Page 1

Electronic Shelf Label

The ESL demo kit is intended for demonstration and

development purposes of the Opticon ESL solution.

User Manual

DEMO KIT

Page 2

Opticon ESL

Model Number:

ESL DEMO KIT

Specification Number:

Edition:

0.2

Original Spec Number:

Date:

2011

SUPPORT

USA

Europe

Phone: 800-636-0090

Phone: +31 235692728

Email: support@opticonusa.com

Email: support@opticon.com

Web: www.opticonusa.com

Web: www.opticon.com

DEMO KIT

User Manual

All information subject to change without notice.

Document History

Copyright 2011 Opticon. All rights reserved.

This manual may not, in whole or in part, be copied, photocopied, reproduced, translated or converted to any

electronic or machine readable form without prior written consent of Opticon.

Limited Warranty and Disclaimers

PLEASE READ THIS MANUAL CAREFULLY BEFORE INSTALLING OR USING THE

PRODUCT.

Serial Number

A serial number appears on all Opticon products. This official registration number is directly related to the device

purchased. Do not remove the serial number from your Opticon device. Removing the serial number voids the

warranty.

Warranty

Unless otherwise agreed in a written contract, all Opticon products are warranted against defects in materials and

workmanship for two years after purchase. Opticon will repair or, at its option, replace products that are defective in

materials or workmanship with proper use during the warranty period. Opticon is not liable for damages caused by

modifications made by a customer. In such cases, standard repair charges will apply. If a product is returned under

warranty and no defect is found, standard repair charges will apply. Opticon assumes no liability for any direct, indirect,

consequential or incidental damages arising out of use or inability to use both the hardware and software, even if

Opticon has been informed about the possibility of such damages.

Packaging

The packing materials are recyclable. We recommend that you save all packing material to use should you need to

transport your scanner or send it for service. Damage caused by improper packaging during shipment is not covered

by the warranty.

Trademarks

Trademarks used are the property of their respective owners.

Opticon Inc. and Opticon Sensors Europe B.V. are wholly owned subsidiaries of OPTOELECTRONICS Co., Ltd., 12-

17, Tsukagoshi 4-chome, Warabi-shi, Saitama, Japan 335-0002. TEL +81-(0) 48-446-1183; FAX +81-(0) 48-446-1184

2

Page 3

Opticon ESL

DEMO KIT

User Manual

Contents

1. Features and Specifications .................................................................................................... 6

1.1. Abstract ............................................................................................................................. 6

1.2. Contents ............................................................................................................................ 6

1.3. Physical Features .............................................................................................................. 6

1.3.1. Dimensions ................................................................................................................................ 6

1.3.2. Weight ........................................................................................................................................ 6

1.4. Environmental Specifications ............................................................................................. 7

1.4.1. Operating Temperature and Humidity (EE200) ......................................................................... 7

1.4.2. Storage Temperature and Humidity (EE200) ............................................................................ 7

1.5. Interface Specifications ..................................................................................................... 7

1.6. Hardware Specifications .................................................................................................... 7

1.7. Electrical Specifications ..................................................................................................... 8

1.7.1. Electrical Characteristics ............................................................................................................ 8

1.7.2. Main Battery: .............................................................................................................................. 8

1.8. Serial Number ................................................................................................................... 9

1.8.1. EBS-10 ....................................................................................................................................... 9

1.8.2. EE200 ........................................................................................................................................ 9

1.9. Safety ................................................................................................................................ 9

1.9.1. Shock ......................................................................................................................................... 9

1.9.2. Temperature Conditions ............................................................................................................ 9

1.9.3. Foreign Materials ....................................................................................................................... 9

1.9.4. Other .......................................................................................................................................... 9

2. Solution Overview .................................................................................................................. 10

3. Getting started ........................................................................................................................ 11

3

Page 4

Opticon ESL

DEMO KIT

User Manual

3.1. Setting up the hardware and software ............................................................................. 11

3.1.1. Installing the ESL Demo kit ...................................................................................................... 11

3.1.2. Installing the base station ........................................................................................................ 12

3.1.3. Installing the ESLs ................................................................................................................... 12

3.1.4. Installing the bar code terminal ................................................................................................ 13

3.2. Linking a back office system to the ESL server ................................................................ 13

3.3. Resetting the ESL system ............................................................................................... 13

3.4. Designing the ESL image layout ...................................................................................... 14

4. Back office .............................................................................................................................. 15

4.1. Database format .............................................................................................................. 15

5. ESL Server application ........................................................................................................... 16

5.1. Handling of incoming CSV-files from the back office ........................................................ 17

5.2. Handling of modified ESL-product links (linked.csv) ........................................................ 17

5.3. Detecting new/changed ESL image and configuration files .............................................. 18

5.4. Configuring of ESLs ................................................................................................ ......... 19

5.4.1. Associate interval ..................................................................................................................... 20

5.4.2. Poll Info Ratio ........................................................................................................................... 20

5.4.3. Poll Interval .............................................................................................................................. 20

5.4.4. Poll timeout .............................................................................................................................. 21

5.4.5. Scan channels ......................................................................................................................... 21

5.5. ESL status information .................................................................................................... 21

5.6. Configuring of base stations ............................................................................................ 21

5.6.1. Configuring the RF channel ..................................................................................................... 21

5.6.2. Changing the name of a base station ...................................................................................... 23

5.6.3. Configuring the Ethernet settings ............................................................................................ 23

4

Page 5

Opticon ESL

DEMO KIT

User Manual

5.7. Setup of the ESL server application ................................................................ ................. 25

6. Middleware applications ........................................................................................................ 28

6.1. CSV-parser ..................................................................................................................... 28

6.2. Image generator .............................................................................................................. 28

7. Barcode terminal application ................................................................................................. 29

7.1. Setting up the barcode terminal ....................................................................................... 29

7.2. Loading the database files on the terminal ...................................................................... 30

7.3. Creating links between ESLs and products/locations ....................................................... 30

7.4. Deleting existing links ...................................................................................................... 31

7.5. Verifying existing links ................................ ..................................................................... 31

7.6. Sending the modified link-database to the PC ................................................................. 31

7.7. Settings menu ................................................................................................................. 31

7.8. Version ............................................................................................................................ 31

8. Version history ....................................................................................................................... 32

Appendix A: Editing the ESL template files ................................................................................ 33

A.1. Editing the Information template ...................................................................................... 33

A.2. Editing the Image layout template .................................................................................... 34

A.2.1. Text ................................................................................................................................ 36

A.2.2. Rectangles ..................................................................................................................... 37

A.2.3. Lines............................................................................................................................... 37

A.2.4. Images ........................................................................................................................... 38

A.2.5. Barcodes ........................................................................................................................ 38

A.3 Trouble shooting ................................................................................................................. 39

Appendix B: Demo barcodes ....................................................................................................... 40

5

Page 6

1. Features and Specifications

1.1. Abstract

This manual provides a preliminary description on how to set-up a customized Electronic

Shelf Labels (ESL) demonstration and how to set-up a pilot project with e-Paper ESLs from

Opticon Sensors Europe BV.

1.2. Contents

The ESL demo kit consists of the following components:

Ethernet ESL base station (EBS-10)

6 2” e-paper ESLs (EE200) including 6x2 CR2450 batteries

UTP cable

6.0V 2A Power supply (European)

PC Installation Software + examples

Opticon ESL

DEMO KIT

User Manual

Opticon Demo Kit User Manual

The demo kit does NOT include a barcode terminal with communication cradle, which can

be used to link ESLs to products using barcodes. Any of the following Opticon Barcode

Terminals can be used for this purpose:

OPH1004 (+ CRD1001 cradle)

H13 (+ CRD13 cradle)

OPL9728 (+ CRD9723RU cradle)

1.3. Physical Features

1.3.1. Dimensions

2” e-paper ESL (EE200): W 70.0 x D 32.0 x H 15.0 mm

Base station (EBS-10): W 129.0 x D 102.0 x H 28.0 mm (excl. antenna)

1.3.2. Weight

2” e-paper ESL (EE200): 25 g (incl. 2 batteries)

Base station (EBS-10): 125 g (excl. power supply)

6

Page 7

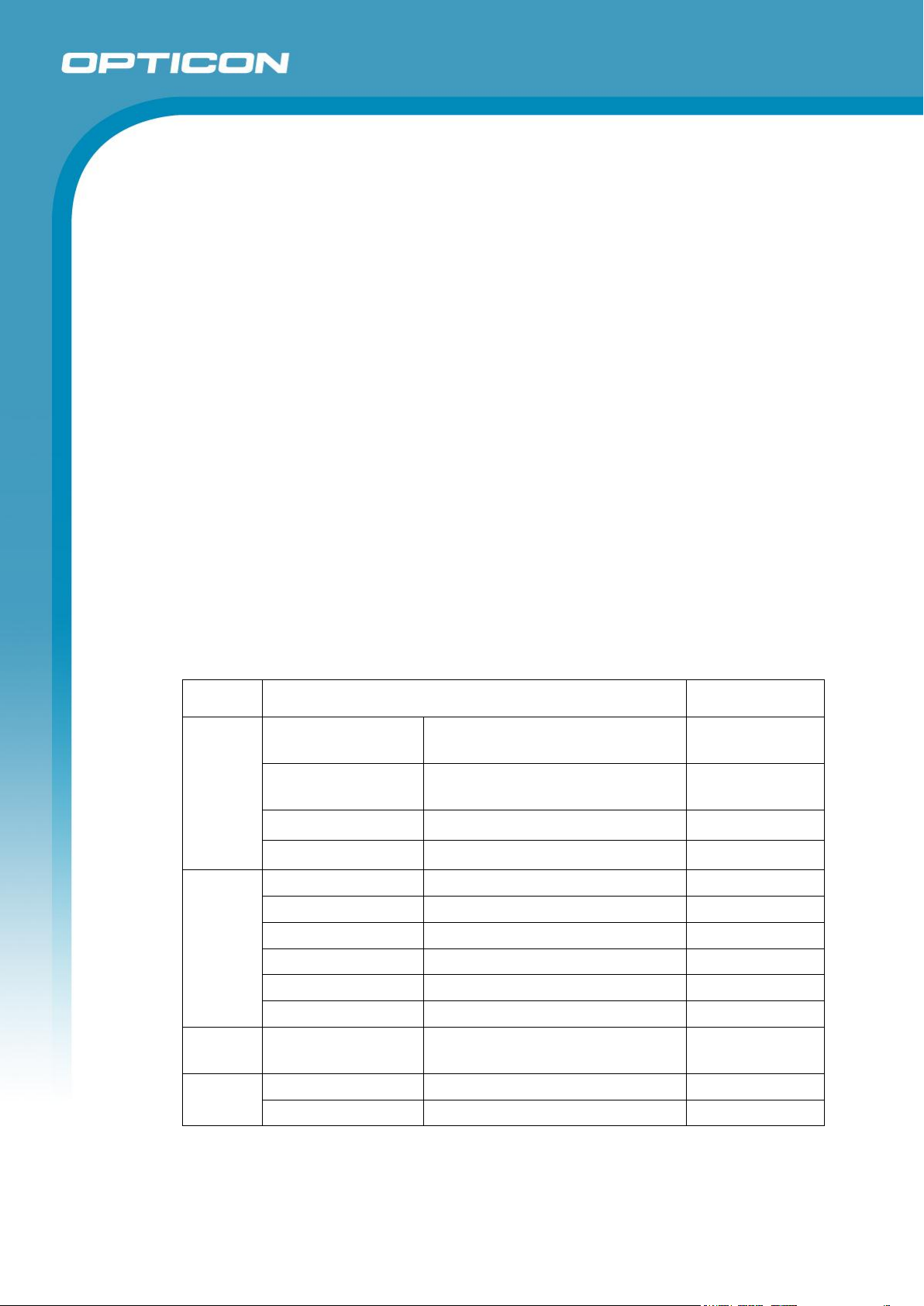

1.4. Environmental Specifications

Items

Specifications

Remarks

CPU

Type

CC2530-F128 (EE200)

CC2530-F256 (EBS-10)

Internal ROM

256 KB (EBS-10)

128 KB (EE200)

Internal RAM

8 KB

Clock frequency

32 MHz

Display

(EE200)

Active area

W 45 x H 22 mm

Number of dots

W 200 x H 96

Model

EG020AS183

Gray scale level

1 bit

Black and white

Contrast ratio

10:1

Pixel pitch

111 dpi

Connector

(EBS-10)

Ethernet

10/100 Mbit

Radio

Frequency

2.4gHz

Protocol

IEEE 802.15.4

1.4.1. Operating Temperature and Humidity (EE200)

Temperature: 0 to 50° C

Humidity: 0-85%

1.4.2. Storage Temperature and Humidity (EE200)

Temperature: -20 to 60° C

Humidity: 0-85%

1.5. Interface Specifications

Opticon ESL

DEMO KIT

User Manual

The radio interface of both the base stations and ESLs have the following

specifications:

2.4gHz IEEE 802.15.4 compatible

Transmission speeds: up to 250 kbps

1.6. Hardware Specifications

7

Page 8

1.7. Electrical Specifications

Parameter

Typical

Unit

Remarks

Operating voltage

2.8–3.2 V 2 x CR2450 Lithium battery

Operating current

7-33

mA

During RF and image refresh only

Sleep current

1

uA

EE200 in sleep state >99,9%

Parameter

Typical

Unit

Remarks

Operating voltage

6.0

V

Power adapter

Operating current

<200

mA

Factor

Default values and

estimated averages

Correlation *

(Higher is better)

Influence

Polling for data &

reporting settings

Interval: 20 seconds

Retransmissions: 10%

Report ratio: 1 to 39

Yes

No

Yes

61%

Display updates

4 per day

Temperature: 15-25° C

No

No

20%

Out of range /

base station OFF %

Not connected: 2%

Number of channels: 5

No

No

4%

Sleep time

99,9%

Yes

9%

Battery self-discharge

1 % / year

No

6%

1.7.1. Electrical Characteristics

EE200:

EBS-10:

Opticon ESL

DEMO KIT

User Manual

1.7.2. Main Battery:

The main batteries in the EE200 are 2 CR2450 Li-Mn batteries:

Nominal capacity: 2x600 mAh

Nominal voltage: 3V.

Low voltage: Less than 2.8 V

Operating time: >7 years (default settings; 4 refreshes/day; 15-25° C)

The operating time of the batteries is based on a realistic estimation of any of the

following factors that influence the battery life:

* The correlation shows whether increasing the listed value increases or decreases the

power consumption.

8

Page 9

For example:

Increasing the poll interval lowers the power consumption

Turning off the base stations increases the power consumption

A lower operating temperature increases the power consumption

More display updates per day increase the power consumption

1.8. Serial Number

1.8.1. EBS-10

The serial number can be found on the back of the Base station. The EBS-10 is

currently only available as Engineering Sample, which can be recognized by the

serial number starting with „ES‟. The EBS-10 will soon be replaced by a more

powerful, faster and advanced model with a more sophisticated design.

Opticon ESL

DEMO KIT

User Manual

1.8.2. EE200

The serial number of the ESLs is based on the 16 hexadecimal digits MAC-address

of the RF-module. However, the first 6 digits of the MAC address (00124B) have

been replaced by the letter „A‟.

The default barcode that is shown on the display of the ESL is identical to the bar

code on the back of the ESL.

1.9. Safety

Handle this product carefully. Do not deliberately subject it to any of the following.

1.9.1. Shock

Do not throw or drop the devices

1.9.2. Temperature Conditions

Do not use the devices at temperatures outside the specified range.

Do not pour boiling water on the devices.

Do not throw the devices into the fire.

Do not forcibly bend the cable at low temperatures.

1.9.3. Foreign Materials

Do not immerse the devices in liquids.

Do not subject the devices to chemicals.

1.9.4. Other

Do not plug/unplug the connectors before disconnecting the power.

Do not disassemble this product.

The device may be damaged by power surges

9

Page 10

Opticon ESL

IEEE 802.15.4

Barcode terminal (OPH1004/

H13/OPL9728)

- Receives product and link

databases from server application

- Creates/modifies links between

ESLs and products

- Sends link database back to

server application.

ESL server application

- Detects incoming CSV-files (from the back office)

and processes them by calling DbConv.exe

- Detects any new/changed ESL-product links (from

the barcode terminal) and processes them by

calling DbConv.exe

- Detects and processes new/changed ESL images

and product XML-files (from DbConv.exe)

- Sends image data to ESLs (via base stations)

- Configures ESLs and base stations

- Shows status / settings of all ESLs and base stations

- Logs all events and executed tasks

- Installs software updates on base stations and ESLs

Middleware applications

CSV-parser:

- Parse product modifications

into a combined CSV-database

containing all product info.

- Generate truncated article

database (CSV-format) for the

barcode terminal.

Image Generator:

- Generate ESL images and XML-

files for the server application

from the link- and productdatabase.

Base stations

- Forwards ESL status & settings

information to PC

- Sends images / commands

from server application to ESLs

- Handles software updates for

ESLs

ESLs

- Show images

- Provide status reports

- Poll for data

- Search base stations

Back office

- Places product modifications

as CSV-file into shared folder.

Rename file event

Cradle

(RS232 / OseComm)

Ethernet

DEMO KIT

User Manual

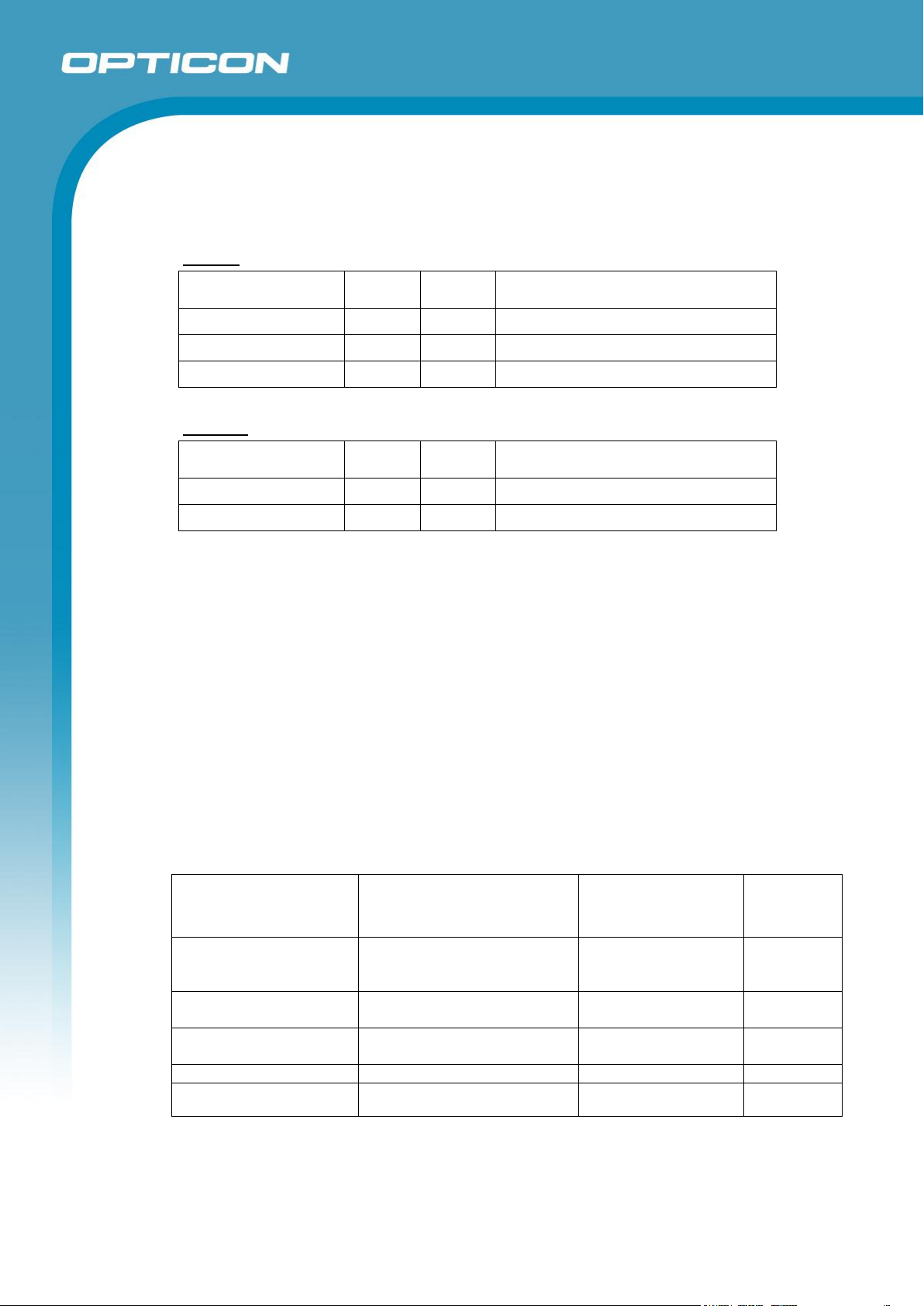

2. Solution Overview

The current solution operates by running the provided ESL server application that monitors an

incoming folder in which any mutations in the product database are being placed by the back

office system of the user. Any detected changes will be automatically processed and sent to the

ESLs and displayed.

A global overview of the current solution is shown below. The following chapters will describe the

different parts of this system in more detail and how to get started.

10

Page 11

3. Getting started

3.1. Setting up the hardware and software

This SDK contains the following pieces of hardware and software that will have to be

installed in order to get an ESL demonstration or pilot up and running:

The ESL Demo kit installer containing:

o The ESL server application

o Middleware applications

o Example database files and image templates

o Firmware for the barcode terminal, base station and ESLs

o Appload (optional)

o USB drivers for the barcode terminal cradle (optional)

o XTAdminXXL (optional)

o User manual

1 EBS10 Base station(s) that includes:

o 6V Power supply

o Ethernet cable

6 EE200 2-inch e-paper ESLs (batteries included)

If you want to be able to quickly link ESLs to products, you will also need an OPH1004, H13 or

OPL9728 barcode terminal that includes:

Opticon ESL

DEMO KIT

User Manual

A communication cradle

An RS232 and/or USB cable.

A 6V Power supply

To install and run the software you will also need a PC running Windows 7 or Windows XP

(with server pack 3) as server.

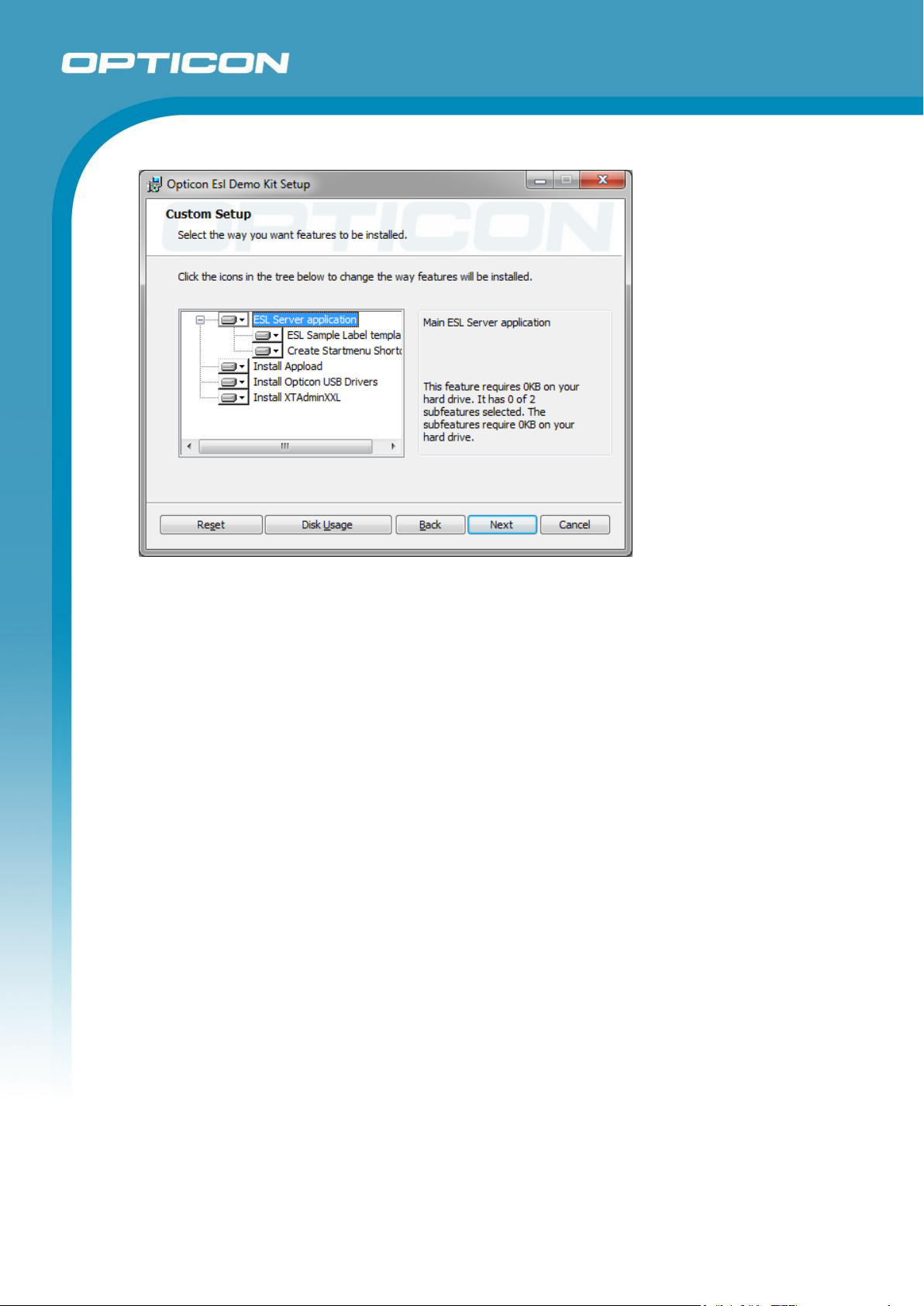

3.1.1. Installing the ESL Demo kit

Make sure you have administrator rights before installing the software. Run the SDK

installer by starting the „setup.exe‟ file.

If your PC doesn‟t have .NET Framework 3.5 (or higher) installed, the installer will

automatically install it on your system, since the ESL Server application requires it to run.

Select the components that you wish to install. If you haven‟t installed Appload or the

Opticon USB drivers on your PC before, make sure you install those components as well.

The XTAdminXXL tool is a 3rd party tool from AK-NORD that allows you to discover your

base stations on an Ethernet network and configure the Ethernet settings of base

stations. (See chapter 5.6.3)

11

Page 12

Opticon ESL

DEMO KIT

User Manual

Note that only the installer of XTAdminXXL will be copied to the „Tools‟-folder of your

installation. To actually install the program this installer needs to be run manually.

3.1.2. Installing the base station

The base station can be easily installed by powering it up, connecting it to the Ethernet

and placing it within 10 meter (the actual maximum range is bigger) of your ESLs. The PC

will need to be connected to the same LAN, so it can communicate with the base station

*. See chapter 5.6.3 for more information on configuring the Ethernet settings of your

base station. Other information on how to configure the base stations (i.e. selecting the

best RF channel) can be found in chapter 5.6.

* Note: The base station can also be controlled over the Internet or via a public network,

but it won’t be a secure solution, since SSL isn’t supported yet in this SDK.

3.1.3. Installing the ESLs

On arrival the ESLs usually already have their two CR2450 batteries inserted. If not, the

batteries can be easily inserted by removed the back shell. When the batteries are

inserted the ESL‟s will be periodically seeking for an Opticon base station, so as soon as

an Opticon base station is within range, they will associate with it and start sending data

requests and status information to it. When a base station is turned off or an ESL is

moved out of range, an ESL will time out after a couple of minutes and starts seeking for

another base station in range. See chapter 5.4 for more information about configuring

ESLs.

12

Page 13

Since there are many types of mechanisms to mount shelf labels to shelves, the ESLs of

the demo kit are supplied without mounting clips. Please contact Opticon for more

information on the mounting possibilities of the ESLs to your shelves. For simple

demonstration purposes with small amounts of ESLs one might also consider using

double sided foam tape as a temporarily solution.

3.1.4. Installing the bar code terminal

The supplied barcode terminal can be used to link an ESL (using its unique MAC

addresses) to any type of product, objects or location as long as it has a unique identifier it

can be linked with. (I.e. an EAN-barcode, serial number, position, room number, etc.)

More information on how to set-up the barcode terminal can be found in chapter 7.1.

3.2. Linking a back office system to the ESL server

The ESL server application is triggered by CSV-files that are being placed in the specified

„Input Folder‟ by the back office. Using a shared folder it‟s possible to allow external access

by the back office from anywhere in the world.

If the back office link to the ESL system is not yet available, then it‟s also possible to

manually place (and rename) some CSV-files in the „Input folder‟ (see chapter 5.1) for

demonstration purposes and testing.

See chapter 4 for information about on setting up the back office system.

Opticon ESL

DEMO KIT

User Manual

3.3. Resetting the ESL system

After installing and configuring all the components listed in this chapter, it will be necessary

to reset the complete ESL system, since on start-up the ESL server will already have

parsed the example database file, which will have to be replaced with your own CSVexport.

Also, if the field sequence of your CSV-export is ever changed, it will be necessary to reset the ESL

system by deleting the existing product database. However, do NOT delete the link database (step

3) because otherwise you will have to manually link all ESLs again using the barcode terminal. The

existing database files can also be replaced remotely by the back office by placing a complete

database CSV-file in the ‘Input folder’ that contains only empty modification fields. (See chapter

4.1).

To reset the ESL system manually, the following steps have to be taken:

1. If still present, delete the (sample) database file from the ‘Input folder’ of your installation

(“ProductData_1.csv). If it was already moved to the processed folder, then it’s not mandatory

to delete it.

2. Go to the Setup-window of the ESL server application and press the ‘Delete database’ button

to delete the generated database files: ‘dbase.csv’ and ‘scan.csv’.

3. (Optional) If you’ve manually linked any ESLs using the sample database or want to redo the

linking of all ESLs, then press the ‘Delete links’ button to delete the link file (linked.csv). Before

13

Page 14

closing the Setup window, delete any existing links from the barcode terminal as well by using

“4 settings > 1 Delete Data” to prevent any links to be resend by the terminal.

After deleting the necessary files and closing the Setup window, the system will

automatically starts detecting any incoming CSV-files in the configured „Input folder‟

again. (See chapter 4)

3.4. Designing the ESL image layout

Probably the most important step in the customization process of the ESL system is

determining the desired end-result, being the images that should be displayed on the

ESLs.

When designing the layout of an e-paper ESL it‟s important to know the limitations of what

can and what can‟t be displayed.

The main characteristics are:

Fixed resolution of 200x96 pixels

Monochrome images only (black/white)

No anti-aliasing can be used on fonts (limiting the amount of available fonts)

Monochrome company logos and other product (group) images can be added to the layout.

Barcodes can be added using data of CSV-database

Texts can be rotated only in 90° angles (currently only horizontal is supported in this version)

Dynamic texts, using information from the database, can be added and aligned as desired.

Different templates for groups of ELSs is possible by adding objects to the template using

logical conditions (i.e. condition: ‘field x’ (group) equals ‘5’)

Currently, the layout of an ESL image is specified using a template file, which is XMLbased. Using very basic XML-tags it‟s possible to manually edit the included example

template. Default location of the template is "./Templates/Image.xml".

Detailed instructions on how to edit the XML-based image template file can be found in

Appendix A: Editing the ESL template files.

Note: In the near future a graphical user interface will be added to the ESL system that

will allow you to design the image layout more easily and with more features.

Opticon ESL

DEMO KIT

User Manual

14

Page 15

Opticon ESL

DEMO KIT

User Manual

4. Back office

The back office triggers the ESL server application by placing a file containing either only

product modifications or a complete product database in a predefined folder. Only one file

may reside in this folder to enforce sequential handling. This means that the Back office may

only store another file, when the current file has been processed and moved to a different

folder.

To avoid read/write conflicts the database files should first be copied into the specified folder

under a temporary name (i.e. *.tmp) and renamed to the correct name afterwards. The ESL

server application will only trigger on „rename file‟-events. If any database file is placed in the

folder while the server application isn‟t running, the file will be processed as soon as the

server application is started again.

4.1. Database format

Currently the only supported database format is CSV (comma separated values) with the

following properties:

Allowed field separator(s): 1) semi-colons

Methods: 1) modification database (add, replace, delete) and 2) complete database

Each product in the database must contain a unique product ID field to allow linking of an ESL

to a product.

If there’s a 1-to-many relation between the unique product ID and the barcode on this

product, then the same product should be added to the database multiple times for each

unique barcode, but all other fields must be identical. Also any product modifications (like

price) should be applied on each record for this product.

The adding of a product barcode field to the database isn’t mandatory. However it is

recommended, since it adds the possibility to quickly link ESLs to a product by simply scanning

the barcodes on the product and the ESL using the barcode terminal.

If any, comment lines should start with ‘#’.

When using a modification database, the modification field should be located at the

beginning of each line. As modification code the characters ‘I’ (Insert), ‘R’ (replace)

and ‘D’ (delete) should be used.

The typical record format of a product modification database would be:

<Modification code>;<Unique ID>;<Barcode>;<Description>;<Field 4>;<Field 5>;etc.

When a complete database is used (meaning any new database file replaces the

previous one), the first (modification) field of each line must be left empty.

The typical record format of a complete product database would be:

;<Unique ID>;<Barcode>;<Description>;<Field 4>;<Field 5>;etc.

15

Page 16

Opticon ESL

DEMO KIT

User Manual

It is recommended to add any fields that should be displayed on the ESL in the same

formatting as they should be displayed on the ESL. This way the middleware application

that generates the images, won‟t have to be modified and only the image template has to

be customized.

The ESL server application never directly uses the provided CSV-files, because the

actual processing of these files is done by the middleware software. For this reason only

the middleware applications have to be customized or configured and not the ESL server

application itself.

Note 1: Due to the 1-to-1 relation between a product and an ESL, it is currently not

possible to link multiple ESLs to the same product.

Note 2: Database formats other than CSV can be supported, but require modifications to

the existing middleware application, so this is not recommended when time is critical.

5. ESL Server application

The ESL server application controls the whole ESL system by detecting all external triggers

and processing the given data. Its main tasks are:

Detecting incoming CSV-files from the back office

Detecting new/changed ESL-product links from barcode terminal

Processing new/changed ESL images and configuration files from the middleware application

Calling of the middleware application to process all input files to create the images and

configuration files needed to update the ESLs.

Configuring of ESLs and base stations

Sending image data to the ESLs (via the base stations)

Showing the current status and settings of all ESLs and base stations

Logging all events, errors and executed tasks

Handling of software updates for base stations and ESLs

In the following chapters these tasks of the ESL server application will be described.

16

Page 17

5.1. Handling of incoming CSV-files from the back office

The placing and processing of incoming CSV-files is done as follows:

The file is moved/copied to a configurable local folder, called the ‘Input folder’.

When moving/copying the file from the Back office to the folder a temporary name is used,

i.e. ‘productdata_1.tmp’, ‘productdata_2.tmp’, etc.

After a check that the complete file has been moved/copied, the file will be renamed to its

final name, i.e. ‘productdata_1.csv’, ‘productdata_2.csv’, etc.

The server application will pick up the CSV-file as soon as it detects this rename file event.

The numbers in the filenames should be sequential, interval is 1. The ESL server application

currently does not check the number of these files.

The file will be processed instantly, as the records contain no start/end date.

Once a file is processed, it will be moved to the configurable ‘Processed’ folder and the Back

office is able to put another file in the folder.

When errors occur, they will be reported in an error log in the ‘Log’ folder. The data file will

not be moved in case of errors.

The ESL server application will call the middleware applications to parse the incoming CSV-file

into a combined database file and generates the required configuration and image files that

are used to update the ESLs.

Opticon ESL

DEMO KIT

User Manual

5.2. Handling of modified ESL-product links (linked.csv)

The link between an ESL label and a product is made by linking the unique MAC address

of the ESL label to the unique product ID.

To create, modify or delete a link, a barcode terminal can used (see chapter 7). Once the

links have been made, they will automatically be transferred back to the PC as soon as the

terminal is placed back into its cradle.

To process the modified links, the middleware applications will automatically be called by

the server application as soon as the link-database is received.

If no barcode terminal is being used and the ESL are linked using a different method (i.e.

using the existing cash register), then the „linked.csv‟ file should be placed in the „Output‟

folder as follows:

When moving/copying the link-file a temporary name should be used, i.e. ‘linked.tmp’

After that, the file should be renamed to its final name: ‘linked.csv’ (and overwrite the existing

file is present).

Each record of the link-file should have the following exact format:

<Unique ID>;H;<16-digit MAC address>

17

Page 18

For example: *

10244;H;00124B00011B344D

12345;H;00124B00011B432F

197;H;00124B00011B432F

The ESL server application will automatically pick up the new link file as soon as it detects

this rename file event.

* Note: The character 'H' is added to specify the hardware variant of the ESL. Currently only the 2" e-paper

(‘H’) and 2.7" e-paper (‘K’) are supported.

5.3. Detecting new/changed ESL image and configuration files

After the server application has detected a new product data file from the back office, it will

call the middleware applications to parse the incoming CSV-file into a combined database

file and generate the required configuration and image files that are used to update the

ESLs.

Both the configuration and image files will be placed into the configurable „Output‟ folder.

The files will be placed in the sub-folder: „Images‟. (Once processed the images and XML-

files will be moved to the subdirectory: „Images/Completed‟)

The server application will automatically process the BMP- and XML-files that have been

placed in the „Images in‟ folder. Once it has successfully processed a file, by sending the

image to an ESL, it moves the files to the sub-directory „/Completed‟ of the „Images in‟

folder.

The middleware application will only generate new configuration and images files for

products that are not found in the „Completed‟ subfolder or have been changed.

The ESL server application processes any changed files and checks the images folder for

unprocessed files:

on startup

after receiving a new link-database from the terminal

after a rename event of:

o any new product CSV-file in the ‘Input folder’

o the ESL-product link file (‘linked.csv’) in the ‘Output folder’

o the Image layout file (default: image.xml)

o the XML-template file (default: info.xml)

If any manual changes to the image folder have been made (like deleting image files from

the „Completed‟ folder), these changes aren‟t automatically detected. To force an update,

select the „Data‟-tab in the server application and press the F5-key.

Opticon ESL

DEMO KIT

User Manual

18

Page 19

5.4. Configuring of ESLs

Besides sending images to the ESL, there are a number of configurations that can be

made in the ESLs to control, customize and to regulate power consumption.

To edit configurations of an ESL, go to the base station tab to which the ESL is currently

linked and right click on the ESL. After doing so, a settings dialog should appear, showing

the current status and settings of that ESL. (If the base station has not yet received the

settings from this ESL, then it will automatically request the settings the next time the ESL

sends a poll for data.)

To edit configurations, check the checkbox „Edit Settings‟ in the left bottom corner. After

that, there will be 5 configurations that can be edited. These configurations will be

described in the following chapters:

Associate Interval

Poll info ratio

Poll interval

Poll timeout

Scan channels

Opticon ESL

DEMO KIT

User Manual

To edit multiple ESLs at the same time, press the shift- or ctrl-key in the base station tab to

select and configure multiple ESLs at the same.

19

Page 20

5.4.1. Associate interval

When an ESL is not connected to any base station it will automatically start looking for

nearby base stations. Since searching for base station consumes a relative large amount of

power it will not continuously search, but only once every couple of seconds. The associate

interval determines the time (in seconds) between two associating attempts of an ESL. The

default associate interval is currently 15 seconds.

Please note that ESLs consume much more power while not being connected to a base

station than when they‟re connected, so it‟s strongly recommended to never turn off the

base stations once a network of ESL‟s is operating. If ESLs are not being used for a long

period of time the associate interval can best be set to a much longer interval like 300

seconds. For an even longer period of time, removing the batteries might be the best

option.

The amount of power that is being consumed by the ESL, when it‟s not connected to any

base station is also strongly related to the number of RF channels it is configured to search

for base stations. More information about the configuration of the „Scan Channels‟ can be

found in chapter 5.4.5.

Opticon ESL

DEMO KIT

User Manual

5.4.2. Poll Info Ratio

The poll info ratio determines how often ESLs will automatically send their current status

and settings to the base stations. By default the ESLs will transmit this information once

every 40 polls, so a ratio of 1:39.

The status and information of an ESL is also requested immediately by opening the

settings dialog of an ESL by right clicking on the ESL. This will cause the base station to

request the settings the next time this ESL polls for data.

The poll info ratio is set to a relative high value, because settings and status usually don‟t

vary a lot and because sending settings and status information uses more bandwidth and

consumes more power than regular polls for data.

5.4.3. Poll Interval

The poll interval specifies the interval (in seconds) at which the ESL sends a poll for data to

the base station. This parameter is the most significant configuration of an ESL since it

strongly determines the response time of an ESL (how fast is an image displayed) as well

as the battery life time.

By default the ESLs poll every 15 seconds once they‟re connected to a base station. This

means that to response time of an ESL can be anywhere in between 0 to 15 seconds

(unless the poll doesn‟t arrive at the base station due to interference).

The poll interval greatly influence the battery life time, so lowering it is not recommended.

For example, changing the poll interval from 15 seconds to 5 seconds will roughly double

the power consumption and thereby shorten the battery life time by a factor of 2.

An advantage of making the poll interval bigger is the reduction of the used bandwidth per

ESL, making it possible to connect more ESLs to a single base station.

20

Page 21

5.4.4. Poll timeout

The poll timeout specifies the number of polls without acknowledge from the base station

after which the ESL will time out its connection and start searching for another base station.

The default poll time out is currently 30 polls, so by default the time out is 30x15 seconds =

450 seconds.

5.4.5. Scan channels

Once an ESL has associated (connected) to a base station, it operates on a single RF

channel. However when it‟s not yet connected to a base station, the ESL will automatically

scan a range of RF-channels for base stations. The range of RF channels that an ESL will

scan for base station is configurable. All channels in the range of channel 11 to 26 can be

scanned by adding the channel in the dash-separated list of channels.

By default the channels 11 to 15 are enabled (11-12-13-14-15). Channel 11 can‟t be

disabled to make sure that when an ESL that is not associating to any base station and its

RF channel range is unknown, it can always be retrieved by configuring a nearby base

station to channel 11.

Opticon ESL

DEMO KIT

User Manual

5.5. ESL status information

Each ESL will also periodically transmit the following status information.

Battery voltage Current battery voltage

Boot counter Number of times the ESL has been reset (automatically and manually)

LQI Indicator of the signal strength from an ESL (from ESL to base station)

LQI BS Indicator of the signal strength from an ESL (from base station to ESL)

MAC 16-digit MAC address of the ESL

Poll Time of the latest poll that has been received from the ESL

Type Hardware variant of the ESL

Version Software version of the ESL

5.6. Configuring of base stations

Base stations have very few configurations besides the configuration of the Ethernet

module (which will be described in chapter 5.6.3). The only main configuration is the RF

channel on which the base station operates.

5.6.1. Configuring the RF channel

The base station always operates on a single RF channel, which can be selected in a

range of channel 11 to 26 (as specified by the IEEE 802.15.4 standard).

When using multiple base stations it‟s also strongly recommended to use a different RF

channel for each base station within range to improve the maximum throughput of data and

reduce data collisions.

Since the base station / ESLs, which apply the IEEE 802.15.4 standard, operate on the

same frequencies as i.e. WIFI and Bluetooth it‟s important to make sure that a base station

21

Page 22

Opticon ESL

DEMO KIT

User Manual

does not operate on the same RF channel as any nearby WIFI network to minimize

interference.

To detect which RF-channels are least active, the base station can perform an energy scan

on all 16 available channels and graphically show the energy levels in a real-time graph.

To start an energy scan simply press the „scan‟ button in a base station-tab of the server

application.

After checking which RF channels show least activity, one of these channels can be

selected by pressing the „Set Channel‟ button.

If the RF channel was changed the base station will automatically reset to apply the new

setting.

Be aware that any ESLs that were already associated with the base station before

changing the RF channel will lose their connection with the base station. By default it will

take 30 polls (times the poll interval of 15 seconds) before the ESLs will time out and start

looking for another base station.

To avoid having to wait a couple of minutes before the ESLs starts looking for the base

station on the new RF-channel it‟s possible to disassociate all the ESLs from the base

station prior to changing the RF channel. This can be done using by pressing the „select all‟

button and then the „Remove‟ button. This will disassociate all ESL‟s from the base station

and the ESLs will start to disappear from the base station. Once they‟re all gone, quickly

change the RF channel and the ESLs should start to appear again on the new channel.

Be aware that ESLs don‟t search for base stations on all 16 RF channel, but only on a

configurable range of channels (default: channel 11 to 15). So if the RF channel of the base

station is set to a channel outside this range, the ESLs will not find the base station. For

this reason it‟s important to first configure the RF channel range on all ESLs before

configuring the base stations. (See chapter 5.4.5)

If an ESL is not associating to any base station and its RF channel range is unknown, then

configure a base station to channel 11. This channel will always be scanned by any ESL to

make sure they can always be found and reconfigured without having to look for it on all

channels.

22

Page 23

5.6.2. Changing the name of a base station

To make it easier to distinguish multiple base stations, it‟s possible to assign a name to

base stations. This can be done by editing the text field besides the „Set Name‟ button and

pressing this button afterwards to store the name inside the base station.

5.6.3. Configuring the Ethernet settings

To setup the base station for use within an existing network its DHCP configuration, IP

address and subnet masks need to be configured.

To prevent IP address conflicts when a base station is connected to a network, DHCP is

enabled by default. On most installations a fixed IP address setup will be recommended.

If DHCP is used, make sure the DHCP server always assigns the same IP address to the

same base station.

Before IP and DHCP settings can be changed, the base stations need to be found on the

network. If no DHCP server is available the IP address of a base station defaults to

192.168.100.100 with subnet mask 255.255.0.0. If a DHCP server is available, then the

base station can be found using an external tool called XTAdminXXL, which is included in

the „Tools‟ folder of the installation.

Opticon ESL

DEMO KIT

User Manual

The base stations are clearly identifiable under ‘OPTICON SENSORS EUROPE, BASE

STATION, XT-NANO-XXL-F0’.

To configure the network settings of the base station, use telnet with the found IP address

(i.e. C:\>telnet 192.168.0.17) or press „Telnet‟ in XTAdminXXL.

23

Page 24

When using Windows 7, telnet can be enabled as follows:

Start > Control Panel

Programs And Features

Turn Windows features on or off

Check Telnet Client

Hit OK

Opticon ESL

DEMO KIT

User Manual

Default password „xt‟ then press „N‟ (Network menu)

Only DHCP and IP need to be configured, all other options need to stay as is. If DHCP is

not used please make sure all base stations have a unique IP address and the subnet

mask is set correctly.

Trouble shooting:

When for some reason all network settings have been deleted, for instance when the

‘Factory settings menu’ was used, then the settings can be restored by uploading a

configuration file via ftp. Contact Opticon for the latest configuration file and upload

instructions.

24

Page 25

5.7. Setup of the ESL server application

By opening the setup window of the ESL server application, most settings of application

can be configured. The image below shows a typical ESL pilot configuration and a

matching file system tree.

Opticon ESL

DEMO KIT

User Manual

(a) Base stations

After configuring the network settings of the base stations add them to this list. The only

supported configuration at this moment is a TCP Client (TCPC). This means that the ESL

Server actively connects to a base station. For every base station add a line with the

following format:

TCPC:aaa.bbb.ccc.ddd:port

25

Page 26

Opticon ESL

DEMO KIT

User Manual

(b) Input Folder

The folder in which the back office uploads the new product data files.

File mask: File name mask of the product data file. Currently the only supported

mask is <name>_#.csv where # is any number.

(c) Output

Output directory for the middleware applications. It will contain 3 CSV-files:

dbase.csv (combined product database)

linked.csv (ESL-products links)

scan.csv (truncated article database that is sent to the terminal)

Also all automatically generated BMP- and XML-files will be placed in the sub-folder:

„Images‟. (Once processed the images and XML-files will be moved to the subdirectory:

„/Completed‟ inside this folder.)

(d) Delete Links

Deletes all existing links between ESLs and products. Be aware that all links will have to be

manually created again using the barcode terminal after doing this. See chapter 3.3 for

more information about re-installing an ESL system.

(e) Delete Database

Deletes the complete (combined) database file from your system (dbase.csv). Be aware

that a new full database will have to be placed in the „Input‟ folder in order to get the ESL

system to fully operate again. See chapter 3.3 for more information about resetting an ESL

system.

(f) Processed Folder

The folder to which all processed product data files are copied when all labels have been

updated.

(g) CSV parser

Executable of the middleware application that parses new product data files into a

combined database (dbase.csv) and generates the truncated article database (scan.csv)

that is sent to the barcode terminal to allow linking of products to ESLs.

By default the CSV-parser expects the following field sequence in the CSV-files:

<Modification code>;<Unique ID>;<Barcode>;<Description>;…;…;…;…etc.

Unique Id field: Field number of the unique product ID in a CSV-record

Barcode field: Field number of the product barcode in a CSV-record

Description field: Field number of the product description in a CSV-record.

(The description is shown by the barcode terminal when a link is created, so the user can

verify the correct product was linked).

Note 1: The first field is field number ‘0’, the second is ‘1’, etc!

26

Page 27

Note 2: When changing the field sequence of your database, make sure you delete the

existing product database files. (See chapter 3.3 for more information)

(h) Image generator

Executable of the middleware application that parses the product database (dbase.csv)

and the link database (linked.csv) into BMP- and XML-files for each linked ESL. The layout

of the generated images and XML-files can be customized by changing the image layoutfile (XML-based) and the XML-template file.

Image layout: XML-based layout file that determines the layout of the images that will be

displayed on the ESLs. Currently the layout file can only be manually edited using a

text/XML editor. This process is described in the Appendix A: Editing the ESL template

files. (In the future it will be possible to design the layout using a graphical user interface.)

Info template: Template for the automatically generated XML-files for each linked ESL. In

most situations this template can be left untouched. Only if the positions of the unique ID

and/or the product description aren‟t located at respectively field 1 and field 3 in the CSVdatabase, then these field numbers can easily be corrected. (See Appendix A: Editing the

ESL template files)

Opticon ESL

DEMO KIT

User Manual

(i) Barcode terminal

The barcode terminal will be polling on the specified serial port for new ESL-product links

(link.csv) and will update the barcode terminal with the latest product database (scan.csv).

(j) Log files

Folder that will contain all ESL status information (EslLog.txt). The „SentImages‟-subfolder

is used by the server application to store the last sent image to an ESL.

(k) Apply

Save all settings and restart the Application.

(l) Reset

Restore settings to last known state.

(m) Cancel

Exit without saving settings.

27

Page 28

Opticon ESL

DEMO KIT

User Manual

6. Middleware applications

The ESL server application uses middleware applications to process the information from the

Back office into file formats that the ESL server application uses to update ESL‟s.

The main tasks of the middleware are divided into 2 applications: the CSV-parser and the

Image generator. These will be described in the following chapters.

6.1. CSV-parser

The tasks of the CSV-parser are:

Parse product database files (modifications or complete databases) into a combined CSV-

database containing all product info.

Generate a reduced article database (CSV-format) for the barcode terminal.

The typical record format of a product modification database would be:

<Modification code>;<Unique ID>;<Barcode>;<Description>;<Field 4>;<Field 5>;etc.

The typical record format of a complete product database would be:

;<Unique ID>;<Barcode>;<Description>;<Field 4>;<Field 5>;etc.

Besides the first field (modification code) the order and amount of remaining fields can be

changed. See chapter 4.1 for more information on the CSV-format.

The record format of the truncated database file (scan.csv) for the bar code terminal that is

generated will have the following format:

<Barcode>;<Unique ID>;<Description>

If no barcodes are used in your application or the Unique ID is the barcode, then the

<Barcode> field will be the same as the Unique ID.

The ESL server manager will call the CSV-parser with the following parameters as

specified in the setup window of the ESL server application:

<CSV-parser>.exe –O <Output folder> -i<Id field> -b<Barcode field> -d<Description

field> <Database file>.csv

So the default call by the ESL server application would be:

CsvParser.exe –O "Output" -i1 -b2 -d3 "Input\ProductData_1.csv"

6.2. Image generator

The task of the Image generator is to generate BMP- and XML-files for each linked ESL from the

combined product database (dbase.csv) and the link database (linked.csv).

28

Page 29

Opticon ESL

DEMO KIT

User Manual

As long as there are no MAC addresses in the link database (linked.csv) the middleware

won‟t generate any images for ESLs. Use the barcode terminal to create a link database

(see chapter 7).

The ESL server manager will call the Image generator with the following parameters as

specified in the setup window of the ESL server application:

<Image generator>.exe –O <Output folder> <Image layout>.xml <Info template>.xml

So the default call by the ESL server application would be:

ImgGen.exe -O "Output" "Templates\image.xml" "Templates\info.xml"

Note: The option ‘-f’ can be added to force an update of all the images of all ESLs in the

network. To force such an update on all ESLs, select the ‘Data’-tab in the server application

and press the F8-key.

7. Barcode terminal application

The barcode terminal can be used to link an ESL (using its unique MAC addresses) to

products, objects or locations. How to create these links will be described in the following

chapters.

7.1. Setting up the barcode terminal

The barcode terminal that is included with this SDK is OPH1004, H13 or the OPL9728 with

a communication cradle and USB and/or RS232 cradle. When using the USB cable it‟s

necessary to install Opticon‟s USB driver pack, which can be selected in the installer. The

drivers can also be found in the „Tools‟ folder of this installation.

If the „ESL Linking Application‟ is not yet loaded on the terminal or needs to be updated,

then the software can be loaded by using the „Update Firmware‟ option in the „Setup‟

window of the ESL server manager. *

To load the software, open the „Setup‟ window of the ESL server application. Make sure

you‟ve selected the correct COM port. Then press the „Update Firmware‟ button and select

the correct firmware file, being:

‘XPA3693x.HEX’ for the OPH1004/H13

‘LBF3693x.S32’ for the OPL9728

These files can be found in the „Firmware‟ folder of this installation.

After loading the software the terminal should show a menu stating “ESL LINKING (APPL.)”

* Note: Updating the firmware of the barcode terminal requires Appload to be installed.

Appload can be installed by selecting „Appload‟ in the installer or it can be found in the

„Tools‟ folder.

29

Page 30

7.2. Loading the database files on the terminal

Before any links can be created the reduced product database (scan.csv) first has to be

loaded on the terminal to allow the reading of the barcodes on product.

To be able to transfer files between the ESL server application and the barcode terminal

the serial port of the PC is used. Make sure you‟ve enabled and configured the correct

serial port in the setup windows of the server application (See chapter 5.7).

Also verify that the field numbers of the unique ID, barcode and description match your

CSV-database file (See chapter 5.7). Note that the first field is field number 0; the second is

1, etc.

Loading any files onto the terminal and sending back the resulting link database

(linked.csv) is done by placing the terminal into its cradle. As soon as the combined article

database (scan.csv) or the link database has been changed, the server application will

automatically synchronize the barcode terminal with the PC and process any modifications.

Opticon ESL

DEMO KIT

User Manual

7.3. Creating links between ESLs and products/locations

The first step in creating a link is pressing „1‟ (Link ESLs) and then selecting the used ESL

variant by pressing „1‟ (2" e-paper) or „2‟ (2.7" e-paper).

The next step is scanning the barcode on the back of an ESL, after which the terminal

should sound an OK-beep and display the full MAC address.

If the barcode on the e-paper ESLs is not accessible, it‟s also possible to display this same

barcode on the e-paper ESLs. To do so, select all ESLs in the server application that have

not yet been linked, then select the „image‟ checkbox and press the „Reset‟ button. All

ESLs should now start displaying the (default) barcode image containing the MAC address.

After scanning the MAC address you can either manually enter the unique ID or scan the

barcode of the product that you want to link to this ESL.

After scanning/entering the product the terminal should say that the linking was successful

(„Linking successful!‟). If the product wasn‟t found in the database it will show a message

that the product wasn‟t found („Product not found‟).

If you accidently linked the wrong product to an ESL, then you can correct this by scanning

the ESL‟s MAC address again and linking it to the correct product.

30

Page 31

7.4. Deleting existing links

Press „2‟ (Unlink ESLs) to delete existing links from the link database. Deleting an existing

link can be done by either entering the product ID or by scanning the product barcode or

the MAC address of the ESL.

7.5. Verifying existing links

It‟s possible to check whether a product has been correctly linked by pressing „3‟ (Product

Info). When entering the product ID or by scanning the product barcode or the MAC

address of the ESL, then it will show the product information and the linked ESL.

7.6. Sending the modified link-database to the PC

After all links have been created using the barcode terminal, this information needs to be

send back to the PC, so they can be processed by the server application. This can be done

by placing the terminal back into its cradle. The terminal should now automatically send the

link database (linked.csv) back to the PC.

After the barcode terminal has sent back the link database, the ESL server application will

call the middleware application to parse the combined database and link database into ESL

image files (bitmaps) and configuration (XML) files and update the ESLs if necessary.

Opticon ESL

DEMO KIT

User Manual

7.7. Settings menu

The settings menu of the terminal can be accessed by pressing „4‟ („Settings). This menu

contains 2 options:

1. Delete data Deletes all files from the terminal, so also all links that have

not yet been sent back to the PC.

2. Barcodes This menu can enable/disable different barcode

symbologies, so almost all barcodes can be scanned.

7.8. Version

Shows the version of the terminal application, which can be useful for support purposes.

31

Page 32

8. Version history

V0.1

First preliminary release

October 11, 2011

V0.2

Added following features:

- OPL9728 compatibility (LFD36931)

- 2.7" e-paper compatibility

- Support of alphanumeric product IDs

Fixed adding images to image templates

Fixed delete database button

Updated manual to match Opticon style

November 10, 2011

Fixed cross-references

November 18, 2011

Opticon ESL

DEMO KIT

User Manual

32

Page 33

Appendix A: Editing the ESL template files

The ESL template files are XML-based and can be manually edited to design your own

label layout.

The ESL server application uses two templates.

An image template that specifies the actual image layout of the images that will be generated.

An information template that is used to generate XML-files that provide the ESL server

application with all the necessary information about the linked ESL and product (Unique ID,

MAC address and description)

Note: In the near future a graphical user interface will be added to the ESL system that will

allow you to design the image layout more easily and with more features.

Opticon ESL

DEMO KIT

User Manual

A.1. Editing the Information template

As mentioned above, the information template is used to provide the ESL server

application with all the required information of each ESL, being the Unique ID, MAC

address and a description of the linked product *.

* Note: The description will be shown in the ‘data’ tab of the ESL server application.

The default location of the information template is "./Templates/Info.xml".

This template will have the following content:

<?xml version="1.0" encoding="utf-8"?>

<EslImageInfo>

<Label></Label>

<ImageFile>%1%.bmp</ImageFile>

<X>0</X>

<Y>0</Y>

<Width></Width>

<Height></Height>

<HOffset>0</HOffset>

<VOffset>0</VOffset>

<Ix>0</Ix>

<Variant></Variant>

<Note>%3%</Note>

</EslImageInfo>

Only two fields of this template may have to be changed, which depend on the field

sequence of your CSV-database. The fields that need to be correct are:

<ImageFile> Needs to contain the field number of the Unique ID

<Note> Needs to contain the field number of the product description.

The field number is specified between the „%‟ „%‟ inside these lines. Note that the first field

has field number „0‟.

33

Page 34

For example, if the CSV-file has the following field sequence:

<Modification code>;<Barcode>;<Unique ID>;<Price>;<Description>;etc. etc.

The lines should be changed to:

<ImageFile>%2%.bmp</ImageFile> and <Note>%4%</Note>

A.2. Editing the Image layout template

The image layout template is also XML-based and can be manually edited to design your

own label layout.

The default location of the image template is "./Templates/Image.xml".

The image template currently supports 5 types of objects that can be added to design the

ESL layout:

Text (fixed and dynamic)

Lines

Rectangles (filled)

Images (monochrome; fixed and dynamic)

Barcodes

These objects should be added to the template file using the following formatting:

<?xml version="1.0" encoding="utf-8"?>

<EslLayoutInfo>

<EslTemplate>

<Variant>H</Variant>

<Width>200</Width>

<Height>96</Height>

<Object>

<Text>

…

</Text>

</Object>

<Object>

<Rectangle>

…

</Rectangle>

</Object>

<Object>

<Image>

…

</Image>

</Object>

<Object>

<Line>

…

</Line>

</Object>

<Object>

<Barcode>

…

</Barcode>

</Object>

</EslTemplate>

</EslLayoutInfo>

Opticon ESL

DEMO KIT

User Manual

34

Page 35

Opticon ESL

DEMO KIT

User Manual

The image will be generated by parsing the template from top to bottom, so if one object

needs to be drawn on top of another, then this can be done by changing the sequence of

the objects in the image template.

The ‘Variant’ field specifies the hardware variant of the ESL of each template. Multiple templates can be

added if more than one hardware variant is used.

The dynamic content of texts, barcodes and images can be inserted to your template from

the CSV-database. To add a certain field from a CSV-record to your image, add the field

number between two „%‟-characters in the content field of the object.

For example, if the CSV-file has the following field sequence:

<Modification code>;<Barcode>;<Unique ID>;<Price>;<Description>;<Weight>;<Unit>;etc. etc.

Then the price field would be added by using %3%, since it is field number 3 (starting from

0).

It‟s also allowed to combine multiple fields as dynamic content.

Example (to add the weight plus standard unit):

<Content>Weight: %5% %6%</Content>

Special characters can be added using the standard XML notation, so for instance an Euro

sign can be added using: € (since its Unicode is U+20AC)

Any type of object can be added to the template conditionally if needed, meaning that it is

only shown in the resulting image if a certain field in a CSV-record contains a value or

equals a certain value.

This is can be done by adding one of the following lines to any type of object.

<!-- Object if only displayed if field 'x' contains a value -->

<Condition>%x%</Condition>

<!-- Object if only displayed if field 'x' equals 'y' -->

<Condition>%x%=y</Condition>

The following chapters will describe the 5 object types in more detail.

35

Page 36

A.2.1. Text

Text can added to the template using the following format:

<Object>

<Condition>%6%</Condition>

<Text>

<Content>From: %6%</Content>

<Color>0</Color>

<X>0</X>

<Y>33</Y>

<Width>40</Width>

<Height>20</Height>

<Font>

<Type>Arial</Type>

<Size>9</Size>

<Italic>0</Italic>

<Bold>0</Bold>

</Font>

<Lines>2</Lines>

<HAlignment>LEFT</HAlignment>

<VAlignment>BOTTOM</VAlignment>

</Text>

</Object>

<Condition> (optional) Displaying conditions

<Content> The Dynamic/fixed text to be rendered

<Color> Text color (0=Black; 1=White)

<X> <Y> <Width> <Height> Specify the rectangle within the text is rendered

<Font> Specifies the type, style and size of the used font

<Lines> Number of lines the text may be wrapped if needed

<HAlignment> Horizontal alignment (LEFT, CENTER or RIGHT)

<VAlignment> Vertical alignment (TOP, CENTER, BOTTOM)

Opticon ESL

DEMO KIT

User Manual

36

Page 37

A.2.2. Rectangles

A (filled) rectangle can be added to the template using the following format:

<Object>

<Condition>%6%</Condition>

<Rectangle>

<Color>0</Color>

<X>0</X>

<Y>0</Y>

<Width>200</Width>

<Height>32</Height>

</Rectangle>

</Object>

<Condition> (optional) Displaying conditions

<Color> Color (0=Black; 1=White)

<X> <Y> <Width> <Height> Specify the position and size of the rectangle

A non-filled rectangle can be added by simply drawing two rectangles on top of each other

in opposite colors.

Opticon ESL

DEMO KIT

User Manual

A.2.3. Lines

A line can be added to the template using the following format:

<Object>

<Condition>%6%</Condition>

<Line>

<Color>0</Color>

<X1>0</X1>

<Y1>77</Y1>

<X2>200</X2>

<Y2>77</Y2>

<Size>1</Size>

</Line>

</Object>

<Condition> (optional) Displaying conditions

<Color> Color (0=Black; 1=White)

<X1> <Y1> <X2> <Y2> Specify start/end coordinates

<Size> Thickness of the line

37

Page 38

A.2.4. Images

An image (fixed or dynamic) can be added to the template using the following format:

<Object>

<Condition>%4%</Condition>

<Image>

<File>Templates\images\G%4%.bmp</File>

<X>173</X>

<Y>33</Y>

</Image>

</Object>

<Condition> (optional) Displaying conditions

<File> Image file path (absolute or relative to working directory)

<X> <Y> Coordinates of the upper-left corner of the image

Opticon ESL

DEMO KIT

User Manual

A.2.5. Barcodes

Almost any type of barcode can be added to the template using the following format:

<Object>

<Condition>%4%</Condition>

<Barcode>

<Content>%4%</Content>

<Color>0</Color>

<Type>5</Type>

<X>50</X>

<Y>80</Y>

<Width>100</Width>

<Height>20</Height>

<HAlignment>CENTER</HAlignment>

<VAlignment>BOTTOM</VAlignment>

</Barcode>

</Object>

<Condition> (optional) Displaying conditions

<Content> Content of the barcode

<Color> Foreground Color (0=Black; 1=White)

<Type> Specifies the bar code type (See list below)

<X> <Y> <Width> <Height> Specify the rectangle within the barcode is rendered

<HAlignment> Horizontal alignment (LEFT, CENTER or RIGHT)

<VAlignment> Vertical alignment (TOP, BOTTOM)

The barcode type can be one of the following values:

1. UPC-A

2. UPC-E

3. UPC 2 Addon/supplemental chars

4. UPC 5 Addon/supplemental chars

5. EAN-13

38

Page 39

6. EAN-8

7. Interleaved 2of5

8. Standard 2of5

9. Industrial 2of5

10. Code-39

11. Code-39 Full ASCI

12. Codabar

13. PostNet

14. BOOKLAND

15. ISBN

16. JAN13

17. MSI (Mod10)

18. MSI (Mod10/Mod10)

19. MSI (Mod11)

20. MSI (Mod11/Mod10)

21. Modified Plessey

22. Code-11

23. USD8

24. UCC-12

25. UCC-13

26. LOGMARS6

27. Code-128

28. Code-128 (Code-set A)

29. Code-128 (Code-set B)

30. Code-128 (Code-set C)

31. ITF14 (Interleaved 2of5 14 digits)

32. Code-93

33. Telepen

Please note that the content of a barcode usually must match various criteria (i.e. fixed

length and check digits) in order it to render properly. If a barcode is not (correctly)

rendered, then please check the log-file of the parsed CSV-file in the „Processed‟ folder for

more information about the cause of the problem.

Opticon ESL

DEMO KIT

User Manual

A.3 Trouble shooting

Formatting errors:

If an XML-file contains a format error, then no images will be generated. Information about

format error can be found in the log-file of the parsed CSV-file in the „Processed‟ folder.

Also opening the XML-files in an Internet Browser can often quickly reveal the problem.

Barcode rendering problems:

The content of a barcode usually must match various criteria (i.e. fixed length and check

digits) in order it to render properly. Please check the log-file of the parsed CSV-file in the

„Processed‟ folder for more information about the cause of rendering issues.

Incorrectly configured field numbers:

Make sure that the field numbers (Unique ID, barcode and description) in the „Setup‟

window of the ESL server application match the field sequence of your CSV-export (field

numbers start at 0).

39

Page 40

Make sure the Unique ID field is correctly set in the <ImageFile> field of the information

template.

Make sure the field numbers in the image layout template are correct.

Appendix B: Demo barcodes

The quickest way to setup an ESL demonstration is to simply use the included sample

database and example templates. After installation of the software and hardware, the only

configuration step necessary are configuring the IP address of the base station and the

serial port of the barcode terminal in the Setup windows of the ESL server application. After

that, the demo database file should be automatically sent to the barcode terminal and then

you can link your ESLs using the barcode terminal and the product barcodes in the images

below. (See chapter 7).

Opticon ESL

DEMO KIT

User Manual

40

Loading...

Loading...