查询CS5151H供应商

CS5151H

CPU 4-Bit Nonsynchronous

Buck Controller

The CS5151H is a 4–bit nonsynchronous N–Channel buck

controller. It is designed to provide unprecedented transient response

for today’s demanding high–density, high–speed logic. The regulator

operates using a proprietary control method, which allows a 100 ns

response time to load transients. The CS5151H is designed to operate

over a 4.25–20 V range (V

12 V as the main supply for conversion.

The CS5151H is specifically designed to power Pentium

processors with MMX Technology and other high performance core

logic. It includes the following features: on board, 4–bit DAC, short

circuit protection, 1.0% output tolerance, V

programmable Soft Start capability. The CS5151H is upwards

compatible with the 5–bit CS5156H, allowing the mother board

designer the capability of using either the CS5151H or the CS5156H

with no change in layout. The CS5151H is available in 16 pin surface

mount package.

Features

• N–Channel Design

• Excess of 1.0 MHz Operation

• 100 ns Transient Response

• 4–Bit DAC

• Upward Compatible with 5–Bit CS5155H/CS5156H

• 30 ns Gate Rise/Fall Times

• 1.0% DAC Accuracy

• 5.0 V & 12 V Operation

• Remote Sense

• Programmable Soft Start

• Lossless Short Circuit Protection

• V

Monitor

CC

• Adaptive Voltage Positioning

2

• V

Control Topology

• Current Sharing

• Overvoltage Protection

) using 12 V to power the IC and 5.0 V or

CC

monitor, and

CC

http://onsemi.com

16

1

SOIC–16

D SUFFIX

CASE 751B

A = Assembly Location

WL, L = Wafer Lot

YY, Y = Year

WW, W = Work Week

PIN CONNECTIONS

1

V

ID0

ID1

ID2

V

ID3

C

OFF

V

FFB

ORDERING INFORMATION

Device Package Shipping

CS5151HGD16 SO–16

CS5151HGDR16

16

1

16

SO–16

MARKING

DIAGRAM

CS5151H

AWLYWW

V

FB

COMPV

LGNDV

V

CC1

NCSS

PGNDNC

V

GATE

V

CC2

48 Units/Rail

2500 Tape & Reel

Semiconductor Components Industries, LLC, 2001

January , 2001 – Rev. 3

1 Publication Order Number:

CS5151H/D

CS5151H

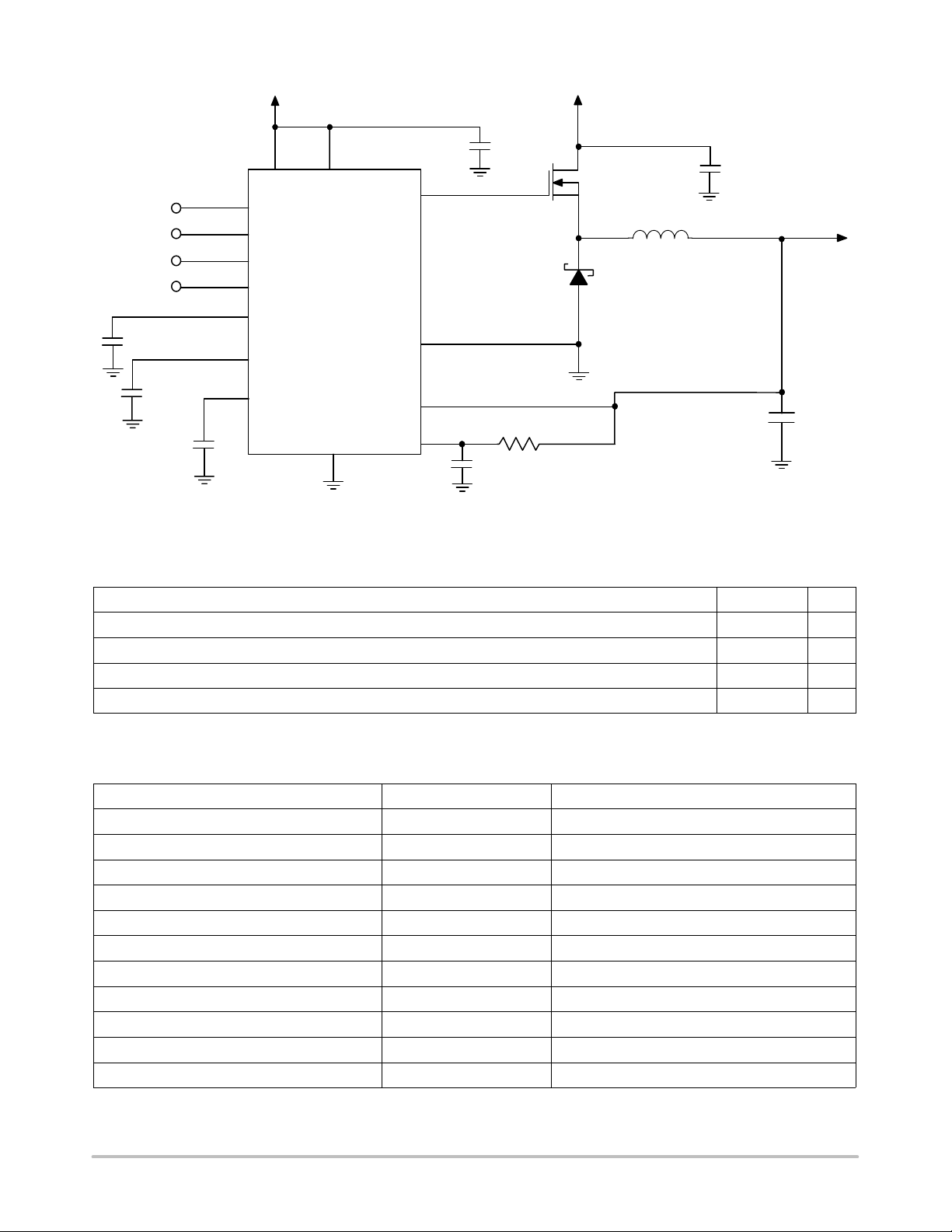

12 V

5.0 V

0.1 µF

1200 µF/16 V × 3

AIEI

2.1 V to 3.5 V @ 13 A

V

ID0

V

ID1

V

ID2

V

ID3

330 pF

CC1

V

CC2

CS5151H

V

GATE

MBR735

IRL3103

2.0 µH

3

1,2

V

V

ID0

V

ID1

V

ID2

V

ID3

C

OFF

PGND

SS

0.1 µF

0.33 µF

COMP

LGND

V

FB

3.3 k

V

FFB

1200 µF/16 V × 5

AIEI

100 pF

Figure 1. Application Diagram, Switching Power Supply for Core Logic – Pentium Processor with

MMX Technology

ABSOLUTE MAXIMUM RATINGS*

Rating Value Unit

Operating Junction Temperature, T

J

0 to 150 °C

Lead Temperature Soldering: Reflow: (SMD styles only) (Note 1.) 230 peak °C

Storage Temperature Range, T

S

–65 to +150 °C

ESD Susceptibility (Human Body Model) 2.0 kV

1. 60 second maximum above 183°C.

*The maximum package power dissipation must be observed.

ABSOLUTE MAXIMUM RATINGS

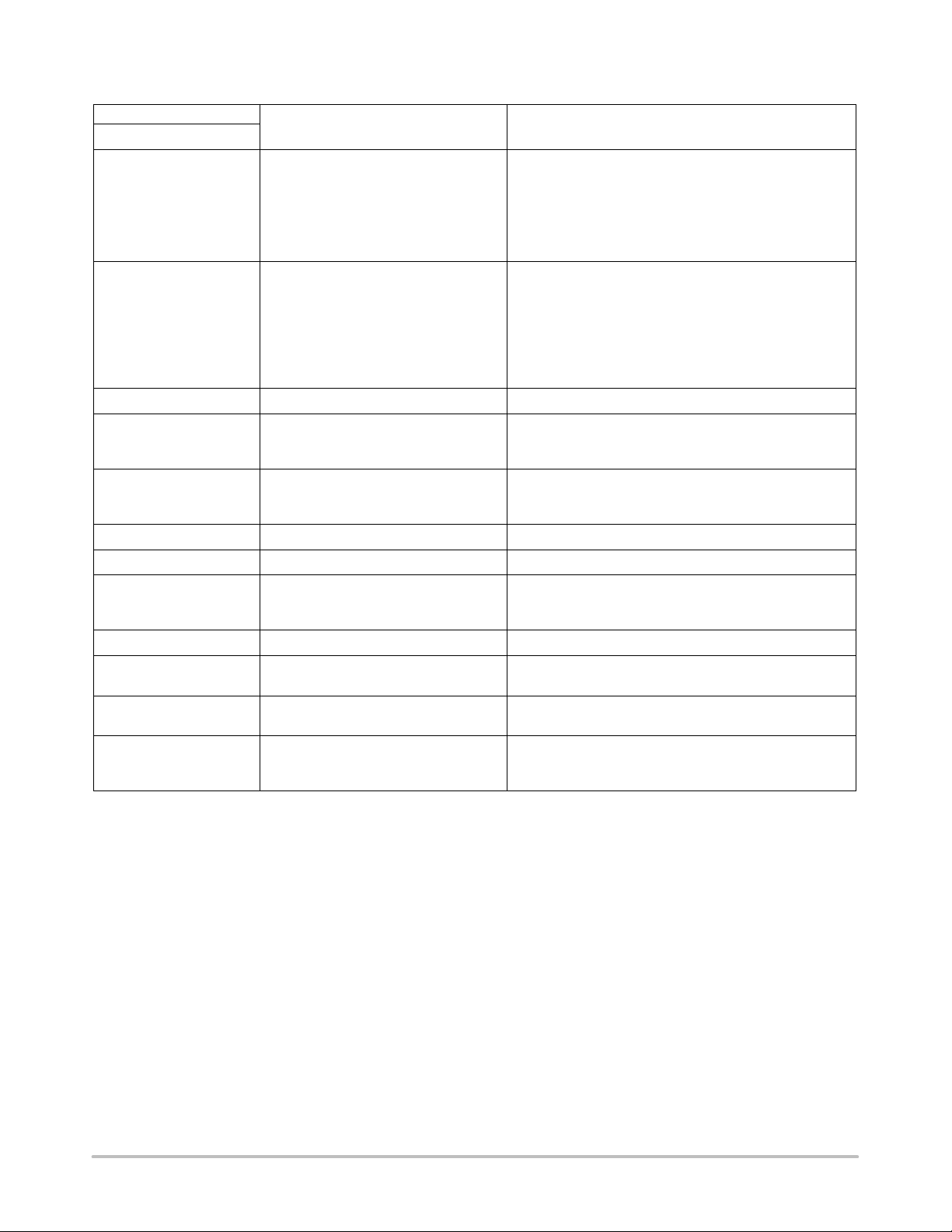

Pin Name Max Operating Voltage Max Current

V

CC1

V

CC2

SS 6.0 V/–0.3 V –100 µA

COMP 6.0 V/–0.3 V 200 µA

V

FB

C

OFF

V

FFB

V

– V

ID0

ID3

V

GATE

LGND 0 V 25 mA

PGND 0 V 100 mA DC/1.5 A peak

16 V/–0.3 V 25 mA DC/1.5 A peak

20 V/–0.3 V 20 mA DC/1.5 A peak

6.0 V/–0.3 V –0.2 µA

6.0 V/–0.3 V –0.2 µA

6.0 V/–0.3 V –0.2 µA

6.0 V/–0.3 V –50 µA

20 V/–0.3 V 100 mA DC/1.5 A peak

http://onsemi.com

2

CS5151H

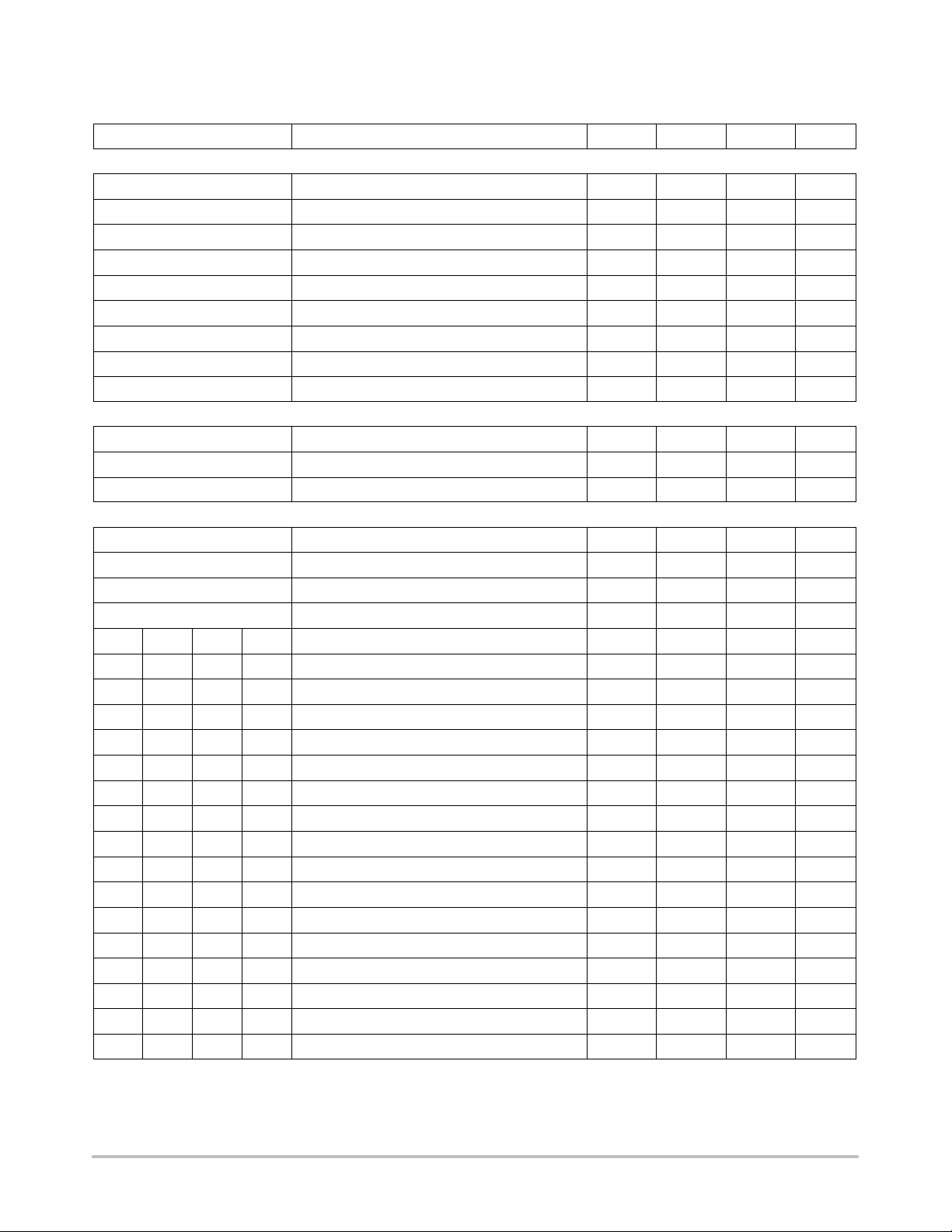

ELECTRICAL CHARACTERISTICS (0°C < T

DAC Code: V

Characteristic

ID2

= V

ID1

= V

ID0

= 1; V

ID3

= 0

CV

;

GATE

< +70°C; 0°C < TJ < +125°C; 8.0 V < V

A

= 1.0 nF; C

= 330 pF; CSS = 0.1 µF, unless otherwise specified.)

OFF

< 14 V; 5.0 V < V

CC1

Test Conditions Min Typ Max Unit

CC2

< 20 V;

Error Amplifier

Bias Current VFB = 0 V – 0.3 1.0 µA

V

FB

Open Loop Gain 1.25 V < V

< 4.0 V; Note 2. 50 60 – dB

COMP

Unity Gain Bandwidth Note 2. 500 3000 – kHz

COMP SINK Current V

COMP SOURCE Current V

COMP CLAMP Current V

= 1.5 V; VFB = 3.0 V; VSS > 2.0 V 0.4 2.5 8.0 mA

COMP

= 1.2 V; VFB = 2.7 V; VSS = 5.0 V 30 50 80 µA

COMP

= 0 V; VFB = 2.7 V 0.4 1.0 1.6 mA

COMP

COMP High Voltage VFB = 2.7 V; VSS = 5.0 V 4.0 4.3 5.0 V

COMP Low Voltage VFB = 3.0 V – 160 600 mV

PSRR 8.0 V < V

V

Monitor

CC1

< 14 V @ 1.0 kHz; Note 2. 60 85 – dB

CC1

Start Threshold Output switching 3.75 3.90 4.05 V

Stop Threshold Output not switching 3.70 3.85 4.00 V

Hysteresis Start–Stop – 50 – mV

DAC

Input Threshold V

Input Pull Up Resistance V

ID0,

ID0,

V

, V

, V

ID1

ID2

ID3

V

, V

, V

ID1

ID2

ID3

1.00 1.25 2.40 V

25 50 100 kΩ

Pull Up Voltage – 4.85 5.00 5.15 V

Accuracy (all codes except 1111) Measure VFB = V

V

ID3

V

ID2

V

ID1

V

ID0

, 25°C ≤ TJ ≤ 125°C – – 1.0 %

COMP

1 1 1 1 – 1.2191 1.2440 1.2689 V

1 1 1 0 – 2.1186 2.1400 2.1614 V

1 1 0 1 – 2.2176 2.2400 2.2624 V

1 1 0 0 – 2.3166 2.3400 2.3634 V

1 0 1 1 – 2.4156 2.4400 2.4644 V

1 0 1 0 – 2.5146 2.5400 2.5654 V

1 0 0 1 – 2.6136 2.6400 2.6664 V

1 0 0 0 – 2.7126 2.7400 2.7674 V

0 1 1 1 – 2.8116 2.8400 2.8684 V

0 1 1 0 – 2.9106 2.9400 2.9694 V

0 1 0 1 – 3.0096 3.0400 3.0704 V

0 1 0 0 – 3.1086 3.1400 3.1714 V

0 0 1 1 – 3.2076 3.2400 3.2724 V

0 0 1 0 – 3.3066 3.3400 3.3734 V

0 0 0 1 – 3.4056 3.4400 3.4744 V

0 0 0 0 – 3.5046 3.5400 3.5754 V

2. Guaranteed by design, not 100% tested in production.

http://onsemi.com

3

CS5151H

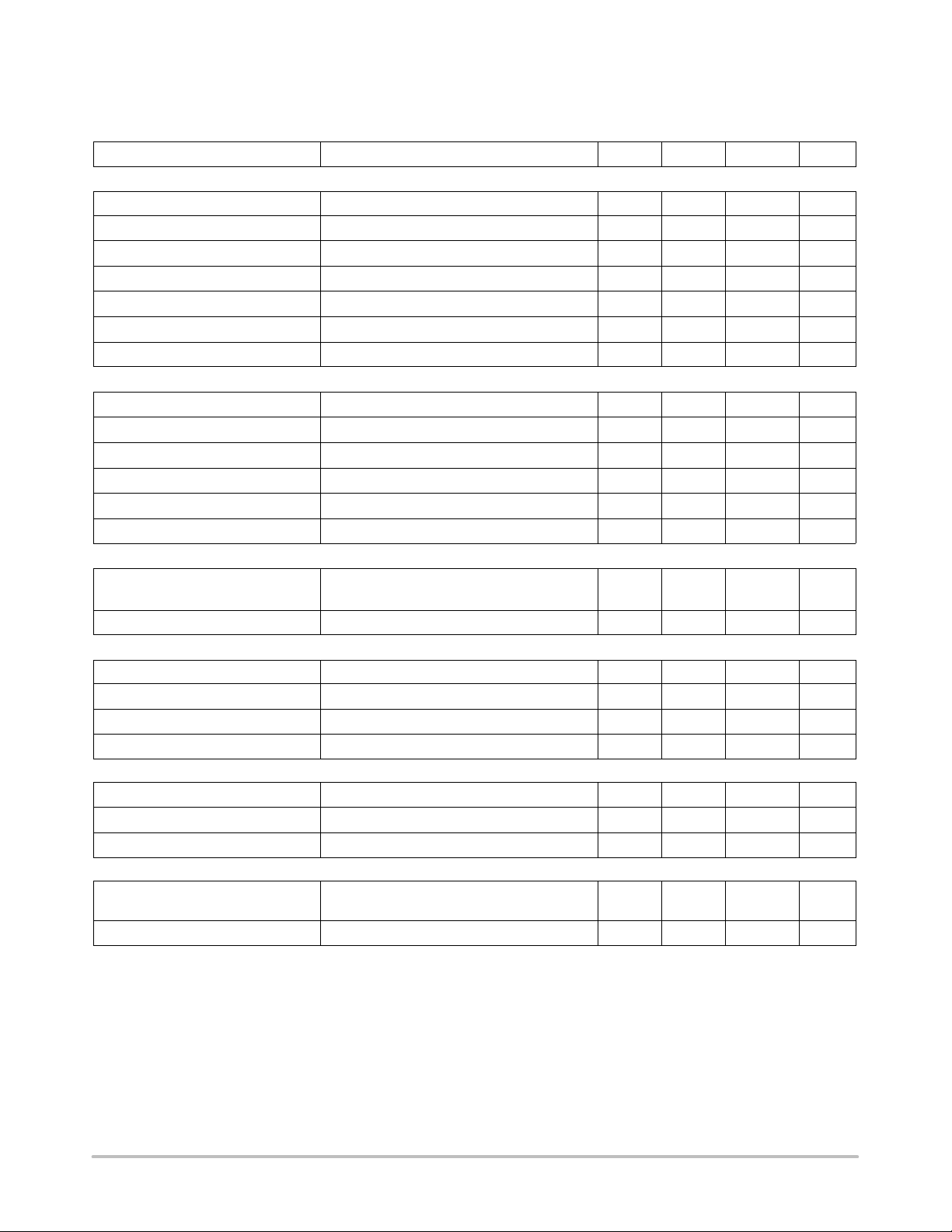

ELECTRICAL CHARACTERISTICS (continued) (0°C < T

5.0

V < V

< 20 V; DAC Code: V

CC2

ID2

= V

ID1

= V

ID0

=1; V

ID3

< +70°C; 0°C < TJ < +125°C; 8.0 V < V

A

=

CV

0;

GATE(L)

and CV

GATE(H)

= 1.0 nF; C

< 14 V;

CC1

= 330 pF; CSS = 0.1 µF, unless

OFF

otherwise specified.)

Characteristic

V

GATE

Out SOURCE Sat at 100 mA Measure V

Out SINK Sat at 100 mA Measure V

Out Rise Time 1.0 V < V

Out Fall Time 9.0 V > V

Test Conditions Min Typ Max Unit

CC2

GATE

GATE

GATE

– V

GATE

– V

PGND

< 9.0 V; V

> 1.0 V; V

CC1

CC1

= V

= 12 V – 30 50 ns

CC2

= V

= 12 V – 30 50 ns

CC2

– 1.2 2.0 V

– 1.0 1.5 V

Shoot–Through Current Note 3. – – 50 mA

V

Resistance Resistor to LGND. Note 3. 20 50 100 kΩ

GATE

V

Schottky LGND to V

GATE

@ 10 mA – 600 800 mV

GATE

Soft Start (SS)

Charge Time – 1.6 3.3 5.0 ms

Pulse Period – 25 100 200 ms

Duty Cycle (Charge Time /Pulse Period) × 100 1.0 3.3 6.0 %

COMP Clamp Voltage VFB = 0 V; VSS = 0 0.50 0.95 1.10 V

V

SS Fault Disable V

FFB

= Low 0.9 1.0 1.1 V

GATE

High Threshold – – 2.5 3.0 V

PWM Comparator

Transient Response

V

Bias Current V

FFB

V

= 0 to 5.0 V to V

FFB

V

= V

CC2

= 12 V

CC1

= 0 V – 0.3 – µA

FFB

= 9.0 V to 1.0 V;

GATE

– 100 125 ns

Supply Current

I

CC1

I

CC2

Operating I

Operating I

C

OFF

CC1

CC2

Normal Charge Time V

Extension Charge Time VSS = V

Discharge Current C

No Switching – 8.5 13.5 mA

No Switching – 1.6 3.0 mA

VFB = COMP = V

VFB = COMP = V

= 1.5 V; VSS = 5.0 V 1.0 1.6 2.2 µs

FFB

FFB

to 5.0 V; VFB > 1.0 V 5.0 – – mA

OFF

FFB

FFB

= 0 5.0 8.0 11.0 µs

– 8.0 13 mA

– 2.0 5.0 mA

Time Out Timer

Time Out Time

Fault Mode Duty Cycle V

VFB = V

Record V

FFB

; V

COMP

= 2.0 V;

FFB

Pulse High Duration

GATE

10 30 65 µs

= 0V 35 50 70 %

3. Guaranteed by design, not 100% tested in production.

http://onsemi.com

4

CS5151H

PACKAGE PIN DESCRIPTION

PACKAGE PIN #

16 Lead SO Narrow

1, 2, 3, 4 V

5 SS Soft Start Pin. A capacitor from this pin to LGND in conjunc-

6, 12 NC No Connection.

7 C

PIN SYMBOL FUNCTION

ID0–VID3

OFF

Voltage ID DAC input pins. These pins are internally pulled

up to 5.0 V providing logic ones if left open. The DAC range

is 2.14 V to 3.54 V with 100 mV increments. V

select the desired DAC output voltage. Leaving all 4 DAC

ID0

– V

ID3

input pins open results in a DAC output voltage of 1.244 V,

allowing for adjustable output voltage, using a traditional

resistor divider .

tion with internal 60 µA current source provides Soft Start

function for the controller. This pin disables fault detect function during Soft Start. When a fault is detected, the Soft Start

capacitor is slowly discharged by internal 2.0 µA current

source setting the time out before trying to restart the IC.

Charge/discharge current ratio of 30 sets the duty cycle for

the IC when the regulator output is shorted.

A capacitor from this pin to ground sets the time duration for

the on board one shot, which is used for the constant off time

architecture.

8 V

FFB

Fast feedback connection to the PWM comparator. This pin

is connected to the regulator output. The inner feedback loop

terminates on time.

9 V

10 V

CC2

GATE

Boosted power for the gate driver.

MOSFET driver pin capable of 1.5 A peak switching current.

11 PGND High current ground for the IC. The MOSFET driver is refer-

enced to this pin. Input capacitor ground and the anode of

the Schottky diode should be tied to this pin.

13 V

CC1

Input power for the IC.

14 LGND Signal ground for the IC. All control circuits are referenced to

this pin.

15 COMP Error amplifier compensation pin. A capacitor to ground

should be provided externally to compensate the amplifier.

16 V

FB

Error amplifier DC feedback input. This is the master voltage

feedback which sets the output voltage. This pin can be connected directly to the output or a remote sense trace.

http://onsemi.com

5

V

CC1

SS

V

ID0

V

ID1

V

ID2

V

ID3

V

FB

COMP

V

FFB

LGND

V

CC1

Comparator

–

+

3.90 V

3.85V

4 BIT

DAC

Slow Feedback

Fast Feedback

Monitor

Error

Amplifier

+

–

1.0 V

60 µA

2.0 µA

PWM

Comparator

–

+

–

+

V

FFB

Comparator

5.0 V

Low

2.5 V

CS5151H

SS Low

Comparator

–

+

0.7 V

SS High

Comparator

+

–

Maximum

On–Time

Timeout

Normal

Off–Time

Timeout

Extended

Off–Time

Timeout

Q

R

Q

S

FAULT

Latch

Off–Time

Timeout

FAULT

FAULT

R

S

PMW

Latch

Q

Q

GATE = ON

GATE = OFF

C

OFF

One Shot

R

Q

S

V

CC2

V

GATE

PGND

C

OFF

PWM COMP

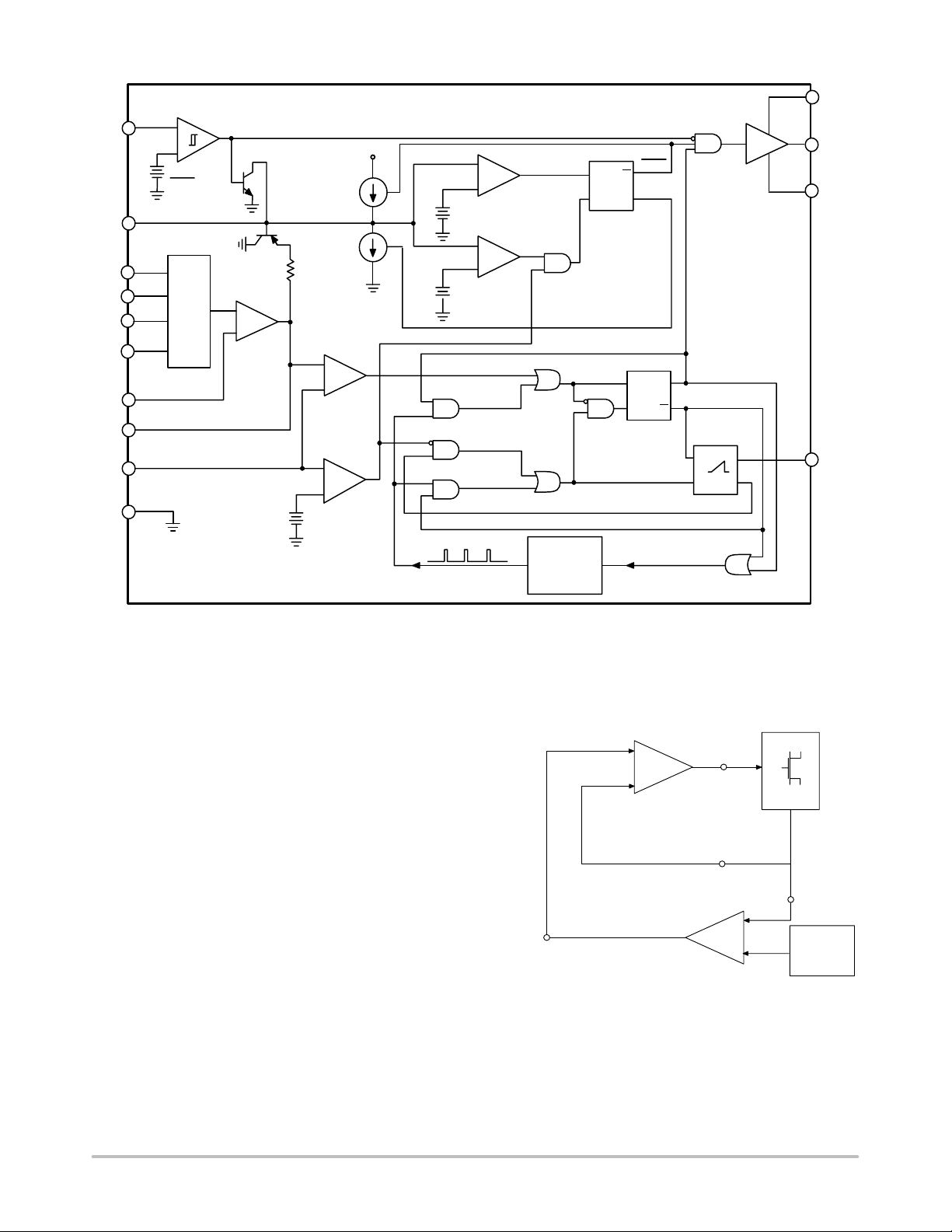

Figure 2. Block Diagram

APPLICATIONS INFORMATION

THEORY OF OPERATION

V2 Control Method

The V2 method of control uses a ramp signal that is

generated by the ESR of the output capacitors. This ramp is

proportional to the AC current through the main inductor

and is offset by the value of the DC output voltage. This

control scheme inherently compensates for variation in

either line or load conditions, since the ramp signal is

generated from the output voltage itself. This control

scheme differs from traditional techniques such as voltage

mode, which generates an artificial ramp, and current mode,

which generates a ramp from inductor current.

COMP

Time–Out

Timer

(30 µs)

Edge Triggered

PWM

Comparator

+

C

–

Ramp

Signal

Error

Amplifier

Error

Signal

Figure 3. V2 Control Diagram

V

V

GATE

FFB

E

Output

Voltage

Feedback

V

FB

–

+

Reference

Voltage

http://onsemi.com

6

CS5151H

The V2 control method is illustrated in Figure 3. The

output voltage is used to generate both the error signal and

the ramp signal. Since the ramp signal is simply the output

voltage, it is a ffected by any change in the output regardless

of the origin of that change. The ramp signal also contains

the DC portion of the output voltage, which allows the

control circuit to drive the main switch to 0% or 100% duty

cycle as required.

A change in line voltage changes the current ramp in the

inductor, affecting the ramp signal, which causes the V

control scheme to compensate the duty cycle. Since the

change in inductor current modifies the ramp signal, as in

current mode control, the V2 control scheme has the same

advantages in line transient response.

A change in load current will have an affect on the output

voltage, altering the ramp signal. A load step immediately

changes the state of the comparator output, which controls

the main switch. Load transient response is determined only

by the comparator response time and the transition speed of

the main switch. The reaction time to an output load step has

no relation to the crossover frequency of the error signal

loop, as in traditional control methods.

The error signal loop can have a low crossover frequency,

since transient response is handled by the ramp signal loop.

The main purpose of this ‘slow’ feedback loop is to provide

DC accuracy. Noise immunity is significantly improved,

since the error amplifier bandwidth can be rolled off a t a lo w

frequency. Enhanced noise immunity improves remote

sensing of the output voltage, since the noise associated with

long feedback traces can be effectively filtered.

Line and load regulation are drastically improved because

there are two independent voltage loops. A voltage mode

controller relies on a change in the error signal to

compensate for a deviation in either line or load voltage.

This change in the error signal causes the output voltage to

change corresponding to the gain of the error amplifier,

which is normally specified as line and load regulation. A

current mode controller maintains fixed error signal under

deviation in the line voltage, since the slope of the ramp

signal changes, but still relies on a change in the error signal

for a deviation in load. The V

2

method of control maintains

a fixed error signal for both line and load variation, since the

ramp signal is affected by both line and load.

Constant Off Time

To maximize transient response, the CS5151H uses a

constant of f time method to control the rate of output pulses.

During normal operation, the off time of the high side switch

is terminated after a fixed period, set by the C

capacitor.

OFF

To maintain regulation, the V2 control loop varies switch on

time. The PWM comparator monitors the output voltage

ramp, and terminates the switch on time.

Constant off time provides a number of advantages.

Switch duty cycle can be adjusted from 0 to 100% on a pulse

by pulse basis when responding to transient conditions. Both

0% and 100% duty cycle operation can be maintained for

extended periods of time in response to load or line

transients. PWM slope compensation to avoid

sub–harmonic oscillations at high duty cycles is avoided.

Switch on time is limited by an internal 30 µs timer,

minimizing stress to the power components.

2

Programmable Output

The CS5151H is designed to provide two methods for

programming the output voltage of the power supply . A four

bit on board digital to analog converter (DAC) is used to

program the output voltage from 2.14 V to 3.54 V in 100 mV

steps, depending on the digital input code. If all four bits are

left open, the CS5151H enters adjust mode. In adjust mode,

the designer can choose any output voltage by using resistor

divider feedback to the V

FB

and V

pins, as in traditional

FFB

controllers. The CS5151H is specifically designed to be

upwards compatible with the CS5156H, which uses a five

bit DAC code.

Start Up

Until the voltage o n t he V

supply p in e xceeds t he 3 .9 V

CC1

monitor threshold, the Soft Start and gate pins are held low.

The FAULT latch is reset (no Fault condition). The output

of the error amplifier (COMP) is pulled up to 1.0 V by the

comparator clamp. When the V

pin exceeds the monitor

CC1

threshold, the GATE output is activated, and the Soft Start

capacitor begins charging. The GATE output will remain on,

enabling the NFET switch, until terminated by either the

PWM comparator, or the maximum on time timer.

If the maximum on time is exceeded before the regulator

output voltage achieves the 1.0 V level, the pulse is

terminated. The G ATE pin drives low for the duration of the

extended off time. This time is set by the time out timer and

is approximately equal to the maximum on time, resulting in

a 50% duty cycle. Then, the GATE pin will drive high, and

the cycle repeats.

When regulator output voltage achieves the 1.0 V level

present at the COMP pin, regulation has been achieved and

normal off time will ensue. The PWM comparator

terminates the switch on time, with off time set by the C

capacitor. The V2 control loop will adjust switch duty cycle

as required to ensure the regulator output voltage tracks the

output of the error amplifier.

The Soft Start and COMP capacitors will charge to their

final levels, providing a controlled turn on of the regulator

output. Regulator turn on time is determined by the COMP

capacitor charging to its final value. Its voltage is limited by

OFF

http://onsemi.com

7

CS5151H

o

the Soft Start COMP clamp and the voltage on the Soft Start

pin (see Figures 4 and 5).

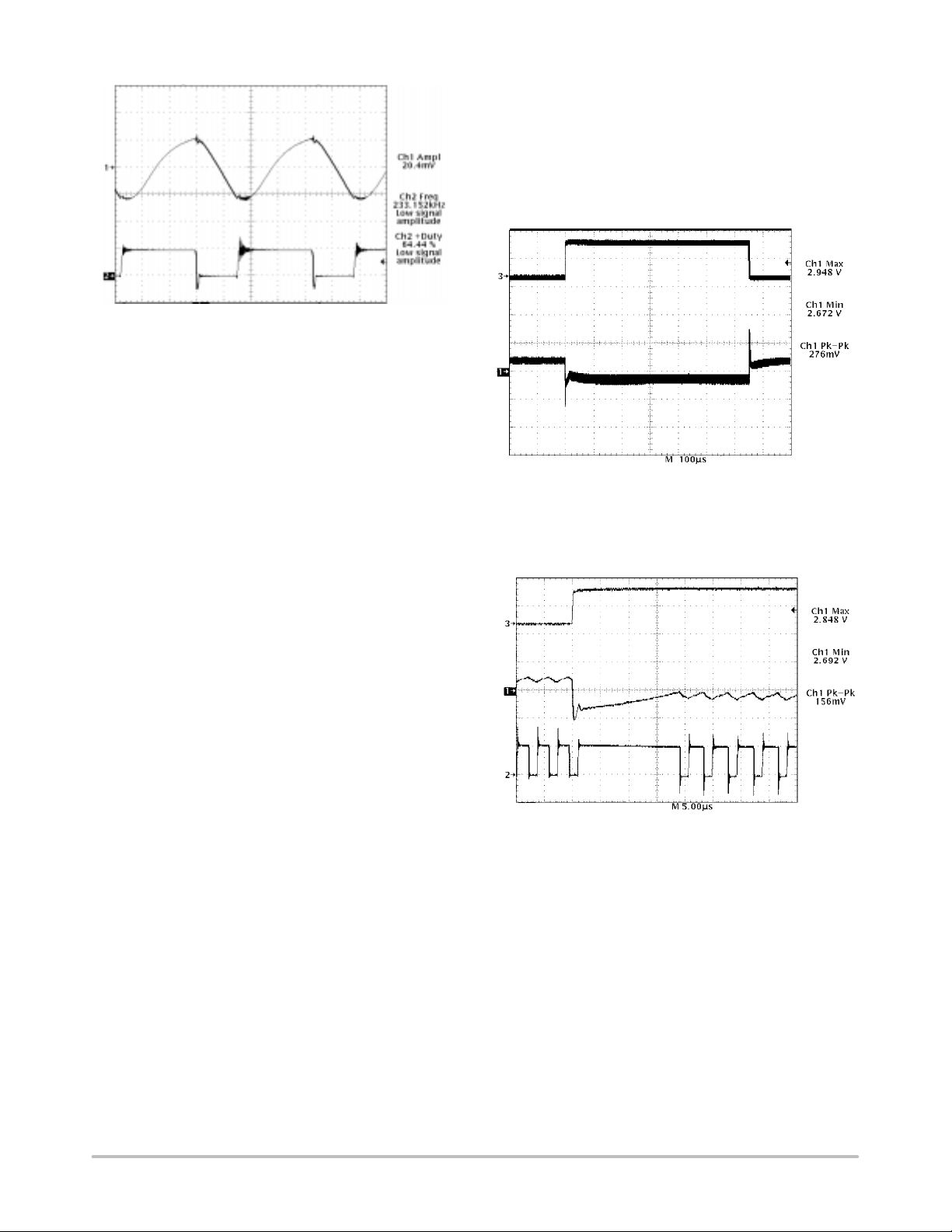

M 250 µs

Trace 1– Regulator Output Voltage (1.0 V/div.)

Trace 2– Inductor Switching Node (2.0 V/div.)

Trace 3– 12 V Input (V

Trace 4– 5.0 V Input (1.0 V/div.)

Figure 4. CS5151H Demonstration Board Startup in

Response to Increasing 12 V and 5.0 V Input Voltages.

Extended Off Time is Followed by Normal Off Time

Operation when Output Voltage Achieves Regulation t

and V

CC1

) (5.0 V/div.)

CC2

the Error Amplifier Output.

M 10.0 µs

Trace 1– Regulator Output Voltage (5.0 V/div.)

Trace 2– Inductor Switching Node (5.0 V/div.)

Figure 6. CS5151H Demonstration Board Enable

Startup Waveforms

Normal Operation

During normal operation, switch off time is constant and

set by the C

capacitor. Switch on time is adjusted by the

OFF

V2 control loop to maintain regulation. This results in

changes in regulator switching frequency, duty cycle, and

output ripple in response to changes in load and line. Output

voltage ripple will be determined by inductor ripple current

working into the ESR of the output capacitors (see Figures

7 and 8).

M 2.50 ms

Trace 1– Regulator Output Voltage (1.0 V/div.)

Trace 3– COMP PIn (error amplifier output) (1.0 V/div.)

Trace 4– Soft Start Pin (2.0 V/div.)

Figure 5. CS5151H Demonstration Board Startup

Waveforms

If the input voltage rises quickly, or the regulator output

is enabled externally, output voltage will increase to the

level set by the error amplifier output more rapidly, usually

within a couple of cycles (see Figure 6).

http://onsemi.com

Trace 1– Regulator Output Voltage (10 mV/div.)

Trace 2– Inductor Switching Node (5.0 V/div.)

Figure 7. Peak–to–Peak Ripple on V

I

OUT

8

M 1.00 µs

= 0.5 A (Light Load)

OUT

= 2.8 V,

CS5151H

M 1.00 µs

Trace 1– Regulator Output Voltage (10 V/div.)

Trace 2– Inductor Switching Node (5.0 V/div.)

Figure 8. Peak–to–Peak Ripple on V

I

= 13 A (Heavy Load)

OUT

Transient Response

The CS5151H V2 control loop’s 100 ns reaction time

provides unprecedented transient response to changes in

input voltage or output current. Pulse by pulse adjustment of

duty cycle is provided to quickly ramp the inductor current

to the required level. Since the inductor current cannot be

changed instantaneously, regulation is maintained by the

output capacitor(s) during the time required to slew the

inductor current.

Overall load transient response is further improved

through a feature called “adaptive voltage positioning”. This

technique pre–positions the output capacitor’s voltage to

reduce total output voltage excursions during changes in

load.

Holding tolerance to 1.0% allows the error amplifier’s

reference voltage to be targeted +40 mV high without

compromising DC accuracy. A “droop resistor”,

implemented through a PC board trace, connects the error

amplifier’s feedback pin (V

) to the output capacitors and

FB

load and carries the output current. With no load, there is no

DC drop across this resistor, producing an output voltage

tracking the error amplifier’s, including the +40 mV offset.

When the full load current is delivered, an 80 mV drop is

developed across this resistor. This results in output voltage

being offset –40 mV low.

The result of adaptive voltage positioning is that

additional margin is provided for a load transient before

reaching the output voltage specification limits. When load

current suddenly increases from its minimum level, the

output capacitor is pre–positioned +40 mV. Conversely,

when load current suddenly decreases from its maximum

OUT

= 2.8 V,

level, the output capacitor is pre–positioned –40 mV (see

Figures 9, 10, and 11). For best transient response, a

combination of a number of high frequency and bulk output

capacitors are usually used.

If the maximum on time is exceeded while responding to

a sudden increase in load current, a normal off time occurs

to prevent saturation of the output inductor.

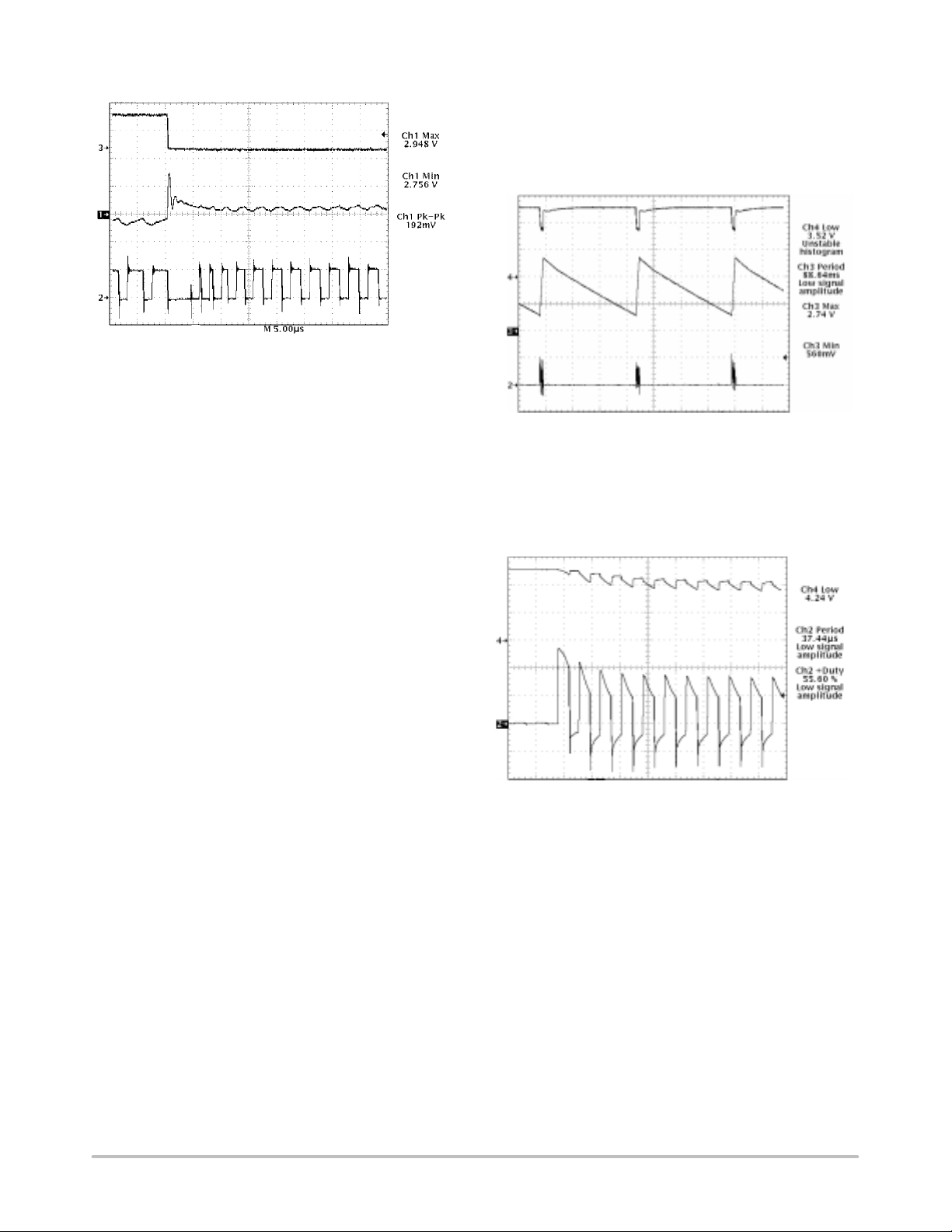

Trace 1– Regulator Output Voltage (1.0 V/div.)

Trace 2– Regulator Output Voltage (20 V/div.)

Figure 9. CS5151H Demonstration Board Response

to a 0.5 to 13 A Load Pulse (Output Set for 2.8 V)

Trace 1– Regulator Output Voltage (1.0 V/div.)

Trace 2– Inductor Switching Node (5.0 V/div.)

Trace 3– Output Current (0.5 to 13 Amps) (20 V/div.)

Figure 10. CS5151H Demonstration Board Response to

13 A Load Turn On (Output Set for 2.8 V). Upon

Completing a Normal Off Time, The V

Immediately Connects the Inductor to the Input

Voltage, Providing 100% Duty Cycle. Regulation is

Achieved in Less Than 20 s

2

Control Loop

http://onsemi.com

9

CS5151H

Trace 1– Regulator Output Voltage (1.0 V/div.)

Trace 2– Inductor Switching Node (5.0 V/div.)

Trace 3– Output Current (13 to 0,5 Amps) (20 mV/div.)

Figure 11. CS5151H Demonstration Board Response to

13 A Load Turn Off (Output Set for 2.8 V). V

Topology Immediately Connects Inductor to Ground,

Providing 0% Duty Cycle. Regulation is Achieved in

Less Than 10 s

PROTECTION AND MONITORING FEATURES

V

Monitor

CC1

To maintain predictable startup and shutdown

characteristics an internal V

monitor circuit is used to

CC1

prevent the part from operating below 3.75 V minimum

startup. The V

monitor comparator provides hysteresis

CC1

and guarantees a 3.70 V minimum shutdown threshold.

2

Control

traces than occurs with constant current limit protection (see

Figures 12 and 13).

If the short circuit condition is removed, output voltage

will rise above the 1.0 V level, preventing the FAULT latch

from being set, allowing normal operation to resume.

M 25.0 ms

Trace 4– 5.0 V Supply Voltage (2.0 V/div.)

Trace 3– Soft Start Timing Capacitor (1.0 V/div.)

Trace 2– Inductor Switching Node (2.0 V/div.)

Figure 12. CS5151H Demonstration Board Hiccup

Mode Short Circuit Protection. Gate Pulses are

Delivered While the Soft Start Capacitor Charges, and

Cease During Discharge

Short Circuit Protection

A lossless hiccup mode short circuit protection feature is

provided, requiring only the Soft Start capacitor to

implement. If a s hort c ircuit condition o ccurs ( V

the V

low comparator sets the F AULT latch. This causes

FFB

FFB

< 1.0 V),

the MOSFET to shut off, disconnecting the regulator from

it’s input voltage. The Soft Start capacitor is then slowly

discharged by a 2.0 µA current source until it reaches it’s

lower 0.7 V threshold. The regulator will then attempt to

restart normally, operating in it’s extended off time mode

with a 50% duty cycle, while the Soft Start capacitor is

charged with a 60 µA charge current.

If the short circuit condition persists, the regulator output

will not achieve the 1.0 V low V

comparator threshold

FFB

before the Soft Start capacitor is charged to it’s upper 2.5 V

threshold. If thi s happens the cycle will repeat itself until the

short is removed. The Soft Start charge/discharge current

ratio sets the duty cycle for the pulses (2.0 µA/60 µA =

3.3%), while actual duty cycle is half that due to the

extended off time mode (1.65%).

This protection feature results in less stress to the

regulator components, input power supply, and PC board

Trace 4– 5.0 V from PC Power Supply (2.0 V/div.)

Trace 2– Inductor Switching Node (2.0 V/div.)

Figure 13. Startup with Regulator Output Shorted

Overvoltage Protection

M 50.0 µs

Overvoltage protection (OVP) is provided as result of the

normal operation of the V

2

control topology and requires no

additional external components. The control loop responds

to an overvoltage condition within 100 ns, causing the

MOSFET to shut off, disconnecting the regulator from it’s

input voltage.

External Output Enable Circuit

On/off control of the regulator can be implemented

through two additional discrete components (see Figure 14).

http://onsemi.com

10

CS5151H

This circuit operates by pulling the Soft Start pin high, and

the V

Figure 14. Implementing Shutdown with the CS5151H

External Power Good Circuit

the use of four additional external components (see Figure

15). The threshold voltage of the Power Good signal can be

adjusted per the following equation:

the Power Good output to ground for regulator voltages less

than V

Figure 15. Implementing Power Good with the CS5151H

pin low, emulating a short circuit condition.

FFB

5.0 V

MMUN2111T1 (SOT–23)

5

SS

CS5151H

8

V

FFB

IN4148

Shutdown

Input

An optional Power Good signal can be generated through

V

Power Good

(R1 R2) 0.65 V

R2

This circuit provides an open collector output that drives

V

OUT

.

10 k

R1

R2

6.2 k

5.0 V

R3

10 k

PN3904

Power Good

PN3904

Power Good

CS5151H

M 2.50 ms

Trace 3 – 12 V Input (V

Trace 4– 5.0 V Input (2.0 V/div.)

Trace 1– Regulator Output Voltage (1.0 V/div.)

Trace 2– Power Good Signal (2.0 V/div.)

CC1

) and (V

) (10 V/div.)

CC2

Figure 16. CS5151H Demonstration Board During

Power Up. Power Good Signal is Activated when

Output Voltage Reaches 1.70 V.

Selecting External Components

The CS5151H can be used with a wide range of external

power components to optimize the cost and performance of

a particular design. The following information can be used

as general guidelines to assist in their selection.

NFET Power Transistors

Both logic level and standard MOSFETs can be used. The

reference designs derive gate drive from the 12 V supply

which is generally available in most computer systems and

use logic level MOSFETs. A charge pump may be easily

implemented to permit use of standard MOSFETs or support

5.0 V or 12 V only systems (maximum of 20 V). Multiple

MOSFETs may be paralleled to reduce losses and improve

efficiency and thermal management.

Voltage applied to the MOSFET gates depends on the

application circuit used. The gate driver output is specified

to drive to within 1.5 V of ground when in the low state and

to within 2.0 V of its bias supply when in the high state. In

practice, the MOSFET gate will be driven rail to rail due to

overshoot caused by the capacitive load it presents to the

controller IC. For the typical application where V

V

= 12 V and 5.0 V is used as the source for the regulator

CC2

CC1

=

output current, the following gate drive is provided;

V

12 V 5.0 V 7.0 V

GATE

(see Figure 17.)

http://onsemi.com

11

CS5151H

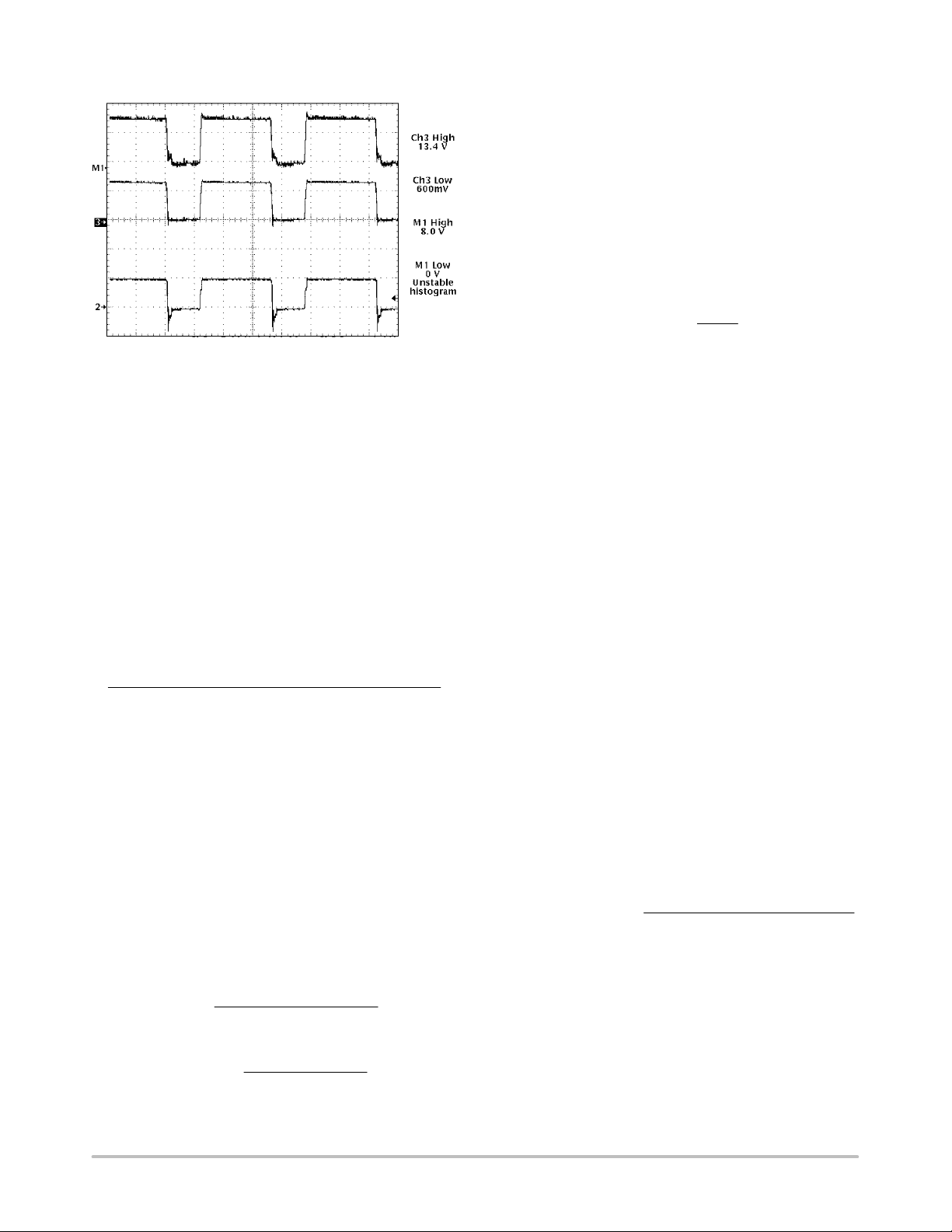

M 1.00 µs

Channel 3 = V

Channel 2– Inductor Switching Node

Figure 17. CS5151H Gate Drive Waveforms Depicting

The most important aspect of MOSFET performance is

RDSON, which effects regulator efficiency and MOSFET

thermal management requirements.

The power dissipated by the MOSFET and the Schottky

diode may be estimated as follows;

Switching MOSFET:

Schottky diode:

Duty Cycle =

VIN V

GATE

M1 = V

GATE

Power I

Power V

FORWARD

– 5.0 V

IN

Rail to Rail Swing

2

LOAD

FORWARD

RDSON duty cycle

V

V

OUT

(I

LOAD

I

LOAD

FORWARD

RDS

(

1 duty cycle

ON OF SYNCH FET

)

“Droop” Resistor for Adaptive Voltage Positioning

Adaptive voltage positioning is used to reduce output

voltage excursions during abrupt changes in load current.

Regulator output voltage is offset +40 mV when the

regulator is unloaded, and –40 mV at full load. This results

in increased margin before encountering minimum and

maximum transient voltage limits, allowing use of less

capacitance on the regulator output (see Figure 9).

To implement adaptive voltage positioning, a “droop”

resistor must be connected between the output inductor and

output capacitors and load. This is normally implemented by

a PC board trace of the following value:

R

DROOP

80 mV

I

MAX

Adaptive voltage positioning can be disabled for

improved DC regulation by connecting the VFB pin directly

to the load using a separate, non–load current carrying

circuit trace.

Input and Output Capacitors

These components must be selected and placed carefully

to yield optimal results. Capacitors should be chosen to

provide acceptable ripple on the input supply lines and

regulator output voltage. Key specifications for input

capacitors are their ripple rating, while ESR is important for

output capacitors. For best transient response, a combination

of low value/high frequency and bulk capacitors placed

close to the load will be required.

)

Output Inductor

The inductor should be selected based on its inductance,

current capability, and DC resistance. Increasing the

inductor value will decrease output voltage ripple, but

degrade transient response.

Off Time Capacitor (C

The C

When the V

the C

timing capacitor sets the regulator off time:

OFF

T

OFF

pin is less than 1.0 V, the current charging

FFB

capacitor is reduced. The extended off time can be

OFF

OFF

C

)

OFF

4848.5

calculated as follows:

T

C

OFF

Off time will be determined by either the T

OFF

24,242.5

time, or the

OFF

time out timer, whichever is longer.

The preceding equations for duty cycle can also be used

to calculate the regulator switching frequency and select the

C

timing capacitor:

OFF

C

OFF

Perioid (1 duty cycle

4848.5

)

where:

Period

switching frequency

1

http://onsemi.com

THERMAL MANAGEMENT

Thermal Considerations for Power

MOSFETs and Diodes

In order to maintain good reliability, the junction

temperature of the semiconductor components should be

kept to a maximum of 150°C or lower. The thermal

impedance (junction to ambient) required to meet this

requirement can be calculated as follows:

Thermal Impedance

T

JUNCTION(MAX)

Power

T

AMBIENT

A heatsink may be added to TO–220 components to

reduce their thermal impedance. A number of PC board

layout techniques such as thermal vias and additional copper

foil area can be used to improve the power handling

capability of surface mount components.

12

CS5151H

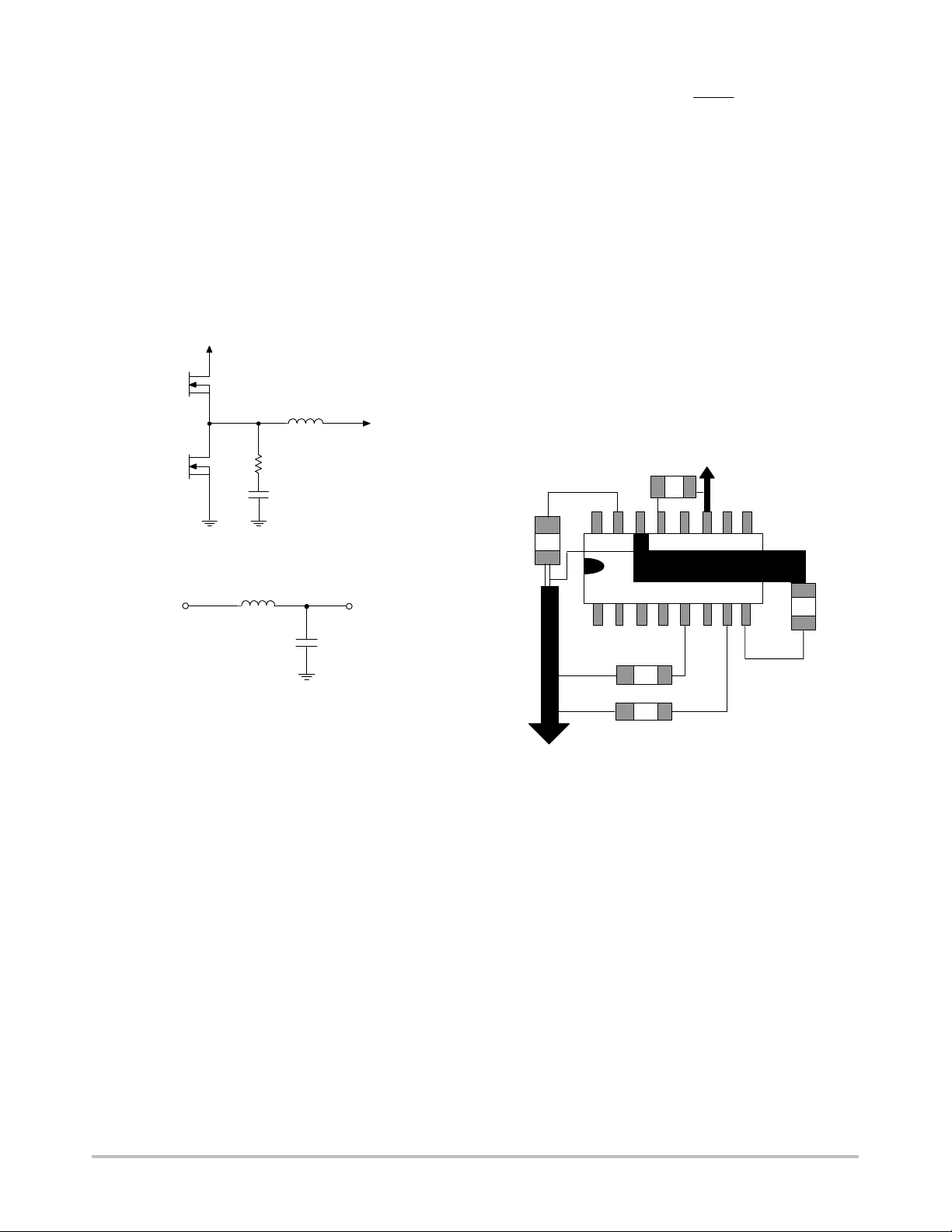

EMI Management

As a consequence of large currents being turned on and off

at high frequency, switching regulators generate noise as a

consequence of their normal operation. When designing for

compliance with EMI/EMC regulations, additional

components may be added to reduce noise emissions. These

components are not required for regulator operation and

experimental results may allow them to be eliminated. The

input filter inductor may not be required because bulk filter

and bypass capacitors, as well as other loads located on the

board will tend to reduce regulator di/dt effects on the circuit

board and input power supply. Placement of the power

component to minimize routing distance will also help to

reduce emissions.

2.0 µH

33 Ω

1000 pF

Figure 18. Filter Components

R

TRACE

80 mV

I

MAX

This causes the output voltage to be +40 mV with no

load, and –40 mV with a full load, improving regulator

transient response. This trace must be wide enough to

carry the full output current. (T ypical trace is 1.0 inch

long, 0.17 inch wide). Care should be taken to

minimize any additional losses after the feedback

connection point to maximize regulation.

7. If DC regulation is to be optimized (at the expense of

degraded transient regulation), adaptive voltage

positioning can be disabled by connecting to V

directly to the load with a separate trace (remote

sense).

8. Place 5.0 V input capacitors close to the switching

MOSFET.

Route gate drive signals V

(pin 10) with a trace

GATE

that is a minimum of 0.025 inches wide.

To the negative terminal

of the input capacitors

1.0 µF

V

COMP

V

CC

0.1 µF

15 11

FB

pin

2.0 µH

+

1200 pF × 3.0/16 V

Figure 19. Input Filter

Layout Guidelines

1. Place 12 V filter capacitor next to the IC and connect

capacitor ground to pin 11 (PGND).

2. Connect pin 11 (PGND) with a separate trace to the

ground terminals of the 5.0 V input capacitors.

3. Place fast feedback filter capacitor next to pin 8 (V

and connect it’s ground terminal with a separate, wide

trace directly to pin 14 (LGND).

4. Connect the ground terminals of the Compensation

capacitor directly to the ground of the fast feedback

filter capacitor to prevent common mode noise from

effecting the PWM comparator.

5. Place the output filter capacitor(s) as close to the load

as possible and connect the ground terminal to pin 14

(LGND).

6. To implement adaptive voltage positioning, connect

both slow and fast feedback pins 16 (V

(V

) to the regulator output right at the inductor

FFB

) and 8

FB

terminal. Connect inductor to the output capacitors via

a trace with the following resistance:

FFB

8

5

SOFT START

OFF TIME

To the negative terminal of the output capacitors

Figure 20. Layout Guidelines

100 pF

V

FFB

)

http://onsemi.com

13

5.0V

CS5151H

MBRS

120

0.1 µF

0.1 µF

330 pF

0.33 µF

MBRS120

MBRS120

1.0 µF

1.0 µF

V

CC1

V

ID0

V

ID1

V

ID2

V

ID3

C

OFF

V

CC2

CS5151H

V

GATE

Si4410DY

MBR1535CT

+

2

1,3

PGND

SS

COMP

LGND

V

FB

V

FFB

3.3 k

100 pF

Figure 21. Additional Application Diagram, 5.0 V to 3.3 V/10 A Converter

12 V

3.3 V

100 µF/10 V × 3

Tantalum

3.0 µH

3.3 V/10 A

+

100 µF/10 V × 3

Tantalum

1.0 µF

+

CC1

V

CC2

CS5151H

V

GATE

V

FB

Si9410

MBR1535CT

2

1,3

V

V

ID0

V

ID1

V

ID2

V

ID3

C

OFF

330 pF

0.1 µF

0.1 µF

SS

COMP

LGND

0.33 µF

PGND

V

FFB

3.3 k

100 pF

Figure 22. Additional Application Diagram, 3.3 V to 2.5 V/7.0 A Converter with 12 V Bias

33 µF/25 V × 3

Tantalum

5.0 µH

+

2.5 V/7.0 A

100 µF/10 V × 2

Tantalum

http://onsemi.com

14

MBRS

120

0.1 µF

CS5151H

5.0V

MBRS120

2

1,3

+

100 µF/10 V × 3

Tantalum

3.0 µH

10 Ω

MBRS120

1.0 µF

1.0 µF

V

CC1

V

ID0

V

ID1

V

ID2

V

ID3

C

OFF

V

CC2

CS5151H

V

GATE

V

FB

Si4410

MBR1535CT

330 pF

0.1 µF

SS

COMP

LGND

0.33 µF

PGND

V

FFB

3.3 k

100 pF

Figure 23. Additional Application Diagram, 5.0 V to 3.3 V/10 A Converter with Current Sharing

Remote

Sense

3.3 V/10 A

100 µF/10 V × 3

+

Tantalum

Connect to other

circuits for current

sharing

http://onsemi.com

15

–T–

–A–

16 9

–B–

18

G

K

C

SEATING

PLANE

D

16 PL

0.25 (0.010) A

M

S

B

T

S

CS5151H

PACKAGE DIMENSIONS

SO–16

D SUFFIX

CASE 751B–05

ISSUE J

8 PLP

M

0.25 (0.010) B

M

S

X 45

R

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

F

J

DIM MIN MAX MIN MAX

A 9.80 10.00 0.386 0.393

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.054 0.068

D 0.35 0.49 0.014 0.019

F 0.40 1.25 0.016 0.049

G 1.27 BSC 0.050 BSC

J 0.19 0.25 0.008 0.009

K 0.10 0.25 0.004 0.009

M 0 7 0 7

P 5.80 6.20 0.229 0.244

R 0.25 0.50 0.010 0.019

INCHESMILLIMETERS

PACKAGE THERMAL DATA

Parameter

R

Θ

JC

R

Θ

JA

V2 is a trademark of Switch Power, Inc.

Pentium is a registered trademark and MMX is a trademark of Intel Corporation.

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without

further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

Typical 28 °C/W

Typical 115 °C/W

16–SO Unit

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 Toll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone: (+1) 303–308–7140 (Mon–Fri 2:30pm to 7:00pm CET)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (Mon–Fri 2:00pm to 7:00pm CET)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (Mon–Fri 12:00pm to 5:00pm GMT)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, UK, Ireland

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

ASIA/PACIFIC: LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

Toll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan 141–0031

Phone: 81–3–5740–2745

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

http://onsemi.com

16

CS5151H/D

Loading...

Loading...