drive its analog input from the

6200’s monitor output. This is not recommended because the 6200’s monitor output will

overshoot in the analog domain because of the physics of the system.

Peak control in the 6200 occurs at a 48kHz sample frequency. This is sufficient to prevent any samples from exceedin g the thresho ld of limiting . However, after reconstruction, the analog output may overshoot the nominal

100% level because these overshoots “fall between the samples,” so the

processing cannot be aware of them. If you use this output to feed the analog

input of a digital STL, the new samples in the STL will not be synchronous

with the samples inside the 6200. Therefore, they may well fall on the overshoots, causing loss of peak modulation control. It is therefore very important to use a link with an AES/EBU input to ensure correct peak control.

The same sort of thing can happen if you use the output sample rate converter, because the output samples are no longer synchronous with the peakcontrolled samples in the processing. Always use 48kHz output sample rate

to achieve best peak control.

If you

digital links driven by the 6200 because the 6200’s output spectrum is

tightly controlled. This ensures the most accurate possible transient response,

given the limitations of asynchronous sampling described above.

NICAM is a sort of hybrid between PCM and lossy data reduction systems. It uses a

block-companded floating-point representation of the signal with J.17 pre-emphasis.

Older technology converters (including some older NICAM encoders) may exhibit quantization distortion unless they have been correctly dithered. Additionally, they can exhibit rapid changes in group delay around cut-off because their analog filters are ordinarily not group-delay equalized. The installing engineer should be aware of all of these

potential problems when designing a transmission system.

Any problems can be minimized by always driving a digital STL with the 6200’s

AES/EBU digital output, which will provide the most accurate interface to the STL. The

digital input and output accommodate sample rates of 32kHz, 44.1kHz, and 48kHz.

Microwave STLs

In general, an analog microwave STL provides high audio quality, as long as there is a

line-of-sight transmission path from studio to transmitter of less than 10 miles (16 km).

If not, RF signal-to-noise ratio, multipath distortion, and diffraction effects can cause

serious quality problems. However, the noise and non-linear distortion characteristics of

such links are likely to be notably poorer than 16-bit digital even if propagation conditions are ideal.

use an analog input, you may bypass any anti-aliasing filters in

must

OPTIMOD INTRODUCTION

As discussed above, asynchronous sampling problems will cause overshoots if any ana-

log path (even a perfectly transparent one) passes the 6200’s processed output to the

transmitter. Lack of transparency in the analog path will cause even more overshoot.

Unless carefully designed, microwave STLs can introduce non-constant group delay in

the audio spectrum, distorting peak levels when used to pass processed audio. Nevertheless, in a system using a microwave STL the 6200 is sometimes located at the studio and

any overshoots induced by the link are tolerated or removed by the transmitter’s protection limiter (if any). The 6200 can only be located at the transmitter if the signal-to-noise

ratio of the STL is good enough to pass unprocessed audio. The signal-to-noise ratio of

the STL can be used optimally if an Orban 8200ST Compressor/Limiter/HF Limiter/Clipper or an Orban Transmission Limiter protects the link from overload.

If the 6200 is located at the transmitter and fed unprocessed audio from a microwave

STL, it may be useful to use a companding-type noise reduction system (like dbx Type 2

or Dolby SR) around the link. This will minimize any audible noise buildup caused by

compression within the 6200.

Some microwave links may be modified such that the deviation from linear phase is less

than +

10° 20-20kHz, and frequency response is less than 3dB down at 0.15Hz and less

than 0.1dB down at 20kHz This specification results in less than 1% overshoot with

processed audio. Many such links have been designed to be easily configured at the factory for composite operation, where an entire FM stereo baseband is passed. The requirements for maintaining stereo separation in composite operation are similar to the

requirements for high waveform fidelity with low overshoot. Therefore, most links have

the potential for excellent waveform fidelity if they are configured for composite operation (even if a composite FM stereo signal is not actually being applied to the link).

1-9

Further, it is not unusual for a microwave STL to bounce because of a large infrasonic

peak in its frequency response caused by an under-damped automatic frequency control

(AFC) phase-locked loop. This bounce can increase the STL’s peak carrier deviation by

as much as 2dB, reducing average modulation. Many commercial STLs have this problem.

Some consultants presently offer modifications to minimize or eliminate this problem. If

your exciter or STL has this problem, you may contact Orban Customer Service for the

latest information on such services.

Analog landline (PTT/post office line)

Analog landline quality is extremely variable, ranging from excellent to poor. Whether

landlines should be used or not depends upon the quality of the lines locally available,

and upon the availability of other alternatives. Even the best landlines tend to slightly

veil audio quality, due to line equalizer characteristics and phase shifts. They will certainly be the weakest link in a DAB broadcast chain.

Slight frequency response irregularities and non-constant group delay characteristics will

alter the peak-to-average ratio, and will thus reduce the effectiveness of any peak limiting performed prior to their inputs.

1-10

INTRODUCTION ORBAN Model 6200

Location of OPTIMOD-DAB

At the Transmitter is Best

The best location for OPTIMOD-DAB is as close as possible to the transmitter so that

OPTIMOD-DAB’s AES/EBU output can be connected to the transmitter through a circuit path that introduces no change in OPTIMOD-DAB’s output bitstream. A highquality AES/EBU cable is ideal.

Where Access to the Transmitter Plant is Not Possible

Sometimes it is not possible to locate OPTIMOD-DAB at the transmitter. Instead, it

must be located on the studio side of the link connecting the audio plant to the transmitter. If the transmitter plant is not accessible, all audio processing must be done at the

studio, and you must tolerate any damage that occurs later.

If an uncompressed digital link is available, this is an ideal situation because such a link

will pass OPTIMOD-DAB’s output with little or no degradation. However, such a link is

not always available.

If only a 32kHz sample rate link is available, the sample rate conversion

necessary to downsample the audio will cause overshoots when the 6200 is

operated at 20kHz bandwidth because the sample rate converter removes

spectral energy. In this case you can minimize overshoot by operating the

6200 at 15kHz bandwidth.

Unless the path is a digital path using no lossy compression, this situation will yield

lower performance than if OPTIMOD-DAB is connected directly to the transmitter, because artifacts that cannot be controlled by OPTIMOD-DAB will be introduced by the

link to the transmitter. These artifacts can result in 2-4dB lower average modulation

level, and can also add noise and audible non-linear distortion. In the case of lossy digital compression this deterioration will be directly related to the bit rate. In the case of an

analog path, the deterioration will depend on the amount of linear and non-linear distortion in the path. In addition, there will be an unavoidable amount of overshoot caused by

asynchronous re-sampling (see page 1-8).

One strategy is to apply the same lossy compression to OPTIMOD-DAB’s output signal

that the DAB transmitter would apply. If a digital link is available with sufficient bit rate

to pass this compressed signal, it can then be passed directly to the DAB transmitter

without further processing if synchronization issues can be resolved. Consult with the

manufacturer of your DAB transmitter to see if this can be done.

Where only an analog or lossy digital link is available, feed the audio output of

OPTIMOD-DAB directly into the link. If available, the transmitter’s protection limiter

should be adjusted so that audio is normally just below the threshold of limiting: The

transmitter protection limiter should respond only to signals caused by faults or by spurious peaks introduced by imperfections in the link.

OPTIMOD INTRODUCTION

Where maximum quality is desired, it is wise to request that all equipment in the signal

path after the studio be carefully measured and aligned and qualified to meet the appropriate standards for bandwidth, distortion group delay and gain stability. Such equipment

should be measured at reasonable intervals.

OPTIMOD-DAB at the Transmitter:

Gain Control before the STL

The audio received at OPTIMOD-DAB’s input should have the highest possible quality.

To achieve the full audible benefit of OPTIMOD-DAB processing, use a studiotransmitter link (STL) that is as flat as the bandwidth of OPTIMOD-DAB as used in

your plant (usually 20kHz). Ideally, you should use a 20-bit (or better) uncompressed

digital link with at least 44.1kHz sample frequency.

Because the audio processor controls peaks, it is not important that the audio link feeding OPTIMOD-DAB’s input terminals be phase-linear. However, the link should have

low noise, the flattest possible frequency response from 20-20,000Hz, and low nonlinear distortion.

If the audio link between the studio and the transmitter is noisy (or, if digital, is limited

to 16 bits or less), performing the AGC function at the studio site can minimize the audibility of this noise. AGC applied before the audio link improves the signal-to-noise ratio

because the average level on the link will be greater. Further, many STLs require level

control to prevent the STL from being overloaded.

1-11

To apply such level control and compression, we recommend the Orban Model 8200ST

Compressor/Limiter/HF Limiter/Clipper before the STL transmitter. The 8200ST performs the function of OPTIMOD-DAB’s internal broadband automatic gain control

(AGC), while simultaneously protecting the STL. If this is done, defeat OPTIMODDAB’s broadband AGC by accessing the

and setting it to

In DTV applications, the AGC function in Two-Band presets is normally off. We do not

recommend using additional AGC ahead of the STL in this application. Instead, either

align STL operating levels to allow sufficient headroom to pass unprocessed audio, or

use an Orban Transmission Limiter (which is ordinarily operated below threshold) to

protect the link from operator error.

yes

.

ST CHASSIS

function within the Setup menu

Using Lossy Data Reduction in the Studio

Many stations are now using lossy data reduction algorithms like MPEG-1 Layer 2 or

Dolby AC2 to increase the storage time of digital playback media. In addition, source

material is often supplied through a lossy data reduction algorithm, whether from satellite or over landlines.

1-12

INTRODUCTION ORBAN Model 6200

Sometimes, several encode/decode cycles will be cascaded before the material is finally

presented to OPTIMOD-DAB’s input.

All such algorithms operate by increasing the quantization noise in discrete frequency

bands. If not psychoacoustically masked by the program material, this noise may be perceived as distortion, “gurgling,” or other interference. Psychoacoustic calculations are

used to ensure that the added noise is masked by the desired program material and not

heard. Cascading several stages of such processing can raise the added quantization

noise above the threshold of masking, such that it is heard. In addition, there is at least

one other mechanism that can cause the noise to become audible at the radio.

OPTIMOD-DAB’s multi-band limiter performs an “automatic equalization” function

that can radically change the frequency balance of the program. This can cause noise that

would otherwise have been masked to become unmasked because the psychoacoustic

masking conditions under which the masking thresholds were originally computed have

changed.

Accordingly, if you use lossy data reduction in the studio, you should use the highest

data rate possible. This maximizes the headroom between the added noise and the

threshold where it will be heard. Also, you should minimize the number of encode and

decode cycles, because each cycle moves the added noise closer to the threshold where

the added noise is heard.

Interfacing to the Transmitter

Sync Input

In the Eureka-147 system several programs are combined into one “ensemble multiplex.” This requires synchronization of the sample rates applied to the transmitter. DTV

also requires synchronization. OPTIMOD-DAB provides a second AES/EBU input to

accept “house sync,” which allows OPTIMOD-DAB’s output to be synchronized to a

master sync generator. Regardless of whether its analog or digital inputs are used, its

AES/EBU output will be synchronized to the AES/EBU signal at its

cause OPTIMOD-DAB’s digital input is equipped with a sample rate converter, the

SYNC INPUT

while ensuring that OPTIMOD-DAB’s output is in sync with the master sync generator.

If there is no signal present at the SYNC input, the 6200 can still sync its output to the

signal present at the AES/EBU input.

allows an asynchronous digital input to be applied to OPTIMOD-DAB

Sample Rate and Audio Bandwidth

Most DAB audio is at a 48kHz sample rate. However, several of the proposed AM IBOC

systems operate at 32kHz, requiring 15kHz audio bandwidth. The Eureka-147 system

offers a 24kHz sample rate option, requiring 10kHz audio bandwidth. The proposed

shortwave systems require audio bandwidths as low as 4.5kHz for speech-grade services.

SYNC INPUT

. Be-

Loading...

Loading...