Page 1

OPTI-UPS

User’s Guide

Durable Series

Models DS-D33

www.opti-ups.com

Page 2

Contents Page

1. SYSTEM OVERVIEW

1.1. Construction of the UPS

1.2. Features and

1.3. Rectifier

1.4.

Inv

1.5. Static Switch

erter

Advantages......................................................................

...............................................................................................

.................................................................................................

......................................................................................

1.6. Maintenance Bypass Switch

1.7. Dimension & Drawings

1.8. Front Panel

.........................................................................................

2. TECHNICAL SPECIFICATION

..............................................................................

......................................................................

..............................................................

.....................................................................

...................................................................

2.1. 20KVA ~ 60KVA UPS 3–Phase Input / 3-Phase

2.2. 80KVA ~ 160KVA UPS 3–Phase Input / 3-Phase

2.3. 20KVA ~ 50KVA UPS 3–Phase Input / 1-Phase

3. INSTALLATION

3.1. Site & Environment

3.2.

Unp

ack

3.3. Cable Selection

3.4. Terminal

4. OPERATIONS

4.1. Switch on Procedure

4.2. Shutdown Procedure

4.3. From Inverter to Bypass Procedure

4.4. From Bypass to Inverter Procedure

5. LCD

DISPLAY ..............................................................................................

5.1. Menu 0 – Main

5.2. Menu 1 – Select Menu

5.3. Menu 2 – Status / Warning

5.4. Menu 3 – Real Time Data

...........................................................................................

Consideration ......................................................

ing ............................................................................................

....................................................................................

Conn

ect

ion ............................................................................

...............................................................................................

............................................................................

............................................................................

.....................................................

.....................................................

Menu...........................................................................

.........................................................................

Menu.........................................................

Menu ..........................................................

1-10

1-11

1-12

1-17

Output ......................

Output ....................

Output ......................

1-1

1-1

1-5

1-8

1-9

2-1

2-1

2-4

2-7

3-1

3-1

3-4

3-5

3-7

4-1

4-1

4-2

4-3

4-4

5-1

5-1

5-2

5-3

5-4

Page 3

Contents Page

5.5. Menu 4 – Historical Event

5.6. Menu 5 – Parameter Setting

5.7. Menu 6 – Rectifier Data Menu

5.8. Menu 7 – Output Data Menu

5.9. Menu 8 – Other Data Menu

5.10. Menu 9 – Reserve Data

5.11. Menu 10 – Boost Charge Setting

5.12. Menu 11 – Data Time Setting

5.13. Menu 12 – Other Setting

6. INTERFACE C

6.1. Dry Contacts

6.2. External

6.3. DB9

7.

OPTIONS .......................................................................................................

7.1. Battery Cabinet

ONNECTIONS .....................................................................

........................................................................................

Shutdown ...............................................................................

Conn

ection

...................................................................................

....................................................................................

7.2. Emergent Stop Switch

7.3. Remote Control Panel –

7.4. Software for PC Monitoring –

7.5. Auto Dialing Module –

7.6. Battery Monitoring Module -

8.

REDUNDANCY ............................................................................................

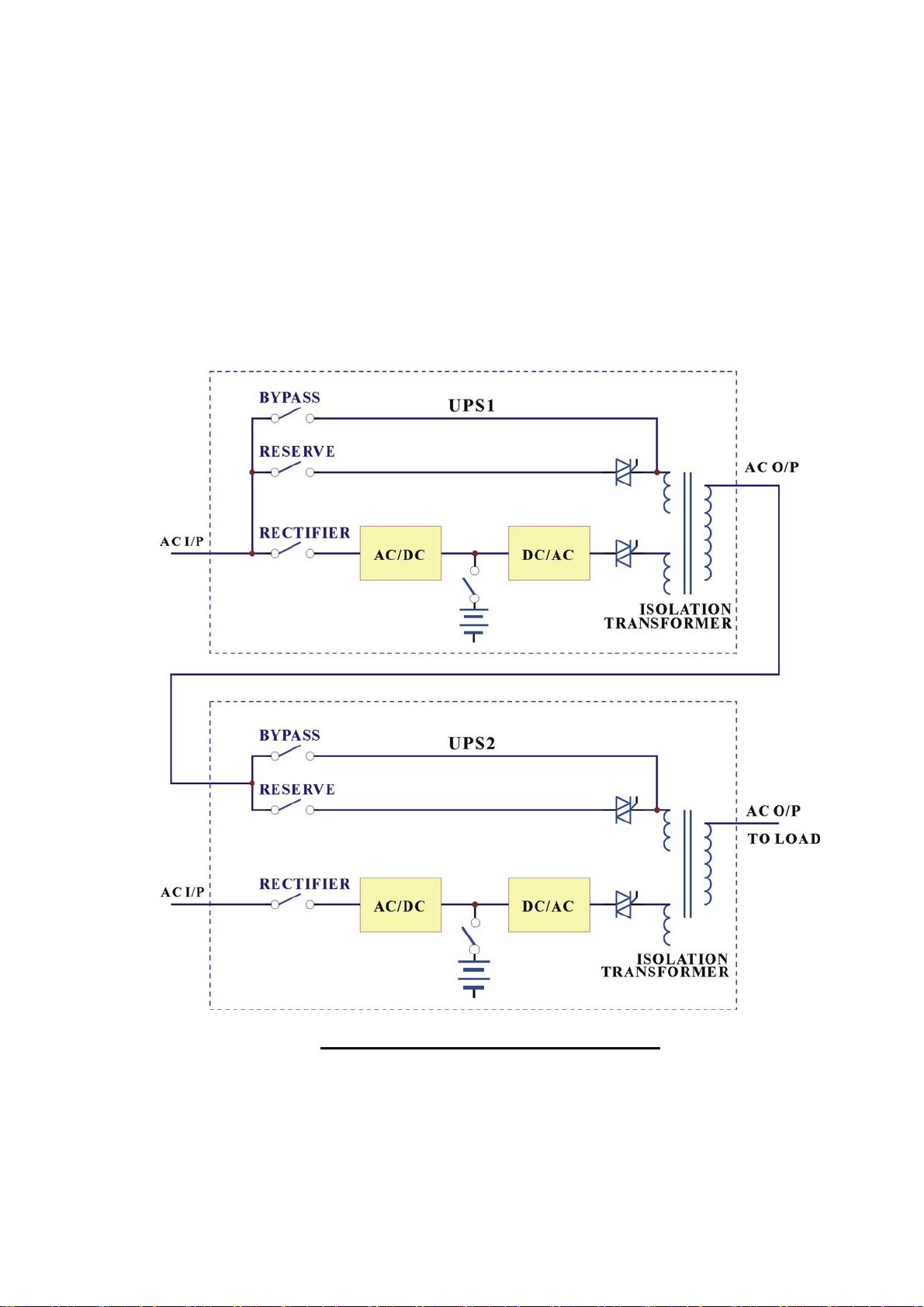

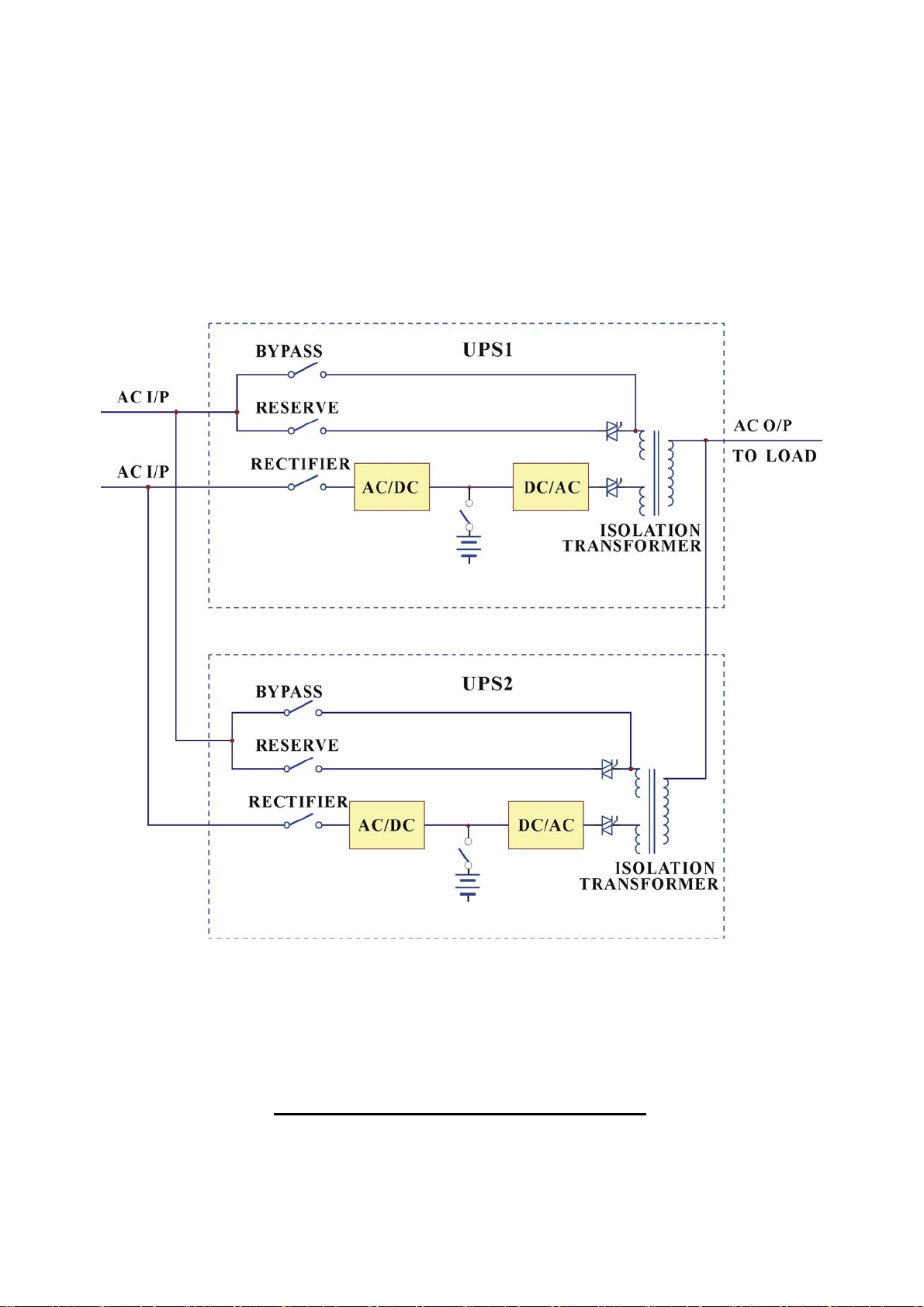

8.1. Serial Redundancy

9.

HELP..............................................................................................................

...............................................................................

Menu .........................................................

Menu.......................................................

............................................................

...............................................................

.................................................................

Menu..............................................................

Menu ...............................................

Menu ..................................................

Menu..........................................................

..........................................................................

UPSCAN™

UPSCOM™

UPSCALL™

DCMAN™

...................................................

.........................................

..................................................

............................................

5-5

5-6

5-7

5-8

5-8

5-9

5-9

5-11

5-12

6-1

6-1

6-3

6-3

7-1

7-1

7-2

7-2

7-2

7-3

7-3

8-1

8-1

9-1

Page 4

CAUTION !

☆ Hazardous voltage exits inside the UPS (includes the connection

terminals), cable connection and maintenance should be done by

professional or qualified personnel.

☆ The UPS has its own internal battery source (battery). The output

terminals may be live even when the UPS is not connected to the

AC supply.

☆ DC capacitors are employed in this unit, hazardous voltage still

exists even when the unit is not energized. Do not touch any part

of the UPS inside.

WA RNING !

☆ Be sure to operate the UPS within the rated power of the UPS.

☆ Prevent direct exposure to direct sunlight rain or contaminating

environment.

☆ Only qualified technicians should replace the batteries. Since

batteries have high short-circuit current capacity. Mistakes in

connection or disconnection can cause severe burns or death to

servicing personnel.

Page 5

1-1

1. SYSTEM OVERVIEW

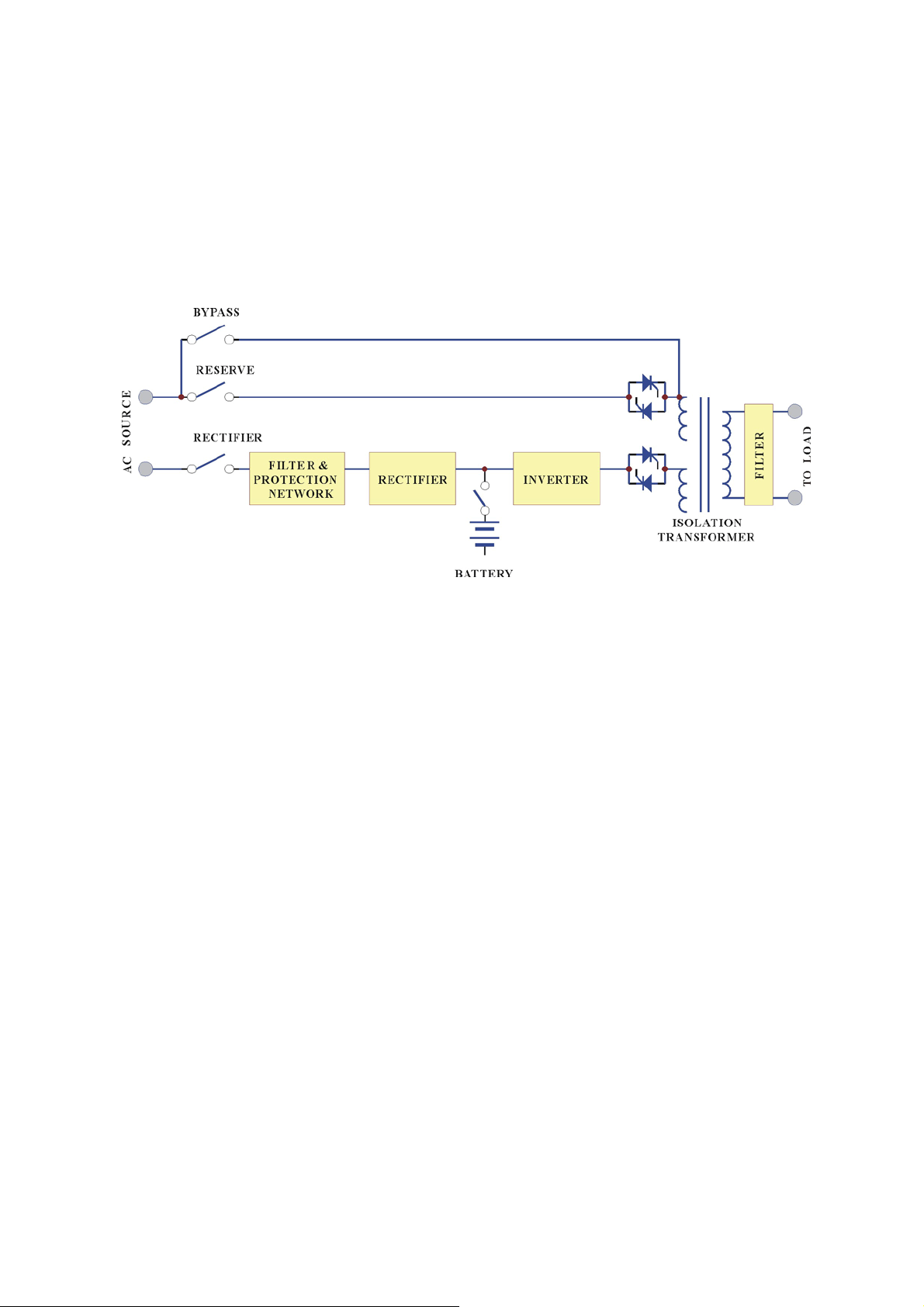

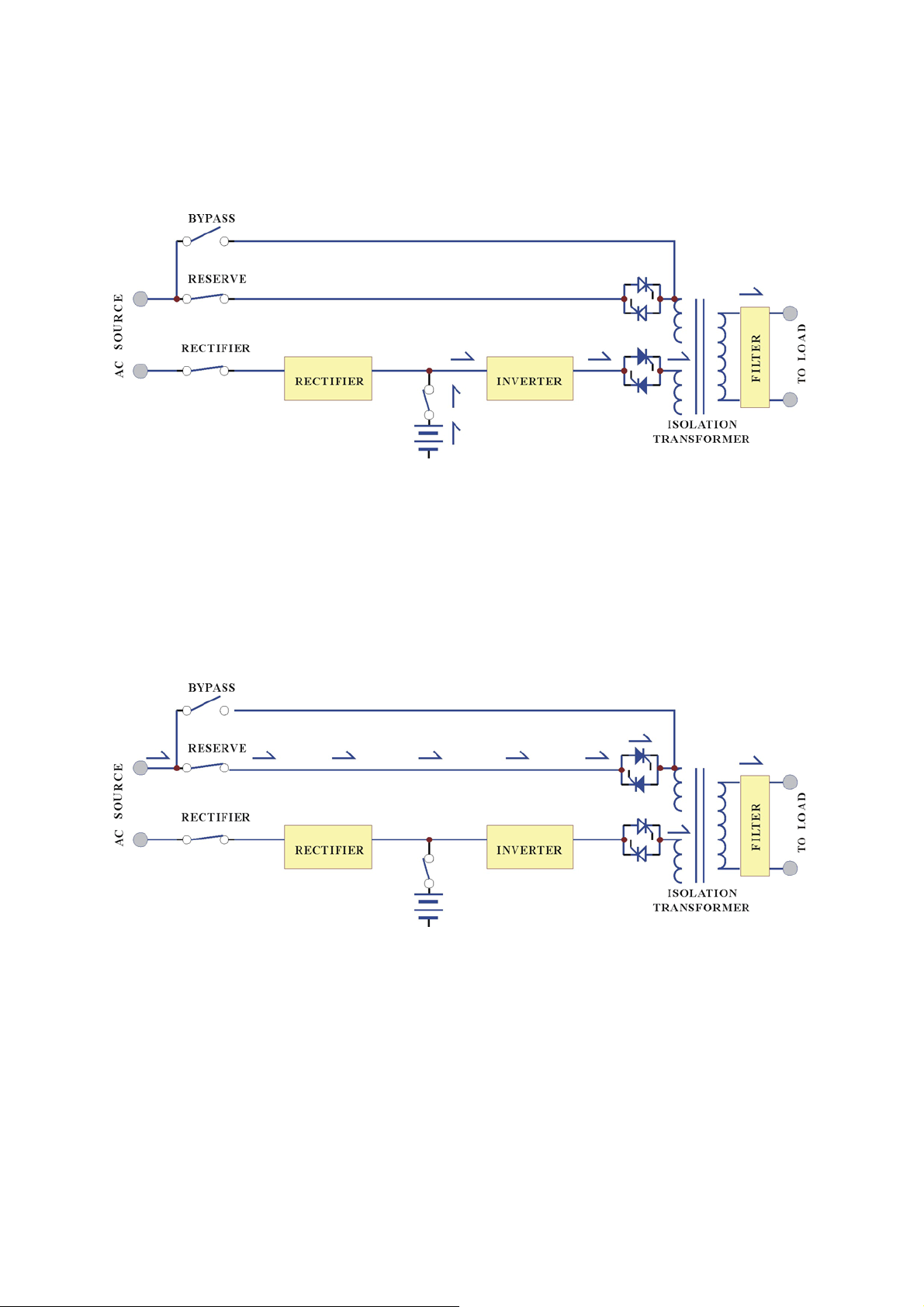

1.1. Construction of the UPS

General Topology:

The UPS system is composed of input breakers, input filter & protection network,

rectifier, battery

bank, inve

rte

r,

static switch, bypass breaker, isolation transformer

and output filter. The basic topology is shown in the diagram above. Under normal

AC mode, energy from the AC source is converted to DC power and supply to the

inverter and charge the battery to its full capacity all the time, ready to support the

output load in case of AC source failure.

Perhaps one may doubt if it is worthwhile to buy a UPS. But when you use a

calculator to add up the

dire

ct and indirect loss caused by AC failure, you will

immediately find that the money you save in 2 or 3 times of AC failure can already

compensate the cost of a UPS. Besides, the life expectancy of a UPS is at least 5 to

8 years, you may already get back the expense on the UPS within one year.

Although the principle and operation of a UPS seems simple and straightforward,

for

the requirement

a reliable and intelligent UPS makes the design and

manufacturing of a high power UPS requires advanced technology, intelligence,

experience and the most important, be c

ons

iderate to the user. Therefore we spend

years and huge investment in developing the most rugged, intelligent and reliable

UPS for the market, safe and convenient UPS for the user.

Page 6

1-2

Besides, the knowledge of choosing the best and most suitable UPS can be easy or

can be difficult, it depends on whether you know the key points or not. The most

g

obvious specification is the power, it depends on how lar

e is your load. Usually, an

allowance of 50% more power must be added to the current power you needed, both

for tolerance and future expansion. Of course you can add more than 50% if you

expect a larger increase of load in the future.

Another important point is the reliability, the prime aim of a UPS is to protect your

load, and therefore the UPS should be much more reliable than the AC source.

Those unfortunate UPS users who bought a unreliable

UPS

may suffer the

problem of frequent break down of the UPS, even more frequent than AC failure,

the cost of repairing is more the cost of the unit itself.

The last point is to choose an honest and experienced suppler who can help you

to choose the correct UPS, react promptly in case of UPS problem. Then, you can

save your money as well as buy a correct, suitable, and reliable UPS that is the

same as buy insurance to your load.

Generally, there are four different modes of operation, the NORMAL OPERATION

MODE, the BACK-UP (BATTERY) MODE, the RESERVE MODE and the

MAINTENANCE BYPASS MODE. They are explained as below.

Normal Operation Mode:

The rectifier converts the AC input to DC power to supply the inverter and charge the

battery simultaneously. All the fluctuations, surges and spikes of the AC input is

removed during AC to DC conversion, therefore the AC supplied by the inverter is

clean and stable.

Page 7

1-3

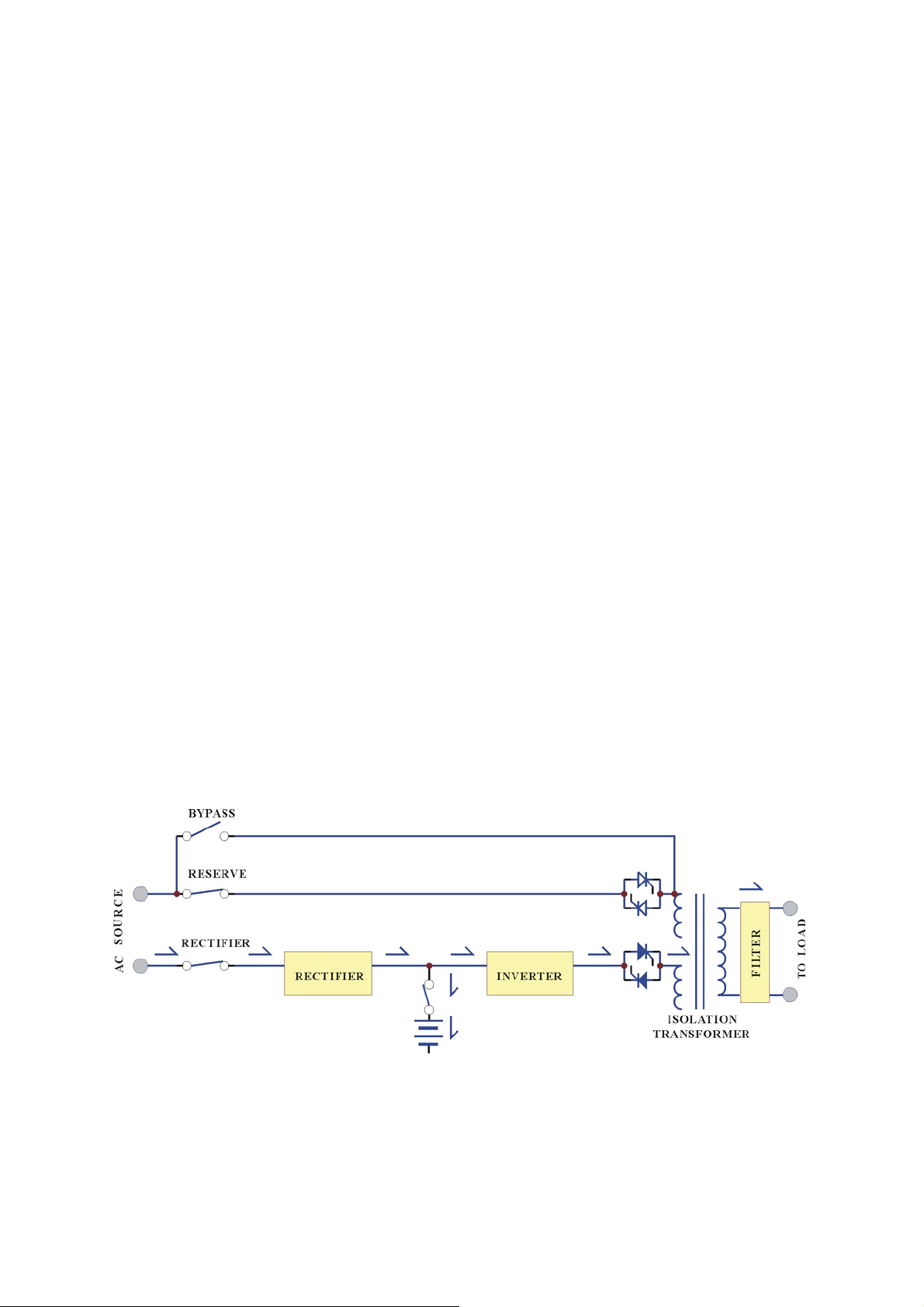

Back-up Mode:

Since the battery is connected directly to the DC bus, when the AC failure, the

battery change immediately

instead of receiving energy from the rectifier. The

from

receiver to donor, supply energy to the inverter

output AC

is not interrupted.

Therefore, the load connected to the output is protected.

Reserve Mode:

When the inverter is in abnormal conditions, such as over temperature, short circuit,

abnormal output voltage or overloaded for a period exceed the inverter’s limit, the

inverter will automatically shutdown, in order to protect itself from damage. If the

utility power is normal, the static switch shall transfer the load to the reserve source

without interruption of AC output.

Page 8

1-4

Maintenance Bypass Mode:

In case of UPS maintenance or battery replacement, and the load cannot be

interrupted, the user can turn off the inverter, close the bypass breaker and then

open the rectifier and reserve breakers. The AC output will

not be

interrupted during

manual bypass transfer procedure. Therefore maintenance bypass switch keeps

continuously power supply to the load. Electricity will not exist in UPS except the

output transformer, thus ensure the safety of service personnel.

Generally, the UPS is expected to run 24 Hours a day in normal operation mode

once it is installed, except when the utility power is fail, under overload condition,

or during maintenance.

The normal operation with battery connected can provide a clean, stable, free from

any spikes and surges, regulated and uninterruptible power to the load. Therefore,

the UPS and be regarded as a perfect AC

power source

except the back-up time

under mains failure is limited by the capacity of battery connected.

Page 9

1-5

1.2. Features and Advantages

(a) Reliable input protection: Circuit breakers is put in each individual input

loop to ensure power can continue through the other loop in case of breaker trip

caused abnormal condition in either rectifier or load.

(b) Input surge protection: MOV (surge protector) is added at the input, provide

sufficient protection to both UPS and the load from any lightning or surge

caused by neighboring large loads.

(c) EMI suppression: EMI filter is added to meet the international EMC limits,

therefore, very low

noise

is emitted and never interfere other equipment

connected to the same AC source.

(d) Ruggedness: The rectifier employ phase control technology to regulate the

DC bus voltage, so it can charge the battery directly, it is the most efficient

method to charge the battery. Besides, the component used is SCR, the

component get merits by its ruggedness under poor condition. Also, big inductor

is added at the input to avoid deforming the AC source waveform.

(e) High frequency design: The inverter uses high frequency, high efficiency

IGBT, PWM method

to conv

ert the DC power to AC power. Therefore, number

of components is fewer, in return, reliability is improved, size and weight of

UPS is reduced, then the transportation cost is cheaper, performance improved

and the acoustic noise is eliminated too.

(f) True Galvanic isolation: An isolated transformer is put at the output, can

solve the problem of

poor input

grounding and can accept a different ground

between input and output, can avoid the annoying problem of ground leakage

current and can be tied to any potential provided on site. The AC output is

isolated

under

every mode of operation. Besides, the user gets the bonus of

attenuation of common mode noise from the output isolation transformer.

Page 10

1-6

(g) P&P Modular design: The power circuit is separated into several modules

plugged into slots in

th

e

UPS,

which is easy to pull out, permit quick

maintenance and easier trouble shooting. Therefore, it can be regarded as plug

and play modules.

(h) Cold start function: the UPS can be started without AC source, that is, can

be started with battery only, because current limit circuitry is added. It can

prevent the problem of many UPS that the big inrush current blow the battery

fuse and hurts the DC capacitors when battery is connected to empty DC bus

(before the DC bus is energized).

(i) Multi-CPU design: Several CPUs are employed in the control circuit, critical

functions are designed to parallel redundancy to improve reliability. Therefore,

in case of one CPU fails the other CPUs keep on their duty and the output AC

will not be affected.

(j) Defense to mis-operation: The UPS is designed with breaker on/off sensor,

power supply sensor etc. Therefore any operational mistake made by the user

causes no harm to the UPS.

(k) Wide input range: The UPS is designed to accept extra wide input range, so

that it can work comfortable under poor AC source. Also, all the input

components used are especially selected to handle extreme high voltage and

high current.

(l) Tolerate harsh environment: Each component of the UPS is chosen with

larger safe margin to accept extreme environment, such as temperature, humidity,

attitude, shock or contamination.

(m) Intelligent charger: The UPS will automatically recharge (boost charge) the

battery every time after the battery is consumed to a voltage 2V/Cell, so that the

battery can be recovered to the full capacity as soon as possible to be ready for

the next back-up. Besides, in order to keep the battery in the best condition, the

UPS will boost charge the battery for several hours (selectable) automatically

every month. To avoid over charging the battery, Boost charge will stop when

the ambient temperature is over 35 ℃(95℉).

Page 11

1-7

(n) Intelligent battery test: Battery is tested after every boost charge of battery

(either initiated by battery discharge or by one month has elapsed) without

stopping the rectifier to prevent the risk of output AC failure in case of battery

bad. And can inform the user the battery condition, so that the user can take

action before the capacity of the battery is needed.

(o) Huge charging power: The charge power is selectable (Lo/Me/Hi) according

to Ah of the battery, and can charge up battery of more than 8Hrs back-up time

without adding extra charger.

(p) MTBF of fans is extended: Fans will slow down under light load, so that

the life expectancy of the fans are longer than it is specified.

(q) Redundant power supply: An extra power supply is connected redundantly

to supply power of the static switch, so that, there will be AC output no matter

what happen to the UPS.

(r) Intelligent interface: One remote control panel (or one PC) can monitor up to

99 UPS, all of them can be remotely switched on or off, and when any one of

them encounters emergent condition, it will warn the user immediately. All the

to

UPS status, data or commands are transmitted

external modules through 4

RS-485 ports (for long distance communication under harsh environment).

(s) Emergent stop is available: In case of hazard, for example electric shock,

fire or earthquake, the UPS can be shutdown (will have no AC at the output)

either through a switch (can be added upon request) or through smoke detector

signal (can be added upon request) to prevent further injuries or destruction.

Page 12

1-8

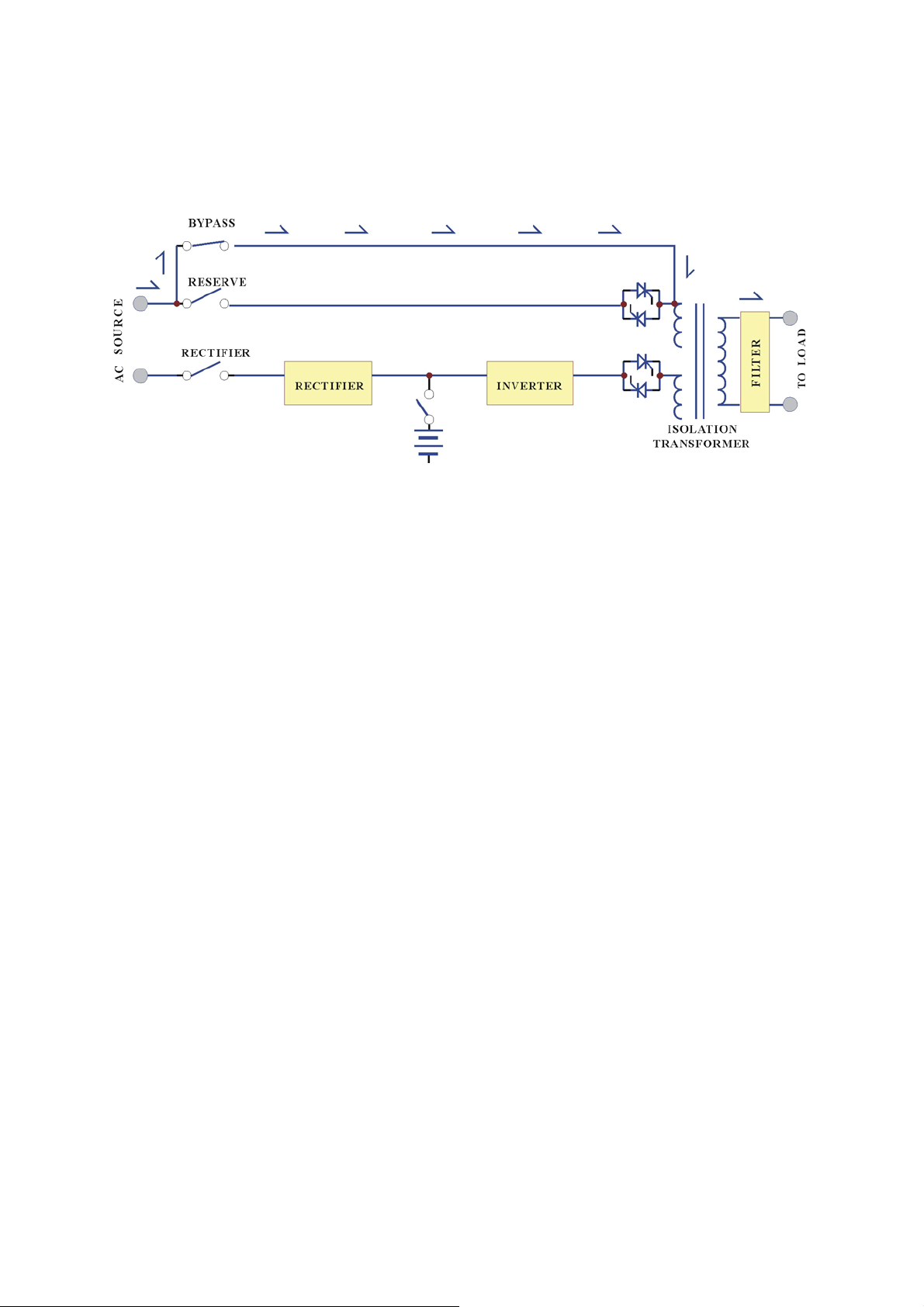

1.3. Rectifier

The main function of a rectifier is to convert the AC input to DC power, supply it to

the inverter; the inverter then converts the DC power to AC power to the load. Our

UPS use the DC power to charge the battery as well, which i

s th

e most efficient way

of charging.

AC

INPUT

6-PULS E FULL CONTROL RECTIFIER

RECTIFIER

BREAKER INDUCTOR

SCR

DC

OUTPUT

CAPACITOR

The rectifier of from 20KVA to 80KVA UPS uses 6-pulse full controlled rectifier.

An inductor is added before the rectifier to improve the power factor, smooth the

current waveform and eliminate the harmonic current as well. The control circuit

regulates the DC bus within 1%. Soft walk-in circuitry (approximately 20sec.) and

current limit circuitry is used to prevent over current or instantaneous surge current.

Extra under-voltage and over-voltage protections are added to improve reliability and

to shutdown the rectifier in case of abnormal conditions. The DC bus is adjustable to

fit different types of battery. The power component use in rectifier is especially

selected to handle extreme high voltage and high current. The rectifier is designed to

operate under wide range of AC input, from 177 to 300VAC, to fit the poor power

conditions in some area.

Page 13

1-9

PHASE SHIFT

AC

INPUT

RECTIFIER

BREAKER INDUCTOR

TRANSFORMER

SCR

SCR

DC

OUTPUT

CAPACITOR

12-PULSE FULL CONTROL RECTIFIER

In order to further improve the power factor and reduce harmonic current drawn by

the rectifier, our UPS from 100KVA and above use the 12-pulse full controlled

rectifier. The total current harmonic current can be reduced to around 15%, and

power factor is improved to over 0.8. A phase shift transformer is added to achieve

the performance. The input inductor is retained too to obtain the best result. Although

the cost is higher, it is most reliable and rugged topology. Users need not to increase

the input breaker and cable, input KVA and harmonic current drawn is minimized to

fulfill the worldwide energy saving requirements.

The harmonic current can be further lowered by adding harmonic filters (install upon

request). The total harmonic current will be around 9%.

Another alternative method to reduce the harmonic current (especially for very large

KVA UPS) is to employ 18-pulse full controlled rectifier. The total harmonic current

will be around 7%.

1.4. Inverter

DC+

AC

DC-

IGBT

INVERTER

AC

Page 14

1-10

TO LOAD

TO LOAD

The inverter is composed of IGBT, inductor, capacitor, snubber, control circuitry and

protection circuitry. It can convert the DC power from the DC bus to AC power

supply to the output load. Our UPS use IGBT technology which can switched to

frequency beyond audible range, therefore no audible noise.

Our UPS use voltage regulation circuitry to limit the voltage variation within 1%.

Also special compensation circuitry is added to eliminate the output distortion. Every

component is oversized to accept the wide DC input range (from 285 to 420VDC), so

that the output waveform remains sinusoidal throughout the range. With the aid of

dynamic feedback loop the inverter will keep a sine waveform even under non-linear

load.

We use independent inverter for each phase. Although it is more expensive, each

inverter has its independent feedback, so that the voltage is unaffected when load is

added to the adjacent phase, that is excellent voltage regulation under 100%

unbalanced load.

The IGBT is operated in its optimal condition to obtain best efficiency, so as to

minimize the electricity cost of the user.

Usually, the most frequent failure of UPS happens at the inverter, therefore we added

redundant protection circuitry

suppress the spikes and noise, use over sized and

to

protect the inverter, strong snubber is added to

high

quality components, add

semi-conductor fuse and good ventilation etc. Every step aims at a rugged, reliable

and high efficient inverter. At the same time, the inverter can sustain overload and

high peak current drawn by the load. And the MTBF must be long than one expects.

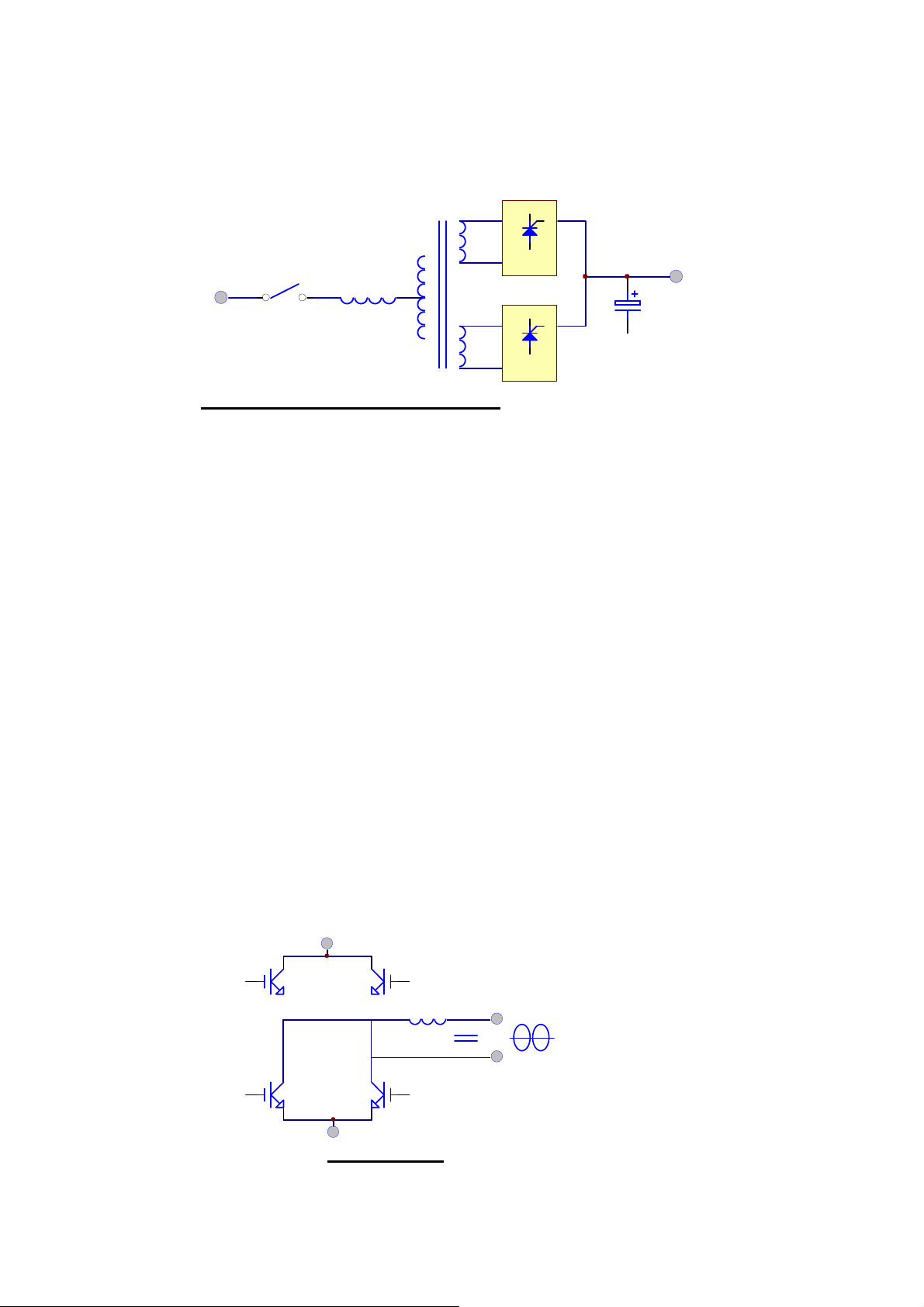

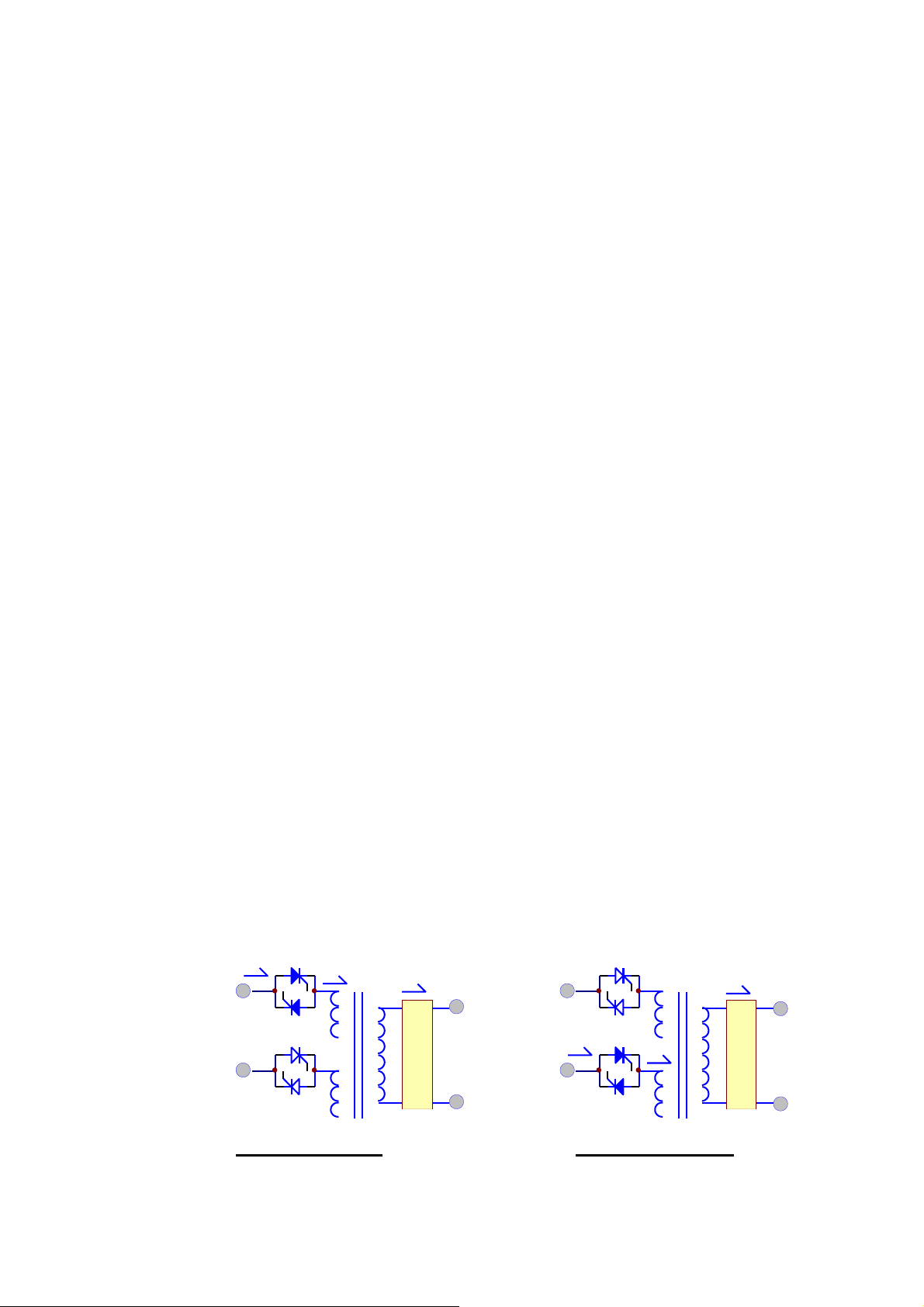

1.5. Static Switch

RESERVE

INVERTER

FILTER

RESERVE

INVERTER

FILTER

RESERVE MO DE INVERT ER MO DE

Page 15

1-11

The static switch is composed of two pairs of back-to-back connected SCR. It can

transfer the load from reserve to inverter or from inverter to reserve without dead

time at the output. Therefore, it is a very important portion of a UPS.

Detection circuitry is added to the control circuit to achieve zero dead time transfer.

Extra detection logic is employ to control when should the static switch transfer. For

example, when output is short circuited under normal mode operation, the UPS

detect the short circuit and stop the inverter after a period which the inverter can

endure,

then the static switch will not transfer to reserve to prevent tripping and

hurting the reserve breaker. But in case of overload, the UPS will stop the inverter

after a period the inverter can endue, and then transfer the load to reserve

because the

overload capability of the static switch is higher than the inverter.

Also the transfer action is determined according to the reserve-input voltage and

frequency to protect the load from supplying incorrect power to the load. At last,

there is a double check by the CPU whether the transfer is successful or not.

1.6. Maintenance Bypass Switch

Unlike other UPS, the maintenance bypass switch is already installed inside the UPS

for convenience. It should be opened under normal operation, and only closed during

maintenance. For the sake of maintenance personnel’s safety, all power supply inside

the UPS should be disconnected before touch any parts inside the UPS; therefore, the

maintenance bypass switch is a necessity to maintain AC power at the output and can

keep safe at the same time. If the bypass breaker is closed under normal operation,

the inverter will stop and the load will be automatically transferred to reserve to

prevent the inverter connect directly to the AC source. Of course, you cannot switch

on the in

verter as long as the maintenance bypass breaker is closed.

The operation of the maintenance bypass breaker is that, switch off the inverter first

then the static switch will automatically transfer the load to reserve without dead

time. Then now you can close the maintenance bypass breaker now, and then open

the reserve breaker, so that the load can get AC from the output without interruption.

Page 16

1-12

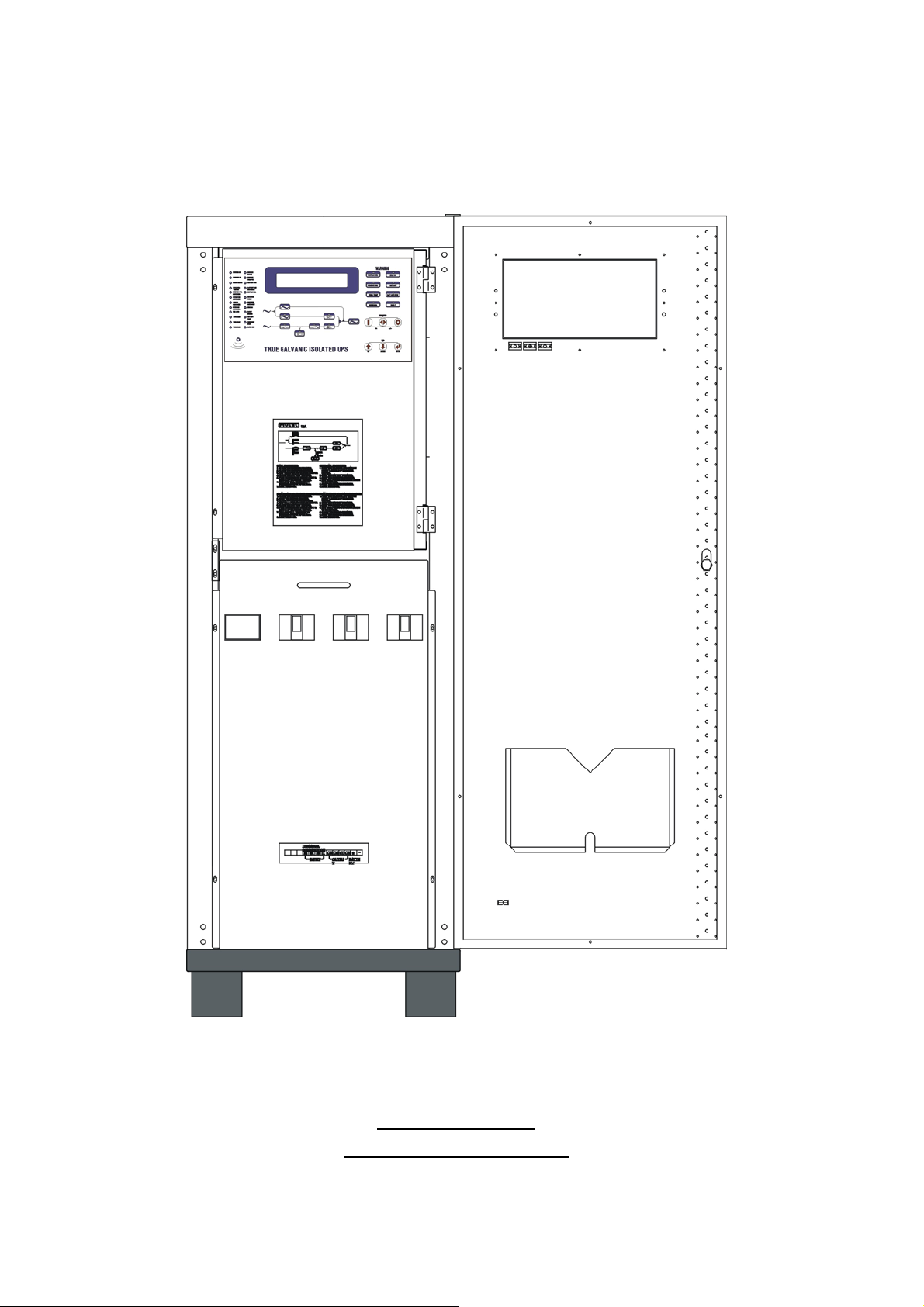

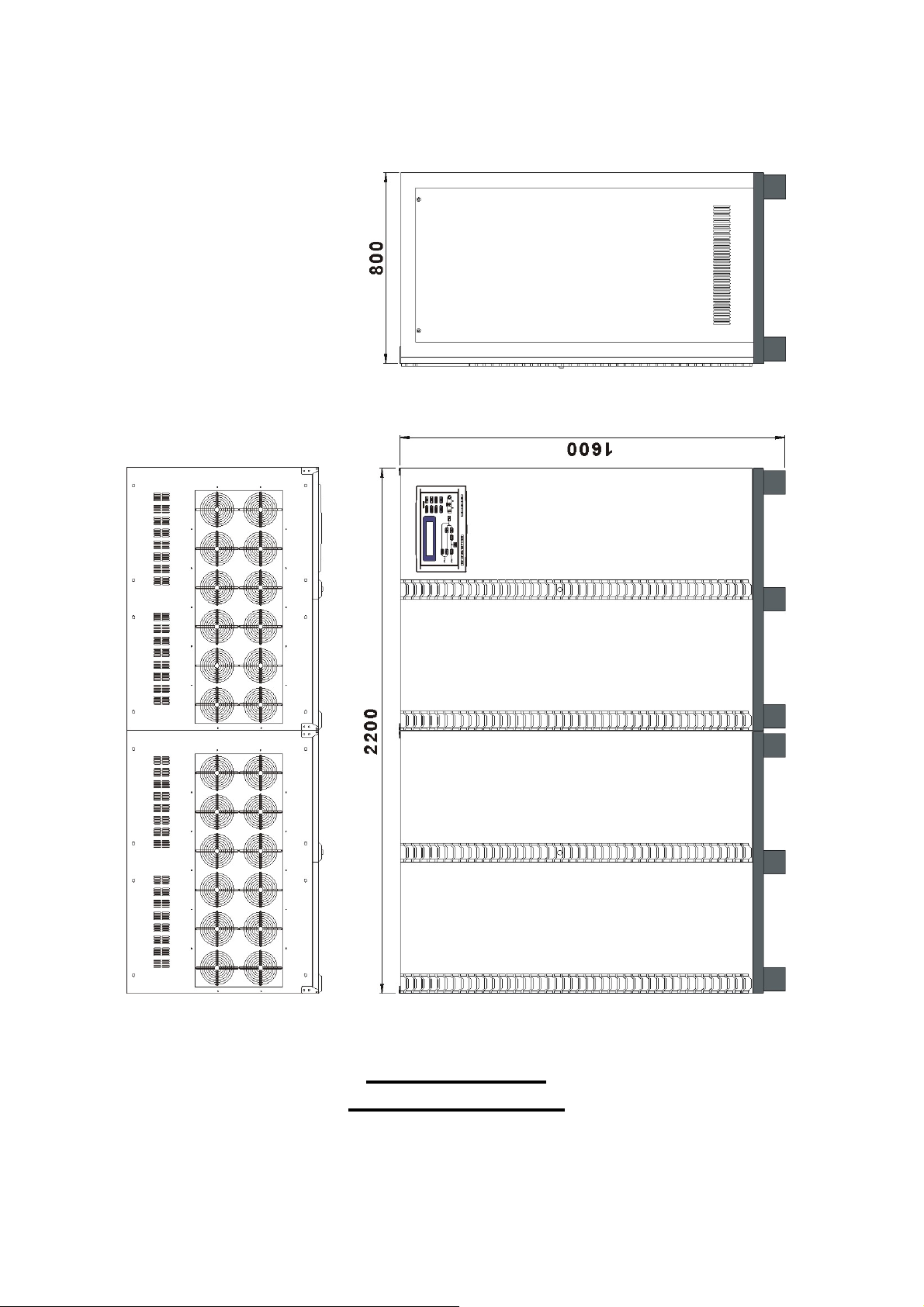

1.7. Dimension & Drawings

20KVA ~ 60KVA

OUTLINE DRAWING

Page 17

1-13

20KVA ~ 60KVA

INTERIOR DRAWING

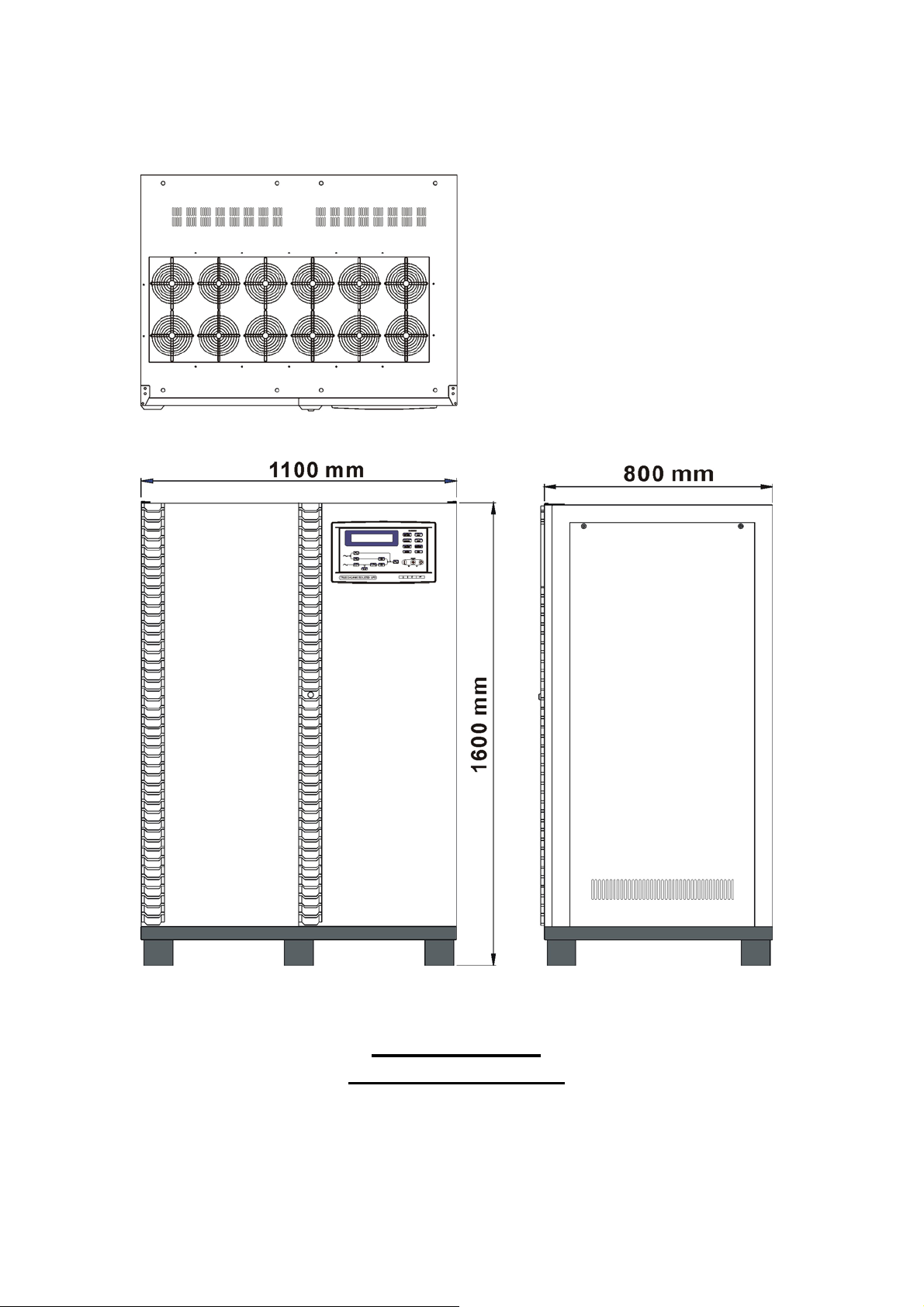

Page 18

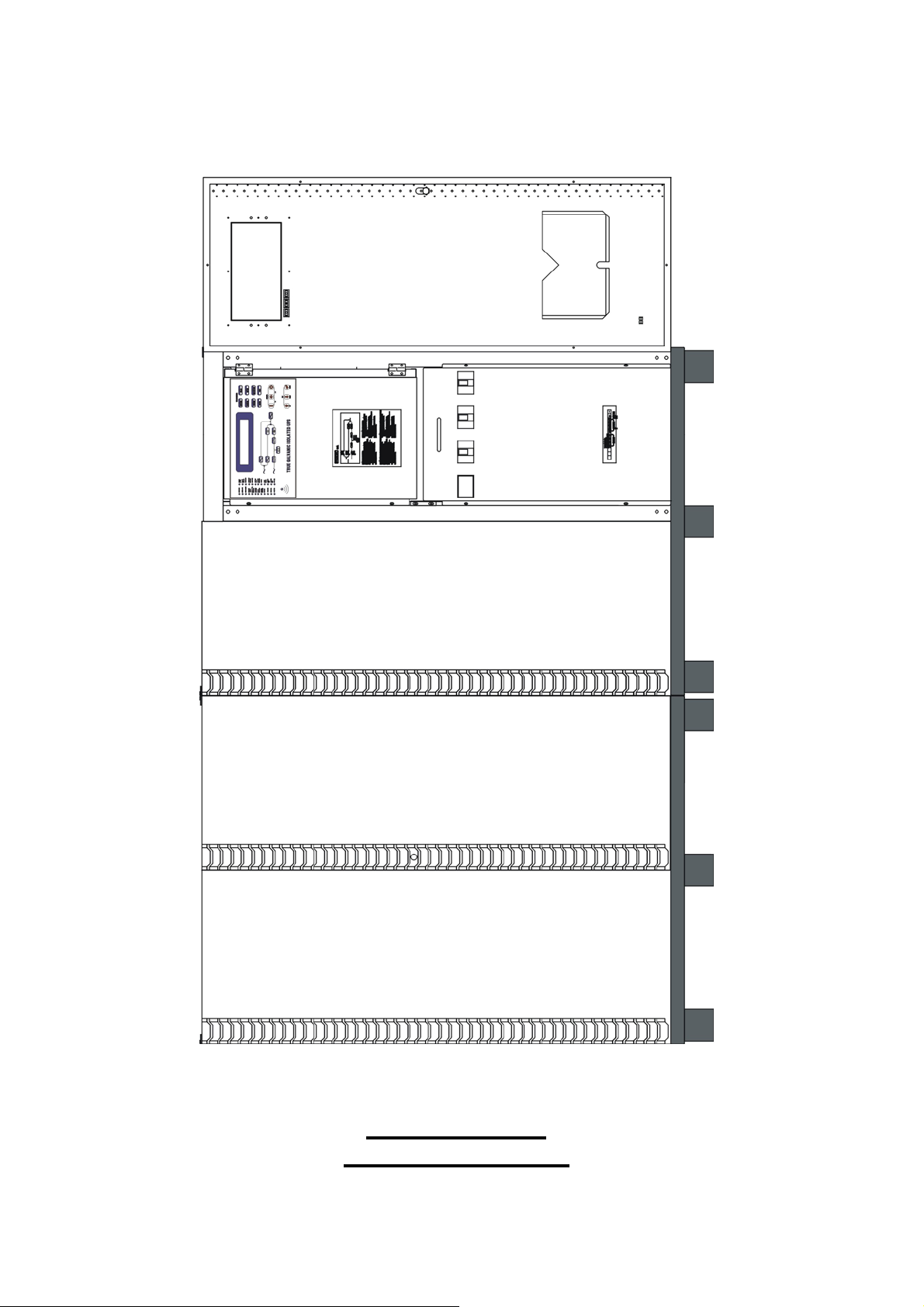

1-14

80KVA ~ 160KVA

OUTLINE DRAWING

Page 19

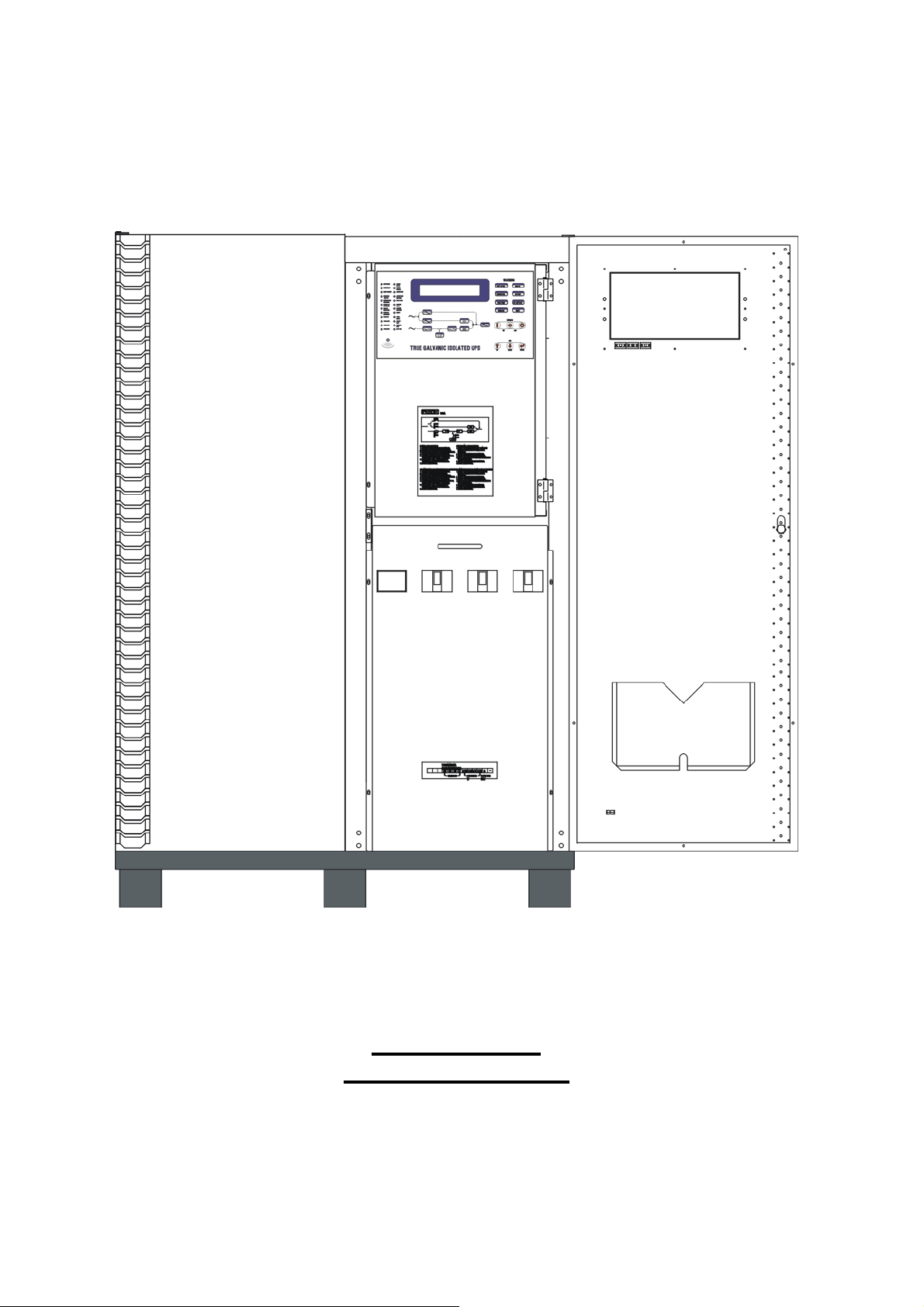

1-15

80KVA ~ 160KVA

INTERIOR DRAWING

Page 20

1-16

200KVA ~ 320KVA

OUTLINE DRAWING

Page 21

1-17

200KVA ~ 320KVA

INTERIOR DRAWING

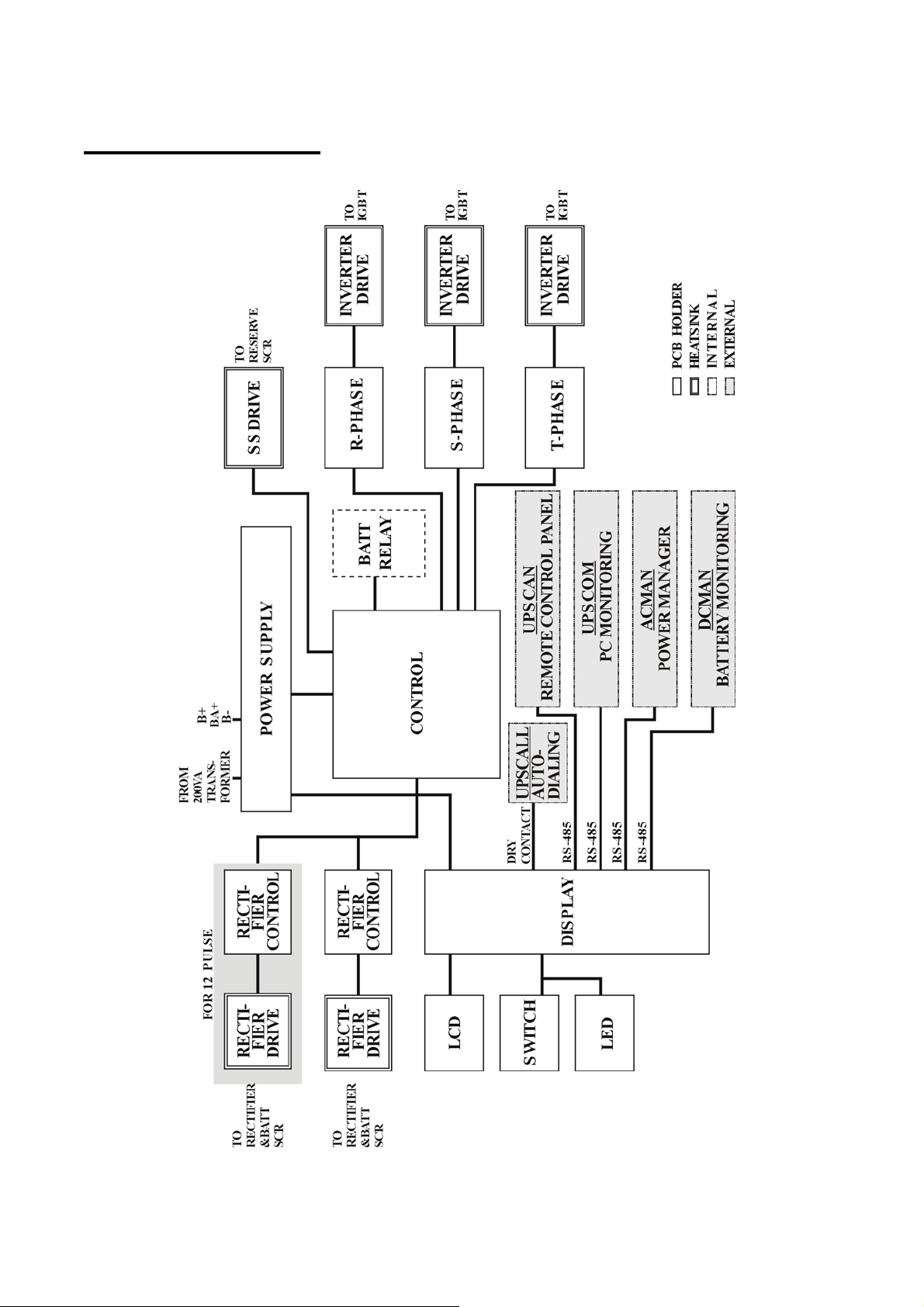

Page 22

1-18

INTER-PCB DIAGRAM

Page 23

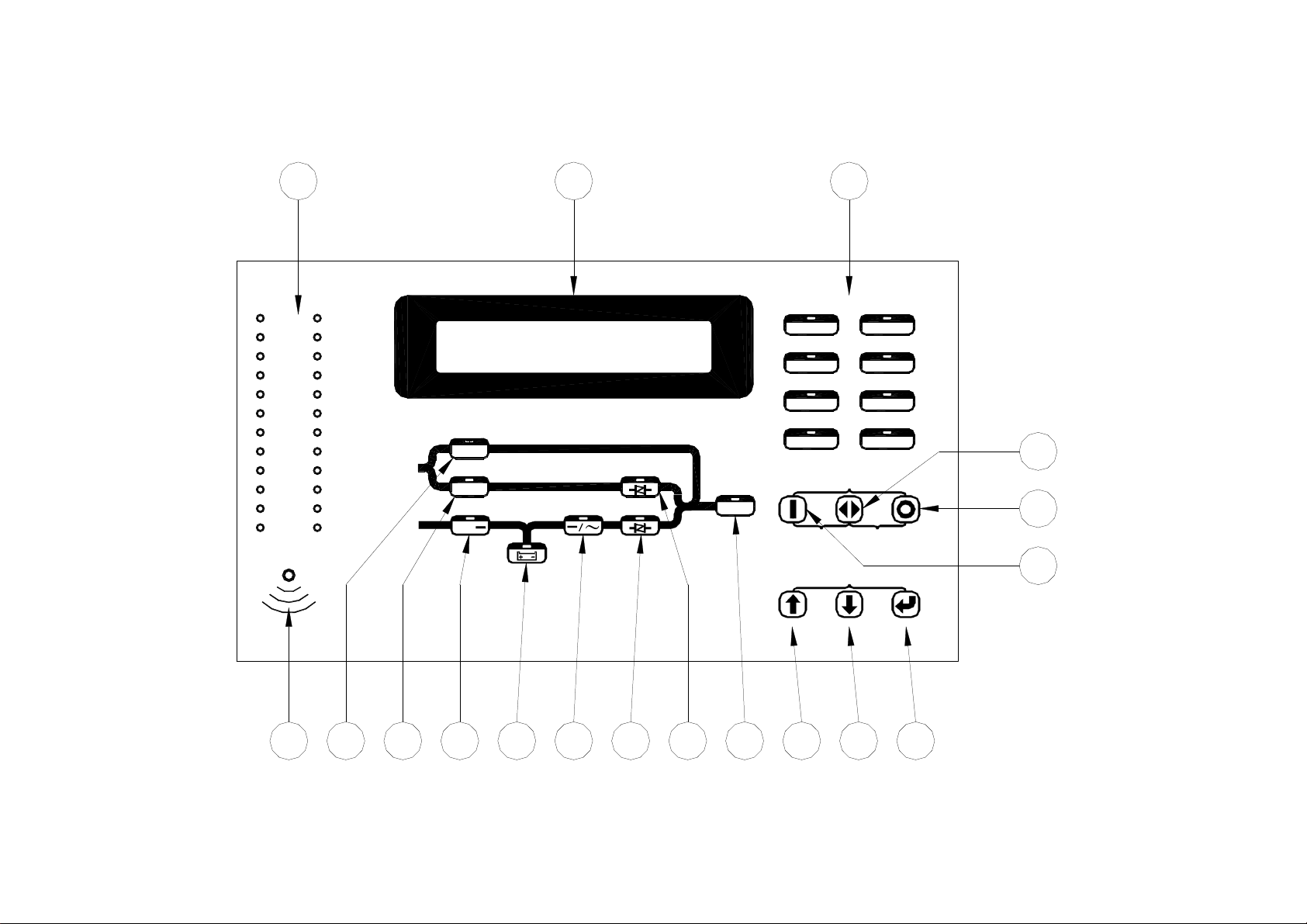

1.8.

Front Panel

1-19

~

B

A

C

INVERTER ON

INVERTER SS

SHORT CIRCUIT

FUSE/OVER

TEMP SD

INVERTER FAIL

SHUTDOWN

BYPASS ON

SHUTDOWN

HIGH DC

SHUTDOWN

OVERLOAD

SHUTDOWN

70%LOAD

110%LOAD

125%

150%LOAD

LOAD

RESERVE

AC FAIL

RESERVE

FREQ FAIL

BATTERY LOW

BATTERY LOW

SHUTDOWN

RECT AC FAIL

ROTATION

ERROR

RECTIFIER

SHUTDOWN

HIGH DC

BOOST

CHARGE

BATTERY

TEST

EM

STOP

DATA LINE

ERGENT

~

~

~

~

/

~

TRUE GALVANIC ISOLATED UPS

~

RECT AC FAIL

FAIL

RESERVE

FUSE

/

TEMP

OVERLOAD

ON

UP

WARN

INVERTER

LCD

DOWN

ING

HIGH DC

BAT

BAT LOW STOP

FAULT

OFF

LOW

Q

R

P

ENTER

D E F G H I J K L M N O

Page 24

1-20

The front panel is located at the front of the PCB holder. It gathers the real time

information of the UPS

for controlling and setting the UPS. So, through this

and shows

them clearly to the user. It also provides switches

panel,

the UPS can be not only a

stand alone machine supplying the load but closely related to the user. Each part of

the panel is explained below.

A: LCD display: Real time status, data or historical events is displayed on the LCD.

The UPS parameters, real time clock, inverter, buzzer also can be set through this

LCD. The LCD is

light

ed

by LEDs for purpose of a sharp display, but in

back

order to lengthen the LED’s life time, the LED will be automatically shut off 3

minute a

fter

no key is activated, will light

up

again when one of the

up/down/enter key is pushed.

B: Status LEDs: 24 LEDs representing all the important information of the UPS

provide most update information to the user. Therefore these LEDs are especially

important when abnormal conditions happen. The 24 information are as below:

INVERTER ON – inverter is running.

INVERTER SS – inverter static switch conducts while the reserve static

switch is opened.

SHORT CIRCUIT – UPS output is in short circuit state.

FUSE/OVER TEMP SD – inverter shutdown due to either fuse broken or

temperature too high.

INVERTER FAIL SHUTDOWN – inverter shutdown due to inverter output

voltage too low.

BYPASS ON SHUTDOWN – inverter shutdown due bypass breaker is closed

when the inverter is running.

HIGH DC SHUTDOWN – inverter shutdown due to DC bus too high when

the inverter is running.

OVERLOAD SHUTDOWN – inverter shutdown due overload the inverter

for a period over the inverter can endue, will restart after 7 seconds.

70% LOAD – load connected to the output is over 70% of the UPS rating.

110% LOAD – load connected to the output is over 110% of the UPS rating.

125% LOAD – load connected to the output is over 125% of the UPS rating.

150% LOAD – load connected to the output is over 150% of the UPS rating.

Page 25

1-21

RESERVE AC FAIL – reserve AC magnitude is out of range.

RESERVE FREQ FAIL – reserve frequency is out of range.

BATTERY LOW – DC bus (or battery) is lower than 320VDC, low battery

shutdown is approaching.

BATTERY LOW SHUTDOWN – inverter shutdown due to DC bus (or

battery) is lower than 295VDC (lower than the acceptable DC voltage of

the inverter.

RECT AC FAIL – rectifier AC magnitude is out of range.

ROTATION ERROR – rectifier AC phase rotation is incorrect.

RECTIFIER SHUTDOWN – rectifier shutdown due to DC bus too high

(over 445VDC), will automatically restart 30 seconds after abnormal

situation has been cleared.

HIGH DC – DC voltage over 430VDC and the bus voltage will be limited at

this voltage.

BOOST CHARGE – the battery is being boost charged by the rectifier.

BATTERY TEST – battery is being tested.

EMERGENT STOP –inverter shutdown due to emergent stop switch is

pushed.

DATA LINE – blinks when data is transmitted to or received from the

communication port.

C: Warning LEDs: When abnormal condition happens, these LEDs will lit to warn

the user according to the cause of the faulty condition. Therefore all these LEDs

should be extinguished under normal condition. These LEDs are as below:

RECT AC FAIL – rectifier AC input is abnormal either due to AC magnitude

out of the range or phase rotation error, rectifier shutdown.

RESERVE FAIL – reserve AC input is abnormal either due to AC magnitude

out of range or frequency out of range.

FUSE/TEMP

– either inverter fuse is blown or over temperature.

OVERLOAD – output is overloaded by over 110%, 125% or 150%.

HIGH DC – the LED will lit as long as the DC voltage is over 430VDC.

Page 26

1-22

BAT LOW – the LED will lit as long as the DC voltage is lower than

320VDC.

BAT LOW STOP – the LED will lit as long as the DC voltage is lower than

295VDC, inverter on is prohibited.

FAULT – the inverter is shutdown due to abnormal conditions such as

overload, short circuit, high DC, fuse over temperature, bypass breaker on

or emergent stop.

Since these LEDs are located behind the transparent window, the user can see

them clearly

without opening

the door.

D: Buzzer outlet: The buzzer is located inside the PCB holder; therefore, a hole is

opened to let the beep

sound

can be heard outside. Usually, the user should not be

expected to watch the UPS all the time, therefore when abnormal conditions

happen audible sound should be emitted to warn the user come over to check

what happens to the UPS. The buzzer will beep under either one of the following

conditions:

INVERTER IS OVERLOADED-

>110%, beep once / 3 seconds

>125%, beep once / second

>150%, beep twice / second

BACK- UP

>320VDC, beep once / 3 seconds

<320VDC, beep twice / second

<295VDC, no beeping

INVERTER IS SHORT CIRCUITED - beep continuously

FUSE BROKEN - beep continuously

HEAT SINK OVER TEMPERATURE - beep continuously

HIGH DC SHUTDOWN - beep continuously

BYPASS ON STOP - beep continuously

Page 27

1-23

EMERGENT STOP - beep continuously

The buzzer will also beep once every time the inverter is switched on or off to

acknowledge the user his key is valid and accepted.

E. Bypass LED: This LED will lit when the maintenance bypass breaker is closed.

When the maintenance bypass breaker is closed, the inverter cannot be switched

on and will stop immediately even when inverter is already running.

F. Reserve LED: This LED will lit when the reserve breaker is closed, and there is

AC power supply present at the reserve terminal.

G. Rectifier LED: This LED will lit when the rectifier is operating normally, it

means the rectifier Mains is within the range specified, the rotation sequence of

three phases are correct, rectifier breaker is closed and no high DC voltage in the

bus.

H. Back-up LED: This LED will lit when the UPS is in back-up mode. This is also

as the indicator for battery test result. If the battery test do not pass, this LED will

flash even the UPS is not in back-up mode to prompt the user to change the

battery.

I. Inverter LED: This LED will lit when the inverter is switched on, therefore this

LED indicates whether the inverter is running or not.

J. Inverter SS LED: This LED will lit when the inverter static switch is turned on

sw

and the reserve static

itch is turned off. That is, the load is supplied from the

inverter. Usually this LED will lit 7sec. after the inverter is switched on.

K. Reserve SS LED: This LED will lit when the reserve static switch is turned on

sw

and the inverter static

itch is turned off. That is, the load is supplied from the

reserve. Since the reserve static switch and inverter static switch will never both

turn on simultaneously, the Inverter SS LED and the Reserve SS LED should

never both lit simultaneously.

L. Output LED: This LED will lit when there is AC power present at the output

terminal. This is an important indication to the user that whether AC is available

at the output or not.

Page 28

1-24

M. Up key: This is a LCD control key. It is for moving the cursor one item upward

when items are

being s

elected or for changing the number/character forward

when data or parameter of the UPS is being set.

N. Down key: This is a LCD control key. It is for moving the cursor one item

downward when items are being selected or for changing the number/ character

backward when data or parameter of the UPS is being set.

O. Enter key: This is a LCD control key. It is for changing backward to the previous

page, and also for

confirming th

e number/character /item is selected.

P. Inverter on switch: It is the inverter control switch. When this key is pushed with

the control key simultaneously, the inverter will be switched on.

Q. Inverter control switch: It is the inverter control switch. When this key is pushed

with the inverter on key simultaneously, the inverter will be switched on.

Similarly, when this key is pushed with the inverter off key simultaneously, the

inverter will be switched off. There this key is a guard for mistaken keys.

R. Inverter on switch: It is the inverter control switch. When this key is pushed with

the control key simultaneously, the inverter will be switched on.

Page 29

2-1

MAXIMUM CHARGE

CURRENT (ADC)

2. TECHNICAL SPECIFICATION

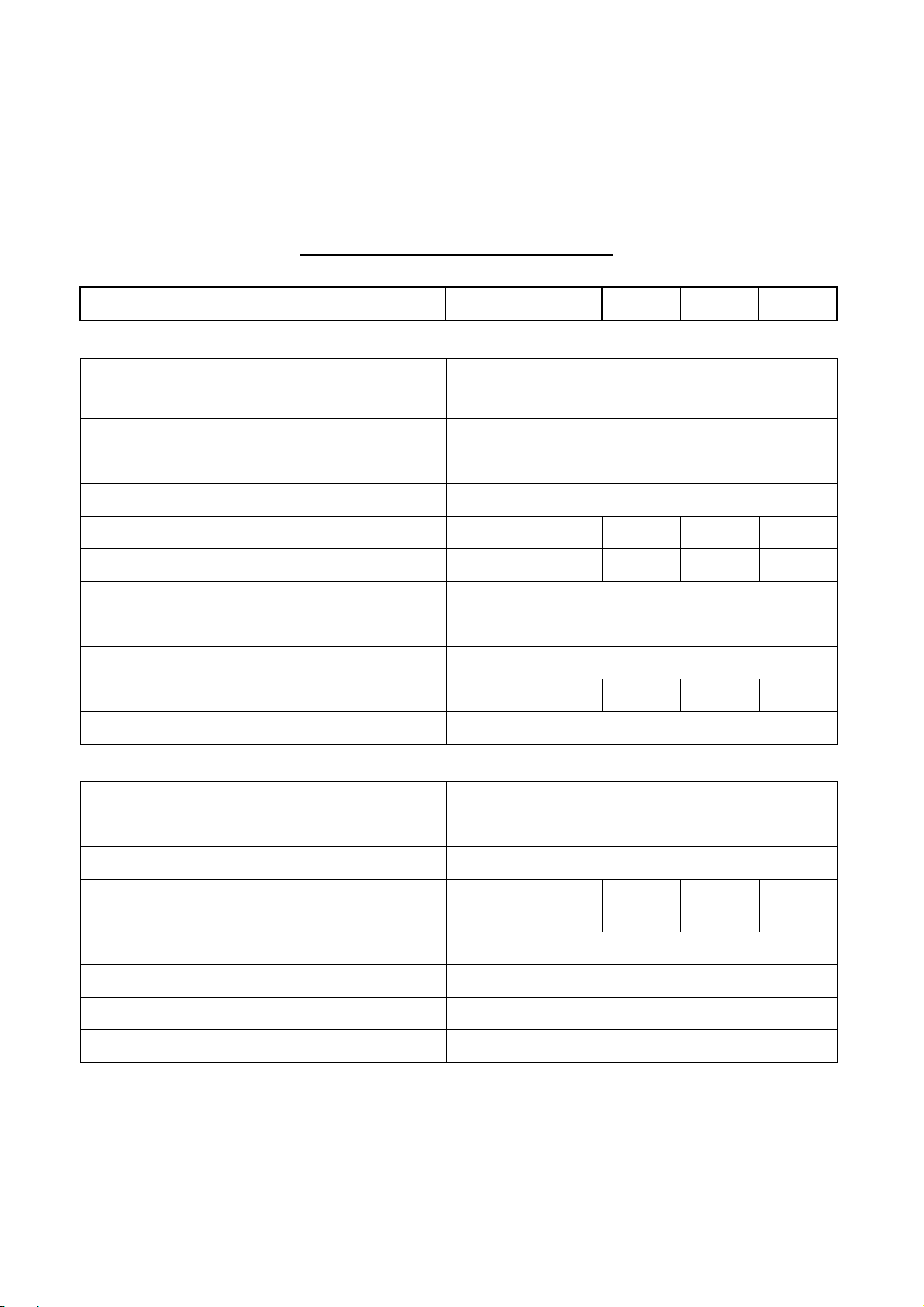

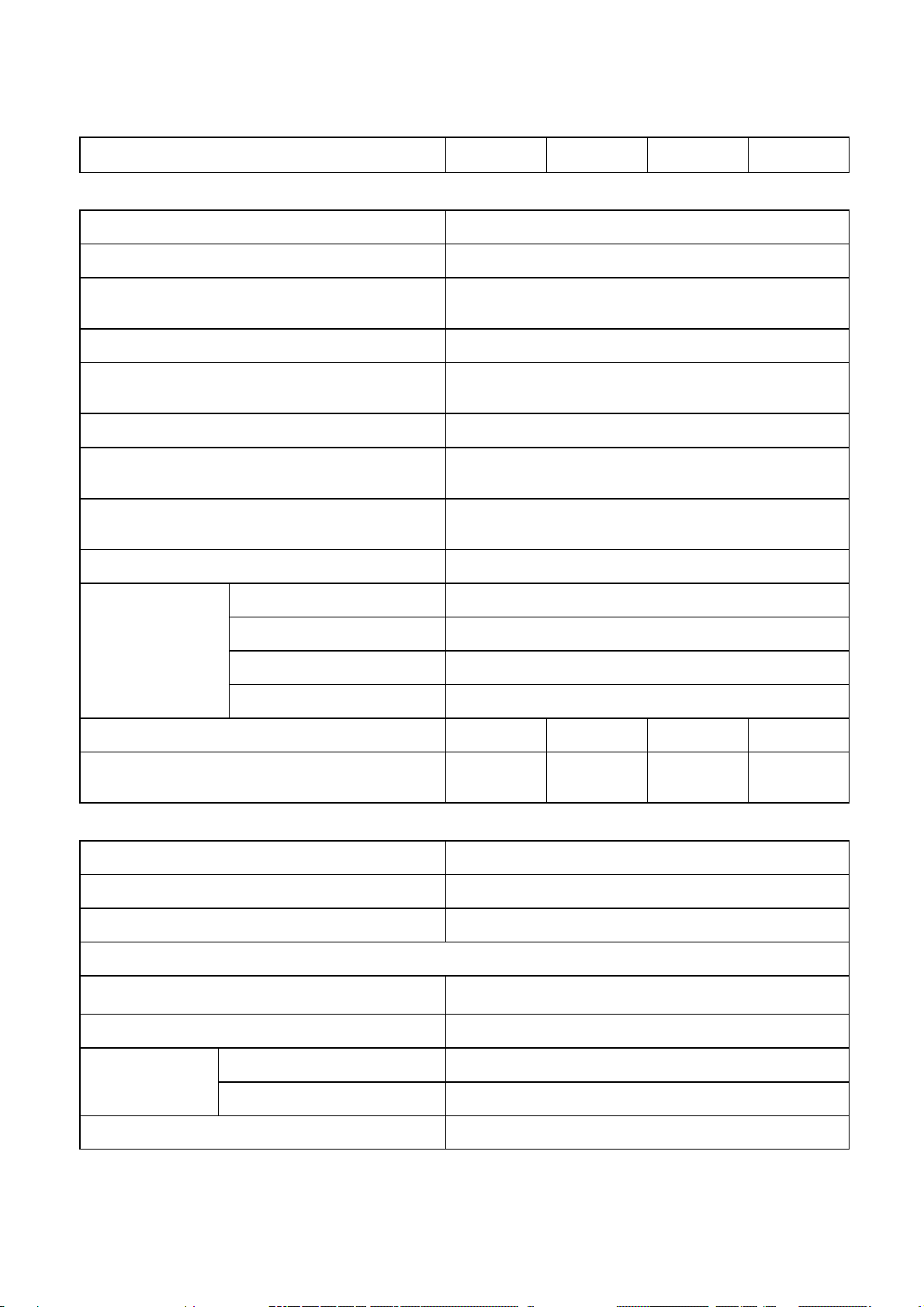

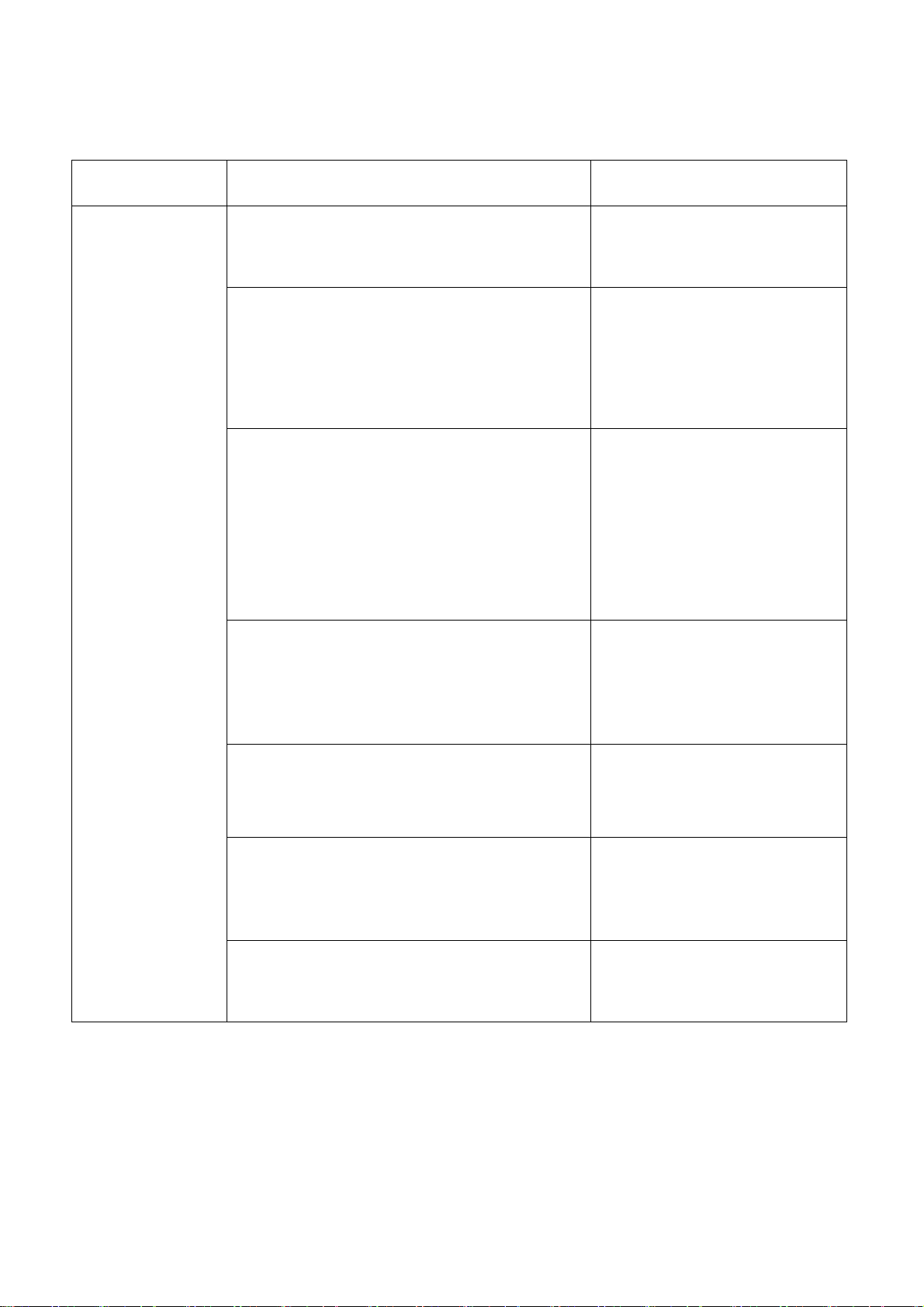

2.1. 20KVA ~ 60KVA UPS 3-Phase Input / 3-Phase Output

TECHNICAL SPECIFICATION

KVA

20

30

40

50

60

RECTIFIER

220V∆ / 380V∆ / 460V∆, 208VY /

INPUT VOLTAGE

380VY / 400VY /

INPUT RANGE 307 –

520V

415VY

INPUT FREQUENCY 50 / 60 Hz +/- 7%

INPUT POWER FACTOR

0.8

NORMAL INPUT CURRENT(A) 36 54 72 90 108

MAXIMUM INPUT CURRENT(A) 45 68 90 113 136

POWER WALK IN 0% - 100% : 20 sec

EFFICIENCY

VOLTAGE REGULATION

99%

1%

CURRENT LIMIT(A) 54 81 108 135 162

RIPPLE VOLTAGE

BATTERY

0.5%

BATTERY TYPE SEAL LEAD ACID / NiCd

NO. OF CELLS 174 /

VOLTAGE RANGE 295 – 410VDC / 285-415VDC

BATTERY LOW VOLTAGE 320VDC / 305VDC

BATTERY LOW STOP VOLTAGE 295VDC / 285VDC

BOOST CHARGE 410VDC / 415VDC

FLOAT CHARGE 396VDC / 410VDC

271

10

15

20

25

30

Page 30

2-2

FREQUENCY LOCK RANGE

45 – 55 Hz / 55 – 65 Hz

THD (LINEAR LOAD)

< 2

%

- <110% CONTINUOUS

- 110 – 125% 15

min

- 125 – 150% 10

min

- > 150% 60 sec

EFFICIENCY (100% LOAD)

93%

93%

93.5%

93.5%

94%

- MAINS -> INVERTER

0

ms

KVA

20

30

40

50

60

INVERTER

DC INPUT RANGE 285 – 415VDC

WAVE FORM

OUTPUT VOLTAGE

208 / 380 / 400 / 415 VY 3 PHASE

SINUSOID

WITH NEUTRAL

OUTPUT POWER FACTOR

VOLTAGE REGULATION 100%

UNBALANCE LOAD

OUTPUT FREQUENCY

(FREE RUNNING)

50 / 60 Hz + / - 0.1 Hz

0.8

+ / - 1

PHASE SHIFT UNDER

100% UNBALANCE LOAD

120 % + / -

OVERLOAD

%

0.5

∘

MAXIMUM OUTPUT

PEAK CURRENT(A)

STATIC SWITCH

87

130

174

218

VOLTAGE RANGE 173 – 277 VAC (LINE TO NEUTRAL)

FREQUENCY RANGE 45 – 55 Hz / 55 – 65 Hz

EFFICIENCY

99.5%

TRANSFER TIME:

- INVERTER -> MAINS 0

ms

- 100% 30 sec

OVERLOAD

- 300% 1 sec

ISOLATION WITH OUTPUT

YES

260

Page 31

2-3

0 – 40℃ ( 32 –

104℉ )

- HEIGHT(mm) 1600

- WIDTH(mm)

550

- LED,LCD,BUZZER

YES

KVA

20

30

40

50

60

OVERALL

CHARACTERISTICS

OVERALL EFFICIENCY 91% 91% 91.5% 92% 92%

OPERATING ENVIRONMENT:

- TEMPERATURE

- HUMIDITY 0% - 90% ( NON–CONDENSING )

-

ALTITUDE <1500 M ABOVE SEA LEVEL

MAXIMUM HEAT

DISSIPATION(KW)

1.3

1.9

2.6

3

WEIGHT(Kg) 250 400 480 550 680

DIMENSION:

- DEPTH(mm)

-

AUDIBLE NOISE < 65 dBA (AT 1 m)

800

STANDARDS:

- EN50091-1,-2

YES

3.5

- FCC CLASS A

YES

PROTECTIONS:

- SHORT CIRCUIT RECTIFIER, RESERVE, BYPASS NFB

- LIGHTNING

MOV

- EMC FILTER INPUT & OUTPUT

- GALVANIC ISOLATION BETWEEN INPUT & OUTPUT

DATA DISPLAY BY LCD

YES

INDICATIONS & ALARMS:

DRY CONTACT

BATTERY START

YES

YES

☆All specifications mentioned above are subject to change without prior notice.

Page 32

2-4

220V∆ / 380V∆ / 460V∆, 208VY /

380VY / 400VY /

415VY

MAXIMUM CHARGE

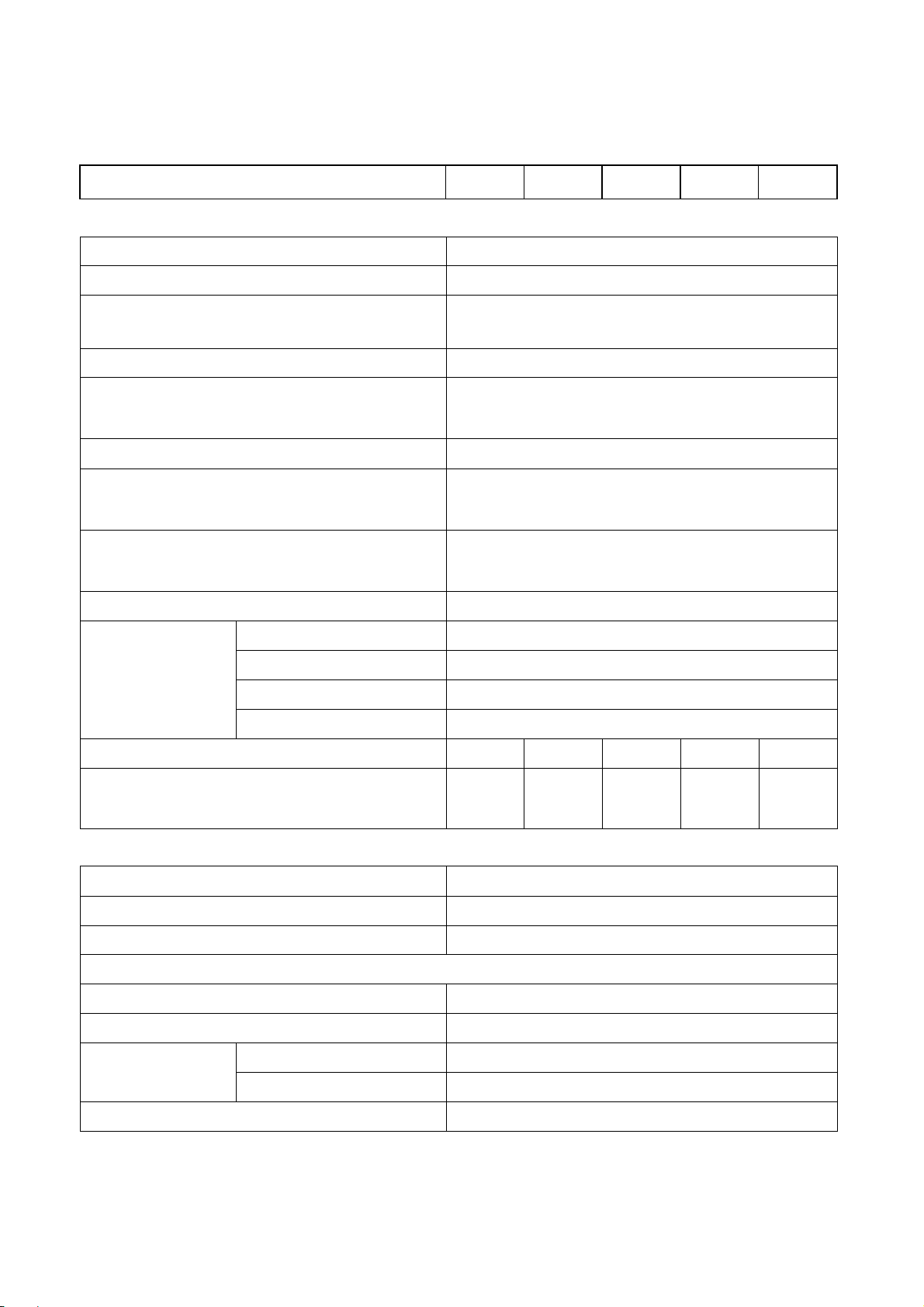

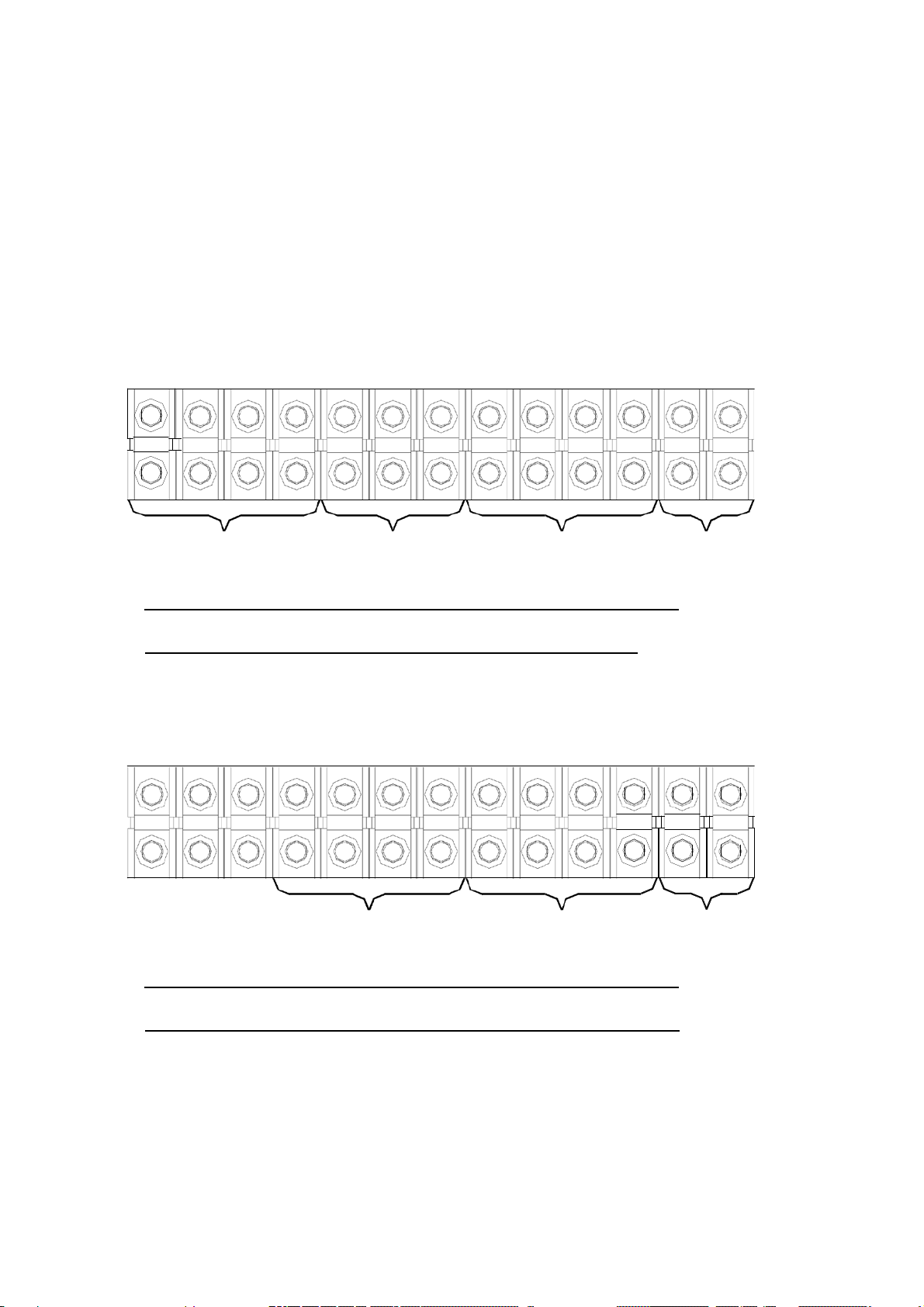

2.2. 80KVA ~ 160KVA UPS 3-Phase Input / 3-Phase Output

TECHNICAL SPECIFICATION

KVA

80

100 120 160

RECTIFIER

INPUT VOLTAGE

INPUT RANGE 307 –

520V

INPUT FREQUENCY 50 / 60 Hz +/- 7%

INPUT POWER FACTOR

0.8

NORMAL INPUT CURRENT(A) 144 180 216 288

MAXIMUM INPUT CURRENT(A) 180 225 270 360

POWER WALK IN 0% - 100% : 20 sec

EFFICIENCY

VOLTAGE REGULATION

99%

1%

CURRENT LIMIT(A) 216 270 324 432

RIPPLE VOLTAGE

BATTERY

0.5%

BATTERY TYPE SEAL LEAD ACID / NiCd

NO. OF CELLS 174 /

VOLTAGE RANGE 295 – 410VDC / 285-415VDC

CURRENT (ADC)

BATTERY LOW VOLTAGE 320VDC / 305VDC

BATTERY LOW STOP VOLTAGE 295VDC / 285VDC

BOOST CHARGE 410VDC / 415VDC

FLOAT CHARGE 396VDC / 410VDC

40

50

271

60

80

Page 33

2-5

OUTPUT POWER FACTOR

0.8

VOLTAGE RANGE

173 – 277 VAC (LINE TO NEUTRAL)

FREQUENCY RANGE

45 – 55 Hz / 55 – 65 Hz

EFFICIENCY 99.5%

TRANSFER TIME:

- MAINS -> INVERTER

0

ms

- INVERTER -> MAINS

0

ms

- 100%

30 sec

- 300%

1 sec

ISOLATION WITH OUTPUT

YES

KVA

80

100 120 160

INVERTER

DC INPUT RANGE 285 – 415VDC

WAVE FORM

OUTPUT VOLTAGE

208 / 380 / 400 / 415 VY 3 PHASE

SINUSOID

WITH NEUTRAL

VOLTAGE REGULATION

100% UNBALANCE LOAD

+ / - 1

%

FREQUENCY LOCK RANGE 45 – 55 Hz / 55 – 65 Hz

OUTPUT FREQUENCY

(FREE RUNNING)

50 / 60 Hz + / - 0.1 Hz

PHASE SHIFT UNDER

100% UNBALANCE LOAD

120 % + / -

THD (LINEAR LOAD) < 2

- <110% CONTINUOUS

- 110 – 125% 15

%

min

0.5

OVERLOAD

- 125 – 150%

10min

∘

- > 150% 60 sec

EFFICIENCY (100% LOAD) 94.5% 94.5% 95% 95%

MAXIMUM OUTPUT

PEAK CURRENT(A)

STATIC SWITCH

348

432

520

OVERLOAD

693

Page 34

2-6

92.5%

0 - 40℃ ( 32 -

104℉ )

- HEIGHT(mm) 1600

- WIDTH(mm) 1100

- LED,LCD,BUZZER

KVA

80

100 120 160

OVERALL

CHARACTERISTICS

OVERALL EFFICIENCY 92.5%

93% 93%

OPERATING ENVIRONMENT:

- TEMPERATURE

- HUMIDITY 0% - 90% ( NON–CONDENSING )

-

ALTITUDE <1500 M ABOVE SEA LEVEL

MAXIMUM HEAT

DISSIPATION(KW)

4.6

5.4

6.5

WEIGHT(Kg) 820 950 1180 1450

DIMENSION:

- DEPTH(mm)

-

AUDIBLE NOISE < 65 dBA (AT 1 m)

800

STANDARDS:

- EN50091-1,-2

YES

8.7

- FCC CLASS A

YES

PROTECTIONS:

- SHORT CIRCUIT RECTIFIER, RESERVE, BYPASS NFB

- LIGHTNING

MOV

- EMC FILTER INPUT & OUTPUT

- GALVANIC ISOLATION BETWEEN INPUT & OUTPUT

DATA DISPLAY BY LCD

YES

INDICATIONS & ALARMS:

DRY CONTACT

BATTERY START

YES

YES

YES

☆All specifications mentioned above are subject to change without prior notice.

Page 35

2-7

220V∆ / 380V∆ / 460V∆, 208VY /

380VY / 400VY /

415VY

MAXIMUM CHARGE

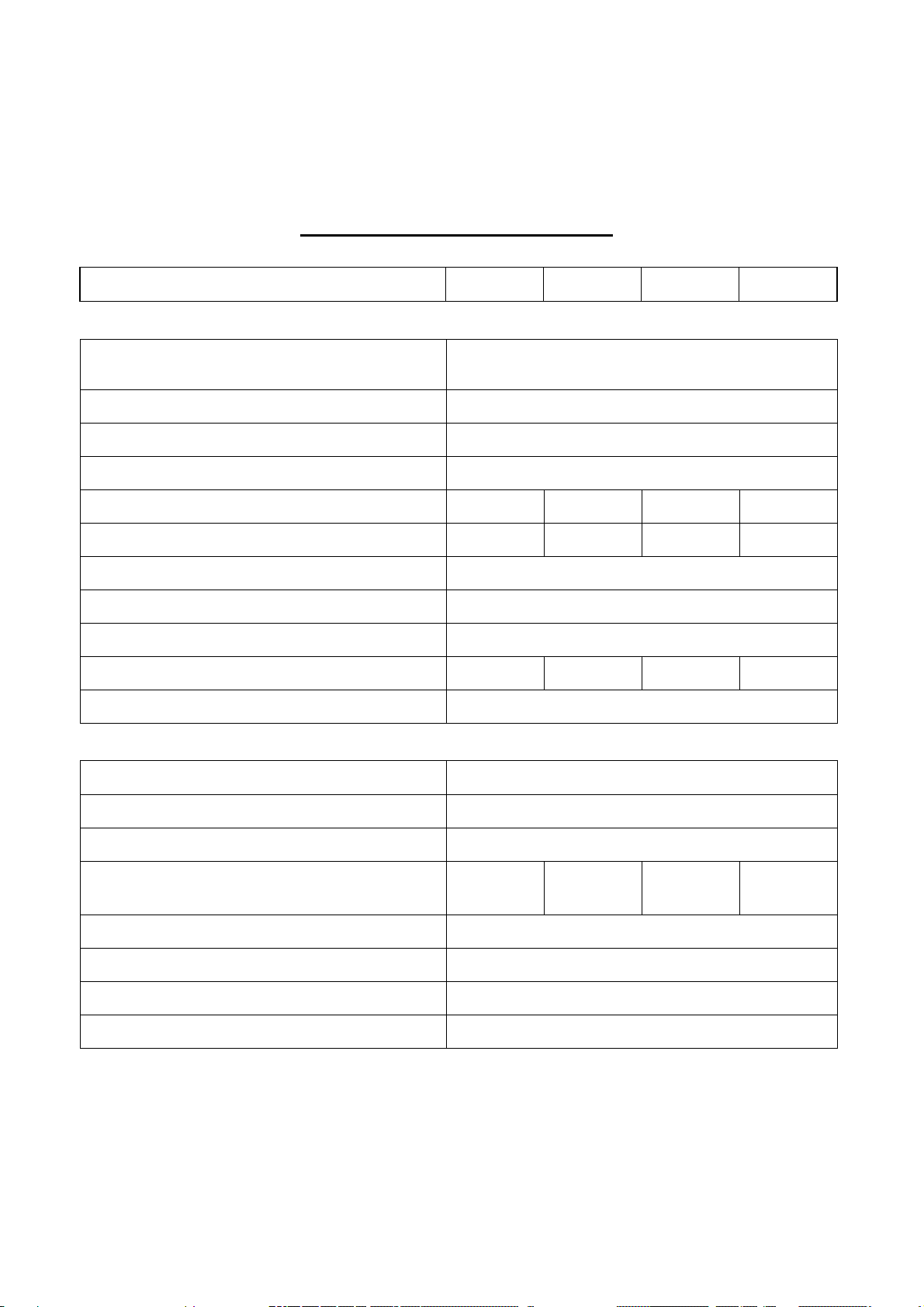

2.3. 20KVA ~ 50KVA UPS 3–Phase Input / 1-Phase Output

30

TECHNICAL SPECIFICATION

KVA

20

40

50

RECTIFIER

INPUT VOLTAGE

INPUT RANGE 307 –

520V

INPUT FREQUENCY 50 / 60 Hz +/- 7%

INPUT POWER FACTOR

0.8

NORMAL INPUT CURRENT(A) 36 54 72 90

MAXIMUM INPUT CURRENT(A) 45 68 90 113

POWER WALK IN 0% - 100% : 20 sec

EFFICIENCY

VOLTAGE REGULATION

99%

1%

CURRENT LIMIT(A) 54 81 108 135

RIPPLE VOLTAGE

BATTERY

0.5%

BATTERY TYPE SEAL LEAD ACID / NiCd

NO. OF CELLS 174 /

271

VOLTAGE RANGE 295 – 410VDC / 285-415VDC

10

15

20

CURRENT (ADC)

BATTERY LOW VOLTAGE 320VDC / 305VDC

BATTERY LOW STOP VOLTAGE 295VDC / 285VDC

BOOST CHARGE 410VDC / 415VDC

FLOAT CHARGE 396VDC / 410VDC

25

Page 36

2-8

FREQUENCY LOCK RANGE

45 – 55 Hz / 55 – 65 Hz

THD (LINEAR LOAD)

< 2

%

EFFICIENCY (100% LOAD)

93%

93%

93.5%

93.5

173 – 277 VAC (LINE TO

- MAINS -> INVERTER

0

ms

KVA

20

30

40

50

INVERTER

DC INPUT RANGE 285 – 415VDC

WAVE FORM

SINUSOID

OUTPUT VOLTAGE 220 / 230 / 240 V, 1p2w or 1p3w

OUTPUT POWER FACTOR

0.8

VOLTAGE REGULATION

0-100% LOAD

OUTPUT FREQUENCY

(FREE RUNNING)

+ / - 1

50 / 60 Hz + / - 0.1 Hz

%

PHASE DIFFERENCE WITH

+ / -

0.5

∘

RESERVE INPUT

- <110% CONTINUOUS

- 110 – 125% 15

min

OVERLOAD

- 125 – 150% 10

min

- > 150% 60 sec

MAXIMUM OUTPUT

PEAK CURRENT(A)

STATIC SWITCH

260

390

520

VOLTAGE RANGE

FREQUENCY RANGE 45 – 55 Hz / 55 – 65 Hz

EFFICIENCY

99.5%

TRANSFER TIME:

- INVERTER -> MAINS 0

ms

- 100% 30 sec

OVERLOAD

- 300% 1 sec

ISOLATION WITH OUTPUT

YES

650

Page 37

2-9

0 - 40℃ ( 32 -

104℉ )

WEIGHT(Kg)

300

400

480

550

- DEPTH(mm)

800

- LED,LCD,BUZZER

KVA

20

30

40

50

OVERALL

CHARACTERISTICS

OVERALL EFFICIENCY 91% 91% 91.5% 92%

OPERATING ENVIRONMENT:

- TEMPERATURE

- HUMIDITY 0% - 90% ( NON–CONDENSING )

-

ALTITUDE <1500 M ABOVE SEA LEVEL

MAXIMUM HEAT

DISSIPATION(KW)

1.3

1.9

2.6

DIMENSION:

- HEIGHT(mm)

- WIDTH(mm)

-

AUDIBLE NOISE < 65 dBA (AT 1 m)

1600

550

STANDARDS:

- EN50091-1,-2

YES

3

- FCC CLASS A

YES

PROTECTIONS:

- SHORT CIRCUIT RECTIFIER, RESERVE, BYPASS NFB

- LIGHTNING

MOV

- EMC FILTER INPUT & OUTPUT

- GALVANIC ISOLATION BETWEEN INPUT & OUTPUT

DATA DISPLAY BY LCD

YES

INDICATIONS & ALARMS:

DRY CONTACT

BATTERY START

YES

YES

YES

☆All specifications mentioned above are subject to change without prior notice.

Page 38

2-10

220V∆ / 380V∆ / 460V∆, 208VY / 380VY

/ 400VY / 415VY

MAXIMUM CHARGE

CURRENT (ADC)

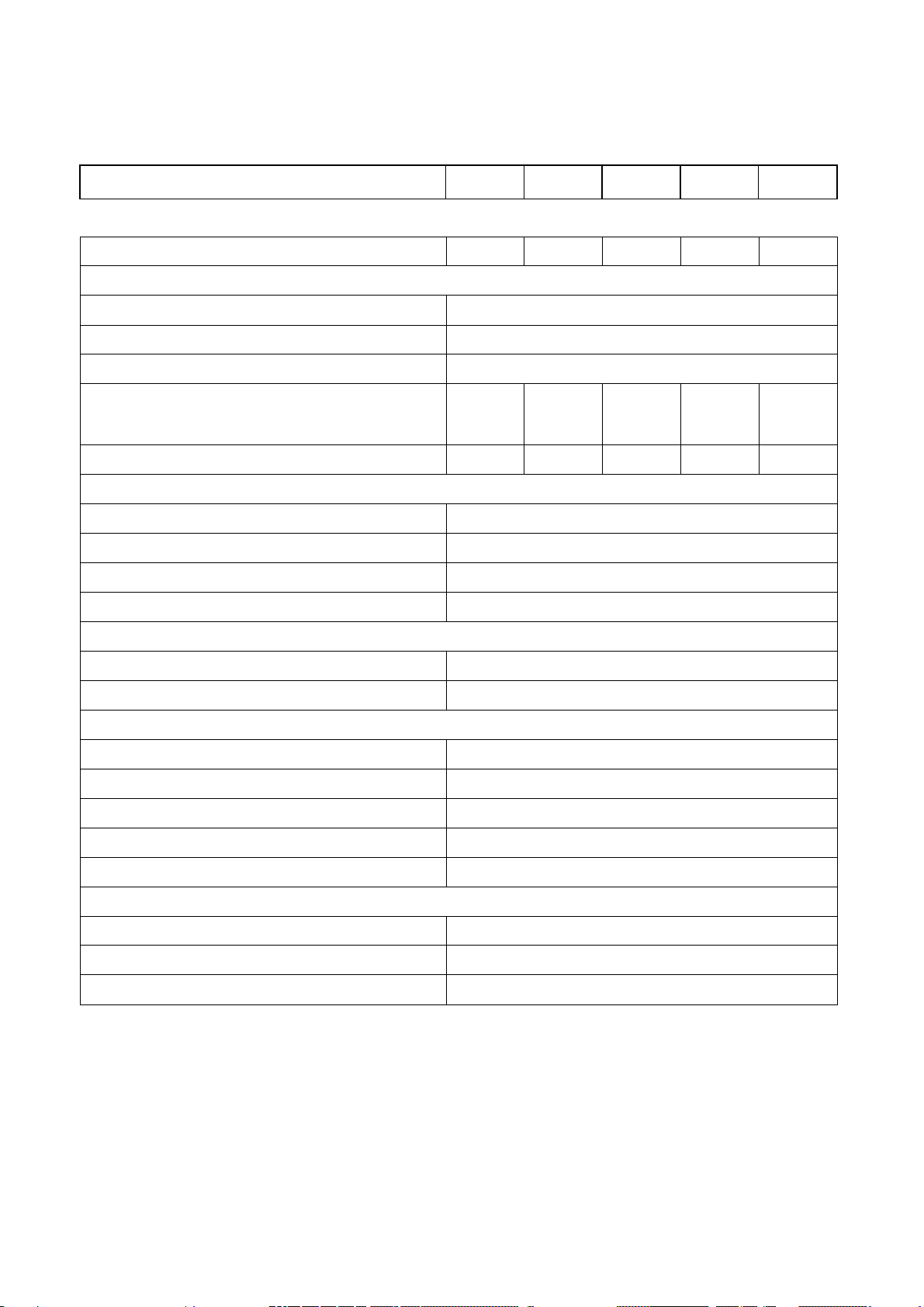

2.4. 200KVA ~ 320KVA UPS 3-Phase Input / 3-Phase Output

TECHNICAL SPECIFICATION

KVA

200 240 300 320

RECTIFIER

INPUT VOLTAGE

INPUT RANGE 307 – 520V

INPUT FREQUENCY 50 / 60 Hz +/- 7%

INPUT POWER FACTOR 0.8

NORMAL INPUT CURRENT(A) 350 420 525 560

MAXIMUM INPUT CURRENT(A) 437 525 656 700

POWER WALK IN 15% - 100% : 15 sec

EFFICIENCY 99%

VOLTAGE REGULATION 1%

CURRENT LIMIT(A) 525 630 788 840

RIPPLE VOLTAGE 0.5%

BATTERY

BATTERY TYPE SEAL LEAD ACID / NiCd

NO. OF CELLS 174 / 271

VOLTAGE RANGE 295 – 410VDC / 285-415VDC

100

120

BATTERY LOW VOLTAGE 320VDC / 305VDC

BATTERY LOW STOP VOLTAGE 295VDC / 285VDC

BOOST CHARGE 410VDC / 415VDC

FLOAT CHARGE 396VDC / 410VDC

150

160

Page 39

2-11

380 / 400 / 415 V 3 PHASE WITH

NEUTRAL

VOLTAGE REGULATION

0-100% LOAD

OUTPUT FREQUENCY

(FREE RUNNING)

PHASE DIFFERENCE WITH

RESERVE INPUT

MAXIMUM OUTPUT

PEAK CURRENT(A)

- MAINS -> INVERTER

0

ms

KVA

200 240 300 320

INVERTER

DC INPUT RANGE 285 – 415VDC

WAVE FORM SINUSOID

OUTPUT VOLTAGE

OUTPUT POWER FACTOR 0.8

+ / - 1 %

FREQUENCY LOCK RANGE 45 – 55 Hz / 55 – 65 Hz

50 / 60 Hz + / - 0.1 Hz

120°+ / -

0.5

°

THD (LINEAR LOAD) < 5 %

OVERLOAD

- <110% CONTINUOUS

- 110 – 125% 15

- 125 – 150% 10

min

min

- > 150% 60 sec

EFFICIENCY(100% LOAD) 95% 95% 95% 95%

STATIC SWITCH

800

1000

1250

VOLTAGE RANGE 173 – 277 VAC (LINE TO NEUTRAL)

FREQUENCY RANGE 45 – 55 Hz / 55 – 65 Hz

EFFICIENCY 99.5%

TRANSFER TIME:

- INVERTER -> MAINS 0

ms

- 100% 30 sec

OVERLOAD

-

300%

ISOLATION WITH OUTPUT

1 sec

YES

1300

Page 40

2-12

MAXIMUM HEAT

DISSIPATION(KW)

- LED,LCD,BUZZER

KVA

200 240 300 320

OVERALL

CHARACTERISTICS

OVERALL EFFICIENCY 93% 93% 93% 93%

OPERATING ENVIRONMENT:

- TEMPERATURE

0 - 40℃ ( 32 - 104℉ )

- HUMIDITY 0% - 90% ( NON–CONDENSING )

-

ALTITUDE <1500 M ABOVE SEA LEVEL

11.5

13

16.3

WEIGHT(Kg) 2500 2700 3000 3100

DIMENSION:

- HEIGHT(mm) 1600

- WIDTH(mm) 2200

- DEPTH(mm) 800

-

AUDIBLE NOISE < 67 dBA (AT 1 m)

17.4

STANDARDS:

-EN50091-1,2

YES

-FCC CLASS A YES

PROTECTIONS:

- SHORT CIRCUIT RECTIFIER, RESERVE, BYPASS NFB

- LIGHTNING

MOV

- EMC FILTER INPUT & OUTPUT

- GALVANIC ISOLATION BETWEEN INPUT & OUTPUT

DATA DISPLAY BY LCD

YES

INDICATIONS & ALARMS:

DRY CONTACT

BATTERY START

YES

YES

YES

☆All specifications mentioned above are subject to change without prior notice.

Page 41

3-1

3. INSTALLATION

3.1. Site & Environment Consideration

The main function of the UPS is to provide an safe, clean independent electrical

supply to the load so that it is free from any random variations, disturbances or

interruptions of the utility Mains, provide a constant power supply which is

perfectly regulated in both voltage and frequency. And when the Mains is not

available, the UPS can provide optimal back-up time depends on the battery bank

capacity connected to it.

Usually the life expectancy of the UPS is 5 to 10 years (battery is not included,

because life expectancy of battery depend on the type of battery, the temperature

and humidity of the environment it is installed and the type of charger is applied to

the battery). Therefore optimal life expectancy of the UPS can be achieved by

careful consideration of the site and environment.

The following precautions and recommendations should be checked in considering

the site and environment of the UPS:

(a) The UPS should be located on place with adequate ventilation (refer to the

specification of the heat dissipation of the UPS). If the UPS is installed indoors,

care must be taken in insuring the evacuation of heat from the closed room.

(b) Adequate space (at least 1M) should be allowed to open the door without

obscured by other objects for operation or maintenance. Adequate space (at least

1M) should be allowed at the top of the UPS, because heat dissipation is

ventilated through the top openings (ventilation booth is available upon request).

(c) Do not put any objects on the top of the UPS to obscure the ventilation. Do

not locate the UPS near to any heat source, or machinery, which produce

metallic coil dust or powder, or facility that will produce corrosive substances or

vapor.

(d) Do not locate the UPS below the shower of fire extinguishing system

(abnormal conditions of the UPS should be protected by cutoff the power

supply).

Page 42

3-2

(e) It is necessary to guarantee the temperature and humidity values of the site

into which the UPS will be installed should be within the range allowed by the

specification. The UPS is capable of

continuous norm

al operation within a

temperature range of 0℃(32℉) to 40℃(104℉). For optimal performance and

reliability to prolong UPS’s lifetime, it is recommended to keep the environment

temperature below 25℃, and humidity below 80%.

(f) If the UPS is installed outdoor, avoid direct exposure of the UPS to the

sunlight and rain. Avoid direct confrontation with sand, dust or wind.

(g) The floor loading capacity should be big enough to endure the weight of the

UPS. Four tough right angled steel foot stands are attached with the UPS, please

insert the corresponding screw nut (dia.1/2”) into the floor for securing the UPS

on the floor when it is locate on territory where earthquake is expected or

moving vehicle, or tanker etc. Dimensions of the 1/2” nut on the to secure the

UPS are shown below.

Page 43

3-3

(h) Walls, ceilings, floors or anything near to the UPS should be preferably

constructed

of non-combustibl

e materials. The portable fire extinguisher should

be accessible nearby in case of hazard.

(i) Avoid accumulating litter or trash of any sort in or around the UPS system.

The floor area surrounding the UPS should be kept clean so that metallic powder

and filings are not

sucked into

the unit thus causing a short circuit and damage

to the system.

(j) Access to the UPS room should be limited to a minimum number of operation

and maintenance personnel only. The doors should be kept locked and the keys

should be confined to authorized personnel only.

(k) Personnel who operate or maintain the UPS system should be proficient in

normal and emergency operational procedures. New personnel should be

trained and qualified prior to operate the equipment.

(l) Although the UPS has past the international EMC tests, it is not

recommended to install the UPS near to any equipment that is susceptible to

electro-magnetic interference, such as computer system, monitors, radio etc.

(m) It preferably to place the UPS near to the source than near to the load.

Page 44

3-4

3.2. Unpacking

Carefully take off all the packaging material of the UPS, then carefully locate the

UPS onto site which has selected with all the points in section 3.1 kept in mind.

The UPS had past the production testing and QC checking all the electrical and

mechanical characteristics in detail prior to shipment from the factory, therefore the

UPS should be in proper conditions upon receipt. Once receive the UPS, first check

visually the outlook and mechanical structure if any physical damage was made

during transportation.

Then check if all the accessories/options (match with your purchase order) have

been attached.

- DOOR KEY

- THIS INSTRUCTION MANUAL

- BATTERY FUSE (FOR BATTERY CABINET ONLY)

- SPARE SCREWS FOR COVER PLATE

- SPARE SCREWS FOR CONNECTION TERMINALS etc.

Lastly, check if the specification of the UPS identical to the specification you order.

The key items in the specification you must check are:

- RATED POWER OF THE UPS,

- INPUT VOLTAGE & FREQUENCY

- OUTPUT VOLTAGE & FREQUENCY

- NO. OF OUTPUT PHASES (1Φ OR 3Φ)

- BATTERY VOLTAGE OR CELL NO.

Check also the necessary documentation that is attached:

- GUARANTEE CARD

-

AGENT/SERVICE CENTER INFORMATION

Page 45

3-5

230/400V 3Φ

230/400V 3Φ

230/400V 3Φ

230/400V 3Φ

3.3. Cable Selection

The following tables list all the information between KVA of the UPS and the size

and rating of the cables. Inadequate cable size or over sized breaker will incur risk

of fire or damage of insulation. Therefore, please look up the following tables to

determine the input circuit breaker rating and the size of cable for input, output and

battery connections. These data are for reference; final decision should be made in

accordance with the local electrical regulations.

BREAKER RATING FOR INPUT

KVA INPUT Imax(A) NFB(A)

20

230/400V 3Φ

30

230/400V 3Φ

40

230/400V 3Φ

50

230/400V 3Φ

60

230/400V 3Φ

80

230/400V 3Φ

100 230/400V 3Φ

120

160

240

320

CABLE SIZE FOR INPUT

50

73

98

122

147

172

215

258

344

520

692

50

75

100

125

150

175

225

300

350

500

700

KVA INPUT In(A) R/S/T(mm2) N(mm2)

20

230/400V 3Φ

30

230/400V 3Φ

40

230/400V 3Φ

50

230/400V 3Φ

60

230/400V 3Φ

36

54

72

90

108

8

14

22

30

38

14

22

30

38

50

Page 46

3-6

230/400V 3Φ

230/400V 3Φ

230/400V 3Φ

230/400V 3Φ

230/400V 3Φ

230/400V 3Φ

230/400V 3Φ

230/400V 3Φ

230/400V 3Φ

230/400V 3Φ

230/400V 3Φ

80

230/400V 3Φ

144

50

80

100 230/400V 3Φ

120 230/400V 3Φ

160 230/400V 3Φ

240 230/400V 3Φ

320 230/400V 3Φ

CABLE SIZE FOR OUTPUT

KVA OUTPUT In(A) R/S/T(mm2) N(mm2)

20

30

40

50

60

180

216

288

416

100*2 125*2

554

150*2 200*2

29

46

58

72

91

80

100

60*2

8

14

22

30

38

100

125

80*2

14

22

30

38

60

80

100

120

160

240

320

20

230V 1Φ

30

230V 1Φ

40

230V 1Φ

50

230V 1Φ

116

144

182

232

348

100*2 125*2

463

125*2 150*2

91

130

182

217

60

80

100

60*2

38

60

100

150

80

100

125

80*2

60

80

125

60*2

Page 47

3-7

30 90 100 38

80 240

125*2

38*2

100 300

160*2

50*2

320 960

200*4

80*4

FUSE RATING & CABLE SIZE FOR BATTERY

☆ THE BATTERY VOLTAGE IS 295 – 410V

KVA Imax(A) FUSE(A)

20

40

50

60

60

120

150

180

63

125

160

200

CABLE(mm2)

22

38

50

80

120

160

240

360

200*2

480

200*2

720

200*4

80*2

80*2

80*4

Page 48

3-8

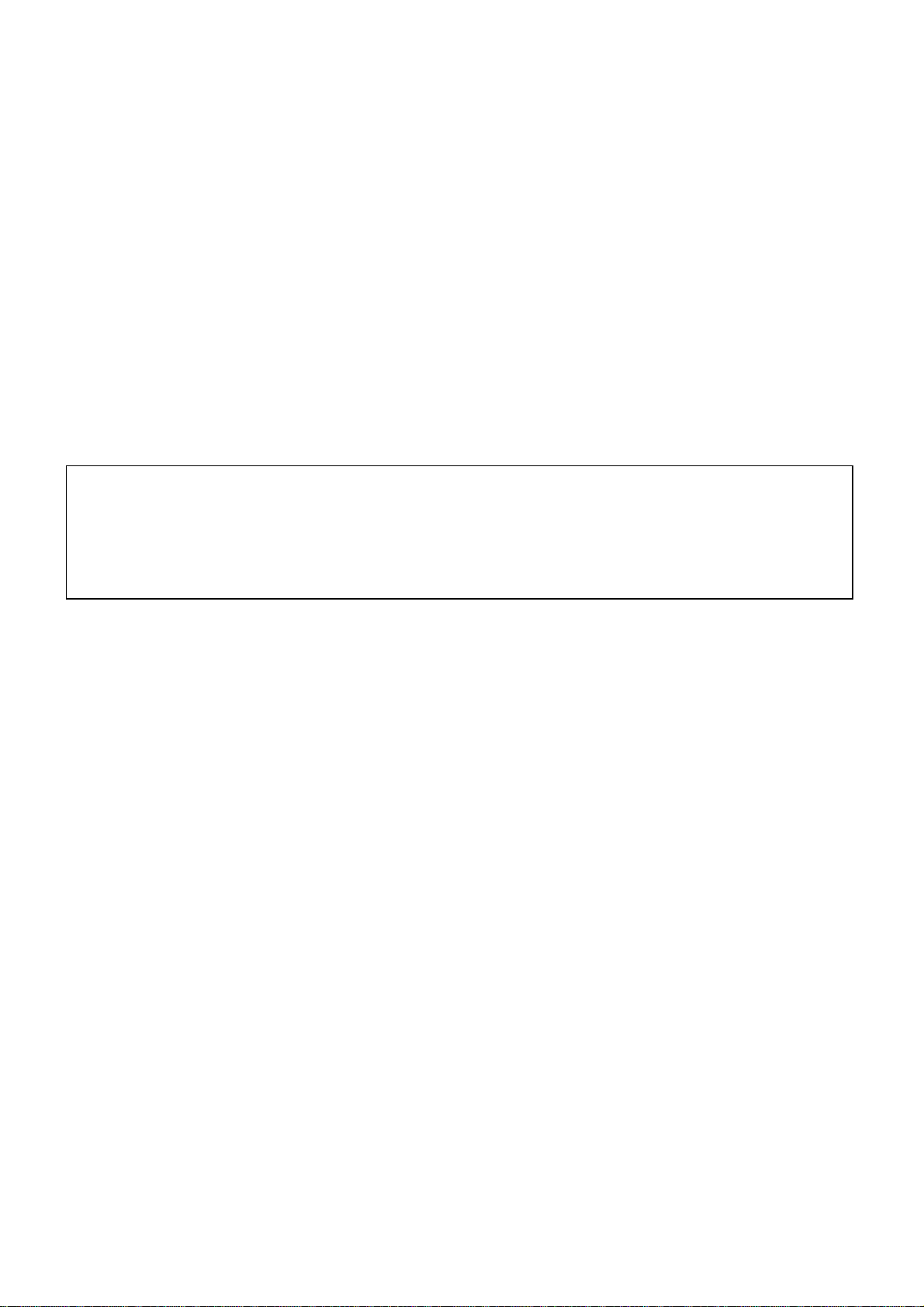

3.4. Terminal Connection

Although different KVA of the UPS may have different cable connection terminal,

all our standard UPS connection terminal alignment falls into one of the following

types:

RR RS RT IN IR IS IT OR OS OT ON B+ B-

RESERVE

INPUT

INPUT OUTPUT INPUT

RECTIFIER

UPS

BATTERY

3 PHASE INPUT / 3 PHASE OUTPUT

TERMINAL WITH TWO SOURCE

IN IR IS

RECTIFIER & RESERVE

INPUT

IT OR OS OT ON B+ B-

UPS

OUTPUT

BATTERY

INPUT

3 PHASE INPUT / 3 PHASE OUTPUT

TERMINAL WITH SINGLE SOURCE

☆☆☆ Three extra terminals are installed for convenience of changing the unit to

separate reserve input.

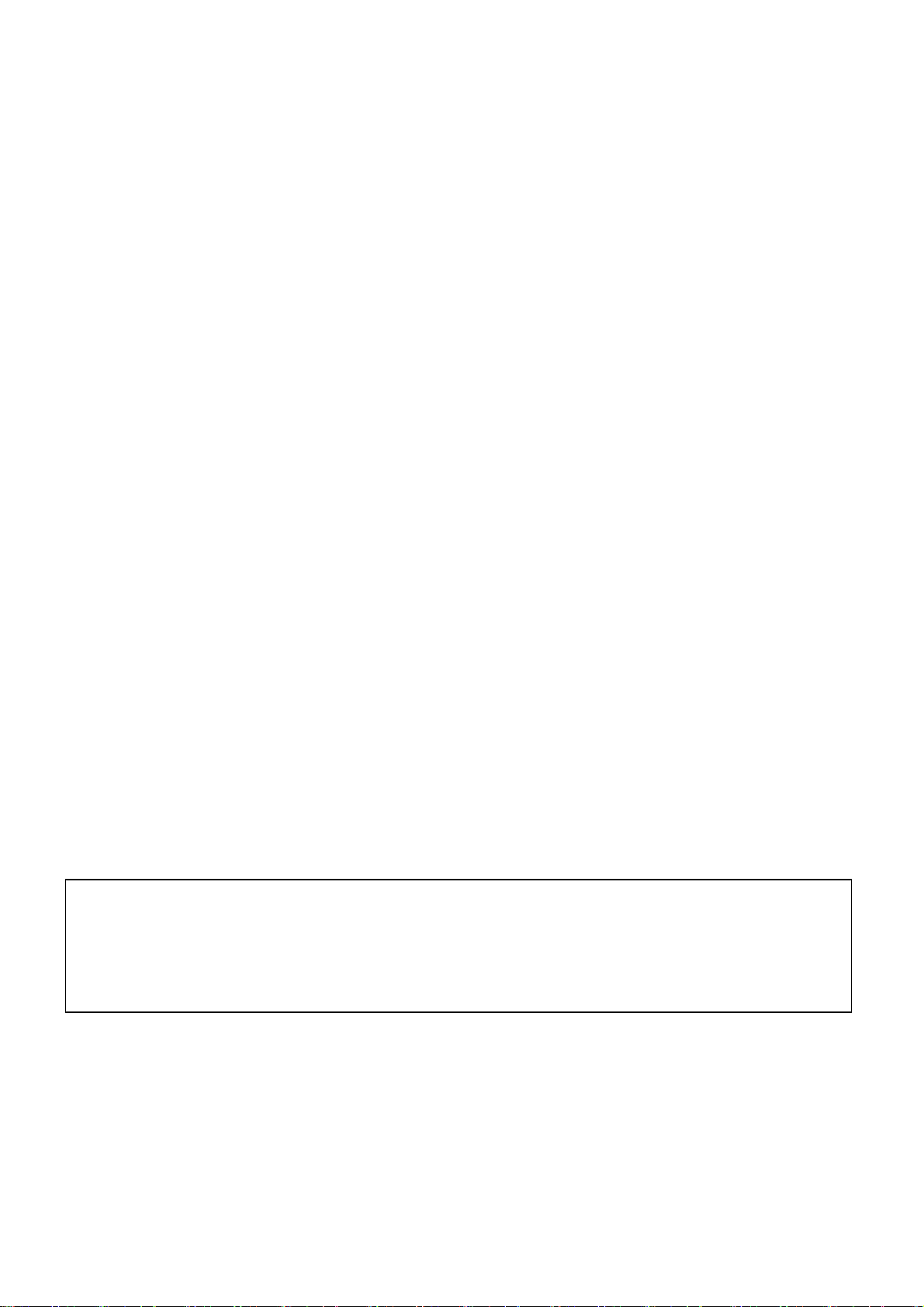

Page 49

3-9

RT

IN

IR

IS

IT

OR

ON

B+

B-

RT

IN

IR

IS

IT

OR

ON

B+

B-

For single phase output UPS, the current is very much larger in single phase

terminal, therefore the terminal looks bigger than it is needed.

RESERVE

INPUT

RECTIFIER

INPUT

UPS

OUTPUT

3 PHASE INPUT / 1 PHASE OUTPUT

TERMINAL WITH TWO SOURCE

BATTERY

INPUT

RECTIFIER & RESERVE

INPUT

UPS

OUTPUT

BATTERY

INPUT

3 PHASE INPUT / 1 PHASE OUTPUT

TERMINAL WITH SINGLE SOURCE

☆☆☆ Extra empty terminals are installed for convenience of changing the unit to

separate reserve input.

Page 50

4-1

4. OPERATIONS

After all cables have been connected, the UPS is ready to operate once power

source is available at the

input

terminal. Before turn on any switch or breaker,

check once again the following points listed below:

(a) Check the input voltage if it conforms with the UPS’s rated input

voltage.

(b) Check the input frequency if it conforms with the UPS’s rated input

frequency.

(c) Check if all load at the output is switched off.

(d) All breakers and the battery dis-connector are opened.

(e) If there is anything not belongs to the UPS exits inside the UPS.

4.1. Switch on Procedure

If you want to start the UPS from completely shutoff to normal operation, you can

follow the steps below to turn on the UPS. (But this procedure is for standard

system, 380/220V 3 phases 4 wires Input, 10~160KVA. For special specification

and those above 160KVA, please refer to the brief instruction label stuck in front

of the PCB holder.)

(a) Close the reserve breaker – The reserve and output LED on the mimic will

lit up, indicating the reserve static switch loop is energized,

therefore the output has power now. The power supply in the UPS

also established. The fans will rotate too.

(b) Close the rectifier breaker - The rectifier will be automatically started if the

power source connected is correct. The DC voltage will slowly

rise up (15 – 30 sec.) until the designated voltage is reached, and

will keep the value anyhow. Now, the DC is already ready for the

inverter.

(c) Close the battery breaker - A fuse holder is employed the battery to the DC

bus for safety purpose. Now the battery will take over to supply

the DC bus if rectifier mains fail.

Page 51

4-2

~

~

~

~

/

~

(d) Push inverter on switch – To on the inverter, the inverter on switch and the

(e) Check if the mimic LED is correct, as shown in the figure. All warning

~

MIMIC DISPLAY UNDER NORMAL OPERATION

control switch must be pressed simultaneously. The inverter will

start working and inverter output will be established in 4 sec. The

load will be automatically transferred to the inverter 3 sec. later.

Now the UPS is in normal operation now.

/

~

LEDs on the right hand

and ‘INVERTER SS’ on the left hand side should lit.

over 70%, the ‘70% LOAD’ LED will also lit.

4.2. Shutdown Procedure

If you want to shutdown the UPS completely (no power at output or inside),

please follow the

380/220V 3 phases 4 wires Input, 10~160KVA. For special specification and those

above 160KVA, please refer to the brief instruction label stuck in front of the PCB

holder.)

(a) Switch off the inverter – The inverter can be switched off by pressing the

steps

below.

inverter off switch and the control switch simultaneously. And the

load will be automatically transferred to reserve without

interruption.

(But this procedure is for standard system,

side

is off, two LEDs: ‘INVERTER ON’

If

the load is

Page 52

4-3

(b) Open the battery breaker – If you want to shutdown all the power of the

UPS, continue to open the battery breaker. Now the DC bus is

(c) Open the rectifier breaker – Open the rectifier breaker will then further

take the power source away from the DC bus; therefore the DC

bus will start to drop slowly. After 5 min., the DC bus will drop to

a safe level (let say 20VDC).

only supported by the rectifier.

(d) Open the reserve breaker – Before opening the reserve breaker, there is

power exists at the output, but after opening the reserve breaker,

the output (or load) will no longer have power supply now.

Therefore, before opening the reserve breaker must make sure

there is no critical load connected to the output.

(e) At last all power has been cut off now, there should none of the LED or

LCD lit. The UPS now is completely shut off.

4.3. From Inverter to Bypass Procedure

If you want to stop the UPS for maintenance and do not stop the power supply

from the load, you can follow the steps below to turn the UPS to maintenance

bypass mode without interrupting the output power

supply. (But

this procedure is

for standard system, 380/220V 3 phases 4 wires Input, 10~160KVA. For special

specification and those above 160KVA, please refer to the brief instruction label

stuck in front of the PCB holder.)

(a) Switch off the inverter – The inverter can be switched of by pressing the

inverter off switch and the control switch simultaneously. And the

load will be automatically transferred to reserve without

interruption.

Page 53

4-4

(b) Open the battery breaker – You have to shutdown the power inside the UPS;

therefore, continue to

open

the battery breaker.

(c) Open the rectifier breaker – Open the rectifier breaker will then further

take the power source away from the DC bus; therefore, the DC

bus will start to drop slowly. After 5 min., the DC bus will drop to

a safe level (let say 20VDC).

(d) Close the bypass breaker – Now the reserve breaker and reserve static

switch is still conducting, therefore when maintenance bypass

breaker is closed, power will flow through the bypass loop instead

of the reserve loop because the impedance of bypass loop is lower.

(e) Open the reserve breaker – You can now open the reserve breaker to free

the UPS from any

power supply.

4.4. From Bypass to Inverter Procedure

If the UPS is in maintenance bypass mode, and you want to turn the UPS to

normal mode without interrupting the output AC, please follow the steps below.

(But this procedure is for standard

system, 380/220V

3 phases 4 wires Input,

10~160KVA. For special specification and those above 160KVA, please refer to

the brief instruction label stuck in front of the PCB holder.)

(a) Close the reserve breaker – The reserve and output LED on the mimic will

lit up, indicating the reserve static switch loop is energized,

therefore the output has power now. The power supply in the UPS

also established. The fans will rotate too.

(b) Open the bypass breaker – The inverter cannot be switched on with the

maintenance bypass

breaker

is closed (because the CPU will

sense the breaker and prevent the inverter to connect directly to

AC source). And the reserve breaker has already closed, therefore

power goes through the reserve loop if bypass breaker is open, AC

at output will not be interrupted.

Page 54

4-5

(c) Close the rectifier breaker - The rectifier will be automatically started if the

power source connected is correct. The DC voltage will slowly

rise up (15 – 30sec.) until the designated voltage is reached, and

will keep the value anyhow. Now, the DC is already ready for the

(d) Close the battery breaker - A fuse holder is employed in the battery to the

inverter.

DC bus for

safety purpose.

Now the batteries will take-over to

supply the DC bus if rectifier mains fail.

(e) Push inverter on switch – To on the inverter, the inverter on switch and the

control switch must be pressed simultaneously. The inverter will

start working and inverter output will be established in 4 sec. The

load will be automatically transferred to the inverter 3 sec. later.

Now the UPS comes again into normal operation now.

Page 55

5-1

5. LCD DISPLAY

The LCD can display information much more than LED can do. In order to make

the display sharp

and readab

le, the LCD is back-lighted by LEDs. But since we

want to further prolong the life time of the LED, the CPU will cut off the power

of the LED 3 minutes after the last key of either UP, DOWN or ENTER is pressed.

Of course the back light will continue if the UP, DOWN or ENTER key is

consecutively being pressed. We start from the first page of the LCD. This screen

will pop out once the system power is enabled (i.e. the default screen).

5.1. Menu 0 – Main Menu

W E L C O M E T O U S E T H E U P S

M O D E L : 5 0 3 3 A S / N : 1 2 3 4 5 6 7 8 9 0 I D : 0 1

5 0 K V A I : 2 2 0 / 3 8 0 V / 5 0 H Z O : 2 2 0 / 3 8 0 V / 5 0 H Z

2 0 0 2 / 0 2 / 0 1 T U E 0 8 : 0 0 A M

The first row will display the greeting context being set by the factory or sole

agent. Changing the

context of

this row is not recommended. The model no.

(MODEL), serial no.(S/N), and the identification no.(ID) are displayed in the

second row. While the third row will display the KVA rating, input rating and

output rating of the UPS. Changing the model no. of the second row will change

the rating displayed in the second row too (rating is automatically generated by

CPU inside the UPS according to the MODEL no.).

WARNING: Never change the model number yourself, because some

parameters will be changed along with the model number.

Page 56

5-2

Serial number is set by factory for the convenience of maintenance personnel who

may need to take

down

the serial no. of the UPS he has attended. The

identification no. is set only when external module connect to more than one UPS,

each UPS must have a unique number to identify itself, and it should be set by

installation technical personnel after installation. The YEAR/MONTH/DATE,

DAY OF THE WEEK, HOUR: MINUTE and AM (PM) from the real time clock

inside the UPS are displayed in the fourth row for user’s reference and stamping

the date and time in the historical data when abnormal conditions happen. By

pressing one of the UP, DOWN or ENTER key, the LCD will change to another

screen, the MENU 1.

5.2. Menu 1 – Select Menu

< S E L E C T M E N U >

→ S T A T U S / W A R N / F A U L T P A R A M E T E R S E T

R E A L T I M E D A T A

H I S T O R I C A L D A T A E X I T

It is a select menu with cursor (→) for user to select what type of data the user

what to view or may the user would like to change the settings of the UPS, such

as inverter on/off, buzzer on/off, charging time and magnitude, date/time etc. The

cursor

( → ) can be moved upward by the

downward by the

DOWN(

↓ ) key. The selection is confirmed by pressing the

UP( ↑ ) key, and can be moved

ENTER (←┘), and change to the menu which the cursor is pointing at. If the

item ‘PARAMETER SET’ is selected, the LCD will jump into a screen which will

ask the user to key in the password. See the figure below.

P A S S W O R D : 1 2 3 4

Page 57

5-3

The number can be changed upward or downward by the UP( ↑ ) or the

DOWN(↓) key, and can be confirmed by the ENTER(←┘) key. The password is

a 4 digit number. The selection will continue if correct password is entered, or

will go back to MENU 0 the MAIN MENU if

no

correct password is entered after

3 trials. The password for entering the < PARAMETER SET > menu is 1-2-3-4.

The entering of MENU 12 – the OTHER SETTING menu is permitted by another

password, only released to the maintenance personnel. User can ask the sole agent

if he really need it.

If ‘EXIT’ is selected (blinking instead of pointed by cursor), the screen will go

back to the MENU 0.

5.3. Menu 2 – Status / Warning Menu

< S T A T U S > < W A R N I N G >

R E C T I F I E R = O N

I N V E R T E R = O F F

L O A D O N I N V E R T E R

It is a display menu jump from MENU 1 when STATUS/WARN/FAULT is

selected. The left hand side of this menu shows the real time status of the rectifier,

inverter and static switch states. While the right hand side shows the warning or

fault condition if any. Therefore, under normal condition, the LCD display should

be exactly the same as the figure shown above. When minor abnormal condition

happens it will be shown under the title < WARNING >, but will be overridden by

fault message if more serious abnormal condition happens, and the title <

WARNING > will change to < FAULT >. For example, short circuit happens at

the output, this screen will display as follows:

< S T A T U S > < F A U L T >

R E C T I F I E R = O N S H O R T C I R C U I T !

I N V E R T E R = O F F

L O A D O N I N V E R T E R

Page 58

5-4

The inverter should be shut off under short circuit. Since the CPU detect it is

short circuit, in order to avoid unnecessary tripping and hurting of the breaker, the

static switch remains in conducting the inverter (will not transfer to reserve).

List below are all the warning conditions that can be displayed (they are arranged

in order of priority, start with the highest priority):

1st row : BYPASS ON / RECT AC FAIL / RECTIFIER PHASE ERROR /

2nd row : 170% OVERLOAD / 150% OVERLOAD / 125% OVERLOAD /

110% OVERLOAD

RESERVE FREQ. ERROR

3rd row : BATTERY LOW STOP / BATTERY LOW / BATTERY BAD /

BATTERY GND FAULT / BATTERY TESTING

Lists below are all the fault conditions that can be displayed:

1st row : HIGH DC SHUTDOWN

2nd row: SHORT CIRCUIT! / FUSE/OVERHEAT / OVERLOAD

SHUTDOWN / EMERGENT STOP / INVERTER ABNORMAL

3rd row : BYPASS ON SHUTDOWN

The UP (↑ ) or DOWN (↓ ) key has no function in this menu. The screen will

go back to MENU 1 – the SELECT menu, when ENTER (←┘) is pressed.

5.4. Menu 3 – Real Time Data Menu

< R E A L T I M E D A T A >

→ R E C T I F I E R D A T A O T H E R D A T A

R E S E R V E D A T A

O U T P U T D A T A E X I T

Page 59

5-5

It is a select menu jump from MENU 1 when the REAL TIME DATA is selected.

The cursor (→) is used to select what type of real time data the user what to view,

such as RECTIFIER DATA, RESERVE DATA, OUTPUT DATA, OTHER DATA

etc. The cursor (→) can be moved upward by the UP (↑) key, and can be moved

downward by the DOWN (↓) key. The selection is confirmed by pressing the

ENTER (←┘), and change to the menu which the cursor is pointing at.

If ‘EXIT’ is selected (blinking instead of pointed by cursor), the screen will go

back to the MENU 1- the SELECT MENU.

5.5. Menu 4 – Historical Event Menu

< D A T E / T I M E / E V E N T S > R U N : 2 1 Y R 0 3 M O

2 0 0 0 \ 0 3 \ 2 9 0 9 : 3 2 S H O R T C I R C U I T !

2 0 0 0 \ 1 2 \ 0 1 2 2 : 1 5 S H O R T C I R C U I T !

2 0 0 1 \ 0 1 \ 1 0 1 5 : 4 7 H I G H D C S H U N T D O W N

It is a display menu jump from MENU 1 when HISTORICAL DATA is selected.

The records stored in EEPROM when abnormal events happened are displayed in

this menu. The record display is started with the date and time stamped when the

abnormal condition happened. Therefore, it is possible for the user or

maintenance personnel to trace back what happen to the UPS in the past. 77

records can be stored in one EEPROM, can be increased to 154 records with 2

EEPROMs. All these records will not be erased by cutting off of the power supply

or complete shutdown of the UPS, i.e. they will be kept in EEPROM forever

except over written by the 78th (or the 155th) records.

3 records can be displayed each time on the screen. The records displayed (once

this menu is popped) are the 3 most update records in the EEPROM. The

displayed records will move one record upward when the UP (↑) key is pressed,

and move one record downward when the DOWN (↓) key is pressed.

Page 60

5-6

The abnormal conditions can be displayed are listed below:

HIGH DC SHUTDOWN / SHORT CIRCUIT! / FUSE/OVERHEAT /

OVERLOAD SHUTDOWN / EMERGENT STOP / INVERTER ABNORMAL

/ BYPASS ON SHUTDOWN

Besides, on the top right corner the screen, the UPS run time is displayed in

year/month for the reference of the user or maintenance personnel to estimate the

time for maintenance.

The screen will go back to MENU 1- SELECT MENU by pressing the ENTER

(←┘) key.

5.6. Menu 5 – Parameter Setting Menu

< P A R A M E T E R S E T T I N G >

→ I N V E R T E R = O N / O F F D A T E / T I M E

B U Z Z E R = O N / O F F

B O O S T C H A R G E E X I T

It is a parameter setting menu jump from the MENU 1 - SELECT MENU when

the item < PARAMETER SET > is selected and correct password has been

entered. The cursor (→) is used to select what type parameter the user want to set,

such as INVERTER ON/OFF, BUZZER ON/OFF, BOOST CHARGE,

DATE/TIME etc. The cursor (→) can be moved upward by the UP (↑) key, and

can be moved downward by the DOWN (↓) key. The selection is confirmed by

pressing the ENTER (←┘) key.

The first item can be set is the INVERTER ON/OFF, when it is selected

‘INVERTER ON/OFF’ will be displayed, where the ‘ON’ will blink if the inverter

status is on, and the ‘OFF’ will blink if the inverter status is off. The intended

(

status can be changed by UP

↑ ) or DOWN ( ↓ ) key, and is confirmed by

ENTER

selected

(

← ┘

or

) key. Then ‘INVERTER = ON’ will be displayed if ‘ON’ is

‘INVERTER = OFF’ will be displayed if ‘OFF’ is selected, the UPS

will switch on or off the inverter according to your selection.

Page 61

5-7

The second item can be set is the BUZZER ON/OFF, when it is selected

‘BUZZER ON/OFF’ will be displayed, where the ‘ON’ will blink if the buzzer

status is on, and the ‘OFF’ will blink if the buzzer status is off. The intended

(

status can be changed by UP

↑ ) or DOWN ( ↓ ) key, and is confirmed by

ENTER (←┘) key. Then ‘BUZZER = ON’ will be displayed if ‘ON’ is selected