Page 1

DPC-5.3

SERVICE MANUAL

Ref. No. 3736

SERVICE MANUAL

DVD CHANGER

MODEL DPC-5.3

Black model

120V AC, 60HzBUDD

Sep, 2002

DISC SKIP

RC-503DV

SAFETY-RELATED COMPONENT

WARNING!!

COMPONENTS IDENTIFIED BY MARK ON THE

SCHEMATIC DIAGRAM AND IN THE PARTS LIST ARE

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE THESE COMPONENTS WITH ONKYO

PARTS WHOSE PART NUMBERS APPEAR AS SHOWN

IN THIS MANUAL.

MAKE LEAKAGE-CURRENT OR RESISTANCE

MEASUREMENTS TO DETERMINE THAT EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE

SUPPLY CIRCUIT BEFORE RETURNING THE

APPLIANCE TO THE CUSTOMER.

www.denom.com

Page 2

SPECIFICATIONS

DVD Changer

Power supply AC 120 V, 60 Hz

Power consumption 20 W

Weight 15.0 lbs

External dimensions 17

Signal system NTSC

Frequency range (digital audio) 48 kHz sampling 4 Hz to 22 kHz

Signal-to-noise ratio (digital audio) More than 98 dB

Audio dynamic range (digital audio) More than 95 dB

1

/8" x 5 1/16" x 16 15/16" (W/H/D)

96 kHz sampling 4 Hz to 42 kHz

DPC-5.3

Harmonic distortion (digital audio) Less than 0.008 %

Wow and flutter Below measurable level

Operating conditions Temperature: 5 C to 35 C (41 F to 95 F)

Operation status: Horizontal

Outputs

V ideo output 1.0 V (p-p), 75 ohm, negative sync., pin jack x 1

S-video output (Y) 1.0V (p-p), 75 ohm , negative sync.

(C) 0.286 V (p-p), 75 ohm , Mini DIN 4-pin x 1

Component video output (Y) 1.0 V (p-p), 75 ohm , negative sync., pin jack x 1

(P

B)/(PR) 0.7 V (p-p), 75 ohm pin jack x 2

Audio output (digital output Optical) Optical connecter x 1

Audio output (digital output Coaxial) 0.5 V (p-p), 75 ohm , pin jack x 1

Audio output (analog output) 2.0 V (r ms), 320 ohm , pin jack (L, R) x 2

Specifications and features are subject to change without notice.

www.denom.com

Page 3

SERVICE PROCEDURE

PRECAUTIONS

1. Ground for the work-desk.

Place a conductive sheet such as a sheet of copper (with impedance lower than 10M ohm) on the work-desk and

place the set on the conductive sheet so that the chassis.

2. Grounding for the test equipments and tools.

Test equipments and toolings should be grounded in order that their ground level is the same the ground of the power source.

3. Grounding for the human body.

Be sure to put on a wrist-strap for grounding whose other end is grounded.

Be particularly careful when the workers wear synthetic fiber clothes, or air is dry.

4. Select a soldering iron that permits no leakage and have the tip of the iron well-grounded.

5. Do not check the laser diode terminals with the probe of a circuit tester or oscilloscope.

DPC-5.3

1. Replacing the fuses

This symbol located near the fuse indicates that the

fuse used is show operating type, For continued protection against

fire hazard, replace with same type fuse , For fuse rating, refer to

the marking adjust to the symbol.

Ce symbole indique que le fusible utilise est e lent.

Pour une protection permanente, n'utiliser que des fusibles de meme

type. Ce demier est indique la qu le present symbol est apposre.

REF.NO.

F1

PART NO.

SR-5, T 2A

DESCRIPTION

250VCA T 2.0A

2. Safety-check out

(Only U.S.A. model)

After correcting the original service problem perform the

following safety check before releasing the set to the customer

Connect the insulating-resistance tester between the plug of

power supply cord and terminal GND on the back panel.

Specifications: More than 10M ohm at 500V

LASER CAUTION

The lightning flash with arrowhead symbol, within an equilateral triangle, is

intended to alert the user to the presence of uninsulated "dangerous voltage"

within the product's enclosure that may be of sufficient magnitude to constitute

a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user

to the presence of important operating and maintenance (servicing) instruction

in the literature accompanying the appliance.

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS APPLIANCE TO RAIN

WARNING :

OR MOISTURE. DANGEROUS HIGH VOLTAGES ARE PRESENT INSIDE THE ENCLOSURE. DO NOT OPEN THE

CABINET. REFER SERVICING TO QUALIFIED PERSONNEL ONLY.

CAUTION :

TO PREVENT ELECTRIC SHOCK, MATCH WIDE BLADE OF PLUG TO WIDE SLOT, FULLY INSERT.

POUR EVITER LES CHOCS ELECTRIQUE, INTRODUIRE LA LAME LA PLUS LARGE DA LA FICHE DANS LA

ATTENTION :

BORNE CORRESPONDANTE DA LA PRISE ET POUSSER JUSQU' AU FOND.

Initialization of setup

1. Press the "CD PLAY" and "DISC 3" key to the same timing on the front panel.

You will see that the program is updated by watching the version in the FL tube.

2. Push the power switch.

www.denom.com

Page 4

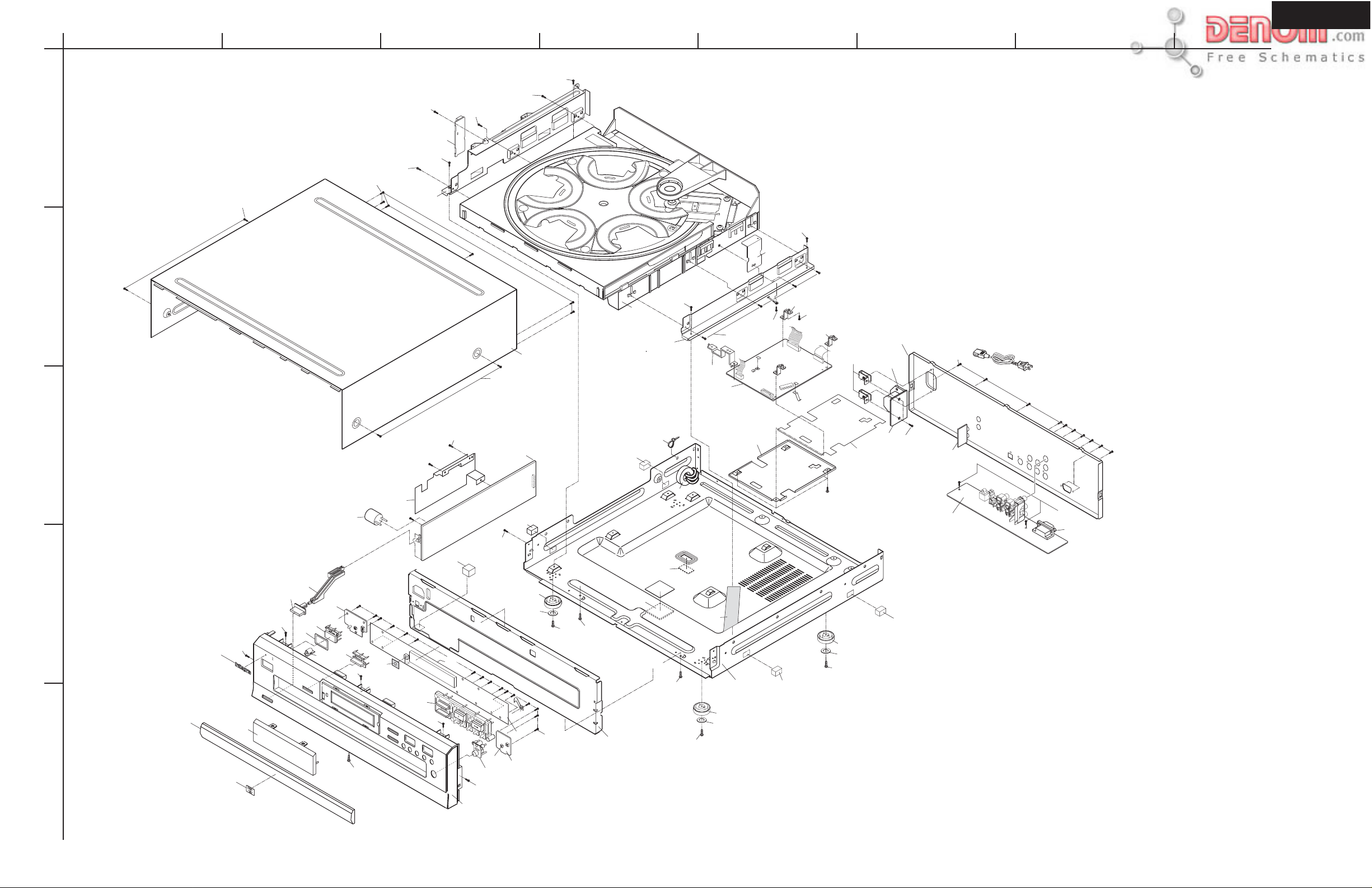

DP-C5.3

A

EXPLODED VIEW-1

CHASSIS

1

2

S3

BCDEFGH

S1

S3

1

S2

43

S1

2

42

S1

S2

50

49

41

40

S2

51

S2

51

56

39

S6

54

S6

S2

S2

S2

46

S1

44

48

55

23

S2

58

30

S2

36

16

S4

13

S2

22

S5

15

17

S2

18

19

52

23

20

24

25

S2

S2

S2

21

23

38

29

28

27

S2

24

25

S2

3

53

60

7

S4

8

10

9

6

11

5

S4

12

S2

4

S5

4

2

3

5

1

26

47

24

25

S2

23

14

www.denom.com

Page 5

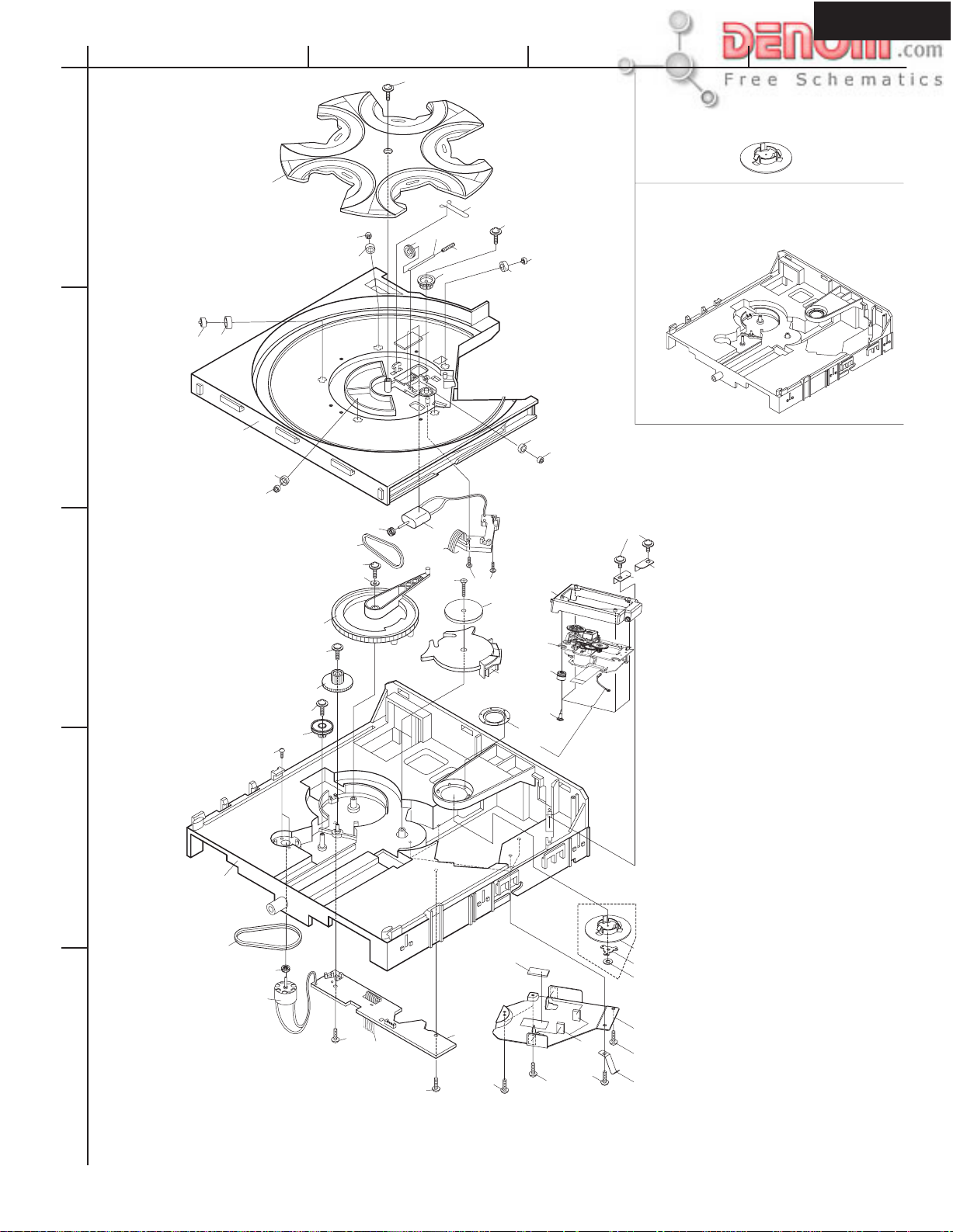

DPC-5.3

A

EXPLODED VIEW-2

DVD Mechanism

1

150

160

2

170

160

50

150

160

150

BCD

280

CLAMPER DVD ASS'Y

Part No. 55542660

130

90

120

110

100

140

240

150

160

150

160

BASE ASS'Y - CDM5G

Part No.55542650

70

80

280

420

3

270 * 2

200

240

220

240

230

60

310

300

* 2

320

210

470

480

290

450

* 4

460

* 4

280

* 2

440

430

4

190

260

250

70

530

Assy Part No.

55542660

490

510

550

520

300

560

300

5000

300

300

540

300

*2

300

500

5

www.denom.com

Page 6

DPC-5.3

A

BLOCK DIAGRAM -5

POWER SUPPLY UNIT

1

AC INPUT

2

SW1 F1

HOT >

NUT >

LINE FILTER

BCDE

FL OUTPUT

RECTIFIER &

SMOOTHING

CIRCUIT

R2

R3

SNUBBER

CIRCUIT

-27V OUTPUT

RECTIFIER &

SMOOTHING

CIRCUIT

-9V OUTPUT

RECTIFIER &

SMOOTHING

CIRCUIT

+12V OUTPUT

RECTIFIER &

SMOOTHING

CIRCUIT

+9V OUTPUT

RECTIFIER &

SMOOTHING

CIRCUIT

RECTIFIER &

SMOOTHING

CIRCUIT

+5V OUTPUT

RECTIFIER &

SMOOTHING

CIRCUIT

. DRIVER CIRCUIT

+5.5V OUTPUT

RECTIFIER &

SMOOTHING

CIRCUIT

. VOLTAGE CONTROLLER CIRCUIT

. OVER CURRENT PROTECTOR CIRCUIT

3

+3.5V OUTPUT

RECTIFIER &

SMOOTHING

CIRCUIT

+2.5V OUTPUT

RECTIFIER &

SMOOTHING

CIRCUIT

VOLTAGE

DETECTOR

CIRCUIT

PC1

4

www.denom.com

Page 7

DPC-5.3

A

BLOCK DIAGRAM -4

DVD MECHANISM & OUTPUT CIRCUIT

1

MECHANISM CONTROL PC BOARD

2

BCDE

AUDIO/VIDEO JACK

Main circuit PC board

3

PICK UP

Flat cable

AUDIO/VIDEO JACK

4

www.denom.com

Page 8

DPC-5.3

A

BLOCK DIAGRAM -3

DISPLAY SECTION

1

2

BCDE

From Power supply unit

To Main PC board

3

Key matrix

4

www.denom.com

Page 9

DPC-5.3

A

BLOCK DIAGRAM -2

1

POWER SUPPLY UNIT

2

To Mechanism control

BCDE

MAIN CIRCUIT BOARD

IC-LOGIC 74HC74

FLIF/FLOP CMOS

IC61

IC-CONV WN8728 D/A

IC-LOGIC 74HC86

GATE HCMOS

IC-OPEAMP

BA4560F

To OUT

CP25:04PIN

CP25:06PIN

To OUT

CN27:SPDIF

INVERTER HCT

IC-LOGIC M74HCU04M1R

IC- VIDEOPROC STI5519

MPEG VIDEO DECODER

3

To Pick up

IC41

IC MEMFLASH

M29W800A T901N1

TR SWITCH CIRCUIT

P SCAN ON/OFF

To OUT

CP25:08PIN

CP25:10PIN

CP25:12PIN

CP25:14PIN

CP25:16PIN

CP25:18PIN

IC31

To Display

IC-DRAM HY57V651620BTC-8

125M 64M(1M x 16 x 4)

4

www.denom.com

Page 10

DPC-5.3

A

BLOCK DIAGRAM-1

OVER ALL

1

2

BCDEFGH

3

4

5

www.denom.com

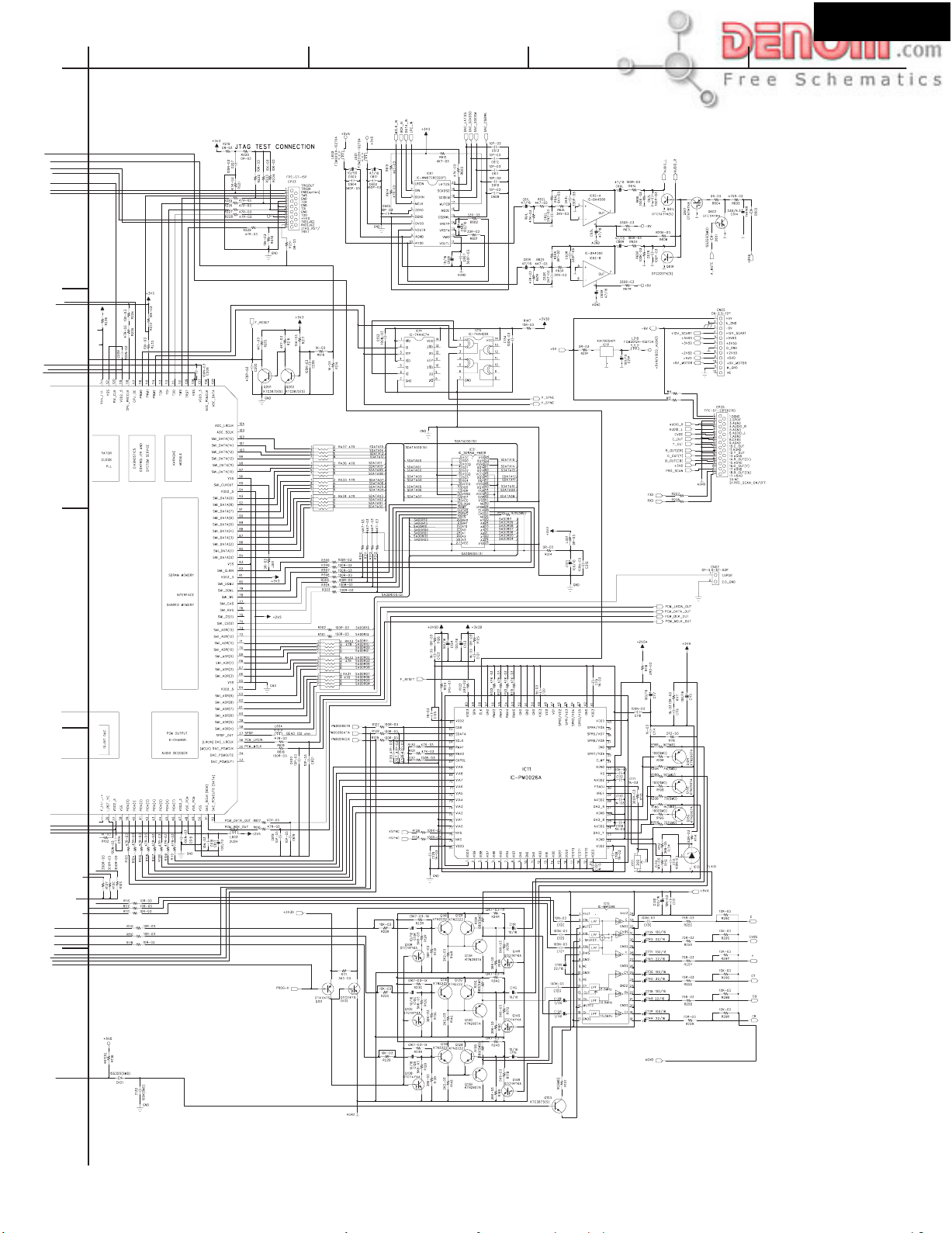

Page 11

DV-CP500

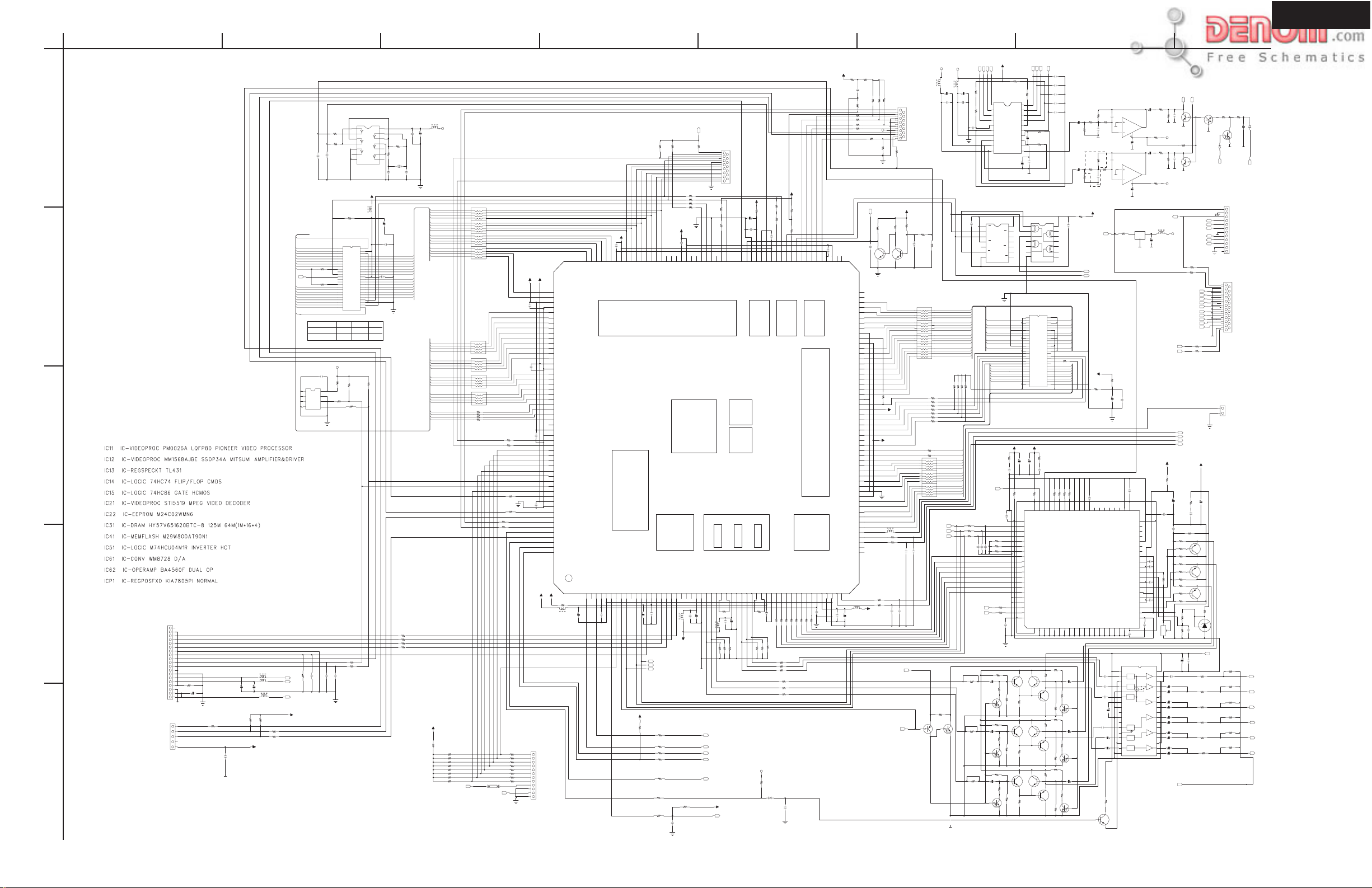

A

SCHEMATIC DIAGRAM

Main circuit PC board-1

1

2

F_ADDR17

F_ADDR16

F_ADDR15

F-ADDR14

F_ADDR13

F_ADDR12

F_ADDR11

F_ADDR10

F_ADDR09

F_ADDR20

F_RESET

F_ADDR19

F_ADDR18

F_ADDR08

F_ADDR07

F_ADDR06

F_ADDR05

F_ADDR04

F_ADDR03

F_ADDR02

F_ADDR01

BCD

L501

FCM2012H-102T04

100R-03

R504

100R-03

R501

C501

C506

20P-03

20P-03

+3.3VM

47K-03

R413

IC41

IC-M29F400T-90N1

1

A15

A16

2

A14

BYTE

3

A13

VSS

4

A12

DQ15

5

A11

DQ7

6

A10

DQ14

7

A9

DQ6

8

A8

DQ13

9

NC

DQ5

10

NC

DQ12

R411

11

WE

DR-03

R412

DR-03

DQ4

12

RP

VCC

13

NC

DQ11

14

NC

DQ3

15

RY/BY

DQ10

16

A18

DQ2

17

A17

DQ9

18

A7

DQ1

19

A6

DQ8

20

A5

DQ0

21

A4

QE

22

A3

VSS

23

A2

CE

24

A1

A0

R415

ADD

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

FCM2012H-102T04

1M-03

R503

R502

56R-03

X501

X-TAL

C502

22P-03

C406

100/10

D3V3

C504

C505

100N-03

470/6.3

C503

22P-03

GND

Down load Jig

+5V6S

100N-03

C228

R245

IC22

10R-03

IC-M24C02

1

8

E0

VDD

2

7

E1

WC

R248

3

6

E2

SCL

47R-03

4

5

VSS

SDA

GND

R247

R246

1K8-03

1K8-03

R249

47R-03

3

4

CP21

FPC-19P Pickup to Main PCB

1

NC

2

D_GND

3

SECTOR_START

4

DATA_VALID

5

DATA

6

BIT_CLOCK

7

D_GND

8

RESET

9

DXX_INTERRUPT

10

SCL

11

SDA

12

D_GND

13

DRIVE_GND

14

+3V3D

15

+5VD

16

D_GND

17

A_GND

18

DISC_M_POWER

19

TRACK_M_POWER

From Display circuit PC board

(To Connection PCB)

5

To Mechanism control PCB (P406)

www.denom.com

Page 12

DPC-5.3

A

SCHEMATIC DIAGRAM

Main circuit PC board-2

1

2

BCD

To Power supply unit (CN2)

NC

NC

To Output terminal PCB (CN01)

NC

NC

To Output PCB (CP01)

3

4

Video signal out

5

www.denom.com

Page 13

DPC-5.3

A

SCHEMATIC DIAGRAM-1

MAIN CIRCUIT PC BOARD

1

2

3

4

CP21

FPC-19P From Pickup to Main PCB

1

NC

2

D_GND

3

SECTOR_START

4

DATA_VALID

(EXT_DATA)

5

DATA

(EXT_BCLK)

6

BIT_CLOCK

7

D_GND

(3V3_R)

8

RESET

(IRQ2)

9

DXX_INTERRUPT

10

SCL

11

SDA

12

D_GND

13

DRIVE_GND

14

+3V3D

15

+5VD

16

0R-03

D_GND

R250

17

A_GND

DISC_M_POWER

TRACK_M_POWER

5

18

19

AGND

CN21

CN-2.0-05P

1 RESET_MAIN

2 FRONT_TXD

3 FRONT_RXD

4 OPTION_NC

5 +5V6S

From Display circuit PC board

(to connection PCB)

47/16

C222

0R-03

R254

C233 100P-03

BCDEFGH

+3V3

MCLK_IN

BCK_IN

DATA_IN

47/16

C601

C602

C605

10P-03

GND

C133

SDATA07

SDATA06

SDATA05

SDATA04

4K7-03

4K7-03

R312

R313

SADDR(00:13)

R127 100R-03

R128 100R-03

R129 100R-03

10K-03

R22R

10K-03

DTC114YKA

100N-03

R22G

Q10G

10K-03

R22B

CTC114YKA

R615

4K7-03

R614

47R-03

C128 47P-03

VSYNC

HSYNC

Q10B

1

1RD

2

1D

3

1CP

4

1SD

5

1Q

6

1Q

7

GND

SDATA00

SDATA01

SDATA02

SDATA03

SDATA04

SDATA05

SDATA06

SDATA07

F_RESET

C127 47P-03

C126 47P-03

13K7-03-1%

DTC114YKA

LRC_IN

1

LRCIN

2

DIN

3

BCKIN

4

MCLK

5

ZERO

6

DGND

7

DVDD

8

VOUTR

9

AGND

10

AVDD

IC14

74AHC74

GND

SDATA(00:15)

SADDR12

SADDR13

SADDR10

SADDR00

SADDR01

SADDR02

SADDR03

R130 47K-03

R131 47K-03

R132 100R-03

R138 100R-03

R134 100R-03

R23R

10/16

C10R

5K6-03

Q10R

13K7-03-1%

R23G

10/16

C10G

5K6-03

13K7-03-1%

R23B

C10B

10/16

5K6-03

IC61

WM8728(SSOP)

14

VCC

13

2RD

12

2D

11

2CP

10

2SD

2Q

2Q

+2V5D

10R-03

1N-03

1N-03

C129

1N-03

GND

KTN2222

R12R

36K-03

KTN2222

R12G

36K-03

KTN2222

R12B

36K-03

SDIDEM

CSBIWL

9

8

C125

R13R

Q11G

R13G

R13B

R612

4K7-03

LAT125

SCKSD

MUTEB

MODE

VREFP

VREFN

VOUTL

R126

C123

Q11R

Q11B

VMID

+5VD

1: TRIGOUT

2: TRIGIN

3: GND(Option)

4: TMS

5: GND

6: TCK

7: GND

8: TDI

9: GND

10: TDO

11: +5VD

12: TDX(JIG)

13: RXD(JIG)

14: JTAG_RST/

15: TRST

R217

10K-03

10P-03

100N-03

10P-03

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

C206

C621

DTA114TS

1K-03

R218

R309

R308

R307

R306

R305

R304

R303

R302 100R-03

R301 100R-03

1

3

5

7

1

3

5

7

1

3

5

7

Q101

+5VA

L602

FCM2012H_102T04

R214

1K-03

RA37 47R

2

4

6

8

RA36 47R

2

4

6

8

RA35 47R

2

4

6

8

2

RA34 47R

4

6

8

100R-03

100R-03

100R-03

100R-03

100R-03

100R-03

100R-03

2

4

6

8

2

4

6

8

2

4

6

8

PM0026STB

PM0026DATA

PM0026CLK

R111

3K3-03

DTC114YS

RA33

AGND

560P-03

47R

RA32

47R

RA31

47R

10/50

C603

C604

Q102

L601

FCM2012H_102T04

560P-03

SDATA15

SDATA14

SDATA13

SDATA12

SDATA 11

SDATA 10

SDATA 09

SDATA 08

SDATA 03

SDATA 02

SDATA01

SDATA00

4K7-03

4K7-03

R310

R311

SASSR13

SADDR12

SADDR11

SADDR10

SADDR00

SADDR01

SADDR02

SADDR03

SADDR09

SADDR08

SADDR07

SADDR06

SADDR05

SADDR04

+3V3

R219

JTAG TEST CONNECTION

0R-03

R220

0R-03

C207

100N-03

47K-03

F_DATA15

F_DATA07

F_DATA14

F_DATA06

F_DATA13

F_DATA05

F_DATA12

F_DATA04

F_DATA11

F_DATA03

F_DATA10

F_DATA02

F_DATA09

F_DATA01

F_DATA08

F_DATA00

100R-03

100R-03

100R-03

100R-03

L501

FCM2012H-102T04

D3V3

C504

C505

100N-03

470/6.3

10K-03

C503

22P-03

GND

F_DATA(00:15)

F_ADDR(01:21)

F_ADDR01

F_ADDR02

F_ADDR03

F_ADDR04

F_ADDR05

F_ADDR06

F_ADDR07

F_ADDR08

F_ADDR09

F_ADDR10

F_ADDR11

F_ADDR12

F_ADDR13

F_ADDR14

F_ADDR15

F_ADDR16

F_ADDR17

F_ADDR18

F_ADDR19

F_ADDR20

+3V3D

0R-03

F_DATA00

F_DATA01

F_DATA02

F_DATA03

F_DATA04

F_DATA05

F_DATA06

F_DATA07

F_DATA08

F_DATA09

F_DATA10

F_DATA11

F_DATA12

F_DATA13

F_DATA14

F_DATA15

R260

R261

R262

R263

R264

R265

R266

R267

R268

+12V_MOTOR

RA41 47R

2

1

4

3

6

5

8

7

2

1

RA42 47R

4

3

6

5

8

7

RA43 47R

2

1

4

3

6

5

8

7

RA44 47R

2

1

4

3

6

5

8

7

+3V3 +2V5

157 CPU_DATA(14)

158 CPU_DATA(15)

159 VDD3_3

160 VSS

C214

100N-03

161 CPU_ADR(1)

162 CPU_ADR(2)

163 CPU_ADR(3)

164 CPU_ADR(4)

165 CPU_ADR(5)

47R-03

47R-03

47R-03

47R-03

47R-03

47R-03

47R-03

47R-03

GND

C215

100N-03

C216

C217

CN26

CP-2.0-AN-12P

1

2

3

4

5

6

7

8

9

10

11

12

100N-03

100N-03

166 CPU_ADR(6)

167 CPU_ADR(7)

168 CPU_ADR(8)

169 CPU_ADR(9)

170 CPU_ADR(10)

171 VDD2_5

172 VSS

173 CPU_ADR(11)

174 CPU_ADR(12)

175 CPU_ADR(13)

176 CPU_ADR((14)

177 CPU_ADR(15)

178 CPU_ADR(16)

179 CPU_ADR(17)

180 CPU_ADR(18)

181 CPU_ADR(19)

182 CPU_ADR(20)

183 CPU_ADR(21)

184 VDD3_3

185 VSS

186 PIO0(0) T_STROBE

187 PIO0(1) MOD_SW

188 PIO0(2)

189 PIO0(3)

190 PIO0(4)

191 PIO0(5)

192 PIO0(6) SLIDER_SENSOR_OPEN/VLOSE

193 PIO0(7) SLIDER_IN (DRAWER_CCW_CTRL)

194 PIO1(0) SDA

195 PIO1(1) SCL

196 PIO1(2) SLIDER_OUT (DRAWER_CW_CTRL)

197 PIO1(3) TXD(JIG)

198 VDD2_5

199 VSS

200 PIO1(4) RXD(JIG)

201 PIO1(5) FRONT_TXD1

202 TRIGGER_IN

203 TRIGGER_OUT

204 PIO2(0) VIDEO_MUTE

205 PIO2(1) FRONT_RXD

206 PIO2(2) AUDIO_MUTE

207 PIO2(3) DAC_LATI2S_OUT

208 PIO2(4) DAC_SCKDSD_OUT

+3V3 +2V5

L201

0R-03

2U2H

L202

C201

ROU-MOROU-MO+

ROU-SEN

DISC-SEN

CLOSE-SEN

OPEN-SEN

ID-MOID-MO+

+12V MOTOR

M GND

+5VD

M GND

100/10

RA45 47R

1

2

3

4

5

6

7

8

RA46 47R

1

2

3

4

5

6

7

8

RA47 47R

1

2

3

4

5

6

7

8

RA48 47R

1

2

3

4

5

6

7

8

47R-03

R407

47R-03

R408

47R-03

R409

47R-03

R410

47R-03

R239

47R-03

R240

47R-03

R241

47R-03

R242

R243

75R-03 TRIGIN

75R-03 TRIGOUT

R244

2R2-1/2W

R277

R269

R270

R271

R272

R273

R274

R275

R276

+5VD

47K-03

47K-03

47K-03

47K-03

47K-03

47K-03

47K-03

47K-03

+2V5

C213

100N-03

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

VSS

VDD2_5

CPU_DATA(9)

CPU_DATA(8)

CPU_DATA(13)

CPU_DATA(12)

CPU_DATA(7)

CPU_DATA(11)

CPU_DATA(10)

141

CPU_DATA(6)

CPU_DATA(5)

CPU_DATA(4)

CPU_DATA(3)

CUP_DATA(2)

CPU_DATA(1)

CPU_DATA(0)

FLASH MEMORY

3-PWM Outputs

12C Controller

2-UARTS

38-Bit Programable I/O

PIO2(5) DAC_SDIOEM_IN/OUT

PIO2(6) DAC_MUTEB_IN/OUT

PIO2(7) DAC_CSBIWL_OUT

VDD3_3

VSS

PIO3(0) PRO_SCAN_ON/OFF

PIO3(1)

PIO(2)

100N-03

PIO(3)

C202

12345678910111213141516171819

PIO3(4) IR(REMOTECONT)

B_DATA

PIO3(5)

PIO3(6)

PIO3(7) DVD_RESET

DVV2_5

VSS

C204

100N-03

C203

470/6.3

PM0026STB

PM0026DATA

PM0026CLK

+3V3D

R609

4K7-03

R613 47R-03

R611 47R-03

R610 47R-03

R608 47R-03

R607 47R-03

100R-03

R135

47R-03

R205

+5VD

DOWN LOAD JIG

10K-03

139

CPU_CAS0

R405

+3V3

100N-03

138

CPU_RAS1

R414

10R-03

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

GND

FPC-ST_15P

47R-03

47R-03

47R-03

47R-03

GND

135

134

CPU_CE(0)

CPU_CE(1)

CPU MEMORY

PROGRAMABLE

133

132

CPU_CE(2)

CPU_CE(3)

INTERFACE

CP22

R237

10K-03

R238

47R-03

131

130

129

128

CPU_RW

CPU_WAIT

CPU_BE(1)

CPU_BE(0)

R404

R403

R402

R401

C212

137

136

VSS

VDD3_3

R406

140

CPU_CAS1

IC21

STI5519

ST20 CPU

PAL/NTSC/SECAM ENCODER

10-BIT DAC

B_WCLK

B_V4

NRSS_OUT

VDD_RGB

VSS_RGB

B_out

G_OUT

R_OUT

V_REF_RG

C102

C101

100/10

AGND

I_REF_RG

18K-03

R101

10N-03

L102

2U2H

R10B

300R-03

DAC_CSBIWL_OUT

DAC_SDIDEM_IN/OUT

DAC_SCKSD_OUT

DAC_LATI3S_OUT

AUDIO_MUTE

+3V3D

PRO_SCAN_ON_OFF

21222324252627282930313233343536373839

20

10N-03

L101

2U2H

+2.5VA

R206

10K-03

B_BCLK

INTERFACE

FRONT-END

B_FLAG

B_SYNC

C229

10N-03

127

IRQ(0)

4KB SRAM

DATA-CACHE

INSTRUCTION

VDD_YCC

VSS_YCC

C104

R10R

R10G

300R-03

300R-03

126

IRQ(1)

CACHE

C103

122

PLL

R102

300R-03

+5VD

R236

121

VSS

10-BIT DAC

I_REF_YC

300R-03

R10Y

4K7(S)

1SS355(SMD)

100N-03

R136

120

PIX_CLK

VDD2_5

300R-03

R10C

D101

C209

119

VDD2_5

VSS

C105

R10S

+3V3

R234

10K-03

R232 10K-03

R235

47R-03

R233

10K-03

100N-03

118

117

116

115

114

113

TCK

PWM0

PWM1

PWM2

CPU_OE

CPU_PROCLK

DIAGNOSTICS

SYSTEM SERVICE

CONTROLLER AND

AUDIO DECODER

PIO4(0)

PIO4(1)

PIO4(2)

PIO4(3)

PIO4(4)

PIO4(5)

40

4142434445464748495051

47R-03

47R-03

47R-03

47R-03

47R-03

47R-03

R103

R104

R105

R106

R107

R108

10R-03

R11S

10R-03

R11C

10R-03

R11Y

R11R

10R-03

R11G

10R-03

R11B

10R-03

C132

100N(SMD)

GND

112

111

TDI

TDO

KARAOKE

MODULE

SDRAM MEMORY

INTERFACE

SHARED MEMORY

PCM OUT

6-CHANNEL

PIO4(6)

PIO4(7)

47R-03

47R-03

100N-03

R109

R110

+2V5

10R-03

C210

100/10

10N-03

C211

125

124

123

IRQ(2)

RESET

VSS_PLL

VDD_PLL

GENERATOR

CLOCK

2KB

2KB

10-BIT DAC

V_REF_YC

Y_OUT

C_OUT

CV_OUT

18K-03

100/10

IC51

74HCU04

1

14

FCM2012H-102T04

47K-03

R413

IC41

M29F400T-90N1

1

A15

2

A14

3

A13

4

A12

5

A11

6

A10

7

A9

8

A8

9

NC

NC

WE

RP

NC

NC

RY/BY

A18

A17

A7

A6

A5

A4

A3

A2

A1

R245

1K8-03

R249

47R-03

R252

100R-03

BYTE

DQ15

DQ14

DQ13

DQ12

DQ11

DQ10

R246

2

3

4

5

6

7

A16

VSS

DQ7

DQ6

DQ5

DQ4

VCC

DQ3

DQ2

DQ9

DQ1

DQ8

DQ0

VSS

R253

100R-03

VCC

13

12

11

1M-03

10

R503

9

R502

56R-03

8

GND

R415

ADD

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

QE

27

26

CE

25

A0

X501

X-TAL

C502

22P-03

+3.3VM

C406

100/10

1N-03

C405

1N-03

C404

GND

R247

1K8-03

R201

R202

R203

R204

100R-03

R504

100R-03

R501

C501

C506

20P-03

20P-03

F_ADDR17

F_ADDR16

F_ADDR15

F-ADDR14

F_ADDR13

F_ADDR12

F_ADDR11

F_ADDR10

F_ADDR09

F_ADDR20

F_RESET

F_ADDR19

F_ADDR18

F_ADDR08

F_ADDR07

F_ADDR06

F_ADDR05

F_ADDR04

F_ADDR03

F_ADDR02

F_ADDR01

1

2

3

4

FCM2012H-102T04

L203

L204

FCM2012H-102T04

47/16

47/16

C224

C223

FCM2012H-102T04

R259

R258

10K-03

10K-03

+5V6S

10K-03

+3V3

+5VD

L205

+9VM

+5V6S

R256

47R-03

R257

47R-03

10

R411

11

DR-03

12

13

R412

14

DR-03

15

16

17

18

19

20

21

22

23

24

R411 R412 R413

ATMEL 16M 0 ohm NC 4K7

ST 16M NC 0 ohm

+5V6S

100N-03

C228

IC22

10R-03

IC-M24C02

8

E0

VDD

7

E1

WC

R248

6

E2

SCL

47R-03

5

VSS

SDA

GND

R251

C226

C227

C225

68P-03

68P-03

100N-03

GND

110

TMS

VDD3_3]

109

TRST

VDD_PCM

C615

GND

108

VSS

VSS_PCM

C208

100N-03

107

106

105

VDD3_3

ADC_DATA

ADC_PCMCLK

ADC_LRCLK

ADC_SCLK

SMI_DATA(15)

SMI_DATA(14)

SMI_DATA(13)

SMI_DATA(12)

SMI_DATA(11)

SMI_DATA(10)

SMI_CLKOUT

VDD2_5

SMI_DATA(9)

SMI_DATA(8)

SMI_DATA(7)

SMI_DATA(6)

SMI_DATA(5)

SMI_DATA(4)

SMI_DATA(3)

SMI_DATA(2)

SMI_DATA(1)

SMI_DATA(0)

SMI_CLKIN

VDD3_3

SMI_DQMU

SMI_DQML

SMI_WE

SMI_CAS

SMI_RAS

SMI_CS(1)

SMI_CS(0)

SMI_ADR(13)

SMI_ADR(12)

SMI_ADR(11)

SMI_ADR(10)

SMI_ADR(0)

SMI_ADR(1)

SMI_ADR(2)

SMI_ADR(3)

VDD2_5

SMI_ADR(9)

SMI_ADR(8)

SMI_ADR(7)

SMI_ADR(6)

SMI_ADR(5)

SMI_ADR(4)

SPDIF_OUT

(LRCIN) DAC_LRCLK

(MCLK) DAC_PCMCLK

DAC_PCMOUT2

DAC_PCMOUT1

VSS

DAC_SCLK (BCK)

DAC_PCMOUT0 (DATA)

52

PCM_DATA_OUT R617 47R-03

PCM_BCK_OUT R616 47R-03

C616

10N-03

C617

100/10

R225 47R-03

R226 47R-03

R227 47R-03

R228 47R-03

VSS

VSS

VSS

104

103

102

101

100

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57 SPDIF

56 PCM_LR$CIN

55 PCM_MCLK

54

53

L603

2U2H

R221

R229 47R-03

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

470P-03

+2V5

F_RESET

C205

R222 10K-03

R223 10K-03

10K-03

R215

4K7-03

Q201

KTC3875(S)

GND

0R-03

GND

R224 10K-03

R230

GND

J301

+3V3

+2V5

L604

47R-03

R618

100R-03

C618

PROG_H

R619

10P-03

FPC_ST_15P

CP23

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

R231

R216

4K7-03

Q202

KTC3875(S)

BEAD 120 ohm

C620

C619

+3V3D

0R-03

+3V3

10P-03

DAC_CSBIWL

DAC_LAT125

DAC_SCKDSD

DAC_SDIOEM

10P-03

C613

10P-03

C612

10P-03

R605

C611

47K-03

10P-03

20

C610

19

10P-03

18

C609

NC

NC

A9

A8

A7

A6

A5

A4

R125

C121

CLK

VIB8

680(SMD)

680(SMD)

R15B

VCC

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

GND

VIB7

13K7-03-1%

R24R

13K7-03-1%

13K7-03-1%

680(SMD)

14

13

12

11

10

9

8

SDATA15

SDATA14

SDATA13

SDATA12

SDATA11

SDATA10

SDATA09

SDATA08

R315 47K(SMD)

SADR11

SADDR09

SADDR08

SADDR07

SADDR06

SADDR05

SADDR04

R122 47K-03

R121 47K-03

RAM2

RAM3

VIB6

VIB5

5K6-03

R16R

36K-03

R24G

5K6-03

R16G

36K-03

R24B

5K6-03

R16B

36K-03

C61L

47/16

R61L

47K-03

C61R

47/16

47K-03

R147

10R-03

C134

100N-03

R120 47K-03

R119 47K-03

GND

GND

GND

RAM4

RAM5

IC

PM0026A

VIB4

VIB3

GND

GND

GND

1011121314151617181920

C11R

10/16

R17R

Q14R

DTC114YKA

C11G

10/16

R17G

Q14G

DTC114YKA

10/16

C11B

R17B

Q14B

DTC114YKA

KTC3875(S)

17

16

33R-03

15

R602

14

13

C608

100/10

33R-03

12

R601

11

C607

C606

10/16

560P-03

AGND

IC15

74AHC86

1

2

3

4

5

6

7

GND

SDATA(00:15)

IC31

SDRAM_4Mx16

VSS

1

VCC

DQ15

2

DQ0

VSSQ

3

VCCQ

DQ14

4

DQ1

DQ13

5

DQ2

VCCQ

6

VSSQ

DQ12

7

DQ3

DQ11

8

DQ4

VSSQ

9

VCCQ

DQ10

10

DQ5

DQ9

11

DQ6

VCCQ

12

VSSQ

DQ8

13

DQ7

VSS

14

VCC

15

LDQM

UDQM

16

WE

CLK

17

CAS

CKE

18

RAS

19

CS

A11

20

BA0

21

BA1

22

A10

23

A0

24

A1

25

A2

26

A3

VSS

27

VCC

SADDR(00:13)

+3V3D

10R-03

C122

C124

100/16

100/16

1N-03

R124

R123

2R2-03

2R2-03

60595857565554535251504948474645444342

SRN

VDD3

61

VDD2

62

CSB

63

SDTA

64

SCLK

65

RAM1

66

RAM0

67

CKPOL

68

VIA9

69

VIA8

70

VIA7

71

VIA6

72

VIA5

73

VIA4

74

VIA3

75

VIA2

76

VIA1

77

VIA0

78

NVS

79

NHS

80

VDD3

VDD3

VIB9

123456789

Q12R

KTN2222

R15R

Q13R

R14R

2K2-03

KTN2907A

Q12G

KTN2222

R15G

Q13G

R14G

2K2-03

KTN2907A

Q12B

KTN2222

Q13B

R14B

KYN2907A

2K2-03

AUDIO_L

C67L

R66L

100P-03

100K-03

Q61L

DTC323TK(S)

-9V

820K-03

R606

C67R

R66R

100P-03

100K-03

Q61R

DTC323TK(S)

+9V

-9V

L210

+5VA

(VIDEO_AUDIO)

W4 0R_03

W3 0R_03

AUDIO_R

R_OUT(Cr)

G_OUT(Y)

B_OUT(Cb)

PRO_SCAN

TXD

RXD

PCM_LRCIN_OUT

PCM_DATA_OUT

PCM_BCK_OUT

PCM_MCLK_OUT

+2V5A +5VA

R118

2R2-03

C117

100/16

100N-03

C118

C114

1N-03

R18R 1K(SMD)

100(SMD)

R19R

R20R 75(SMD)

R18B 1K(SMD)

100(SMD)

R19B

R20B 75(SMD)

R115

R18G 1K(SMD)

360R-03

100(SMD)

R19C

R20G 75(SMD)

R113

3K6-05

1

3

200

VR11

0.5%

R112

1K4-05

2

G

C130

10N-03

100/16

100N-03

C13C

C13S 100/16

C14S 22/16

13Y 100/16

C14Y 22/16

C13G 100/16

C14G 22/16

C13B 100/16

C14B 22/16

C13R 100/16

C14R 22/16

AGND

AUDIO_R

+12V_SCART

+5V5S

+3V5D

+2V5D

+9V_MOTOR

AUDIO_L

CVBS

C_OUT

Y_OUT

+5VD

R207 47R_03

R208 47R_03

R117

10R-03

C116

1N-03

2R2-03

R116

0.5%

3

C113

100N-03

C131

75R-03

75R-03

470R-03

0R-03

R605

R604

330/6.3

Q602

DTA114YKA

AGND

C115

Q15R

Q15B

Q15G

82R-03

2

1

KTN2907A

KTN2907A

KTN2907A

R114

DTC114YKA

1SS355(SMD)

FPC_ST_23P(6216)

CP_2.0_ST_02P

1

2

TL431

+5VA

D601

A_MUTE

CN25

CN_2.5_12P

1

2

3

4

5

6

7

8

9

10

11

12

CP25

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

CN27

1.SPDIF

2.D_GND

10K-03

10K-03

10K-03

10K-03

R29C

10K-03

R29B

10K-03

R29R

C614

+9V

A_GND

-9V

+12V_SCART

+5V6S

+3V5D

D_GND

+2V5D

+5VD

+9V_MOTOR

M_GND

NC

1. DGND

2. SPDIF

3. AGND

4. AUDIO_R

5. AGND

6. AUDIO_L

7. AGND

8. CVBS

9. AGND

10. C_OUT

11. AGND

12. Y_OUT

13. AGND

14. R_OUT(Cr)

15. AGND

16. G_OUT(Y)

17. AGND

18. B_OUT(Cb)

19. +5VD

20. NC

21. PRO_SCAN_ON_OFF

R29C

R29S

R29Y

1N414B

CVBS

D602

+9VA

C

Y

CY

Cb

Cr

Q601

+5VD

100/16

IC13

R25C

75R-03

R25S

75R-03

R25Y

75R-03

R25G

R25B

75R-03

R25R

100R-03

47/16

R65L

C66L

R62L

4K7-03

C62L

R62R

4K7-03

C32R

R61R

IC62-A

R64L

BA4560

C63L

9K1-03

330P-03

3

R63L

3K9-03

2N7-03

R64R

9K1-03

R63R

3K9-03

2N7-03

1

OUT

2

330R-03

R67L

C65L

47/16

100R-03

AGND

47/16

R65R

C66R

BA4560

C63R

IC62-B

330P-03

5

7

OUT

6

330R-03

8

R67R

47/16

C65R

AGND

+3V3D

KIA7805API

FCM2012H-102T04

IC1P

0R-03

+9V

1N-03

Q103

V_SYNC

H_SYNC

VDD3

VIB2

R21P

+3V3

L301

0R-03

0R-03

R314

C311

100/10

100N-03

GND

C120

VO0

VO1

GND

SPR0/VO2

SPR1/VO3

SPR2/VO4

SPR3/VO5

VIB1

VIB0

DOS1

DOS0

TEST2

TEST1

TEST0

1

VCC1

10N-03

2

CIN

C12C

3

MUTE1

100N-03

4

VIN

C12S

5

SELECT

100N-03

6

YIN

C12Y

7

BIAS

8

GND1

C106

9

NC

22/16

10

GND1

11

NC

100N-03

12

CY

C12C

13

CLP

C12B

14

Cb

1/50

15

MUTE2

C12R

16

Cr

1/50

17

GND2

R137

1K(SMD)

C312

SPR4/VO6

SPR5/VO7

SPR6/VO8

SPR7/VO9

41

VDD3

CLMP

AGND

AVDD2

FSADJ

AVDD2

DAO_R

AGND

DAO_B

AVDD2

DAO_Y

AGND

VDD3

1N-03

IC-MM1568

LPF

LPF

LPF

LPF

LPF

LPF

C21P

100/10

C119

1N-03

VDD3

40

39

38

37

GND

36

35

34

33

100N-03

VG

32

C112

31

C111

1N-03

30

VREF

29

C110

28

1N-03

27

26

25

24

C109

1N-03

23

22

VDD2

21

C108

1N-03

C107

IC12

34

VCC2

33

C

6dB

32

GND2

31

CVBS

6dB

30

29

GND2

28

Y

6dB

27

26

GND2

25

CY

6dB

24

23

GND2

13.5MHz

22

Cb

6dB

21

13.5MHz

20

GND2

19

Cr

6dB

13.5MHz

18

www.denom.com

Page 14

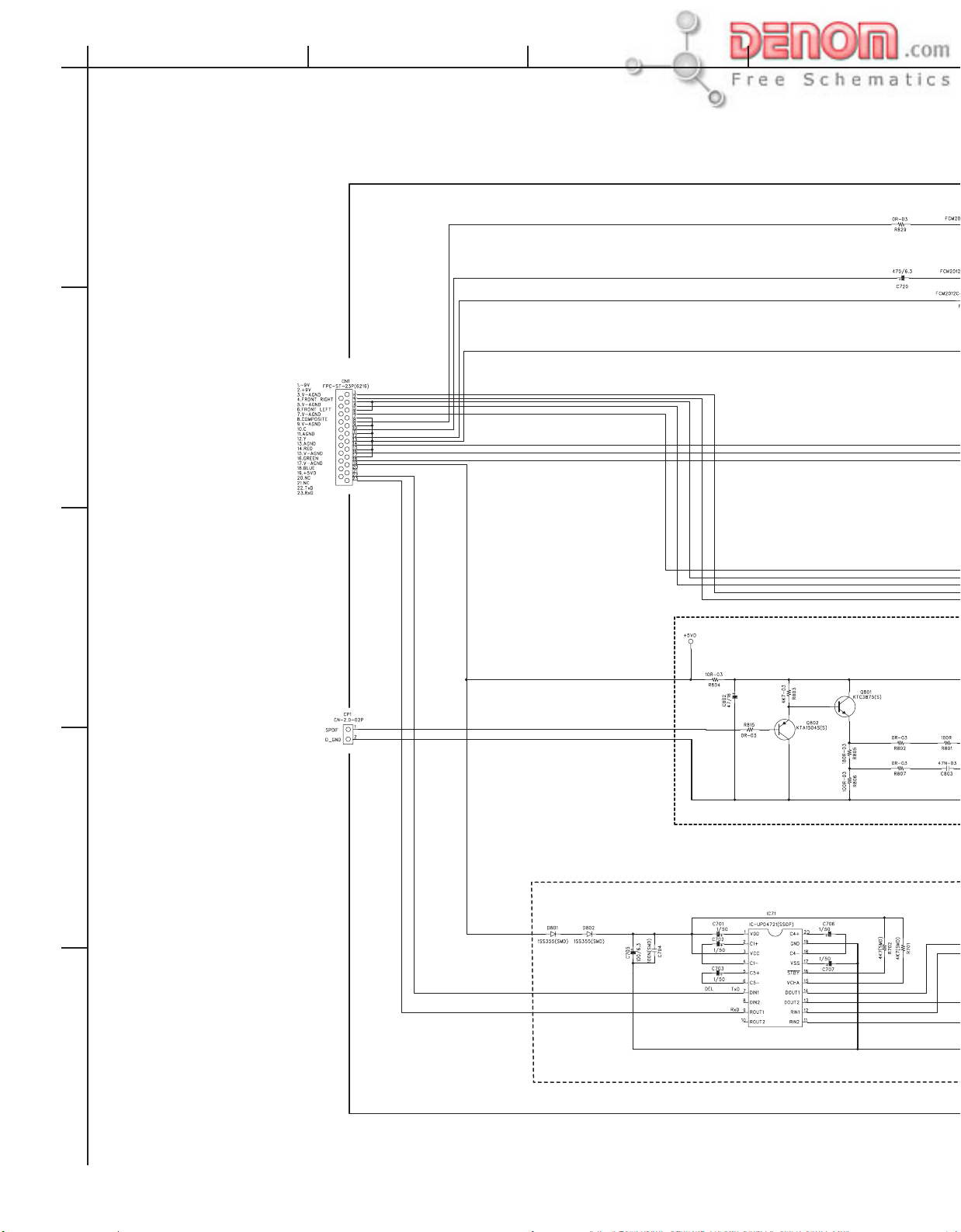

A

SCHEMATIC DIAGRAM-2

BCDEFGH

1

OUTPUT TERMINAL PC BOARD

From Main PCB

2

3

4

RS-232C TERMINAL

5

www.denom.com

Page 15

VIDEO OUT

S-VIDEO OUT

VIDEO

DPC-5.3

RI IN/OUT JACJ PC BOARD

COMPONENT OUT

1K

NC

NC

NC

NC

100R

100R

1K

FILTER CIRCUIT

www.denom.com

Page 16

DPC-5.3

A

SCHEMATIC DIAGRAM-2

1

2

BCDEFGH

OUTPUT TERMINAL PC BOARD

From Main PCB

VIDEO OUT

S-VIDEO OUT

RI IN/OUT JACJ PC BOARD

VIDEO

COMPONENT OUT

1K

NC

NC

NC

NC

3

100R

100R

1K

4

RS-232C TERMINAL

5

FILTER CIRCUIT

www.denom.com

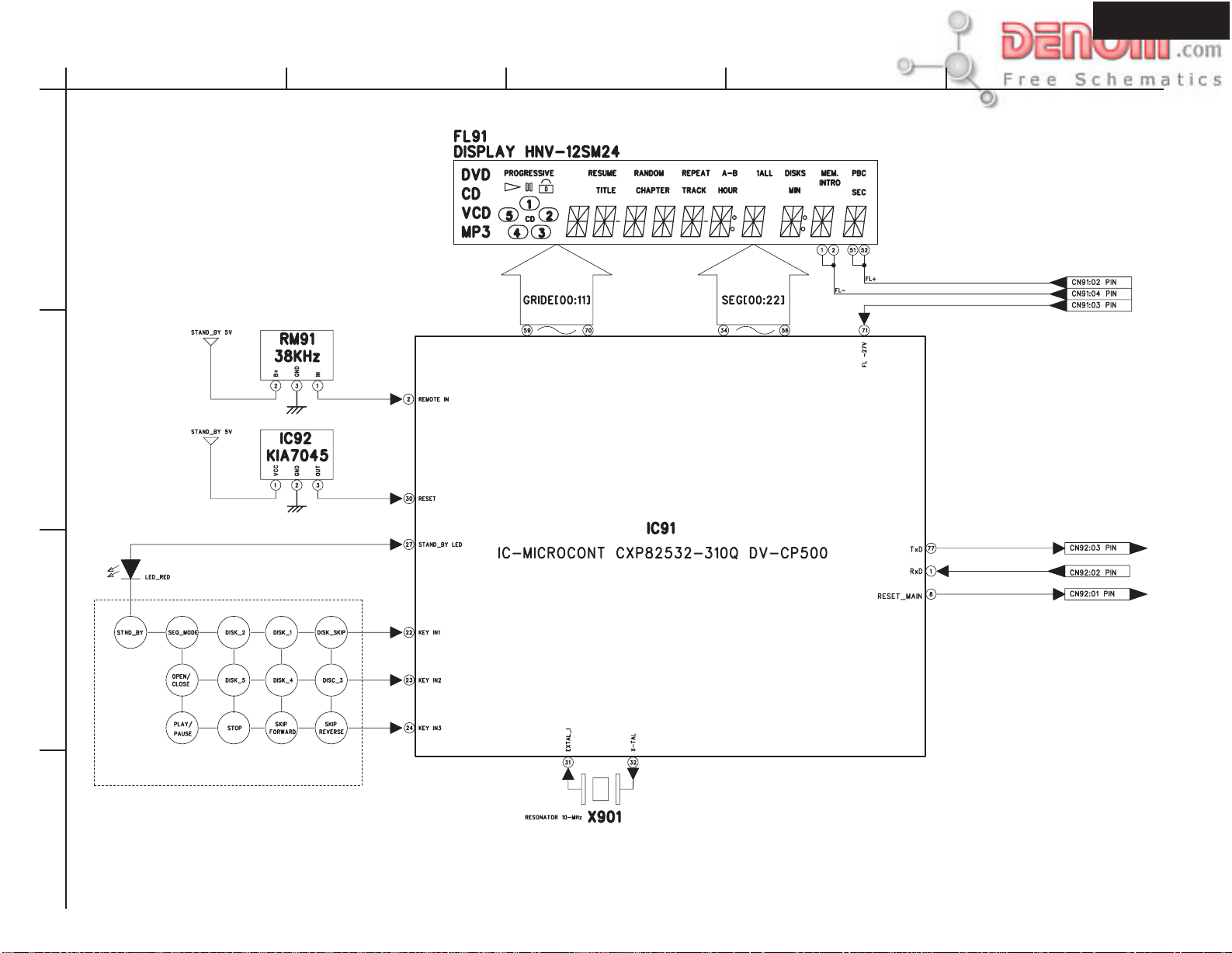

Page 17

From Power supply unit

DPC-5.3

FL Tube

FL91

www.denom.com

Page 18

A

SCHEMATIC DIAGRAM

1

2

BCDEFGH

DISPLAY CIRCUIT PC BOARD

3

STANDBY LED PC BOARD

To OUTPUT TERMINAL PC BOARD

To Standby LED

To Front

4

5

www.denom.com

Page 19

DPC-5.3

A

SCHEMATIC DIAGRAM

1

2

BCDEFGH

DISPLAY CIRCUIT PC BOARD

From Power supply unit

FL Tube

FL91

3

STANDBY LED PC BOARD

To OUTPUT TERMINAL PC BOARD

To Standby LED

To Front

4

5

www.denom.com

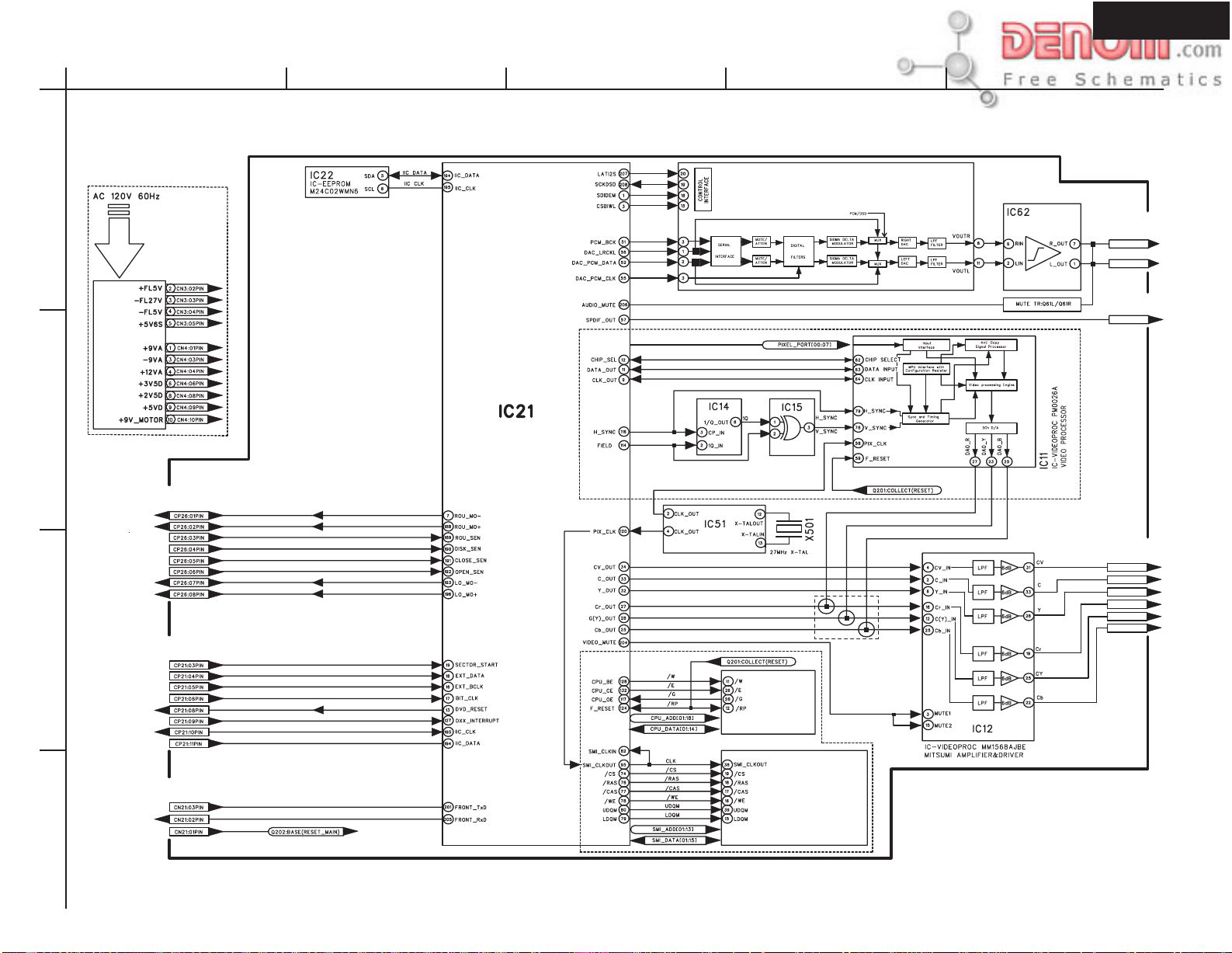

Page 20

DPC-5.3

A

SCHEMATIC DIAGRAM 5

POWER SUPPLY UNIT

1

SW1

F1

TNR1

10471K

250V2A

1/4W

R1

1M

AC

POWER

2

NOTE

1. Resistor values are indicated in ohms

unless otherwise specified

( K = 1.000 M = 1.000.000 )

2. Capacitor values are indicated in

3

microfarades or picofarades

( :microfarades :pocofarades)

CAUTION

Safety precaution to be followed during

servicing

1) Since those parts marked with

are critical parts for safety.

use only the one described in the parts list.

2) Before returning the set to the customer

make apprppriate laekage current or

resistance measurements to determine the

exposed parts are prpperly insulated from

the supply circuit.

BCDE

D7

R40

1N5819

2.2

C4

630V472

R3

330K

D6

1N4148

C6

50V22

T1

EER2828

R4

22

C21

152Y1

C10

1KV102

R41

3.3

R39

2.2

D10

SR206

SR204

D12

SR204

C17

10V1000

D8

UF4003

D9

UF4003

L3

4.7uH

R9

C11

4.7

25V470

D11

C14

10V1000

R21

1K

L2

4.7uH

PC18

817

NT1

10D-9

ZD3

9.1V

C3

200V100

C19

1KV101

1

C5

333

R2

2W47K

D5

UF4007

U1

KA1L0365R

VCC

FB

LF1

C1

104

20MH

C2

104

D1-D4

1N4007

C22

101

C23

102

R5

C7

1K

10V470

R6

10

ZD1

3.3V

C8

R7

50V100

4.7K

C9

R8

50V100

1K

U3

KA7809

C18

10V470

D13

SR1A0

IO

G

R18

1K

D14

1N4007

R19

330

R20

330

C13

50V22

C12

R15

R10

18K

R13

2.2K

680

R16

150

R17

820

25V470

C16

10V470

L1

4.7uH

R14

R22

1.5KF

100

PC1/A

C15

50V1

U2

431

1

GND

2

+FL

3

-27

4

-FL

5

+5.65

CN1

1

+B

2

GND

3

-12V

4

+12V

5

RST

6

+2.5

7

GND

8

+2.5

9

+5

10

+9

11

GND

12

NC

CN2

4

www.denom.com

Page 21

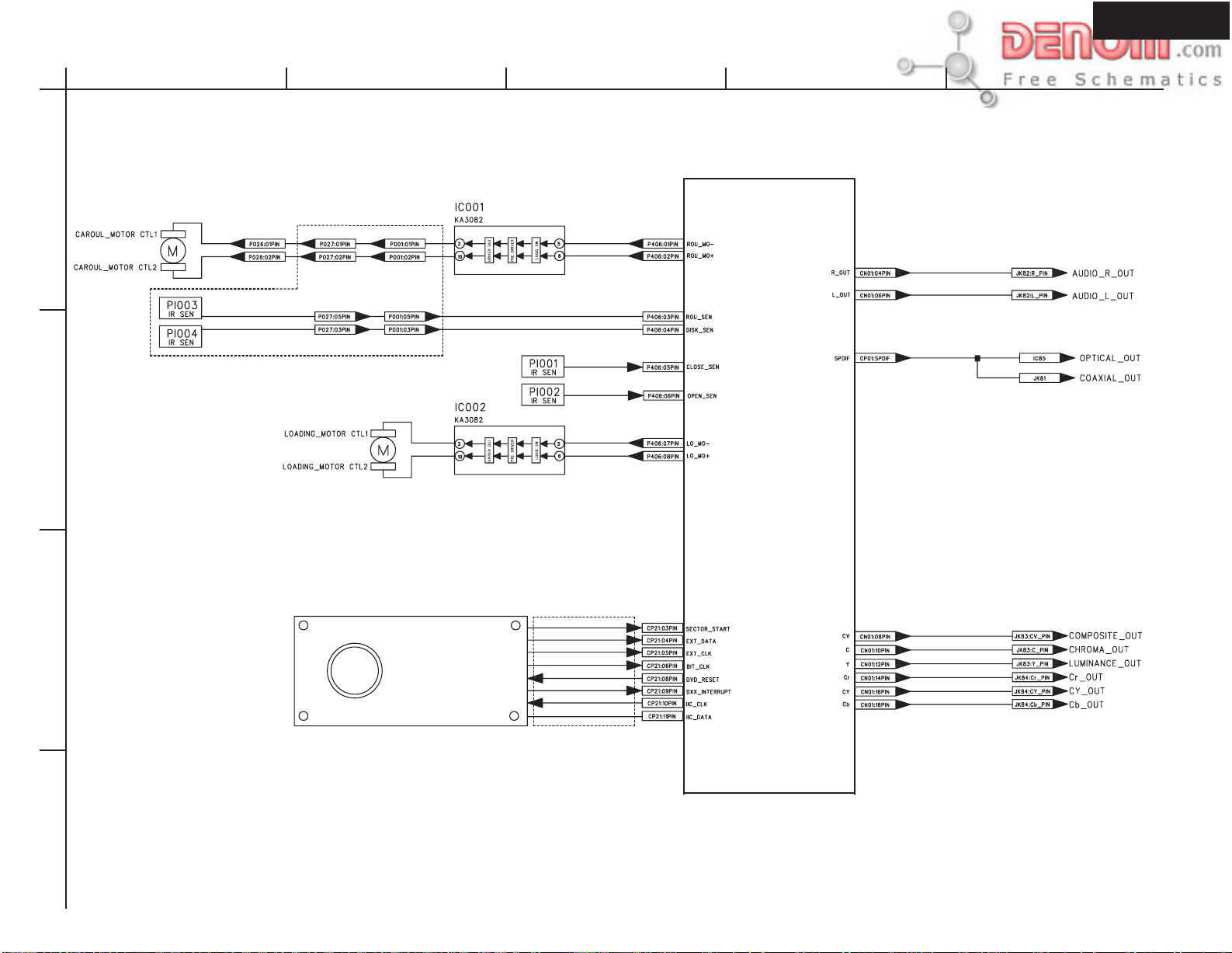

DPC-5.3

A

SCHEMATIC DIAGRAM 4

MECHANISM SECTION

1

2

BCDE

3

4

CAROUSEL MOTOR PC BOARD

www.denom.com

Page 22

PC BOARD CONNECTION DIAGRAM

DPC-5.3

AC120V 60Hz

STANDBY LED

CN2

CN1

POWER SUPPLY UNIT

CN3

CP94

CP95

CN96CN91

CP96

CN25

MAIN CIRCUIT

CN27

CN21

CN92

PC BOARD

CP22

FFC

CP25

CN01

CP21

MECHANISM CONTROL

CN26

FFC

To Roulette

motor

PC BOARD

Roulette motor

PC board

DISPLAY CIRCUIT PC BOARD

RI IN/OUT JACK

PC BOARD

CP01

OUTPUT TERMINAL PC BOARD

P406

P003

P027

RS-232C

TERMINAL

TRAVERSE MECHA.

B10

CN93

STANDBY LED PC BOARD

www.denom.com

OPEN/CLOSE

SWITCH PC BOARD

CP93

OPEN/CLOSE

Page 23

DPC-5.3

A

PRINTED CIRCUIT BOARD VIEW 1

MAIN CIRCUIT PC BOARD

1

2

BCD

3

4

5

Bottom pattern and Bottom component

www.denom.com

Page 24

DPC-5.3

A

PRINTED CIRCUIT BOARD VIEW 1

MAIN CIRCUIT PC BOARD

1

2

BCD

3

4

5

Top pattern and Top component

www.denom.com

Page 25

A

BCDEFGH

PRINTED CIRCUIT BOARD FROM SOLDERING SIDE VIEW 2

1

Display circuit PC board

2

CN93

S927

PLAY/PAUSE

S907

DISC5

S924

DISC4

S921

DISC3

S917

STOP

S905

DISC2

S915

DISC1

FF

S903

DISC SKIP

S911

FR

S901

J902

Component side

3

4

S905

S915

S917

S927

S907

S924

S921

5

www.denom.com

Page 26

DPC-5.3

J901

Component side

J920

FL91

C909

RM91

CN92

+

+

+

C907

+

C901

C906

J904

J903

S913

CN91

CN96

IC91

Soldering side

FL91

www.denom.com

CN92

S913

CN91

CN96

Page 27

DPC-5.3

A

BCDEFGH

PRINTED CIRCUIT BOARD FROM SOLDERING SIDE VIEW 2

1

Display circuit PC board

2

CN93

S927

PLAY/PAUSE

S907

DISC5

S924

DISC4

S921

DISC3

S917

STOP

S905

DISC2

S915

DISC1

FF

S903

DISC SKIP

S911

FR

S901

J902

J901

J920

FL91

C909

RM91

CN92

+

+

+

C907

+

C901

C906

J904

J903

S913

CN91

CN96

Component side

3

4

CN92

S913

CN91

CN96

S927

S907

S924

S921

S917

S905

S915

FL91

IC91

Soldering side

5

www.denom.com

Page 28

DPC-5.3

A

BCDEFGH

PRINTED CIRCUIT BOARD FROM SOLDERING SIDE VIEW 3

1

2

Output terminal PC board

9 8 7 6

5 4 3 2 1

JK83

JK82

CP01

JK81

IC85

C802

+

CN01

D711

Component side

3

9 8 7 6

5 4 3 2 1

4

Soldering side

5

www.denom.com

Page 29

A

BCDEFGH

PRINTED CIRCUIT BOARD FROM SOLDERING SIDE VIEW 3

1

Output terminal PC board

9 8 7 6

5 4 3 2 1

2

Component side

3

9 8 7 6

5 4 3 2 1

4

Soldering side

5

www.denom.com

Page 30

DPC-5.3

JK83

JK82

CP01

JK81

IC85

C802

+

CN01

D711

Soldering side

www.denom.com

Page 31

A

BCDEFGH

PRINTED CIRCUIT BOARD VIEW FROM SOLDERING SIDE 4

Roulette motor PC board

1

D-PHOTO RP1574/GP1S58V

P1003

D-PHOTO GP2S28

WCL 060-05 UL24

P1004

Component side view

2

Mechanism control PC board

3

JW13

JW17

JW6

JW21

JW3

JW7

R001

4

5

www.denom.com

Page 32

Ri IN/OUT Jack PC board

Component side view

DPC-5.3

R002

C002

JW14

C003

R003

JW22

C004

Component side view

R004

JW18

JW8

JW10

C001

D001

D002

IC001

JW20

IC002

L001

C005

JW15

-

Soldering side view

www.denom.com

Page 33

DPC-5.3

A

BCDEFGH

PRINTED CIRCUIT BOARD VIEW FROM SOLDERING SIDE 4

Roulette motor PC board

1

D-PHOTO RP1574/GP1S58V

P1003

D-PHOTO GP2S28

WCL 060-05 UL24

Component side view

2

P1004

Ri IN/OUT Jack PC board

Component side view

Mechanism control PC board

R004

JW18

JW8

JW10

C001

D001

D002

IC001

JW20

IC002

L001

C005

JW15

-

C002

3

JW13

JW17

JW6

JW21

JW3

JW7

R001

R002

JW14

C003

R003

JW22

C004

Component side view

4

5

Soldering side view

www.denom.com

Page 34

DPC-5.3

A

BCD

PRINTED CIRCUIT BOARD FROM SOLDERING SIDE VIEW 5

1

Connection PC board

CP94

2

Standby LED PC board

CP96

Component side

S931

D905

CP95

Soldering side

3

Soldering side

Inlet terminal PC board

OPEN/CLOSE Switch PC board

4

CP93

OPEN/CLOSE

S930

Soldering side

Soldering side

5

www.denom.com

Page 35

FW DOWNLOAD

Confirm the firmware

"CD PLAY" button and "DISC 3" button on the front panel

should be pressed at the same time. --------- Factory EEPROM reset.

Wattching the version of firmware in the FL tube.

When the name of the binaly file you wantto downloding is "dvcp5111.bin",

you may type "ttcmake dpc5.3fw1" in thr DOS prompt.

Space

Adifferent bin file requires a new data.

1. "TTCMAKE.EXE" file is downloaded to its own personal computer. (C-Drive)

DPC-5.3

2. "dvcp5111.bin" file is downloaded to its own personal computer.

(The same drive as 1.)

3. Call the "ttcmake dvcp5111" in the DOS prompt.

4. Call the file name of "dpc5.3" holder, and

"ttcmake dvcp5111" .

5. Created the "ENTRISE. TTC" Fig. 3

6. File created by 5. is copied to CD-R.

Caution: File format should be "ISO9660"

Fig. 2

TTCMAKE.EXE : application file

dvcp5111.bin : Binaly file

dps5.3

C: >cd..

C: cd dpc5.3

cd dpc5.3

dps5.3

Fig. 1

Fig. 1

C: dpc5.3>ttcmake dvcp5111

www.denom.com

dpc5.3

Fig. 2

Fig. 3

Page 36

DISASSEMBLY PROCEDURE

Replacement of DVD mechanism

The laser diode in the optical pickup block so

sensitive to static electricity, surge current and

etc..

That the components are liable to be broken down

or its reliability remarkable deteriorated.

During repair, carefully take the

following precautions.

Do not touch the optical

pickup object lens with the

hands.

1. Remove the top cover with six screws.

2. Remove the tray.

3. Remove the roulette assembly.

4. Remove the roulette. (Roulette is removed as written below.)

5. Solder the LD output lands on the DVD optical pickup.

Please perform right photo to reference.

6. Replace the pickup mechanism assembly etc. . After unsolder the laser diodes

output lands.

DPC-5.3

Short Land

Remove the roulette

1. Pull out the tray.

2. Stops in the position (cut deeply).

3. Remove in the direction of arrow.

4. Reassembly is performed by 3 to 1.

Roulette

Cut deep

www.denom.com

Page 37

P A CKING VIEW

DPC-5.3

240

RC-503DV

250

220

100

80

150

120

60

110

50

130

210

170

105

205

230

DPC-5.3

Rear side

www.denom.com

Page 38

PRINTED CIRCUIT BOARD PARTS LIS

T

R

D

R

R

R

R

G

R

D

R

L

R

R

F

W

%

%

W

%

%

M

A

A

A

M

M

M

A

A

A

W

W

MAIN CIRCUIT PC BOARD

CIRCUIT NO. PART NO. Pkg Unit DESCRIPTION

C13B 20269020 30 PCE CE 100U0F +20% 16.0V 85C

C13G 20269020 30 PCE CE 100U0F +20% 16.0V 85C

C13R 20269020 30 PCE CE 100U0F +20% 16.0V 85C

C13S 20269020 30 PCE CE 100U0F +20% 16.0V 85C

C13Y 20269020 30 PCE CE 100U0F +20% 16.0V 85C

CC21 55532610 N

CC25 55238420 NRPCE FFC-JUMPER 23X 1.25MM 100MM

CN21 55182960 N

CN25 55182970 N

CN26 55123450 PCE CONNECTOR 2.0MM 12 MA R NAT LW2003P12 0 0

CN27 55541130 N

CP21 55124680 PCE CONNECTOR 1.25MM 19 FE R WH GF120-19S-LS 2794 A6

CP22 55125910 N

CP25 55124620 PCE CONNECTOR 1.25MM 23 FE ST WH GF120-23S-TS 2794 A6

D602 70436540 16 PCE D-SLP 1N4148 100.0V 150E-3A

FIN

GND1 55135980 N

IC13 15069010 56 PCE IC-REGSPECKT TL431

IC1P 55491690 N

R277 55232770 NRPCE RMF 2R2 OHM +5% 500MI0W

VR11 55307870 N

X501 55128980 N

J301 10328750 91 PCE RMGCFMIC 0 OHM +0% 62MI5

L101 55188040 91 PCE LF-SMD 2U2H +10

L102 55188040 91 PCE LF-SMD 2U2H +10

L201 10328750 91 PCE RMGCFMIC 0 OHM +0% 62MI5

L202 55188040 91 PCE LF-SMD 2U2H +10

L203 55126670 50 PCE FBEAD SURFACE MT 1000OHM FCM2012H-102T04

L204 55126670 50 PCE FBEAD SURFACE MT 1000OHM FCM2012H-102T04

L205 55126670 50 PCE FBEAD SURFACE MT 1000OHM FCM2012H-102T04

L210 55126670 50 PCE FBEAD SURFACE MT 1000OHM FCM2012H-102T04

L601 55126670 50 PCE FBEAD SURFACE MT 1000OHM FCM2012H-102T04

L602 55126670 50 PCE FBEAD SURFACE MT 1000OHM FCM2012H-102T04

L603 55188040 91 PCE LF-SMD 2U2H +10

Q101 55133190 92 PCE TR-SSD DTA114YKA P 10K0 OHM 47K0 OH

Q12B 55388740 92 PCE TR-SLPSWA KTN2222AS P 40V -600MI0

Q12G 55388740 92 PCE TR-SLPSWA KTN2222AS P 40V -600MI0

Q12R 55388740 92 PCE TR-SLPSWA KTN2222AS P 40V -600MI0

Q14B 55133180 92 PCE TR-SSD DTC114YKA N 10K0 OHM 47K0 OH

Q14G 55133180 92 PCE TR-SSD DTC114YKA N 10K0 OHM 47K0 OH

Q14R 55133180 92 PCE TR-SSD DTC114YKA N 10K0 OHM 47K0 OH

Q15B 55137830 92 PCE TR-SLPSWA KTN2907AS N 50V -600MI0

Q15G 55137830 92 PCE TR-SLPSWA KTN2907AS N 50V -600MI0

Q15R 55137830 92 PCE TR-SLPSWA KTN2907AS N 50V -600MI0

W003 10328750 91 PCE RMGCFMIC 0 OHM +0% 62MI5

W004 10328750 91 PCE RMGCFMIC 0 OHM +0% 62MI5

C101 20268940 30 PCE ELECT. CAPCITOR 100U0F +20% 10.0V 85C

C103 20268940 30 PCE ELECT. CAPCITOR 100U0F +20% 10.0V 85C

C106 20251930 30 PCE ELECT. CAPCITOR 22U0F +20% 16.0V 85C

C10B 15002130 30 PCE ELECT. CAPCITOR 10U0F +20% 16.0V 85C

C10G 15002130 30 PCE ELECT. CAPCITOR 10U0F +20% 16.0V 85C

C10R 15002130 30 PCE ELECT. CAPCITOR 10U0F +20% 16.0V 85C

C115 20269020 30 PCE ELECT. CAPCITOR 100U0F +20% 16.0V 85C

C117 20269020 30 PCE ELECT. CAPCITOR 100U0F +20% 16.0V 85C

C11B 15002130 30 PCE ELECT. CAPCITOR 10U0F +20% 16.0V 85C

C11G 15002130 30 PCE ELECT. CAPCITOR 10U0F +20% 16.0V 85C

C11R 15002130 30 PCE ELECT. CAPCITOR 10U0F +20% 16.0V 85C

C122 20269020 30 PCE ELECT. CAPCITOR 100U0F +20% 16.0V 85C

C124 20269020 30 PCE ELECT. CAPCITOR 100U0F +20% 16.0V 85C

C12B 20268840 30 PCE ELECT. CAPCITOR 1U0F +20% 50.0V 85C

C12R 20268840 30 PCE ELECT. CAPCITOR 1U0F +20% 50.0V 85C

C130 20269020 30 PCE ELECT. CAPCITOR 100U0F +20% 16.0V 85C

C14B 20251930 30 PCE ELECT. CAPCITOR 22U0F +20% 16.0V 85C

C14G 20251930 30 PCE ELECT. CAPCITOR 22U0F +20% 16.0V 85C

C14R 20251930 30 PCE ELECT. CAPCITOR 22U0F +20% 16.0V 85C

C14S 20251930 30 PCE ELECT. CAPCITOR 22U0F +20% 16.0V 85C

C14Y 20251930 30 PCE ELECT. CAPCITOR 22U0F +20% 16.0V 85C

C201 20268940 30 PCE ELECT. CAPCITOR 100U0F +20% 10.0V 85C

C203 20268620 30 PCE ELECT. CAPCITOR 470U0F +20% 6.3V 85C

C210 20268940 30 PCE ELECT. CAPCITOR 100U0F +20% 10.0V 85C

C21P 20268940 30 PCE ELECT. CAPCITOR 100U0F +20% 10.0V 85C

C222 20267830 30 PCE ELECT. CAPCITOR 47U0F +20% 16.0V 85C

C223 20267830 30 PCE ELECT. CAPCITOR 47U0F +20% 16.0V 85C

C224 20267830 30 PCE ELECT. CAPCITOR 47U0F +20% 16.0V 85C

C311 20268940 30 PCE ELECT. CAPCITOR 100U0F +20% 10.0V 85C

C406 20268940 30 PCE ELECT. CAPCITOR 100U0F +20% 10.0V 85C

C505 20268620 30 PCE ELECT. CAPCITOR 470U0F +20% 6.3V 85C

C601 20267830 30 PCE ELECT. CAPCITOR 47U0F +20% 16.0V 85C

C603 20268880 30 PCE ELECT. CAPCITOR 10U0F +20% 50.0V 85C

55178960 PCE SPRING PLATE

PCE FFC-JUMPER 19X 1.25MM 220MM FOL

PCE WIRECONASY UNIQUE 5P 130MM UL1007 PVC DISCRETE 26 1

PCE WIRECONASY UNIQUE 12P 150MM UL1007 PVC DISCRETE 26 1

PCE SOCKET AS DL 2.0MM BLUE 2P 270MM UL1533 SHIELD 26 1

PCE CONNECTOR 1.0MM 15 FE ST BK 00-6232-015-006-800 0 0

PCE LUG TERMINAL GN

PCE IC-REGPOSFXD KIA7805AP NORMA

PCE PR 200R0 OHM +30% 100MI0W

PCE FILQZ 27M0 HZ +15 PPM 50.0 OHM FUNDAMENTAL 16P5

www.denom.com

Page 39

C606 15002130 30 PCE ELECT. CAPCITOR 10U0F +20% 16.0V 85C

R

R

P

S

R

V

T

A

P

W

M

A

M

M

M

A

A

A

A

A

A

A

A

M

M

M

M

T

D

R

8

R

R

A

G

R

4

0

P

W

W

4

4

4

4

W

W

C608 20268940 30 PCE ELECT. CAPCITOR 100U0F +20% 10.0V 85C

C614 20269110 30 PCE ELECT. CAPCITOR 330U0F +20% 6.3V 85C

C617 20268940 30 PCE ELECT. CAPCITOR 100U0F +20% 10.0V 85C

C61L 20267830 30 PCE ELECT. CAPCITOR 47U0F +20% 16.0V 85C

C61R 20267830 30 PCE ELECT. CAPCITOR 47U0F +20% 16.0V 85C

C65L 20267830 30 PCE ELECT. CAPCITOR 47U0F +20% 16.0V 85C

C65R 20267830 30 PCE ELECT. CAPCITOR 47U0F +20% 16.0V 85C

C66L 20267830 30 PCE ELECT. CAPCITOR 47U0F +20% 16.0V 85C

C66R 20267830 30 PCE ELECT. CAPCITOR 47U0F +20% 16.0V 85C

D101 20496510 85 PCE D-SLP 1SS355 35.0V 225MI0A

D601 20496510 85 PCE D-SLP 1SS355 35.0V 225MI0A

IC11 55388940 MS PCE IC-VIDEOPROC PM0026A LQFP80 PIONEER VIDEO PROCESSO

IC12 55389040 CP PCE IC-VIDEOPROC MM1568AJBE SSOP34A MITSUMI AMPLIFIER&DRIVE

IC14 20997870 CQ PCE IC-SPECFUNC MC74HC74AD DUAL-D FLIP FLO

IC15 15178670 CQ PCE IC-LOGIC 74HC86 GATE HCMO

IC21 55130350 IC PCE IC-VIDEOPROC STI5519 MPEG VIDEO DECODE

IC22 20940740 65 PCE IC-EEPROM M24C02WMN6

IC31 55156290 MS PCE IC-DRAM 100M0 HZ 8N0 64M(1M*16*4) HY57V651620BTC-8 125M

IC41 55136720 MS PCE IC-MEMFLASH M29W800AT90N1

IC51 55133310 K

IC61 55291470 IP PCE IC-CONV WM8728 D/

IC62 55128990 CQ PCE IC-OPERAMP BA4560F DUAL O

L301 10328750 91 PCE RMGCFMIC 0 OHM +0% 62MI5

L501 55126670 50 PCE FBEAD SURFACE MT 1000OHM FCM2012H-102T04

L604 55126710 50 PCE FBEAD SURFACE MT 120OHM FCM2012C-121T06

Q102 55133180 92 PCE TR-SSD DTC114YKA N 10K0 OHM 47K0 OH

Q103 20970460 92 PCE TR-SLPSWA KTC3875Y N 50V 150MI0

Q10B 55133180 92 PCE TR-SSD DTC114YKA N 10K0 OHM 47K0 OH

Q10G 55133180 92 PCE TR-SSD DTC114YKA N 10K0 OHM 47K0 OH

Q10R 55133180 92 PCE TR-SSD DTC114YKA N 10K0 OHM 47K0 OH

Q11B 55388740 92 PCE TR-SLPSWA KTN2222AS P 40V -600MI0

Q11G 55388740 92 PCE TR-SLPSWA KTN2222AS P 40V -600MI0

Q11R 55388740 92 PCE TR-SLPSWA KTN2222AS P 40V -600MI0

Q13B 55137830 92 PCE TR-SLPSWA KTN2907AS N 50V -600MI0

Q13G 55137830 92 PCE TR-SLPSWA KTN2907AS N 50V -600MI0

Q13R 55137830 92 PCE TR-SLPSWA KTN2907AS N 50V -600MI0

Q201 20970460 92 PCE TR-SLPSWA KTC3875Y N 50V 150MI0

Q202 20970460 92 PCE TR-SLPSWA KTC3875Y N 50V 150MI0

Q601 55133190 92 PCE TR-SSD DTA114YKA P 10K0 OHM 47K0 OH

Q602 55133180 92 PCE TR-SSD DTC114YKA N 10K0 OHM 47K0 OH

Q61L 55039430 91 PCE TR-SSD DTC323TK N 2K2 OH

Q61R 55039430 91 PCE TR-SSD DTC323TK N 2K2 OH

PRINTED CIRCUIT BOARD PARTS LIS

PCE IC-LOGIC M74HCU04M1R INVERTER HC

DISPLAY CIRCUIT PC BOAR

CIRCUIT NO. PART NO. Pkg Unit DESCRIPTION

DISP C901 20342060 30 PCE ELECT. CAPACITOR 47U0F +20% 16.0V 85C

DISP C903 20288040 91 PCE CCCFMIC 100N0F +80% -20% 16.0V Y5V

DISP C904 20288040 91 PCE CCCFMIC 100N0F +80% -20% 16.0V Y5V

DISP C905 20288040 91 PCE CCCFMIC 100N0F +80% -20% 16.0V Y5V

DISP C906 20252050 30 PCE ELECT. CAPACITOR 100U0F +20% 6.3V 85C

DISP C907 20268620 41 PCE ELECT. CAPACITOR 470U0F +20% 6.3V 85C

DISP C908 20288040 91 PCE CCCFMIC 100N0F +80% -20% 16.0V Y5V

DISP C909 20268840 30 PCE ELECT. CAPACITOR 1U0F +20% 50.0V 85C

DISP C911 20288040 91 PCE CCCFMIC 100N0F +80% -20% 16.0V Y5V

DISP C917 20288040 91 PCE CCCFMIC 100N0F +80% -20% 16.0V Y5V

DISP CN91 55255440 N

DISP CN92 55182990 NRPCE SOCKET AS UNIQUE 5P 220MM UL1007 PVC DISCRETE 26 1

DISP CN93 55199600 N

DISP CN94 55123320 PCE CONNECTOR 2.0MM 5 MA ST NAT LW2002P05 0 0

DISP CN95 55123320 PCE CONNECTOR 2.0MM 5 MA ST NAT LW2002P05 0 0

DISP CN96 55199610 N

DISP D904 70436540 16 PCE D-SLP 1N4148 100.0V 150E-3A

DISP D906 55177870 88 PCE D-SR SCHOTTKY RB501V-40 40.0V 100MI0

DISP D917 20496510 85 PCE D-SLP 1SS355 35.0V 225MI0A

DISP FIN

DISP FL91 55390980 N

DISP IC91 55443360 MS PCE IC-MICROCONT CXP82532-310Q DV-CP50

DISP IC92 55191090 NRPCE IC-REGNEGFXD KIA7045P LOW VOLTAGE DRO

DISP L901 14039360 91 PCE LF-SMD 22U0H +10%

DISP L902 10328750 91 PCE RMGCFMIC 0 OHM +0% 62MI5

DISP L903 20538660 91 PCE RMGCFMIC 4R7 OHM +5% 62MI5W

DISP L904 20538660 91 PCE RMGCFMIC 4R7 OHM +5% 62MI5W

DISP L905 10328750 91 PCE RMGCFMIC 0 OHM +0% 62MI5

DISP L909 55126670 50 PCE FBEAD SURFAELECT. CAPACITOR MT 1000OHM FCM2012H-102T0

DISP L912 55126670 50 PCE FBEAD SURFAELECT. CAPACITOR MT 1000OHM FCM2012H-102T0

DISP L913 55126670 50 PCE FBEAD SURFAELECT. CAPACITOR MT 1000OHM FCM2012H-102T0

DISP L914 55126670 50 PCE FBEAD SURFAELECT. CAPACITOR MT 1000OHM FCM2012H-102T0

DISP L917 80440510 91 PCE RMGCFMIN 0 OHM +0% 100MI0

DISP L918 80440510 91 PCE RMGCFMIN 0 OHM +0% 100MI0

55178960 PCE SPRING PLATE SPRING GND C5212 0.2T AVR520

PCE SOCKET AS UNIQUE 5P 380MM UL2791 SHIELD 2

PCE SOCKET AS UNIQUE 2P 40MM UL1007 RIBBON 26 1

PCE SOCKET AS UNIQUE 4P 70MM UL1007 RIBBON 26 1

PCE DISPLAY HNV-12SM2

www.denom.com

Page 40

DISP RM91 55156010 NRPCE IC-REMOTE NJL63H380A REELECT. CAPACITOR IVER 38KH

Z

P

P

P

P

P

P

P

P

P

P

P

)

T

T

T

P

)

L

L

P

)

Y

Y

D

M

P

T

D

R

R

R

T

L

S

P

6

6

6

A

A

M

M

T

S

0

P

L

P

R

P

DISP S901 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

DISP S903 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

DISP S905 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

DISP S907 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

DISP S911 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

DISP S913 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

DISP S915 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

DISP S917 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

DISP S921 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

DISP S924 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

DISP S927 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

DISP X901 55126140 NRPCE RESONATOR 10M0 HZ 25.0 OHM 0F

INLET TERMINAL PC BOARD (INCLUDED DISPLAY PCB

CIRCUIT NO. PART NO. Pkg Unit DESCRIPTION

INL

DCN1 55384200 NRPCE SOCKET AS UNIQUE 3P 630MM UL2547 26

INL

MCN1 55548930 NRPCE SOCKET AS DL 3.96MM 2P 500MM UL1617

INL

MCN2 55222010 PCE SOCKET MAINS INLET A/C INLET 7014-NG

OPEN/CLOSE SWITCH PC BOARD (INCLUDED DISPLAY PCB

CIRCUIT NO. PART NO. Pkg Unit DESCRIPTION

OPN/C

CP93 55090070 PCE CONNECTOR 2.0MM 2 MA ST NAT LW2002P0200T 0 0

OPN/C

S930 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

STANDBY SWITCH PC BOARD (INCLUDED DISPLAY PCB

CIRCUIT NO. PART NO. Pkg Unit DESCRIPTION

STB

CP96 55123310 PCE CONNECTOR 2.0MM 4 MA ST NAT LW2002P04 0 0

STB

D905 55125510 NRPCE D-LEM LTL-1CHE RD RND 3.0 DIFU 5.6C

STBYQ901 55133180 92 PCE TR-SSD DTC114YKA N 10K0 OHM 47K0 OH

STBYS931 55145270 KXPCE SWITACT VERTICAL TACTILE F/B 50MI0A 12.0V 500MI0OHM 1T 1

PRINTED CIRCUIT BOARD PARTS LIS

OUTPUT TERMINAL PC BOAR

CIRCUIT NO. PART NO. Pkg Unit DESCRIPTION

C701 20268840 30 PCE ELECT. CAPACITOR 1U0F +20% 50.0V 85C

C702 20268840 30 PCE ELECT. CAPACITOR 1U0F +20% 50.0V 85C

C703 20268840 30 PCE ELECT. CAPACITOR 1U0F +20% 50.0V 85C

C705 20252050 30 PCE ELECT. CAPACITOR 100U0F +20% 6.3V 85C

C706 20268840 30 PCE ELECT. CAPACITOR 1U0F +20% 50.0V 85C

C707 20268840 30 PCE ELECT. CAPACITOR 1U0F +20% 50.0V 85C

C802 20267830 30 PCE ELECT. CAPACITOR 47U0F +20% 16.0V 85C

CN01 55124620 PCE CONNECTOR 1.25MM 23 FE ST WH GF120-23S-TS 2794 A6

CN71 67472300 N

CP01 55090070 PCE CONNECTOR 2.0MM 2 MA ST NAT LW2002P0200T 0 0

D711 70436540 16 PCE D-SLP 1N4148 100.0V 150E-3A

D801 20496510 85 PCE D-SLP 1SS355 35.0V 225MI0A

D802 20496510 85 PCE D-SLP 1SS355 35.0V 225MI0A

FCN1 55171520 PCE CONNECTOR 2.0MM 5 MA ST NAT MOLEX 35336-0510 0 0

FCN2 55177410 PCE CONNECTOR 2.0MM 3 MA ST NAT MOLEX 35336-0310 0 0

GND1 55135980 N

GND2 55135980 N

IC71 55197900 CQ PCE IC-SPECFUNC UPD4721 DRIVERS/REELEC

IC85 55164740 NRPCE D-LEM GP1F32T RD RND C

JK81 55270580 PCE JACK 1P W/GND RCA-139PJ

JK82 55266550 PCE JACK 2P WR W/GND CAP RCA-235P

JK83 55266570 PCE JACK DIN SCKT MIX SOCKET RCA & S-VIDEO RCA-138JP1

JK84 55266540 PCE JACK PHONO SCKT RCA 3P RUG W/GND CAP RCA-328

L801 55126710 50 PCE FBEAD SURFAELECT. CAPACITOR MT 120OHM FCM2012C-121T0

L802 55126710 50 PCE FBEAD SURFAELECT. CAPACITOR MT 120OHM FCM2012C-121T0

L803 55126710 50 PCE FBEAD SURFAELECT. CAPACITOR MT 120OHM FCM2012C-121T0

Q801 20970460 92 PCE TR-SLPSWA KTC3875Y N 50V 150MI0

Q802 20970480 92 PCE TR-SLPSWA KTA1504Y P -50V -150MI0

Q87L 55039430 92 PCE TR-SSD DTC323TK N 2K2 OH

Q87R 55039430 92 PCE TR-SSD DTC323TK N 2K2 OH

PRINTED CIRCUIT BOARD PARTS LIS

DIGITAL FILTER PC BOARD

CIRCUIT NO. PART NO. Pkg Unit DESCRIPTION

DCP1 55090080 PCE CONNECTOR 2.0MM 3 MA ST NAT LW2002P03 0 0

DG91 55190890 PCE CON PHONO SCKT REMOTEIH 2 PIN

DP91 55207930 KVPCE PHOTCOUP PC-17T1

FCP1 55206580 PCE CONNECTOR 2.0MM 5 MA R NAT BD'BD SOCKET MOLEX 35237-0510 0

DD01 20496510 85 PCE D-SLP 1SS355 35.0V 225MI0A

IC01 55164460 CQ PCE IC-OPERAMP NJM4556AM DUAL O

IC1

IC1

C04L 20267830 30 PCE ELECT. CAPACITOR 47U0F +20% 16.0V 85C

C04R 20267830 30 PCE ELECT. CAPACITOR 47U0F +20% 16.0V 85C

55164460 CQ PCE IC-OPERAMP NJM4556AM DUAL O

55164460 CQ PCE IC-OPERAMP NJM4556AM DUAL O

PCE CONNECTOR -SPE 87204-6063 SUB D FE 2.77MM 9 -- 1630 A1

PCE LUG GND

PCE LUG GND

www.denom.com

Page 41

C05L 20267830 30 PCE ELECT. CAPACITOR 47U0F +20% 16.0V 85C

C05R 20267830 30 PCE ELECT. CAPACITOR 47U0F +20% 16.0V 85C

DC01 20267830 30 PCE ELECT. CAPACITOR 47U0F +20% 16.0V 85C

www.denom.com

Page 42

DPC-5.3 EX-VIEW PARTS LIST

NO.PARTS N

o

PARTS NAME

1

55384980

PLATE BADGE DVD

2

55382960

DOOR TRAY

3

55223420

WINDOW DISPLAY

4

55204210

LOGO BADGE INTEGRA

5

55186710

FACET STANDBY

6

55259110

COVER POWER BUTTON

7

55184600

SHAFT POWER SWITCH

8

55204250

POWER BUTTON

9

55184650

STANDBY BUTTON

10

55448310

POWER/STANDBY SWITCH PC BOARD ASSY (INCLUDE DISP

11

55244670

BUTTON CD PLAY

12

55221140

SHIELD COVER SENSOR

13

55164930

HOLDER FL

14

55382610

PANEL FRONT

15

55204260

BUTTON OPEN/CLOSE DPC5.2

16

55244680

BUTTON 9KEY

17

55145270

TACT SWITCH VERTICAL

18

55448310

OPEN/CLOSE SWITCH PC BOARD ASSY (INCLUDE DISP. PCB)

19

55448310

DISPLAY PC BOARD ASSY

20

55178960

SPRING GND C5212 0.2T

21

55236110

CABINET CHASSIS FRONT

22

55201610

RUBBER SPACER 14.5*14.5*22

23

55174550

SHIELD GASKET 12 X 8 X 20

24

55125120

FOOT

25

55141370

FOOT RUBBER

26

5518662A

CABINET CHASSIS MAIN

27

55190770

FELT 38X120X0.3T BK

28

55405550

SHIELD COVER

29

55190690

SHIELD COVER DOWN LOAD

30

55448320

OUTPUT TERMINAL PC BOARD ASSY

36

67472300

D SUB CONNECTOR

39

55383140

REAR PANEL

40

55174610

BRACKET MECHA RIGHT

41

55371600

MECHANISM ASSY CDM5G(TVM503R-1)

42

55186680

BRACKET FRAME MECHA R

43

55186600

COVER TOP

44

5518667A

BRACKET FRAME MECHA L

46

55190680

SHIELD COVER CONNECT BOARD

47

55516410

SHIELD PLATE MPEG

48

55514090

SHIELD COVER PROTECT

49

55448290

MAIN PC BOARD ASSY

50

55190160

BRACKET GROUND

51

55186640

BRACKET MAIN PCB

52

55332110

POWER SUPPLY UNIT

53

55202510

SHIELD COVER POWER SUPPLY UNIT

54

55222010

INLET TERMINAL

55

55448310

INLET TERMINAL PC BOARD

56

55222020

BRACKET INLET

58

55448330

RI IN/OUT JACK PC BOARD

60

SR-5, T2A

FUSE, 250VCA T 2.0A

S1

838130068

SCREW 3TTB+6B

S2

838130088

SCREW 3TTB+8B

S3

238440088

SCREW 4TTB+8BC(BC)

S4

55127120

SCREW 3MM 8MM WITH WASHER

S5

55127180

SCREW 3MM 8MM

S6

838430108

SCREW 3TTB+8B(BC)

.

www.denom.com

Page 43

DPC-5.3 EX-VIEW

P

NO. PARTS No

1 55384980

2 55382960

3 55223420

4 55204210

5 55186710

6 55259110

7 55184600

8 55204250

9 55184650

10 55448310

11 55244670

12 55221140

13 55164930

14 55382610

15 55204260

16

17 55145270

18 55448310

19 55448310

20 55178960

21

22 55201610

23 55174550

24 55125120

25 55141370

26 5518662A

27 55190770

28 55405550

29 55190690

30 55448320

36 67472300

39 55383140

40 55174610

41 55371600

42 55186680

43 55186600

44 5518667A

46 55190680

47 55516410

48 55514090

49 55448290

50 55190160

51 55186640

52 55332110

53 55202510

54 55222010

55 55448310

56 55222020

58 55448330

55244680

55236110

www.denom.com

Page 44

PACKING VIEW PARTS LIS

T

NO. PART NO. Unit DESCRIPTION

50 55383370 PCE CARTON BOX DPC5.3 INTEGRA

60 55184410 PCE ENDCAP CUSHION RIGHT

70 55184420 PCE ENDCAP CUSHION LEFT

100 55176530 PCE AUDIO CONNECTION CABLE

105 55547410 PCE POWER CORD

110 55383400 PCE INSTRUCTION MANUAL

120 55231700 PCE POLY BAG FOAM SHEET

130 55188250 PCE WARRANTY CARD

150 55170650 PCE POLY BAG 260MM X 410MM

170 20194780 PCE CABLE-TIE THE FITMOS PLASTIC

205 29110148 M PP TAPE

210 55208740 PCE CUSHION -- 80.0MM X 35.0MM 0 0

220 2010389 PCE RI CABLE

230 5544550A PCE AC PRI LABEL POS DPC-5.3(B)

240 55445530 PCE REMOTE CONTROLLER RC-503DV

250 3010054 PCE BATTERY 1.5V AAA 1.15 AH

www.denom.com

Page 45

Pos Tocom# SName Step

M

W

W

3

W

3

W

W

3

W

W

0010 55448270 ASSY MECH BOM DPC-5.3 OE

0020 55448280 ASSY BOM PKG DPC-5.3 ENGPAW

0030 55448290 ASSY EMBD IMA MAIN BD DPC-5.

0040 55448310 ASSY EMBD IMA FRONT BD DPC-5.

0050 55448320 ASSY EMBD IMA OUT BD DPC-5.3 ENGCAW

0060 55448330 ASSY EMBD IMA DIGI/FILTER BD DPC-5.

0070 55371600 ASSY MSA ASY CDM5G(TVM503R-1) ENGPAW

ENGPAW

ENGCAW

ENGCAW

ENGCAW

www.denom.com

Page 46

DPC-5.3

Integra Division of

ONKYO CORPORATION

Sales & Product Planning Div. : 2-1, Nisshin-cho, Neyagawa-shi, OSAKA 572-8540, JAPAN

Tel: 072-831-8111 Fax: 072-833-5222 http://www.onkyo.co.jp/

Integra Division of

ONKYO U.S.A. CORPORATION

18 Park Way, Upper Saddle River, N.J. 07458, U.S.A.

Tel: 201-785-2600 Fax: 201-785-2650 E-mail: integra@onkyousa.com http://www.integrahometheater.com

PN 0Mxxxx D01xx Printed in Japan

www.denom.com

Loading...

Loading...