查询MCR100-003G供应商

MCR100 Series

Preferred Device

Sensitive Gate

Silicon Controlled Rectifiers

Reverse Blocking Thyristors

PNPN devices designed for high volume, line-powered consumer

applications such as relay and lamp drivers, small motor controls, gate

drivers for larger thyristors, and sensing and detection circuits.

Supplied in an inexpensive plastic TO-226AA package which is

readily adaptable for use in automatic insertion equipment.

Features

• Sensitive Gate Allows Triggering by Microcontrollers and Other

Logic Circuits

• Blocking Voltage to 600 V

• On−State Current Rating of 0.8 Amperes RMS at 80°C

• High Surge Current Capability − 10 A

• Minimum and Maximum Values of IGT, VGT and IH Specified

for Ease of Design

• Immunity to dV/dt − 20 V/sec Minimum at 110°C

• Glass-Passivated Surface for Reliability and Uniformity

• Pb−Free Packages are Available*

http://onsemi.com

SCRs

0.8 A RMS

100 thru 600 V

G

A

3

TO−92 (TO−226)

CASE 029

STYLE 10

1

2

K

MARKING

DIAGRAM

MCR

100−x

AYWW

*For additional information on our Pb−Free strategy and soldering details, please

download the ON Semiconductor Soldering and Mounting Techniques

Reference Manual, SOLDERRM/D.

Semiconductor Components Industries, LLC, 2005

January, 2005 − Rev. 6

1 Publication Order Number:

x = Specific Device Code

A = Assembly Location

Y = Year

WW = Work Week

PIN ASSIGNMENT

1

2

3

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 2 of this data sheet.

Preferred devices are recommended choices for future use

and best overall value.

Cathode

Gate

Anode

MCR100/D

MCR100 Series

(

)

(Pb−Free)

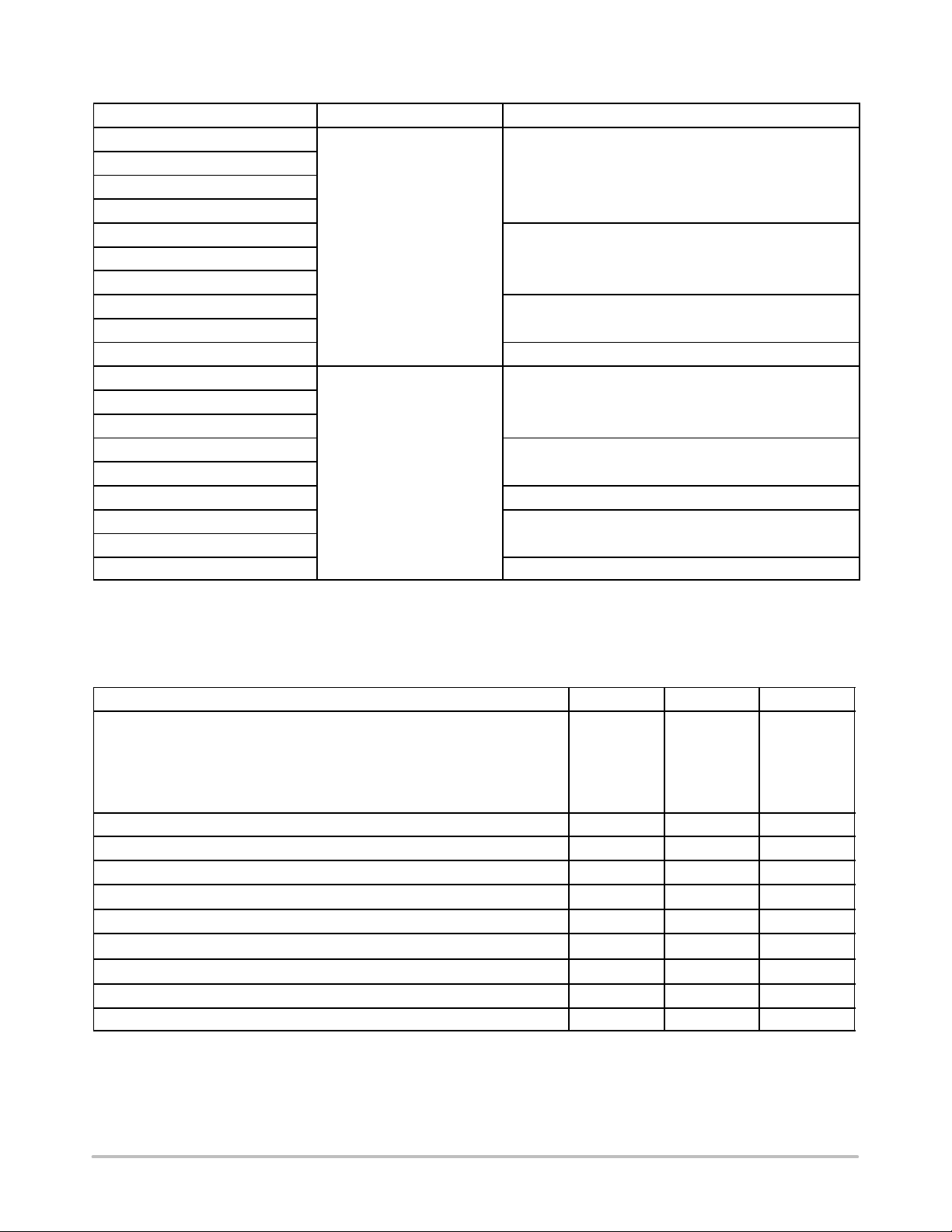

ORDERING INFORMATION

Device Package Code Shipping

MCR100−003

MCR100−004

MCR100−006

5000 Units / Bulk

MCR100−008

MCR100−3RL

MCR100−6RL

TO−92 (TO−226)

2000 Units / Tape & Reel

MCR100−6RLRA

MCR100−6RLRM

MCR100−6ZL1

2000 Units / Tape & Ammunition Box

MCR100−8RL 2000 Units / Tape & Reel

MCR100−003G

MCR100−006G

5000 Units / Bulk

MCR100−008G

MCR100−3RLG

MCR100−6RLG

MCR100−6RLRAG

TO−92 (TO−226)

Pb−Free

2000 Units / Tubes

2000 Units / Tape & Reel

MCR100−6RLRMG

MCR100−6ZL1G

2000 Units / Tape & Ammunition Box

MCR100−8RLG 2000 Units / Tape & Reel

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

†

p

p

MAXIMUM RATINGS (T

Peak Repetitive Off−State Voltage (Note 1)

(T

= 40 to 110°C, Sine Wave, 50 to 60 Hz; Gate Open)

J

On-State RMS Current, (TC = 80°C) 180° Conduction Angles I

Peak Non-Repetitive Surge Current, (1/2 Cycle, Sine Wave, 60 Hz, TJ = 25°C) I

= 25°C unless otherwise noted)

J

Rating

MCR100−3

MCR100−4

MCR100−6

MCR100−8

Symbol Value Unit

V

V

DRM,

RRM

V

100

200

400

600

T(RMS)

TSM

0.8 A

10 A

Circuit Fusing Consideration, (t = 8.3 ms) I2t 0.415 A2s

Forward Peak Gate Power, (TA = 25°C, Pulse Width 1.0 s)

Forward Average Gate Power, (TA = 25°C, t = 8.3 ms) P

Forward Peak Gate Current, (TA = 25°C, Pulse Width 1.0 s)

Reverse Peak Gate Voltage, (TA = 25°C, Pulse Width 1.0 s)

Operating Junction Temperature Range @ Rate V

RRM

and V

DRM

V

Storage Temperature Range T

P

GM

G(AV)

I

GM

GRM

T

stg

J

0.1 W

0.10 W

1.0 A

5.0 V

−40 to 110 °C

−40 to 150 °C

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously . If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

1. V

and V

DRM

voltage shall not be applied concurrent with negative potential on the anode. Blocking voltages shall not be tested with a constant current

for all types can be applied on a continuous basis. Ratings apply for zero or negative gate voltage; however, positive gate

RRM

source such that the voltage ratings of the devices are exceeded.

http://onsemi.com

2

THERMAL CHARACTERISTICS

Thermal Resistance,Junction−to−Case

Junction−to−Ambient

Lead Solder Temperature

(1/16″ from case, 10 secs max)

MCR100 Series

Characteristic Symbol Max Unit

R

JC

R

JA

T

L

75

°C/W

200

260 °C

ELECTRICAL CHARACTERISTICS (T

= 25°C unless otherwise noted)

C

Characteristic

OFF CHARACTERISTICS

Peak Repetitive Forward or Reverse Blocking Current (Note 2)

= Rated V

(V

D

DRM

and V

; RGK = 1 k)T

RRM

T

C

C

ON CHARACTERISTICS

Peak Forward On−State Voltage

(ITM = 1.0 A Peak @ TA = 25°C)

Gate Trigger Current (Continuous dc) (Note 3) TC = 25°C

(V

= 7.0 Vdc, RL = 100 )

AK

Holding Current

(V

= 7.0 Vdc, Initiating Current = 20 mA) TC = −40°C

AK

(2)

Latch Current TC = 25°C

(V

= 7.0 V, Ig = 200 A) TC = −40°C

AK

Gate Trigger Voltage (Continuous dc) (Note 3) TC = 25°C

(V

= 7.0 Vdc, RL = 100 )TC = −40°C

AK

*

TC = 25°C

DYNAMIC CHARACTERISTICS

Critical Rate of Rise of Off−State Voltage

(V

= Rated V

D

Critical Rate of Rise of On−State Current

(I

= 20 A; Pw = 10 sec; diG/dt = 1 A/sec, Igt = 20 mA)

PK

*Indicates Pulse Test: Pulse Width ≤ 1.0 ms, Duty Cycle ≤ 1%.

2. R

= 1000 included in measurement.

GK

3. Does not include R

, Exponential Waveform, RGK = 1000 ,TJ = 110°C)

DRM

in measurement.

GK

= 25°C

= 110°C

Symbol Min Typ Max Unit

I

, I

DRM

RRM

V

TM

I

GT

I

H

I

L

V

GT

−

−

−

−

10

100

− − 1.7 V

− 40 200 A

−

−

−

−

−

−

0.5

−

0.6

−

0.62

−

5.0

10

10

15

0.8

1.2

dV/dt 20 35 − V/s

di/dt − − 50 A/s

A

mA

mA

V

Symbol Parameter

V

I

DRM

V

I

RRM

V

I

H

DRM

RRM

TM

Peak Repetitive Off State Forward Voltage

Peak Forward Blocking Current

Peak Repetitive Off State Reverse Voltage

Peak Reverse Blocking Current

Peak on State Voltage

Holding Current

Voltage Current Characteristic of SCR

on state

at V

I

RRM

Reverse Avalanche Region

Anode −

http://onsemi.com

RRM

Reverse Blocking Region

(off state)

3

+ Current

V

TM

I

H

Forward Blocking Region

(off state)

I

DRM

Anode +

at V

DRM

+ Voltage

MCR100 Series

100

GATE TRIGGER CURRENT ( A)

1000

90

80

70

60

50

40

30

20

10

TJ, JUNCTION TEMPERATURE (°C)

Figure 1. Typical Gate Trigger Current versus

Junction Temperature

1.0

0.9

0.8

0.7

0.6

0.5

0.4

GATE TRIGGER VOLTAGE (VOLTS)

0.3

958065

1105035205−10−25−40

0.2

TJ, JUNCTION TEMPERATURE (°C)

9580

110655035205−10−25−40

Figure 2. Typical Gate Trigger Voltage versus

Junction Temperature

1000

100

HOLDING CURRENT ( A)

10

TJ, JUNCTION TEMPERATURE (°C)

9580

110655035205−10−25−40

Figure 3. Typical Holding Current versus

Junction Temperature

120

110

100

90

80

70

60

50

, MAXIMUM ALLOWABLE CASE TEMPERATURE ( C)°

C

T

I

, RMS ON-STATE CURRENT (AMPS)

T(RMS)

30° 60° 90° 120°

DC

180°

0.50.40.30.20.10

Figure 5. Typical RMS Current Derating

100

LATCHING CURRENT ( A)

10

TJ, JUNCTION TEMPERATURE (°C)

Figure 4. Typical Latching Current versus

Junction Temperature

10

MAXIMUM @ TJ = 25°C

MAXIMUM @ TJ = 110°C

1

, INSTANTANEOUS ON−STATE CURRENT (AMPS)

0.140

T

I

VT, INSTANTANEOUS ON-STATE VOLTAGE (VOLTS)

Figure 6. T ypical On−State Characteristics

110655035205−10−25−40

9580

2.92.6

3.53.22.32.01.71.41.10.80.5

http://onsemi.com

4

MCR100 Series

TO−92 EIA RADIAL TAPE IN FAN FOLD BOX OR ON REEL

H2A H2A

H

W2

H4

H5

L1

H1

W1

W

F1

F2

P2 P2

P1

P

L

D

H2B H2B

T1

T

T2

Figure 7. Device Positioning on T ape

Specification

Inches Millimeter

Symbol Item

D

D2

F1, F2

H

H1

H2A

H2B

H4

H5

L

L1

P

P1

P2

T

T1

T2

W

W1

W2

Tape Feedhole Diameter

Component Lead Thickness Dimension

Component Lead Pitch

Bottom of Component to Seating Plane

Feedhole Location

Deflection Left or Right

Deflection Front or Rear

Feedhole to Bottom of Component

Feedhole to Seating Plane

Defective Unit Clipped Dimension

Lead Wire Enclosure

Feedhole Pitch

Feedhole Center to Center Lead

First Lead Spacing Dimension

Adhesive Tape Thickness

Overall Taped Package Thickness

Carrier Strip Thickness

Carrier Strip Width

Adhesive Tape Width

Adhesive Tape Position

NOTES:

1. Maximum alignment deviation between leads not to be greater than 0.2 mm.

2. Defective components shall be clipped from the carrier tape such that the remaining protrusion (L) does not exceed a maximum of 11 mm.

3. Component lead to tape adhesion must meet the pull test requirements.

4. Maximum non−cumulative variation between tape feed holes shall not exceed 1 mm in 20 pitches.

5. Holddown tape not to extend beyond the edge(s) of carrier tape and there shall be no exposure of adhesive.

6. No more than 1 consecutive missing component is permitted.

7. A tape trailer and leader, having at least three feed holes is required before the first and after the last component.

8. Splices will not interfere with the sprocket feed holes.

Min Max Min Max

0.1496 0.1653 3.8 4.2

0.015 0.020 0.38 0.51

0.0945 0.110 2.4 2.8

.059 .156 1.5 4.0

0.3346 0.3741 8.5 9.5

0 0.039 0 1.0

0 0.051 0 1.0

0.7086 0.768 18 19.5

0.610 0.649 15.5 16.5

0.3346 0.433 8.5 11

0.09842 — 2.5 —

0.4921 0.5079 12.5 12.9

0.2342 0.2658 5.95 6.75

0.1397 0.1556 3.55 3.95

0.06 0.08 0.15 0.20

— 0.0567 — 1.44

0.014 0.027 0.35 0.65

0.6889 0.7481 17.5 19

0.2165 0.2841 5.5 6.3

.0059 0.01968 .15 0.5

http://onsemi.com

5

SEATING

PLANE

MCR100 Series

PACKAGE DIMENSIONS

TO−92 (TO−226)

CASE 029−11

ISSUE AL

NOTES:

A

B

R

P

L

K

XX

H

V

1

G

C

N

D

J

SECTION X−X

N

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. CONTOUR OF PACKAGE BEYOND DIMENSION R

IS UNCONTROLLED.

4. LEAD DIMENSION IS UNCONTROLLED IN P AND

BEYOND DIMENSION K MINIMUM.

DIM MIN MAX MIN MAX

A 0.175 0.205 4.45 5.20

B 0.170 0.210 4.32 5.33

C 0.125 0.165 3.18 4.19

D 0.016 0.021 0.407 0.533

G 0.045 0.055 1.15 1.39

H 0.095 0.105 2.42 2.66

J 0.015 0.020 0.39 0.50

K 0.500 −−− 12.70 −−−

L 0.250 −−− 6.35 −−−

N 0.080 0.105 2.04 2.66

P −−− 0.100 −−− 2.54

R 0.115 −−− 2.93 −−−

V 0.135 −−− 3.43 −−−

STYLE 10:

PIN 1. CATHODE

2. GATE

3. ANODE

MILLIMETERSINCHES

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 61312, Phoenix, Arizona 85082−1312 USA

Phone: 480−829−7710 or 800−344−3860 Toll Free USA/Canada

Fax: 480−829−7709 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Japan: ON Semiconductor, Japan Customer Focus Center

2−9−1 Kamimeguro, Meguro−ku, Tokyo, Japan 153−0051

Phone: 81−3−5773−3850

http://onsemi.com

ON Semiconductor Website: http://onsemi.com

Order Literature: http://www.onsemi.com/litorder

For additional information, please contact your

local Sales Representative.

MCR100/D

6

Loading...

Loading...