MC14536B

Programmable Timer

The MC14536B programmable timer is a 24–stage binary ripple

counter with 16 stages selectable by a binary code. Provisions for an

on–chip RC oscillator or an external clock are provided. An on–chip

monostable circuit incorporating a pulse–type output has been

included. By selecting the appropriate counter stage in conjunction

with the appropriate input clock frequency, a variety of timing can be

achieved.

0

• 24 Flip–Flop Stages — Will Count From 2

• Last 16 Stages Selectable By Four–Bit Select Code

• 8–Bypass Input Allows Bypassing of First Eight Stages

• Set and Reset Inputs

• Clock Inhibit and Oscillator Inhibit Inputs

• On–Chip RC Oscillator Provisions

• On–Chip Monostable Output Provisions

• Clock Conditioning Circuit Permits Operation With Very Long Rise

and Fall Times

• Test Mode Allows Fast Test Sequence

• Supply Voltage Range = 3.0 Vdc to 18 Vdc

• Capable of Driving Two Low–power TTL Loads or One Low–power

Schottky TTL Load Over the Rated Temperature Range

MAXIMUM RATINGS (Voltages Referenced to V

Symbol

V

DD

Vin, V

Iin, I

P

T

T

stg

T

2. Maximum Ratings are those values beyond which damage to the device

may occur.

3. Temperature Derating:

Plastic “P and D/DW” Packages: – 7.0 mW/C From 65C To 125C

This device contains protection circuitry to guard against damage due to high

static voltages or electric fields. However, precautions must be taken to avoid

applications of any voltage higher than maximum rated voltages to this

high–impedance circuit. For proper operation, V

to the range V

Unused inputs must always be tied to an appropriate logic voltage level (e.g.,

either V

DC Supply Voltage Range –0.5 to +18.0 V

Input or Output Voltage Range

out

Input or Output Current

out

Power Dissipation,

D

Operating Temperature Range –55 to +125 °C

A

Storage Temperature Range –65 to +150 °C

Lead Temperature

L

SS

or VDD). Unused outputs must be left open.

SS

Parameter Value Unit

(DC or Transient)

(DC or Transient) per Pin

per Package (Note 3.)

(8–Second Soldering)

and V

(Vin or V

) VDD.

out

in

24

to 2

) (Note 2.)

SS

–0.5 to VDD + 0.5 V

±10 mA

500 mW

260 °C

should be constrained

out

http://onsemi.com

MARKING

DIAGRAMS

16

PDIP–16

P SUFFIX

CASE 648

SOIC–16

DW SUFFIX

CASE 751G

SOEIAJ–16

F SUFFIX

CASE 966

A = Assembly Location

WL, L = Wafer Lot

YY, Y = Year

WW, W = Work Week

MC14536BCP

AWLYYWW

1

16

14536B

AWLYYWW

1

16

MC14536B

ALYW

1

ORDERING INFORMATION

Device Package Shipping

MC14536BCP PDIP–16 2000/Box

MC14536BDW SOIC–16 47/Rail

MC14536BDWR2 SOIC–16 1000/Tape & Reel

MC14536BF SOEIAJ–16 See Note 1.

1. For ordering information on the EIAJ version of

the SOIC packages, please contact your local

ON Semiconductor representative.

Semiconductor Components Industries, LLC, 2001

February, 2001 – Rev. 7

1 Publication Order Number:

MC14536B/D

MC14536B

OSC. INHIBIT14

IN

1

3

OUT

SET

RESET

IN 1

OUT 1

OUT 2

8-BYPASS

CLOCK INH

V

1

2

3

4

6

7

8

SS

16

15

14

13

125

11

10

9

V

DD

MONO-IN

OSC INH

DECODE

D

C

B

A

Figure 1. Pin Assignment

A9

B10

C11

D12

8 BYPASSSETRESETCLOCK INH.

STAGES 9 THRU 24

Q24Q23Q22Q21Q20Q19Q18Q17Q16Q15Q14Q13Q12Q11Q10Q

9

DECODER

MONOSTABLE

MULTIVIBRATOR

13MONO-IN15

DECODE

OUT

7216

STAGES

1 THRU 8

4

5

OUT

1

2

V

= PIN 16

DD

V

= PIN 8

SS

Figure 2. Block Diagram

http://onsemi.com

2

MC14536B

ELECTRICAL CHARACTERISTICS (Voltages Referenced to V

SS

)

– 55C 25C 125C

Typ

(Note 4.)

0

0

0

5.0

10

15

2.25

4.50

6.75

2.75

5.50

8.25

– 1.7

– 0.36

– 0.9

– 3.5

– 4.2

– 0.88

– 2.25

– 8.8

0.88

2.25

8.8

0.010

0.020

0.030

Max Min Max

0.05

0.05

0.05

—

—

—

1.5

3.0

4.0

—

—

—

—

—

—

—

—

—

—

—

—

—

—

5.0

10

20

DD

DD

DD

—

—

—

4.95

9.95

14.95

—

—

—

3.5

7.0

11

– 0.7

– 0.14

– 0.35

– 1.1

– 1.7

– 0.36

– 0.9

– 2.4

0.36

0.9

2.4

—

—

—

0.05

0.05

0.05

Characteristic Symbol

Output Voltage “0” Level

V

= VDD or 0

in

“1” Level

V

= 0 or V

in

DD

Input Voltage “0” Level

(V

= 4.5 or 0.5 Vdc)

O

= 9.0 or 1.0 Vdc)

(V

O

(V

= 13.5 or 1.5 Vdc)

O

“1” Level

(V

= 0.5 or 4.5 Vdc)

O

= 1.0 or 9.0 Vdc)

(V

O

(V

= 1.5 or 13.5 Vdc)

O

Output Drive Current

(V

= 2.5 Vdc) Source

OH

= 4.6 Vdc) Pins 4 & 5

(V

OH

(V

= 9.5 Vdc)

OH

(V

= 13.5 Vdc)

OH

(VOH = 2.5 Vdc) Source

(V

= 4.6 Vdc) Pin 13

OH

= 9.5 Vdc)

(V

OH

(V

= 13.5 Vdc)

OH

(VOL = 0.4 Vdc) Sink

(V

= 0.5 Vdc)

OL

(V

= 1.5 Vdc)

OL

Input Current I

Input Capacitance

(V

= 0)

in

Quiescent Current

(Per Package)

Total Supply Current (Note 5., 6.)

(Dynamic plus Quiescent,

Per Package)

(C

= 50 pF on all outputs, all

L

V

DD

Vdc

V

OL

5.0

10

15

V

OH

5.0

10

15

V

IL

5.0

10

15

V

IH

5.0

10

15

I

OH

5.0

5.0

10

15

5.0

5.0

10

15

I

OL

5.0

10

15

in

C

in

I

DD

15 — ±0.1 — ±0.00001 ±0.1 — ±1.0 µAdc

— — — — 5.0 7.5 — — pF

5.0

10

15

I

T

5.0

10

15

Min Max Min

—

—

—

4.95

9.95

14.95

—

—

—

3.5

7.0

11

– 1.2

– 0.25

– 0.62

– 1.8

– 3.0

– 0.64

– 1.6

– 4.2

0.64

1.6

4.2

—

—

—

0.05

0.05

0.05

—

—

—

1.5

3.0

4.0

—

—

—

—

—

—

—

—

—

—

—

—

—

—

5.0

10

20

14.95

– 0.25

– 2.4

– 0.51

—

—

—

4.95

9.95

—

—

—

3.5

7.0

11

– 1.0

– 0.5

– 1.5

– 1.3

– 3.4

0.51

1.3

3.4

—

—

—

IT = (1.50 µA/kHz) f + I

IT = (2.30 µA/kHz) f + I

IT = (3.55 µA/kHz) f + I

buffers switching)

4. Data labelled “Typ” is not to be used for design purposes but is intended as an indication of the IC’s potential performance.

5. The formulas given are for the typical characteristics only at 25C.

6. To calculate total supply current at loads other than 50 pF:

IT(CL) = IT(50 pF) + (CL – 50) Vfk

where: I

is in µA (per package), CL in pF, V = (VDD – VSS) in volts, f in kHz is input frequency, and k = 0.003.

T

—

—

—

1.5

3.0

4.0

—

—

—

—

—

—

—

—

—

—

—

—

—

—

150

300

600

Unit

Vdc

Vdc

Vdc

Vdc

mAdc

mAdc

mAdc

µAdc

µAdc

http://onsemi.com

3

MC14536B

SWITCHING CHARACTERISTICS (Note 7.) (C

Characteristic Symbol V

= 50 pF, T

L

= 25C)

A

DD

Min Typ

Max Unit

(Note 8.)

Output Rise and Fall Time (Pin 13)

t

, t

TLH

t

TLH

t

TLH

= (1.5 ns/pF) CL + 25 ns

THL

, t

= (0.75 ns/pF) CL + 12.5 ns

THL

, t

= (0.55 ns/pF) CL + 9.5 ns

THL

Propagation Delay Time

Clock to Q1, 8–Bypass (Pin 6) High

, t

t

PLH

t

PLH

t

PLH

= (1.7 ns/pF) CL + 1715 ns

PHL

, t

= (0.66 ns/pF) CL + 617 ns

PHL

, t

= (0.5 ns/pF) CL + 425 ns

PHL

Clock to Q1, 8–Bypass (Pin 6) Low

t

, t

PLH

t

PLH

t

PLH

= (1.7 ns/pF) CL + 3715 ns

PHL

, t

= (0.66 ns/pF) CL + 1467 ns

PHL

, t

= (0.5 ns/pF) CL + 1075 ns

PHL

Clock to Q16

t

, t

PHL

t

PHL

t

PHL

Reset to Q

t

PHL

t

PHL

t

PHL

= (1.7 ns/pF) CL + 6915 ns

PLH

, t

= (0.66 ns/pF) CL + 2967 ns

PLH

, t

= (0.5 ns/pF) CL + 2175 ns

PLH

n

= (1.7 ns/pF) CL + 1415 ns

= (0.66 ns/pF) CL + 567 ns

= (0.5 ns/pF) CL + 425 ns

Clock Pulse Width t

Clock Pulse Frequency

(50% Duty Cycle)

Clock Rise and Fall Time t

t

TLH

t

t

PLH

t

t

PLH

t

t

PLH

t

t

TLH

t

THL

PHL

PHL

PHL

PHL

WH

f

cl

THL

,

5.0

10

15

—

—

—

100

50

40

200

100

80

,

5.0

10

15

—

—

—

1800

650

450

3600

1300

1000

,

5.0

10

15

—

—

—

3.8

1.5

1.1

7.6

3.0

2.3

,

5.0

10

15

5.0

10

15

5.0

10

15

5.0

10

15

,

5.0

10

—

—

—

—

—

—

600

200

170

—

—

—

7.0

3.0

2.2

1500

600

450

300

100

85

1.2

3.0

5.0

No Limit

14

6.0

4.5

3000

1200

900

—

—

—

0.4

1.5

2.0

15

Reset Pulse Width t

WH

5.0

10

15

1000

400

300

500

200

150

—

—

—

7. The formulas given are for the typical characteristics only at 25C.

8. Data labelled “Typ” is not to be used for design purposes but is intended as an indication of the IC’s potential performance.

ns

ns

µs

µs

ns

ns

MHz

—

ns

http://onsemi.com

4

MC14536B

PIN DESCRIPTIONS

INPUTS

SET (Pin 1) — A high on Set asynchronously forces

Decode Out to a high level. This is accomplished by setting

an output conditioning latch to a high level while at the same

time resetting the 24 flip–flop stages. After Set goes low

(inactive), the occurrence of the first negative clock

transition on IN

causes Decode Out to go low. The

1

counter’s flip–flop stages begin counting on the second

negative clock transition of IN

. When Set is high, the

1

on–chip RC oscillator is disabled. This allows for very

low–power standby operation.

RESET (Pin 2) — A high on Reset asynchronously

forces Decode Out to a low level; all 24 flip–flop stages are

also reset to a low level. Like the Set input, Reset disables

the on–chip RC oscillator for standby operation.

IN

(Pin 3) — The device’s internal counters advance on

1

the negative–going edge of this input. IN

may be used as an

1

external clock input or used in conjunction with OUT1 and

OUT2 to form an RC oscillator. When an external clock is

used, both OU T1 and OU T2 may be left unconnected or

used to drive 1 LSTTL or several CMOS loads.

8–BYPASS (Pin 6) — A high on this input causes the first

8 flip–flop stages to be bypassed. This device essentially

becomes a 16–stage counter with all 16 stages selectable.

Selection is accomplished by the A, B, C, and D inputs. (See

the truth tables.)

CLOCK INHIBIT (Pin 7) — A high on this input

disconnects the first counter stage from the clocking source.

This holds the present count and inhibits further counting.

However, the clocking source may continue to run.

Therefore, when Clock Inhibit is brought low, no oscillator

start–up time is required. When Clock Inhibit is low, the

counter will start counting on the occurrence of the first

negative edge of the clocking source at IN

.

1

OSC INHIBIT (Pin 14) — A high level on this pin stops

the RC oscillator which allows for very low–power standby

operation. May also be used, in conjunction with an external

clock, with essentially the same results as the Clock Inhibit

input.

MONO–IN (Pin 15) — Used as the timing pin for the

on–chip monostable multivibrator. If the Mono–In input is

connected to V

, the monostable circuit is disabled, and

SS

Decode Out is directly connected to the selected Q output.

The monostable circuit is enabled if a resistor is connected

between Mono–In and V

. This resistor and the device’s

DD

internal capacitance will determine the minimum output

pulse widths. With the addition of an external capacitor to

V

, the pulse width range may be extended. For reliable

SS

operation the resistor value should be limited to the range of

5 kΩ to 100 kΩ and the capacitor value should be limited to

a maximum of 1000 pf. (See figures 3, 4, 5, and 10).

A, B, C, D (Pins 9, 10, 11, 12) — These inputs select the

flip–flop stage to be connected to Decode Out. (See the truth

tables.)

OUTPUTS

OUT1, OUT2 (Pin 4, 5) — Outputs used in conjunction

with IN1 to form an RC oscillator. These outputs are

buffered and may be used for 2

0

frequency division of an

external clock.

DECODE OUT (Pin 13) — Output function depends on

configuration. When the monostable circuit is disabled, this

output is a 50% duty cycle square wave during free run.

TEST MODE

The test mode configuration divides the 24 flip–flop

stages into three 8–stage sections to facilitate a fast test

sequence. The test mode is enabled when 8–Bypass, Set a nd

Reset are at a high level. (See Figure 8.)

http://onsemi.com

5

Input

Stage Selected

Stage Selected

8–Bypass D C B A

0 0 0 0 0 9

0 0 0 0 1 10

0 0 0 1 0 11

0 0 0 1 1 12

0 0 1 0 0 13

0 0 1 0 1 14

0 0 1 1 0 15

0 0 1 1 1 16

0 1 0 0 0 17

0 1 0 0 1 18

0 1 0 1 0 19

0 1 0 1 1 20

0 1 1 0 0 21

0 1 1 0 1 22

0 1 1 1 0 23

0 1 1 1 1 24

TRUTH TABLES

for Decode Out

MC14536B

8–Bypass D C B A

Input

for Decode Out

1 0 0 0 0 1

1 0 0 0 1 2

1 0 0 1 0 3

1 0 0 1 1 4

1 0 1 0 0 5

1 0 1 0 1 6

1 0 1 1 0 7

1 0 1 1 1 8

1 1 0 0 0 9

1 1 0 0 1 10

1 1 0 1 0 11

1 1 0 1 1 12

1 1 1 0 0 13

1 1 1 0 1 14

1 1 1 1 0 15

1 1 1 1 1 16

FUNCTION TABLE

Clock

In

X 1 0 0 0 0 1 1

X 0 1 0 0 0 1 0

X 0 0 1 0 — — No

X 0 0 0 1 0 1 No

0 0 0 0 X 0 1 No

1 0 0 0 Advance to

X = Don’t Care

1

Set Reset

0 0 0 0 No

0 0 0 0 Advance to

Inh

OSC

Inh

Out 1 Out 2

Decode

Out

Change

next state

Change

Change

Change

next state

http://onsemi.com

6

8-BYPASS

MC14536B

LOGIC DIAGRAM

2417

23

STAGES

18 THRU

OUT

DECODER

16

15

STAGES

10 THRU

9

6

T

C11

A9

B10

D12

DECODER

13

= PIN 8

= PIN 16

SS

DD

V

V

15

MONO-IN

2

RESET

14

OSC INHIBIT

3

8

STAGES

2 THRU 7

1

T

Q

S

R

En

C

OUT 2 5

4

OUT 1

1

IN

SET

7

CLOCK

INHIBIT

1

http://onsemi.com

7

TYPICAL RC OSCILLATOR CHARACTERISTICS

(For Circuit Diagram See Figure 11 In Application)

8.0

VDD = 15 V

4.0

0

10 V

-4.0

-8.0

FREQUENCY DEVIATION (%)

-12

= 56 kΩ,

R

TC

C = 1000 pF

-16

-55 -25 0 25 50 75 100 125

*Device Only.

RS = 0, f = 10.15 kHz @ VDD = 10 V, T

R

= 120 kΩ, f = 7.8 kHz @ V

S

T

, AMBIENT TEMPERATURE (°C)*

A

5.0 V

= 10 V, T

DD

A

Figure 1. RC Oscillator Stability Figure 2. RC Oscillator Frequency as a

MONOSTABLE CHARACTERISTICS

(For Circuit Diagram See Figure 10 In Application)

100

FORMULA FOR CALCULATING tW IN

MICROSECONDS IS AS FOLLOWS:

= 0.00247 R

t

W

WHERE R IS IN kΩ, C

µs)

10

X

• C

X

0.85

IN pF.

X

MC14536B

= 25°C

= 25°C

A

100

50

20

10

VDD = 10 V

f AS A FUNCTION

OF R

TC

(C = 1000 pF)

(R

≈ 2R

)

S

TC

5.0

f AS A FUNCTION

2.0

1.0

0.5

f, OSCILLATOR FREQUENCY (kHz)

0.2

0.1

1.0 k 10 k 100 k 1.0 M

0.0001 0.001 0.01 0.1

(R

(R

OF C

= 56 kΩ)

TC

= 120 k)

S

R

, RESISTANCE (OHMS)

TC

C, CAPACITANCE (µF)

Function of RTC and C

100

FORMULA FOR CALCULATING tW IN

MICROSECONDS IS AS FOLLOWS:

= 0.00247 R

t

W

WHERE R IS IN kΩ, C

µs)

10

• C

0.85

X

X

IN pF.

X

R

= 100 kΩ

X

50 kΩ

1.0

, PULSE WIDTH (t

W

0.1

10 kΩ

5 kΩ

, EXTERNAL CAPACITANCE (pF)

C

X

T

= 25°C

A

V

DD

= 5 V

1000100101.0

Figure 3. T ypical CX versus Pulse Width

@ VDD = 5.0 V

100

FORMULA FOR CALCULATING tW IN

R

= 100 kΩ

X

50 kΩ

1.0

, PULSE WIDTH (t

W

0.1

10 kΩ

5 kΩ

C

, EXTERNAL CAPACITANCE (pF)

X

T

V

= 25°C

A

= 10 V

DD

1000100101.0

Figure 4. Typical CX versus Pulse Width

@ VDD = 10 V

MICROSECONDS IS AS FOLLOWS:

= 0.00247 R

t

W

WHERE R IS IN kΩ, C

µs)

10

R

= 100 kΩ

X

1.0

, PULSE WIDTH (t

W

50 kΩ

10 kΩ

5 kΩ

0.1

• C

0.85

X

X

IN pF.

X

, EXTERNAL CAPACITANCE (pF)

C

X

T

A

V

DD

= 25°C

= 15 V

1000100101.0

Figure 5. T ypical CX versus Pulse Width

@ V

= 15 V

DD

http://onsemi.com

8

500 µF

MC14536B

V

DD

0.01 µF

I

D

CERAMIC

SET

RESET

PULSE

GENERATOR

20 ns

8-BYPASS

IN

1

C INH

MONO-IN

OSC INH

A

B

C

D

90%

10%

50%

DUTY CYCLE

OUT 1

OUT

DECODE

OUT

V

50%

SS

C

L

2

C

20 ns

L

C

L

PULSE

GENERATOR

Figure 6. Power Dissipation Test

Circuit and Waveform

FUNCTIONAL TEST SEQUENCE

Test function (Figure 8) has been included for the

reduction of test time required to exercise all 24 counter

stages. This test function divides the counter into three

8–stage sections and 255 counts are loaded in each of the

8–stage sections in parallel. All flip–flops are now at a “1”.

The counter is now returned to the normal 24–stages in

series configuration. One more pulse is entered into In

which will cause the counter to ripple from an all “1” state

to an all “0” state.

20 ns

50%

t

TLH

SET

RESET

8-BYPASS

IN

1

C INH

MONO-IN

OSC INH

A

B

C

DECODE

D

V

DD

OUT 1

OUT

OUT

V

SS

20 ns

IN

1

t

WL

OUT

t

PLH

2

C

L

90%

10%

Figure 7. Switching Time Test Circuit and Waveforms

V

DD

SET

RESET

PULSE

GENERATOR

1

8-BYPASS

IN

1

C INH

MONO-IN

OSC INH

A

B

C

DECODE

D

OUT 1

OUT

OUT

V

SS

2

t

THL

t

WH

50%

t

PHL

http://onsemi.com

9

Figure 8. Functional Test Circuit

MC14536B

All 24 stages are in Reset mode

FUNCTIONAL TEST SEQUENCE

Inputs Outputs Comments

Decade Out

In

1 0 1 1 0

1 1 1 1 0 Counter is in three 8 stage sections in parallel mode.

0 1 1 1 0 First “1” to “0” transition of clock.

1

0

—

—

—

0 1 1 1 1 The 255 “1” to “0” transition.

0 0 0 0 1 Counter converted back to 24 stages in series mode.

1 0 0 0 1 In1 Switches to a “1”.

0 0 0 0 0 Counter Ripples from an all “1” state to an all “0” state.

Set Reset 8–Bypass

1

1 1 1 255 “1” to “0” transitions are clocked in the counter.

Q1 thru Q24

All 24 stages are in Reset mode.

Set and Reset must be connected together and simultaneously

go from “1” to “0”.

.

http://onsemi.com

10

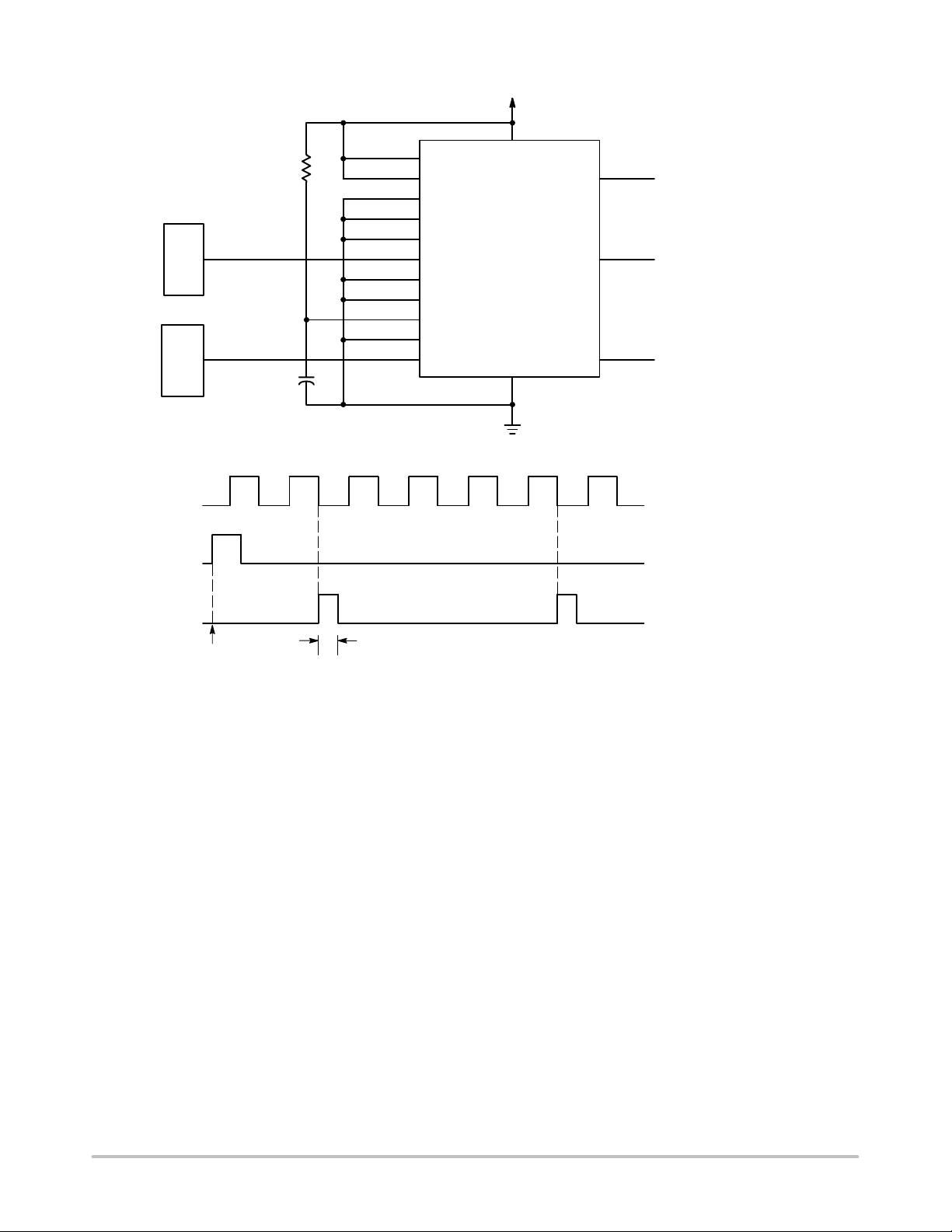

PULSE

GEN.

PULSE

GEN.

CLOCK

IN

1

MC14536B

+V

16

6

8-BYPASS

9

A

10

B

11

C

12

D

2

RESET

14

OSC INH

15

MONO-IN

1

SET

7

CLOCK INH

313

IN

1

V

DD

DECODE OUT

V

SS

8

OUT 1

OUT 2

4

5

SET

CLOCK INH

DECODE OUT

POWER UP

NOTE: When power is first applied to the device, DECODE OUT can be either at a high or low state.

On the rising edge of a SET pulse the output goes high if initially at a low state. The output

remains high if initially at a high state. Because CLOCK INH is held high, the clock source

on the input pin has no effect on the output. Once CLOCK INH is taken low , the output goes

low on the first negative clock transition. The output returns high depending on the 8–BYPASS, A, B, C, and D inputs, and the clock input period. A 2

= the number of stages selected from the truth table) is obtainable at DECODE OUT. A

0

–divided output of IN1 can be obtained at OUT1 and OUT2.

2

n

frequency division (where n

Figure 9. Time Interval Configuration Using an External Clock, Set,

and Clock Inhibit Functions

(Divide–by–2 Configured)

http://onsemi.com

11

PULSE

GEN.

CLOCK

IN

MC14536B

+V

16

6

R

X

C

X

1

8-BYPASS

9

A

10

B

11

C

12

D

2

RESET

1

SET

7

CLOCK INH

15

MONO-IN

14

OSC INH

313

IN

1

V

DD

DECODE OUT

V

SS

8

OUT 1

OUT 2

4

5

RESET

*tw ≈ .00247 • RX • CX0.85

t

in µsec

DECODE OUT

*t

w

w

R

C

in kΩ

X

in pF

X

POWER UP

NOTE: When Power is first applied to the device with the RESET input going high, DECODE OUT initializes low. Bringing the

RESET input low enables the chip’s internal counters. After RESET goes low, the 2

n

/2 negative transition of the clock

input causes DECODE OUT to go high. Since the MONO–IN input is being used, the output becomes monostable. The

pulse width of the output is dependent on the external timing components. The second and all subsequent pulses occur

n

at 2

x (the clock period) intervals where n = the number of stages selected from the truth table.

Figure 10. Time Interval Configuration Using an External Clock, Reset,

and Output Monostable to Achieve a Pulse Output

(Divide–by–4 Configured)

http://onsemi.com

12

PULSE

GEN.

MC14536B

+V

R

16

6

8-BYPASS

9

A

10

B

11

C

12

D

2

RESET

14

OSC INH

15

MONO-IN

1

SET

7

CLOCK INH

313

IN

1

V

DD

DECODE OUT

V

SS

OUT 1

OUT 2

4

5

8

S

C

R

TC

RESET

OUT 1

OUT 2

1

2.3RtcC

tc

≥ R

= Hz

= Ohms

= FARADS

DECODE OUT

POWER UP

f

osc

R

s

t

w

F

R

C

NOTE: This circuit is designed to use the on–chip oscillation function. The oscillator frequency is deter-

mined by the external R and C components. When power is first applied to the device, DECODE

OUT initializes to a high state. Because this output is tied directly to the OSC INH input, the oscillator

is disabled. This puts the device in a low–current standby condition. The rising edge of the RESET

pulse will cause the output to go low . This in turn causes OSC INH to go low. However, while RESET

is high, the oscillator is still disabled (i.e.: standby condition). After RESET goes low, the output remains low for 2

n

/2 of the oscillator’s period. After the part times out, the output again goes high.

Figure 11. Time Interval Configuration Using On–Chip RC Oscillator and

Reset Input to Initiate Time Interval

(Divide–by–2 Configured)

http://onsemi.com

13

PACKAGE DIMENSIONS

PLASTIC DIP PACKAGE

–A–

916

B

18

F

H

G

D

16 PL

0.25 (0.010) T

C

S

SEATING

–T–

PLANE

K

M

A

MC14536B

PDIP–16

P SUFFIX

CASE 648–08

ISSUE R

J

M

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD FLASH.

5. ROUNDED CORNERS OPTIONAL.

DIM MIN MAX MIN MAX

L

M

A 0.740 0.770 18.80 19.55

B 0.250 0.270 6.35 6.85

C 0.145 0.175 3.69 4.44

D 0.015 0.021 0.39 0.53

F 0.040 0.70 1.02 1.77

G 0.100 BSC 2.54 BSC

H 0.050 BSC 1.27 BSC

J 0.008 0.015 0.21 0.38

K 0.110 0.130 2.80 3.30

L 0.295 0.305 7.50 7.74

M 0 10 0 10

S 0.020 0.040 0.51 1.01

MILLIMETERSINCHES

16 9

M

B

H8X

M

0.25

0.25 B

14X

SOIC–16

DW SUFFIX

PLASTIC SOIC PACKAGE

CASE 751G–03

ISSUE B

D

B16X

M

S

A

T

e

A

NOTES:

1. DIMENSIONS ARE IN MILLIMETERS.

2. INTERPRET DIMENSIONS AND TOLERANCES

PER ASME Y14.5M, 1994.

E

h X 45

81

B

S

A

L

A1

SEATING

PLANE

T

C

3. DIMENSIONS D AND E DO NOT INLCUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.13 TOTAL IN EXCESS

OF THE B DIMENSION AT MAXIMUM MATERIAL

CONDITION.

MILLIMETERS

DIM MIN MAX

A 2.35 2.65

A1 0.10 0.25

B 0.35 0.49

C 0.23 0.32

D 10.15 10.45

E 7.40 7.60

e 1.27 BSC

H 10.05 10.55

h 0.25 0.75

L 0.50 0.90

0 7

http://onsemi.com

14

16 9

1

Z

D

e

b

0.13 (0.005)

M

8

H

E

E

A

A

1

0.10 (0.004)

MC14536B

PACKAGE DIMENSIONS

SOEIAJ–16

F SUFFIX

PLASTIC EIAJ SOIC PACKAGE

CASE 966–01

ISSUE O

L

E

M

L

DETAIL P

VIEW P

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS D AND E DO NOT INCLUDE MOLD

FLASH OR PROTRUSIONS AND ARE MEASURED

Q

1

c

AT THE PARTING LINE. MOLD FLASH OR

PROTRUSIONS SHALL NOT EXCEED 0.15 (0.006)

PER SIDE.

4. TERMINAL NUMBERS ARE SHOWN FOR

REFERENCE ONLY.

5. THE LEAD WIDTH DIMENSION (b) DOES NOT

INCLUDE DAMBAR PROTRUSION. ALLOWABLE

DAMBAR PROTRUSION SHALL BE 0.08 (0.003)

TOTAL IN EXCESS OF THE LEAD WIDTH

DIMENSION AT MAXIMUM MATERIAL CONDITION.

DAMBAR CANNOT BE LOCATED ON THE LOWER

RADIUS OR THE FOOT. MINIMUM SPACE

BETWEEN PROTRUSIONS AND ADJACENT LEAD

TO BE 0.46 ( 0.018).

MILLIMETERS

DIM MIN MAX MIN MAX

--- 2.05 --- 0.081

A

A

0.05 0.20 0.002 0.008

1

0.35 0.50 0.014 0.020

b

0.18 0.27 0.007 0.011

c

9.90 10.50 0.390 0.413

D

5.10 5.45 0.201 0.215

E

1.27 BSC 0.050 BSC

e

H

7.40 8.20 0.291 0.323

E

0.50 0.85 0.020 0.033

L

L

1.10 1.50 0.043 0.059

E

0

M

Q

0.70 0.90 0.028 0.035

1

--- 0.78 --- 0.031

Z

INCHES

10

10

0

http://onsemi.com

15

MC14536B

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 Toll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone: (+1) 303–308–7140 (Mon–Fri 2:30pm to 7:00pm CET)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (Mon–Fri 2:00pm to 7:00pm CET)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (Mon–Fri 12:00pm to 5:00pm GMT)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, UK, Ireland

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

Toll–Free from Mexico: Dial 01–800–288–2872 for Access –

then Dial 866–297–9322

ASIA/PACIFIC: LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

Toll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan 141–0031

Phone: 81–3–5740–2700

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

http://onsemi.com

16

MC14536B/D

Loading...

Loading...