Page 1

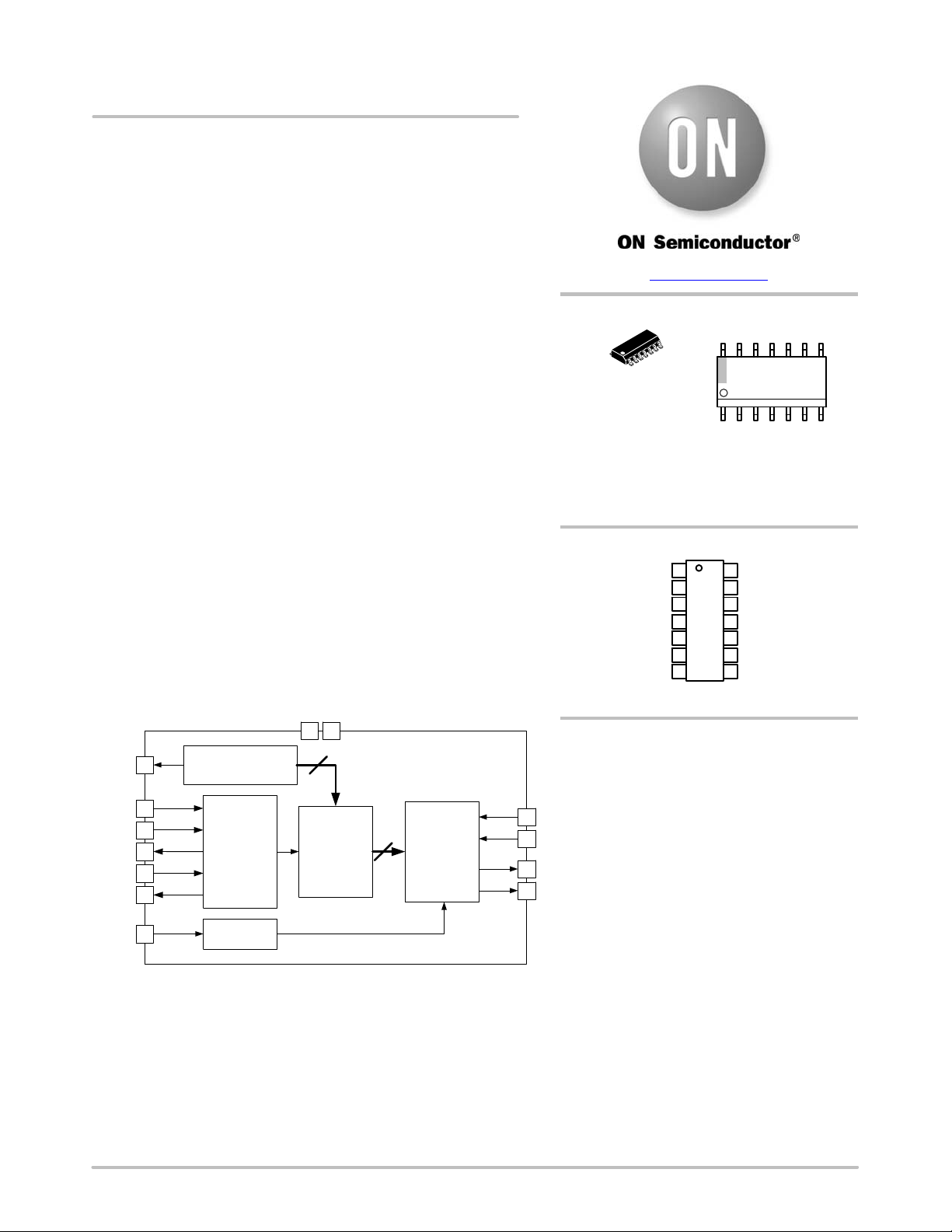

NCS36000

Passive Infrared (PIR)

Detector Controller

The NCS36000 is a fully integrated mixed−signal CMOS device

designed for low−cost passive infrared controlling applications. The

device integrates two low−noise amplifiers and a LDO regulator to

drive the sensor. The output of the amplifiers goes to a window

comparator that uses internal voltage references from the regulator.

The digital control circuit processes the output from the window

comparator and provides the output to the OUT and LED pin.

Features

• 3.0 − 5.75 V Operation

• −40 to 85°C

• 14 Pin SOIC Package

• Integrated 2−Stage Amplifier

• Internal LDO to Drive Sensor

• Internal Oscillator with External RC

• Single or Dual Pulse Detection

• Direct Drive of LED and OUT

• This is a Pb−Free Device

Typical Applications

• Automatic Lighting (Residential and Commercial)

• Automation of Doors

• Motion Triggered Events (Animal photography)

14VDD

7VSS

6VREF

LDO &

Voltage References

2

www.onsemi.com

MARKING

DIAGRAM

14

1

SOIC−14

D SUFFIX

CASE 751A

A = Assembly Location

WL = Wafer Lot

Y = Year

WW = Work Week

G = Pb−Free Package

14

NCS36000G

AWLYWW

1

PIN CONNECTIONS

OP2_O

OP2_N

OP1_O

OP1_N

OP1_P

VREF

VSS

1

2

3

4

5

6

7

(Top View)

14

13

12

11

10

9

8

VDD

OSC

MODE

NC

xLED_EN

LED

OUT

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 7 of this data sheet.

5OP1_P

4OP1_N

3OP1_O

2OP2_N

1OP2_O

13OSC

Amplifier

Circuit

System

Oscillator

Comparator

Figure 1. Simplified Block Diagram

© Semiconductor Components Industries, LLC, 2015

December, 2015 − Rev. 3

Window

12 MODE

Digital

2

Control

Circuit

1 Publication Order Number:

10 xLED_EN

9 LED

8 OUT

NCS36000/D

Page 2

NCS36000

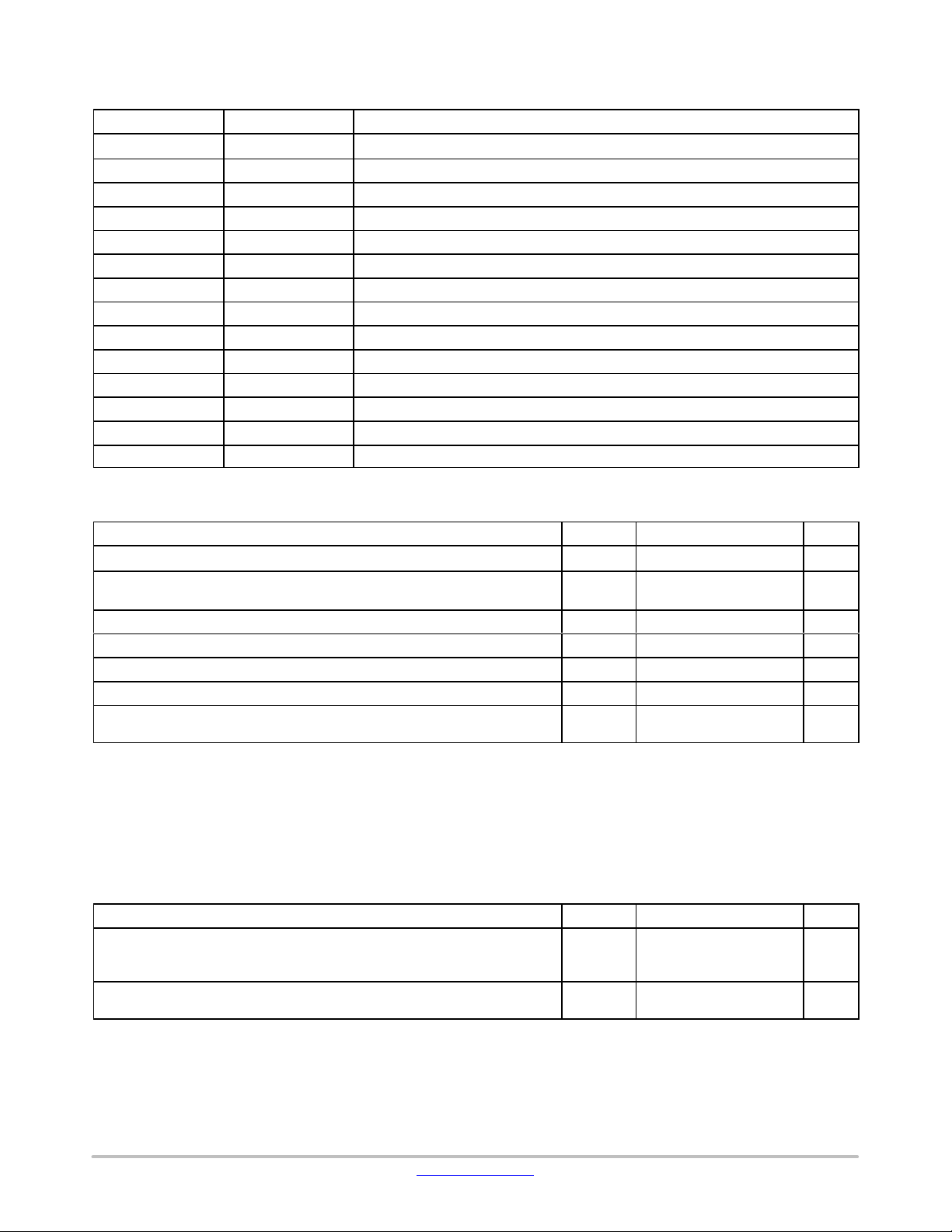

PIN FUNCTION DESCRIPTION

Pin No. Pin Name Description

1 OP2_O Output of second amplifier

2 OP2_N Inverting input of second amplifier

3 OP1_O Output of first amplifier

4 OP1_N Inverting input of first amplifier

5 OP1_P Non−inverting input of first amplifier

6 VREF Regulated voltage reference to drive sensor

7 VSS Analog ground reference.

8 OUT CMOS output (10 mA Max)

9 LED CMOS output to drive LED (10mA Max)

10 xLED_EN Active low LED enable input

11 NC No Connect

12 MODE Pin used to select pulse count mode

13 OSC External oscillator to control clock frequency

14 VDD Analog power supply

ABSOLUTE MAXIMUM RATINGS

Rating Symbol Value Unit

Input Voltage Range (Note 1) V

Output Voltage Range V

Maximum Junction Temperature T

J(max)

Storage Temperature Range T

ESD Capability, Human Body Model (Note 2) ESD

ESD Capability, Machine Model (Note 2) ESD

Lead Temperature Soldering

T

Reflow (SMD Styles Only), Pb−Free Versions (Note 3)

in

out

STG

HBM

MM

SLD

−0.3 to 6.0 V

−0.3 to 6.0 V or (Vin + 0.3),

whichever is lower

140 °C

−65 to 150 °C

2 kV

200 V

260 °C

V

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Refer to ELECTRICAL CHARACTERISTICS and APPLICATION INFORMATION for Safe Operating Area.

2. This device series incorporates ESD protection and is tested by the following methods:

ESD Human Body Model tested per AEC−Q100−002 (EIA/JESD22−A114)

ESD Machine Model tested per AEC−Q100−003 (EIA/JESD22−A115)

Latchup Current Maximum Rating: v150 mA per JEDEC standard: JESD78

3. For information, please refer to our Soldering and Mounting Techniques Reference Manual, SOLDERRM/D

THERMAL CHARACTERISTICS

Rating Symbol Value Unit

Thermal Characteristics, DFN6, 3x3.3 mm (Note 4)

Thermal Resistance, Junction−to−Air (Note 5)

Thermal Reference, Junction−to−Lead2 (Note 5)

R

q

JA

R

Y

JL

Thermal Characteristics, TSOP−5 (Note 4)

Thermal Resistance, Junction−to−Air (Note 5)

4. Refer to ELECTRICAL CHARACTERISTICS and APPLICATION INFORMATION for Safe Operating Area.

5. Values based on copper area of 645 mm

2

(or 1 in2) of 1 oz copper thickness and FR4 PCB substrate.

R

q

JA

Will be Completed once

package and power

consumption is finalized

See note above.

°C/W

°C/W

www.onsemi.com

2

Page 3

NCS36000

OPERATING RANGES (Note 6)

Rating

Analog Power Supply V

Analog Ground Reference V

Supply Current (Standby, No Loads) I

Digital Inputs (MODE)

Digital Output (OUT, LED) Push−Pull Output (10 mA Load)

OP1_P (Sensor Input) (Note 7) AMP 1 IN 0.1 VDD −

Ambient Temperature T

6. Refer to ELECTRICAL CHARACTERISTICS and APPLICATION INFORMATION for Safe Operating Area.

7. Guaranteed By Design (Non−tested parameter).

Symbol Min Typ Max Unit

DD

SS

DD

V

ih

V

il

V

oh

V

ol

A

3.0 5.0 5.75 V

0.0 0.1 V

0.7 *

V

DD

V

DD

VDD +

VSS VDD *

0.67 *

V

DD

VSS VDD *

−40 85 °C

170m

0.3

0.28

V

DD

0.3

1.1

A

V

V

V

ELECTRICAL CHARACTERISTICS V

Parameter

= 1 V, Cin = 100 nF, C

in

Test Conditions Symbol Min Typ Max Unit

= 100 nF, for typical values TA = 25°C; unless otherwise noted.

out

LDO Voltage Reference

Output Voltage

VDD = 3.0 V to 5.75 V VREF 2.6 2.7 2.8 V

Supply Current VDD = 3.0 V to 5.75V IREF 20 50

Comparator High Trip Level V

Comparator Low Trip Level V

Reference voltage for non−inverting input of

second amplifier

h

l

V

m

2.413 2.5 2.588 V

1.641 1.7 1.760 V

2.007 2.1 2.174 V

System Oscillator

Oscillator Frequency

VDD = 5.0 V

= 220 kW

R

3

C2 = 100 nF

OSC 62.5 Hz

Window Comparator

Lower Trip Threshold

See Vl above

Higher Trip Threshold See Vh above

Differential Amplifiers (Amplifier Circuit)

DC Gain

VDD = 5.0 V (Note 8) Av 80 dB

Common−mode Input Range VDD = 5.0 V (Note 8) CMIR 0.1 VDD −

1.1

Power Supply Rejection Ratio VDD = 5.0 V (Note 8) PSRR 60 dB

Output Drive Current VDD = 5.0 V (Note 8) I

out1

25

POR

POR Release Voltage

V

POR

1.35 2.85 V

8. Guaranteed By Design (Non−tested parameter).

mA

V

mA

www.onsemi.com

3

Page 4

NCS36000

APPLICATIONS INFORMATION

Oscillator

The oscillator uses an external resistor and capacitor to set

the system clock frequency. Multiple clock frequencies can

be selected using different combinations of resistors and

capacitors. Figure 2 shows a simplifier block diagram for

the system oscillator.

VDD

14

OSC

13

Figure 2. Block Diagram of System Oscillator Circuit

LDO Regulator

−

+

−

+

SET

Q

S

CLR

Q

R

The LDO regulator provides the reference voltage for the

sensor and all other analog blocks within the system. The

nominal voltage reference for the sensor is 2.7 V ±5%. An

external capacitor is needed on the VREF pin to guarantee

stability of the regulator.

Differential Amplifiers

The two differential amplifiers can be configured as a

bandpass filter to condition the PIR sensor signal for the post

digital signal processing. The cutoff frequencies and

passband gain are set by the external components. See

Figure 5.

80

70

60

50

40

30

20

−1

10

0

10

1

10

Figure 3. Plot Showing Typical Magnitude Response

of Differential Amplifiers When Configured as a

Bandpass Filter

Window Comparator

The window comparator compares the voltage from the

second dif ferential amplifier to two reference voltages from

the LDO regulator. COMP_P triggers if OP2_O is greater

than the Vh voltage and COMP_N triggers if OP2_O is

lower than the Vl voltage. See Figures 4 and 5.

OP2_O

Vh

Vm

Vl

Vdd

Comp_P

Vss

Vdd

Comp_N

Vss

Figure 4. Plot Showing Functionality of Window Comparator for an Analog Input OP2_O

www.onsemi.com

4

Page 5

VREF

D

G

Sensor dependent

components

Figure 5. Figure Showing Simplified Block Diagram of Analog Conditioning Stages

NCS36000

VREF 6

1

Vh

OP2_O

Vl

LDO6

5

+

4

−

Application dependent

components

Vm

+

23

−

−

Comp_P

+

−

Comp_N

+

Vh

Vm

Vl

Digital Signal Processing Block (all times assume a

62.5 Hz system oscillator frequency)

The digital signaling processing block performs three

major functions.

The first function is that the device toggles LED during the

start−up sequencing at approximately two hertz regardless

of the state of the XLED_EN pin. The startup sequence lasts

for thirty seconds. During that time the OUT pin is held low

regardless of the state of OP2_O.

The second function of the digital signal processing block

is to insure a certain glitch width is seen before OUT is

toggled. The digital signal processing block is synchronous

with the system oscillator frequency and therefore the

deglitch time is related to when the comparators toggle

within the oscillator period. A signal width less than two

clock period is guaranteed to be deglitched as a zero. A

signal width of greater than three clock cycles is guaranteed

to be de−glitched. It should be noted that down−sampling

can occur if sufficient anti−aliasing is not performed at the

input of the circuit (OPI_P) or if noise is injected into the

amplifiers, an example would be a noisy power supply.

T

V

H

OP 2_O

= 2,5V

SP

< 3T

CLK

T

> 3T

SP

CLK

The third function of the digital signal processing block is

to recognize different pulse signatures coming from the

window comparator block. The device is equipped with two

pulse recognition routines. Single pulse mode (MODE tied

to VSS) will trigger the OUT pin if either comparator toggles

and the deglitch time is of the appropriate length. (See

Figure 6). Dual pulse mode (MODE tied to V

) requires

DD

two pulses with each pulse coming from the opposite

comparator to occur within a timeout window of five

seconds or 312 clock cycles (See Figure 7). If the adjacent

pulses occur outside the timeout window then the digital

processing block will restart the pulse recognition routine.

xLED_EN Pin

The xLED_EN pin enables the LED output driver when

motion has been detected. If xLED_EN is tied high the LED

pin will not toggle after motion is detected. If the xLED_EN

is tied low the LED pin will toggle when motion is detected.

During start-up the LED pin will toggle irrespective of how

the xLED_EN pin is tied. (See Figure 6).

V

M

V

L

= 2,1V

= 1,7V

OUT

4T

CLK

120 T

CLK

Figure 6. Timing Diagram for Single−Pulse Mode Detection

www.onsemi.com

5

Page 6

NCS36000

C2

C1

R1

V

H

V

M

V

L

OP 2_O

= 2,5V

= 2,1V

= 1,7V

OUT

C3

R2

C6

R3

< 3T

T

SP

CLK

> 3T

T

SP

CLK

TDP< 360 T

CLK

T

3T

SP

1T

> 3T

CLK

CLK

CLK

Figure 7. Timing Diagram for Dual−Pulse Mode Detection

Power Supply /

OP2_O

OP2_N

OP1_O

OP1_N

OP1_P

VREF

VSS

AC to DC Rectifier

VDD

OSC

MODE

nc

xLED_EN

LED

OUT

14

13

12

11

10

9

8

C4

R4

D

G

R5

1

2

3

4

5

6

7

C5

120 T

CLK

J1

R6

D1

R7

C7

J2

Microcontroller

Sensor dependent

components

Figure 8. Typical Application Diagram Using NCS36000

R1 = 10 kW C1 = 33 mF

R2 = 560 kW

C2 = 10 nF J2 (Jumper for Mode Select)

R3 = 10 kW C3 = 33 mF

R4 = 560 kW

R5 = 43 kW

R6 = 1 kW

R7 = 220 kW

C4 = 10 nF

C5 = 100 nF

C6 = 100 nF

C7 = 100 nF

9. R1, C1, R2, C2, R3, C3, R4, C4 setup bandpass filter characteristics. With components as shown above the passband gain is approximately

70 dB with the 3 dB cutoff frequency of the filter at approximately 700 mHz and 20 Hz.

10.R4 can be replaced by a potentiometer to adjust sensitivity of system. Note dynamically changing R4 will also change the pole location for

the second amplifier.

11.R5 and C5 are sensor dependant components and R6 may need to be adjusted to guarantee the AMP 1 IN parameter outlined within the

Operating Ranges section of this document.

12.R7 and C7 may be adjusted to change the oscillator frequency. R7 may not be smaller than 50 kW.

J1 (Jumper for xLED_EN)

D1 (LED)

www.onsemi.com

6

Page 7

NCS36000

ORDERING INFORMATION

Device Package Shipping

NCS36000DG SOIC−14

(Pb−Free)

†

55 Units / Rail

NCS36000DRG SOIC−14

(Pb−Free)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

3000 / Tape & Reel

www.onsemi.com

7

Page 8

−T−

P

al

SEATING

PLANE

NCS36000

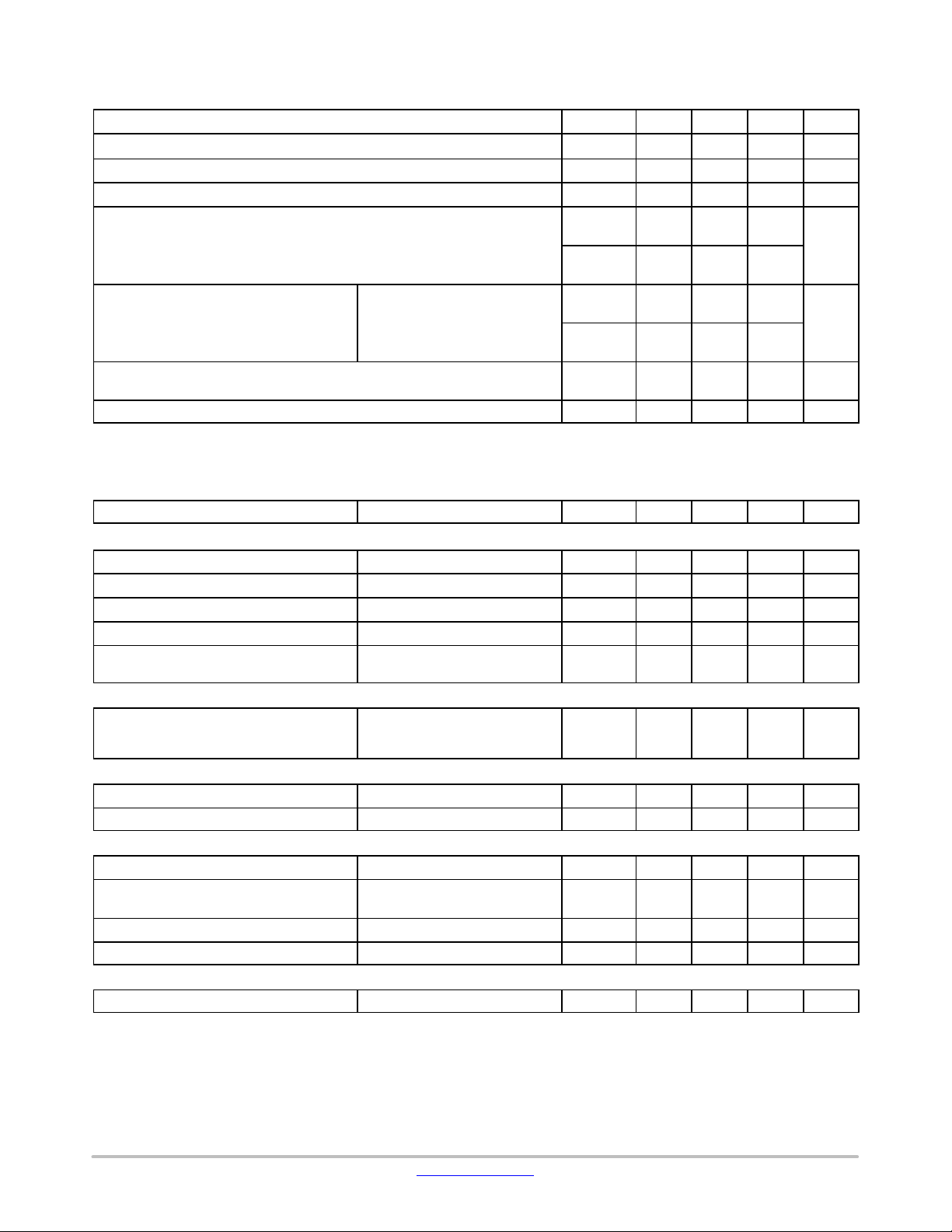

PACKAGE DIMENSIONS

SOIC−14

D SUFFIX

CASE 751A−03

−A−

14

8

−B−

P

7 PL

0.25 (0.010) B

1

7

G

C

D 14 PL

0.25 (0.010) A

K

M

S

B

T

S

ISSUE J

M

M

X 45

R

_

M

J

SOLDERING FOOTPRINT*

7X

7.04

1.52

1

14X

0.58

14X

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE

DAMBAR PROTRUSION. ALLOWABLE

DAMBAR PROTRUSION SHALL BE 0.127

(0.005) TOTAL IN EXCESS OF THE D

DIMENSION AT MAXIMUM MATERIAL

F

CONDITION.

DIM MIN MAX MIN MAX

A 8.55 8.75 0.337 0.344

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.054 0.068

D 0.35 0.49 0.014 0.019

F 0.40 1.25 0.016 0.049

G 1.27 BSC 0.050 BSC

J 0.19 0.25 0.008 0.009

K 0.10 0.25 0.004 0.009

M 0 7 0 7

__ __

P 5.80 6.20 0.228 0.244

R 0.25 0.50 0.010 0.019

INCHESMILLIMETERS

1.27

PITCH

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC owns the rights to a number of patents, trademarks,

copyrights, trade secrets, and other intellectual property. A listing of SCILLC’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. SCILLC

reserves the right to m ake c hanges w ithout f urt her n otice t o a ny p roducts h erein. SCILLC makes no warranty, representation or guarantee regarding the s uitability o f i ts p roducts f or a ny

particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without

limitation special, consequent ial o r i ncidental d amages. “ Typical” parameters which m ay b e p rovided i n S CILLC d at a s heets and/or specifications can a nd d o v ary i n d iff erent applications

and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC

does not convey any license under its patent rights nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for

surgical implant into t he b ody, or other a pplications i ntended t o s upport or sustain life, or f or a ny o ther a pplication i n w hich the failure of the SCILLC p roduct c ould creat e a s ituat ion w here

personal injury or death may occur. S hould B uyer p urchase o r u se S CILLC p r oduct s for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and

its officers, e mployees, s ubsidiaries, a ffiliat es, a nd d istributor s h arm less a gainst a ll c laims, c osts, d amages, a nd e xpenses, and r easonable a ttorney f ees a rising o ut o f, d irectly o r i ndirectly,

any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim a lleges t hat SCILLC was negligent regarding the design or manufacture

of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

UBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

www.onsemi.com

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your loc

Sales Representative

NCS36000/D

8

Loading...

Loading...