Page 1

User’s Manual

LGZ 7225

Long Range Handheld

CCD Scanner

25-ULGZMU01-01

Keyboard Wedge Interface

USB Interface

RS232 Interface

8 Olympic Drive

Orangeburg, NY 10962

Tel 800.636.0090

Fax 845.365.1251

www.opticonUSA.com

1

Page 2

Contents

General Information

Unpacking .

Opticon Customer Service and Support

Installation

Default Settings

Interface Selection

Scanning Modes

Beeper Settings

Symbology Options

Prefix/Suffix Strings

Transmission Setting

Parameter Settings List

Programming Bar Codes

2

Page 3

Getting Started

General Information

The LGZ 7225 CCD Scanner utilizes state-of-the art imaging technology similar to that found in digital

cameras, fax machines and video camcorders. The captures an “image” of the bar code and converts it into

digital signals that the host computer understands.

The scanner automatically recognizes most common bar code symbologies.

The scanner, which utilizes miniature, surface-mounted electronics, has no moving parts and will provide

years of trouble-free operation.

The LGZ 7225 is available in several different interface configurations.

Keyboard Wedge (PS2 or AT/XT)

RS 232

USB

Unpacking

Remove the scanner from its packaging and inspect it for damage. Save the carton and packing material. If

the scanner was damaged in transit, call the dealer or distributor from whom you purchased it. If you

purchased it directly from Opticon, call Opticon Customer Service Dept. at 800-636-0090.

Opticon Customer Service and Support

If you have any questions or need assistance with installing or programming your scanner call Opticon

Customer Service Department at (800) 636-0090.

Before you call, record the model number of the scanner. This information is located on the bottom side of

the scanner. Also please have the scanner available plus some bar codes to scan.

3

Page 4

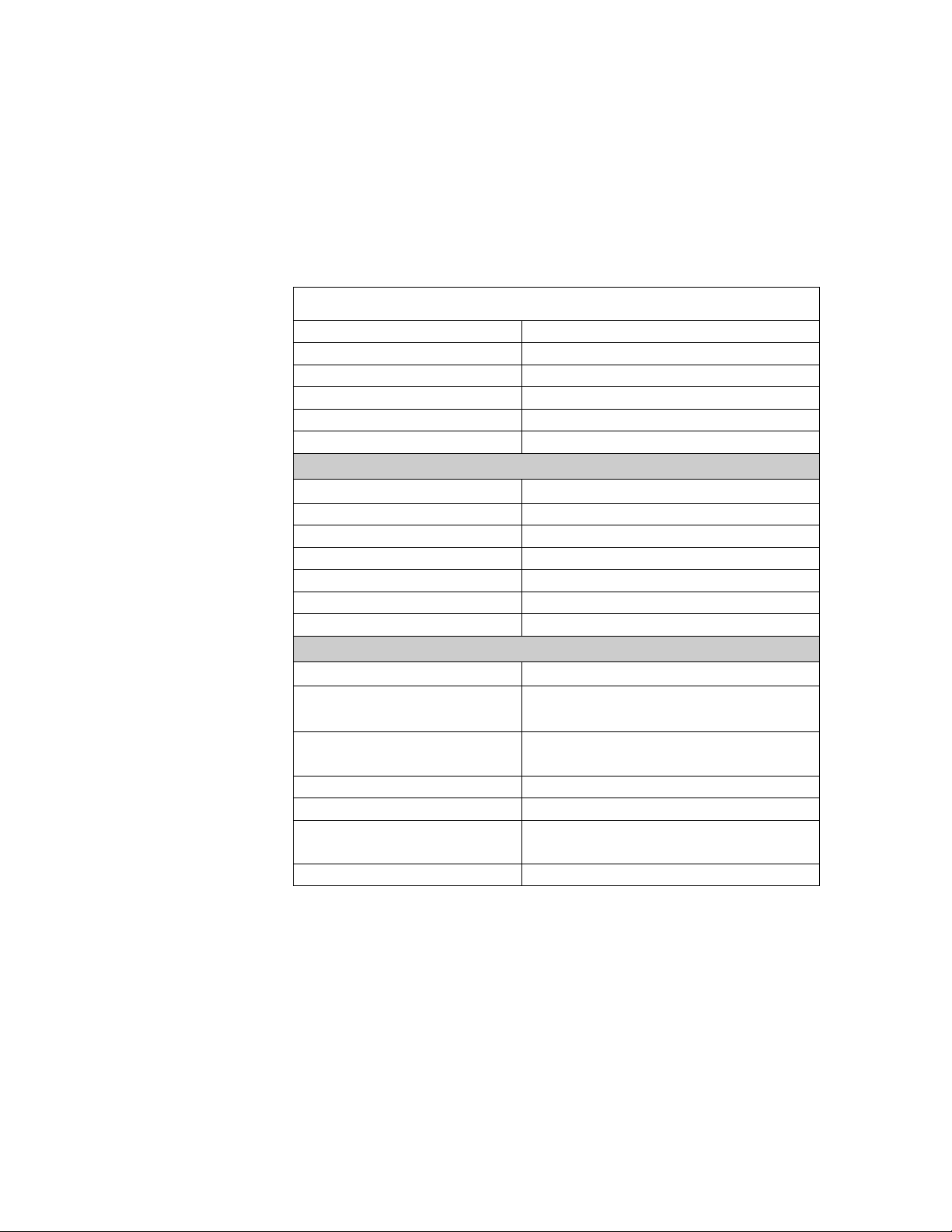

LGZ7225 Long Range Handheld CCD Spec

Cable - K/B Wedge Straight 2.0 m

Cable - universal type Straight 2.3 m

Connector type RJ-45 phone jack connector

Case material ABS plastic

Cushion material Rubber

Electrical

Input Voltage

Power - Operating 1275 mW

Power - Standby 600 mW

Current - Operating 255 mA @ 5VDC

Current - Standby 120 mA @ 5VDC

DC Transformers Class 2; 5VDC @ 450 mA

Agency listing UL, FCC Class A

Environmental

Operating Temperature

Storage

Humidity

Light Level Up to 60000 Lux

Shock 1.5m drop onto concrete

Contaminants

Ventilation None required

160 g (cable not included)

5 VDC r 0.25V

0q to 45qC (32qF to 113qF)

-40qC to 60qC

(-40qF to 140qF)

5% to 90% relative humidity,

non-condensing

Seals to resist airborne particulate

contaminants

4

Page 5

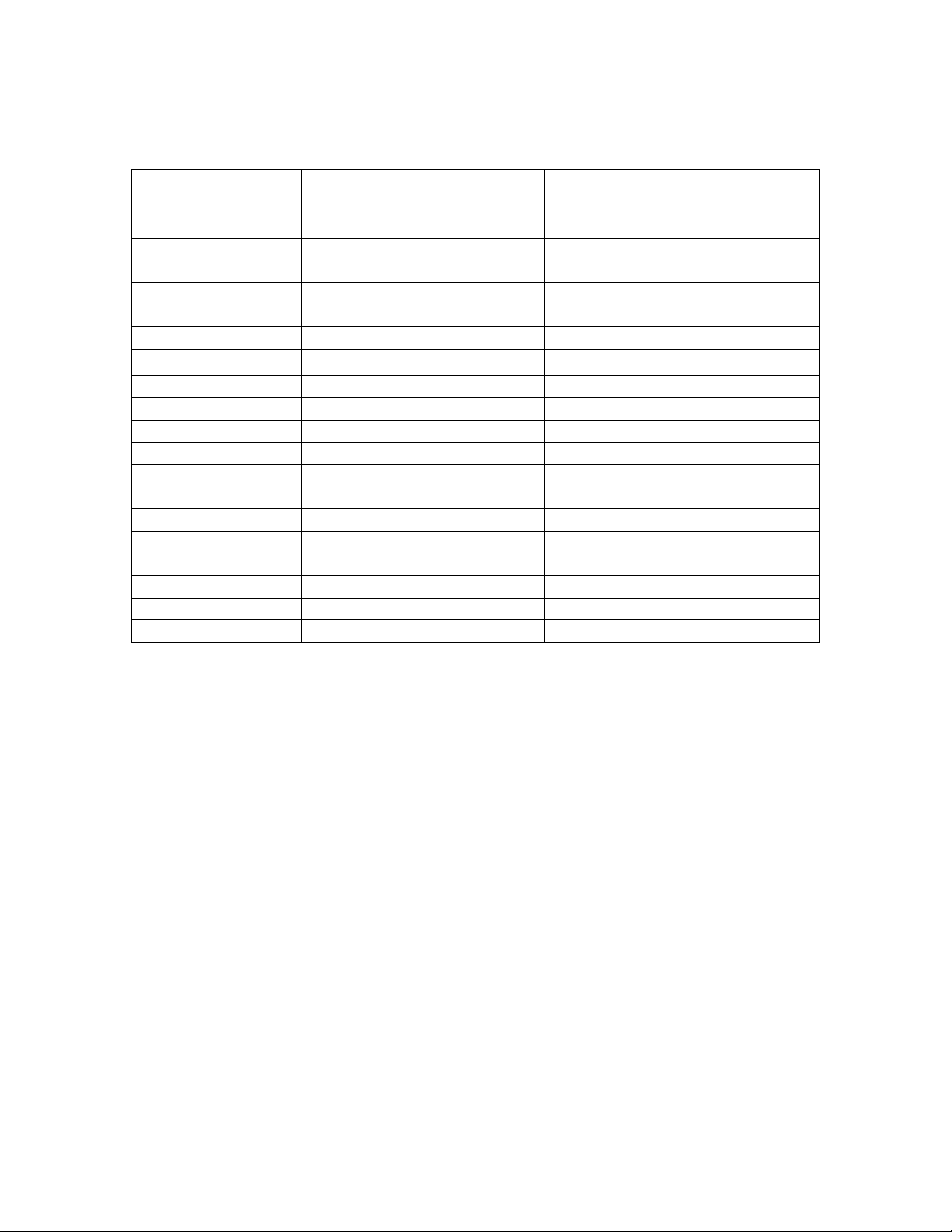

Default Setting for each barcode shown as below:

Code Type Read Checksum

Verifacation

UPC-A X X X A

UPC-E X X X E

EAN-13 X X X F

EAN-8 X X X FF

Code-39 X *

Interleaved 2of5 X X i

Industrial 2of5 i

Matrix 2of5 B

Standard 2of5 i

China Post t

Codabar %

Code-128 X X #

Code-93 &

Code-11 O

MSI/Plessey @

UK/Plessey @

Telepen S

Italian Pharmaode. p

Checksum

Transmission

Code ID

5

Page 6

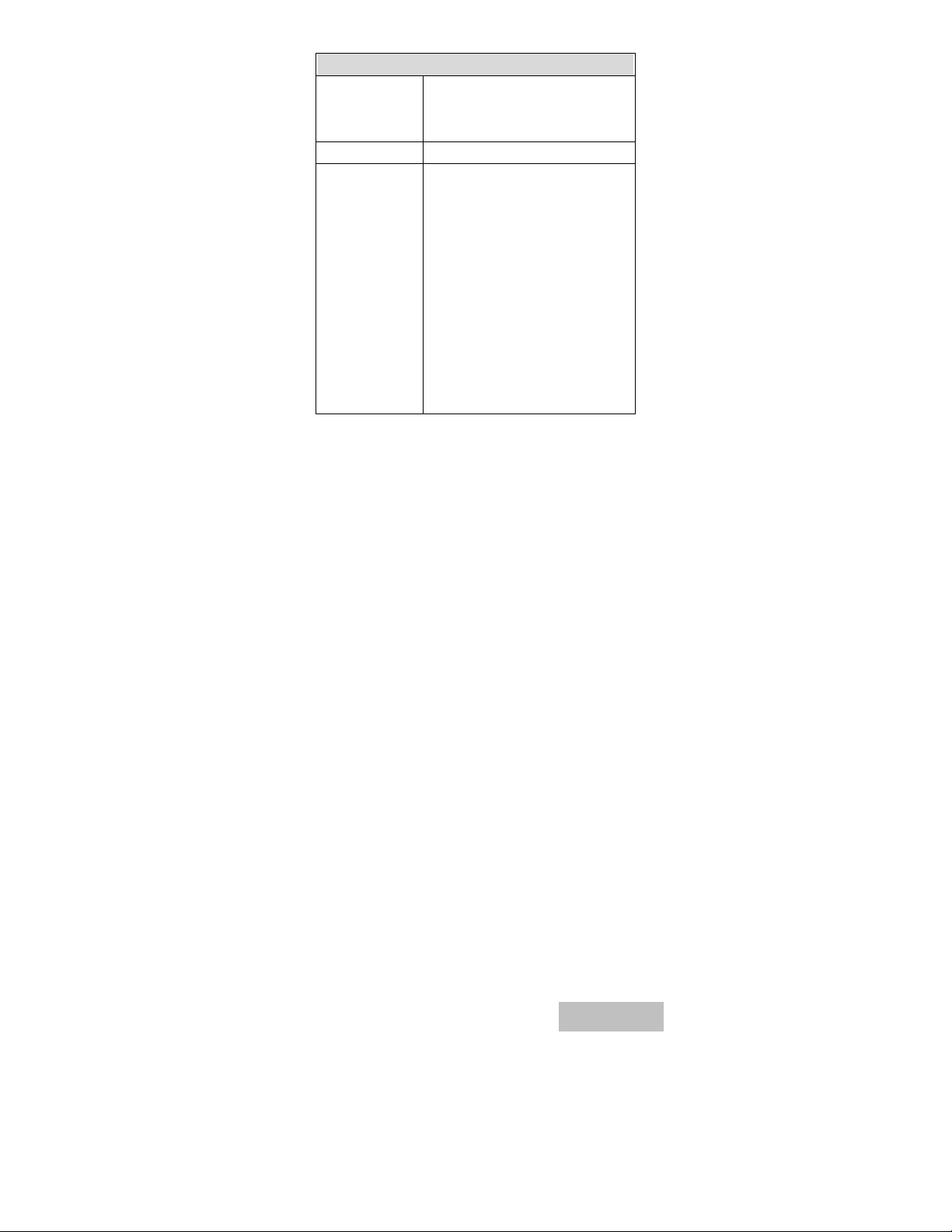

Programming

Programming

method

Program upgrade Enabled by built-in flash memory

Programmable

characteristics

Manual (Reading special barcode) DOS

command through RS-232, Windows

configuration program

Code type selection, check digit

selection Decoding option Decoding

option Transmitted character delay,

Header selection, trailer selection,

message suffix, good read beep tone

and volume, scanner trigger selection

Keyboard emulation type

(intermessage delay, keyboard type

and keyboard language)

Serial interface type (ACK/NAK,

Xon/Xoff, RTS/CTS, good read LED

control, start/stop bits)

6

Page 7

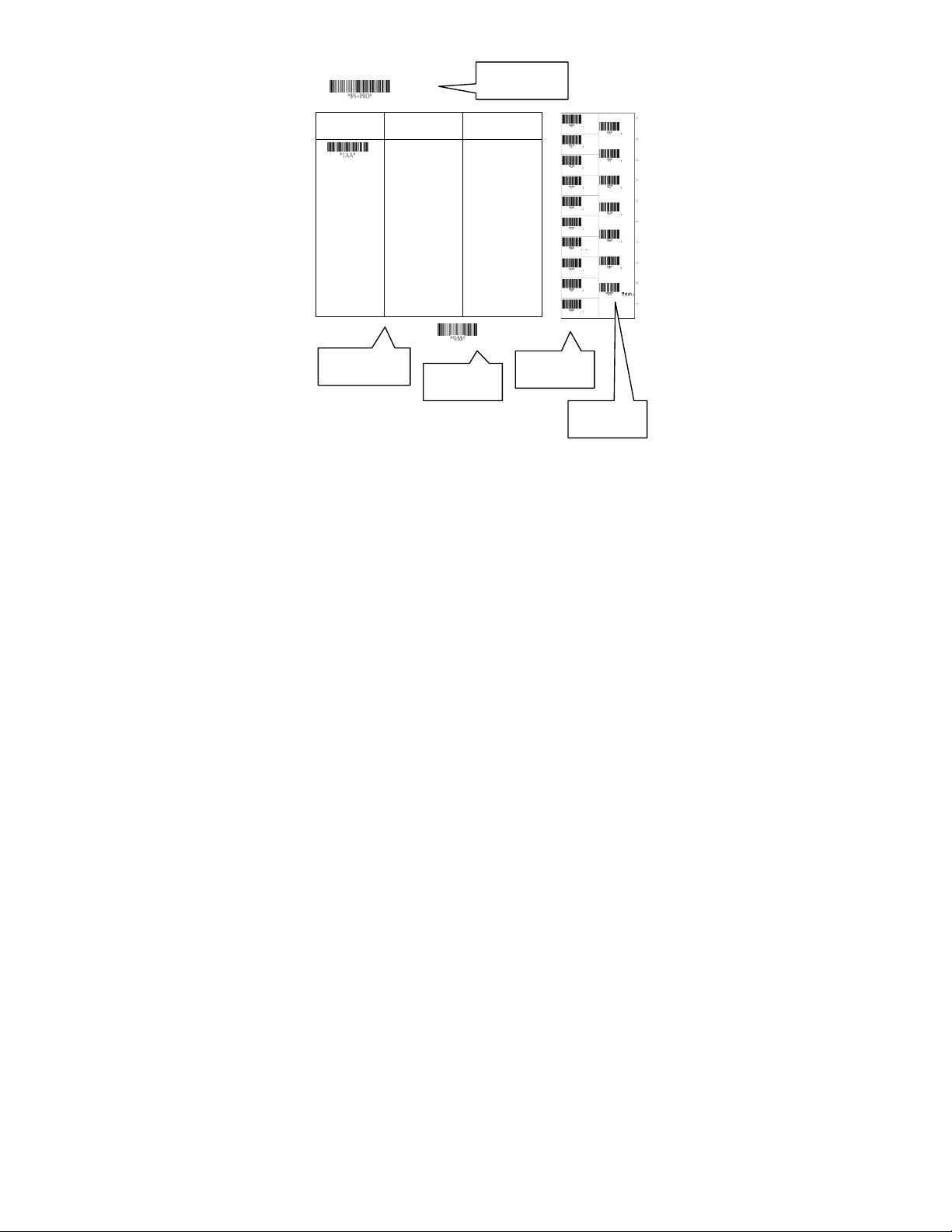

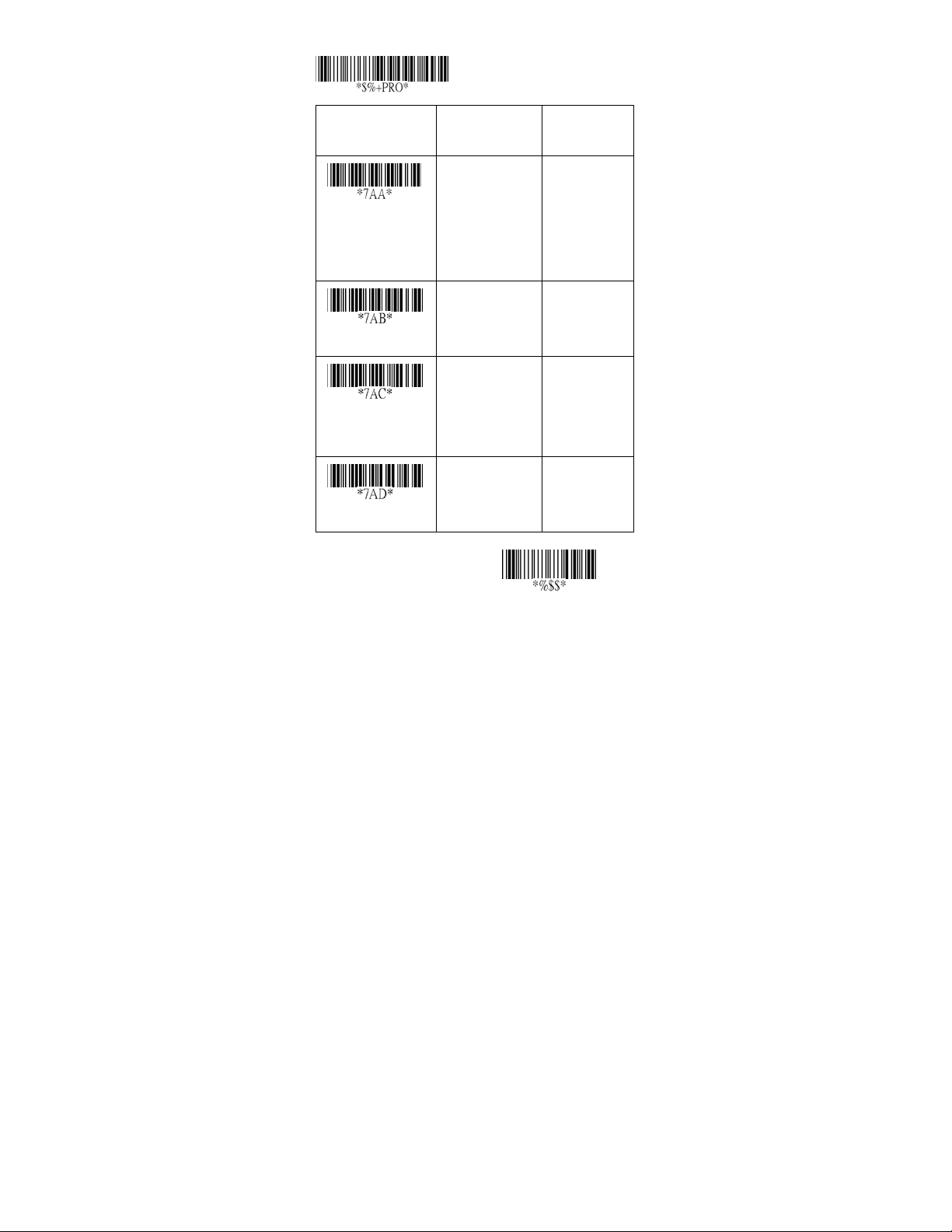

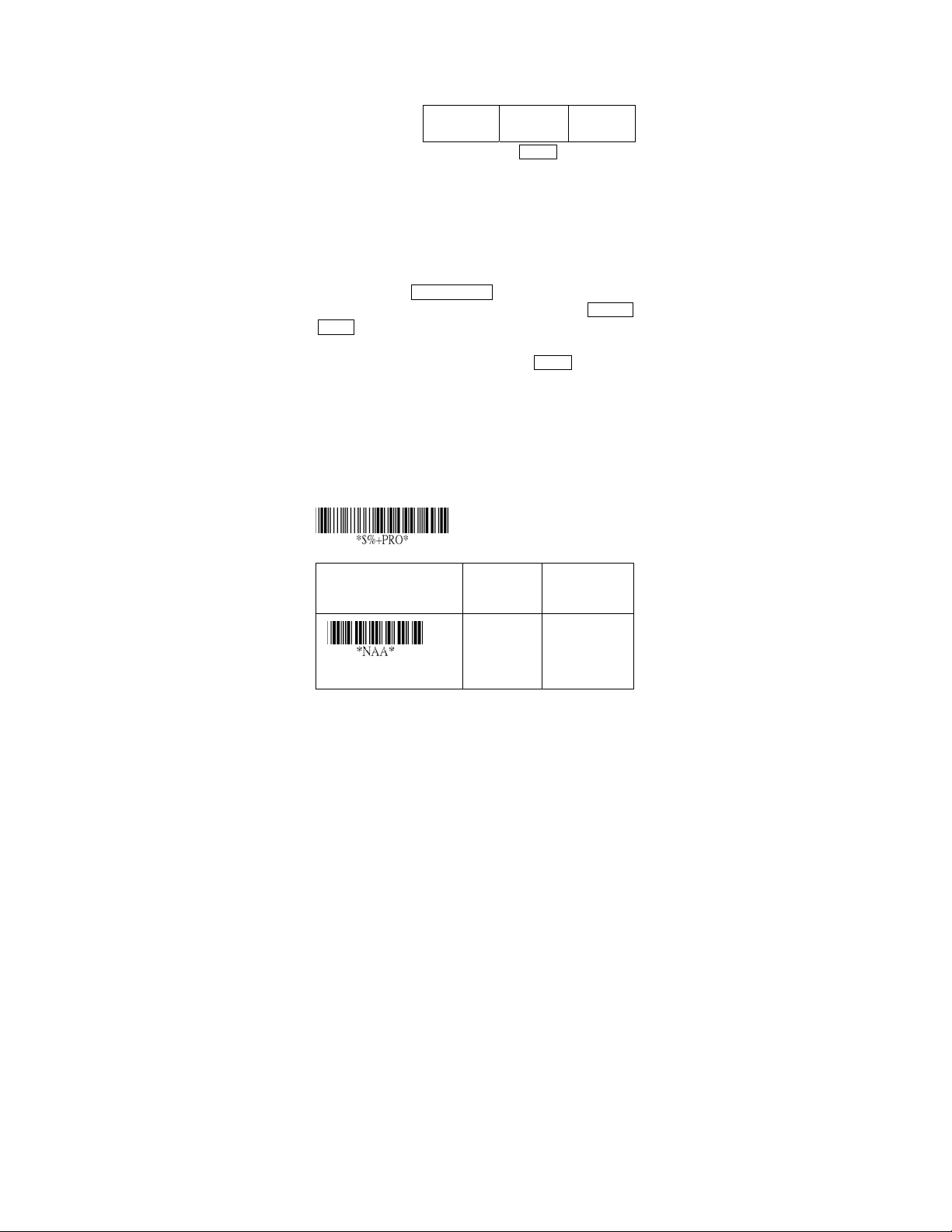

Programming the

LGZ7225

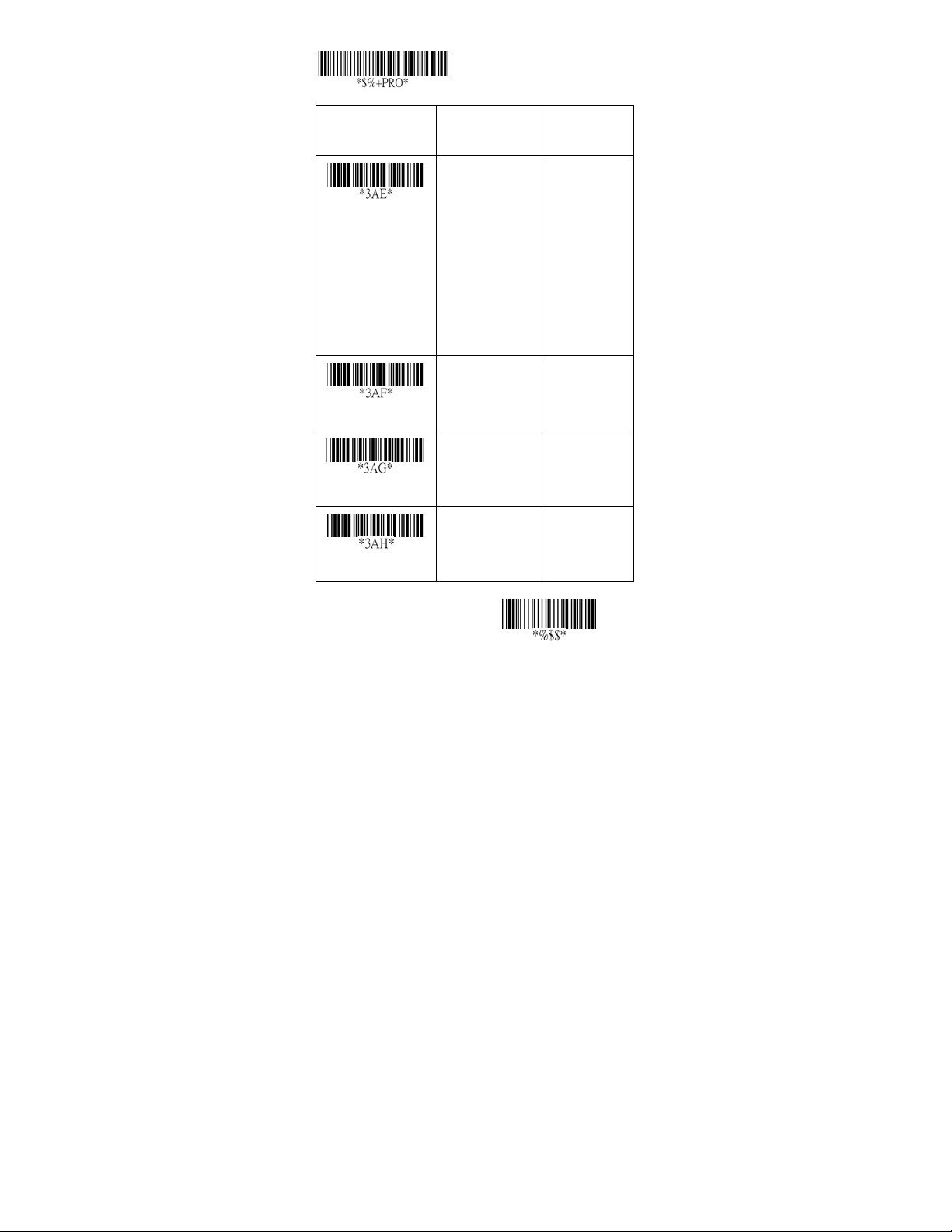

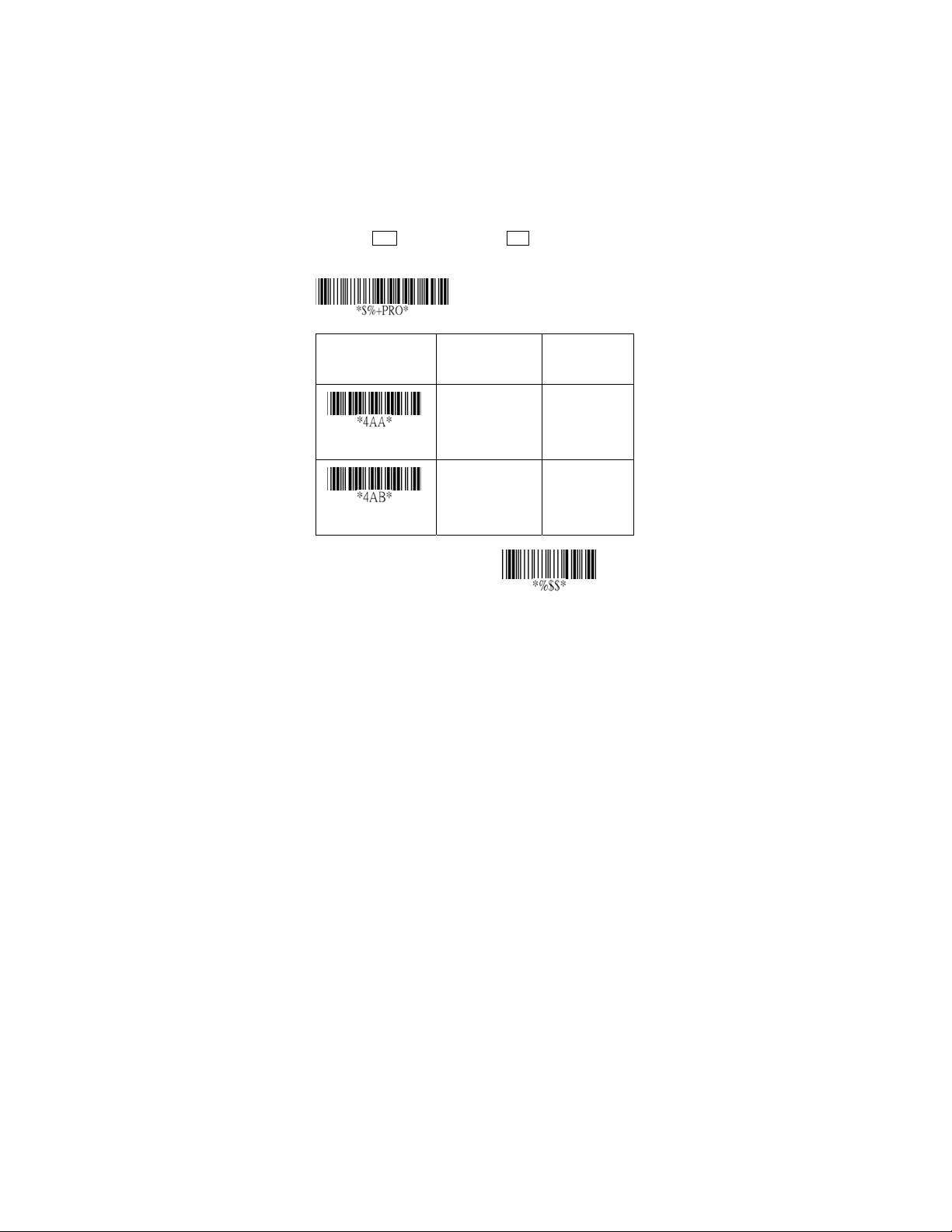

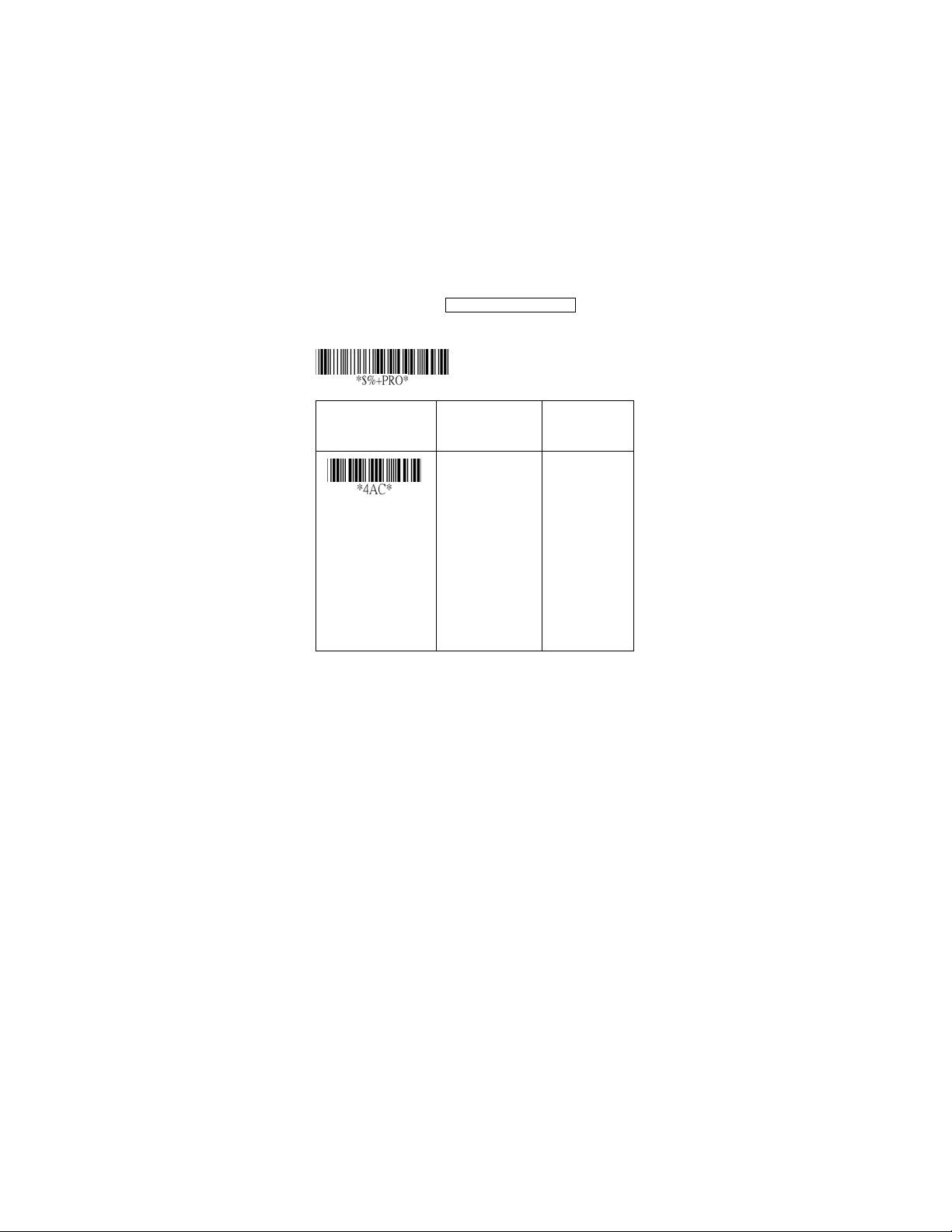

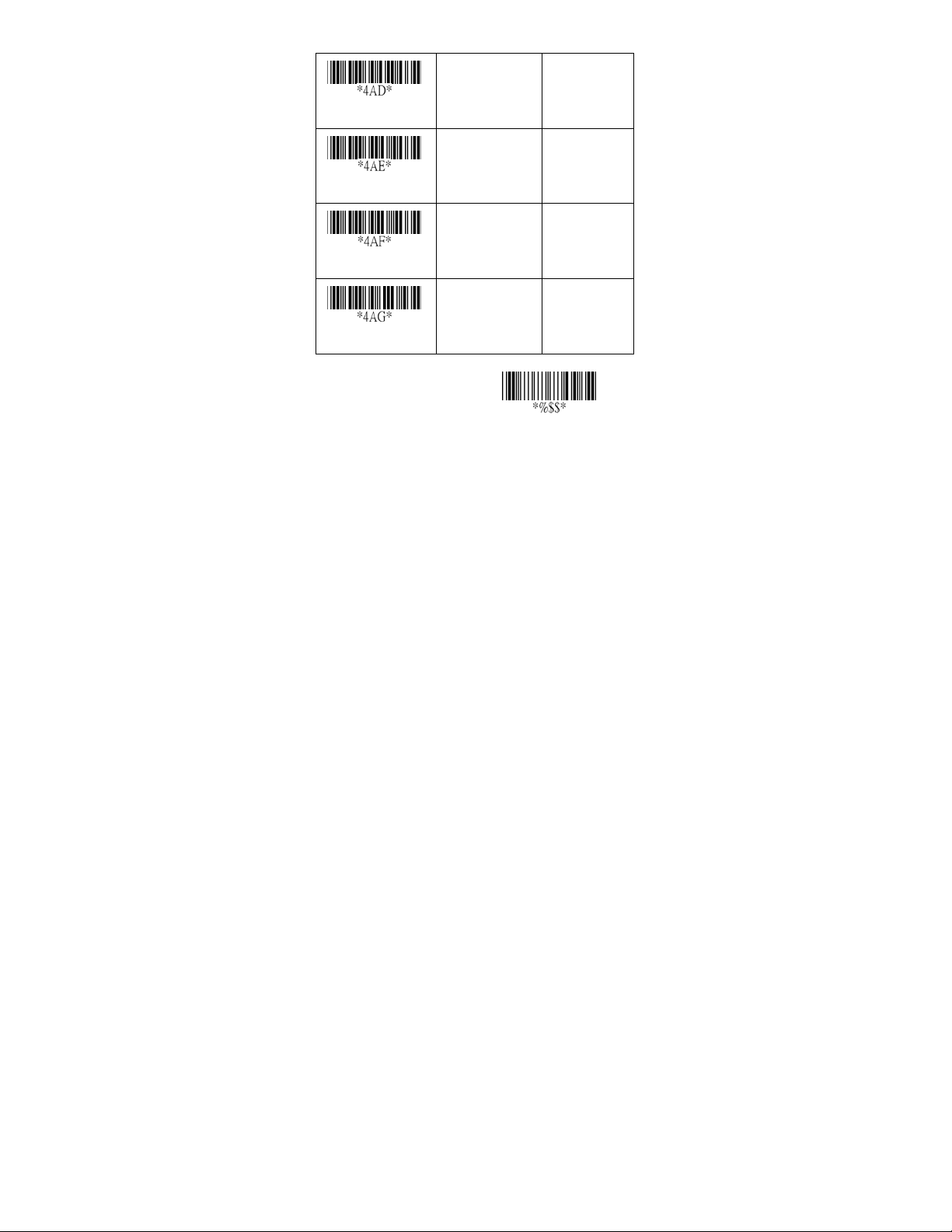

To program the LGZ7225 you must scan a series of

programming barcode in the correct order. Fold out the back

cover of this manual. You will see a table of alphanumeric

barcodes, which are used to program the various options

presented.

To program each option, you must:

1. Scan the Program barcode on the parameter setting part.

2. Enter the option mode by scanning the Option Bar Code

(also on the Parameter setting part).

3. To the right of the option barcode, the necessary

alphanumeric inputs are listed. Scan these alphanumeric

entries from the back fold out page. To confirm above

steps, you must scan the Finish barcode on the back fold

out page.

4. Once you have finished programming. Scan the Exit

barcode, listed on the lower right hand corner of each

parameter setting part.

7

Page 8

Program

Program Barcode

Option Bar Code Option Alphanumeric Entry

Interface

selection

Option Barcode

Keyboard Wedge

RS-232

Wand emulation

USB

Keyboard/RS-232

Auto detection

reserved

Exit Barcode

00ഖ

01

02

03

04

05

Exit

Back Fold Out

Finish barcode

8

Page 9

Interface Selection

This decoder built-in scanner comes in one model and

supports interfaces such as keyboard wedge, RS232 serial

wedge, wand emulation, and the latest USB interface. In

most of the cases, simply sutilizing the an appropriate cable with

a device code will work for a specific interface.

Interface selection: You can change factory interface

default for other type interface. By plugging different cables,

setting correct interface, then the scanner will be changed to

another interface. However, you must make sure which cable

you need.

Keyboard/RS232/UBS Auto detection: By setting this

function, it will automatically select the Keyboard wedge or

RS-232 or UBS interface for user.

Program

Option Bar Code Option Alphanumeric

Entry

Interface selection

Note:ഖ-Default

Keyboard Wedge

RS-232

Wand emulation

USB

Keyboard

/RS232/USB

Auto detection

Reserved

00

01

02

03

04

05

ഖ

Exit

9

Page 10

Keyboard wedge

As a keyboard interface, the scanner supports most of the

popular PCs and IBM terminals. The installation of the wedge

is a fairly simple process without any changes of software or

hardware.

Keyboard Type: Select keyboard type connector of your

host computer. Scanner must be selected to the appropriate

host interface cable converter.

Program

Option Bar Code Option Alphanumeric

Entry

Keyboard type

IBM AT, PS/2

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

00

01

02

03

04

05

06

ഖ

Exit

10

Page 11

Keyboard wedge

Keyboard Layout: The selecting of keyboard layout

supports many country languages other than USA keyboard

layout. First you need to confirm country language that you

desire. In DOS, using command “keyb” to select the

desirable keyboard layout or in WINDOWS entry “Control”

then pops “Keyboard” to select country at “language” item.

For details, please refer to your DOS or WINDOWS user’s

manual.

Keyboard Speed: By selecting, you can change output

speed of scanner to match with host computer. Generally, set

00 or 01 in working high speed. If some output characters of

barcode have been lost, you may need to set 05 or 06 to

match your host keyboard speed.

Function Key: Set Enable , scanner can output code as

pressing function-key in your application program while the

barcode datas contain ASCII value between 0116 to 1F16.

Refer to ASCII table, page 94.

Numeric Key: The Keypad has to be selected if your

application program is only keypad numeric code acceptable.

So, scanner will output code as press numeric keypad when

it read numeric digit. (The keypad is in the right side of

keyboard, and Num Lock control key is also on.) If

Alt+Keypad is selected, Caps Lock and output will be

independent.

Program

Option Bar Code Option Alphanumeric

Entry

11

Page 12

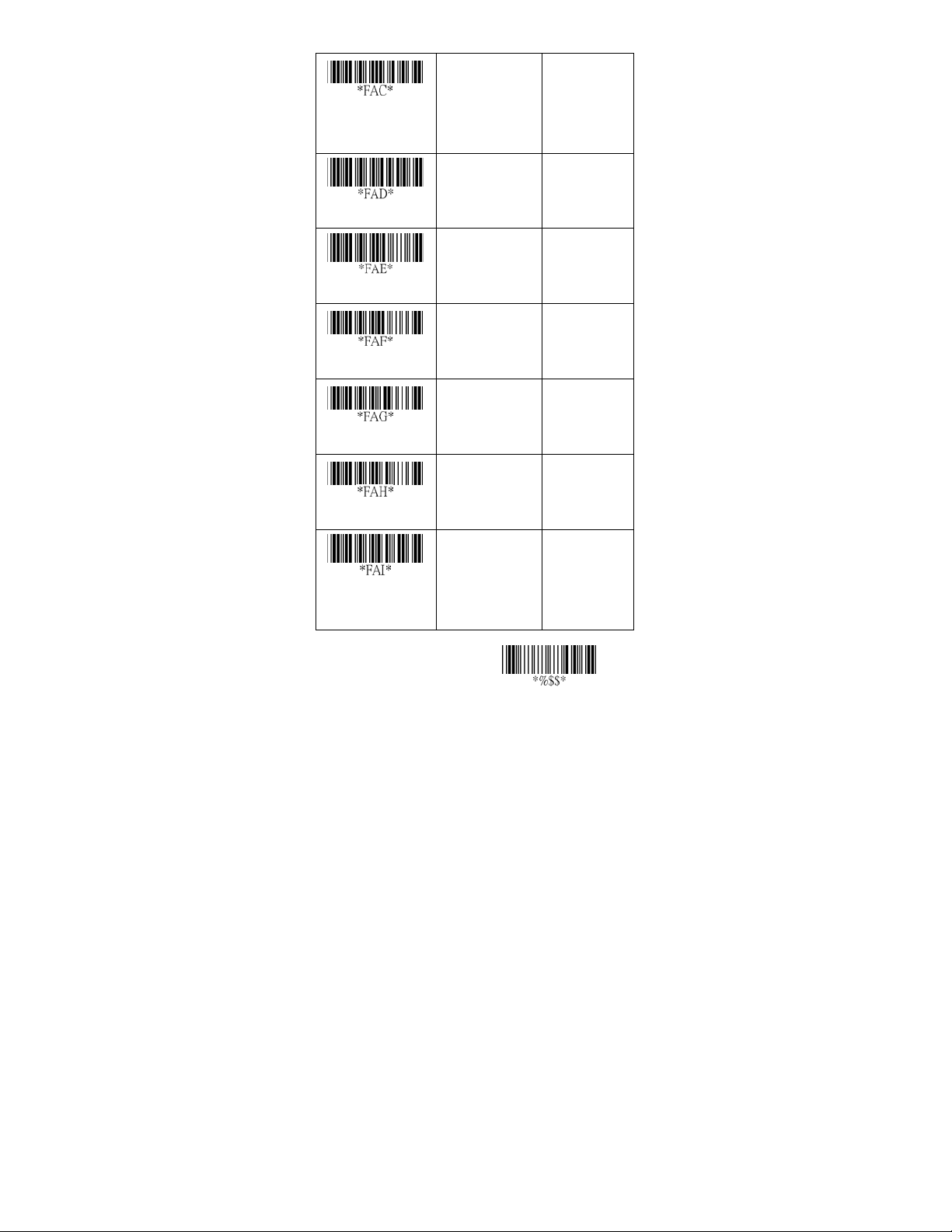

Keyboard layout

Keyboard speed

Function key

Numeric key

USA

Belgium

Danish

France

Germany

Italian

Portuguese

Spanish

Swedish

Switzerland

UK

Latin American

0-8

0 : high clock rate

8 : low clock rate

Disable

Enable

Alphabetic key

Numeric keypad

(Num lock state

only)

Alt+Keypad

00

ഖ

01

02

03

04

05

06

07

08

09

10

11

00-08

01

ഖ

00

ഖ

01

00

ഖ

01

02

Exit

12

Page 13

Keyboard wedge

Caps Lock: By selecting Caps Lock or No Caps Lock,

scanner can get Caps Lock status.

Power-on simulation: All of the PCs check the keyboard

status during power-on selftest. It is recommended to Enable

function if you are working without keyboard installation. It

simulates keyboard timing and pass keyboard present status

to the PC during power-on.

Inter-character delay: This delay is inserted after each data

characters transmitted. If the transmission speed is too high,

the system may not be able to receive all characters. Adjust it

and try out suited delay to make system work properly.

Block transmission delay: It is a delay timer between

barcode data output. The feature is used to transfer

continually with shorter barcode data or multi-field scanning.

13

Page 14

Program

Option Bar Code Option Alphanumeric

Entry

Caps lock”ON”

Caps lock”OFF”

Caps lock

Disable

Enable

Power-on simulation

00-99 msec 00-99

Inter-character delay

00-99 10 msec 00-99

Block transmission

delay

00

01

00

01

02

10

ഖ

ഖ

ഖ

ഖ

Exit

14

Page 15

RS-232

CTS: Clear To Send (Hardware Signal)

RTS: Request To Send (Hardware Signal)

Xon: Transmit On (ASCII Code 11

Xoff: Transmit Off (ASCII Code13

Flow control:

None-The communication only uses TxD and RxD signals

without regard for any hardware or software handshaking

protocol.

RTS/CTS-If the scanner wants to send the barcode data to

host computer, it will issue the RTS signal first, wait for the

CTS signal from the host computer, and then perform the

normal data communication. If there is no replied CTS signal

from the host computer after the timeout (Response Delay)

duration, the scanner will issue a 5 warning beeps.

Xon/Xoff- When the host computer is unable to accept data,

it sends a Xoff code to inform the scanner to suspend data

transmission, and Xon to continue.

ACK/NAK- When the ACK/NAK protocol is used, the

scanner waits for an ACK (acknowledge) or (not

acknowledge) from the host computer after data transmission,

and will resend in response to a NAK.

Inter-character delay: It is delay time between data

character’s data output. It is also same as Inter-char. delay of

keyboard wedge.

16)

16)

Block transmission delay: It is a delay time between

barcode data output. It is also same as Block transmission

delay of keyboard wedge.

Response delay: This delay is used for serial

communication of the scanner to waiting for handshaking

acknowledgment from the host computer.

15

Page 16

Program

Option Bar Code Option Alphanumeric

Entry

Flow control

Inter-character delay

Block transmission

delay

Response delay

None

RTS/CTS

Xon/Xoff

ACK/NAK

00-99 (msec)

00-99 (10 msec)

00-99 (100 msec)

00

ഖ

01

02

03

00-99

ഖ

00

00-99

00

ഖ

00-99

ഖ

20

Exit

16

Page 17

Program

Option Bar Code Option Alphanumeric

Entry

Baud rate

Parity

Data bit

Stop bit

300 BPS

600 BPS

1200 BPS

2400 BPS

4800 BPS

9600 BPS

19200 BPS

38400 BPS

None

Odd

Even

8 bits

7 bits

One bit

Two bits

00

01

02

03

04

05

06

07

00

01

02

00

01

00

01

ഖ

ഖ

ഖ

ഖ

Exit

17

Page 18

Wand Emulation

Bar/space polarity:

High/low- Black will be transmitted as a high voltage level

(+5) and space as low level (0V).

Low/high- Black will be transmitted as a low voltage level

(0V) and space as high level (+5).

Initial polarity: You must make sure what is Initial polarity of

your wand decode device in stand-by (idle). So, initial signal

state as a High voltage level (+5) or Low voltage level (0V).

Program

Option Bar Code Option Alphanumeric

Entry

High/low

Low/high

Bar/space polarity

Low

High

Initial polarity

00

01

00

01

ഖ

ഖ

Exit

18

Page 19

Wand Emulation

Output speed: This setting is same as serial transmission

baud rate, and it must be approbated your wand decode

resolution. The unit of speed is a width of minimum narrow

bar.

Margin delay: It is a timer of zone like space zone of

barcode label margin. The width of margin time will be added

before and after in each barcode data automatically when it

is transmitted.

Transmit delay: It is a delay time between barcode data

output. It is the same as Block transmission delay of

keyboard wedge.

Program

Option Bar Code Option Alphanumeric

Entry

Output speed

620 pps

1250 pps

2500 pps

5000 pps

10000 pps

20000 pps

*pps: pixel per

second

00

01

02

03

04

05

ഖ

19

Page 20

Reserved

Reserved

Margin delay

Transmit delay

00-99 (10 pixel)

00-99 (10 msec)

00

ഖ

00

ഖ

00-99

ഖ

15

00-99

30

ഖ

Exit

20

Page 21

Scan

Scanning mode:

Good-read off-The trigger button must be pressed to

activate scanning. The light source of scanner stops

scanning when there is a successful reading or no code is

decoded after the Stand-by duration elapsed.

Momentary-The trigger button acts as a switch. Press button

to activate scanning and release button to stop scanning.

Alternate-The trigger button acts as a toggle switch. Press

button to activate or stop scanning.

Timeout off-The trigger button must be pressed to activate

scanning, and scanner stops scanning when no code is

decoded after the Stand-by duration elapsed.

Continue-The scanner always keeps reading, and it does

not matter when trigger button is pressed or duration is

elapsed.

Same Barcode delay time: If the barcode has been

scanned twice, then only the first barcode will be accepted.

Double confirm: If it is enabled, the scanner will require a

several times successful decoding to confirm the barcode

data. The more confirming times required the more inhibitive

miss-reading code will be shown. If you set Double confirm,

the Multi field scan Enable function won’t be able to work.

21

Page 22

Program

Option Bar Code Option Alphanumeric

Entry

00

01

02

03

04

10

50

00-09

00

ഖ

ഖ

ഖ

ഖ

Scanning mode

Stand-by duration

Same barcode delay

time

Double confirm

Good-read off

Momentary

Alternate

Timeout off

Continue

01-99 (second) 00-99

01-99 (10 msec) 01-99

00-99

(00: no double

confirm)

Exit

22

Page 23

Scan

Multi field scan: The scanner can be read many sets of

barcode data on the same scanning line at the same time,

even if they are different kinds of barcode symbology.

Global min./max. code length: Global Minimum and

Maximum length can be set to qualify data entry. The length

is defined as the actual barcode data length to be sent. Label

with length exceeds these limits will be rejected. Make sure

that the Minimum length setting is no greater than the

Maximum length setting, or otherwise the labels of the

symbology will not be readable. In particular, you can set the

same value for both Minimum and Maximum reading length

to force the fixed length barcode decoded. The values of

setting have no effect on certain symbologies with fixed

length.

Notes 1): Please set the min/max length if you have special

demand for individual barcode.

2): Include the Check sum digits if you want to set

Global min/max code length.

Inverted image scan:. Set Enabled the scanner will scan

both black/white barcode with white/black background.

CTS trigger: This operation enabled an external device to

control scanning. The CTS trigger is controlled by apply an

external trigger signal to the CTS input. When active, this

signal causes scanning to begin as the scanner’s trigger was

depressed.

Position indication: This function can indicate the specific

location before scanning. You can also set up the time of

indication(except AS-8110).

Program

Option Bar Code Option Alphanumeric

Entry

23

Page 24

Multi field scan

Global min. code length

Global max.code length

Inverted image scan

CTS trigger

Position indication

Disable

Enable

00-63 00-63

00-63 04-63

Disable

Enable

Disable

Enable

Disable

30 second

60 second

90 second

120 second

150 second

180 second

Continue

00

01

04

63

00

01

00

01

00

01

02

03

04

05

06

07

ഖ

ഖ

ഖ

ഖ

ഖ

ഖ

Exit

24

Page 25

Indication

Power on alert: After power-on the scanner it will generate

an alert signal to indicate a successful self-test.

LED indication: After each successful reading, the LED

above the scanner will light up to indicate a good barcode

reading.

Buzzer indication: After each successful reading, the

scanner will beep buzzer to indicate a good barcode reading,

and its Beep loudness, Beep tone freq. and Beep tone

duration are adjustable.

Beep loudness/Beep tone freq./Beep tone duration: Yo u

can adjust Beep Loudness , Beep tone and Beep duration for

a good reading upon favorite usage.

Exit

25

Page 26

Program

Option Bar Code Option Alphanumeric

Entry

Disable

Enable

Power on alert

Disable

Enable

LED indication

Disable

Enable

Buzzer indication

00-07 00-07

Beep loudness

00-99 (100Hz) 00-99

Beep tone freq.

00-99 (10 msec) 00-99

Beep tone duration

00

01

00

01

00

01

07

26

10

ഖ

ഖ

ഖ

ഖ

ഖ

ഖ

Exit

26

Page 27

UPCA

Read: Format

Leading

Zero

Check-sum transmission: By setting Enable, checks sum

will be transmitted.

Truncate leading/ending: The leading or ending digits of

barcode data characters can be truncated when these values

are set to non-zero. It will beep instead of reading anything

when the truncate value is more than the barcode data digits

or the value of Truncate Leading is overlapped with that of

the Ending. The maximum value of truncate digits is 15.

Code ID setting: Code ID setting is a character used to

represent the symbol upon a succeeding reading. A Code ID

setting is prefixed to the data begin or end transmitted if the

feature is selected. If you want application to transmit Code

ID, you must set Code ID transmission to Enable first. Refer

to Code ID transmission.

Insertion group selection: The scanner offer one or two

insertion group for own symbology. By setting one or two

digits to indicate which insertion group you want to insert.

You may refer to Character insertion.

Example: Group 2 ඎ set 02 or 20.

Group 1 and 4 ඎ set 14 or 41.

Data Digits

(11 Digits)

Check

Digit

Program

Option Bar Code Option Alphanumeric

Entry

Disable

Enable

Read

00

01

ഖ

27

Page 28

Check-sum verification

Check-sum transmission

Max.code length

Min.code length

Truncate leading

Truncate ending

Code ID setting

Insert group selection

Disable

Enable

Disable

Enable

00-64 00-64

00-64 00-64

0-15 00-15

0-15 00-15

00-ffH ASCII

code

00-44 00-44

00

01

00

01

64

01

00

00

00-ffH

< A >

00

ഖ

ഖ

ഖ

ഖ

ഖ

ഖ

ഖ

ഖ

Exit

28

Page 29

UPCA

Supplement digits: The Supplement digits barcode is the

supplemental 2 or 5 characters for WPC code.

Format

Leading

Truncate Leading zero: The leading “0” digits of UPCA data

characters can be truncated when the function is enabled.

Option Bar Code Option Alphanumeric

Supplement digits

Truncate Leading zero

Zero

Data Digits

(11 Digits)

Program

Supplement Digits

Check

Digit

None

2 digits

5 digits

UCC/EAN 128

Auto detection

Disable

Enable

UCC / EAN 128

2 or 5 or

00

01

02

03

04

00

01

Entry

ഖ

ഖ

The

Exit

29

Page 30

UPCE

Read: Format

Leading

Zero

Check-sum verification: The checksum of EAN-13 is

optional and made as the sum of the numerical value of the

data digits.

Check-sum transmission: By setting Enable, checks sum

will be transmitted.

Option Bar Code Option Alphanumeric

Read

Check-sum

verification

Check-sum

transmission

Program

Disable

Enable

Disable

Enable

Disable

Enable

Data Digits (6

Digits)

00

01

00

01

00

01

Check

Digits

Entry

ഖ

ഖ

ഖ

Exit

30

Page 31

UPCE

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Supplement digits:

Format

Leading

Zero

Truncate Leading zero: Refer to Truncate Leading zero of

UPCA.

Expansion: The expansion function is used only for UPCE

and EAN-8 code reading. It extends to 13-digits with “0” digits

when the feature is enabled.

Example: Barcode “0123654”

Output: “0012360000057”

Data Digits

(6 Digits)

Check

Digit

Supplement Digits

2 or 5 or

UCC/EAN 128

Option Bar Code Option Alphanumeric

Truncate leading

Program

0-15 00-15

ഖ

00

Entry

31

Page 32

Truncate ending

Code ID setting

Insert group

selection

Supplement digits

Truncate Leading

zero

Expansion

0-15 00-15

ഖ

00

00-ffH ASCII

code

00-44 00-44

None

2 digits

5 digits

UCC/EAN 128

Auto detection

Disable

Enable

Disable

Enable

00-ffH

< E >

00

ഖ

00

ഖ

01

02

03

04

00

ഖ

01

00

ഖ

01

ഖ

Exit

32

Page 33

EAN-13

Read: Format

Data Digits (12 Digits) Check Digits

Check-sum verification: The checksum of EAN-13 is

optional and made as the sum of the numerical value of the

data digits.

Check-sum transmission: By setting Enable, checks sum

will be transmitted.

Max./Min. code length: Each symbology has own Max./Min.

Code Length. They can be set to qualify data entry. If their

Max./Min. Code Length is zero, the Global Min./Max. Code

Length is in effect. The length is defined as to the actual

barcode data length to be sent. Label with length exceeds

these limits will be rejected. Make sure that the Minimum

length setting is no greater than the Maximum length setting,

or otherwise all the labels of the symboblogy will not be

readable. In particular, you can see the same value for both

Minimum and Maximum reading length to force the fixed

length barcode decoded.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

The

Option Bar Code Option Alphanumeric

Read

Program

Disable

Enable

00

01

Entry

ഖ

33

Page 34

Check-sum

verification

Check-sum

transmission

Max.code length

Min.code length

Truncate leading

Truncate ending

Disable

Enable

Disable

Enable

00-64 00-64

00-64 00-64

0-15 00-15

0-15 00-15

00

01

00

01

01

00

00

64

ഖ

ഖ

ഖ

ഖ

ഖ

ഖ

Exit

34

Page 35

EAN-13

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Supplement digits:

Format

Data Digits

(12 Digits)

ISBN/ISSN: The ISBN (International Standard Book Number)

and ISSN (International Standard Serial Number) are two

kinds of barcode for book and magazines. The ISBN is 10

digits with leading “978” and the ISSN is 8 digits with leading

“977” of the “EAN-13” symbobolgy.

Example: Barcode “9789572222720” - Output: “9572222724”

Example: Barcode “9771019248004” - Output: “10192484”

Check

Digits

Supplement Digits

2 or 5 or

UCC / EAN 128

35

Page 36

Program

Option Bar Code Option Alphanumeric

Entry

Code ID setting

Insert group

selection

Supplement digits

ISBN/ISSN

conversion

00-ffH ASCII

code

00-44 00-44

None

2 digits

5 digits

UCC/EAN 128

Auto detection

Disable

Enable

00-ffH

< F >

00

ഖ

00

ഖ

01

02

03

04

00

ഖ

01

ഖ

Exit

36

Page 37

EAN-8

Read: Format

Data Digits

(7 Digits)

Check-sum verification: The checksum of EAN-8 is

optional and made as the sum of the numerical value of the

data digits.

Check-sum transmission: By setting Enable, checks sum

will be transmitted.

Max./Min. code length: Refer to Max./Min. code length of

EAN-13.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA

Insertion group selection: Refer to Insertion group

selection of UPCA.

Option Bar Code Option Alphanumeric

Read

Check-sum

verification

Program

Disable

Enable

Disable

Enable

00

01

00

01

Check

Digits

Entry

ഖ

ഖ

37

Page 38

Check-sum

transmission

Max.code length

Min.code length

Truncate leading

Truncate ending

Code ID setting

Insert group

selection

Disable

Enable

00-64 00-64

00-64 00-64

0-15 00-15

0-15 00-15

Two characters

00-ffH ASCII

code

00-44 00-44

00

ഖ

01

ഖ

64

ഖ

01

00

ഖ

ഖ

00

00-ffH, 00-ffH

< FF >

00

ഖ

ഖ

Exit

38

Page 39

EAN-8

Supplement digits: Format

Data Digits

(7 Digits)

Truncate Leading zero: Refer to Truncate Leading zero of

UPCE.

Expansion: Refer to Expansion of UPCE.

Option Bar Code Option Alphanumeric

Supplement digits

Truncate Leading

zero

Expansion

Check

Digits

Program

None

2 digits

5 digits

UCC/EAN 128

Auto detection

Disable

Enable

Disable

Enable

Supplement Digits

2 or 5 or

UCC/EAN 128

Entry

00

ഖ

01

02

03

04

00

ഖ

01

00

ഖ

01

Exit

39

Page 40

Code 39

Read: Format

Start

Data Digits

“့”

( Variable)

Check-sum verification: The checksum of Code-39 is

optional and made as the sum module 43 of the numerical

value of the data digits.

Check-sum transmission: By setting Enable, checksum

and will be transmitted.

Option Bar Code Option Alphanumeric

Read

Check-sum

verification

Check-sum

transmission

Program

Disable

Enable

Disable

Enable

Disable

Enable

Checksum

(Optional)

00

ഖ

01

00

ഖ

01

00

ഖ

01

End

“့”

Entry

Exit

40

Page 41

Code 39

Max./Min. code length: Each symbology has own Max./Min.

Code Length. They can be set to qualify data entry. If their

Max./Min. Code Length is zero, the Global Min./Max. Code

Length is in effect. The length is defined as to the actual

barcode data length to be sent. Label with length exceeds

these limits will be rejected. Make sure that the Minimum

length setting is no greater than the Maximum length setting,

or otherwise all the labels of the symboblogy will not be

readable. In particular, you can see the same value for both

Minimum and Maximum reading length to force the fixed

length barcode decoded.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Format: The Full ASCII Code-39 is an enhanced set of

Code-39 that is the data with total of 128 characters to

represent Full ASCII code. It is combined one of the digits +,

%, $ and/ with one of the alpha digits (A to Z).

Program

Option Bar Code Option Alphanumeric

Entry

41

Page 42

Max. code length

Min. code length

Truncate leading

Truncate ending

Code ID setting

Insert group

selection

Format

00-64 00-64

ഖ

00

00-64 00-64

00

ഖ

0-15 00-15

ഖ

00

0-15 00-15

00

ഖ

00-ffH ASCII

code

00-44 00-44

Standard

Full ASCII

00-ffH

<

ഖ>

00

ഖ

00

ഖ

01

Exit

42

Page 43

Code 39

Append: This function allows several symbols to be

concatenates and be treat as one single data entry. The

scanner will not transmit the embedded appending code

(space for Code-39). If Enable and other symbols were read

again with the appended code, then codes will be transmitted

without Code ID, Preamble and Prefix. When a symbol was

decoded without the appended code, the data will be

transmitted without Code ID and Prefix, but the Postamble

Suffix codes are appended. This function is used when the

first number of code 39 is a space. Example: 123456.

Start/end transmission: The start and end characters of

Code-39 are“့”. You can transmit all data digits including two

“့”.

Program

Option Bar Code Option Alphanumeric

Entry

Disable

Enable

Append

Disable

Enable

Start/end

transmission

00

01

00

01

ഖ

ഖ

Exit

43

Page 44

Interleaved 2 of 5

Read: Format

Data Digits

(Variable)

Check-sum verification: The checksum is made as the sum

module 10 of the numerical values of all data digits.

Check-sum transmission: By setting Enable, checksum

and will be transmitted.

Program

Option Bar Code Option Alphanumeric

Disable

Enable

Read

Disable

Enable

Check-sum

verification

Disable

Enable

Check-sum

transmission

Checksum

(Optional)

Entry

00

ഖ

01

00

01

ഖ

00

ഖ

01

Exit

44

Page 45

Interleaved 2 of 5

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Program

Option Bar Code Option Alphanumeric

Entry

00-64 00-64

00

ഖ

Max. code leading

00-64 00-64

00

ഖ

Min. code leading

0-15 00-15

ഖ

00

Truncate leading

0-15 00-15

ഖ

00

Truncate ending

45

Page 46

Code ID setting

Insert group

selection

00-ffH ASCII

code

00-44 00-44

00-ffH

< i >

00

ഖ

ഖ

Exit

46

Page 47

Industrial 2 of 5

Read: Format

Data Digits

(Variable)

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Program

Option Bar Code Option Alphanumeric

Disable

Enable

Read

00-64 00-64

Max. code length

00-64 00-64

Min. code length

Checksum

(Optional)

Entry

ഖ

00

01

00

ഖ

00

ഖ

47

Page 48

Truncate leading

Truncate ending

Code ID setting

Insert group

selection

0-15 00-15

ഖ

00

0-15 00-15

00

ഖ

00-ffH ASCII

code

00-44 00-44

00-ffH

< i >

00

ഖ

ഖ

Exit

48

Page 49

Matrix 2 of 5 Eur

Read: Format

Data Digits

(Variable)

Checksum Verification: The checksum is made as the sum

module 10 of the numerical values of all data digits.

Checksum Transmission: By setting Enable, checksum

and will be transmitted.

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Checksum

(Optional)

Option Bar Code Option Alphanumeric

Read

Checksum

Verification

Program

Disable

Enable

Disable

Enable

00

01

00

01

Entry

ഖ

ഖ

49

Page 50

Checksum

Transmission

Max. code length

Min. code length

Truncate leading

Truncate ending

Code ID setting

Insert group

selection

Disable

Enable

00-64 00-64

00-64 00-64

0-15 00-15

0-15 00-15

00-ffH ASCII

code

00-44 00- 44

00

ഖ

01

ഖ

00

ഖ

00

00

ഖ

ഖ

00

00-ffH

< B >

00

ഖ

ഖ

Exit

50

Page 51

Codabar

Read: Format

Start Data Digits (Variable) Checksum (Optional) End

Checksum Verification: The checksum is made as the sum

module 16 of the numerical values of all data digits.

Checksum Transmission: By setting Enable, checksum

and will be transmitted.

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Program

Option Bar Code Option Alphanumeric

Entry

Disable

Enable

Read

Disable

Enable

Checksum

Verification

ഖ(8150/8210)

00

01ഖ(8110)

00

ഖ

01

51

Page 52

Checksum

Transmission

Max. code length

Min. code length

Truncate leading

Truncate ending

Code ID setting

Disable

Enable

00-64 00-64

00-64 00-64

0-15 00-15

0-15 00-15

00-ffH ASCII

code

00

ഖ

01

ഖ

00

ഖ

00

00

ഖ

ഖ

00

00-ffH

< % >

ഖ

Exit

52

Page 53

Codabar

Insertion group selection: Refer to Insertion group

selection of UPCA.

Start/End type: The Codabar has four pairs of Start/End

pattern; you may select one pair to match your application.

Start/End Transmission: Refer to Start/End Transmission of

Code 39.

Program

Option Bar Code Option Alphanumeric

Entry

00-44 00-44

00

ഖ

Insert group

selection

Start/End type

Start/End

transmission

ABCD/ABCD

abcd/abcd

ABCD/TN*E

Abcd/tn*e

Disable

Enable

00

01

02

03

00

01

ഖ

ഖ

Exit

53

Page 54

Code-128

Read: Format

Data Digits

(Variable)

Checksum Verification: The checksum is made as the sum

module 103 of all data digits.

Checksum Transmission: By setting Enable, checksum

and will be transmitted.

Program

Option Bar Code Option Alphanumeric

Disable

Enable

Read

Disable

Enable

Checksum

Verification

Disable

Enable

Checksum

Transmission

Checksum

(Optional)

00

ഖ

01

00

01

ഖ

00

ഖ

01

Entry

Exit

54

Page 55

Code-128

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Format: The Code-128 can be translated to UCC/EAN-128

format if it starts with FNC1 character. The first FNC1 will

be translated to “]C1”,and next to be a field separator code as

<GS>(1D

]C1 Datas <GS> Datas Checksum

Append: When the function is enabled, it won't show the

data immediately if scanner read the barcode includes FNC2

code. It will show all data until it read the barcode, which

doesn't have FNC2 code.

Field separator code: This feature is only used for

UCC/EAN-128 format. This Field separator code means you

can reassign second or after a FNC1 for your usage. The

default of ASCII code is <GS>(1D

16).

16).

Program

Option Bar Code Option Alphanumeric

Entry

00-64 00-64

00

ഖ

Max. code length

00-64 00-64

00

ഖ

Min. code length

55

Page 56

Truncate leading

Truncate ending

Code ID setting

Insert group selection

Format

Append

UCC/EAN-128

ID setting

Field separator code

0-15 00-15

00

ഖ

0-15 00-15

00

ഖ

00-ffH ASCII

code

00-44 00-44

Standard

UCC/EAN-128

Disable

Enable

00-ffH ASCII

code

00-ffH ASCII

code

00-ffH

< # >

00

00

01

00

01

00-ffH

< # >

00-ffH

1DH

ഖ

ഖ

ഖ

ഖ

ഖ

ഖ

56

Exit

Page 57

Code-93

Read: Format

Data Digits

(Variable)

Checksum Verification: The checksum is made as the sum

module 47 of the numerical values of all data digits.

Checksum Transmission: By setting Enable, checksum

and will be transmitted.

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Program

Option Bar Code Option Alphanumeric

Disable

Enable

Read

Disable

Enable (two

Checksum

Verification

digits)

Checksum1

(Optional)

Checksum2

(Optional)

Entry

ഖ

00

01

00

01

ഖ

57

Page 58

Checksum

Transmission

Max. code length

Min. code length

Truncate leading

Truncate ending

Code ID setting

Insert group

selection

Disable

Enable

00-64 00-64

00-64 00-64

0-15 00-15

0-15 00-15

00-ffH ASCII

code

00-44 00-44

00

ഖ

01

ഖ

00

00

ഖ

00

ഖ

ഖ

00

00-ffH

< & >

00

ഖ

ഖ

Exit

58

Page 59

Code-11

Read: Format

Data Digits

(Variable)

Checksum Verification: The checksum is presented as the

sum module 11 of all data digits.

Checksum Transmission: By setting Enable, checksum1

and checksum2 will be transmitted upon your selected

checksum verification method.

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Program

Option Bar Code Option Alphanumeric

Disable

Enable

Read

Disable

One digit

Checksum

Verification

Two digits

Checksum1

(Optional)

Checksum2

(Optional)

Entry

ഖ

00

01

00

01

ഖ

02

59

Page 60

Checksum

Transmission

Max. code length

Min. code length

Truncate leading

Truncate ending

Code ID setting

Insert group

selection

Disable

Enable

00-64 00-64

00-64 00-64

0-15 00-15

0-15 00-15

00-ffH ASCII

code

00-44 00-44

00

ഖ

01

ഖ

00

ഖ

00

00

ഖ

ഖ

00

00-ffH

< O >

00

ഖ

ഖ

Exit

60

Page 61

MSI/plessey

Read: Format

Data Digits

(Variable)

Checksum Verification: The MSI/Plessey has one or two

optional checksum digits. The checksum is presented 3

kinds of method Mod10, Mod10/10 and Mod 11/10. The

checksum1 and checksum2 will be calculated as the sum

module 10 or 11 of the data digits.

Checksum Transmission: By setting Enable, checksum1

and checksum2 will be transmitted upon your selected

checksum verification method.

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Program

Option Bar Code Option Alphanumeric

Disable

Enable

Read

Disable

Mod 10

Checksum

Verification

Mod 10/10

Mod 11/10

Checksum1

(Optional)

Checksum2

(Optional)

Entry

ഖ

00

01

00

ഖ(8110)

01ഖ(8150/8210)

02

03

61

Page 62

Checksum

Transmission

Max. code length

Min. code length

Truncate leading

Truncate ending

Code ID setting

Insert group

selection

Disable

Enable

00-64 00-64

00-64 00-64

0-15 00-15

0-15 00-15

00-ffH ASCII

code

00-44 00-44

00

ഖ

01

ഖ

00

ഖ

00

00

ഖ

ഖ

00

00-ffH

< @ >

00

ഖ

ഖ

Exit

62

Page 63

UK/plessey

Read: Format

Data Digits

(Variable)

Checksum Verification: The UK/Plessey has one or two

optional checksum digits. The checksum1 and checksum2

will be calculated as the sum module 10 or 11 of the data

digits.

Checksum Transmission: By setting Enable, checksum will

be transmitted.

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Program

Option Bar Code Option Alphanumeric

Disable

Enable

Read

Disable

Enable

Checksum

Verification

Checksum1+2

(Optional)

Entry

ഖ

00

01

00

01

ഖ

63

Page 64

Checksum

Transmission

Max. code length

Min. code length

Truncate leading

Truncate ending

Code ID setting

Insert group

selection

Disable

Enable

00-64 00-64

00-64 00-64

0-15 00-15

0-15 00-15

00-ffH ASCII

code

00-44 00-44

00

ഖ

01

ഖ

00

ഖ

00

00

ഖ

ഖ

00

00-ffH

< @ >

00

ഖ

ഖ

Exit

64

Page 65

Telepen

Read: IATA (International Air Transport Association).

Checksum Verification: The checksum is presented as the

sum module 10 or 11 of the data digits.

Checksum Transmission: By setting Enable, checksum will

be transmitted.

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Program

Option Bar Code Option Alphanumeric

Entry

Disable

Enable

Read

Disable

Enable

Checksum

Verification

Disable

Enable

Checksum

Transmission

00

01

00

01

00

01

ഖ

ഖ

ഖ

65

Page 66

Max. code length

Min. code length

Truncate leading

Truncate ending

Code ID setting

Insert group

selection

)RUPDW

00-64 00-64

ഖ

00

00-64 00-64

00

ഖ

0-15 00-15

00

ഖ

0-15 00-15

00

ഖ

00-ffH ASCII

code

00-44 00-44

1XPHULFRQO\

)XOO$6&,,RQO\

00-ffH

< S >

00

ഖ

ഖ

ഖ

Exit

66

Page 67

Standard 2 of 5

Read: Format

Data Digits

(Variable)

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Program

Option Bar Code Option Alphanumeric

Disable

Enable

Read

00-64 00-64

Max. code length

00-64 00-64

Min. code length

Checksum1

(Optional)

ഖ

00

01

00

ഖ

00

ഖ

Entry

67

Page 68

Truncate leading

Truncate ending

Code ID setting

Insert group

selection

0-15 00-15

ഖ

00

0-15 00-15

00

ഖ

00-ffH ASCII

code

00-44 00-44

00-ffH

< i >

00

ഖ

ഖ

Exit

68

Page 69

China Post

Read: Format

Data Digits

(Variable)

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Program

Option Bar Code Option Alphanumeric

Disable

Enable

Read

00-64 00-64

Max. code length

00-64 00-64

Min. code length

Checksum1

(Optional)

ഖ

00

01

11

ഖ

11

ഖ

Entry

69

Page 70

Truncate leading

Truncate ending

Code ID setting

0-15 00-15

00

ഖ

0-15 00-15

00

ഖ

00-ffH ASCII

code

00-ffH

< t >

ഖ

Insert group

selection

00-44

01-44

00

ഖ

Exit

70

Page 71

Italian Pharmacode

Read: Format

Data Digits

(Variable)

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group selection: Refer to Insertion group

selection of UPCA.

Leading “A”: If this function is enabled, each prefix of data

shall be A.

Program

Option Bar Code Option Alphanumeric

Disable

Enable

Read

00-64 00-64

Max. code length

Checksum1

(Optional)

ഖ

00

01

10

ഖ

Entry

71

Page 72

Min. code length

Truncate leading

Truncate ending

Code ID setting

Insert group

selection

Leading “A”

00-64 00-64

09

ഖ

0-15 00-15

00

ഖ

0-15 00-15

00

ഖ

00-ffH ASCII

code

00-44 00-44

Disable

Enable

01-ffH

< p >

00

ഖ

00

ഖ

01

ഖ

Exit

72

Page 73

String setting

Prefix characters: Up to 22 ASCII characters may be sent

before data digits.

Prefix Data Digits Suffix

Suffix characters: Up to 22 ASCII characters may be sent

after data digits.

Preamble/ Postamble characters: They are appended to

the data automatically when each barcode is decoded.

Example:

Add a prefix/suffix or preamble/postamble for all symbologies.

In this example, you are sending a $ symbol as a prefix for all

symbologies.

Steps:

1) Scan Programming and Prefix characters setting barcode.

2) Use the ASCII code table to find the value of $ඎ24.

3) Scan 2 and 4 from the barcode on the fold out back page.

4) Scan Finish from the barcode on the fold out page.

5) Scan Exit barcode.

Program

Option Bar Code Option Alphanumeric

Entry

None

1-22 characters

Prefix characters

setting

None

1-22 characters

Suffix characters

setting

00

ഖ

00-ffH ASCII

code

0D

ഖ

00-ffH ASCII

code

73

Page 74

Preamble characters

setting

Postamble

characters setting

Insert G1 characters

setting

Insert G2 characters

setting

Insert G3 characters

setting

Insert G4 characters

setting

None

1-22 characters

None

1-22 characters

None

1-22 characters

None

1-22 characters

None

1-22 characters

None

1-22 characters

00

ഖ

00-ffH ASCII

code

00

ഖ

00-ffH ASCII

code

00

ഖ

00-ffH ASCII

code

00

ഖ

00-ffH ASCII

code

00

ഖ

00-ffH ASCII

code

00

ഖ

00-ffH ASCII

code

Exit

74

Page 75

String setting

Insert G1/G2/G3/G4 character setting: The scanner offer 4

positions and 4 characters to insert among the symbol.

Example: Barcode “1 2 3 4 5 6”.

Output- Barcode “1 2 A B 3 4 C D 5 6”.

Steps:

1) Scan Programming and Insert G1 characters setting

barcode.

2) Use the ASCII code table to find the value of Aඎ41,Bඎ 42.

3) Scan 4, 1 and 4, 2 from the barcode on the fold out back

page.

4) Scan Finish from the barcode on the fold out page.

5) Repeat the same procedure in Insert G2 characters

setting.

6) Scan Exit barcode.

7) Insert data group 1-4 position. Please refer to Chapter-

Transmission, page 65 and in specific barcode that you

want to use.

Program

Option Bar Code Option Alphanumeric

Entry

None

1-22 characters

Insert G1 characters

setting

None

1-22 characters

Insert G2 characters

setting

00

ഖ

00-ffH ASCII

code

00

ഖ

00-ffH ASCII

code

75

Page 76

Insert G3 characters

setting

Insert G4 characters

setting

None

1-22 characters

None

1-22 characters

00

ഖ

00-ffH ASCII

code

00

ഖ

00-ffH ASCII

code

Exit

76

Page 77

Transmission

Preamble transmission: By setting Enable , Preamble will

be appended before the data transmitted.

Postamble transmission: By setting Enable, Postamble will

be appended after the data is transmitted.

Insert data group 1-4 position: The scanner offers 4

positions to insert among the symbol. The position default

value is “00” to indicate no character insertion. Beside, make

sure insertion positions are not greater than the symbols;

otherwise the insertion data is not effective.

Code ID position: Upon your usage, the transmitting

position of Code ID can be selected to place Before Code

Data or After Code Data when it is transmitted.

Program

Option Bar Code Option Alphanumeric

Entry

Disable

Enable

Preamble

transmission

Disable

Enable

Postamble

transmission

00

01

00

01

ഖ

ഖ

77

Page 78

Insert data group 1

position

Insert data group 2

position

Insert data group 3

position

Insert data group 4

position

Code ID position

00-64

(00: no insertion)

00-64

(00: no insertion)

00-64

(00: no insertion)

00-64

(00: no insertion)

Before code data

After code data

00-64

ഖ

00

00-64

00

ഖ

00-64

00

ഖ

00-64

ഖ

00

ഖ

00

01

Exit

78

Page 79

Transmission

Code ID transmission: If your application is needed to

transmit Code ID, you must set this to Proprietary ID or AIM

ID.

Code length transmission: A number of data digits can be

transmitted before the code data when Enable is selected.

The total length of the barcode is the number of barcode data

except Truncate Leading/Ending Digits. And the length is a

number with two digits.

Code name transmission: This function is to show

unknown barcode symbologies that include all readable

symbologies of the scanner. When Enable is selected,

Code Name will be transmitted before code data, you will

know what kind of barcode symbology is.

Case conversion: Under the barcode, you can set the

alphabet in either upper case or lower case.

Program

Option Bar Code Option Alphanumeric

Entry

Code ID

transmission

Disable

Proprietary ID

AIM ID

00

01

02

ഖ

79

Page 80

Disable

Enable

Code length

transmission

Disable

Enable

Code name

transmission

Disable

Upper case

Case conversion

Lower case

*For barcode

data only

Format of barcode data transmission:

Code

Prefix Name Preamble ID

Barcode

Length

data

00

ഖ

01

00

ഖ

01

00

ഖ

01

02

Exit

ID Postamble Suffix

Insert groups

80

Page 81

7HVW&KDUW

CODABAR-PARA

CODE-11 PARA

CODE-128 PARA

CODE-39 PARA

CODE-93 PARA

EAN-13 PARA

81

Page 82

PDF-417

STANDRAD-25 PARA

CODE-16K

EAN-8 PARA

INDUSTRIAL-25 PARA

UPCE PARA

82

Page 83

INTERLEAVED-25 PARA

MATRIX 25 PARA

MSI/PLESSEY PARA

UPCA PARA

UK/PLESSEY PARA

83

Page 84

ASCII Code Table

/+

1XOO 18/ '/(

8S ) 62+ '&

'RZQ ) 67; '&

/HIW ) (7; '&

5LJKW ) (27 '&

3J8S ) (14 1$.

3J'Q ) $&. 6<1

) %(/ (7%

%V ) %6 &$1

7DE ) +7 (0

$ ) /) 68%

% +RPH (VF 97 (6&

& (QG ) )) )6

' (QWHU ) &5 *6

( ,QVHUW &WUO 62 56

) 'HOHWH $OW 6, 86

/+

63 # 3 C S

$ 4 D T

ಮ % 5 E U

& 6 F V

' 7 G W

( 8 H X

) 9 I Y

ಪ * : J Z

+ ; K [

, < L \

$ ့ - = M ]

% . > N 옧

& 웍 / 웽 O 옂

' 0 @ P 온

( ! 1 A Q ᅘ

) " 2 B R '(/

1RWH )RUNH\ERDUGZHGJHRQO\

84

Page 85

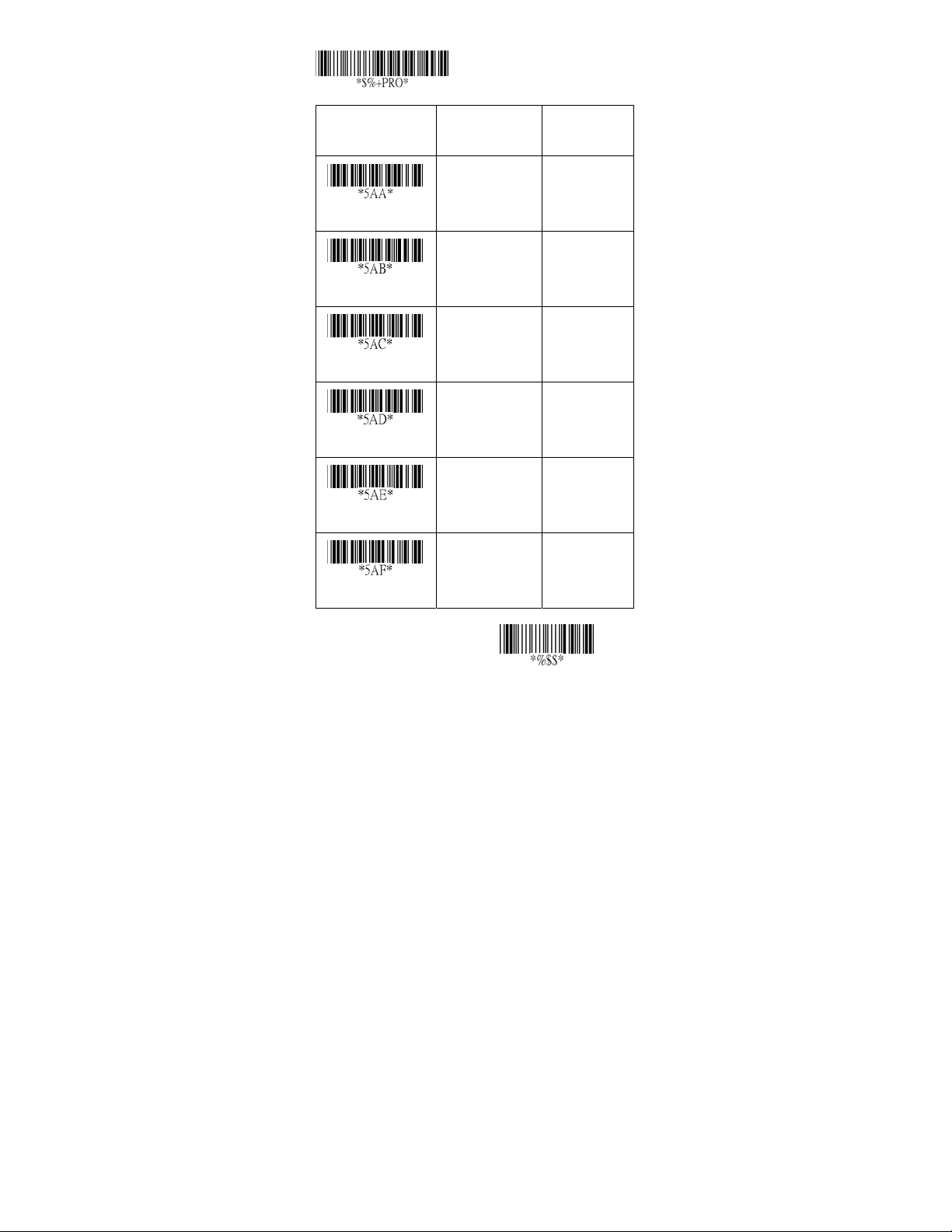

Parameter Setting List

Program

Barcode standard parameter setting list

If you wish to display the current configuration of your

LGZ7225, scanner over the host terminal/computer

scan the Barcode standard parameter setting list

bar code.

Unique parameter list

If you wish to display the unique parameter setting list, scan

the unique parameter list bar code

System parameter setting list

If you wish to display the product information and revision

number for your LGZ7225 scanner over the host

terminal/computer, scan the System parameter setting list

bar code.

String setting list

If you wish to display the string format list, scan the String

setting list bar code.

85

Page 86

Firmware version list

If you wish to display the firmware version, scan the

Firmware version list.

WARNING

If you wish to return theLGZ 7225 to all the factory

default settings, scan the Default value initialization bar code.

: Default value initialization

Exit

86

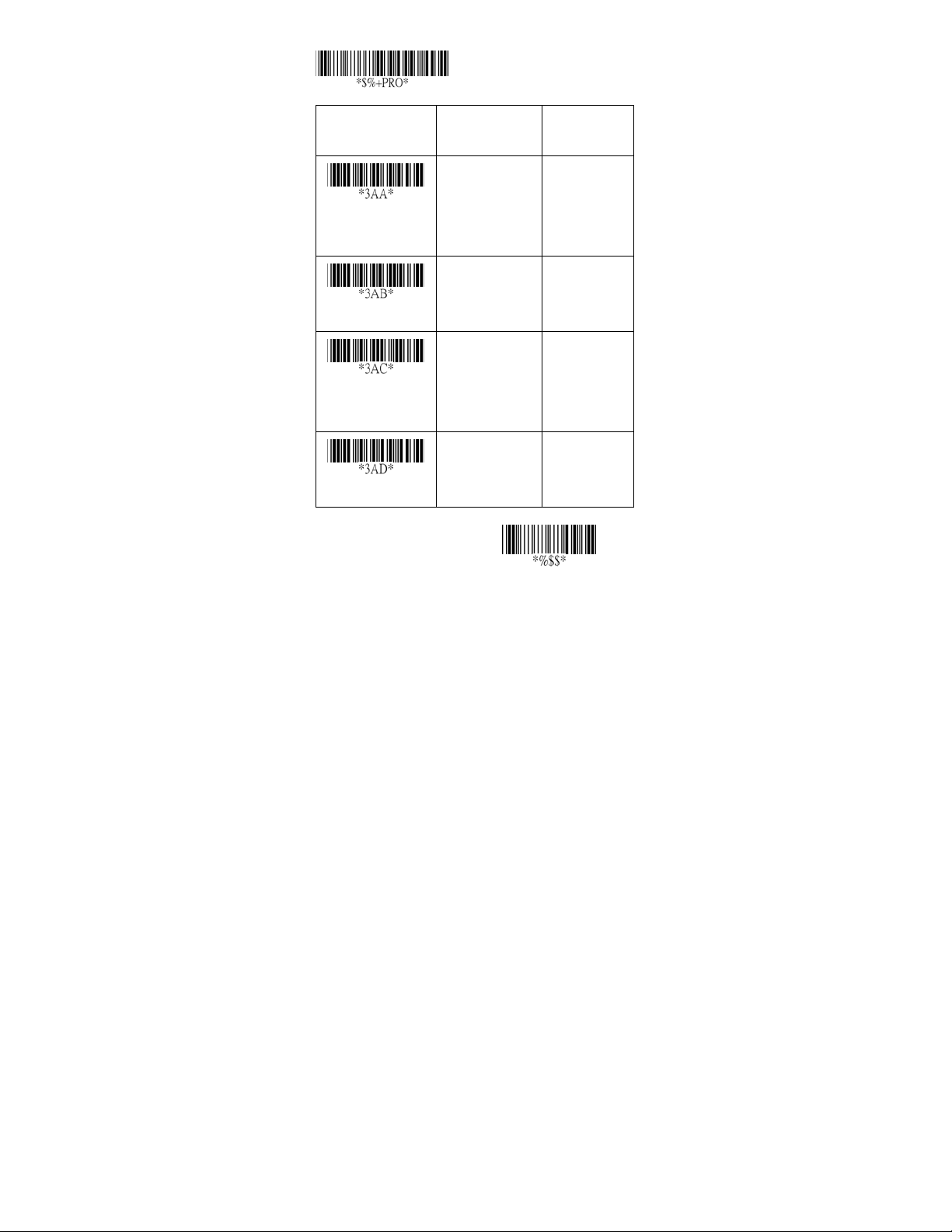

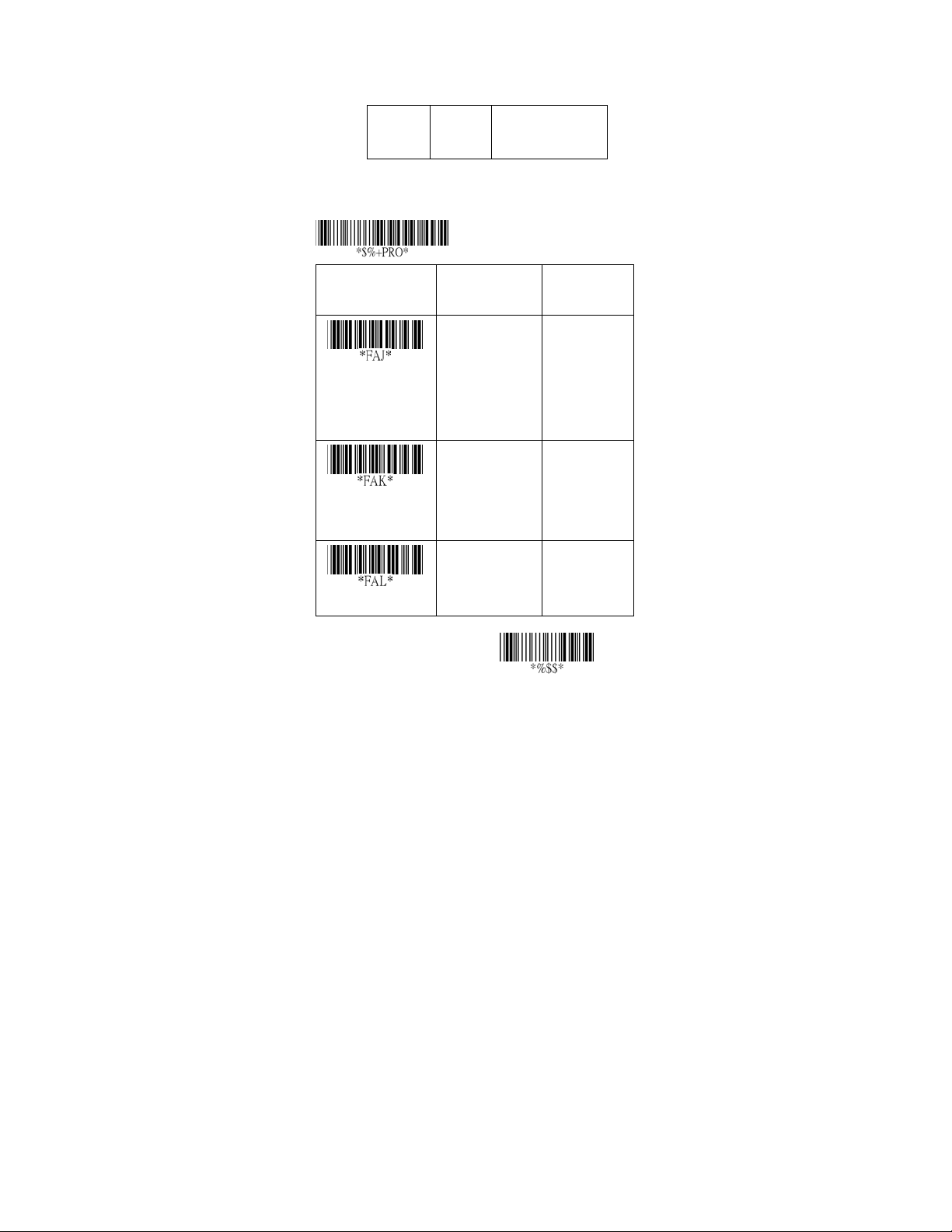

Page 87

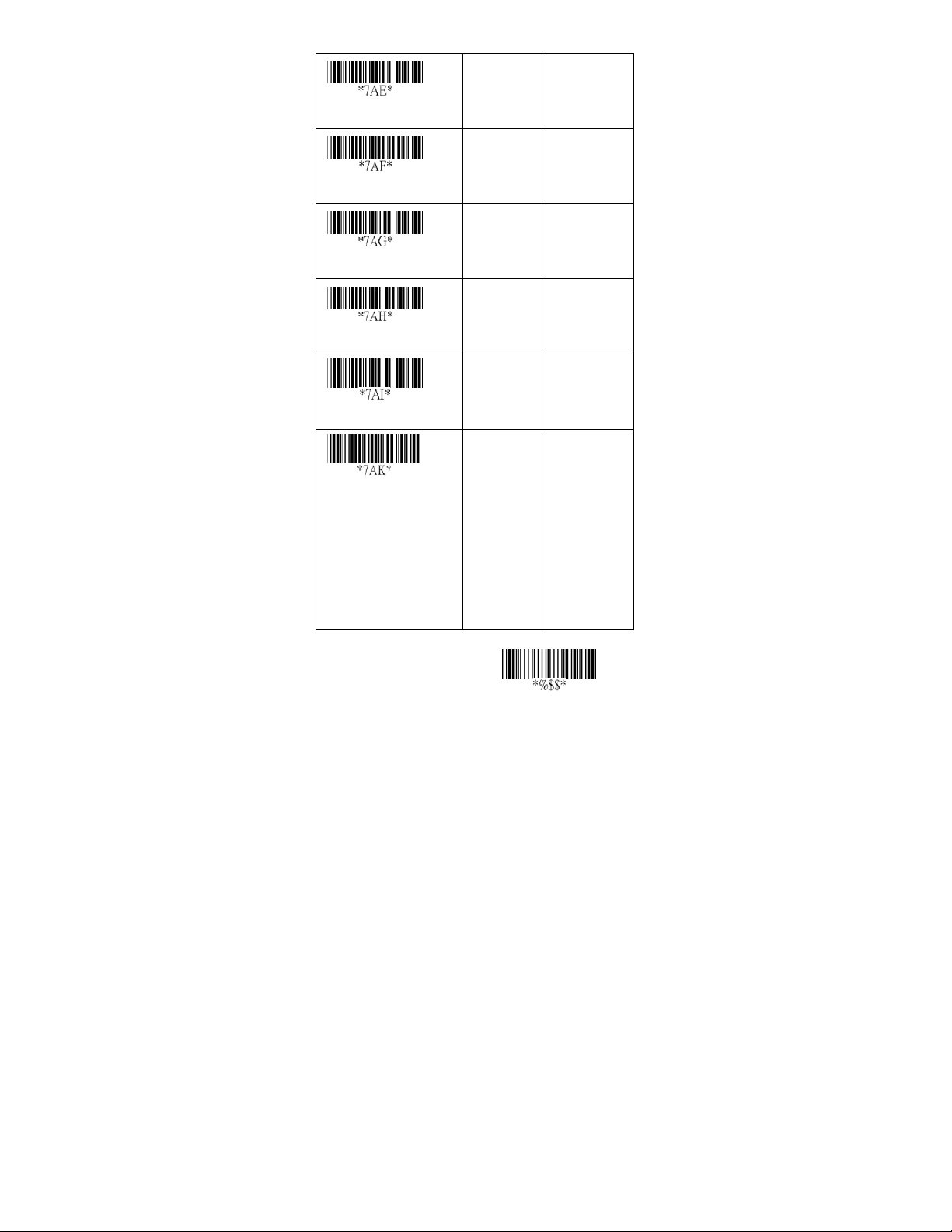

0

A

1

B

2

C

3

D

4

E

5

F

6

7

8

Finish

9

97

87

Loading...

Loading...