Page 1

Undecoded Laser Scan Engine

MSL 2000

The MSL 2000 is an undecoded compact laser bar

code scan engine that can be installed in various

handheld products.

Specifications Manual

Page 2

All information subject to change without notice.

Document History

Opticon

MSL 2000

Specifications Manual

Model Number:

Edition:

Date:

MSL 2000

1

2006-08-01

Specification Number:

Original Spec Number:

SS06026

SS05045

Copyright 2008 Opticon. All rights reserved.

This manual may not, in whole or in part, be copied, photocopied, reproduced, translated or converted to any

electronic or machine readable form without prior written consent of Opticon.

Limited Warranty and Disclaimers

PLEASE READ THIS MANUAL CAREFULLY BEFORE INSTALLING OR USING THE

PRODUCT.

Serial Number

A serial number appears on all Opticon products. This official registration number is directly related to the device

purchased. Do not remove the serial number from your Opticon device. Removing the serial number voids the

warranty.

Warranty

Unless otherwise agreed in a written contract, all Opticon products are warranted against defects in materials and

workmanship for two years after purchase. Opticon will repair or, at its option, replace products that are defective in

materials or workmanship with proper use during the warranty period. Opticon is not liable for damages caused by

modifications made by a customer. In such cases, standard repair charges will apply. If a product is returned under

warranty and no defect is found, standard repair charges will apply. Opticon assumes no liability for any direct, indirect,

consequential or incidental damages arising out of use or inability to use both the hardware and software, even if

Opticon has been informed about the possibility of such damages.

Packaging

The packing materials are recyclable. We recommend that you save all packing material to use should you need to

transport your scan engine or send it for service. Damage caused by improper packaging during shipment is not

covered by the warranty.

Trademarks

Trademarks used are the property of their respective owners.

Opticon Inc. and Opticon Sensors Europe B.V. are wholly owned subsidiaries of OPTOELECTRONICS Co., Ltd., 1217, Tsukagoshi 4-chome, Warabi-shi, Saitama, Japan 335-0002. TEL +81-(0) 48-446-1183; FAX +81-(0) 48-446-1184

SUPPORT

USA Europe

Phone: 800-636-0090

Email: support@opticonusa.com Email: support@opticon.com

Web: www.opticonusa.com Web: www.opticon.com

2

Page 3

Opticon

MSL 2000

Specifications Manual

Contents

1. Abstract....................................................................................................................................... 5

2. Overview...................................................................................................................................... 5

3. Physical Features....................................................................................................................... 5

3.1. Dimensions ......................................................................................................................... 5

3.2. Weight ................................................................................................................................. 5

4. Environmental Specifications ...................................................................................................6

4.1. Operating Temperature and Humidity................................................................................. 6

4.2. Storage Temperature and Humidity .................................................................................... 6

4.3. Ambient Light Immunity....................................................................................................... 6

5. Electrical Specifications ............................................................................................................ 7

5.1. Absolute Maximum Ratings ................................................................................................ 7

5.2. Electrical Characteristics..................................................................................................... 7

6. Optical Specifications................................................................................................................ 9

6.1. Laser Scan Specifications................................................................................................... 9

6.1.1. Tilt of Laser Scan Line ...............................................................................................................9

6.1.2. Curvature of Scanning ............................................................................................................... 9

7. Technical Specifications.......................................................................................................... 10

7.1. Print Contrast Signal (PCS) .............................................................................................. 10

7.2. Minimum Resolution.......................................................................................................... 10

7.3. Scan Area and Resolution ................................................................................................ 11

7.3.1. Depth of Field...........................................................................................................................11

7.4. Pitch, Skew, and Tilt.......................................................................................................... 13

7.4.1. Pitch Angle ...............................................................................................................................13

7.4.2. Skew Angle and Dead Zone ....................................................................................................13

7.4.3. Tilt Angle ..................................................................................................................................13

7.5. Curvature .......................................................................................................................... 14

8. Interface Specifications ...........................................................................................................15

8.1. Interface Connector........................................................................................................... 15

8.1.1. Filter Mode Settings .................................................................................................................16

8.1.2. Comparison of Scanning Performance with Different Filter Modes.........................................17

8.2. Interface Circuit ................................................................................................................. 19

8.3. Timing Waveform .............................................................................................................. 21

8.4. Laser Light Specifications ................................................................................................. 22

9. Serial Number ........................................................................................................................... 23

10. Packaging Specifications........................................................................................................24

3

Page 4

Opticon

MSL 2000

Specifications Manual

10.1. Collective Packaging Specification ................................................................................... 24

11. Durability................................................................................................................................... 25

11.1. Electrical Noise ................................................................................................................. 25

11.2. Shock ................................................................................................................................ 25

11.2.1. Drop Test (without packaging) .................................................................................................25

11.3. Vibration Strength ............................................................................................................. 25

12. Reliability................................................................................................................................... 25

13. Regulatory Compliance ...........................................................................................................26

13.1. Laser Safety ...................................................................................................................... 26

13.2. RoHS................................................................................................................................. 26

14. Safety......................................................................................................................................... 26

14.1. Shock ................................................................................................................................ 26

14.2. Temperature Conditions.................................................................................................... 26

14.3. Foreign Materials .............................................................................................................. 26

14.4. Other ................................................................................................................................. 26

15. Mechanical Drawing................................................................................................................. 27

Table of Figures

Figure 1. Current waveform.......................................................................................................... 8

Figure 2: Curvature....................................................................................................................... 9

Figure 3: Depth of field ................................................................................................................11

Figure 4: Pitch, skew, and tilt ...................................................................................................... 13

Figure 5: Curvature..................................................................................................................... 14

Figure 6: Standard barcode scanning performance.................................................................... 17

Figure 7: Modulation scanning performance .............................................................................. 18

Figure 8: Low PCS scanning performance................................................................................. 18

Figure 9: Timing waveform ......................................................................................................... 21

Figure 10: Laser light specifications ...........................................................................................22

Figure 11: Serial number diagram .............................................................................................. 23

Figure 12: Individual packaging.................................................................................................. 24

Figure 13: Mechanical drawing...................................................................................................27

4

Page 5

Specifications Manual

1. Abstract

This document provides specifications of the MSL 2000 laser scan engine.

2. Overview

The MSL 2000 (hereafter called “the scan engine”) is an undecoded compact laser barcode

scan engine that can be installed in various handheld products such as portable terminals.

When scanning a target at the minimum decode distance, this scan engine can scan up to

44 mm wide at an angle of 44°. The use of a short-wavelength red laser beam enhances

the visibility of the laser beam when scanning barcodes.

This scan engine scans barcodes using laser light and outputs those barcode images as a

logic level signal (hereinafter called the “signal”). This scan engine also outputs timing

waveforms (signals) synchronized with scanning. Such timing waveforms (signals) are

hereinafter referred to as “TIMING”. This scan engine can be turned on and off via an

external input signal, “POWER EN”. The laser light emission of this scan engine can be

controlled via an external input signal, “LASER EN”.

Opticon

MSL 2000

This scan engine is compliant with RoHS.

3. Physical Features

3.1. Dimensions

W 20.4 x D 14.0 x H 11.0 mm

3.2. Weight

3.9 g (max.)

5

Page 6

4. Environmental Specifications

4.1. Operating Temperature and Humidity

Temperature: -20 to 65° C

Humidity: 5 to 90% RH

4.2. Storage Temperature and Humidity

Temperature: -30 to 70° C

Humidity: 5 to 90% RH

4.3. Ambient Light Immunity

Decoding performance is guaranteed when the range of illumination on a barcode

surface is between zero and the following values:

Incandescent light 4,000 lx

Fluorescent light 4,000 lx

Sunlight 80,000 lx

Opticon

MSL 2000

Specifications Manual

Conditions

Barcode Sample: OPTOELECTRONICS Test Sample

PCS: 0.9

Resolution: 0.25 mm

Symbology: 9-digit Code 39

Quiet zone: 10 mm

N/W ratio: 1:2.5

Distance: 150 mm from the exit window

Angle (see note below): α = 0° β = 15° γ = 0°

Curvature: R = ∞

Power supply voltage: 3.3 V

Direct light or specular reflection from a light source should be prevented from

entering the acceptance area.

Note: α, β and γ respectively represent pitch, skew and tilt. Please see section 6.1.1

for how these values are defined.

6

Page 7

5. Electrical Specifications

5.1. Absolute Maximum Ratings

Parameter Symbol Value Unit

Power Supply Voltage (Vcc to GND) VCC 6.0 V

Input Voltage VI -0.3 to

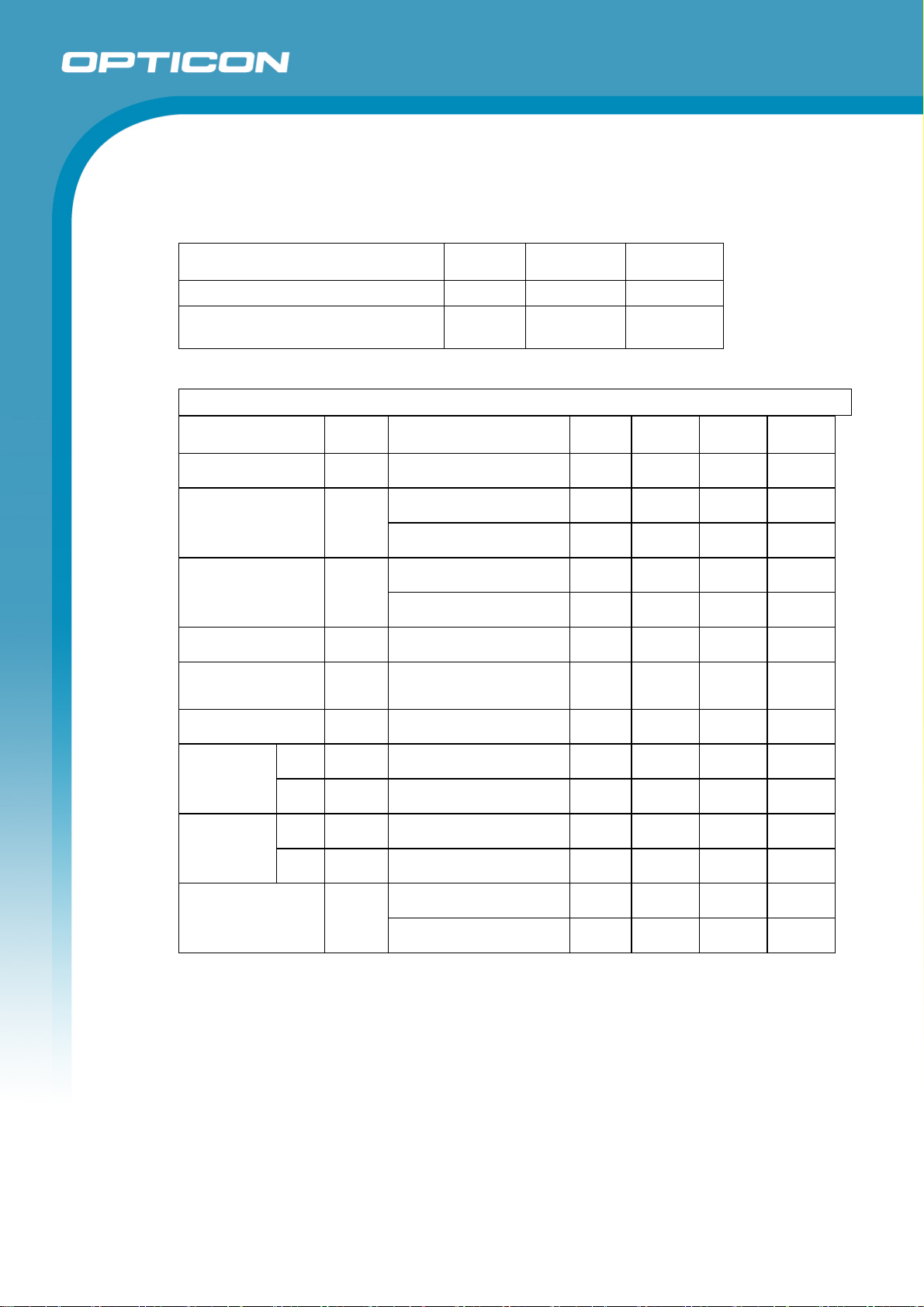

5.2. Electrical Characteristics

Vcc = 3.3V, Ta = 25° C

Parameter Symbol Conditions Min Typical Max Unit

Opticon

MSL 2000

Specifications Manual

V

V

+0.3

CC

Power Supply Voltage

Operating Current 1

Operating Current 2

Rush Current Peak

Standby Current

Stop Current

H-level

Input Voltage

L-level

H-level

Output Voltage

L-level

Input Current

3.0 - 3.6 V

V

CC

I

OP1

I

OP2

I

PEEK

I

STAN

I

STOP

V

V

V

OH

V

OL

Vcc = 3.3V, Ta = 25° C

Vcc = 3.3V, Ta = 65° C

Vcc = 3.3V, Ta = 25° C

Vcc = 3.3V, Ta = 65° C

With Vcc Applied

POWER EN = ON,

LASER EN = OFF

POWER EN=OFF

IH

IL

V

- - 0.5 V

IOH<1mA

IOL<1mA

- 35 45 mA

- 45 55 mA

- 55 65 mA

- 65 75 mA

- 250 500 mA

- 35 45 mA

- - 1 μA

-0.5 - - V

CC

-0.3 - - V

V

CC

- - 0.3 V

VIN=3.3V - - -50 μA

I

IN

VIN=0V - - 10 μA

7

Page 8

Vcc

POWER EN

LASER EN

Ipeek

Iop2

Iop1

Istan

Opticon

MSL 2000

Specifications Manual

ON

OFF

ON

OFF

ON

OFF

8.33 ~ 12.5ms

2.5ms Max

500μs Max

Current Waveform

Figure 1. Current waveform

8

Page 9

6. Optical Specifications

6.1. Laser Scan Specifications

Parameter Specification Unit

Light-emitting element Red laser diode —

Emission wavelength 650 ±10 (25° C) nm

Light output 1.0 or less mW

Scanning method Bi-directional scanning —

Scanning speed 100 ±20 scans/s

6.1.1. Tilt of Laser Scan Line

(The maximum tilt in between both ends of the scan line.)

• Less than 1.2 degrees upward tilt from the scan origin (MM mirror).

Opticon

MSL 2000

Specifications Manual

Scan angle: 54 ±5 ° Scan angle

Read angle: 44 (Min) °

• Maximum of 3.1 millimeters when measured at the point 150

millimeters away from the scan origin.

(The measurement is taken at the center of the scan line.)

6.1.2.

Curvature of Scanning

(The maximum gap between the straight line connecting both ends of the laser

scan line and the actual laser scan line.)

• Less than 1.27 degrees curvature from the scan origin.

• Maximum of 3.3 millimeters when measured at the point 150

millimeters away from the scan origin.

(The measurement is taken at the center of the scan line.)

C

u

r

v

a

t

u

r

e

t

l

i

T

Figure 2: Curvature

Horizontal Line

9

Page 10

Specifications Manual

7. Technical Specifications

The conditions for technical specifications are as follows, unless otherwise specified in each

section.

Conditions

Ambient temperature and humidity: Room temperature (5 to 35º C)

Room humidity (45% to 85% RH)

Ambient light: 500 to 900 lx

Background: Barcode = black

Space = white

Margin = white

Background of label = black

Power supply voltage: 3.3 V

Decoding test: Over 95% decode

Opticon

MSL 2000

7.1. Print Contrast Signal (PCS)

0.45 or higher (over 70% of reflectivity of space and quiet zone).

Reflectance of white bar-Reflectance of black bar

PCS=

Reflectance of white bar

Scanning performance may decline if dirt or scratches mar the optical window. Keep

the optical window clean.

7.2. Minimum Resolution

0.127 mm

10

Page 11

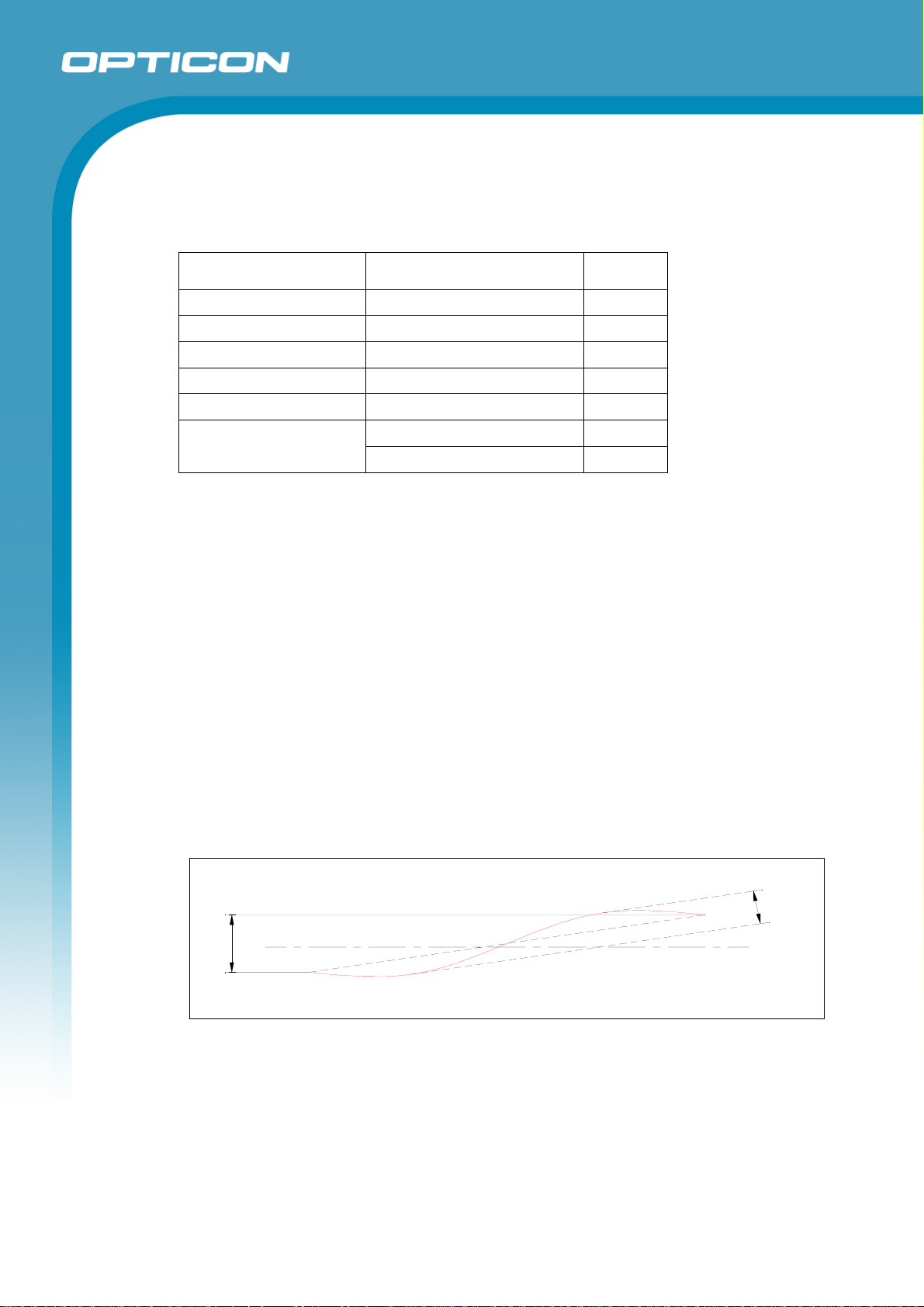

7.3. Scan Area and Resolution

7.3.1. Depth of Field

The depth of field is measured from the edge of the exit window. The decode

area is rectilinear near the exit window and expands in an arc centered on a

virtual reference point in the distance.

Resolution

0.127

60 - 110

Opticon

MSL 2000

Specifications Manual

0.15

0.25

0.5

1.0

50 - 130

50 - 230

50 - 380

70 - 550

(in millimeters)

Figure 3: Depth of field

PCS Resolution

(mm)

0.9 1.0 70–550

0.9 0.5 50–380

0.9 0.25 50–230

0.9 0.15 50–130

0.9 0.127 60–110

Decode Depth (mm)

11

Page 12

Conditions

Opticon

MSL 2000

Specifications Manual

Filter Selection: Standard Mode

Details: The depth of field is measured from the edge of the exit window.

The decode area is rectilinear near the exit window and expands in an arc

centered on a virtual reference point in the distance.

Barcode Sample: OPTOELECTRONICS Test Sample

N/W ratio: 1:2.5

Angle: α = 0°, β = 15°, γ = 0°

Curvature: R = ∞

Resolution (mm) Symbology PCS Quiet Zone Digits

1.0 Code 39 0.9 25 mm 1

0.5 Code 39 0.9 18 mm 3

0.25 Code 39 0.9 10 mm 8

0.15 Code 39 0.9 7 mm 10

0.127 Code 39 0.9 5 mm 4

12

Page 13

7.4. Pitch, Skew, and Tilt

7.4.1. Pitch Angle

α = ±35°

Opticon

MSL 2000

Specifications Manual

7.4.2.

7.4.3.

Skew Angle and Dead Zone

Skew angle: β = ±50° (Excluding dead zone)

Dead zone: β = ±8° (There are some areas in which decoding fails due to

specular reflection)

Tilt Angle

γ = ±20°

Figure 4: Pitch, skew, and tilt

Conditions

Barcode Sample: OPTOELECTRONICS Test Sample

Distance: 110 mm from the exit window

Label:

Angle: Curvature: R = ∞, Skew Angle = β +15° (for measuring Pitch Angle and Tilt Angle)

Pitch, Skew Angle, Dead Zone

PCS = 0.9, Resolution = 0.25 mm, Symbology = 9-digit Code 39,

Quiet Zone = 10 mm, N/W Ratio = 1:2.5

Tilt Angle

PCS = 0.9, Resolution = 0.26 mm, Symbology = 13-digit JAN, Quiet Zone = 10 mm

13

Page 14

Specifications Manual

7.5. Curvature

With 8-digit JAN/UPC/EAN barcodes, decoding performance is guaranteed when

R≥15 mm.

With 13-digit JAN/UPC/EAN barcodes, decoding performance is guaranteed when

R≥20 mm.

Opticon

MSL 2000

Figure 5: Curvature

Conditions

Barcode Sample: OPTOELECTRONICS Test Sample

Distance: 110 mm from the exit window

Label: PCS = 0.9, Resolution = 0.26 mm, Quiet Zone = 10 mm

Angle: Skew Angle β = +15°

14

Page 15

8. Interface Specifications

8.1. Interface Connector

Opticon

MSL 2000

Specifications Manual

Name Pin

I/O Electrical Specifications

No.

VCC 1 - Power Supply: DC 3.0 to 3.6V

LASER EN 2 I CMOS Logic Level for Laser Control (ON/OFF: High = ON, Low = OFF)

POWER EN 3 I CMOS Logic Level for Power Supply (ON/OFF: High = ON, Low =

OFF)

SIGNAL 4 O CMOS Logic Level for Logic Output of Bar Code Image:

(High = Bars, Low = Spaces)

TIMING 5 O CMOS Logic Level for Synchronously-scanned Output:

(High = Left to Right, Low = Right to Left)

POLARITY 6 I CMOS Logic Level for Selecting Signal Polarity:

(High = Inverse Symbol, Low = Normal)

Filter SEL 1 7 I CMOS Logic Level for Selecting Analog Processing Filter

Filter SEL 2 8 I SEL1/2 (00 = Standard Mode, 01 = Mode 1, 10 = Mode 2, 11 = Mode

3)

TEST 9 I Set to Low or Open

GND 10 - Ground

Connector type: KYOCERA ELCO Corp. No. 04 6238 010 010 883+

10 PIN, 0.5mm Pitch, FCC Connector (Bottom Contact)

Note

1. When the input pin is left unconnected, it will be set to low by the pull-down

resistor.

2. For information on the filter mode specifications, read the following sections.

15

Page 16

8.1.1. Filter Mode Settings

A number of factors affect barcode quality, some of which cause them to be

unreadable. The readability of poor-quality barcodes can be improved by

correcting the defective parameters during signal processing to compensate

for the barcode defects.

There are several methods of signal processing. However, while one

processing method may improve the reading performance of one unreadable

barcode, it may degrade reading performance for another. For example, if you

set the signal processing sensitivity to high it may enable the reading of a

barcode with low modulation but degrade the reading performance of a

damaged barcode.

To optimize scanning performance for specific barcode parameters, the MSL

2000 provides four reading options (noise filter modes). By setting the scan

engine to one of these four modes, various types of poor-quality barcodes can

be read.

Opticon

MSL 2000

Specifications Manual

Filter Selection Filter Sel 1 Filter Sel 2 Scanning Performance

Mode 1 0 0 Standard mode

Mode 2 0 1 High detection mode

Mode 3 1 0 Low detection mode 1

Mode 4 1 1 Low detection mode 2

Mode 1: Standard Mode

The standard mode meets the performance criteria in this specification.

Mode 2: High Detection Mode

High detection mode broadens the analog signal processing frequency and

sets the detection range to high. It improves scanning performance of most

barcodes where the barcodes have poor ANSI Modulation grade.

Mode 3: Low Detection Mode 1

Low detection mode lowers the detection range and ignores noise degradation

during scanning. It improves scanning performance of barcodes with low

contrast (PCS) and low resolution as well as those at long distances.

Mode 4: Low Detection Mode 2

This low detection mode narrows the analog signal processing frequency and

lowers the detection range. It improves reading performance of barcodes that

have spots and voids or similar printing defects.

16

Page 17

Opticon

MSL 2000

Specifications Manual

8.1.2. Comparison of Scanning Performance with Different Filter Modes

a) Standard Barcode

St andard Bar C ode

1.0mm Mode1

Mode2

Mode3

Mode4

0.5mm Mode1

Mode2

Mode3

Mode4

0.25mm Mode1

Mode2

Mode3

Mode4

0.15mm Mode1

Mode2

Mode3

Mode4

0.127m m Mode1

Mode2

Mode3

Mode4

0

100 200 300 400 500 600 700 800

Depth of Field (mm)

Figure 6: Standard barcode scanning performance

17

Page 18

b) Modulation

Modulation will degrade with Mod. BC1 to 4

Modulat ion BC Scanning

Mod. BC1 Mode1

Mode2

Mod. BC2 Mode1

Mode2

Mod. BC3 Mode1

Mode2

Mod. BC4 Mode1

Mode2

Opticon

MSL 2000

Specifications Manual

c) Low PCS

0.25m m Mode1

0.15m m Mode1

0.127m m Mode1

0.1m m Mode1

Mode3

Mode3

Mode3

Mode3

0

50 100 150 200 250 300

Depth of Field (mm)

Figure 7: Modulation scanning performance

PC S=0.3

0

20 40 60 80 100 120 140 160 180

Depth of Field (mm)

Figure 8: Low PCS scanning performance

18

Page 19

8.2. Interface Circuit

Opticon

MSL 2000

Specifications Manual

Pin

Name Circuit Composition

No.

1 Vcc

VCC

LASER EN Input

2

High = ON (Minimum Vcc -0.5V)

Low = OFF (Maximum 0.5V)

Power EN Input

3

High = ON (Minimum Vcc -0.5V)

Low = OFF (Maximum 0.5V)

LASER EN

100K

VCC

POWER EN

100K

1K

1K

SIGNAL Output

4

High = Bars (Minimum Vcc -0.3V)

Low = Spaces (Maximum 0.3V)

VCC

Signal

19

Page 20

Opticon

MSL 2000

Specifications Manual

Pin

No.

5

6

Name Circuit Composition

TIMING Output

High = Left to Right (Minimum Vcc -0.3V)

Low = Right to Left (Maximum 0.3V)

Polarity Input

High = ON (Minimum Vcc -0.5V)

Low = OFF (Maximum 0.5 V)

VCC

Timing

VCC

1K

POLARITY

100K

Filter SEL 1 Input

7

High = ON (Minimum Vcc -0.5V)

Low = OFF (Maximum 0.5 V)

VCC

1K

Filter SEL1

100K

20

Page 21

Opticon

MSL 2000

Specifications Manual

Pin

No.

Filter SEL2 Input

8

High = ON (Minimum Vcc -0.5V)

Low = OFF (Maximum 0.5V)

9 Test Terminal (Open or GND)

10 GND

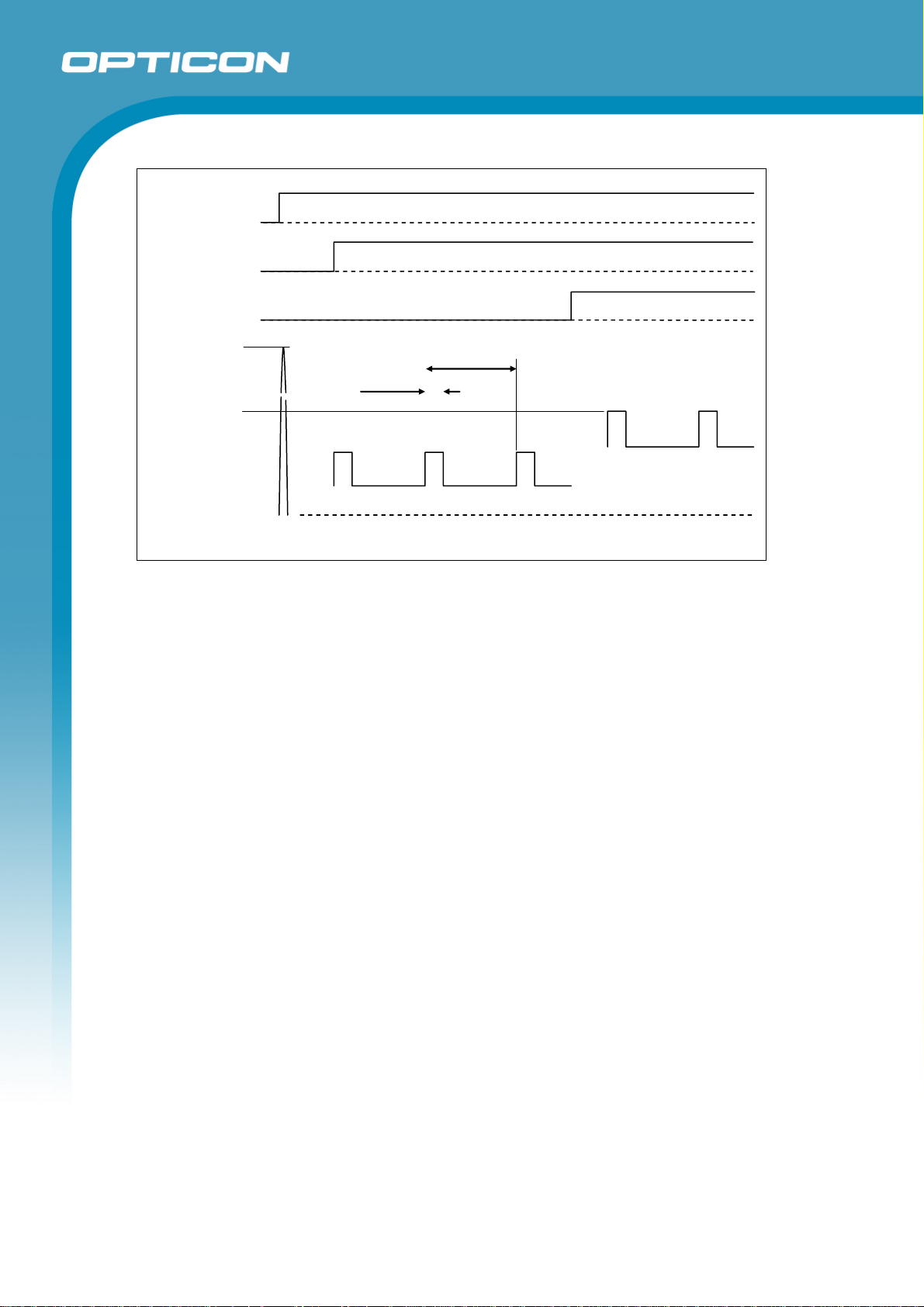

8.3. Timing Waveform

Name Circuit Composition

VCC

1K

Filter SEL2

100K

1. 2. 3. 4. 5. 6. 7.

VCC

POWER EN

LASER EN

SIGNAL

TIMING

ON

OFF

ON

OFF

N/F

N/F

N/F = Not Fixed

Figure 9: Timing waveform

Interface Timing

Timing Parameter Symbol Min Max Unit

1 - 2 POWER EN (ON) TPS 0 - ms

2 - 3 LASER EN (ON) TLS 10 - ms

2 – 4 TIMING (ON) TTUP - 60 ms

3 – 5 SIGNAL (ON) TSUP 0 100 ms

6 - 7 TIMING (Width) TTW 8.33 12.5 ms

21

Page 22

Specifications Manual

p

• The interface timings listed above are conditional on the quality of barcodes.

Barcodes must be positioned within the range of the depth of field.

• When there is a defect in a scanning circuit, the Timing signal does not satisfy the

Timing (Width) above. In order to detect a defect in the scanning circuit, monitor

the TIMING signal 60ms after POWER EN is ON.

• The TIMING (ON) and the SIGNAL (ON) are conditional on the POWER EN (ON)

and the LASER EN (ON) satisfying these specifications.

Note: Rising and falling time periods for “LASER EN” must be set within 100μs. The

laser may be damaged due to the anomalous emission of light if the time period is

longer than 100μs.

8.4. Laser Light Specifications

Laser Beam Emission Specifications

Item Condition Min. Typ. Max. Unit

Opticon

MSL 2000

Time Delayed LASER EN = ON

Start-up Time LASER EN = ON

Falling Time LASER EN = OFF

-

-

- -

100 200 μs

10 50 μs

1 μs

ON

LASER EN

LASER Output

OFF

Usual Laser

Out

ut

50

μ

200μs Max

s Max

Figure 10: Laser light specifications

90%

10%

1μs Max

22

Page 23

Specifications Manual

9. Serial Number

The serial number shown below is affixed to the scan engine.

Center Management Quick

Response Code (QR Code),

For administrative use

Right side Serial number

Bottom Product name

Figure 11: Serial number diagram

Serial numbers are seven-digit numbers and start from number 0000001 regardless of

batch.

Opticon

MSL 2000

23

Page 24

10. Packaging Specifications

10.1. Collective Packaging Specification

Size of the package (after assembly: 355 (W) x 290 (D) x 185 (H) mm

Opticon

MSL 2000

Specifications Manual

Figure 12: Individual packaging

Note: The “RO” mark labeled on the package tray or package box guarantees that the

applicable product has passed our test of RoHS restrictions compliance (the

restriction of the use of certain hazardous substances in electrical and electronic

equipment, 2002/95 EC). However, this document does not have any legal weight in

the European Union.

24

Page 25

11. Durability

11.1. Electrical Noise

No malfunction occurred when sinusoidal electrical noise (50 Hz–100 kHz, < 0.1 Vpp) was added to the power supply line.

Conditions

Barcode Sample: OPTOELECTRONICS Test Sample

PCS 0.9

Resolution 0.25 mm

Symbology 9-digit Code 39

Quiet Zone 10 mm

N/W Ratio 1:2.5

Distance Measured at any point in the range 50 to 150 mm away from

Angle α = 0° β = 15° γ = 0°

Curvature R = ∞

Power Supply Voltage 3.3 V

Opticon

MSL 2000

Specifications Manual

the exit window.

11.2. Shock

11.2.1. Drop Test (without packaging)

No malfunction occurred after the following drop test.

Drop Test: Fixed an MSL 2000 inside a dummy case and dropped it on its top,

bottom, front, back, left, right, top-left, top-right, bottom-left and bottom-right

sides from 1.8 meters above the concrete floor. Repeated this routine 10

times.

11.3. Vibration Strength

No malfunction occurred after the following vibration test.

Vibration test: Increase the frequency of the vibration from 12 Hz to 200 Hz with

accelerated velocity 3.3 G for over 10 minutes. Repeated this routine for 2 hours to Xdirection, 2 hours to Y-direction and 4 hours to Z-direction.

12. Reliability

MTBF (Mean Time Between Failures) of this product except for the laser diode and the

mirror motor scan unit is 30,000 hours.

Life cycle of the laser diode is 10,000 hours and that of the mirror motor scan unit is also

10,000 hours.

The estimate of MTBF and product life cycle is based on standard operation of the product

within the recommended temperature range and without extreme electronic or mechanical

shock.

25

Page 26

13. Regulatory Compliance

13.1. Laser Safety

The scan engine emits laser beams.

JIS C6802: 2005: Laser class 2

13.2. RoHS

RoHS: The restriction of the use of certain hazardous substances in electrical and

electronic equipment, 2002/95 EC.

14. Safety

Handle this product carefully. Do not deliberately subject it to any of the following.

14.1. Shock

Do not throw or drop the scan engine.

Opticon

MSL 2000

Specifications Manual

Do not place heavy objects on the cables.

14.2. Temperature Conditions

Do not use the scan engine at temperatures outside the specified range.

Do not pour boiling water on the scan engine.

Do not throw the scan engine into the fire.

Do not forcibly bend the cables at low temperatures.

14.3. Foreign Materials

Do not immerse the scan engine in liquids.

Do not subject the scan engine to chemicals.

14.4. Other

Do not plug/unplug the connectors before disconnecting the power.

Do not disassemble this product.

Do not place the product near a radio or a TV receiver, as the scan engine may cause

reception problems.

The scan engine may be damaged by voltage drops.

The scan engine may not perform properly in environments when placed near a

flickering light, such as a computer monitor, television, etc.

26

Page 27

15. Mechanical Drawing

Opticon

MSL 2000

Specifications Manual

Figure 13: Mechanical drawing

27

Loading...

Loading...