OnLine Power Power Wave 4 User Manual

Power Wave 4

Emergency Lighting Inverter (ELI)

10 – 160 KVA

*200 - 500 KVA

User Manual

Installation

Operation

Maintenance

Doc #. 6005-145

Rev. A

Due to continuous product improvement this document is subject to change without prior notice.

CAUTION!

HAZARDOUS VOLTAGE EXISTS INSIDE THE ELI (INCLUDES THE

CONNECTION TERMINALS). CABLE CONNECTION AND MAINTENANCE

SHOULD BE DOBE BY PROFESSIONAL OR QUALIFIES PERSONNEL.

THE ELI HAS ITS OWN INTERNAL POWER SOURCE (BATTERIES). THE

OUTPUT TERMINALS MAY BE LIVE EVEN WHEN THE ELI IS NOT CONNECTED

TO THE AC SUPPLY.

DC CAPACITORS ARE EMPLOYED IN THIS UNIT. HAZARDOUS VOLTAGE

STILL EXITS EVEN WHEN THE UNIT IS NOT ENERGIZED. DO NOT TOUCH ANY

PART OF THE INSIDE OF THE ELI.

WARNING!

BE SURE TO OPERATE THE ELI WITHIN THE RATED POWER LEVEL.

PREVENT DIRECT EXPOSURE TO DIRECT SUNLIGHT, RAIN OR

CONTAMINATING ENVIRONMENT.

ONLY QUALIFIED TECNICIANS SHOULD REPLACE THE BATTERIES. SINCE

BATTERIES HAVE HIGH SHORT-CIRCUIT CURRENT CAPACITY, MISTAKES IN

CONNECTION OR DISCONNECTION CAN CAUSE SEVERE BURS OR DEATH

TO SERVICING PERSONNEL.

6005-145 Rev. A a

TABLE OF CONTENTS

CONTENTS …………………………………………….……………………….……………………….Page

SAFETY

1.

SYSTEM OVERVIEW

1.1. Construction of the ELI ............................................................................................................................... 1-1

1.2. Features and Advantages............................................................................................................................. 1-5

1.3. Rectifier ....................................................................................................................................................... 1-8

1.4. Inverter ....................................................................................................................................................... 1-10

1.5. Static Switch ..............................................................................................................................................1-11

1.6. Maintenance Bypass ................................................................................................................................. 1-12

1.7. Main Input Circuit Breaker ....................................................................................................................... 1-12

1.8. Main Output Circuit Breaker .................................................................................................................... 1-12

1.9. Battery Circuit Breaker ............................................................................................................................. 1-12

..................................................................................................................... a

............................................................................................. 1-1

1.10 Battery ....................................................................................................................................................... 1-12

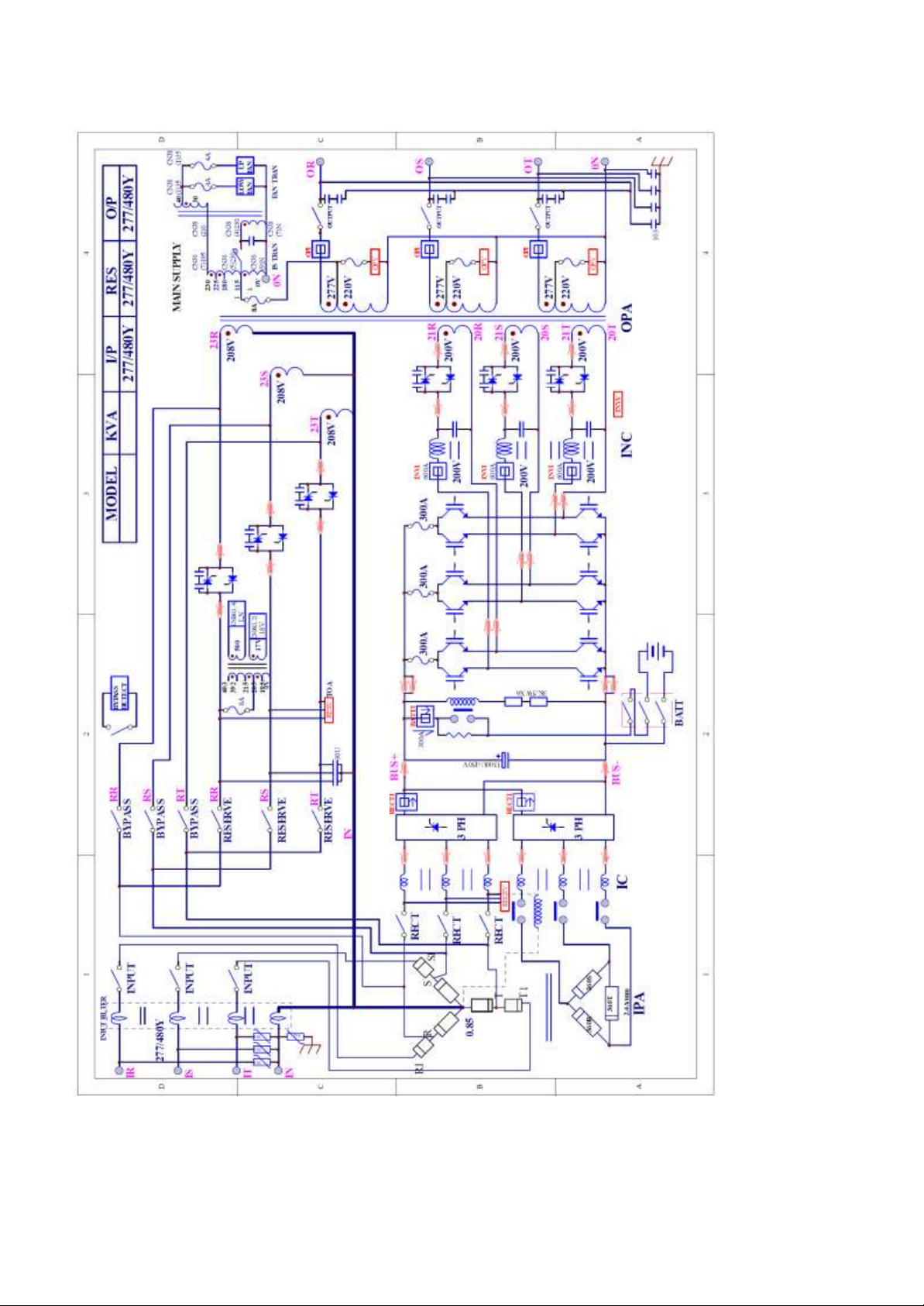

1.11 Single Line Diagram (120/208Y) ............................................................................................................ 1-13

1.12 Single Line Diagram (277/480Y) ............................................................................................................ 1-14

1.13 Dimensions & Drawings .......................................................................................................................... 1-15

1.14 Front Panel ................................................................................................................................................ 1-21

2.

TECHNICAL SPECIFICATION

2.1. Specification for 208/120V Unit ............................................................................................................................... 2-1

2.2. Specification for 480/277V Unit ............................................................................................................................... 2-2

2.3 Model Number Chart .................................................................................................................................... 2-3

3.

INSTALLATION

3.1. Site & Environment Consideration ............................................................................................................ 3-1

3.2. Unpacking .................................................................................................................................................... 3-4

3.3. Cable Selection ............................................................................................................................................ 3-5

3.4. Input/Output Protective Device Rating Chart ............................................................................................ 3-6

3.5. Terminal Connection ................................................................................................................................... 3-7

4.

OPERATIONS

............................................................................................................................................. 3-1

.................................................................................................................................................. 4-1

................................................................................................. 2-1

4.1. Start-up Procedure ....................................................................................................................................... 4-1

4.2. Shutdown Procedure .................................................................................................................................... 4-2

4.3. From Inverter to Maintenance Bypass Procedure ..................................................................................... 4-3

4.4. From Maintenance Bypass to Inverter Procedure ..................................................................................... 4-4

4.5.

Green mode selection

6005-145 Rev. A b

.................................................................................................................................... 4-5

CONTENTS ................................................................................................................................................. Page

5.

LCD DISPLAY

5.1. Menu 0 – Main Menu ................................................................................................................................ 5-1

5.2. Menu 1 – Select Menu .............................................................................................................................. 5-2

5.3. Menu 2 – Status / Warning Menu .................................................................................................................... 5-3

5.4. Menu 3 – Real Time Data Menu ...................................................................................................................... 5-4

5.5. Menu 4 – Historical Event Menu .............................................................................................................. 5-5

5.6. Menu 5 – Parameter Setting Menu ........................................................................................................... 5-6

5.7. Menu 6 – Rectifier Data Menu .................................................................................................................. 5-7

5.8. Menu 7 – Output Data Menu ..................................................................................................................... 5-8

5.9. Menu 8 – Other Data Menu ....................................................................................................................... 5-8

5.10. Menu 9 – Reserve Data Menu ......................................................................................................................................... 5-9

5.11. Menu 10 – Boost Charge Setting Menu ................................................................................................................ 5-9

5.12. Menu 11 – Data Time Setting Menu ........................................................................................................................... 5-11

5.13. Menu 12 – Other Setting Menu ........................................................................................................................... 5-12

.................................................................................................................................. 5-1

6.

INTERFACE CONNECTIONS

6.1. Dry Contacts .............................................................................................................................................. 6-1

6.2. External Shutdown ..................................................................................................................................... 6-4

6.3. DB9 Connection ......................................................................................................................................... 6-4

7.

OPTIONS

7.1. Emergency Power Off Switch (EPO) ....................................................................................................... 7.1

7.2. Remote Control Panel ................................................................................................................................ 7.1

7.3. Software for PC Monitoring ...................................................................................................................... 7.2

7.4. Auto Dialing Module ................................................................................................................................. 7.2

7.5. Battery Monitoring Module - DCMAN .................................................................................................... 7.2

7.6. Input Transient Voltage Surge Suppressor (TVSS) ................................................................................. 7.2

7.7. Web/SNMP Card ........................................................................................................................................ 7.3

7.8. Output AUX Circuit Breakers ................................................................................................................... 7.3

7.9. Higher Kaic Circuit Breakers .................................................................................................................... 7.3

7.10. Delta Input ................................................................................................................................................ 7.3

................................................................................................ ..................................... 7-1

................................................................................................ .. 6-1

7.11. Dual Input ................................................................................................................................................. 7.3

7.12. Seismic Bracket. ....................................................................................................................................... 7.3

7.13. Factory Set Green Mode .......................................................................................................................... 7.3

7.14. Battery Cabinet and Battery run time...................................................................................................... 7. 4

7.15. Battery Cabinet Arrangement Drawings ................................................................................................. 7.6

7.16. Replaceable Parts List ............................................................................................................................ 7.11

6005-145 Rev. A c

CONTENTS ................................................................................................................................................. Page

8.

REDUNDANCY

8.1. Serial Redundancy ....................................................................................................................................... 81

8.2. Parallel Redundancy .................................................................................................................................. 8-4

9.

MAINTENANCE

9.1. Safety and Precautions .............................................................................................................................. 9-1

9.2. When to call ............................................................................................................................................... 9-3

9.3. Step to take ................................................................................................................................................. 9-3

9.4. Preventive Maintenance ............................................................................................................................ 9-4

9.4.1 Maintenance Log ..................................................................................................................................... 9-4

9.4.2 Periodic Testing of Unit .......................................................................................................................... 9-5

.............................................................................................................................................. 8-1

............................................................................................................................................ 9-1

9.4.3 Maintaining Batteries .............................................................................................................................. 9-5

9.4.4 Battery Cabinets ...................................................................................................................................... 9-7

9.4.5 Power Connections .................................................................................................................................. 9-7

9.4.6 Battery Terminals .................................................................................................................................... 9-8

9.5. Online Power Customer Service and Support ......................................................................................... 9-8

9.5.1 Start-Up Services ..................................................................................................................................... 9-8

9.5.2 Maintenance Agreements........................................................................................................................ 9-8

9.5.3 Warranties ................................................................................................................................................ 9-8

9.5.4 Help .......................................................................................................................................................... 9-9

Appendix A

Battery Exerciser setting ................................................................................................................................ 9-15

6005-145 Rev. A d

OnLine Power, Inc.

Reproduction or Distribution forbidden

NOTICE: THIS DOCUMENT CONTAINS PROPRIETARY

INFORMATION

This document contains proprietary and confidential information of

OnLine Power, Inc. (”OnLine Power”). In consideration of the

receipt of this document, the recipient agrees not to copy any of its

contents, nor to disclose them to or allow them to be used by any

person not currently an OnLine Power employee or an employee of

the recipient having a need to know, without the express written

consent of OnLine Power, and further agrees to surrender this

document to OnLine Power when the reason for its receipt has

terminated. Due to continuous product improvement this document

is subject to change without prior notice.

© 2009 OnLine Power, Inc. – All rights reserved

6005-145 Rev. A e

Serial Number:

KVA/Power Rating:

Input Voltage:

Output Voltage:

Manufacturer Date:

Congratulations on selecting one of the fine products from OnLine Power, the leader in

power protection technology. Our wide product offering includes UPS (Uninterruptible

Power Systems), power conditioners, automatic voltage regulators and specialty

transformers (e.g., computer-grade, medical-grade). Since our founding in 1972, OnLine

Power has shipped many of these fine products to discerning customers around the world

for use on sensitive equipment and in critical applications.

One of our goals is to make our manuals both comprehensive and easy to use. The new

format of our user manual is the result of ideas and inputs from customers like you who

have taken an active interest in our continued success. We invite and appreciate your

feedback on our products and documentation via e-mail, fax, mail, or telephone.

HEADQUARTERS

OnLine Power

5701 Smith Street

Commerce, CA 90040

SALES

Phone: (800) 227-8899

FAX No: (323) 721-5017

E-mail: sales@onlinepower.com

Office Hours are 7:00 AM to 5:00 PM PST

SERVICE

If you require assistance, please call our 24-hour toll free hot line 800-PWR-

SRVC (800-797-7782) or email to info@800pwrsrvc.com. Please have the

following information from your unit’s nameplate available to speed

assistance:

Due to continuous product improvement this document is subject to change without prior notice.

6005-145 Rev. A f

Danger!

ONLY FACTORY TRAINED OR AUTHORIZED PERSONNEL SHOULD ATTEMPT

TO INSTALL OR REPAIR THE UNIT OR ITS BATTERY SYSTEM. IMPROPER

INSTALLATION HAS PROVEN TO BE THE SINGLE MOST SIGNIFICANT CAUSE

OF START-UP PROBLEMS. HIGH AC AND DC ELECTRICAL VOLTAGES ARE

PRESENT THROUGHOUT THE UNIT (S) AND INCORRECT INSTALLATION OR

SERVICING COULD RESULT IN ELECTROCUTION, FIRE, EXPLOSION, OR

EQUIPMENT MALFUNCTION.

Danger!

READ THIS MANUAL IN ITS ENTIRETY BEFORE PERFORMING

INSTALLATION, START-UP, OPERATION, AND MAINTENANCE OF THE UNIT

OR BATTERY SYSTEMS. FAILURE TO DO SO COULD RESULT IN

ELECTROCUTION, FIRE, EXPLOSION, OR EQUIPMENT MALFUNCTION.

Caution

SAFETY

Following safety precautions is important when operating or servicing electrical

equipment. The symbols shown are used extensively throughout this manual.

Always heed these precautions since they are essential to the safe operation and

servicing of this product.

Boxes labeled with the “ Danger!” symbol indicate that there is a high risk of

personal injury or death if instructions are not followed.

Warnings labeled with the symbol indicate that there is a high

probability of equipment malfunction, damage, or destruction if instructions are not

followed.

6005-145 Rev. A g

Danger!

EXERCISE EXTREME CARE WHEN HANDLING UNIT AND BATTERY

CABINETS TO AVOID EQUIPMENT DAMAGE OR INJURY TO PERSONNEL.

CABINETS WEIGH SEVERAL HUNDRED POUNDS.

Danger!

ALL POWER CONNECTIONS MUST BE COMPLETED BY A LICENSED

ELECTRICIAN WHO IS EXPERIENCED IN WIRING THIS TYPE OF EQUIPMENT.

WIRING MUST BE INSTALLED IN ACCORDANCE WITH ALL APPLICABLE

NATIONAL AND LOCAL ELECTRICAL CODES. IMPROPER WIRING MAY

CAUSE DAMAGE TO THE EQUIPMENT, INJURY OR DEATH OF PERSONNEL.

VERIFY THAT ALL HIGH AND LOW VOLTAGE INPUT POWER CIRCUITS ARE

DE-ENERGIZED AND LOCKED OUT BEFORE INSTALLING CABLES OR

MAKING ANY ELECTRICAL CONNECTIONS.

Danger!

OBSERVE ALL BATTERY SAFETY PRECAUTIONS DURING INSTALLATION

OR SERVICE OF THE UNIT OR BATTERIES. EVEN WITH THE BATTERY

CIRCUIT BREAKER IN THE OFF POSITION, THE DANGER OF

ELECTROCUTION MAY STILL BE PRESENT. THE BATTERY POWER TO THE

UNIT MUST BE LOCKED AND TAGGED “OFF” BEFORE PERFORMING ANY

SERVICE OR WORK ON THE UNIT. THE BATTERY MANUFACTURER’S

SAFETY INFORMATION AND MATERIAL SAFETY DATA SHEET IS LOCATED

IN A POCKET ATTACHED TO THE INSIDE OF LEFT DOOR OF EACH UNIT.

FAILURE TO FOLLOW INSTRUCTION LISTED ABOVE AND ELSEWHERE IN

THIS MANUAL COULD RESULT IN AN EXPLOSION, FIRE, EQUIPMENT

MALFUNCTION, OR ELECTROCUTION.

Danger!

TEST LIFT AND BALANCE THE CABINETS BEFORE MOVING. MAINTAIN

MINIMUM TILT FROM VERTICAL AT ALL TIMES. THE BOTTOM STRUCTURE

WILL SUPPORT THE UNIT ONLY IF THE FORKLIFT FORKS ARE

COMPLETELY UNDERNEATH THE UNIT.

6005-145 Rev. A h

Danger!

ALL POWER TO THE UNIT MUST BE LOCKED AND TAGGED “OFF” BEFORE

PERFORMING ANY SERVICE OR WORK ON THE UNIT. FAILURE TO DO SO

COULD RESULT IN ELECTROCUTION.

Danger!

EXTREME CAUTION IS REQUIRED WHEN PERFORMING MAINTENANCE.

LETHAL VOLTAGES EXIST WITHIN THE EQUIPMENT DURING OPERATION.

OBSERVE ALL WARNINGS AND CAUTIONS IN THIS MANUAL. FAILURE TO

COMPLY MAY RESULT IN SERIOUS INJURY OR DEATH. OBTAIN QUALIFIED

SERVICE FOR THIS EQUIPMENT AS INSTRUCTED.

Danger!

BE CONSTANTLY AWARE THAT THE UNIT SYSTEM CONTAINS HIGH DC AS

WELL AS AC VOLTAGES. WITH INPUT POWER OFF AND THE BATTERY,

DISCONNECTED, HIGH VOLTAGE AT THE FILTER CAPACITORS AND POWER

CIRCUITS SHOULD DISCHARGE WITHIN 30 SECONDS. HOWEVER, POWER

CIRCUIT MALFUNCTIONS CAN OCCUR, SO YOU SHOULD ALWAYS ASSUME

THAT HIGH VOLTAGE MIGHT STILL EXIST AFTER SHUTDOWN. VERIFY

THAT POWER IS OFF USING AC AND DC VOLTMETERS BEFORE MAKING

CONTACT.

Danger!

IN A FIRE INVOLVING ELECTRICAL EQUIPMENT, ONLY USE CARBON

DIOXIDE FIRE EXTINGUISHERS, OR THOSE APPROVED FOR USE ON

ELECTRICAL EQUIPMENT. USE OF WATER ON FIRES INVOLVING HIGH

VOLTAGE ELECTRICAL CIRCUITS COULD RESULT IN ELECTROCUTION .

Danger!

SOME COMPONENTS WITHIN THE CABINETS ARE NOT CONNECTED TO

CHASSIS GROUND. ANY CONTACT BETWEEN FLOATING CIRCUITS AND

THE CHASSIS IS A LETHAL SHOCK HAZARD.

6005-145 Rev. A i

Danger!

LEAD-ACID BATTERIES CONTAIN HAZARDOUS MATERIALS. BATTERIES MUST BE

HANDLED, TRANSPORTED, AND RECYCLED OR DISCARDED IN ACCORDANCE

WITH FEDERAL, STATE, AND LOCAL REGULATIONS. BECAUSE LEAD IS A TOXIC

SUBSTANCE, LEAD-ACID BATTERIES MUST BE RECYCLED OR DISCARDED AS

HAZADEROUS WAIST.

HARMFUL TO THE SKIN AND EYES AND MAY BE TOXIC.

OF ELECTRICAL SHOCK. THE FOLLOWING PRECAUTIONS SHOULD BE

OBSERVED WHEN WORKING ON BATTERIES:

1. REMOVE WATCHES, RINGS OR OTHER METAL OBJECTS.

2. USE TOOLS WITH INSULATED HANDLES.

3. WEAR RUBBER GLOVES AND BOOTS.

4. DO NOT LAY TOOLS OR METAL PARTS ON TOP OF BATTERIES.

5. DISCONNECT CHARGING SOURCE PRIOR TO CONNECTING OR

DISCONNECTING BATTERY TERMINALS.

6 DETERMINE IF BATTERY IS INADVERTENTLY GROUNDED. IF SO,

REMOVE THE SOURCE OF THE GROUND. CONTACT WITH ANY PART OF

A GROUNDED BATTERY CAN RESULT IN ELECTRICAL SHOCK. THE

LIKELIHOOD OF SUCH SHOCK WILL BE REDUCED IF SUCH GROUNDS

ARE REMOVED DURING INSTALLATION AND MAINTENANCE.

7 LEAD-ACID BATTERIES CAN PRESENT A RISK OF FIRE BECAUSE THEY

GENERATE HYDROGEN GAS. THE FOLLOWING PROCEDURES SHOULD

BE FOLLOWED:

1. DO NOT SMOKE WHEN NEAR BATTERIES.

2. DO NOT CAUSE FLAME OR SPARK IN BATTERY AREA.

8 DISCHARGE STATIC ELECTRICITY FROM YOUR BODY BEFORE

TOUCHING BATTERIES BY FIRST TOUCHING A GROUNDED SURFACE.

Danger!

INTERNAL BATTERY STRAPPING MUST BE VERIFIED BY THE CUSTOMER

PRIOR TO MOVING THIS UNIT.

THIS UNIT CONTAINS NON-SPILLABLE BATTERIES. KEEP THE UNIT

UPRIGHT. DO NOT STACK. DO NOT TIP. ALWAYS FOLLOW THE BATTERY

MANUFACTURER’S SAFETY INFORMATION LOCATED IN A POCKET

ATTACHED TO THE INSIDE OF THE LEFT DOOR OF YOUR UNIT TO PREVENT

AN ACCIDENT THAT COULD RESULT IN INJURY OR DEATH.

6005-145 Rev. A j

................................................................................................. 6-4

6005-145 Rev. A 1-1

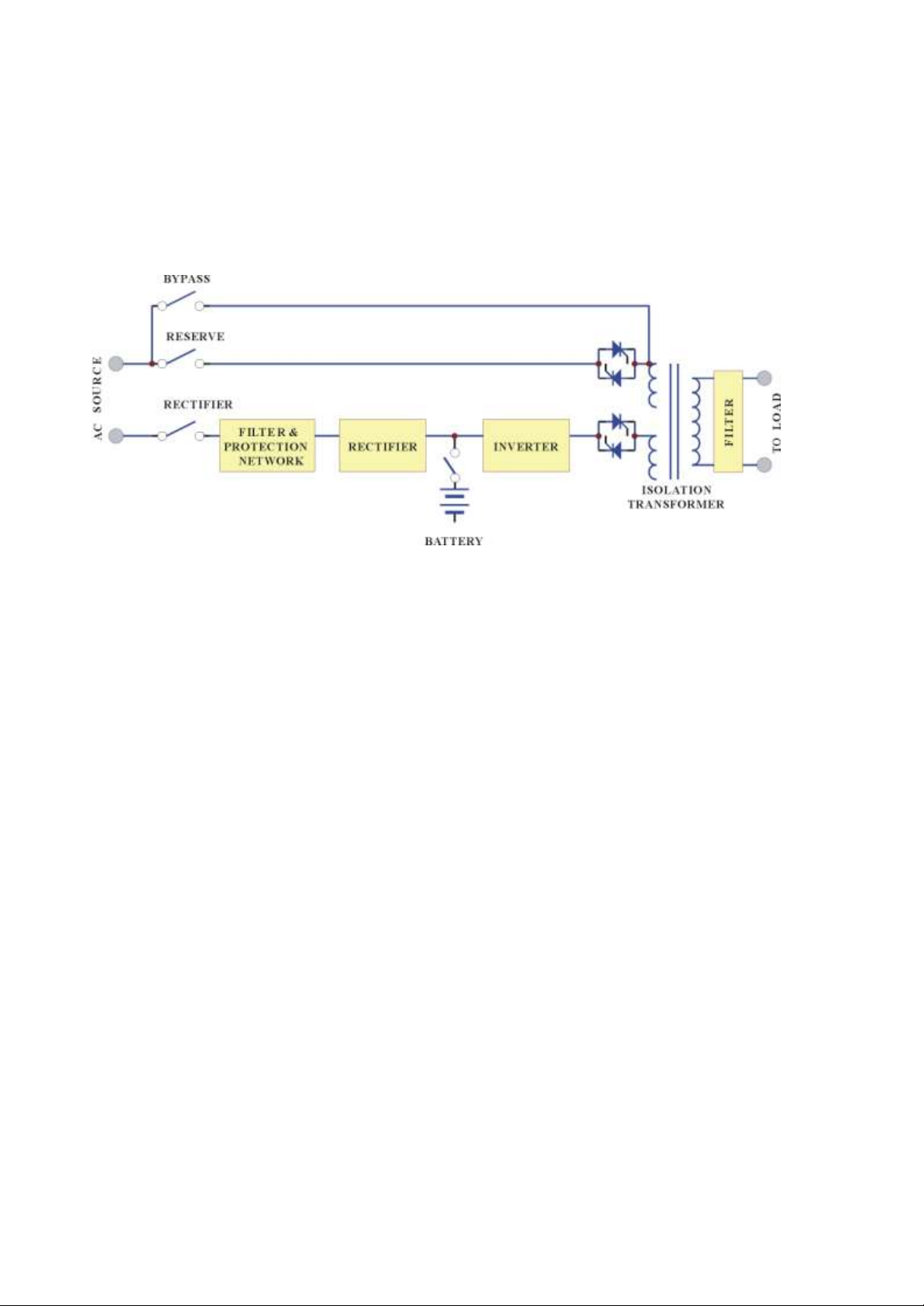

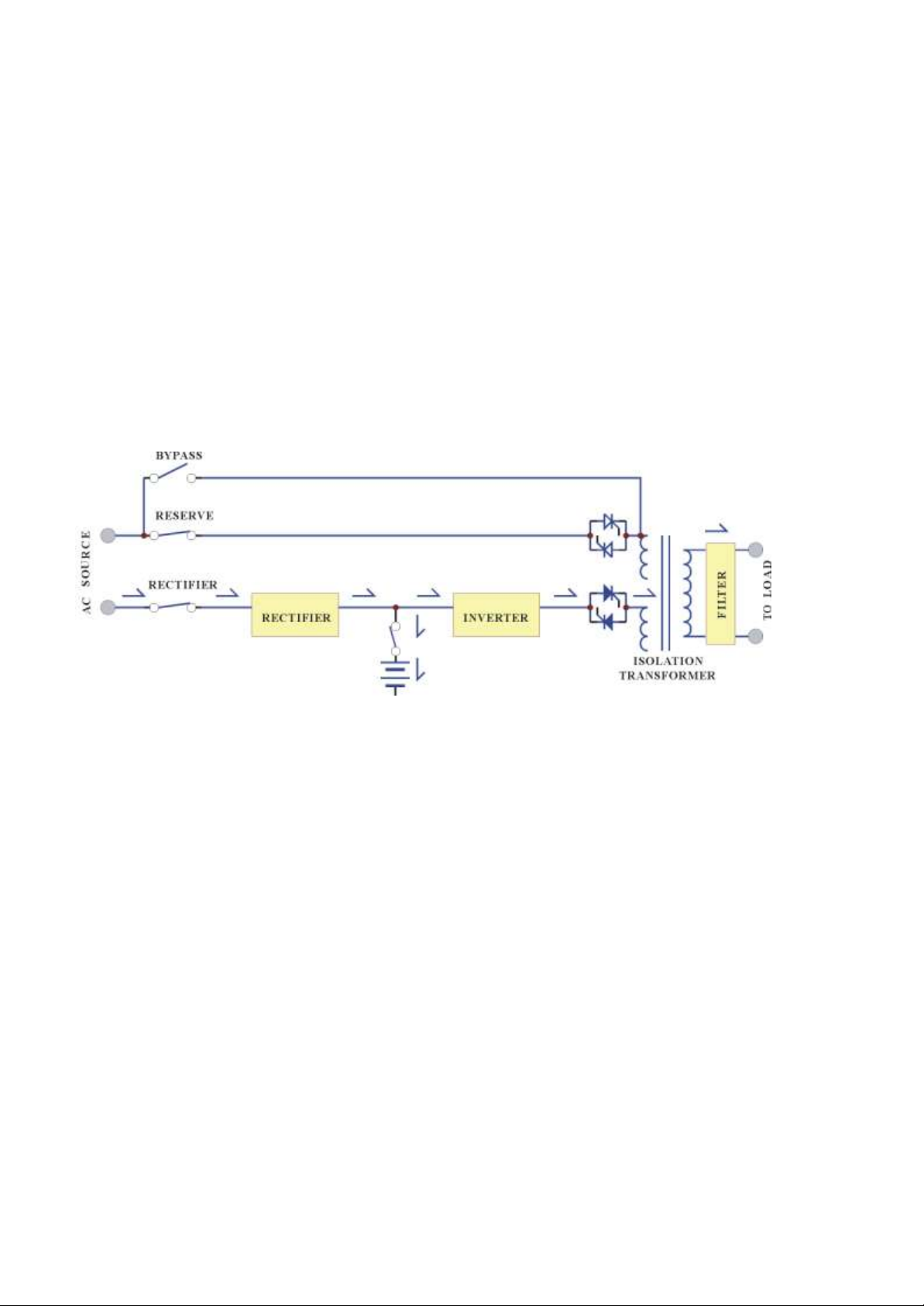

1. SYSTEM OVERVIEW

1.1. Construction of the ELI

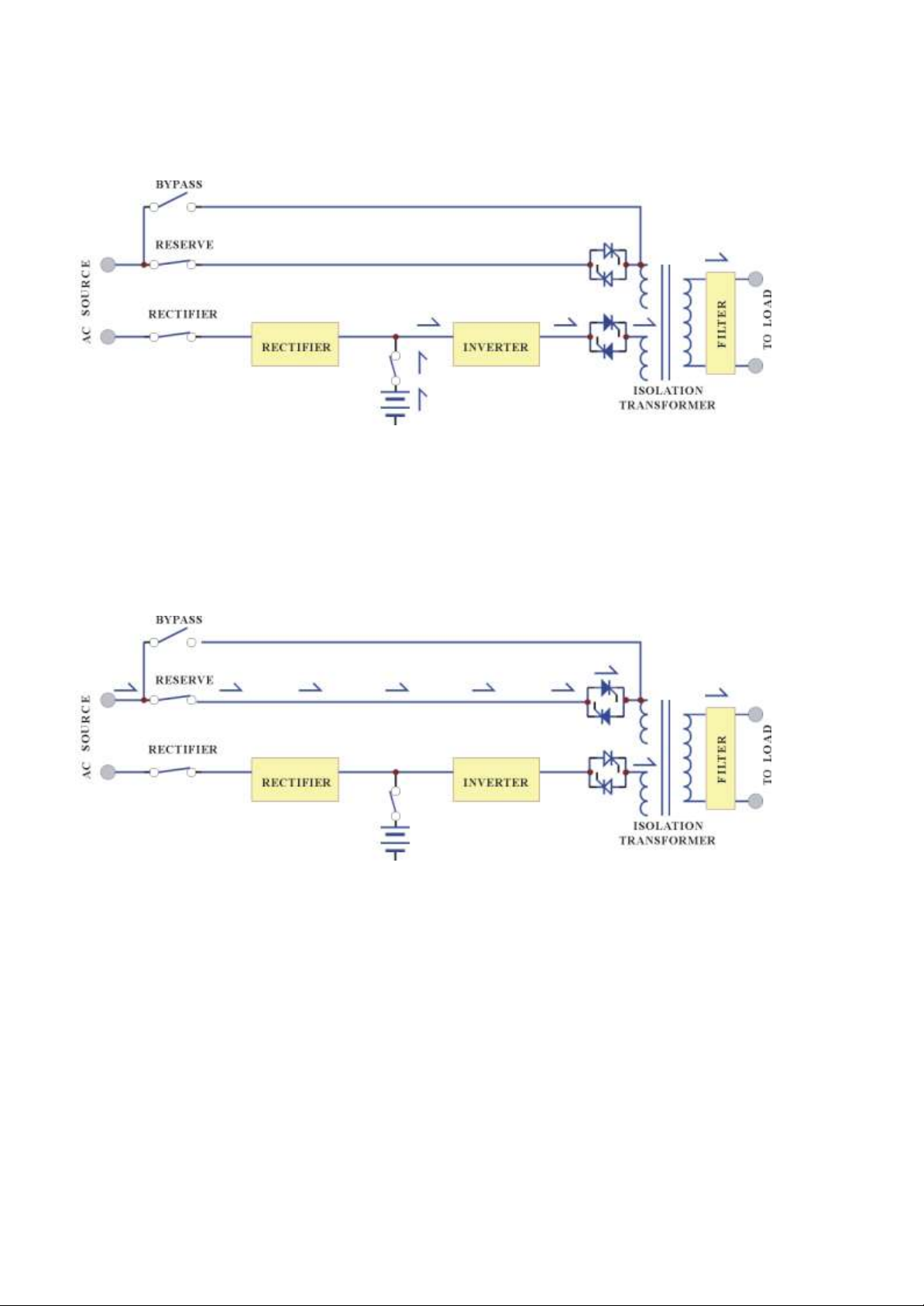

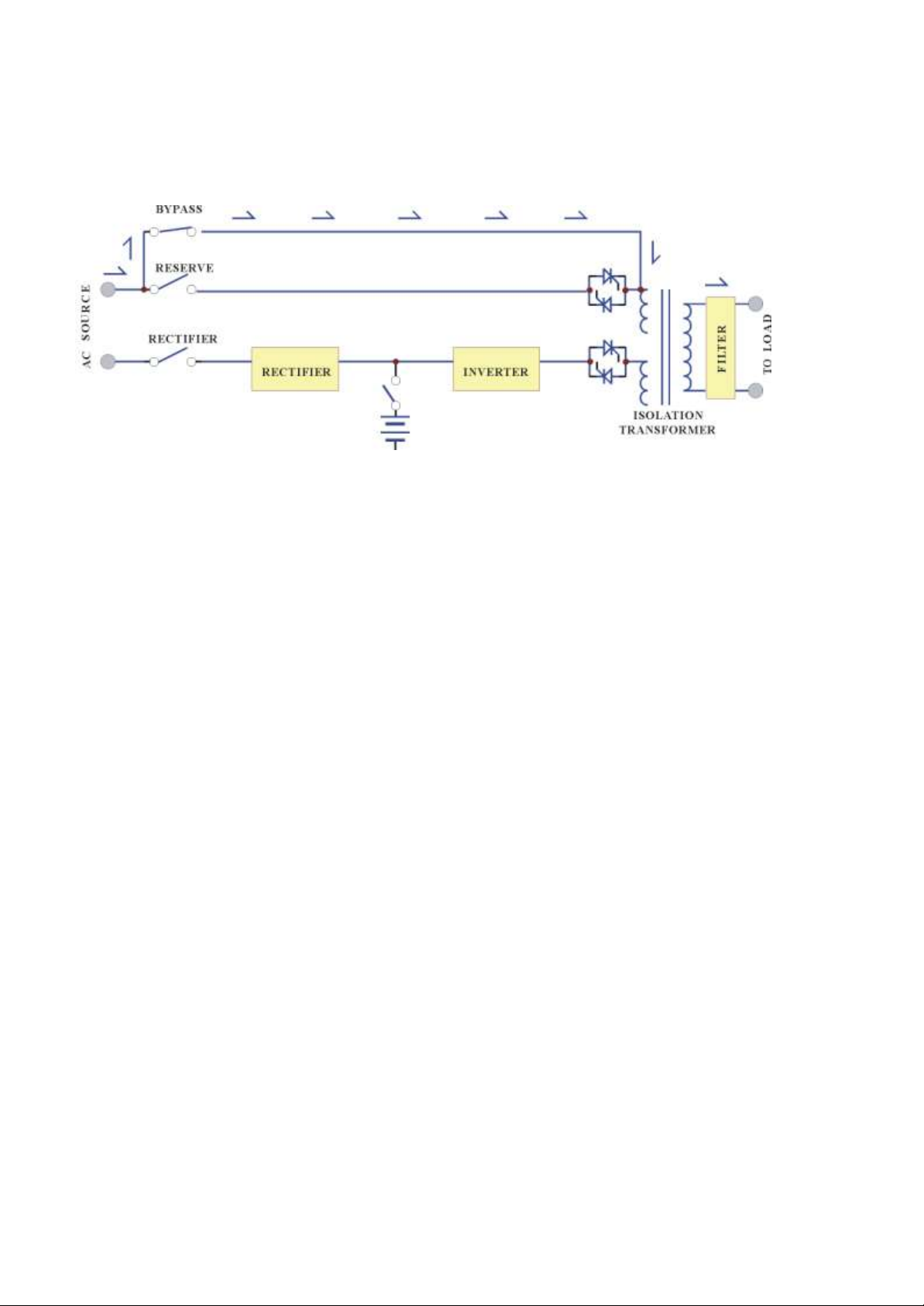

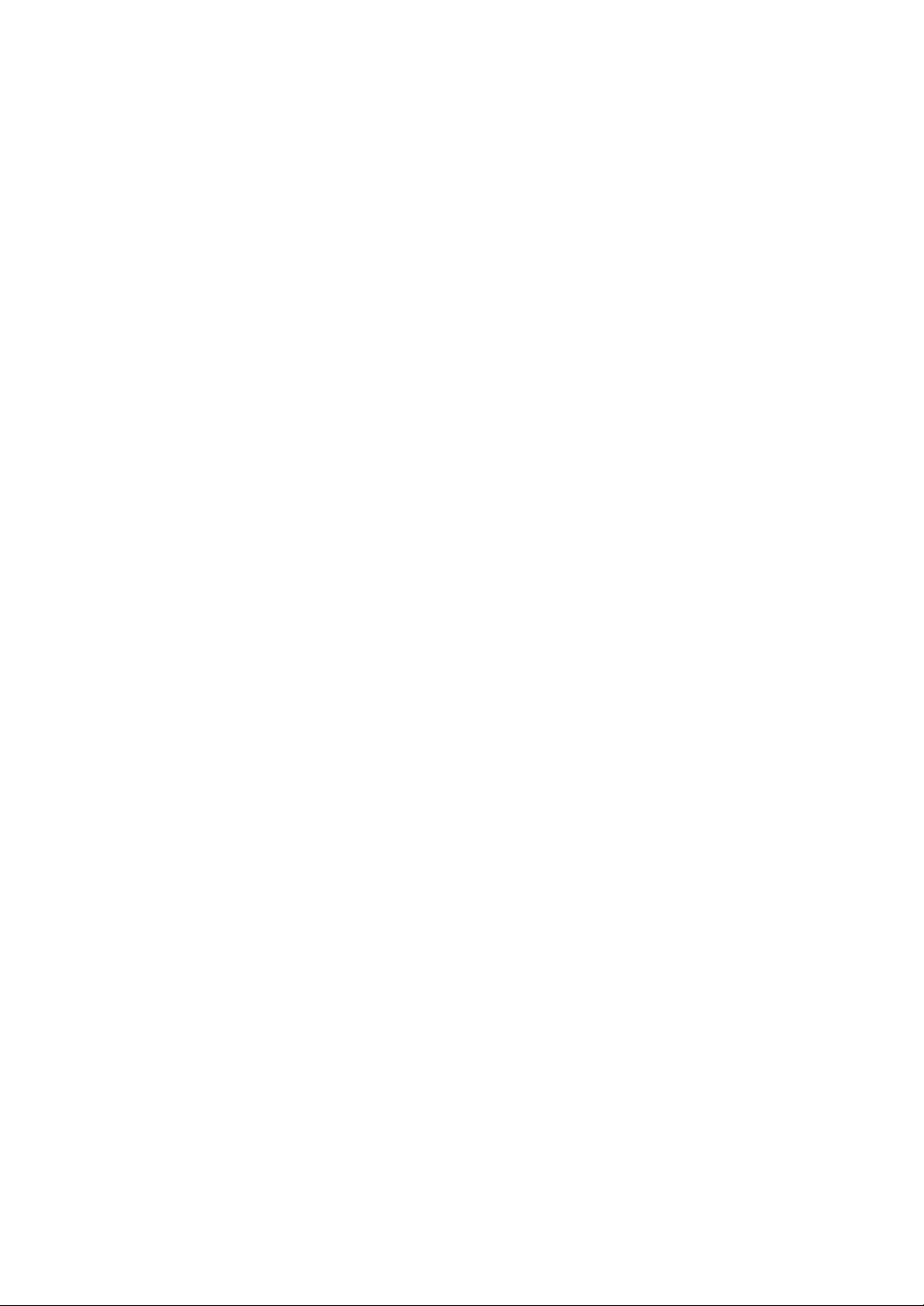

General Topology

The ELI system is composed of input breakers, input filter & protection

network, rectifier, battery bank, inverter, static switch, bypass breaker,

isolation transformer and output filter. The basic topology is shown in the

diagram above. Under normal AC mode, energy from the AC source is

converted to DC power and supplied to the inverter to charge the batteries to its

full capacity all the time, ready to support the output load in case of AC source

failure.

Although the principle and operation of a ELI seems simple and

straightforward, the requirement for a reliable and intelligent ELI makes the

design and manufacturing of a high power ELI one requiring advanced

technology, intelligence, experience and most important, consideration of the

user interface. Many years have been spent in designing the most rugged,

intelligent and reliable ELI for the market, and a safe and convenient ELI for

the user.

Choosing the best and most suitable ELI for a given application can be easy or

difficult, depending on the client’s knowledge of key parameters. The most

obvious specification, output power, depends on the size of the load. Often, an

allowance of 50% more power is added to the present load requirement, both

for tolerance and for future expansion.

6005-145 Rev. A 1-2

Another important issue is reliability. The prime aim of a ELI is to protect your

load. Therefore, the ELI should be much more reliable than the AC source. An

unreliable ELI may suffer the problem of frequent break down, even more

frequent than AC failure, and the cost of repair may become more than the cost

of the unit itself.

Generally, there are four different modes of operation, the NORMAL

OPERATION MODE, the BACK-UP (BATTERY) MODE, the RESERVE

MODE and the MAINTENANCE BYPASS MODE. These are explained

below.

Normal Operation Mode:

The rectifier converts the AC input to DC power to supply the inverter and

charge the batteries simultaneously. All the fluctuations, surges and spikes of

the AC input are removed during AC to DC conversion. Therefore, the AC

supplied by the inverter is clean and stable.

6005-145 Rev. A 1-3

Back-up Mode:

Since the batteries are connected directly to the DC bus, when the AC fails, the

batteries change immediately from receiver to donor, supplying energy to the

inverter instead of receiving energy from the rectifier. The output AC is not

interrupted. Therefore, the load connected to the output is protected.

Reserve Mode:

When the inverter is in an abnormal condition, such as over temperature, short

circuit, abnormal output voltage or overloaded for a period exceeding the

inverter’s limit, the inverter will automatically shut down in order to protect

itself from damage. If the utility power is normal, the static switch shall

transfer the load to the reserve source without interruption of AC output.

6005-145 Rev. A 1-4

Maintenance Bypass Mode:

In case of ELI maintenance or battery replacement, and where the load cannot

be interrupted, the user can turn off the inverter, close the bypass breaker and

then open the rectifier and reserve breakers. The AC output will not be

interrupted during manual bypass transfer procedure. Therefore, the

maintenance bypass switch keeps continuously supplying power to the load.

Electricity will not exist in ELI except the output transformer, thus ensuring

the safety of service personnel.

Generally, the ELI is expected to run 24 Hours a day in normal operation mode

once it is installed, except when the utility power fails, under overload

conditions, or during maintenance.

Normal operation with batteries connected provides clean, stable, regulated and

uninterrupted power to the load, free from any spikes and surges. Therefore,

the ELI can be regarded as a perfect AC power source, limited in back-up time,

under mains failure, only by the capacity of the batteries.

Green Mode:

Hybrid design allows customer to select this operation mode for higher

efficiency (fast transfer less than 2ms).

6005-145 Rev. A 1-5

1.2. Features and Advantages

(a) Reliable input protection: Circuit breakers are placed in each individual

input loop to ensure power can continue through another loop in case of

breaker trip caused by an abnormal condition in either rectifier or load.

(b) Input surge protection: An MOV (surge protector) is added at the input,

providing protection to both ELI and the load from any lightning surges,

or surges caused by neighboring large loads.

(c) EMI suppression: An EMI filter is added to meet the international EMC

limits. Therefore, very low noise is emitted, and no interference is

supplied to other equipment connected to the same AC source.

(d) Ruggedness: The rectifier employs phase control technology to regulate

the DC bus voltage. This is the most efficient method to charge the

batteries. The SCR used are inherently rugged. Additionally, a large

inductor is added at the input to avoid deforming the AC source

waveform.

(e) High frequency design: The inverter uses high frequency, high efficiency

IGBT, PWM methodology to convert the DC power to AC power.

Therefore, the number of components is fewer, reliability is improved, and

the size and weight of ELI is reduced, performance is improved, and

acoustic noise is minimized.

(f) True Galvanic isolation: An isolation transformer is placed at the output.

This can solve the problem of poor input grounding, can allow a different

ground between input and output, can avoid the annoying problem of

ground leakage current, and can be tied to any potential provided on site.

The AC output is isolated under every mode of operation. Additionally, the

user gets the bonus of attenuation of common mode noise from the output

isolation transformer.

6005-145 Rev. A 1-6

(g) Plug & Play Modular design: The power circuit is separated into several

modules plugged into slots in the ELI, which are easy to pull out,

permitting quick maintenance and easier trouble shooting.

(h) Cold start function: the ELI can be started without an AC source, that is,

can be started with battery power only. This is possible because current

limit circuitry is added, preventing the problem of large inrush current

blowing the battery fuse and damaging the DC capacitors when batteries

are connected to an empty DC bus (before the DC bus is energized).

(i) Multi-CPU design: Several CPUs are employed in the control circuit, and

critical functions are designed with parallel redundancy to improve

reliability. Therefore, in case of one CPU failure, the other CPUs keep the

ELI operational, and the output AC is not affected.

(j) Protection against misuse: The ELI is designed with breaker on/off

sensor, power supply sensor, etc. Therefore, any operational mistake made

by the user causes no harm to the ELI.

(k) Accepts wide input range: The ELI is designed to accept a wide input

range, so that it can work effectively under an unstable AC source. All of

the input components used are specifically selected to handle extreme high

voltage and high current.

(l) Operating environment: Each component of the ELI is chosen with large

safety margin to accommodate extreme environments, such as

temperature, humidity, altitude, shock or contamination.

(m) Intelligent charger: The ELI will automatically recharge (boost charge)

the batteries every time the batteries are depleted to a voltage level equal

to 2V/Cell. Thus, the batteries can be restored to full capacity as soon as

possible, and made ready for the next back-up requirement. In order to

keep the batteries in the best condition, the ELI will boost charge the

batteries for several hours (selectable) automatically every month. To

avoid over charging the batteries, boost charge will stop when the ambient

temperature is over 35oC (95oF).

6005-145 Rev. A 1-7

(n) Intelligent battery test: The batteries are tested after every boost

(initiated by battery discharge or by the monthly boost charge cycle). This

is done without interrupting the operation of the rectifier, preventing the

risk of output AC failure in case of a bad battery. The user is informed of

the battery condition, so that action can be taken before the full capacity of

the batteries is needed.

(o) Huge charging power: The charging power is selectable (Lo/Me/Hi)

according to Ah rating of the batteries, and can charge up battery banks

providing more than 8Hrs back-up time without adding an extra charger.

(p) MTBF of fans are extended: Fans used to cool the ELI, are designed to

slow down under light load, so that the life expectancy of the fans is

extended beyond the normal.

(q) Redundant power supply: A supplemental power supply is added to

provide redundancy for supplying power to the static switch, so that there

will be AC output no matter what happens to the ELI.

(r) Variety of accessory (options): With built-in intelligent communication

interface as well as output ports of RS-232, RS-485, and dry contacts,

there are several options are hence available such as remote control panel,

3 phases software for PC monitoring, auto dialing module, battery

monitoring module, 3 phases SNMP card.

6005-145 Rev. A 1-8

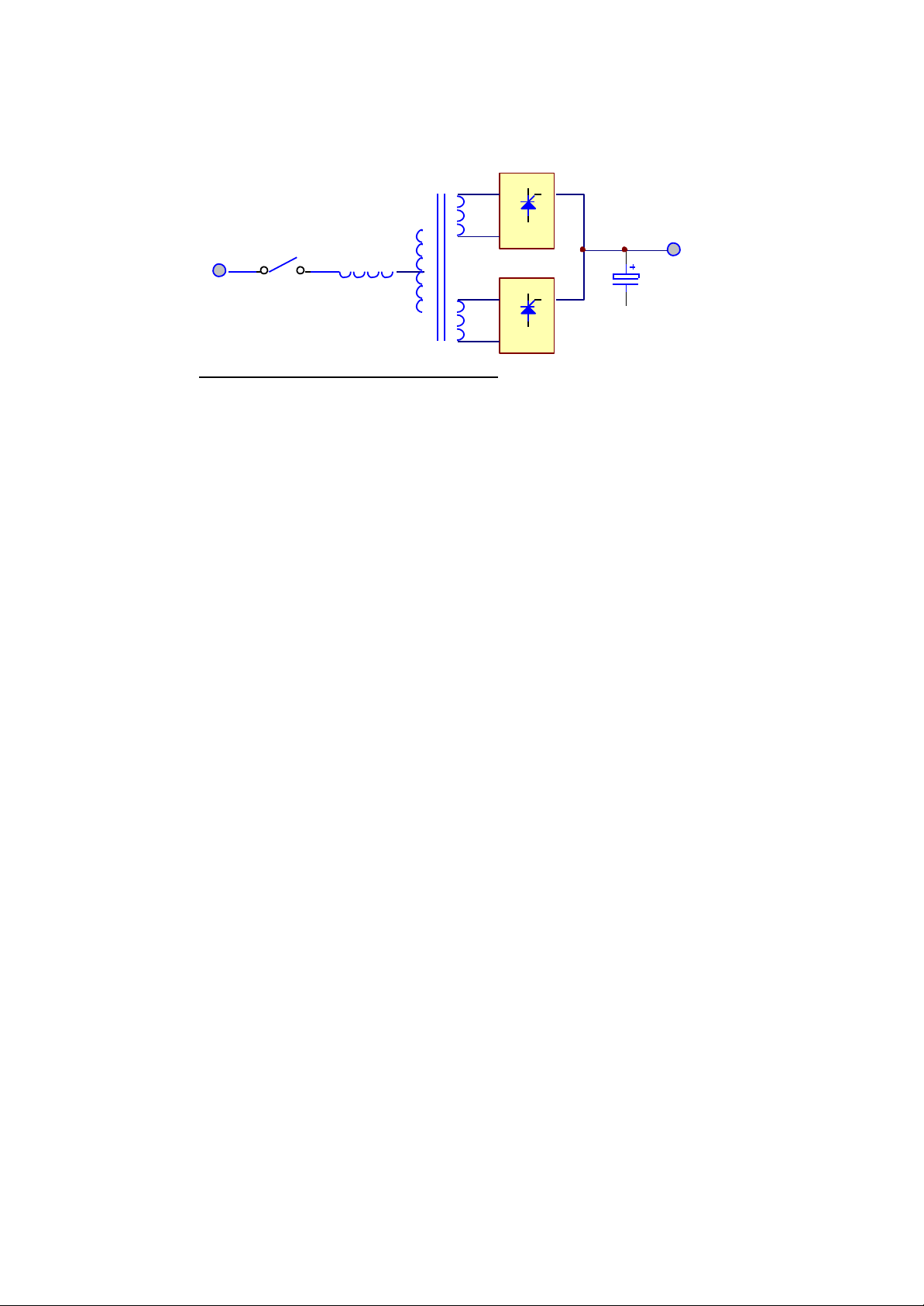

6-PULSE FULL CONTROL RECTIFIER

INPUT

RECTIFIER

BREAKER INDUCTOR

CAPACITOR

SCR

AC

OUTPUT

DC

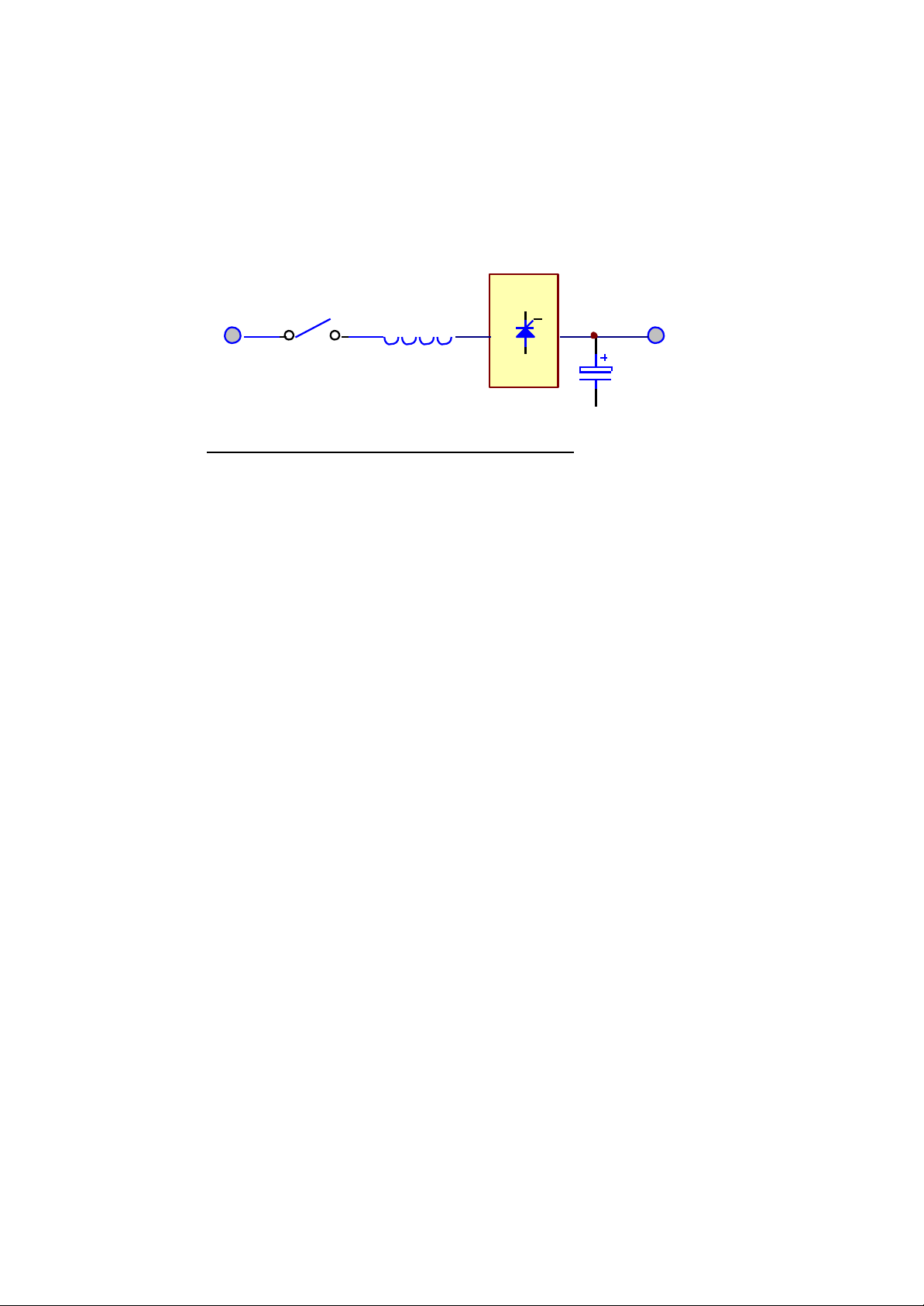

1.3. Rectifier

The main function of a rectifier is to convert the AC input to DC power, and

supply it to the inverter. The inverter then converts the DC power to AC power

for the load. The ELI use the DC power to charge the batteries as well, which is

the most efficient method of charging.

ELIs in the sizes 10KVA to 100KVA use 6-pulse fully controlled rectification

(optional 12-pulse). An inductor is added before the rectifier to improve the

power factor, smooth the current waveform and eliminate the harmonic current.

The control circuit regulates the DC bus within 1%. Soft walk-in circuitry

(approximately 20sec.) and current limit circuitry is used to prevent over current

or instantaneous surge current.

Extra under-voltage and over-voltage protections are added to improve

reliability and to shutdown the rectifier in case of abnormal conditions. The DC

bus is adjustable to fit different types of batteries. The power component used in

the rectifier is specially selected to handle extreme high voltage and high

current. The rectifier is designed to operate under a wide range of AC input,

from 177 to 300VAC, to operate under the poor power conditions found in some

areas.

6005-145 Rev. A 1-9

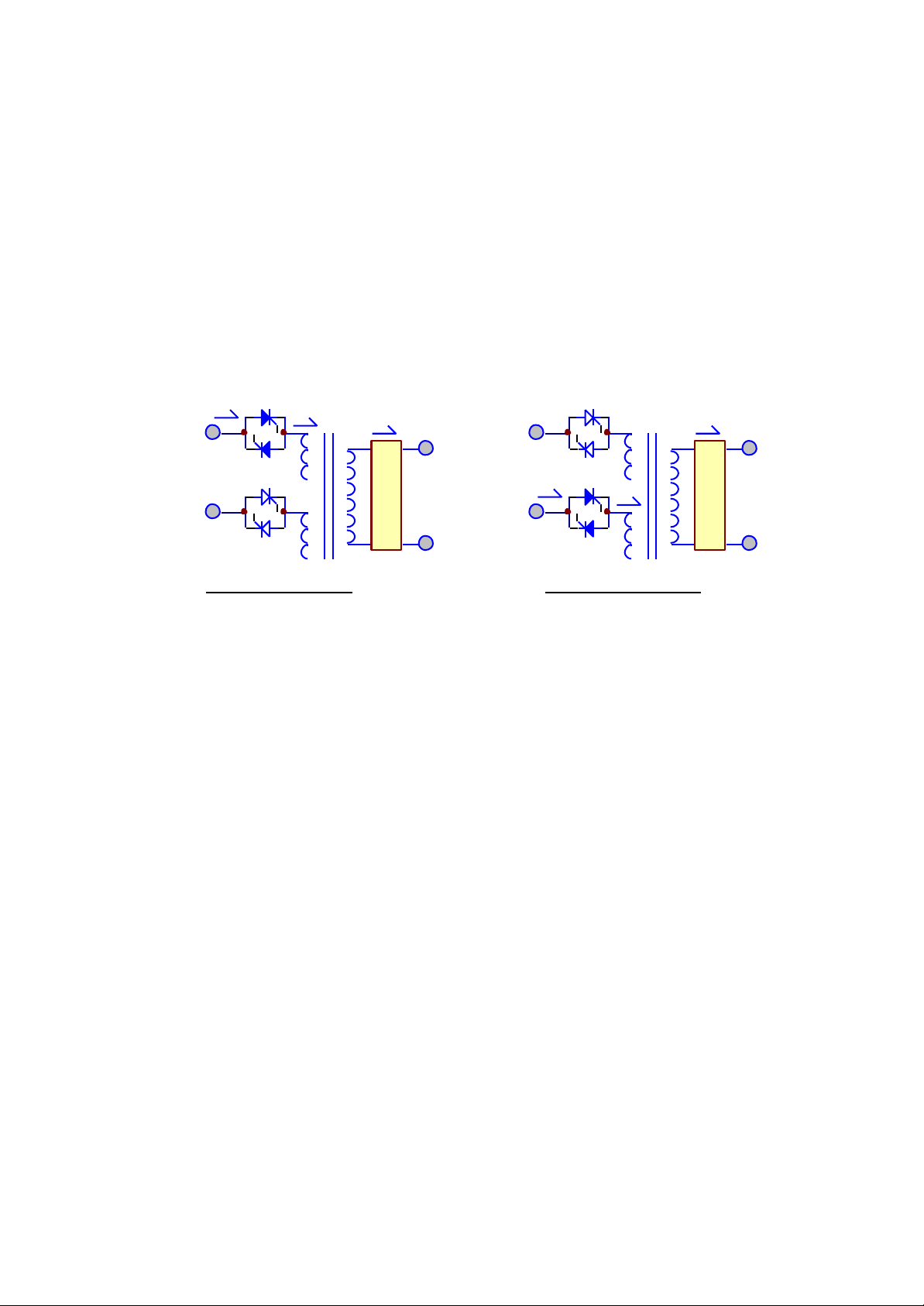

12-PULSE FULL CONTROL RECTIFIER

INPUT

RECTIFIER

BREAKER INDUCTOR

CAPACITOR

SCR

AC

OUTPUT

DC

SCR

PHASE SHIFT

TRANSFORMER

In order to further improve the power factor and reduce harmonic current drawn

by the rectifier, ELI at 120KVA and above, use the 12-pulse full controlled

rectifier. The total current harmonic current can be reduced to around 15%, and

power factor improved to over 0.8. A phase shift transformer is added to achieve

this performance. The input inductor is retained also to obtain the best result.

Although this results in higher cost, the unit is much more reliable and rugged.

Users do not need to increase the input breaker and cable sizes, since input KVA

and harmonic current drawn is minimized, fulfilling the worldwide energy

saving requirements.

The harmonic current can be further lowered by adding harmonic filters (factory

installation available). The total harmonic current can be reduced to

approximately 9%.

Another alternative method to reduce the harmonic current (especially for very

large KVA unit) is to employ 18-pulse full controlled rectifier (available as an

option). The total harmonic current can be reduced to approximately 7%.

6005-145 Rev. A 1-10

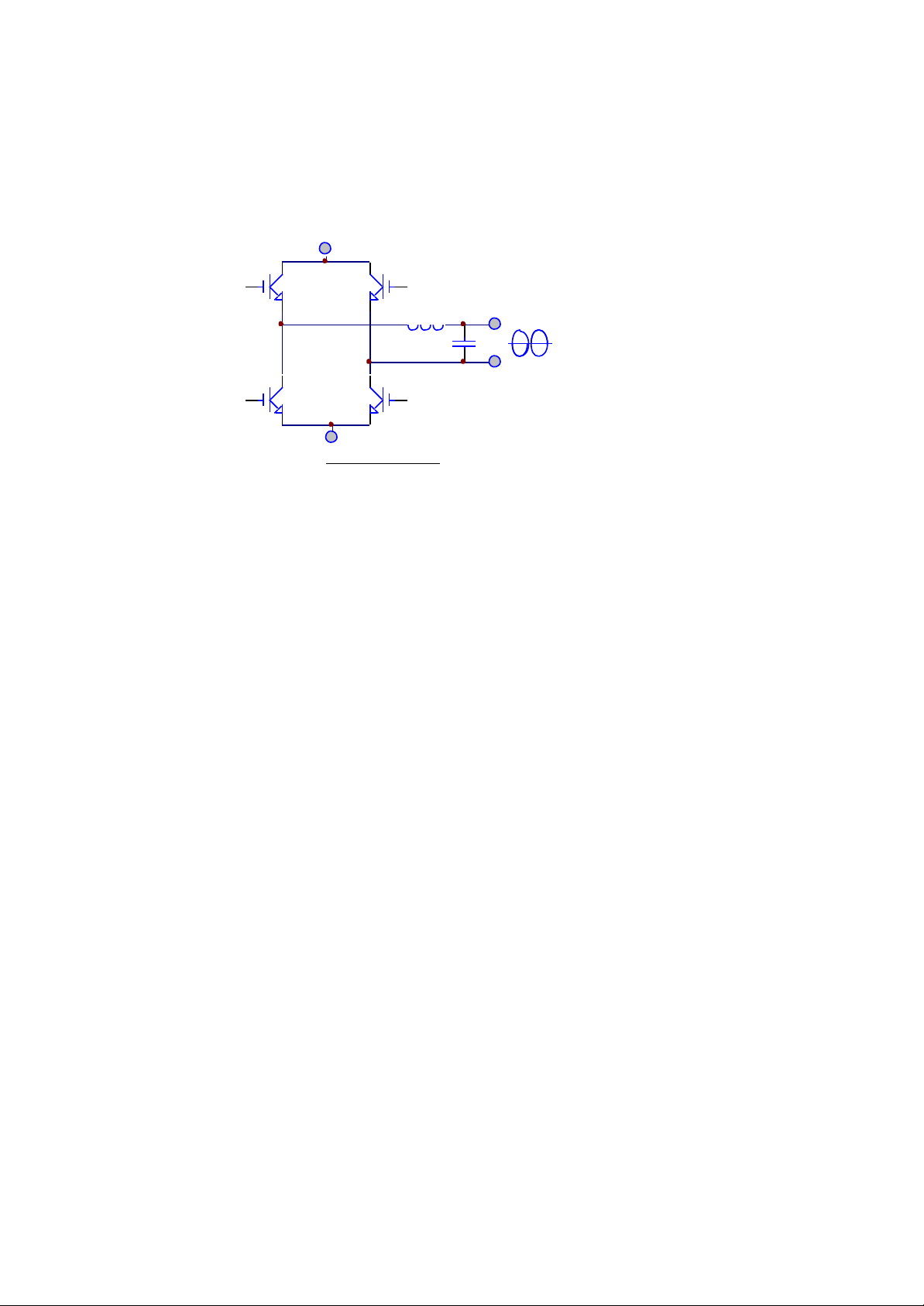

DC+

DC-

AC

AC

IGBT INVERTER

1.4. Inverter

The inverter is composed of IGBT, inductor, capacitor, snubber, control circuitry

and protection circuitry. The inverter converts the DC power from the DC bus to

AC power to supply the output load. The ELI uses IGBT technology which

switches at frequencies beyond the audible range, therefore producing no

audible noise.

The ELI uses voltage regulation circuitry to limit the voltage variation within

1%. Special compensation circuitry is added to eliminate the output distortion.

Every component is oversized to accept the wide DC input range (from 285 to

420VDC), so that the output waveform remains sinusoidal throughout the range.

With the aid of dynamic feedback loop the inverter will keep a sine waveform

even under non-linear load.

An independent inverter is used for each phase. Although it is more expensive,

each inverter has its independent feedback, so that the voltage is unaffected

when load is added to the adjacent phase, producing excellent voltage regulation

under 100% unbalanced load.

The IGBT is operated in its optimal condition to obtain best efficiency, so as to

minimize the power cost of the user.

6005-145 Rev. A 1-11

FILT E R

TO L O A D

RESERVE

FILT E R

TO L O A D

INVERTER

RESERVE

INVERTER

RESERVE MODE INVERTER MODE

Usually, the most frequent failures of the ELI occur at the inverter. Therefore,

we have added redundant protection circuitry to protect the inverter. A strong

snubber is added to suppress the spikes and noise, oversized, high quality

components are used throughout, semi-conductor fuses are provided, and

ventilation is maximized. The result of this design is a more rugged, reliable and

high efficient inverter. At the same time, the inverter can sustain overload and

high peak current drawn by the load. Additionally, a longer MTBF is achieved.

1.5. Static Switch

The static switch is composed of two pairs of SCRs, connected back-to-back.

The switch can transfer the load from reserve to inverter or from inverter to

reserve without losing power at the output. Therefore, it is a very important

portion of a ELI.

Detection circuitry is added to the control circuit to achieve zero dead time

transfer. Extra detection logic is employed to control when the static switch

should transfer. For example, when output is short circuited, under normal mode

operation, the ELI detects the short circuit and stops the inverter. The static

switch will not transfer power to the reserve circuit, which might damage the

reserve breaker. In case of an overload, the ELI will stop the inverter after a

period the inverter can endure, and then transfer the load to the reserve circuit,

since the overload capability of the static switch is higher than the inverter.

The transfer action is determined according to the reserve-input voltage and

frequency to protect supplying incorrect power to the load. Finally, there is a

double check by the CPU as to whether the transfer is successful or not.

6005-145 Rev. A 1-12

1.6. Maintenance Bypass

Unlike other ELI, the maintenance bypass switch is already installed inside the

ELI for convenience. It should be open under normal operation, and only closed

during maintenance. For the sake of safety of maintenance personnel, all power

supplies inside the ELI should be disconnected before touching any parts inside

the ELI. Thus, the maintenance bypass switch is a necessity to maintain AC

power at the output and yet keep maintenance personnel safe at the same time. If

the bypass breaker is closed under normal operation, the inverter will stop and

the load will be automatically transferred to reserve to prevent the inverter

connecting directly to the AC source. Of course, you cannot switch on the

inverter as long as the maintenance bypass breaker is closed.

To properly use the maintenance bypass breaker, switch off the inverter first.

The static switch will automatically transfer the load to reserve without dead

time. Then one can close the maintenance bypass breaker, then open the reserve

breaker, so that the load gets power from the output without interruption.

1.7. Main Input Circuit Breaker

The main input circuit breaker provides the unit with incoming power

isolation as a well as means of disconnect and input over current

protection.

1.8. Main Output Circuit Breaker

1.9. Battery Circuit Breaker

1.10. Battery

The battery bank; Provides the reserve energy to sustain the load when

suitable AC input power is not present. The batteries are designed and

tested to meet UL 924 requirements. The standard VRLA (Valve

Regulated Lead Acid) batteries are sealed and maintenance-free.

6005-145 Rev. A 1-13

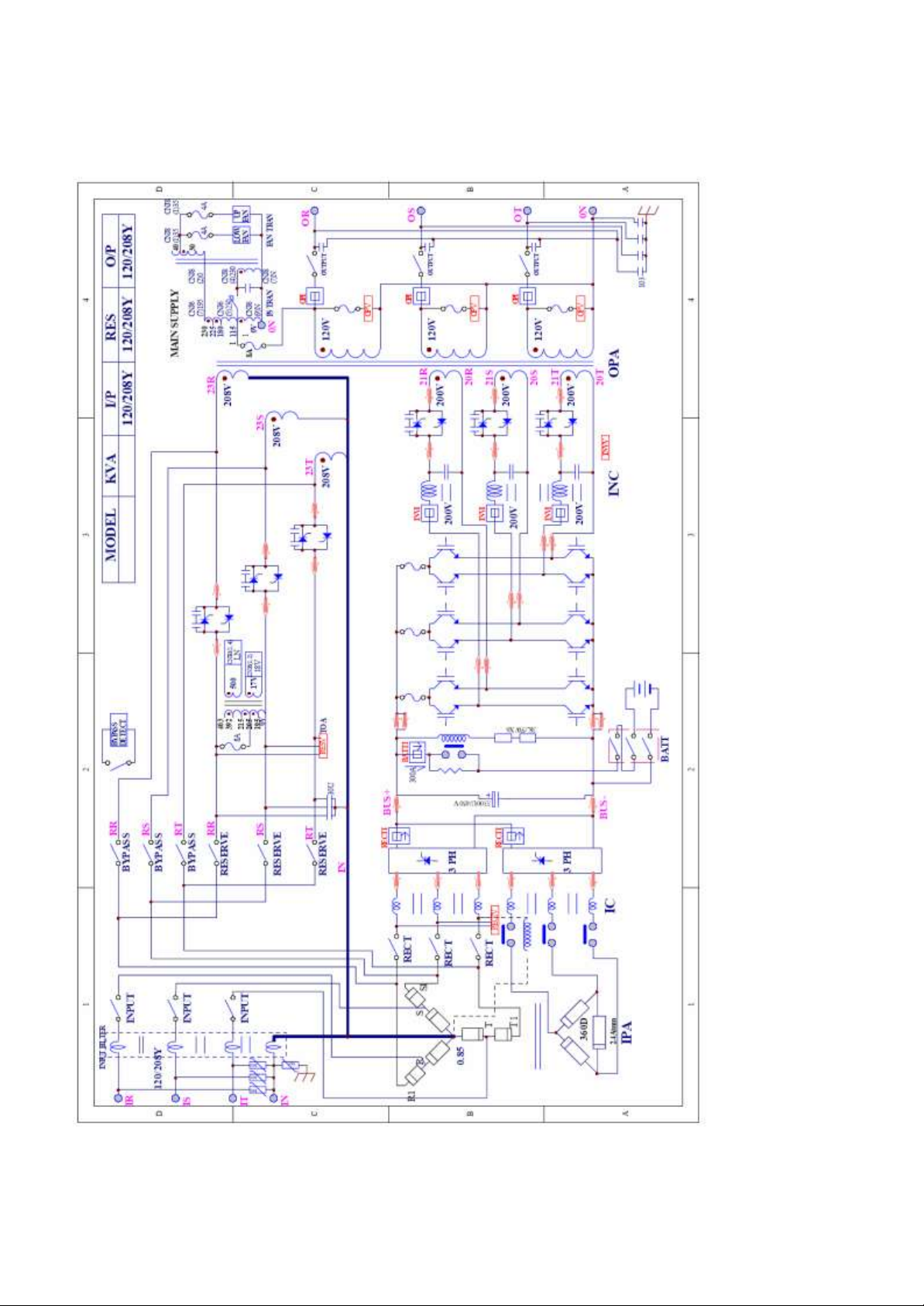

1.11. SINGLE LINE DIAGRAM – (120/208Y)

6005-145 Rev. A 1-14

1.12. SINGLE LINE DIAGRAM – (277/480Y)

6005-145 Rev. A 1-15

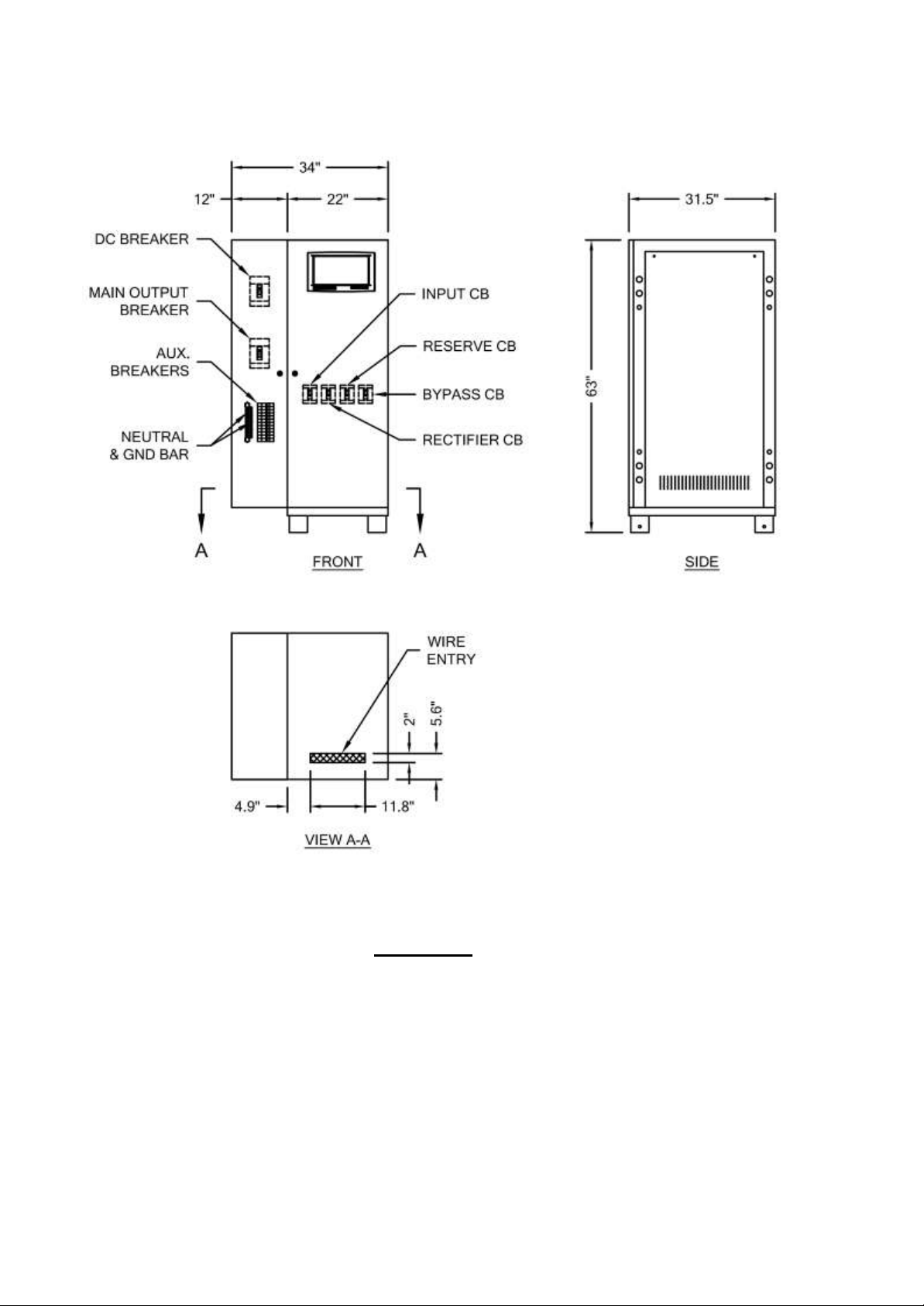

1.13 Dimension & Drawings (electronic cabinet, off white), for

battery cabinet refer to section

CABINET

10KVA - 60KVA

OUTLINE DRAWING

6005-145 Rev. A 1-16

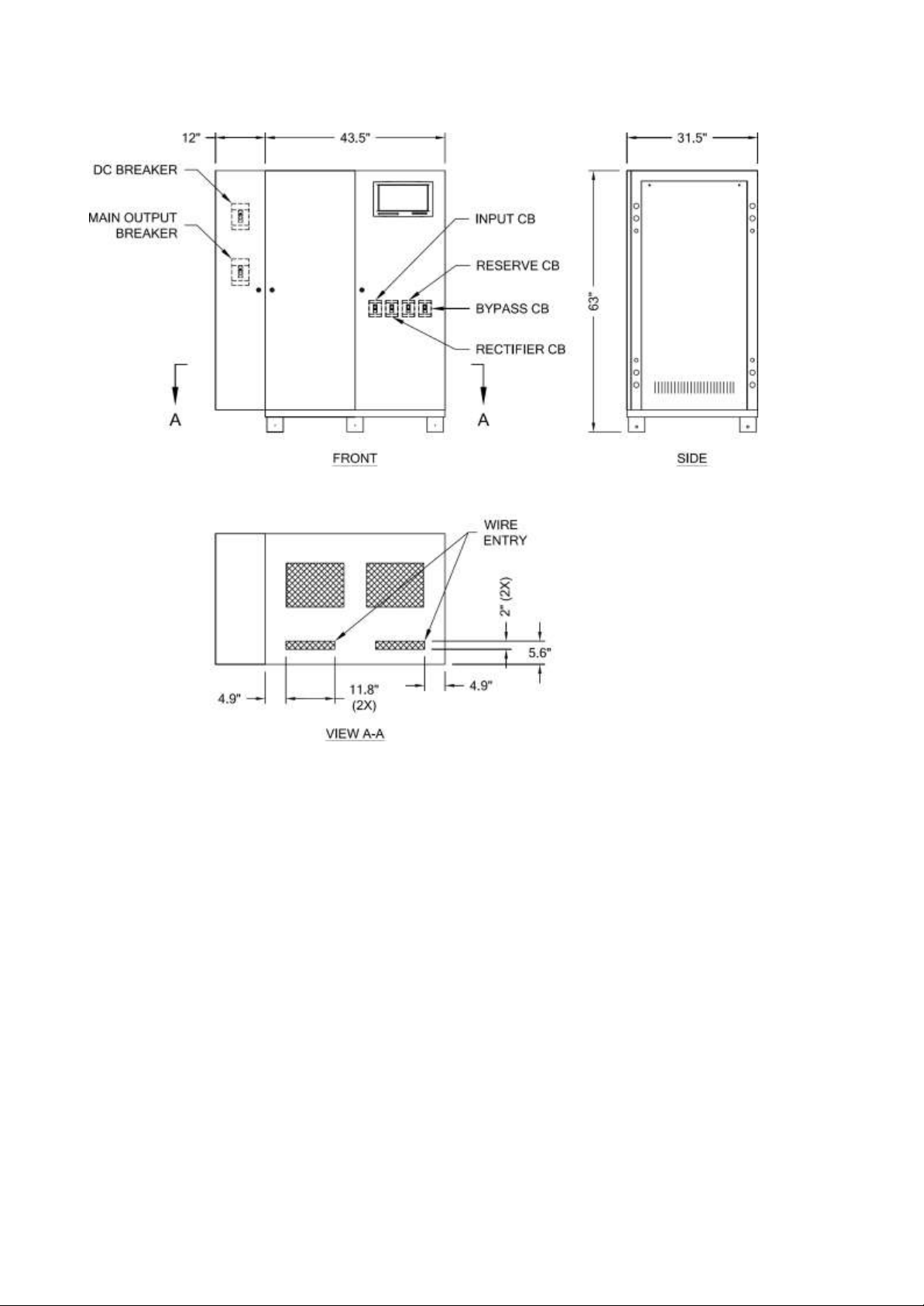

80KVA - 160KVA

OUTLINE DRAWING

6005-145 Rev. A 1-17

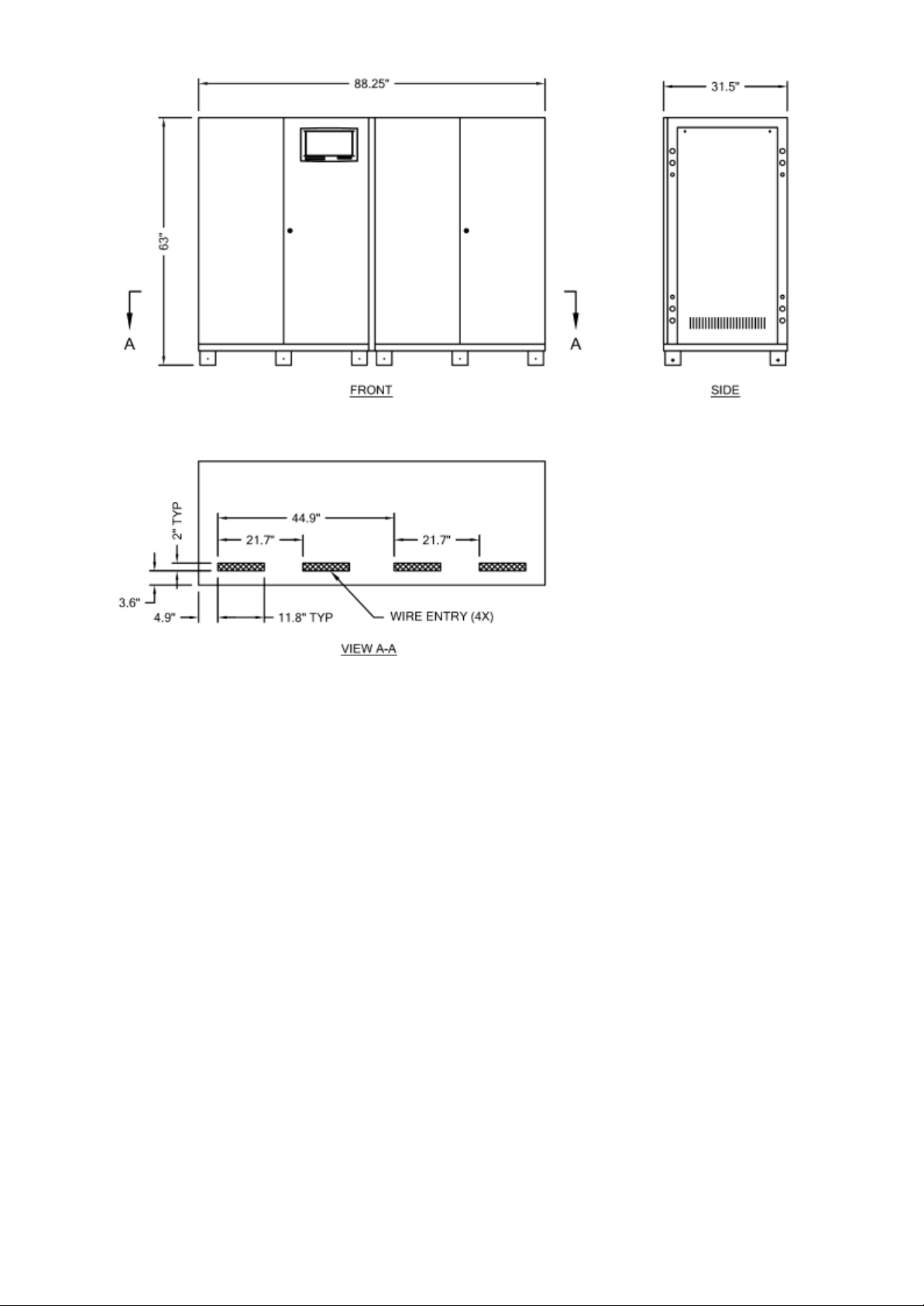

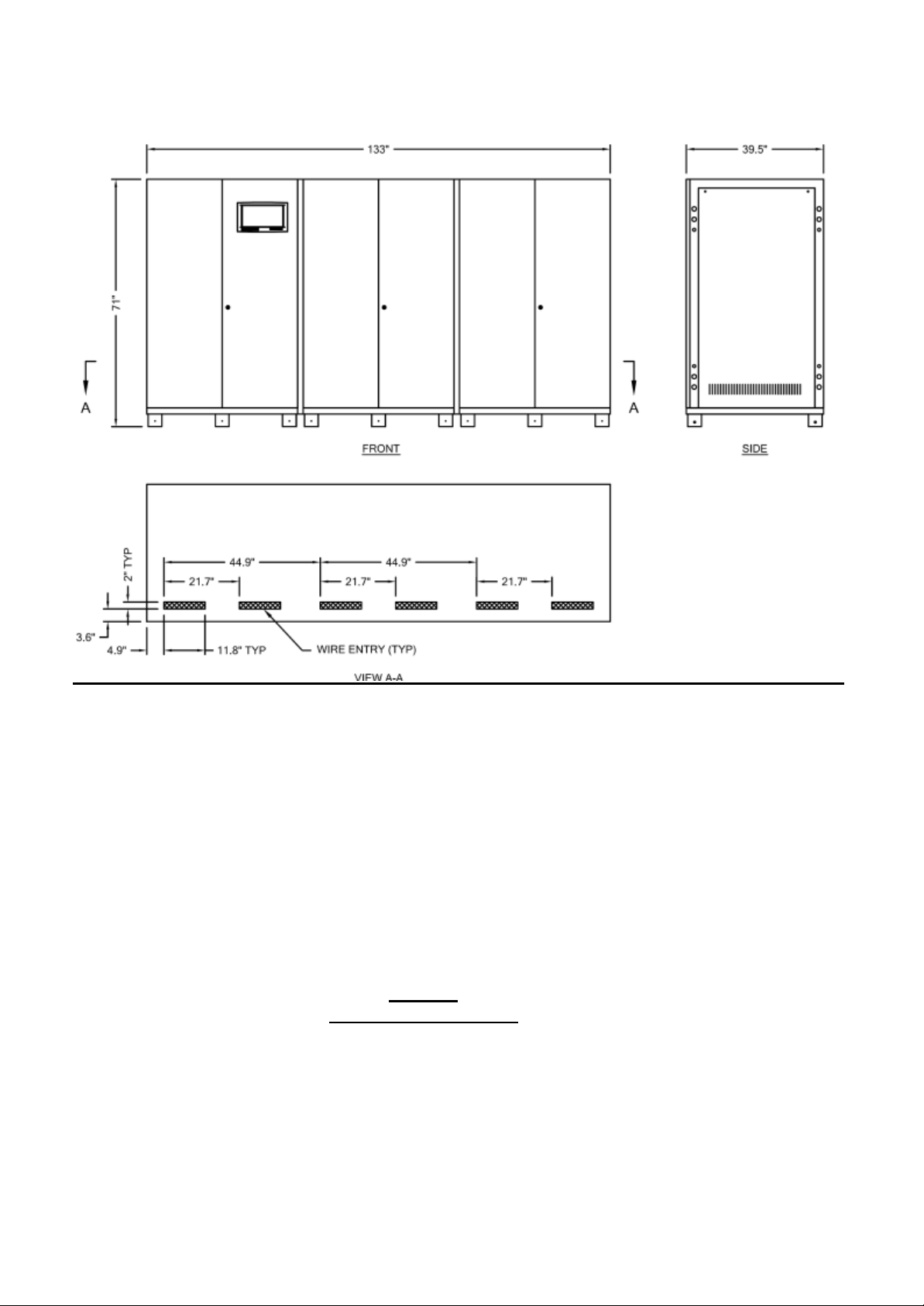

200KVA - 320KVA

OUTLINE DRAWING

6005-145 Rev. A 1-18

400KVA

OUTLINE DRAWING

6005-145 Rev. A 1-19

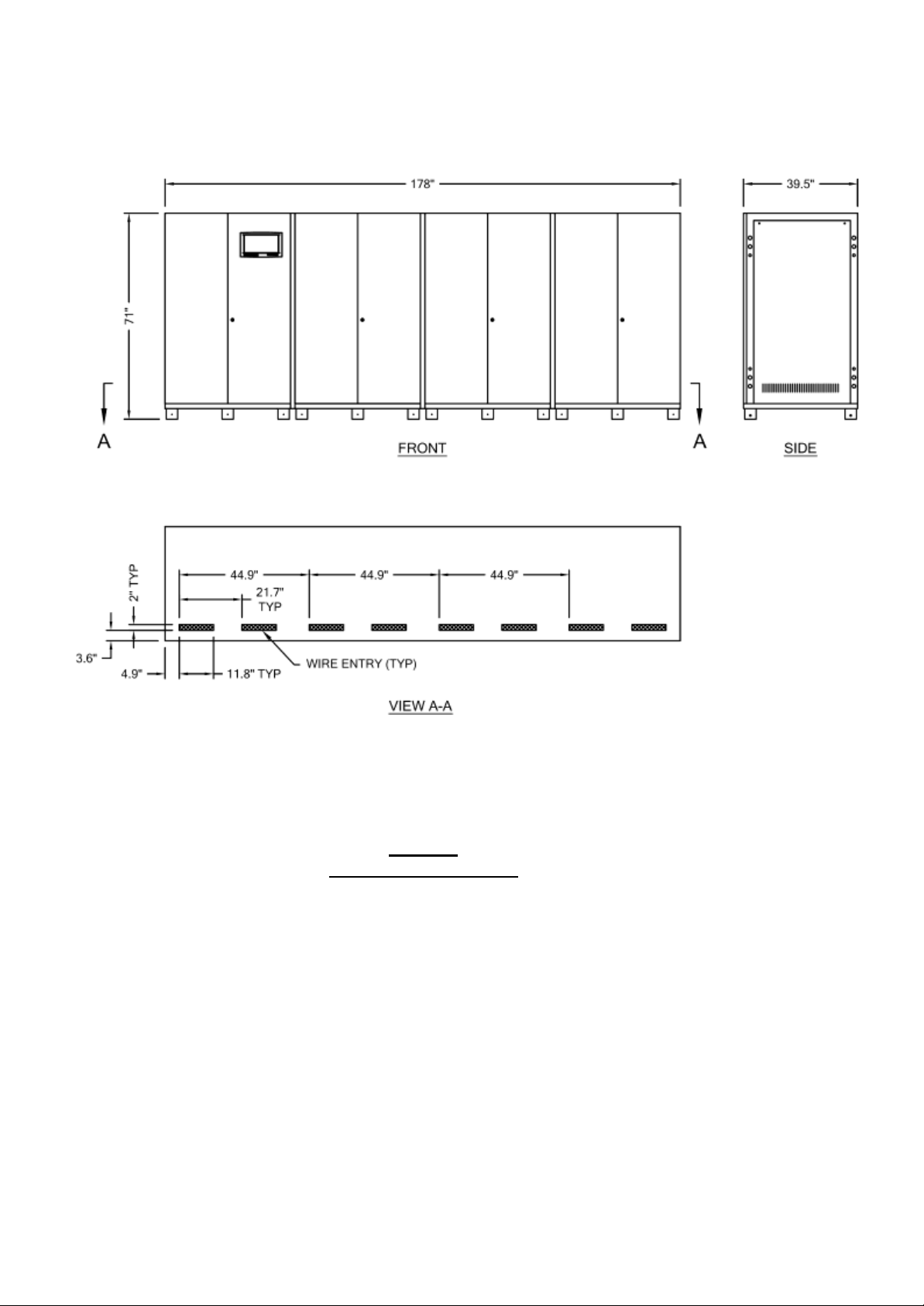

500KVA

OUTLINE DRAWING

Loading...

Loading...