Page 1

DLV-100

Ref. No. 3701

SERVICE MANUAL

Digital Light Processing Projector

MODEL

E

L

C

N

A

C

R

E

T

CT

N

LE

E

SE

U

N

E

M

ADJUST

AUTO

DLV-100

CESS

PC CARD AC

CE

OUR

S

BY

STAND

ON/

OWER

P

TUS

STA

Nov, 2001

INPUT

100 - 120 / 200 - 240 V AC, 50 / 60 HzUUD

SAFETY-RELATED COMPONENT

WARNING!!

COMPONENTS IDENTIFIED BY MARK ON THE

SCHEMATIC DIAGRAM AND IN THE PARTS LIST ARE

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE THESE COMPONENTS WITH ONKYO

PARTS WHOSE PART NUMBERS APPEAR AS SHOWN

IN THIS MANUAL.

MAKE LEAKAGE-CURRENT OR RESISTANCE

MEASUREMENTS TO DETERMINE THAT EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE

SUPPLY CIRCUIT BEFORE RETURNING THE

APPLIANCE TO THE CUSTOMER.

Page 2

1. Application

This specification sheet applies for DLV-100.

Model DLV-100

NEC Model code 01152009

2. General

2. General

2. General2. General

2.1 Operation temperature range

+5 ~ +35 degree C (Humidity 20-80%RH, not in the dewfall.)

2.2 Storage temperature range

-10 ~ +50 degree C

2.3 Power source

100 ~ 120 VAC / 200 ~ 240 VAC +/-10%, 50 / 60 Hz

2.4 Input Current

2.2/1.1A (MAX.)

2.5 Inspection condition

Inspection shall be done by AC120V / 60 Hz unless no rule is specified.

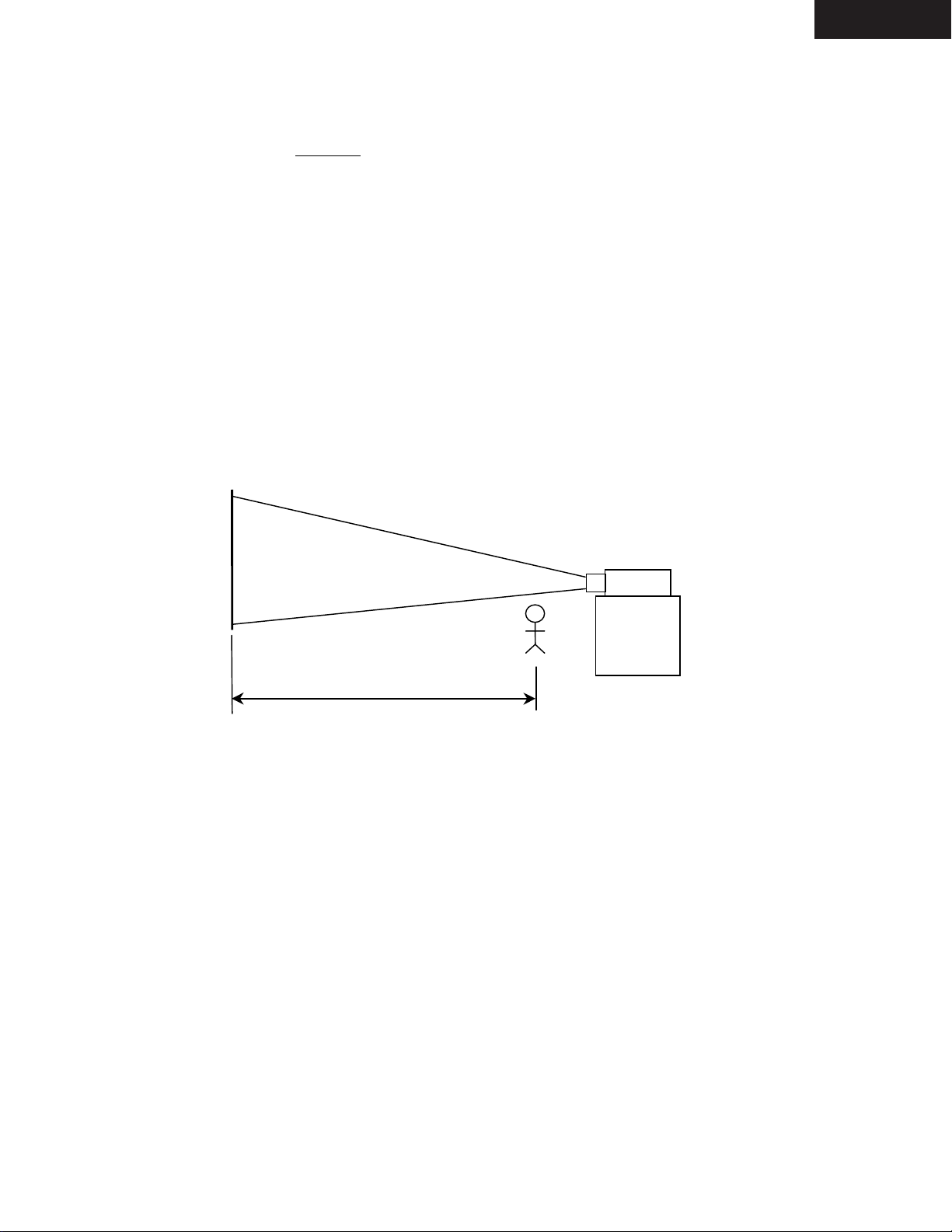

As for the projection condition, t h e screen is perpendicularly installed to the set and the

projection screen is in WIDE condition of 60 inches. When test, inspector shall be 2 +/- 0.3 m

away from the screen.

DLV-100

Screen

Inspector

2±0.3 m

Fig. 1 Condition

3. Main parts specifications

3. Main parts specifications

3. Main parts specifications3. Main parts specifications

3.1 DMD panel

Single Chip Digital Micromirror Device(DMD)

1024

3.2 Lens

x 768 pixels

Manual zoom and focus

F-no.=2.61~2.84, f=28.35~34.02mm

3.3 Lamp

135W DC Lamp

Average lifetime 1,000H

The definition of average lifetime is the time that light becomes half with the continuous

lighting-up.

(Notes)

The lamp bulb can be ruptured, while using a projector.

When the lamp bulb is ruptured, there is a small crack and pieces of glass, which may be

scattered in the lamp case.

Page 3

4. Electric specifications

4. Electric specifications

4. Electric specifications4. Electric specifications

4.1 Input signal band width

RGB 80MHz

Video 6.5MHz

4.2 Graduation

256 grade full color (16,777,216 color)

4.3 Display resolution

NTSC/PAL/YCbCr 550TV lines

SECAM 300TV lines

RGB 1024dots(H)×768dots(V)

4.4 Input terminal

RGB 1 input: Mini D-SUB 15pin

VIDEO 1 input: RCA

S-VIDEO 1 input: DIN 4pin

Audio 1 input: Stereo mini jack

PC Control 1 input: DIN 8pin

USB 1 input: Type A

PC Card 1 input: CompactFlash

4.5 PC Card Viewer

This Viewer can disp lay t he JP EG/BM P ima ge whic h is pres erved i n Compa ctF las h (CF ).

CF correspond to SanDisk CF 128Mbytes media.

4.6 Y/C Separation

NTSC/PAL

4.7 Input signal (RGB)

Horizontal Freq. 15 ~ 100KHz(RGB: 24KHz or over)

Vertical freq. 50 ~ 120Hz

Pixel clock freq. Less than 100MHz

Capable resolution UXGA 1600dot(H)×1200dot(V) Max.

Sync system Separate Sync/Composite Sync/Sync on G

4.8 Input signal level

RGBHV Input R,G,B 0.7Vp-p / 75ohm positive

VIDEO 1.0Vp-p / 75 ohm

S-VIDEO Y: 1.0Vp-p / 75 ohm

C: 0.283Vp-p / 75 ohm

AUDIO 0.5Vrms / 22 K ohm

4.9 Audio output

1W monaural Speaker

DLV-100

YCbCr:shares with the RGB terminal

Y 1.0Vp-p / 75ohm positive

Cb,Cr(Pb,Pr) 0.7Vp-p / 75ohm

H/V Sync 4.0Vp-p / TTL posi./nega

Composite Sync 4.0Vp-p / TTL posi./nega

Sync on G 0.3Vp-p / 75 ohm negative

Page 4

4.10 On Screen Display

1. Pull down menu

Basic/Custom menu <> Advanced menu

2. Multilingual menu

English / French /German / Italian / Japanese / Spanish / Swedish

4.11 Remote

Palm type remote unit

4.12 Input current

2.2A 100 ~ 120VAC/1.1A 200 ~ 240VAC

4.13 Plug & Play data

Tab.1 EDID data

00001

12

23

11

22

00

00

0000

00 FF FF FF FF FF FF 00 38 A3 D3 00 01 00 00 00

10

10

1010

27 0B 01 02 0E 00 00 78 0A 34 70 95 59 4F 88 26

20

20

2020

15 4A 53 FF FF 80 31 59 45 59 61 59 71 59 81 4F

30

30

3030

81 99 A9 4F 01 01 EA 24 00 60 41 00 28 30 30 60

40

40

4040

13 00 00 00 00 00 00 1E F9 15 20 F8 30 58 1F 20

50

50

5050

20 40 13 00 00 00 00 00 00 1E 00 00 00 FD 00 32

60

60

6060

78 0F 64 0A 00 0A 20 20 20 20 20 20 00 00 00 FC

70

70

7070

00 4F 4E 4B 59 4F 20 44 4C 56 31 30 30 0A 00 E2

34

45

33

44

56

67

55

66

78

89

77

88

9A

AB

99

AA

BC

CD

BB

CC

DE

EF

DD

EE

DLV-100

F

FF

4.14 Safety test

(1)Dielectric strength test

By the test vessel, under the condition of main power supply ON,

Apply AC voltage of 1500V(+50/-0) ,at 50Hz or 60Hz for 1.5~2 second between power supply

circuit part(AC) and exposure metal part.

No insulation destruction, catching fire, and so on is allowed.

(2) Insulation resist ance test

Measure insulation resistance between power supply circuit part(AC) and exposure metal

part (FG) under the condition of main power ON(Stand By mode) by using 500V insulate

ohmmeter.

Insulation resistance shall be more than 50M ohm.

(3)Leakage electric current test

Measure leakage electric current by the leakage ammeter under the condition of main power

supply ON (Standby condition). The measurement impedance should be measured by

the build in resistor of 1.5KΩ, with the bypass capacitor of 0.15μF.

The leakage electric current should be less than 2mA each.

4.15 Signal table

Refer to Tab.2.

Page 5

5. Optical specifications

5. Optical specifications

5. Optical specifications5. Optical specifications

5.1 Brightness

Normal : 630 ANSI lumens minimum

High Brightness : 750 ANSI lumens minimum

(It contains 5 % of measurement tolerance.)

5.2 Contrast ratio

700 : 1 typical

(It contains 20 % of measurement tolerance.)

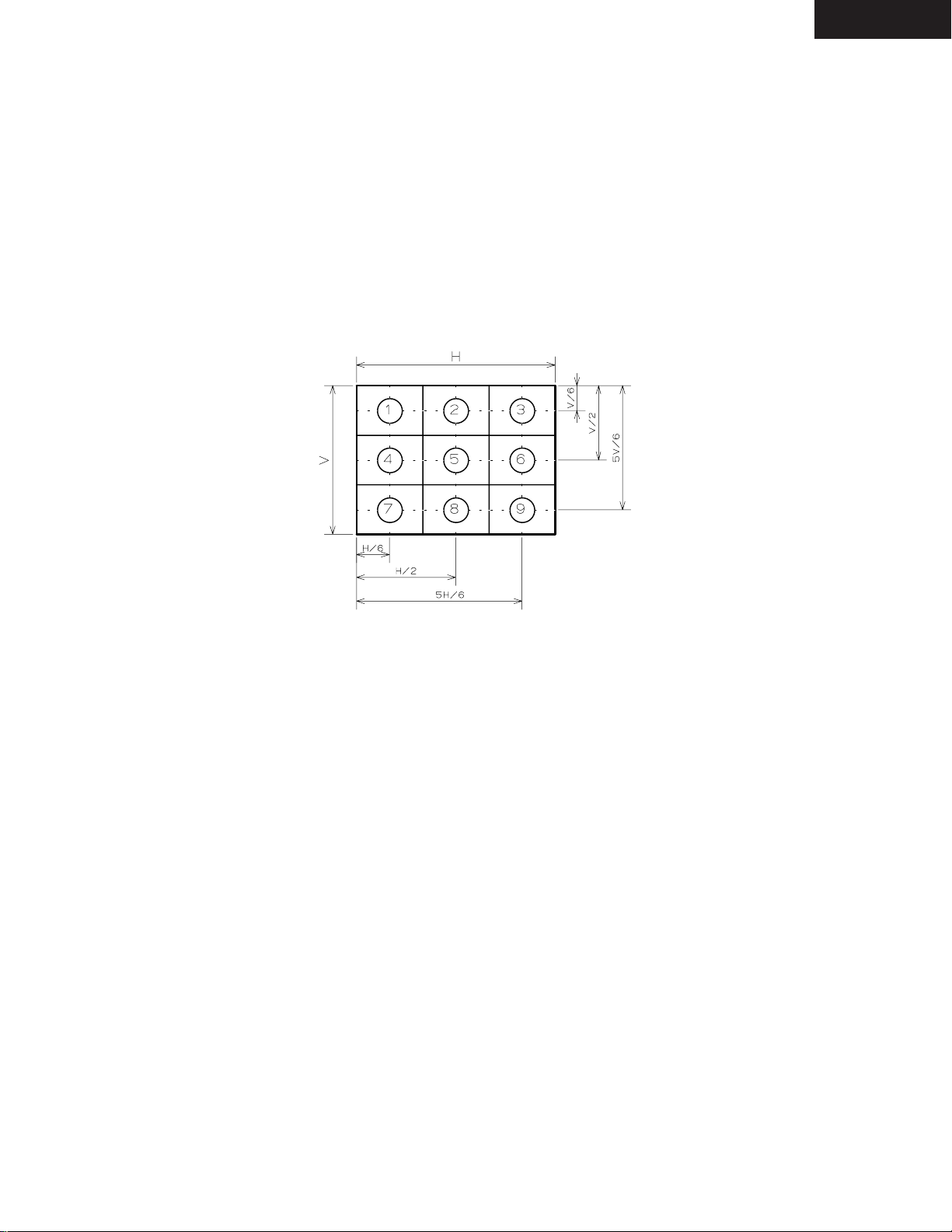

5.3 Relative illumination

More than 70%

On the screen which is shown in figure 2, apply following formula with condition of

Aj as the illumination of point j.

Relative illumination = ( A1 + A3 + A7 + A9 ) / ( 4 x A5 ) x 100 [%]

DLV-100

Fig.2 The measurement point

5.4 Chromaticity

x=0.234 – 0.344(0.289 +/- 0.055)

y=0.269 – 0.379(0.324 +/- 0.055)

5.5 Throwing angle

14.3 degree(+/- 5%)

5.6 Projection size

Min. 30 inch / 1.16 m (wide)

Max. 200 inch / 9.67 m (tele)

(For the details, refers to Tab.3.)

5.7 Geometry distortion

Less than 1.11%

5.8 Pixel defects and blemishes

1. No adjacent dark pixels.

2. No bright pixels.

3. No unstable pixels.

4. ≦ 5 dark pixels.

5. ≦ 7 blemishes

6. No dark blemishes.(Using the blue 180 screen)

7. No bright blemishes.(Using the gray 35 screen)

Note) Blue 180 screen

All areas of the screen are colored a Microsoft paintbrush blue 180(green and red set at 0).

Note) Gray 35 screen

All areas of the screen are colored a Microsoft paintbrush gray 35(green, red, and blue set

at 91).

5.9 Stray light

In all the black signals , a thing with no stray light in the inside of the display area.

Page 6

6. Mechanical specifications

6. Mechanical specifications

6. Mechanical specifications6. Mechanical specifications

6.1 Dimensions

243 (w) x 196 (D) x 53 (H)

Not including lens, feet and prominence.

6.2 Weight

1.5 Kg / 3.3 Lbs

6.3 Outside figure

Refer to the separate sheet (drawing number 2410447_)

There shall be no scratch and dirt, which becomes a problem for actual use.

6.4 Tilt foot

5 degree adjustable (Front foot)

6.5 Fan noise

39dB (Normal) / 43 dB (High)

The way of measuring and the measurement condition is based on the following.

“Guidelines for LCD Projector Measuring Procedures and Measuring Conditions”

Established in June 1999

Issued by Japan Business Machine Makers Association

Data Projector Committee

URL http://www.jbma.or.jp

6.6 After cooling

90 sec, approx.

DLV-100

7. Safety and EMC regulations

7. Safety and EMC regulations

7. Safety and EMC regulations7. Safety and EMC regulations

7.1 Safety regulations

UL1950, CSA950

7.2 EMC regulations

FCC Class B

8. Accessories

8. Accessories

8. Accessories8. Accessories

Power Cable, RGB Signal Cable, Remote Control, Batteries AAx2, Lens Cap, String & Rivet,

Soft Carrying Case, Manual, Quick Connect Guide, Warranty Card (Refer to PA_DLV100.pdf)

Page 7

9. Packing specifications

9. Packing specifications

9. Packing specifications9. Packing specifications

9.1 Packing dimensions

366 (W) x 465 (D) x 197 (H)

9.2 Packing weight

5.0 Kg

9.3 Packing method

Refer to Fig.5.

10. Doubtful point

10. Doubtful point

10. Doubtful point10. Doubtful point

When doubtful point occurred to this specification and when changes will become necessary,

ONKYO and NEC Viewtechnology, Ltd. shall discuss each other and shall

issue a revised spec.

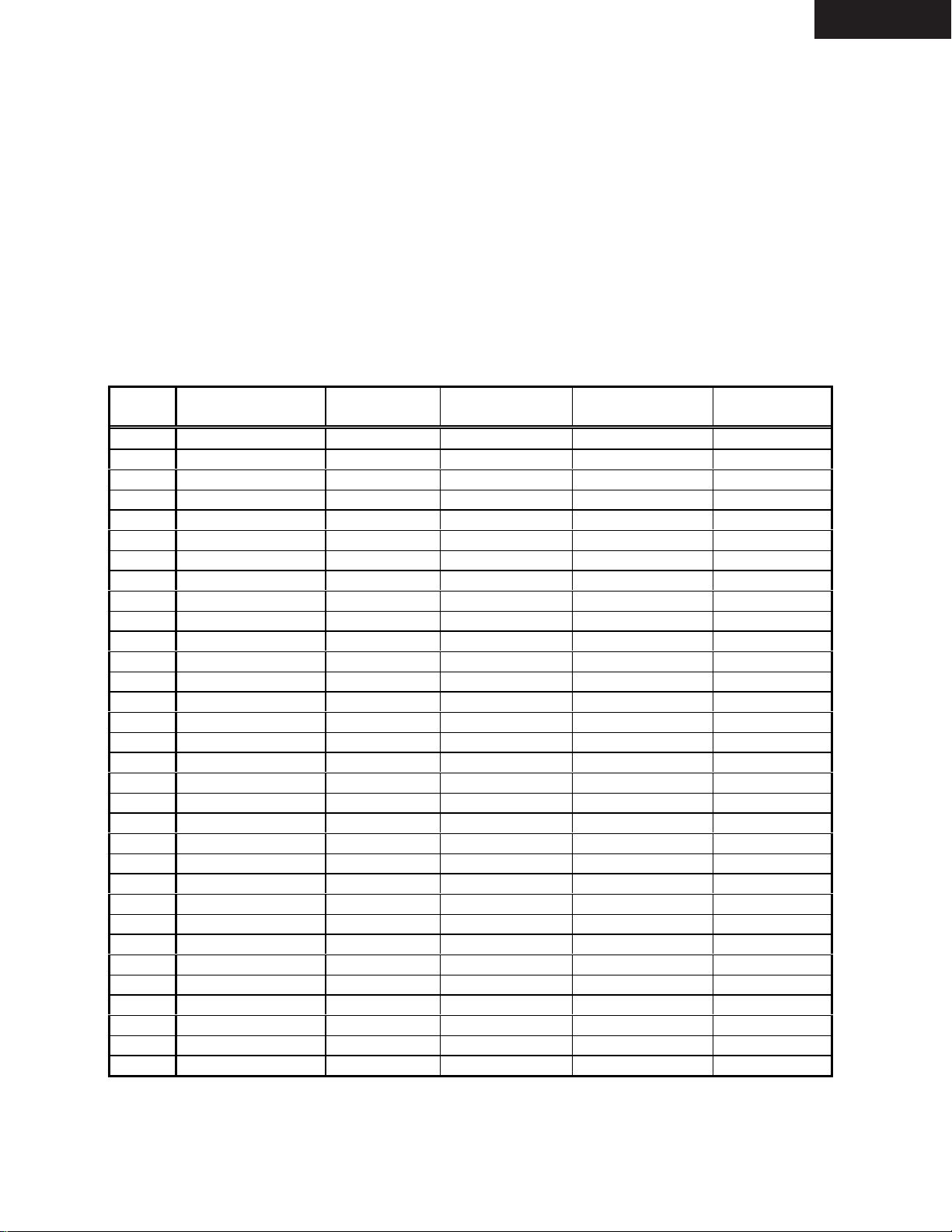

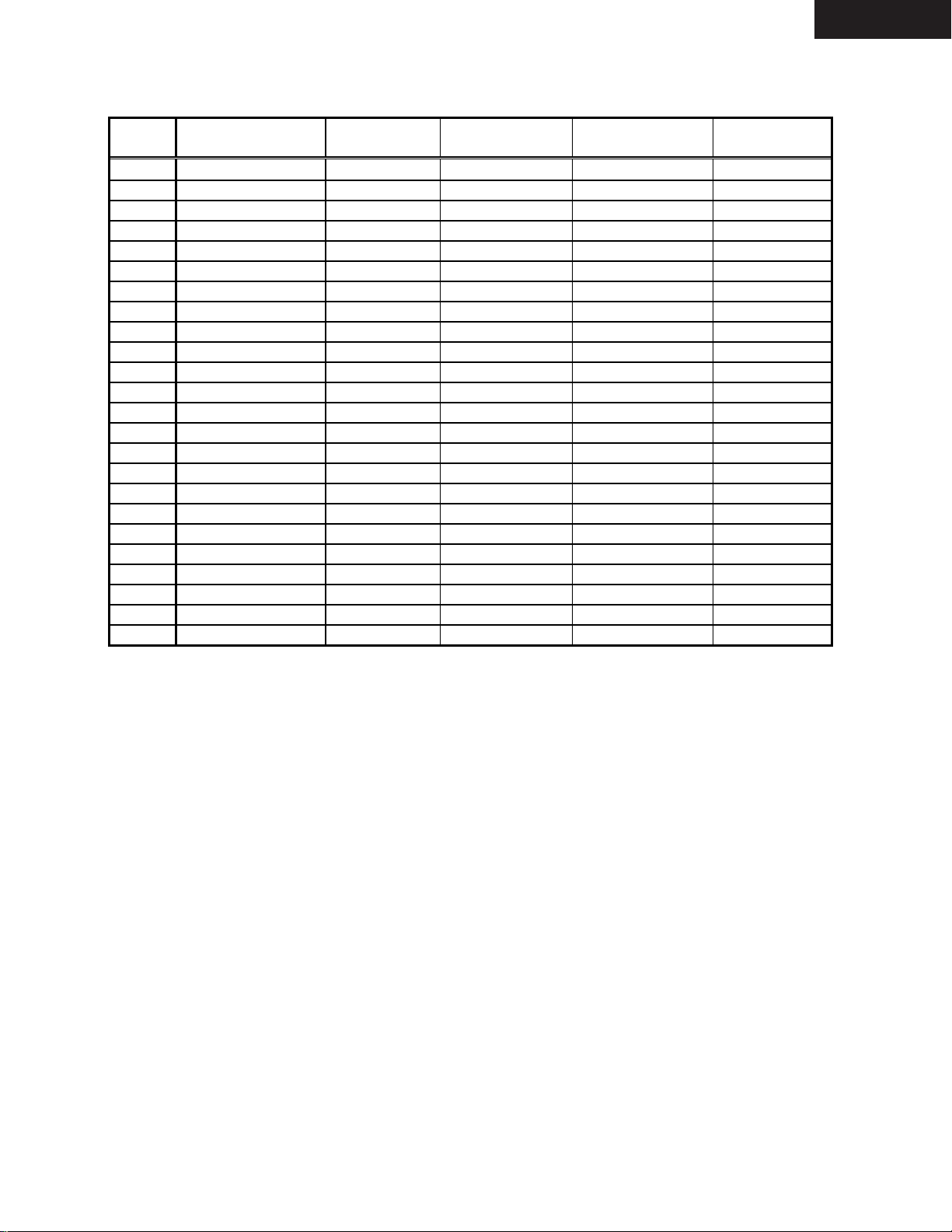

Tab.2 Signal table

No. Signal

1 NTSC 15.734 60 2 PAL 15.625 50 3 PAL60 15.734 60 4 SECAM 15.625 50 5 VESA 640 x 350 37.86 85.08 31.5

6 NEC 640 x 400 24.83 56.43 21.053

7 MAC 640 x 400 35 66 30.24

8 NEC 640 x 400 31.47 70 25.175

9 IBM 640 x 400 31.47 70 25.175

10 VESA 640 x 400 37.86 85.08 31.5

11 VESA 640 x 480 31.47 59.94 25.175

12 IBM 640 x 480 31.47 60 25.175

13 MAC 640 x 480 31.47 60 25.175

14 NEC 640 x 480 31.47 60 25.175

15 MAC 640 x 480 34.97 66.67 31.334

16 MAC 13" 640 x 480 35 66.67 30.24

17 VESA 640 x 480 37.86 72.81 31.5

18 VESA 640 x 480 37.5 75 31.5

19 IBM 640 x 480 39.375 75 31.49

20 VESA 640 x 480 43.269 85.01 36

21 IBM 720 x 350 31.469 70.09 28.322

22 VESA 720 x 400 37.927 85.04 35.5

23 IBM 720 x 350 39.44 87.85 35.5

24 IBM 720 x 400 39.44 87.85 35.5

25 VESA 800 x 600 35.16 56.25 36

26 VESA 800 x 600 37.879 60.32 40

27 VESA 800 x 600 48.077 72.19 50

28 VESA 800 x 600 46.88 75 49.5

29 VESA 800 x 600 53.674 85.06 56.25

30 MAC 16" 832 x 624 49.725 74.55 57.283

31 VESA 1024 x 768 35.5 43 INT 44.9

32 VESA 1024 x 768 48.363 60 65

Resolution

(dots)

H Frequency

(KHz)

V Refresh Rate

(Hz)

DLV-100

Dot Clock

(MHz)

Page 8

DLV-100

No. Signal

33 VESA 1024 x 768 57.476 70.07 75

34 MAC 19" 1024 x 768 60.241 74.93 80

35 VESA 1024 x 768 60.023 75.03 78.75

36 VESA 1024 x 768 68.677 85 94.5

#37 VESA 1152 x 864 67.5 75 108

#38 MAC 21" 1152 x 870 68.681 75.06 100

#39 SUN 1152 x 900 61.796 65.95 92.94

#40 SGI 1152 x 900 71.736 76.05 105.6

#41 VESA 1280 x 960 60 60 108

#42 VESA 1280 x 960 85.94 85 148.5

#43 VESA 1280 x 1024 63.981 60.02 108

#44 MAC(1280EG) 1280 x 1024 69.87 65.18 118.5

#45 NEC(EWS4800) 1280 x 1024 75.12 71.2 125

#46 VESA 1280 x 1024 79.976 75.03 135

#47 VESA 1280 x 1024 91.146 85.02 157.5

#48 VESA 1600 x 1200 75 60.0 162

#49 VESA 1600 x 1200 81.25 65.0 175.5

#50 VESA 1600 x 1200 87.5 70.0 189

#51 VESA 1600 x 1200 93.75 75.0 202.5

#52 HDTV (1080i) 1920 x 1080 33.75 60 Interlace 74.25

#53 HDTV (720p) 1280 x 720 45 60Progressive 74.25

54 SDTV (480p) 720 x 483 31.47 59.94 Progressive 27

55 DVD YCbCr 15.734 59.94 Interlace 56 DVD YCbCr 15.625 50 Interlace -

# Images are compressed by Advanced AccuBlend

Only separate sync is available for UXGA signals.

Resolution

(dots)

H Frequency

(KHz)

V Refresh Rate

(Hz)

Dot Clock

(MHz)

Page 9

Tab.3 Projection size and throwing angle

C

D

H

Screen Size

a

Diagonal

(inch) (mm)

Projection

Distance

HED g C

Width

(mm)

a/5*4

Height

(mm)

a/5*3

Half

height

(mm)

E/2

Projector

base to

lens center

(mm)

Distance

(mm)

Wide Tele

α

Degree

tan

1

(D+B/

C)

-

Screen

bottom

BC

Height of

Screen

Bottom

(mm)

Projection

Distance

Distance

(mm)

α

Degree

tan

1

(D+B/

C)

-

Screen

bottom

B

Height of

Screen

Bottom

(mm)

30 762 610 457 229 1158 14.7 77 1411 12.2 78

40 1016 813 610 305 1560 14.6 103 1897 12.1 104

60 1524 1219 914 457 2363 14.4 154 2869 12 155

80 2032 1626 1219 610 3167 14.4 206 3841 12 207

100 2540 2032 1524 762 3971 14.3 257 4813 12 259

38

120 3048 2438 1829 914 4775 14.3 309 5785 11.9 311

150 3810 3048 2286 1143 5981 14.3 386 7243 11.9 389

180 4572 3658 2743 1372 7186. 14.3 463 8701 11.9 466

200 5080 4064 3048 1524

7990 14.3 515 9673 11.9 518

( Note )

The value in the table is a design value including +/- 5 % tolerance

DLV-100

Screen center

A

α

Screen bottom

Ground line

Fig.4 Projection figure

Projection Screen

E

a

B

g

Page 10

SAFETY PRECAUTIONS

CAUTION

DLV-100

RISK OF ELECTRIC SHOCK

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE

COVER. NO USER-SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

This symbol warns the user that uninsulated voltage within the unit may

have sufficient magnitude to cause electric shock. Therefore, it is dangerous

to make any kind of contact with any part inside of this unit.

This symbol alerts the user that important literature concerning the

operation and maintenance of this unit has been included.

Therefore, it should be read carefully in order to avoid any problems.

DO NOT OPEN

ATTENTION

RISQUE D'ELECTROCUTION

NE PAS OUVRIR

MISE EN GARDE: AFIN DE REDUIRE LES RISQUES D' ELECTROCUTION, NE PAS

DEPOSER LE COUVERCLE, IL N'Y A AUCUNE PIECE

UTILISABLE A L'INTERIEUR DE CET APPAREIL. NE CONFIER

LES TRAVAUX D'ENTRETIEN QU'A UN PERSONNEL QUALIFIE.

Ce symbole a pour but de prévenir I' utilisateur de la présence d'

une tension dangereuse, non isolée se trouvant à l' intérieur de l'

appareil. Elle est d' une intensité suffisante pour constituer un risque

d' électrocution. Eviter le contact avec les pièces à l' intérieur de

cet appareil.

Ce symbole a pour but de prévenir l' utilisateur de la présence d'

importantes instructions concernant l' entretien et le fonctionnement

de cet appareil. Par conséquent, elles doivent être lues

attentivement afin d' éviter des problèmes.

Page 11

SAFETY PRECAUTIONS

DLV-100

During servicing carefully observe the following.

1. OBSERVE ALL PRECAUTIONS

Items and locations that require special care during servicing, such as the cabinet, chassis, and parts are labelled

with individual safety instructions. Carefully comply with

these instructions and all precautions in the instruction

manual.

2. BE CAREFUL OF ELECTRIC SHOCK

The chassis carries an AC voltage. If you touch the

chassis while it is still alive, you will get a severe shock.

If you think the chassis is alive, use an isolating

transformer or gloves, or pull out the plug before

replacing any parts.

3. USE SPECIFIED PARTS

The components have been chosen for minimum

flammability and for specific levels of resistance value

and withstand voltage. Replacement parts must match

these original specifications. Parts whose specifications

are particularly vital to safe use and maintenance of the

set are marked on the circuit diagrams and parts list.

Substitution of these parts can be dangerous for you

and the customer, so use only specified parts.

4. REMOUNT ALL PARTS AND RECONNECT ALL

WIRES AS ORIGINALLY INSTALLED

For safety, insulating tape and tubes are used

throughout, but some lift-off parts on the printed wiring

board require special attention.

All wires are positioned away from high-temperature and

high-voltage parts, and, if removed for servicing, they

must be retuned precisely to their original positions.

5. LAMP

Be very careful of the lamp because it generates high

heat while it is used at high voltage. When replacing

the bulb, make sure it is cool enough.

6. LENS

Do not look into the lens during projection. This important

to avoid damage to the eyes.

7. SERVICING

At the time of repair or inspection services, use an earth

band (wrist band), without fail.

8. RUN A COMPLETE SAFETY CHECK AT THE

COMPLETION OF SERVICING

After completion of servicing, confirm that all screws,

parts, and wiring, removed or disconnected for servicing,

have been returned to their original positions. Also

examine if the serviced sections and peripheral areas

have suffered from any deterioration as a result of

servicing. In addition, check insulation between external

metallic parts and blades of wall-outlet plugs. This

examination is indispensable in confirming complete

establishment of safety.

(Insulation check)

Pull out a plug from a wall outlet to disconnect the

connection cable. Then turn on the POWER switch.

Use a 500V megger (Note 2) and confirm that the

insulation resistance is 1MΩ or more between each

terminal of the plug and exposed external metal (Note

1). If the measured value is below the specified level,

then it is necessary to inspect and fix the set.

(Note 1)

Exposed external metal....RGB input terminals, control

terminals, etc.

(Note 2)

If a 500V megger is not available for an unavoidable

reason, then use a circuit tester or the like for inspection.

Page 12

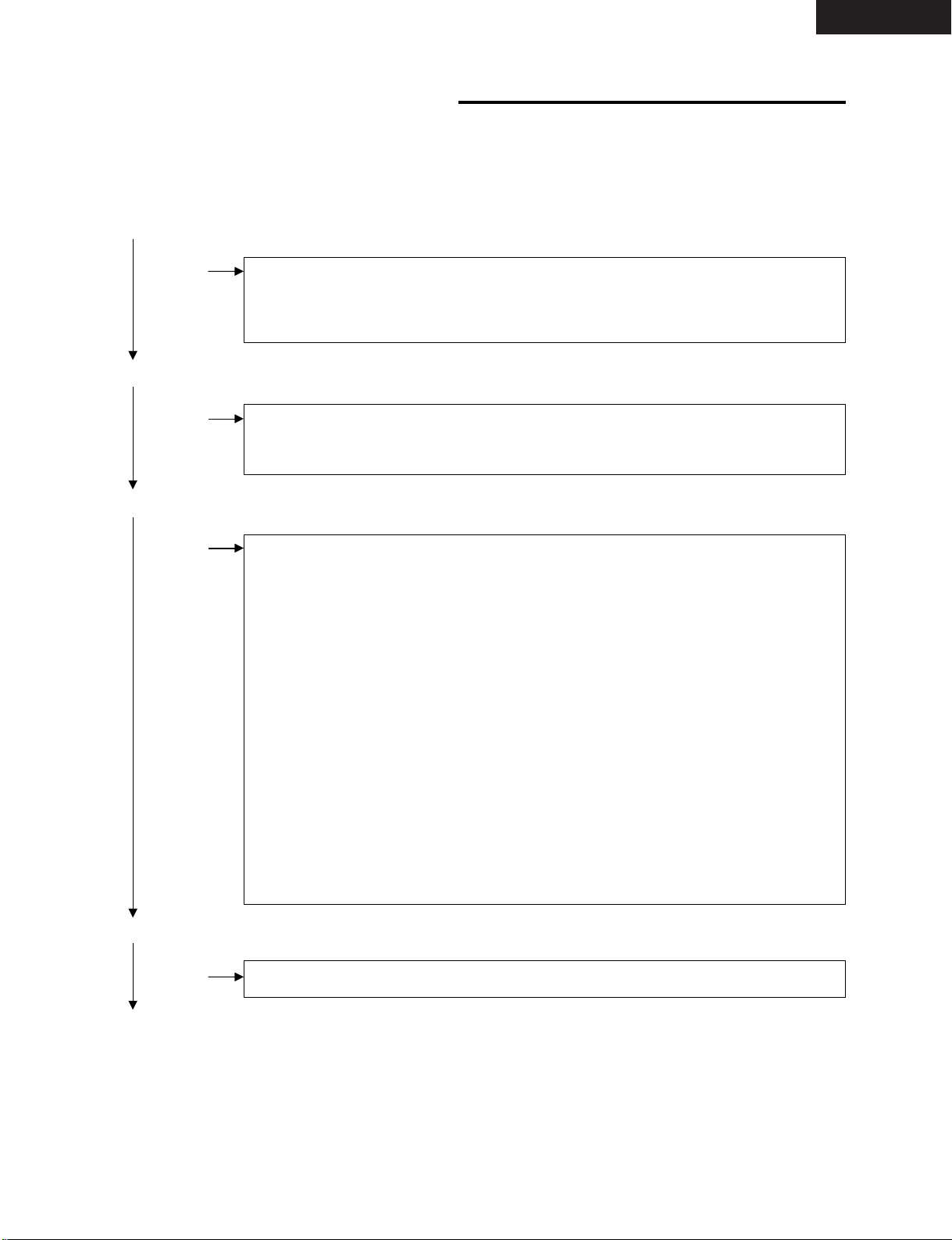

TROUBLESHOOTING

1. Operation check

A certain degree of diagnosis can be carried out by examining the equipment operation in the state of ordinary

usage.

Prior to the removal of the top cover, check the points shown below.

• Is the POWER indicator lit in orange when in standby?

No • The POWER cord is not correctly inserted.

• A connector (POPA, POPB, POSW) is pulled out.

• The POWER unit is defective.

• The MAIN PWB, SUB PWB, or the membrane switch is defective.

Yes

• Is the POWER indicator lit in green when POWER is ON?

No • The lamp’s life has expired. (The STATUS indicator is lit.)

• The connector (POSW) is pulled out.

• The optical engine is defective.

Yes

DLV-100

• Is the STATUS indicator flashing?

Yes • The lamp fails to light. (Flash in a 12-second cycle. ON for 6 seconds and OFF for

6 seconds)

• The lamp is broken. (Flash in a 12-second cycle. ON for 6 seconds and OFF for 6

seconds)

• Connector (PODB or DC) is pulled out. (Flash in a 12-second cycle. ON for 6 seconds and OFF for 6 seconds)

• Connector (POFA or POFB) is pulled out. (Flash in an 8-second cycle. ON for 4

seconds and OFF for 4 seconds)

• The fan stops due to failure or intrusion of foreign substance. (Flash in an 8-second

cycle. ON for 4 seconds and OFF for 4 seconds)

• Deviation from the range of normal operating ambient temperature conditions. (Flash

in a 4-second cycle. ON for 2 seconds and OFF for 2 seconds)

• The connector (POLA) is pulled out. (Flash in a 4-second cycle. ON for 2 seconds

and OFF for 2 seconds)

• The lamp house is dislodged. (Flash in a 1-second cycle. ON for 0.5 seconds and

OFF for 0.5 seconds)

• The connector (POLB) is pulled out. (Flash in a 1-second cycle. ON for 0.5 seconds

and OFF for 0.5 seconds)

• The POWER unit or peripheral circuits of the CPU are defective.

No

• Is the STATUS indicator lit?

Yes • Lamp timer has reached 1000 hours.

No

• CPU’s peripheral circuit malfunction. Breakage of programs and data.

Page 13

TROUBLESHOOTING

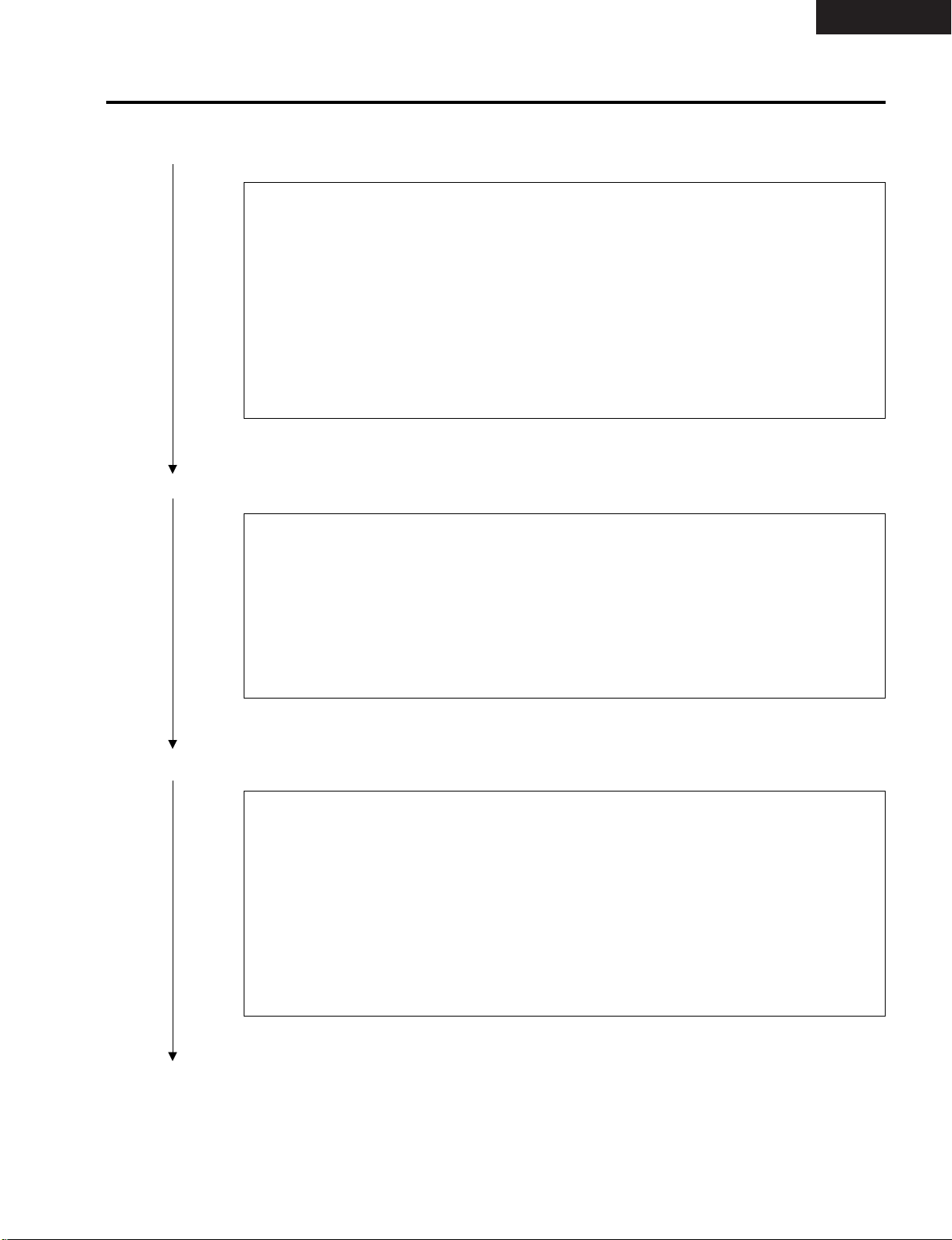

2. MAIN PWB, SUB PWB (PWC-4448A)

• Are the following voltage inputs available at POPA (connection between POWER unit and POPA)?

Pin No. Related circuits

1 +12V AUDIO circuit

2 GND GND

3 +5V RGB, VIDEO signal processing system

4 +5V RGB, VIDEO signal processing system

5 GND GND

6 GND GND

7 +5V CPU, FLASHROM, DRAM, G/A

8 +5V CPU, FLASHROM, DRAM, G/A

9 GND GND

10 GND GND

11 —

No → Connections of the POPA connector are defective. The POWER unit is defective.

Yes

DLV-100

• Are the following voltage inputs available at POPB (connection between POWER unit and POPB)?

Pin No. Related circuits

1 +12V Fan and formatter board

2 GND FANGND

3 +3.3V Formatter board

4 +3.3V Formatter board

5 +3.3V Formatter board

6 GND GND

7 GND GND

8 GND GND

No → Connections of the POPB connector are defective. The POWER unit is defective.

Yes

• Are the following signal outputs available at PODA (connection between Optical Engine unit and PODA)?

Pin No.

6, 8, 10, 12, 14, 16, 18 +3.3V

61, 63, 65 +12V

67, 69, 71 +5V

92 Horizontal sync signal (TTL)

31 Vertical sync signal (TTL)

33 Enable signal (TTL)

35 Clock sync signal (TTL)

37, 39, 41, 43, 96, 98, 100, 102 B-ch signal (TTL)

45, 47, 49, 51, 104, 106, 108, 110 R-ch signal (TTL)

53, 55, 57, 59, 114, 116, 118, 120 G-ch signal (TTL)

No → Connections of the PODA connector are defective. The MAIN or SUB PWB is defective.

Yes

• Optical engine unit out of order

• Miscellaneous. Problem in the MAIN and SUB PWBs.

Poor contact in the connector (POMA1–POMA2, POMB1–POMB2) between MAIN PWB and SUB PWB.

Inadequate soldering or cracks in PWB.

Page 14

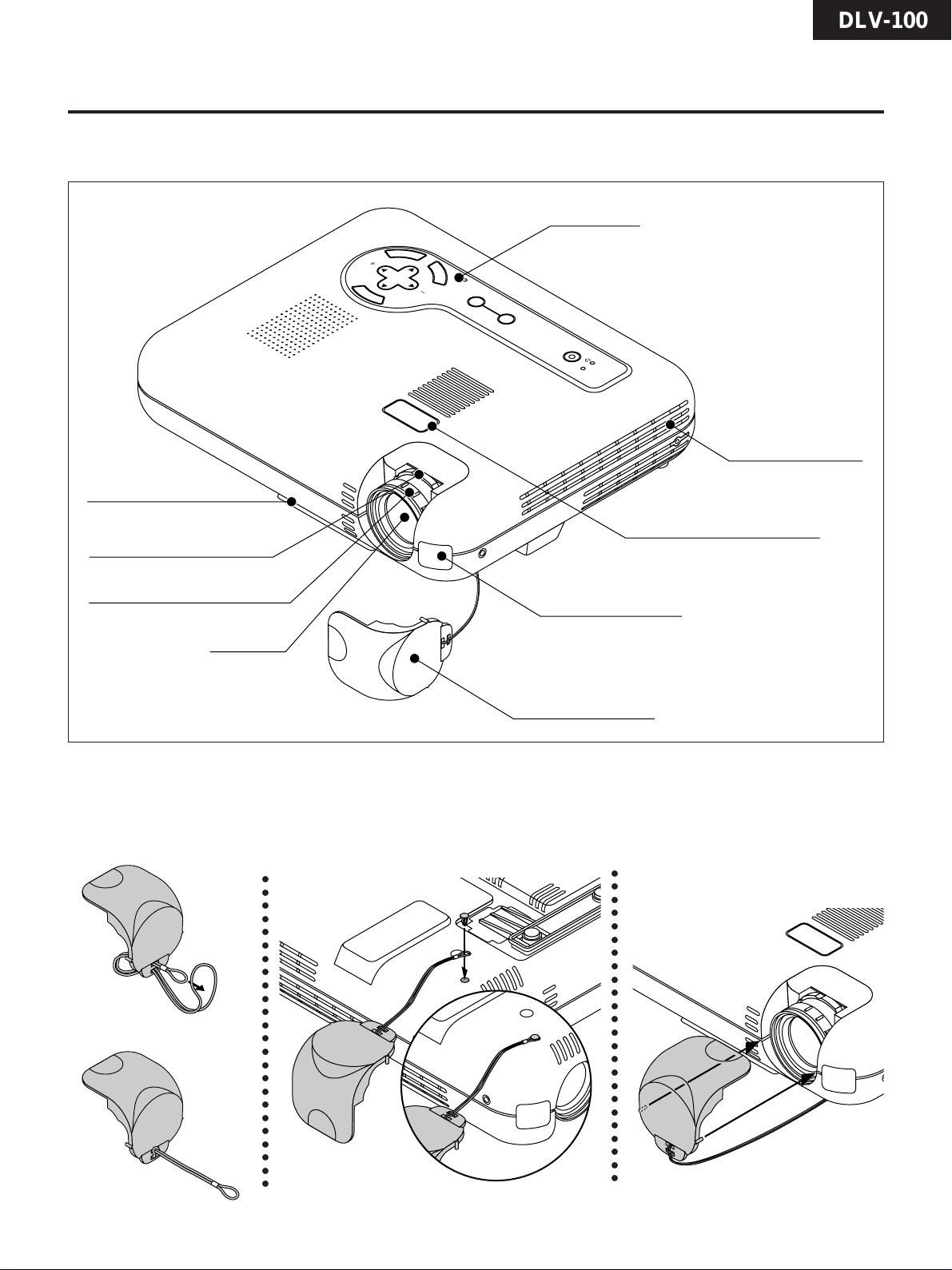

Getting to Know Your Projector DLV-100

DLV-100

Front/ Side Features

Adjustable Tilt Foot

Zoom Ring

Focus Ring

Lens

Controls

L

E

C

N

A

C

R

E

T

N

E

SELECT

U

N

E

M

AUTO

ADJUST

PC CARD ACCESS

SOURCE

STAND BY

ON/

POWER

STATUS

Ventilation (inlet)

Adjustable Tilt Foot Button

Remote Sensor

Lens Cap

Attaching the lens cap to the lens hood with the supplied string and rivet

1. Thread the string through the hole on the lens cap and then tie a knot in the string.

2. Use the rivet to attach the string to the bottom of the lens hood.

○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○

Attaching the lens cap

Page 15

Rear/ Side Features

Monaural Speaker (1W)

POWER

STATUS

ON/

STAND BY

DLV-100

SOURCE

AUDIO

Remote Sensor

Terminals and PC card

AC Input

Bottom

PC CARD ACCESS

RGB

S-VIDEO

PC CONTROL

VIDEO

USB

PC CARD

Slot for Kensington

MicroSaver

Security System

Rear Foot

Rotate to fine-adjust horizontally

position

Lamp cover

AUTO

ADJUST

AC IN

M

E

N

U

SELECT

E

N

T

E

R

C

A

N

C

E

L

Ventilation (inlet)

Ventilation (outlet)

Heated air is exhausted from here

Rear Foot

Spacer (black rubber)

Spacer (black rubber)

To fine-adjust the height of the rear foot, remove

the spacer and rotate the rear foot to the desired

height.

Ventilation (inlet)

Lamp cover screw

Rear Foot

(not adjustable)

NOTE: The projector has an internal temperature sensor. The sensor controls the speed of the fan to keep

constant temperature in the inside.

When the internal temperature rises, the built-in fan automatically runs at a high speed (high-speed mode).

During this time, the sound of exhaust may be heard.

This is not a malfunction.

Page 16

DLV-100

STATUS

2

ON/

STAND BY

Top Features

POWER

3

1

AUDIO

RGB

S-VIDEO

PC CONTROL

VIDEO

USB

1. Power Button (ON / STAND BY)

Use this button to turn the power on and off when the power is

supplied and the projector is in standby mode.

2. Status Indicator

When this is lit red continually, it's warning you that the projection

lamp has exceeded 1500 hours (1000 hours in High-Bright mode)

of service. After this light appears, it is advisable to replace the

projection lamp as soon as possible. (See page 44). In addition the

message "The lamp has reached the end of its usable life. Please

replace the lamp!!." appears continually until the lamp is replaced.

If this light blinks red rapidly, it indicates that the lamp cover is not

attached properly or the projector is overheated.

See the Power/Status Light Messages on page 45 for more details.

3. Power Indicator ( )

When this indicator is green, the projector is on; when the indicator is orange, it is in standby mode.

4. Source Button

Use this button to select a video source such as a PC, VCR, DVD

player or PC Card Viewer (CompactFlash card).

Each time this button is pressed, the input source will change as

follows:

→ RGB → Video → S-Video → PC Card Viewer

If no input signal is present, the input will be skipped.

SOURCE

PC CARD

4

5

10

9

PC CARD ACCESS

AUTO

ADJUST

M

E

N

U

C

A

SELECT

N

C

E

L

E

N

T

E

R

6

7

8

5. Auto Adjust Button (RGB only)

Use this button to adjust Position-H/V and Pixel Clock/Phase for

an optimal picture. Some signals may not be displayed correctly or

take time to switch between sources.

6. PC Card Access Indicator

Lights while accessing a CompactFlash memory card.

7. Enter Button

Executes your menu selection and activates items selected from

the menu.

8. Cancel Button

Press this button to exit "Menus". Press this button to return the

adjustments to the last condition while you are in the adjustment

or setting menu.

9. Select (▲▼ ) / Volume (+) (–) Buttons

▲▼: Use these buttons to select the menu of the item you wish

to adjust.

When no menus appear, these buttons work as a volume

control.

: Use these buttons to change the level of a selected menu

item.

A press of the button executes the selection.

When the menus or the Viewer tool bar is not displayed,

these buttons can be used to select a slide, or to move the

cursor in Folder List or Slide List.

When the magnifying glass is displayed, these ▲▼

buttons move the magnifying glass.

10. Menu Button

Displays the menu.

Page 17

Terminal Panel Features

TU

PO

1

AUDIO

RGB

WER

2

S-VIDEO

PC CONTROL

DLV-100

S

ON/

STAND BY

3

SOURCE

4

PC CARD ACCESS

5

VIDEO

AUTO

ADJUST

6

M

E

N

U

C

A

SELECT

N

C

E

L

E

N

T

E

R

USB

7

8

1. Audio Input Mini Jack (3.5 mm ∅)

This is where you connect audio output from your computer, VCR,

DVD player or laser disc player.

A commercially available audio cable is required.

2.

RGB Input/ Component Input Connector (Mini D-Sub 15 pin)

Connect your PC or other RGB equipment such as IBM or compatible computers. Use the supplied RGB cable to connect to a PC.

Or connect a Macintosh computer here using the supplied RGB

cable. This also serves as a component input connector that allows

you to connect a component video output of component equipment such as a DVD player.

3. S-Video Input (Mini DIN 4 Pin)

Here is where you connect the S-Video input from an external source

like a VCR.

NOTE: S-Video provides more vivid color and higher resolution than the

traditional composite video format.

4. Video Input (RCA)

Connect a VCR, DVD player, laser disc player, or document camera here to project video.

5. PC Card Eject Button

Press to eject a CompactFlash memory card.

6. PC Card Slot

Insert a CompactFlash memory card here.

7. PC Control Port (Mini DIN 8 Pin)

Use this port to connect your PC to control your projector via a

serial cable. This enables you to use your PC and serial communication protocol to control the projector.

PC CARD

AC IN

9

If you are writing your own program, typical PC control codes are

on the back cover page.

A cap is put on the port at the factory. Remove the cap when using

the port.

8. USB Terminal

Connect a commercially available mouse that supports USB. You

can operate the menu or PC Card Viewer with the USB mouse via

this terminal.

Note that this terminal is not used with a computer and that there

may be some brands of USB mouse that the projector does not

support.

9. AC Input

Connect the supplied power cable's three-pin plug here. When you

plug the other end into an active wall outlet, the POWER indicator

turns orange and the projector is in standby mode.

10. Built-in Security Slot (

This security slot supports the MicroSaver® Security System.

MicroSaver® is a registered trademark of Kensington Microware

Inc.

The logo is trademarked and owned by Kensington Microware Inc.

10

)

Page 18

5

6

4

0

DLV-100

Remote Control Features

1. Infrared Transmitter

Direct the remote control toward the remote sensor on the projector cabinet.

2. Standby/On Button

If the main power is applied, you can use this button to turn your

projector on or put it in standby.

3. S-Video Button

Press this button to select an S-Video source from a VCR.

4. Video Button

Press this button to select an NTSC, PAL, SECAM or NTSC4.43

compatible video source from a VCR, DVD player, laser disc player

or document camera.

5. RGB Button

Press this button to select a video source from computer or component equipment connected to your RGB port.

6. Auto Adjust Button

Use this button to adjust an RGB source for an optimal picture.

Some signals may not be displayed correctly or take time to switch

between sources.

Supplied Remote Control

5

6

7

11

12

13

17

INPUT

1

2

3

4

8

9

1

1

1

1

7. Magnify + - Buttons

Use this button to adjust the image size up to 400%.

To change the position of the magnified screen, press one of the

▲▼

8. Volume + - Buttons

Press + button to increase the volume and - button to decrease

it.

9. ASPECT Button

Press this button to select the screen size.

10. Mute Button

This button turns off an image and sound for a short period of time.

Press again to restore the image and sound.

NOTE: When the menu is displayed, a press of this button mutes an image

and sound without turning off the menu.

11. PICTURE Button

Press this button to recall and display the screen-related menu.

12. Freeze Button

This button will freeze a picture. Press again to resume motion.

13. Menu Button

Displays the menu for various settings and adjustments.

14. LAMP RESET Button

If the lamp has been turned on for more than 1,600 hours (Normal

mode), the power to the unit will be cut off and no messages will

be displayed. Press and hold down this button for 10 seconds or

more while the unit is in stand-by mode to clear the lamp available

time and the lamp usage time.

buttons to recall the magnifying glass, then use the ▲▼

buttons to move the screen.

15. ▲▼

▲,▼: Use these buttons to select the menu of the item you wish

16. Cancel Button

Press this button to exit "Menus". Press this button to return to the

previous menu without storing the current settings or adjustments

when you are in the submenu or adjustment screen.

17. Enter Button

Press this button to execute the selected item. When this is pressed,

the adjustments and settings are saved, and the display is returned

to the menu.

(Select) Buttons

to adjust.

, : Use these buttons to change the level of a selected menu

item.

A press of the button executes the selection.

When the magnifying glass is displayed, these ▲▼

buttons move the magnifying glass.

Page 19

DISASSEMBLY

• In regard to the part name and the part number of each symbol,

DLV-100

M08

E02

M01

M07

M03

S05

S07

M13

M14

E04

S05

S05

E06

M22

M11

M21

S05

E05

S05

M19

M11

M20

S05

M12

A02

E11

E10

S05

S05

S01

E08

S13

S08

S08

M17

S14

M23

S12

S08

S08

M16

M46

S11

M18

S08

E07

E09

please refer to the parts table.

S15

S05

S10

M15

E12

S16

S09

S08

M04

S16

M28

M29

M30

M34

E14

M33

A03

E13

S05

M10

S05

M32

S17

M36

S18

M05

M06

S06

S02

A01

M09

S03

S04

M27

E01

M26

S01

M26

M25

S01

M24

S01

M26

S08

E03

M47

M31

S05

M37

M48

S05

M45

M38

S05

M43

S05

M42

S05

M35

M40

M44

M39

M41

Page 20

DLV-100

BLOCK DIAGRAMS

Page 21

DLV-100

Page 22

DLV-100

Page 23

DLV-100

Page 24

DLV-100

Page 25

DLV-100

Page 26

DLV-100

Page 27

DLV-100

Page 28

DLV-100

Page 29

DLV-100

Page 30

DLV-100

CONNECTION DIAGRAMS

Page 31

REPLACEMENT PART LIST

DLV-100

C-No Description Part number

PWB ASSYS

E08 MAIN PWB ASSY 81E94FA1

E07 SUB PWB ASSY 81E94FB1

E03 REM PWB ASSY 81E94FC1

ELECTRICAL PARTS & MISCELLANOUS PARTS

4 POWER SUPPLY(BALLAST) 3N100131

5 POWER SUPPLY(DC) 3N100002

E05 FAN (LAMP) 3N170021

E06 FAN (PSU) 3N170022

SW5501 POWER SWITCH LM3525MX-H 3N7J0001

SPEAKER 20*35MM 8H 1W 6N300004

CN3P(RM)105W,1685-26 7NW3W005

CN8P(PB)175W,1685-26 7NW8W001

CN11P(PA)65W,1685-26 7NWAW001

M37 ZOOM LENS(01 DLP) 12JS2691

M24 BOTTOM COVER BK ASSY 24PS2901

COVER(LENS Z) 24F35271

M47 FILTER(F) 24F32641

CAP(PC CONTROL) 24F32691

M03 PANEL(FAN B) 24F34621

M09 HOLDER(BALLAST B) 24F34641

21 HOLDER(FAN 20) 24F34651

M48 LENS CAP ZK 24F35641

TERMINAL PANEL B ASSY 24FT8071

FILTER(B) 24F32651

M04 TERMINAL PANEL B 24F35331

COVER(VIEWER B) 24F35341

SPRING(VIEWER) 24H35091

BRACKET(I/O) 24H37602

BRACKET(I/O) 24H37611

BRACKET(TOP) 24H39781

M15 PLATE(I/O B) 24H41781

M16 SHEET,INSULATOR(TOP) 24J16122

M17 SHEET,INSULATOR(CPU-PWB) 24J16133

M46 SHEET,INSULATOR(POWER) 24J16143

SPACER(7*7*3.5) 24J16401

SPACER(210*10*5) 24J16411

SPACER(70*10*5) 24J16421

SPACER(50*10*5) 24J16431

SPACER(REAR FOOT) 24J16451

SHEET(LENS CAP Z) 24J18241

41 CUSHION(T1*5*28) 24J19401

CAUTION LABEL(SERVICE U) 24L45241

CAUTION LABEL(SERVICE J) 24L45251

NAME PLATE 24L47221

CAUTION LABEL(LENS K) 24L47231

CAUTION LABEL(HOT K) 24L47241

CAUTION LABEL(ELEC SHOCK K) 24L47251

M01 TOP COVER ASSY K(XGA-Z) 24PS2891

BUTTON(TILT FOOT A) 24G07911

BRACKET(TOP) 24H37401

SPRING(TILT BUTTON) 24H37421

CUSHION(T8*7*4) 24J19391

SW PANEL(PA14) 7N900221

54 LABEL(1*10) 25765841

S09 SCREW(D-SUB) 24N03112

56 CBIPS*2.6*6*15BF 24N04011

S11 STAD(M2.5,H23.7,M/FM) 24N04861

S13 STAD(M2.5,H13,FM/FM) 24N04871

S01 SPECIAL SCREW(M2.5*6*3KF) 24N04881

S12 SPECIAL SCREW(P2*6*15BF) 24N04891

PUSH NUT(1.5) 24N04901

S08 SPECIAL SCREW(2.5*4*3GF) 24N04911

SPECIAL SCREW(2.5*4*3GF) 24N04921

SPECIAL SCREW(4*4*3KF) 24N04931

SCREW,SL-CPIMS*2*6*15BF 910D2031

NUT,AHEXIN*2*15BF 91430201

M11 FAN RUBBER 79T08867

M14 FAN GUARD 79T08870

C-No Description Part number

A02 LAMP HOUSE ASSY

(M20+M19+M22+M21+M23) 79T09114

E11 THERMISTOR ASSY 79T08873

M10 LENS BASE POLYURETHANE FOAM 79T08877

E10 LIMIT SW BOARD ASSY 79T08878

M18 BRACKET"(I/O) 79T08879

M07 BALLAST LOCK BASE 79T08880

M08 INSULATE SHEET L/D-N 79T08881

E04 BALLAST CONNECTOR 79T08884

M26 REAR FOOT RUBBER 79T08886

M27 REAR FOOT 79T08887

M25 FRONT FOOT 79T08888

A01 LAMP COVER ASSY

(M05+M06+S03+S04) 79T09113

S02 POLYSLIDER CUT W 79T08930

S15 WHEEL SCREW 79T08893

E12 WHEEL SENSOR BOARD ASSY 79T08894

M28 WHEEL COVER 79T08895

M29 COLOR WHEEL UNIT 79T09112

M30 RUBBER SHEET 79T08896

M32 FORMATTER BRACKET 79T08933

A03 DMD SET(XGA)

(E13+M33+M34+E14) 79T09115

M33 ELASTOMER HOLDER 79T08900

M34 ELASTOMER 79T08901

1M35 HEAT SINK A 79T08934

1M36 HEAT SINK B 79T08935

1M39 LENS BASE ASSY

(M31+M40+M41+M42) 79T09111

M43 LENS BASE COVER 79T08906

M44 APERTURE 79T08907

M45 INSULATE SHEET LB-U 79T08908

S18 SCREW No.6-12 79T08918

S14 SCREW φ2.6-5 79T08922

S07 SCREW φ3-6 79T08923

S06 SCREW M3-6 79T08924

PRINTED & PACKING MATERIALS

BAND (L=100) 24280701

SOFT CASE(DLV-100) 24BS6971

SPACER 24M16321

PROTECTION BOX(300*460) 24M16531

CARTON BOX 24MU6831

BATTERY LR6GRSP2A 6N800005

POWER CODE UC3 L3.0 M K 7N080201

RC-473E 7N900271

STRAP 24C05051

PUSH RIVET 24C04531

CABLE,RGB 7N520001

Page 32

METHOD OF DISASSEMBLY

2. TOP COVER ASSY

(1) Remove the five screws 1, and take out the TOP

COVER ASSY.

Note) This action must be taken carefully because the

FFC of SW PANEL and SPEAKER CABLE is

connected to the MAIN PWB ASSY.

TOP COVER ASSY

DLV-100

SW PANEL

1

1

1

1

Page 33

3. PANEL (FAN)/TERMINAL PANEL/FILTER (F)

(1) Take out the PANEL (FAN) and the TERMINAL

PANEL, FILTER (F).

PANEL (FAN)

DLV-100

METHOD OF DISASSEMBLY

TERMINAL PANEL

FILTER (F)

Page 34

3. PANEL (FAN)/TERMINAL PANEL/FILTER (F)

(1) Take out the PANEL (FAN) and the TERMINAL

PANEL, FILTER (F).

PANEL (FAN)

DLV-100

METHOD OF DISASSEMBLY

TERMINAL PANEL

FILTER (F)

Page 35

METHOD OF DISASSEMBLY

4. REPAIR LAMP/LAMP COVER/LAMP COVER GUARD

(1) Loosen the one screw 1 and remove the LAMP

COVER. Then take out the LAMP COVER GUARD

and REPAIR LAMP successively.

DLV-100

REPAIR LAMP

LAMP COVER GUARD

LAMP COVER

POLYSLIDER CUT W

LAMP COVER SCREW SP

1

Page 36

DLV-100

METHOD OF DISASSEMBLY

5. LAMP DRIVER/BALLAST HOLDER N/BALLAST LOCK BASE/BALLAST CONNECTOR/

INSULATE SHEET L/D-N/REM PWB ASSY

(1) Remove the one screw 1, and disconnect the

CONNECTOR of the LAMP DRIVER.

(2) Remove the one screw 2 and another screw 4,

and take out the LAMP DRIVER.

(3) Remove the one screw 5 and take out the REM

PWB ASSY.

BALLAST LOCK BASE

INSULATE SHEET

L/D-N

4

1

LAMP DRIVER

CONNECTOR

3

BALLAST HOLDER N

LAMP DRIVER

2

BALLAST CONNECTOR

5

REM PWB ASSY

Page 37

METHOD OF DISASSEMBLY

6. OPTICAL ENGINE ASSY

(1) Remove the four screws 1, and take out the OP-

TICAL ENGINE ASSY.

DLV-100

1

LENS BASE POLYURETHANE FOAM

1

OPTICAL ENGINE ASSY

Page 38

7. 40 FAN ASSY (L-F)/40 FAN ASSY (DC)/FAN BASE

(1) Remove the two screws 1, and take out the FAN

BASE.

(2) Remove the 40 FAN ASSYs (L-F) and the 40 FAN

ASSYs (DC).

40 FAN ASSY (L-F)

DLV-100

METHOD OF DISASSEMBLY

FAN CUSHION

FAN GUARD

40 FAN ASSY (DC)

FAN RUBBER

FAN RUBBER

1

1

FAN BASE

Page 39

METHOD OF DISASSEMBLY

8. MAIN PWB ASSY/SUB PWB ASSY/POWER SUPPLY/LIMIT SW BOARD ASSY/

SHEET INSULATOR/PLATE (I/O)

(1) Remove the one screw 1.

(2) Remove the one screw 2and one screw 7, and

take out the SHEET INSULATOR.

(3) Remove the three screws 3, and take out the

MAIN PWB ASSY and the SUB PWB ASSY.

2

SHEET INSULATOR

(4) Remove the two screws 4, and take out the PLATE

(I/O).

(5) Remove the one screw 5 and the three STAD 1,

and take out the POWER SUPPLY.

(6) Remove the one screw 6, and take out the LIMIT

SW BOARD ASSY.

7

DLV-100

SPACER

SHEET INSULATOR

6

LIMIT SW BOARD ASSY

MAIN PWB ASSY

2

STAD

3

1

STAD

5

SPACER

3

7

1

STAD

POWER SUPPLY

INSULATING SHEET (D-SUB)

SUB PWB ASSY

4

1

PLATE (I/O)

BRACKET (I/O)

SHEET, INSULATOR

Page 40

METHOD OF DISASSEMBLY

9. LAMP HOUSE/THERMISTOR ASSY/FRONT FOOT/REAR FOOT

(1) Remove the one screw 2, and take out the THER-

MISTOR ASSY.

(2) Remove the three screws 1, and take out the

LAMP HOUSE.

LAMP HOUSE GUARD

1

LAMP HOUSE

THERMISTOR ASSY

DLV-100

1

LAMP HOUSE

MESH TEPE

REAR FOOT

LAMP HOUSE

MESH

LAMP HOUSE

MESH

TEPE

BOTTOM COVER ASSY

2

1

LAMP HOUSE

GUARD F

REAR FOOT RUBBER

REAR FOOT RUBBER

FRONT FOOT

REAR FOOT RUBBER

Page 41

METHOD OF DISASSEMBLY

10. OPTICAL ENGINE ASSY

(1) Remove the one screw 1 and the two screws 2,

and take out the WHEEL SENSOR BOARD ASSY

and WHEEL COVER.

(2) Remove the one screw 3, and take out the

COLOR WHEEL and RUBBER SHEET.

(3) Remove the three screws 4 and take out the

LIGHT TUNNEL ASSY.

(4) Remove the three screws 5 and take out the LENS

UNIT.

(5) Remove the one screw 6 and take out the MIR-

ROR ASSY.

WHEEL SENSOR BOARD ASSY

(6) Remove the one screw 7 and take out the APER-

TURE/LENS BASE COVER.

(7) Remove the one screw 8 and take out the CYL-

INDER MIRROR ASSY.

(8) Remove the two screws 9, and take out the HEAT

SINK A and HEAT SINK B.

0

(9) Remove the four screws

1

, and take out the

FORMATTER BOARD, FORMATTER BRACKET,

ELASTOMER HOLDER, ELASTOMER, and DMD.

DLV-100

1

2

4

LIGHT TUNNEL

ASSY

4

INSULATE

SHEET

LB-U

5

LENS UNIT

POINT RING COVER

2

5

WHEEL COVER

COLOR WHEEL

3

MIRROR

ASSY

6

RUBBER SHEET

ELASTOMER

HOLDER

ELASTOMER

LENS BASE

COVER

8

DMD

LENS

BASE

CYLINDER

MIRROR ASSY

FORMATTER BOARD

FORMATTER BRACKET

APERTURE

7

HEAT SINK B

10

9

HEAT SINK A

Page 42

HD15RCA5

HD15 pin to RCA Cabl

Shipped Separetly

e

Page 43

DLV-100

Integra Division of

ONKYO U.S.A. CORPORATION

18 Park Way, Upper Saddle River, N.J. 07458, U.S.A.

Tel: 201-785-2600 Fax: 201-785-2650 http://www.integrahometheater.com

Integra Division of

ONKYO CORPORATION

Sales & Product Planning Div. : 2-1, Nisshin-cho, Neyagawa-shi, OSAKA 572-8540, JAPAN

Tel: 072-831-8111 Fax: 072-833-5222

Page 44

METHOD OF ADJUSTMENTS

PC Control Software :

The completely adjusted servicing PWB ASSY are in stock.

Therefore, it is unnecessary to use the adjusting software.

For this model, adjustments are carried out only for the opticaln system.

DLV-100

Page 45

METHOD OF ADJUSTMENTS

Control of Optical System

The description below covers the control program for the color wheel sensor of the optical engine unit.

1. Preliminary arrangements for adjustment

i Appropriate spanner (across 5.0mm) Part No. : 9N000002

i Signal generator (with signals of all white, all black, all red, all green, all blue)

i Card remote control (set accessory)

2. Preliminary work for adjustment

i Remove the top cabinet. Remove the membrane switch and the speaker cables from the main unit.

i Actuate the set while a signal input is fed from the signal generator.

* Caution points during work (white area)

DLV-100

Page 46

METHOD OF ADJUSTMENTS

3. Adjustment steps

1. Check the color wheel sensor position.

DLV-100

2. Loosen the sensor lock nut. (About 1/4 turns counterclockwise)

Page 47

METHOD OF ADJUSTMENTS

3. Adjust the sensor by means of tweezers, using only a green image and viewing the screen.

DLV-100

4. Tighten the nut to its original position. (About 1/4 turns clockwise)

(Note: Never tighten it too much.)

Page 48

METHOD OF ADJUSTMENTS

5. When the nut has been completely tightened, check each screen of all white, all red, all blue, all green, and

all black in order to confirm the freedom from any abnormality (chromaticity).

If any abnormality is perceived, adjust the sensor again (in the state of that screen) and check the resultant

conditions again.

6. Apply a screw lock agent to the area of the sensor and the nut.

DLV-100

Note) At the time of adjustments and operation check under the condition that the top cover is open, use a

small-sized cooling fan or the like to avoid excessive temperature rise inside the set.

(The effect of cooling will be lowered if the top cover is removed. In case when the thermal protector

should operate as a result of temperature rise inside the set, pull out the power cord and wait until the

inside is cooled down. Restart is possible after confirming that the inside temperature has been sufficiently low.)

Loading...

Loading...