Page 1

User’s Manual

LH2 Fixed Position 2D Imager

25-ULH2R101-01 Preliminary

This version of the manual supports rmware 2232 and greater. Release date: Mar 05

Page 2

Statement of Agency Compliance

The LH2 has been tested for compliance with FCC regulations and

was found to be compliant with all applicable FCC Rules and Regu-

lations.

IMPORTANT NOTE: To comply with FCC RF exposure compliance

requirements, this device must not be co-located or operate in

conjunction with any other antenna or transmitter.

CAUTION: Changes or modications not expressly approved by

the party responsible for compliance could void the user’s authority

to operate the equipment.

The LH2 has been tested for compliance to CE standards and

guidelines and was found to conform to applicable CE standards,

specically the EMC requirements EN 55024, ESD EN 61000-4-2,

Radiated RF Immunity EN 61000-4-3, ENV 50204, EFT EN 61000-

4-4, Conducted RF Immunity EN 61000-4-6, EN 55022, Class B

Radiated Emissions, and Class B Conducted Emissions.

The LH2 can be set to use targeting lasers. If the targeting lasers are

activated, do not stare into the beams. The LH2’s targeting lasers

have been rated as Class IIa Lasers by IEC 60825-1.

The LH2 has been tested by an independent electromagnetic compat-

ibility laboratory in accordance with the applicable specications and

instructions.

Page 3

LH2 User’s Manual

Copyright © 2004 the Opticon, Inc..

All Rights Reserved.

The software described in this manual may only be used in accordance with the terms of its license

agreement.

No part of this publication may be reproduced in any form or by any means without written permission

from the Opticon, Inc. This includes electronic or mechanical means such as photocopying or recording

in information storage and retrieval systems.

NO WARRANTY. This technical documentation is provided AS-IS. Further, the documentation does

not represent a commitment on the part of Opticon, Inc. Opticon, Inc. does not warrant that it is

accurate, complete or error free. Any use of the technical documentation is at the risk of the user.

Opticon reserves the right to make changes in specications and other information contained in this

document without prior notice, and the reader should in all cases consult Opticon to determine whether

any such changes have been made. Opticon shall not be liable for technical or editorial errors or

omissions contained herein; nor for incidental or consequential damages resulting from the furnishing,

performance, or use of this material. Opticon, Inc. does not assume any product liability arising out of or

in connection with the application or use of any product or application described herein.

NO LICENSE. No license is granted, either by implication, estoppel, or otherwise under any intellectual

property rights of The Opticon, Inc. Any use of hardware, software and/or technology of the Opticon, Inc.

is governed by its own agreement.

All other product names mentioned in this manual may be trademarks of their respective companies and

are hereby acknowledged.

The software and/or products of Opticon, Inc. include inventions that are patented or that are the subject

of patents pending.

Page 4

Table of Contents

Organization of this Manual 8

Chapter 1 9

Introduction and Getting Started 9

Product Overview 9

Quick Start-Up Procedure 10

Chapter 2 13

Technical Specication 13

OPTICAL 13

ELECTRICAL 13

ENVIRONMENTAL 14

PHYSICAL 14

SYMBOLOGIES 14

PINOUTS 14

ORDERING INFORMATION 15

Chapter 3 17

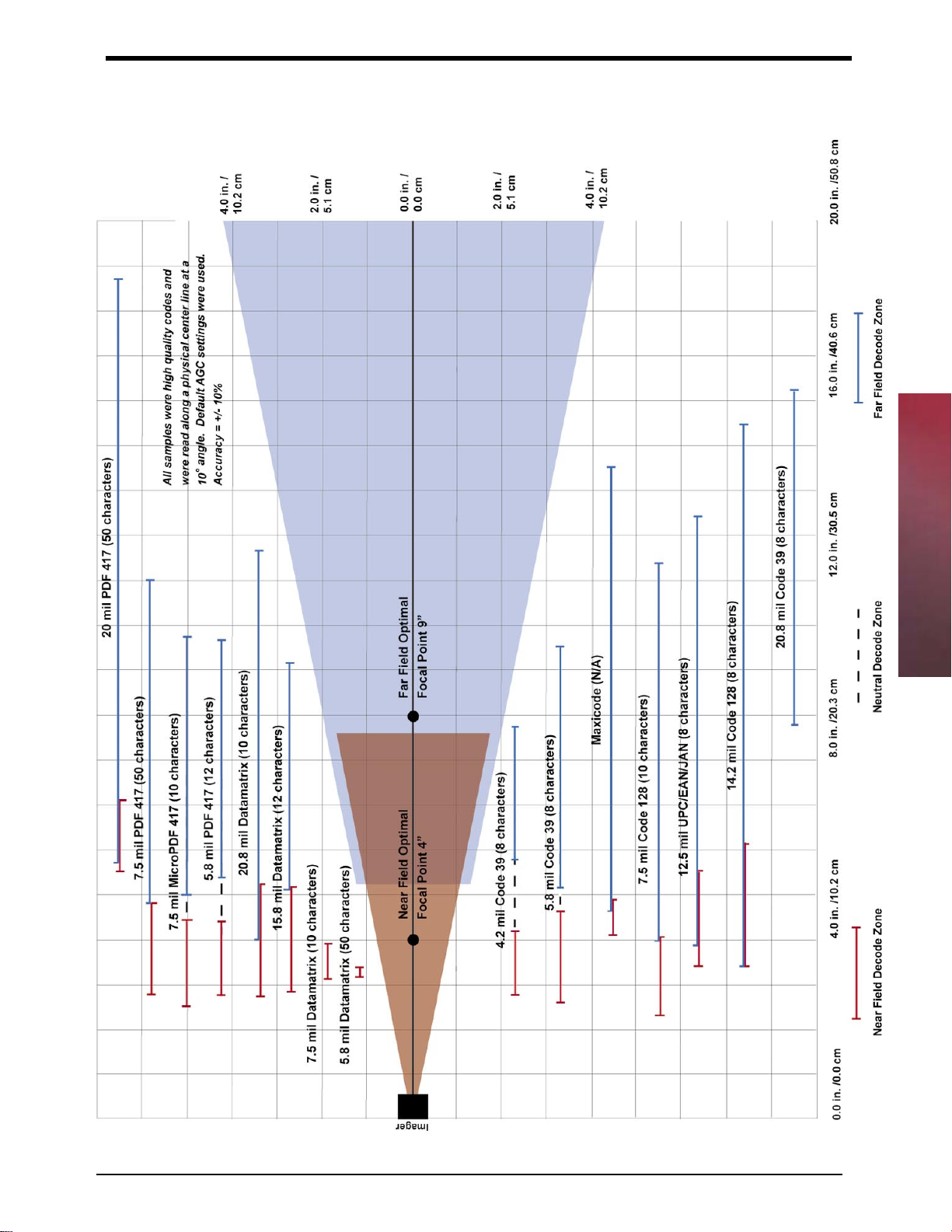

Positioning the Imager for Optimal Performance 17

Achieving Optimum Performance 17

1) Distance to the Bar Code 17

Focal Distance 17

Depth-of-Field 17

LH2 Decode Zone 19

2) Avoiding Specular Reection 20

3) Quality Bar Code Labels 20

Barcode Readability Index 20

Code Readability Index Rule: 21

4) Imager Field of View & Resolution 22

Left Trigger Optimization Matrix 27

Page 5

Right & Left Trigger Optimization Matrix 27

Continuous Trigger Optimization Matrix 28

Right Trigger Optimization Matrix 28

Application Notes 29

Tips for Achieving High Throughput 29

Tips for Insuring Highest Data Integrity 29

Chapter 4 31

Conguring the Imager 31

Programming Menus & Commands 31

Default Settings 31

RS-232 Interface Setting Defaults 31

Symbology Defaults: 32

Control Setting Defaults: 32

Chapter 5 33

Application Engineering Support 33

Technical Assistance and Support 33

Common Causes of Poor Performance 33

Modied and/or Customized Imagers 34

Chapter 6 35

Imager Servicing and Maintenance 35

How to use the Appendix? 37

Appendix A 37

Programming Menus & Commands 37

Programming Bar Codes 38

CRB Files 39

Example: test1.crb 40

General Options 41

Reset to Factory Defaults 41

Save Settings 42

Page 6

Clear All CodeXML Rules 43

Reader ID & Firmware Version 44

Example: test2.crb 45

Barcode Readability Index 46

Software Trigger 48

Read Near and Far Field 48

Read Near Field only 48

Read Far Field only 48

Symbology Options 49

Aztec Symbology 49

Codabar Symbology 50

Codablock F Symbology 51

Code 128 Symbology 52

Code 93 Symbology 53

Code 39 Symbology 54

Composite Symbologies 56

Data Matrix Symbology 57

Interleaved 2 of 5 Symbology 58

Maxicode Symbology 60

Micro PDF 417 Symbology 61

MSI Plessy Symbology 62

PDF 417 Symbology 63

Postal Symbologies 64

QR Code Symbology 66

RSS Symbology 68

UPC / EAN / JAN Symbologies 70

Communication Parameters 72

Baud Rate 72

Data Bits 74

Page 7

Stop Bits 75

Parity 76

Hardware Settings 77

Beep Volume 77

Laser Targeting 78

Laser Brightness 79

Left Key Programming 80

Right Key Programming 81

Continuous Scan 82

Continuous Scan 82

Continuous Scan - Trigger Delays 84

Duplicate Scan Delay 85

Advance Settings 86

Decode Time & LED’s for Non Standard Inks 86

Targeting Zone Tolerance 88

Windowing 90

VGA & SXGA Mode 92

Prex & Sufx Settings 93

Prex Settings 93

Sufx Settings 95

Optimization Matrix 97

SET 1 - Serial Commands for a Single Trigger 99

SET 1 - Barcodes for a Single Trigger 99

SET 2 - Barcodes for Continuous Trigger 100

SET 2 - Serial Commands for Continuous Trigger 100

Appendix B 101

Mechanical Layout 101

Page 8

Organization of this Manual

This manual provides the necessary instructions for installing and using an Opticon LH2 Fixed Position

Imager. The manual is organized as follows:

Chapter 1 Introduction and Getting Started

Describes the general operation of a LH2 Fixed Position Imager. Also provides a Quick

Start-Up Procedure that allows you to begin using the imager immediately.

Chapter 2 Technical Specications

Provides complete specications, including mechanical details, optical performance,

RS232 communications and other technical data.

Chapter 3 Positioning the Imager for Optimal Performance

Provides detailed instructions and tips for mounting and positioning the imager to

obtain the best scanning performance. Application Notes describe guidelines for

maximizing specic characteristics.

Chapter 4 Conguring the Imager

Describes how various parameters can be programmed to customize the imager for

your specic application.

Chapter 5 Application Engineering Support

Discusses the most common questions and concerns when adapting a LH2 Fixed

Position Imager in your application.

Chapter 6 Imager Servicing and Maintenance

Discusses the LH2 Fixed Position Imager warranty, maintenance and cleaning

procedures.

Appendices Detailed Supporting Information

Provides detailed information in specic areas such as the programming commands for

conguring various parameters of the LH2 Fixed Position Imager.

Page 9

Chapter

1

Chapter 1

Introduction and Getting Started

Product Overview

The LH2 xed position imager is truly a revolutionary new 2D imager. The omnidirectional

decoding allows the reading of linear, stacked linear and matrix bar codes in any

orientation.

These state-of-the-art imagers with superior 32-Bit, 400 mHz microprocessors provide a

one piece solution combining illumination, imaging and decoding in an extremely small

package.

Dual optics used by the 1.3 million pixel SXGA (1280 x 1024) CMOS sensor provide

exceptional depth of eld. The near and far eld cameras can be programmed to be

switched ON and OFF in different combinations to tailor the reading capabilities of the

LH2 to t your applications.

The laser beam facilitates targeting. The adjustable targeting zone allows precise selection

of specic bar codes in the eld of view. The LH2 can be customized with advanced logic

through the internal embedded application engine. The embedded engine may be utilized

to intelligently process or manipulate scanned data before it is sent to an application.

Advanced functions such as Barcode Readability Index provide quantitative measures

for optimizing imager settings to realize maximum performance. The LH2 is rugged and

built to last. These 100% solid state imagers use proven CMOS technology, assuring

continuing performance and high reliability. It is designed for rough handling in tough

environments and has a small footprint to t into tight spaces.

The LH2 is available in standard RS232 interface. Custom mounting options, cable

lengths, connector types and pinouts are available.

9

Page 10

Chapter 1

11

Quick Start-Up Procedure

This section is for those who wish to start using the imager before reading the complete

manual. In only a few steps the imager will be operable.

Follow the appropriate steps depending upon whether your LH2 is congured to operate

with a RS232 interface.

Chapter 1

Turn off the power to your PC and connect the imager to the RS232 communications port

depending on your cable conguration.

Note: You must provide +5 Volt DC power to the imager. This can be accomplished using

the power supply available from Opticon. If the power supply is obtained from another

source verify that it is identied with the CE mark. Turn on the power to the PC.

1) If you are operating in a Microsoft Windows 95/98/ 2000/ XP environment, you can set

the communication parameters using Hyper Terminal as follows:

• Open Hyper Terminal.

This can be done from Start>Programs>Accessories> Communications

• Select Hypertrm.exe to create a New Connection

• In the Connection Description dialog screen enter a name for the new le. If

desired, select an Icon. Click OK

• In the Connect To (Phone Number) dialog screen, in the box entitled: Connect

using. Select the communication port, for example, “Direct to Com 1” Click OK

• In the Com 1 Properties screen, enter the appropriate Port Settings:

Bits per second = 57600

Data bits = 8

Parity = None

Stop Character = 1

Handshaking = None

Click OK

• The hyper-terminal folder you just created will open. From the File pull-down

menu, select Properties then click on the Setting Tab

• In the Properties Settings dialog screen, Select Terminal keys for the Function,

arrow and control key; then Select ANSI for Emulation; the Back scroll buffer line

can remain at the default 500

10

Page 11

• Click on the ASCII Setup button. In the ASCII Setup screen, select Echo typed

locally so that any keyboard commands you input will appear on your screen. Click

OK. This returns you to the Properties Setting. Click OK

2) Your PC and the imager should now communicate.

3) To verify that the imager and the PC are communicating properly, send the following

command from your PC keyboard to receive a response from the imager.

Send these commands and at the end of the command send a carriage return.

( <┘ represents a carriage return)

;>PA7<┘

I<┘

Note: Be sure to use capital letters, e.g. “I”, not “i”.

4) The LH2 will send back the rmware version of the Imager.

Example:

Xap/i2232223006000010002363A06 sd+sq

Chapter 1

5) Send the following command to turn OFF the serial command mode.

PA8<┘

This Quick Start-Up procedure will get you started. However, to best understand the full

capabilities of this imager, you should read the complete manual.

11

Page 12

Chapter 1

This page is left blank intentionally

12

Page 13

Chapter 2

Technical Specication

OPTICAL

Field of View 21º horizontal x 15º vertical (approx)

Optical Resolution 1024 x 1280

Chapter

2

Bar Code Density

Linear 0.11 mm (4.2 mil) minimum

2D 0.15 mm (5.8 mil) minimum

Min. PCS Value 0.35

Pitch ±60º

Skew ±60º

Rotation ±180º

ELECTRICAL

Voltage 2.5 to 5.5 VDC

Current

Operating 140 mA

Standby 3 mA

Maximum 310 mA

Interface RS232

13

Page 14

Chapter 2

15

ENVIRONMENTAL

Temperature

Operating 0º to +40º C (+32º to +104º F)

Storage -20º to +60º C (-4º to +140º F)

Humidity 5 - 95% RH non-condensing

Shock Withstands multiple drops to concrete of 2 m (6.56 ft)

Regulatory FCC Class B, CE Certied

Targeting Beam Class IIA Visible Laser Diode (630 nm)

PHYSICAL

Chapter 2

Case Material PC/ABS Plastic

Dimension (L x W x H) 118 x 51 x 40 mm (4.6 x 2 x 1.6 in)

Weight 136 g (4.8 oz)

Cable Length

RS232 1.8 m (6 ft) straight

SYMBOLOGIES

2D BAR CODES MaxiCode, PDF417, Data Matix, QR Code, MicroPDF,

UCC RSS Composite, Aztec Code

LINEAR BAR CODES Code 39, Code 128, UPC/EAN/JAN, I 2 of 5, Codabar

(NW7), Code 93, UCC RSS, POSTNET, PLANET,

Japanese Post, Australia Post

PINOUTS

9 Pin Female mini-DIN Connector

Pin Function

1 Trigger

2 SD

3 RD

5 Signal Ground

9 +5 VDC

14

Page 15

ORDERING INFORMATION

Part No. Description

LH2RRIS-056 LH2, RS232 Interface

LH2-R1-SK1 Developers test and evaluation kit

* Additional industry standard conguration mounting brackets available.

Developer’s Test and Evaluation Kit is available that contain all the items needed to install

and evaluate the LH2 imager.

The LH2-R1-SK1 kit includes:

• LH2 Imager

• Cable (Connects LH2 to the Evaluation Board)

• Engineering Test & Evaluation Board

• 5V Power Supply

• Extension Cable (Connects host PC to Evaluation Board)

• User Manual

Chapter 2

15

Page 16

Chapter 2

This page is left blank intentionally

16

Page 17

Chapter

3

Chapter 3

Positioning the Imager for Optimal Performance

Achieving Optimum Performance

Four items greatly impact performance:

1) Distance (from the scan window) to the bar code

2) Specular Reection; and

3) Quality of Bar Code Labels

4) Imager eld of view and resolution

1) Distance to the Bar Code

The operation of the imager is similar to a camera. If you photograph an object that is

out of focus, the resulting picture will be blurry. The same is true with the imager. If the

bar code label is out of focus, the imager may have difculty decoding what appears to

be fuzzy bars and spaces.

Focal Distance

Ideally, the distance from the window of the imager to the bar code label should be equal

to the focal distance of the imager.

Depth-of-Field

Just as with a camera, the imager has a depth-of-eld. It can read bar codes that are not

precisely at the focal distance - maybe a little closer, or a little farther away. However, if

the bar code label is positioned too far from the focal distance, the imager may not be

able to successfully decode it.

The depth-of-eld varies based on the density of the bar code, i.e., the thickness of the

bars. Very high density bar codes (which have very narrow bars) are readable over a

17

Page 18

Chapter 3

19

much shorter distance range than low density bar codes with larger bars.

The following chart in gure 3.1 shows the “typical” depth-of-eld (closest to farthest

reading distances ) for the LH2 imagers. The actual performance may differ slightly from

unit to unit. Also, it is important to note that this data was measured under ideal conditions

using high quality bar code labels. In a “real world” environment the conditions will not be

as ideal. Therefore, the best practice is to position the imager at its focal distance rather

than at the extremes of its depth-of-eld.

The chart also shows the eld-of-view at various distances from the window. The eldof-view is the maximum width that the imager is capable of reading. A bar code label

positioned anywhere within this eld-of-view can be decoded. The eld-of-view is also a

measure of the widest bar code label that can be read. Remember: The width of a bar

code label includes not only the bars and spaces but also the required white space (quiet

zone) on each end.

Good design policy is to position the imager at its focal distance and at the center of the

eld-of-view. Do not position it near the extremes of the reading range.

Chapter 3

18

Page 19

LH2 Decode Zone

Chapter 3

Figure 3.3

19

Page 20

Chapter 3

21

2) Avoiding Specular Reection

Do not position the imager at an angle that causes the LED illumination to be reected

directly back into the imager. This is called specular reection. Too much reected light

can “blind” the imager preventing a good decode.

If the bar code label is located on a at surface, specular reectivity occurs between 0 to 10

degrees off perpendicular. (See diagram) If the bar code label is located on a cylindrical

surface, such as a test tube, the angle of specular reection is measured tangent to the

curve. If the curved surface is also moving, there may be more than one position causing

specular reection.

3) Quality Bar Code Labels

The quality of the bar code label can affect the scanning performance. Poor quality labels

are more difcult to decode and may result in non-reads or potential misreads. The bar

code label should be printed to specications. This means that the bars are printed within

spec, with the correct widths, no ink spread, crisps edges and no voids. There should be

a sufcient quiet zone on both end of the bar code label. For best results, the paper or

label stock should have a matte nish to diffuse light. The print contrast signal (which is

a comparison of the reectance of the bars and the background stock) should be as high

as practical.

Chapter 3

Barcode Readability Index

The Readability Index provides a measurement of a specic symbol’s ease or difculty to

be decoded by the LH2. The Readability Index is specic to the LH2, and should not be

confused with a verication quality measurement.

The Readability Index is a blend of information obtained from the internal operations of the

decoding algorithm pertaining to contrast, symbology construct, error detection, forward

error correction (if applicable), and other symbology-specic characteristics.

The Readability Index is a score on a scale of 01 (very poor) to 100 (very readable).

Due to differences based on motion, skew, reection, focus, and ambient lighting, the

Readability Index on the same symbol may vary somewhat from read to read. However, a

poor contrast or damaged symbol will score lower than a high contrast undamaged symbol.

The Readability Index can be used as a quick check on the reliability of label generation or

marking systems. When determining the ideal distance from the reader to the symbol, and

constant ambient light, the Readability Index provides a symbol quality assurance tool and

check point for feedback to an overall label or marking quality control system.

The Readability Index is enabled by rst reading a CodeXML rule into the permanent LH2

Memory.

20

Page 21

Code Readability Index Rule:

The Reader will store the rule and reset, but will not output the Readability Index until the

Readability Index Output Enable code is read. To remove this rule, scan the Clear All Prex

& Sufx code in Appendix A.

Readability Index Output Enable

Once read, each time a data symbol is read, the index will be output, followed by a comma,

(,) followed by the decoded data.

Example:

Code Qual = 98, 071589812308

The Reader will continue to output the Readability Index upon every read until disabled,

either by reset or by reading the Readability Index Output Disable.

Readability Index Output Disable

Chapter 3

21

Page 22

Chapter 3

23

4) Imager Field of View & Resolution

The LH2’s dual eld optical system may be modied based on your scanning environment.

The LH2’s mega pixel imager may be set to the following two modes:

SXGA Mode: In standard SXGA mode (default), the 1.3 Million Pixel imager is divided

into near eld and far eld decode zones. In each zone the resolution is 1024 x 640 pixels

(see gure 3.2). In this mode of operation, the highest resolution, and therefore, widest

working range on symbols of all densities is achieved. The trade-off is the amount of

time the reader spends processing the image. This time can be reduced by optimization

functions.

If only the near eld is used (small, high density symbols), the far eld image can be

ignored. If only the far eld is used (large, lower density symbols), the near eld can be

ignored. Further optimization may be obtained by “windowing” the eld to a smaller area.

Each focal area may be narrowed by enabling the windowing feature found in Appendix

A.

VGA Mode: In VGA mode (optional selection), the 1.3 Million Pixels are sampled on a 4to-1 basis. This greatly reduces the amount of time necessary for the transfer of the image

to the CPU and the resulting processing time (gure 3.3). The trade-off for this increased

speed is a reduction in resolution and working range.

Chapter 3

NOTE: In the following section the LH2 can ONLY be programmed

by scanning the bar codes. For detail serial commands read the

Appendix A - Optimization Matrix section.

22

Page 23

1024

SXGA

Imaging Area

Far

Near

480

Far

640

640

Figure 3.2

320

Chapter 3

VGA

Imaging Area

Near

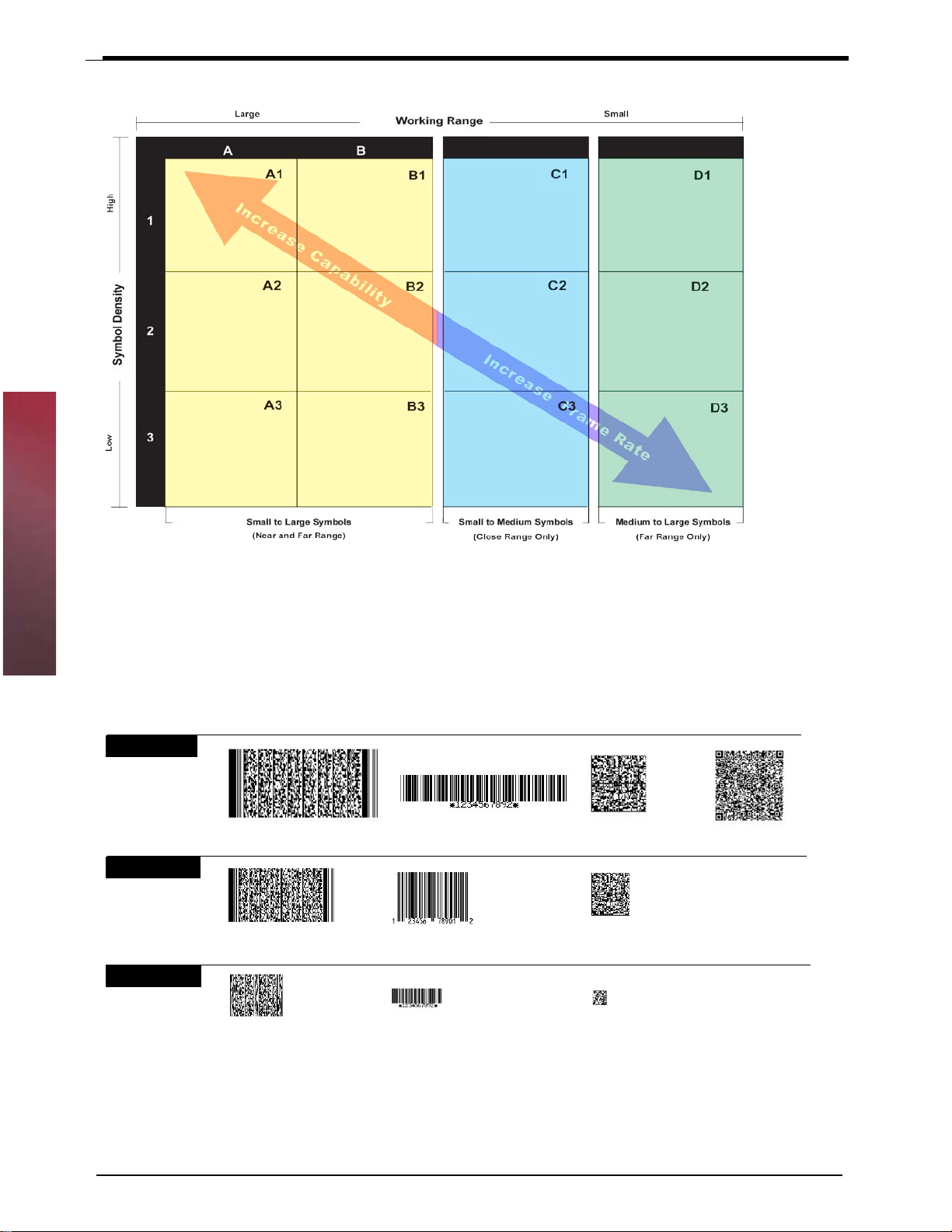

The LH2 may be easily optimized for any workplace. By setting a few parameters from your

scanning environment you can take advantage of the readers dual path 1.3 mega pixel imager

and 400 MHz processor.

If you are scanning large barcodes, small barcodes or even multiple sizes of different barcodes,

by dening the working range and the type of symbols the reader must process, the LH2 will

offer lightning fast decodes.

Look at the charts below to assess your environment. You may program each trigger on the LH2

unit for a different environment by scanning barcodes from the next few pages.

320

Figure 3.3

23

Page 24

Chapter 3

25

* Factory Default

Setting

* All triggers programmed to this setting at shipment

Chapter 3

Symbol Size - Here are a few approximate examples of large, medium and small symbols.

Figure 3.4

All of the codes below have been modied for representation purposes and do not scan

Large Symbols

PDF 417 - 20+ mil Code 128 - 14.2+ mil Data Matrix - 15+ mil QR Code - 15+ mil

Medium Symbols

Data Matrix - 10+ milUPC/EAN/JAN - 12.5+ milPDF 417 - 15+ mil

Small Symbols

Code 39 - 4.2+ milMicroPDF 417 - 7.5+ mil Data Matrix - 6.5+ mil

.

24

Page 25

When choosing the correct setting for your environment (i.e. printed labels, direct marks...)

we recommend trying several settings. For a large majority of users, the B1 or B3 settings are

satisfactory. If you would like to greatly improve the reader’s performance on medium to large

1-D codes, try the D1 or D3 setting, The chart and denitions below will help you understand

the readers conguration for each setting.

SXGA Mode

High

Near Field Decoding: On

Far Field Decoding: On

1

NF Resolution: 1024 x 640

FF Resolution: 1024 x 640

Decode Try Time: Long

SXGA Mode

Near Field Decoding: On

Far Field Decoding: On

2

NF Resolution: 832 x 640

FF Resolution: 1024 x 640

Decode Try Time: Normal

Symbol Density

SXGA Mode

Near Field Decoding: On

3

Low

Far Field Decoding: On

NF Resolution: 480 x 480

FF Resolution: 640 x 480

Decode Try Time: Short

Large

Working Range

Small

A B C

A1 B1 C1 D1

SXGA Mode

Near Field Decoding: On

Far Field Decoding: On

NF Resolution: 1024 x 640

FF Resolution: 1024 x 640

Decode Try Time: Normal

* Factory Default Setting

SXGA Mode

Near Field Decoding: On

Far Field Decoding: Off

NF Resolution: 1024 x 640

FF Resolution: NA

Decode Try Time: Normal

SXGA Mode

Near Field Decoding: Off

Far Field Decoding: On

NF Resolution: NA

FF Resolution: 1024 x 640

Decode Try Time: Normal

A2 B2 C2 D2

SXGA Mode

Near Field Decoding: On

Far Field Decoding: On

NF Resolution: 640x 512

FF Resolution: 832 x 640

Decode Try Time: Short

SXGA Mode

Near Field Decoding: On

Far Field Decoding: Off

NF Resolution: 640 x 640

FF Resolution: NA

Decode Try Time: Normal

SXGA Mode

Near Field Decoding: Off

Far Field Decoding: On

NF Resolution: NA

FF Resolution: 832 x 512

Decode Try Time: Normal

A3 B3 C3 D3

VGA Mode

Near Field Decoding: On

Far Field Decoding: On

NF Resolution: 480 x 320

FF Resolution: 480 x 320

Decode Try Time: Short

VGA Mode

Near Field Decoding: On

Far Field Decoding: Off

NF Resolution: 480 x 320

FF Resolution: NA

Decode Try Time: Short

VGA Mode

Near Field Decoding: Off

Far Field Decoding: On

NF Resolution: NA

FF Resolution: 480 x 320

Decode Try Time: Short

D

Chapter 3

Small to Large Symbols

Near and Far Range

Small to Medium Symbols

(Close Range Only)

* All triggers programmed to this setting at shipment

Medium to Large Symbols

(Far Range Only)

Denitions

Symbol Density: The amount of information versus the total area occupied by the symbol.

In order to achieve high density, the individual elements of a symbol must shrink. The highest

density symbols can only be resolved in the LH2 near-eld image, where the resolution of the

imager is 1024 x 640 DPI. Symbol density is usually expressed in “Mils” - ie, thousandths of

inches. This size refers to the smallest width of a linear barcode or the “cell size” (individual

square) in a matrix barcode.

Working Range: The range from nearest to farthest that the object (the target symbol)

can be resolved and decoded. Parameters that effect working range are SYMBOL DENSITY

and the OVERALL SIZE of the symbol, the SYMBOLOGY used, the reectivity of the surface,

the contrast of the symbol in relation to its background, the amount and type of illumination

available, and other environmental factors.

Resolution: Resolution is expressed in the table is the pixel array available for decoding a

25

Page 26

Chapter 3

27

symbol. It affects both the density and the size of the barcode that can be decoded.

Near Field (NF): The nearest eld of the LH2’s two image elds. The Near Field has the

highest resolution (1024 x 640 DPI). It has an optimal focal point of 4” (101.6 mm) away

from the lens of the reader. It has a size of 8.5” long (215.9 mm) by 4” wide (101.6 mm).

It has an overall viewing angle of 21° x 12°.

Far Field (FF): The farthest eld of the LH2’s two image elds. The Far Field has the

lowest resolution (480 x 320 DPI). It has an optimal focal point of 9” (228.6 mm) away from

the lens of the reader. It has a size of 4” wide (101.6 mm) at the optimal focal point.

Frame Rate: The number of decode attempts in a given amount of time.

Decode Try Time: The speed of decoding a given symbol. The time of decoding is

dramatically affected by the number of attempts at decoding images (frame speed)

available. An attempt includes the time used in the photographic exposure of an image,

and includes the transfer of the image to the CPU and the time taken to analyze the image,

locate a symbol, and decode the symbol into data or abandon the attempt because no data

could be derived.

There are four different Optimization Matrix available.

1) Right & Left Key Optimization

Chapter 3

2) Left Key Optimization

3) Right Key Optimization

4) Continuous Trigger Optimization

You can use any of the options to ne tune the scanning performance of the LH2 to t your

application.

26

Page 27

Right & Left Trigger Optimization Matrix

High

1

2

Symbol Density

3

Low

Large

Working Range

Small

A B C

A1 B1 C1 D1

* Factory Default

A2 B2 C2 D2

A3 B3 C3 D3

D

Small to Large Symbols

Near and Far Range

* All triggers programmed to this setting at shipment.

After setting the conguration, you must scan the save settings code or your reader will lose its settings if the reader is powered off.

Small to Medium Symbols

(Close Range Only)

Left Trigger Optimization Matrix

Large

A B C

A1 B1 C1 D1

High

1

A2 B2 C2 D2

2

Symbol Density

A3 B3 C3 D3

Working Range

Medium to Large Symbols

(Far Range Only)

Small

D

Chapter 3

Low

3

Small to Large Symbols

Near and Far Range

Small to Medium Symbols

(Close Range Only)

Medium to Large Symbols

(Far Range Only)

27

Page 28

Chapter 3

29

Right Trigger Optimization Matrix

High

1

2

Symbol Density

3

Low

Chapter 3

Large

Working Range

Small

A B C

A1 B1 C1 D1

A2 B2 C2 D2

A3 B3 C3 D3

Small to Large Symbols

Near and Far Range

Small to Medium Symbols

(Close Range Only)

Medium to Large Symbols

(Far Range Only)

D

Continuous Trigger Optimization Matrix

High

1

2

Symbol Density

3

Low

Large

A B C

A1 B1 C1 D1

A2 B2 C2 D2

A3 B3 C3 D3

Working Range

Small

D

28

Small to Large Symbols

Near and Far Range

Small to Medium Symbols

(Close Range Only)

Medium to Large Symbols

(Far Range Only)

Page 29

Application Notes

Tips for Achieving High Throughput

In some applications your primary objective may be to achieve the highest possible

throughput rate. The following list identies the parameters and imager settings that

can maximize scanning and decode throughput speed. Note, by emphasizing maximum

throughput, other areas of performance may be affected. For example, the number of nonreads could increase.

If high throughput is critical, consider some or all of these settings:

• Only enable those symbologies that you will be decoding.

• Eliminate all sufxes and prexes.

• Minimize the number of redundant reads required before transmitting data.

• Transmit the decoded data at the highest baud rate, 115,200 baud.

• Disable buzzer functions.

Tips for Insuring Highest Data Integrity

There are several parameters that can enhance your condence that the correct bar code

data is transmitted. Note that by emphasizing the accuracy and security of the data other

areas of the imager operation may be affected, for example, you may not achieve the

highest throughput.

If accuracy and data integrity are critical, consider some or all of these settings:

• Program the imager to higher Decode Time. For example, program the imager

to decode a bar code exactly the same way with Extra Long Decode Time before

transmitting the data. The default settings for the LH2 are designed for optimal,

general purpose performance with good quality symbols on typical surfaces. For

poor quality barcodes or barcodes on non-standard surfaces (shiny, low-contrast),

the unit may require more time to process the barcode before the system abandons

the image and restarts on a new decode attempt. It may require manipulating LED’s

too.

• The quality of the printed bar code must be excellent.

• Do not use a symbology with poor internal verication, or subject to partial

decodes, such as 2 of 5 or MSI/Plessey.

Chapter 3

• Only enable those symbologies that you will be decoding.

• Transmit data at low baud rates to minimize communication errors.

29

Page 30

Chapter 3

This page is left blank intentionally

30

Page 31

Chapter

4

Chapter 4

Conguring the Imager

Since the operation of a LH2 imager is microprocessor controlled, it is possible to modify or

program its operation to match your specic application. Changes in parameter settings can

be changed or programmed in two ways:

(1) The rst method employs specially designed programming bar codes which instruct the

imager to modify specic parameters. You can scan any of the barcodes from Appendix A

to program the LH2.

(2) The imager can also be programmed by sending software instructions from the host PC

to the imager via the RS232 connection only for the commands that are available.

Programming Menus & Commands

Appendix A contains full instructions on how to congure the imager as well as a complete

listing of the host serial commands and programming bar codes that are available to

customize the imager for your application.

Default Settings

Default settings are indicated throughout the menus to follow.

To restore the “out-of-the-box” settings shown in the following table, use the Reset to

Factory defaults setting and Clear All Prex & Sufx barcode settings

RS-232 Interface Setting Defaults

Baud Rate 57600

Stop Bits 1

Data Bits 8

Parity None

31

Page 32

Symbology Defaults:

All 1D Codes ON

Aztec OFF

Codabar ON

Code 128 ON

Code 93 ON

Code 39 ON

Composite OFF

Data Matrix ON

DM Inverse OFF

DM Rect. ON

Interleaved 2 0f 5 ON

MaxiCode OFF

MSIP OFF

PDF 417 ON

Micro PDF OFF

Postal Codes OFF

QR OFF

Chapter 4

RSS OFF

UPC ON

Control Setting Defaults:

Left Button All Decodes

Right Button All Decodes

Beeper Volume High

Laser Targeting On

32

Time Stamp Off

Continuous Scan Off

Page 33

Chapter

5

Chapter 5

Application Engineering Support

Technical Assistance and Support

Opticon is eager to help you integrate the LH2 imager into your application. Our technical support staff

is available to answer any questions or work with you to adapt the imager to your specic situation.

We are happy to answer your questions, assist in conguring and positioning the imager for optimum

operation, and help resolve any problems you encounter. Call us at 1 (800) 636-0090.

Common Causes of Poor Performance

The most common reasons for poor scanning performance are listed below:

• Bar codes are not positioned at the focal distance of the imager.

• Specular reection is impacting the imager. Change the angle/position of the imager or the

bar code.

• Poor quality of printed bar codes. Bar codes are out of specication.

• The paper on which the bar code is printed is highly reective or has a glossy nish causing

light to be reected into the imager.

• The distance from the imager to the bar code is not suitable for the density of the bar code.

Or the density of the bar code beyond the imagers capability.

33

Page 34

Modied and/or Customized Imagers

Opticon will work with you to modify or customize imagers to match your requirements.

Imagers can be modied in terms of connectors type, pin-outs, cable length, default

settings, custom software and many other areas.

Opticon will modify imagers in our factory and ship you imagers that match your specic

requirements. By incorporating your modications directly into production imagers, you

receive imagers tailored for your need. They can be used immediately without the need for

further modication or rework.

Chapter 5

34

Page 35

Chapter

6

Chapter 6

Imager Servicing and Maintenance

The LH2 imager contains no user adjustable or serviceable parts in the interior of the imager. All

product service must be performed by the Opticon Service Department in Orangeburg, NY. Opening

the imager will void the warranty and could expose the operator to laser light.

CAUTION: The LH2 utilizes a laser for targeting purpose only. If the laser is activated, do not

stare into the beam.

The LH2 is warranted for 5 years including parts and workmanship. If you need warranty or out-ofwarranty repair, rst call 1-800-636-0090 to obtain a Returned Material Authorization (RMA)

number. You will be provided a number and shipping instructions. Please visit our web site for a detail

warranty statement.

http://www.opticonusa.com

There is no scheduled maintenance required for the LH2. The imager can be cleaned using a water

dampened, lint free or lens cloth. Be careful to avoid excessive moisture that would penetrate the

housing or obscure the window. While use of cleaning uids other than water are not recommended,

a neutral detergent or ethanol would be preferred if necessary. Do not use bleach at full or diluted

strength as damage to the painted case and/or window may result.

35

Page 36

This page is left blank intentionally

Chapter 6

36

Page 37

Appendix

A

Appendix A

Programming Menus & Commands

How to use the Appendix?

The appendix has all the programming commands laid out in a standard format in the

whole section. All the programming commands have these attributes - Command Name,

Usage, Description, Default, Programming Code, Note and Options. For certain commands

you might not have all the attributes and are intentionally not mentioned.

Following are the details on each attributes of a programming command.

Command Name:

Usage:

Description:

Default:

The general name of a programming command.

A brief description of the command name and the function of the

command.

Here you will nd a detail description on the programming

command.

The default setting will be mentioned here.

37

Page 38

Appendix A

39

Programming Code: Serial Command:

A bar code to program the command. If a serial command is available then you can

send the program the LH2 via serial port.

All the commands end with a carriage

return.

<┘ represents a carriage return.

Appendix A

Example:

P%081<┘

Note:

Options:

Extra notes on the command will be mentioned here. Usually these

notes are important so please pay special attention to this section.

If extra programming command options are available then it will

be listed here. It follows the same syntax as mentioned in the

Programming Code and Serial Command section.

Programming Bar Codes

The LH2 imagers are pre programmed at the factory with default settings representing the

settings most commonly used by our customers. In most applications, the imager will work

right out of the box without the need for additional programming.

You can scan the barcodes from the appendix to change the settings of the LH2. The LH2

will automatically recognize the barcode as a programming barcode and change the settings

accordingly. You can scan multiple programming barcodes to change the settings.

NOTE: Always scan the “Save Settings“ bar code to save all the changes you made. If

you do not save the settings then the next time you power ON the LH2, it will go to the

previously saved settings.

38

Page 39

CRB Files

The CRB le is a convenient method for creating and maintaining a set of commands that

can be easily sent to the reader. The CRB les are regular text les with the .crb extension.

These CRB les can be created in any text editor such as “Notepad” and saved with the le

extension of .crb.

The CRB le can be sent to the reader using any standard serial program. You can use

HyperTerminal Program to send the le. Please refer the topic in Chapter 1 - Quick StartUp Procedure to set up the HyperTerminal program. After setting the connection use the

Transfer pull-down menu, select “Send Text File...“ (gure) and then select the le you want

to send to the LH2.

Appendix A

The CRB le allows for combining multiple functions into a single le.

NOTE: You can comment your CRB le with a semicolon(;) as shown below.

The standard format of the CRB le is

;>PA7 ;enable programming mode

commands

commands

.

.

commands

~ ;save the settings

PA8 ;disable the programming mode

39

Page 40

For example you can create a test.crb le that contains commands to enable Aztec symbology

and make the reader beep three times. Note you can also comment your CRB le with a

semicolon (;) as shown below.

NOTE: The only command which is not ignored in the CRB le when a semicolon

(;) is used is ;>PA7. In all other cases anything that follows the semicolon is

commented out.

Appendix A

Example: test1.crb

;>PA7 ;enable programming mode

P%501 ;enable aztec symbology

#%03 ;beep reader 3 times

~ ;save the settings

PA8 ;disable the programming mode

40

Page 41

General Options

Command Name:

Usage:

Description:

Default:

Programming Code: Serial Command:

Reset to Factory Defaults

Use this option to reset the imager to RS232 factory defaults.

This command will set the imager to factory defaults. This command

is extremely helpful if you have set the imager to different settings

and want to erase those settings and reset the imager back to the

factory defaults. It does not erase the Clear Prex & Sufx

commands.

ON

J<┘

P%1b1<┘

P%420<┘

P%081<┘

General Options

Note:

Options:

This code does not reset the Prex & Sufx settings to factory

defaults. In order to reset the Prex & Sufx settings to factory

defaults, use the “Erase Prex” and “Erase Sufx“ commands.

---

41

Page 42

General Options

43

Command Name:

Save Settings

Usage:

Description:

Default:

Programming Code: Serial Command:

General Options

This command saves the current settings on the imager.

Always use this command to save any the changes you make to the

imager. If you change the settings on the reader and do not use this

command then the imager will not save them if you turn the power

OFF. The imager will default to the previously saved settings next

time you power ON.

---

~<┘

Note:

Options:

---

---

42

Page 43

Command Name:

Clear All CodeXML Rules

Usage:

Description:

Default:

Programming Code: Serial Command:

Notes:

Options:

Clears any rules and also the prex and sufx settings.

This command will clear any special command rules and prex or

sufx settings from the imager.

---

1<┘

5<┘

See the Prex/Sufx section to clear only the prex or sufx.

---

General Options

43

Page 44

General Options

45

Command Name:

Reader ID & Firmware Version

Usage:

Description:

General Options

To nd out the Reader ID and Firmware version of the imager.

You will get a text string with your rmware version and LH2 ID

number (see below):

Xap/iVVVVWWWWXXXXSSSSSSSSSSPXX sd+sq

Xap/i - Opticon Internal ID

VVVV is the application rmware version number (4 digits)

WWWW is the bootloader rmware version number (4 digits)

XXXX is reserved (4 digits)

SSSSSSSSSS Reader’s serial number (10 digits)

P is “A” if running rmware is the application, “B” if bootLoader

XX - Opticon Internal ID

sd+sq - Reserved characters

Example:

Xap/i2098201206000010002363A06 sd+sq

Default:

Programming Code: Serial Command:

Note:

---

I<┘

Opticon, Inc. will periodically release new rmware for LH2 units.

For information on latest rmware versions, call Opticon at (800)

636-0090. To upgrade the rmware please visit Opticon web site at

http://www.opticonusa.com to download the latest les.

Options:

44

---

Page 45

Example: test2.crb

;>PA7 ;enable programming mode

J ;4 line commands to reset the imager

P%1b1

P%420

P%081

I ;check the rmware id

~ ;save the settings

PA8 ;disable the programming mode

General Options

On sending the test2.crb le, the LH2 will be reset to factory defaults and on your screen

you will receive the Firmware ID string from the imager.

45

Page 46

General Options

47

Command Name:

Barcode Readability Index

Usage:

Description:

General Options

The Readability Index provides a measurement of a specic symbol’s

ease or difculty to be decoded by the LH2.

The Readability Index is specic to the LH2, and should not be

confused with a verication quality measurement.

The Readability Index is a blend of information obtained from the

internal operations of the decoding algorithm pertaining to contrast,

symbology construct, error detection, forward error correction (if

applicable), and other symbology-specic characteristics.

The Readability Index is a score on a scale of 01 (very poor) to

100 (very readable). Due to differences based on motion, skew,

reection, focus, and ambient lighting, the Readability Index on

the same symbol may vary somewhat from read to read. However,

a poor contrast or damaged symbol will score lower than a high

contrast undamaged symbol. The Readability Index can be used as a

quick check on the reliability of label generation or marking systems.

When determining the ideal distance from the reader to the symbol,

and constant ambient light, the Readability Index provides a symbol

quality assurance tool and check point for feedback to an overall

label or marking quality control system.

The Readability Index is enabled by rst reading a CodeXML rule into

the permanent LH2 Memory.

Default:

Programming Code: Serial Command:

Notes:

There is No Bar code Readability Index installed.

---

The Reader will store the rule and reset, but will not output the

Readability Index until the Readability Index Output Enable code is

read. To remove this rule, scan the Clear All Prex & Sufx code.

46

Page 47

Options:

Programming Code: Serial Command:

Readability Index Output Enable

P%da1<┘

Once read, each time a data symbol is read, the index will be output, followed by a comma,

(,) followed by the decoded data.

Example:

Code Qual = 98, 071589812308

The Reader will continue to output the Readability Index upon every read until disabled,

either by reset or by reading the Readability Index Output Disable.

Read Index Output Disable

P%da0<┘

General Options

47

Page 48

Command Name:

Software Trigger

Usage:

Description:

Default:

Programming Code:

(There are no programming barcodes)

Notes:

General Options

Options: Serial Command:

Read Near and Far Field $%03<┘

Simulates a trigger.

This command will post a single simulated software

trigger. You can read with both the elds, only the near

eld or only the far eld.

---

See continuous trigger option.

Read Near Field only $%05<┘

Read Far Field only $%06<┘

48

Page 49

Symbology Options

Command Name:

Usage:

Description:

Default:

Programming Code: Serial Command:

Aztec OFF (Default) P%500<┘

Aztec Symbology

Sets the Aztec bar code symbology options.

This command allows you to turn ON or OFF the Aztec 2D bar code

symbology.

Aztec is OFF

Options:

Programming Code: Serial Command:

Aztec ON P%501<┘

Symbology Options

49

Page 50

51

Symbology Options

Command Name:

Codabar Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

Codabar ON (Default) P%6f1<┘

Options:

Programming Code: Serial Command:

Sets the Codabar bar code symbology options.

This command allows you to turn ON or OFF the Codabar bar code

symbology.

Codabar is ON

Symbology Options

Codabar OFF P%6f0<┘

50

Page 51

Command Name:

Codablock F Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

Codablock ON P%6d0<┘

Options:

Programming Code: Serial Command:

Sets the Codablock F bar code symbology options.

This command allows you to turn ON or OFF the Codablock F bar

code symbology.

Codablock F is OFF

P%ce1<┘

Codablock OFF (Default) P%6d1<┘

P%ce0<┘

Note:

When Codablock F and Code 128 decoding are enabled, there is some

danger of mistakenly decoding a damaged Codablock F symbol as a Code

128 symbol. Therefore, whenever possible, Code 128 decoding should be

disabled when Codablock F decoding is enabled.

Symbology Options

51

Page 52

53

Symbology Options

Command Name:

Code 128 Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

Code 128 ON (Default) P%6d1<┘

Options:

Programming Code: Serial Command:

Sets the Code 128 bar code symbology options.

This command allows you to turn ON or OFF the Code 128 bar code

symbology.

Code 128 is ON

Symbology Options

Code 128 OFF P%6d0<┘

52

Page 53

Command Name:

Code 93 Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

Code 93 ON (Default) P%6c1<┘

Options:

Programming Code: Serial Command:

Sets the Code 93 bar code symbology options.

This command allows you to turn ON or OFF the Code 93 bar code

symbology.

Code 93 is ON

Code 93 OFF P%6c0<┘

Symbology Options

53

Page 54

55

Symbology Options

Command Name:

Code 39 Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

Code 39 ON (Default) P%6b1<┘

Sets the Code 39 bar code symbology options.

This command allows you to turn ON or OFF the Code 39 bar code

symbology.

Code 39 is ON

Disable Checksum is ON

Code 39 Extended Full ASCII is OFF

Options:

Programming Code: Serial Command:

Symbology Options

Code 39 OFF P%6b0<┘

Enable Checksum P%701<┘

Disable Checksum (Default) P%700<┘

54

Page 55

Programming Code: Serial Command:

Enable checksum and strip from result P%702<┘

Code 39 Extended Full ASCII ON P%491<┘

Code 39 Extended Full ASCII OFF (Default) P%490<┘

Symbology Options

55

Page 56

57

Symbology Options

Command Name:

Composite Symbologies

Usage:

Description:

Default:

Programming Code: Serial Command:

Composite ON P%344<┘

Options:

Programming Code: Serial Command:

Sets the Composite bar code symbology options.

This command allows you to turn ON or OFF the Composite bar code

symbology.

Composite is OFF

P%4a1<┘

Symbology Options

Composite OFF (Default) P%4a0<┘

56

Page 57

Command Name:

Data Matrix Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

Data Matrix ON (Default) P%161<┘

Options:

Programming Code: Serial Command:

Sets the Data Matrix 2D bar code symbology options.

This command allows you to turn ON or OFF the Data Matrix 2D bar

code symbology.

Data Matrix is ON

Data Matrix Inverse is ON

Data Matrix OFF P%160<┘

Data Matrix Inverse ON (Default) P%193<┘

Data Matrix Inverse OFF P%191<┘

Symbology Options

57

Page 58

59

Symbology Options

Command Name:

Interleaved 2 of 5 Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

I 2 of 5 ON (Default) P%6e1<┘

Options:

Programming Code: Serial Command:

Sets the Interleaved 2 of 5 bar code symbology options.

This command allows you to turn ON or OFF the Interleaved 2 of 5

bar code symbology.

I 2 of 5 is ON

Symbology Options

I 2 of 5 OFF P%6e0<┘

I 2 of 5 Two digits ON O%c91

I 2 of 5 Two digits OFF Q%c90

58

Page 59

Programming Code: Serial Command:

I 2 of 5 Four digits ON O%c92

I 2 of 5 Four digits OFF Q%c92

Symbology Options

59

Page 60

61

Symbology Options

Command Name:

Maxicode Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

Maxicode ON ---

Sets the Maxicode 2D bar code symbology options.

This command allows you to turn ON or OFF the Maxicode 2D bar

code symbology.

Maxicode is OFF

Symbology Options

Options:

Programming Code: Serial Command:

Maxicode OFF (Default) P%470<┘

Note:

For certain Maxicode (commonly used by UPS™) barcodes printed

on thermal labels may require to manipulate the LED’s on the LH2.

For more information on different settings, please refer to section

“Advanced Settings” on Page 86.

60

Page 61

Command Name:

Micro PDF 417 Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

Micro PDF 417 ON P%2a1<┘

Options:

Programming Code: Serial Command:

Sets the Micro PDF 417 2D bar code symbology options.

This command allows you to turn ON or OFF the Micro PDF 417 2D

bar code symbology.

Micro PDF 417 is OFF

Micro PDF 417 OFF (Default) P%c2a0<┘

Symbology Options

61

Page 62

63

Symbology Options

Command Name:

MSI Plessy Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

MSI Plessy ON P%4f1<┘

Options:

Programming Code: Serial Command:

Sets the MSI Plessy bar code symbology options.

This command allows you to turn ON or OFF the MSI Plessy bar code

symbology.

MSI Plessy is OFF

Symbology Options

MSI Plessy OFF (Default) P%4f0<┘

62

Page 63

Command Name:

PDF 417 Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

PDF 417 ON (Default) P%291<┘

Options:

Programming Code: Serial Command:

Sets the PDF 417 2D bar code symbology options.

This command allows you to turn ON or OFF the PDF 417 2D bar

code symbology.

PDF 417 is ON

PDF 417 OFF P%290<┘

Symbology Options

63

Page 64

65

Symbology Options

Command Name:

Postal Symbologies

Usage:

Description:

Default:

Programming Code: Serial Command:

Disable All Postal Codes (Default) P%4b0<┘

Options:

Programming Code: Serial Command:

Sets different Postal bar code symbology options.

This command allows you to turn ON or OFF different Postal bar

code symbologies.

All Postal Symbologies are OFF.

Symbology Options

Australian Post ON P%4b8<┘

Japan Post ON P%4b20000<┘

KIX ON P%4b200001<┘

Planet ON P%4b80<┘

64

Page 65

Programming Code: Serial Command:

Postnet ON P%4b2000<┘

Postnet and Planet ON P%4b2080<┘

Royal Mail ON P%4b200000<┘

Symbology Options

65

Page 66

67

Symbology Options

Command Name:

QR Code Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

QR Code ON P%2b1<┘

Options:

Programming Code: Serial Command:

Sets the QR Code 2D bar code symbology options.

This command allows you to turn ON or OFF the QR Code 2D bar

code symbology.

QR Code is OFF.

Checksum is Disabled.

Symbology Options

QR Code OFF (Default) P%2b0<┘

Enable Checksum P%481<┘

Disable Checksum P%480<┘

66

Page 67

Programming Code: Serial Command:

QR Code Inverse ON P%2b2<┘

Both Inverse and Standard ON P%2b3<┘

Symbology Options

67

Page 68

69

Symbology Options

Command Name:

RSS Symbology

Usage:

Description:

Default:

Programming Code: Serial Command:

All RSS Codes ON P%4c#31<┘

Options:

Programming Code: Serial Command:

Sets different RSS bar code symbology options.

This command allows you to turn ON or OFF different RSS bar code

symbologies.

All RSS Symbologies are OFF.

Symbology Options

All RSS Codes OFF (Default) P%4c0<┘

RSS Limited ON P%4c4<┘

RSS 14 and RSS 14 Truncated ON P%4c8<┘

68

Page 69

RSS 14 Stacked ON P%4c#16<┘

RSS Expanded ON P%4c1<┘

Symbology Options

69

Page 70

71

Symbology Options

Command Name:

UPC / EAN / JAN Symbologies

Usage:

Description:

Default:

Programming Code: Serial Command:

UPC ON (Default) P%6a1<┘

UPC Short Margin Disabled P%740<┘

Sets the UPC/EAN/JAN bar code symbology options.

This command allows you to turn ON or OFF the UPC/EAN/JAN bar

code symbology.

UPC is ON

UPC Short Margin is Disabled

Symbology Options

Options:

Programming Code: Serial Command:

UPC OFF P%6a0<┘

UPC Short Margin Enabled P%741<┘

70

Page 71

UPC Extension ON P%4d1<┘

UPC Extension OFF P%4d0<┘

Symbology Options

71

Page 72

Communication Parameters

73

Communication Parameters

Command Name:

Usage:

Description:

Default:

Programming Code: Serial Command:

57600 (Default) P%1cE100<┘

Baud Rate

Sets the RS-232 baud rate.

This command allows you to set different baud rates for RS-232

communication.

57600

Options:

Programming Code: Serial Command:

1200 P%1c4B0<┘

Communication Parameters

2400 P%1c960<┘

72

Page 73

4800 P%1c12C0<┘

9600 P%1c2580<┘

19200 P%1c4B00<┘

38400 P%1c9600<┘

115200 P%1c1C200<┘

Communication Parameters

73

Page 74

Communication Parameters

75

Command Name:

Data Bits

Usage:

Description:

Default:

Programming Code: Serial Command:

8 Data Bits (Default) P%1e8<┘

Options:

Programming Code: Serial Command:

Sets the RS-232 Data Bits options.

This command allows you to set the appropriate data bit

8 Data Bits is ON

7 Data Bits P%1e7<┘

Communication Parameters

74

Page 75

Command Name:

Stop Bits

Usage:

Description:

Default:

Programming Code: Serial Command:

1 Stop Bit (Default) P%1d1<┘

Options:

Programming Code: Serial Command:

Sets the RS-232 Stop Bits options.

This command allows you to set the appropriate stop bit

1 Stop Bit is ON

2 Stop Bit P%1d2<┘

Communication Parameters

75

Page 76

Command Name:

Parity

Usage:

Description:

Default:

Programming Code: Serial Command:

None (Default) P%220<┘

Options:

Programming Code: Serial Command:

Sets the RS-232 Parity options.

This command allows you to set appropriate parity.

None is ON

Even P%222<┘

Communication Parameters

Odd P%221<┘

76

Page 77

Hardware Settings

Command Name:

Usage:

Description:

Default:

Programming Code: Serial Command:

Beep High (Default) P%2664<┘

Beep Volume

Sets the buzzer volume.

This command allows you to set the beep volume to high or low.

You can also turn off the beep for a quite operation.

Beep is set to High volume.

Options:

Programming Code: Serial Command:

Beep Low P%2632<┘

Beep Off P%260<┘

Hardware Settings

77

Page 78

Hardware Settings

79

Command Name:

Laser Targeting

Usage:

Description:

Default:

Programming Code: Serial Command:

Laser ON (Default) P%0f1<┘

Sets the targeting laser beam.

This command allows you to turn ON or OFF the laser targeting

beam. The laser targeting beam is extremely help full to set the

imager during the initial set up. You can easily read a bar code by

pointing the laser dot in the center of the bar code.

Laser aiming dot is turned ON.

Options:

Programming Code: Serial Command:

Laser OFF P%0f0<┘

Hardware Settings

78

Page 79

Command Name:

Laser Brightness

Usage:

Description:

Default:

Programming Code: Serial Command:

High (Default) P%9C100<┘

Sets the targeting laser brightness.

This command allows you to change the brightness of the targeting

laser.

Targeting laser is set to High.

Options:

Programming Code: Serial Command:

Medium P%9C50<┘

Low P%9C1<┘

Hardware Settings

79

Page 80

Hardware Settings

81

Command Name:

Left Key Programming

Usage:

Description:

Default:

Programming Code: Serial Command:

Read with Both Imagers (Default) P%3a3<┘

Programs the left key to different options.

This command allows you to program the left key to perform different

functions. You can program the key so that it can make use of a

different imager ( Near / Far ) to read a barcode. This function is

useful while doing the initial setup.

The key is set to read with Both the imagers.

Options:

Programming Code: Serial Command:

Read with Far-Field Imager only P%3a6<┘

Read with Near-Field Imager only P%3a5<┘

Hardware Settings

80

Page 81

Command Name:

Right Key Programming

Usage:

Description:

Default:

Programming Code: Serial Command:

Read with Both Imagers (Default) P%393<┘

Programs the right key to different options.

This command allows you to program the right key to perform

different functions. You can program the key so that it can make use

of a different imager ( Near / Far ) to read a barcode. This function

is useful while doing the initial setup.

The key is set to read with both the imagers.

Options:

Programming Code: Serial Command:

Read with Far-Field Imager only P%396<┘

Read with Near-Field Imager only P%395<┘

Hardware Settings

81

Page 82

Continuous Scan

83

Continuous Scan

Command Name:

Usage:

Description:

Default:

Programming Code: Serial Command:

Both Near & Far Field ON P%c43<┘

Continuous Scan

Sets the imager in continuous scan mode.

This command allows you to set the imager into a continuous scan

mode. You can program the imager so that it can make use of

different imagers ( Near / Far ) to read a barcode in a continuous

mode.

Continuous Scan is OFF

Options:

Programming Code: Serial Command:

Near Field Only ON P%c45<┘

Far Field Only ON P%c46<┘

Continuous Scan

82

Page 83

Continuous Scan OFF (Default) P%c40<┘

83

Continuous Scan

Page 84

Continuous Scan

85

Command Name:

Continuous Scan - Trigger Delays

Usage:

Description:

Default:

Programming Code: Serial Command:

3 Seconds P%a2#3000<┘

Sets the delay time for continuous scan.

This command allows you to program the delay time between scans

while in continuous scan mode.

Delay is set to 0 seconds

Options:

Programming Code: Serial Command:

1 Second P%a2#1000<┘

0 Second (Default) P%a2#0<┘

Continuous Scan

84

Page 85

Command Name:

Duplicate Scan Delay

Usage:

Description:

Default:

Programming Code: Serial Command:

3 Seconds P%d63<┘

Sets the duplicate scan delay time in the continuous scan mode.

This command allows you to program the delay time between scans

while in continuous scan mode so that the imager will not read the

same bar code again.

Duplicate Scan Delay is set to 0 seconds

Options:

Programming Code: Serial Command:

1 Second P%d61<┘

0 Second (Default) P%d60<┘

85

Continuous Scan

Page 86

Advance Settings

87

Advance Settings

Command Name:

Usage:

Description:

Advance Settings

Default:

Decode Time & LED’s for Non Standard Inks

Sets the Decode Time and LED to read a bar code.

The default settings for the LH2 are designed for optimal, general

purpose performance with good quality symbols on typical surfaces.

For poor quality barcodes or barcodes on non-standard surfaces

(shiny, low-contrast), the unit may require:

• More time to process the barcode before the system abandons the

image and restarts on a new decode attempt.

• May require manipulating LED’s.

To allow for additional processing time or to change the LED settings

for marginal symbols, use one of the following commands.

Normal Decode Time is ON.

LED’s for Non Standard Inks are OFF.

Programming Code: Serial Command:

Extra Long Decode Time P%AA0200<┘

Note:

Options:

Programming Code: Serial Command:

Normal Decode Time (Default) P%AA100<┘

Utilizing this feature may affect the overall performance of the

reader, but “unreadable” barcodes may become readable.

86

Page 87

Short Decode Time P%aa80<┘

Long Decode Time P%AA180<┘

LED’s for Non Standard Inks ON P%b61<┘

Advance Settings

LED’s for Non Standard Inks OFF (Default) P%b60<┘

87

Page 88

Advance Settings

89

Command Name:

Targeting Zone Tolerance

Usage:

Description:

Advance Settings

Default:

Programming Code: Serial Command:

50 P%9d32<┘

Sets the Targeting Zone Tolerance of the imager.

This command allows you to program the decode accuracy of the

LH2. The 50 setting is the most accurate while the 1600 barcode is

the most tolerant. If you set the unit to a 50 setting, you have to aim

the targeting dot directly on the desired barcode for it to be read.

This setting is helpful when you are trying to read a single bar code

amongst a group of bar codes on a label.

Targeting Zone Tolerance is set to 1600.

Options:

Programming Code: Serial Command:

1600 (Default) P%9d640<┘

75 P%9d4b<┘

88

Page 89

100 P%9d64<┘

125 P%9d7d<┘

150 P%9d96<┘

Advance Settings

200 P%9dc8<┘

400 P%9d190<┘

89

Page 90

Advance Settings

91

Command Name:

Windowing

Usage:

Description:

Sets the imaging window size.

You may optimize the LH2 decode zone if the application only

requires one barcode format. If the size and density of the barcodes

to be scanned are consistent, please select the setting below that

best describes your environment.

Advance Settings

Default:

Programming Code: Serial Command:

1D & 2D Bar Codes P%53#640<┘

640 X 1024 Pixels (Default) P%54#1024<┘

The window size is set to 640 x 1024 pixels

P%C7#640<┘

P%C8#1024<┘

Options:

Programming Code: Serial Command:

1D Bar Codes Only P%53#200<┘

200 x 1024 Pixels P%c7#200<┘

Small 2D Bar Codes P%53#480<┘

480 x 480 Pixels P%54#480<┘

P%C7#480<┘

P%C8#480<┘

90

Page 91

Medium 2D Bar Codes P%53#512<┘

P%54#512<┘

P%C7#512<┘

P%C8#512<┘

Large 2D Bar Codes P%53#640<┘

P%54#640<┘

P%C7#640<┘

P%C8#640<┘

Advance Settings

91

Page 92

Command Name:

VGA & SXGA Mode

Usage:

Description:

Advance Settings

Default:

Programming Code: Serial Command:

SXGA Mode - 1280 x 1024 (Default) P%e20<┘

Sets the imager optical resolution.

User’s may optimize the LH2’s mega pixel (SXGA) imager (1280 x

1024) to a VGA (640 x 480). This feature is used to decrease the

pixel sampling area, which will greatly increase processing speed.

This is an advanced feature used for the rapid decoding of 1D/linear

barcodes and larger size 2D barcodes. Opticon recommends testing

this feature, as it may not work with certain high density codes.

Optical resolution is set to 1280 x 1024

P%640<┘

Options:

Programming Code: Serial Command:

VGA Mode - 640 x 480 P%e21<┘

P%640<┘

92

Page 93

Prex & Sufx Settings

Command Name:

Usage:

Description:

Default:

Programming Code: Serial Command:

Erase Prex (No Prex)

Prex Settings

Sets the prex for a bar code.

Scan the following barcodes to set appropriate prex. Make sure to

save settings on your reader before scanning the prex barcodes. If

you scan more than one prex you will receive each scanned prex

in your scanned data (i.e. If you scan comma prex twice, you will

get two comma prexes).

There is no prex by default.

---

Prex \ Sufx

Options:

Programming Code: Serial Command:

Prex - Comma

Prex - Space

Prex - Tab

---

---

---

93

Page 94

Prex \ Sufx

95

Prex - Carriage Return & Line Feed

---

Prex / Sufx

Note: For custom prex commands or to create serial commands for the above

settings download the Prex-Sufx Builder program from Opticon, Inc website at

http://www.opticonusa.com.

94

Page 95

Command Name:

Sufx Settings

Usage:

Description:

Default:

Programming Code: Serial Command:

Erase Sufx (No Sufx)

Sets the sufx for a bar code.

Scan the following barcodes to set appropriate sufx. Make sure to

save settings on your reader before scanning the sufx barcodes. If

you scan more than one sufx you will receive each scanned sufx

in your scanned data (i.e. If you scan comma sufx twice, you will

get two comma sufxes).

There is no sufxe by default.

---

Prex \ Sufx

Options:

Programming Code: Serial Command:

Sufx - Comma

Sufx - Space

---

---

95

Page 96

Sufx - Tab

---

Sufx - Carriage Return

Prex / Sufx

Sufx - Line Feed

Sufx - Carriage Return & Line Feed

---

---

---

Note: For custom sufx commands or to create serial commands for the above

settings download the Prex-Sufx Builder program from Opticon, Inc website at

http://www.opticonusa.com.

96

Page 97

Command Name:

Optimization Matrix

Usage:

Description:

Default:

Note:

Sets the imager to read different sizes of barcodes.

By setting a few parameters of the imager you can take advantage

of the dual path imager to read barcodes of different sizes. For your

convenience there are some preset standard settings created to read

different variety of barcodes. Look at the charts on the next page to

assess your environment.

More details are in Chapter 3, sub topic “4) Imager Field of

View & Resolution”.

The B1 non continuos mode setting is the default.

1. The tables on the next page represents the settings for each cell.

2. On the following pages there are 2 sets of tables (4 tables

altogether).

3. The rst set is the setting for single trigger and the second set is

for continuous trigger.

4. In each set one table has barcodes and the other table has the

corresponding serial commands. For example:

Barcode in cell A1 from SET 1 = Serial command in cell A1 from SET

1.

5. All the serial commands have a carriage return at the end of each

line.

6. If you use commands from SET 2 - “Continuous trigger“ then you

can turn OFF the continuous trigger by using the “Continuous Scan

OFF” command.

Optimization Matrix

97

Page 98

99

Optimization Matrix

* Factory Default

Setting

* All triggers programmed to this setting at shipment

Large

A B C

Optimization Matrix

SXGA Mode

High

Near Field Decoding: On

Far Field Decoding: On

1

NF Resolution: 1024 x 640

FF Resolution: 1024 x 640

Decode Try Time: Long

A1 B1 C1 D1

SXGA Mode

Near Field Decoding: On

Far Field Decoding: On

NF Resolution: 1024 x 640

FF Resolution: 1024 x 640

Decode Try Time: Normal

* Factory Default Setting

A2 B2 C2 D2

SXGA Mode

Near Field Decoding: On

Far Field Decoding: On

2

NF Resolution: 832 x 640

FF Resolution: 1024 x 640

Decode Try Time: Normal

Symbol Density

SXGA Mode

Near Field Decoding: On

Far Field Decoding: On

NF Resolution: 640x 512

FF Resolution: 832 x 640

Decode Try Time: Short

A3 B3 C3 D3

Low

SXGA Mode

Near Field Decoding: On

3

Far Field Decoding: On

NF Resolution: 480 x 480

FF Resolution: 640 x 480

Decode Try Time: Short

VGA Mode

Near Field Decoding: On

Far Field Decoding: On

NF Resolution: 480 x 320

FF Resolution: 480 x 320

Decode Try Time: Short

Working Range

SXGA Mode

Near Field Decoding: On

Far Field Decoding: Off

NF Resolution: 1024 x 640

FF Resolution: NA

Decode Try Time: Normal

SXGA Mode

Near Field Decoding: On

Far Field Decoding: Off

NF Resolution: 640 x 640

FF Resolution: NA

Decode Try Time: Normal

VGA Mode

Near Field Decoding: On

Far Field Decoding: Off

NF Resolution: 480 x 320

FF Resolution: NA

Decode Try Time: Short

Small

SXGA Mode

Near Field Decoding: Off

Far Field Decoding: On