OnLine Power PBC I User Manual

User's Manual

HARSH ENVIRONMENT UPS

POWER BACKUP CABINET – I (PBC-I)

650 W UPS – NEMA- 3R (UL0.4XXX)

1300 W UPS – NAMA – 3R (LU1.5XXX)

400 W UPS – NAMA 4 (LU0.7XXX)

(FROM 100 WATT TO 1400 WATT)

OLP # 6005-031 REVISION "A"

SAFETY

This manual contains important instructions for the PBC models. Follow

instructions during Installation and maintenance of the UPS, Electronic Tray

and Battery Tray.

When using electrical equipment, basic safety precautions should all

always be followed including the following:

READ and FOLLOW ALL SAFETY INSTRUCTIONS

• Do not mount near gas or electric heaters.

• Check by inspection that all electrical connections are clean and tight.

• Equipment should be mounted in a location where it will not readily be subject to

tampering by unauthorized personal.

• Equipment should be kept under lock and key.

• Only qualified electrical personal should be permitted to maintain or service

equipment.

• Only accessories or equipment recommend by manufacturer shall be used with this

equipment, contact factory for approval.

• Check by inspection that all electrical connections are clean and tight.

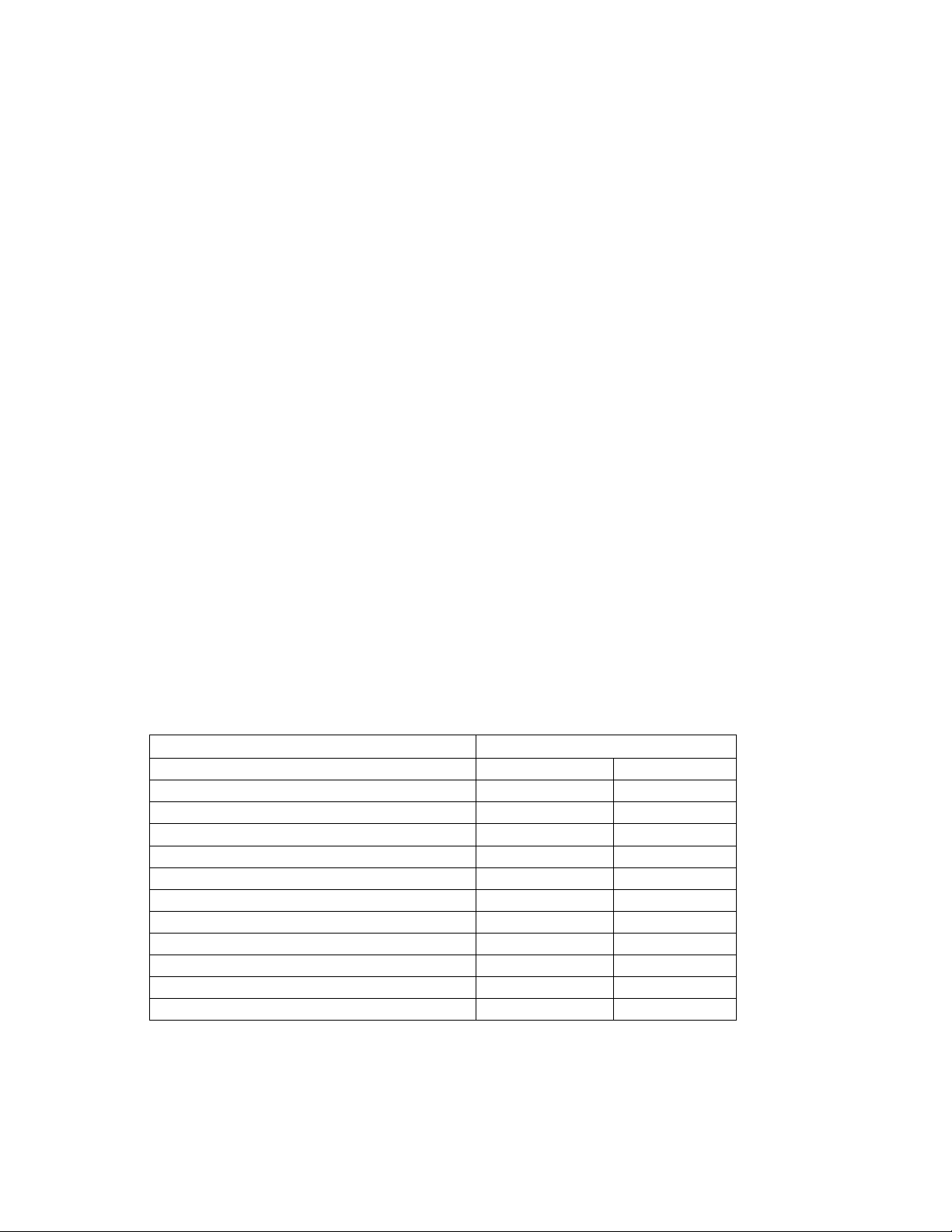

• All terminal connections shall be TORQUE to value in table below.

Terminal Torque

In / lbs. N-meter

TB 1 18.0 2.03

TB 2 18.0 2.03

TB 3 5.0 .56

XFMR LEADS 30.0 .56

CB 2 TRMINALS 30.0 .56

CABINET GND 30.0 .56

DOOR GND 30.0 .56

GROUND LUG 50.0 5.65

LIFTING PLATES 94.0 10.62

PAD MOUNTING BRACKET 94.0 10.62

TRAY TO CABINET BOLTS 76.0 8.58

A

WORK SAFETY INSTRUCTIONS

Definition: The Caution and Warning markings and labels.

!

Indicates the surface temperature may be HOT! (label is red).

HOT

!

Indicates Caution (label is yellow).

Caution

1. Located by Input CB1 indicates turning these breakers to ON energizes unit.

As the unit maybe energized even after input CB1 is turned to OFF by the power

supplied by the batteries, turn the battery tray CB2 breakers to OFF.

2. Located by Output CB3 indicates that turning this breaker to OFF, shuts OFF all

output power that is connected at TB2.

3. Located by battery tray CB2 indicates that turning ON this breaker supplies an

alternate battery power source to electronic tray and the output even when the input

CB1 is OFF. Turn breaker CB2 to OFF prevents the batteries from supplying power

to the output when in-out fails or drips (goes low in voltage).

4. Located by the door locks indicates the requirement of a special tool, #8 allen key.

a. Only qualified personnel shall use the Allen Key in the ¼ turn lock to open the

door and access the inside of unit.

5. Located by the RED labels on the front panel of battery tray warns that Electric

Shock Hazard may be present with the input power disconnected. Ups may be

energized from the batteries.

6. Located by the YELLOW labels on the left front side panel of battery tray warns

tery terminals are coated with PRO-OX to seal and protect. bat

a. PRO-OX contains petroleum distillates.

b. WASH! hands thoroughly after touching with soap and water.

c. If ingested induce vomiting.

1. Located by the RED labels on the front panel of battery tray warns Electric Shock

2. Located by the RED labels on the front panel of battery tray warns to use the same

RED LABEL is for WARNING!

Hazard may be present, DO NOT TOUCH uninsulated battery terminals as from 12

volts DC to 72 volts DC, present at all times.

type and rating of FUSE to reduce the risk of fire.

B

3. Located by the TB1 and TB3 on the front panel of electric tray and inside of tray by

TB4 warns electric shock hazard may be present from live voltages and DO NOT

TOUCH the terminals of connector.

4. Located by the TB1 and TB3 on the front panel of electronic tray. See installation

manual before making connections.

5. By the RED labels on the front panel of battery tray warns to use COPPER

conductors only for customer's connections.

Follow all safety precautions:

CAUTION! ALL POWER TO THE UNIT SHALL BE

LOCKED AND TAGED “ OFF ” BEFORE ANY

SERVICING OR OTHER WORK ON THE UNIT.

CAUTION! THE BATTERY POWER TO THE UNIT

SHALL BE LOCKED AND TAGED “ OFF ” BEFORE

ANY SERVICING OR OTHER WORK ON THE UNIT.

CAUTION! THE BATTERY VOLTAGE CAN CAUSE

THE UNIT TO OPERATE WITH AC LINE POWER

“ OFF ” CARE SHOULD BE USED AT ALL TIMES.

CAUTION! A BATTERY CAN PRESENT A RISK OF

ELECTRICAL SHOCK AND

HAVE A VERY HIGH SHORT CIRCUIT CURRENT.

CAUTION! ALL BATTERY WORK SHOULD BE PERFORMED

ON THE GROUND, AS THE BATTERY TRAY WITH BATTERIES

CAN WEIGHT OVER 290 LBS. HANDLE CAREFULLY.

WEIGHT OF COMPONENTS

LU0.4XXX UNIT / LU0.7XX

650 WATT MODEL (TYPICAL)

• The 650 W Unit weight is approximately 365 lbs.

• The 650 W Electronic Tray weight is approximately 90 lbs.

• The 650 W Battery Tray weight, set of 4 batteries, is approximately 200 lbs.

LU1.5XXX UNIT

1300 WATT MODEL (TYPICAL)

• The 1300 W Unit weight is approximately 455 lbs.

• The 1300 W Electronic Tray weight is approximately 95 lbs.

• The 1300 W Battery Tray, set of 6 batteries, weight is approximately 200 lbs.

C

CAUTION !

Units are very heavy, use proper equipment to lift & move.

HANDLE CAREFULLY.

BOTH MODELS

• The Pole / Wall mount adapter plate (2 required) weight is approximately 26 lbs.

• The Pole / Wall mount adapter hardware kit weight is approximately 1 lb.

• The Pad / Roof plates (2 required) weight are approximately 12 lbs. each.

• The Pad / Roof hardware kit weight is approximately 8 oz.

• The Empty Cabinet weight is approximately 85 lbs.

WARNING !

• Battery shelf life, when stored under temperature conditions of 66ºF ~ 90ºF is five(5) months maximum after

the ship date.

• Battery must be recharged after this date otherwise they will be damaged.

• Over current protection for the output AC circuits is to be provided by the contractor during the

installation of system.

• Only on special order is multi- output AC over current protection supplied.

D

TABLE OF CONTENTS

SECTION 1 – UNIT OPERATION AND FEATURES:................................................ 1

1 - 1 Overview ..................................................................................................... 1

1 – 2 Features ......................................................................................................1

1 – 3 Ruggedization Features ............................................................................. 3

1 – 4 Safety and EMI Regulatory Aspects ......................................................... 4

1 – 5 Domestic/International ...............................................................................4

1 – 6 Mounting Features......................................................................................4

1 – 7 Other Important Design Features ............................................................. 4

1 – 8 Electrical – Input/Outputs .......................................................................... 8

1 – 9 Electrical – Outputs Characteristic ........................................................... 8

1 – 10 Mechanical Overall Dimensions and Weight............................................8

1 – 11 Theory of Operation....................................................................................9

SECTION 2 – PREINSTALLATION:..........................................................................13

2 - 1 Location Considerations ........................................................................... 13

2 – 2 Positioning................................................................................................... 13

2 – 3 Mechanical Overall Dimensions & Weight ............................................... 13

2 – 4 Site Planning Specifications......................................................................13

2 – 5 Site Detail Electrical Specifications...........................................................13

2 – 6 Mechanical Overall Outline Dimensions...................................................14

2 – 7 Pad Mounting Layout..................................................................................14

SECTION 3 - PCB INSTALLATION: ......................................................................... 15

3 – 1 PBC Unpacking .......................................................................................... 15

3 – 2 Inspection....................................................................................................15

3 – 3 PBC Storage ............................................................................................... 15

3 – 4 PBC Installation .......................................................................................... 16

3 – 5 Lifting Requirements .................................................................................. 16

3 – 6 PBC Pole Installation ................................................................................. 17

3 – 7 PBC to Pole Grounding .............................................................................. 18

3 – 8 PBC Grounding Test .................................................................................. 19

3 – 9 PBC Conduit Installation: .......................................................................... 20

3 – 10 Electronic Tray Wiring: ..............................................................................20

3 – 11 Electronic Tray Input & Output Wiring ..................................................... 21

3 – 12 Electronic Tray Output Wiring to Heaters ................................................24

3 – 13 Electronic Tray Wiring Checkout ..............................................................25

3 – 14 PBC Battery Tray Connection ................................................................... 25

3 – 15 PBC Ready for Normal Operation Check: ................................................25

3 – 16 PBC Ready for Check Battery Backup Operation ..................................26

3 – 17 PBC is Ready for Usage ............................................................................. 26

3 – 18 PBC Pad Layout..........................................................................................26

3 – 19 PBC Pad Installation................................................................................... 26

E

TABLE OF CONTENTS (cont.)

SECTION 4 – SERVICING OF A UNIT...................................................................... 27

4 – 1 Modularity of Internal Components...........................................................27

4 – 2 Servicing Safety .......................................................................................... 27

4 – 3 Electronic Tray Removal ............................................................................ 28

4 – 4 Replacing Electronic Tray ......................................................................... 28

4 – 5 Battery Tray Removal & Servicing............................................................. 28

4 – 6 Replacement of Battery Tray...................................................................... 28

4 – 7 Replacing a Battery..................................................................................... 29

4 – 8 Removing the Battery from Battery Tray .................................................. 29

4 – 9 Removing Filter Screen..............................................................................29

Appendix A: Summary of Indicators and Controls: .............................. 30

Appendix B: Installation Accessory Kit - Parts List : ............................ 31

Appendix C: Battery Maintenance Testing & Specifications: .............. 33

Appendix D: Troubleshooting & Diagnostics: ....................................... 35

F

SECTION 1 - UNIT OPERATION AND FEATURES

1-1 Overview

Within each Power Backup Cabinet is an Uninterruptible Power Supply (UPS). The purpose of this device is to

provide power to the critical load during brown out, or black out conditions, without disruption of operation of the

load equipment. When the unit operates in the backup mode, the AC power for the load comes from a set of

internal batteries and Inverter. The battery charger keeps the batteries charged and ready to fulfill the unit's

function to supply reserve power.

Also, these cabinets provide an additional level of power protection from transients, surges, electrical noise, and

other power disturbances.

What differentiates this PBC from, off-the-shelf, UPS equipment is the high level to which these units have been

“hardened” (ruggedized) to ensure continuous operation in very harsh environments, particularly outdoors.

1-2 Features

Status Indicators

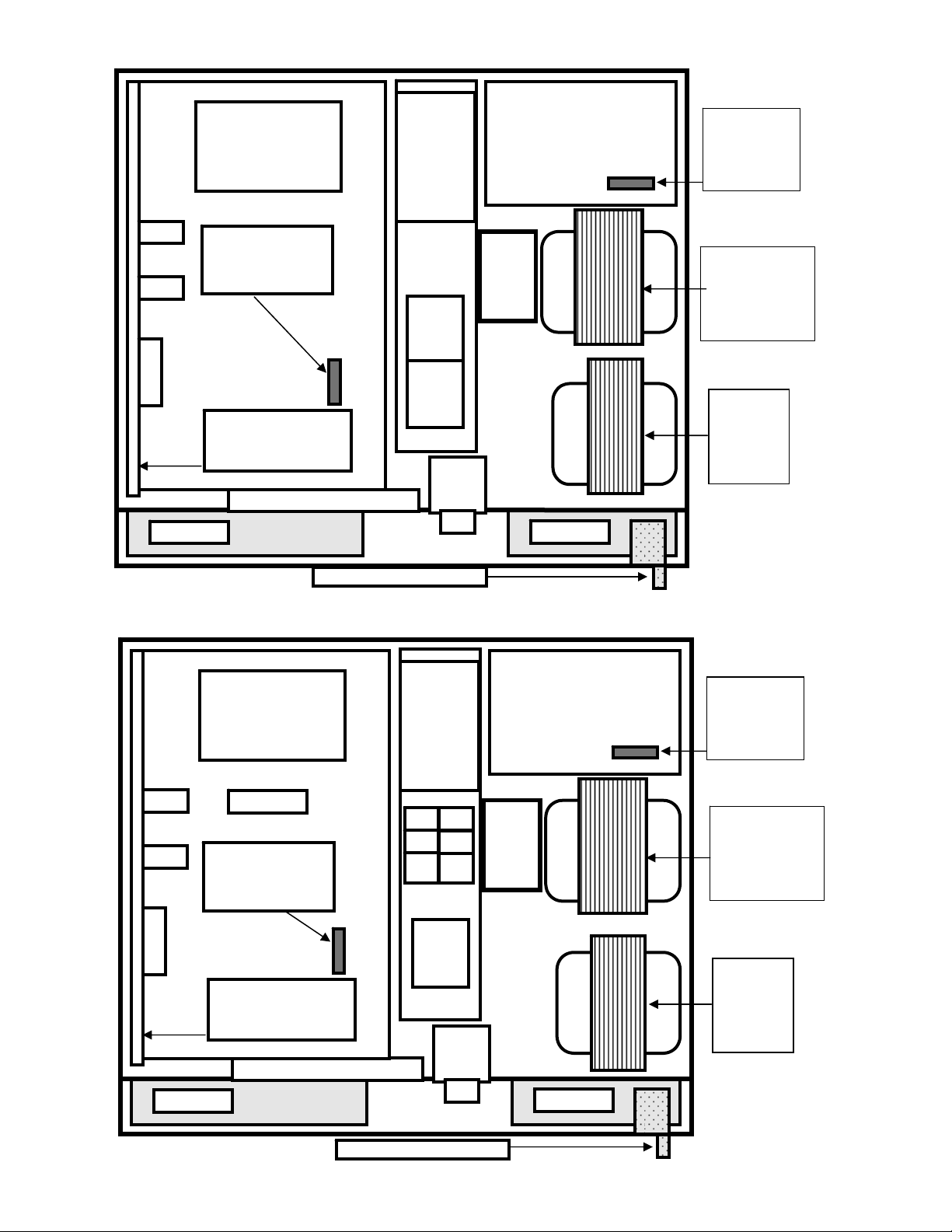

The unit has two major component trays. The Electronic Tray contains the battery charger, Inverter circuitry, input

and output transformers, as well as the input/output terminals. The lower tray is the battery compartment. The

Electronic Tray set of indicator lamps on the front panel display the unit's operational mode. (See Illustration 1-1

below) These lamps provide a positive visual indication of specific aspects of the units functional operation. These

are as follows:

• AC AC On

• INV Inverter On

• SUM Summary Alarm Warning

• LB Low Battery Warning

• HB and FB Battery Voltage Level indicators.

HB shows half charge % voltage and FB Full charge % voltage.

• LL HL FL Load Level Usage.

LL= Low level load

HL Half level load

FL Full level load,

• OL Over Load of Unit

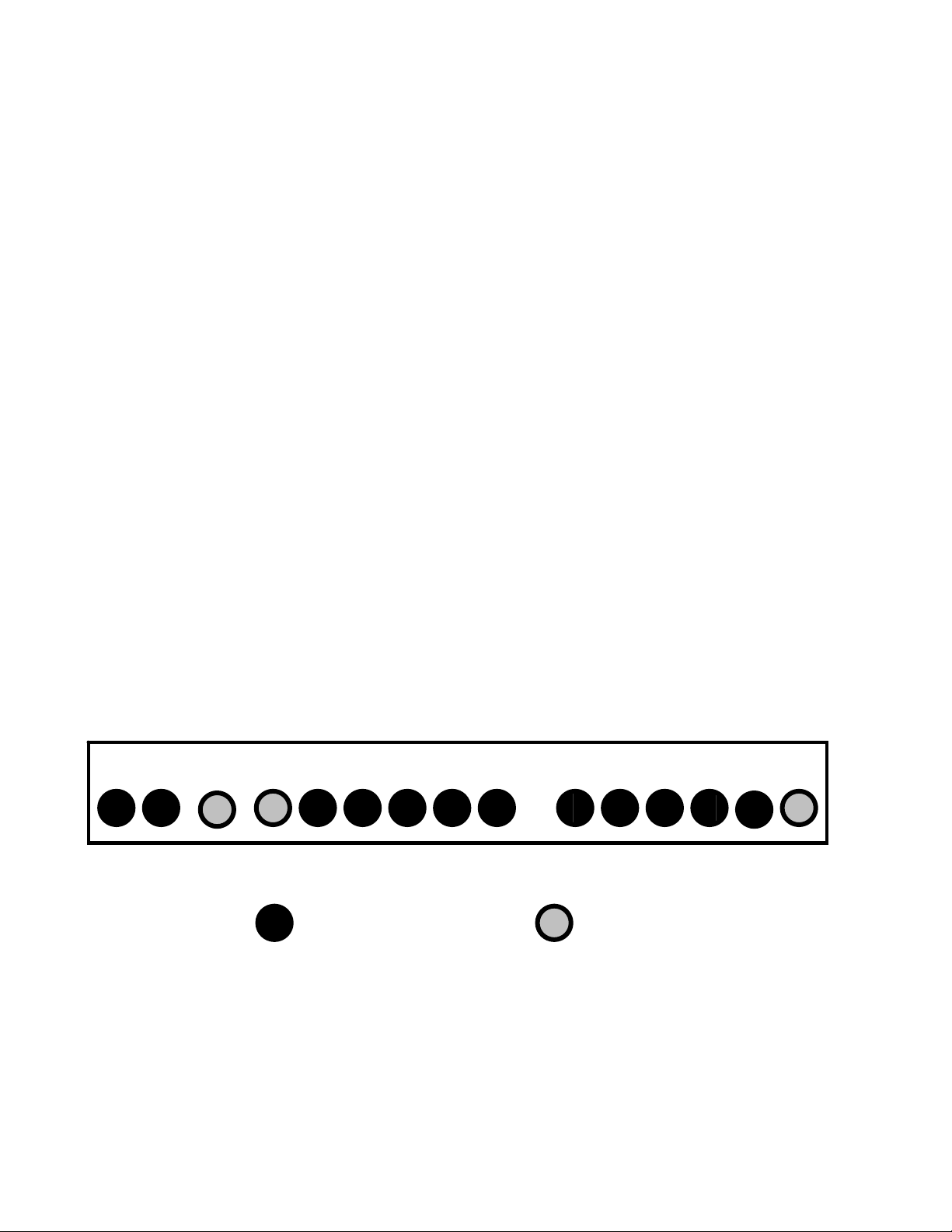

AC INV ALM LB HB FB LL HL FL OL

GREEN LED RED LED

BATTERY VOLTAGE % LOAD IN % OF RATED AMPS

Electronic Tray - Status Panel

Illustration 1-1

1

• Alarm Signals

Also providing information on the unit’s status/particular aspects to the outside world by way of electrical

signals is a DB-9 connector. This DB-9 connector is on the front console of the Electronic Tray. The interface

provides a set of open and closed contacts, which relate the status of PBC to the outside world. An interface

DB-9 connector and cable permit the unit to bring out the following signals with their normal sta t e (open or

closed). If the contact is not energized and the contact is closed, it is named "Normally Closed". If the contact

is not energized and the contact is open, it is named "Normally Open".

• Inverter LED is “ On ” the relay contacts are Normally Open (NO).

• Loss of Input Power, AC LED is “ Off ” the relay contacts are Normally Closed (NC).

• Low Battery LED is “ On ” the relay contacts are Normally Open (NO).

• Intrusion Switch, when the door is open the switch contacts are Normally Closed (NC).

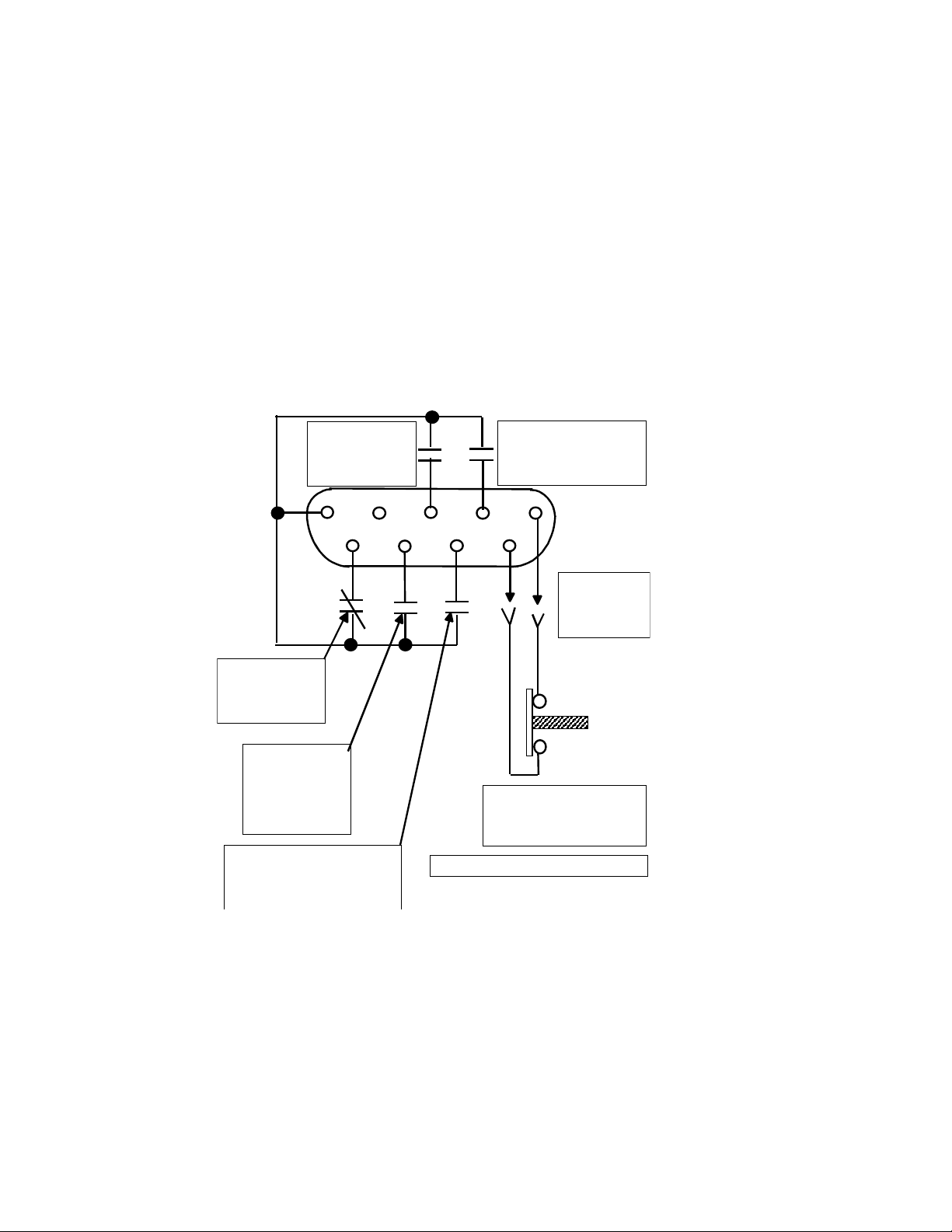

For the detailed pin out for the DB-9 connector see Illustration 1-2 below.

ALARM

K 3 RELAY

9 & 13 NO

" ON " BATTERY

K 5 RELAY

9 & 13 NO

5 9 4 8 3 7 2 6 1

CN 304

DOOR

CIRCUIT

AC " OFF "

K 1 RELAY

11 & 13 NC

INVERTER

" ON "

K 2 RELAY

9 & 13 NO

SW 2

DOOR SWI TC H

NORMALY CLOSED

LOW BATTERY

K 4 RELAY

9 & 13 NO

DETA IL OF CONTACTS

Relays are dry contacts rated 2 AMPS @ 250 VAC

Illustration 1-2: DB-9 Connector

2

• Alarm cable

The PBC units come with an Alarm Cable, 20 feet long, which connects to the DB-9 jack so the signals are

available for external monitoring/status reporting equipment. The wiring of the cable matches the pin out detail

as shown in Illustration 1-2 for the DB-9 jack.

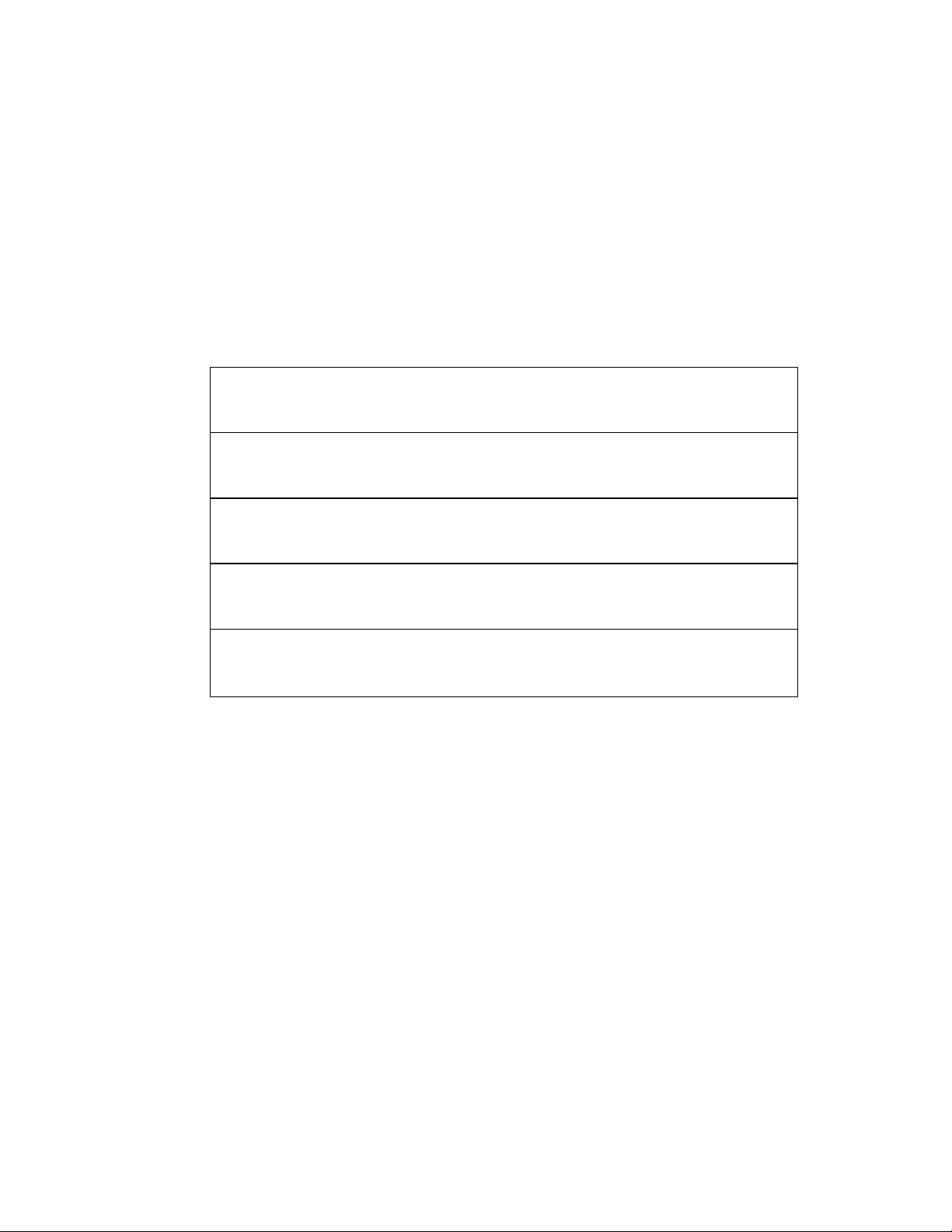

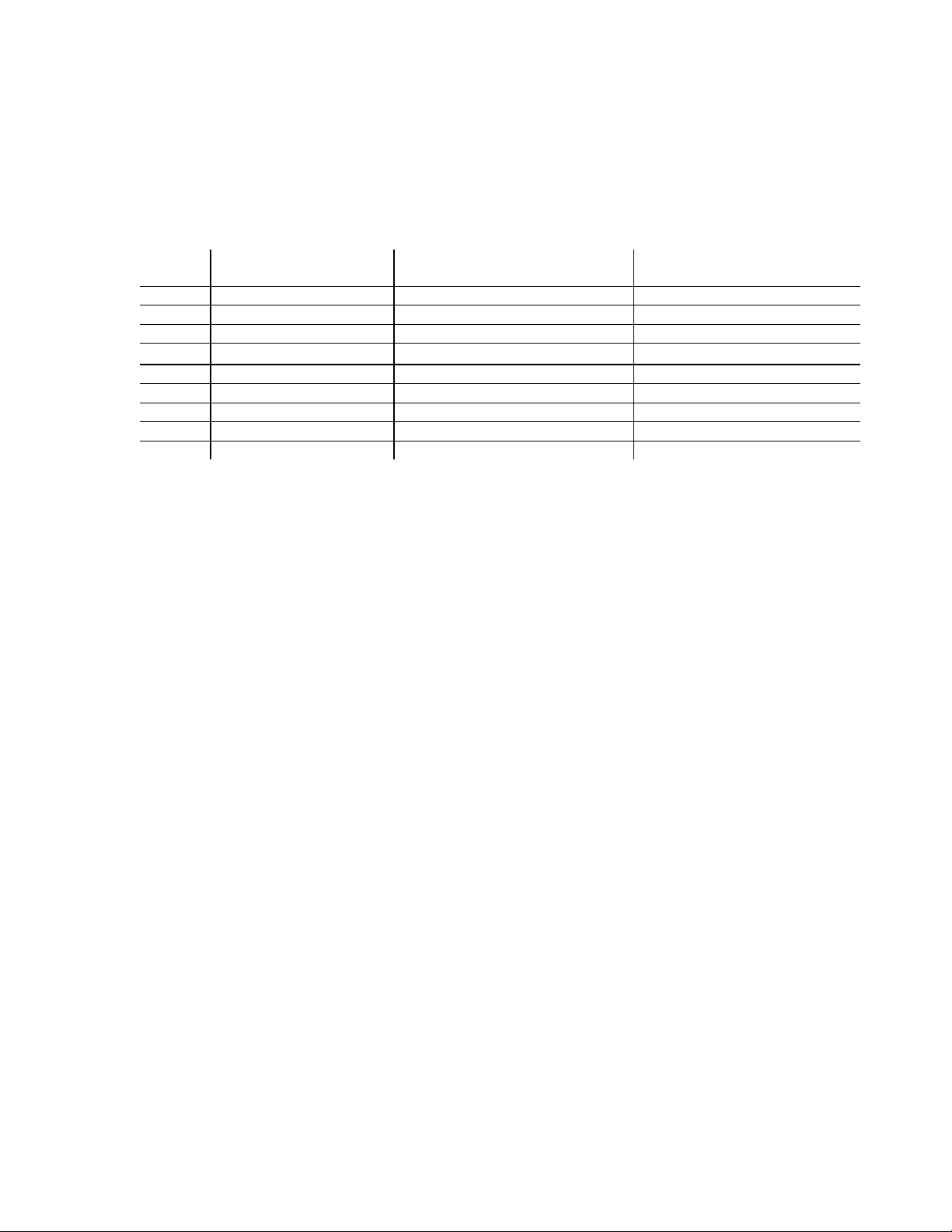

• DB-9 Connector Color Code:

• The normal contactact condition is generally shown with power OFF.

PIN

WIRE COLOR FUNCTION NORMAL CONTACT

OUT

1

2

3

4

5

6

7

8

9

Black of Black / Blue Door Switch, Intrusion Alarm Normally Open

Black of Black / Red ON BATTERY FLASHING Normally Open

Black of Black / White Summary Alarm Warning Normally Open

Open no wire N/A

Black of Black / Green Return Common Ground

Blue of Black / Blue Door Switch Normally Open

Red of Black / Red Low Battery Normally Open

White of Black / White UPS “ ON ” , Inverter “ ON ” Normally Open

Green of Black / Green Input Failed Normally Closed

• Intrusion Switch

An intrusion alarm switch resides within the cabinet to relay that unwanted entrance into the cabinet as been

made. The plunger of the switch is in by the door when it's closed. In this condition, the switch presents an

open circuit and the alarm is in the “off” state. When the door is open, the switch presents a closed circuit and

the alarm is in the “on” state. One additional state is available on the switch. A technician working on the unit

can pull the plunger out to a “neutral” position. The switch will be in the open state ( “off” ) and thus no alarm

condition by-passed while he or she is working on the unit. See Illustration 1-3 for its location.

• ESD Receptacle and Wrist Strap

The ESD wrist strap plugs into the red connector receptacle on the front panel of the Electronic Tray. An ESD

wrist strap is in the bottom of the cabinet. Any personnel working on the unit should be wearing the strap. The

strap plugs into the RED banana plug receptacle to minimize the risk of damage to the ESD sensitive circuitry

that of the electronics assembly.

1-3 Ruggedization Features

All PBC’s designed to operate in most outdoors harsh environments. The unit has been subjected to outside

independent labs to demonstrate that they are capable of withstanding severe outdoors operating conditions.

Below is a listing of many of those conditions:

• Wide Temperature Range

The PBC designed and tested to operate in the outdoors over a wide range of temperatures, from -40 oC to +

o

C plus a solar load of 70 watts / Ft 2. The 1300 W unit has option of having internal heaters for the

52

batteries to allow it to operate over a range of –40

o

C to + 52 oC.

• Shock and Vibration

These devices are designed and tested to meet Bellcore specs for shock and vibration namely GR-63CORE Issue 1 section 4.3 and GR-63-Core Issue 1 section 4.4 and earthqua ke zone 4.

3

• High Input Voltage Surge Withstand Capability

The unit internally has AC Surge protector ( ACT’s TVSS) to ensure that lightning or other types of high

voltage surges do not damage them. They meet IEEE 62.41 1991 (UL1449) level C3 input voltage surge, of

20,000 Volts @ 10,000 Amps.

• Corrosion Resistant Cabinet

The sheet -metal parts paint have been chosen by design and verified by testing to be rustproof.

• Rain-Proofed Cabinet

The cabinets designed and tested to meet UL50 (Type 3R) requirements and thereby to ensure that rain will

not reach the critical electronics.

• Easy Front Door Access

This makes for effective field service ac cess.

• Filter for Dust, Dirt and Bug Resistant

The cabinet has protection through filters to prevent adverse effects do to dust and dirt, as well as the intrusion

of creatures such as bugs and rodents.

1-4 Safety and EMI Regulatory Aspects

• Safety

The units designed and tested to meet UL 1778 and CSA 107.2 requirements.

• EMC (Domestic)

The PBC’s design meets the requirements of FCC, 47 CFR, Part 15, Subpart B.

• EMI (International)

The PBC’s conformity to EN55022 (CISPR22) FOR EMI compliance.

1-5 Domestic/International

• Input Frequency Selection

The PBC’s design will operate at 50 or 60 Hz. The frequency selection can be made by changing the jumper on

terminal block TB 3. See the location of TB 3 on the Electronic Tray, in Illustration 1-3 and

Details of connections in Illustration 3-5.

1-6 Mounting Features

• Pad or Floor Mounting

PBC shall mount on a concrete pad, outdoor/indoor. The pad rail mounting comes with the hardware required.

The rails can be in-line with door or crossways to door.

• Pole or Wall Mounting

PBC can be Pole or Wall mounts. The mounting brackets are an option and need to be order. Select options

at time of purchase of individual units. The part numbers for these options are part of Appendix C of this

manual.

1-7 Other Important Design Features

• Modularity of Internal Components

The cabinet contains two physical assemblies;

• The Electronic Tray, with the UPS System.

• The Battery Tray contains the reserve stand-by batteries.

4

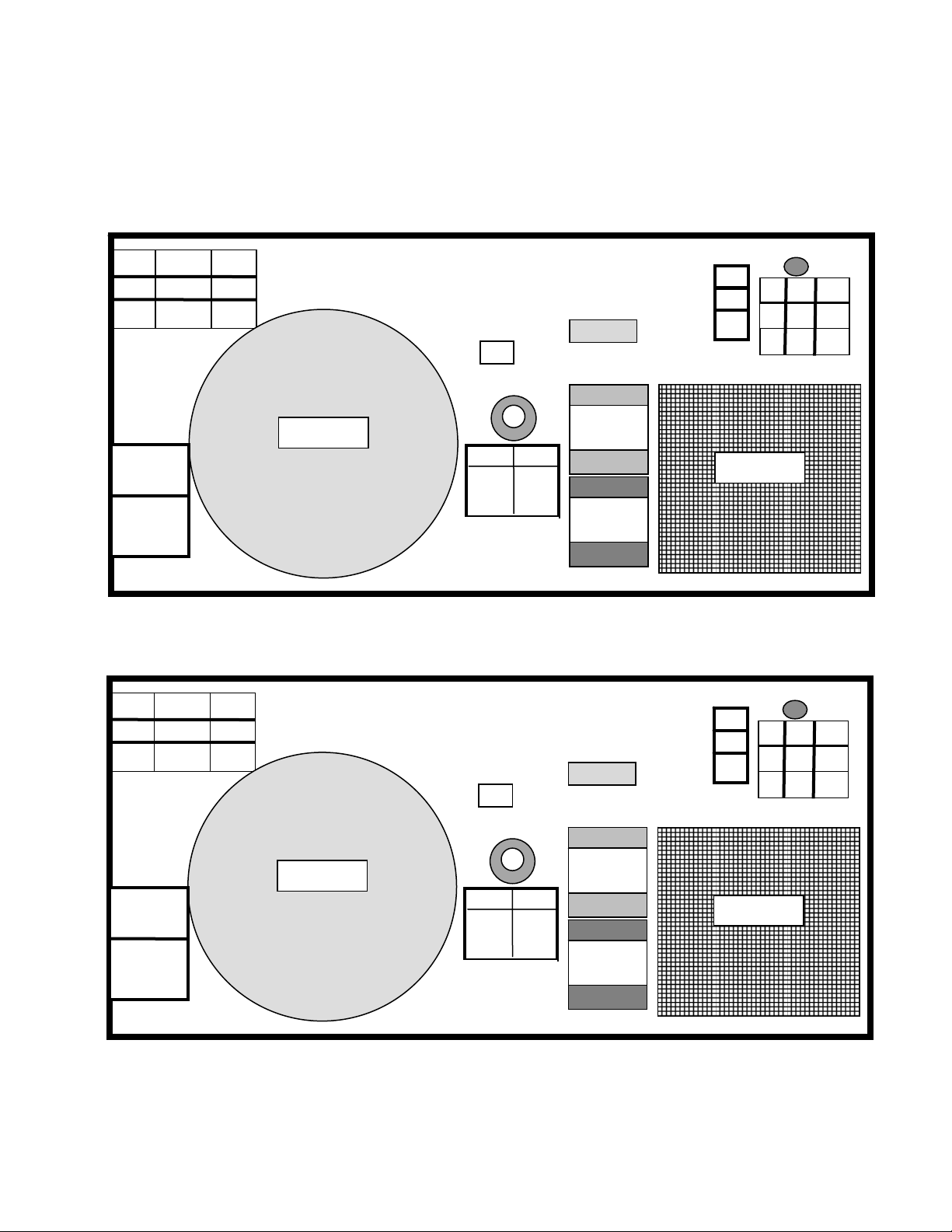

1–7 Other Important Design Features (continued)

• Electronic Tray

The inverter circuitry, front panel with connectors terminals and status panel, input and output isolatio n

transformers ( as well as power for heaters in 1300 W ) and cooling fans are all located on this mechanical

structure. (See Illustration 1- 3) Directly below for the front panel Illustration for an overview showing the

components layout. Details of the connectors are shown in section 3 for

electrical wiring of unit.

O

1

X1

X2N

O

2

O

3

X1

AC INV ALM LB HB FB LL HL FL OL

O O O OOOOOO OOOOOO

DOOR SW JACK

TB 1 INPUT

O O

GROUND

LUG

B 3 FAN

RED BLK

J3-1 J3-2

+ -

BATTERY JACK

Electronics Tray ( Upper Tray )

Illustration 1-3

DOOR SWITCH

O

1

L1

O

2

O

3

L2

AC INV ALM LB HB FB LL HL FL OL

O O O OOOOOO OOOOOO

DOOR SW JACK

TB 1 INPUT

B 3 FAN

RED BLK

O O

GROUND

LUG

Electronics Tray ( Upper Tray ) IEC International Model

J3-1 J3-2

+ -

BATTERY JACK

Illustration 1-3A

ESD

ESD

5

DB 9 JACK

DB 9 JACK

CB 1

INPUT

CB 3

OUTPUT

CB 1

INPUT

CB 3

OUTPUT

50HZ

60HZ

FREQ

SELECT

50HZ

60HZ

FREQ

SELECT

TB 3

1

O 1 H1

2

O 2 H2

3

O 3 H3

B 2 FAN

TB 3

1

O 1 P1

2

O 2

3

O 3 P2

B 2 FAN

DOORS WITCH

TB2

OUT PUT

TB2

OUT PUT

C208

C202

C

2

0

6

B 3 FAN

C208

C202

C

2

0

6

B 3 FAN

Electronic Tray Top View (Upper Tray)

A1 PCBA

UPS

ASSEMBLY

FUSE FOR DC

OUTPUT UNDER

HEATSINK

A2 PCBA

CONTROL

A4 PCBA STATUS

ILLUSTRATION 1-4

ACT’s

1690-135

A 10

EMI B

A9

EMI A

A8

CB

1&3

A7 PCBA

BATTERY

CHARGER

C1

&

CR1

B 2 FAN

SW 1 DOOR SWITCH

Electronic Tray Top View (Upper Tray) IEC International Model

ILLUSTRATION 1-4A

A1 PCBA

UPS

ASSEMBLY

TVSS

1690-135

A 10

A7 PCBA

BATTERY

CHARGER

TB4

FUSE FOR DC

OUTPUT UNDER

HEATSINK

O

O

O

EMI A

A9

1

2

3

C1

&

CR1

A2 PCBA

CONTROL

A4 PCBA STATUS

CB

1&3

B 2 FAN

SW 1 DOOR SWITCH

FUSE DC

OUTPUT

SOLDER

INPLACE

T2

OUTPUT

ISOLATION

XFMR

T1

INPUT

AUTO

XFMR

FUSE DC

OUTPUT

SOLDER

INPLACE

T2

OUTPUT

ISOLATION

XFMR

T1

INPUT

AUTO

XFMR

6

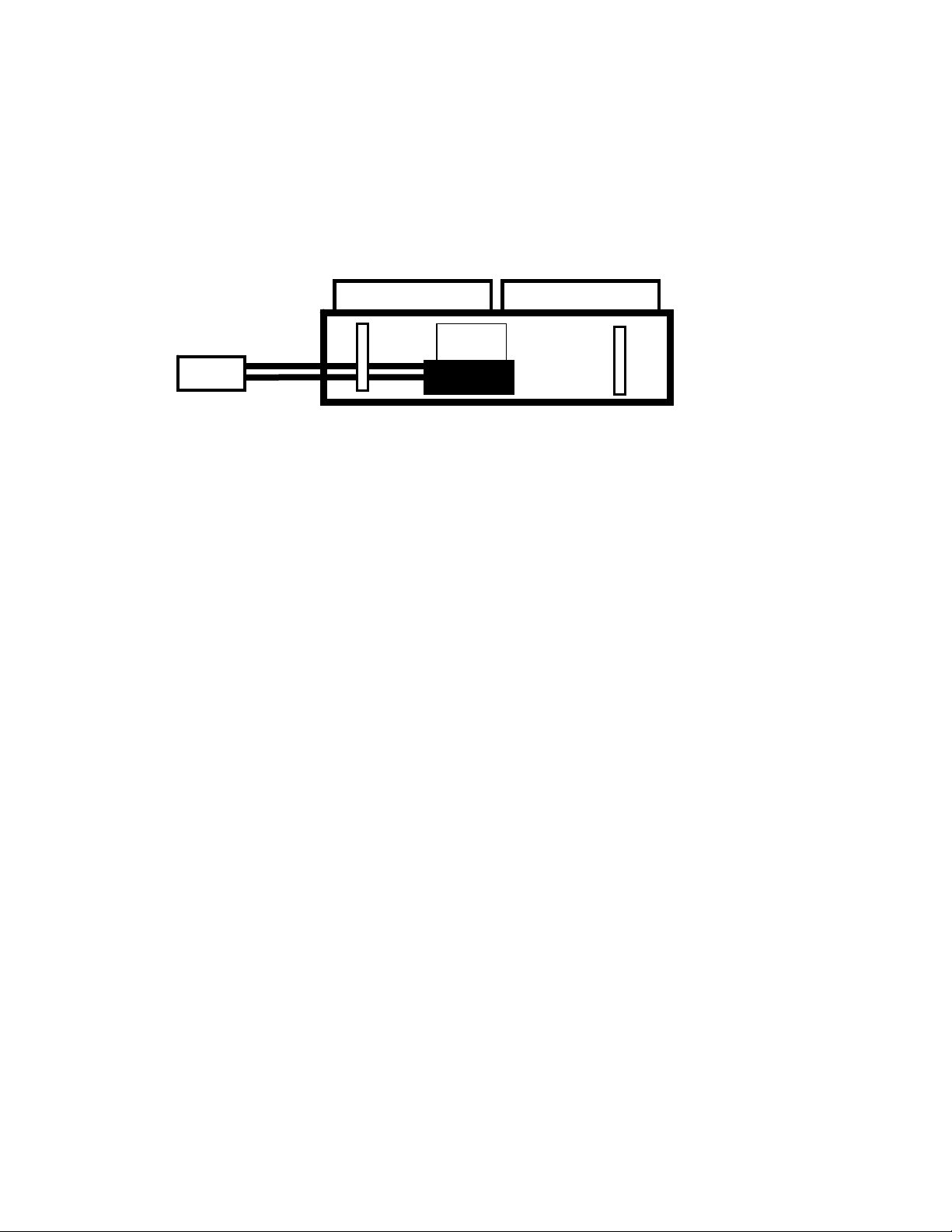

Battery Tray

Houses the internal backup batteries:

The 650 W version, with 4 x 50A/hr batteries are mounted in the tray, supplying 48VDC to UPS

The 1300 W version, with 6 x 50A/hr batteries are mounted in the tray, supplying 72VDC to UPS(

Also, the Battery Tray has the OPTION of heaters to ensure operation down to –40

will be kept at a temperature of 0

• The front view of the battery tray (see iIllustration 1-5).

Ο

C ± 5 ΟC .

Ο

C where the batteries

(LU0.4XXX).

LU1.5XXX).

BATTERY BATTERY

P3

CB 2

BATTERY PLUG

Battery Tray (Lower Tray)

Illustration 1-5

The simplified construction into two major components makes for fast and easy repair of the unit in the field whe re

the batteries, Battery Tray, Electronics Tray composes the only FRU items within the unit.

• Temperature Compensated Fast Battery Charger (A 7 PCBA)

The Fast Charger will charge the batteries when discharged as well as to keep the batteries charged. The

recharging time varies based on the backup time and the critical load supported by the batteries during the

input power outage.

650 W uses 1625-229-01 Charger, 55 VDC @ 4 AMPS. approximate 1.8 watts (LU0.7XXX & LU0.4XXX UNITS).

1300 W uses 1625-229-02 Charger, 81 VDC @ 2.7 AMPS. approximate 1.8 watts (LU1.5XXX UNITS).

• Automatic Internal Bypass Switch

The PBC has a UPS assembly designed to operate reliably for many years. However if there is an internal

Inverter failure within the UPS, it will use the automatic internal bypass switch. This switch will bypass the

inverter, when utility power is available via the transformers, to support the full rated load.

• External Padlock

The cabinet possesses an external padlock receptacle to prevent unauthorized personn el from gaining access to

the interior of the cabinet via the front door when used in conjunction with a customer supplied padlo c k.

• Over Temperature Shutdown

While the PBC has several internal fans operating when the PBC & UPS Is “ ON ” to prevent an overheating

condition, further protection has been built into the UPS to ensure against circuit failure due to internal

overheating. If there is an Over Temperature condition, the UPS shall shut down. It has an auto-recovery

feature, so that when the temperature reaches a safe level, the UPS will come back on. There is a built-in

hysteretic feature to prevent any oscillatory condition of the UPS turning “ ON ” and “OFF” at the Over

Temperature trip point from taking place.

• Over Current Protection

If there is the load or loads draw excessive output current from the PBC. The sensing circuit in the Inverter will

provide feedback to cause the Inverter to limit the current and thereby prevent the unit from being damaged

due to such a condition.

7

Loading...

Loading...