MC34163, MC33163

3.4 A, Step-Up/Down/

Inverting Switching

Regulators

The MC34163 series are monolithic power switching regulators that

contain the primary functions required for dc–to–dc converters. This

series is specifically designed to be incorporated in step–up,

step–down, and voltage–inverting applications with a minimum

number of external components.

These devices consist of two high gain voltage feedback

comparators, temperature compensated reference, controlled duty

cycle oscillator, driver with bootstrap capability for increased

efficiency, and a high current output switch. Protective features consist

of cycle–by–cycle current limiting, and internal thermal shutdown.

Also included is a low voltage indicator output designed to interface

with microprocessor based systems.

These devices are contained in a 16 pin dual–in–line heat tab plastic

package for improved thermal conduction.

• Output Switch Current in Excess of 3.0 A

• Operation from 2.5 V to 40 V Input

• Low Standby Current

• Precision 2% Reference

• Controlled Duty Cycle Oscillator

• Driver with Bootstrap Capability for Increased Efficiency

• Cycle–by–Cycle Current Limiting

• Internal Thermal Shutdown Protection

• Low Voltage Indicator Output for Direct Microprocessor Interface

• Heat Tab Power Package

• Moisture Sensitivity Level (MSL) Equals 1

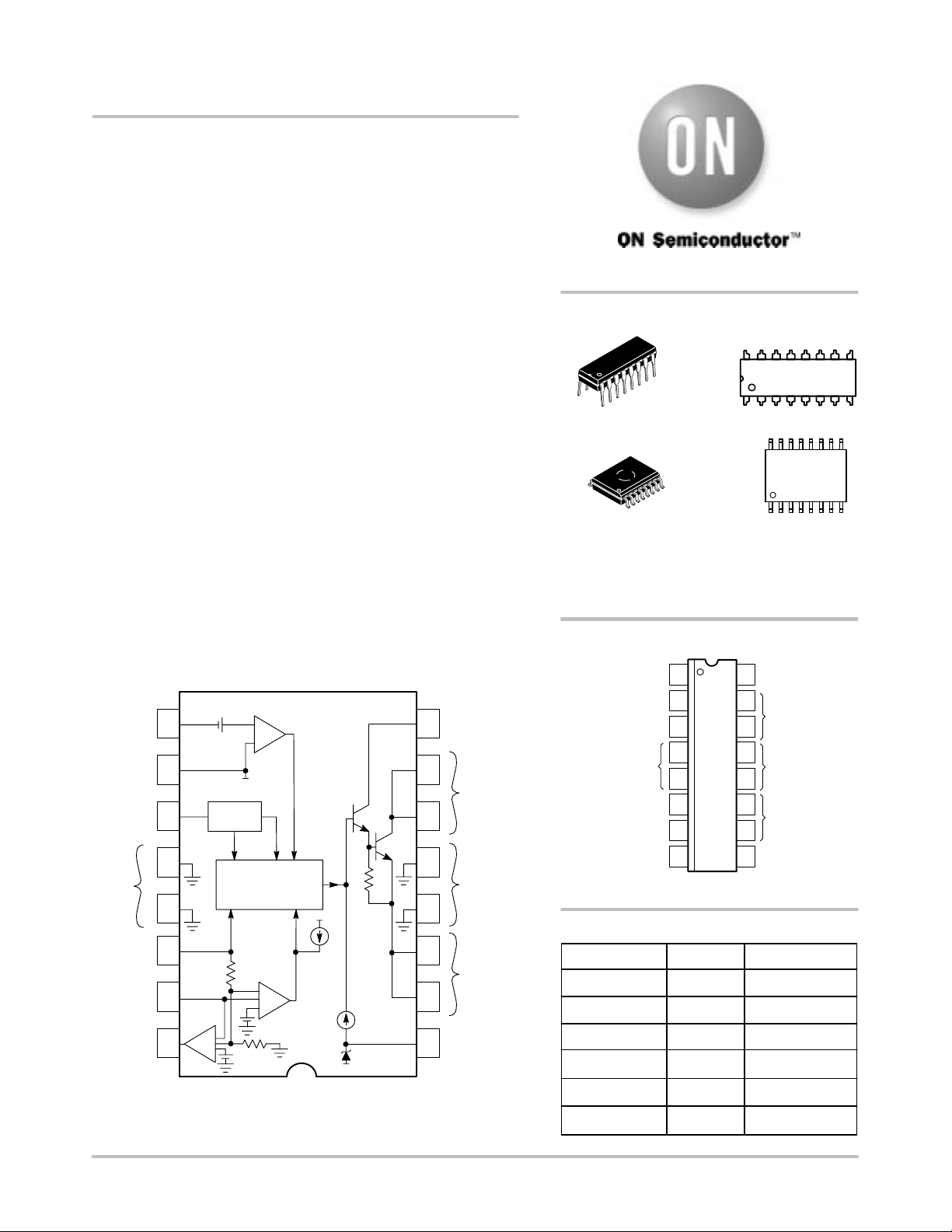

Ipk Sense

V

Timing

Capacitor

Gnd

Voltage

Feedback 1

Voltage

Feedback 2

LVI Output

8

7

CC

6

5

4

3

2

1

LVI

OSC

+

+

-

I

Limit

-

+

+

Control Logic

and Thermal

Shutdown

VFB

+

+

-

+

+

9

10

11

12

13

14

15

16

Driver

Collector

Switch

Collector

Gnd

Switch

Emitter

Bootstrap

Input

http://onsemi.com

MARKING

DIAGRAMS

16

16

16

PDIP–16

P SUFFIX

CASE 648C

1

SO–16W

DW SUFFIX

CASE 751G

1

x = 3 or 4

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

MC3x163P

AWLYYWW

1

16

MC3x163DW

AWLYYWW

1

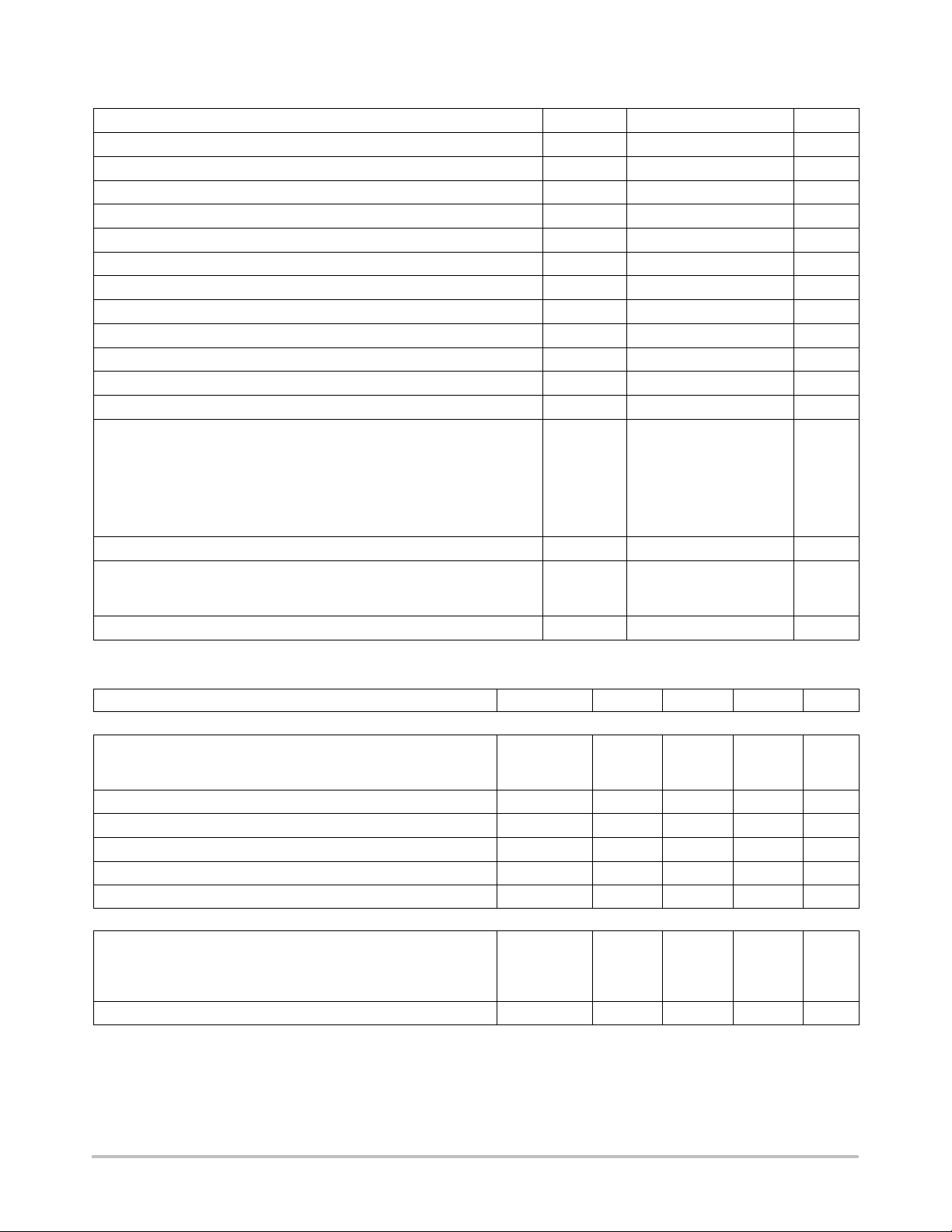

PIN CONNECTIONS

LVI Output

Voltage Feedback 2

Voltage Feedback 1

Gnd

Timing Capacitor

V

Ipk Sense

116

2

3

4

5

6

7

CC

8

(Top View)

Bootstrap Input

15

Switch

Emitter

14

13

Gnd

12

11

Switch Collector

10

Driver Collector

9

ORDERING INFORMATION

Device Package Shipping

MC33163DW SO–16W 47 Units/Rail

MC33163DWR2 SO–16W 1000 Tape & Reel

MC33163P PDIP–16

MC34163DW SO–16W

25 Units/Rail

47 Units/Rail

This device contains 114 active transistors.

(Bottom View)

Figure 1. Representative Block Diagram

Semiconductor Components Industries, LLC, 2002

January , 2002 – Rev. 4

MC34163DWR2 SO–16W 1000 Tape & Reel

MC34163P PDIP–16 25 Units/Rail

1 Publication Order Number:

MC34163/D

MC34163, MC33163

MAXIMUM RATINGS (Note 1)

Rating

Power Supply Voltage V

Switch Collector Voltage Range V

Switch Emitter Voltage Range V

Switch Collector to Emitter Voltage V

Switch Current (Note 2) I

Driver Collector Voltage V

Driver Collector Current I

Bootstrap Input Current Range (Note 2) I

Current Sense Input Voltage Range V

Feedback and Timing Capacitor Input Voltage Range V

Low Voltage Indicator Output Voltage Range V

Low Voltage Indicator Output Sink Current I

Thermal Characteristics

P Suffix, Dual–In–Line Case 648C

Thermal Resistance, Junction–to–Air

Thermal Resistance, Junction–to–Case (Pins 4, 5, 12, 13)

DW Suffix, Surface Mount Case 751G

Thermal Resistance, Junction–to–Air

Thermal Resistance, Junction–to–Case (Pins 4, 5, 12, 13)

Operating Junction Temperature T

Operating Ambient Temperature (Note 4)

MC34163

MC33163

Storage Temperature Range T

Symbol Value Unit

CC

C(switch)

E(switch)

CE(switch)

SW

C(driver)

C(driver)

BS

Ipk (Sense)

in

C(LVI)

C(LVI)

(VCC–7.0) to (VCC+1.0) V

40 V

–1.0 to + 40 V

– 2.0 to V

C(switch)

40 V

3.4 A

–1.0 to +40 V

150 mA

–100 to +100 mA

–1.0 to + 7.0 V

–1.0 to + 40 V

10 mA

V

°C/W

R

θ

JA

R

θ

JC

R

θ

JA

R

θ

JC

J

T

A

80

15

94

18

+150 °C

°C

0 to +70

– 40 to + 85

stg

– 65 to +150 °C

ELECTRICAL CHARACTERISTICS (V

= 15 V, Pin 16 = VCC, CT = 620 pF, for typical values TA = 25°C, for min/max values T

CC

the operating ambient temperature range that applies (Note 4), unless otherwise noted.)

Characteristic

Symbol Min Typ Max Unit

OSCILLATOR

Frequency

= 25°C

T

A

Total Variation over V

= 2.5 V to 40 V, and Temperature

CC

Charge Current I

Discharge Current I

Charge to Discharge Current Ratio I

Sawtooth Peak Voltage V

Sawtooth Valley Voltage V

f

OSC

chg

dischg

chg/Idischg

OSC(P)

OSC(V)

46

45

50

–

– 225 – µA

– 25 – µA

8.0 9.0 10 –

– 1.25 – V

– 0.55 – V

FEEDBACK COMPARATOR 1

Threshold Voltage

= 25°C

T

A

Line Regulation (V

= 2.5 V to 40 V, TA = 25°C)

CC

Total Variation over Line, and Temperature

Input Bias Current (V

= 5.05 V) I

FB1

V

th(FB1)

IB(FB1)

4.9

–

4.85

5.05

0.008

–

– 100 200 µA

1. This device series contains ESD protection and exceeds the following tests:

Human Body Model 1500 V per MIL–STD–883, Method 3015.

Machine Model Method 150 V.

2. Maximum package power dissipation limits must be observed.

3. Low duty cycle pulse techniques are used during test to maintain junction temperature as close to ambient as possible.

=0°C for MC34163 T

4. T

low

=–40°C for MC33163 = + 85°C for MC33163

=+70°C for MC34163

high

54

55

5.2

0.03

5.25

kHz

V

%/V

V

is

A

http://onsemi.com

2

MC34163, MC33163

ELECTRICAL CHARACTERISTICS (continued) (V

values T

is the operating ambient temperature range that applies (Note 6), unless otherwise noted.)

A

Characteristic

= 15 V, Pin 16 = VCC, CT = 620 pF, for typical values TA = 25°C, for min/max

CC

Symbol Min Typ Max Unit

FEEDBACK COMPARATOR 2

Threshold Voltage

T

= 25°C

A

Line Regulation (V

= 2.5 V to 40 V, TA = 25°C)

CC

Total Variation over Line, and Temperature

Input Bias Current (V

= 1.25 V) I

FB2

V

th(FB2)

IB(FB2)

1.225

–

1.213

1.25

0.008

–

– 0.4 0 0.4 µA

CURRENT LIMIT COMPARATOR

Threshold Voltage

= 25°C

T

A

Total Variation over V

Input Bias Current (V

= 2.5 V to 40 V, and Temperature

CC

Ipk (Sense)

= 15 V) I

V

th(Ipk Sense)

IB(sense)

–

230

250

–

– 1.0 20 µA

DRIVER AND OUTPUT SWITCH (Note 5)

Sink Saturation Voltage (I

Non–Darlington Connection (R

Darlington Connection (Pins 9, 10, 11 connected)

Collector Off–State Leakage Current (VCE = 40 V) I

Bootstrap Input Current Source (VBS = VCC + 5.0 V) I

Bootstrap Input Zener Clamp Voltage (IZ = 25 mA) V

= 2.5 A, Pins 14, 15 grounded)

SW

= 110 Ω to VCC, ISW/I

Pin 9

DRV

≈ 20)

V

CE(sat)

C(off)

source(DRV)

Z

–

–

0.6

1.0

– 0.02 100 µA

0.5 2.0 4.0 mA

VCC + 6.0 VCC + 7.0 VCC + 9.0 V

LOW VOLTAGE INDICATOR

Input Threshold (V

Input Hysteresis (V

Output Sink Saturation Voltage (I

Output Off–State Leakage Current (VOH = 15 V) I

Increasing) V

FB2

Decreasing) V

FB2

= 2.0 mA) V

sink

th

H

OL(LVI)

OH

1.07 1.125 1.18 V

– 15 – mV

– 0.15 0.4 V

– 0.01 5.0 µA

TOTAL DEVICE

Standby Supply Current (V

= 2.5 V to 40 V, Pin 8 = VCC,

CC

I

CC

– 6.0 10 mA

Pins 6, 14, 15 = Gnd, remaining pins open)

5. Low duty cycle pulse techniques are used during test to maintain junction temperature as close to ambient as possible.

=0°C for MC34163 T

6. T

low

=–40°C for MC33163 = + 85°C for MC33163

=+70°C for MC34163

high

1.275

0.03

1.287

–

270

1.0

1.4

V

%/V

V

mV

V

100

10

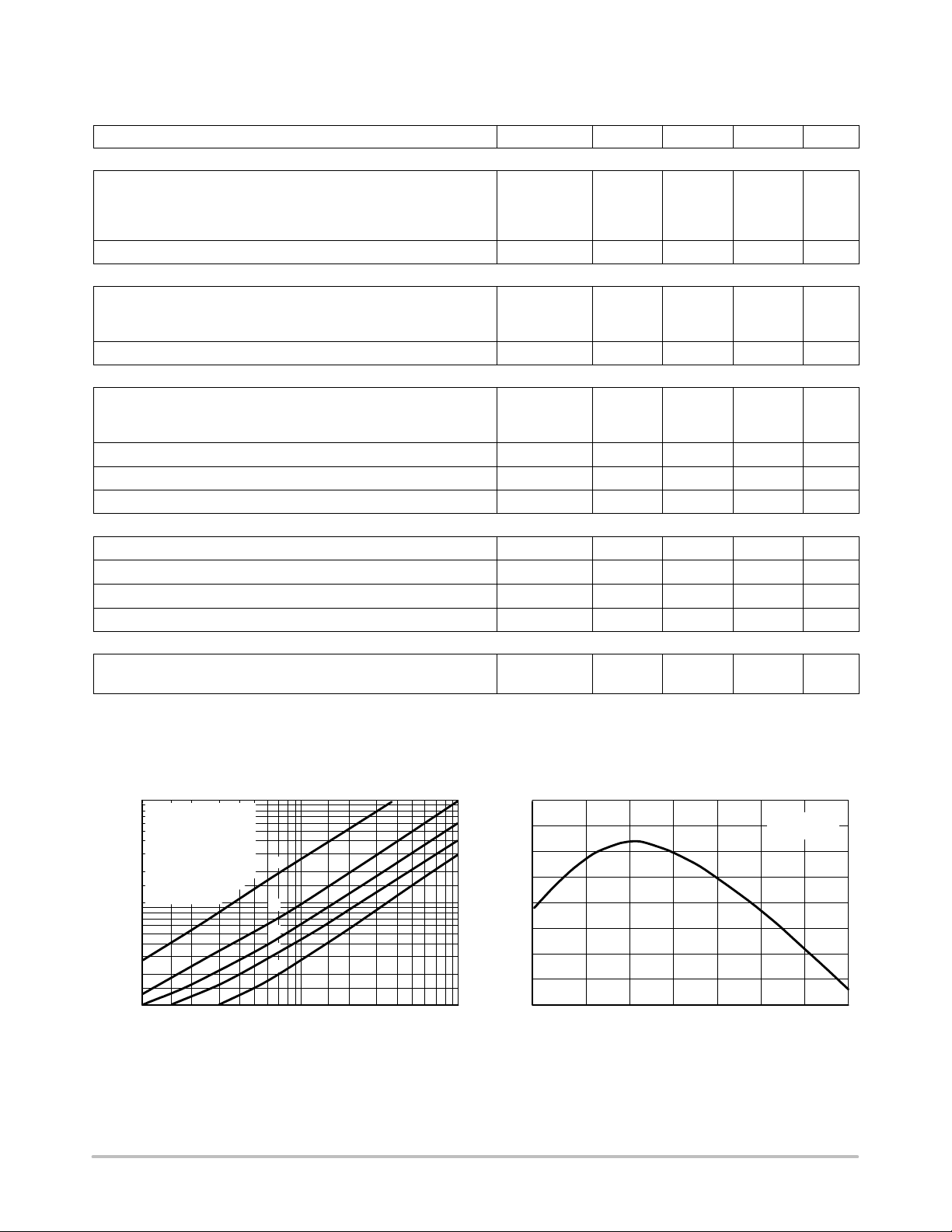

, OUTPUT SWITCH ON-OFF TIME ( s)t

off

-t µ

1.0

on

0.1

V

= 15 V

CC

T

= 25°C

A

1)ton, R

2)ton, RDT = 20 k

3)ton, t

4)t

5)t

= ∞

DT

, RDT = 10 k

off

, RDT = 20 k

off

, R

= ∞

off

DT

1

2

3

4

5

1.0 10

C

, OSCILLATOR TIMING CAPACITOR (nF)

T

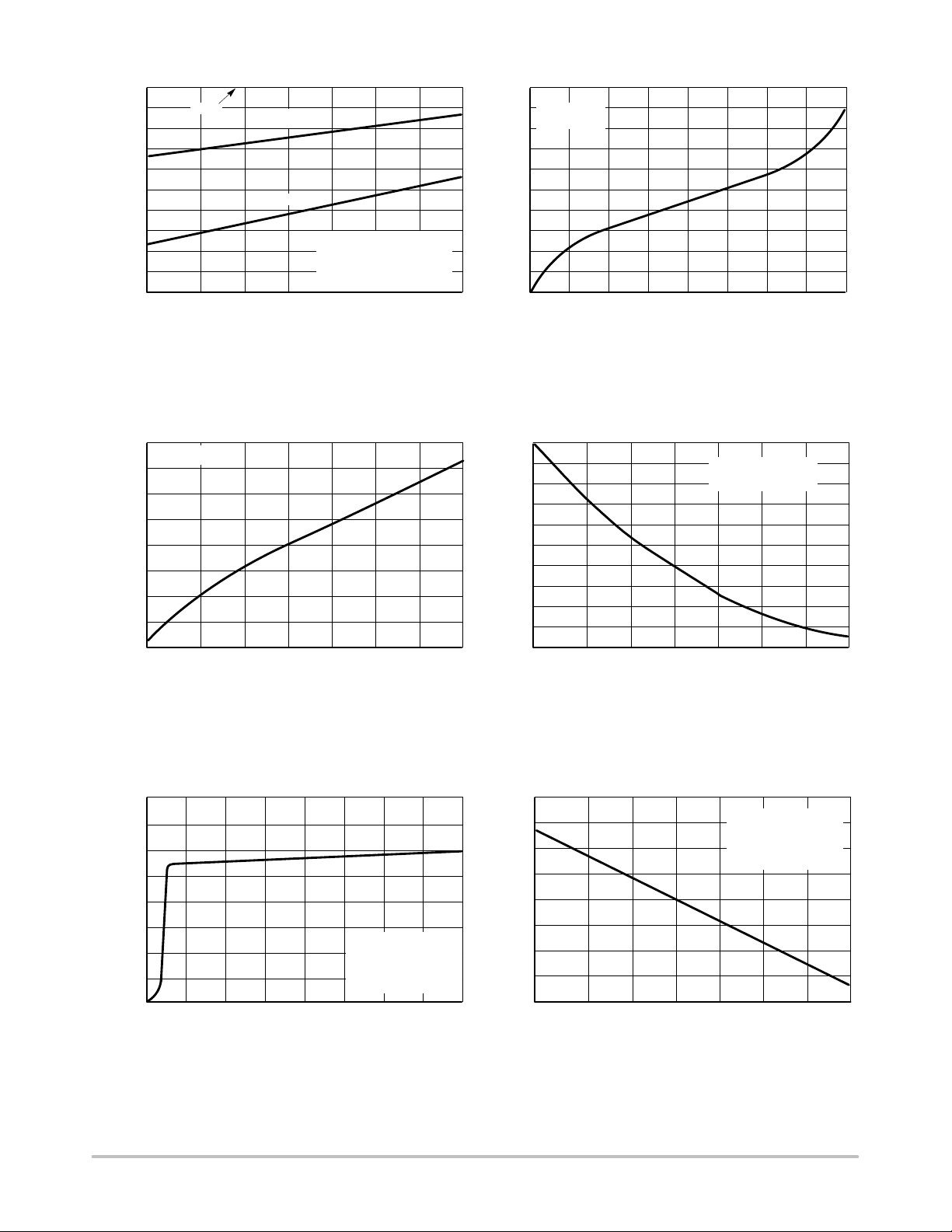

Figure 2. Output Switch On–Off Time

versus Oscillator Timing Capacitor

2.0

0

-2.0

-4.0

, OSCILLATOR FREQUENCY CHANGE (%)∆

-6.0

-55

OSC

f

http://onsemi.com

3

VCC = 15 V

CT = 620 pF

-25 0 25 50 75 100 125

, AMBIENT TEMPERATURE (°C)

T

A

Figure 3. Oscillator Frequency Change

versus Temperature

MC34163, MC33163

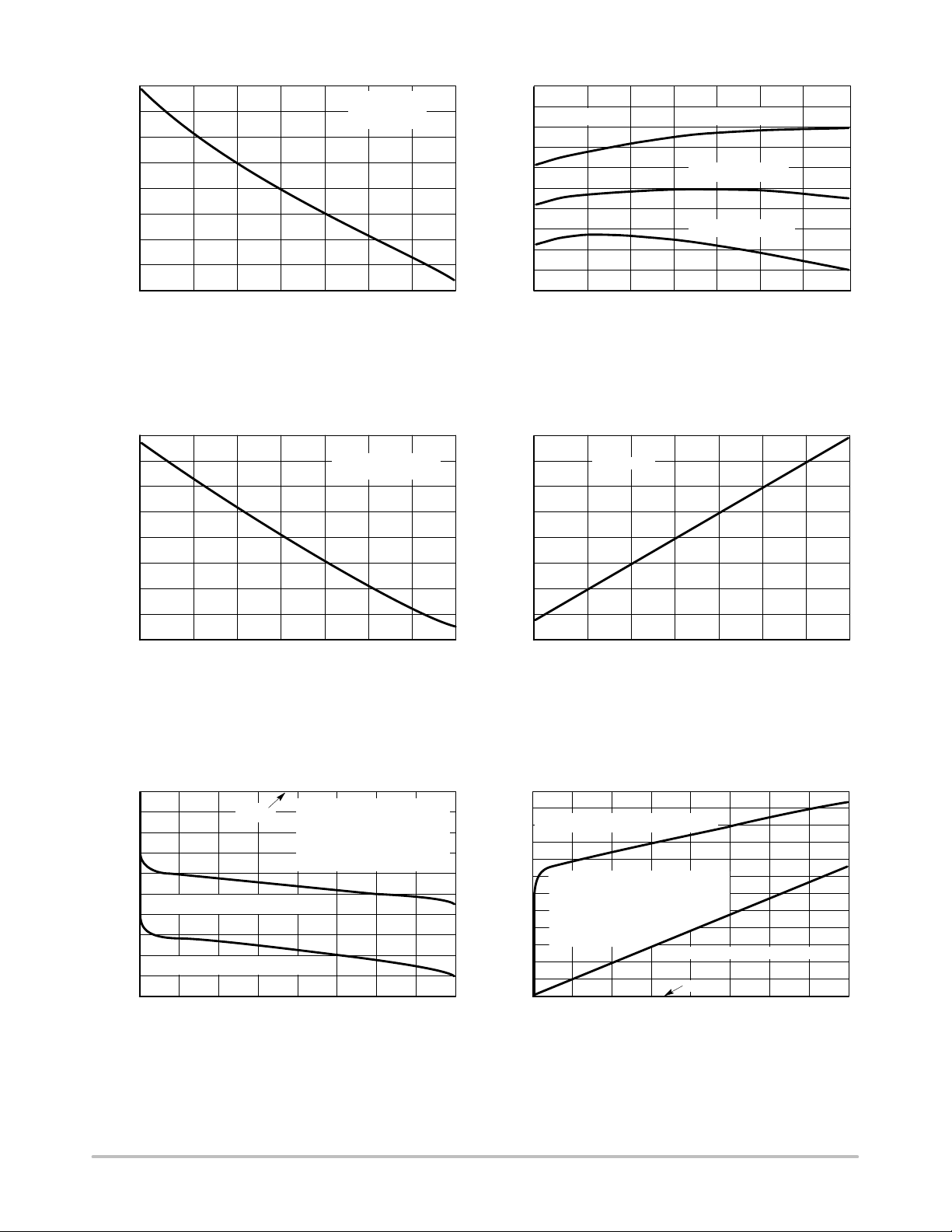

5

)

140

1300

VCC = 15 V

V

120

FB1

= 5.05 V

1280

1260

VCC = 15 V

Vth Max = 1275 mV

Vth Typ = 1250 mV

100

1240

80

, INPUT BIAS CURRENT (A)µ

IB

I

60

-55

-25 0 25 50 75 100 125

, AMBIENT TEMPERATURE (°C)

T

A

Figure 4. Feedback Comparator 1 Input Bias

Current versus Temperature

2.8

VCC = 15 V

2.4

2.0

Pin 16 = VCC + 5.0 V

1220

1200

, COMPARATOR 2 THRESHOLD VOLTAGE (mV

-55

th(FB2)

V

-25 0 25 50 75 100 125

, AMBIENT TEMPERATURE (°C)

T

A

Figure 5. Feedback Comparator 2 Threshold

Voltage versus Temperature

7.6

IZ = 25 mA

7.4

7.2

Vth Min = 1225 mV

1.6

, BOOTSTRAP INPUT CURRENT SOURCE (mA)

1.2

-55 -25 0 25 50 75 100 125

T

, AMBIENT TEMPERATURE (°C)

source (DRV)

I

A

Figure 6. Bootstrap Input Current

Source versus T emperature

0

V

CC

-0.4

-0.8

Bootstrapped, Pin 16 = VCC + 5.0 V

-1.2

, SOURCE SATURATION (V)

-1.6

CE (sat)

V

-2.0

Non-Bootstrapped, Pin 16 = V

0 0.8 2.4 3.2

, EMITTER CURRENT (A)

I

E

Darlington Configuration

Emitter Sourcing Current to Gnd

Pins 7, 8, 10, 11 = V

Pins 4, 5, 12, 13 = Gnd

T

= 25°C, (Note 2)

A

CC

CC

1.6

Figure 8. Output Switch Source Saturation

versus Emitter Current

7.0

6.8

-55 -25 0 25 50 75 100 12

, BOOTSTRAP INPUT ZENER CLAMP VOLTAGE (V)

Z

V

T

, AMBIENT TEMPERATURE (°C)

A

Figure 7. Bootstrap Input Zener Clamp

Voltage versus Temperature

1.2

Darlington, Pins 9, 10, 11 Connected

1.0

0.8

Grounded Emitter Configuration

Collector Sinking Current From V

0.6

Pins 7, 8 = VCC = 15 V

, SINK SATURATION (V)

CE (sat)

V

Pins 4, 5, 12, 13, 14, 15 = Gnd

0.4

T

= 25°C, (Note 2)

A

0.2

0

0 0.8 2.4 3.21.6

CC

Saturated Switch, R

Gnd

I

, COLLECTOR CURRENT (A)

C

= 110 Ω to V

Pin9

Figure 9. Output Switch Sink Saturation

versus Collector Current

CC

http://onsemi.com

4

MC34163, MC33163

0

Gnd

-0.4

I

= 10 µA

C

-0.8

-1.2

, EMITTER VOLTAGE (V)

E

V

-1.6

IC = 10 mA

VCC = 15 V

Pins 7, 8, 9, 10, 16 = V

Pins 4, 6 = Gnd

Pin 14 Driven Negative

-2.0

-55 -25 0 25 50 75 100 125

, AMBIENT TEMPERATURE (°C)

T

A

Figure 10. Output Switch Negative Emitter

Voltage versus Temperature

254

VCC = 15 V

252

250

, THRESHOLD VOLTAGE (mV)

248

th (Ipk Sense)

V

246

-55 -25 0 25 50 75 100 125

, AMBIENT TEMPERATURE (°C)

T

A

Figure 12. Current Limit Comparator Threshold

Voltage versus Temperature

0.5

VCC=5 V

T

=25°C

A

0.4

0.3

0.2

CC

0.1

, OUTPUT SATURATION VOLTAGE (V)

0

OL (LVI)

0 2.0 4.0 6.0 8.0

V

I

, OUTPUT SINK CURRENT (mA)

sink

Figure 11. Low Voltage Indicator Output Sink

Saturation Voltage versus Sink Current

1.6

µ

1.4

VCC = 15 V

V

Ipk (Sense)

= 15 V

1.2

1.0

INPUT BIAS CURRENT ( A)

,

0.8

IB (Sense)

I

0.6

-55 -25 0 25 50 75 100 125

T

, AMBIENT TEMPERATURE (°C)

A

Figure 13. Current Limit Comparator Input Bias

Current versus Temperature

8.0

6.0

4.0

, SUPPLY CURRENT (mA)

2.0

CC

I

0

0 10203040

, SUPPLY VOLTAGE (V)

V

CC

Pins 7, 8, 16 = V

Pins 4, 6, 14 = Gnd

Remaining Pins Open

T

= 25°C

A

CC

Figure 14. Standby Supply Current

versus Supply V oltage

http://onsemi.com

7.2

VCC = 15 V

6.4

Pins 7, 8, 16 = V

Pins 4, 6, 14 = Gnd

Remaining Pins Open

CC

5.6

, SUPPLY CURRENT (mA)

4.8

CC

I

4.0

-55 -25 0 25 50 75 100 125

, AMBIENT TEMPERATURE (°C)

T

A

Figure 15. Standby Supply Current

versus Temperature

5

MC34163, MC33163

ÎÎ

ÎÎ

ÎÎÎ

ÎÎÎ

ÎÎ

ÎÎ

3.0

2.6

2.2

1.8

Pin 16 Open

Pin 16 = V

CC

CT = 620 pF

Pins 7,8 = V

Pins 4, 14 = Gnd

CC

Pin 9 = 1.0 kΩ to 15 V

Pin 10 = 100 Ω to 15 V

1.4

, MINIMUM OPERATING SUPPLY VOLTAGE (V)

1.0

-55 -25 0 25 50 75 100 125

, AMBIENT TEMPERATURE (°C)

T

CC(min)

V

Figure 16. Minimum Operating Supply

A

Voltage versus Temperature

100

90

80

70

60

50

JAθ

JUNCTION-TO-AIR ( C/W)°

R , THERMAL RESISTANCE

40

30

02030504010

100

80

60

40

JAθ

20

JUNCTION-TO-AIR ( C/W)°

R , THERMAL RESISTANCE

0

0

Figure 17. P Suffix (DIP–16) Thermal Resistance

P

for T

2.0 oz.

Copper

= 50°C

A

D(max)

Graph represents symmetrical layout

L

R

θ

JA

L, LENGTH OF COPPER (mm)

Printed circuit board heatsink example

2.0 oz

L

Copper

R

P

D(max)

θ

JA

for T

= 70°C

A

L

Graphs represent symmetrical layout

3.0 mm

10 20 30 40 50

L, LENGTH OF COPPER (mm)

and Maximum Power Dissipation

versus P.C.B. Copper Length

2.8

2.4

2.0

1.6

1.2

3.0 mmL

0.8

0.4

0

, MAXIMUM POWER DISSIPATION (W)

D

P

5.0

4.0

3.0

2.0

1.0

0

, MAXIMUM POWER DISSIPATION (W)

D

P

Figure 18. DW Suffix (SOP–16L) Thermal Resistance and

Maximum Power Dissipation versus P.C.B. Copper Length

http://onsemi.com

6

MC34163, MC33163

V

Timing Capacitor

Shutdown

Voltage Feedback 1

Voltage Feedback 2

Comparator Output

1.25 V

Timing Capacitor C

0.55 V

Oscillator Output

Output Switch

Nominal Output

Voltage Level

CC

T

On

Off

I

pk Sense

R

SC

C

T

R

DT

Gnd

LVI Output

1

0

1

0

+

Thermal

+

+

+

-

+

45 k

+

+

-

+

1.125 V

Current

Limit

R

Q

S

Latch

+

Feedback

Comparator

15 k1.25 V

+

Q

60

2.0 mA

7.0 V

9

Driver Collector

10

Switch Collector

11

1

Q

2

12

Gnd

13

14

Switch Emitter

15

16

Bootstrap Input

8

7

6

5

4

3

2

1

0.25 V

+

Oscillator

LVI

(Bottom View)

Figure 19. Representative Block Diagram

t

9t

+

-

Sink Only

=

Positive True Logic

Output Voltage

Startup Quiescent Operation

Figure 20. Typical Operating Waveforms

http://onsemi.com

7

MC34163, MC33163

INTRODUCTION

The MC34163 series are monolithic power switching

regulators optimized for dc–to–dc converter applications.

The combination of features in this series enables the system

designer to directly implement step–up, step–down, and

voltage–inverting converters with a minimum number of

external components. Potential applications include cost

sensitive consumer products as well as equipment for the

automotive, computer, and industrial markets. A

Representative Block Diagram is shown in Figure 19.

OPERATING DESCRIPTION

The MC34163 operates as a fixed on–time, variable

off–time voltage mode ripple regulator. In general, this

mode of operation is somewhat analogous to a capacitor

charge pump and does not require dominant pole loop

compensation for converter stability. The Typical Operating

Waveforms are shown in Figure 20. The output voltage

waveform shown is for a step–down converter with the

ripple and phasing exaggerated for clarity. During initial

converter startup, the feedback comparator senses that the

output voltage level is below nominal. This causes the

output switch to turn on and off at a frequency and duty cycle

controlled by the oscillator , thus pumping up the output filter

capacitor. When the output voltage level reaches nominal,

the feedback comparator sets the latch, immediately

terminating switch conduction. The feedback comparator

will inhibit the switch until the load current causes the output

voltage to fall below nominal. Under these conditions,

output switch conduction can be inhibited for a partial

oscillator cycle, a partial cycle plus a complete cycle,

multiple cycles, or a partial cycle plus multiple cycles.

Oscillator

The oscillator frequency and on–time of the output switch

are programmed by the value selected for timing capacitor

CT. Capacitor CT is charged and discharged by a 9 to 1 ratio

internal current source and sink, generating a negative going

sawtooth waveform at Pin 6. As CT charges, an internal

pulse is generated at the oscillator output. This pulse is

connected to the NOR gate center input, preventing output

switch conduction, and to the AND gate upper input,

allowing the l a t c h to be re s e t i f the comparator output is low.

Thus, the output switch is always disabled during ramp–up

and can be enabled by the comparator output only at the start

of ramp–down. The oscillator peak and valley thresholds are

1.25 V and 0.55 V, respectively, with a charge current of

225 µA and a discharge current of 25 µA, yielding a

maximum on–time duty cycle of 90%. A reduction of the

maximum duty cycle may be required for specific converter

configurations. This can be accomplished with the addition

of an external deadtime resistor (R

) placed across CT. The

DT

resistor increases the discharge current which reduces the

on–time of the output switch. A graph of the Output Switch

On–Off Time versus Oscillator Timing Capacitance for

various values of RDT is shown in Figure 2. Note that the

maximum output duty cycle, t

on/ton

+ t

, remains constant

off

for values of CT greater than 0.2 nF. The converter output

can be inhibited by clamping CT to ground with an external

NPN small–signal transistor.

Feedback and Low Voltage Indicator Comparators

Output voltage control is established by the Feedback

comparator. T he i nverting i nput i s i nternally b iased a t 1 .25 V

and is not pinned out. The converter output voltage is

typically divided down with two external resistors and

monitored by t he h igh im pedance n oninverting i nput a t Pin 2.

The maximum i nput b ias c urrent i s ±0.4 µA, which can c ause

an output v oltage e rror t hat i s e qual t o t he p roduct o f t he i nput

bias current and the upper divider resistance value. For

applications that require 5.0 V, the converter output can be

directly connected t o t he n oninverting i nput a t P in 3 . T he h igh

impedance input, Pin 2, must be grounded to prevent noise

pickup. The internal resistor divider is set for a nominal

voltage of 5.05 V. The additional 50 mV compensates for a

1.0% voltage drop in the cable and connector from the

converter output to the load. The Feedback comparator’s

output state is controlled by the highest voltage applied to

either of the two noninverting inputs.

The Low Voltage Indicator (LVI) comparator is designed

for use as a reset controller in microprocessor–based

systems. The inverting input is internally biased at 1.125 V,

which sets the noninverting input thresholds to 90% of

nominal. The LVI comparator has 15 mV of hysteresis to

prevent erratic reset operation. The Open Collector output is

capable of sinking in excess of 6.0 mA (see Figure 11). An

external resistor (R

program a reset delay time (t

below, where V

) and capacitor (C

LVI

DLY

is the microprocessor reset input

th(MPU)

DLY

) by the formula shown

) can be used to

threshold. Refer to Figure 21.

1

V

t

= R

DLY

Current Limit Comparator, Latch and Thermal

Shutdown

LVI CDLY

In

1 –

th(MPU)

V

out

With a voltage mode ripple converter operating under

normal conditions, output switch conduction is initiated by

the oscillator and terminated by the Voltage Feedback

comparator. Abnormal operating conditions occur when the

converter output is overloaded or when feedback voltage

sensing is lost. Under these conditions, the Current Limit

comparator will protect the Output Switch.

http://onsemi.com

8

MC34163, MC33163

The switch current is converted to a voltage by inserting

a fractional ohm resistor, RSC, in series with VCC and output

switch transistor Q2. The voltage drop across RSC is

monitored by the Current Sense comparator. If the voltage

drop exceeds 250 mV with respect to VCC, the comparator

will set the latch and terminate output switch conduction on

a cycle–by–cycle basis. This Comparator/Latch

configuration ensures that the Output Switch has only a

single on–time during a given oscillator cycle. The

calculation for a value of R

R

SC

is:

SC

0.25 V

Ipk(Switch)

Figures 12 and 13 show that the Current Sense comparator

threshold is tightly controlled over temperature and has a

typical input bias current of 1.0 µA. The propagation delay

from the comparator input to the Output Switch is typically

200 ns. The parasitic inductance associated with R

and the

SC

circuit layout should be minimized. This will prevent

unwanted voltage spikes that may falsely trip the Current

Limit comparator.

Internal thermal shutdown circuitry is provided to protect

the IC in the event that the maximum junction temperature

is exceeded. When activated, typically at 170°C, the Latch

is forced into the “Set” state, disabling the Output Switch.

This feature is provided to prevent catastrophic failures from

accidental device overheating. It is not intended to be used

as a replacement for proper heatsinking.

Driver and Output Switch

To aid in system design flexibility and conversion

efficiency, the driver current source and collector, and

output switch collector and emitter are pinned out

separately. This allows the designer the option of driving the

output switch into saturation with a selected force gain or

driving it near saturation when connected as a Darlington.

The output switch has a typical current gain of 70 at 2.5 A

and is designed to switch a maximum of 40 V collector to

emitter, with up to 3.4 A peak collector current. The

minimum value for R

R

SC(min)

SC

is:

0.25 V

3.4 A

0.0735

When configured for step–down or voltage–inverting

applications, as in Figures 21 and 25, the inductor will

forward bias the output rectifier when the switch turns off.

Rectifiers with a high forward voltage drop or long turn–on

delay time should not be used. If the emitter is allowed to go

sufficiently negative, collector current will flow, causing

additional device heating and reduced conversion

efficiency.

Figure 10 shows that by clamping the emitter to 0.5 V, the

collector current will be in the range 10 µA over

temperature. A 1N5822 or equivalent Schottky barrier

rectifier is recommended to fulfill these requirements.

A bootstrap input is provided to reduce the output switch

saturation voltage in step–down and voltage–inverting

converter applications. This input is connected through a

series resistor and capacitor to the switch emitter and is used

to raise the internal 2.0 mA bias current source above V

An internal zener limits the bootstrap input voltage to V

CC

CC

+7.0 V. The capacitor’s equivalent series resistance must

limit the zener current to less than 100 mA. An additional

series resistor may be required when using tantalum or other

low ESR capacitors. The equation below is used to calculate

a minimum value bootstrap capacitor based on a minimum

zener voltage and an upper limit current source.

C

B(min)

I

t

4.0 mA

V

t

on

4.0 V

0.001 t

on

Parametric operation of the MC34163 is guaranteed over

a supply voltage range of 2.5 V to 40 V. When operating

below 3.0 V, the Bootstrap Input should be connected to

V

. Figure 16 shows that functional operation down to

CC

1.7 V at room temperature is possible.

Package

The MC34163 is contained in a heatsinkable 16–lead

plastic dual–in–line package in which the die is mounted on

a special heat tab copper alloy lead frame. This tab consists

of the four center ground pins that are specifically designed

to improve thermal conduction from the die to the circuit

board. Figures 17 and 18 show a simple and effective

method of utilizing the printed circuit board medium as a

heat dissipater by soldering these pins to an adequate area of

copper foil. This permits the use of standard layout and

mounting practices while having the ability to halve the

junction–to–air thermal resistance. These examples are for

a symmetrical layout on a single–sided board with two

ounce per square foot of copper.

APPLICATIONS

The following converter applications show the simplicity

and flexibility of this circuit architecture. Three main

converter topologies are demonstrated with actual test data

shown below each of the circuit diagrams.

.

http://onsemi.com

9

MC34163, MC33163

p

(

)

-

+

+

Thermal

Current

Limit

9

10

11

Q

1

Q

R

Q

S

Latch

+

2

12

60

13

14

V

12 V

0.25 V

R

0.075

in

330

680 pF

8

SC

7

+

6

+

Oscillator

C

in

C

T

5

4

3

45 k

+

Low Voltage

Indicator Output

R

10 k

C

LVI

DLY

2

1

LVI

+

+

+

-

+

-

+

1.125 V

Feedback

Comparator

15 k1.25 V

+

2.0 mA

7.0 V

1N5822

15

0.02

16

R

C

B

B

(Bottom View)

Test Condition Results

Line Regulation Vin = 8.0 V to 24 V, IO = 3.0 A 6.0 mV = ±0.06%

Load Regulation Vin = 12 V, IO = 0.6 A to 3.0 A 2.0 mV = ±0.02%

Output Ripple V

Short Circuit Current V

Efficiency, Without Bootstrap V

Efficiency, With Bootstrap V

= 12 V, IO = 3.0 A 36 mVpp

in

= 12 V, RL = 0.1 Ω 3.3 A

in

= 12 V, IO = 3.0 A 76.7%

in

= 12 V, IO = 3.0 A 81.2%

in

2200

180 µH

L

Coilcraft LO451-A

+

C

O

V

out

5.05 V/3.0 A

Figure 21. Step–Down Converter

8

7

+

6

5

4

+

3

2

1

+

9

10

11

Q

1

Q

2

12

13

14

Q

3

15

16

(Bottom View)

8

7

+

6

5

4

+

3

2

1

+

9

10

11

Q

1

Q

2

12

13

14

15

16

(Bottom View)

Figure 22A. External NPN Switch Figure 22B. External PNP Saturated Switch

Figure 22. External Current Boost Connections for I

k

Greater Than 3.4 A

Switch

Q

3

http://onsemi.com

10

MC34163, MC33163

p

(

)

180 µH

V

12 V

-

+

+

Thermal

Current

Limit

9

10

11

Q

1

Q

R

Q

S

Latch

+

2

12

60

13

0.25 V

C

330

8

SC

7

+

6

+

Oscillator

in

C

T

R

0.075

in

680 pF

5

4

Coilcraft

L

LO451-A

1N5822

3

14

45 k

+

+

-

+

1.125 V

(Bottom View)

Feedback

Comparator

15 k1.25 V

+

2.0 mA

7.0 V

15

16

V

+

C

O

330

out

28 V/600 mA

Low Voltage

Indicator

Output

2.2 k

2

1

R

LVI

1.0 k

R

1

R

47 k

2

LVI

+

+

+

-

Test Condition Results

Line Regulation Vin = 9.0 V to 16 V, IO = 0.6 A 30 mV = ±0.05%

Load Regulation Vin = 12 V, IO = 0.1 A to 0.6 A 50 mV = ±0.09%

Output Ripple V

Efficiency V

= 12 V, IO = 0.6 A 140 mVpp

in

= 12 V, IO = 0.6 A 88.1%

in

Figure 23. Step–Up Converter

8

7

+

6

5

4

+

3

2

1

+

9

10

11

Q

1

Q

2

12

13

14

Q

3

15

16

(Bottom View)

8

7

+

6

5

4

+

3

2

1

+

9

10

11

Q

1

Q

2

12

13

14

Q3

15

16

(Bottom View)

Figure 24A. External NPN Switch Figure 24B. External PNP Saturated Switch

Figure 24. External Current Boost Connections for I

k

Greater Than 3.4 A

Switch

http://onsemi.com

11

MC34163, MC33163

p

(

)

+

Thermal

45 k

+

+

+

-

Current

Limit

+

+

+

-

+

1.125 V

(Bottom View)

R

Q

S

Latch

+

Feedback

Comparator

15 k1.25 V

+

Q

1

60

2.0 mA

7.0 V

9

10

11

Q

2

12

13

Coilcraft LO451-A

14

L

180 µH

15

0.02

16

R

B

C

B

1N5822

V

out

2200

C

O

+

-12 V/1.0 A

V

in

12 V

C

470 pF

0.25 V

R

0.075

330

T

8

SC

7

+

6

+

Oscillator

C

in

5

4

3

2

1

LVI

R

2

R

953

1

8.2 k

Test Condition Results

Line Regulation Vin = 9.0 V to 16 V, IO = 1.0 A 5.0 mV = ±0.02%

Load Regulation Vin = 12 V, IO = 0.6 A to 1.0 A 2.0 mV = ±0.01%

Output Ripple V

Short Circuit Current V

Efficiency, Without Bootstrap V

Efficiency, With Bootstrap V

= 12 V, IO = 1.0 A 130 mVpp

in

= 12 V, RL = 0.1 Ω 3.2 A

in

= 12 V, IO = 1.0 A 73.1%

in

= 12 V, I

in

= 1.0 A 77.5%

O

Figure 25. Voltage–Inverting Converter

8

7

+

6

5

4

+

3

2

1

+

9

10

11

Q

1

Q

2

12

13

14

15

Q

3

16

(Bottom View)

8

7

+

6

5

4

+

3

2

1

+

9

10

11

Q

1

Q

2

12

13

14

15

16

(Bottom View)

Figure 26A. External NPN Switch Figure 26B. External PNP Saturated Switch

Figure 26. External Current Boost Connections for I

k

Greater Than 3.4 A

Switch

Q

3

http://onsemi.com

12

MC34163, MC33163

+

+

MC34163 Step–Down

++

+

+

V

in

+-

in

C

+

V

+

2

LVI

R

R

1

R

T

C

R

SC

Bottom View Top View

++

MC34163 Step–Up

++

+

V

in

+

-

in

C

+

+

V

+

2

LVI

R

R

1

R

T

C

R

SC

O

-

B

C

B

R

L

O

-

O

C

+

O

C

+

+

+

+

L

+

MC34163 Voltage–Inverting

+

Bottom View Top View

++

+

+

V

in

+

-

in

C

+

+

V

O

+

2

R

T

C

R

B

1

C

R

SC

Bottom View Top View

All printed circuit boards are 2.58" in width by 1.9" in height.

Figure 27. Printed Circuit Board and Component Layout

(Circuits of Figures 21, 23, 25)

+

-

O

C

B

R

+

L

+

http://onsemi.com

13

MC34163, MC33163

Calculation Step–Down Step–Up Voltage–Inverting

|V

t

on

t

(Notes 1, 2, 3)

off

V

out

Vin V

sat

V

F

V

out

V

out

VF–V

Vin–V

in

sat

| V

out

Vin V

F

sat

t

on

t

t

on

C

T

I

L(avg)

I

pk (Switch)

R

SC

Vin V

L

V

ripple(pp)

V

out

The following Converter Characteristics must be chosen:

I

L

t

on

ƒ

t

off

32.143 · 10

I

L(avg)

I

pk (Switch)

sat

I

1

ƒ

8C

O

V

ref

off

1

ƒ

I

out

0.25

L

2

R

R

2

1

–6

I

L

2

V

out

(ESR)

1

t

on

2

t

ƒ

t

32.143 · 10

I

out

I

L(avg)

I

pk (Switch)

Vin V

I

V

ref

t

on

t

off

on

off

ƒ

t

on

t

off

0.25

L

tonI

C

R

2

R

1

1

1

sat

out

O

1

–6

I

2

t

t

on

t

off

t

on

L

on

ƒ

32.143 · 10

I

out

I

L(avg)

I

pk (Switch)

Vin V

I

V

ref

t

off

t

t

ƒ

on

off

0.25

L

tonI

C

R

2

R

1

1

1

sat

out

O

1

–6

I

t

L

2

on

Nominal operating input voltage.

Vin –

Desired output voltage.

V

–

out

Desired output current.

–

I

out

Desired peak–to–peak inductor ripple current. For maximum output current it is suggested that

∆I

–

L

than 10% of the average inductor current I

threshold set by R

reduce converter output current capability.

Maximum output switch frequency.

–

V

ripple(pp)

NOTES: 1. V

NOTES: 2. V

NOTES: 3. The calculated t

NOTES: 3. operating input voltage.

Desired peak–to–peak output ripple voltage. For best performance the ripple voltage should be kept to a low value

–

since it will directly affect line and load regulation. Capacitor C

electrolytic designed for switching regulator applications.

– Saturation voltage of the output switch, refer to Figures 8 and 9.

sat

– Output rectifier forward voltage drop. Typical value for 1N5822 Schottky barrier rectifier is 0.5 V.

F

on/toff

∆I

be chosen to be less

. This will help prevent I

. If the design goal is to use a minimum inductance value, let ∆IL = 2(I

SC

must not exceed the minimum guaranteed oscillator charge to discharge ratio of 8, at the minimum

L(avg)

O

Figure 28. Design Equations

pk (Switch)

should be a low equivalent series resistance (ESR)

from reaching the current limit

L

). This will proportionally

L(avg)

http://onsemi.com

14

MC34163, MC33163

PACKAGE DIMENSIONS

PDIP–16

P SUFFIX

CASE 648C–04

ISSUE D

A

16 9

A

B

B

18

F

N

K

E

G

D

16X

0.005 (0.13) T

M

B

M

J

L

16X

0.005 (0.13) T

C

SEATING

T

PLANE

M

A

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD FLASH.

DIM MIN MAX MIN MAX

A 0.744 0.783 18.90 19.90

B 0.240 0.260 6.10 6.60

C 0.145 0.185 3.69 4.69

D 0.015 0.021 0.38 0.53

E 0.050 BSC 1.27 BSC

F 0.040 0.70 1.02 1.78

G 0.100 BSC 2.54 BSC

J 0.008 0.015 0.20 0.38

K 0.115 0.135 2.92 3.43

L 0.300 BSC 7.62 BSC

M 0 10 0 10

N 0.015 0.040 0.39 1.01

MILLIMETERSINCHES

SO–16W

DW SUFFIX

CASE 751G–03

ISSUE B

16 9

M

B

H8X

M

0.25

0.25 B

14X

D

B16X

M

S

A

T

e

A

NOTES:

1. DIMENSIONS ARE IN MILLIMETERS.

2. INTERPRET DIMENSIONS AND TOLERANCES

PER ASME Y14.5M, 1994.

E

h X 45

81

B

S

A

L

A1

T

SEATING

PLANE

C

3. DIMENSIONS D AND E DO NOT INLCUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.13 TOTAL IN EXCESS

OF THE B DIMENSION AT MAXIMUM MATERIAL

CONDITION.

MILLIMETERS

DIM MIN MAX

A 2.35 2.65

A1 0.10 0.25

B 0.35 0.49

C 0.23 0.32

D 10.15 10.45

E 7.40 7.60

e 1.27 BSC

H 10.05 10.55

h 0.25 0.75

L 0.50 0.90

0 7

http://onsemi.com

15

MC34163, MC33163

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

http://onsemi.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan 141–0031

Phone: 81–3–5740–2700

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

MC34163/D

16

Loading...

Loading...