Page 1

NLV-5201

Fixed Position 2D Imager Scanner

User's Manual

Page 2

The information in this document is subject to change without notice.

Document History

Model Number: NLV-5201 Specification Number: TS18047

Edition: 1st Original Spec Number: (TS18046)

Date: 22-February-2019

© 2019 Opticon. All rights reserved.

This manual may not, in whole or in part, be copied, photocopied, reproduced, translated or converted

to any electronic or machine readable form without prior written consent of Opticon.

Limited Warranty and Disclaimers

Please read this manual carefully before installing or using the product.

Serial Number

A serial number appears on all Opticon products. This official registration number is directly related to

the device purchased. Do not remove the serial number from your Opticon device. Removing the

serial number voids the warranty.

Warranty

Unless otherwise agreed in a written contract, all Opticon products are warranted against defects in

materials and workmanship for two years after purchase excluding batteries. Opticon will repair or, at

its option, replace products that are defective in materials or workmanship with proper use during the

warranty period. Opticon is not liable for damages caused by modifications made by a customer. In

such cases, standard repair charges will apply. If a product is returned under warranty and no defect is

found, standard repair charges will apply. Opticon assumes no liability for any direct, indirect,

consequential or incidental damages arising out of use or inability to use both the hardware and

software, even if Opticon has been informed about the possibility of such damages.

Packaging

The packing materials are recyclable. We recommend that you save all packing material to use should

you need to transport your data collector or send it for service. Damage caused by improper

packaging during shipment is not covered by the warranty.

Trademarks

Trademarks used are the property of their respective owners.

Opticon Inc. and Opticon Sensors Europe B.V. are wholly owned subsidiaries of

OPTOELECTRONICS CO.,LTD., 12-17, Tsukagoshi 4-chome, Warabi-shi, Saitama, Japan 335-0002.

TEL +81-(0) 48-446-1183; FAX +81-(0) 48-446-1184

SUPPORT

USA Europe

Phone: 800-636-0090 Phone: +31235692728

Email: support@opticonusa.com Email: support@opticon.com

Web: www.opticonusa.com Web: www.opticon.com

Page 3

NLV-5201

i

User's Manual 1st

Caution and Warning

Read following caution carefully before installing and/or using this product. Incorrect handling may

cause malfunction, overheating, smoke, fire, injury and electric shock etc.

Caution

Electrical handling

・In case any abnormality occurs in the scanner or stops working, unplug the cable and the AC

adapter and contact the dealer. Leaving as is may cause malfunction, overheating, smoke and fire.

・Do not use this product at voltage outside the specified range. It may cause overheating, smoke and

fire.

・Do not let the AC adapter get wet. It may cause overheating, smoke, fire and electric shock.

・Do not plug/unplug the connectors while power is supplied.

Excessive shock / stress

・Do not drop this product.

・Do not push or place this product under or between heavy items.

・Do not swing the product around by the cable. It may cause injury or damage to the device.

Cable handling

・Do not wrap NLV-5201 cable around a host device (PC, tablet etc.). It may cause breakage to the

strain relief and the cable jacket, and could cause malfunction, overheating, smoke and fire.

・Do not place this product and AC adapter under or between heavy items.

・Do not bend the cable at extremely low temperatures.

・Immediately unplug the cable and AC adapter, then contact your dealer if:

If the cable jacket tears open or separates from the connector.

If any core wire, become exposed.

If the cable generates heat, even if it looks normal.

Continued use in any of these conditions may cause malfunction, overheating, and/or fire.

Operating environment

・Do not use this product at temperatures outside the specified range.

・Do not use this product near combustible materials (gas, gunpowder etc.). It may cause smoke and

fire.

・Do not immerse this product in water or any other liquid.

・If any condensation forms on the product, abstain from the use of it until moisture has evaporated to

prevent malfunctions.

・Do not store this product in dusty environments and in extremely high humidity.

・Do not store this product in extremely cold or hot places.

・Avoid exposure to direct sunlight for long periods of time.

・Avoid static electricity and do not put the product near a radio or a TV. Excessive static electricity

may cause malfunction.

・Do not place in an unstable place.

Others

・Do not disassemble this product.

・Do not stare into the LED light from the scan window. It may damage your eyes.

・Do not soil or scratch the scan window. It may have a bad effect on the reading.

・Do not expose this product to edible / industrial fat and chemicals.

・This product may be affected by an instantaneous power-on condition of machinery, lighting, or

motors, etc.

・Do not let children use this product.

Page 4

NLV-5201 User's Manual

ii

1st

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: ( 1 ) this device may not cause harmful Interference, and ( 2 ) this device must accept

any interference received, including interference that may cause undesired operation.

この装置は、クラスB機器です。この装置は、住宅環境で使用することを目的としています

が、この装置がラジオやテレビジョン受信機に近接して使用されると、受信障害を引き起こすこ

とがあります。

取扱説明書に従って正しい取り扱いをして下さい。 VCCI-B

Regulatory Compliance

(1) LED Safety

IEC 62471 Exempt Risk Group

(2) EMC

EN 55024, EN 55032 Class B

FCC Part 15 Subpart B Class B

VCCI クラス B

Disclaimer:

OPTOELECTRONICS CO.,LTD. Will not bear any responsibility in case of malfunction, accident,

repair and damage assurance.

Page 5

NLV-5201 User's Manual

iii

1st

Edition

Date

Page

Section

Description of Changes

Prelimina

ry

2019/02/22

-

-

Initial release

Revision History

Document Name : NLV-5201 User's Manual

Page 6

NLV-5201 User's Manual

iv

1st

Contents

Caution and Warning ............................................................................................................................. i

1 Abstract .......................................................................................................................................... 1

Features of the Scanner ........................................................................................................... 2 1.1

Usage of the Scanner ............................................................................................................... 3 1.2

Flow to Integrate ....................................................................................................................... 4 1.3

Flow to Integrate for Industrial Uses ................................................................................. 4 1.3.1

Flow to Integrate for General Uses ................................................................................... 5 1.3.2

2 Before Using .................................................................................................................................. 6

Model Details ............................................................................................................................ 7

2.1

Standard ........................................................................................................................... 7 2.1.1

Model Description ............................................................................................................. 7 2.1.2

Package Contents .................................................................................................................... 8 2.2

Connect to the Host .................................................................................................................. 9 2.3

How to Read ........................................................................................................................... 11 2.4

Depth of Field and Focus Type .............................................................................................. 12 2.5

Standard Model (SR) Depth of Field .............................................................................. 12 2.5.1

High Resolution Model (HD) Depth of Field ................................................................... 13 2.5.2

Ultra High Resolution model (UD) Depth of Field ........................................................... 14 2.5.3

Detailed View ......................................................................................................................... 15 2.6

Operation Mode and Control Panel Description .................................................................... 16 2.7

Operation Mode .............................................................................................................. 16 2.7.1

Control Panel Operation Specifications .......................................................................... 17 2.7.2

LED Indicator Specifications ........................................................................................... 18 2.7.3

Buzzer and LED Indicator ............................................................................................... 19 2.7.4

Operation Transition ............................................................................................................... 20 2.8

Normal Trigger ................................................................................................................ 20 2.8.1

Auto Trigger .................................................................................................................... 21 2.8.2

Operation Invalid Transition Diagram ............................................................................. 22 2.8.3

Installation of the Scanner ...................................................................................................... 23 2.9

Scan Area ............................................................................................................................... 24 2.10

Image Range .................................................................................................................. 24 2.10.1

Optical Path .................................................................................................................... 25 2.10.2

Scanned Media and Placement ............................................................................................. 26 2.11

Solution for Specular Reflection of the LED Illumination ................................................ 26 2.11.1

Solution for Specular Reflection of the External Illumination.......................................... 27 2.11.2

Exit Window Placement .......................................................................................................... 28 2.12

Exit Window Material ...................................................................................................... 28 2.12.1

Solution for Specular Reflection of the Illumination ........................................................ 29 2.12.2

3 Configurations ............................................................................................................................. 30

Configuring with Commands .................................................................................................. 31 3.1

Page 7

NLV-5201 User's Manual

v

1st

Command Packet ........................................................................................................... 31

3.1.1

Configuring with 2D Menu .............................................................................................. 32 3.1.2

Configuring with 1D Menu Code ..................................................................................... 33 3.1.3

Command Packet Sending Precautions ................................................................................ 34 3.2

Each interface Default Setting ........................................................................................ 34 3.2.1

Save Settings .................................................................................................................. 35 3.2.2

Custom Setting ............................................................................................................... 35 3.2.3

Basic Commands ................................................................................................................... 36 3.3

ACK/NAK for Serial Commands ..................................................................................... 36 3.3.1

Diagnostic Commands .................................................................................................... 36 3.3.2

Enable/Disable 2D Menu Code ...................................................................................... 36 3.3.3

Enable/Disable 1D Menu Code ...................................................................................... 36 3.3.4

Image Settings ................................................................................................................ 37 3.3.5

Disable Reading Operation ............................................................................................ 38 3.3.6

Buzzer and Indicator ....................................................................................................... 38 3.3.7

Reboot the Scanner ........................................................................................................ 38 3.3.8

Enable/Disable Mode Key .............................................................................................. 38 3.3.9

Direct Numerical Input Command .................................................................................. 39 3.3.10

4 Indicator Options ......................................................................................................................... 40

Buzzer .................................................................................................................................... 41 4.1

Buzzer Loudness ............................................................................................................ 41 4.1.1

Good Read Buzzer ......................................................................................................... 41 4.1.2

Start-up Buzzer ............................................................................................................... 42 4.1.3

Read Timeout Buzzer ..................................................................................................... 42 4.1.4

Intermediate Buzzer ........................................................................................................ 42 4.1.5

Status LED ............................................................................................................................. 43 4.2

Status LED Lighting Time ............................................................................................... 43 4.2.1

Good Read Aiming ................................................................................................................. 44 4.3

Indicator in General ................................................................................................................ 45 4.4

Indicator Timing .............................................................................................................. 45 4.4.1

5 Interface ........................................................................................................................................ 46

RS-232C ................................................................................................................................. 47 5.1

RS-232C Basic Information ............................................................................................ 48 5.1.1

Baud Rate (Transfer Speed) .......................................................................................... 48 5.1.2

Character Format ............................................................................................................ 49 5.1.3

Handshaking (Flow Control) ........................................................................................... 49 5.1.4

Inter Character Delay (RS-232C) ................................................................................... 54 5.1.5

Trouble Shooting (RS-232C) .......................................................................................... 54 5.1.6

USB-HID ................................................................................................................................. 55 5.2

USB-HID Basic Information ............................................................................................ 56 5.2.1

Connection Confirmation (USB-HID) .............................................................................. 57 5.2.2

NumLock CapsLock control ............................................................................................ 57

5.2.3

Page 8

NLV-5201 User's Manual

vi

1st

Data Output Speed (USB-HID) ....................................................................................... 58

5.2.4

Inter Character Delay (USB-HID) ................................................................................... 58 5.2.5

Keyboard Language ....................................................................................................... 59 5.2.6

Trouble Shooting (USB-HID) .......................................................................................... 60 5.2.7

USB-COM .............................................................................................................................. 61 5.3

USB-COM Basic Information .......................................................................................... 62 5.3.1

Integration (USB driver) .................................................................................................. 62 5.3.2

Connection Confirm ........................................................................................................ 62 5.3.3

Fixed USB-COM Port ..................................................................................................... 63 5.3.4

Connection Method ......................................................................................................... 63 5.3.5

COM to HID Output ........................................................................................................ 63 5.3.6

Trouble Shooting (USB-COM) ........................................................................................ 64 5.3.7

Common Settings ................................................................................................................... 65 5.4

Data Buffer Mode ............................................................................................................ 65 5.4.1

6 Reading and Timing .................................................................................................................... 66

Reading and Trigger Control .................................................................................................. 67 6.1

Code Read Timing .......................................................................................................... 67 6.1.1

Command Trigger Control .............................................................................................. 68 6.1.2

External Trigger Signal Control ...................................................................................... 69 6.1.3

Read Time Setting .......................................................................................................... 70 6.1.4

Trigger Delay .................................................................................................................. 71 6.1.5

Decode Timeout ............................................................................................................. 72 6.1.6

OK/NG Signal ......................................................................................................................... 73 6.2

Enable/Disable OK/NG signal ........................................................................................ 73 6.2.1

OK/NG Signal Behavior Settings .................................................................................... 74 6.2.2

7 Tuning and Bank Function ......................................................................................................... 75

Tuning Overview .................................................................................................................... 76 7.1

Tuning Function .............................................................................................................. 76 7.1.1

Tuning Setting Flow ........................................................................................................ 77 7.1.2

Tuning..................................................................................................................................... 78 7.2

Execute Tuning ............................................................................................................... 78 7.2.1

Setting the Exposure Adjustment Range of Tuning ....................................................... 79 7.2.2

Reading Test .......................................................................................................................... 80 7.3

Reading Test Command ................................................................................................. 80 7.3.1

Bank Function ........................................................................................................................ 81 7.4

Bank Selection ................................................................................................................ 81 7.4.1

Bank Specify Trigger ...................................................................................................... 81 7.4.2

Confirm Current Bank ..................................................................................................... 81 7.4.3

Initialize Bank .................................................................................................................. 81 7.4.4

8 Read Options ............................................................................................................................... 82

Read Modes Overview ........................................................................................................... 83 8.1

Read Operation Flow ...................................................................................................... 83

8.1.1

Page 9

NLV-5201 User's Manual

vii

1st

Read Modes ................................................................................................................... 84

8.1.2

Batch Reading ................................................................................................................ 86 8.1.3

Data Edit Function .......................................................................................................... 86 8.1.4

Auto Trigger ............................................................................................................................ 87 8.2

Normal Auto Trigger (Without Stand) ............................................................................. 87 8.2.1

Auto Trigger Sensitivity ................................................................................................... 87 8.2.2

Double Read Reset Time ............................................................................................... 87 8.2.3

Read Time Adjustment ................................................................................................... 88 8.2.4

Auto Trigger Sleep Mode ................................................................................................ 88 8.2.5

Illumination and Aiming .......................................................................................................... 89 8.3

Reading LED Illumination ............................................................................................... 89 8.3.1

LED Aiming ..................................................................................................................... 89 8.3.2

9 Code Options ............................................................................................................................... 90

Setting of Readable Codes .................................................................................................... 91 9.1

1D Codes ........................................................................................................................ 91 9.1.1

Postal Code .................................................................................................................... 92 9.1.2

GS1 DataBar .................................................................................................................. 93 9.1.3

GS1 Composite Code ..................................................................................................... 93 9.1.4

2D Codes ........................................................................................................................ 94 9.1.5

Other Options for Codes ................................................................................................. 94 9.1.6

OCR ................................................................................................................................ 95 9.1.7

Setting of Code Common Options ......................................................................................... 96 9.2

GS1 Convert ................................................................................................................... 96 9.2.1

Positive and Negative Image of Barcodes (1D code common) ...................................... 97 9.2.2

Redundancy (1D code common) .................................................................................... 98 9.2.3

Add-on waiting time ........................................................................................................ 98 9.2.4

ECI Protocol Output ........................................................................................................ 99 9.2.5

OCR Free Edit .............................................................................................................. 100 9.2.6

Setting of Code Specific Options ......................................................................................... 101 9.3

UPC .............................................................................................................................. 101 9.3.1

EAN/JAN ....................................................................................................................... 104 9.3.2

Code 39 and It. Pharm (Code 32) ................................................................................ 108 9.3.3

Codabar ........................................................................................................................ 110 9.3.4

Interleaved 2 of 5 and S-Code ...................................................................................... 112 9.3.5

Code128 ....................................................................................................................... 113 9.3.6

IATA .............................................................................................................................. 114 9.3.7

MSI/Plessey .................................................................................................................. 114 9.3.8

UK/Plessey ................................................................................................................... 114 9.3.9

Telepen ......................................................................................................................... 114 9.3.10

Code 11 ........................................................................................................................ 115 9.3.11

Korean Postal Authority ................................................................................................ 115 9.3.12

GS1 DataBar ................................................................................................................ 116

9.3.13

Page 10

NLV-5201 User's Manual

viii

1st

Composite GS1 DataBar .............................................................................................. 117

9.3.14

PDF 417 ........................................................................................................................ 118 9.3.15

QR Code ....................................................................................................................... 119 9.3.16

Data Matrix ................................................................................................................... 121 9.3.17

Aztec Code ................................................................................................................... 122 9.3.18

Setting of Number of Characters .......................................................................................... 123 9.4

Fixed Length ON, Minimum / Maximum Length for Selected Codes ........................... 123 9.4.1

Command List: Fixed Length ON/Minimum/Maximum Length ..................................... 124 9.4.2

10 String Options ............................................................................................................................ 125

Prefix / Suffix (appending character function) ...................................................................... 126 10.1

Program Value: ............................................................................................................. 127 10.1.1

Set Prefix / Suffix .......................................................................................................... 128 10.1.2

Command List: Settings of the Prefix / Suffix ............................................................... 129 10.1.3

ASCII (Prefix / Suffix Values) ........................................................................................ 131 10.1.4

Code ID ......................................................................................................................... 132 10.1.5

Code Length ................................................................................................................. 132 10.1.6

Code Coordinates ......................................................................................................... 133 10.1.7

Scan Time ..................................................................................................................... 134 10.1.8

Case Conversion .................................................................................................................. 135 10.2

11 Appendix .................................................................................................................................... 136

Code ID Table ...................................................................................................................... 137 11.1

Opticon Code ID prefix / suffix value ............................................................................ 137 11.1.1

Code Option AIM / ISO15424 Code ID prefix / Suffix value ......................................... 138 11.1.2

NLV-5201 Specification Overview ........................................................................................ 142 11.2

Common Specification Overview .................................................................................. 142 11.2.1

Technical Specifications ............................................................................................... 145 11.2.2

Detailed View ................................................................................................................ 148 11.2.3

Product Label ................................................................................................................ 149 11.2.4

Sample Codes ...................................................................................................................... 150 11.3

1D Barcode ................................................................................................................... 150 11.3.1

Postal Code .................................................................................................................. 154 11.3.2

GS1 DataBar ................................................................................................................ 155 11.3.3

GS1 Composite Code ................................................................................................... 156 11.3.4

2D Code ........................................................................................................................ 158 11.3.5

OCR Font (Machine Readable Travel Document) ....................................................... 159 11.3.6

OCR Font (Free OCR Edit)........................................................................................... 160 11.3.7

Page 11

Chapter-1

NLV-5201 User's Manual

1

1st

Abstract

1 Abstract

This document provides the user’s manual for the NLV-5201 2D handy scanner (hereafter called

“scanner”)

1.1 Feature of the Scanner

1.2 Usage of the Scanner

1.3 Flow to Integrate

Page 12

Chapter-1

NLV-5201 User's Manual

2

1st

Abstract

Features of the Scanner

1.1

The NLV-5201 is a fixed position 2D imager scanner that enables high speed reading of a standard

barcode, 2D code and OCR font. Main features are as follows:

● High-speed reading

The high-speed CMOS sensor (100fps) and high-speed CPU enables stress-free scanning and fast

response from fast movement and poor/bright lighting conditions.

● Tune function

Integrated tuning function enables locked settings based on the target environment for the quickest

possible decodes. Tuning can be enabled by pressing the mode key and watching the 3-color

indicators.

● Motion tolerance

Fast shutter technology and new tune feature provides for the best prevention of image blur and

quickest decode times. Perfect for in-motion automation applications.

● 3 Focus Model

NLV-5201 has 3 focus models to choose from: The standard model, (fixed focus @ 113mm). A

High Density model ‘HD’ @ 63mm focus and Ultra Density ‘UD’ @ 43mm focus models

● Data edit programming (data output formatting)

This scanner features a unique script program function called “Data Editing” which gives a user an

almost unlimited flexibility to format the scanned data before it is sent out. Multiple 1D code, 2D code

and OCR can be (partially) combined and fixed parts can be added, subtracted, or substituted

before its final output. It also supports GS1 application identifier and allows data edit outputting for

logistics, POS, medicines and medical instruments barcodes.

● Green LED aiming and Warm-White LED Illumination

A well-defined single line of green LED light and efficient warm-white LED illumination makes it easy

to aim the scanner while providing safety and long-life.

● The Scanner is a RoHS compliant product, as declared by OPTOELECTRONICS CO.,LTD.

Page 13

Chapter-1

NLV-5201 User's Manual

3

1st

Industrial use

Common use

Example of use: Factory line etc.

Example of use: Holing an product to read etc.

Exposure Control

Tuning

Auto Adjustment (default)

When reading distance and the code to read is

fixed, reading will stabilized by setting the optimum

exposure.

Adjust exposure automatically when the

reading distance and the code to read is not

fixed.

Usage of the Scanner

1.2

The scanner can be used from common usage to industrial use like factory production line etc.

Integration varies depending on the usage.

Exposure control has auto adjustment and tuning. Select according the usage.

Abstract

Page 14

NLV-5201 User's Manual

4

1st

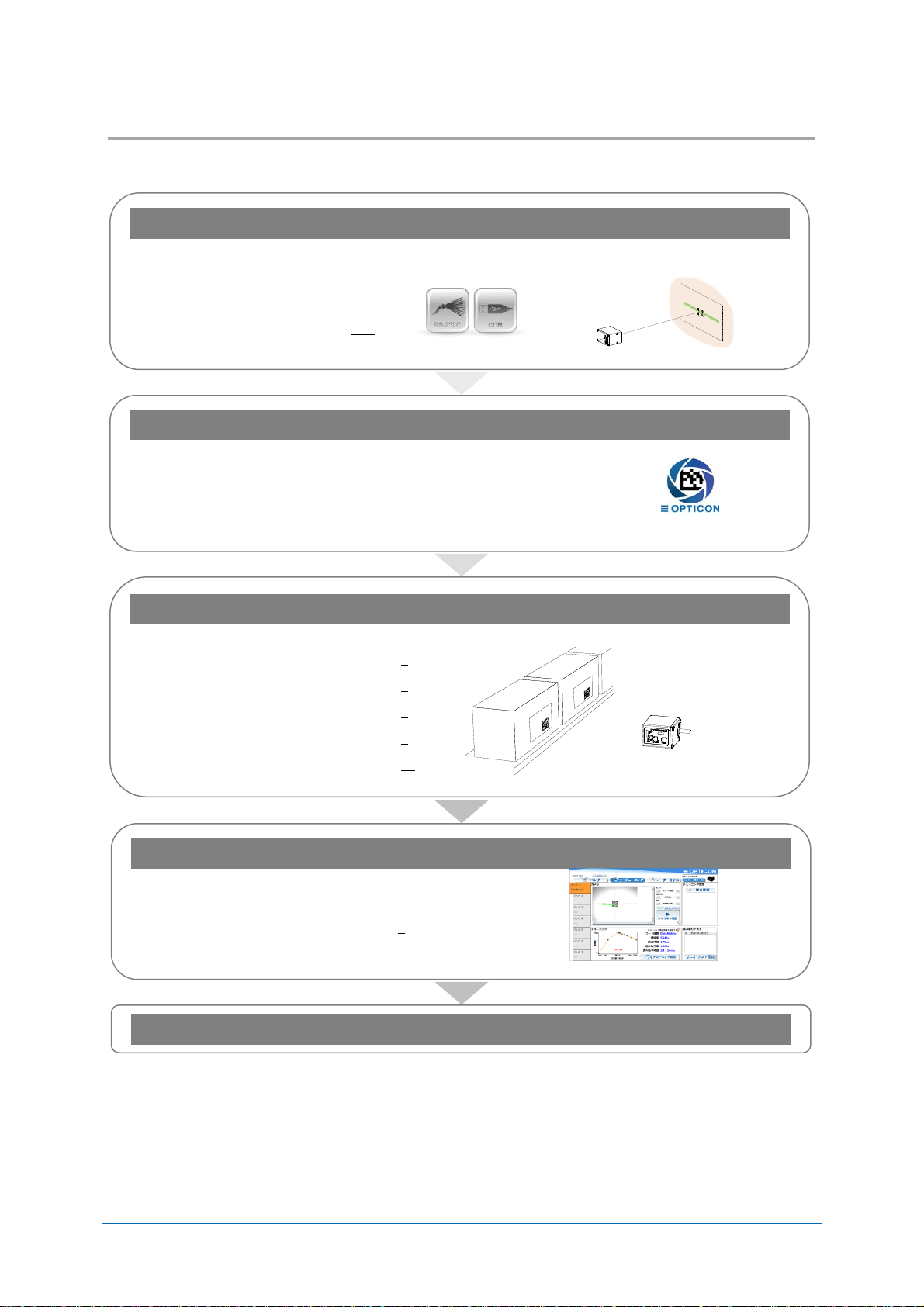

Flow to Integrate

1. Examine and Select the Scanner

Examine technical introduction in

advance.

“Communication”

“Reading position and focus model”

● Before using

→ (Refer to 2)

● Product specification

overview

→(Refer to 11.2)

2. Download Tools

According to the operation, download necessary tools from our website.

● Install condition image confirmation, tuning and

other settings.

→ ”UniversalTuningTool”

UniversaTuningTool

● For USB-COM

→ ”USB Driver”

3. Fixing Position and Setting for operation

Confirm the optimun setting according to the operation.

● Configurations

→ (Refer to 3)

● Interface

→ (Refer to 5)

● Reading and Timing

→ (Refer to 6)

● Read options

→ (Refer to 8)

● String Options

→ (Refer to 10)

4. Tuning and Testing

Tune and test in the acturla envirioment.

● Tuning and bank function

→ (Refer to 7)

Integrate

1.3

Flow to Integrate for Industrial Uses 1.3.1

Flows to integrate the scanner for industrial use are described below.

Chapter-1

Abstract

Page 15

NLV-5201 User's Manual

5

1st

Flow to Integrate for General Uses

1. Examine and Select the Scanner

Examine technical introduction in

advance.

“Communication”

“Reading code”

● Before using

→ (Refer to 2)

● Product specification

overview

→ (Refer to 11.2)

2. Download Tools

According to the operation, download necessary tools from our website.

● Setting, Image acquisition, confirm

communication

→ “UniversalConfig”

UniversalConfig

● USB-COM

→ “USB Driver”

3. Setting and Testing

In the actual enviroment, evaluate the optimum setting according to the operation and perform a

reading test.

● Configurations

→ (Refer to 3)

● Indicator

→ (Refer to 4)

● Interface

→ (Refer to 5)

● Code Options

→ (Refer to 9)

● String Options

→ (Refer to 10)

● Read Options

→ (Refer to 8)

4. Create Setting Menu

Create a 2D menu code suitable for operation.

● 2D menu code

→ (Refer to 3.1.2)

Integrate

1.3.2

Flows to integrate the scanner for general use are described below.

Chapter-1

Abstract

Page 16

NLV-5201 User's Manual

6

1st

2 Before Using

Following explains the items required before using.

2.1 Model Details

2.2 Package Contents

2.3 Connect to the Host

2.4 How to Read

2.5 Depth of Field and Focus Type

2.6 Detailed View

2.7 Operation Mode and Control Panel Description

2.8 Operation Transition

2.9 Installation of the Scanner

2.10 Scan Area

2.11 Scanned Media and Placement

2.12 When Placing Exit Window

Chapter-2

Before Using

Page 17

NLV-5201 User's Manual

7

1st

Model Details

Model

name

Focus Interface

Cable length

Optional

AC Adapter

NLV-5201

None

or

-HD

or

-UD

-RS232C(LE)

or

-USB

or

-USB-COM

or

-RS232C(9P)

None

None

or

-RS232C

+PS

Standard

Description

NLV-5201-RS232C(LE)

Standard focus, RS-232C loose end

NLV-5201-USB

Standard focus, USB-HID

Symbol

Description

None

Standard focus model (focus distance: 113 mm)

-HD

High density focus model (focus distance: 63 mm)

-UD

Ultra-high density focus model (focus distance: 43 mm)

Symbol

Description

-RS232C(LE)

RS-232C loose end cable (open wires, no connector)

-USB

USB cable is connected and interface default setting is USB-HID.

-USB-COM

USB cable is connected and interface default setting is USB-COM.

-RS232C(9P)

RS-232C cable (power supply input connected to D-sub 9 pin 9)

-RS232C

RS-232C cable with power pigtail (external AC power supply spec) is

connected.

Symbol

Description

None

Cable length 1.5 m

Symbol

Description

None

AC adapter not included.

+PS

AC adapter for RS-232C external power supply is included.

2.1

The NLV-5201 model name is constructed by a combination of following.

Standard 2.1.1

The following specs are the standard products.

Chapter-2

Before Using

Note: Other combinations only as special order, please contact sales offices for this.

Model Description 2.1.2

Focus

Interface Cable

Cable Length

Optional AC adapter

Page 18

NLV-5201 User's Manual

8

1st

Package Contents

Scanner with USB cable

NLV-5201 Quick Start Guide

(1 copy)

Scanner with RS-232C (loose end) cable

NLV-5201 Quick Start Guide

(1 copy)

USB-HID / USB-COM Interface Model

RS-232C Interface Model

2.2

Following items are packed to this product. Please check before using.

Chapter-2

Before Using

Following are included to USB interface model.

Following are packed to RS-232C interface model.

Page 19

Chapter-2

NLV-5201 User's Manual

9

1st

Host

USB Connector

X X X X X X

1500

Φ 3.8

[Unit: mm]

USB plug A

USB-COM/ USB-HID Interface Connection Diagram

Before Using

Connect to the Host

2.3

This section describes how to connect each interface to the host.

For interface setting details, refer to “5. Interface”

For details of installing the scanner, refer to “Installation of the Scanner”.

Connecting with the Host device

Connect interface connector to the host. When power is on, the scanner makes startup sound.

After startup sound is completed, the scanner will be ready for reading.

* USB-COM and USB-HID interface can be changed by the setting.

* For the USB-COM interface model, the Opticon USB-COM driver must be installed on your host device.

* While using USB-COM and not connected to the host, the scanner makes an error sound when reading.

Page 20

Chapter-2

NLV-5201 User's Manual

10

1st

Cable Color

Signal Name

Notes

Red

VCC

Power-supply voltage 4.5-5.5V (Typ.5V)

Brown

Trigger

External trigger input terminal

Yellow

OK

External OK output terminal

Orange

NG

External NG output terminal

Black

S-GND

Gray

RTS Blue

CTS Green

TxD White

RxD (Black)

Shield GND

Heat shrinkable tube

X X X X X X

1500

60

Φ 3.8

AWG28

[Unit: mm]

Host

RS-232C

Communication connector

Barcode

reader main

circuit

VCC

DC 5V

+

Load

MAX DC 24V

+

TxD

RxD

RTS

CTS

OK / NG

Trigger

S-GND

F-GND

TxD

RxD

CTS

RTS

External

device

NLV-5201

RS-232C (Loose End) Interface Connection Diagram

Before Using

Loose end Pin Assignment

Loose end Circuit

Page 21

NLV-5201 User's Manual

11

1st

How to Read

2.4

The scanner read target code by acquiring the image.

Reading starts by the following method.

1. Send command trigger “Z” via serial communication. (RS-232C, USB-COM)

2. Turn ON external trigger input. (RS-232C loose end)

3. Detect target to read in auto trigger mode.

4. Press trigger key. (Used when testing and maintenance etc.)

Chapter-2

Before Using

Reading Reference Standard mode (SR): Approx. 113 cm Scan Area (Refer to 2.10)

Distance (Refer to 2.5.1)

High Resolution model (HD): Approx. 63 cm

(Refer to 2.5.2)

Ultra High Resolution model (UD): Approx. 43 mm

(Refer to 2.5.3)

Page 22

NLV-5201 User's Manual

12

1st

Depth of Field and Focus Type

0.127mm (5mil)

53 126

0.254mm (10mil)

52

237

0.508mm (20mil)

69

433

0.20mm (7.9mil)

191

62

0.33mm (13mil)

50

291

0.169mm (6.7mil)

49

146

0.254mm (10mil)

42

211

0.169mm

60

111

0.381mm (15mil)

22

250

0.169mm (6.7mil)

62

116

0.254mm (10mil)

173

43

0

50 100 150

200 250

300

0

50

50

25

25

75

100

[Unit: mm ]

100 75

Code 39

Code 128

EAN/UPC

PDF417

QR Code

Data Matrix

2.5

Select the focus type according to reading distance and code resolution.

Standard Model (SR) Depth of Field 2.5.1

Chapter-2

Before Using

* The depth of field is the typical value measured by tilting the test chart 15° from the optical axis. (25C°)

* Refer to 11.2.2 Technical Specifications Standard Model Reading Depth of Field for specified value.

Page 23

NLV-5201 User's Manual

13

1st

High Resolution Model (HD) Depth of Field

0

50 100

150

200

0 50

50

25

75

75

25

Code 39

Code 128

EAN/UPC

PDF417

QR Code

Data Matrix

0.076mm(3.0mil)

45 72

0.127mm(5.0mil)

35

119

0.254mm (10mil)

55

179

0.20mm (7.9mil)

159

68

0.33mm (13mil)

48

200

0.127mm (5.0mil)

39

109

0.254mm (10mil)

46

154

0.127mm (5.0mil)

43

91

0.381mm (15mil)

24

180

0.127mm (5.0mil)

48

78

0.254mm (10mil)

139

28

[ Unit:mm ]

2.5.2

Chapter-2

Before Using

* The depth of field is the typical value measured by tilting the test chart 15° from the optical axis. (25C°)

* Refer to 11.2.2 Technical Specifications High Resolution Model (HD) Reading Depth of Field for specified value.

Page 24

NLV-5201 User's Manual

14

1st

Ultra High Resolution model (UD) Depth of Field

0

0

25

50

[Unit: mm ]

Code 39

EAN/UPC

QR Code

Data Matrix

0.076mm(3mil)

28

65

0.127mm(5mil)

23

82

0.254(10mil)

53

108

0.33mm(13mil)

50

0.084mm(3.3mil)

33

55

0.381mm(15mil)

22

109

25

50

75

100

2550

120

0.084mm(3.3mil)

35

55

0.254mm(10mil)

22

86

2.5.3

Chapter-2

Before Using

* The depth of field is the typical value measured by tilting the test chart 15° from the optical axis. (25C°)

* Refer to 11.2.2 Technical Specifications Ultra High Resolution model (UD) Reading Depth of Field for specified

value.

Page 25

NLV-5201 User's Manual

15

1st

Detailed View

No.

Name

Description

1

Scan Window

Light paths of the imager, LED illumination and aiming. Ensure that

the lens is free from dust and dirt before scanning.

2

Mounting Holes

Screw holes that can be used to mount the scanner. Two holes on

the bottom and side. Refer to the mechanical drawing for the

mounting holes dimension.

The screw hole is M3, effective depth 3.5mm.

3

Control Panel

Control panel to execute Test mode, Tuning mode and Aiming mode.

Can also select the bank.

4

Buzzer Holes

Sound from a built-in buzzer comes out through these holes. When

they are covered, the buzzer sound will be diminished. The sound

varies depending on the settings. Buzzer sound settings are

configurable for frequency, loudness and duration.

5

Status LEDs

Indicates status by the combination of 3-color LEDs (red, orange,

green).

Refer to 2.7.3 LED Indicator Specifications for detail.

6

Trigger Key

Default is trigger key. When selecting mode, it operates as execution

key.

7

Mode Key

The key to select and cancel the mode.

Shift to bank select mode by long press.

Mode key can be disabled, refer to 3.3.9 for detail.

X X X X X X

2. Mounting Holes

1. Scan Window

4. Buzzer Holes

7. Mode Key

6. Trigger Key

5. Status LED

3. Control Panel

2.6

Chapter-2

Before Using

Page 26

Chapter-2

NLV-5201 User's Manual

16

1st

Mode name

Mark

Description

Normal

mode

-

Following are use as reading trigger in a readable state like operation.

・Command trigger by serial communication (USB-COM/RS-232C)

・External trigger signal (RS-232C)

・Auto trigger

・Trigger key

Test mode

TEST

Used when testing the read rate.

The read rate is displayed on the indicator LED every 10 times.

Tuning mode

TUNE

When reading distance and the code to read is fixed, reading will

stabilized by setting the optimum exposure.

When the tuning is successes, code limited and exposures setting etc.

are registered to the current bank. Also, the reading rate is displayed on

the LED indicator.

Bank

-

Area to register the exposure etc. adjusted in the tuning mode. 1-7 can

be register to the bank, default is 1.

Aiming mode

AIM

Aiming lights and if code can be read, displays whether the code is close

to the center coordinate of the image sensor to LED indicator.

Buzzer Holes

Mode Key

Trigger Key

Status LED

Control Panel

Before Using

Operation Mode and Control Panel Description

2.7

Normally, the scanner is operated by serial communication control, but simple operation setting by the

control panel is also available.

Operation Mode 2.7.1

Page 27

NLV-5201 User's Manual

17

1st

Control Panel Operation Specifications

LED Indication

Mode Key

Trigger Key

Operation

Mode

Operation description

Trigger Key

for reading

Normal

Normal operation status.

Press once

(within 2 sec)

Mode

transition by

pressing once

Test

Used when testing the read rate.

The read rate is displayed on the indicator LED

every 10 times.

Press twice

(within 2 sec)

Mode

transition by

pressing once

Tuning

Tuning automatically perform optimum exposure

setting etc. according to the read code. When the

tuning is successes, the code is limited, and

exposures setting etc. are registered to the current

bank. Also, the reading rate when tuning is

successes is displayed on the LED indicator.

Press 3 times

(within 2 sec)

Mode

transition by

pressing once

Aiming

In the aiming mode, aiming lights and if code can

be read, displays whether the code is close to the

center coordinate of the image sensor to indicator

LED.

Press 4 times

(within 2 sec)

Press

2 seconds

or more

(Press again

to select)

Mode

transition by

pressing once

Bank

selection

By pressing the mode key for more than 2

seconds, the bank currently used will be display on

the LED. Pressing the mode key again, bank

becomes selectable in order, and by pressing the

trigger key, the bank displayed becomes effective.

Press both key at same

time for 5 seconds,

becomes initialization

standby. And initialize by

pressing trigger key again.

Initialize

Pressing mode key and trigger key at same time

for 5 seconds, it enters to the initialization standby.

Initialized by pressing trigger key with that status,

and initialization standby will be cancel by pressing

mode key.

2.7.2

Operation specification of the control panel allocated on the side of housing are as follows.

Chapter-2

Before Using

Page 28

Chapter-2

NLV-5201 User's Manual

18

1st

Status

Reading success

Waiting for

USB communication

Communication/

Reading error

LED

indication

Reading

rate

0 - 40 %

50 - 70 %

80 - 90%

100%

Central

coordinate

Within 1/2 image

Within 1/4 image

Within 1/8 image

Within 1/16 image

LED

indication

Bank No.

No.1

No.2

No.3

No.4

No.5

No.6

No.7

LED

indication

: OFF

: Blinking

: ON

1/2 Image

1/4 Image

1/8 Image

1/16 Image

Code center

Center position

Before Using

LED Indicator Specifications

2.7.3

The status LED’s indicate the reading result and USB communication status. In read rate mode, the

reading success rate is indicated by these three 3-color LED’s. Below is a more in-depth description

on these LED’s.

Normal mode status LED indication

“Test mode”, “Tuning mode” and “Aiming mode” LED indication

Test and tuning display the reading rate for 10 times.

*Judgement range at aiming.

“Bank. No.” LED indication

The LED of the bank currently used will blink by pressing the mode key for more than 2 seconds.

* Status LED legend

Page 29

NLV-5201 User's Manual

19

1st

Buzzer and LED Indicator

Item

Rumble timing

Tone interval

LED color

Enable/Disable

Start-up sound

When powered on.

Low - Low middle 2 time -

Middle tone

3 color

Combination

Configurable

(Default: Enable)

Good read sound

When reading successes

Middle tone 1 time

Light blue

Configurable

(Default: Enable)

Data transmission

error

In USB, when connection is not established.

(Middle - Middle low tone)

6 times

Red

Enable (Fixed)

Batch reading

Intermediate

sound

When one code is read and if it does not yet

meet the conditions to output data in batch

reading or concatenated code reading.

Short High tone 1 time

None

Configurable

(Default: Enable)

Read timeout

sound

When code is not read within the effective

time period.

Low tone 2 times

Red

Configurable

(Default: Disable)

1D ZZ menu

Reading sound

When reading start ZZ menu code.

Middle - Middle low -

Middle high tone

Yellow

Enable (Fixed)

When reading defined menu code.

Middle - Middle low -

Middle-high tone

Yellow

Enable (Fixed)

When reading not defined menu code.

Low tone 2 times

Red

Enable (Fixed)

When reading end ZZ menu code.

Middle - Middle low -

Middle-high tone

Yellow

Enable (Fixed)

When save setting is complete

(Middle - Middle low -

Middle high tone) 3 times

None

Enable (Fixed)

2D menu

Reading sound

When reading 2D menu code.

Middle - Middle low -

Middle high tone

Yellow

Enable (Fixed)

When save setting is complete.

(Middle - Middle low -

Middle high tone) 3 times

None

Enable (Fixed)

High temperature

protection mode

If internal temperature exceeds a certain

temperature, reading operation becomes

disabled. While in this mode, it beeps with a 3

seconds interval.

High tone 2 times

Orange

Enable (Fixed)

Buzzer Holes

Status LED

2.7.4

Buzzer sound and lighting color of LED indicates status of the scanner.

The scanner status, buzzer sound and status LED are described as below.

Chapter-2

Before Using

* Low: around 1000 Hz, Low middle: around 1000-2000 Hz, Middle low: around 2500 Hz, Middle: around 3000 Hz,

Middle high: around 3500 Hz, High: around 4000Hz.

* Refer to 4. Indicator for setting detail.

* Above is the definition of the representative status and does not indicate all of the operations.

Page 30

NLV-5201 User's Manual

20

1st

Operation Transition

Status

Description

Read

Acquiring image and reading is in progress with the warm white LED and

green aiming LED on.

Standby

Can start reading by serial command, pushing side trigger or the external

trigger input becomes active.

Reading operation stop*

The reading operation can be stopped by a successful decode, a stop

command, or a timeout period after release of the trigger.

Power-OFF

Standby

Read

Non-Operation

Power

applied

Transition command

Recovery

command

Trigger

Scanning completes

or

Time out

2.8

Following are the operation status transition of the scanner.

Normal Trigger 2.8.1

Chapter-2

Before Using

Status Description

* "Reading operation stop” is configured using commands. This cannot be done while using USB-HID interface.

Page 31

NLV-5201 User's Manual

21

1st

Auto Trigger

Power-OFF

Standby

[Auto Trigger]

Auto Trigger Sleep

Configured

(Default is 60 seconds)

Power

applied

Read

Scanning completes

or

Time out

Non-Operation

Detect target

Detect target

Transition command

Recovery

command

Status

Description

Read

Processes reading. Illumination fully ON

Auto trigger standby

When the target is within the scan area and detected, the scanner

starts the reading mode. AIM pulses.

Auto trigger sleep

Auto-trigger mode will sleep after 60 seconds (default time). This sleep

time can be re-configured or disabled.

Reading operation stop*

Operation of the scanner is stopped.

2.8.2

Chapter-2

Before Using

Status Description

* "Reading operation stop” is configured using commands. This cannot be done while using USB-HID interface.

Page 32

Chapter-2

NLV-5201 User's Manual

22

1st

Read Operation

Enable

Read Operation

Disable

Read operation enable command

Read operation disable command

Before Using

Operation Invalid Transition Diagram

2.8.3

For USB-COM and RS-232C, scanner operation can be disabled by command’s serial communication.

When disabled, auto trigger operation becomes invalid.

Refer to 3.3.6 for setting command.

Page 33

Chapter-2

NLV-5201 User's Manual

23

1st

Mounting Holes

M3 Depth 3.5

41.1

33

10.9

12

24

35.9

15

8

18.8

Mounting Holes

M3 Depth 3.5

11

2.6

X X X X X X

13.11

[Unit: mm]

Before Using

Installation of the Scanner

2.9

The installation of the scanner is described as below.

・Mount the scanner using the assigned screw holes on the bottom or side.

・Do not screw down further than the limitation of its depth.

・The scanner’s anti-shock reliability is confirmed only in case impulse (acceleration) is applied via the

contact surface. However, the scanner cannot withstand direct shock since it consists of precise

optical elements.

NLV-5201 Installation

Recommend screw type: M3

Recommend torque: Less than 20 Ncm.

Maximum screw depth: 3.5 mm from the mounting surface of the scanner.

Dimensions: Approx. 41.1 (W) ×33.0 (H) ×24.0 (D)

Weight: Approx. 30 g (excluding cable)

Cable: 1.5 m

Please contact sales for 3D CAD data.

Page 34

NLV-5201 User's Manual

24

1st

Scan Area

L: Distance from the front edge of scanner

[mm]

40

60

80

100

120

140

160

180

Horizontal FOV

[mm]

29.6

43.4

57.1

70.9

84.7

98.5

112.3

126.0

Vertical FOV

[mm]

22.1

32.4

42.7

53.0

63.3

73.6

83.9

94.2

Horizontal image width

Vertical image width

Aiming width

Distance:L

2.10

Image range is as follows.

Image Range 2.10.1

NLV-5201 image range is as follows.

Install a frame with sufficient clearance for the field of view.

Chapter-2

Before Using

The range is ±5% from the following values.

Image Range

* The table above shows the field of view which should not be obstructed by any parts of a housing.

Page 35

Chapter-2

NLV-5201 User's Manual

25

1st

Horizontal Field of View

Illumination LED

Vertical Field of View

Illumination LED

Vertical

Horizontal

Standard (SR) Focus (113 mm)

Aiming (LED)

Aiming (LED)

HD Focus (63 mm)

UD Focus (43 mm)

Before Using

2.10.2

Optical Path

Install the Exit Window with sufficient clearance for the field of view, LED illumination and LED aiming.

Provide the exit window with sufficient clearance with respect to the optical path, as depicted below.

*Obtain the image in the actual environment and evaluate it. The software tools for image capture can be found

on the Opticon website.

Page 36

Chapter-2

NLV-5201 User's Manual

26

1st

θ

L

Background

Scanned target

Before Using

Scanned Media and Placement

2.11

When an object is being scanned, there are conditions where specular reflection of the LED

illumination and intense ambient light can occur easily.

Solution for Specular Reflection of the LED Illumination 2.11.1

Problem: Glossy label

Specular reflection of the LED illumination from the scanner can occur when the target label is on a

highly reflective surface.

Solution:

Specular reflection does not occur when an angle is created between the scanner and the target label

as shown in the figure below. The conditions for the occurrence of specular reflection depend on the

distance L and the inclination angle θ. The recommended inclination angle is about 15 degrees. Note

that as the angle becomes bigger, it becomes more difficult to read the target label.

*For the background, use non-specular surface within the image range.

*Obtain the image in the actual environment and evaluate it. The software tools for image capture can be found

on the Opticon website.

Page 37

Chapter-2

NLV-5201 User's Manual

27

1st

Shade

Scanned target

Before Using

2.11.2

Solution for Specular Reflection of the External Illumination

Problem: Label on metal, code on the display

Strong ambient light (fluorescent and sunlight) causes a specular reflection on metal surface or glass

surface of display

Solution:

It is recommended to shield the reading position from strong ambient light.

*Obtain the image in the actual environment and evaluate it. The software tools for image capture can be found

on the Opticon website.

Page 38

Chapter-2

NLV-5201 User's Manual

28

1st

LED illumination appears to the exit window

Before Using

Exit Window Placement

2.12

LED illumination appears to the exit window depending on the exit window material and placement.

The distance and angle limitation to prevent this are described below.

Exit Window Material 2.12.1

Below is a list of recommendations for constructing the exit window. These recommendations help to

prevent reflection from the LED illumination off the exit window and help to prevent degradation of the

image by scratches and dirt.

● For the best optical quality, use an acrylic material (cast or extruded)

● Select a high-quality achromatic acrylic material with a smooth, flat surface without scratches and

dents.

● Use acrylic material with an anti-reflective (AR) coating applied to both sides.

● Apply an anti-scratch coating to the surface of the exit window to protect it from scratches during

operation.

● Hard coated acrylic sheets are readily available. Such a coating greatly enhances anti-scratch

properties without degrading the optical characteristics of the acrylic material.

Recommended acrylic material:

Nitto Jushi Kogyo Co., Ltd. Clarex Precision Thin Sheet

MITSUBISHI CHEMICAL CO., LTD. Shinkolite

Page 39

Chapter-2

NLV-5201 User's Manual

29

1st

➔

➔

➔

Exit window

Scanned target

18

°

18

°

Before Using

2.12.2

Solution for Specular Reflection of the Illumination

Placement of the exit window has limitation on the distance and angle to prevent reflection of the LED

illumination.

To avoid the reflection of LED, tilt the scanner and exit window for about 18 degrees in vertically.

* Obtain the image in the condition range to be used and design placement so that there is no reflection of the

LED illumination.

* Keep a minimum clearance between the scanner and the exit window of 1mm because of the dimensional

tolerances of the mounting holes

* Use of AR coated material for the exit window is recommended.

* External light is not factored in.

* Confirm that there is no reflection of the LED illumination off the exit window by acquiring images from the

scanner.

Page 40

Configurations

NLV-5201 User's Manual

30

1st

3 Configurations

This chapter explains the scanner configuration, default setting and saving setting, and basic

commands.

3.1 Configuring with Commands

3.2 Command Packet Sending Precautions

3.3 Basic Commands

Chapter-3

Page 41

Chapter-3

NLV-5201 User's Manual

31

1st

Command Header*2

Command ID*1

Command Terminator*2

<ESC>

(0x1B)

None

1-2 digits (ASCII)

<CR>

(0x0D)

[(0x5B)

3 digits (ASCII)

Configurations

Configuring with Commands

3.1

The scanner can be configured by sending commands via the serial interface or by reading 1D or 2D

menu labels. This section describes the serial commands.

Command Packet 3.1.1

The command packet, from header to terminator, is defined as below.

*1 It is possible to send multiple command IDs between a single header and terminator, except for single digit IDs.

*2 A combination of command header <STX>(0x02) and terminator <ETX>(0x03) is also possible.

Input examples:

1-digit command <ESC>Δ<CR>

2-digit command <ESC>ΔΔ<CR>

3-digit command <ESC>[ΔΔΔ<CR>

Two 2 digit commands <ESC>ΔΔΔΔ<CR>

2 and 3 digits command <ESC>ΔΔ[ΔΔΔ<CR>

Command can be sent via “UniversalConfig” Command can be sent via “UniversalTunigTool”

* Commands entered in the “command:” box of this utility do not require the beginning command header <ESC>.

The command or commands will be sent to the reader upon a ENTER key or a click of the [Send] button.

Page 42

Chapter-3

NLV-5201 User's Manual

32

1st

“@MENU_OPTO”

(Start key)

“@”

(Separator)

“ZZ”

(Start menu)

“@”

(Separator)

← Multiple sets allowed

“Any menu command”

(U2 etc)

“@”

(Separator)

“ZZ”

(END menu)

“@”

(Separator)

“OTPO_UNEM@”

(Stop key)

Print

Configurations

Configuring with 2D Menu

3.1.2

A single 2D menu code can contain multiple settings that will be processed in order, in one operation.

Therefore, you can configure the scanner with multiple settings by reading only one 2D menu code.

Scanning a 2D menu code will always perform a ‘save settings’ upon completion, so a Z2 command to

save current settings is not needed.

Data Packet:

@MENU_OPTO@ZZ@MenuCommand 1@MenuCommand 2@ZZ@OTPO_UNEM@

● 2D menu code can be created at “UniversalConfig”.

*Please contact sales offices for the tools.

Page 43

Chapter-3

NLV-5201 User's Manual

33

1st

Scan SET menu code (ZZ). The scanner now enters menu mode.

Scan one or more desired options.

Read END menu code (ZZ). All the settings are saved in non-volatile memory.

Print

Configurations

Configuring with 1D Menu Code

3.1.3

By scanning a series of 1D menu codes specially designed to configure the required functions, you

can set up the scanner to optimize its performance for your particular application.

The basic procedures are as follows:

Multiple menu codes can be read when you want to configure more than one option.

* 1D Menu codes encode an ID consisting of two to five alphanumeric characters. 1D Menu codes are Code39

labels with modified start/stop characters and therefore the scanner will not acknowledge a 1D menu code as a

normal barcode.

● Menu barcode can be created at “UniversalConfig”.

*Please contact sales offices for the tools.

Page 44

NLV-5201 User's Manual

34

1st

Command Packet Sending Precautions

Active Settings

Settings that is currently active.

(Including newly added settings from power on)

Startup Settings

Custom Settings

The setting to be read when power is turned on.

Custom setting to be saved on another memory area.

Factory Default Settings

Default setting is the same as the initial setting described in this manual.

Various interfaces require switching setting.

Item

Command

Interface

Description

Remark

Factory

Default

Settings

SU

USB-HID

Restore USB-HID to factory default settings

[C01

USB-COM

Restore USB-COM to factory default settings

U2

RS-232C

Restore RS-232C to factory default settings

Custom Settings Active Settings

Each interface

Factory Default

Settings

Start-up

Settings

Readout custom setting

Command “[BAP”

Save custom setting

Command “[BAQ”

Readout factory default settings

Command “SU”, “[C01”, “U2”

Power-ON

/Software reset

Start-up setting

Save command “Z2”

Setting command (Serial communication)

3.2

Following are the scanner setting method.

Setting value, writing and reading diagram

Chapter-3

Configurations

* Menu barcode and 2D menu code setting are always saved in “Startup setting”.

* When updating the firmware, status of interface will remained, but “Startup setting” and “Custom setting” will be

initialized.

Each interface Default Setting 3.2.1

The Active Settings can be returned to the factory default settings. Set the command that corresponds

to the interface being used.

Page 45

Chapter-3

NLV-5201 User's Manual

35

1st

Item

Command

Description

Remark

Save settings

Z2

Save the Active Settings as Startup Settings

Command only

Item

Command

Description

Remark

Custom settings

[BAP

Read out Custom Settings

[BAQ

Save to Custom Settings

Configurations

Save Settings

3.2.2

The Active Settings can be written into the “Startup Settings”.

* Place “Z2” at the end of command packet to be saved.

* Saving settings for more than 30,000 times may destroy memory. Avoid saving every time.

* There are options that will not be enabled until “Save settings” is sent, such as baud rate setting.

Custom Setting 3.2.3

* Place “[BAQ” at the end of command packet to be saved.

* To save both “Custom settings” and “Active Settings” at same time, send “[BAQZ2”.

* Custom settings for more than 30,000 times may destroy memory. When setting frequently, avoid saving every

time.

Page 46

Chapter-3

NLV-5201 User's Manual

36

1st

Item

Command

Description

Default

ACK/NAK

WC

Enable ACK/NAK for serial commands

WD

Disable ACK/NAK for serial commands

Item

Command

Description

Remark

Diagnostics

Z1

Transmit software version

ZA

Transmit ASCII printable string

YV

Transmit ASCII control string

Item

Command

Description

Default

Enable/Disable 2D menu code

[D1Y

Enable 2D menu code

[D1Z

Disable 2D menu code*

Item

Command

Description

Default

Enable/Disable 1D menu code

[DFB

Q0

Q1

Enable when using trigger key.

Q0

Q0

Disable when using trigger key.*

Q1

Q1

Enable when using external trigger signal.

Q1

Q0

Disable when using external trigger signal.*

Q2

Q1

Enable when using command trigger or auto trigger.

Q2

Q0

Disable when using command trigger or auto trigger.*

Configurations

Basic Commands

3.3

Following are the basic commands for the scanner.

ACK/NAK for Serial Commands 3.3.1

When "ACK/NAK for serial commands" is enabled, the scanner will send an ACK (0x06) when a

command is received and accepted, and a NAK (0x15) when a command is rejected.

Diagnostic Commands 3.3.2

These commands can be used to get diagnostics information from the scanner.

Enable/Disable 2D Menu Code 3.3.3

To enable/disable the processing of 2D menu codes, use the settings below.

Setting ‘Disable 2D menu codes’ is recommended when 2D menu codes are not used.

* Indicates reading 2D menu code as normal 2D code. Therefore, 2D menu code data will be output when reading

success.

Enable/Disable 1D Menu Code 3.3.4

To enable/disable the decoding of 1D menu codes, use the settings below.

Setting ‘Disable 1D menu codes’ is recommended when 1D menu codes are not used.

* Indicates that 1D menu code reading is prohibited.

Page 47

Chapter-3

NLV-5201 User's Manual

37

1st

Item

Command

Description

Default

Horizontal mirrored

image

[EFU

Disable horizontal mirrored image configuration

[EFV

Enable horizontal mirrored image configuration

Vertical mirrored

image

[E8J

Disable vertical mirrored image configuration

[E8I

Enable vertical mirrored image configuration

Style

Commands

Horizontal mirror

Vertical mirror

Normal image

[EFU[E8J

Disable

Disable

Horizontal mirror image

[EFV[E8J

Enable

Disable

Vertical mirror image

[EFU[E8I

Disable

Enable

180° rotated image

[EFV[E8I

Enable

Enable

Horizontal

Mirror

Horizontal

Mirror

Vertical

Mirror

Vertical

Mirror

①Normal Image

③Vertical Mirrored Image

②Horizontal Mirrored Image

④180° Rotated Image

Top (Device)

Bottom (Device)

[①Normal image]

[②Horizontal mirror image]

[③Vertical mirror image]