Page 1

Form 2267

groov EPIC

USER’S GUIDE

Page 2

Page 3

groov EPIC

USER’S GUIDE

for

GRV-EPIC-PR1

Form 2267-200618—June 2020

43044 Business Park Drive • Temecula • CA 92590-3614

Phone: 800-321-OPTO (6786) or 951-695-3000

Fax: 800-832-OPTO (6786) or 951-695-2712

www.opto22.com

Product Support Services

800-TEK-OPTO (835-6786) or 951-695-3080

Fax: 951-695-3017

Email: support@opto22.com

Web: support.opto22.com

groov EPIC User’s Guide

i

Page 4

groov EPIC User’s Guide

Form 2267-200618—June 2020

Copyright © 2018-2020 Opto 22.All rights reserved.

Printed in the United States of America.

The information in this manual has been checked carefully and is believed to be accurate; however, Opto 22 assumes no

responsibility for possible inaccuracies or omissions. Specifications are subject to change without notice.

Opto 22 warrants all of its products to be free from defects in material or workmanship for 30 months from the

manufacturing date code. This warranty is limited to the original cost of the unit only and does not cover installation, labor,

or any other contingent costs. Opto 22 I/O modules and solid-state relays with date codes of 1/96 or newer are guaranteed

for life. This lifetime warranty excludes reed relay modules, groov and SNAP serial communication modules, SNAP PID

modules, and modules that contain mechanical contacts or switches. Opto 22 does not warrant any product, components,

or parts not manufactured by Opto 22; for these items, the warranty from the original manufacturer applies. Refer to Opto

22 form 1042 for complete warranty information.

Wired+Wireless controllers and brains are licensed under one or more of the following patents: U.S. Patent No(s). 5282222,

RE37802, 6963617; Canadian Patent No. 2064975; European Patent No. 1142245; French Patent No. 1142245; British Patent

No. 1142245; Japanese Patent No. 2002535925A; German Patent No. 60011224.

Opto 22 FactoryFloor, groov, groov EPIC, groov RIO, mobile made simple, Optomux, and Pamux are registered trademarks of

Opto 22. Generation 4, groov Server, ioControl, ioDisplay, ioManager, ioProject, ioUtilities, mistic, Nvio, Nvio.net Web Portal,

OptoConnect, OptoControl, OptoDataLink, OptoDisplay, OptoEMU, OptoEMU Sensor, OptoEMU Server, OptoOPCServer,

OptoScript, OptoServer, OptoTerminal, OptoUtilities, PAC Control, PAC Display, PAC Manager, PAC Project, PAC Project Basic,

PAC Project Professional, SNAP Ethernet I/O, SNAP I/O, SNAP OEM I/O, SNAP PAC System, SNAP Simple I/O, SNAP Ultimate

I/O, and Wired+Wireless are trademarks of Opto 22.

ActiveX, JScript, Microsoft, MS-DOS, VBScript, Visual Basic, Visual C++, Windows, and Windows Vista are either registered

trademarks or trademarks of Microsoft Corporation in the United States and other countries. Linux is a registered

trademark of Linus Torvalds. ARCNET is a registered trademark of Datapoint Corporation. Modbus is a registered trademark

of Schneider Electric, licensed to the Modbus Organization, Inc. Wiegand is a registered trademark of Sensor Engineering

Corporation. Allen-Bradley, CompactLogix, ControlLogix, MicroLogix, SLC, and RSLogix are either registered trademarks or

trademarks of Rockwell Automation. CIP and EtherNet/IP are trademarks of ODVA. Raspberry Pi is a trademark of the

Raspberry Pi Foundation. The registered trademark Ignition by Inductive Automation® is owned by Inductive Automation

and is registered in the United States and may be pending or registered in other countries. CODESYS® is a registered

trademark of 3S-Smart Software Solutions GmbH.

groov includes software developed by the OpenSSL Project for use in the OpenSSL Toolkit. (http://www.openssl.org)

All other brand or product names are trademarks or registered trademarks of their respective companies or organizations.

ii

groov EPIC User’s Guide

Opto 22

Automation Made Simple.

The equipment covered by this report is considered to be a component intended to be professionally configured/installed

into another manufacturer’s end-product equipment. Also the equipment is intended to be mounted in an #IP54

enclosure according to the manual. No cleaning instruction is provided in manual. Therefore, testing and evaluation for the

requirements of these clauses is not considered necessary.

IMPORTANT INSTALLATION INSTRUCTIONS

Power, input, and output wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4

(b) of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the

Canadian Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction.

The following warning must be heeded:

Page 5

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS 1,

DIV. 2.

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE REPLACING

OR WIRING MODULES.

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN SWITCHED

OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

MVI (Multi Vendor Interface) Modules

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN SWITCHED

OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D’EXPLOSION - AVANT DE DÉCONNECTER L’ÉQUIPEMENT, COUPER LE COURANT OU

S’ASSURER QUE L’EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

WARNINGS

North America Warnings

Power, input, and output wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4

(b) of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the

Canadian Electrical Code for installation sin Canada, and in accordance with the authority having jurisdiction.

The following warnings must be heeded:

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class 1, Div. 2.

E Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring

modules.

F Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the

area is known to be non-hazardous.

Avertissement - Risque d’explosion - Avant de déconnecter l’équipment, couper le courant ou s’assurer que

l’emplacement est désigné non dangereux.

G Suitable for use in Class I, Division 2 Groups A, B, C and D Hazardous Locations or Non-Hazardous Loca-

tions.

ATEX Warnings and Conditions of Safe Usage

Power, input, and output (I/O) wiring must be in accordance with the authority having jurisdiction.

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring

modules.

E Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the

area is known to be non-hazardous.

F These products are intended to be mounted in an IP54 enclosure. The devices shall provide external

means to prevent the rated voltage being exceeded by transient disturbances of more than 40%. This

device must be used only with ATEX certified backplanes.

G DO NOT OPEN WHEN ENERGIZED.

MARKINGS

Electrical Ratings

• Power Requirements: 7.1 W typical, 9.1 W max.

• Operating Temperature: -20 °C to +70 °C

• Storage Temperature: -40 °C to +85 °C

• Relative Humidity: 5–95%

For the electrical ratings of power supplies, I/O modules, and chassis, see their respective data sheets.

Label Markings

groov EPIC User’s Guide

iii

Page 6

ATEX

II3 G Ex NA IIC T4 Gc

-20 °C ≤ Ta ≤ 70 °C

cULus

Class 1 Division 2, Groups A, B, C, D

T4

-20 °C ≤ Ta ≤ +70 °C

Agency Approvals and Certifications

Agency Applicable Standard

RoHS

CE EMC-EN61326- 1:2006; EN61000-6- 4:2007

Hazardous Locations

ATEX EN60079-15:2003; EN60079-15:2010

cULus

DFARS

ANSI/I.S.A. 12.12.01-2015, Rev. 2015-11-17; CAN/CSA C22.2

No. 213-16, 2nd Ed., Issued 2016-05-11

UL61010-1: 2010, 3rd Ed.; UL61010-201, 1st Ed.

iv

groov EPIC User’s Guide

Page 7

Table of Contents

Chapter 1: Welcome to groov EPIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

What’s in This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2: Additional Safety and Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety instructions for installing the groov EPIC unit as part of machinery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Explanation of labels or symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Service and maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Service (Product Support) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3: Assembling your groov EPIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Gathering your equipment and information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Familiarize yourself with the Processor and groov I/O modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

groov I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Verifying serial number on the processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Activating the groov EPIC unit and downloading the license file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Assembling your unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connecting power supply wires and field device wires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting field devices to the groov I/O modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting power supply wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting the Ethernet cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Turn on unit and continue with initializing the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 4: Initializing the groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

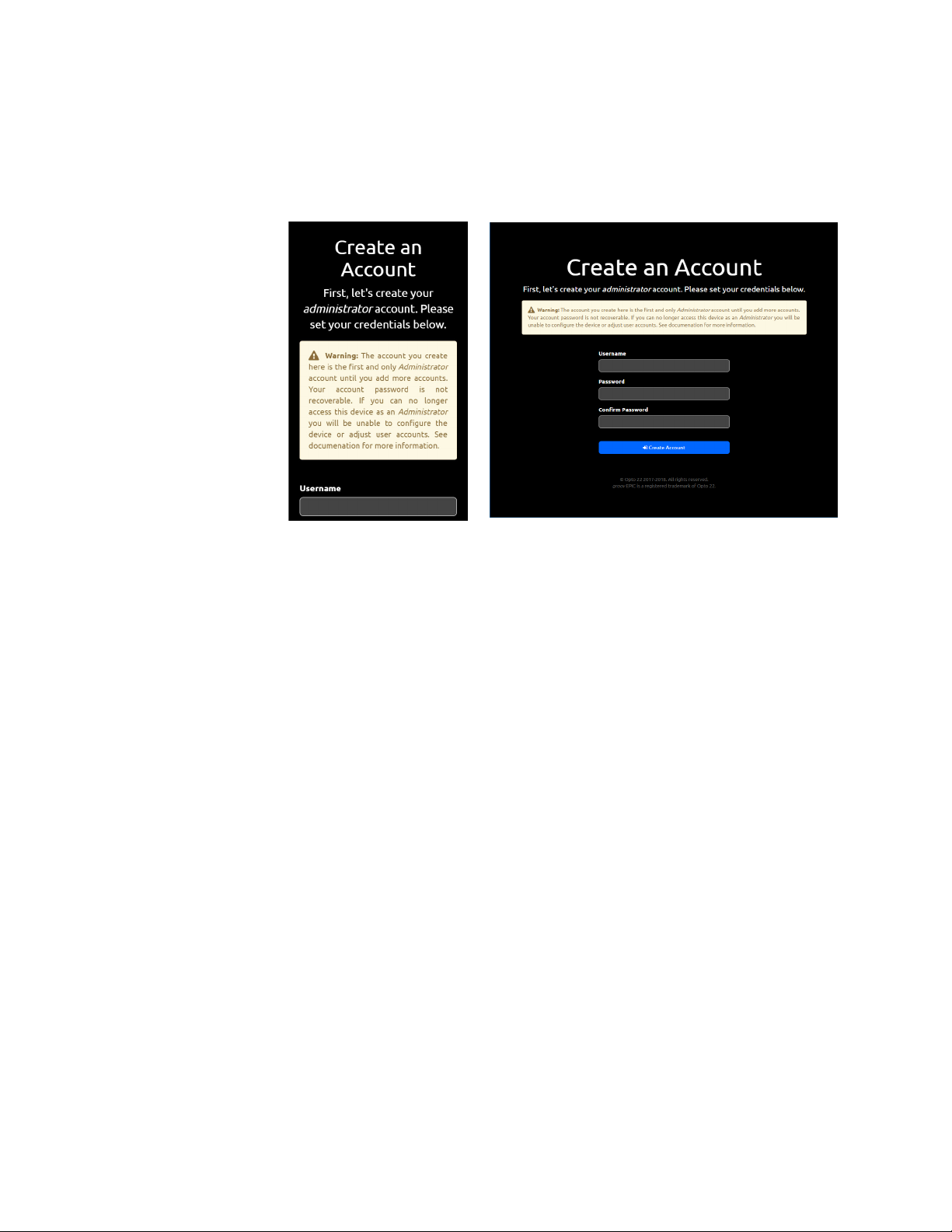

Creating the First Administrator Account . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Choosing Between Quick Start and Configure Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Completing the Quick Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 5: Navigating Through the groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . 29

groov EPIC User’s Guide v

v

Page 8

Click or Tap Your Way Around groov Manage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Learning the Screen Navigation Aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Navigating Through groov Manage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Navigating Through groov Manage on the groov EPIC Processor Touchscreen . . . . . . . . . . . . . . . . . . 32

Navigating Through groov Manage on a Computer or Mobile Device . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Finding Information About I/O Modules and Their Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 6: Controlling Access to groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Part of an Overall Security System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Creating User IDs and Configuring Their Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Choosing Access Levels for Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Creating User IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Managing the SSL Security Features of your groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Learning How SSL Works on groov EPIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Why Change the SSL Security Features on Your groov EPIC Processor? . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Creating a Self-Signed Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Switching to a CA-signed Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Uploading a Public Key Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Changing SSL Security Features for Sparkplug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Configuring the Firewall. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Creating a Firewall Rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Changing a Firewall Rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 7: Connecting groov EPIC to a Network or Multiple Networks . . . . . . . . . . . . 49

Selecting a Network Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Initializing with ETH0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Keeping Networks Separate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Reviewing Network Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Collecting Network Configuration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Collecting Information for Automatic Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Collecting Information for Manual Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Collecting Network Configuration Information for OpenVPN Connection . . . . . . . . . . . . . . . . . . . . . . . 55

Configuring the Network Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Configuring ETH0 or ETH1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Configuring WLAN0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Saving the Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Connecting to a Virtual Private Network (VPN). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Testing the Network Connections and Fine-Tuning Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Chapter 8: Enabling MQTT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

What is MQTT?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Choosing an MQTT Transmission Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Combining MQTT Transmission Options on a groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Configuring and Enabling MQTT with String Payloads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Collecting Information and Reviewing Processor Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Configuring and Enabling MQTT Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Configuring and Enabling MQTT with Sparkplug B Payloads from GRV-EPIC-PR1 . . . . . . . . . . . . . . . . . . . . . 68

vi

groov EPIC User’s Guide

Page 9

Collecting Information and Reviewing Processor Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configuring and Enabling MQTT Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Configuring and Enabling MQTT with Sparkplug Payloads Published through Ignition Edge Software . 72

What is Ignition Edge? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Configuring and Starting Ignition Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Configuring the Ignition Edge System Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Licensing Ignition Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Changing the Default Password for Ignition Edge Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Installing the OPC UA groov EPIC and SNAP PAC Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Installing the Ignition Edge MQTT Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Chapter 9: Configuring System Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Switching Between PAC Control Engine and CODESYS Runtime Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Setting and Adjusting Date, Time, and Time Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Setting the Date and Time Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Setting the Date, Time, and Time Zone by Synchronizing with Time Servers . . . . . . . . . . . . . . . . . . . . 82

Setting the Time and Time Zone by Selecting a Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Selecting Which App to Load After User Log In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Configuring the groov EPIC Processor for Shell Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Connecting Serial Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Connecting a Serial Device Directly to the groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Connecting a Serial Device Through a groov Serial Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Device Name, Port Number, CAN Port Number, and CAN Port Name . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Finding Device Names, Port Numbers, CAN Port Names, or CAN Port Numbers . . . . . . . . . . . . . . . . . 86

Configuring the Communication Ports or Handles to Serial Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Connecting a Mouse and a Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Connecting an External Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Connecting an External Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Disconnecting an External Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Connecting a USB Storage Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Disabling Access to USB Storage Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Mounting and Unmounting USB Storage Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Copying, Moving, or Downloading a File on a USB Storage Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Installing an Approved USB WiFi Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Calibrating the Processor’s Touchscreen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Uploading Files to the groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Chapter 10: Configure CODESYS and groov EPIC for IEC61131-3 . . . . . . . . . . . . . . . . . . 99

Obtaining Your CODESYS Activation Key Certificate and Ticket ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Downloading and Installing CODESYS Development System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Adding the Opto 22 Library Package to CODESYS Development System . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Reviewing Network Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Enable the CODESYS Control Engine on the groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Connecting Processor to Gateway and Entering the CODESYS Ticket ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Managing CODESYS Runtime Engine and CODESYS Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Enabling the CODESYS Runtime Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Disabling the CODESYS Runtime Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

groov EPIC User’s Guide

vii

Page 10

Transferring the CODESYS License to Another GRV-EPIC-PR1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Chapter 11: Working with groov EPIC Devices in CODESYS Projects . . . . . . . . . . . . . .105

Adding a groov EPIC Device to a CODESYS Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Creating a New CODESYS Project and Adding a groov EPIC Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Editing an Existing Project to Add a groov EPIC Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Updating groov EPIC and groov I/O Module Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Creating Network Interfaces for the groov EPIC Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Setting Up Local I/O – Adding groov EPIC to the Device Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Setting Up Local I/O – Plugging in groov I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Plugging in I/O modules automatically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Plugging in I/O modules manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Configuring Processor Parameters and Channel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Configuring Processor Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Setting Channel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Reading or Clearing Latches and States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Creating a Symbol Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Referencing Files Stored in the groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Downloading and Running CODESYS Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Starting or Stopping CODESYS Applications on the groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . 117

Monitoring Latches, States, and Counters: CODESYS or groov Manage? . . . . . . . . . . . . . . . . . . . . . . . . 117

Chapter 12: Downloading and Running PAC Control Programs . . . . . . . . . . . . . . . . . . . 119

Downloading and Running PAC Control Strategies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Identifying the Strategy that is Running on the groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Enabling or Disabling Background Downloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Identifying Serial Devices Accessible to the Control Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Disabling the PAC Control Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Enabling the PAC Control Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Chapter 13: Downloading and Running Custom Control Programs . . . . . . . . . . . . . . . .123

Verifying SSH Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Stopping the SSH Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Starting the SSH Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Chapter 14: Developing and Deploying Node-RED flows . . . . . . . . . . . . . . . . . . . . . . . . . 127

What is Node-RED and how does it work in groov EPIC?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Node-RED in the groov EPIC processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Creating your first Node-RED flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Opening the Node-RED Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Creating a flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Deploying the flow and testing it . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Adding a Function node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Installing groov View nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Adding an Opto 22 PAC Control node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

viii

Chapter 15: Monitoring and Configuring Modules and Channels . . . . . . . . . . . . . . . . . .139

groov EPIC User’s Guide

Page 11

Checking the Health (Status) of a Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Checking Module Status Through the Module LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Checking Module Status Through groov Manage on a Browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Configuring groov I/O Modules and Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Understanding How Quality Errors are Reported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Viewing Information About a Quality Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Chapter 16: Maintaining Your groov EPIC Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Backing up Your groov EPIC Processor Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Backing up Your Ignition Edge Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Restoring a Backup or Specific Settings from a Backup File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Restoring your Ignition Edge Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Updating Firmware on a groov EPIC Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Applying a Firmware Update to the groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Installing an I/O Module Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

How to Reset to Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Collecting Information for Product Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Conducting an OptoSupport Remote Support Service (RSS) Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Initiating an RSS Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Pausing and Resuming an RSS Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Ending the RSS Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Chapter 17: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Cannot Connect to the SSH Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

One of the Modules is Blinking Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

One of the Modules is Blinking Violet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

SSH Server User ID and Password are Rejected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Changes Aren’t Saved or They Suddenly Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

groov EPIC Processor Touchscreen Keeps Jumping to Module Information Page. . . . . . . . . . . . . . . . . . . . 171

Touchscreen Doesn’t Respond Accurately to Finger taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Ethernet Cable is Plugged In, but No IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Web Browser Can’t Connect to Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

The SPEED LED on the Processor Changed Color. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Time zone change not shown in Ignition Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

CODESYS: Can’t Connect to groov EPIC Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Troubleshooting Network Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Ping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Test TCP Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Traceroute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

NsLookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Appendix A: Processor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

GRV-EPIC-PR1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Appendix B: Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

GRV-EPIC-PSAC, GRV-EPIC-PSDC, GRV-EPIC-PSPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

groov EPIC User’s Guide

ix

Page 12

Appendix C: Chassis Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

GRV-EPIC-CHS0, GRV-EPIC-CHS4, GRV-EPIC-CHS8, GRV-EPIC-CHS16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Appendix D: I/O Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

GRV-CCANI-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

GRV-CSERI-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

GRV-IAC-24, GRV-IACI-12, GRV-IACS-24, GRV-IACIS-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

GRV-IACDCTTL-24, GRV-IACDCTTLS-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

GRV-IACHV-24, GRV-IACIHV-12, GRV-IACHVS-24, GRV-IACIHVS-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

GRV-IDC-24, GRV-IDCI-12, GRV-IDCS-24, GRV-IDCSW-12, GRV-IDCIS-12, GRV-IDCIFQ-12. . . . . . . . . . . . . . 192

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Specifications for GRV-IDC-24, GRV-IDCI-12, GRV-IDCS-24, GRV-IDCIS-12, GRV-IDCIFQ-12 . . . . . . . 193

Specifications for GRV-IDCSW-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

GRV-IICTD-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

GRV-IMA-24, GRV-IMAI-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

GRV-ITM-12, GRV-ITMI-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

GRV-ITR-12, GRV-IRTD-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Specifications for GRV-ITR-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Specifications for GRV-IRTD-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

GRV-IV-24, GRV-IVI-12, GRV-IVIRMS-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

GRV-OAC-12, GRV-OACI-12, GRV-OACS-12, GRV-OACIS-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

GRV-ODCI-12, GRV-ODCIS-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

GRV-ODCSRC-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

GRV-OMRIS-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

GRV-OVMAILP-8, GRV-OVMALC-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

x

groov EPIC User’s Guide

Page 13

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Appendix E: I/O Module Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

GRV-CCANI-2 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

GRV-CSERI-4 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

GRV-IAC-24, GRV-IACS-24 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

GRV-IACI-12, GRV-IACIS-12 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

GRV-IACDCTTL-24, GRV-IACDCTTLS-24 Pinout and Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

GRV-IACHV-24, GRV-IACHVS-24 Pinout and Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

GRV-IACIHV-12, GRV-IACIHVS-12 Pinout and Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

GRV-IDC-24, GRV-IDCS-24 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

GRV-IDCSW-12 Pinout and Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

GRV-IDCI-12, GRV-IDCIS-12 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

GRV-IDCIFQ-12 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Wiring to Quadrature Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Wiring to Typical (Signal) Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

GRV-IICTD-12 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

GRV-IMA-24 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

GRV-IMAI-8 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

GRV-IRTD-8 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

GRV-ITM-12 Pinout and Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

GRV-ITMI-8 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

GRV-ITR-12 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

GRV-IV-24 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

GRV-IVI-12 Pinout and Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

GRV-IVIRMS-10 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

GRV-OAC-12, GRV-OACS-12 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

GRV-OACI-12, GRV-OACIS-12 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

GRV-ODCI-12, GRV-ODCIS-12 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

GRV-ODCSRC-24 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

GRV-OMRIS-8 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

GRV-OVMAILP-8 Pinout and Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

GRV-OVMALC-8 Pinout and Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Appendix F: Installing the Correct License . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Installing Licenses on Processors with Firmware Earlier Than 1.3.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Installing the groov Plus or groov Enterprise License . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Adding Ignition Edge or CODESYS when you Upgrade to 1.3.0 or Later . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Appendix G: Advanced Networking Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Redirecting Traffic Initiated by an Incoming Connection Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Outbound Traffic Not Initiated by an Incoming Connection Request . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

groov EPIC User’s Guide

xi

Page 14

xii

groov EPIC User’s Guide

Page 15

Appendix A

1: Welcome to groov EPIC

The groov EPIC® system is the next step in the evolution of automation. The system includes:

• An Edge Programmable Industrial Controller with an embedded Linux® operating system and gateway

functions. We call it the groov EPIC processor because it can do controller functions and so much more:

– Edge–Moving more visualization, control, and data acquisition functions to the place where it all

happens: at the edge.

– Programmable–Offering more ways to support the creation of control programs that fit your needs:

flowchart programming through PAC Control, IEC 61131-3 compliant programming through

CODESYS®, or custom programming in popular programming languages with access to the Linux

operating system through a secure shell.

– Industrial–Designed to work in a wide range of environments, meeting UL and ATEX requirements

for hazardous locations.

– Controller®–You can rely on real-time control and I/O from an automation manufacturer with 45+

years of experience. Opto 22’s worldwide reputation for quality was built on solid state relays and

I/O, and all our experience is poured into the design of groov EPIC.

• groov® I/O modules, most guaranteed-for-life and available in discrete, analog, and serial models. All are

configurable by the groov EPIC processor and have up to 24 channels per module.

• groov EPIC power supplies for AC power, DC conversion, and adapters for pass-through connections from

a DC power supply you already own.

• groov EPIC chassis that holds the processor, I/O modules, and power supply. Available in 4-, 8-, and

16-module models.

SYSTEM REQUIREMENTS

• To build PAC Control strategies with the PAC Project Basic Software Suite that comes with groov EPIC, you

will need:

– A computer with a standard or mainstream processor and (at least) the minimum memory required

for your version of Microsoft Windows. (Low-end CPUs are not recommended.) Additional memory

may be required for some configurations.

– One of the following operating systems:

– Microsoft Windows 10 Professional (32-bit or 64-bit)

– Windows 8.1 Professional (32-bit or 64-bit)

– Windows 7 Professional (32-bit or 64-bit)

• To build operator interfaces with groov View, you’ll need:

– Any computer with a web browser (does not have to be a Windows PC)

– One or more of the following:

– A Modbus/TCP device

groov EPIC User’s Guide 1

1

Page 16

ABOUT THIS GUIDE

– A database, online service, or software program to get data from or put data into a Data Store

using the groov API

–A groov EPIC processor or SNAP PAC controller (SNAP PAC S-series, R-series, or SoftPAC, with

firmware R9.2a or newer), running a PAC Control strategy

– An Opto 22 SNAP PAC I/O unit

– A database, cloud application, API, or serial device accessible via a Node-RED node.

– OPC UA-compatible automation system or equipment. Ignition Edge supplies an internal

server and drivers for groov EPIC. Additional drivers or an external OPC UA server may be

required for your equipment.

• To build control programs with the CODESYS Development System, you’ll need:

– A computer that meets the minimum requirements established by CODESYS. For more information,

visit the CODESYS website (www.codesys.com).

– The Opto 22 Library Package, which contains the information that CODESYS Development System

needs to correctly configure and connect to a groov EPIC processor. For instructions on

downloading and installing this package, see “Adding the Opto 22 Library Package to CODESYS

Development System” on page 64.

– CODESYS Development System, V3.5 SP13 Patch 1 or newer (32-bit version). For instructions, see

“Downloading and Installing CODESYS Development System” on page 64.

If you are using CODESYS PROFINET Controller SL, you will need CODESYS Development System,

V3.5 SP15 Patch 10 or newer. You also want to make sure the CODESYS PROFINET device is at version

3.5.15.10 or newer. To check:

1. Click Tools > Device Repository.

2. Expand Fieldbusses > Profinet I/O > Profinet I/O Device.

3. Find CODESYS Profinet Device and check the version.

–A groov EPIC processor (GRV-EPIC-PR1) with minimum firmware version 1.3.0.

ABOUT THIS GUIDE

This user’s guide shows you how to assemble and initialize your groov EPIC unit, how to configure the software

and I/O modules, how to configure system settings, and much more.

Note: If you are using CODESYS PROFINET Controller SL, you need version 1.5.0 or newer.

2

groov EPIC User’s Guide

Page 17

CHAPTER 1: WELCOME TO GROOV EPIC

Throughout this guide, you might see two versions of the same page. This is done to show you important

differences between viewing a page through the groov EPIC processor’s touchscreen and viewing the same

page through a computer web browser or mobile device.

groov EPIC touchscreen Computer web browser

groov EPIC User’s Guide

3

Page 18

ABOUT THIS GUIDE

What’s in This Guide

Chapter 1: Welcome to groov EPIC (this chapter) introduces this user’s guide and groov EPIC.

Chapter 2: Additional Safety and Operating Instructions describes important safety and operating

information.

Chapter 3: Assembling your groov EPIC describes how to assemble the parts of a groov EPIC unit (the

processor, the power supply, the chassis, and the I/O modules).

Chapter 4: Initializing the groov EPIC Processor describes the configuration steps you might want to do

first to get your groov EPIC system up and running.

Chapter 5: Navigating Through the groov EPIC Processor describes how to navigate through software on

the groov EPIC processor touchscreen, some differences between navigating on the touchscreen and

navigating through a web browser, and introduces you to some of the important features of some of the

screens, like the Modules page.

Chapter 6: Controlling Access to groov EPIC Processor describes the security features available on the

groov EPIC processor and how you might want to configure these features to control who has access to your

unit.

Chapter 7: Connecting groov EPIC to a Network or Multiple Networks describes the options available to

connect a groov EPIC processor to more complex networking environments.

Chapter 8: Enabling MQTT describes the options available for publishing automation data in a MQTT

infrastructure, as well as what to do to set up these options.

Chapter 9: Configuring System Features describes how to modify features (like networking) so they work

the way you need them to in your application.

Chapter 10: Configure CODESYS and groov EPIC for IEC61131-3 describes how to enable the CODESYS

Runtime Engine so you can build and download applications developed with the CODESYS Development

System.

Chapter 11: Working with groov EPIC Devices in CODESYS Projects describes how to add and configure

a groov EPIC processor to your CODESYS Development System, and how to configure processor parameters

and channel features so you can begin programming.

Chapter 12: Downloading and Running PAC Control Programs describes how to download and run PAC

Control strategies.

Chapter 13: Downloading and Running Custom Control Programs describes how to access the secure

shell feature to develop and download control programs written in other programming languages.

Chapter 14: Developing and Deploying Node-RED flows describes how to get started building and

deploying Node-RED flows, including how to add the Opto 22 nodes.

Chapter 15: Monitoring and Configuring Modules and Channels describes the features available on the

groov EPIC processor to help view the status of your modules and how to configure them.

Chapter 16: Maintaining Your groov EPIC Unit describes the tasks you can do to keep your groov EPIC unit

running in top shape, like applying maintenance. It also describes how to start an OptoSupport Remote

Support Service session.

4

groov EPIC User’s Guide

Chapter 17: Troubleshooting describes what to do when you encounter problems (troubleshooting).

Appendix A: Processor Specifications provides the technical specifications of the groov EPIC processor.

Appendix B: Power Supply Specifications provides the technical specifications of the groov EPIC power

supply, power converter, and power adapter.

Appendix C: Chassis Specifications provides the technical specifications of the groov EPIC chassis.

Page 19

CHAPTER 1: WELCOME TO GROOV EPIC

Appendix D: I/O Module Specifications provides the technical specifications of all the groov I/O modules.

Appendix E: I/O Module Wiring Diagrams provides the wiring diagrams for all the groov I/O modules.

Appendix F: Installing the Correct License describes how to properly install licenses for groov EPIC

processors that have versions of firmware older than 1.3.0.

Appendix G: Advanced Networking Configurations describes special networking functions that are

usually managed by network administrators for specific and rare situations.

groov EPIC User’s Guide

5

Page 20

ABOUT THIS GUIDE

6

groov EPIC User’s Guide

Page 21

Appendix B

2: Additional Safety and Operating Instructions

SAFETY INSTRUCTIONS

Read all the guidelines described in this section before operating or servicing your groov EPIC unit:

• CAUTION: There is a possibility of electric shock. Before accessing any terminals connected to modules

rated as HAZARDOUS LIVE voltage, disconnect or isolate the groov EPIC unit from HAZARDOUS LIVE

voltage.

• Use only Opto 22-provided parts or accessories and in a manner instructed in this guide; do not use

un-authorized parts or accessories. If un-authorized parts or accessories are used on your groov EPIC unit,

the protection provided by the groov EPIC unit may be impaired.

• Use your groov EPIC unit only in a manner in which it complies with all safety and additional instructions

described in this guide. If the groov EPIC unit is used in a manner not specified by Opto 22, the protection

provided by the groov EPIC unit may be impaired.

• The normal environmental conditions for a groov EPIC unit in regards to temperature and humidity are

those conditions that fall within the ranges described in the specifications listed in Appendix A: Processor

Specifications, Appendix B: Power Supply Specifications, Appendix C: Chassis Specifications, and

Appendix D: I/O Module Specifications.

• The groov EPIC unit is to be used indoors or installed in a protective cabinet that provides the conditions

described in Appendix A: Processor Specifications, Appendix B: Power Supply Specifications, Appendix C:

Chassis Specifications, and Appendix D: I/O Module Specifications.

• The groov EPIC unit is rated to withstand transient overvoltages up to the levels of overvoltage

category II.

• The groov EPIC unit is rated to be installed in environments where non-conductive pollution occurs

except where occasionally a temporary conductivity caused by condensation might be expected

(Pollution Degree 2).

• The groov EPIC unit can operate in altitudes of up to 2000 m.

SAFETY INSTRUCTIONS FOR INSTALLING THE groov EPIC UNIT AS PART OF MACHINERY

When you permanently install your groov EPIC unit into another machine, you must attach a power

disconnect device to your groov EPIC unit. The power disconnect device must comply with the following

requirements:

• It must be a switch or a circuit breaker that is easy to reach and operate from the outside of the machine.

• It must disconnect all power lines simultaneously.

• It must be clearly labeled as a power disconnecting device for the controller.

groov EPIC User’s Guide 7

7

Page 22

EXPLANATION OF LABELS OR SYMBOLS

EXPLANATION OF LABELS OR SYMBOLS

The following table explains the labels or symbols you might see on the groov EPIC power supplies, processor,

or modules:

Label or Symbol Explanation

CAUTION: Please consult the user’s guide for additional safety information and

instructions for proper installation, operation, maintenance, and service of this unit.

CAUTION: Possibility of electric shock.

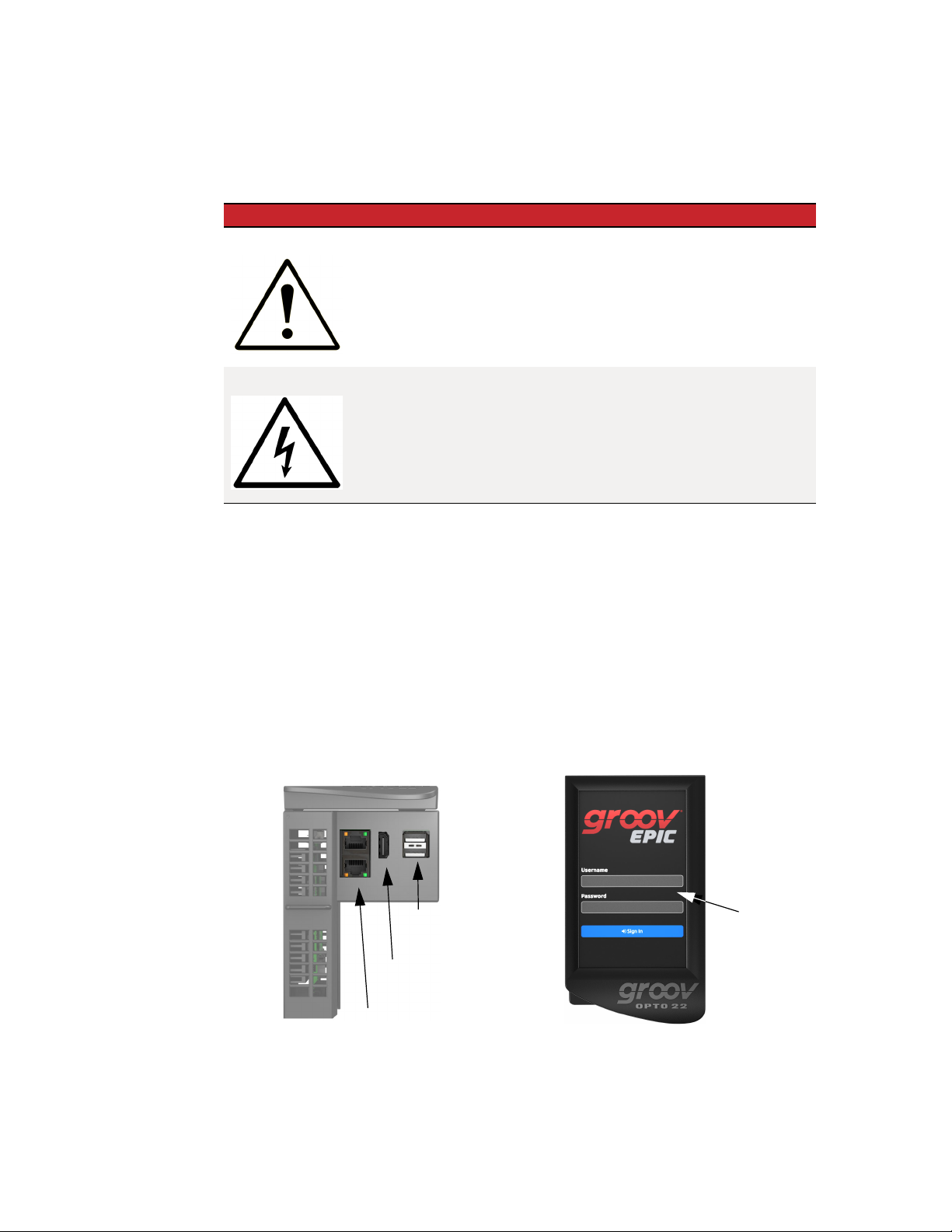

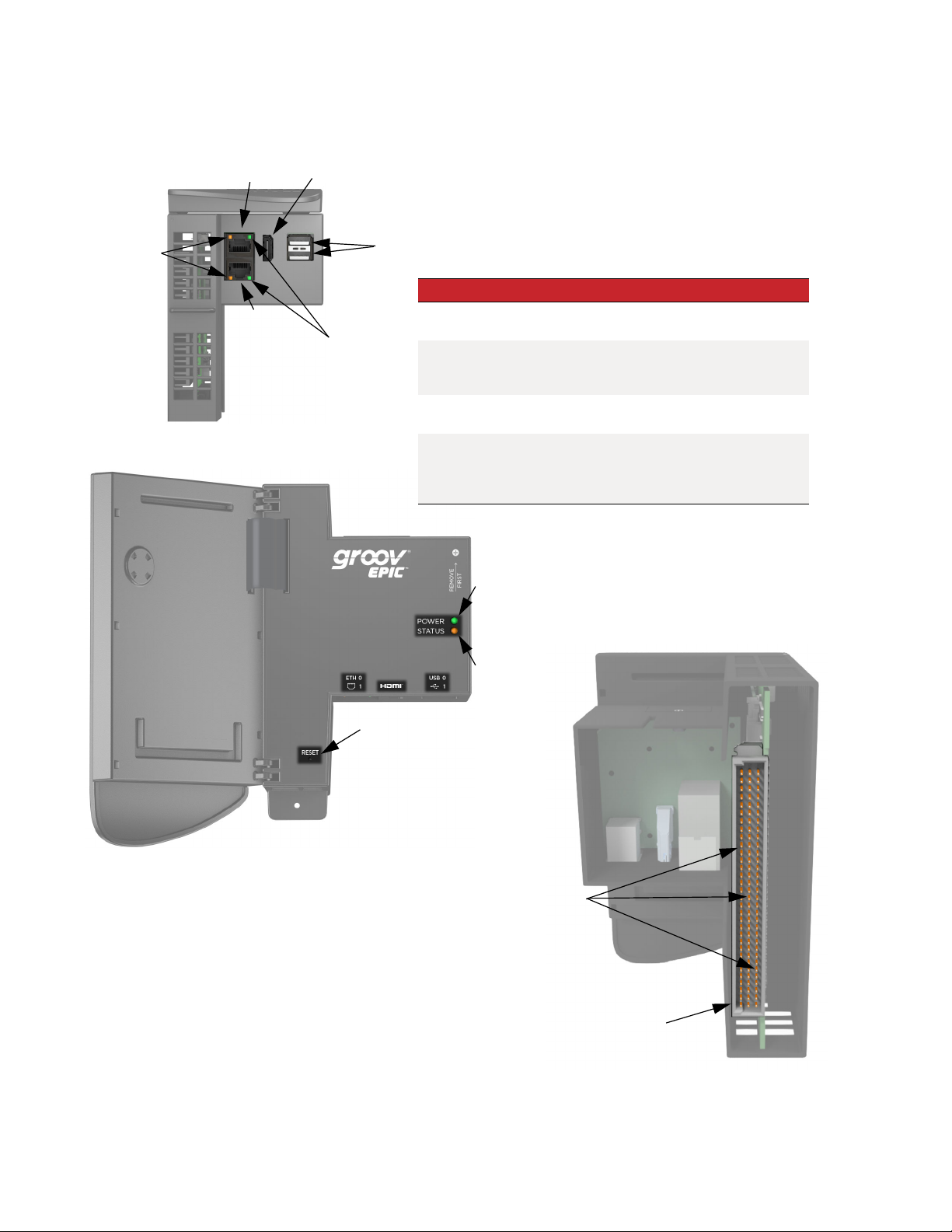

OPERATING CONTROLS

The following diagrams describe the operating controls available on the groov EPIC processor. The bottom

view shows the network interfaces and ports. The front view shows the processor’s touchscreen.

Administrator and operator controls are provided through the touchscreen interface.

• If you log in with a user ID that has administrator level privileges, you can access controls to view and

change settings such as network addresses, channel IDs, or to do some tasks, like restarting the device.

• If you log in with a user ID that has operator level privileges, you can access controls that run the

machinery, equipment, and processes that are controlled and monitored by the control program running

on the groov EPIC processor.

(bottom view)

USB port (2)

HDMI port

Touchscreen

8

groov EPIC User’s Guide

Ethernet Interface (2)

(front view)

Page 23

SERVICE AND MAINTENANCE

To keep your groov EPIC unit up-to-date with the latest software and firmware fixes and features, you’ll want to

regularly check for and apply maintenance to your unit, as described in “Updating Firmware on a groov EPIC

Unit” on page 157.

If you encounter any problems with your groov EPIC unit, follow the instructions in “Collecting Information for

Product Support” on page 165 to collect information before contacting Opto 22 Product Support.

Service (Product Support)

If you are having problems installing or using groov EPIC products and cannot find the help you need in this

guide or on our website, contact Opto 22 Product Support.

CHAPTER 2: ADDITIONAL SAFETY AND OPERATING INSTRUCTIONS

Phone: 800-TEK-OPTO (800-835-6786 toll-free

in the U.S. and Canada)

951-695-3080

Monday through Friday,

7 a.m. to 5 p.m. Pacific Time

Fax: 951-695-3017

Email: support@opto22.com

Opto 22 website: www.opto22.com

NOTE: Email messages and phone calls

to Opto 22 Product Support are

grouped together and answered in the

order received.

groov EPIC User’s Guide

9

Page 24

SERVICE AND MAINTENANCE

10

groov EPIC User’s Guide

Page 25

Appendix C

3: Assembling your groov EPIC

GATHERING YOUR EQUIPMENT AND INFORMATION

Gathering up all the supplies, information, and equipment you need to help you assemble your groov EPIC

unit can make assembling your unit easier:

• A work table and good lighting.

• An accessible power source that complies with the requirements described in Appendix B: Power Supply

Specifications or in the groov EPIC Power Supplies, Converters, and Adapters Data Sheet (form 2246).

• The proper gauge wires to connect the groov EPIC power supply to your power source. For guidance on

selecting the correct wire gauge, see Appendix B: Power Supply Specifications or the groov EPIC Power

Supplies, Converters, and Adapters Data Sheet (form 2246).

• The proper gauge wires to connect your field devices to the I/O modules. For guidance on selecting the

correct wire gauge, see “Connecting field devices to the groov I/O modules” on page 20 or review the

groov I/O module data sheets.

• Pen and paper to note important information that you might need during this process or to keep for

future reference.

• If you are connecting the processor to a network, an Ethernet cable.

• The groov EPIC power supply you selected for your project.

• The groov EPIC chassis you selected for your project. Make sure you have the correct size chassis to hold

the number of modules you are installing.

• The groov I/O modules that you selected for your project.

• The screwdriver that ships with your I/O modules, which helps you connect field device wires to the

terminal connector.

In addition, make sure you have a list of all the I/O channels (sometimes referred to as points) that you need

set up. This might be in a form of a document that maps which channel of which module will connect to a

specific field device/point. If you are working with a terminal strip, review the terminal number assignments,

making sure you understand which terminal numbers are assigned to specific modules and channels.

Any additional information you might need will depend on other factors, like any special configurations for

your network or whether you need to create additional users that have limited access.

After you assemble your unit, you’ll initialize it as described in Chapter 4: Initializing the groov EPIC Processor.

After you finish initializing the unit, it will be ready to run.

FAMILIARIZE YOURSELF WITH THE PROCESSOR AND groov I/O MODULES

Take a few minutes to review the next couple of pages, which show you the different features of the processor and groov I/O modules.

The installation instructions in the documentation rely on these terms to explain how to handle a processor and a module.

groov EPIC User’s Guide 11

11

Page 26

FAMILIARIZE YOURSELF WITH THE PROCESSOR AND GROOV I/O MODULES

groov EPIC Processor

Bottom View:

SPEED LED

Face View:

ETH0

ETH1

HDMI

LINK ACT LED

USB

LED Indicates

SPEED LED

LINK ACT LED

POWER LED

STATUS LED

POWER LED

Indicates link speed (Off = 10 Mbps,

Green = 100 Mbps, Orange = 1000 Mbps)

Indicates link status or activity

(on/solid = link present, blinking = link

present and local activity)

Indicates status of power (Green = on;

Red = on, resetting)

Indicates whether the unit is running with

full functionality. (Green = all normal; blink

green and red = starting a restore to

defaults)

RESET button

Back View:

STATUS LED

Connector Pins

Connector

12

groov EPIC User’s Guide

Page 27

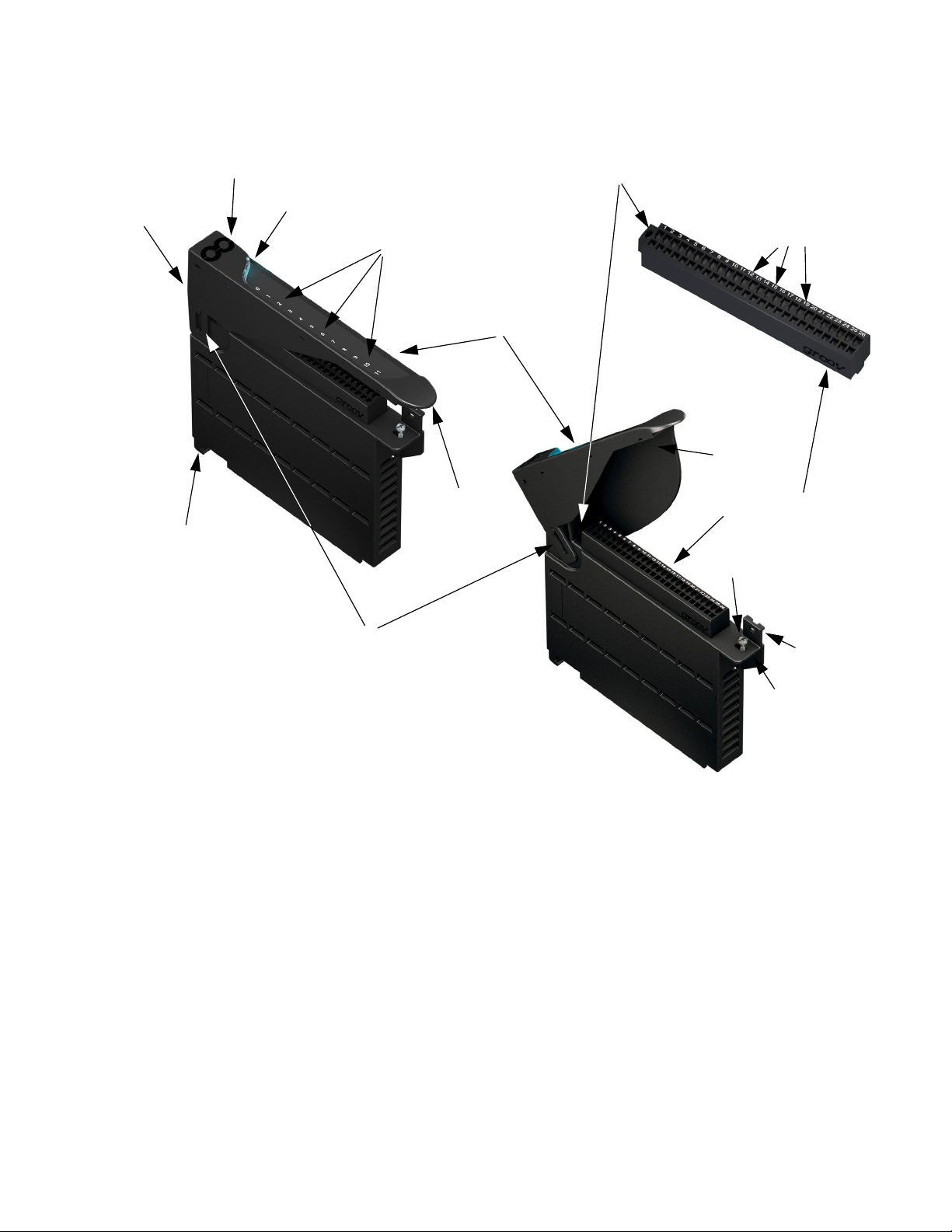

groov I/O Modules

CHAPTER 3: ASSEMBLING YOUR GROOV EPIC

Catch tab

(on the

top of the

module)

Alignment tab (on the

underside of the module)

Touch-sensitive pad

Module LED

Discrete channel indicators

(discrete modules only)

Module cover

Module cover

grip tab

Terminal connector screw

Channels

Wireway

Terminal connector (removable)

Module retention screw

Hinge (2-position)

Module grip tab

To learn what colors the module LED displays, see “Checking Module Status Through the Module LED” on

page 140.

VERIFYING SERIAL NUMBER ON THE PROCESSOR

When you unpack your groov EPIC processor, open the LCD display and verify that you can find the serial

number on the label attached to the back of the LCD display.

ACTIVATING THE groov EPIC UNIT AND DOWNLOADING THE LICENSE FILE

Each groov EPIC processor comes with an activation code, which helps you obtain your license file.

1. Make a note of the serial number of your groov EPIC processor, which is on a label attached to the back of

the LCD display.

2. On a computer or mobile device connected to the Internet, go to manage.groov.com.

Strain relief tab

groov EPIC User’s Guide

13

Page 28

ASSEMBLING YOUR UNIT

3. Follow the directions for activating your groov EPIC processor and obtaining a license file.

4. Save the license file onto your computer or mobile device and remember where you saved it. You’ll need

that information when you initialize your groov EPIC unit, as described in Chapter 4: Initializing the groov

EPIC Processor.

ASSEMBLING YOUR UNIT

After you complete the steps in this section, you will have mounted the power supply, the processor, and the

I/O modules on to the chassis. In the section that follows, you’ll wire the I/O modules to field devices, and the

power supply to the power source.

CAUTION: For electrical safety, do not turn on the power supply. Make sure to de-energize field devices wired

to the module terminal connectors before proceeding with these steps.

1. Orient the groov EPIC chassis so that the module connector numbers are right-side up, with zero on the

left, as shown in the diagram below.

14

2. Install the power supply:

a. Hold the power supply at a 45° angle, with the tabs at the back of the supply aligned with the

notches on the chassis.

groov EPIC User’s Guide

Page 29

CHAPTER 3: ASSEMBLING YOUR GROOV EPIC

b. Lower the front-end of the supply onto the chassis until you feel the plug snap into the slot.

3. Install the processor:

groov EPIC User’s Guide

15

Page 30

ASSEMBLING YOUR UNIT

a. Lift the LCD display so you can see the notch on the processor.

Notch

b. Hold the processor by the left side, and make sure that the notch on the processor aligns with the

guide tab on the power supply.

16

c. Align and then seat the processor:

groov EPIC User’s Guide

Page 31

CHAPTER 3: ASSEMBLING YOUR GROOV EPIC

– Align the processor. With the LCD display open, slowly guide the processor straight onto the

chassis—holding it flush against the side of the power supply—until you feel the processor

start to touch the connector on the chassis.

When it touches, lightly jiggle the processor to help the pins on the processor’s connector

properly align themselves into the holes of the chassis’ connector.

– Seat the processor. Push the processor (not the LCD display) into the connector until it resists

further pressure.

groov EPIC User’s Guide

17

Page 32

ASSEMBLING YOUR UNIT

IMPORTANT: Do not push on the LCD display.

d. Tighten the retention screws that attach the processor to the power supply and the chassis to the

recommended torque listed in Appendix A: Processor Specifications.

Retention screws

e. Close the LCD display.

4. Install the modules:

a. Hold the module at a 45° angle, lining up the alignment tab on the back tip of the module with the

slot at the back of the chassis.

18

groov EPIC User’s Guide

Page 33

CHAPTER 3: ASSEMBLING YOUR GROOV EPIC

b. Pivot the front of the module down to the module connector on the chassis. Push to snap the

module into the connector.

c. Swing the module cover up so you can access the module hold-down screw. Secure the module

into position by tightening the module hold-down screw.

groov EPIC User’s Guide

19

Page 34

CONNECTING POWER SUPPLY WIRES AND FIELD DEVICE WIRES

CAUTION: Do not over-tighten. See the torque specs inAppendix D: I/O Module Specifications.

Hold-down screw

CONNECTING POWER SUPPLY WIRES AND FIELD DEVICE WIRES

After you complete the steps in this section, you will turn on you groov EPIC unit and move on to initializing

the unit.

Connecting field devices to the groov I/O modules

Before you begin wiring, do the following tasks:

• Select the appropriate wire. The terminal connectors are rated for 28–14 AWG wire. If you’re using

stranded wire, tin the strands for an easier, better connection.

• Ensure that you have the screwdriver supplied with your module.

• If you are unfamiliar with the names of some of the parts of the module, review the diagrams on the

following page and in “Familiarize yourself with the Processor and groov I/O modules” on page 11.

• It may be easier to insert wires if you remove the terminal connector from the module. To remove the

terminal connector, loosen the terminal connector screw at one end of the connector, then pull the

connector up to remove it from the module.

• If you have never used a spring-clamp wiring system, take a moment to familiarize yourself with the

diagram on the following page. The clamp release hole is where you will insert the screwdriver. The field

wiring hole is where you will insert your field wires. If you look into the field wiring hole, you will see a

highly reflective surface. If you can see that surface, that means that the clamp is closed.

20

groov EPIC User’s Guide

Page 35

CHAPTER 3: ASSEMBLING YOUR GROOV EPIC

In this example, pin 3’s clamp release hole and corresponding field