Onwa KR-1338, KR-1668 Service Manual

KR-1338/1668

άÐÞÊÖ²á

KR-1338/1668

SERVICE MANUAL

10.4 TFT COLOR MARINE RADAR

TABLE OF CONTENTS

1.GENRAL 1

2.BLOCK DESCRIPTION 6

1.1 Outline 1

1.2 Boards & Major Components 2

1.3 Specifications 3

2.1 Overview 6

2.2 Display Unit 7

Block Diagram of Power Supply 9

Block Diagram of Processor PCB Main 0910 10

2.3 Transceiver Unit 14

Block Diagram of IF 0711 15

Block Diagram of Modulator 17

2.4 Different Points of Similar PCBs 18

3. ADJUSTMENT 19

3.1 Adjustment of Display Unit 20

3.2 Adjustment of Scanner Unit 29

Location of Parts on MAIN 0910 24

VIDEO Signal adjustment 25

Location of parts on PWR-0913 28

Location of parts on MOD-0904 30

Location of Parts on IF-0711 31

Location of PCBs in Transceiver Module (KR-1668) 32

BEARING SIG GEN Board (HBP0904) 32

Location of Parts on MOD 0904B 33

Location of Parts on IF-0711 34

4. MAINTENANCE 35

4.1 Remarks on Replacement of Major Parts 35

4.2 Life Expectancy of Expendable Parts 36

4.3 Menu tree 37

5.TROUBLESHOOTING 38

5.1 Outline 38

5.2 Troubleshooting Flow Charts 39

5.3 Message Indication 51

Display Unit Exploded view 52

Scanner Unit Exploded View 54

Schematic circuit diagram 58

1. GENERAL

1.1 Outline

This manual provides the information necessary for the servicing and adjustment

of the radars MODEL 1338, 1668.

The antenna unit uses a Log IF amplifier.

The table below shows the major specifications of the each model. The same

program is installed on all models, but the menu setting through factory menu is

different between the models.

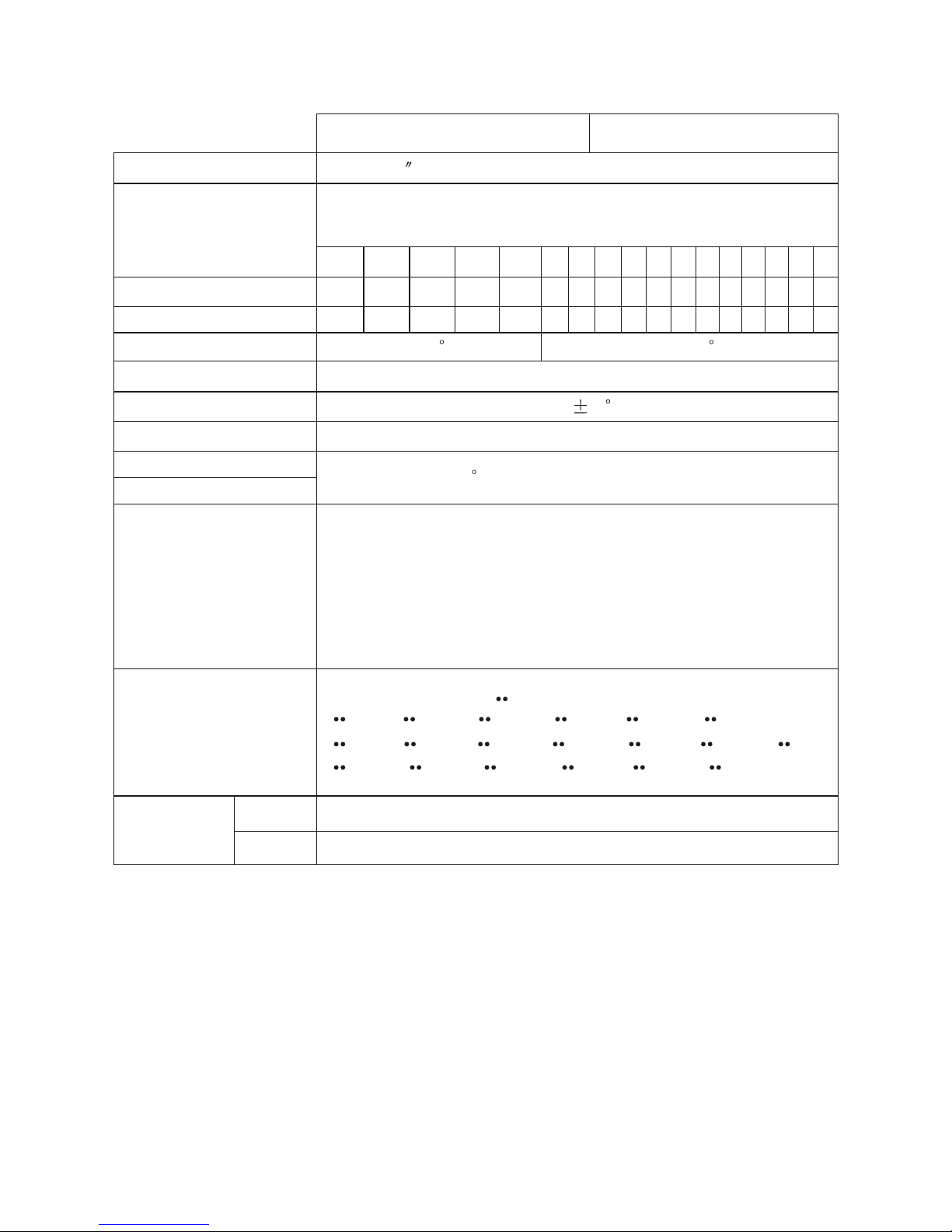

Functions KR-1338

KR-1668

Maximum range

Program Number

Tuning Voltage

(displayed at manual tuning)

Antenna Rotation

Antenna Rotation

36 NM 64 NM

4.9 V to 32V

about 24 rpm

4 kW

4/6 kW

KR-1338-SME-1

The major parts and P.C. Boards used in the display and scanner units are tabulated

on the next page.

1002XX XX

1

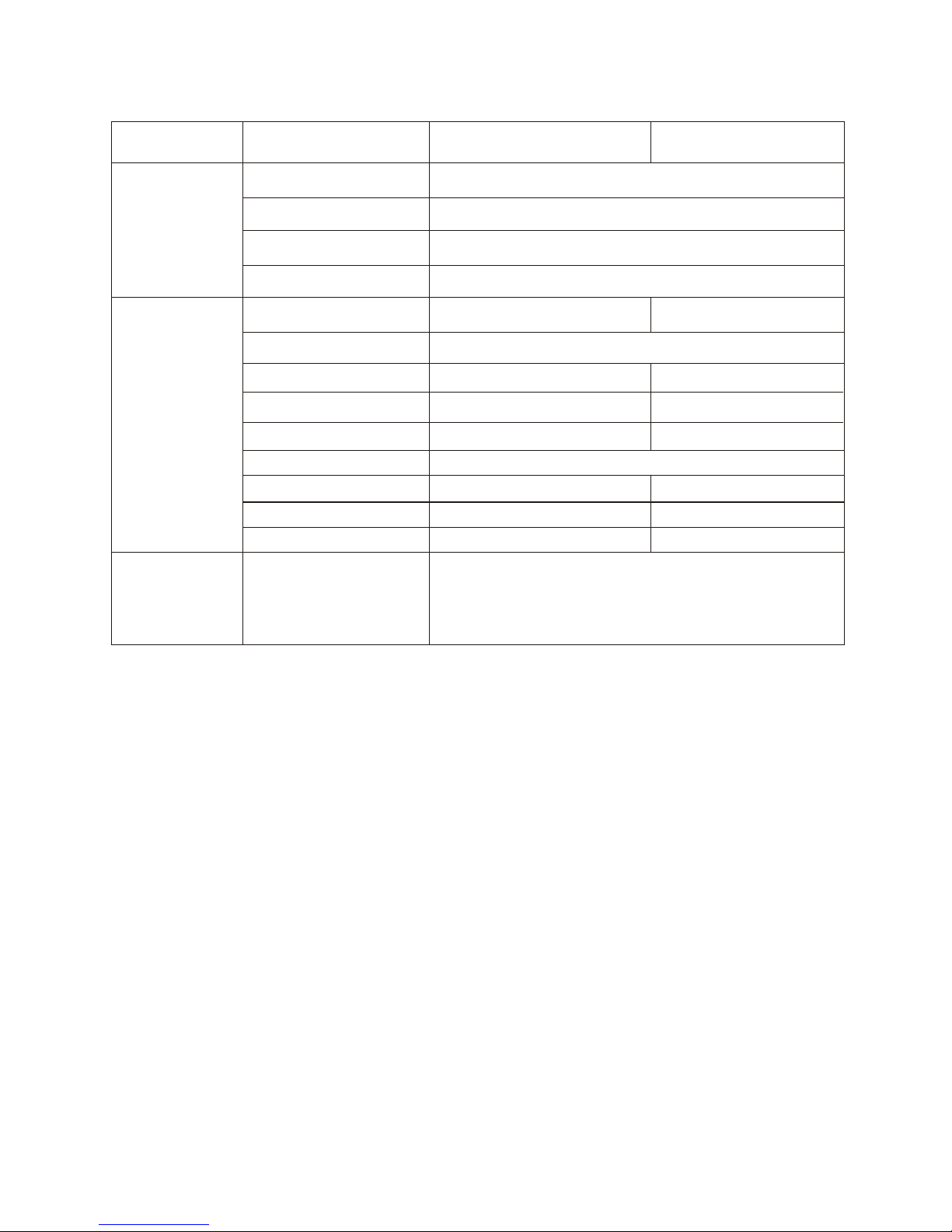

1.2 Boards & Major Components

Board

KR-1338 KR-1668

DISPLAY

UNIT

SCANNER

UNIT

PROCESSOR Board

POWER SUPPLY Board

FILTER Board

PANEL Board

MODULATOR Board

IF AMP Board

RTB Board

BEARING SIG G

EN Board

MIC Board

MIC

Magnetron

Circulator

Scanner Motor

Signal Cable

MAIN 0910

PWR 0913

FIL 0912

KEY 0912

MOD 0904A

MOD 0904B

IF 0711

-

HBP 0905

-

RCN 0907

NJT-1968B

MAF1421B/MSF1421B

MAF1421/MAF1422B

KRC-003-10(10m)

KRC-003-15(15m)

KRC-003-20(20m)

KRC-003-30(30m)

KR-1338-SME-2

CON 0906

FCX73C

BM-8256

-

BM-9256

Cable

2

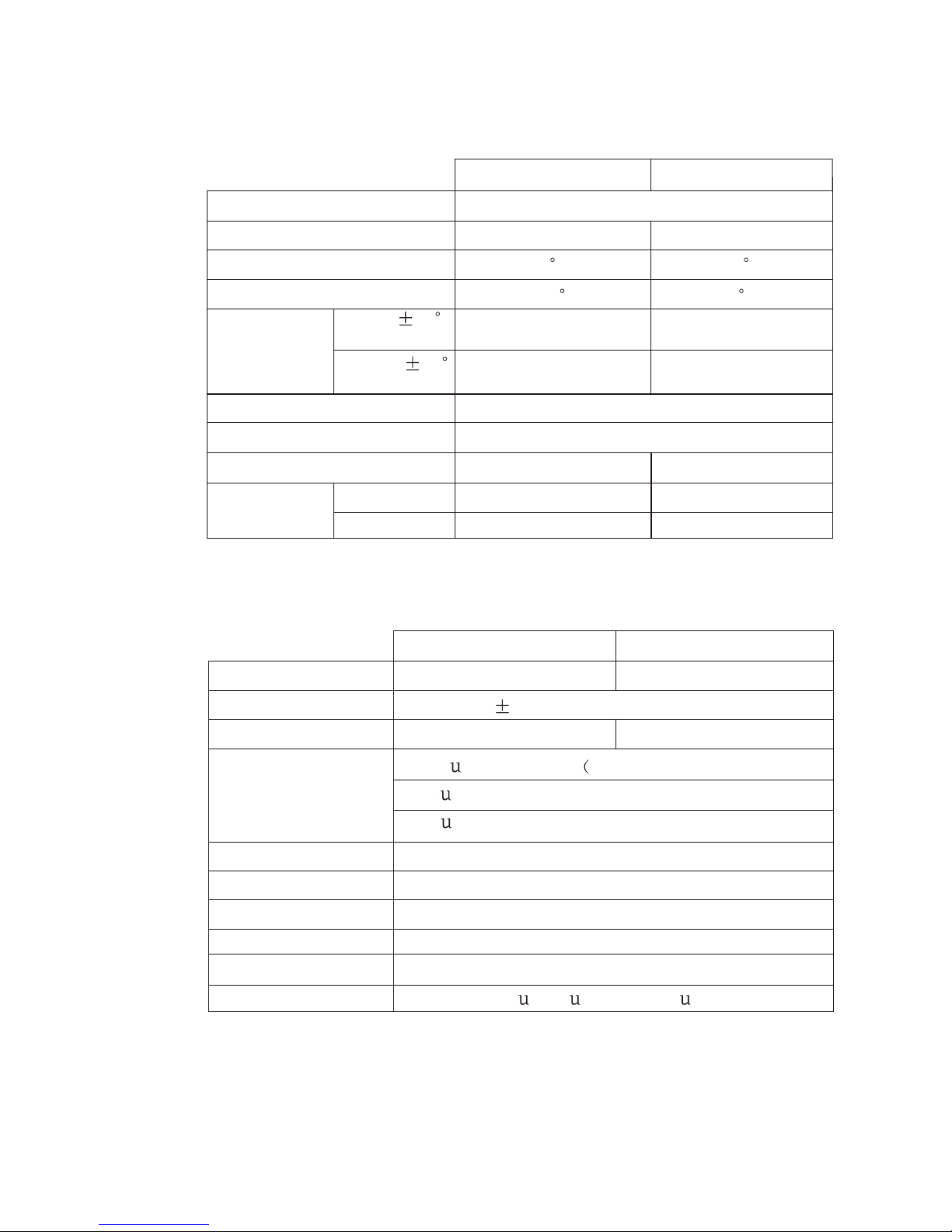

1.3 Specifications

SCANNER UNIT

KR- 1338

KR-1668

Radiator Type

Radiator Length

Horizontal Beamwidth

Vertical Beamwidth

Slotted Waveguide Array

56cm

120 cm

4 1.9

20 22

Sidelobe

Attenuation

Within 20

of mainlobe

Outside 20

of mainlobe

Polarization

Antenna Rotation

Scanner Housing Stureruct

Compass Safe

Distance

-18 dB or less -24 dB or less

-23 dB or less

-30 dB or less

Horizontal

24 rpm nominal

Radome

Open nominal

Standard

Steering

0.9 m

0.7 m

1.0 m

0.74 m

TRANCEIVER

KR-1338 KR-1668

MAF1421/MAF1422B

KR-1338-SME-3

Magnetron

Frequency &Modulation

9410 M z 30M z,P0N

HH

Peak Output Power

4 kW nominal

6 kW nominal

Pulse Length &

Pulse Repetition

Rate

0.3

Modulator

Duplexer

Receiver Front End

Tuning

Intermediate Frequency

Bandwidth

FET Switch

Circulator with diode limiter

MIC(Microwave IC)

Automatic or Manual

60 M z

H

25 M z(0.08

H

Short Ranges:0.25 nm -1.5 nm)

S, approx 2100 Hz

0.08

S, approx 1200 Hz(Middle Ranges: 1.5nm - 3nm)

0.8

S, approx 600 Hz(Long Ranges: 3 nm and above)

S, 0.3 S), 3 M z (0.8

H

S)

KR-1338-SME-4

MAF1421B/MSF1421

3

DISPLAY UNIT

KR- 1338 KR-1668

Picture Tube

10.4 LCD(LED backlight ,32 bit TFT color LCD)

Range Scale(nm)

KR-1338:36 nm

KR-1668:64 nm

0.125 0.25 0.5 0.75 1 1.5 2 3 4 6 8 12 16 24 36 48 64

1/16

0.125 0.125 0.25 0.25 0.5 0.5 1 1 2 2 3 4 6 12 12 16

2 2 4 43 3 4 4 4 4 4 4 4 43 3 3

4 1.9

Range Ringe Interval

Number of Rings

Bearing Resolution

Range Discrimination

Bearing Accuracy

Minimum Range

Range Ring Accuracy

VRM Accuracy

Input/Output Terminal

Nav Data

Compass safe

Distance

Better than 20 m

1

Better than 25 m

0.9 or 8m,whichever is the greater

NMEA (three input): NMEA 0183

NMEA (output) :NMEA 0183($RATLL, $RARSD, $RATLL:

Internal easy ARPA version.)

External Buzzer (output) : +12 V source pulse Open Collector

Slave Display (output): TRU-HD, BP, TRU-TRIG, VIDEO

NMEA 0183 Format ( :any talker)

$ APB, $ BWC, $ BWR, $ D

$ GLC, $ GTD, $ HDG, $ HDM, $ HDT, $ MDA, $ MTW,

$ RMA, $ RMB, $ RMC, $ VTG, $ VHW, $ XTE,

PT, $ GGA, $ GLL,

Standard

Steering

0.75 m

0.6 m

KR-1338-SME-5

4

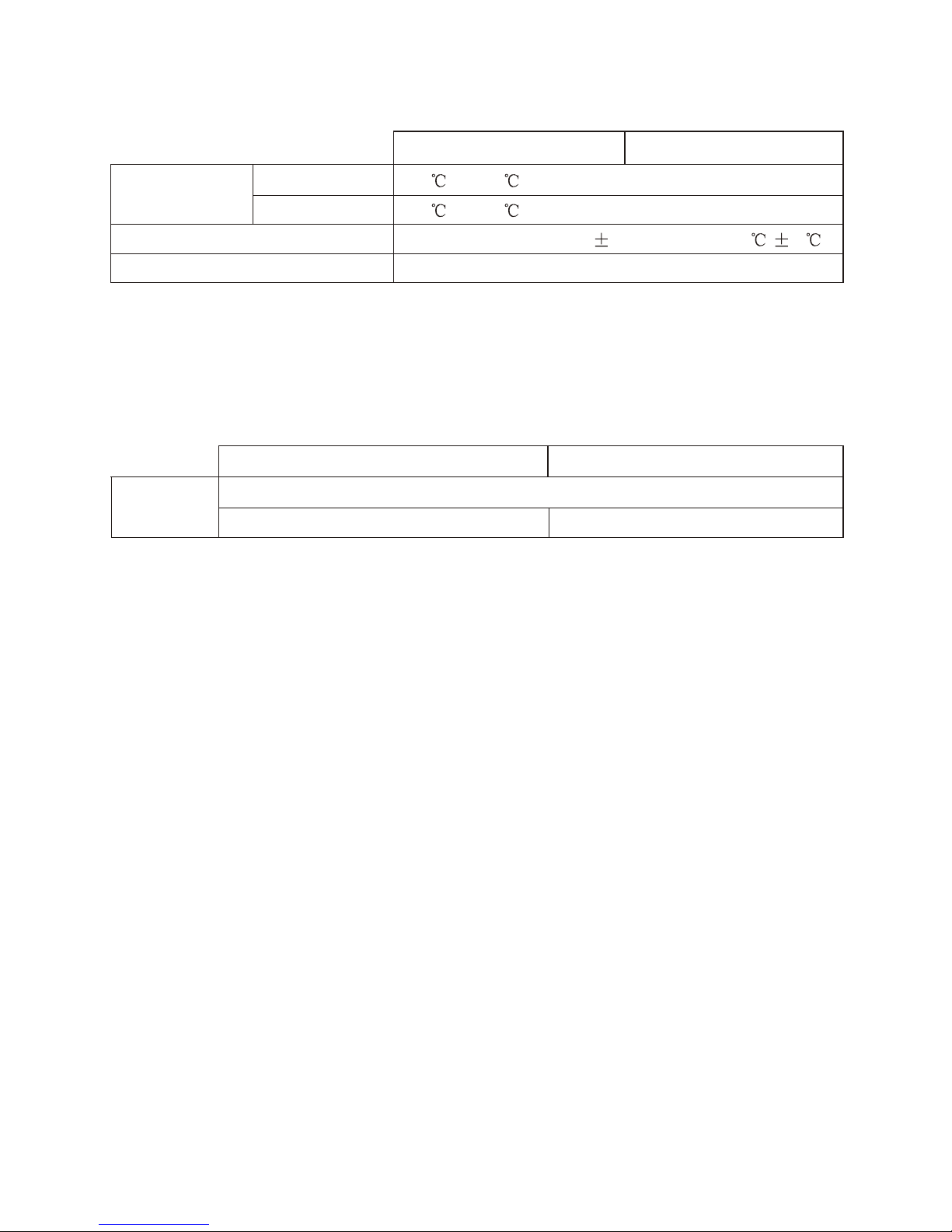

ENVIRONMENTAL CONDITIONS

KR-1338

KR-1668

Ambient

Temperature

Scanner Unit

Display Unit

Humidity

Vibration

-25 to +70

-15 to +55

Relative humidity 93% 2% or less at +40 3

-IEC 60945

KR-1338-SMJ-6

POWER SUPPLY & POWER CONSUMPTION

KR-1338 KR-1668

DC Power

10.5 V to 40.0V

48 W approx

56 W approx

KR-1338-SME-7

5

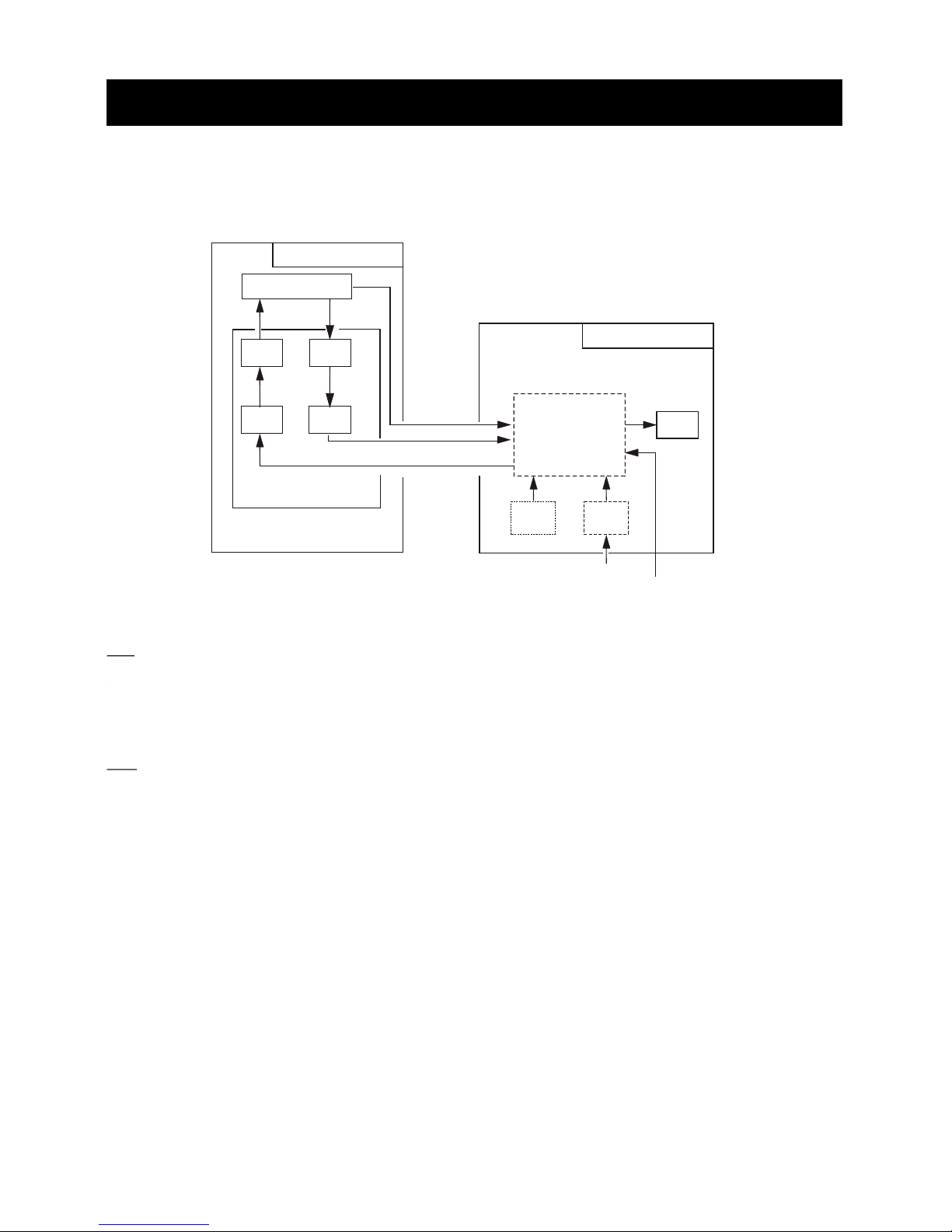

2. BLOCK DESCRIPTION

2.1 Overview

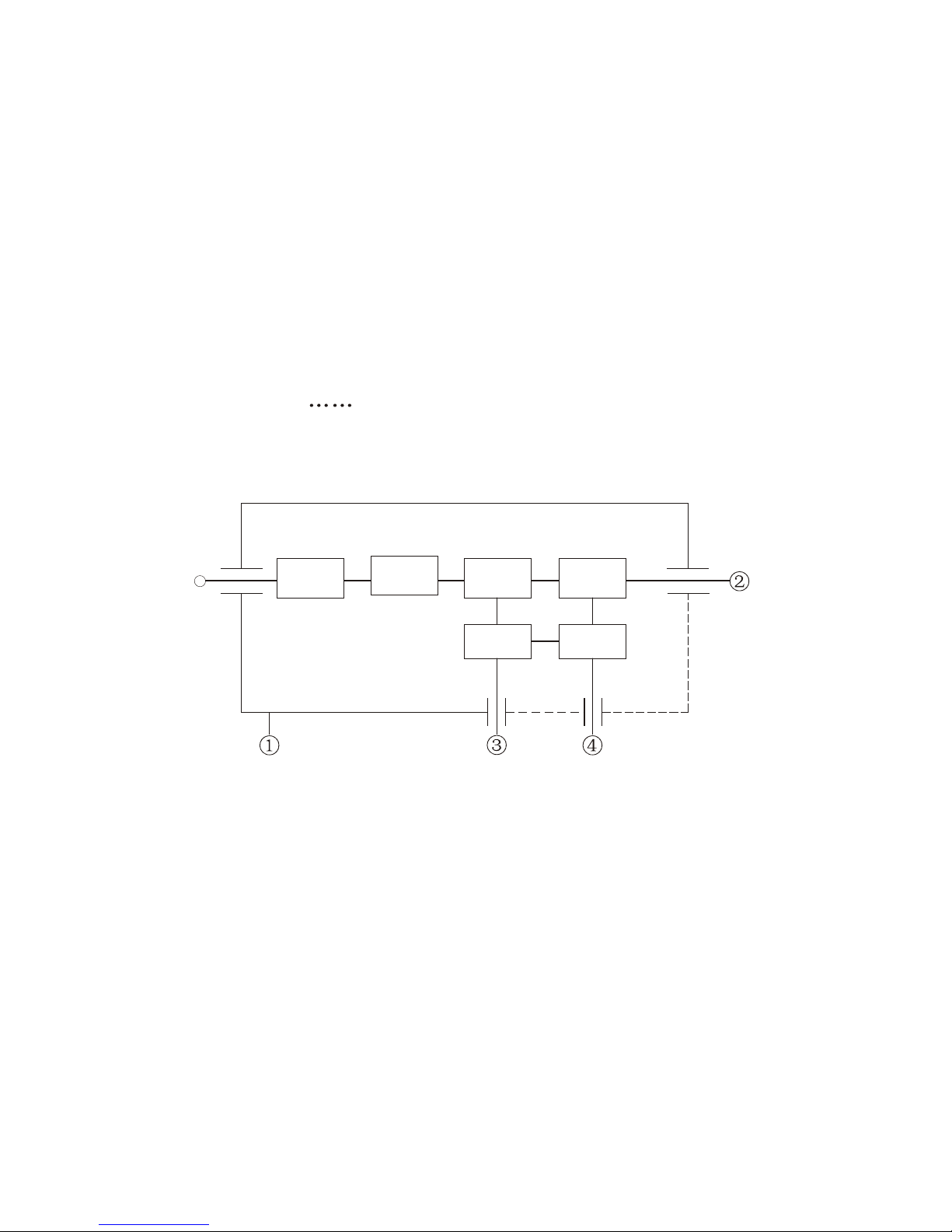

The simpified block diagram of the system is illustrated below.

TX

The trigger pulse from the PROCESSOR Board is delivered to the MODULATOR

Board, oscillates the magnetron, and then radar wave is emitted from the radiator.

RX

The 9.4 Ghz echo signal received by the antenna is converted to 60 Mhz signal by

the MIC, amplified by IF Amp, and fed to the PROCESSOR Board as video signal.

It is digitally processed and then displayed on the LCD.

Scanner Unit

Antenna

Mag. MIC

IF

Amp

Mod.

RF Module

Processor

LCD

Panel Power

Display Unit

Ship s mains'

Nav.

Gyro

HD.BP

Video

Trigger

6

2.2 Display Unit

Power Supply Circuit (PWR 0913)

The constant voltage generator Q1 is in operation even when power switch is off,

ship s mains is supplied. The power supply circuit is basically consists of a main

inverter and a sub inverter. The main inverter derives the isolated line voltages

+12 V/ANT+12 V and -12 V/ANT -12 V from the main input. The sub inverter

derives +5 V and +32 V from +12 V output of the main inverter.

Main inverter

The PWR switch becomes "open" when it is set to on position.

When the PWR switch is pressed, about 9 V is input via PWR line (P1302 #13),

Q2 is on, and DC+10 V is applied to the PWM.

When power is supplied to the PWM controller, it starts operation and alternately

turns on and off two switching FETs Q3/Q4 connected to the primary widing of

T1. The resultant AC voltage obtained on the secondary windings are rectified and

smoothed to +12 V and -12 V, and delivered to various circuits in the equipment.

The voltage taken from the +12V line is fed back to the PWM controller through

the Vr1 to maintain the +12 V output constant.

Sub inverter

U5 and the associated circuit form a PWM switching regulator for +5V and +32V.

The voltage taken from +5 V line is fed back to U5 through R37 resistance to

maintain the +5 V output constant.

Protectors

Protection of power supply circuit is achieved by stopping the drive signals to the

switching FETs Q3/4.

'

7

Qverload on +5 V and + 32 V line is detected by U6. Overload on +12 V(MOTOR+)

line is detected by U7. When the +5 V and + 32 V line is reduced by a heavy load,

U6 or U7 becomes condctive and consequently disables the PWM controller through Q6, Q7 and Q8. Overcurrent on the main input line is detected by R13, R14

and R15. The voltage drop across Q6, Q7 and Q8 bec- omes large when the inverter is overload. Overcurrent detector U3 disables PWM inverter U2 when the

voltage drop exceeds a certain level.

Overvoltage of mains input is detected by the U1. When the input voltage exceeds

41.6 V, the U1 becomes active and disables PWM controller U2

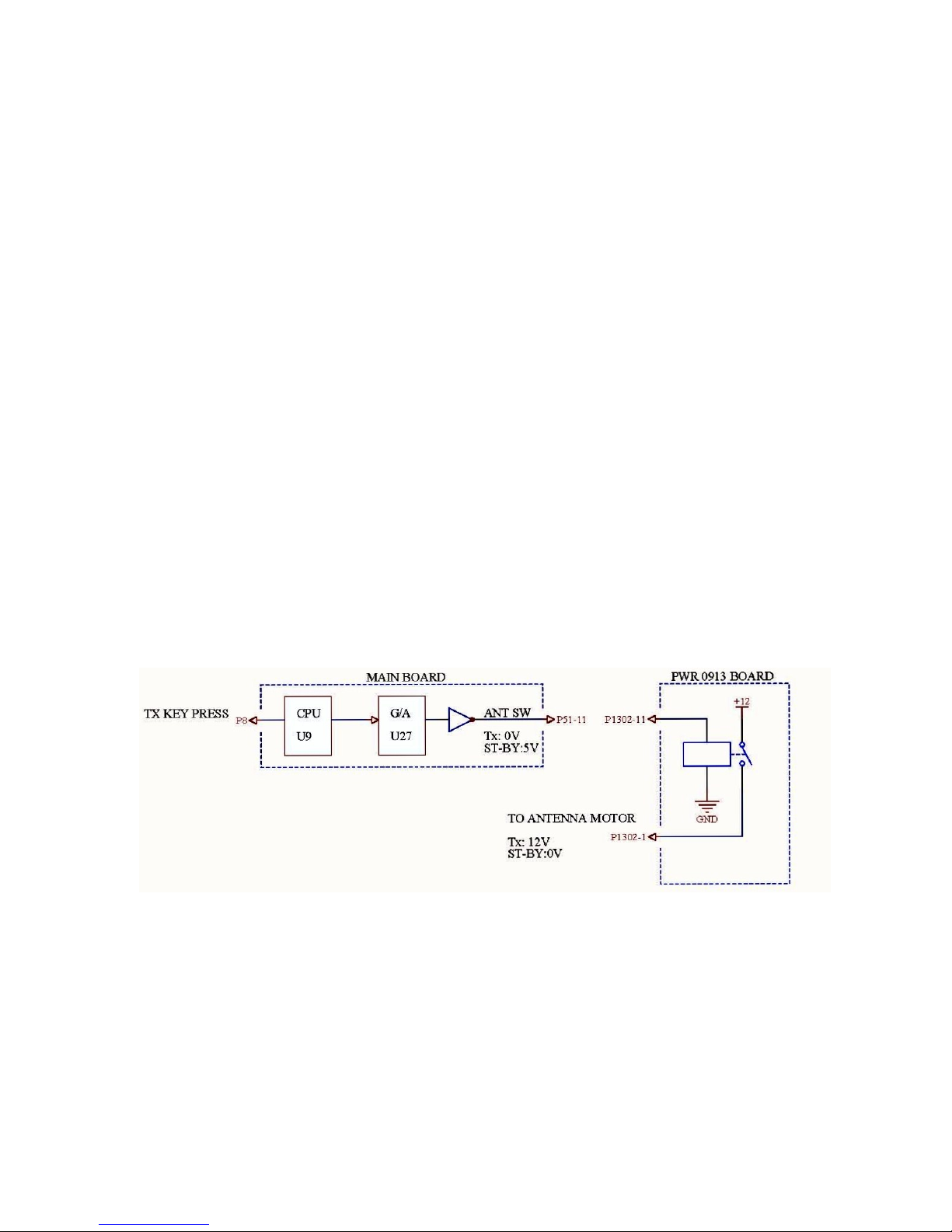

Scanner motor power (ANT+12V/ -12 V)

+12 V and -12 V (ANT +12 V/ANT -12 V) are used to drive 24 V scanner motor.

The power to the motor is turned on/off by the relay(K1) on the POWER SUPPLY

Board. The relay control signal from the SPU Board is supplied to Q52 and Q53

on the POWER SUPPLY Board. Pressing the TX key changes the ANT SW signal

state from 5 V to 0 V, and K1 is on to supply +12V.

.

8

BLOCK DIAGRAM OF POWER SUPPLY

9

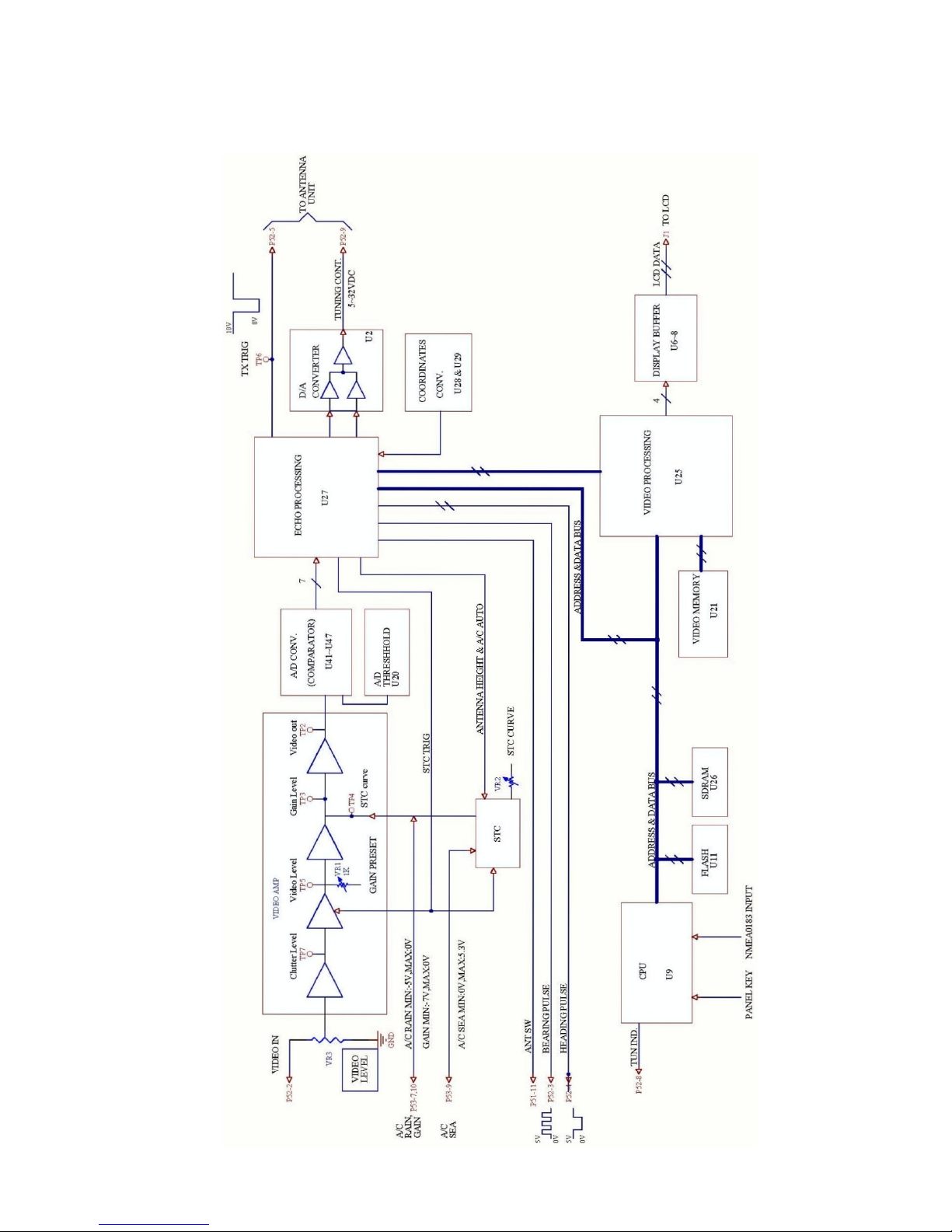

BLOCK DIAGRAM OF PROCESSOR PCB MAIN 0910

10

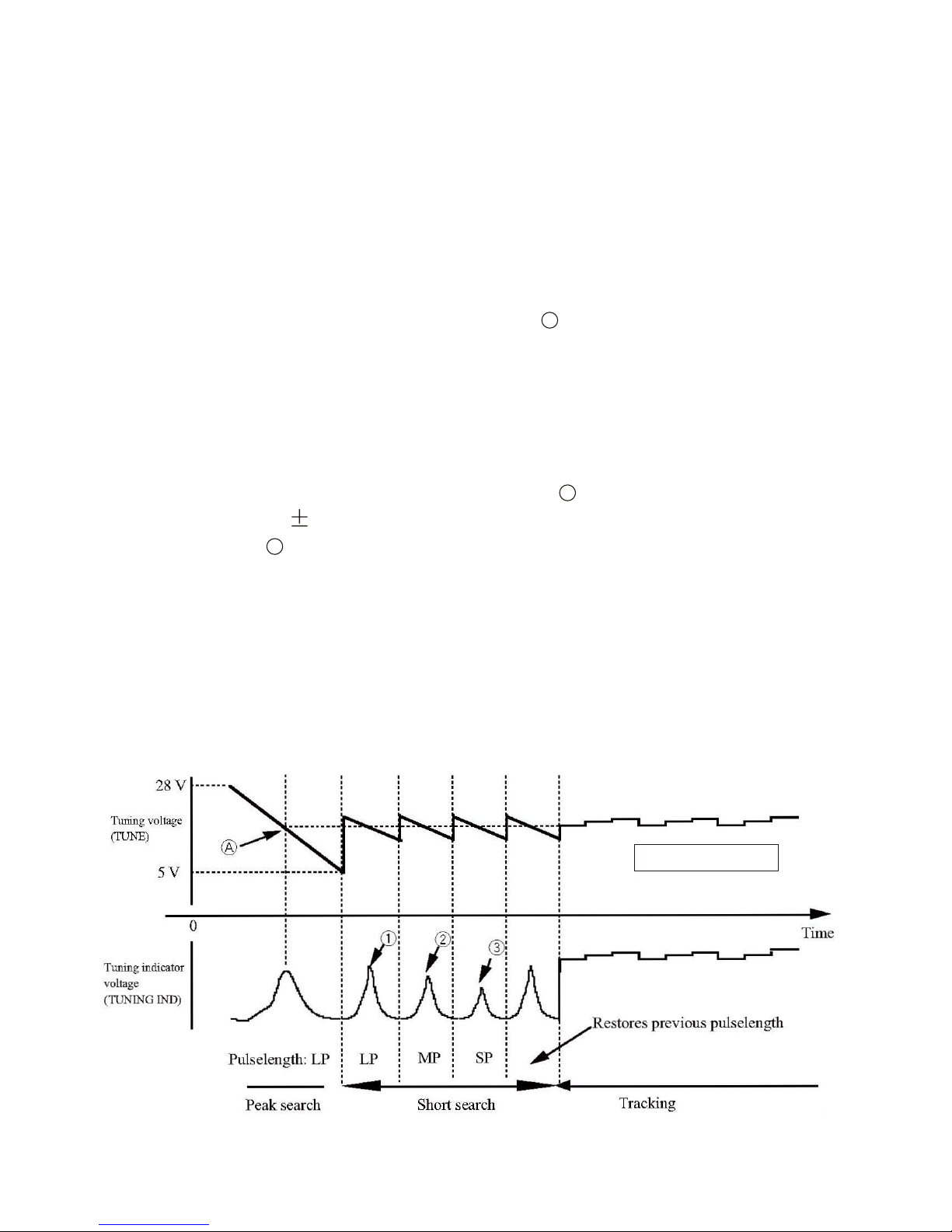

AUTOMATIC TUNING

There are two types of automatic tuning: peak search and short search. The tuning

voltage differs from model to model.

KR-1338/1668 : 5 V to 28 V

Peak search: Tuning voltage (TUNING), point in the figure below, is searched

in the tuning voltage range 5V to 28V. Tuning In voltage

(TUNING IND) is maximum at point .

Search conditions: After initial tuning adjustment.

Search time: 3 sec approx

Short search: Maximum tuning indicator voltage is searched in the tuning

voltage range of 2.5V.

1)After initial tuning adjustment.

2)When tuning method is switched from manual to automatic.

3)When the radar is switched from ST-BY to TX.

4)When a range where pulselength is changed from short to middle

and from middle to long is selected.

Tracking: After short search, tracking takes place.

Tracking voltage: 0 V to 32 V

dicator

A

A

A

KR-1338/1668

11

TUNING INDICATOR

After tuning adjustment, peak TUNING IND voltages, , and in the figure

on page are stored on to EEPROM.

The automatic and manual tuning point is also memorized. Using these data,

the tuning indicator extends more than 80% on ALL TX pulses.

Note that the extension on short pulse is shorter than on long pulse. The indication becomes shorter with the magnetron deteriorated.

MANUAL TUNING

The manual tuning voltage changes from 5 to 32 V on M 1668 at the steps

of about 0.1 V.

Manual Tuning is carried out by using omnipad: pressing "Right" side in-

creases.

The TUNING continue voltage displayed on the screen differs by about 1V

from the measured voltage at P52 # 9. Manual Tuning and tuning adjustment

are required when automatic tuning is abnormal (that is ,low sensitivity).

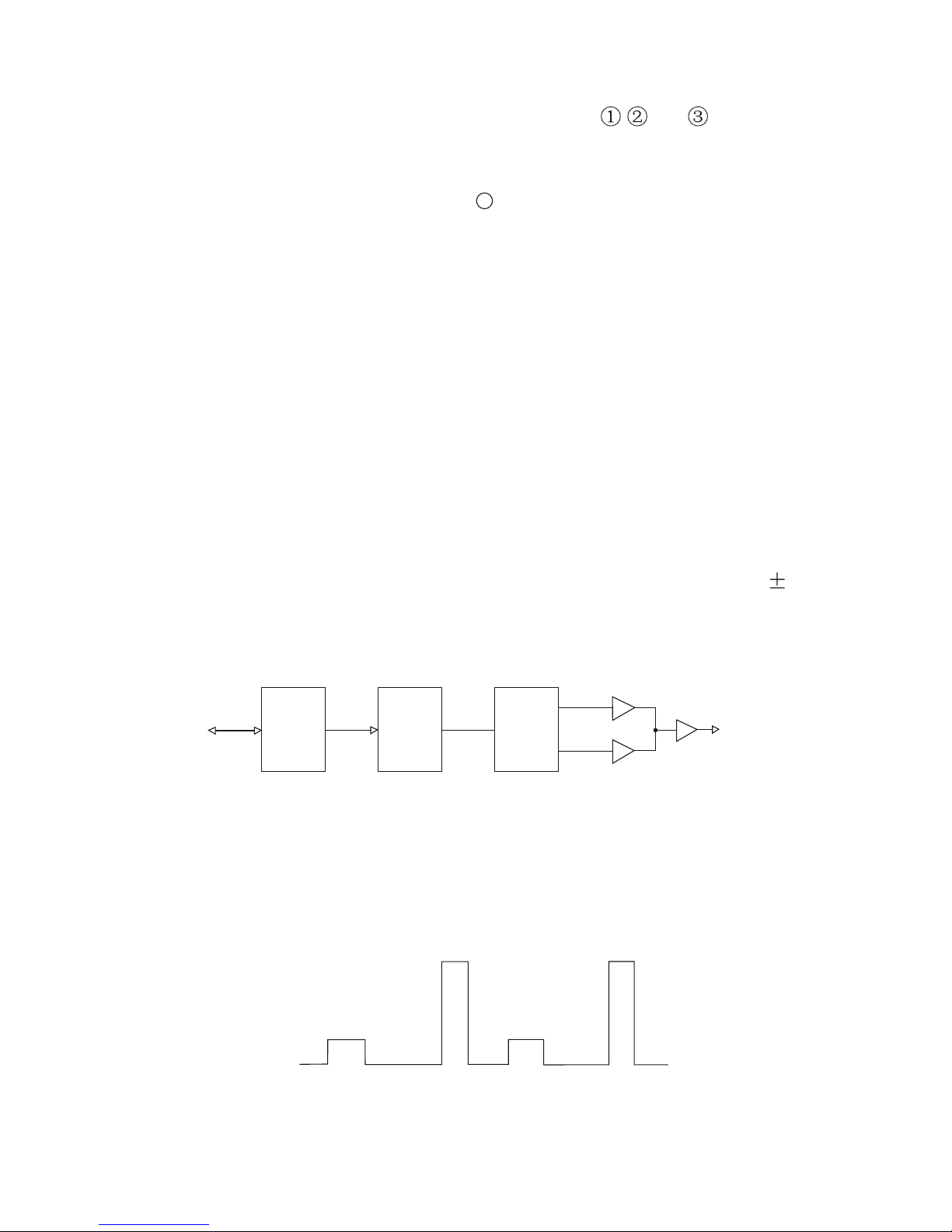

TUNING CONT. Operation (from power-on stand-by)

A square wave is automatically output as a TUNING CONT signal during standby just after power-on the model as follows.

2-5

A

0V

5V

34V

F VT

C VT

KR-1838/1968/1948

FROM PANEL BOARD

P8

CPU

U9

P/S

CONV.

U27

D/A

CONV.

U20

CVT

FVT

#5#3#7

U2

#1

#10

#8

P8

TUNING CONTROL

(TO RF UNIT)

12

Heading and NAV data

Heading data in NMEA format HEADING DATA (HDT, HDG, HDM, VHW)and

NAV data (NMEA-0183)can be input from any NMEA input connection. THE

data from the KEY board(KEY 0912) to P8#3 of MAIN board .

NOTE:

1.If only one NMEA signal input may select any connection, if several connections

have time the signal input, be please main and the most commonly used signal

meets in the connection 1, because the complete signal's input is 1 comes the

synchronization by the connection, i.e. the connection 1 signal is fastest;

2.The NMEA signal after or before radar starting in may, but in signaling process,

if the NMEA port 1 loss of signal, will possibly cause other port data not to be

able to transmit normally. Must remove this kind of condition only to be able again

starting.

Turning on/off antenna rotation

The SPU board controls antenna rotation. In normal operation, the antenna

rotates during the TX condition. However, the antenna can be stopped during

the TX condition thru the Installation setup menu.

13

2.3 Transceiver Unit

MIC

The following description is for reference only.

As a general rule of thumb, the radar requires better noise figure (NF) and better

dynamic range. Both factors, however, are reciprocal. The NF affects long range

performance, while the dynamic range dose short range performance.

To improve noise figure, amplifier and MBS circuit into the MIC, RU-9360.

MIC w/RF amplifier NJT-1968B(MODEL 1338/1668)

IF OUT

(+5V to 35V)(+5V)GND

RF IN

W.G.TO

COAX CONV.

LIMTER

FET AMP

DOUBLEBALANCED

MIXER

POWER FET OSC.

Block Diagram of MIC NJT-1968B (MODEL 1338/1668)

14

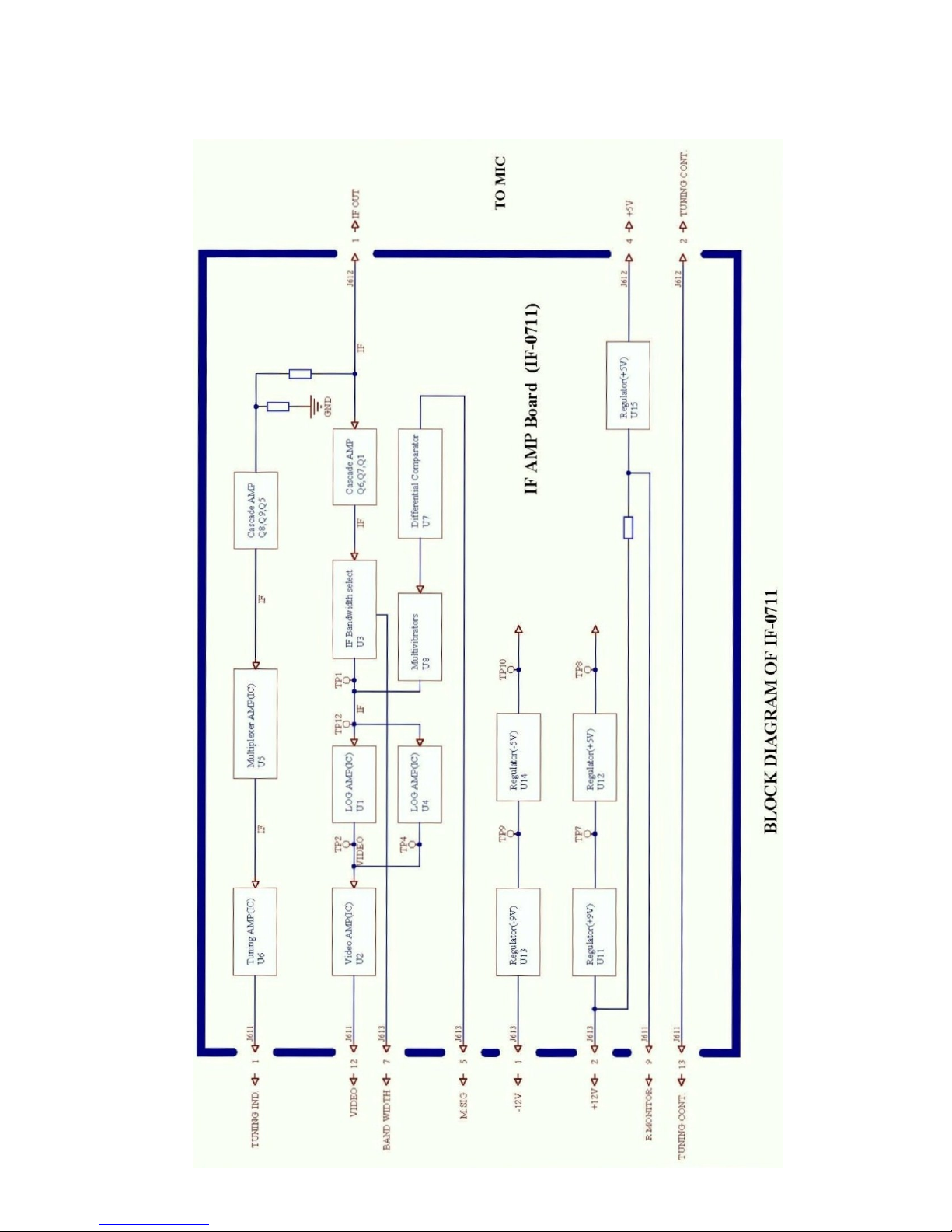

BLOCK DIAGRAM OF IF 0711

15

Modulator

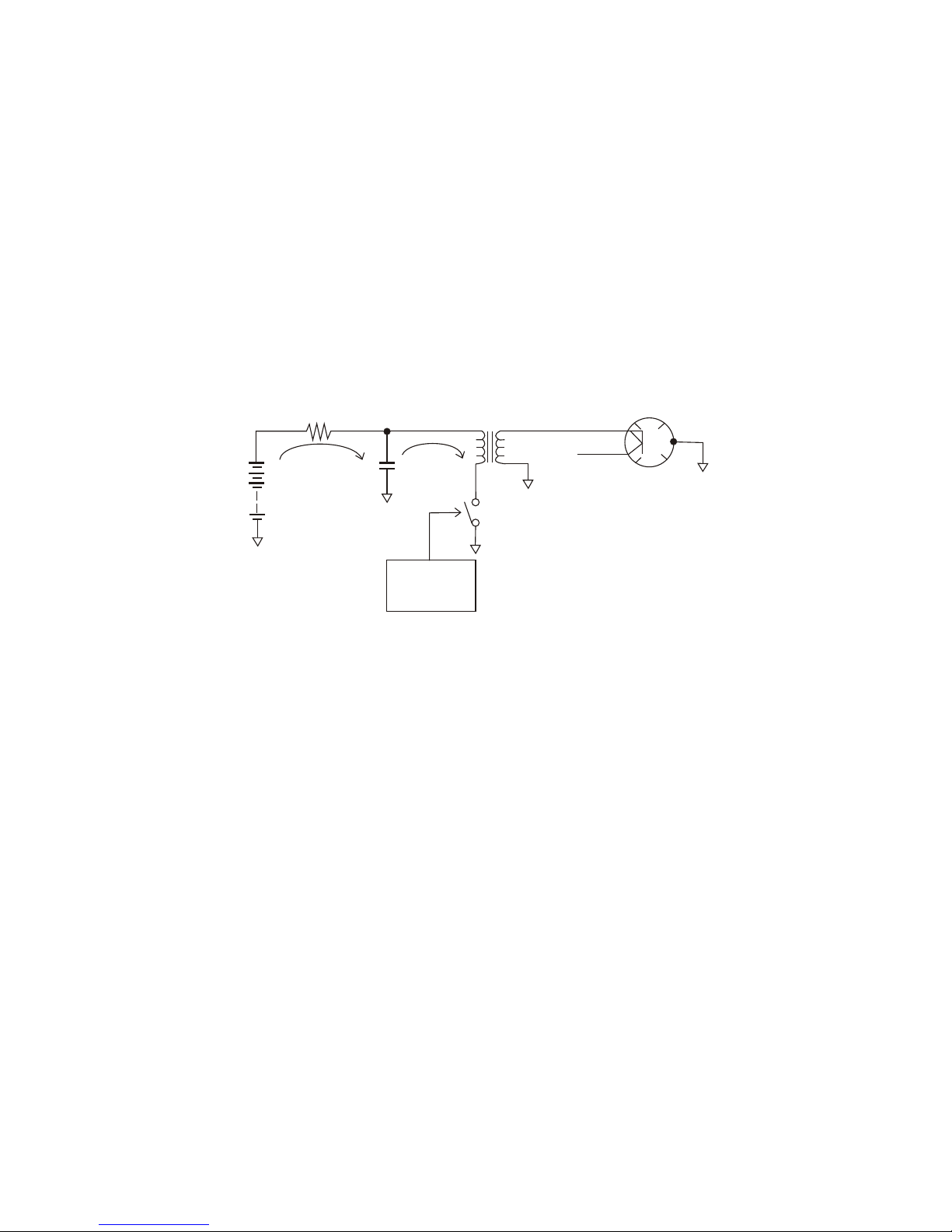

PRINCIPLE OF FET SWITCHING MODULATOR

High voltage is charged into C through R while the magnetron is inactive.

When the trigger is applied to the power MOS-FET, the FET turns on and the high

voltage appears at the primary winding of the pulse transformer. This transformer

boots the voltage, which makes the magnetron oscillate.

One advantage of this method is that the magnetron oscillates only when the FET

is conducive, that is the transmission pulsewidth can be changed by the TX trigger

pulsewidth. Therefore, parts such as relay and coil can be eliminated.

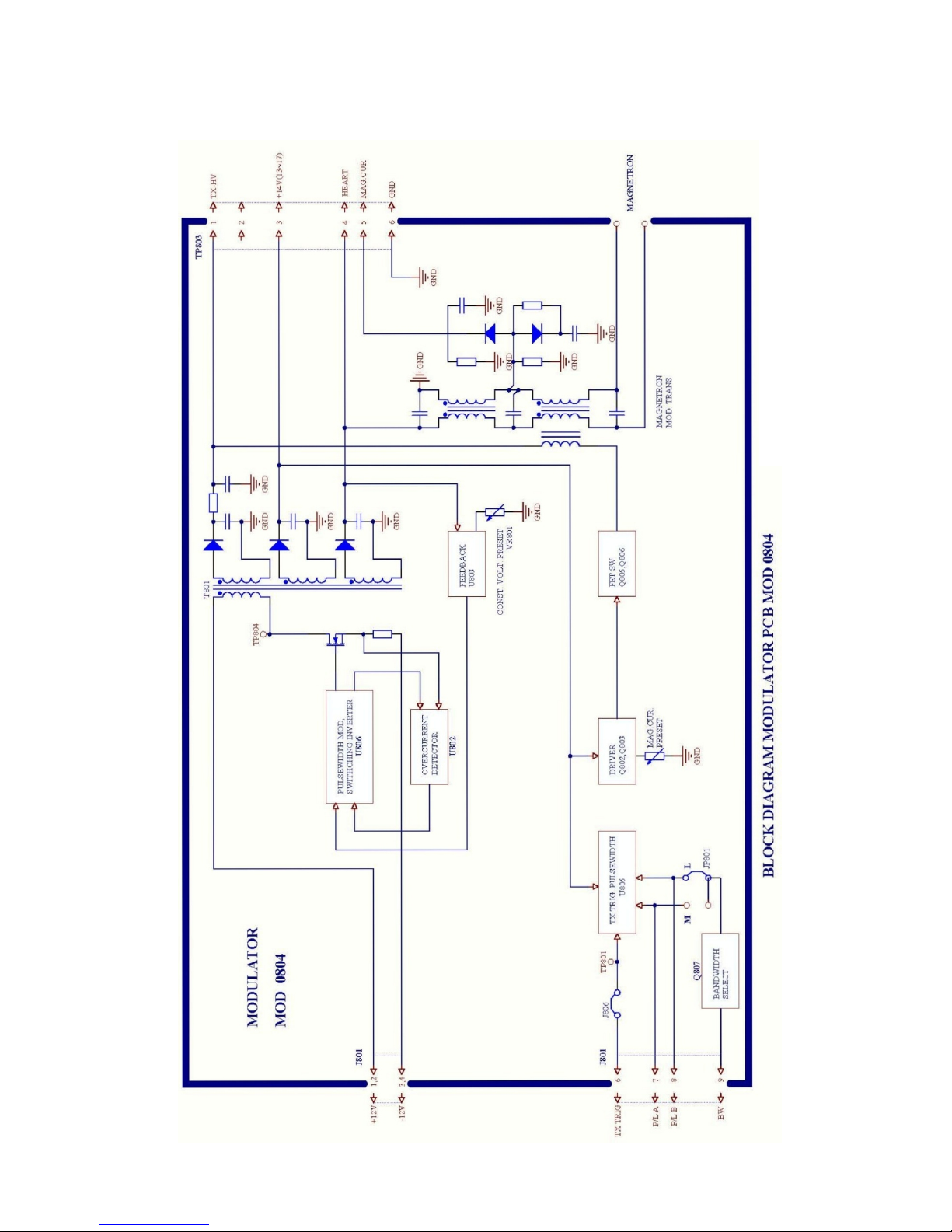

MODULATOR BOARD MOD-0904

The main function of the modulator section is to produce high voltage pulses to

drive the magnetron. To produce these pulse, the MODULATOR Board has a

modulator trigger circuit, modulator pulse generator and booster pulse transformer.

The modulator trigger circuit consists of U805 and associated components. This

circuit generates the pulses which cause modulation FETs Q805,Q806 to conduct.

The pulses are produced when the TX TRIG pulses from the display unit is received and U805 conducts. The voltage of the pulses is raised at pulse transformer

T802 until it is 3.5 kV. This circuit adjusts the electrical curent flowing into the

magnetron so it is 3 A.

The MODULATOR Board also contains the TX high voltage circuit and the magnetron heater circuit. The TX high voltage circuit charges capacitors with 300 V

high voltage produced at the primary windings of T801 and discharges them once

the TX TRIG pulse is received. The magnetron heater circuit produces stable +7.5V.

Modulator section simple block diagram

R

PULSE TRANS

MAGNETRON

HIGH VOLTAGE

MOST-FET

Charge

Discharge

TRIGGER

C

D

16

BLOCK DIAGRAM OF MODULATOR PCB MOD 0904

17

2.4 Different Points of Similar PCBs

1. How to set SPU (MAIN 0910) Board

This board is set at factory for use in the KR-1338. For use in the or 1668, change

the factory menu as below.

While pressing and holding down the GAIN(HM-OFF) control, press the [MENU]

key five times to display the factory menu.

1) MAX range

36 nm: KR-1338, 48 nm: KR-1648, 64nm: KR-1668

2) Type

R: Regular, G: German, N:Netherland, K:Korea

3)Model

Selects the Antenna Unit.

KR-1338 KR-1648 KR-1668

4)Language

CHN: Chinese English

5)Default Setting

Default settings (except factory menu) can be restored by selecting Default Setting

and pressing the [ENTER] key three times. Restart radar settings. After changing

the setting, the installation adjustment (heading, timing, etc.) Must be carried out

again.

2.MODULATOR board MOD-0904 A/B

E version of MOD-0904 is not compatible with A version. This is because B has a

larger pulse transformer.

[Factory MENU]

1. Max Range 36 48 64

2. Typ e R G N K

3. Model KR-1338 KR-1648

KR-1668

4. Language ENG CHN

5. Default Setting ENTER 3

<Press MENU key to escape >

M1338-SME-09D

18

Loading...

Loading...