Page 1

2D CMOS Imager

MDI 1000

This manual provides specifications for the MDI 1000

2D imager scan engine.

Specifications Manual

Page 2

All information subject to change without notice.

Document History

Opticon

MDI 1000

Specifications Manual

Model Number:

Edition:

Date:

MDI 1000

4b

2008-10-02

Specification Number:

Original Spec Number:

SS06044

SS06020

Copyright 2008 Opticon. All rights reserved.

This manual may not, in whole or in part, be copied, photocopied, reproduced, translated or converted to any electronic or

machine readable form without prior written consent of Opticon.

Limited Warranty and Disclaimers

PLEASE READ THIS MANUAL CAREFULLY BEFORE INSTALLING OR USING THE

PRODUCT.

Serial Number

A serial number appears on all Opticon products. This official registration number is directly related to the device

purchased. Do not remove the serial number from your Opticon device. Removing the serial number voids the warranty.

Warranty

Unless otherwise agreed in a written contract, all Opticon products are warranted against defects in materials and

workmanship for two years after purchase. Opticon will repair or, at its option, replace products that are defective in

materials or workmanship with proper use during the warranty period. Opticon is not liable for damages caused by

modifications made by a customer. In such cases, standard repair charges will apply. If a product is returned under

warranty and no defect is found, standard repair charges will apply. Opticon assumes no liability for any direct, indirect,

consequential or incidental damages arising out of use or inability to use both the hardware and software, even if Opticon

has been informed about the possibility of such damages.

Packaging

The packing materials are recyclable. We recommend that you save all packing material to use should you need to

transport your scanner or send it for service. Damage caused by improper packaging during shipment is not covered by

the warranty.

Trademarks

Trademarks used are the property of their respective owners.

Opticon Inc. and Opticon Sensors Europe B.V. are wholly owned subsidiaries of OPTOELECTRONICS Co., Ltd., 12-17,

Tsukagoshi 4-chome, Warabi-shi, Saitama, Japan 335-0002. TEL +81-(0) 48-446-1183; FAX +81-(0) 48-446-1184

SUPPORT

USA Europe

Phone: 800-636-0090

Email: support@opticonusa.com Email: support@opticon.com

Web: www.opticonusa.com Web: www.opticon.com

2

Page 3

Opticon

MDI 1000

Specifications Manual

Contents

1. Abstract....................................................................................................................................... 6

2. Overview...................................................................................................................................... 6

3. Physical Features....................................................................................................................... 7

3.1. Dimensions ......................................................................................................................... 7

3.2. Weight ................................................................................................................................. 7

4. Environmental Specifications ...................................................................................................7

4.1. Operating Temperature and Humidity................................................................................. 7

4.2. Storage Temperature and Humidity .................................................................................... 7

4.3. Ambient Light Immunity....................................................................................................... 7

5. Electrical Specifications ............................................................................................................ 8

5.1. Absolute Maximum Ratings ................................................................................................ 8

5.2. Electrical Characteristics..................................................................................................... 8

5.3. Consumption Current with Default Settings ........................................................................ 8

5.4. Consumption Current with Standard Scanning Mode ......................................................... 9

5.5. Timing ............................................................................................................................... 10

5.6. Power Mode Transition ..................................................................................................... 11

6. Optical Specifications.............................................................................................................. 12

6.1. Laser Scan Specifications................................................................................................. 12

6.2. Imager Output ...................................................................................................................12

7. Technical Specifications.......................................................................................................... 13

7.1. Test Samples: 1D Symbologies ........................................................................................ 13

7.1.1. Code 39....................................................................................................................................13

7.1.2. JAN ..........................................................................................................................................13

7.2. Test Samples: 2D Symbologies ........................................................................................ 14

7.2.1. PDF417 ....................................................................................................................................14

7.2.2. Data Matrix...............................................................................................................................14

7.2.3. Maxi Code ................................................................................................................................14

7.2.4. QR Code (Model–2) .................................................................................................................14

7.3. Print Contrast Signal (PCS) .............................................................................................. 15

7.4. Minimum Resolution.......................................................................................................... 15

7.5. Scan Area and Resolution ................................................................................................ 16

7.5.1. Depth of Field...........................................................................................................................16

3

Page 4

Opticon

MDI 1000

Specifications Manual

7.6. Pitch, Skew, and Tilt.......................................................................................................... 17

7.6.1. Pitch Angle ...............................................................................................................................17

7.6.2. Skew Angle ..............................................................................................................................17

7.6.3. Tilt Angle ..................................................................................................................................17

7.7. Curvature .......................................................................................................................... 18

8. Aiming ....................................................................................................................................... 19

8.1. Aiming Patterns.................................................................................................................19

8.2. Aiming Guide..................................................................................................................... 20

9. Interface Specifications ...........................................................................................................20

9.1. Interface Signals ...............................................................................................................20

9.2. Interface Circuit ................................................................................................................. 22

10. Integration Specifications........................................................................................................ 23

10.1. Camera Module and Decoder Board ................................................................................ 23

10.2. Connection between a Camera Module and Decoder Board............................................ 23

10.3. Connection between a Decoder Board and a Host System .............................................. 23

11. Serial Number........................................................................................................................... 24

12. Packaging Specifications........................................................................................................25

12.1. Collective Packaging Specification ................................................................................... 25

13. Durability................................................................................................................................... 26

13.1. Electrical Noise ................................................................................................................. 26

13.1.1. Scanning Symbologies ............................................................................................................26

13.1.2. Acquisition of Image Data........................................................................................................26

13.2. Shock ................................................................................................................................ 27

13.2.1. Drop Test (with individual packaging)......................................................................................27

13.3. Vibration ............................................................................................................................ 27

14. Reliability................................................................................................................................... 27

15. Regulatory Compliance ...........................................................................................................28

15.1. LED Safety ........................................................................................................................ 28

15.2. RoHS................................................................................................................................. 28

16. Safety......................................................................................................................................... 28

16.1. Shock ................................................................................................................................ 28

16.2. Temperature Conditions.................................................................................................... 28

16.3. Foreign Materials .............................................................................................................. 28

16.4. Other ................................................................................................................................. 28

17. Mechanical Drawing.................................................................................................................29

4

Page 5

Specifications Manual

17.1. Camera Module................................................................................................................. 29

17.2. Decoder Board .................................................................................................................. 30

Table of Figures

Figure 1: Timing Chart................................................................................................................ 10

Figure 2:Power mode transition...................................................................................................11

Figure 3: The reading range in millimeters ................................................................................. 16

Figure 4: Angles.......................................................................................................................... 17

Figure 5: Curvature..................................................................................................................... 18

Figure 6: Aiming patterns............................................................................................................ 19

Figure 7: Camera module serial number .................................................................................... 24

Figure 8: Decoder board serial number...................................................................................... 24

Figure 9: Packaging.................................................................................................................... 25

Figure 10: Camera module......................................................................................................... 29

Figure 11: Decoder board ........................................................................................................... 30

Opticon

MDI 1000

5

Page 6

1. Abstract

This manual provides specifications for the MDI 1000 2D imager scan engine.

2. Overview

The MDI 1000 includes the following features:

• A 1.3 million-pixel (SXGA) CMOS area image sensor and a compact camera

module with wide-angle lens that enables scanning of high-resolution and wide

symbologies.

• Wide-lens optics that make it possible to scan wider symbologies from up close.

• A small, high-performance, energy-saving decoder that processes data of 1.3

million pixels and realizes smoother scanning of both linear (1D) and 2D

symbologies.

• Supported symbologies

Opticon

MDI 1000

Specifications Manual

Linear (1D) 2D

JAN/UPC/EAN, incl. add-on Aztec Code

Codabar/NW-7 Data Matrix (ECC 0-140, ECC200)

Code 39 Maxi Code (mode 0–5)

Code 93 Micro PDF417

Code 128 Micro QR Code

Composite Codes: (incl. CC-A/B/C) PDF417

GS1-128 (EAN/UCC-128) QR Code

GS1 DataBar (RSS)

IATA

Industrial 2of5

Interleaved 2of5

MSI/Plessey

• The ability to change symbology settings, scanning settings, communication

settings, and other feature settings by sending commands.

• Command input and image data output between the host system and the MDI

1000 is transmitted using serial communication.

• The MDI 1000 complies with the Restriction of Hazardous Substances (RoHS).

6

Page 7

3. Physical Features

3.1. Dimensions

Camera module: W 21.5 mm x D 14.2 mm x H 11.8 mm

Decoder board: W 25.2 mm x D 39.0 mm x H 4.2 mm

3.2. Weight

Camera module: 3.9 grams (max.)

Decoder board: 3.8 grams (max.)

4. Environmental Specifications

4.1. Operating Temperature and Humidity

Temperature: -20 to 55° C

Humidity: 5 to 90% RH

Opticon

MDI 1000

Specifications Manual

4.2. Storage Temperature and Humidity

Temperature: -25 to 70° C

Humidity: 5 to 90% RH

4.3. Ambient Light Immunity

Decoding performance is guaranteed when the range of illumination on a barcode

surface is between zero and the following values:

Incandescent light to 10,000 lx

Fluorescent light to 10,000 lx

Sunlight to 100,000 lx

Conditions

Barcode Sample: PDF417 with 0.254mm resolution

Distance: 110 mm from the mask of the camera module

Angle: α = 0°, β = +15°, γ = 0°

Curvature: R = ∞

Power Supply Voltage: 3.3 V

Scanning performance is guaranteed as long as direct light or a reflection from a light

source does not impact the light detection range of the MDI 1000.

Note: α, β and γ respectively represent pitch, skew and tilt. Please see section 7 for how

these values are defined.

7

Page 8

5. Electrical Specifications

5.1. Absolute Maximum Ratings

Parameter Symbol Value Unit

Power supply voltage (VCC to GND) VCC 3.9 V

Input voltage VI -0.3 to VCC +0.3 V

Output voltage IO ±4 mA

5.2. Electrical Characteristics

VCC =3.3 V, TA=25° C

Parameter Symbol Condition Min Typ Max Unit

Opticon

MDI 1000

Specifications Manual

Range of power supply voltage1 V

Rush current2 I

H level VIH 2.4 - V

L level V

H level VOH I

Output voltage

L level V

3.15 3.3 3.45 V

cc

- 6 7 A

PK

+0.3 V Input voltage

cc

-0.3 0.9 V

IL

-4 mA 2.8 - - V

OH =

IOL = 4 mA - - 0.5 V

OL

5.3. Consumption Current with Default Settings

When the scan engine is configured to “Prior snapshot ON” and “Snapshot and decoding

parallelism ON”.

Parameter Symbol Min Typ Max Unit

Operating current IOP - 310 410 mA

Stand-by current I

Power-down current3 I

1

Input connector.

2

Vcc is supplied by a direct-current power of 10 A and is measured using a current probe. If it is necessary to

decrease impressed current, please supply the power slowly.

3

When configured with the SLEEP command or power-down mode.

- 125 155 mA

STB

- 25 50 mA

SLP

8

Page 9

5.4. Consumption Current with Standard Scanning Mode

When the scan engine is configured to “Prior snapshot OFF” and “Snapshot and

decoding parallelism OFF”.

Parameter Symbol Min Typ Max Unit

Operating current IOP - 250 390 mA

Stand-by current I

Power-down current4 I

4

When configured with the SLEEP command or power-down mode.

- 90 110 mA

STB

- 10 25 mA

SLP

Opticon

MDI 1000

Specifications Manual

9

Page 10

5.5. Timing

Opticon

MDI 1000

Specifications Manual

Figure 1: Timing Chart

Conditions

Timing Chart

Input Voltage 3.3 V

Down peak 2.36 V / 1.00 V fall after 0.7 ms

Peak 2.7 A during 0.01 ms after 0.7 ms

10

Page 11

5.6. Power Mode Transition

Opticon

MDI 1000

Specifications Manual

Figure 2:Power mode transition

When in Power Down mode, the MDI 1000 automatically enters the power-down state

from Power On.

When the MDI 1000 is in Power Down mode and the MDI 1000 is switched to a Standby

state by sending a CTS signal or AIM/WUPn signal, or there is no event that causes the

MDI 1000 to switch to another mode, the MDI 1000 enters Power Down mode after the

time-out.

If the MDI 1000 enters a power-down state while using USB_VCP as an interface, it may

cause defects that affect the operation of a Windows device driver.

11

Page 12

6. Optical Specifications

6.1. Laser Scan Specifications

Parameter Specification Unit

Opticon

MDI 1000

Specifications Manual

Scan method CMOS area sensor

(grayscale)

Scan rate 30 fps

Range of readable pixels 1280 (H) x 1024 (V) pixel

Center wave length of aiming LED (2 green LEDs) 527 nm

Center wave length of LED for Lighting (4 red LEDs) 630 nm

View angle Horizontal: 47

Vertical: 37.5

-

°

6.2. Imager Output

Item Specification

Image data format Windows Bitmap, JPEG, TIFF

Shades of gray 256, 16, 2

Range of output image Select in horizontal and vertical scale.

Resolution of output image Full, 1/2, 1/3, 1/4

Interface of output image RS-232C, USB-VCP

Transmission time USB-VCP (Full speed) About 4 sec

RS-232C (115.2 kbps) About 120 sec

Conditions:

Shades of gray: 256

Resolution: full

12

Page 13

Specifications Manual

7. Technical Specifications

The conditions for technical specifications are as follows, unless otherwise specified in each

section.

Conditions

Opticon

MDI 1000

Ambient temperature and

humidity

Ambient light 1000 to 1500 lx (on the surface of a barcode)

Light source 3 wavelength inverter fluorescent light

Power supply voltage 3.3 V

Scan performance 70% and higher

Barcode sample Refer to the chart below

21º C/70º F, 60% RH

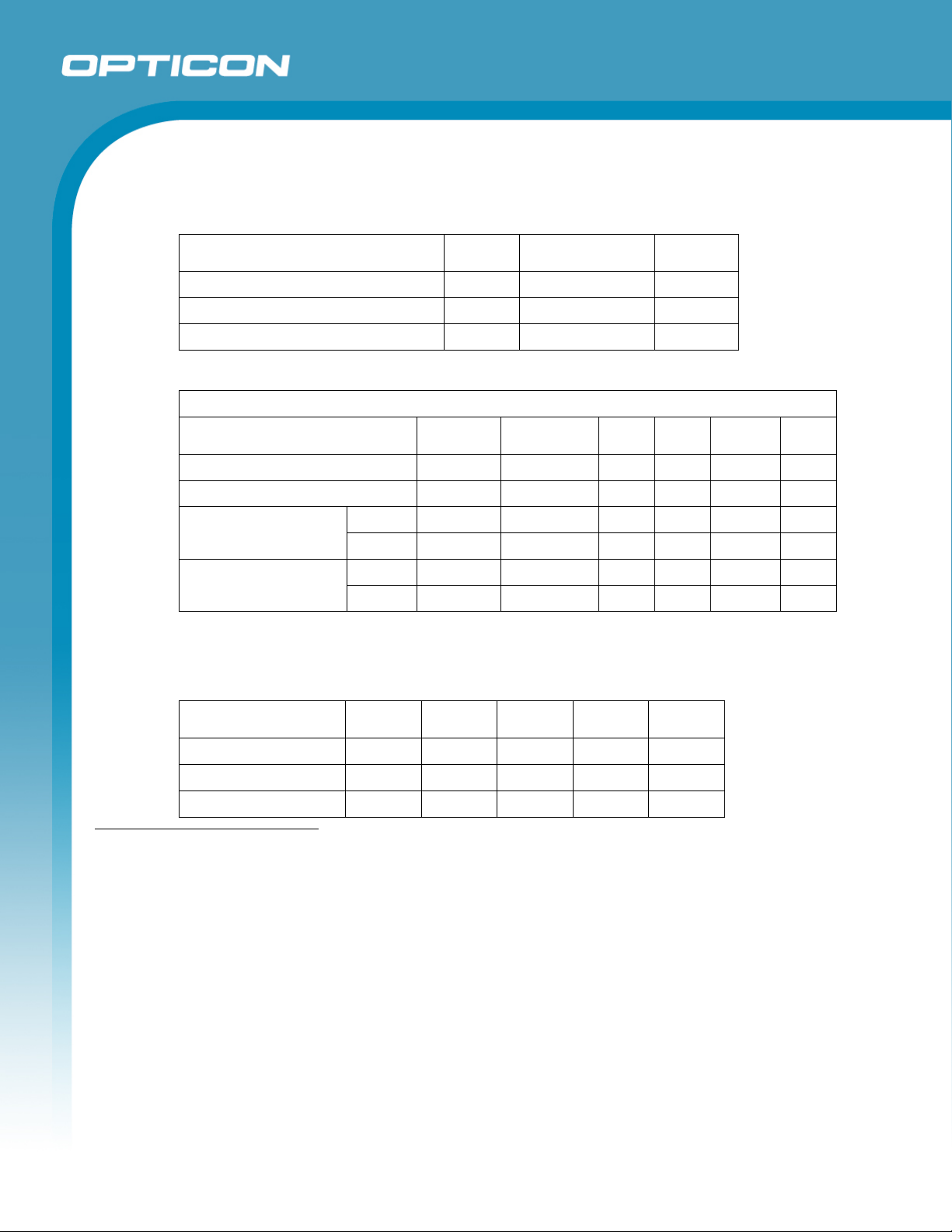

7.1. Test Samples: 1D Symbologies

7.1.1. Code 39

Resolution Symbology PCS Size (mm) Digits

0.127 mm Code 39 0.9 11 x 10 4

0.254 mm Code 39 0.9 14 x 10 2

0.508 Code 39 0.9 29 x 25 2

7.1.2. JAN

Resolution Symbology PCS Size (mm) Digits

0.26 mm 8-digit JAN 0.9 17.5 x 15.5 8

0.26 mm 13-digit JAN 0.9 25 x 19 13

Barcode samples with 0.127 mm and 0.26 mm resolution are

OPTOELECTRONICS test samples. Other charts are printed by a regular printer.

N/W ratio 1:2.5

Angle α = 0°, β = 15°, γ = 0°

Curvature R = ∞

13

Page 14

7.2. Test Samples: 2D Symbologies

7.2.1. PDF417

Resolution Error Correction PCS Size (mm) Characters

0.127 mm Level-4 0.9 13 x 8 17

0.254 mm Level-4 0.9 26 x 16 17

0.339 mm Level-4 0.9 35 x 22 17

Charts are printed by a regular printer.

Horizontal to Vertical ratio is 3:1.

Opticon

MDI 1000

Specifications Manual

7.2.2.

7.2.3.

7.2.4.

Data Matrix

Resolution Model PCS Size (mm) Characters

0.169 mm ECC200 0.9 4 x 4 40

0.212 mm ECC200 0.9 5 x 5 40

0.339 mm ECC200 0.9 8 x 8 40

Charts are printed by a regular printer.

Maxi Code

Resolution Model PCS Size (mm) Characters

0.889 mm Standard 0.9 26 x 26 29

Charts are printed by a regular printer.

QR Code (Model–2)

Resolution Error Correction PCS Size (mm) Characters

0.169 mm M 0.9 5 x 5 44

0.212 mm M 0.9 6 x 6 44

0.339 mm M 0.9 10 x 10 44

Charts are printed by a regular printer.

14

Page 15

7.3. Print Contrast Signal (PCS)

0.45 (MRD 32%) or higher (over 70% of reflectivity of space and quiet zone).

Reflectance of white bar-Reflectance of black bar

PCS=

Reflectance of white bar

Scanning performance may decline if dirt or scratches mar the optical window. Keep the

optical window clean.

7.4. Minimum Resolution

Resolution Symbology

0.127 mm Code 39 & PDF417

0.169 mm Data Matrix & QR Code

0.889 mm Maxi Code

Opticon

MDI 1000

Specifications Manual

15

Page 16

7.5. Scan Area and Resolution

7.5.1. Depth of Field

The depth of field is measured from the mask of a camera module.

Opticon

MDI 1000

Specifications Manual

Figure 3: The reading range in millimeters

*1 Typical value of depth of field (horizontal and vertical).

16

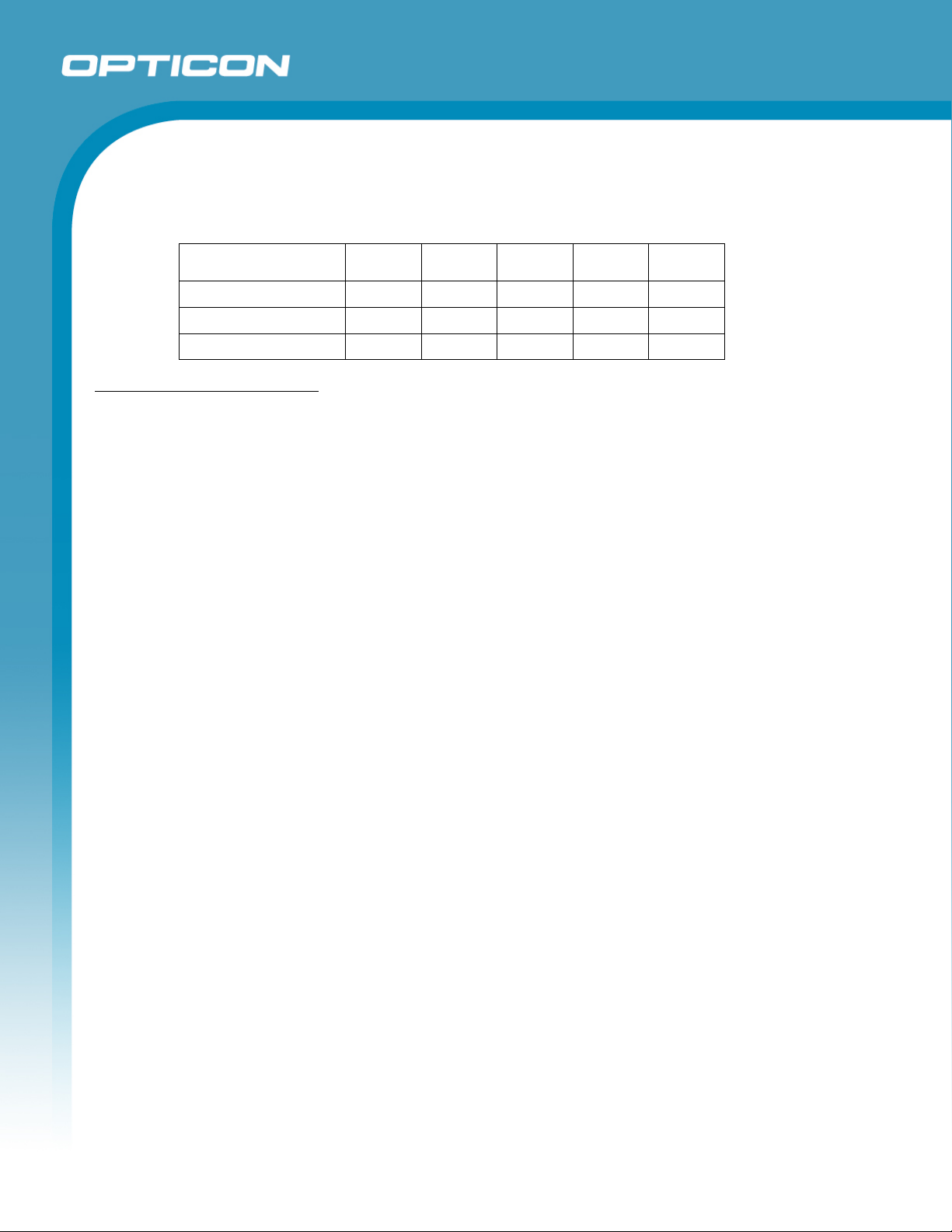

Page 17

The size of barcodes does not include quiet zones.

Symbology Resolution (mm) Decode Depth (mm) PCS

Opticon

MDI 1000

Specifications Manual

Code 39 0.127

Data Matrix 0.212

MaxiCode 0.889 70–230 0.9

PDF417 0.127

QR Code 0.212

7.6. Pitch, Skew, and Tilt

7.6.1. Pitch Angle

α = ±50°

7.6.2.

7.6.3.

Skew Angle

Skew angle: β = ±60°

Tilt Angle

γ = 360°

0.254

0.508

0.339

0.339

0.339

95–135

65–175

50–245

95–130

75–165

95–135

50–215

90–135

70–170

0.9

0.9

0.9

0.9

-

+

-

Figure 4: Angles

17

+

+-

Page 18

Conditions

Barcode Sample: Code 39 and PDF417 with 0.245 mm resolution

Distance 110mm from the mask of the camera module

Angle

Curvature: R = ∞

(The calculation of pitch and tilt angles is based on the skew angle

formula being β = +15°)

Notes

When a barcode is printed on glossy paper or a card case, it may cause difficulties in

scanning due to the reflection of red LEDs. To improve scanning performance under

these circumstances, scan the barcode with a scan angle of 15 degrees or with red

LEDs turned off. When scanning a barcode with red LEDs turned off, confirm that the

ambient lighting intensity is higher than 1000 lux, or scanning performance may

decline. Scanning performance may also decline if room lights reflect on the camera.

7.7. Curvature

With 8-digit JAN/UPC/EAN barcodes, decoding performance is guaranteed when

R≥15 mm.

Opticon

MDI 1000

Specifications Manual

With 13-digit JAN/UPC/EAN barcodes, decoding performance is guaranteed when

R≥20 mm.

Figure 5: Curvature

Conditions

Barcode Sample: JAN barcode

Distance: 110 mm from the mask of the camera module

Angle:

α = 0°, β =+15°, γ = 0°

18

Page 19

8. Aiming

8.1. Aiming Patterns

Opticon

MDI 1000

Specifications Manual

Figure 6: Aiming patterns

Notes

Aiming is a guide to assist with scanning. An aiming pattern does not indicate the exact

scannable width or distance between a scanner and a barcode.

19

Page 20

8.2. Aiming Guide

• The focal point is where two central LED light patterns (green and square-shaped)

overlap—where two dots meet.

• To scan a barcode within the aiming range, make sure that two central LED light

patterns overlap, then place the center of the overlapping LED light patterns on

the center of the barcode.

• To scan a barcode wider than a width of the aiming range, aim at the barcode

from further away. Make sure that the barcode is between two LED light patterns

on both the right and left.

9. Interface Specifications

9.1. Interface Signals

Connector used was produced by Molex Incorporated.

Product No.: 52437-3071 (bottom contact)

Opticon

MDI 1000

Specifications Manual

No. Signal State Note

Name Function I/O

1 DWNLDn Download control

signal

2 Vcc Power input In

3 GND System ground

4 RxD Received data

signal

5 TxD Transmitted data

signal

6 CTS Communication

control signal from

host system

7 RTS Communication

control signal to

host system

8 POWERDWN Power down of MDI

1000

9 BUZZER Activate external

buzzer

10 GR_LEDn Good read Out L: LED On

11

AIM/WUPn

When in power

down state:

recovery from

Power Down state

In L: Download mode

H: Normal operation

In Asynchronous data from the

Out Asynchronous data to the host

In Request for a data output from

Out Request for a data output from

Out L: Normal

H: Power Down

Out Possible to change tones and

H: LED Off

In L: Recover from

Power Down

H: No action

Check the signal as soon as

the power is supplied and

enables updates of software.

host system

system

the host system

the MDI 1000

sound pressure by sending

PWM signals.

20

Page 21

Opticon

MDI 1000

Specifications Manual

No. Signal State Note

Name Function I/O

When not in Power

Down state: Aiming

control

12 TRIGn Trigger on In L: Start Operation

13 Reserved Out Not connected

14 GND System ground

15 Reserved In Not connected

16 GND System ground

17 Reserved In Not connected

18 Vcc Power input In Not connected

19 Reserved Out Not connected

20 Reserved In Not connected

21 Reserved Out Not connected

22 GND System ground

23 USB+ In/Out USB 1.1

24 USB- In/Out

25 GND System ground

26 Reserved Power On In Not connected

27 USB_Vcc5 USB Power On In Monitoring USB bus power

28 EX_ILLUMn Out L: External

29 Reserved In Not connected

30 Reserved In Not connected

In L: Aiming LED On

H: Aiming LED Off

H: No action

Illumination On

H: External

Illumination Off

Prioritize aiming control of MDI

1000 during the scanning

operation.

Command signal for reading

images and decoding

operation.

supply

Control of an external light

source.

21

Page 22

9.2. Interface Circuit

Opticon

MDI 1000

Specifications Manual

Signal Circuit Configuration

DWNLDn, AIM/WUPn, TRIGn

CTS, RxD

POWERDWN, EX_ILLUMn, GR_LEDn, RTS, TxD,

BUZZER

USB-

Vcc

100K

Vcc

USB+

22

47

1.5K

Vcc

47

Page 23

10. Integration Specifications

10.1. Camera Module and Decoder Board

The nonvolatile memory on the MDI 1000 decoder board contains information concerning

the sensor chip for a MDI 1000 camera module. This information is vital to the scanning

and image acquisition operations of the MDI 1000. The camera module and decoder

board are a set and must both be integrated into your products.

10.2. Connection between a Camera Module and Decoder Board

Use a cable developed in accordance with specifications provided by the connector

manufacturer to connect the MDI 1000 camera module with the MDI 1000 decoder board.

Opticon

MDI 1000

Specifications Manual

Manufacturer

Product No 54809-3373 (33-pin)

Cable Length 70 mm (maximum)

Signal Connection Connect Camera Module 1-pin and Decoder Board 33-pin using a single-sided

Molex Incorporated

FPC.

The cable with connector can also be obtained at Opticon.

• Cable length 49 mm: Product No. 11575.

• Cable length 69 mm: Product No. 11620.

10.3. Connection between a Decoder Board and a Host System

Use a cable developed in accordance with the following specifications provided by the

connector manufacturer to connect the MDI 1000 decoder board with a host system.

Manufacturer

Product No

Cable Length

The cable with connector can also be obtained at Opticon:

• Cable length 76 mm: Product No. 11785.

Molex Incorporated

98266-0319

76 mm (maximum)

23

Page 24

Specifications Manual

11. Serial Number

The serial number is written on the following labels that are attached to camera modules and

decoder boards.

Opticon

MDI 1000

Figure 7: Camera module serial number Figure 8: Decoder board serial number

Center: Administration 2D Code (QR Code)

Right side: Model name and serial number

The serial number is a seven-digit number that starts from 0000001 regardless of batch.

24

Page 25

12. Packaging Specifications

12.1. Collective Packaging Specification

335 mm (W) × 290 mm (D) × 185 mm (H)

Opticon

MDI 1000

Specifications Manual

Figure 9: Packaging

The model number, the number of products in the box, and the name of the manufacturer

must be displayed on the packing box.

Note: The “RO” mark labeled on the package tray or package box guarantees that the

applicable product has passed our test of RoHS restrictions compliance (the restriction of

the use of certain hazardous substances in electrical and electronic equipment, 2002/95

EC). However, this document does not have any legal weight in the European Union.

25

Page 26

13. Durability

13.1. Electrical Noise

13.1.1. Scanning Symbologies

Opticon

MDI 1000

Specifications Manual

No malfunction occurred when sinusoidal electrical noise (50 Hz -100 kHz, <0.1

Vp-p) was added to the power supply line.

Conditions

Scan method: Continuous scanning

Barcode Sample:

Resolution: 0.254 mm

Symbology: PDF417

Distance: 110 mm from the mask of the camera module

Angle: α = 0° β = 15° γ = 0°

Curvature: R = ∞

Power Supply Voltage: 3.3 V

13.1.2. Acquisition of Image Data

There were no outstanding noises or misalignments in acquired images when

sinusoidal electrical noise (50 Hz to 100 kHz, <20 mVp-p) was added to the power

supply line.

Notes

There may be a case where the electrical noise affects the quality of captured

images. The signal processing system of the MDI 1000 is especially designed for

the purpose of scanning symbologies, not for the acquisition of image data.

Therefore, the quality of images captured by the MDI 1000 may be lower than that

of digital cameras in general.

26

Page 27

13.2. Shock

13.2.1. Drop Test (with individual packaging)

No malfunction occurred after the following drop test.

Shock Test: Put the MDI 1000 inside an appointed dummy case and dropped it on

its top, bottom, front, back, left, right, top-left, top-right, bottom-left and bottomright from the height of 1.8 m to a concrete floor. The shock test was done once in

each direction.

Barcode Sample:

Resolution: 0.254 mm

Symbology: PDF417

Distance: 110 mm from the mask of the camera module

Angle: α = 0° β = 15° γ = 0°

Curvature: R = ∞

Power Supply Voltage: 3.3 V

Opticon

MDI 1000

Specifications Manual

13.3. Vibration

No malfunction occurred after the following vibration test.

Vibration Test: Increase the frequency of the vibration from 12 Hz to 200 Hz with

accelerated velocity 3.3 G for over ten minutes. Continued this routine for two hours in X

direction, two hours in Y direction, and four hours in Z direction.

Barcode Sample:

Resolution: 0.254 mm

Symbology: PDF417

Distance: 110 mm from the mask of the camera module

Angle: α = 0° β = 15° γ = 0°

Curvature: R = ∞

Power Supply Voltage: 3.3 V

14. Reliability

MTBF (Mean Time Between Failures) of this product is 50,000 hours.

The estimate of MTBF is based on standard operation of the product within the recommended

temperature range and without extreme electronic or mechanical shock.

27

Page 28

15. Regulatory Compliance

15.1. LED Safety

All LED-based products are LED class 1 and are safe under reasonably foreseeable

operating conditions. Do not stare into the beam.

• JIS C6802: 2005: Class 1

• IEC 60825-1+A2: 2001 Class 1

15.2. RoHS

RoHS: The restriction of the use of certain hazardous substances in electrical and

electronic equipment, 2002/95 EC.

16. Safety

Handle this product carefully. Do not deliberately subject it to any of the following.

16.1. Shock

• Do not throw or drop the scan engine.

Opticon

MDI 1000

Specifications Manual

• Do not place heavy objects on the cables.

16.2. Temperature Conditions

• Do not use the scan engine at temperatures outside the specified range.

• Do not pour boiling water on the scan engine.

• Do not throw the scan engine into the fire.

• Do not forcibly bend the cables at low temperatures.

16.3. Foreign Materials

• Do not immerse the scan engine in liquids.

• Do not subject the scan engine to chemicals.

16.4. Other

• Do not plug/unplug the connectors before disconnecting the power.

• Do not disassemble this product.

• Do not use the scanner near a radio or a TV receiver. It may cause reception

problems.

• The scan engine may be damaged by voltage drops.

• The scan engine may not perform properly in environments when placed near a

flickering light, such as a computer monitor, television, etc.

28

Page 29

17. Mechanical Drawing

17.1. Camera Module

Opticon

MDI 1000

Specifications Manual

Figure 10: Camera module

29

Page 30

17.2. Decoder Board

Opticon

MDI 1000

Specifications Manual

Figure 11: Decoder board

30

Loading...

Loading...