Page 1

DS-C33 II Series

User’s Manual

www.opti-ups.com

Page 2

Contents

1. Preface ........................................................................................................................................................... 3

1-1 Introduction ......................................................................................................................................... 3

1-2 Safe Instructions and Warnings ........................................................................................................... 3

2. System Framework......................................................................................................................................... 4

2-1 Block Diagram ...................................................................................................................................... 4

2-2 System Major Module Function Introduction...................................................................................... 5

2-3 System Operation Modes ..................................................................................................................... 6

3. Touch Display Panel (HMI, Human Machine Interface) ................................................................................. 8

3-1 Introduction ......................................................................................................................................... 8

3-2 LCD Panel ............................................................................................................................................. 8

4. Fixation and Installation ............................................................................................................................... 13

4-1 Fixation ............................................................................................................................................... 13

4-2 Installation.......................................................................................................................................... 21

5. Operation Procedures .................................................................................................................................. 26

5-1 Power-on ............................................................................................................................................ 26

5-2 Power-off............................................................................................................................................ 28

5-3 Maintenance Bypass .......................................................................................................................... 28

5-4 Resumption from Maintenance Procedures ...................................................................................... 28

5-5 Emergency Power Off ........................................................................................................................ 28

5-6 Dry Contact Communication .............................................................................................................. 30

6. Maintenance and Storage ............................................................................................................................ 31

7. Troubleshooting ........................................................................................................................................... 31

8. Specifications ............................................................................................................................................... 32

9. Contact Information ..................................................................................................................................... 34

Page 3

1. Preface

1-1 Introduction

DS-C33 II series features an advanced DSP chip as a system core processor. Wide range capacity from 10KVA

to 200KVA meets a verity of load demands and extends the capacity up to 400KVA through paralleling. High

reliability and rapid transient response fit for critical equipments such as semiconductor, SMT and

communication facilities, etc.

HMI (Human machine interface) touch screen panel provides a user-friendly VIS (visual integrated system)

for real-time monitoring, easy maintenance. Fan operation depending on load condition achieves noise

reduction and energy consumption decrease. DS-C33 II is the best choice for dealing with critical power

needs.

1-2 Safe Instructions and Warnings

For safe operation, warning marks for DS-C33 series are:

DO NOT TOUCH DANGEROUS HIGH VOLTAGE

Dangerous high voltage mark pasted indicates high DC voltage. Do not touch the surface marked with it.

When batteries are being discharged (during blackouts), do not switch off (open circuit) the battery

magnetic switch to avoid danger.

Batteries are consumptive parts. Check if battery voltage, current and appearance are normal every 4

months to make sure the UPS operates normally and safely. If batteries are overheated or deformed,

replace them with new batteries to avoid fire danger because of lead acid liquid leakage.

Without using the UPS or AC mains supply for a long time, remove UPS’s battery fuses, switch off the

battery pack’s breakers or remove batteries in order not to damage batteries.

UPS is power system equipment and it requires grounding. The load of the UPS requires a separate

grounding.

PS: The contents of this manual are subject to change or modification without prior notice.

Page 4

2. System Framework

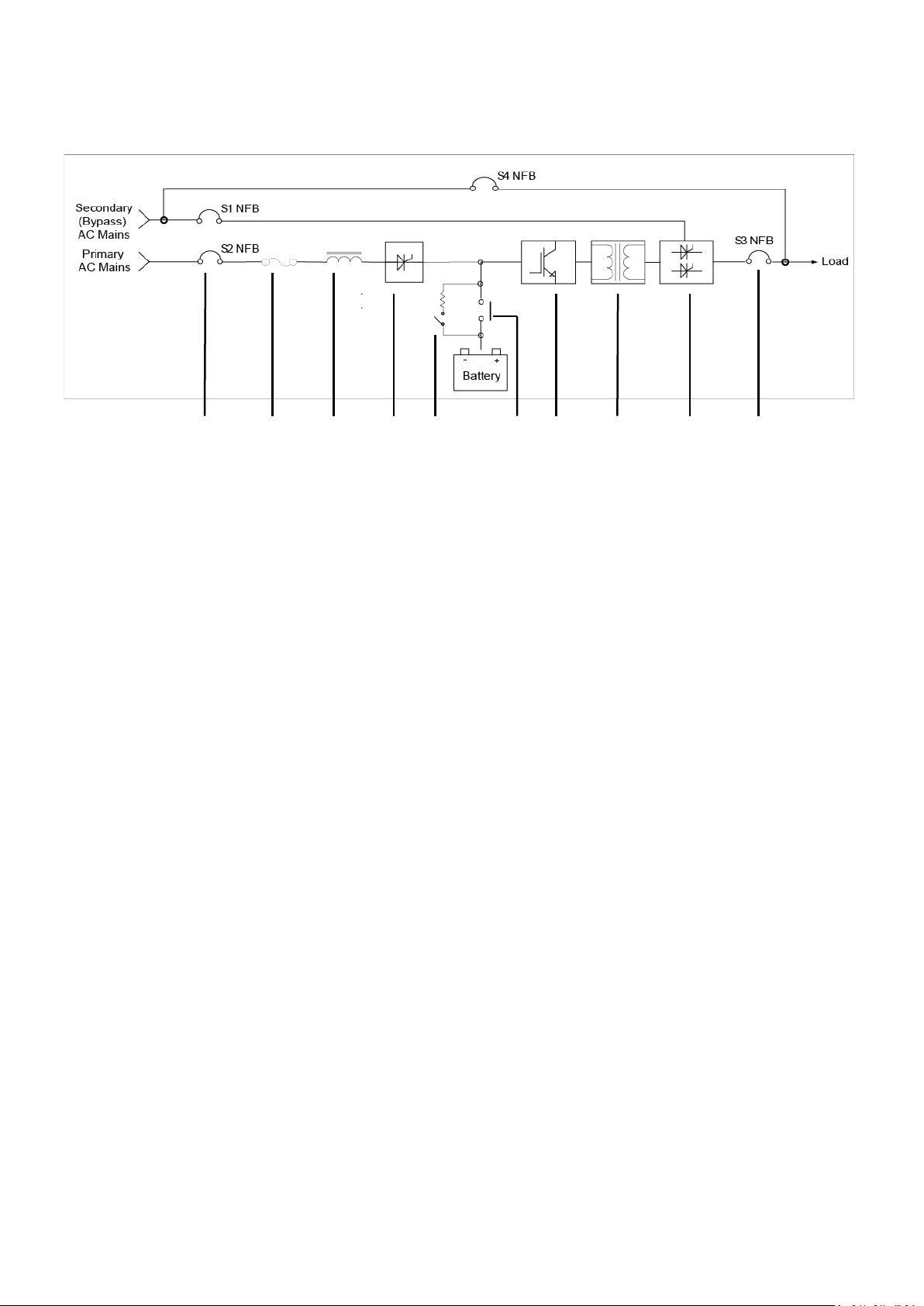

2-1 Block Diagram

(1) (8)

(2) (3) (4) (5) (6) (7) (9) (10) (11) (12)

Fig. 2-1

(1) Secondary (Bypass) AC Mains NFB (S1 NFB)

(2) Primary AC Mains NFB (S2 NFB)

(3) Input Fuse

(4) Three-phase AC Inductor

(5) Rectifier/ Charger

(6) Battery Auxiliary Relay

(7) Battery MS (Magnetic Switch)

(8) Manual Bypass Maintenance NFB (S4 NFB)

(9) Inverter Module

(10) Inverter Isolation Transformer

(11) STS (Static Transfer Switch)

(12) Output NFB (S3 NFB)

Page 5

2-2 System Major Module Function Introduction

2-2-1 Rectifier

(1) Utilization of SCRs inverts AC voltage to DC voltage.

(2) Combination of CPLD and DSP make the rectifier more stable and reliable.

(3) Over-voltage protection.

(4) DC voltage soft starter.

(5) Float charging and equalization charging modes support.

(6) Float charging time is adjustable and available on the display panel.

(7) Battery test can be done with continuous AC supply.

(8) Manual and automatic periodic battery tests are settable on the display panel.

(9) Charging current is settable on the display panel.

(10) 12-pulse rectifier is optional for reducing input THD.

2-2-2 Inverter

(1) IGBT as a power component is adopted.

(2) The inverter is equipped with an output isolation transformer.

(3) DSP digital control processing technology is applied to improve analogue components’ aging,

temperature drift and for the purpose of using fewer components.

(4) Integrated A/D signal processing, 12-bit resolution and fast transition are featured.

(5) Heat dissipation structure combined with temperature protection makes the inverter more reliable.

2-2-3 Static Transfer Switch

(1) Use of SCR for the static transfer function of the inverter and the bypass can work in a variety of

environments.

(2) High-frequency technology isolates the trigger circuit. The trigger circuit effectively triggers the STS

and results in switching without disconnection between inverter and bypass loops.

(3) STS has triggering conditions for disable, bypass and inverter loops and is fully controlled by DSP.

2-2-4 Emergency Power Off (EPO)

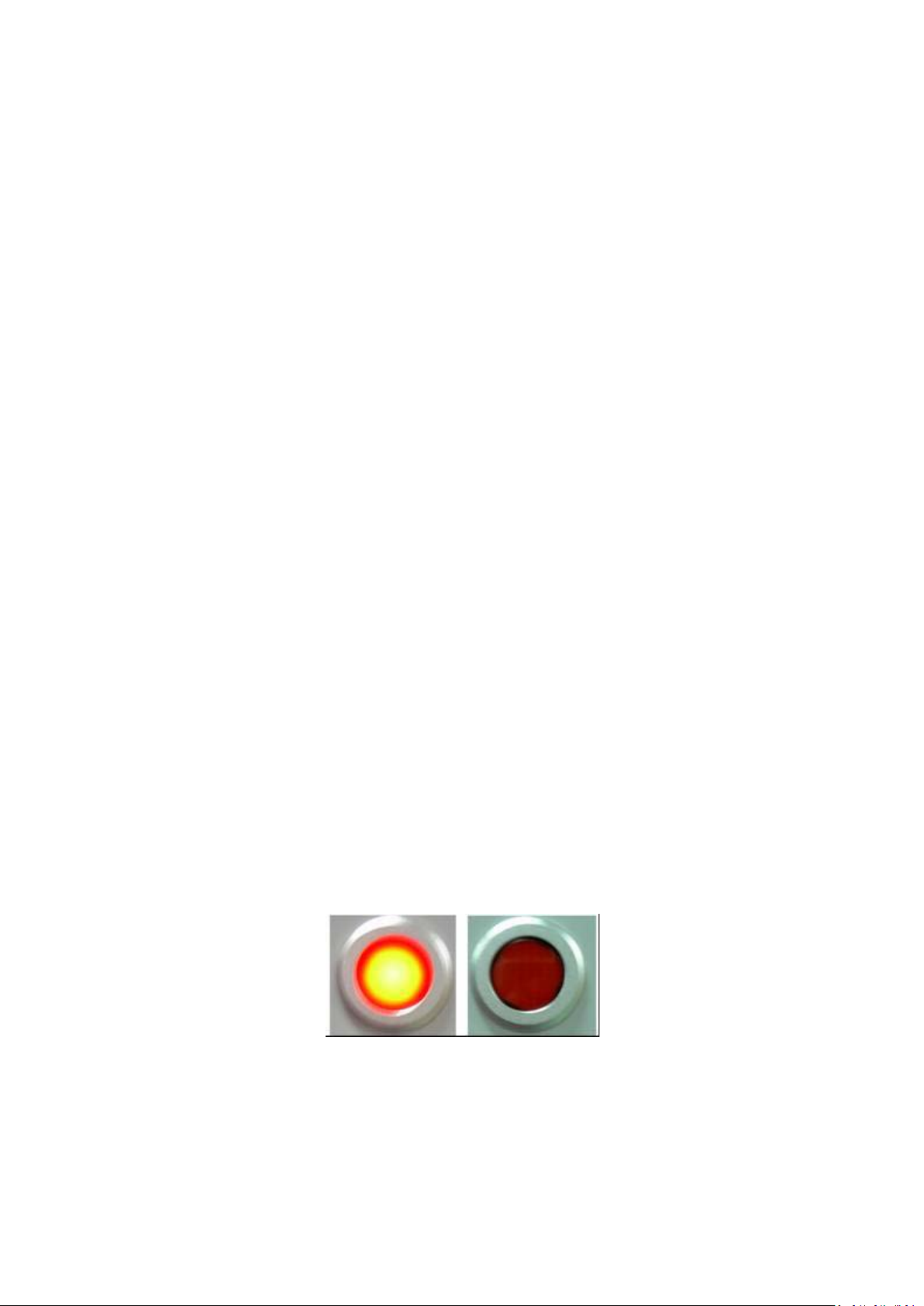

For emergency or force majeure in operation, EPO is used by pressing the button for shutting down the UPS

immediately. Press EPO button to completely stop the UPS and EPO light is turned on (Fig 2-2-4 Left). Press

EPO button and select the button of “Turn off inverter” on the display panel to restart the UPS and EPO

light is turned off (Fig 2-2-4 Right).

Fig. 2-2-4

Page 6

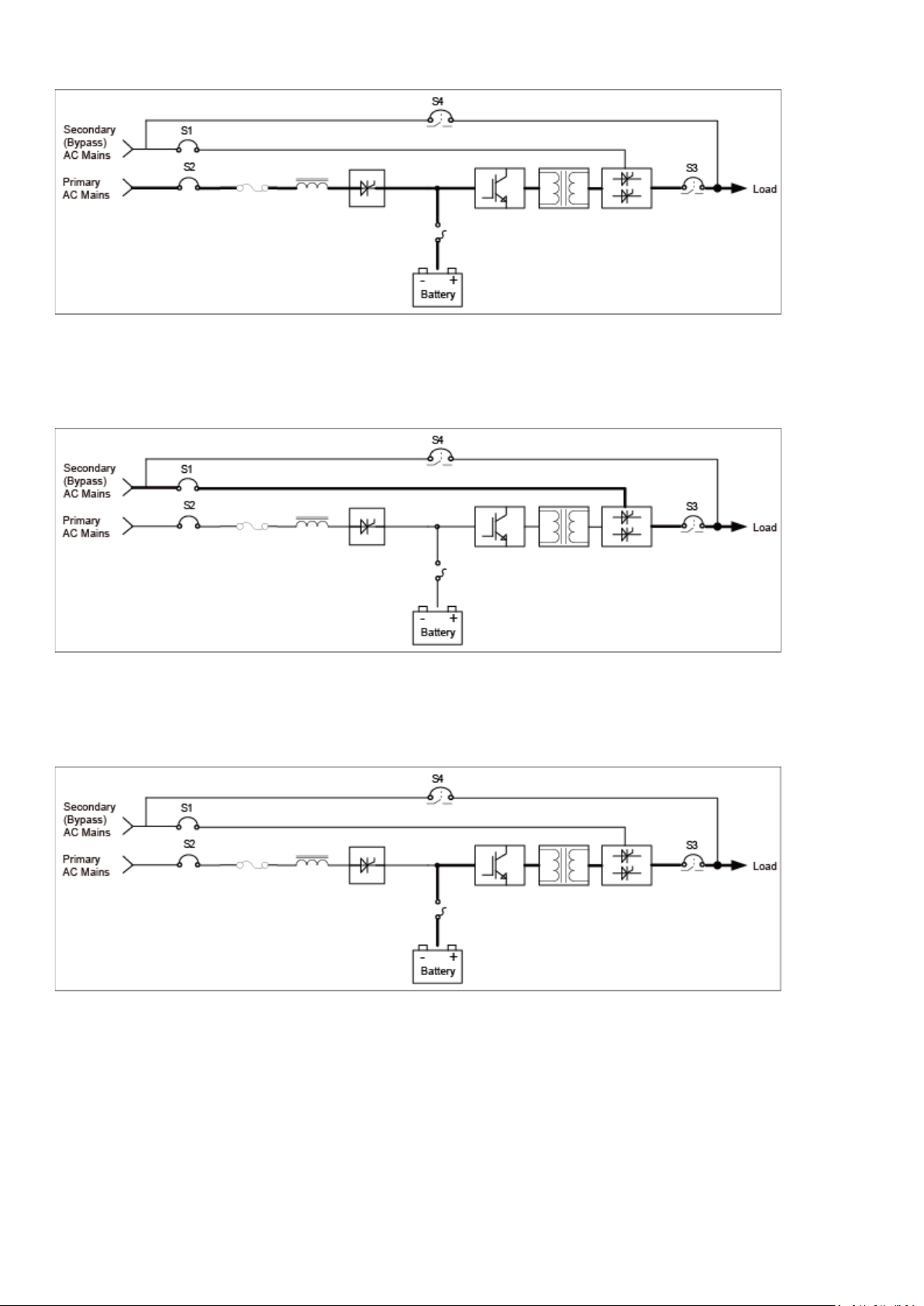

2-3 System Operation Modes

2-3-1 Normal Operation

Fig. 2-3-1 Normal Operation

AC mains power goes through the rectifier, the inverter, the STS to the load.

2-3-2 Bypass Operation

Fig. 2-3-2 Bypass Operation

AC mains power goes through the bypass path and the STS to the load.

2-3-3 Battery Supply Operation

Fig. 2-3-3 Battery Supply Operation

The power supplied from batteries goes through the inverter and the STS to the load. When the load

consumes power from the batteries, its backup time depends on the battery capacity and the load power

consumption. Therefore, save your data and turn off the personal computers as soon as possible when a

blackout occurs.

Page 7

2-3-4 Maintenance Bypass Operation

Fig. 2-3-4 Maintenance Bypass Operation

AC mains power goes through the maintenance bypass switch to the load. This mode is only for trained

professionals to do regular system and cleaning maintenance.

2-3-5 EPO Switch

Fig. 2-3-5 EPO Switch

UPS is going to be turned off and outputs no power in this mode for emergency.

Page 8

3. Touch Display Panel (HMI, Human Machine Interface)

3-1 Introduction

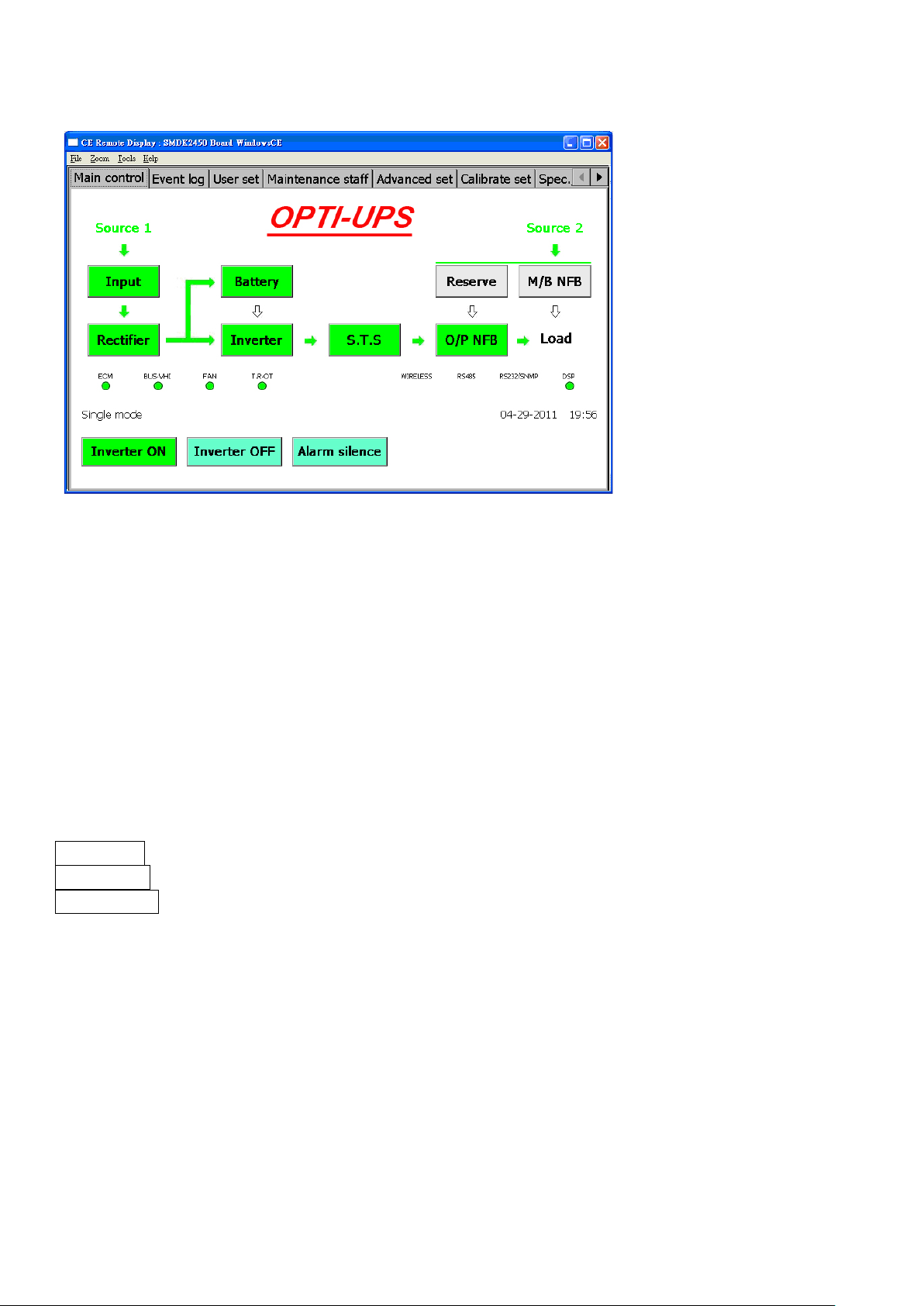

Fig. 3-1

DS-C33 II has an 800x480px TFT touch screen display panel. It can be set and controlled, and its status and

information are displayed on the display panel shown as Fig.3-1.

3-2 LCD Panel

The display consists of main control, event log, user set, maintenance staff, advanced set, calibrate set and

spec./service categories (tabs) and their corresponding pages.

3-2-1 Main control

Main control displays system operation status shown as Fig.3-1. There are input, rectifier, battery, inverter,

STS and O/P NFB status buttons. Press these status buttons for details.

Main control buttons:

Inverter ON Turn on the inverter.

Inverter OFF Turn off the inverter.

Alarm SilenceSwitch on/off alarm sound

Page 9

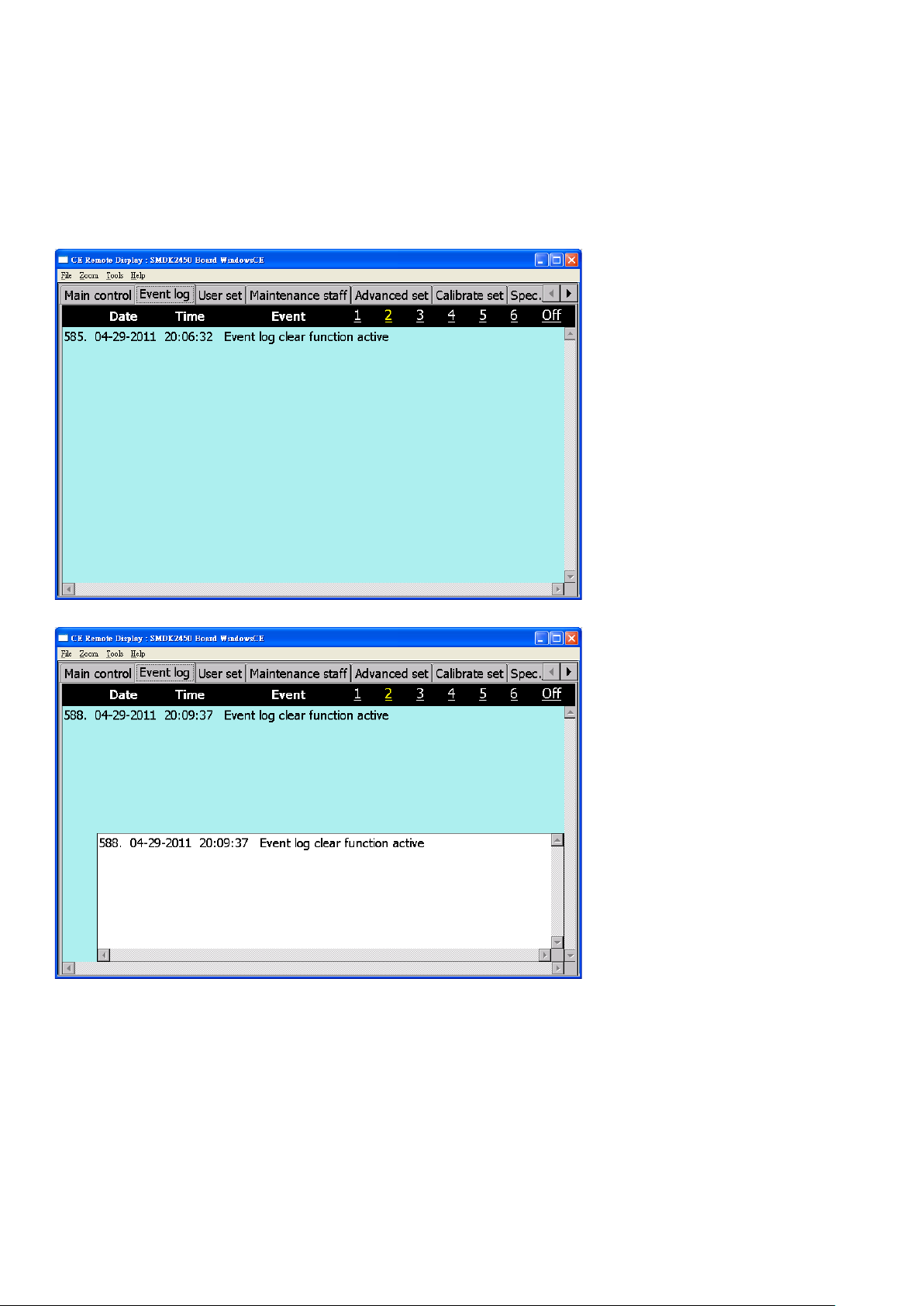

3-2-2 Event log

Up to 2400 events with time in total can be recorded on 6 pages shown as Fig.3-2-2-1. These are helpful for

maintenance engineers to find root causes and solve issues fast.

More functions:

(1) PIP (Picture in picture) event log Different events are shown in separate windows as in Fig.3-2-2-2.

(2) Logs can be exported to a portable disk.

(3) Logs are erasable.

Fig. 3-2-2-1

Fig. 3-2-2-2

Page 10

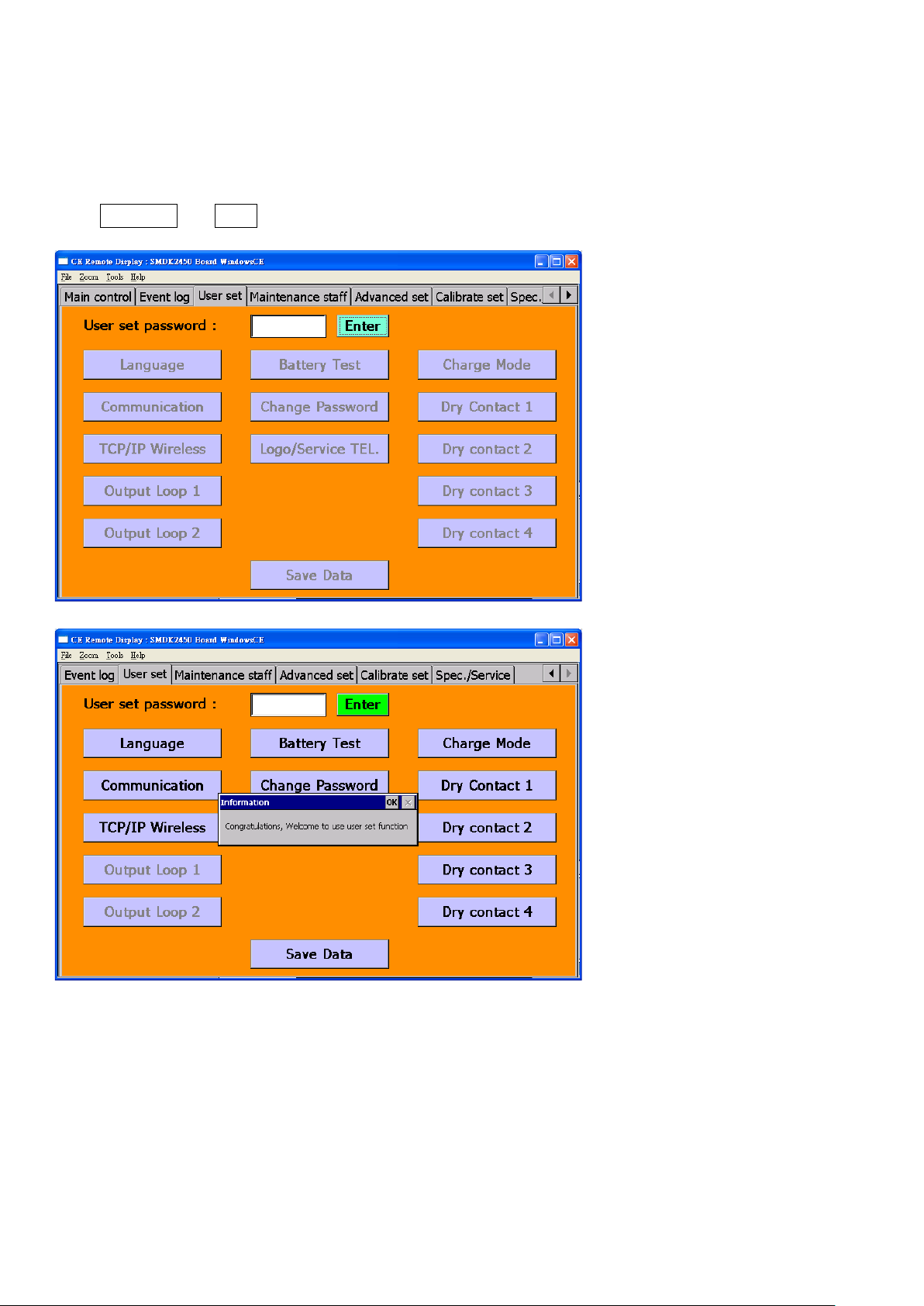

3-2-3 User set

User settings are available for end users to set/select language, battery test, charging mode,

communication mode, password, dry contact programming, brand name/ hotline shown as Fig. 3-2-3-1.

Password is required for access to this function and the default password is 000000. Successful access is

shown as Fig. 3-2-3-2.

Press Save Data and Enter buttons to avoid being reset by other people.

Fig. 3-2-3-1

Fig. 3-2-3-2

Page 11

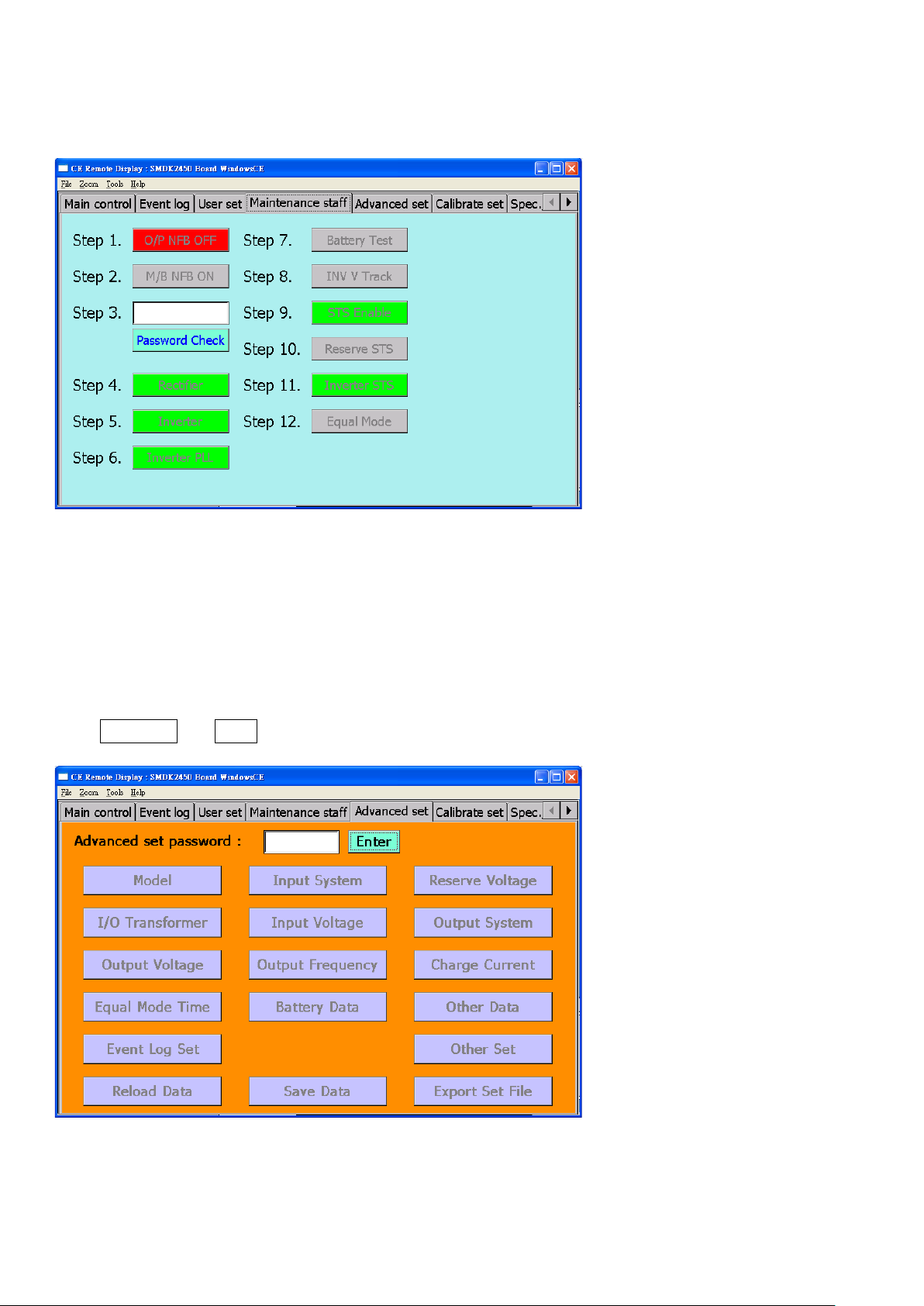

3-2-4 Maintenance staff

This function is only for professionals or qualified technicians. Professionals or qualified technicians will use

the information to find the fault root causes and solve issues timely. Operations are shown as Fig. 3-2-4-1.

Fig. 3-2-4-1

3-2-5 Advanced set

Advanced settings are available for professionals to set parameters such as model, input system, reserve

voltage, I/O transformer, input voltage, output system, output voltage, output frequency, charge current,

equalization mode time, battery data, other data, event log set, other set, reload data, save data, export set

file shown as Fig. 3-2-5-1.

Contact the manufacturer for advanced set password. This password is automatically changed every year.

Press Save Data and Enter buttons to avoid being reset by other people.

Fig. 3-2-5-1

Page 12

3-2-6 Calibrate set

Calibration settings are available for professionals to set voltage, current and temperature, etc shown as Fig.

3-2-6-1.

This function requires an advanced set password.

Press Save Data and Enter buttons to avoid being reset by other people.

Fig. 3-2-6-1

3-2-7 Spec./Service

This function display specification details and service information shown as Fig. 3-2-7-1.

Fig. 3-2-7-1

Page 13

4. Fixation and Installation

4-1 Fixation

4-1-1 Transportation

(1) Fig. 4-1-1a and Fig. 4-1-1b represent the packing.

(2) UPS should be placed in the way indicated by the arrow on the carton.

(3) In order to avoid danger during transportation, UPS or battery packs should be fastened tightly by ropes

and placed in the center of truck front end as Fig. 4-1-1c illustrates.

(4) Do not unpack the UPS during transportation.

(5) Exposing the UPS and the battery pack to liquids (including rain) is strictly prohibited.

(6) The UPS and the battery pack should not be exposed to any rigid external mechanical force, including

but not limited to pushing, punching or dropping.

(7) Moving UPS or battery packs requires forklifts or cranes as Fig. 4-1-1d and Fig. 4-1-1e illustrate.

(8) Elevators can carry UPS or battery packs. Check elevator limits for loading weights and volumes before

carrying.

Front View

Side View

Fig. 4-1-1a Fig. 4-1-1b

Page 14

U.P.S

d

Fig. 4-1-1c

Fig. 4-1-1

Fig. 4-1-1e

Page 15

4-1-2 Unpacking

Unscrew

Unscrew

(1) Cut off packing ropes and take out packing coverings as Fig. 4-1-2a, 4-1-2b and 4-1-2c illustrate.

(2) Unwrap PE coating.

(3) Unscrew screws of L fixers screwed on the pallet as Fig. 4-1-2d and 4-1-2e illustrate.

(4) Follow the arrow marks to unload the UPS as Fig. 4-1-2 illustrates.

Fig. 4-1-2a Fig. 4-1-2b Fig. 4-1-2c

Fig. 4-1-2d Fig. 4-1-2e

Fig. 4-1-2f

Page 16

4-1-3 Placement and Environment

15cm 15cm

50cm

50cm

90cm

door

Top View

DS 160KC33 II

34873

(1) A UPS should be placed in a clean and air conditioned environment and with ambient temperature

between 0℃ and +28℃. The operation temperature ranging from 10℃ to +25℃ is the best.

(2) UPS can’t be closely placed against or surrounded by walls or other objects as it would prevent from

good ventilation. An exhaust is in a rear of the UPS shown as Fig. 4-1-3a.

(3) Make room for opening the door of the UPS cabinet. For ventilation and maintenance purposes the

distances to walls or objects should be at least as shown in Fig. 4-1-3b and Fig.4-1-3c.

(4) The BTU values for DS-C33 II series shown as table 4-1-3d.

(5) The chamber for UPS placement should be sufficiently lit and equipped with an emergency fire

extinction system.

Fig. 4-1-3a Fig. 4-1-3b Fig. 4-1-3c

Table 4-1-3d BTU Values

Model BTU

DS 10KC33 II 3542

DS 15KC33 II 5313

DS 20KC33 II 6539

DS 30KC33 II 9808

DS 45KC33 II 13486

DS 60KC33 II 16347

DS 80KC33 II 21796

DS 100KC33 II 24520

DS 120KC33 II 29424

DS 200KC33 II 43592

Page 17

4-1-4 Outline and Dimension

10 / 15 / 20 / 30K 120V / 208V & 220V / 380V Models

Page 18

45 / 60K 120V / 208V Models

45 / 60 / 80 / 100 / 120K 220V / 380V Models

Page 19

80 / 100 / 120K 120V / 208V Models

Page 20

160 / 200K 220V / 380V Models

Page 21

4-2 Installation

208Vac,

208Vac,

220 / 380V

113A

3P / 125A

68A

3P / 75A

117.7A

4-2-1 UPS Input / Output Specifications

Frequency Topology Voltage

Input 50 / 60Hz 3p3w and PE 220Vac, 380Vac

3p4w and PE 110 / 190Vac, 115 / 200Vac, 120 /

127 / 220Vac, 220 / 380Vac, 230 / 400Vac,

240 / 415Vac, 254 / 440Vac

Output 50 / 60Hz 3p3w and PE 220Vac, 380Vac

3p4w and PE 110 / 190Vac, 115 / 200Vac, 120 /

127 / 220Vac, 220 / 380Vac, 230 / 400Vac,

240 / 415Vac, 254 / 440Vac

Table 4-2-1 Input / Output NFB Specifications

Capacity Voltage Max Input

Current

10KVA

15KVA

20KVA

30KVA

40KVA

45KVA

120 / 208V 43A 3P / 50A 28A 3P / 30A 48.5A

220 / 380V 27A 3P / 30A 14A 3P / 15A 24.2A

120 / 208V 64A 3P / 75A 42A 3P / 50A 72.7A

220 / 380V 39A 3P / 40A 23A 3P / 30A 39.8A

120 / 208V 84A 3P / 100A 56A 3P / 60A 96.9A

220 / 380V 49A 3P / 50A 28A 3P / 30A 48.4A

120 / 208V 124A 3P / 125A 83A 3P / 100A 143.7A

220 / 380V 74A 3P / 75A 45A 3P / 50A 77.9A

120 / 208V 167A 3P / 200A 111A 3P / 125A 192.2A

220 / 380V 101A 3P / 125A 61A 3P / 75A 105.6A

120 / 208V 187A 3P / 200A 124A 3P / 125A 214.7A

Input

NFB

Max Output

Current

Output NFB Max Neutral

Line Current

50KVA

60KVA

80KVA

100KVA

120KVA

160KVA 220 / 380V 389A 3P / 400A 242A 3P / 250A 419.1A

200KVA 220 / 380V 491A 3P / 500A 303A 3P / 350A 524.8A

120 / 208V 207A 3P / 225A 139A 3P / 150A 240.7A

220 / 380V 124A 3P / 125A 74A 3P / 75A 128.1A

120 / 208V 247A 3P / 250A 167A 3P / 175A 289.2A

220 / 380V 149A 3P / 150A 91A 3P / 100A 157.6A

120 / 208V 328A 3P / 350A 222A 3P / 225A 384.5A

220 / 380V 196A 3P / 200A 121A 3P / 125A 209.5A

120 / 208V 399A 3P / 400A 278A 3P / 300A 481.5A

220 / 380V 244A 3P / 250A 149A 3P / 150A 258A

120 / 208V 491A 3P / 500A 333A 3P / 350A 576.7A

220 / 380V 294A 3P / 300A 182A 3P / 200A 315.2A

Page 22

4-2-2 Cable Specifications

600V PVC Insulated Hard Copper Stranded Wire Safe Current Table (60℃ Insulation, Ambient Temperature

under 30℃)

Type

Sectional Area

2)

(mm

Number of

Strands/

Diameter

Safe Current

Sectional Area

2)

(mm

Number of

Strands/

Diameter

Safe Current

3.5 7 / 0.8 37 80 19 / 2.3 257

5.5 7 / 1.0 49 100 19 / 2.6 298

8 7 / 1.2 61 125 19 / 2.9 344

Hard

Copper

Strand

Wire

14 7 / 1.6 88 150 37 / 2.3 395

22 7 / 2.0 115 200 37 / 2.6 469

30 7 / 2.3 139 250 61 / 2.3 556

38 7 / 2.6 162 325 61 / 2.6 650

50 19 / 1.8 190 400 61 / 2.9 745

60 19 / 2.0 217 500 61 / 3.2 842

Temperature and current allowance values are not applicable to UL certified cables. Use of UL certified

cables should be based on cable specifications for temperature and current limits.

4-2-3 Cable Diameter

Table 4-2-3-1 Specifications for AC Input and Output and DC Battery Cables

Capacity Voltage Input (mm

10KVA

15KVA

20KVA

30KVA

40KVA

45KVA

50KVA

60KVA

80KVA

100KVA

120KVA

120 / 208V 8 5.5 8 2.0 14

220 / 380V 5.5 3.5 3.5 1.6 3.5

120 / 208V 14 8 22 5.5 22

220 / 380V 8 3.5 5.5 2.0 8

120 / 208V 22 14 30 5.5 30

220 / 380V 14 5.5 8 2.0 14

120 / 208V 38 22 50 8 50

220 / 380V 22 8 22 5.5 22

120 / 208V 60 38 80 8

220 / 380V 30 14 30 8

120 / 208V 80 38 100 8

220 / 380V 38 14 38 8

120 / 208V 100 50 125 14

220 / 380V 38 22 38 8

120 / 208V 125 60 150 14

220 / 380V 50 22 60 8

120 / 208V 200 100 250 14

220 / 380V 80 38 100 14

120 / 208V 250 150 325 22

220 / 380V 125 50 125 14

120 / 208V 325 200 400 22

220 / 380V 150 80 150 14

2

) Output (mm2) Neutral (mm2) PE (mm2) Battery(mm2)

30

38

50

60

100

125

150

160KVA 220 / 380V 250 125 250 22 250

200KVA 220 / 380V 325 150 400 22 352

Page 23

4-2-4 Terminal Definitions

(1) I/R : Rectifier Input R Phase

(2) I/S : Rectifier Input S Phase

(3) I/T : Rectifier Input T Phase

(4) I/N : Input Neutral Line

(5) I2/R : Slave UPS Input R Phase (from slave UPS input R phase for paralleling system)

(6) I2/S : Slave UPS Input S Phase (from slave UPS input S phase for paralleling system)

(7) I2/T : Slave UPS Input T Phase (from slave UPS input T phase for paralleling system)

(8) BP/R : Bypass Input R Phase

(9) BP/S : Bypass Input S Phase

(10) BP/T : Bypass Input T Phase

(11) BP/N : Bypass Input Neutral Line

(12) O/N : Output Neutral Line

(13) O/R : Output R Phase

(14) O/S : Output S Phase

(15) O/T : Output T Phase

(16) B+ : Battery Input Anode

(17) G : Grounding

(18) B- : Battery Input Cathode

4-2-5 Wiring Notices

Battery

(1) For safety, professional engineers should put on isolated gloves, use tools with isolated handles. It is

recommended that two or more engineers are working on wiring the batteries.

(2) Check if batteries are well grounded and make sure your limbs are dry before you perform battery

disconnection.

(3) Disconnect UPS and batteries (switch off the battery breaker and unplug the battery connector) and

then disconnect cables of batteries on every layer.

(4) During battery disconnection, do not touch neighboring batteries while processing cables or plates of

batteries in order not to cause short circuit.

(5) During battery connection, finish connecting batteries on each layer firstly and then interconnect the

battery layers. Finally connect the battery connector to the battery breaker.

(6) Check terminal voltage and polarity of the batteries and the UPS battery input.

Check the following items after wiring setup:

(1) Every terminal is correctly connected.

(2) PE cable is correctly grounded.

(3) Every screw is tightly screwed.

(4) All switches should stay off (at off position).

(5) Output power distribution panel is not short circuited.

(6) Battery terminals and polarities are correctly connected.

Page 24

4-2-6 Terminals

10 / 15 / 20 / 30K 120V / 208V & 220V / 380V Models

Master / Slave UPS

I/R I/S I/T

I/N

I2/R I2/S I2/T BP/R BP/S BP/T BP/N O/N O/R O/S O/T B+ G B-

45 / 60K 120V / 208V Models

45 / 60 / 80 / 100/ 120K 220V / 380V Models

Master UPS

I/R I/S I/T B+ G BI/N

I2/R I2/S I2/T BP/R BP/S BP/T BP/N O/N O/R O/S O/T

Slave UPS

I/R I/S I/T B+ G BI/N

I2/N BP/N O/N BP/R BP/S BP/T O/R O/S O/T

Page 25

80 / 100 / 120K 120V / 208V Models

Slave UPS

B+ G B-

BP/R BP/S BP/T BP/N O/N O/R O/S O/T

I/R I/S I/T I/N

Page 26

5. Operation Procedures

5-1 Power-on

5-1-1 Initial Power-on Procedures

(1) Switches

BAT Switch: for switching on/off batteries.

SPS Switch: for switching on/off the power board.

S1 Switch: for switching on/off the second AC mains power or the bypass of the model with an input

transformer.

S2 Switch: for switching on/off the primary AC mains po w e r.

S3 Switch: for switching on/off the output

S4 Switch: for switching on/off the manual bypass during maintenance.

(2) Input Phase Sequence Tes t

(3)

Firstly, turn on the power distribution panel and then check each terminal voltage with a multi-meter and

input phase sequence with a three-phase sequence detector. If the phase sequence is correct, continue the

next procedure. If the sequence is reverse, turn off the AC mains and exchange S and T phase input cables,

and turn on the AC mains. Proceed with the next procedure if the phase sequence is correct.

(4) Initial power-on

Switch off the load switch and disconnect all cables from UPS to the load. Follow the below procedures:

(a) Turn on the battery cabinet switch (battery fuse)

(b) Turn on the UPS battery switch

(c) Turn on the SPS power board switch (and wait till HMI control panel program finishes)

(d) Turn on the S1 / S2 / S3 switches

(e) Press the Inverter ON button on the HMI control panel

(f) Press the Ye s button in the pop-up window (UPS operation mode changes from bypass to inverter, and

a dialogue window pops up for this status.)

Finally, check the terminals of O/R, O/S and O/T for AC voltages and frequencies and terminals of B+ and Bfor DC voltages are correct. Operation is shown as Fig. 5-1-1:

Page 27

5-1-2 Normal Power-on Procedures

Initial Power-on Procedures:

Switch on Switch off

Switch on Switch off

SPS

S1

Power-off Proce dures:

Inverter status button

becomes green after

about 50 seconds

Bypass (Reserve) status button

becomes green

Switch on

Switch on

Switch off

Switch off

Switch on

*

S3

Switch on Switch off

S2

BAT

Switch off

Press Inverter ON

Press Yes

Press Inverter OFF

Press Yes

When the initial power-on procedure is done and the UPS is turned on. Press Inverter ON button on the

HMI control panel and Yes button on the pop-up window to restart the UPS. It will be turned on after 3

minutes.

*) for 10K~30KVA models, fuses must be installed before the initial power-on operation.

Fig. 5-1-1 UPS Power-on/off Workflow

Page 28

5-2 Power-off

5-2-1 Normal Power-off Procedures

Press Inverter OFF button on the HMI control panel and Yes button on the pop-up window to shut down

the UPS. UPS operation mode changes from inverter to bypass, and a dialogue window pops up for this

status.

5-2-2 Complete Power-off Procedures

Follow Fig. 5-1-1.

5-3 Maintenance Bypass

5-3-1 Maintenance Bypass Procedures

Follow Fig. 5-3.

5-3-2 DS10KC33 / 15KC33 II Inbuilt Battery Replacement Procedures

(1) Transferring to bypass mode

Follow Fig. 5-3 to transfer to bypass mode.

(2) Replacing old batteries

Remove the rear panel, battery fixers (plates) and disconnect the cables. Rewire the new batteries the same

way the old batteries have been wired. Check voltage and polarity after new batteries have been installed.

(3) Restarting the UPS

Follow Fig. 5-3 to transfer to inverter mode.

5-4 Resumption from Maintenance Procedures

Follow Fig. 5-3.

5-5 Emergency Power Off

EPO (Emergency Power Off) is a device for an accident or emergent power cutoff under abnormal or

unexpected circumstances. EPO makes:

(1) the inverter shut down;

(2) STS (Static Transfer Switch) trip and cut the system output.

(3) RCM (Rectifier Charging Module) stop.

EPO activation and deactivation events and times will be recorded. Communication stays normal during

EPO is active. Press EPO button again and Inverter OFF button on the HMI control panel and Yes button on

the pop-up window and the UPS will resume and operate in bypass mode, and then transfer back to

inverter mode after 3 minutes.

Page 29

Fig. 5-3 Maintenance Bypass Workflow

*) for 10K~30KVA models, fuses must be installed before the initial power-on operation.

Page 30

5-6 Dry Contact Communication

10

BACKUP MODE_NC

FAN FAULT_COM

11

INV ON_NO

FAN FA U LT _ N C

12

INV ON_COM

FUSE FAULT_NO

24

UPS OVERLOAD_COM

FUNCTION RELAY3_NO

25

UPS OVERLOAD_NC

FUNCTION RELAY3_COM

26

SYN. AC FAIL_NO

FUNCTION RELAY3_NC

(1) PCB-3308 Dry contact layout shown as Fig. 5-7-1.

(2) PCB-3308 Dry contact function definitions listed in Table 5-7-2.

Fig. 5-7-1 Dry Contact Layout

Contact CN2 CN3

1 +12V USER0 +12V

2 INV STS_NO EXT. SHUTDOWN

3 INV STS_COM USER1 +12V

4 INV STS_NC EX T. EP O

5 BAT LOW_NO +12V

6 BAT LOW_COM ROLATION ERROR_NO

7 BAT LOW_NC ROLATION ERROR_COM

8 BACKUP MODE_NO ROLATION ERROR_NC

9 BACKUP MODE_COM FAN FAULT_ NO

13 INV ON_NC FUSE FAULT_COM

14 UPS FAULT_NO FUSE FAULT_NC

15 UPS FAULT_COM FUNCTION RELAY1_NO

16 UPS FAULT_NC FUNCTION RELAY1_COM

17 RECIFIER AC FAIL_NO FUNCTION RELAY1_NC

18 RECIFIER AC FAIL_COM COMPOSITE FAULT_NO

19 RECIFIER AC FAIL_NC COMPOSITE FAULT_COM

20 RESERVE FAIL_NO COMPOSITE FAULT_NC

21 RESERVE FAIL_COM FUNCTION RELAY2_NO

22 RESERVE FAIL_NC FUNCTION RELAY2_COM

23 UPS OVERLOAD_NO FUNCTION RELAY2_NC

27 SYN. AC FAIL_COM FUNCTION RELAY4_NO

28 SYN. AC FAIL_NC FUNCTION RELAY4_COM

29 RCM SHUTDOWN_NO FUNCTION RELAY4_NC

30 RCM SHUTDOWN_COM SPEAKER1

31 RCM SHUTDOWN_NC SPEAKER2

32 GND GND

Table 5-7-2 Dry Contact Signal Definitions

Page 31

6. Maintenance and Storage

(1) Clean the UPS placement chamber and the UPS itself from dust every 6 months.

(2) Recharge and discharge batteries every 3 months to maintain their lifetime.

(3) Pay attention to the temperature and humidity of the chamber.

(4) When storing a UPS, disconnect all cables (take out the fuses or batteries for battery-inbuilt models)

and wrap the UPS with PE coating.

(5) If after restarting the UPS that has been returned to operation from storage, the time or date is

incorrect on the HMI display panel, change the Lithium battery.

7. Troubleshooting

Deal with issues relying on events, messages or indications of icons or pop-up windows on the HMI display

panel shown as below. Contact technicians or professionals to assist in solving issues.

Page 32

8. Specifications

Model

Capacity 10KVA 15KVA 20KVA 30KVA 45KVA 60KVA 80KVA 100KVA 120KVA 160KVA 200KVA

Rated Power 8KW 12KW 16KW 24KW 36KW 48KW 64KW 80KW 96KW 128KW 160KW

Power Factor 0.8

Phase 3 Phase 3 Wire or 3 Phase 4 Wire and PE

Voltage Range 10K~120K: 120V/208 or 220V/380V ±20%; 160K~200K: 220V/380V ±20%

Frequency Range 50Hz / 60Hz ±5Hz Auto Sensing

Rectification 6 Pulse (Standard) / 12 Pulse (Optional)

Rectifier Efficiency >97%

Inverter Efficiency >88%

Phase 3 Phase 3 Wire or 3 Phase 4 Wire and PE

Volta ge 120V/208V or 220V/380V

Stabilization ±1%

Transient 90% Resumption after 4 Cycles

Overload Capacity

Inverter Topology IGBT Design, DSP Control, 20KHz PWM Sine Wave

Frequency 50Hz / 60Hz

Frequency Stabilization ±0.1%

Phase Lock Range ±5Hz

Phase Unlock Range >±5Hz

Phase Relock Range ±3Hz

Waveform Sine Wave

Crest Factor 3:1

THD <3% for Linear Load

Transfer

Cold Start Transfer 2 Level Voltage Transfer

Transfer Time

Efficiency >99%

Volta ge DC220V / DC410V DC410V DC435V

Current 1.5~10A 3~20A 5~30A 15~50A

Time 100% discharged and then recharged to 90% in 8 hours (depending on battery specifications)

DS10K

C33 II

DS15K

C33 II

as the voltage and the frequency of the inverter and the utility are synchronized.

DS20K

C33 II

DS30K

C33 II

>101% ~ 124% Transferred to bypass after 30 minutes

>125% ~ 150% Transferred to bypass after 10 minutes

>150% Transferred to bypass after 1 minute

Static Transfer Switch

UPS transfers from bypass mode to inverter mode

DS45K

C33 II

Input

Output

Bypass mode to inverter mode 0ms

Inverter mode to bypass mode 0ms

Charger

DS60K

C33 II

DS80K

C33 II

DS100K

C33 II

DS120K

C33 II

DS160K

C33 II

DS200K

C33 II

* Specifications are subject to change without notice.

Page 33

Model

Battery Configuration

Backup Time Depends on overall battery capacity

Noise <60dB

Operating Temperature 0~40℃

Storage Temperature -25℃~55℃

Storage Altitude <10000M

Operating Altitude <3500M

Relative Humidity 90% Non Condensing

Width 530 530 530 530 810 810 810 810 810

Depth 869 869 869 869 810 810 810 810 810

Height 1010 1010 1010 1010 1900 1900 1900 1900 1900

Width 580 580 580 580 920 920 920 920 920

Depth 900 900 900 900 920 920 920 920 920

Height 1200 1200 1200 1200 2165 2165 2165 2165 2165

DS10K

C33 II

DS15K

C33 II

DS20K

C33 II

DC192V (12V × 16pcs)

DC360V (12V × 30pcs)

DS30K

C33 II

Physical Dimensions

DS45K

C33 II

Packing Dimensions

DS60K

C33 II

DS80K

C33 II

DS100K

C33 II

(12V × 30pcs)

DS120K

C33 II

DC360V

* Specifications are subject to change without notice.

DS160K

C33 II

(12V × 32pcs)

TBD

TBD

TBD

TBD

TBD

TBD

DS200K

C33 II

DC384V

TBD

TBD

TBD

TBD

TBD

TBD

Page 34

9. Contact Information

OPTI-UPS USA:

Tel: +1-909-869-5700

Fax: +1-909-869-5730

info@opti-ups.com

www.opti-ups.com

OPTI-UPS Europe:

Tel: +31-40-401-50-00

Tel: +31-40-262-80-57

Fax: +31-40-254-60-06

eu@opti-ups.com

www.opti-ups.com

OPTI-UPS Middle East:

Tel: +9714-8819-838

Fax: +9714-8819-938

mea@opti-ups.com

www.opti-ups.com

OPTI-UPS Australia & New Zealand:

Tel: +64-9-441-6470

Fax: +64-9-441-6490

aunz@opti-ups.com

www.opti-ups.com

OPTI-UPS Germany:

Tel : +49-7071-5495-148

Fax: +49-7071-5495-149

germany@opti-ups.com

www.opti-ups.com

OPTI-UPS Japan:

Tel: +81-3-3629-5782

Fax: +81-3-5682-0652

japan@opti-ups.com

www.opti-ups.com

OPTI-UPS Asia:

Tel: +886-2-2246-7272

Fax: +886-2-2246-7312

info@opti-ups.com.tw

www.opti-ups.com.tw

Loading...

Loading...