Page 1

© Semiconductor Components Industries, LLC, 2015

1

Publication Order Number:

September 2018- Rev. P0 XXXXXEVBUM/D

NON-CONTROLLED, PRE-PUBLICATION COPY – PROPRIETARY, NOT FOR DISTRIBUTION TO CUSTOMERS

SPSDEVK1-PCB: User Manual

Introduction;

The SPSDEVK1 Predictive Maintenance Turnkey Solution kit enables

fast installation of full Smart Passive Sensor TM systems.

This evaluation kit includes:

•

1 SPSDEVR1-8 UHF SPS Reader

•

1 SPS1DEVA1-W UHF Antenna

A 12V DC power supply is suggested and recommended

for use with the SPSDEVR1-8.

Software Tools

ON Semiconductor has developed a web based application specifically

for reading Smart Passive Sensors that unlocks the full functionality of

the tags. This application utilizes a REST API that includes advanced

reader settings, graphing/logging of sensor data, and a Certification mode.

www.onsemi.com

Figure 1. SPSDEVK1 Hardware Setup

Page 2

XXXXXEVBUM

www.onsemi.com

2

NON-CONTROLLED, PRE-PUBLICATION COPY – PROPRIETARY, NOT FOR DISTRIBUTION TO CUSTOMERS

Hardware Setup

The SPSDEVK1 requires three hardware connections to be

made in the following order:

• Connect at least one antenna to the RF SMA port

on the SPSDEVR1-8 reader

• Connect an Ethernet cable from the SPSDEVR1-8

to the host computer that will be running the

application software

• Plug in a power supply suitable for the

SPSDEVR1-8

Note: please refer to SPS tag datasheets to verify optimal

positioning to achieve best results.

TagReader Software Setup

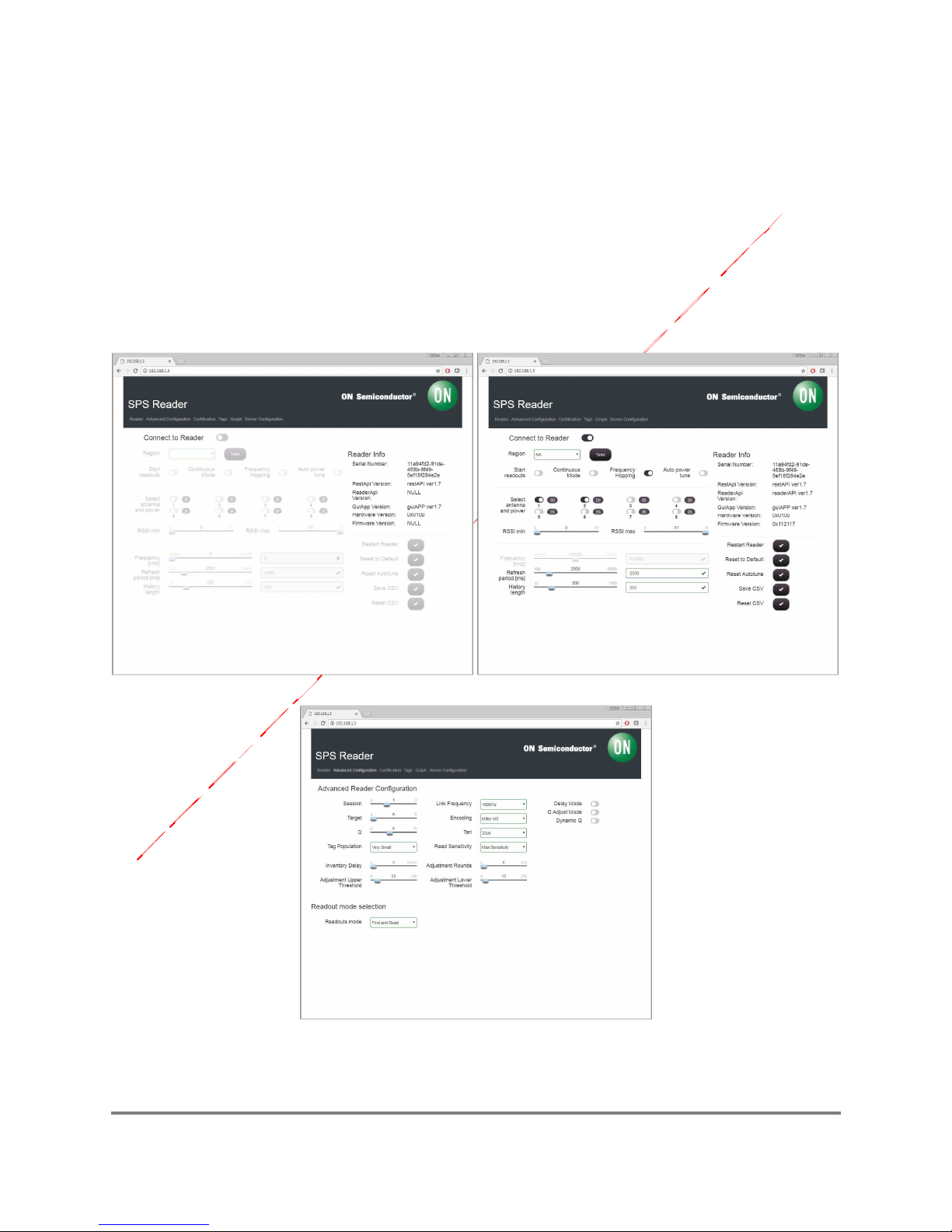

After the reader is powered on, open a web browser and

type in the IP address of the reader into the search bar. The

SPS Reader App startup page will then be shown as seen on

left in Figure 2. Toggling the “Connect to Reader” slider

button will allow the rest of the parameters on the page to

be set, such as frequency region, individual antenna

activation, and individual antenna power as shown on the

right side of Figure 2. The “Advanced Configuration” tab

allows precise tuning of various parameters related to the

UHF protocol and is pictured in Figure 3.

Figure 2. SPS Reader App startup screen

Figure 3. SPS Reader App Advanced Configuration tab

Page 3

XXXXXEVBUM

PRE-PUBLICATION COPY - NOT FOR DISTRIBUTION TO CUSTOMERS - PROPRIETARY

Data Collection and Logging

The SPS Reader App offers three ways to view the SPS

sensor data. In the “Tags” tab, a tabulated list of all sensor

tags found is shown. Various pieces of the data can be

toggled on or off with the slider buttons at the top, such as

Sensor Code, Temp Code, or RSSI. Tags shown in this tab

can have their data plotted visually versus time in the

“Graph” tab. Please see Figure 4 below for sample screens

showing RSSI code information for a SPS tag.

Figure 4. Sensor information displayed under “Tags” and “Graph” tab

Certification

The SPS Reader App has a Certification Mode that should

only be used for Certification testing purposes. Toggling the

slider button will put the reader into Certification Mode

slider and the rest of the options on the page will be enabled.

Frequency, Power, and Wave Time are the three main test

parameters which can be set by the tester. The certification

mode also allows for a random data mode which can be

activated by the slider button at the bottom of the list of

options.

For Certification testing please follow the steps outlined

below:

1. Select Frequency with the [Slider] or enter a

number to the right using keyboard

2. Select Power with the [Slider] or enter a number to

the right using keyboard

3. Click on [Send Wave] button

4. Repeat Steps 1-3 for all required frequencies and

power levels.

Figure 5. Sensor information displayed under “Tags” and “Graph” tab

Page 4

XXXXXEVBUM

PRE-PUBLICATION COPY - NOT FOR DISTRIBUTION TO CUSTOMERS - PROPRIETARY

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of bodily injury, electrical shock, fire, and damage to the equipment observe the following precautions:

1. READ these instructions.

2. KEEP these instructions.

3. PAY ATTENTION to all warnings.

4. FOLLOW all instructions.

5. DO NOT use this apparatus near water.

6. CLEAN ONLY with dry cloth.

7. DO NOT block any ventilation openings.

Allow sufficient distances for adequate ventilation and install in accordance with the manufacturer’s instructions.

8. DO NOT install near any heat sources such as open flames, radiators, heat registers, stoves, or other apparatus (including

amplifiers) that produce heat.

Do not place any open flame sources on the product.

9. DO NOT defeat the safety purpose of the polarized or grounding type plug.

A polarized plug has two blades with one wider than the other.

A grounding type plug has two blades and a third grounding prong.

The wider blade or the third-prong is provided for your safety.

If the provided plug does not fit into your outlet,

consult an electrician for replacement of the obsolete outlet.

10. PROTECT the power cord from being walked on or pinched, particularly at plugs, convenience receptacles, and the

point where they exit from the apparatus.

11. ONLY USE attachments/accessories specified by the manufacturer.

12. UNPLUG this apparatus during lightning storms or when unused for long periods of time.

13. REFER all servicing to qualified service personnel.

Servicing is required when the apparatus has been damaged in any way, such as power supply cord or plug is damaged,

liquid has been spilled or objects have fallen into the apparatus, the apparatus has been exposed to rain or moisture, does not

operate normally, or has been dropped.

14. DO NOT expose the apparatus to dripping and splashing.

DO NOT put objects filled with liquids, such as vases, on the apparatus.

15. The MAINS plug or an appliance coupler shall remain readily operable.

16. The airborne noise of the Apparatus does not exceed 0dB (A).

17. Apparatus with CLASS I construction shall be connected to a MAINS socket outlet

with a protective earth connection.

18. To reduce the risk of fire or electric shock, do not expose this apparatus to rain or moisture.

19. Do not attempt to modify this product.

Doing so could result in personal injury and/or product failure.

20. Operate this product within its specified operating temperature range.

21. Protecting Against Electrostatic Discharge

Static electricity can harm delicate components inside the system.

To prevent static damage, discharge static electricity from your body

before touching any of the electronic components, such as SMA Antenna, USB and Ethernet connectors. This can be done

by periodically touching an unpainted metal surface on the chassis.

The following steps can also be taken prevent damage from electrostatic discharge (ESD):

21.1. When unpacking a static-sensitive component from its shipping carton,

do not remove the component from the antistatic packing material

until ready to install the component in the system.

Just before unwrapping the antistatic packaging,

be sure to discharge static electricity from your body.

21.2. When transporting a sensitive component,

first place it in an antistatic container or packaging.

21.3. Handle all sensitive components in a static-safe area.

If possible, use antistatic floor pads, workbench pads and an antistatic grounding strap.

22. Equipment intended for installation in Restricted Access Location

WARNING:

No user-serviceable parts inside.

Page 5

XXXXXEVBUM

PRE-PUBLICATION COPY - NOT FOR DISTRIBUTION TO CUSTOMERS - PROPRIETARY

Refer all servicing to qualified service personnel.

The safety certifications do not apply when the operating voltage is changed from the factory setting.

SPSDEVR1-8 is with compliance to IEC/EN/UL/CSA 60950 "Safety of information technology equipment"

is one of the world’s most widely-used electrical product safety standards.

Thousands of manufacturers rely on this standard to show that their products meet the safety requirements

for markets around the world.

It is one of the relatively few standards to be harmonized by standards-writing bodies globally

to make the process as efficient as possible for manufacturers.

Caution according to FCC Rule part 15.21

Changes or modifications not expressly approved by the party responsible for compliance

could void the user's authority to operate the equipment.

Caution according to FCC Rule part 15.105

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

RF exposure

Maintain a distance greater than 20 cm between the antenna of this device

and persons during device operation, which is consistent with

how the device is tested for compliance with RF exposure requirements

and satisfies Federal Communications Commission (FCC) exposure requirements.

Operations at closer than this distance are not recommended.

Label

Attach the label on the back side of the Enclosure as recommended on this picture

1.00

26.00

Page 6

XXXXXEVBUM

PRE-PUBLICATION COPY - NOT FOR DISTRIBUTION TO CUSTOMERS - PROPRIETARY

Smart Passive Sensor is a trademark of RFMicron, Inc.

Magnus is a registered trademark of RFMicron, Inc.

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. ON Semiconductor reserves the right to make changes without further notice to any products herein.

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar

classification in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or

unauthorized application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs,

damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized

use, even if such claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative

Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

19521 E. 32nd Pkwy, Aurora, Colorado 80011 USA

Phone: 303

−675−2175

or 800

−344−3860

Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

Loading...

Loading...