Omron ZN-A2502, ZN Series, ZN-A2502D, ZN-A4105D, ZN-A4105 System Manual

...

Clean Sensing System

ZN Series

System Manual

Cat. No. Z267-E1-01

Introduction

Thank you for purchasing the ZN.

This manual provides only information, such as system components and setup procedures, that

is required when using the ZN Series in a system.

For details on product functions, performance and handling methods of individual products, refer

to the Instruction Sheet packaged with the respective product.

When using the ZN, be sure to observe the following:

• The ZN must be operated by personnel knowledgeable in electrical engineering.

• To ensure safe use of the product, please read the Instruction Sheet packaged with each

product and this manual to deepen your understanding of the product.

• Please keep this manual and the Instruction Sheet packaged with each product in a safe place

so that they can be referred to whenever necessary.

Introduction

Section 1

Section 2

Section 3

Section 4

APPLICATION CONSIDERATIONS (Please Read)

FEATURES

UPGRADING THE SYSTEM

BASIC KNOWLEDGE OF CLEAN SENSING SYSTEMS

APPENDICES

Introduction

‚Í‚¶‚ß‚É ‘æ 1 Í‘æ 2 Í‘æ 3 Í‘æ 4 Í

Section 1 Section 2 Section 3 Section 4

System Manual

Clean Sensing System

ZN Series

Introduction

Introduction

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive w arranty is that the products are f ree from defects in materials a nd workmanship for a

period of one year (or othe r pe ri od if specified) from date of sale by OMRO N .

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGA RDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS.

ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT

THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON

DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall responsi bility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE

PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT DESIGNED OR

RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES.

Please refer to separate catalogs for OMRON’s safety rated products.

OMRON shall not be responsible for conform ity with any standards, codes, or regulations that apply to th e

combination of produc ts in the customer’s application or us e of th e pr oduct.

At the customer’s request, OMRON will provide applicable third party certification documents identifying ratings

and limitations of use that apply to the products. This information by itself is not sufficient for a complete

determination of the suitability of the produ cts in comb ination w ith the en d produc t, machi ne, syste m, or other

application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the p ro ducts:

• Outdoor use, uses inv olving potential chemical contamination or electrical interference, or conditions or

uses not described in this document.

ZN

System Manu al

ii

Introduction

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amu sem ent ma chi ne s, v eh ic le s, saf et y eq ui pme nt , an d ins t al la t io ns su bj ec t t o separate industry

or government regulations.

• Systems, machin es, and equipment that could present a ris k to lif e or pro per t y.

Please know and obse rv e all p ro hi bi tio ns of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLED FOR

THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users must correlate

it to actual application requirements. Actual performance i s su bj ect t o th e O M RO N Warranty and Limitations of

Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

Introduction

It is our practice to change model numbers when published ratings or features are changed, or when significant

construction chang es are made. However, some specifications o f the product may be changed without any

notice. When in do ubt, special m odel numbe rs may be a ssigned to fix or establish key s pecificat ions for your

application on your request. Please consu lt with your OMRON repres entative at any time to conf irm actual

specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

ERRORS AND OMISSIONS

The information in this do cument has been carefully checked and i s believed to be accurate; however, no

responsibility is assum ed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s prog ra m m in g of a pro gr ammable product, or any conse quence

thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions w ithout permission.

This document is protected by copyri ght and is inten ded solely for use in conjunc tion with the pr oduct. P lease

notify us before cop ying or reproducing this docum ent in any manner, for any other purpose. I f copying or

transmitting this document to another, please copy or transmit it in its entirety.

ZN

System Manu al

iii

Introduction

Precautions for Safe Use

Introduction

Precautions for Safe Use

The following points are important to ensure safety, so make sure that they are strictly observed.

■ Power Supply and Wiring

• When connecting multiple Air Clean Units to build a system, use a commercially

available LAN cable (straight type: Category 5E or higher).

• On models that can be connecte d t o A ir Clea n Units, such as the Air P artic le S ens or

(ZN-PDA12) and Interfac e Unit (ZN-SF12), use the cable from the body to directly

connect to the unit.

• To extend the cable mentioned above, a commercially available LAN connector

female to female, straight type) and a LAN cable (straight type: Category 5E or

higher) must be used.

• The cables must be 100 m or shorter in total length.

For details on other precautions for safe use and precautions for correct use,

refer to the Instruction Sheet for the respective device, and make sure that they

are strictly observed.

iv

ZN

System Manu al

Editor's Note

● Title of each section

● Header

● Cross-header

● Index label

● Overview and points of the

function described

● Operation procedure and supplementary explanat ion

Indicates the contents of the page.

Shows the chapter number and contents.

Shows the operation flow and setup

method.

Explains the operation procedure and the display status

resulting from execution of the operation.

Helpful information regarding operation and reference

pages is introduced here using symbols.

* This page does not exist.

● Overview of the section

Page Format

Introduction

Editor's Note

Introduction

System Manu al

ZN

v

Introduction

Editor's Note

Introduction

Notational Conventions

■ Menu

In this manual, menu items displayed on the screen are enclosed with [ ].

■ Operation procedure

Operation steps are numbered to indicate their order .

■ Visual Aids

Indicates points that are important to achieve the full product performance, such as operational

precautions and application procedures.

Indicates pages where related information can be found.

Indicates information helpful in operation.

vi

ZN

System Manu al

CONTENTS

Introduction

CONTENTS

Introduction

Precautions for Safe Use iv

Editor's Note v

Page Format v

Notational Conventions vi

CONTENTS vii

Section 1 FEATURES 1

What is the "Clean Sensing System?" 2

System Features 2

Features of the Clean Sensing System 4

System Configuration Examples 7

Direct Clean Sensing System 7

Multi-Clean Sensing System 11

CONTENTS

Section 2 UPGRADING THE SYSTEM 13

Before Upgrading the System 14

Flow of Operations for Upgrading the System 14

Installing the Exclusive Monitoring Software 15

Setup Methods Suited to Specific Applications 18

Automatically Adjusting the Air Volume Level 18

Monitoring/Logging the Amount of Particles 25

Detecting the Cleanliness of Multiple Processes 31

ZN

System Manu al

vii

Introduction

CONTENTS

Introduction

Section 3 BASIC KNOWLEDGE OF CLEAN SENSING SYSTEMS 35

Feedback Control 36

CONTENTS

What is "Feedback?" 36

How Feedback Control Works 40

Clean Sensing 44

Principle of "Particle Count" 44

What is "Cleanliness?" 45

Section 4 APPENDICES 47

Maintenance 48

Troubleshooting 50

Troubleshooting 50

Error Messages and Countermeasures 51

Specifications and Dimensions 53

List of Products 66

INDEX 69

Revision History 72

viii

ZN

System Manu al

Section 1

FEATURES

What is the "Clean Sensing System?" 2

System Features 2

Features of the Clean Sensing System 4

System Configuration Examples 7

Direct Clean Sensing System 7

Multi-Clean Sensi ng Sy st em 11

Section 1 FEATURES

System Manu al

ZN

1

Section 1

OPE1

OPE2

OPE3

■ Clean Monitoring System (ZN-SFW Series)

Monitoring the amount of particles at multiple points in

manufacturing processes is important in improving

product quality. By connecting Interface Units, you can

log the measured data of Air Particle Sensors at up to ten

locations at once on a personal computer.

The Electrostatic Sensor (ZJ-SD) also can be connected,

which means that you can al so asce rtain the re latio nship

between the amount of s tatic electricity and the amount

of particles.

The clean sensing system continuously s enses the amount of particles

in a clean boot h or cl ean b ench, and c ontrols the ai r vol ume le ve l of t he

Air Clean Unit. This way, it can easily ensure an environment having a

fixed cleanliness class at all times.

An environment for removing dust and neu tralizing static electri city can

be built by incorporating a new-concept Ionizer Unit in this system.

What is the "Clean Sensing System?"

What is the "Clean Sensing System?"

Section 1 FEATURES

System Features

OPE3

OPE2

OPE1

Z

N

S

F

12

ZN

System Manu al

2

What is the "Clean Sensing System?"

■ Air Clean Unit (ZN-A Series)

Unique twin-blower structure (ZN-A2502) achieves light weight

and large air volume.

Compact but more powerful.

Incorporating a clogged main filter (HEPA) detection function.

Visibility is improved by indicators located on two corners of

the body.

■ Air Particle Sensor (ZN-PD Series)

High-performance fan used for air suction to ensure

measurement at all times.

Use of a semiconductor laser and high-sensitivity optical

design in the sensor achieves measurement of minute

particles of 0.3 µm, 0.5 µm and 1.0 µm in diameter.

Thinnest in industry, large air volume

■ Ionizer Unit (ZN-J Series)

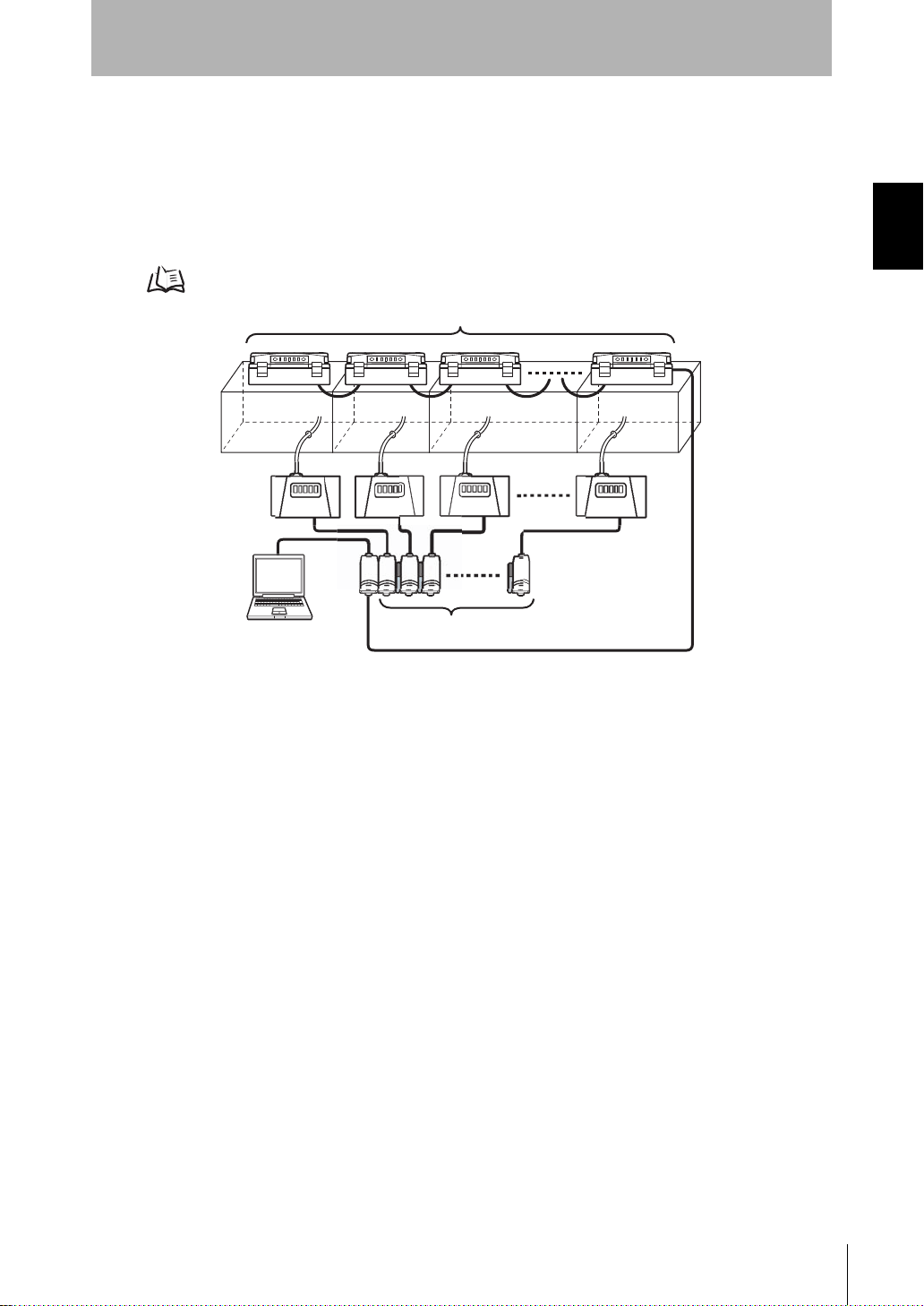

Directly mounted on Air Clean Unit

Open structure does not b lock the laminar ai rflow from the Ai r

Clean Unit.

No more troublesome wiring required. Installation man-hours

can be considerably reduced.

An industry first, one-touch dust removal and static neutralization

Smallest in industry, constant measuring

Main Applications

Electronic component

production processes

Storage or test

environments

Cell manufacturing

processes

Section 1

Section 1 FEATURES

System Manu al

ZN

3

Section 1

What is the "Clean Sensing System?"

Features of the Clean Sensing System

Section 1 FEATURES

■ Feedback-based Automatic Adjustment of Air Volume

The air volume level of the Air Clean Unit can be automati cally controlled based on the

amount of particles measured by the Air Par ticle Sensor. The cleanli ness class in clean

booths can be maintained at the opt imum air volume level in propor tion to the amount of

particles from rapid air feed through to fine air volume operation in the power saving mode.

Setting Method p.18

4

■ Monitoring/Logging the Amount of Particles

The cleanlines s class i nside clean b ooths can be ver ified and ascertained by the amount of particle s

per unit volume. The amount of particles can be verified on the Sensor and the Amplifier Unit.

Measured values can be easily logged on a personal computer using Interface Units and the

exclusive monitoring software (Realtime Clean Air Monitor). Changes in the amount of particles

over time observed in this way can be made use of as data for improving product quality.

Setting Method p.25

ZN

System Manu al

OPE3

OPE2

OPE1

Section 1

Max. 9 units connected

Max. 10 units connected

What is the "Clean Sensing System?"

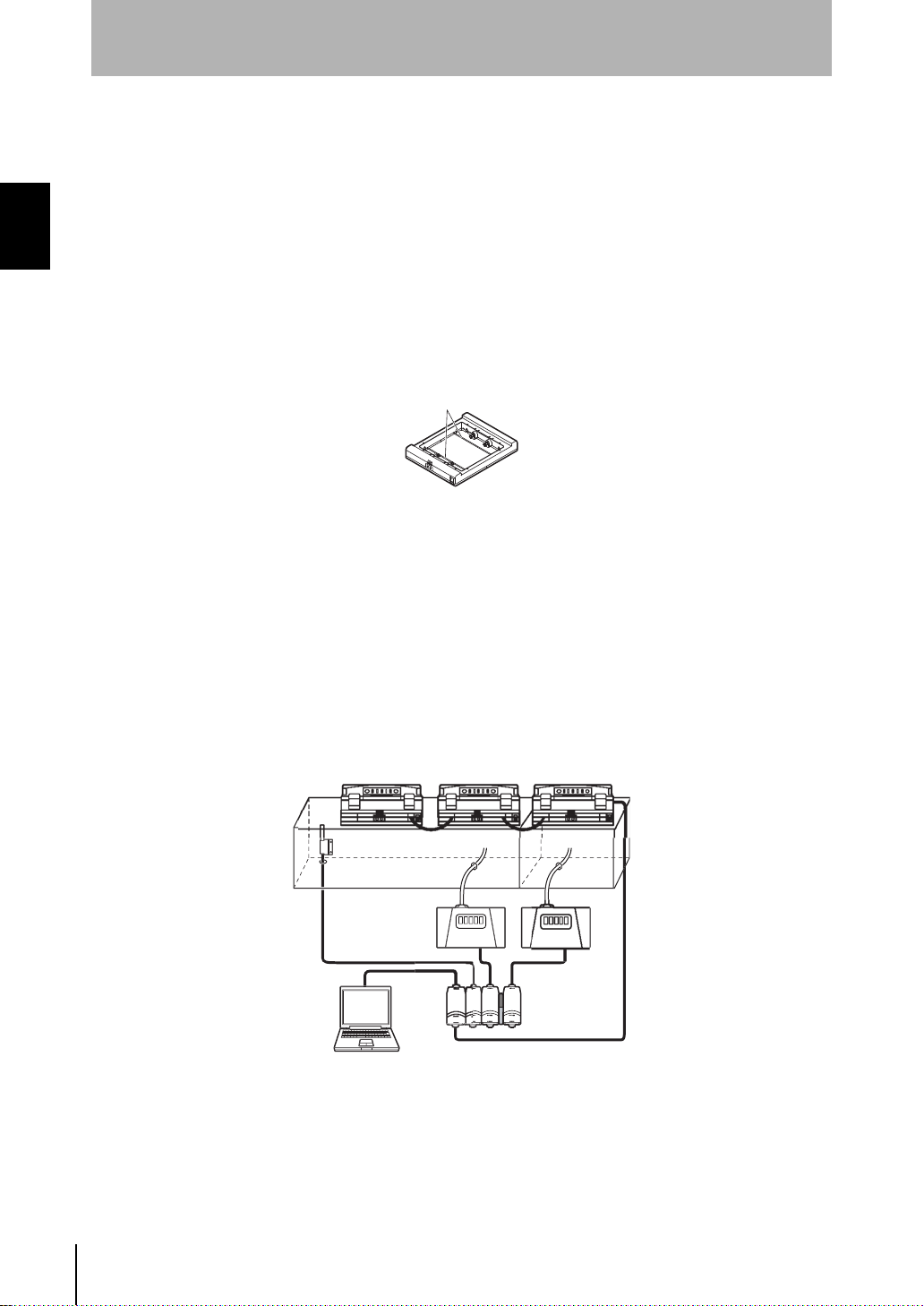

■ Improving Product Quality by Multi-point Measurement

Since Air Clean Units and Air Particle Sensors can be conn ected to each other, the

amount of air particles in multiple clean booths installed in processes can be

comprehensively de tected and controlled. Which process is worseni ng in cleanliness

can be linked to quality control for continual management.

Setting Method p.31

Section 1 FEATURES

System Manu al

ZN

5

Section 1

Ion Balance Sensor

What is the "Clean Sensing System?"

■ Simultaneous Dust Removal and Static Neutralization

The Ionizer Unit ZN-J series, the first in industry to be added on later to an Air Clean

Section 1 FEATURES

Unit, provides you with a new clean environment capable of removing dust and

neutralizing static electricity.

• Sim ultaneous Removal of Particles and Static Electricity

A variable DC sy stem is used for electrostatic di scharge. This system c an neutralize

static electricity in wide spaces.

Two ion balance sensors provide c onstant feedback to maintain uniform neutr alizing

performance.

• Simultaneous Monitoring of Charged Amount of Workpieces

Electrostatic Sensor ZJ-SD can be connected to the clean sensing system. The

problem of adhesion of particles can be solv ed by acc urately asc ertaining the char ged

amount of the workpiece, and using the Ionizer Unit to approp riately neutralize static

electricity.

Also, since ZJ-SD data can also b e cap tured on a person al c omputer via the Inte rfac e

Unit, the amount of particles and charged amount can be acquired and collected

simultaneously, and made use of as basic data for improving product quality.

ZN

System Manu al

6

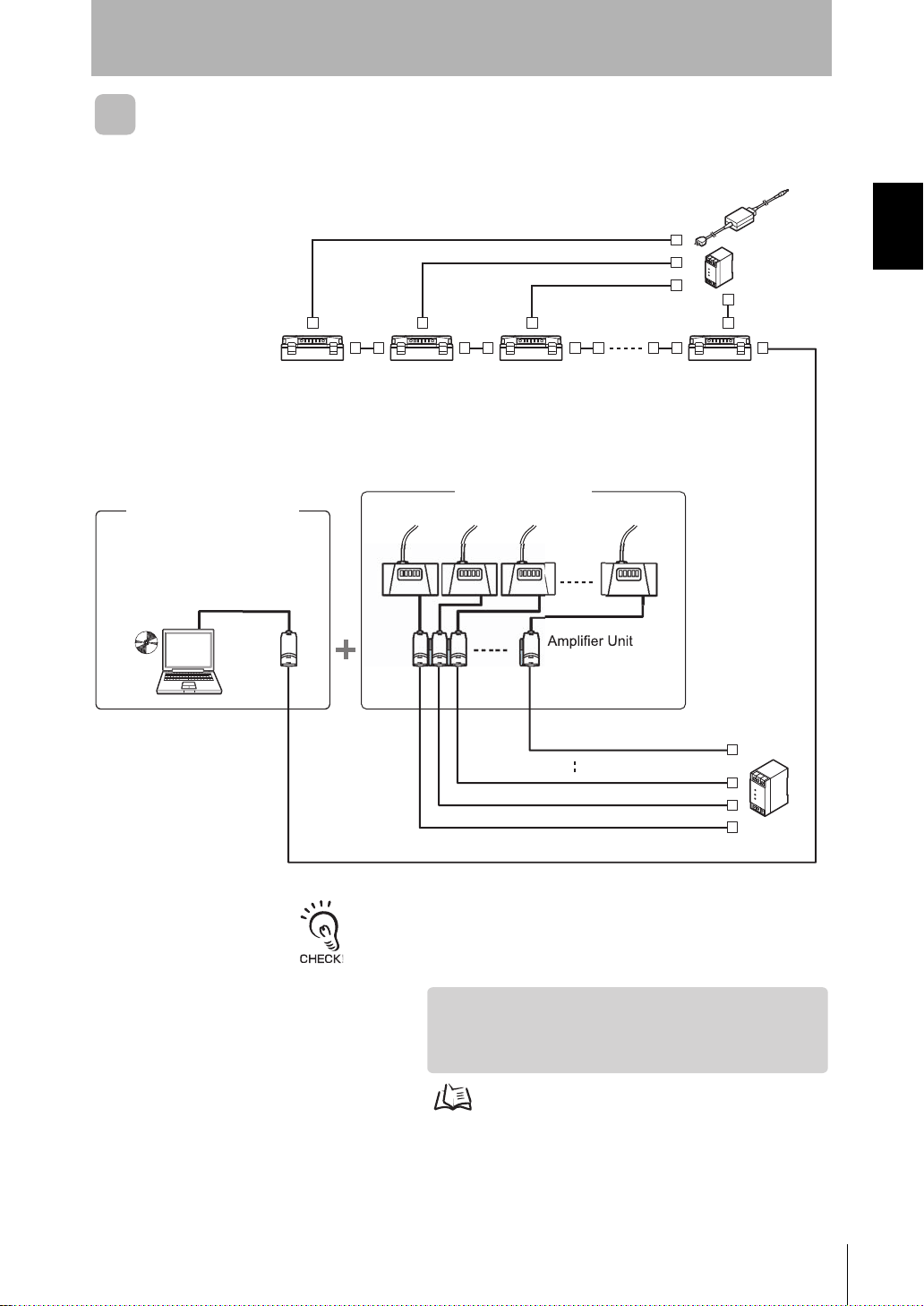

System Configuration Examples

S

For details on settings, see p.25.

System Configuration Examples

Section 1

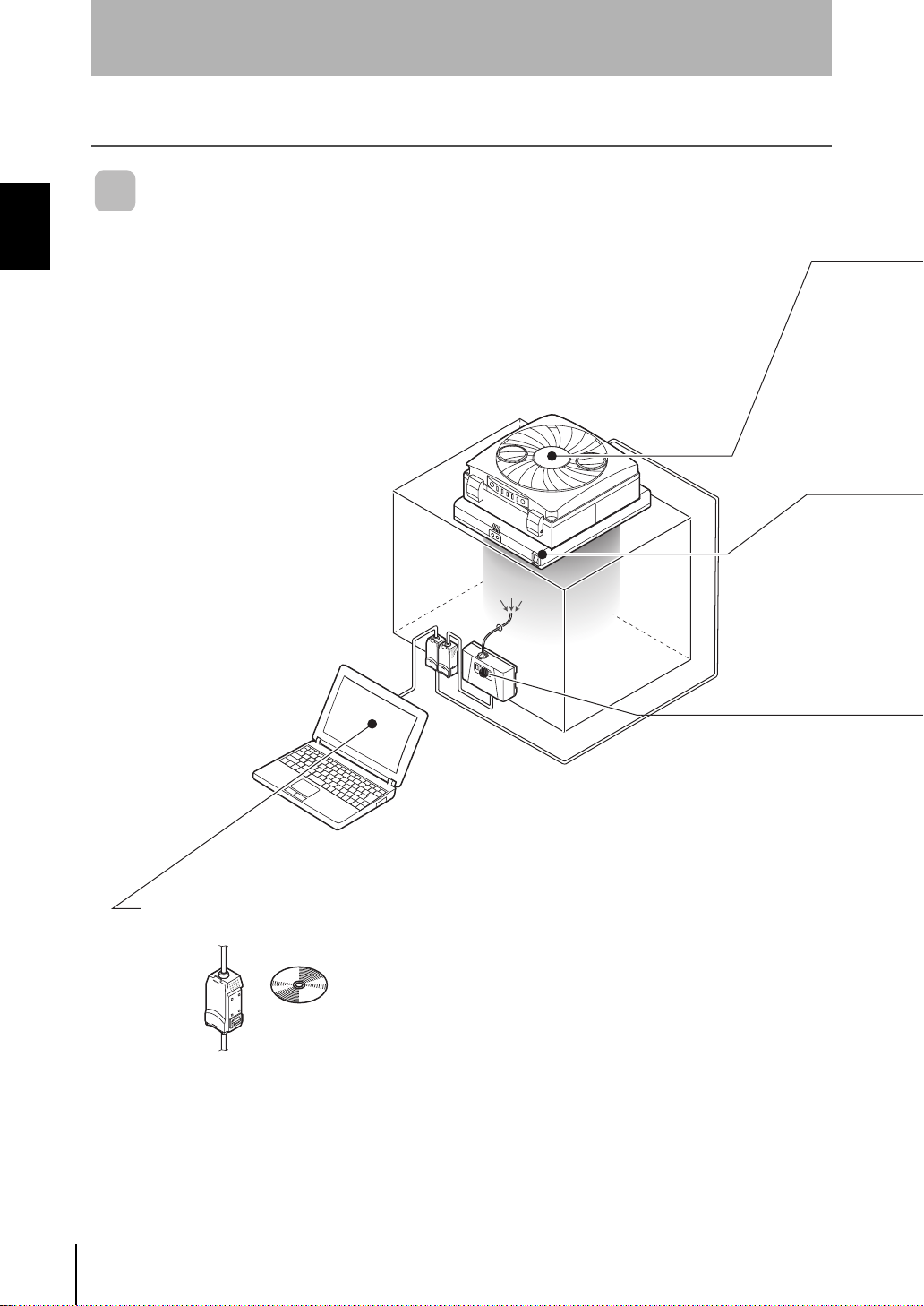

Direct Clean Sensing System

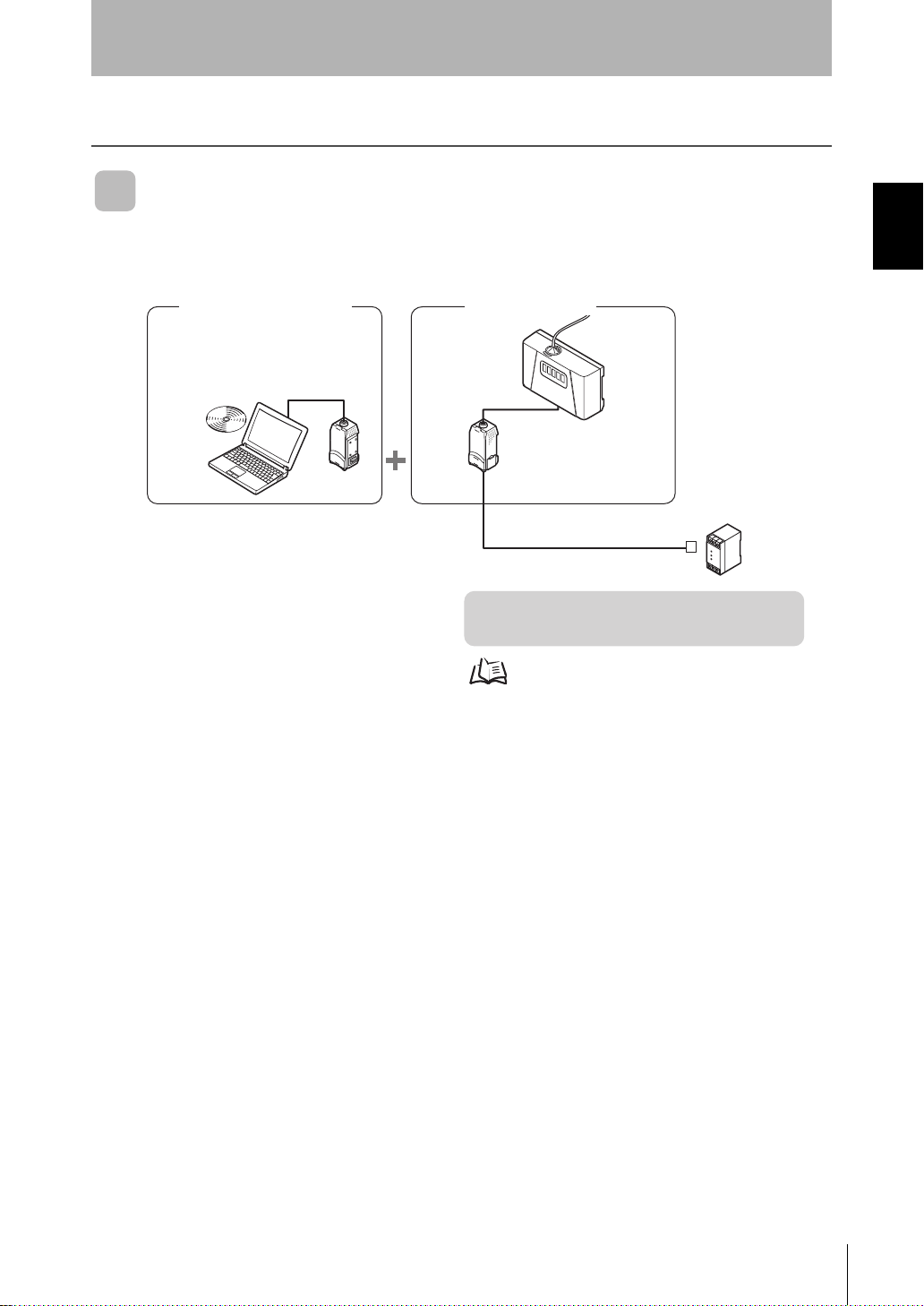

■ Data Logging

Clean Monitoring System

ZN-SFW11

Realtime

Clean Air Monitor

Interface

Unit

Z

N

S

F

1

1

Amplifier

Unit

Section 1 FEATURES

Air Particle Sensor

ensor

ZN-PD03

ZN-PDA11

DC power supply

[Features]

• Monitoring/Logging the Amount of Particles

System Manu al

7

ZN

Section 1

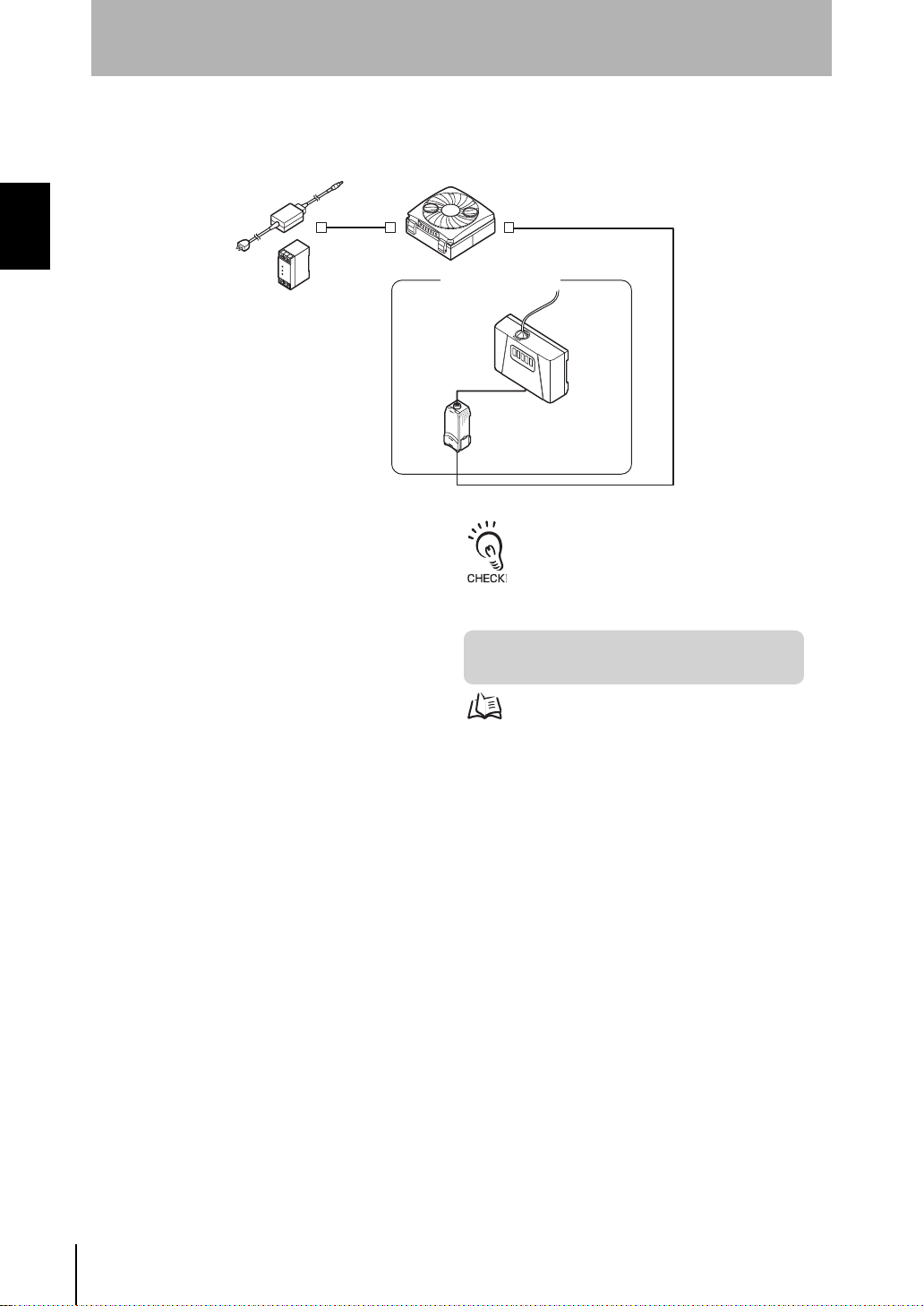

S

r

A

For details on settings, see p.18.

To extend the cable mentioned above, a

commercially available LAN connector (female to

female, straight type) and a LAN cable (straight

type: Category 5E or higher) must be used.

System Configuration Examples

■ Feedback

Section 1 FEATURES

C adapter (provided)

Or, DC power supply

Air Clean Unit

ZN-A2502

ZN-A4105

Air Particle Sensor

enso

Amplifier

Unit

ZN-PD03

ZN-PDA12

Cable length: standard 2 m

[Features]

• Feedback-based Automatic Adjustment of Air Volume

ZN

System Manu al

8

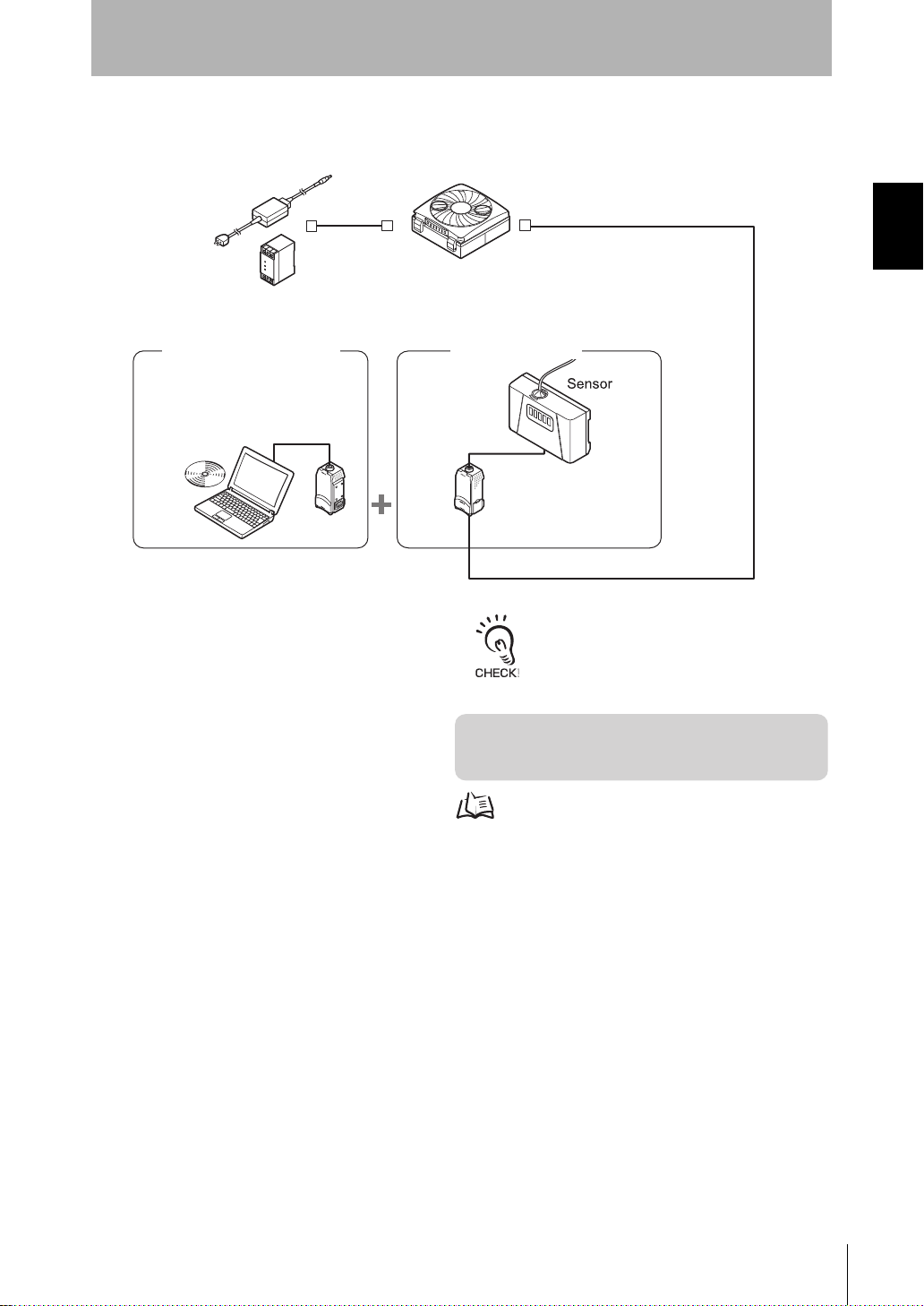

■ Feedback and Data Logging

Z

N

S

F

1

1

Air Clean Unit

ZN-A2502

ZN-A4105

[Features]

• Feedback-based Automatic Adjustment of Air Volume

• Monitoring/Logging the Amount of Particles

Air Particle Sensor

Interface

Unit

Realtime

Clean Air Monitor

ZN-PD03

Amplifier

Unit

ZN-PDA12

Clean Monitoring System

ZN-SFW11

AC adapter (provided)

Or, DC power supply

Cable length: standard 2 m

For details on settings, see p.18, p.25.

To extend the cable mentioned above, a

commercially available LAN connector (female to

female, straight type) and a LAN cable (straight

type: Category 5E or higher) must be used.

Section 1

System Configuration Examples

Section 1 FEATURES

System Manu al

ZN

9

Section 1

For details on settings, see p.18, p.25.

To extend the cable mentioned above, a commercially available LAN

connector (female to female, straight type) and a LAN cable (straight type:

Category 5E or higher) must be used.

System Configuration Examples

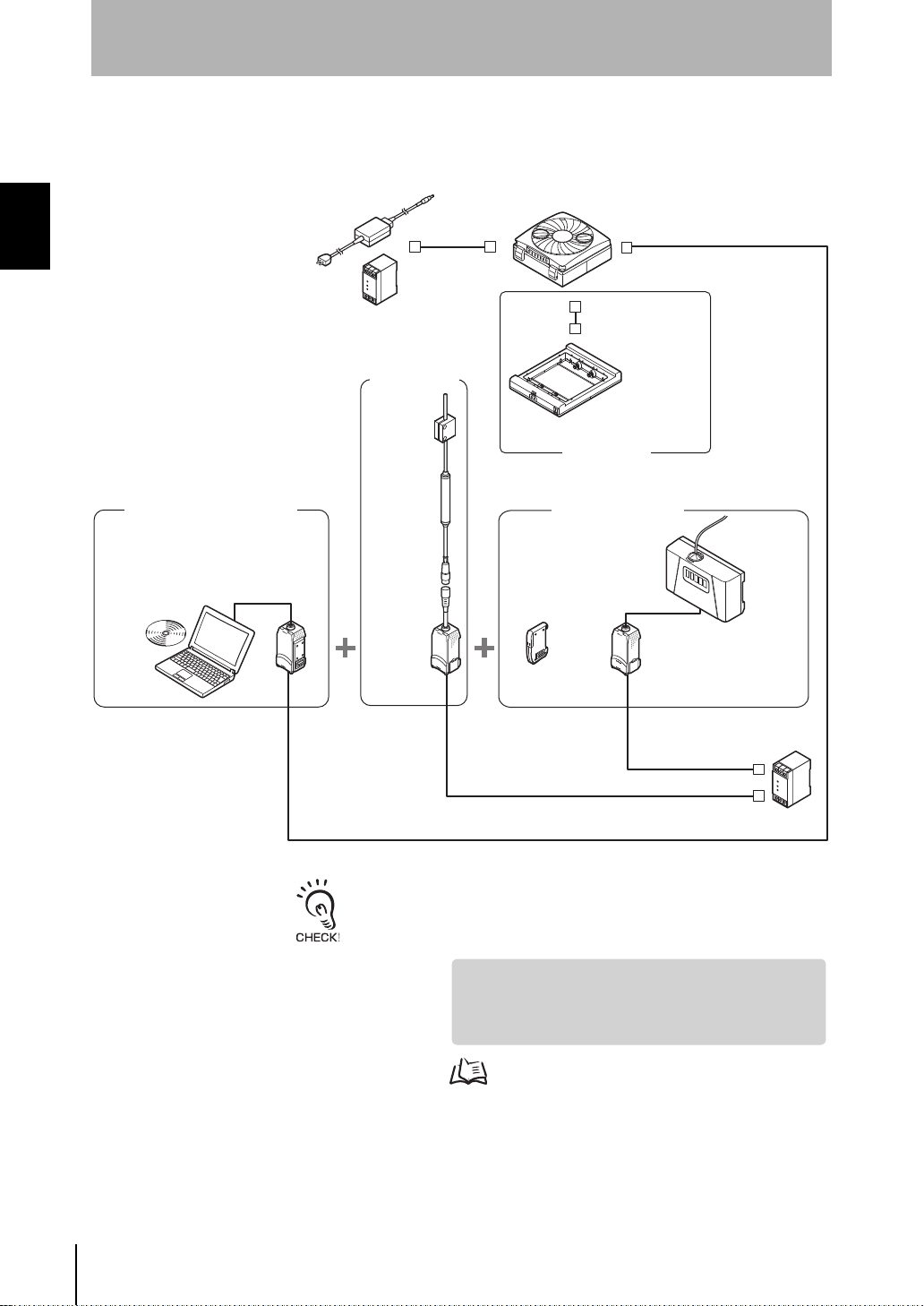

■ Dust Removal and Static Neutralization

Connection Example with Different Models (Electrostatic Sensor)

Section 1 FEATURES

Air Clean Unit

AC adapter (provided)

Or, DC power supply

ZN-A2502

ZN-A4105

Connector cable

(provided)

Clean Monitoring System

Realtime

Clean Air Monitor

Electrostatic

Sensor

ZJ-SD100

ZN-SFW12

Interface

Unit

OPE3

OPE2

OPE1

ZN

SF

1

2

Amplifier

Unit

ZJ-SDA11

Cable length: standard 2 m

Sensor

ZN-J25A

ZN-J41A

Ionizer Unit

Air Particle Sensor

Sensor

ZX-CAL2

Amplifier

Unit

ZN-PD03

ZN-PDA11

Calculating

Unit

OPE3

OPE2

OPE1

ZERO ENABLE

(kV)

Z

J

-S

D

A

1

1

DC power

supply

10

ZN

System Manu al

[Features]

• Simultaneous Monitoring of the Ion Balance

• Feedback-based Automatic Adjustment of Air Volume

• Monitoring/Logging the Amount of Particles

ZN-A2502

ZN-A4105

Air Clean Unit

Air Particle Sensor

Calculating Unit

ZX-CAL2

ZN-PD03

Sensor

ace

Unit

e

r

ZN-SFW12

Clean Monitoring System

Commercially available LAN cable

(straight type: Category 5E or higher)

DC power

supply

[Features]

• Feedback-based Automatic Adjustment of Air Volume

• Monitoring/Logging the Amount of Particles

• Detecting the Cleanliness of Multiple Processes

AC adapter

(provided)

Or,

DC power supply

Cable length: standard 2 m

For details on settings, see p.31.

To extend the cable mentioned above, a commercially available LAN

connector (female to female, straight type) and a LAN cable (straight type:

Category 5E or higher) must be used.

Realtim

Clean Air Monito

Multi-Clean Sensing System

Interf

Section 1

System Configuration Examples

Section 1 FEATURES

-

System Manu al

ZN

11

Section 1

System Configuration Examples

MEMO

Section 1 FEATURES

12

ZN

System Manu al

Section 2

UPGRADING THE SYSTEM

Before Upgrading the System 14

Flow of Operations for Upgrading the System 14

Installing the Exclusive Monitoring Software 15

Setup Methods Suited to Specific Applications 18

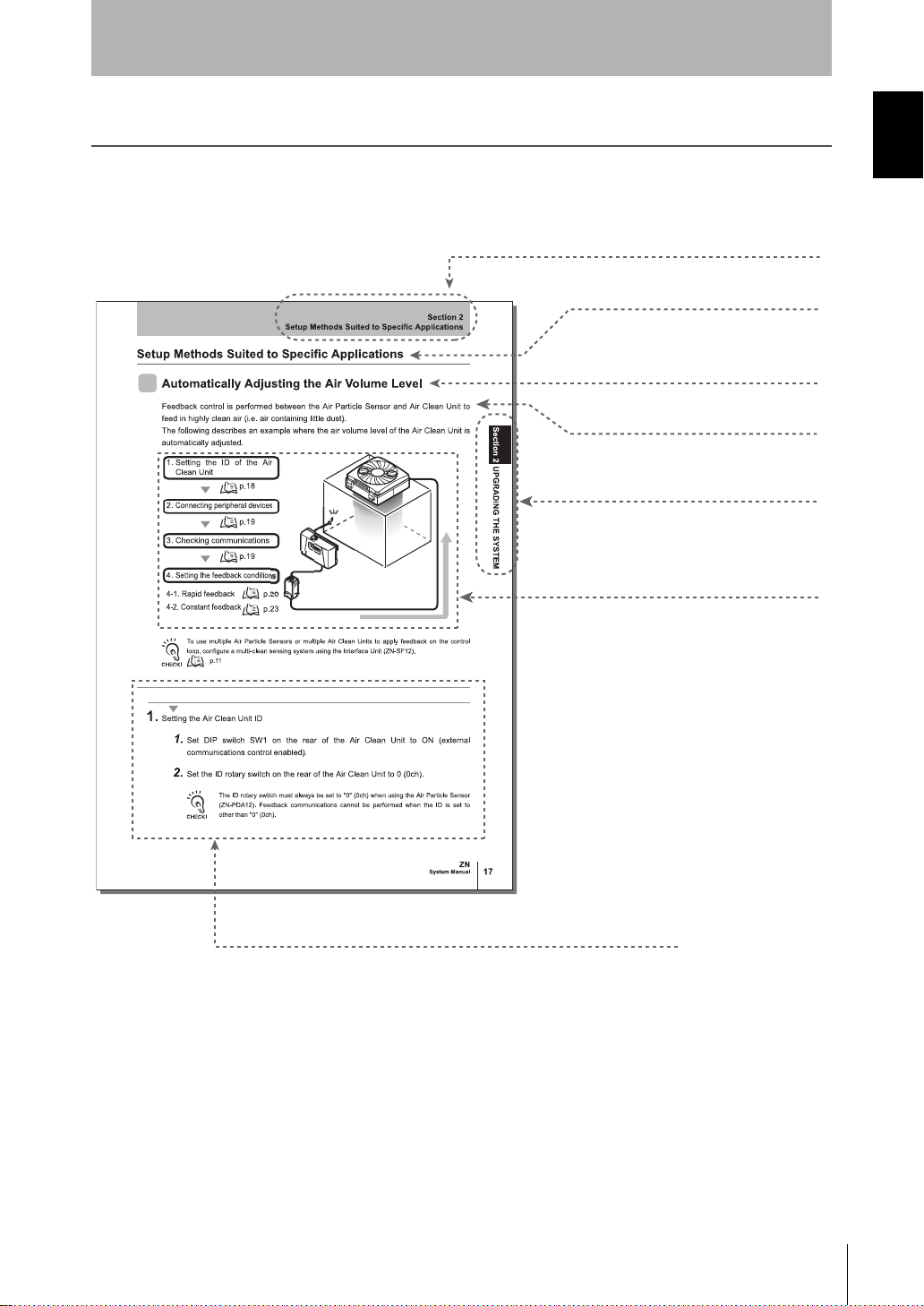

Automatically Adjusting the Air Volume Level 18

Monitoring/Logging the Amount of Particles 25

Detecting the Cleanliness of Multiple Processes 31

Section 2 UPGRADING THE SYSTEM

System Manu al

ZN

13

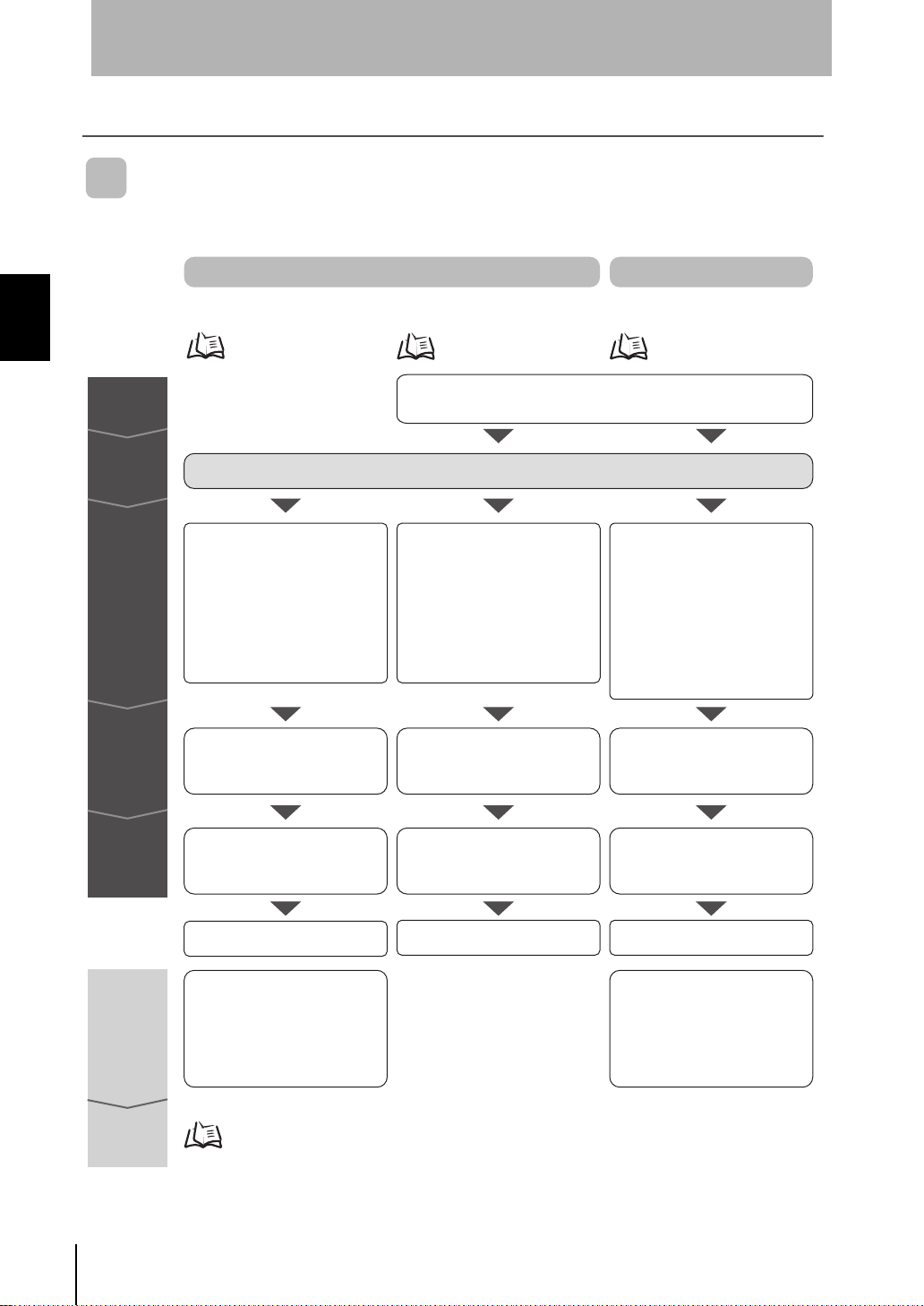

Section 2

p.18 p.25 p.31

p.48

Before Upgrading the System

Before Upgrading the System

Flow of Operations for Upgrading the System

Section 2 UPGRADING THE SYSTEM

Preparation

Installation

Connections

Checks

Direct Clean Sensing System

Automatically Adjusting

the Air Volume Level

Refer to the Instruction Sheet packaged with each device.

• Setting the ID of the Air Clean

Unit

• Connecting the Air Clean Unit

and Air Particle Sensor

• Connecting the Air Clean Unit

power supply

Checking communications Checking system operation Checking system operation

Monitoring/Logging

the Amount of Particles

Installing the exclusive monitoring software

• Connecting the Air Particle

Sensor and Interface Unit

together

• Connecting the Interface Unit

and personal computer

• Connecting the Air Particle

Sensor power supply

Multi-Clean Sensing System

Detecting the Cleanliness of

Multiple Processes

• Setting the ID of the Air Clean Unit

• Connecting the Air Clean Unit

and Interface Unit

Connecting Air Clean Units to each other

•

• Connecting the Air Particle Sensor

and Interface Unit together

• Connecting the Interface Unit

and personal computer

• Connecting the Air Particle

Sensor power supply

Connecting the Air Clean Unit power supply

•

14

Operations

and settings

Resetting

during

operation

Maintenance

ZN

System Manu al

Setting the feedback conditions

Starting operation

• Resetting the feedback method

Resetting the target cleanliness class

•

• Resetting the feedback cycle

Resetting the low power air volume level

•

•

Resetting the high power air volume level

• Resetting the high power time

Trend graph display/data logging

Starting monitoring/logging Starting operation

Setting the feedback conditions

• Resetting the feedback method

Resetting the target cleanliness class

•

• Resetting the feedback cycle

Resetting the low power air volume level

•

• Resetting the calculation type

Resetting the high power air volume level

•

• Resetting the high power time

Section 2

Clean Monitoring System

(ZN-SFW11/SFW12)

Realtime

Clean Air Monitor

Interface Unit

Numerical display of measured

amount of particles

Graphic display of changes in

measured values over time

Logging of data

Display and setting of Air Particle Sensor and Interface Unit settings

Before Upgrading the System

Installing the Exclusive Monitoring Software

The Exclusive Monitoring Software (Realtime Clean Air Monitor) tool is provided for the

ZN Series. This tool allows you to set sensing functions, acquire and collect the amount

of measured particles, and display this information as a graph on a personal computer.

ZN-SF12

• Monitoring of measurement results

Section 2 UPGRADING THE SYSTEM

• Function setup support

■ Operating Environment

The following operating environment for Exclusive Monitoring Software is

recommended. Check the environment before installing the software.

Item Condition

OS Windows 2000/XP

CPU PentiumIII 850 MHz or faster (2 GHz or faster recommended)

RAM 128 MB or more (256 MB or more recommended)

Free space on hard disk At least 50 MB

Display screen 1024 x 768 dots

High Color (16-dot) or higher

• Windows is a trademark or registered trademark of Microsoft Corporation.

System Manu al

ZN

15

Loading...

Loading...