OnLine Power Phase Stabilizer User Manual

-

Technical Publications

POWER-REG (1 and 3 Phase)

ULTRA-REG

PHASE STABILIZER

CONSTANT POWER 18

Operating Documentation

6002-032 Rev. H

OnLine Power

Congratulations on selecting one of the fine products from OnLine Power, the Leader in Power Protection

Technology. Our wide product offering includes Uninterruptible Power Systems (UPS), Power Conditioners,

Automatic Voltage Regulators and Specialty Transformers (e.g. computer-grade, medical-grade). Since our

beginnings in 1975, OnLine Power has shipped thousands of these fine products around the world, to

discerning customers, for use on sensitive equipment and critical applications. Our customers, both new and

long-time, continue to enjoy security and peace of mind as they re alize what it means to ”Stay On Line with

OnLine Power”.

One of our goals is to make these manuals both comprehensive and easy to use. This new-format User’s

Manual is the result of ideas and inputs from customers who have taken an active inte rest in our continued

success. We invite constructive feedback on our products and documentation via fax, mail or telephone.

HEADQUARTERS FACTORY

OnLine Power, Inc OnLine Power, Inc.

5701 Smithway Street 5940 Triumph Street

Commerce, CA 90040 Commerce, CA 90040

SALES

Phone (800) 227-8899

Inside CA (323) 721-5017

FAX No. (323) 721-3929

MANUFACTURING

Phone (323) 720-4125

FAX No. (323) 889-6636

http://www.onlinepower.com

email: Customerservice@onlinepower.com

SERVICE

Phone (800) 797-7782

(PWR-SRVC)

FAX No. (323) 721-3929

6002-032 REV H a

OnLine Power

OnLine Power, Inc.

Proprietary Reproduction or Distribution forbidden

NOTICE: THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION

This document contains proprietary and confidential information of OnLine Power, Inc. (” OnLine Power”). In

consideration of the receipt of this document, the recipient agrees not to copy any of its contents, nor disclose

them to or allow them to be used by any person not currently a OnLine Power employee or an employee of the

recipient having a need to know, without the express written consent of OnLine Po wer, and further agrees to

surrender this document to OnLine Power when the reason for its receipt has terminated.

6002-032 REV H b

OnLine Power

SAFETY

Safety precautions are important when operating or servicing electrical equipment. The following symbols are

used extensively throughout this manual. Always heed these precautions since they are essential to the safe

operation and servicing of this product.

DANGER!!

THIS DANGER SYMBOL IDENTIFIES A CONDITION OR ACTION WHICH

WILL RESULT IN SEVER INJURY OR DEATH TO AN INDIVIDUAL OR SEVER

DAMAGE TO EQUIPMENT OR OTHER PROPERTY.

CAUTION

This Caution symbol identifies a condition or action which may result in minor injury to an

individual or minor damage to the equipment or other property.

This unit was designed for specific applications. It should not be modified and/or used for any application other

than for that which it was designed. Optional equ ipment not described in the sales literature or this manual

should not be installed without first checking with the Service department. If you have any questions about this

unit’s application call the Service department at the number shown on the previous page.

SAVE THESE INSTRUCTIONS

This technical manual contains important instructions for each model that should be followed during installation

and maintenance of the UPS.

6002-032 REV H c

OnLine Power

SAVE THESE INSTRUCTIONS

IMPORTANT SAFEGUARDS

1. READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

2. DO NOT USE OUTDOORS.

3. DO NOT MOUNT NEAR GAS OR ELEC TRIC HEATERS.

4. EQUIPMENT SHOULD BE MOUNTED IN LOCATIONS AND AT HEIGHTS

WHERE IT WILL NOT READILY BE SUBJECTED TO TAMPERING BY

UNAUTHORIZED PERSONNEL.

5. THE USE OF ACCESSORY EQUIPMENT NOT RECOMMENDED BY THE

MANUFACTURER MAY CAUSE AN UNSAFE CONDITION.

6. DO NOT USE THIS EQUIPMENT FOR OTHER THAN INTENDED USE.

6002-032 REV H d

OnLine Power

TABLE OF CONTENTS

SECTION

PAGE

SECTION 1 - OPERATION 1-1

1-1 INTRODUCTION 1-1

1-1-1 Power-Reg and Ultra-Reg 1-2

1-1-2 Phase Stabilizer 1-3

1-1-3 Constant Power 18 1-4

1-2 BENEFITS 1-5

1-3 TRANSFORMER 1-5

1-4 PRODUCT FEATURES 1-5

1-4-1 Bypass Switch 1-12

1-4-2 Main Input Circuit Breaker (IMCB) 1-12

1-4-3 Power On Indicators 1-12

1-4-4 Input and Output Power Terminals 1-12

1-4-5 Input Filter 1-13

1-4-6 Output Filter 1-13

1-5 REGULATION COMPONENTS 1-14

1-6 STARTING THE UNIT 1-18

1-7 OPERATION 1-19

1-7-1 Normal Condition 1-19

1-7-2 Nonregulating Condition 1-19

SECTION 2 - PREINSTALLATION 2-1

2-1 LOCATION CONSIDERATIONS 2-1

2-2 FLOOR LOADING 2-5

2-3 CABLE ACCESS AND FLOOR LAYOUT 2-6

2-3-1 Cable Access 2-6

2-4 MOUNTING 2-9

SECTION 3 - INSTALLATION 3-1

3-1 INSTALLATION 3-1

3-1-1 Unpacking 3-1

3-1-2 Inspection 3-2

3-1-3 Input Cable Installation - Power-Reg, Ultra-Reg & Phase Stabilizer

100 - 400 kVA 3-2

3-1-4 Output Cable Installation - Power-Reg, Ultra-Reg and Phase Stabilizer

125 – 400 kVA 3-4

3-1-5 Input Cable Installation - Phase Stabilizer 15 - 100 kVA

and Constant Power 18 3-5

3-1-6 Output Cable Installa tion - Phase Stabilizer 15 - 100 kVA

and Constant Power 18 3-6

3-1-7 Startup - Power-Reg, Ultra-Reg and Phase Stabilizer (100 - 400 kVA) 3-7

3-1-8 Startup - Phase Stabilizer 15 - 100 kVA and Constant Power 18 3-8

3-1-9 Calibrate Control Logic Board 3-10

6002-032 REV H i

OnLine Power

SECTION

PAGE

3-2 CONFIGURATION 3-13

3-3 RENEWAL PARTS, POWER-REG AND ULT RA-REG 3-14

3-3-1 Vendor Parts List, Power-Reg and Ultra-Reg 3-15

3-4 RENEWAL PARTS, SINGLE PHASE POWER-REG 3-17

3-4-1 Vendor Parts List, Single Phase Power-Reg 3-18

3-5 RENEWAL PARTS, PHASE STABILIZER (100 - 175 kVA) 3-19

3-5-1 Vendor Parts List, Phase Stabilizer (15 - 75 kVA) 3-20

3-5 RENEWAL PARTS, PHASE STABILIZER (15 – 100 Kva) 3-21

3-5-2 Vendor Parts List, Phase Stabilizer (100 - 400 kVA) 3-22

3-6 RENEWAL PARTS, CONSTANT POWER 18 3-23

3-6-1 Vendor Parts List, Constant Power 18 3-24

SECTION 4 - OPTIONS 4-1

4-1 INTRODUCTION 4-1

4-2 REMOTE EMERGENCY POWER OFF STATION, Constant Power 18 4-2

4-2-1 Installation for REPO 4-2

4-3 THERMAL REMOTE EMERGENCY POWER OFF STAT IO N 4-4

4-3-1 Installation for Thermal REPO 4-4

4-4 SURGE PROTECTION 4-6

4-5 MAIN INPUT CIRCUIT BREAKER, Phase Stabilizer (15 - 75 kVA) 4-6

4-5-1 Main Input Circuit Breaker with manual reset option 4-6

4-6 INPUT/OUTPUT FILTERING 4-7

4-7 POWER ISLAND 4-8

4-7-1 Features 4-8

4-7-2 Power Island Specifications 4-9

4-7-3 Preinstallation 4-10

4-7-4 Input/Output Interconnect Cable Installation 4-12

4-7-5 Output Cable Installation 4-13

4-8 OUTPUT METER 4-15

4-9 ALARM, MOV STATUS 4-16

APPENDIX A - SPECIFICATIONS A-1

APPENDIX B – SPECIAL OPTIONS/PROJECT B-1

B.1 POWER REGULATOR, 300KVA, 3 PHASE,

460V INOUT, 460Y/266V OUTPUT.

GLOSSARY G-1

6002-032 REV H ii

OnLine Power

ILLUSTRATION PAGE

Section 1 OPERATIONS

1-1 REGULATED SYSTEM RESPONSE 1-1

1-2 POWER-REG, ULTRA-REG AND PHASE STABILIZER (100 - 400 KVA) 1-2

1-3 CONSTANT POWER 18 AND PHASE STABILIZER (15 - 100 KVA) FOR 480 VAC INPUT

(15 - 75 KVA) FOR 2 08 VAC INPUT 1-4

1-4 POWER-REG AND ULTRA-REG; 15 TO 150 KVA, 480 VAC INPUT

PHASE STABILIZER; 125 - 150 KVA, 480 VAC INPUT 1-6

1-5 SINGLE PHASE POWER-REG (10 - 100 KVA) FEATURES 1-7

1-6 PHASE STABILIZER (15 - 75 KVA) AND CONSTANT POWER 18 FEATURES 1-8

1-7 POWER-REG, ULTRA-REG; 175 KVA TO 400 KVA, 480 VAC INPUT

PHASE-STABILIZER; 125 KVA TO 400 KVA WITH 480 VAC INPUT 1-9

1-8 POWER-REG, ULTRA-REG, PHASE-STABILIZER; 175 KVA TO 400 KVA, 208 VAC INPUT 1-10

1-9 INPUT FILTER WIRING 1-12

1-10 OUTPUT FILTER WIRING 1-12

1-11 REGULATION PANEL ASSEMBLY LAYOUT 1-13

1-12 REGULATION PANEL ASSEMBLY LAYOUT 1-14

1-13 REGULATION BLOCK DIAGRAM 1-15

LIST OF ILLUSTRATIONS

Section 2 PREINSTALLATION

2-1 POWER-REG, ULTRA-REG AND PHASE STABILIZER (100 - 400 KVA) CABLE ACCESS 2-7

2-2 PHASE STABILIZER (15 - 75 KVA) AND CONSTANT POWER 18 CABLE ACCESS 2-7

2-3 PHASE STABILIZER (15 - 75 KVA) AND CP 18 CLEARANCES 2-8

2-4 POWER-REG, ULTRA-REG AND PHASE STABILIZER (100 - 400 KVA) CLEARANCES 2-9

Section 3 INSTALLATION

3-1 CONTROL LOGIC BOARD 3-12

3-2 SCR DRIVER BOARD 3-13

Section OPERATIONS

4-1 REPO BOX 4-2

4-2 REPO WIRING 4-3

4-3 THERMAL REPO WIRING 4-4

4-4 INPUT FILTER WIRING 4-7

4-5 OUTPUT FILTER WIRI NG 4-7

4-6 POWER ISLAND 4-8

4-7 POWER ISLAND FEATURES 4-9

4-8 POWER ISLAND CABLE ACCESS 4-10

4-9 POWER ISLAND FLOOR TILE CUTOUT 4-11

4-10 POWER ISLAND DIMENSIONS AND CLEARANCES 4-11

6002-032 REV H iii

OnLine Power

LIST OF TABLES

TABLE

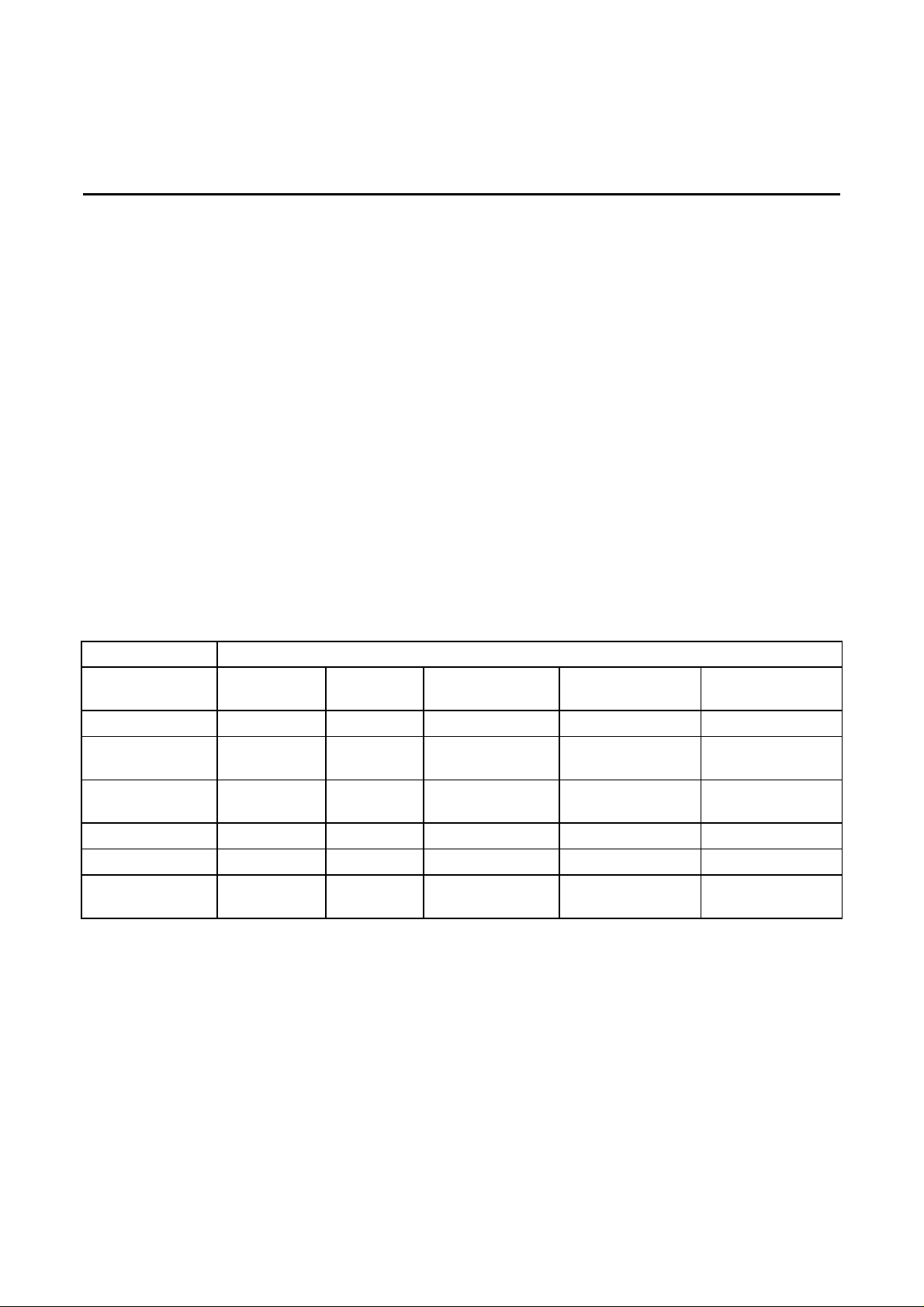

1-1 PRODUCT FEATURES 1-5

2-1 POWER-REG AND ULTRA-REG SITE PLANNING SPECIFICATIONS 2-2

2-2 SINGLE PHASE POWER-REG SITE PLANNING SPECIFICATIONS 2-3

2-3 CONSTANT POWER 18 SITE PLANNING SPECIFICATIONS 2-3

2-4 PHASE STABILIZER SITE PLANNING SPECIFICATIONS 2-4

2-5 POWER-REG AND ULTRA-REG FLOOR LOADING 2-5

2-6 CONSTANT POWER 18 FLO OR LOADING 2-5

2-7 PHASE STABILIZER FLOOR LOADING 2-6

2-8 SINGLE PHASE POWER-REG FLOOR LOADING 2-6

3-1 POWER-REG AND ULTRA-REG CURRENT TRANSFORMERS 3-16

3-2 POWER-REG AND ULTRA-REG CURRENT TRANSFORMERS 3-18

3-3 PHASE STABILIZER (15 - 75 KVA) CURRENT TRANSFORMERS 3-20

3-4 PHASE STABILIZER (100 - 400 KVA) CURRENT TRANSFORMERS 3-22

3-5 CONSTANT POWER 18 CURRENT TRANSFORMERS 3-24

4-1 OPTIONS MATRIX 4-1

A-1 SPECIFICATIONS = POWER-REG AND ULTRA-REG A-1

A-2 SPECIFICATIONS = PHASE STABILIZER A-2

A-3 SPECIFICATIONS = CONSTANT POWER 18 1-3

PAGE

6002-032 REV H iv

On-Line Power

SECTION 1 - OPERATION

1-1 INTRODUCTION

This manual provides installation, operation and maintenance information for the Power-Reg and Ultra-Reg

voltage regulator units as well as for the Constant Power 18 (CP 18) and Phase Stabilizer power conditioner

units. A detailed description of each product is provided in the following subsections.

All components used are of the highest quality and specifically selected to achieve the highest level of

performance. These units are UL listed and conform to National Electric Code (NEC) and Occupation al Safety

and Health Act (OSHA) standards.

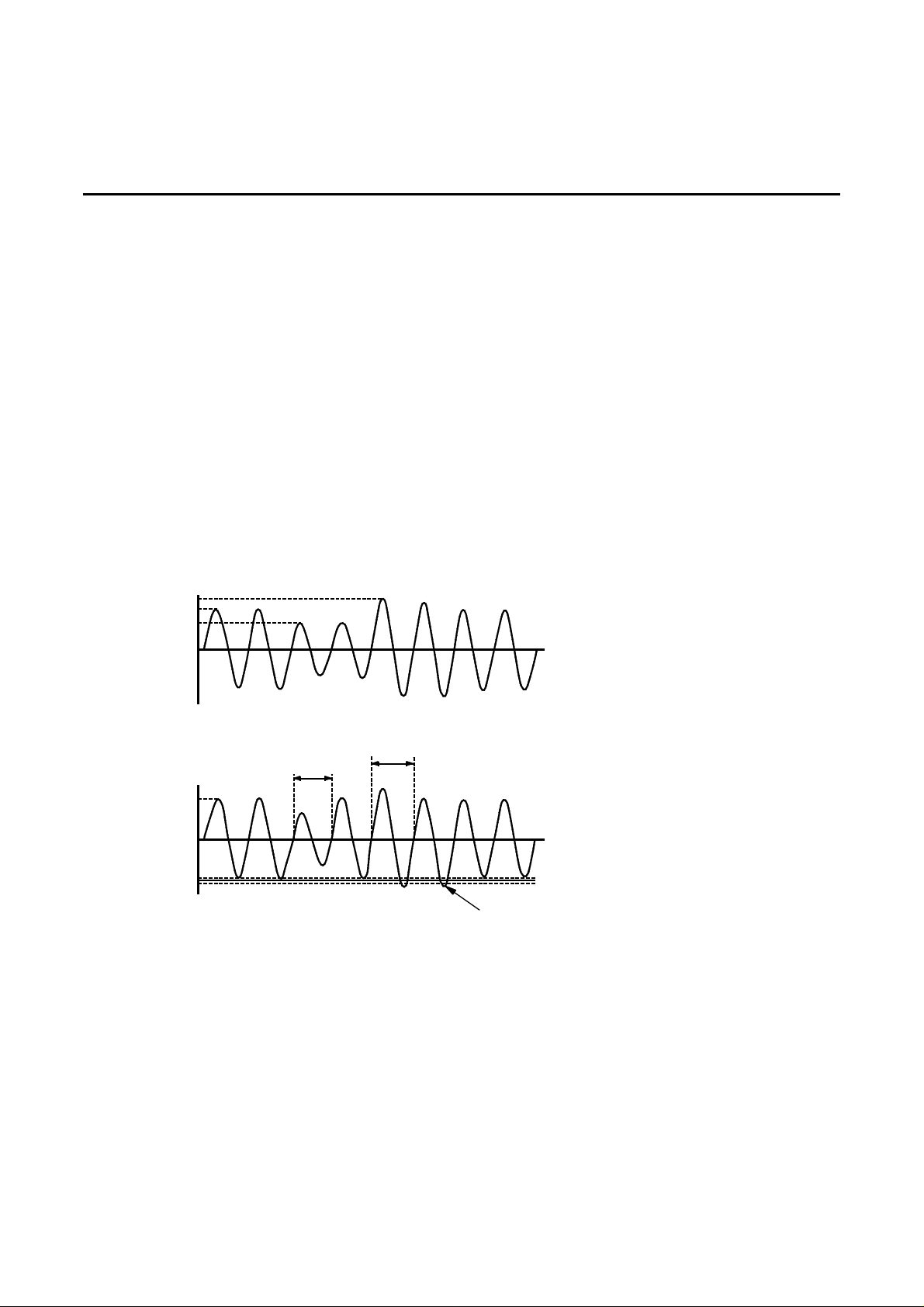

The Power-Reg, Ultra-Reg, Phase Stabilizer and CP 18 have tapped electronic voltage regulators. Six taps are

on each primary winding of the transformer. Each tap is controlled by a silicon-controlled rectifier (SCR) switch

and can become active at any time. Input line-to-line voltage and line current are monitored for each phase.

Peak voltage is compared with a desired reference. Depending on this comparison, the regulation logic

activates the proper SCR switch when the phase current becomes zero. This changes the primary-tosecondary turns ratio which corrects output voltage to the desired nominal. The correction process starts in

less than one cycle. See Illustration 1-1.

500

480

420

-480

480

-480

SURGE

SAG

0

INPUT

CORRECTED

CORRECTED

IN 1 CYCLE

0

IN 1 CYCLE

OUTPUT

REGULATED SYSTEM RESPONSE

ILLUSTRATION 1-1

POWER-REG, ULTRA-REG, CP18:

REGULATED TO +/- 3% OF NOMINAL TYPICAL

PHASE STABILIZER:

+

-

6002-032 REV H 1-1

On-Line Power

1-1-1 Power-Reg and Ultra-Reg

The Power-Reg and Ultra-Reg are designed to provide the reliable, high-quality power necessary to meet the

needs of today’s sensitive electronics.

These three-phase, 60 Hertz, self-contained, modular units provide isolation and regulation of AC power. The

zero-current tap switching voltage regulation circuitry automatically adjusts for an input voltage range between

+10% surge and -26% sag about the nominal rated voltage with an output voltage range of ± 3% typical to ± 4%

maximum. Each phase is regulated independently. And also single phase, 60Hz, self contained units are

available.

The Power-Reg and Ultra-Reg are available in input voltages of 208 or 480 VAC and output voltages of

208Y/120 and 480Y/277 VAC. These units are available in sizes ranging from 15 kVA to 400 kVA . The specific

rating information for your unit is provided on the label plate located on the front panel. Refer to Appendix A.

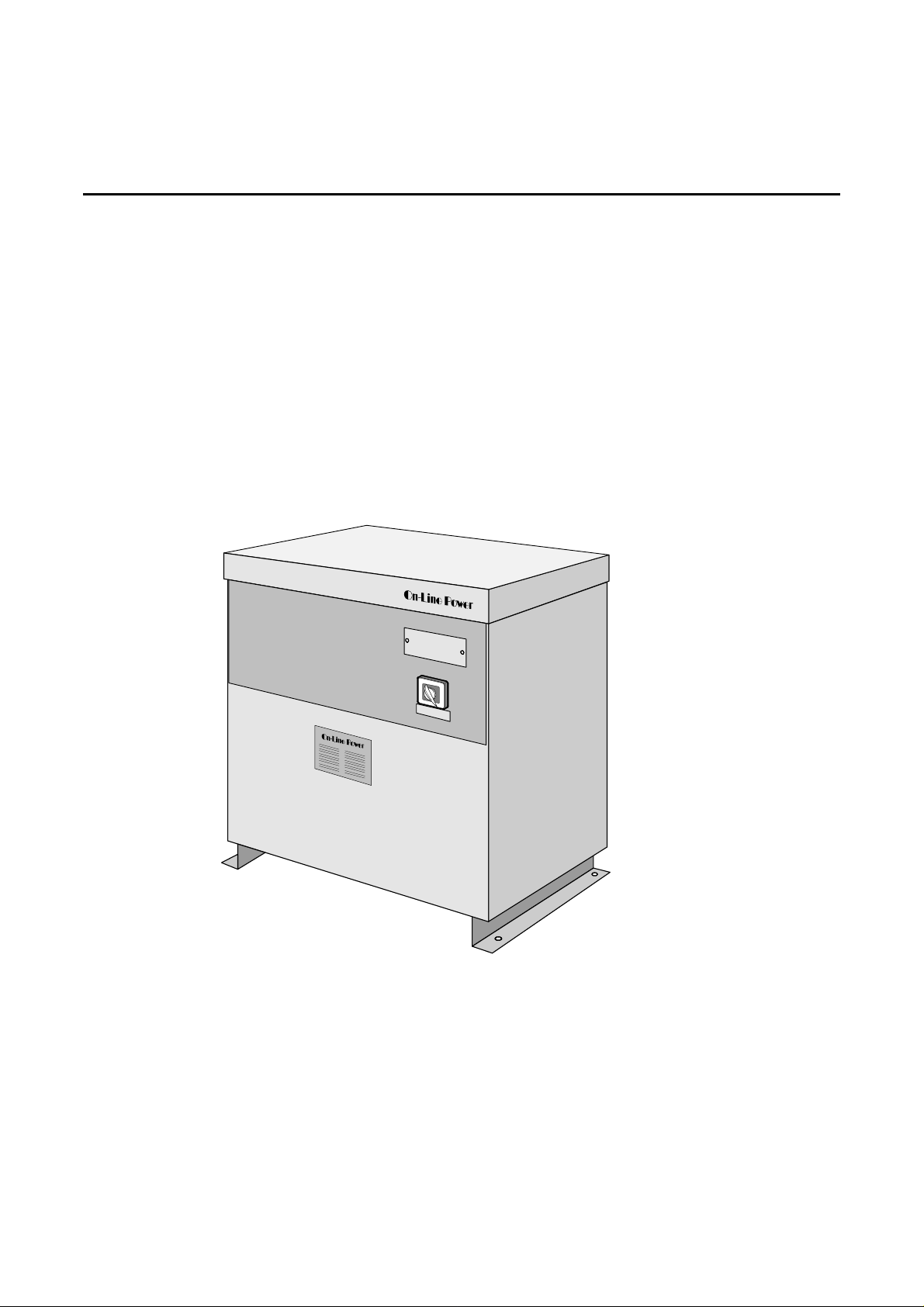

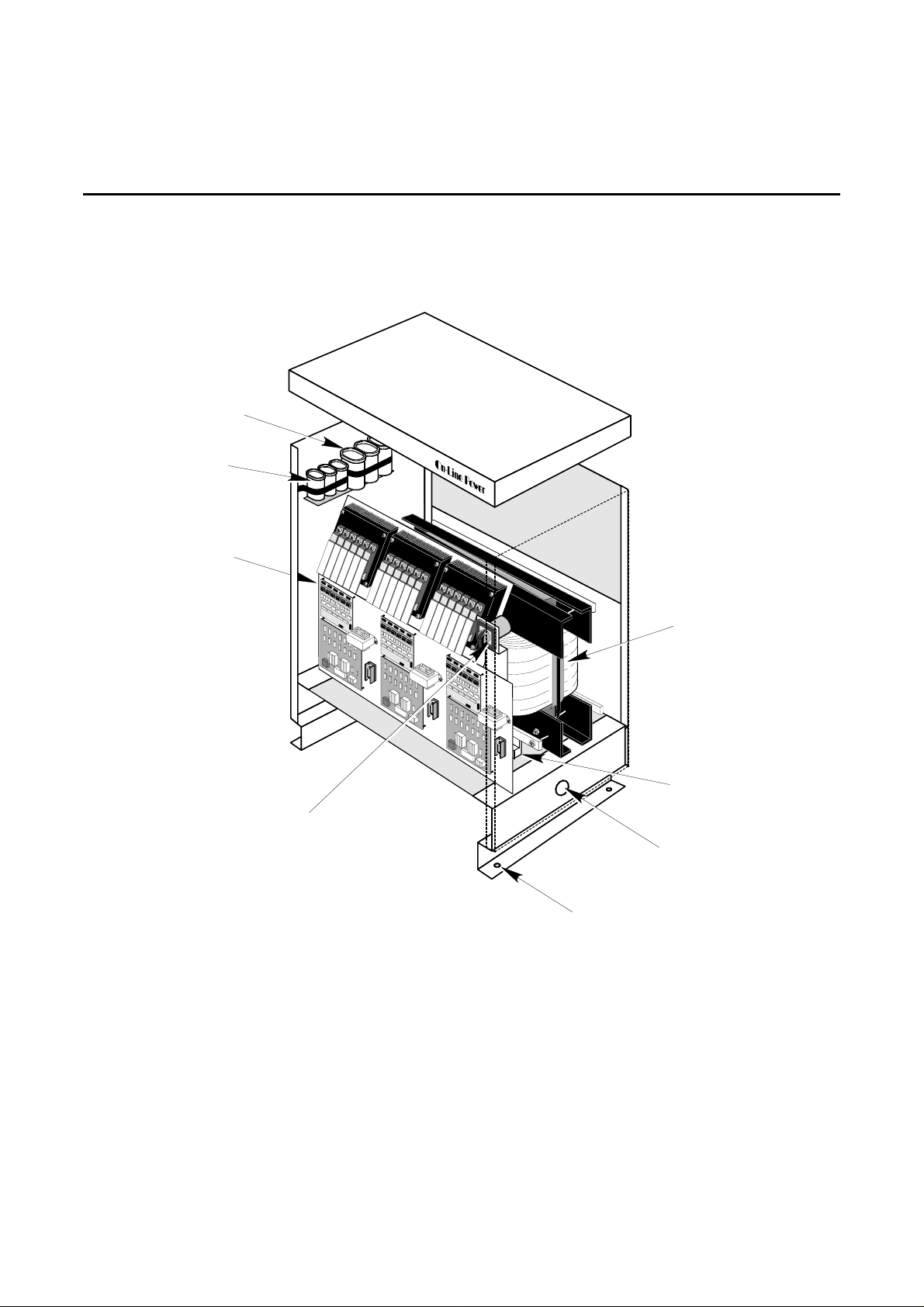

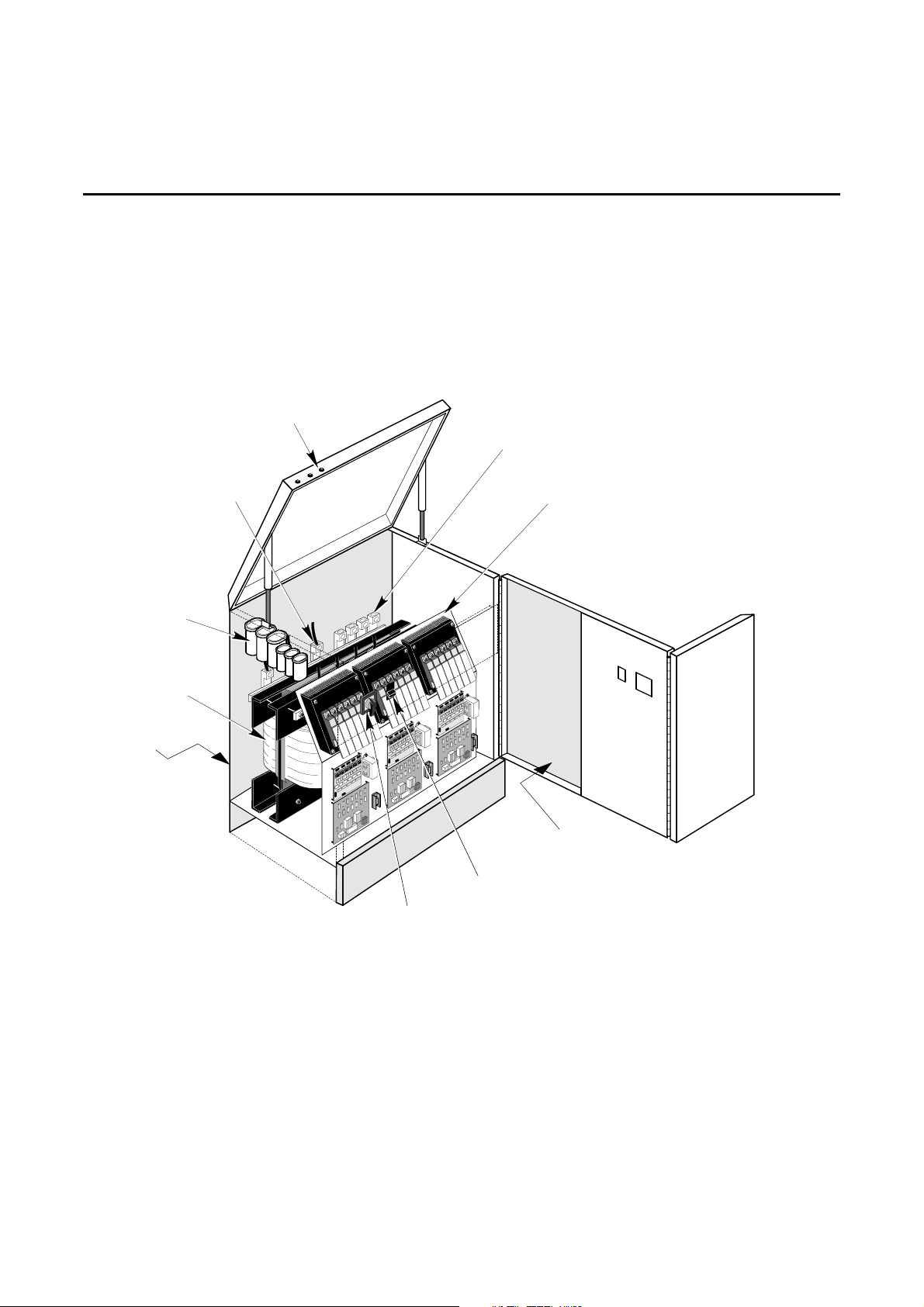

The Power-Reg and Ultra-Reg unit is shown in Illustration 1-2.

POWER-REG, ULTRA-REG AND PHASE STABILIZER (100 - 400 KVA)

WITH 208 VAC INPUT OR (125-300 KVA WITH 480 VAC INPUT

ILLUSTRATION 1-2

6002-032 REV H 1-2

On-Line Power

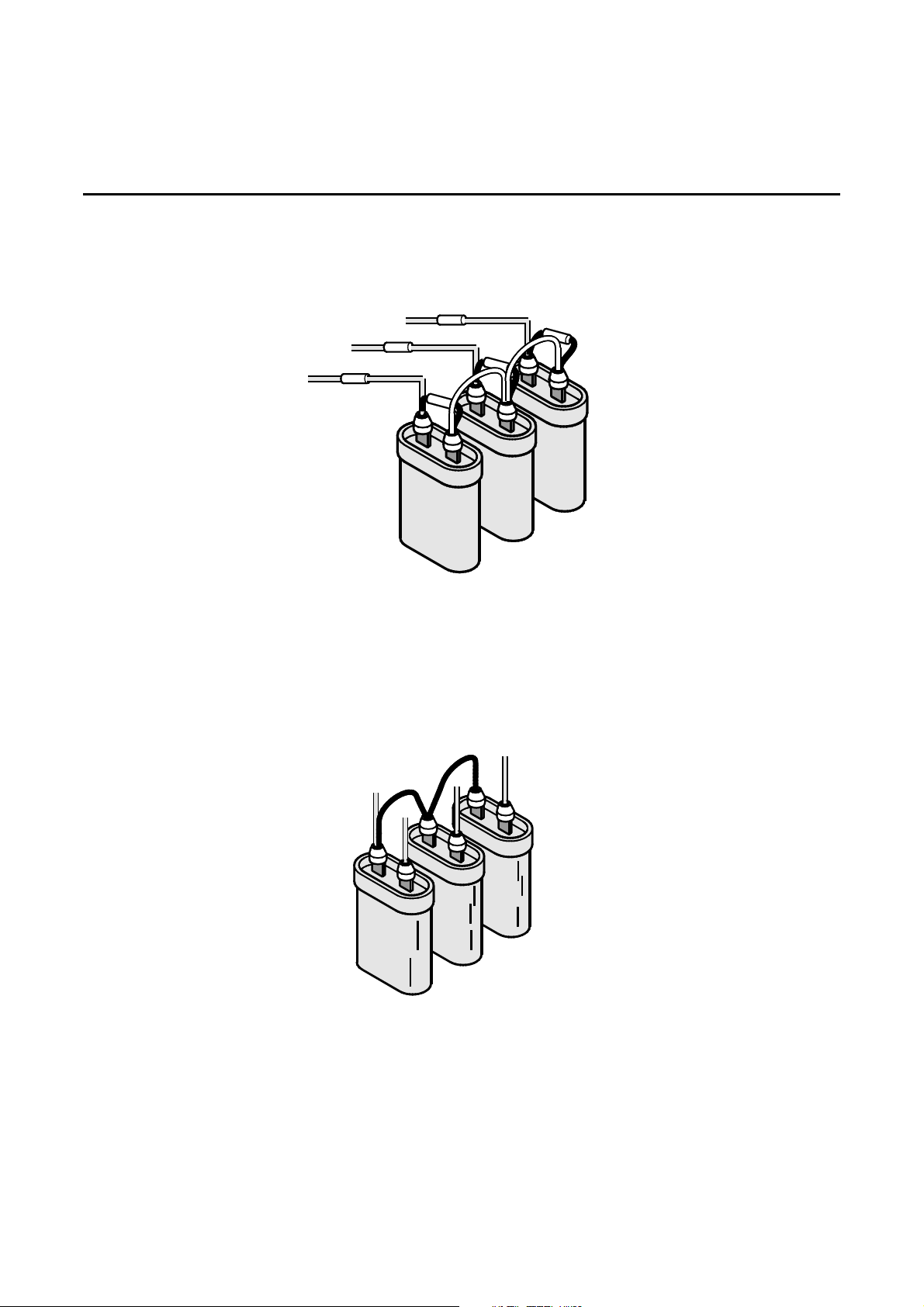

1-1-2 Phase Stabilizer

The medical-grade Phase Stabilizer power conditioner is designed to provide the reliable, high-quality power

necessary to suit the needs of today’s sensitive medical devices.

This three-phase, 60 Hertz, self-contained, modular unit provides isolation and regulation of AC power. T he

zero-current tap switching voltage regulation circuitry automatically ad justs for an input voltage range between

+8% surge and -10% sag about the nominal rated voltage with an output voltage range of ± 1.5% typical to ±

2% maximum. Each phase is regulated independently.

The Phase Stabilizer is available in input voltages of 208 or 480 VAC and output voltages of 208Y/120 and

480Y/277 VAC. This unit is available in sizes ranging from 15 kVA to 400 kVA. The specific rating information

for your unit is provided on the label plate located on the front panel. Refer to Appendix A.

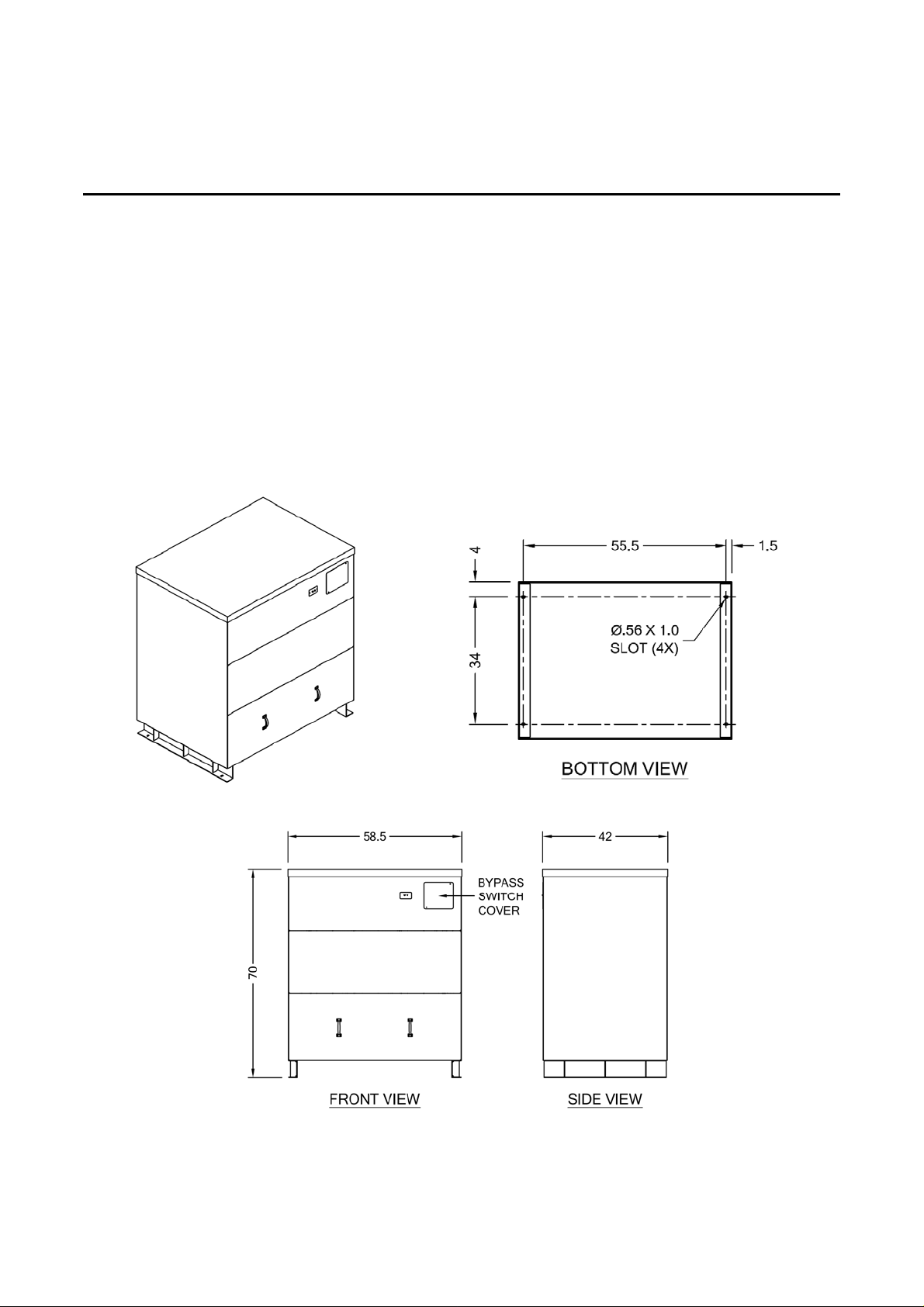

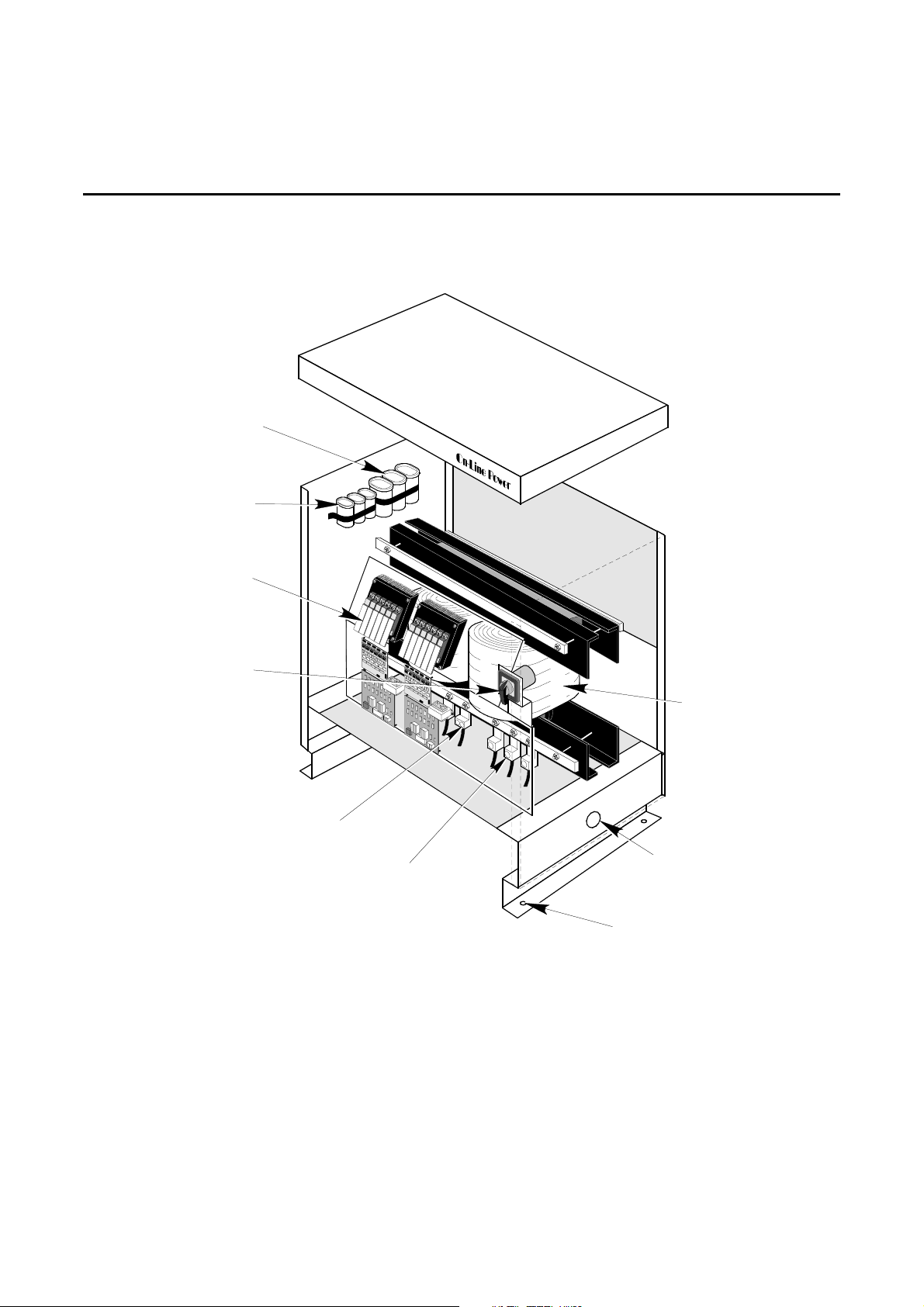

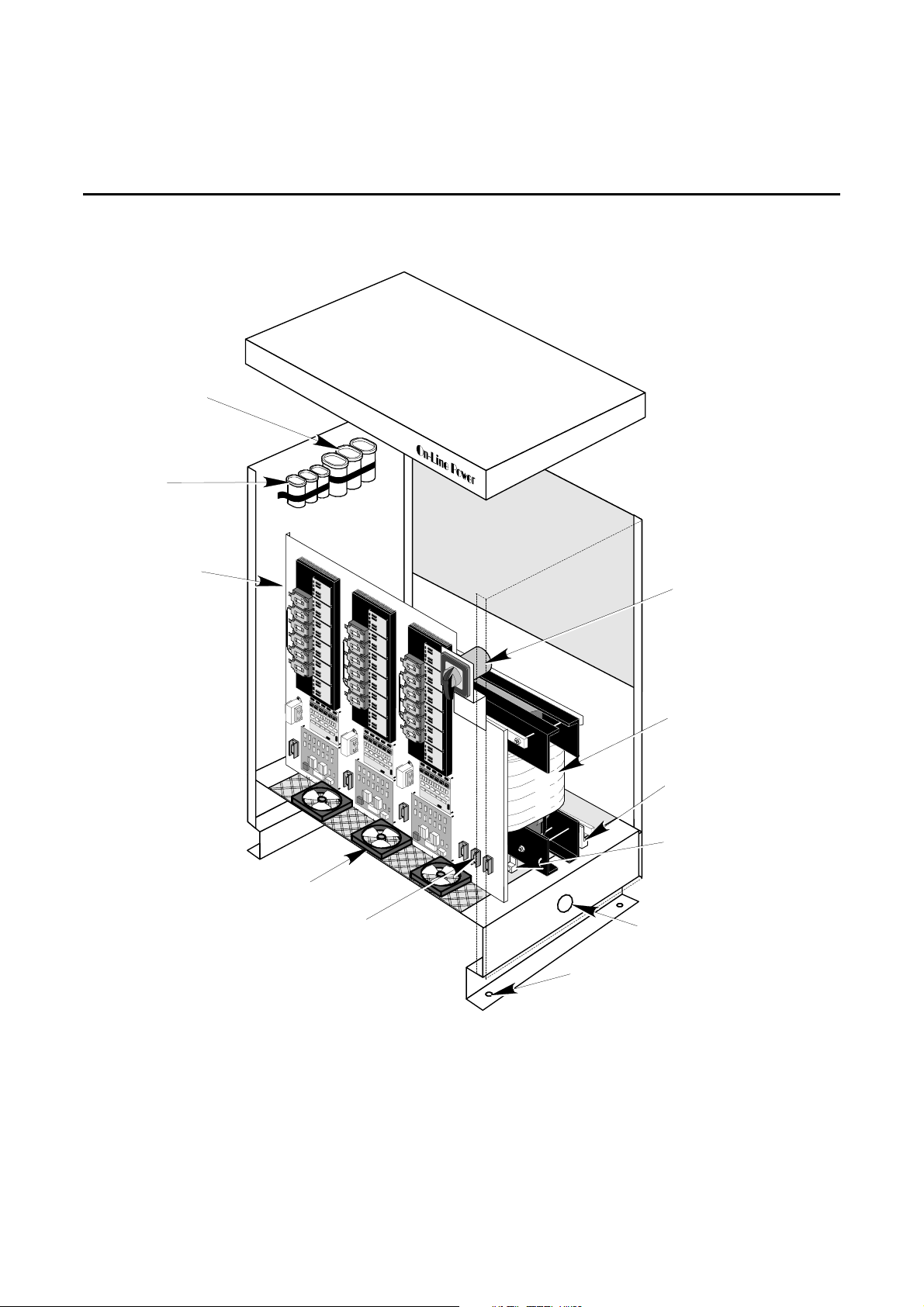

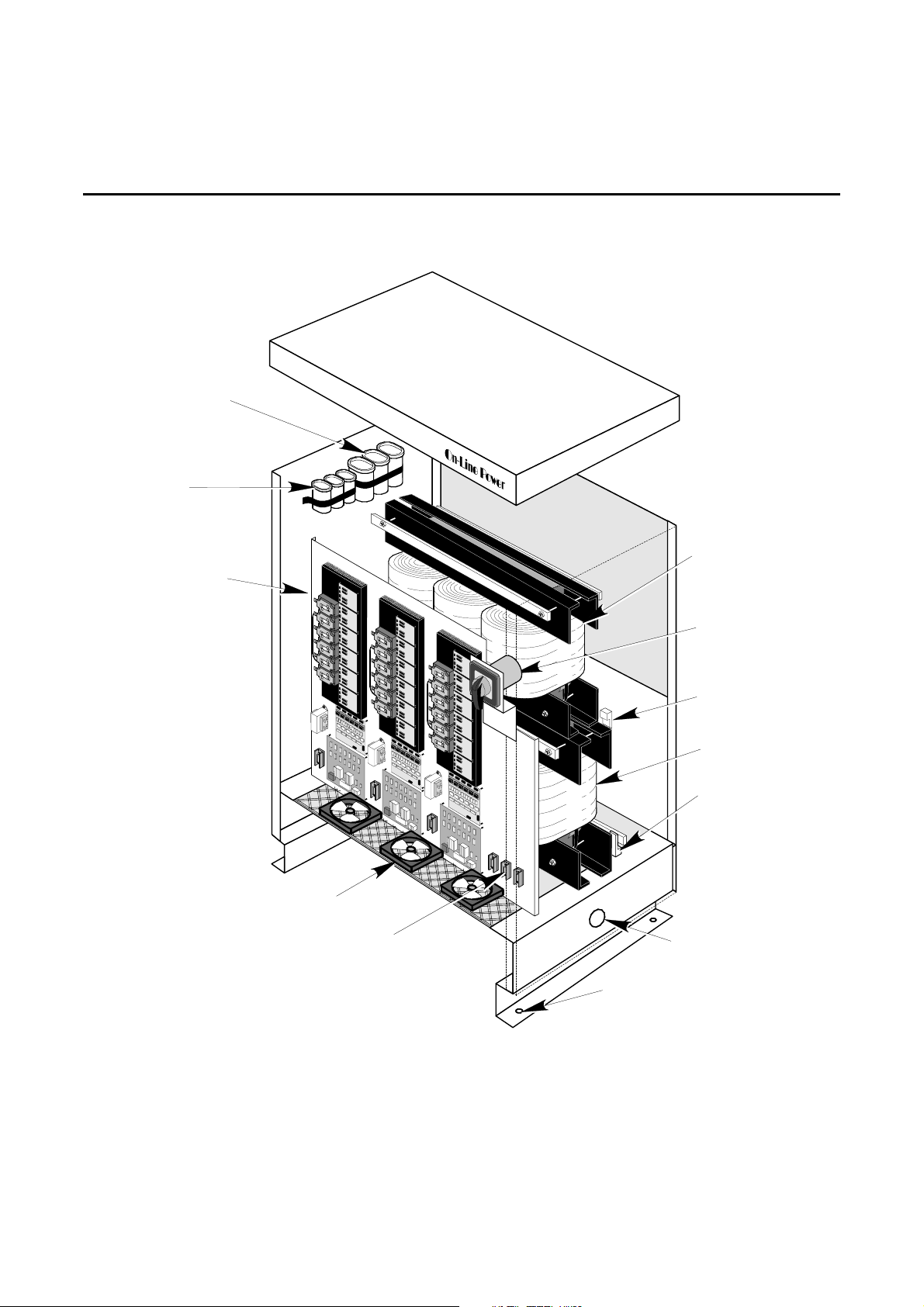

The 15 to 100 kVA Phase Stabilizer with 480 VAC or the 15-75 kVA with 208 VAC is shown in Illustration 1-3.

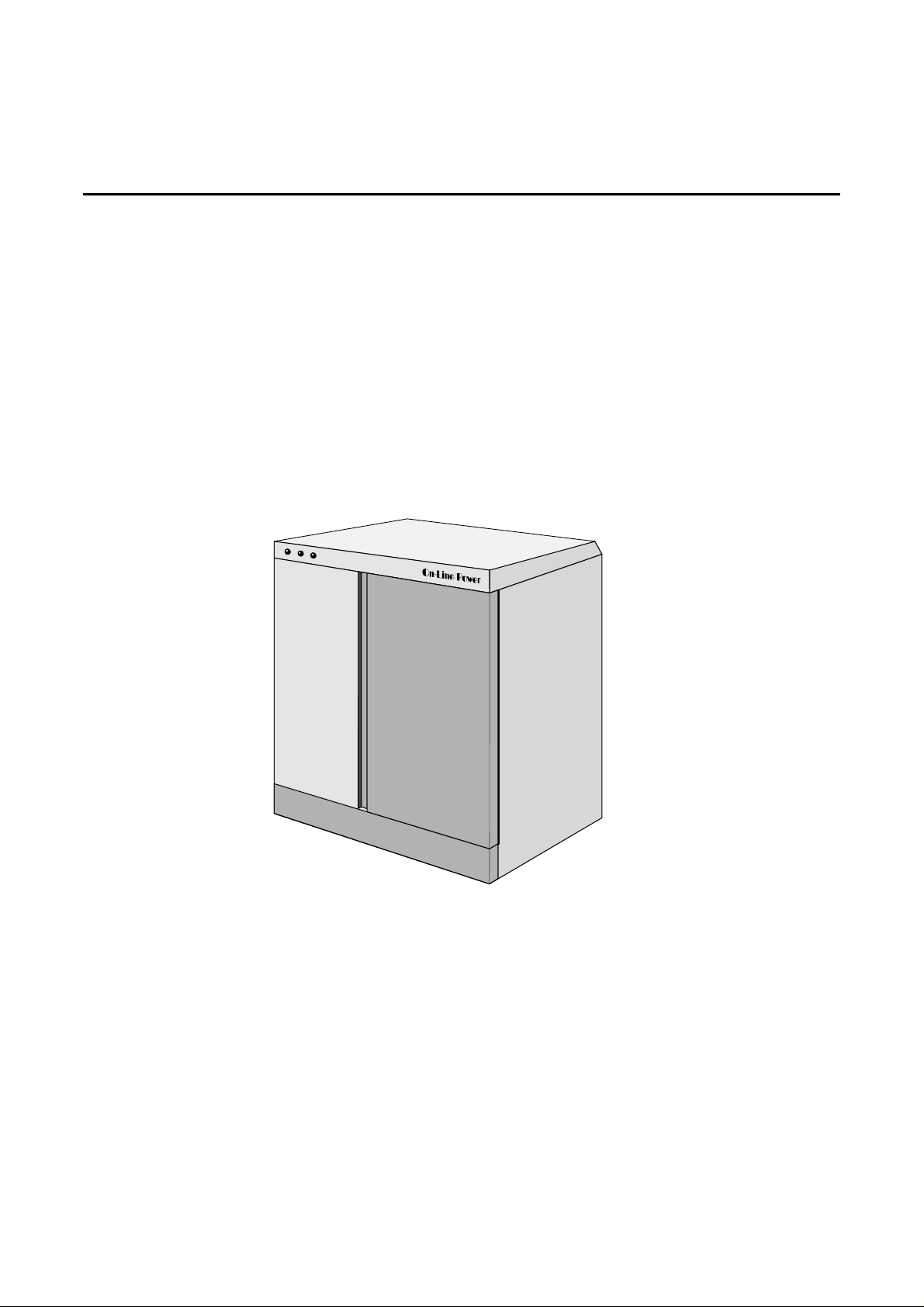

The 125 to 400 kVA Phase Stabilizer with 480 VAC input or the 100-400 kVA with 208 VAC input is shown in

Illustration 1-2.

ILLUSTRATION 1-2-A

6002-032 REV H 1-3

On-Line Power

1-1-3 Constant Power 18

The Constant Power 18 is designed to provide the reliable, high-quality power necessary to suit the nee ds of

today’s sensitive electronics.

This three-phase, 60 Hertz, self-contained, modular unit provides isolation, shielding and regulation of AC

power. The zero-current tap switching voltage regulation circuitry automatically adjusts for an input voltage

range between +10% surge and -26% sag about the nominal rated voltag e with an output voltage range of ±

3% typical to ± 4% maximum. Each phase is regulated independently.

The Constant Power 18 is available in input voltages of 208 or 480 VAC and output voltages of 208Y/120 and

480Y/277 VAC. These units are available in 15, 30, 50, 75, and 100 kVA capacities. The specific rating

information for your unit is provided on the label plate located inside small front door. Refer to Appendix A-3.

The Constant Power 18 is shown in Illustration 1-3.

CONSTANT POWER 18 AND PHASE STABILIZER (15 - 100 KVA) FOR 480 VAC INPUT

(15 - 75 KVA) FOR 208 VAC INPUT

ILLUSTRATION 1-3

6002-032 REV H 1-4

On-Line Power

1-2 BENEFITS

The Power-Reg, Ultra-Reg, Phase Stabilizer and CP 18 protect electronic equipment from an overvoltage

condition during line power surges and an undervoltage condition during sags. In addition, the unit protects

equipment load by attenuating transients present on utility power lines. overvoltage, overcurrent, and transient

conditions stress electronic components and decrease system reliability.

In medical applications, voltage fluctuations affect the image quality of imaging systems. Artifacts are

introduced under sag conditions. Regulating power maintains image quality, resulting in more consistent

images.

1-3 TRANSFORMER

The transformer contained in the unit is designed for convection cooling by means of free circulation of air

through the bottom, front and back of the unit. Maximum ambient temperatures should not exceed 104°F

(40°C). The transformer contains built-in thermal sensors which monitor internal temperatures. In models with

a Input Main Circuit breaker (IMCB), the thermal sensors send a shunt trip signal to the IMCB in the event of an

over temperature condition.

1-4 PRODUCT FEATURES

Sections 1-4 and 1-5 describe the features of the Power-Reg, Ultra-Reg, Phase Stabilizer and CP 18. Some

features described in Section 1-4 are stan dard on all m odels while ot her features ar e offered as options. Refer

to Table 1-1 to determine if the features described in this section are applicable to your unit. Refer to Section 4,

Options, for information on optional features.

TABLE 1-1

PRODUCT FEATURES

OPTION

Bypass Switch

Main Input

Power-Reg Ultra-Reg Constant

S S S S S

N N S O N

Circuit Breaker

Power On

N N S S N

Indicators

Input Filter

Output Filter

Input/Output

S S S S S

O O O S S

S S S S S

Power Terminals

TABLE KEY: S = Standard equipment, O = Available as an option, N = Not available for this model.

MODEL

Power 18

Phase Stabilizer

(15 - 75 kVA)

Phase Stabilizer

(100 - 400 kVA)

6002-032 REV H 1-5

On-Line Power

1-4 PRODUCT FEATURES (continued)

OUTPUT

FILTER

(Optional)

INPUT POWER

FILTER

REGULATION

ELECTRONIC PANEL:

- Heat Sinks

- SCR Snubber Boards

- SCR Power Blocks

- Reference Transformers

- SCR Driver Boards

- SCR Control Boards

- Fuses

BYPASS

SWITCH

MAIN POWER

TRANSFORMER

INPUT AND OUTPUT

POWER

TERMINAL

INPUT & OUTPUT

CABLE ACCESS

(BOTH SIDES)

POWER-REG AND ULTRA-REG; 15 TO 150 KVA, 480 VAC INPUT

PHASE STABILIZER; 125 - 150 KVA, 480 VAC INPUT

ILLUSTRATION 1-4

6002-032 REV H 1-6

9/16" Dia.

Mounting Holes

On-Line Power

1-4 PRODU CT FEATUR ES (CONTINUED)

MAIN OUTPUT

MAIN INPUT

PHASE STABILIZER; 200 - 400 KVA,

ILLUSTRATION 1-4-A

6002-032 REV H 1-7

On-Line Power

1-4 PRODUCT FEATURES (continued)

OUTPUT

FILTER

(OPTIONAL)

INPUT

FILTER

REGULATION

ELECTRONIC

PANEL

BYPASS SWITCH

INPUT POWER

TERMINAL BLOCK

OUTPUT POWER

TERMINAL BLOCKS

SINGLE PHASE POWER-REG; 10 - 100 KVA,

MAIN OUTPUT

TRANSFORMER

600V input

120/240V output

INPUT & OUTPUT

CABLE ACCESS

3/8" Dia. Mounting Holes

ILLUSTRATION 1-5

6002-032 REV H 1-8

On-Line Power

1-4 PRODUCT FEATURES (continued)

POWER ON

INDICATORS

INPUT POWER

TERMINALS

INPUT/OUTPUT

FILTER

OUTPUT POWER

TERMINALS

REGULATION

ELECTRONIC PANEL:

- Heat Sinks

- SCR Snubber Boards

- SCR Power Blocks

- Reference Transformers

- SCR Driver Boards

- SCR Control Boards

- Fuses

MAIN

TRANSFORMER

REAR

VENTILATION

FRONT

VENTILATION

MAIN INPUT

CIRCUIT BREAKER

BYPASS

SWITCH

PHASE STABILIZER (15 - 75 KVA) AND CONSTANT POWER 18 FEATURES

ILLUSTRATION 1-6

6002-032 REV H 1-9

On-Line Power

1-4 PRODUCT FEATURES (continued)

OUTPUT

FILTER

INPUT

FILTER

EGULATION

LECTRONICS

ANEL

BYPASS

SWITCH

FANS for

Electronic

Cooling

FAN FUSE

9/16" Dia.

Mounting Holes

POWER-REG, ULTRA-REG; 175 KVA TO 300 KVA, 480 VAC INPUT

PHASE-STABILIZER; 125 KVA TO 400 KVA WITH 480 VAC INPUT

ILLUSTRATION 1-7

MAIN POWER

TRANSFORMER

OUTPUT POWER

TERMINALS

INPUT POWER

TERMINALS

INPUT & OUTPUT

CABLE ACCESS

(BOTH SIDES)

6002-032 REV H 1-10

On-Line Power

1-4 PRODUCT FEATURES (continued)

OUTPUT

FILTER

INPUT

FILTER

REGULATION

ELECTRONIC

PANEL

FANS for

Electronic Cooling

FAN FUSE

INPUT AUTO

TRANSFORMER

BYPASS SWITCH

INPUT POWER

TERMINALS

MAIN POWER

TRANSFORMER

OUTPUT POWER

TERMINALS

INPUT & OUTPUT

CABLE ACCESS

(BOTH SIDES)

9/16" Dia.

Mounting Holes

POWER-REG, ULTRA-REG, PHASE-STABILIZER; 175 KVA TO 400 KVA, 208 VAC INPUT

ILLUSTRATION 1-8

6002-032 REV H 1-11

On-Line Power

1-4-1 Bypass Switch

The bypass switch is located on the front panel. See Illustrations 1-4 thru 1-8. This switch bypasses voltage

regulation but maintains the functioning o f the voltage change/isolation transformer between input an d output.

In AUTO position line to-neutral voltages are regulated. In MAN (manual) position, regulation log ic is bypassed

and input power is applied to load via transformer without regulation. Select the MAN position if there is a

problem with regulation logic circuitry. Refer to Section 1-7-2, Nonregulating Condition for the procedure to

operate the unit in bypass mode.

CAUTION

The Bypass Switch must never be changed with the unit powered up.

1-4-2 Main Input Circuit Breaker (IMCB)

The MAIN INPUT CIRCUIT BREAKER (IMCB) located on the front pa nel o f the unit, is used to switch p o wer to

the unit ON and OFF. See Illustration 1-6.

The IMCB is shunt tripped by activation of a solenoid within the breaker when remote switches or thermal

switches in the main transformer sense an over temperature condition. If the IMCB is shunt tripped, refer to

Section NO TAG, Miscellaneous Problems for the reset procedure.

An optional undervoltage shunt-trip is available.

Be sure to observe ALL warnings and cautions when setting the IMCB to ON or OFF.

1-4-3 Power On Indicators

Power On Indicators are located on the front of the unit. See Illustration 1-6. There is one neon indicating light

for each of the three phases. If a phase is lost, the corresponding in dicator will extinguish indicating which

phase is not powered.

1-4-4 Input and Output Power Terminals

Input and Output power connections are made at the terminals located beneath the transformer except the

illustration 1-6 where the terminals are located above and to the rear of the main transformer. See Illustration

1-4. Terminals are labeled H1, H2, H3, or L1, L2, L3 for the input cable connections and X0, X1, X2, X3 for the

output cable connections.

6002-032 REV H 1-12

On-Line Power

1-4-5 Input Filter

The Input filter is installed on the primary side of the transfor mer. The input filter consists of a r esistor/capacitor

network which acts as a large snubber circuit to eliminate high frequency impulses from entering the power

system. See Illustration 1-9.

R3

R6

R5

R4

C3

C2

(L1)

H1

(L2)

H2

R1

(L3)

H3

R2

C1

INPUT FILTER WIRING

ILLUSTRATION 1-9

1-4-6 Output Filter

The Output filter is installed on the transformer secondary. It consists of a capacito r network which prevents

noise from being fed back to the unit from noise generating loads. See Illustration 1-10. Output filters are

standard on the Phase Stabilizer and optional on other models.

X3

C4

X2

C6

C5

X0

X1

OUTPUT FILTER WIRING

ILLUSTRATION 1-10

6002-032 REV H 1-13

On-Line Power

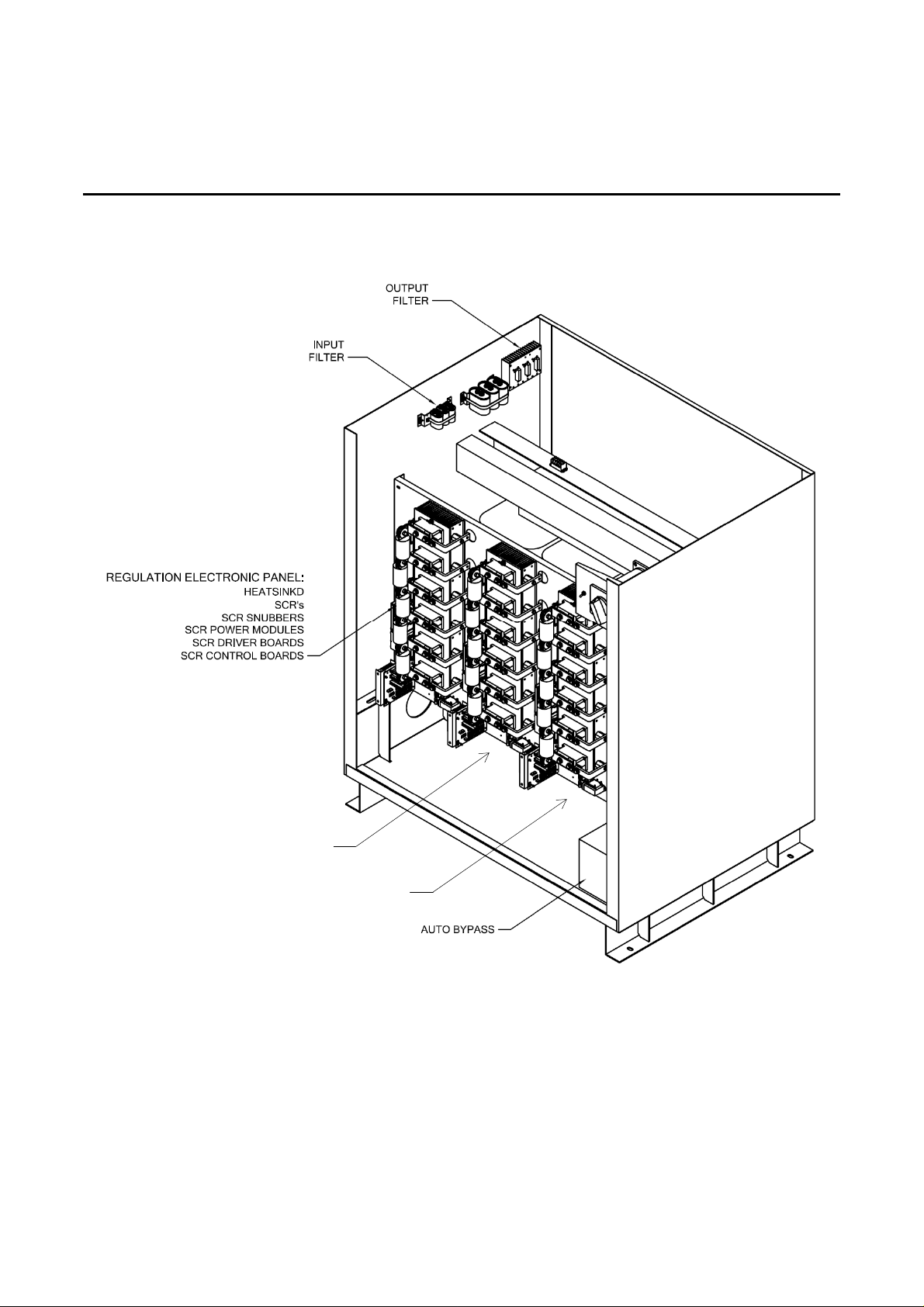

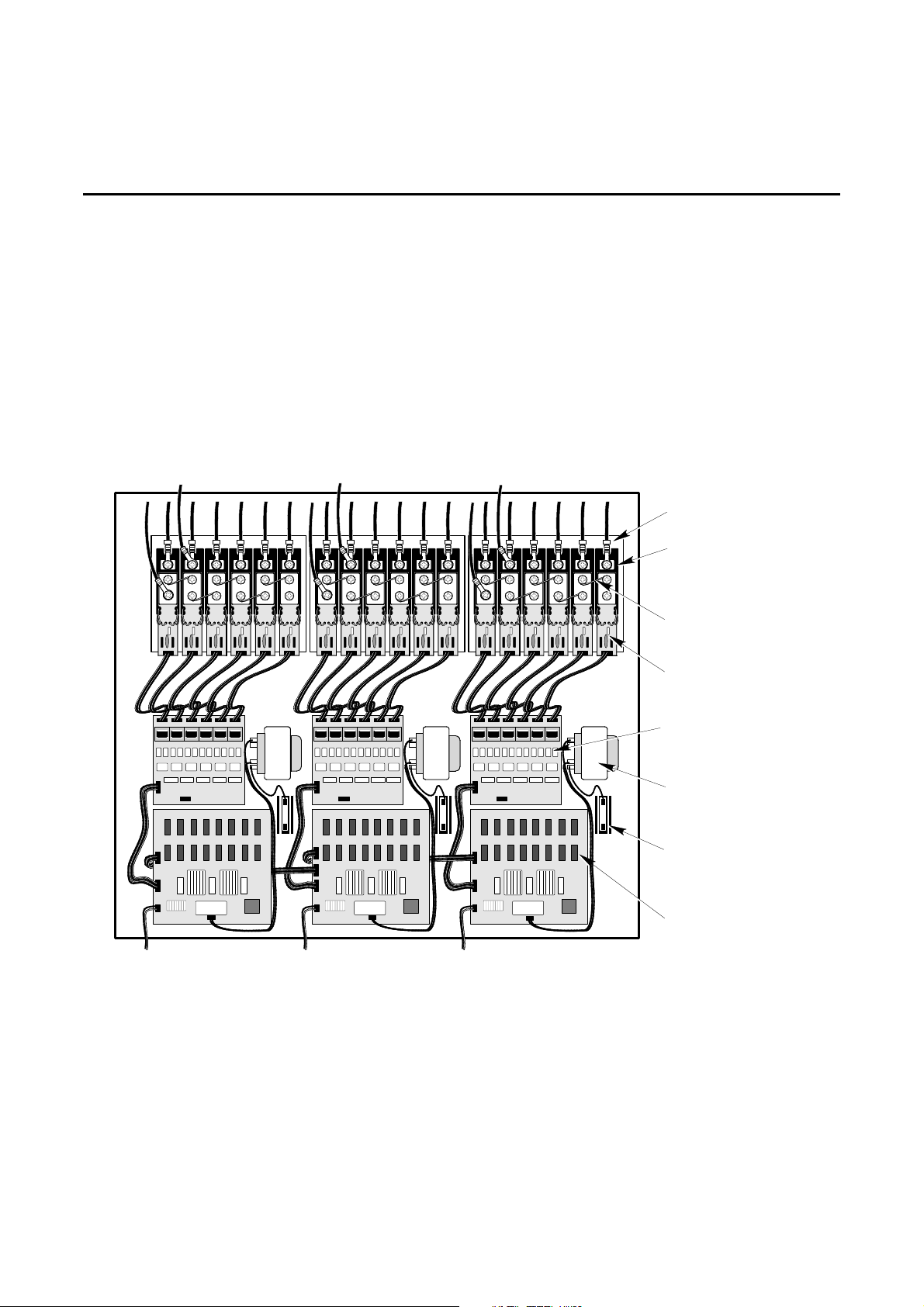

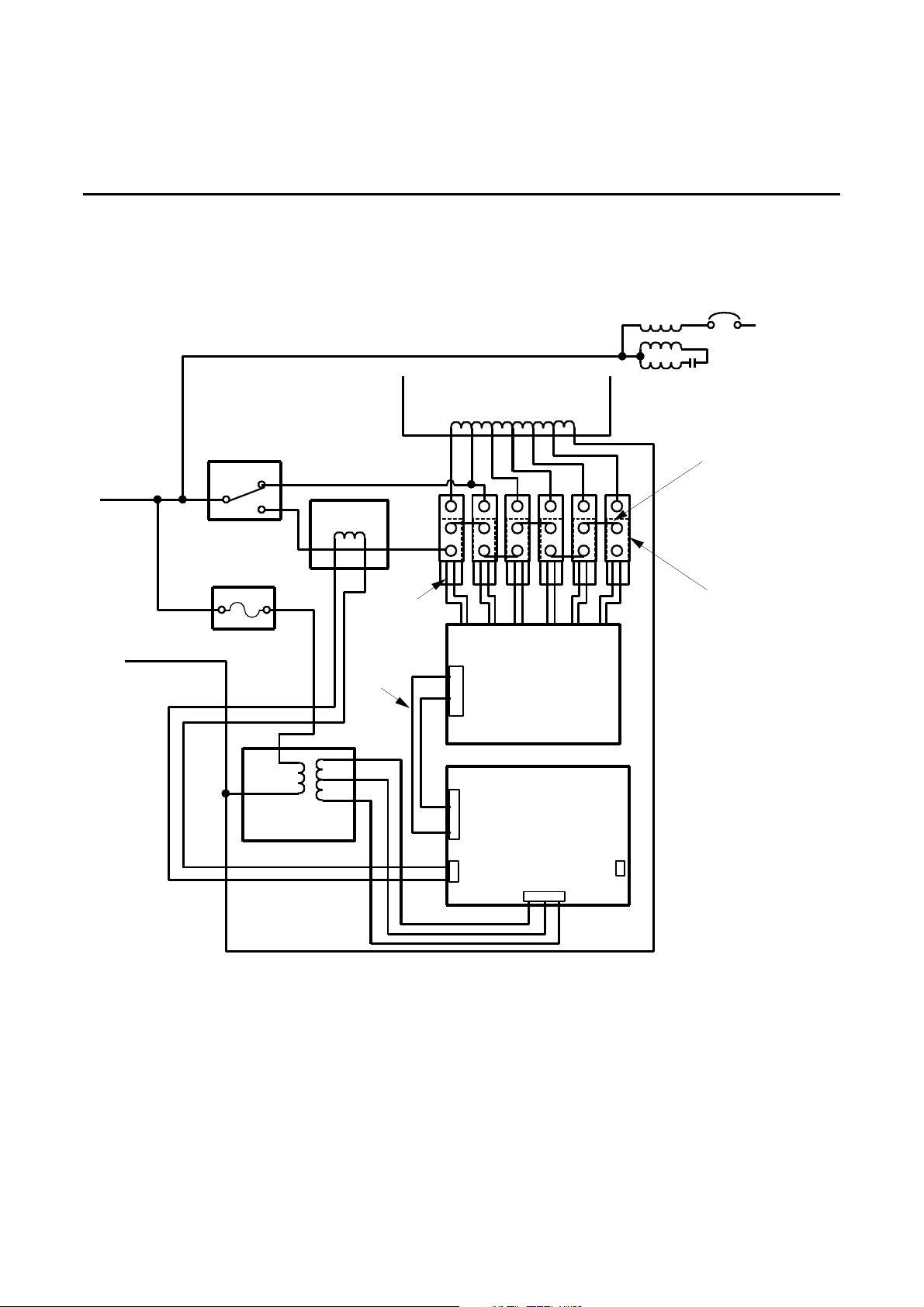

1-5 REGULATION COMPONENTS

Regulation is accomplished by solid-state electronics which control the tap switching function at the zerocurrent-crossing. Refer to Section NO TAG, THEORY OF OPERATION for more detail.

The regulation components are mounted on the regulation panel and can be seen by removing th e front panel.

See Illustration 1-11 and 1-12. The regulation componen ts include 3 SCR Control logic boards, 3 SCR Driver

boards, 18 SCR/SCR Snubber board assemblies, 3 current transformers, 3 reference transformers, and 3

heatsinks. See Illustration 1-13 for a block diagram of the regulation panel components.

Each SCR Control logic board has seven LEDs. The first six LEDs indicate the active tap selection during

operation. LED 7 indicates power is applied to the board and is always lit during operation.

To Bypass To Bypass To Bypass

HEATSINK (3)

66554433221

To

Current

Transformer

66554433221

1

To

Current

Transformer

66554433221

1

To

Current

Transformer

1

SCR (18)

FUSELINK (15)

SCR SNUBBER

BOARD (18)

SCR DRIVER

BOARD (3)

REFERENCE

TRANSFORMER (3)

FUSES FOR

REF. TRANSFORMER (3)

(NOT ON ALL MODELS)

SCR CONTROL

LOGIC BOARD (3)

REGULATION PANEL ASSEMBLY LAYOUT (TYPICAL ONLY)

ILLUSTRATION 1-11

6002-032 REV H 1-14

On-Line Power

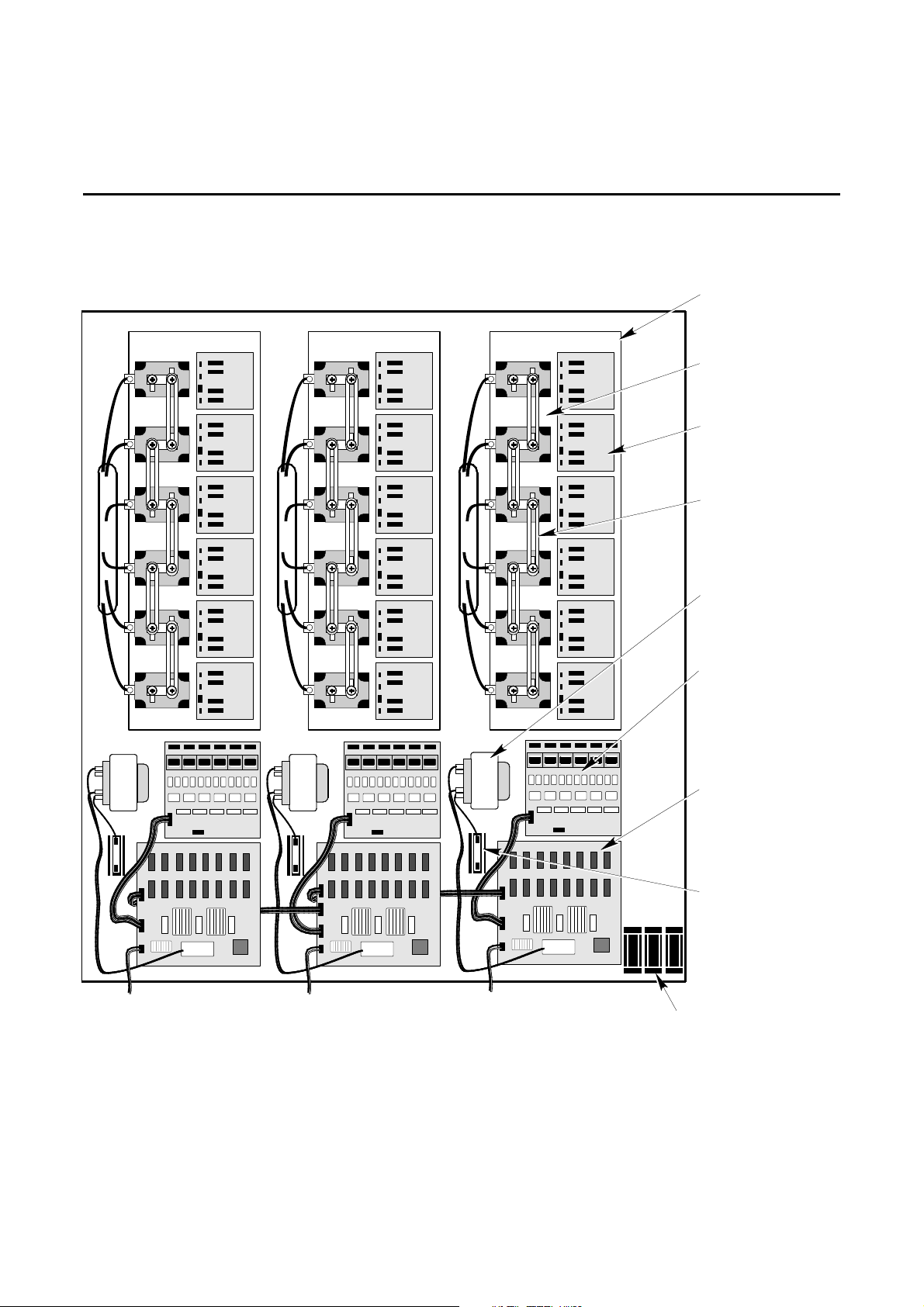

1-5 REGULATION COMPONENTS (continued)

HEATSINK (3)

SCR (18)

SCR SNUBBER

BOARD (18)

FUSELINK (15)

REFERENCE

TRANSFORMER (3)

To

Current

Transformer

To

Current

Transformer

REGULATION PANEL ASSEMBLY LAYOUT (TYPICAL ONLY )

ILLUSTRATION 1-12

To

Current

Transformer

SCR DRIVER

BOARD (3)

SCR CONTROL

LOGIC BOARD (3)

FUSES FOR

REF. TRANSFORMER (3)

FUSES FOR

6002-032 REV H 1-15

On-Line Power

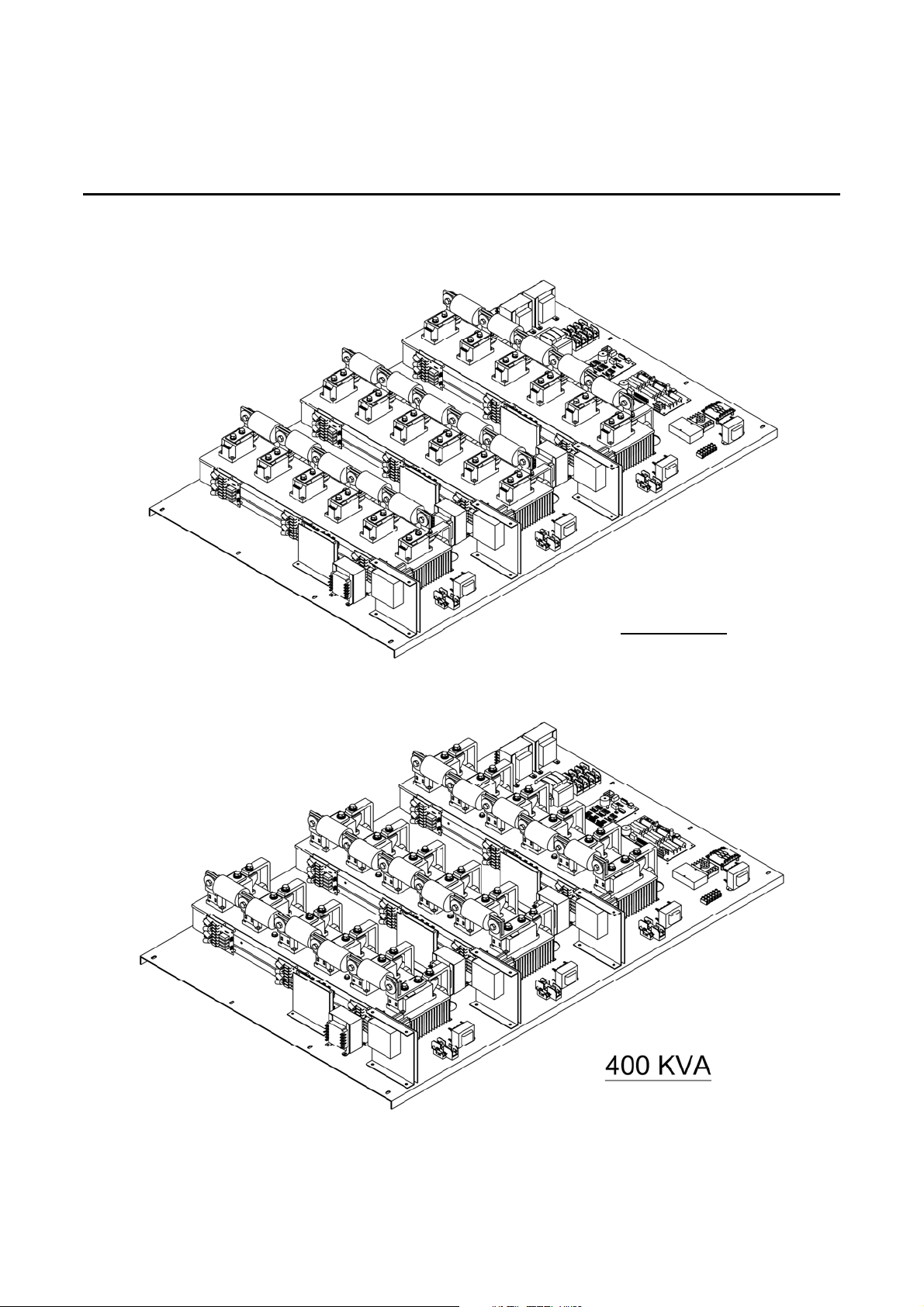

1-5 REGULATION COMPONENTS (CONTINUED)

200 KVA

6002-032 REV H 1-16

On-Line Power

1-5 REGULATION COMPONENTS (continued)

OUTPUT

INPUT

INPUT

BYPASS

SWITCH

3

4

1

FUSE

REFERENCE

TRANSFORMER

MANUAL

CURRENT

XFMR

4 WIRES

8 WIRES

AUTO

P1

P2

P1

SCR

DRIVER

BOARD

CONTROL

LOGIC

BOARD

P3

FUSEWIRE

(5 TIMES)

SCR/

SNUBBER

BOARD

(6 TIMES)

REGULATION BLOCK DIAGRAM

ILLUSTRATION 1-13

Note 1.

On Power-Reg, Ultra-Reg, and CP18, Tap 5 of the transformer is selected. On the Phase Stabilizer,

Tap 4 is selected.

6002-032 REV H 1-17

On-Line Power

1-6 STARTING THE UNIT

This procedure is to be used only for starting the unit during the normal course of operation. Follow this

operating procedure any time the unit has been turned off in a non-emergency situation.

CAUTION

If this is the initial startup or if the unit has been moved, perform the

Startup procedure in Section 3-1-7 before applying power to the unit.

CAUTION

If the unit is connected to a Power Island modular distribution center, verify that all

panelboard output circuit breakers are OFF before turning on branch feeder circuit

breaker.

1. Verify that Bypass Switch is set to AUTO.

2. Verify that connected load is OFF.

3. Energize facility branch circuit breaker.

4. Open front door (Constant Power 18 only).

5. Set IMCB to ON (Constant Power 18 only).

6. Close front door.

7. Turn ON connected load.

6002-032 REV H 1-18

Loading...

Loading...