MC10EP195, MC100EP195

3.3V ECL Programmable

Delay Chip

The MC10/100EP195 is a Programmable Delay Chip (PDC)

designed primarily for clock deskewing and timing adjustment. It

provides variable delay of a differential NECL/PECL input transition.

The delay section consists of a programmable matrix of gates and

multiplexers as shown in the logic diagram, Figure 3. The delay

increment of the EP195 has a digitally selectable resolution of about

10 ps and a net range of up to 10.2 ns. The required delay is selected by

the 10 data select inputs D[9:0] values and controlled by the LEN

(pin 10). A LOW level on LEN allows a transparent LOAD mode of

real time delay values by D[9:0]. A LOW to HIGH transition on LEN

will LOCK and HOLD current values present against any subsequent

changes in D[10:0]. The approximate delay values for varying tap

numbers correlating to D0 (LSB) through D9 (MSB) are shown in

Table 6 and Figure 4.

Because the EP195 is designed using a chain of multiplexers it has a

fixed minimum delay of 2.2 ns. An additional pin D10 is provided for

controlling Pins 14 and 15, CASCADE and CASCADE

by LEN, in cascading multiple PDCs for increased programmable

range. The cascade logic allows full control of multiple PDCs.

Switching devices from all “1” states on D[0:9] with SETMAX LOW

to all “0” states on D[0:9] with SETMAX HIGH will increase the

delay equivalent to “D0”, the minimum increment.

Select input pins D[10:0] may be threshold controlled by

combinations of interconnects between V

(pin 7) and VCF (pin 8)

EF

for LVCMOS, ECL, or LVTTL level signals. For LVCMOS input

levels, leave V

V

(Pins 7 and 8). For LVTTL level operation, connect a 1.5 V

EF

supply reference to V

voltage to V

between V

The V

BB

and VEF open. For ECL operation, short VCF and

CF

and leave open VEF pin. The 1.5 V reference

CF

pin can be accomplished by placing a 2.2 kW resistor

CF

and VEE for a 3.3 V power supply.

CF

pin, an internally generated voltage supply, is available to

this device only. For single−ended input conditions, the unused

differential input is connected to V

V

may also rebias AC coupled inputs. When used, decouple V

BB

as a switching reference voltage.

BB

and VCC via a 0.01 mF capacitor and limit current sourcing or sinking

to 0.5 mA. When not used, V

should be left open.

BB

The 100 Series contains temperature compensation.

• Maximum Input Clock Frequency >1.2 GHz Typical

• Programmable Range: 0 ns to 10 ns

• Delay Range: 2.2 ns to 12.2 ns

• 10 ps Increments

• PECL Mode Operating Range:

= 3.0 V to 3.6 V with VEE = 0 V

V

CC

• NECL Mode Operating Range:

= 0 V with VEE = −3.0 V to −3.6 V

V

CC

, also latched

BB

• Open Input Default State

• Safety Clamp on Inputs

• A Logic High on the EN Pin Will Force Q to Logic

Low

• D[10:0] Can Accept Either ECL, LVCMOS, or LVTTL

Inputs

• V

• Pb−Free Packages are Available

http://onsemi.com

MARKING

DIAGRAM*

AWLYYWWG

LQFP−32

FA SUFFIX

CASE 873A

32

1

QFN32

MN SUFFIX

CASE 488AM

XXX = 10 or 100

A = Assembly Location

WL, L = Wafer Lot

YY, Y = Year

WW, W = Work Week

G or G = Pb−Free Package

(Note: Microdot may be in either location)

*For additional marking information, refer to

Application Note AND8002/D.

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 17 of this data sheet.

Output Reference Voltage

BB

32

1

1

AWLYYWWG

MCXXX

EP195

MCXXX

EP195

G

© Semiconductor Components Industries, LLC, 2006

December, 2006 − Rev. 16

1 Publication Order Number:

MC10EP195/D

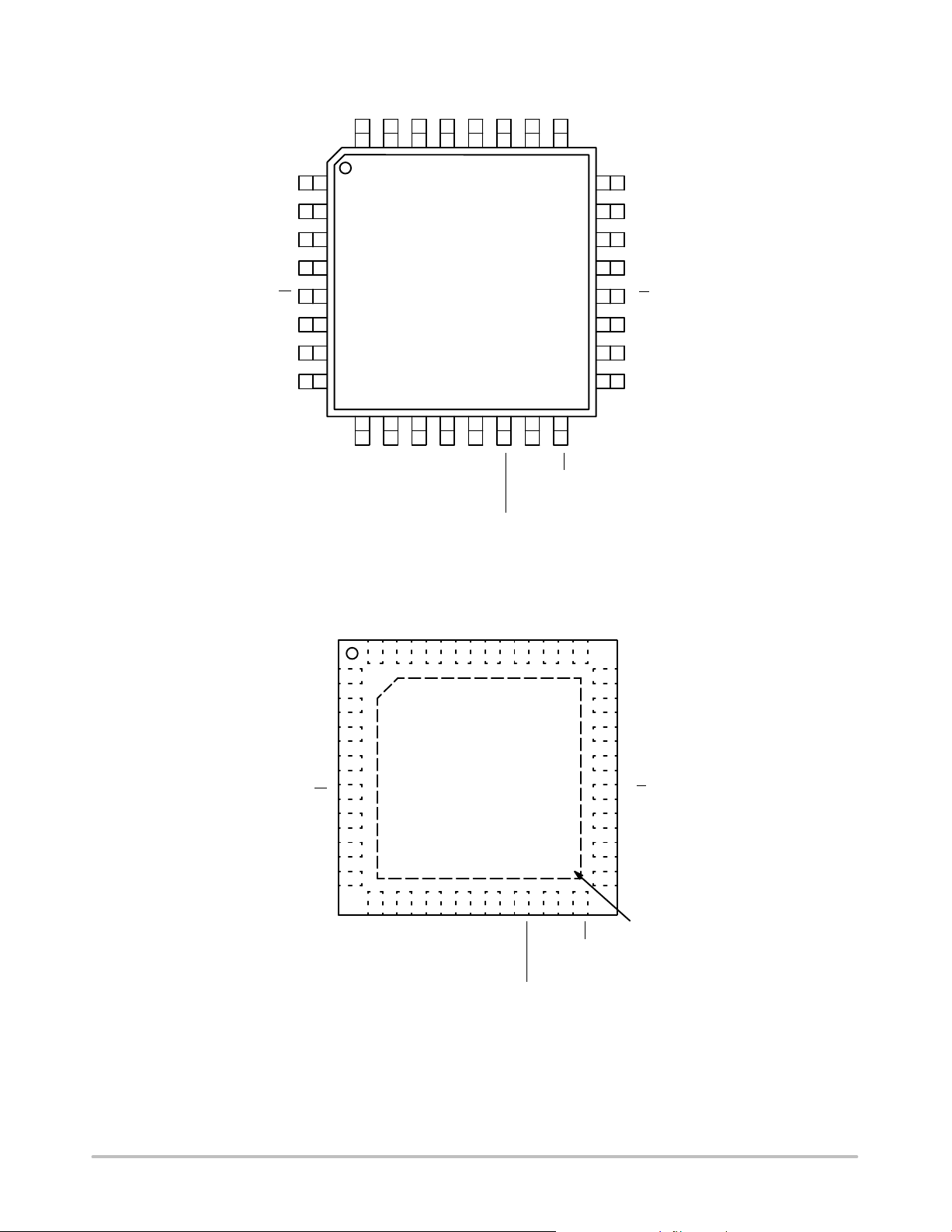

MC10EP195, MC100EP195

D8

D9

D10

IN

IN

V

BB

V

EF

V

CF

D7

D6

D5

D4

EE

V

D3

D2

D1

2526272829303132

1

2

3

4

5

6

7

8

VEELEN

MC10EP195

MC100EP195

SETMAX

SETMIN

CC

V

CASCADE

24

23

22

21

20

19

18

17

16

1514131211109

CASCADE

EN

Figure 1. 32−Lead LQFP Pinout (Top View)

V

D0

V

V

V

NC

EE

CC

Q

Q

CC

CC

D8

D9

D10

IN

IN

V

BB

V

EF

V

CF

V

EE

CC

V

D3

CASCADE

D4

D5

D6

D7

32 31 30 29 28 27 26 25

1

2

3

4

5

6

7

8

9 10 1112 1314 1516

VEELEN

SETMAX

SETMIN

Figure 2. 32−Lead QFN (Top View)

D2

D1

CASCADE

EN

24

V

EE

23

D0

22

V

CC

21

Q

20

Q

V

19

CC

V

18

CC

17

NC

Exposed Pad (EP)

http://onsemi.com

2

MC10EP195, MC100EP195

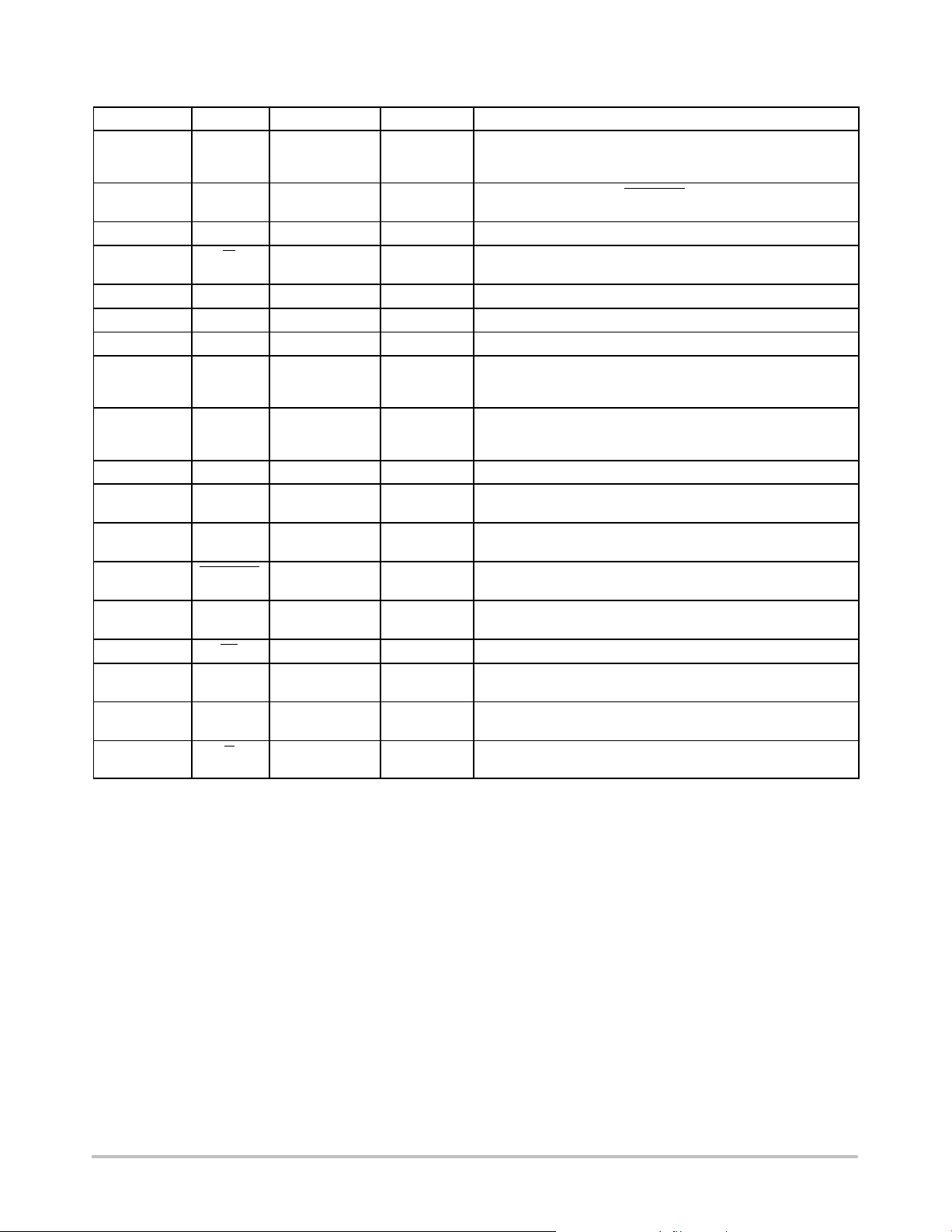

Table 1. PIN DESCRIPTION

Pin Name I/O Default State Description

23, 25, 26, 27,

29, 30, 31, 32,

1, 2

3 D[10] LVCMOS, LVTTL,

4 IN ECL Input Low

5 IN ECL Input High

6 V

7 V

8 V

9, 24, 28 V

13, 18, 19, 22 V

10 LEN ECL Input Low

11 SETMIN ECL Input Low

12 SETMAX ECL Input Low

14 CASCADE ECL Output − Inverted Differential Cascade Output for D[10]. Typically Terminated

15 CASCADE ECL Output − Noninverted Differential Cascade Output. for D[10] Typically

16 EN ECL Input Low

17 NC − − No Connect. The NC Pin is Electrically Connected to the Die and

21 Q ECL Output −

20 Q ECL Output −

1. SETMIN will override SETMAX if both are high. SETMAX and SETMIN will override all D[0:10] inputs.

2. All V

and VEE pins must be externally connected to Power Supply to guarantee proper operation.

CC

D[0:9] LVCMOS, LVTTL,

ECL Input

ECL Input

BB

EF

CF

EE

CC

− − ECL Reference Voltage Output

− − Reference Voltage for ECL Mode Connection

− − LVCMOS, ECL, OR LVTTL Input Mode Select

− − Negative Supply Voltage. All VEE Pins must be Externally

− − Positive Supply Voltage. All VCC Pins must be externally

Low

Low

Single−Ended Parallel Data Inputs [0:9]. Internal 75 kW to VEE.

(Note 1)

Single−Ended CASCADE/CASCADE Control Input. Internal 75 kW

to V

. (Note 1)

EE

Noninverted Differential Input. Internal 75 kW to VEE.

Inverted Differential Input. Internal 75 kW to VEE and 36.5 kW to

V

.

CC

Connected to Power Supply to Guarantee Proper Operation.

(Note 2)

Connected to Power Supply to Guarantee Proper Operation.

(Note 2)

Single−ended D pins LOAD / HOLD input. Internal 75 kW to VEE.

Single−ended Minimum Delay Set Logic Input. Internal 75 kW to

V

. (Note 1)

EE

Single−ended Maximum Delay Set Logic Input. Internal 75 kW to

V

. (Note 1)

EE

with 50 W to V

Terminated with 50 W to V

= VCC − 2 V.

TT

= VCC − 2 V.

TT

Single−ended Output Enable Pin. Internal 75 kW to VEE.

”MUST BE” Left Open

Noninverted Differential Output. Typically Terminated with 50 W to

V

= VCC − 2 V.

TT

Inverted Differential Output. Typically Terminated with 50 W to

VTT = VCC − 2 V.

http://onsemi.com

3

MC10EP195, MC100EP195

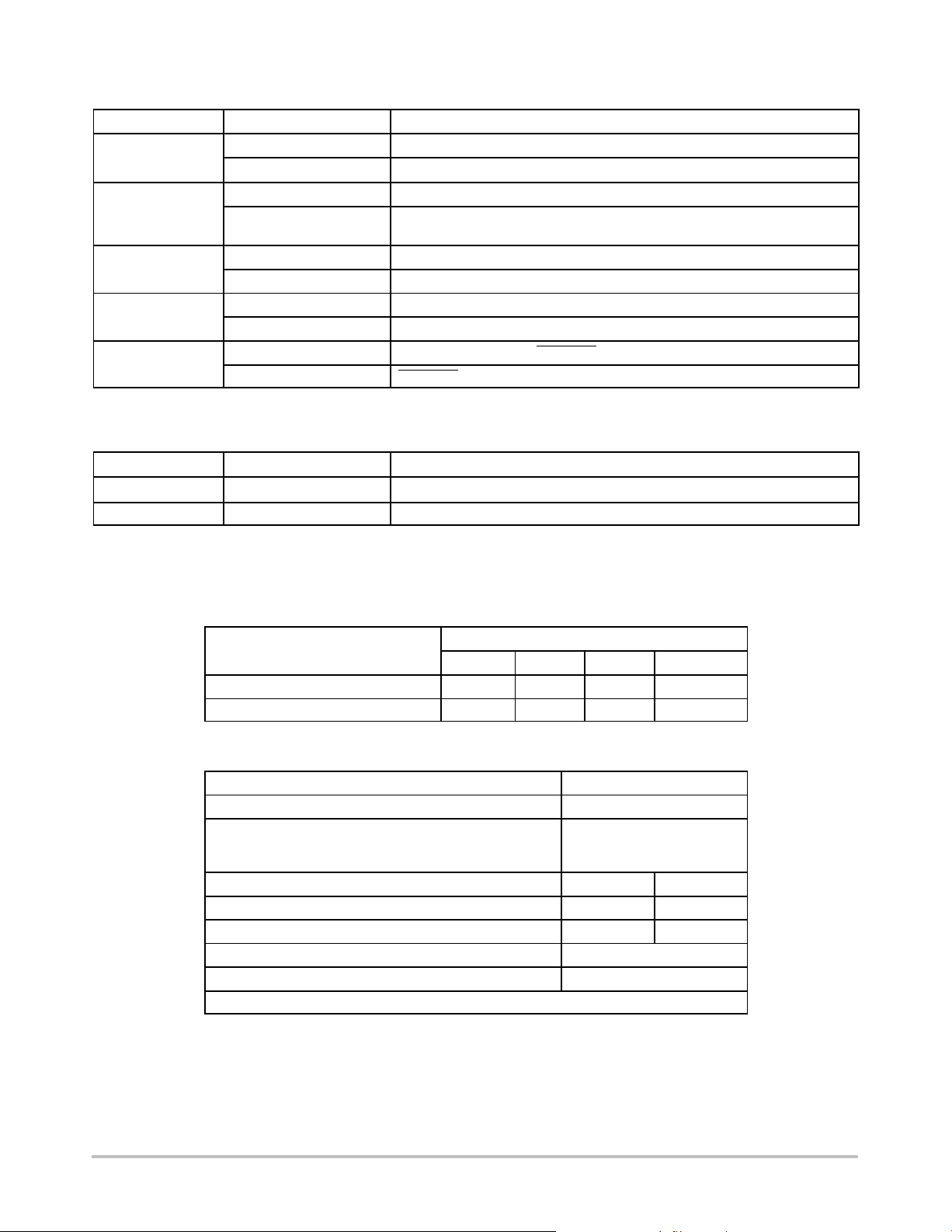

Table 2. CONTROL PIN

Pin State Function

EN

LEN

SETMIN

SETMAX

D10

3. Internal pulldown resistor will provide a logic LOW if pin is left unconnected.

Table 3. CONTROL D[0:10] INTERFACE

V

CF

V

CF

V

CF

4. Short VCF (pin 8) and VEF (pin 7).

5. When Operating in LVTTL Mode, the reference voltage can be provided by connecting an external resistor, R

is 2.2 kW $5%), between V

LOW (Note 3) Input Signal is Propagated to the Output

HIGH Output Holds Logic Low State

LOW (Note 3) Transparent or LOAD mode for real time delay values present on D[0:10].

HIGH LOCK and HOLD mode for delay values on D[0:10]; further changes on D[0:10]

LOW (Note 3) Output Delay set by D[0:10]

HIGH Set Minimum Output Delay

LOW (Note 3) Output Delay set by D[0:10]

HIGH Set Maximum Output Delay

LOW (Note 3) CASCADE Output LOW, CASCADE Output HIGH

HIGH CASCADE Output LOW, CASCADE Output HIGH

VEF Pin (Note 4) ECL Mode

No Connect LVCMOS Mode

1.5 V $ 100 mV LVTTL Mode (Note 5)

and VEE pins.

CF

are not recognized and do not affect delay.

(suggested resistor value

CF

Table 4. DATA INPUT ALLOWED OPERATING VOLTAGE MODE TABLE

CONTROL DATA SELECT INPUTS PINS (D [0:10])

POWER SUPPLY

PECL Mode Operating Range YES YES YES N/A

NECL Mode Operating Range N/A N/A N/A YES

LVCMOS LVTTL LVPECL LVNECL

Table 5. ATTRIBUTES

Characteristics Value

Internal Input Pulldown Resistor (R1)

ESD Protection Human Body Model

Machine Model

Charged Device Model

Moisture Sensitivity, Indefinite Time Out of Drypack (Note 6) Pb Pkg Pb−Free Pkg

LQFP−32 Level 2 Level 2

QFN−32 − Level 1

Flammability Rating Oxygen Index: 28 to 34 UL 94 V−0 @ 0.125 in

Transistor Count 1217 Devices

Meets or exceeds JEDEC Spec EIA/JESD78 IC Latchup Test

6. For additional information, see Application Note AND8003/D.

75 kW

> 2 kV

> 100 V

> 2 kV

http://onsemi.com

4

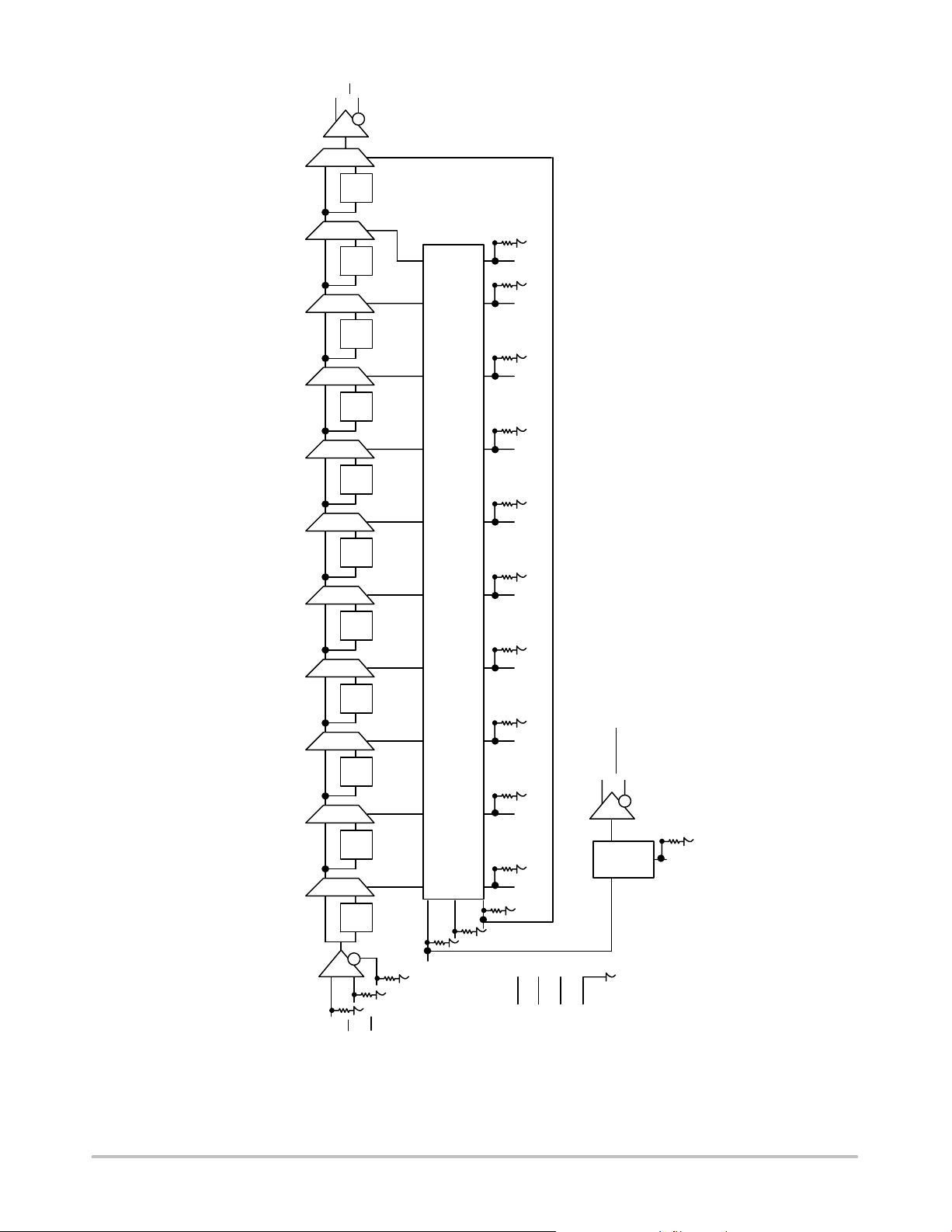

MC10EP195, MC100EP195

Q

Q

0

1

1

GD*

0

1

0

1

1

1

GD*

GD*

0

1

2

GD*

0

1

4

GD*

0

1

8

GD*

R1R1R1R1R1R1R1R1R1R1

D0D1D2D3D4D5D6D7D8D9

0

1

16

GD*

0

1

10 BIT LATCH

(MINIMUM FIXED DELAY APPROX. 2.2 ns)

32

GD*

*GD = (GATE DELAY) APPROXIMATELY 10 ps DELAY PER GATE

0

1

64

GD*

0

1

CASCADE

128

GD*

0

1

256

GD*

0

1

512

GD*

R1

R1

R1

IN

IN

EN

R1

LEN

R1

SET MIN

SET MAX

R1

BBVCFVEF

V

CASCADE

R1

Latch

EE

V

D10

Figure 3. Logic Diagram

http://onsemi.com

5

Table 6. THEORETICAL DELAY VALUES

D(9:0) Value SETMIN SETMAX Programmable Delay*

XXXXXXXXXX H L 0 ps

0000000000 L L 0 ps

0000000001 L L 10 ps

0000000010 L L 20 ps

0000000011 L L 30 ps

0000000100 L L 40 ps

0000000101 L L 50 ps

0000000110 L L 60 ps

0000000111 L L 70 ps

0000001000 L L 80 ps

0000010000 L L 160 ps

0000100000 L L 320 ps

0001000000 L L 640 ps

0010000000 L L 1280 ps

0100000000 L L 2560 ps

1000000000 L L 5120 ps

1111111111 L L 10230 ps

XXXXXXXXXX L H 10240 ps

*Fixed minimum delay not included.

MC10EP195, MC100EP195

http://onsemi.com

6

14000.0

13000.0

12000.0

11000.0

10000.0

9000.0

8000.0

7000.0

6000.0

DELAY ( ps)

5000.0

4000.0

3000.0

2000.0

1000.0

MC10EP195, MC100EP195

85°C

25°C

VCC = 0 V

= −3.3 V

V

EE

0.0

0.0 100.0 200.0 300.0 400.0 500.0 600.0 700.0 800.0 900.0 1000.0

Decimal Value of Select Inputs (D[9:0])

−40°C

Figure 4. Measured Delay vs. Select Inputs

Table 7. MAXIMUM RATINGS

Symbol Parameter Condition 1 Condition 2 Rating Unit

V

CC

V

EE

V

I

I

out

I

BB

T

A

T

stg

q

JA

q

JC

q

JA

q

JC

T

sol

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

Positive Mode Power Supply VEE = 0 V 6 V

Negative Mode Power Supply VCC = 0 V −6 V

Positive Mode Input Voltage

Negative Mode Input Voltage

Output Current Continuous

VEE = 0 V

V

= 0 V

CC

Surge

VI ≤ V

VI ≥ V

CC

EE

6

−6

50

100

V

V

mA

mA

VBB Sink/Source ±0.5 mA

Operating Temperature Range −40 to +85 °C

Storage Temperature Range −65 to +150 °C

Thermal Resistance (Junction−to−Ambient) 0 lfpm

500 lfpm

LQFP−23

LQFP−23

80

55

°C/W

°C/W

Thermal Resistance (Junction−to−Case) Standard Board LQFP−23 12 to 17 °C/W

Thermal Resistance (Junction−to−Ambient) 0 lfpm

500 lfpm

QFN−32

QFN−32

31

27

°C/W

°C/W

Thermal Resistance (Junction−to−Case) 2S2P QFN−32 12 °C/W

Wave Solder Pb

Pb−Free

<2 to 3 sec @ 248°C

<2 to 3 sec @ 260°C

265

265

°C

http://onsemi.com

7

MC10EP195, MC100EP195

Table 8. 10EP DC CHARACTERISTICS, PECL V

= 3.3 V, VEE = 0 V (Note 7)

CC

−40°C 25°C 85°C

Symbol

I

EE

V

OH

V

OL

V

IH

V

IL

V

BB

V

CF

V

EF

V

IHCMR

I

IH

I

IL

Characteristic

Negative Power Supply Current 100 145 175 100 150 180 100 150 180 mA

Output HIGH Voltage (Note 8) 2165 2290 2415 2230 2355 2480 2290 2415 2540 mV

Output LOW Voltage (Note 8) 1365 1490 1615 1430 1555 1680 1490 1615 1740 mV

Input HIGH Voltage (Single−Ended)

LVPECL

LVCMOS

LVTTL

Input LOW Voltage (Single−Ended)

LVPECL

LVCMOS

LVTTL

ECL Output Voltage Reference 1790 1890 1990 1855 1955 2055 1915 2015 2115 mV

LVTTL Mode Input Detect Voltage 1.4 1.5 1.6 1.4 1.5 1.6 1.4 1.5 1.6 V

Reference Voltage for ECL Mode Connection 1900 2020 2150 1875 2080 2150 1850 2130 2150 mV

Input HIGH Voltage Common Mode Range

(Differential Configuration) (Note 9)

Input HIGH Current (@ VIH) 150 150 150

Input LOW Current (@ VIL)IN

Min Typ Max Min Typ Max Min Typ Max

2090

2000

2000

1365

0

0

2415

3300

3300

1690

800

800

2155

2000

2000

1430

0

0

2480

3300

3300

1755

800

800

2215

2000

2000

1490

0

0

2.0 3.3 2.0 3.3 2.0 3.3 V

0.5

−150

IN

0.5

−150

0.5

−150

Unit

2540

3300

3300

1815

800

800

NOTE: Device will meet the specifications after thermal equilibrium has been established when mounted in a test socket or printed circuit

board with maintained transverse airflow greater than 500 lfpm. Electrical parameters are guaranteed only over the declared

operating temperature range. Functional operation of the device exceeding these conditions is not implied. Device specification limit

values are applied individually under normal operating conditions and not valid simultaneously.

7. Input and output parameters vary 1:1 with V

8. All loading with 50 W to V

9. V

min varies 1:1 with VEE, V

IHCMR

input signal.

− 2.0 V.

CC

IHCMR

. VEE can vary +0.3 V to −0.3 V.

CC

max varies 1:1 with VCC. The V

range is referenced to the most positive side of the differential

IHCMR

mV

mV

mA

mA

http://onsemi.com

8

MC10EP195, MC100EP195

Table 9. 10EP DC CHARACTERISTICS, NECL V

= 0 V, V

CC

= −3.3 V to −3.0 V (Note 10)

EE

−40°C 25°C 85°C

Symbol

I

EE

V

OH

V

OL

V

IH

V

IL

V

BB

V

EF

V

IHCMR

Characteristic

Negative Power Supply Current 100 145 175 100 150 180 100 150 180 mA

Output HIGH Voltage (Note 11) −1135 −1010 −885 −1070 −945 −820 −1010 −885 −760 mV

Output LOW Voltage (Note 11) −1935 −1810 −1685 −1870 −1745 −1620 −1810 −1685 −1560 mV

Input HIGH Voltage (Single−Ended)

LVNECL

Input LOW Voltage (Single−Ended)

LVNECL

ECL Output Voltage Reference −1510 −1410 −1310 −1445 −1345 −1245 −1385 −1285 −1185 mV

Reference Voltage for ECL Mode

Connection

Input HIGH Voltage Common Mode

Min Ty p Max Min Typ Max Min Typ Max

Unit

−1210 −885 −1145 −820 −1085 −760

−1935 −1610 −1870 −1545 −1810 −1485

−1400 −1280 −1250 −1425 −1220 −1250 −1450 −1170 −1250 mV

VEE+2.0 0.0 VEE+2.0 0.0 VEE+2.0 0.0 V

Range (Differential Configuration)

(Note 12)

I

IH

I

IL

Input HIGH Current (@ VIH) 150 150 150

Input LOW Current (@ VIL)ININ0.5

−150

0.5

−150

0.5

−150

NOTE: Device will meet the specifications after thermal equilibrium has been established when mounted in a test socket or printed circuit

board with maintained transverse airflow greater than 500 lfpm. Electrical parameters are guaranteed only over the declared

operating temperature range. Functional operation of the device exceeding these conditions is not implied. Device specification limit

values are applied individually under normal operating conditions and not valid simultaneously.

10.Input and output parameters vary 1:1 with V

11.All loading with 50 W to V

12.V

min varies 1:1 with VEE, V

IHCMR

input signal.

CC

− 2.0 V.

IHCMR

max varies 1:1 with VCC. The V

can vary +0.3 V to −0.3 V.

CC. VEE

range is referenced to the most positive side of the differential

IHCMR

mV

mV

mA

mA

http://onsemi.com

9

MC10EP195, MC100EP195

Table 10. 100EP DC CHARACTERISTICS, PECL V

= 3.3 V, VEE = 0 V (Note 13)

CC

−40°C 25°C 85°C

Symbol

I

EE

V

OH

V

OL

V

IH

V

IL

V

BB

V

CF

V

EF

V

IHCMR

I

IH

I

IL

Characteristic

Negative Power Supply Current 100 135 160 100 140 170 100 145 175 mA

Output HIGH Voltage (Note 14) 2155 2280 2405 2155 2280 2405 2155 2280 2405 mV

Output LOW Voltage (Note 14) 1355 1480 1605 1355 1480 1605 1355 1480 1605 mV

Input HIGH Voltage (Single−Ended)

LVPECL

CMOS

Input LOW Voltage (Single−Ended)

LVPECL

CMOS

ECL Output Voltage Reference 1775 1875 1975 1775 1875 1975 1775 1875 1975 mV

LVTTL Mode Input Detect Voltage 1.4 1.5 1.6 1.4 1.5 1.6 1.4 1.5 1.6 V

Reference Voltage for ECL Mode Connection 1900 2020 2150 1875 2080 2150 1850 2130 2150 mV

Input HIGH Voltage Common Mode Range

(Differential Configuration) (Note 15)

Input HIGH Current (@ VIH) 150 150 150

Input LOW Current (@ VIL)IN

Min Typ Max Min Typ Max Min Typ Max

TTL

TTL

2075

2000

2000

1355

0

0

2420

3300

3300

1675

800

800

2075

2000

2000

1490

0

0

2420

3300

3300

1675

800

800

2075

2000

2000

1490

0

0

2.0 3.3 2.0 3.3 2.0 3.3 V

0.5

−150

IN

0.5

−150

0.5

−150

Unit

2420

3300

3300

1675

800

800

NOTE: Device will meet the specifications after thermal equilibrium has been established when mounted in a test socket or printed circuit

board with maintained transverse airflow greater than 500 lfpm. Electrical parameters are guaranteed only over the declared

operating temperature range. Functional operation of the device exceeding these conditions is not implied. Device specification limit

values are applied individually under normal operating conditions and not valid simultaneously.

13.Input and output parameters vary 1:1 with V

14.All loading with 50 W to V

15.V

min varies 1:1 with VEE, V

IHCMR

input signal.

− 2.0 V.

CC

max varies 1:1 with V

IHCMR

can vary +0.3 V to −0.3 V.

CC. VEE

CC.

The V

range is referenced to the most positive side of the differential

IHCMR

mV

mV

mA

mA

http://onsemi.com

10

MC10EP195, MC100EP195

Table 11. 100EP DC CHARACTERISTICS, NECL V

= 0 V, V

CC

= −3.3 V (Note 16)

EE

−40°C 25°C 85°C

Symbol

I

EE

Characteristic

Negative Power Supply Current

Min Ty p Max Min Typ Max Min Ty p Max

Unit

100 135 160 100 140 170 100 145 175 mA

(Note 17)

V

OH

V

OL

V

IH

V

IL

V

BB

V

EF

V

IHCMR

Output HIGH Voltage (Note 18) −1145 −1020 −895 −1145 −1020 −895 −1145 −1020 −895 mV

Output LOW Voltage (Note 18) −1945 −1820 −1695 −1945 −1820 −1695 −1945 −1820 −1695 mV

Input HIGH Voltage (Single−Ended)

LVNECL

−1225 −880 −1225 −880 −1225 −880

Input LOW Voltage (Single−Ended)

LVNECL

−1945 −1625 −1945 −1625 −1945 −1625

ECL Output Voltage Reference −1525 −1425 −1325 −1525 −1425 −1325 −1525 −1425 −1325 mV

Reference Voltage for ECL Mode Con-

−1400 −1280 −1250 −1425 −1220 −1250 −1450 −1170 −1250 mV

nection

Input HIGH Voltage Common Mode

VEE+2.0 0.0 VEE+2.0 0.0 VEE+2.0 0.0 V

Range (Differential Configuration)

(Note 19)

I

IH

I

IL

Input HIGH Current (@ VIH) 150 150 150

Input LOW Current (@ VIL)IN

0.5

−150

IN

0.5

−150

0.5

−150

NOTE: Device will meet the specifications after thermal equilibrium has been established when mounted in a test socket or printed circuit

board with maintained transverse airflow greater than 500 lfpm. Electrical parameters are guaranteed only over the declared

operating temperature range. Functional operation of the device exceeding these conditions is not implied. Device specification limit

values are applied individually under normal operating conditions and not valid simultaneously.

16.Input and output parameters vary 1:1 with V

17.Required 500 lfpm air flow when using +5 V power supply. For (V

protection at elevated temperatures. Recommend V

18.All loading with 50 W to V

19.V

min varies 1:1 with VEE, V

IHCMR

input signal.

CC

− 2.0 V.

IHCMR

max varies 1:1 with VCC. The V

can vary +0.3 V to −0.3 V.

CC. VEE

− VEE operation at ≤ 3.8 V.

CC

− VEE) > 3.3 V, 5 W to 10 W in line with VEE required for maximum thermal

CC

range is referenced to the most positive side of the differential

IHCMR

mV

mV

mA

mA

http://onsemi.com

11

MC10EP195, MC100EP195

Table 12. AC CHARACTERISTICS V

= 0 V; VEE = −3.0 V to −3.6 V or VCC = 3.0 V to 3.6 V; V

CC

= 0 V (Note 20)

EE

−40°C 25°C 85°C

Symbol

f

max

t

PLH

t

PHL

t

RANGE

Dt

Characteristic

Maximum Frequency 1.2 1.2 1.2 GHz

Propagation Delay

IN to Q; D(0−10) = 0

IN to Q; D(0−10) = 1023

to Q; D(0−10) = 0

EN

D0 to CASCADE

Programmable Range

(max) − tPD (min)

t

PD

Step Delay (Note 21)

D0 High

D1 High

D2 High

D3 High

D4 High

D5 High

D6 High

D7 High

D8 High

D9 High

Min Ty p Max Min Typ Max Min Ty p Max

1650

9500

1600

300

2050

11500

2150

420

2450

13500

2600

500

1800

10000

1800

350

2200

12200

2300

450

2600

14000

2800

550

1950

10800

2000

425

2350

13300

2500

525

2750

15800

3000

625

7850 9450 8200 10000 8850 10950

13

27

44

90

130

312

590

1100

2250

4500

14

30

47

97

140

335

650

1180

2400

4800

41

100

145

360

690

1300

2650

5300

Unit

ps

ps

ps

mono Monotonicity (Note 27) TBD

t

SKEW

t

s

t

h

t

R

t

jitter

V

PP

t

r

t

f

Duty Cycle Skew (Note 22)

|t

PHL−tPLH

Setup Time

D to LEN

D to IN (Note 23)

to IN (Note 24)

EN

Hold Time

LEN to D

(Note 25)

IN to EN

Release Time

to IN (Note 26)

EN

SET MAX to LEN

SET MIN to LEN

RMS Random Clock Jitter @ 1.2 GHz

IN to Q; D(0:10) = 0 or SETMIN

IN to Q; D(0:10) = 1023 or SETMAX

Input Voltage Swing

(Differential Configuration)

Output Rise/Fall Time @ 50 MHz

20−80% (Q)

20−80% (CASCADE)

|

200

300

300

200

40060250

150

400

350

25 25 25

0

140

150

−25

200

275

0.86

0.89

200

300

300

200

400

150

400

350

0

160

170

100

280

−75

250

200

1.16

1.09

200

300

300

200

40080300

150

400

350

0

180

180

−50

300

225

1.12

1.02

150 800 1200 150 800 1200 150 800 1200 mV

85

100

100

140

135

20085110

110

150

135

20095130

125

170

155

220

ps

ps

ps

ps

ps

ps

NOTE: Device will meet the specifications after thermal equilibrium has been established when mounted in a test socket or printed circuit

board with maintained transverse airflow greater than 500 lfpm. Electrical parameters are guaranteed only over the declared

operating temperature range. Functional operation of the device exceeding these conditions is not implied. Device specification limit

values are applied individually under normal operating conditions and not valid simultaneously.

20.Measured using a 750 mV source, 50% duty cycle clock source. All loading with 50 W to V

21.Specification limits represent the amount of delay added with the assertion of each individual delay control pin. The various combinations

− 2.0 V.

CC

of asserted delay control inputs will typically realize D0 resolution steps across the specified programmable range.

22.Duty cycle skew guaranteed only for differential operation measured from the cross point of the input to the cross point of the output.

23.This setup time defines the amount of time prior to the input signal the delay tap of the device must be set.

24.This setup time is the minimum time that EN

±75 mV to that IN/IN

transition.

25.This hold time is the minimum time that EN

must be asserted prior to the next transition of IN/IN to prevent an output response greater than

must remain asserted after a negative going IN or positive going IN to prevent an output response

greater than ±75 mV to that IN/IN transition.

26.This release time is the minimum time that EN

must be deasserted prior to the next IN/IN transition to ensure an output response that meets

the specified IN to Q propagation delay and transition times.

27.The monotonicity indicates the increasing delay value for each binary count increment on the control inputs D[9:0].

http://onsemi.com

12

MC10EP195, MC100EP195

IN

V

IN

Q

V

Q

t

PHL

t

PLH

Figure 5. AC Reference Measurement

= VIH(D) − VIL(D)

INPP

= VOH(Q) − VOL(Q)

OUTPP

Cascading Multiple EP195s

To increase the programmable range of the EP195,

internal cascade circuitry has been included. This circuitry

allows for the cascading of multiple EP195s without the

need for any external gating. Furthermore, this capability

requires only one more address line per added E195.

Obviously, cascading multiple programmable delay chips

will result in a larger programmable range: however, this

increase is at the expense of a longer minimum delay.

Need if Chip #3 is used

D3D4D5D6D7

D2 D1

V

EE

D0

V

CC

Q

Q

V

CC

V

CC

INPUT

D8

D9

D10

IN

IN

V

BB

V

EF

V

EP195

CHIP #2

EE

Figure 6 illustrates the interconnect scheme for cascading

two EP195s. As can be seen, this scheme can easily be

expanded for larger EP195 chains. The D10 input of the

EP195 is the CASCADE control pin. With the interconnect

scheme of Figure 6 when D10 is asserted, it signals the need

for a larger programmable range than is achievable with a

single device and switches output pin CASCADE HIGH and

pin CASCADE

LOW. The A11 address can be added to

generate a cascade output for the next EP195. For a 2−device

configuration, A11 is not required.

A11 A10 A9 A8 A7 A6 A5 A4 A3 A2 A1 A0

D8

D9

D10

IN

IN

V

BB

V

EF

ADDRESS BUS

V

EE

EP195

CHIP #1

D3D4D5D6D7

D2 D1

V

EE

D0

V

CC

Q

OUTPUT

Q

V

CC

V

CC

V

CF

VEELEN

SETMAX

SETMIN

CC

V

CASCADE

CASCADE

NC

EN

V

CF

VEELEN

Figure 6. Cascading Interconnect Architecture

http://onsemi.com

13

SETMAX

SETMIN

V

CC

CASCADE

CASCADE

NC

EN

MC10EP195, MC100EP195

An expansion of the latch section of the block diagram is

pictured in Figure 7. Use of this diagram will simplify the

explanation of how the cascade circuitry works. When D10

of chip #1 in Figure 6 is LOW this device’s

CASCADE output will also be low while the CASCADE

output will be high. In this condition the SET MIN pin of

chip #2 will be asserted HIGH and thus all of the latches of

chip #2 will be reset and the device will be set at its minimum

delay.

Chip #1, on the other hand, will have both SET MIN and

SET MAX deasserted so that its delay will be controlled

entirely by the address bus A0—A9. If the delay needed is

greater than can be achieved with 1023 gate delays

TO SELECT MULTIPLEXERS

SET

MIN

SET

MAX

BIT 0

D0 Q0

LEN

Set Reset

BIT 1

D1 Q1

LEN

Set Reset

BIT 2

D2 Q2

LEN

Set Reset

BIT 3

D3 Q3

LEN

Set Reset

BIT 4

D4 Q4

LEN

Set Reset

(1111111111 on the A0—A9 address bus) D10 will be

asserted to signal the need to cascade the delay to the next

EP195 device. When D10 is asserted, the SET MIN pin of

chip #2 will be deasserted and SET MAX pin asserted

resulting in the device delay to be the maximum delay.

Table 13 shows the delay time of two EP195 chips in

cascade.

To expand this cascading scheme to more devices, one

simply needs to connect the D10 pin from the next chip to

the address bus and CASCADE outputs to the next chip in

the same manner as pictured in Figure 6. The only addition

to the logic is the increase of one line to the address bus for

cascade control of the second programmable delay chip.

BIT 5

D5 Q5

LEN

Set Reset

BIT 6

D6 Q6

LEN

Set Reset

BIT 7

D7 Q7

LEN

Set Reset

BIT 8

D8 Q8

LEN

Set Reset

BIT 9

D9 Q9

LEN

Set Reset

Figure 7. Expansion of the Latch Section of the EP195 Block Diagram

http://onsemi.com

14

MC10EP195, MC100EP195

Table 13. Delay Value of Two EP195 Cascaded

VARIABLE INPUT TO CHIP #1 AND SETMIN FOR CHIP #2

INPUT FOR CHIP #1 Total

D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 Delay Value Delay Value

0 0 0 0 0 0 0 0 0 0 0 0 ps 4400 ps

0 0 0 0 0 0 0 0 0 0 1 10 ps 4410 ps

0 0 0 0 0 0 0 0 0 1 0 20 ps 4420 ps

0 0 0 0 0 0 0 0 0 1 1 30 ps 4430 ps

0 0 0 0 0 0 0 0 1 0 0 40 ps 4440 ps

0 0 0 0 0 0 0 0 1 0 1 50 ps 4450 ps

0 0 0 0 0 0 0 0 1 1 0 60 ps 4460 ps

0 0 0 0 0 0 0 0 1 1 1 70 ps 4470 ps

0 0 0 0 0 0 0 1 0 0 0 80 ps 4480 ps

0 0 0 0 0 0 1 0 0 0 0 160 ps 4560 ps

0 0 0 0 0 1 0 0 0 0 0 220 ps 4720 ps

0 0 0 0 1 0 0 0 0 0 0 640 ps 5040 ps

0 0 0 1 0 0 0 0 0 0 0 1280 ps 5680 ps

0 0 1 0 0 0 0 0 0 0 0 2560 ps 6960 ps

0 1 0 0 0 0 0 0 0 0 0 5120 ps 9520 ps

0 1 1 1 1 1 1 1 1 1 1 10230 ps 14630 ps

VARIABLE INPUT TO CHIP #1 AND SETMAX FOR CHIP #2

INPUT FOR CHIP #1 Total

D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 Delay Value Delay Value

1 0 0 0 0 0 0 0 0 0 0 10240 ps 14640 ps

1 0 0 0 0 0 0 0 0 0 1 10250 ps 14650 ps

1 0 0 0 0 0 0 0 0 1 0 10260 ps 14660 ps

1 0 0 0 0 0 0 0 0 1 1 10270 ps 14670 ps

1 0 0 0 0 0 0 0 1 0 0 10280 ps 14680 ps

1 0 0 0 0 0 0 0 1 0 1 10290 ps 14690 ps

1 0 0 0 0 0 0 0 1 1 0 10300 ps 14700 ps

1 0 0 0 0 0 0 0 1 1 1 10310 ps 14710 ps

1 0 0 0 0 0 0 1 0 0 0 10320 ps 14720 ps

1 0 0 0 0 0 1 0 0 0 0 10400 ps 14800 ps

1 0 0 0 0 1 0 0 0 0 0 10560 ps 14960 ps

1 0 0 0 1 0 0 0 0 0 0 10880 ps 15280 ps

1 0 0 1 0 0 0 0 0 0 0 11520 ps 15920 ps

1 0 1 0 0 0 0 0 0 0 0 12800 ps 17200 ps

1 1 0 0 0 0 0 0 0 0 0 15360 ps 19760 ps

1 1 1 1 1 1 1 1 1 1 1 20470 ps 24870 ps

http://onsemi.com

15

MC10EP195, MC100EP195

Multi−Channel Deskewing

The most practical application for EP195 is in multiple

channel delay matching. Slight differences in impedance and

cable length can create large timing skews within a high−speed

system. To deskew multiple signal channels, each channel can

IN Q

IN

IN Q

IN

IN Q

IN

Digital

Control

Logic

Data

be sent through each EP195 as shown in Figure 8. One signal

channel can be used as reference and the other EP195s can be

used to adjust the delay to eliminate the timing skews. Nearly

any high−speed system can be fine−tuned (as small as 10 ps)

to reduce the skew to extremely tight tolerances.

EP195

Q

#1

EP195

Q

#2

EP195

Q

#N

Figure 8. Multiple Channel Deskewing Diagram

Measure Unknown High Speed Device Delays

EP195s provide a possible solution to measure the

unknown delay of a device with a high degree of precision.

By combining two EP195s and EP31 as shown in Figure 9,

the delay can be measured. The first EP195 can be set to

SETMIN and its output is used to drive the unknown delay

device, which in turn drives the input of a D flip−flop of

EP31. The second EP195 is triggered along with the first

EP195 and its output provides a clock signal for EP31.

The programmed delay of the second EP195 is varied to

detect the output edge from the unknown delay device.

CLOCK

CLOCK

IN Q

IN

IN Q

IN

EP195

Q

#1

EP195

Q

#2

If the programmed delay through the second EP195 is too

long, the flip−flop output will be at logic high. On the other

hand, if the programmed delay through the second EP195 is

too short, the flip−flop output will be at a logic low. If the

programmed delay is correctly fine−tuned in the second

EP195, the flip−flop will bounce between logic high and logic

low. The digital code in the second EP195 can be directly

correlated into an accurate device delay.

Unknown Delay

Device

D

EP31

CLK

Q

Q

Control

Logic

Figure 9. Multiple Channel Deskewing Diagram

http://onsemi.com

16

MC10EP195, MC100EP195

Zo = 50 W

Zo = 50 W

50 W 50 W

V

VTT = VCC − 2.0 V

TT

Receiver

Device

Driver

Device

QD

Q D

Figure 10. Typical Termination for Output Driver and Device Evaluation

(See Application Note AND8020/D − Termination of ECL Logic Devices.)

ORDERING INFORMATION

Device Package Shipping

MC10EP195FA LQFP−32 250 Units / Tray

MC10EP195FAG LQFP−32

(Pb−Free)

MC10EP195FAR2 LQFP−32 2000 / Tape & Reel

MC10EP195FAR2G LQFP−32

(Pb−Free)

MC10EP195MNG QFN−32

(Pb−Free)

MC10EP195MNR4G QFN−32

(Pb−Free)

MC100EP195FA LQFP−32 250 Units / Tray

MC100EP195FAG LQFP−32

(Pb−Free)

MC100EP195FAR2 LQFP−32 2000 / Tape & Reel

MC100EP195FAR2G LQFP−32

(Pb−Free)

MC100EP195MNG QFN−32

(Pb−Free)

MC100EP195MNR4G QFN−32

(Pb−Free)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

250 Units / Tray

2000 / Tape & Reel

74 Units / Rail

1000 / Tape & Reel

250 Units / Tray

2000 / Tape & Reel

74 Units / Rail

1000 / Tape & Reel

†

http://onsemi.com

17

MC10EP195, MC100EP195

Resource Reference of Application Notes

AN1405/D − ECL Clock Distribution Techniques

AN1406/D − Designing with PECL (ECL at +5.0 V)

AN1503/D −

AN1504/D − Metastability and the ECLinPS Family

AN1568/D − Interfacing Between LVDS and ECL

AN1672/D − The ECL Translator Guide

AND8001/D − Odd Number Counters Design

AND8002/D − Marking and Date Codes

AND8020/D − Termination of ECL Logic Devices

AND8066/D − Interfacing with ECLinPS

AND8090/D − AC Characteristics of ECL Devices

ECLinPSt I/O SPiCE Modeling Kit

http://onsemi.com

18

MC10EP195, MC100EP195

PACKAGE DIMENSIONS

32 LEAD LQFP

CASE 873A−02

ISSUE C

SEATING

PLANE

9

−T−

B1

−AB−

−AC−

A

A1

32

1

4X

25

−U−

T−U0.20 (0.008) ZAB

P

−T−, −U−, −Z−

AE

VB

AE

DETAIL Y

8

9

−Z−

S1

V1

17

4X

T−U0.20 (0.008) ZAC

DETAIL Y

BASE

METAL

N

T−U

M

DF

S

_

8X

M

G

DETAIL AD

E

C

R

J

SECTION AE−AE

0.20 (0.008) ZAC

0.10 (0.004) AC

H

W

_

Q

K

X

NOTES:

1. DIMENSIONING AND TOLERANCING

PER ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION:

MILLIMETER.

3. DATUM PLANE −AB− IS LOCATED AT

BOTTOM OF LEAD AND IS COINCIDENT

WITH THE LEAD WHERE THE LEAD

EXITS THE PLASTIC BODY AT THE

BOTTOM OF THE PARTING LINE.

4. DATUMS −T−, −U−, AND −Z− TO BE

DETERMINED AT DATUM PLANE −AB−.

5. DIMENSIONS S AND V TO BE

DETERMINED AT SEATING PLANE −AC−.

6. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION. ALLOWABLE

PROTRUSION IS 0.250 (0.010) PER SIDE.

DIMENSIONS A AND B DO INCLUDE

MOLD MISMATCH AND ARE

DETERMINED AT DATUM PLANE −AB−.

7. DIMENSION D DOES NOT INCLUDE

DAMBAR PROTRUSION. DAMBAR

PROTRUSION SHALL NOT CAUSE THE

D DIMENSION TO EXCEED 0.520 (0.020).

8. MINIMUM SOLDER PLATE THICKNESS

SHALL BE 0.0076 (0.0003).

9. EXACT SHAPE OF EACH CORNER MAY

VARY FROM DEPICTION.

DETAIL AD

MILLIMETERS

DIMAMIN MAX MIN MAX

7.000 BSC 0.276 BSC

A1 3.500 BSC 0.138 BSC

B 7.000 BSC 0.276 BSC

B1 3.500 BSC 0.138 BSC

C 1.400 1.600 0.055 0.063

D 0.300 0.450 0.012 0.018

E 1.350 1.450 0.053 0.057

F 0.300 0.400 0.012 0.016

G 0.800 BSC 0.031 BSC

H 0.050 0.150 0.002 0.006

J 0.090 0.200 0.004 0.008

K 0.450 0.750 0.018 0.030

__

M 12 REF 12 REF

N 0.090 0.160 0.004 0.006

P 0.400 BSC 0.016 BSC

Q 1 5 1 5

____

R 0.150 0.250 0.006 0.010

S 9.000 BSC 0.354 BSC

S1 4.500 BSC 0.177 BSC

V 9.000 BSC 0.354 BSC

V1 4.500 BSC 0.177 BSC

W 0.200 REF 0.008 REF

X 1.000 REF 0.039 REF

INCHES

0.250 (0.010)

GAUGE PLANE

http://onsemi.com

19

MC10EP195, MC100EP195

PACKAGE DIMENSIONS

QFN32 5*5*1 0.5 P

CASE 488AM−01

ISSUE O

2 X

32 X

LOCATION

0.15 C

2 X

0.10 C

0.08 C

PIN ONE

0.15

32 X

L

32 X

0.05

C

SIDE VIEW

9

8

1

32

b

A0.10 B

C

C

D

TOP VIEW

D2

(A3)

A1

16

17

24

25

A

B

E

EXPOSED PAD

K

32 X

E2

e

NOTES:

1. DIMENSIONS AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED

TERMINAL AND IS MEASURED BETWEEN

0.25 AND 0.30 MM TERMINAL

4. COPLANARITY APPLIES TO THE EXPOSED

PAD AS WELL AS THE TERMINALS.

MILLIMETERS

DIM MIN NOM MAX

A 0.800 0.900 1.000

A1 0.000 0.025 0.050

A3 0.200 REF

b 0.180 0.250 0.300

D 5.00 BSC

D2 2.950 3.100 3.250

E 5.00 BSC

E2

2.950 3.100 3.250

A

SEATING

PLANE

e 0.500 BSC

K 0.200 −−− −−−

L 0.300 0.400 0.500

C

SOLDERING FOOTPRINT*

5.30

3.20

32 X

0.63

3.20

5.30

BOTTOM VIEW

32 X

0.28

DIMENSIONS: MILLIMETERS

28 X

0.50 PITCH

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

ECLinPS is a trademark of Semiconductor Components Industries, LLC.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5773−3850

http://onsemi.com

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

MC10EP195/D

20

Loading...

Loading...