Page 1

User’s Manual

Laser Terminal PHL 1700

Cradle IRU 1700

Page 2

page

1 INTRODUCTION 3

2 INSTALLATION 4

2.1 UNPACKING 4

2.2 DETAILED VIEW 5

2.2.1 Dimensions of terminal 5

2.2.2 Details of terminal 5

2.2.3 Display of terminal 6

2.2.4 Dimensions of cradle 7

2.2.5 Details of cradle 7

2.3 H

ANDLING PRECAUTIONS 8

2.4 ASSEMBLY 9

2.4.1 Terminal 9

2.4.2 Cradle 9

2.5 I

NSTALLING, REPLACING AND CHARGING

BATTERIES

10

2.5.1 Required batteries 11

2.5.2 When to replace or recharge the

main battery? 11

2.5.3 When to replace the backup

battery? 11

2.5.4 How to remove the main battery? 11

2.5.5 How to install the main battery 12

2.5.6 How to recharge the rechargeable

battery pack in the cradle? 12

2.5.7 How to (re)place the backup battery

in the terminal? 13

2.6 I

NSTALLING IN A SYSTEM 13

2.6.1 Power supply for cradle 13

2.6.2 DIP switch settings on cradle 13

2.6.3 Connect cradle to computer/

modem 13

2.6.4 Connect network of cradles 13

2.6.5 Terminal on cradle 13

3 OPERATION OF THE TERMINAL 15

4 SCANNING BAR CODES 16

4.1 SCAN POSITION 16

4.2 Reading the bar codes 16

4.3 If you have problems with the

read operation 16

U

SER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

PHL-ver6-sv / printed 03 03

CONTENTS

CAUTION: This user’s manual may be revised or

withdrawn at any time without prior notice.

Copyright 2000, Opticon Sensors Europe B.V.

All rights reserved.

This manual may not, in whole or in part, be copied,

photocopied, reproduced, translated or converted to

any electronic or machine readable form without

prior written consent of Opticon Sensors Europe.

Limited warranty and disclaimers

By opening the package of this product you agree to

become bound by the liability and warranty conditions

as described below.

Under all circumstances this manual should be read

attentively, before installing and or using the product.

In no event, Opticon Sensors Europe will be liable

for any direct, indirect, consequential or incidental

damages arising out of use or inability to use both

the hardware and software, even if Opticon has been

informed about the possibility of such damages.

A serial number appears on all Opticon products.

This official registration number is strictly related to

the device purchased. Make sure that the serial

number appearing on your Opticon device has not

been removed. Servicing by our Repair Department

can only be carried out under warranty.

All Opticon products are warranted for a period of

one year after purchase, covering defects in material

and workmanship. Opticon will repair or, at its opinion,

replace products that prove to be defective in material

or workmanship under proper use during the warranty

period.

Opticon will not be liable in case modifications are

made by the customer. In such case the standard

repair charge will be applicable. The standard charge

for repair will also be applicable in case no defect is

found at all. These rules also apply for products that

are still under warranty. Therefore, you are advised

to have the product specifications always at hand.

Trademarks used are property of their respective

owners

Page 3

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

3

page

5 PIN OUT 17

5.1 RS232C cable for terminal PHL1700 17

5.2 Modem cable for terminal PHL1700 17

5.3 RS485 cable for network of cradle

IRU1700 17

5.4 RS232 cable for cradle IRU1700 17

6 SPECIFICATIONS 18

6.1 SPECIFICATIONS TERMINAL 18

6.1.1 Electrical specifications 18

6.1.2 Optical specifications 18

6.1.3 Physical specifications 18

6.1.4 Functionality 18

6.1.5 Environmental specifications 19

6.1.6 Supported symbologies 19

6.2 S

PECIFICATION CRADLE 19

6.2.1 Cradle models 19

6.2.2 Electrical specifications 19

6.2.3 Functionality 19

6.2.4 Environmental specifications 19

6.2.5 Physical specifications 19

7 TROUBLESHOOTING 20

7.1 C

OMMUNICATION PROBLEMS

20

7.2 R

EAD OPERATION PROBLEMS 20

7.3 B

ATTERY CHARGING PROBLEMS 21

7.4 TERMINAL PROBLEMS

22

7.5 C

RADLE PROBLEMS 22

8 PRODUCT ORDERING

INFORMATION 23

This terminal is a compact, programmable

handheld terminal, and is well suited for a

variety of indoor portable applications. It has a

built-in laser scanner that can scan all popular

bar code labels at varying distances.

User’s applications can be downloaded to the

terminal to adapt the terminal to the user’s

situation.

Operating power is supplied by the main

battery. The main battery may consist of a

rechargeable Ni-MH battery pack (to be

charged in cradle), or dry cell batteries, either

non-rechargeable or rechargeable (to be

charged in an external charger).

The cradle can be equipped with a transceiver

function only, for terminals with dry cell batteries,

this will be sufficient. The cradle can also be

equipped with both transceiver and charger.

The charger is needed for terminals with a

rechargable battery pack.

The IrDA interface on the terminal enables

you to communicate with other devices that

use IrDA communication, like portable

computers, notebooks and organisers.

Additionally a RS232 cable can be used.

The RS232 cable can be used for direct

communication between the (host) computer

system and the terminal, for example to

download software to the terminal.

INTRODUCTION

1

The general use and functioning of the

terminal together with the cradle will be

described in this manual.

The exact behavior of the terminal

depends on the user application that is

running. For instructions about applications

please consult the documentation of

that software.

Please read this manual carefully

before using the terminal, to maximise

the efficiency of this terminal.

Page 4

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

When you remove the packing, please check

for any physical damage. We recommend that

you save all packing material, as it should be

used whenever you need to ship your terminal

(eg. for service). Damage due to improper

repacking is not covered by the warranty.

Apart from the terminal or cradle, additional

items might be ordered and supplied.

If there are any missing parts please contact

your supplier.

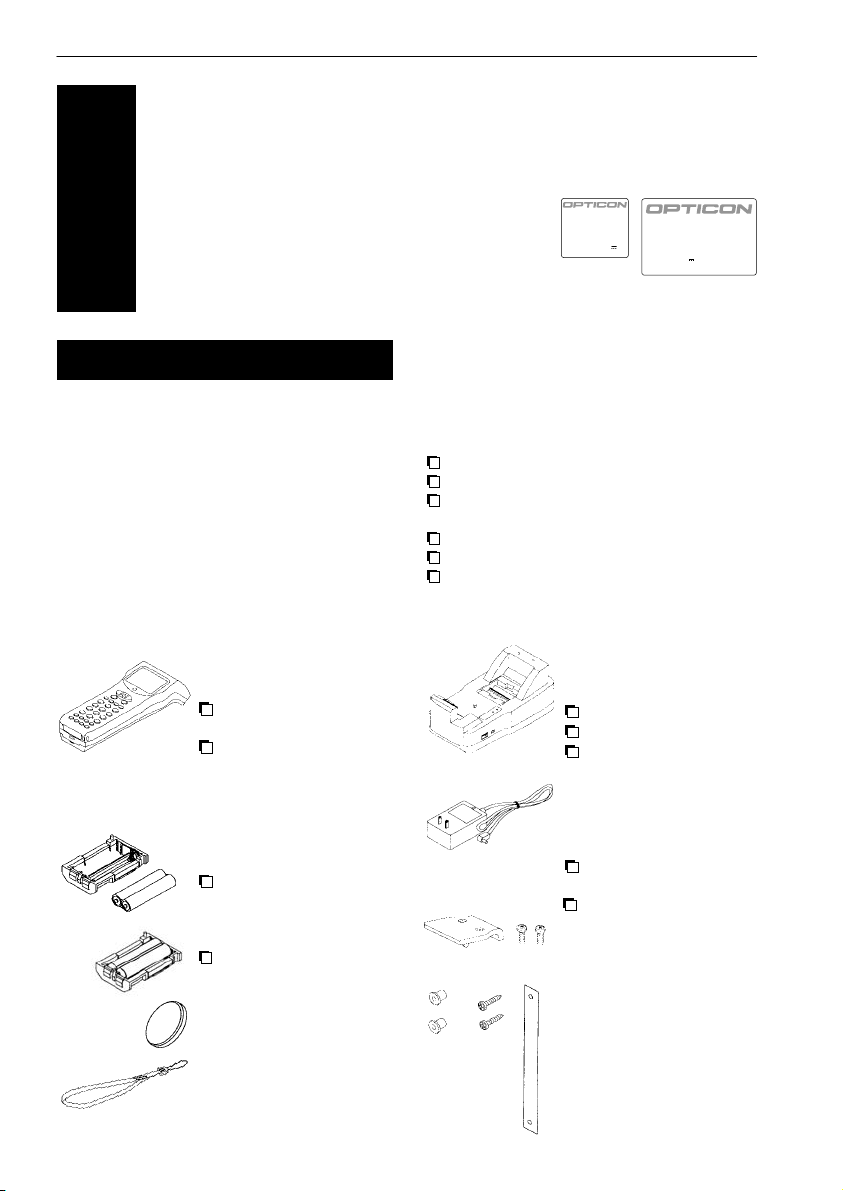

PHL1700: Terminal

Terminal,

can be delivered as:

model with dry cell

batteries

model with rechargeable

battery pack

Battery case,

depending on the model,

there are 2 options:

Do not remove the label !

On the back of every unit you will find a label.

The label is attached by the manufacturer and

includes information about the function it

supports and a serial number.

Do not remove it.

Additional items

only supplied if ordered

RS232 download cable for terminal

Modem cable for terminal

Protective bag for terminal

RS232 cable for cradle

RS485 cable for cradle

Modem cable for cradle

IRU1700: Cradle

Cradle body:

can be delivered as:

model SV

model T

model T/C

AC adaptor

depending on the model:

9V DC adaptor

for model SV and T

5V DC adaptor

for model TC

Wall mount panel + screws

Walll mount spacer +

screws + base plate

Battery case with

2x AA-size dry cell

penlite batteries

NiMH rechargeable

battery pack (1 x)

Backup battery

Hand strap

4

INSTALLATION

2

2.1 UNPACKING

PHL1600-10

part nr: O2500000010

serial nr: 000001

battery: LR6x2 or Ni-MH,

CR2032x1

rating: DC 3V,3V 2

supply 0.48W

IRU-1600 transceiver/charger

part nr: O2520000015

serial nr: 000001

input: DC 5V 4A

SPECIMEN

Page 5

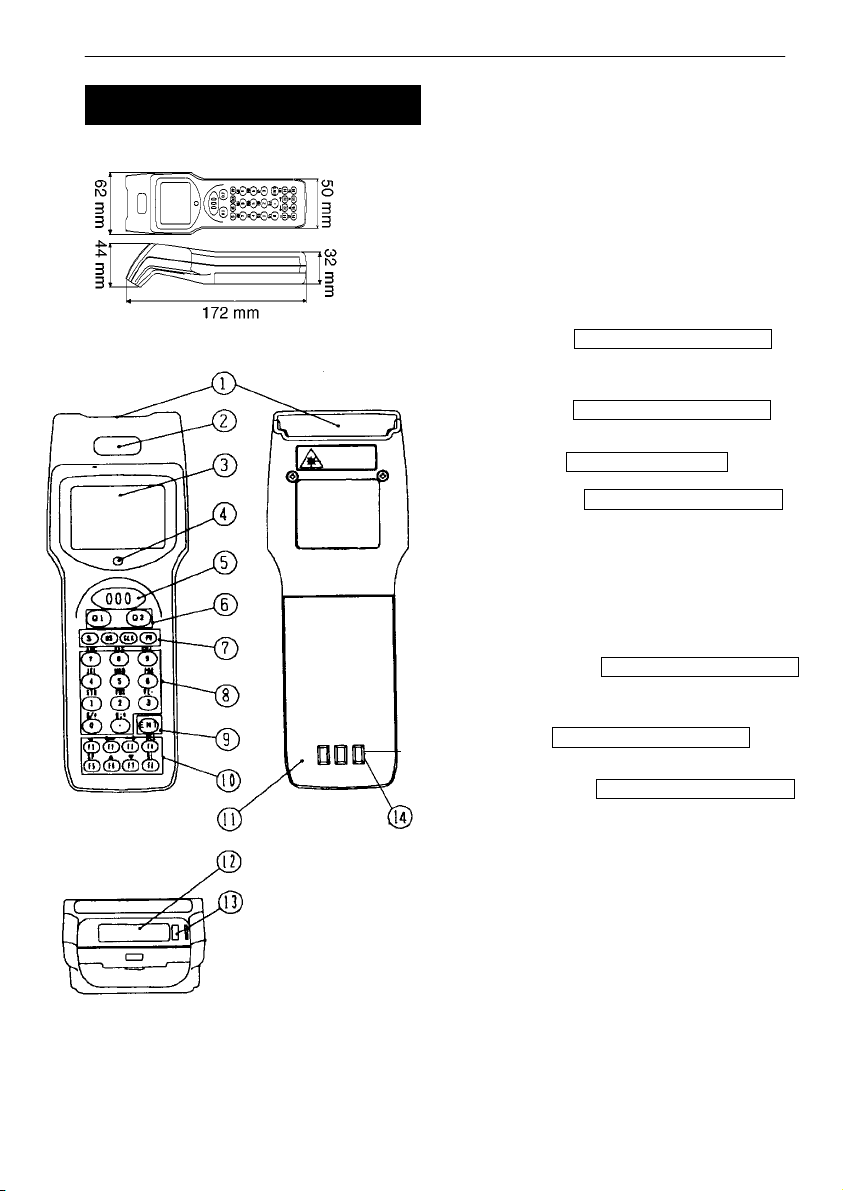

1. Reading window

laser beam for barcode reading will be

emitted from here

2. Optical interface window

for infra red communication

3. LCD Display

for displaying information

4. LED indicator

can be used to indicate results, for example

bar code reading /status of communication

5. Trigger key definable by user’s application

typical use: read key, switches laser beam

on for barcode reading

6. Quick keys

definable by user’s application

typical use: menu scroll keys or yes/no input

7. Power key right key, NOT definable

for switching power On/Off

Control keys definable by user’s application

for controlling basic functions

typical use as below

CLR : Cancel input

BS : Back space

S : Shift key

“S”on the LCD display indicates

the terminal is in the shift mode

8. Character keys

definable by user’s application

typical use: for input of alpha-numeric and

punctuation characters

9. ENT key definable by user’s application

typical use: for confirming input

10. Function keys definable by user’s application

user programmable keys, to be used

together with shift key.

typical use as shown on next page

11. Battery case cover

for housing main battery

12. RS-232C connector

for connecting external device, or for system

expansion, through Opticon RS232 cable

13. Hand strap pillar

for attaching hand strap.

14. Charging contacts

only for the model with rechargeable

battery pack.

U

SER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

5

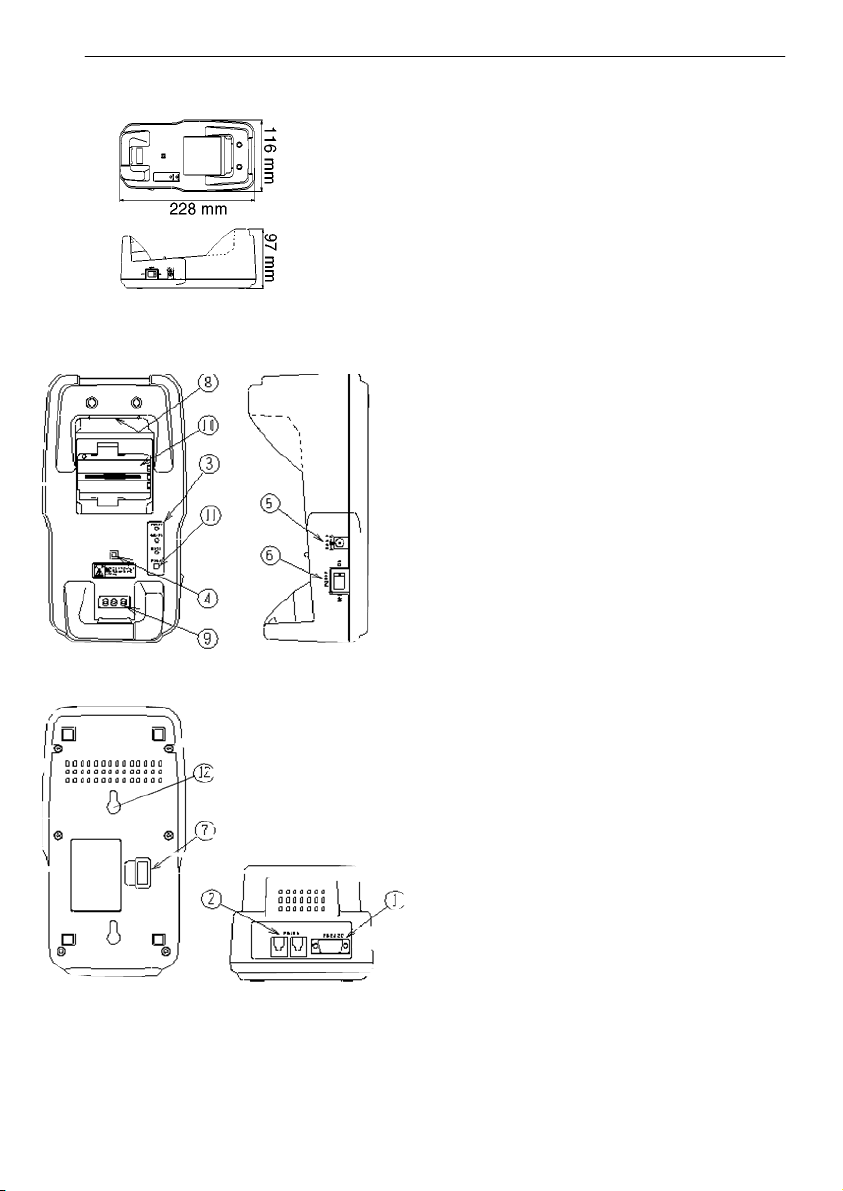

2.2.1 Dimensions of terminal

2.2.1 Details of terminal:

2.2 DETAILED VIEW

Page 6

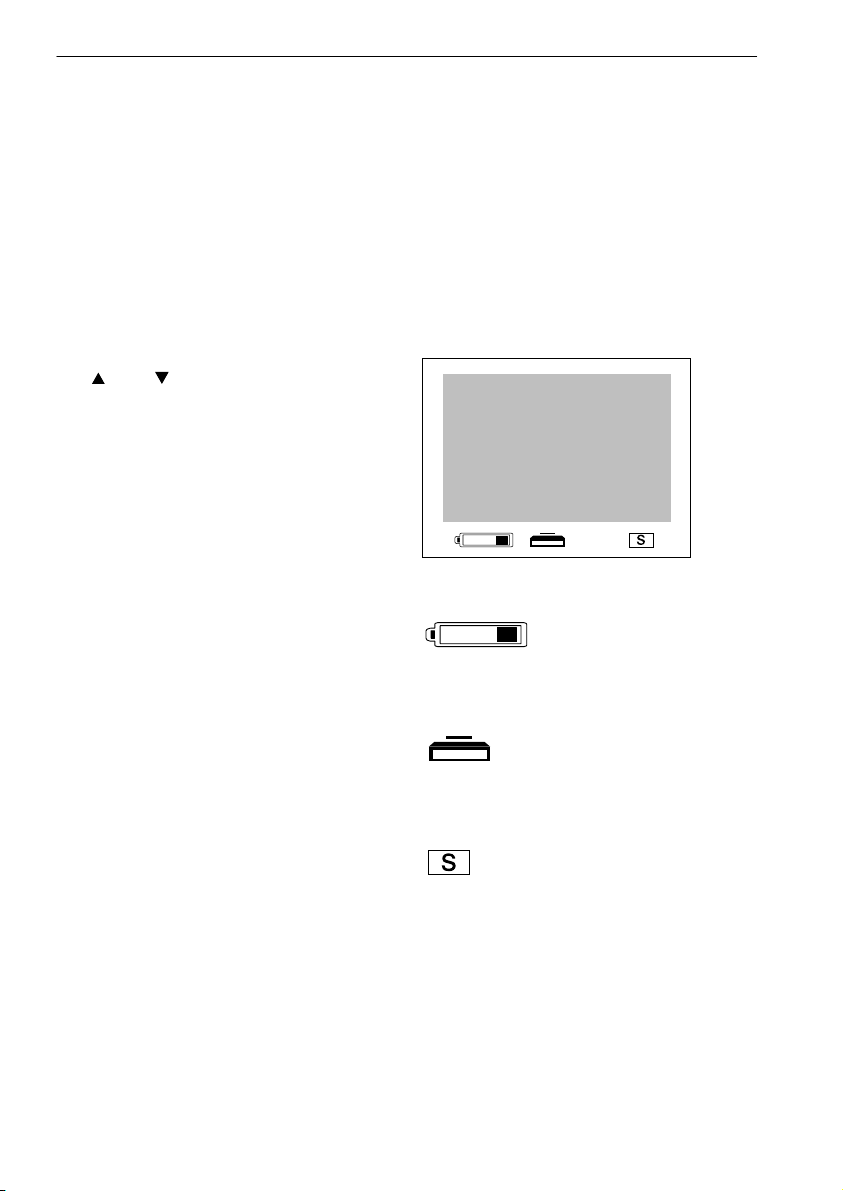

2.2.3 Display of terminal

The liquid crystal display of the terminal is

typically used to show program prompts,

instructions and data, as defined in the user’s

application.

The display has the following default options:

Special purpose symbols in display:

The symbols will be shown in the bottom part

of the display and indicate status.

Description of the display indicators

Main Battery indicator

Off: Sufficient battery power

On: Battery low.

Replace battery immediately.

Backup Battery indicator

Off: Sufficient battery power

On: Battery low.

Replace battery immediately.

Alpha mode on

(Shift-key activated)

Backlight

The display is provided with a backlight.

When the backlight is turned on, the power

consumption increases. To extend the life time

of your batteries use the backlight as little as

possible.

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

6

Description of the function keys

In the shift mode, back light on/off, contrast

adjustment, and cursor movement can be

done by these keys.

The user’s application can give different

definitions to the keys

shift mode

functions:

F1 (-) input minus sign

F2 (DEL) delete one character

F3 (SP) input space

F4 (BL) toggle with back light

F5 (<--), F6 (-->) move cursor

F7 ( ), F8 ( ) adjust contrast

Page 7

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

7

2.2.4 Dimensions of the cradle

2.2.5 Details of cradle

1. RS 232 C socket

for connecting to PC or modem, through

Opticon RS232 cable

2. RS 485 socket

for connecting another cradle in multi-drop

RS485 network, through Opticon RS485

cable

3. LED indicator

indicating status of:

POWER red : power on

green: terminal is on cradle

SD/RD red : receive data

green: send data

BATT * red : charging battery

green: charging is ready

*) BATT status is only for model TC and SV

4. Switch for terminal detection

to detect if a terminal is placed on the

cradle

5. DC input socket

input for AC adaptor

6. Power switch

7. DIP switches

setting parameters of the infra red interface

switches are located behind the cover

8. Data Transmission

Interface for optical data transmission

9. Contact for recharging

only for the model SV and TC

10. Battery spare slot for recharging

quick charge NiMH pack

only for the model transceiver/charger

11. Refresh switch

refresh-discharge NiMH pack

only for the model transceiver/charger

12. Wall mounting holes

Page 8

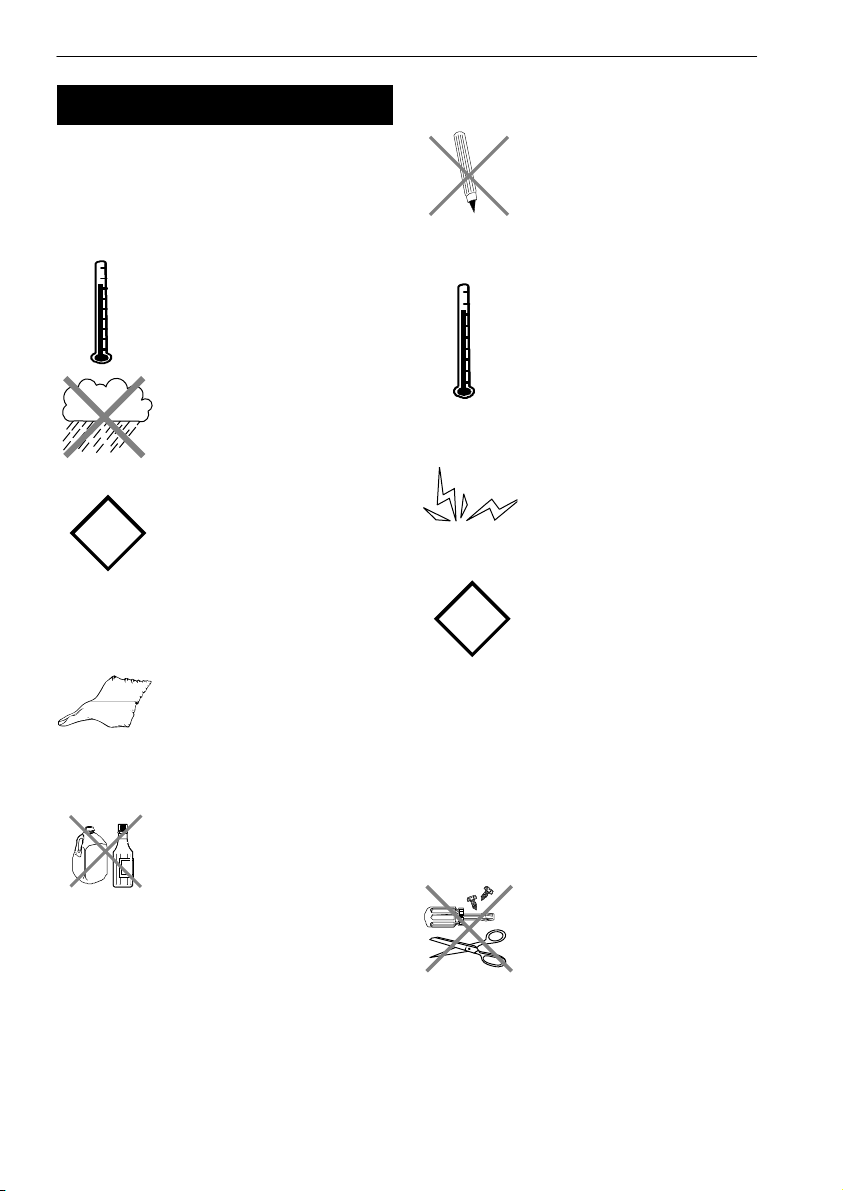

Use of the terminal

Operate the terminal keys by

pressing them lightly with your

fingertips or with something soft

and round.

Pressing the keys with a sharp

pointed object (for eg. a ballpoint) can damage the keys.

Avoid temperature changes.

Sudden temperature changes

can cause condensation to form

on the terminal. Using the terminal while condensation is present can cause malfunction.

Always wait until the condensation

clears naturally before attempting

operation.

Do not leave the terminal in an

area where static charge is accumulated, or near devices where

electromagnetic emission is generated.

Do not place any objects on top

of the terminal. Do not lay the

terminal face down.

Doing so can cause accidental

operation of the [PW] key or

[ENTER] key, which can discharge

your batteries or change settings

you do not want to be changed.

Cleaning of the terminal

Clean the optical interface window periodically.

Maintenance

There are no user-serviceable

parts inside the terminal or the

cradle. So do not try to take it

apart.

The manufacturer will not be

liable for any damage caused

by the customer.

In case of malfunction that can not be solved

by the trouble-shooting instruction in the

appendix, please consult our service

department.

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

8

To avoid malfunctioning and to ensure years

of trouble free operation, pay attention to the

following:

General use

Do not use or leave the product

in extremely hot areas - like

direct sunlight, near a heater,

or in a car - or in areas that are

very cold, humid, moistured or

dusty.

Do not expose the product to

rain or water splash

Do not subject the the product

to very strong impact, do not

throw or drop the terminal from

large heights.

Do not allow a mechanical

shock to the product.

General cleaning instructions

Clean the exterior by wiping it

with a soft, dry cloth. Do not

use much water.

The charging contacts of

terminal and cradle must stay

as clean as possible to maintain optimal charging capacity.

Do not use thinner, white spirit

or other solvents. These can

discolour the case and the keys

and has a negative effect on

the lifetime of the keys.

Use of the cradle

Do not place any other product than the

PHL 1700 terminal in the IRU 1700 cradle.

Cleaning of the cradle

Avoid touching the contacts in the cradle.

Do not use water when cleaning the cradle.

This can cause malfunction in the chargers.

2.3 HANDLING PRECAUTIONS

!

!

Page 9

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

9

Follow the next steps to make your terminal

ready for installation in a system, that is

described further in the manual.

2.4.1. Terminal

To avoid drop use the hand strap.

Fix the small cord of the

strap around the

pillar.

Insert the handle

in the thin loop.

Do not swing the

terminal around.

Start with a full battery

To be sure you start with a full battery,

charge the battery pack according to the

instructions in the next chapter.

Click the battery pack into the terminal,

as instructed in the next chapter.

2.4.2 Cradle

Place for mounting.

Place the cradle in normal office

conditions.

Avoid a place under strong light.

Otherwise IrDa communication may be

disturbed.

Wall mount panel

When the cradle is mounted on the wall, the

wall mount panel will keep the terminal on its

position. As a second function the panel will

protect the IrDa window from both terminal

and cradle from direct sunlight.

!

2.4 ASSEMBLY

Wall mounting instructions

First mount the wall

mount panel on the

cradle.

Locate the place for

mounting and attach

the base plate by

tape.

Mark the position of

the holes of the base

plate. (ref. 1)

Remove the base

plate.

Screw in the screws

with spacers on the

marked positions.

(ref. 2)

Align the body with its

mounting holes to the

spacers. (ref. 3)

Slide down the body

and fix it on the wall.

For power connection read the ‘installing in a

system’ part further in the manual.

Page 10

2.5.1 Required batteries

The terminal needs both main battery and

backup battery for operation.

Main Battery

The main battery can consist of:

Rechargeable Opticon battery pack (NiMH),

to be recharged when placing the terminal

PHL1700 in the cradle IRU1700.

Dry cel Opticon batteries (Alkaline).

To be used together with Opticon battery

case for dry cell batteries.

These batteries are not rechargeable.

Other batteries. All batteries have to be

used together with Opticon battery case

for dry cell batteries.

Batteries that are not supplied by Opticon

must be AA-size and absolutely leakproof.

If rechargeable batteries are used, they

need to be recharged by a separate

battery charging device.

Opticon recommends to use Opticon batteries

(Opticon rechargeable battery pack or Opticon

dry cell batteries) only.

Backup Battery

Use only one type of battery for backup:

Backup battery:

CR2032 Li (Lithium, button type).

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

10

Wrong use of batteries might cause

serious damage

to the terminal or to the cradle.

In order to avoid damage

it is very important to take notice

of the instructions.

Follow the instructions for installing,

changing and removing the batteries

very strictly.

The products are not warranted for

damage, defects, malfunction or loss of

data, resulting from incorrect use of

batteries.

Only use recommended batteries.

When other batteries are used, defects or

other problems can occur. Before installing

(new) batteries, please make sure you are

using the recommended batteries.

Do not make a mistake regarding the

polarity (+ , -) of the battery.

The terminal will not work when the

polarity is incorrect.

Never remove the main battery pack

while the terminal is turned on.

Doing so can cause data in the terminal

to be deleted.

Insert full batteries before use of the

terminal.

When you do not use the terminal for

a long time, make sure the main

battery has enough capacity.

When there is not enough capacity the

backup battery will be used up.

!!!!!

!

2.5 INSTALLING, REPLACING

AND CHARGING BATTERIES

Page 11

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

11

2.5.2 When to replace or recharge the

main battery?

There are 2 reasons for replacing (or charging)

the main battery;

as soon as possible after the battery

indicator appears on the display.

when you are not using the terminal for an

extended period.

For instructions of (re)placing the main battery

see paragraph 2.5.4 and 2.5.5.

For instructions for charging the rechargeable

battery pack see paragraph 2.5.6.

2.5.3 When to replace the backup

battery?

When low battery mark appears,

replace the battery without delay.

For instructions of (re)placing the backup

battery see paragraph 2.5.7.

2.5.4 How to remove the main battery?

Remove the battery

case cover. Press the

shaped part

with some force, and

pull it up.

Remove the entire

battery case cover.

To take the battery

case out, pull one side.

2.5.5 How to install the main battery

Before installing a battery case with penlite batteries:

Make sure you use

the right battery size.

Place 2 batteries in

the battery holder

aligning plus (+) and

minus (-) ends as

shown on the battery

holder.

The instructions for installing the battery pack

are also applicable for the battery holder with

penlite batteries.

Remove the battery

case cover. Press the

shaped part

with some force, and

pull it up.

Remove the entire

battery case cover.

Make sure that the

direction of the

battery case is correct

and put the battery

case in.

Fit battery case cover.

Page 12

2.5.7 How to (re)place the backup battery

in the terminal?

Make sure that the main battery

is full enough while changing the

backup battery.

Only use CR2032 Li

(Lithium, button type) battery.

Remove the battery

case cover. Press the

shaped part

with some force, and

pull it up.

Remove the entire

battery case cover.

Open the lid of the

holder for the backup

battery.

If applicable:

Remove old battery,

using a pointed

object for easy

removal.

Make sure that the

positive side of the

(new) backup battery

is pointed upwards.

Place the backup

battery.

Close the holder

Close the battery

case cover.

!

!

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

12

2.5.6 How to recharge the rechargeable

battery pack in the cradle?

Charging battery pack inside terminal

Applicable for cradle model SV and TC:

Place the terminal in the cradle.

The battery will be charged during approx.

4 hours.

The application in the terminal determines the

indication of the charging procedure as (if

applicable) shown to the user.

Charging separate battery pack in cradle’s

spare slot

Applicable for cradle model TC:

Quick charge

Place the rechargeable battery pack in the

battery holder on the cradle.

After checking the battery status (indicated

by blinking green LED), the recharging

starts (indicated by by a solid blinking red

LED).

After approx. 1 hour the charging is

completed. (indicated by a solid blinking

green LED)

Refresh discharge

A rechargeable battery has an so called ‘memory

effect’, which deteriorates full charging when

recharging is executed before the battery

capacity becomes empty. When the memory

effect is recognised, activate the refresh

discharge. Use this feature sparingly, when too

often used, it may damage the battery.

Place the rechargeable battery pack in the

battery holder on the cradle.

Press the refresh switch and discharging

starts (indicated by an orange LED)

The discharge completes in approx. 4 hours,

and the quick charge follows immediately.

Page 13

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

13

Exercise caution at all times when

working with AC-powered equipment.

Turn off your devices before

installation.

Because of the special pin-out of the

connectors, use the cables supplied

by the manufacturer.

When you need another cable for a

certain device, that is not supplied,

contact your supplier to purchase the

right cable. In case another cable is

used, take notice of the pin-out

specifications further in this manual.

2.6.1 Power supply for cradle

Make sure that you use the right

power supply.

Use for model T and SV: 9V DC adaptor

Use for model TC: 5V DC adaptor

2.6.2 Dip switch settings on cradle

Setting the DIP switches on or off will result in

enabled or disabled functions of the cradle.

(see table on next page)

Make sure power is switched off.

Open the cover of the DIP switches on the

bottom of the cradle in order to reach the

DIP switches.

!!!!!

2.6.3 Connect cradle to computer/modem

Connection sequence (see diagram and

dipswitch settings on next page)

Shutt off the computer.

Make sure cradle is disconnected.

Place the cradle in normal office conditions,

avoid a place under strong light (1).

Set proper baudrate on cradle (2), use

same baudrate as set on computer.

Connect the interface cable (3).

Connect the power supply (4) and power up

by power switch.

Power up the computer.

2.6.4 Connect network of cradles

(see diagram on next page)

Only 1 cradle in the network will be

connected to the PC through one RS232

cable. On this cradle the DIPswitch for

RS232 connection must be enabled.

Through this connection all cradles can

communicate to the PC.

A maximum of 16 cradles can be connected

in a network through RS485 cables. For the

cradles that are not directly connected to

the PC the DIPswitch for RS232 connection

must be set to off.

All cradles need to have the same baudrate,

for model SV to be set by dipswitch.

The first and the last cradle in the network

must have the termination resistors set by

DIPswitch.

2.6.5 Terminal on cradle

Do not place any other product than

the PHL1700 terminal in the IRU1700

cradle.

Place the terminal on the cradle as shown in

the illustration:

(Indicator on cradle: green LED)

!

2.6 INSTALLING IN A SYSTEM

Page 14

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

14

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

*) see DIP switch table on next page

**) see power voltage on previous page

Page 15

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

15

Dip switch settings for cradle IRU-1700

model T and TC:

Dip switch settings for cradle IRU-1700

model SV:

The functionality of the terminal is determined

by software, the so-called user application,

that is running on the terminal.

Usually, the terminal is not equipped with

software and has no functionality. At first the

user application must be loaded before the

terminal can be used for barcode scanning.

Tools for developing a user application on the

PC for use on the terminal, as supplied by

Opticon are:

Application Generator

PotStar (Limited or Professional)

C language: Microtec ANSI-C compiler

and C library for handheld terminals.

The user application must be downloaded

from the PC into the terminal. You can use the

cradle, an RS232 cable or an infrared adapter

for communication between the terminal and

the PC. A program on the PC will send the

user application to the terminal, where it is

stored in FlashROM memory.

When the functionality of the terminal is defined

by the application it is ready for operation.

In a typical application you will press the trigger

key and scan a bar code label as described in

the next chapter. Scanned data and data

entered from the keyboard is stored in the

terminal's RAM. The user application can use

this data in subsequent steps.

The collected data can be transmitted to the PC

for further processing. For data transmission

you can use the cradle, an RS232 cable or an

infrared adapter to connect the terminal to the

PC.

FUNCTIONS

RS 232

ON for connection

SPARE

SPARE

SPARE

SPARE

SPARE

RS485

TERMINATOR

RS485

TERMINATOR

ON

in use

--

--

--

--

--

in use

in use

OFF

not

in use

--

--

--

--

--

not

in use

not

in use

DIP

SWITCH

SW 1

SW 2

SW 3

SW 4

SW 5

SW 6

SW 7

SW 8

1 2 3 4 5 6 7 8

ON

ONOFF

DIP SWITCH

OPERATION OF

THE TERMINAL

3

FUNCTIONS

RS 232

ON for connection

RS485

TERMINATOR

RS485

TERMINATOR

BAUDRATE *

BAUDRATE *

BAUDRATE *

ON

in use

in use

in use

--

--

--

OFF

not

in use

not

in use

not

in use

--

--

--

DIP

SWITCH

SW 1

SW 2

SW 3

SW 4

SW 5

SW 6

1 2 3 4 5 6

O F F

ONOFF

DIP SWITCH

SW

4

OFF

ON

OFF

ON

OFF

ON

OFF

ON

SW

5

OFF

OFF

ON

ON

OFF

OFF

ON

ON

SW

6

OFF

OFF

OFF

OFF

ON

ON

ON

ON

* )

BAUDRATE

1200

2400

4800

9600

19200 (default)

38400

115200

AUTO (PC controlled)

Page 16

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

16

The terminal is a Class I laser product conforming

to the strictest laser safety standards.

However, we recommend that you avoid looking

directly into the laser beam emitter, or pointing

the laser beam directly into someone’s eyes.

Fit the bar code in the laser beam from

margin to margin and pass the scanner

downward over the bar code, as shown in the

scan position illustration.

A ‘Good Read’ means that the scanner has

effectively recognised and decoded the bar

code. In most cases, the application program

will provide an indicator signal or a buzzer

signal to indicate a good read to the user.

When the read is incorrect you can try again,

paying attention to the instructions stated

below.

4.3 If you have problems with the read

operation

Change the angle between the bar code

and the terminal.

Change the distance between the bar

code and the terminal.

If the bar code is larger than the laser

beam, try moving the terminal a bit further

away from the bar code.

Please take care of the handling

precautions.

Please make sure that the terminal is

installed according to the installation

instructions.

Never remove the main battery pack

while the terminal is turned on.

Doing so can cause data in the terminal

to be deleted or corrupted.

4.1 Scan Position

When reading a small bar code, decrease the

distance between the terminal and the bar

code. For larger bar codes, position the terminal

so that the bar code fits into the laser beam.

When reading a very high density bar code,

decrease the distance between the terminal

and the bar code. For a low density bar code,

increase the distance between the terminal

and bar code.

4.2 Reading the bar codes

The scanning sequence is defined by the

user’s application. A typical sequence is:

Press the [PW] key to turn power on.

Check the display for the message:

READ BAR CODE

Point the terminal to the bar code and

press the Trigger key.

Point the laserbeam to the barcode as

shown in the scan position illustration.

The barcode will be read and the reading

results will be indicated.

!

!

!

SCANNING

BAR CODES

4

XX

good read

scan position

X

incorrect read

scan positions

X

X

X

Page 17

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

17

5.1 RS232C cable for terminal PHL1700

5.2 Modem cable for terminal PHL1700

5.3 RS485 cable for network of cradle

IRU1700

5.4 RS232 cable for cradle IRU1700

PIN-OUT

5

Modular

plug

(10 pins)

1

2

3

4

5

6

7

8

9

10

DB 9

connector

Female

-

2

3

8

7

6

4

5

-

Signal

-

RxD

TxD

CTS

RTS

DSR

DTR

GND

-

RS232

cable

DB 9

female

1

Signal

DC IN

DC IN

TxD

RxD

RTS

CTS

DTR

DSR

GND

GND

1

9

5.1

Modular

plug

(6P6)

1

2

3

4

5

6

Modular

plug

(6P6)

2

3

4

5

-

1

6

Network

cable

RS485

Signal

RD+

RDSD+

SD-

-

1

6

DB 9

male

(cradle)

3

2

6 + 1

5

4

8

7

DB 9

female

(PC)

2

3

4

5

6 + 1

7

8

Signal

RxD

TxD

DTR

GND

DSR

RTS

CTS

RS232

cable

Signal

TxD

RxD

DSR

GND

DTR

CTS

RTS

1

9

1

9

In/Out

(cradle)

OUT

IN

-

OUT

OUT

Note

-

not used

ON (fixed)

not used

ON (fixed)

Modular

plug

(10 pins)

1

2

3

4

5

6

7

8

9

10

DB 25

connector

Male

-

2

3

4

5

20

6

7

-

Signal

-

RxD

TxD

CTS

RTS

DSR

DTR

GND

-

Modem

cable

DB 25

male

1

Signal

DC IN

DC IN

TxD

RxD

RTS

CTS

DTR

DSR

GND

GND

25

1

5.2

5.3

5.4

Page 18

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

18

6.1.1 Electrical specifications

Main battery rechargeable pack: Ni-MH

dry cell: Alkaline penlite

optional: other 2 x AA-size

penlite

Main battery Ni-MH: When making every 5

operating time seonds 1 scan with 1 sec

laserbeam on and 0.2 sec.

green LED on and 0.2 sec.

buzzer on, operating time is:

approx. 34 hours

Alkaline: When making every 5

seonds 1 scan with 1 sec

laserbeam on and 0.2 sec.

green LED on and 0.2 sec.

buzzer on, operating time is:

approx. 67 hours

Different operation conditions

affect the operating time

Use of other penlite batteries

affect the operating time

Backup battery Lithium (CR2032)

Backup battery If fully charged:

operating time 4 months backup time

Battery Low voltage indicated on the

management terminal display.

When battery is low the terminal

switches off automatically.

Charging method Rechargeable Ni-MH pack in

terminal via cradle

Replacement Ni-MH pack in

cradle

6.1.2 Optical specifications

Light source 650 nm visible laser diode

Scan rate 100 scans/sec

Decode rate 100 decodes/sec

Reading width 60 mm at 30 mm

98 mm at 100 mm

Resolution

at PCS 0,9 0.15 mm (6mil)

Depth of field 0 - 140 mm

(at PCS 0.9, res. 0.25)

6.1.3 Physical specifications

Dimensions

(l x w x d) 172 x 62 x 44 mm

Case material ABS

Weight body (excl. battery): 180 g

Direct cable

(optional) RS232 - DB9 female

6.1.4 Functionality

Memory ROM: 32 kB

FlashROM (for O/S and

program): 256 kB

fast RAM: 2kB

battery backed up S-RAM

(for data): 1 or 2 MB

Microprocessor 16-bit

Real time clock Quartz RTC, time and date

programmable, leap year

handling,

(accuracy + 60 sec./month)

Display 96x48 Pixels

graphic LCD with backlight

Character fonts:

4/8 lines x 16 characters

Keyboard 27 keys total

(26 keys user definable)

8 Function keys

Alpha/Numeric mode

Trigger mode Manual

Programming Functionality is provided by user

application. The application may

be downloaded from PC via

cable, com port or IrDA.

Interfaces supported RS232 by direct cable

RS232 by cradle

IrDA on terminal

Transmission speed RS232 direct cable:

2400 - 115200 baud

RS232 cradle:

2400 - 38400 baud

IrDA terminal:

2400 - 115200 baud

SPECIFICATIONS

6

6.1 SPECIFICATIONS TERMINAL

Page 19

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

19

6.1.5 Environmental specifications

Temperature -10 - +40 oC in operation

-20 - +60 oC in storage

Humidity 20 - 80 % in operation

(non condensing) 20 - 90 % in storage

Shock: drop: 1.5 m drop onto concrete surface

Shock: vibration: 10 - 50 Hz with 1G for 30 min,

cycle for X,Y,Z.

Ambient light rejection fluorescent 3.000 lux max.

direct sun 50.000 lux max.

Emission According to EN50081, part 1

Immunity According to EN50082, part 1

Protection against

dust and moisture According to IEC529, IP 42

Safety, Laser class According to IEC825,

Class I laserproduct

6.1.6 Supported symbologies

Chinese Post 2of5

Codabar incl. ABC and CX

Code 39

Code 93

Code 128

EAN-8 incl. +2,+5

EAN-13 incl. +2,+5

IATA

Industrial 2of5

Interleaved 2of5

Italian Pharmaceutical

Laetus

Matrix 2of5

MSI/Plessey

UK/Plessey

S-Code

Telepen

UPC-A incl. +2,+5

UPC-E incl. +2,+5

6.2.1 Cradle models

model T: use for communication

model SV: use for communication / charging

battery in terminal

model TC: use for communication / charging

battery in terminal / charging battery in spare slot

6.2.2 Electrical specifications

Battery charging time when battery in terminal:

(transceiver/charger) 4 hours extra charge with

70% nominal capacity

when battery in spare

battery slot: 1 hour full charge

6.2.3 Functionality

Interfaces supported RS232

RS485

Serial communication RS232 Baudrate:

1200 - 38400

RS485 Baudrate:

1200 - 38400

Transmission modes Half duplex RS232

Half duplex RS485

Parity Odd, Even, None

6.2.4 Environmental specifications

Temperature 0 - +40 oC in operation

-20 - +70 oC in storage

Humidity 30 - 85 % in operation

(non condensing) 30 - 90 % in storage

Shock: vibration: 10 - 50 Hz with 1G for 30 min,

cycle for X,Y,Z.

Emission According to EN50081, part 1

Immunity According to EN50082, part 1

6.2.5 Physical specifications

Dimensions

(l x w x d) 228 x 116 x 97 mm (desk top)

Case material ABS

Weight (excl. cables)

model SV: 475 g

model T: 500 g

model TC : 525 g

Standard connector RS232 - D Sub 9P Female

RS485 - 6 pins modular plug

6.2 SPECIFICATIONS CRADLE

Page 20

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

20

This chapter contains information on solving

problems you may encounter when using the

terminal and/or cradle. If problems occur, first

carry out some general checks, before verifying

the problem with the descriptions in this chapter.

General checks:

Make sure everything is installed properly

Check the power supply of all devices

Is the read window of the terminal clean?

Is the optical window of the cradle clean?

Are the bar code labels readable, eg. not

damaged or poorly printed?

If the equipment still does not work after these

checks have been performed, please verify if

one of the problems described in this chapter

applies to the problem you have with the

scanner.

It is possible that you may not solve the

problems, despite our descriptions. In this

instance, please contact your dealer or

Opticon.

When the terminal needs to be repaired,

please ensure that the label with the serial

number is still present. If sending the terminal

or cradle, please use the original packing to

minimise the chances of damage.

No communication from the cradle to the

device, or data is transmitted distorted or

corrupted.

Power indicator of the cradle is not green.

Clean the optical interface window of the

cradle and/or terminal, and try again.

Check all cables.

When the power indicator is still not

green, the cradle needs service.

No data transmitted.

The cradle will only work if connected to

a PC.

Data is corrupted, or no data is

transmitted.

Is the proper baudrate selected?

The computer needs the same baudrate

as the terminal.

Is the baudrate between the min. and max.

value?

For RS 232 : baudrate 1200 - 38400

For RS 485 : baudrate 1200 - 38400

The terminal looses data when the battery

pack is removed for a short period.

The backup battery is empty.

Replace the Lithium CR2032 battery with a

new one.

When the terminal has a problem with reading the label:

The resolution of the bar code is too high.

Decrease the distance between the bar

code and the terminal.

???

?

?

TROUBLE

SHOOTING

7

7.1 COMMUNICATION

PROBLEMS

7.2 READ OPERATION

PROBLEMS

Page 21

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

21

The angle between the label and the

terminal is too high.

Change the angle between the bar code

and the terminal.

The distance is too far or too close.

Change the distance between the bar

code and the terminal.

The bar code is larger than the laser

beam.

Try moving the terminal a bit further away

from the bar code.

The read window is dirty.

Clean the read window of the terminal.

The read window is scratched.

The terminal needs service.

The type of the bar code label is not

enabled.

Enable the bar code symbology in the

application program.

When the terminal is placed in the cradle

(model SV or TC), the main battery is not

charged.

Check cradle type (model SV or TC)

The cradle needs a rechargeable battery

pack to charge. When a battery holder for

dry cell batteries Is used, the charger

does not work at all.

There is no contact between the terminal

and the cradle. Try again to place the

terminal properly, or clean the contacts.

Replace the battery pack and try again.

Terminal is still not charged. Red LED

indicator on terminal is turned on

The charger for the terminal is probably

defect. Take the battery pack out of the

terminal and charge it in the battery pack

charger (model TC). The cradle will need

service, but can still operate for a while.

???

???

?

When a rechargeable battery pack is placed

in the cradle (model TC), the main battery is

not charged.

Green LED indicator is not turned on not

flashing.

Check cradle type (TC)

The cradle needs a rechargeable battery

pack to charge. When a battery holder for

dry cell batteries is used, charger does not

work at all.

The battery pack in the terminal is not

empty enough. The battery voltage has to

be lower than 2.6 V.

The battery voltage reaches 4 V. The voltage

for charging should be between 2 - 4 V.

If the battery temperature reaches 45oC,

the charger will stop charging immediately.

The cradle is waiting for the proper

temperature (0-40oC) and will then

continue.

Green LED indicator keeps flashing.

The battery is too cold or too warm.

The cradle is waiting for the proper

temperature (0-40oC) and will then

continue.

The rechargeable battery pack is still not

charged. Red LED indicator keeps on.

The charger for the battery pack is

probably defect.

Put the battery pack in the terminal and

charge it in the terminal charger.

The cradle will need service, but can still

operate for a while.

Backupbattery is empty.

Indicator in the display of the terminal is on:

Replace the Lithium CR2032 battery with a

new one.

???

?

7.3 BATTERY CHARGING

PROBLEMS

Page 22

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

22

Terminal does not respond to keypresses,

while the display stays on.

Message “Application halted” or

“No application installed” is shown.

There is no user’s application for PHL1700

loaded in the terminal. Contact your

supplier.

For example pressing the shift key does

not toggle the shift indicator.

There is a flaw in the application program.

Disconnect the battery pack, and place it

then back in.

The terminal will be in off-state.

Activate the system menu and restart the

application, or download new application.

If problems appears continously contact

the supplier of the user’s application.

Terminal gets no power, when pressing the

powerkey.

The main battery is exhausted.

Replace the battery pack, or charge the

terminal in the cradle.

Laser stays off, when pressing the triggerkey.

Power is off.

The triggerkey is no powerkey. Press the

powerkey to get power.

If the terminal is not used the scanner will

switch off all functions. Press the powerkey

to reactivate.

Laser temperature has become too high.

The laser is switched off automatically,

when thelaser temperature becomes above

50

o

C. Wait until the temperature has dropped.

???

?

?

Terminal does still not operate and needs a

service

Send the terminal to your supplier for service,

paying attention to the limited warranty.

Indications on the cradle.

Power indicator of cradle is off

No power supply. Check the adaptor.

When the adaptor is good, the cradle

needs service.

Cradle does still not operate and needs a

service

Send the cradle to your supplier for service,

paying attention to the limited warranty.

?

7.4 TERMINAL PROBLEMS

7.5 CRADLE PROBLEMS

Page 23

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

23

Apart from the terminal, additional items

might be ordered.

Article Code

Terminal

PHL 1700-10 (1MB) A73700R0010

PHL 1700-20 (2MB) A73700R0030

Battery Pack for terminal

Rechargeable Battery Pack O2510000020

Dry Cell Battery Pack Assy O2510000030

(assy = case holder + penlite batteries)

Battery Case Holder Q2510000060

Penlite Batteries PBA30000010

Cables for terminal

RS232 cable DB 9 female O2500000020

Modem cable DB 25 male O2500000030

Protective Bags for terminal

Leather bag O2510000050

Leather bag clip O2510000060

Nylon bag O2510000070

Software development tools

Microtec

ANSI-C cross compiler O8010000010

C-library for

handheld terminals D4030000020

Application Generator

Potstar Limited D6010000010

Application Generator

Potstar Professional D6020000010

PRODUCT

ORDERING

INFORMATION

8

Apart from the cradle, additional items

might be ordered.

Article Code

Cradle

IRU-1700-SV A74040N0001

IRU-1700-T TRANCEIVER O2520000010

IRU-1700-T/C

TRANC./CHARGER O2520000015

Power Supply for cradle

5V DC adaptor A50100N0020

for model T and SV

9V DC adaptor A50200N0020

for model TC

Euro Cable A79000N0030

Cables for cradle

RS232 cable DB 9 female O2520000020

Adapter

DB25 female/DB9 male P10AT000040

Modem cable DB 25 male O2520000040

RS485 cable O2520000050

Page 24

USER’S MANUAL PHL 1700 LASER TERMINAL / IRU 1700 CRADLE

24

Opticon Article Code

O0220000020

Loading...

Loading...