Page 1

Cat. No. Z288-E1-01

ZG2 Series

Smart Sensor

2D Profi le Measuring Sensors

USERS MANUAL

Page 2

Page 3

Introduction

Thank you for purchasing the ZG2 series.

This manual provides information regarding functions, performance and operating methods that

are required for using the ZG2.

When using the ZG2, be sure to observe the following:

• The ZG2 must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the

product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

■ How to Switch the Display Language to English

Turn the power ON with the MENU key held down. This displays the display language selection

screen.

PLEASE SELECT

LANGUAGE

ENG JPN

The Controller will start up with the messages displayed in English when it is next started up.

Page 4

READ AND UNDERSTAND THIS

DOCUMENT(Please Read)

1

User’s Manual

BEFORE USE

BASIC OPERATIONS

FUNCTION SETTINGS

CONNECTION WITH EXTERNAL

DEVICES

MEASUREMENT BY GANGMOUNTED CONTROLLERS

APPENDICES

1

2

3

4

5

6

Smart Sensor

2D Profile Measuring Sensors

ZG2 Series

Page 5

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult

your OMRON representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and

workmanship for a period of one year (or other period if specified) from date of sale by

OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR

PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER

ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT

THE PRODUCTS WILL SUITABLY MEET T HE R EQU I RE MENT S OF T HE IR IN TE NDE D

USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY

WAY CONNEC TED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the

product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR

OTHER CLAIMS REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS

CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED,

INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINAT ION, ABUSE,

MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY

ARE NOT DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND

SHOULD NOT BE RELIED UPON AS A SAFETY COMPONENT OR PROTECTIVE

DEVICE FOR SUCH PURPOSES.

Please refer to separate catalogs for OMRON’s safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations

that apply to the combination of products in the customer’s application or use of the

product.

At the customer’s request, OMRON will provide applicable third party certification

documents identifying ratings and limitations of use that apply to the products. This

information by itself is not sufficient for a complete determinatio n of the suitability of the

products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be

given. This is not intended to be an e xhausti ve li st of all possi ble use s of t he produc ts, nor

is it intended to imply that the uses listed may be suit able for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference,

or conditions or uses not described in this document.

2

ZG2 User’s Manual

Page 6

• Nuclear energy control systems, combustion systems, railroad systems, aviation

systems, medical equipment, amusement machines, vehicles, safety equipment, and

installations subject to separate industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO

LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS

BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determin ing

suitability and does not constitute a warranty. It may represent the result of OMRON’s test

conditions, and the users must correlate it to actual application requirements. Actual

performance is subject to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on

improvements and other reasons.

It is our practice to change model numbers when published ratings or features are

changed, or when significant construction changes are made. However, some

specifications of the product may be changed without any notice. When in doubt, special

model numbers may be assigned to fix or establish key specifications for your application

on your request. Please consult with your OMRON representative at any time to confirm

actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes,

even when tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be

accurate; however, no responsibility is assumed for clerical, typographical, or

proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product,

or any consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions wit hout permission.

This document is protected by copyright and is intended solely for use in conjunction with

the product. Please notify us before copying or reproducing this document in any manner,

for any other purpose. If copying or transmitting this document to another, please copy or

transmit it in its entirety.

ZG2 User’s Manual

3

Page 7

Meanings of Signal Words

The following signal words are used in this manual.

Indicates a potentially hazardous situation which, if not

avoided, will result in minor or moderate injury, or may result in

serious injury or death. Additionally there may be significant

property damage.

Meanings of Alert Symbols

The following alert symbols are used in this manual

Indicates general prohibitions for which there is no specific symbol.

Indicates the possibility of laser radiation.

Indicates prohibition when there is a risk of minor injury from electrical

shock or other source if the product is disassembled.

This product is not designed or rated for ensuring safety of persons.

Do not use it for such purposes.

Never look into the laser beam. Doing so continuously will result in

visual impairment.

Do not attempt to dismantle, pressurize, or i ncinerate the product. Doing

so may cause the laser beam to leak, resulting in the danger of visual

impairment.

4

ZG2 User’s Manual

Page 8

Precautions for Safe Use

The following points are important to ensure safety, so make sure that they are strictly

observed.

1. Installation Environment

• Do not use the product in environments where it can be exposed to inflammable/

explosive gas.

• To secure the safety of operation and maintenance, do not install the product close to

high-voltage devices and power devices.

• Install the product in such a way that its ventilation holes are not blocked.

2. Power Supply and Wiring

• The voltage and AC power supply must be within the rated range (DC 24 V ±10%).

• Reverse connection of the power supply is not allowed.

• Open-collector outputs should not be short-circuited.

• Use the power supply within the rated load.

• High-voltage lines and power lines must be wired separately from this product. Wiring

them together or placing in the same duct may cause induction, resulting in

malfunction or damage.

• Use the product within the power supply voltage specified by this manual.

• Use a DC power supply with safety measures against high-voltage spikes (safet y extra

low-voltage circuits on the secondary side).

3. Other

• Do not disassemble, repair, or modify the product.

• Dispose of this product as industrial waste.

• Connect the exclusive device (Sensor). The product might break down or malfunction

if you use a part not included in the exclusive products.

• Should you notice any abnormalities, immediately stop use, turn OFF the power

supply, and contact your OMRON representative.

ZG2 User’s Manual

5

Page 9

Precautions for Correct Use

Observe the following precautions to prevent failure to operate, malfunctions, or

undesirable effects on product performance.

1. Installation Site

Do not install this product in locations subjected to the following conditions:

• Ambient temperature outside the rating

• Rapid temperature fluctuations (causing condensation)

• Relative humidity outside the range of 35 to 85%

• Presence of corrosive or flammable gases

• Presence of dust, salt, or iron particles

• Direct vibration or shock

• Reflection of intense light (such as other laser beams or electric arc-welding

machines)

• Direct sunlight or near heaters

• Water, oil, or chemical fumes or spray

• Strong magnetic or electr ic field

2. Power Supply and Wiring

• When using a commercially available switching regulator, make sure that the FG

terminal is grounded.

• If surge currents are present in the power lines, connect surge absorbers that suit the

operating environment.

• Before turning ON the power after the product is connected, make sure that the power

supply voltage is correct, there are no incorrect connections (e.g. load short-circuit),

and the load current is appropriate. Incorrect wiring may result in breakdown of the

product.

• Before connecting/disconnecting devices, make sure that the Sensor/Controller is

turned OFF. The Sensor or Controller may break down if it is connected/disconnected

while the power is ON.

• Use the extension cable sold separately for extending the cable between the Sensor

and the Controller.

p.17

• Use only combinations of the Sensor and Controller specified in this manual.

• Before turning the Controller ON, connect the Sensor. If the Controller is turned ON

without the Sensor connected, the Controller’s screen will remain dark and messages

cannot be read.

3. Warming Up

After turning the power supply ON, allow the product to stand for at least 30 minutes

before use. The circuits are still unstable just after the power supply is turned ON, so

measurement values may fluctuate gradually.

6

ZG2 User’s Manual

Page 10

4. Maintenance and Inspection

Do not use thinner, benzene, acetone or kerosene to clean the Sensor and Controller. If

large dust particles adhere to the filter on the front of the Sensor, use a blower brush

(used to clean camera lenses) to blow them off. Do not use breath from your mouth to

blow the dust off. To remove dust particles from the Sensor, wipe gently with a soft cloth

(for cleaning lenses) moistened with a small amount of alcohol. Do not use excessive

force to wipe off dust particles. Scratches to the filter might cause error.

5. Measurement Target

The measurement target is a non-transparent object. The sensor cannot detect the

following types of objects accurately: materials with extremely small reflectances, objects

smaller than the beam diameter, objects with large curvatures, or objects tilted to a large

degree.

6. Effect of Peripheral Lighting

Do not install the Sensor in a place where strong light hits the laser emitter/receiver

section of the Sensor.

Also, if a measurement target has a shiny surface, the light from the lighting will be

reflected and a malfunction may occur. In such a case, prevent reflection by, for example,

covering the light to stop reflection.

p.27

7. Compatibility of Mesurement Data

Bank data or System data saved with existing ZG series cannot be processed by ZG2.

ZG2 User’s Manual

7

Page 11

Editor’s Note

Important

Note

■ Meaning of Symbols

Menu items that are displayed on the Controller’s LCD screen, and windows, dialog boxes

and other GUI elements displayed on the PC are indicated enclosed by brackets “[ ]”.

■ Visual Aids

Indicates points that are import ant to achiev e the full product perf ormance,

such as operational precautions.

Indicates application procedures.

Indicates pages where related information can be found.

8

ZG2 User’s Manual

Page 12

CONTENTS

1. BEFORE USE

ZG2 Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . 18

Basic Knowledge for Operation . . . . . . . . . . . . . . . . 21

Profile Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Precautions when designing a production line. . . . 22

Measurement Range in Height Direction and Resolution 22

Trigger Measurement/Continuous Measurement . . . . . 24

Mounting and Connecting Devices. . . . . . . . . . . . . . 27

Mounting the Sensor Head . . . . . . . . . . . . . . . . . . . . . . 27

Mounting the Controller. . . . . . . . . . . . . . . . . . . . . . . . . 39

Connecting Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Overview of Settings and Measurement. . . . . . . . . . 52

Operation Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Tasks and Bank Data . . . . . . . . . . . . . . . . . . . . . . . . . . 53

STD Menu and EXP Menu . . . . . . . . . . . . . . . . . . . . . . 55

Initializing Controller Settings . . . . . . . . . . . . . . . . . . . . 56

1

2. BASIC OPERATIONS

Flow of Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Starting Measurement . . . . . . . . . . . . . . . . . . . . . . . . 66

Monitoring the Measurement Status . . . . . . . . . . . . . . . 66

Magnifying the Profile Display. . . . . . . . . . . . . . . . . . . . 67

Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

ZG2 User’s Manual

9

Page 13

3. FUNCTION SETTINGS

Setting Measurement Conditions . . . . . . . . . . . . . . . 70

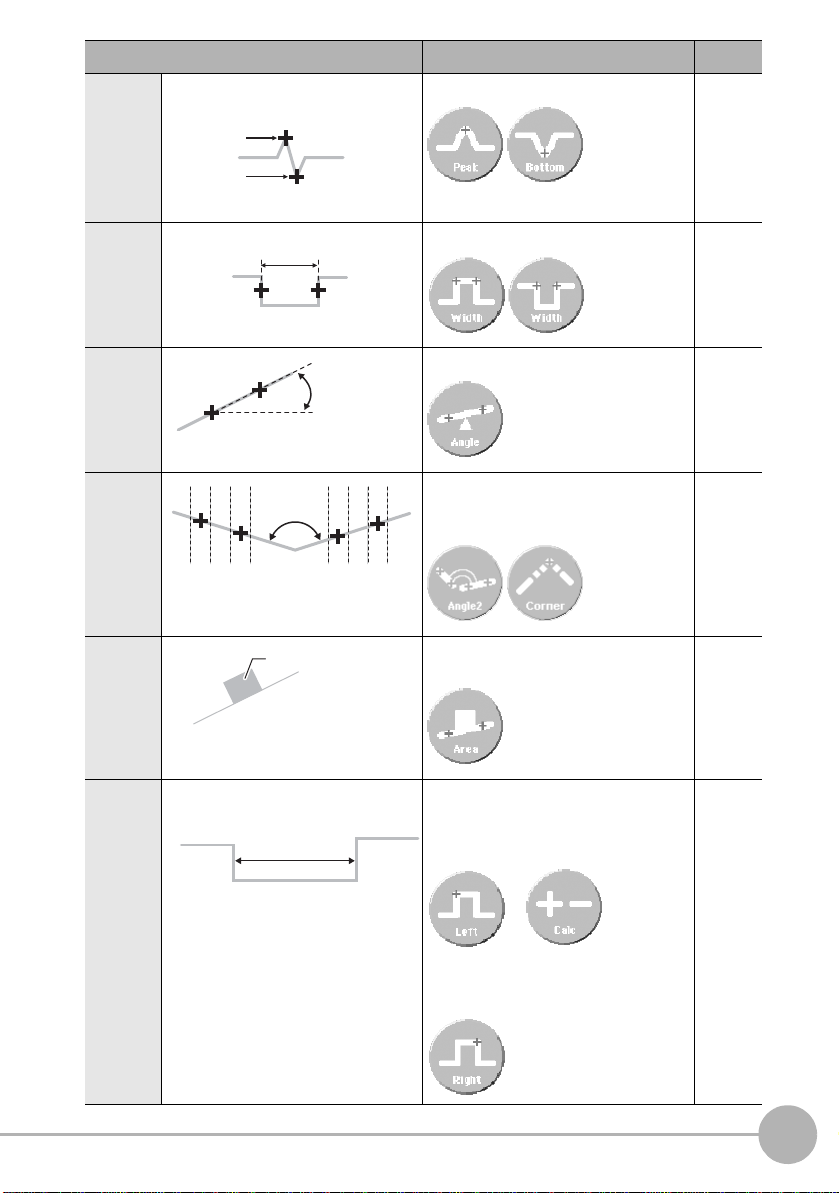

How to Select Measurement Items . . . . . . . . . . . . . . . . 70

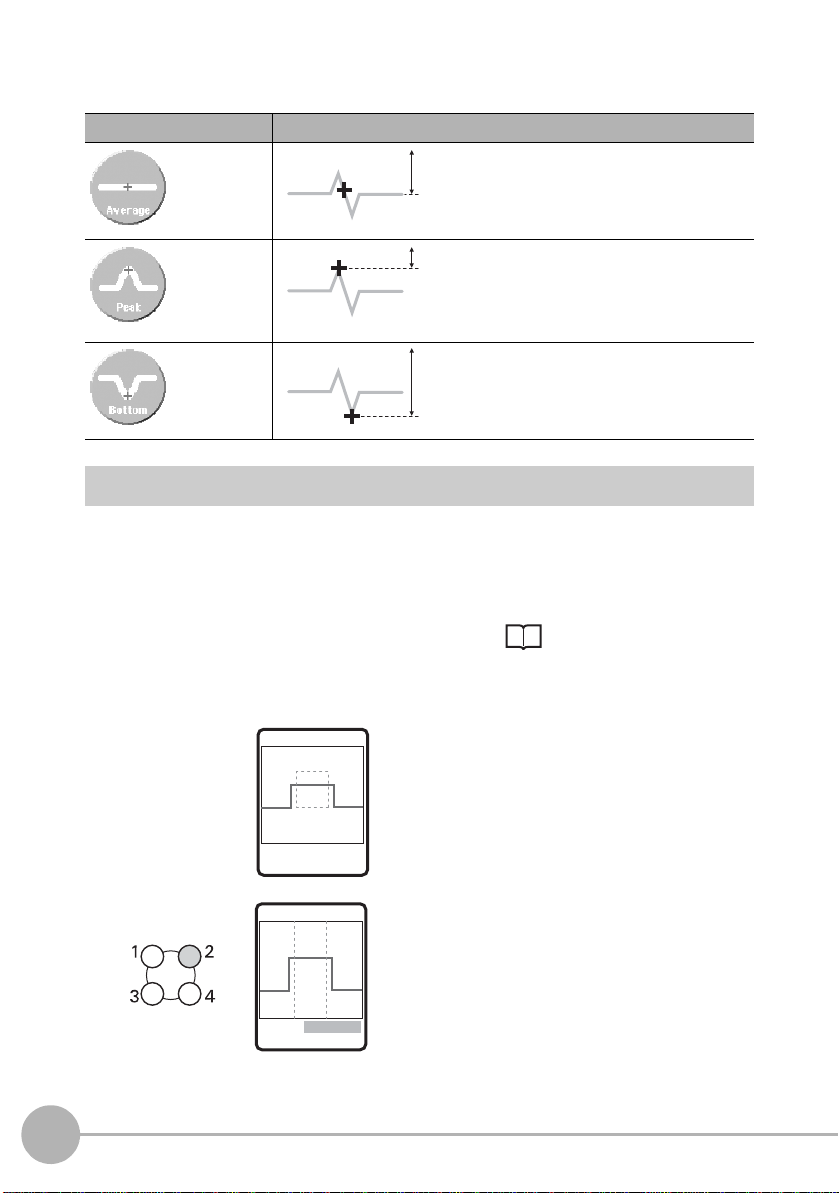

Measuring Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

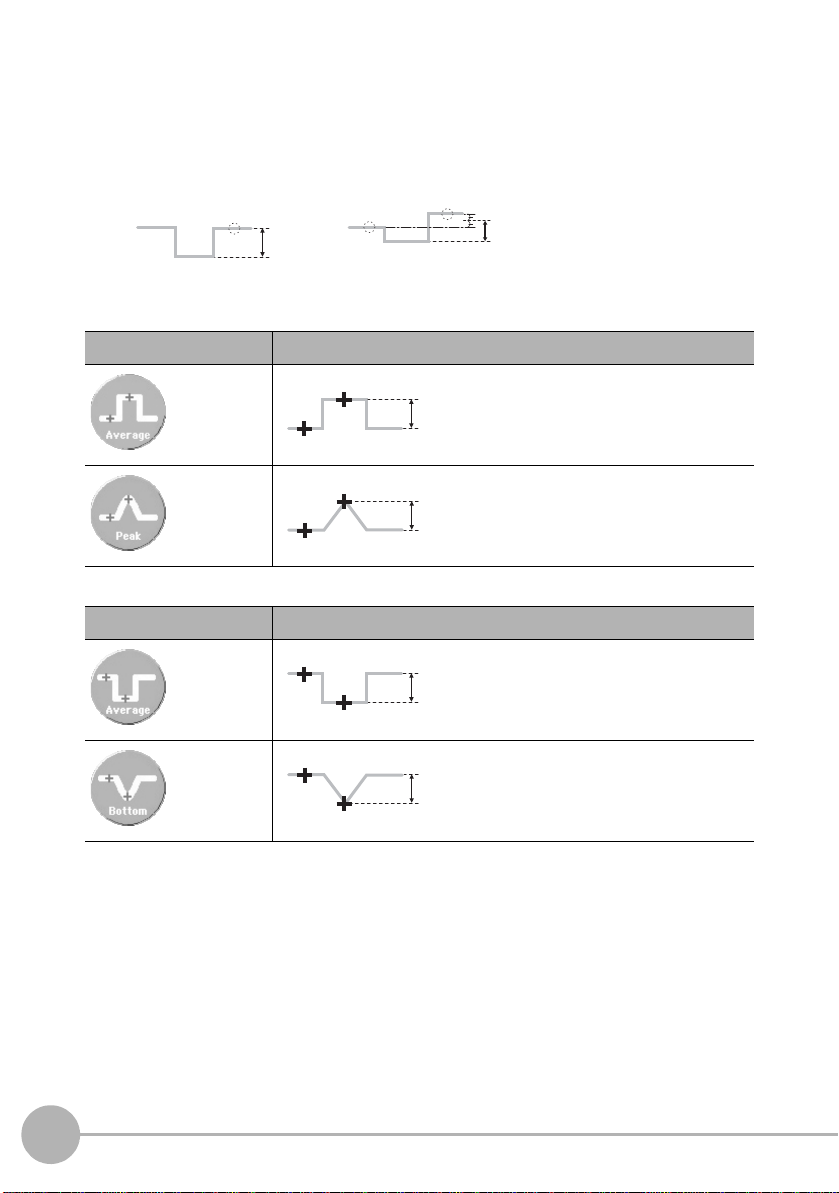

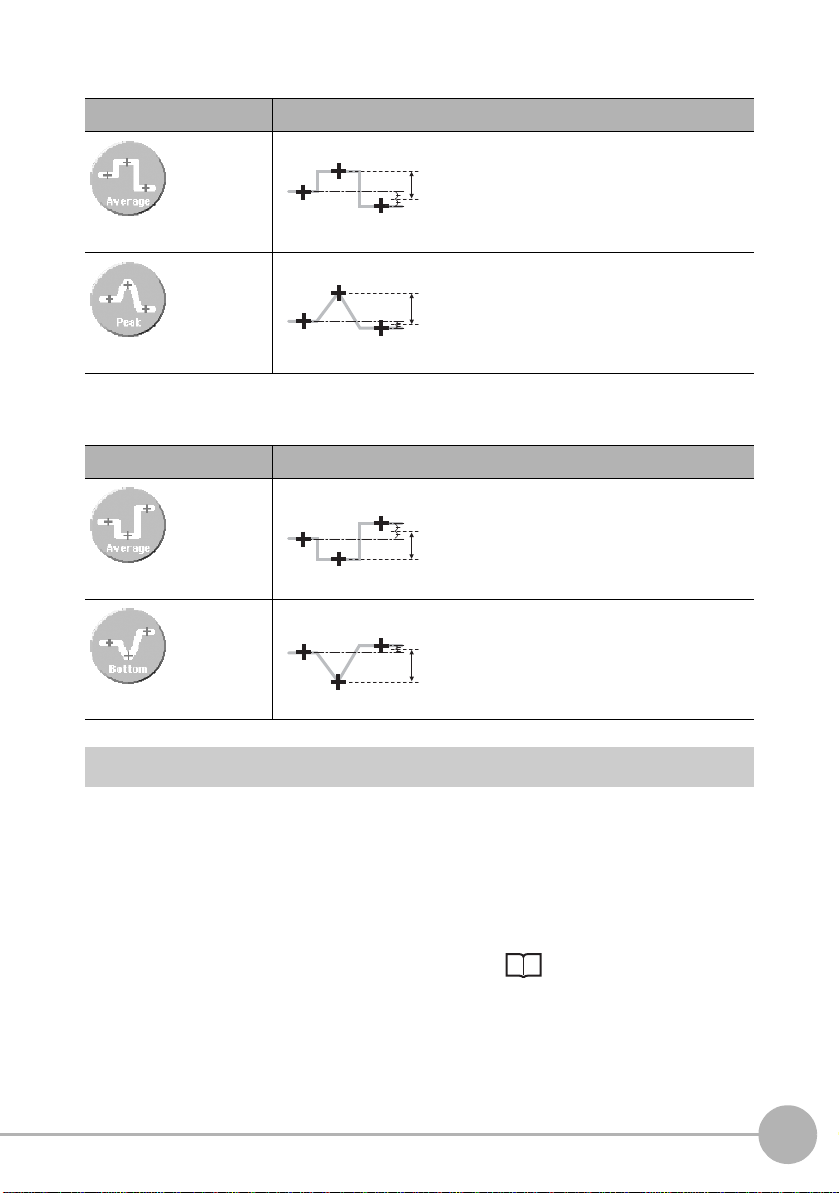

Measuring Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Measuring Position and Width. . . . . . . . . . . . . . . . . . . . 77

Measuring Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Measuring Angle and Point of Intersection . . . . . . . . . . 80

Measuring Cross-sectional Area . . . . . . . . . . . . . . . . . . 82

Measuring Point of Inflection. . . . . . . . . . . . . . . . . . . . . 83

Calculating Measurement Values . . . . . . . . . . . . . . . . . 86

Deleting measurement items. . . . . . . . . . . . . . . . . . . . . 86

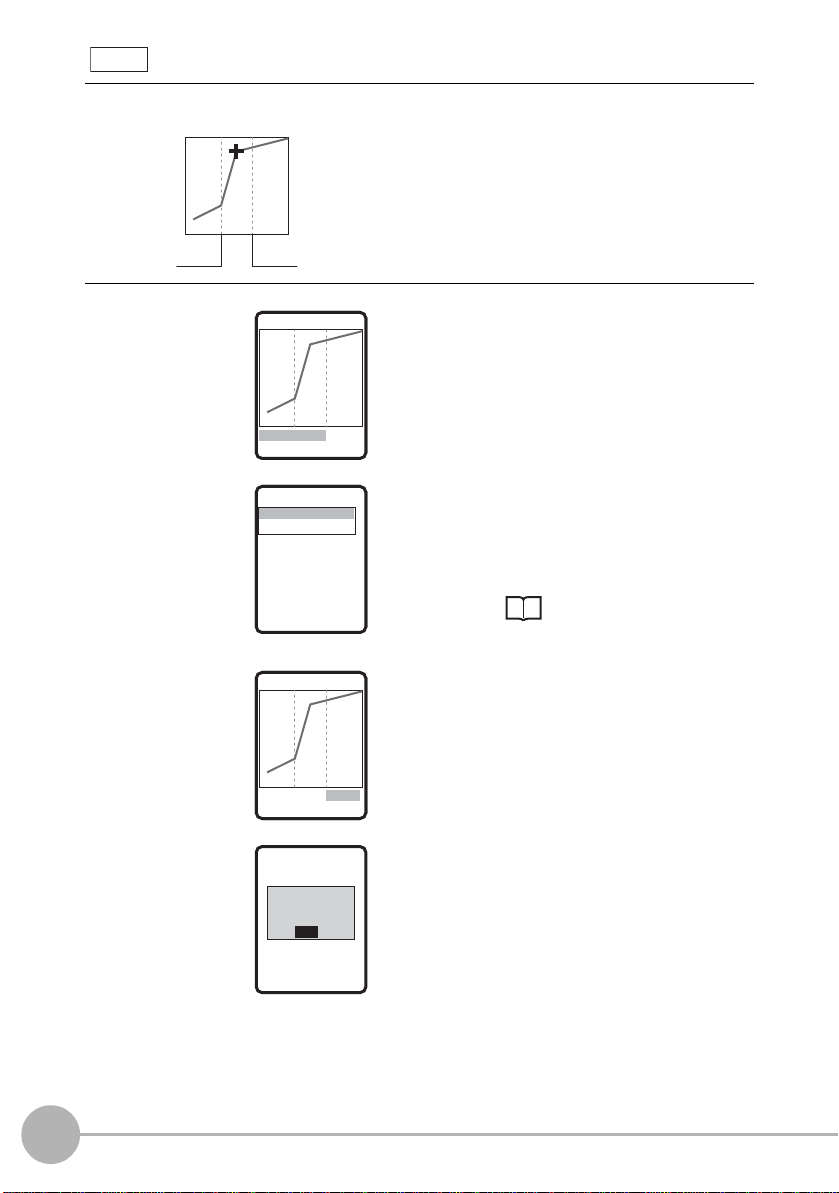

Customizing Measurement Conditions . . . . . . . . . . 87

Magnifying the Profile Display. . . . . . . . . . . . . . . . . . . . 87

Changing Measurement Positions. . . . . . . . . . . . . . . . . 88

Changing Measurement Points. . . . . . . . . . . . . . . . . . . 89

Changing the Edge Level and Edge Direction. . . . . . . . 90

Scaling of Measurement Values . . . . . . . . . . . . . . . . 91

Image Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Adjusting Sensitivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Changing Sensitivity Adjustment Region. . . . . . . . . . . . 99

Adjusting Profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Adjusting the background filtering level. . . . . . . . . . . . 104

Setting noise filtering . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Setting the high-power mode (increasing the amount of

emitted light) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Adjusting received light gain . . . . . . . . . . . . . . . . . . . . 105

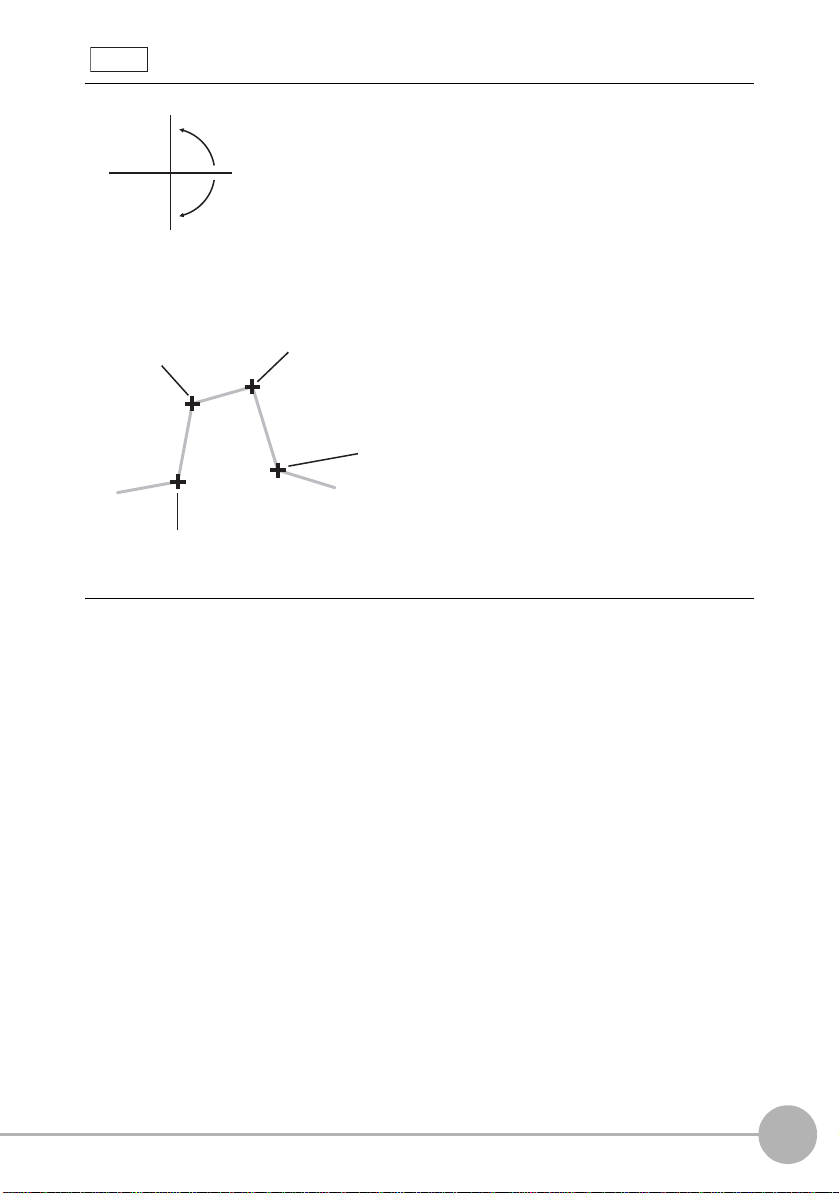

Position Correction . . . . . . . . . . . . . . . . . . . . . . . . . 106

Slope Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Height/Position Correction. . . . . . . . . . . . . . . . . . . . . . 109

Adjusting the Output Conditions of the Measurement

Result. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Setting the Average Number of Measurements . . . . . 111

Setting Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Setting the Hold Function . . . . . . . . . . . . . . . . . . . . . . 112

Setting Zero Reset . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Setting the Offset Value. . . . . . . . . . . . . . . . . . . . . . . . 114

10

ZG2 User’s Manual

Page 14

Executing Reference Zero Reset . . . . . . . . . . . . . . . . 115

Bank Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Bank Switching (change of device setup) . . . . . . . . . . 116

Copying Bank Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Clearing Bank Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Setting the Sensor Head Installation Status . . . . . . . . 118

Sensor Head Inclination Correction. . . . . . . . . . . . . . . 118

Setting the CCD Mode. . . . . . . . . . . . . . . . . . . . . . . . . 121

Setting the Sensor Head Data Loading Method . . . . . 121

Setting the Number of Digits Past the Decimal Point . 122

Setting/Changing the ECO Display . . . . . . . . . . . . . . . 122

Displaying the Controller Information . . . . . . . . . . . . . 122

Setting/Changing the Display Language. . . . . . . . . . . 123

Setting the Icon Color . . . . . . . . . . . . . . . . . . . . . . . . . 123

Saving the Setup Data. . . . . . . . . . . . . . . . . . . . . . . . . 123

4. CONNECTION WITH EXTERNAL DEVICES

ZG2 User’s Manual

Output Data List . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Using the Controller I/O Cable. . . . . . . . . . . . . . . . . 127

Wiring the Controller I/O Cable . . . . . . . . . . . . . . . . . . 127

Assignments and Functions of I/O Signal Wires. . . . . 128

I/O Circuit Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Analog Output Settings . . . . . . . . . . . . . . . . . . . . . . . . 132

Setting for Measurement by the TRIG Signal . . . . . . . 136

Setting for Switching Banks by the BANK Signal . . . . 136

Checking Signal Statuses . . . . . . . . . . . . . . . . . . . . . . 137

Setting the GATE Signal . . . . . . . . . . . . . . . . . . . . . . . 137

Using the Parallel Output Unit (sold separately). . 138

Connecting the Parallel Output Unit . . . . . . . . . . . . . . 138

Layout of Output Terminals. . . . . . . . . . . . . . . . . . . . . 138

Output Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Output Format of Measurement Values . . . . . . . . . . . 140

Output Format of Judgment Results . . . . . . . . . . . . . . 141

Assignment of Terminal Block Output. . . . . . . . . . . . . 143

11

Page 15

Setting the Number of Digits Past

the Decimal Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Setting GATE Signal at Parallel Output. . . . . . . . . . . . 143

I/O Timing Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Serial Communication . . . . . . . . . . . . . . . . . . . . . . . 149

Using the Serial Interface . . . . . . . . . . . . . . . . . . . . . . 149

Connecting Peripheral and External Devices . . . . . . . 152

Serial Auto Output at Trigger Measurement . . . . . . . . 155

Setting Automatic Output. . . . . . . . . . . . . . . . . . . . . . . 155

Setting the RS-232C Communication Specifications . 156

Setting the Node No. . . . . . . . . . . . . . . . . . . . . . . . . . . 156

About Communication Commands . . . . . . . . . . . . . . . 157

Bank Control Commands . . . . . . . . . . . . . . . . . . . . . . 160

Measurement Control/Measurement Value Acquisition

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Setting Acquisition/Change Commands . . . . . . . . . . . 165

Backup/Restore Commands . . . . . . . . . . . . . . . . . . . . 168

Utility commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Command Processing Time . . . . . . . . . . . . . . . . . . . . 181

5. MEASUREMENT BY GANG-MOUNTED CONTROLLERS

Mounting Order and Assignment of CH Numbers. 184

Setup Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Measuring Wide Measurement Targets . . . . . . . . . . . 185

Required Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Setting Mutual Interference Prevention . . . . . . . . . . . . 187

Settings Common to Gang-mounted Controllers. . . . . 189

Calculations Performed on Measurement Values Obtained

on Multiple Channels. . . . . . . . . . . . . . . . . . . . . . . . . . 190

I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

12

ZG2 User’s Manual

Page 16

6. APPENDICES

Specifications and External Dimensions . . . . . . . . 194

Sensor Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Error Messages and Corrective Actions . . . . . . . . 211

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Menu List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

List of Key Operations . . . . . . . . . . . . . . . . . . . . . . . 218

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Label Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Requirements from Regulations and Standards . . 222

Summary of Requirements to Manufactures. . . . . . . . 222

Summary of Requirements to User. . . . . . . . . . . . . . . 226

Definitions of Laser Classification . . . . . . . . . . . . . . . . 229

Compliance with EC Directives. . . . . . . . . . . . . . . . 231

Updating the Firmware. . . . . . . . . . . . . . . . . . . . . . . 232

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

ZG2 User’s Manual

13

Page 17

MEMO

14

ZG2 User’s Manual

Page 18

BEFORE USE

ZG2 Series 16

Basic Knowledge for Operation 21

Precautions when designing a production

line 22

Mounting and Connecting Devices 27

Overview of Settings and Measurement 52

1

BEFORE USE

Page 19

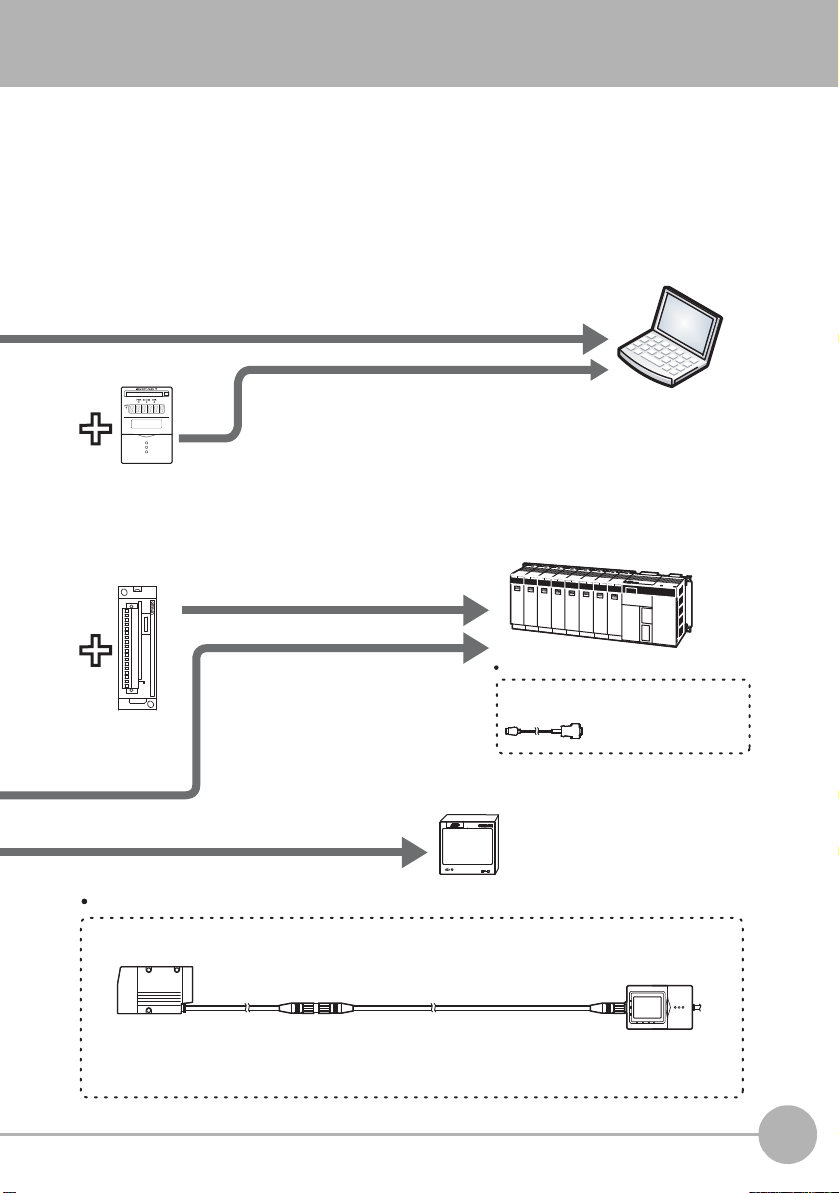

ZG2 Series

Sensor Head

Sensor Head

Controller Controller

ZG2 series

Up to two units

can be

gang-mounted.

ZG2-WDC11/WDC41

PC

Smart Monitor ZG2

(exclusive PC software)

ZG2-WDS70

ZG2-WDS22

ZG2-WDS8T

ZG2-WDS3VT

Detects the

measurement

target.

Performs

measurement

processing and

outputs the result.

Photoelectric sensor, etc.

A trigger signal is

input to control

measurement

timing.

Exclusive PC software allows complex

setups and verification of measurement

values to be performed with ease.

SmartMonitor ZG2 and USB cable are

ZG2-WDC_1A accessories.

Measurement by the ZG2 series can be started immediately merely by connecting the

model of Sensor Head suited to the application to the Controller. Also, the ZG2 series can

support various measurement applications by using it in combination with peripheral

devices.

System Configuration

16

ZG2 Series

ZG2 User’s Manual

Page 20

Sensor Head-Controller extension cable (option)

Extension cable

ZG2-XC_ _CR:

(3 m, 8 m, 15 m, 25 m) (flexible cable)

Cable for Sensor:

0.5 m, 2 m (flexible cable)

Exclusive extension cables are available for extending the installation distance between the

Sensor Head and the Controller.

ZG-RP D

PARALLEL OUTPUT UNIT

RS-23 2 C

DATA

PC

PLC

Graphic Data Controller ZP-C

Data Storage

Unit ZG2-DSU11

/DSU41

RS-232C connector cable (option)

For PC: ZS-XRS2

For PLC/PT: ZS-XPT2

Parallel Output

Unit ZG-RPD11

/RPD41

A USB connection allows measurement data to be

captured easily on a PC. Also, the Controller can be

controlled from a PC (e.g. switching/changing of setup

data and input of measurement trigger).

Measurement values and judgment

results can be output at high speed

on the parallel interface.

Measurement values and judgment

results can be acquired, and the

controller can be controlled (e.g.

setup data can be switched/changed

and measurement triggers can be

input).

The analog signals of measurement values can be displayed

as a waveform, and judgment results can be displayed in

color.

Measurement data can be collected and profiles

saved. Also, up to 4096 banks' (16 banks x 256 files)

of measurement conditions can be registered if the

number of banks on the Controller is insufficient. A

USB connection allows data to be captured on a PC.

For details, refer to the ZG2-DSU User's Manual.

Exclusive cables are available to match

the conn ected dev ice.

1

BEFORE USE

ZG2 User’s Manual

ZG2 Series

17

Page 21

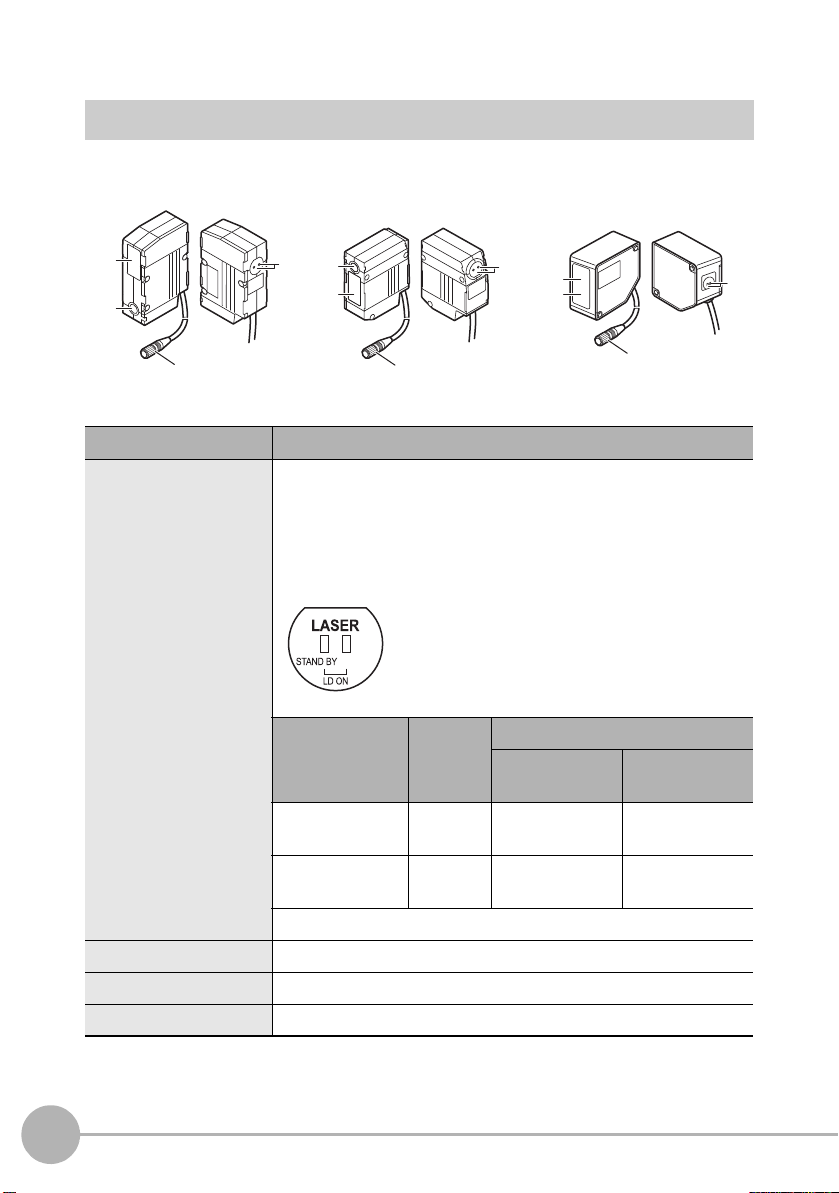

Part Names and Functions

[ZG2-WDS3VT] [ZG2-WDS8T/WDS22] [ZG2-WDS70]

(1)

(3)

(2)

(4)

(1)

(3)

(2)

(4)

(3)

(2)

(1)

(4)

Sensor Head

Name Function

(1) Laser indicator These are laser beam warning indicators. The “standby indicator

(STANDBY)” indicates that the laser beam is ready for emission,

and the “laser energized indicator (LD ON)” indicates that the laser

is energized.

Both indicators are OFF until Controller startup is completed after

the power is turned ON.

Indicator At startup RUN/ADJ/FUN mode

LD OFF in

progress

Standby indicator

(STANDBY)

Laser indicator

(LD ON)

(2) Laser emitter This emits the laser for measurement.

(3) Laser receiver This receives the laser light reflected from the measurement target.

(4) Connector This is the connector for connecting to the Controller.

18

ZG2 Series

OFF ON ON

OFF OFF ON

LD ON in

progress

ZG2 User’s Manual

Page 22

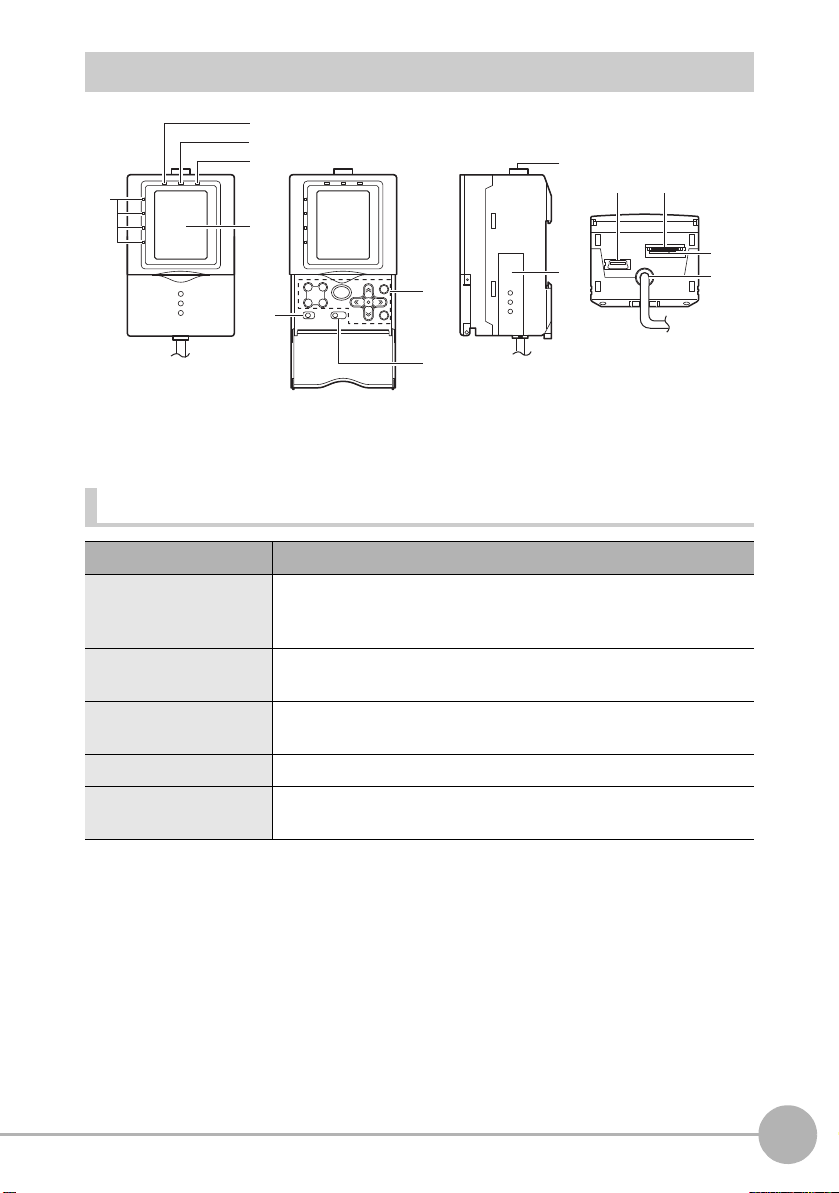

Controller

(2)

(3)

(4)

(1)

(5)

(1)

(3)

(2)

Display Operation Panel Connectors

(2)

(1)

(3)

(4)

(5)

(6)

Display

Name Function

(1)Judgment indicator The indicator turns ON when the result of task judgment is OK, and

turns OFF when a setting is not made, measurement is OFF, the

result of a judgment is NG, or an error occurs.

(2) Laser indicator The laser indicator turns ON while the Sensor Head is emitting a

laser beam.

(3) Zero Reset indicator The Zero Reset indicator turns ON when the zero reset function is

enabled.

(4) Trigger indicator The Trigger indicator turns ON when a trigger signal is input.

(5) LCD monitor The LCD monitor displays setup menus and images captured from

the Sensor Head.

1

BEFORE USE

ZG2 User’s Manual

ZG2 Series

19

Page 23

Operation Panel

Important

Name Function

(1) Control keys These keys are used for setting measurement conditions or

switching the display.

List of Key Operations p.218

(2) Mode switch This switch selects the operation mode.

FUN : Select this mode when setting measurement conditions.

Select this mode when adjusting the judgment threshold value.

ADJ :

RUN : Select this mode when performing measurement.

Measurement results and judgment results are output only when the

RUN mode is currently selected.

(3) Menu switch This switch selects the setup menu.

STD : Standard menu. Select this when setting the minimum

required items for measurement.

EXP : Expert menu. Select this when making a more detailed setup.

Connectors

Name Function

(1) Sensor Head

connector

(2) Function extension

connector

(3) USB port Connect the USB cable (MINI-B) to the USB port to connect to a

(4) RS-232C connector Connect the RS-232C cable (exclusive product) when you are

This connector connects the Sensor Head.

Insert this connector into the Controller Link Unit when gangmounting Data Storage Units and Controllers. Slide the cover

(supplied) downwards to open.

personal computer.

connecting the Controller to a PLC, programmable terminal or

personal computer.

20

RS-232C cable p.17

(5) Voltage/Current

switch

(6) I/O cable The I/O cable connects the Controller to the power supply and

ZG2 Series

This switch is for selecting voltage output or current output as the

analog output.

(default value: voltage output)

Before operating this switch, make sure that the Controller is turned

OFF.

external devices, such as timing sensors or programmable

controllers.

ZG2 User’s Manual

Page 24

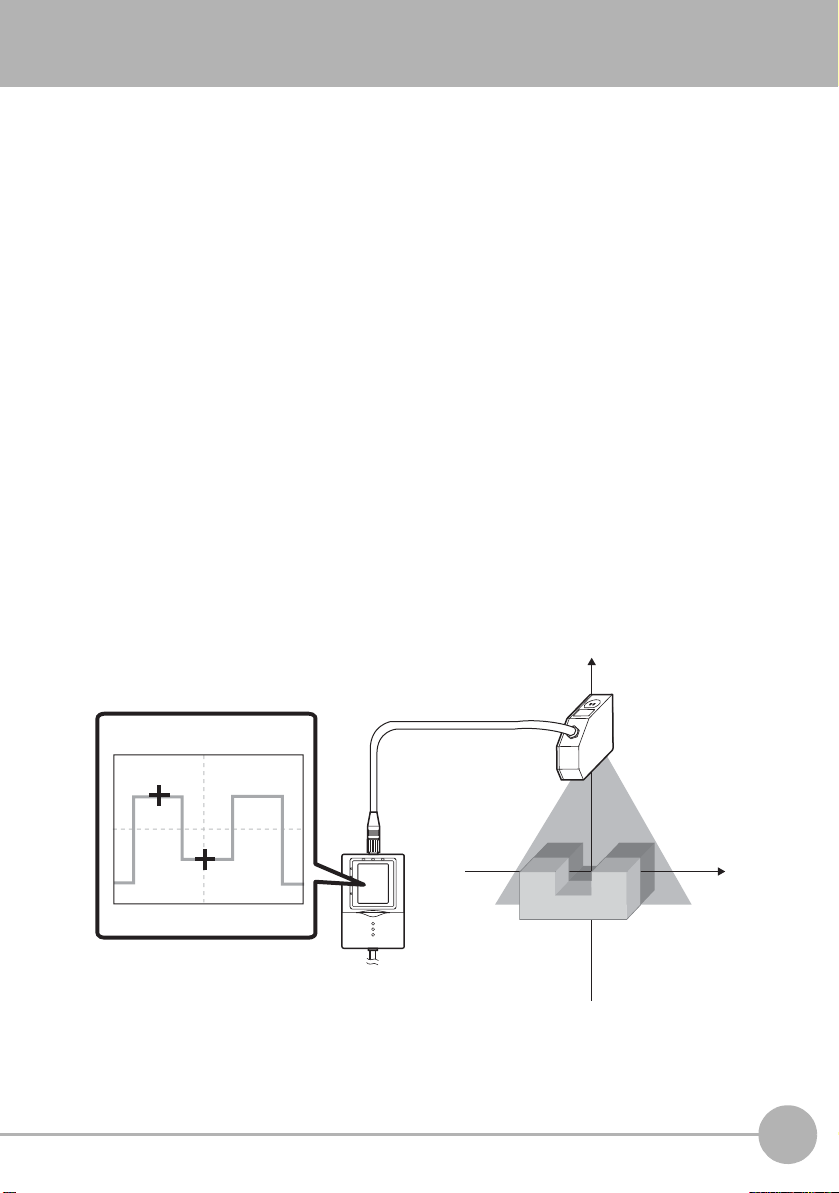

Basic Knowledge for Operation

X-axis +X-axis -

Z-axis -

Z-axis +

NEAR

-5.00 mm

FAR

0

+5.00 mm

The ZG2 series is a non-destructive type sensor that measures cross-section shapes by

emitting a wide band of laser light onto the object and capturing light reflected from the

object by a CCD. This CCD imaging information is used to generate a profile of the

object’s shape, and dimensional shapes, such as height, steps, width, position, points of

intersection, inclination, and cross-sectional area, can be measured instantaneously from

the cross-section shape of the object.

Profile Screen

A cross-section shape of the measurement object displayed on screen is called a

“profile.” Profiles are displayed on screen as a yellow line.

In the RUN/ADJ modes, the measurement state can be visually checked by these

profiles. Also, in the FUN mode, profiles can be used to set the measurement conditions.

Height measurement items are already set as the default, so it is possible to know

immediately the detection status of the Sensor Head by setting the operation mode to the

RUN mode.

On the ZG2 series, measurement points in the height and width directions are measured

on the vertical (Z-axis) and horizontal (X-axis) axes, respectively. Measurement values

are displayed as numerical values prefixed with a + (plus) or - (minus) sign depending on

the coordinate position.

1

BEFORE USE

ZG2 User’s Manual

Basic Knowledge for Operation

21

Page 25

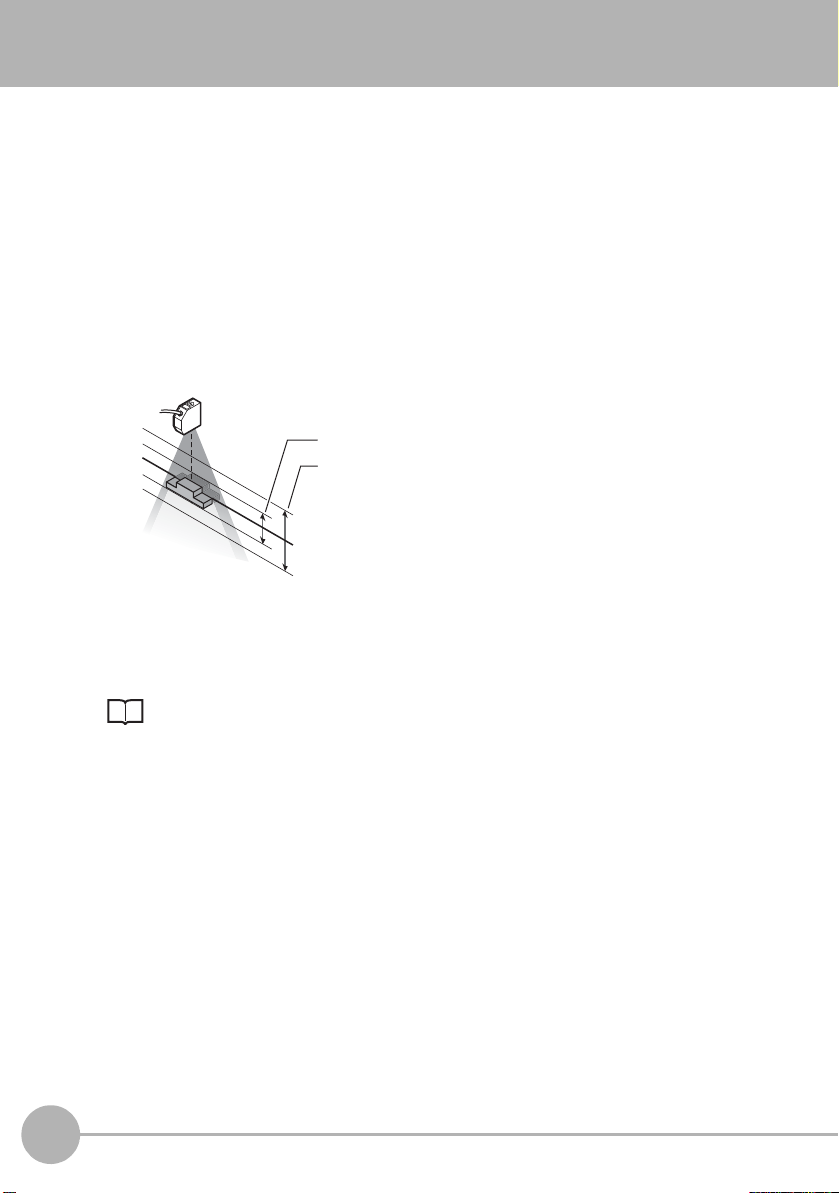

Precautions when designing a production line

Measurement range in high-speed mode

Measurement range in standard/high-resolution mode

Measurement center

The measurement center distance does not

change even if the CCD mode is changed.

The following describes details to be aware of before installing the ZG2 on a production

line.

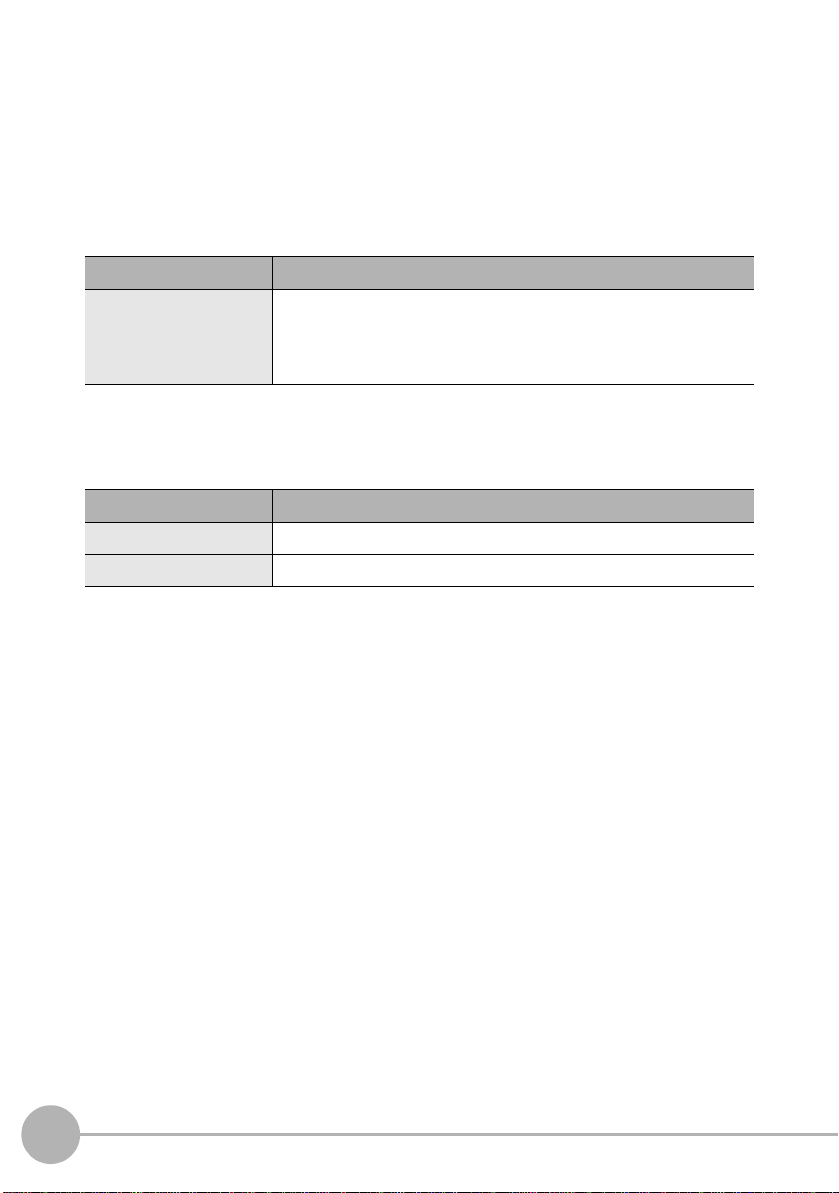

Measurement Range in Height Direction and Resolution

The ZG2 incorporates the CCD mode function that alters how the CCD is used to achieve

high-speed and high-resolution measurement.

When the CCD mode is changed, the measurement range in the height direction and the

resolution are altered.

For actual details of measurement ranges, refer to the respective pages that explain

mounting of each of the sensor heads.

Mounting the Sensor Head p.27

22

Precautions when designing a production line

ZG2 User’s Manual

Page 26

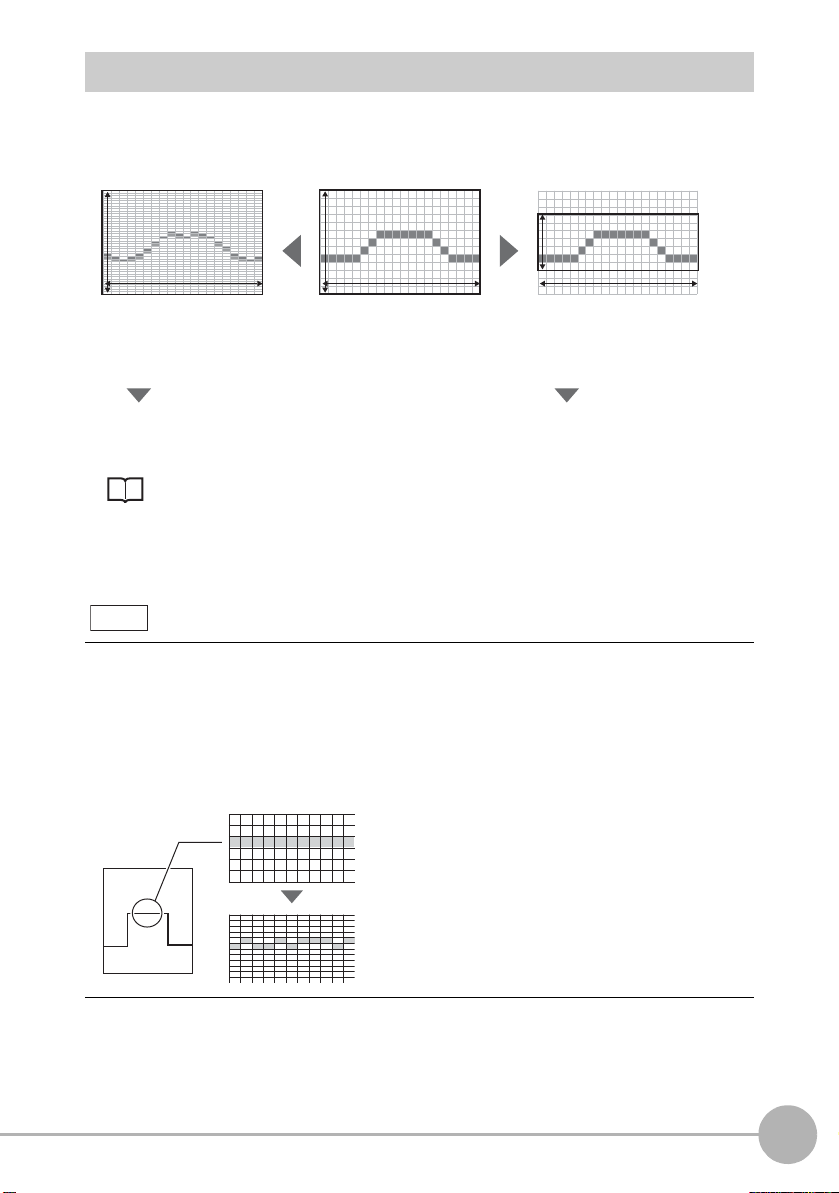

Three CCD Modes and Their Characteristics

High-resolution mode: min. 16 ms

400 pixels 100 pixels 50 pixels

Standard mode: min. 8 ms High-speed mode: min. 5 ms

631 pixels 631 pixels 631 pixels

By quadrupling the number of

pixels in the height direction

By decreasing the number of pixels

into 1/2 in the height direction

High-resolution measurement of

the shape of measurement targets

Shape measurement in fast line

speed processes

Standard images look flat.

Surfaces, in fact, are slightly uneven.

Resolution in the height direction changes as follows according to the CCD mode.

Setting the CCD Mode p.121

The resolution in the horizontal direction does not change. When measuring edge

position or width, select the CCD mode based on the response time as the resolution will

not change whichever mode is selected.

Note

Number of pixels and resolution

To express the clarity on a digital camera or image scanner, the term “resolution” is

used. The same approach is used on the ZG2 series, too. A “high resolution” expresses

a sharp image, while a “low resolution” expresses a grainy image. Resolution is

determined by the number of pixels per unit area. Though a sh arper or highe r re solut ion

image is obtained, the more pixels there are per unit area, processing takes that much

longer proportionate to the amount of information for that image.

1

BEFORE USE

ZG2 User’s Manual

Precautions when designing a production line

23

Page 27

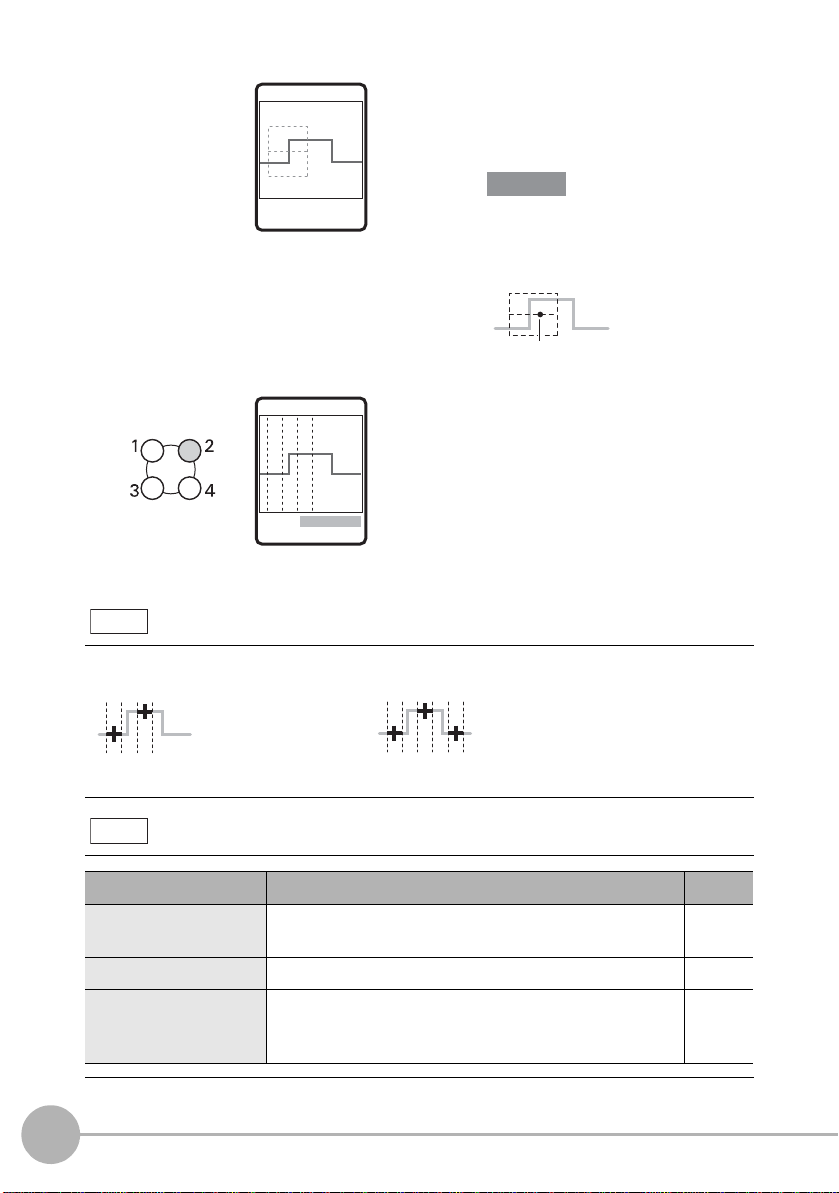

Trigger Measurement/Continuous Measurement

Trigger

Trigger

Trigger

The ZG2 series is provided with two measurement modes, “input of an external trigger to

start measurement” and “continuous measurement with out th e need for inp ut of a trigger.”

Note, however, that available sensitivities are restricted by the type of trigger and

direction in which the measurement object is moving. Select which combination to use to

suit your specific application.

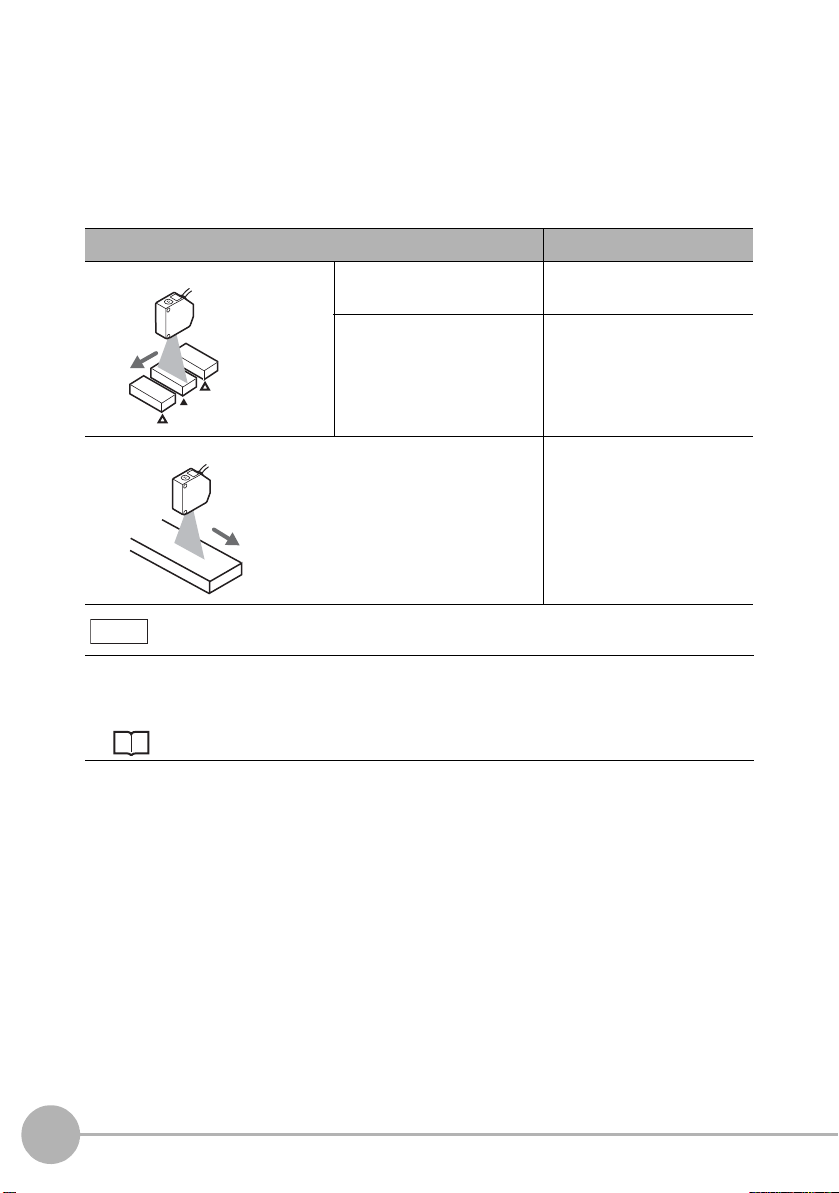

Measurement trigger and direction in which object is flowing Appropriate sensitivity

Measurement by external trigger When object can be made

stationary

When object cannot be

made stationary

Continuous measurement AUTO sensitivity/FIXED

Note

High-speed MULTI

sensitivity/MULTI sensitivity

AUTO sensitivity/FIXED

sensitivity

sensitivity

The default setting is continuous measurement.

To perform measurement by an external trigger, the setting must be changed.

Setting for Measurement by the TRIG Signal p.136

24

Precautions when designing a production line

ZG2 User’s Manual

Page 28

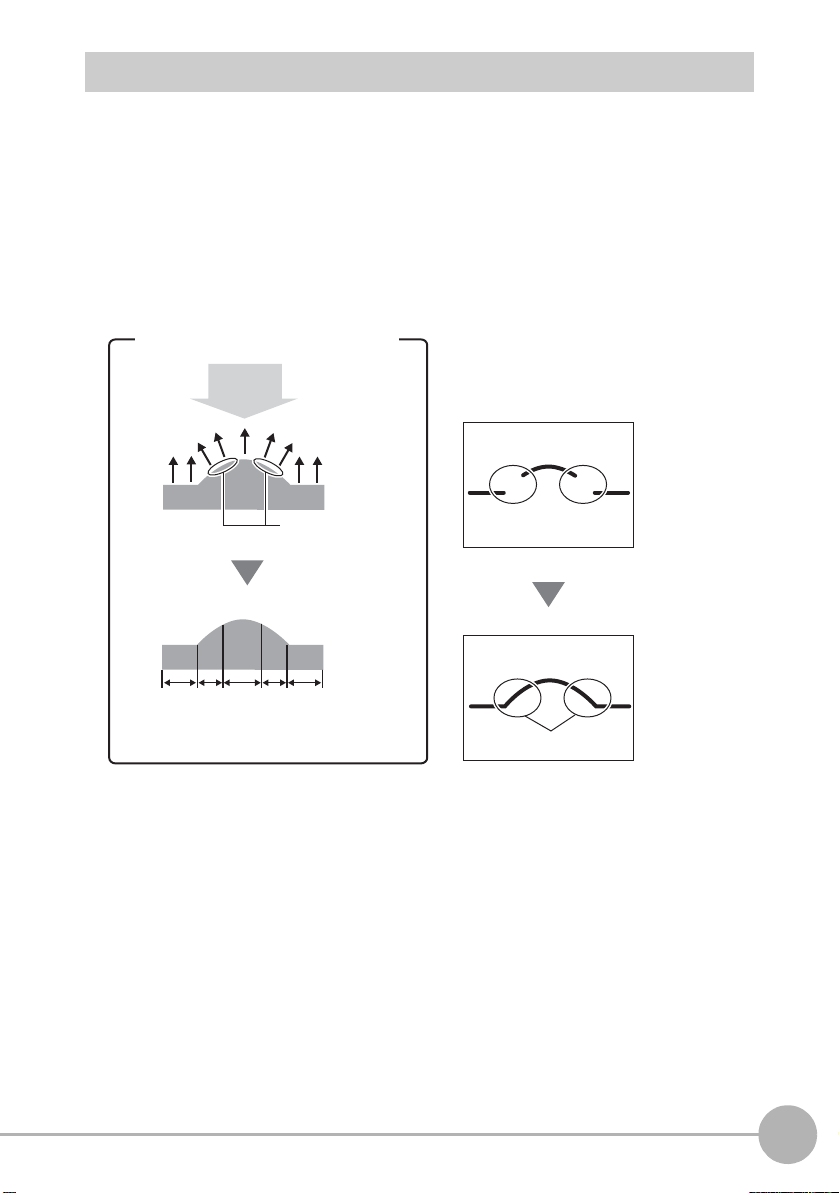

What is “Sensitivity Adjustment?”

In the case of a mountain-shaped

measurement object

Light emitted

from Sensor

Areas where

reflected light will

have difficulty

entering the CCD

High Low Medium Low High

Reference plane

Reflectance

The reflectance of the reference plane

differs from that of inclined surfaces.

Areas having low

reflectance cannot be

measured due to

insufficient light amount.

Sensitivity adjustment

Reproduction of profile

It is relatively easy to measure the shape of a measurement target that receives a

sufficient and uniform amount of light. However, in the case of measurement targets

having a complex shape, inclined surfaces cause reflected light to decrease and areas of

insufficient received light to occur. There are also cases where the amount of received

light is insufficient or, alternatively, saturated caused by the color or material of the

measurement target. In this way, the sensitivity of the Sensor must be adjusted so that

shapes are accurately captured even if the shape, color, material, etc. of the

measurement target is influenced.

1

BEFORE USE

ZG2 User’s Manual

Precautions when designing a production line

25

Page 29

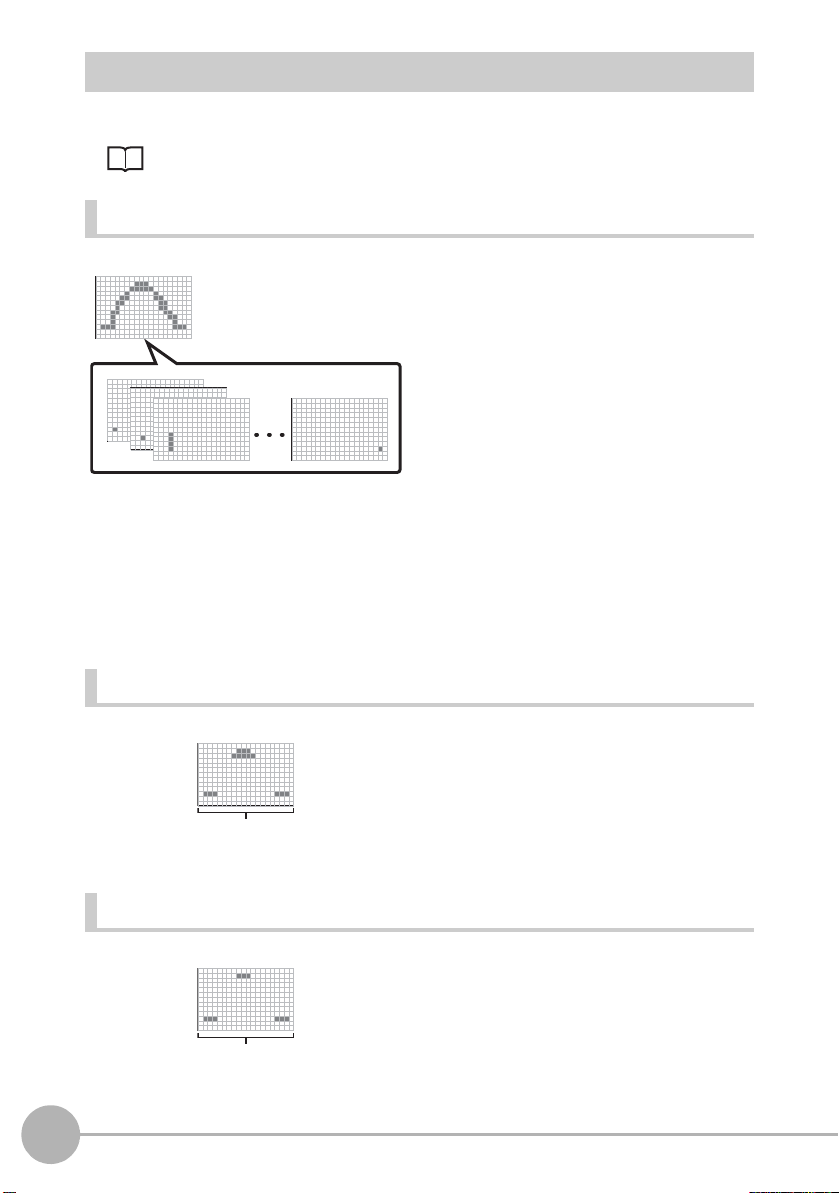

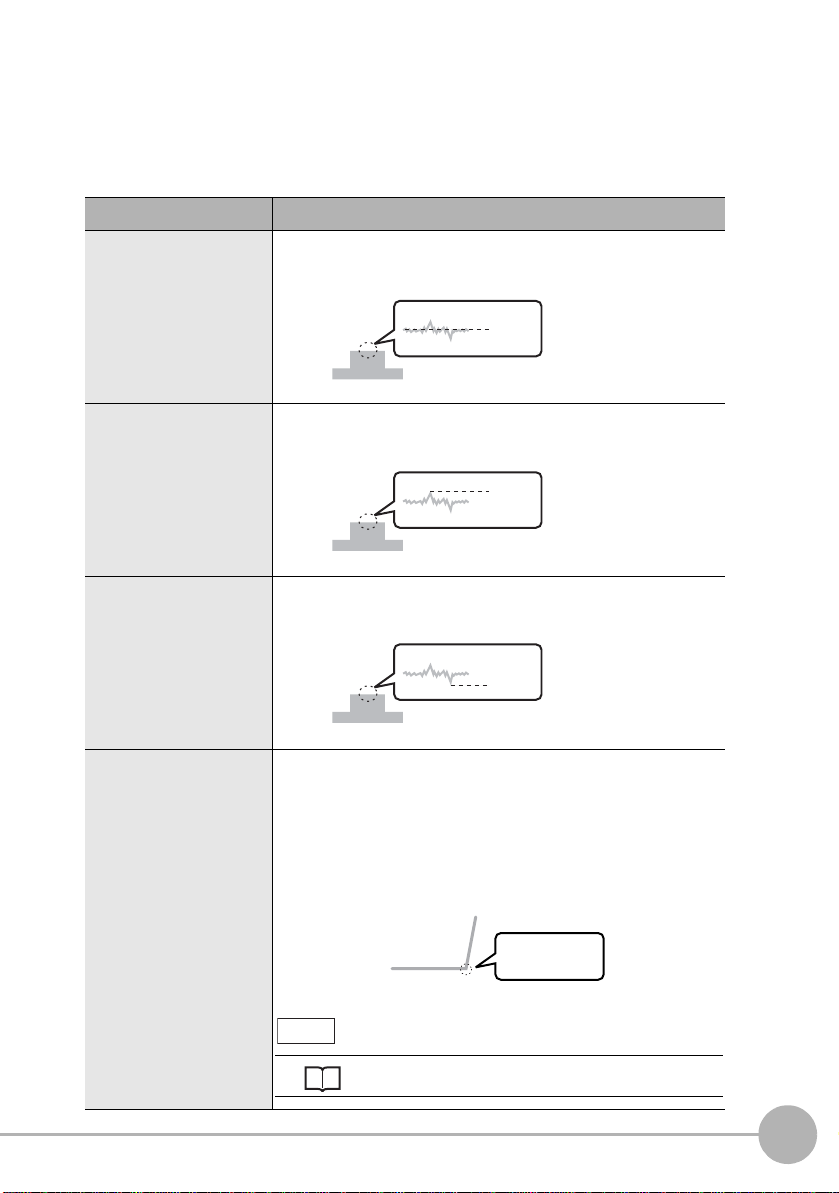

Sensitivity Adjustment Functions of the ZG2 Series

The optimum sensitivity

is adjusted for individual

lines and combined to

form the image.

The optimum sensitivity

common to all lines is

adjusted.

Sensitivity is

fixed for all lines.

The ZG2 series is provided with three sensitivity adjustment functions.

Adjusting Sensitivity p.96

High-speed MULTI sensitivity/MULTI sensitivity

The amount of received light per individual

line is judged and the appropriate sensitivity

for each individual line is adjusted to

accommodate for all kinds of shape, color

and material. The measurement target must

be made stationary as time is required to

capture multiple image frames while

changing the sensitivity.

High-speed MULTI sensitivity is used when

MULTI sensitivity is required on lines having

a fast tact time. The upper/lower limit range at

which sensitivity is switched and the capture

count can be restricted. The optimum

sensitivity and number of image frames are

set automatically within this range. Note,

however, that the measurement must first be

made stationary even in the high-speed

MULTI sensitivity mode.

AUTO sensitivity

FIXED sensitivity

26

Precautions when designing a production line

The amount of received light for all lines is

judged to adjust to the appropriate s ensitivity

for the entire area. As sensitivity is batchadjusted for all lines, the response is not as

slow as that for MULTI sensitivity, so this

mode is a generally applicable mode.

In this mode, a predetermined sensitivity is

used. As sensitivity is not adjusted during

measurement, response is fast, making it

ideal for when a trigger is input at short

intervals to perform measurement.

ZG2 User’s Manual

Page 30

Mounting and Connecting Devices

Mounting the Sensor Head

Never look into the laser beam. Doing so continuously will result in

visual impairment.

Never look into the laser beam.

Do not attempt to dismantle, pressurize, or incinerate the p roduct. Doing so

may cause the laser beam to leak, resulting in the danger of visual

impairment. Do not attempt to dismantle, pressurize, or incinerate the product.

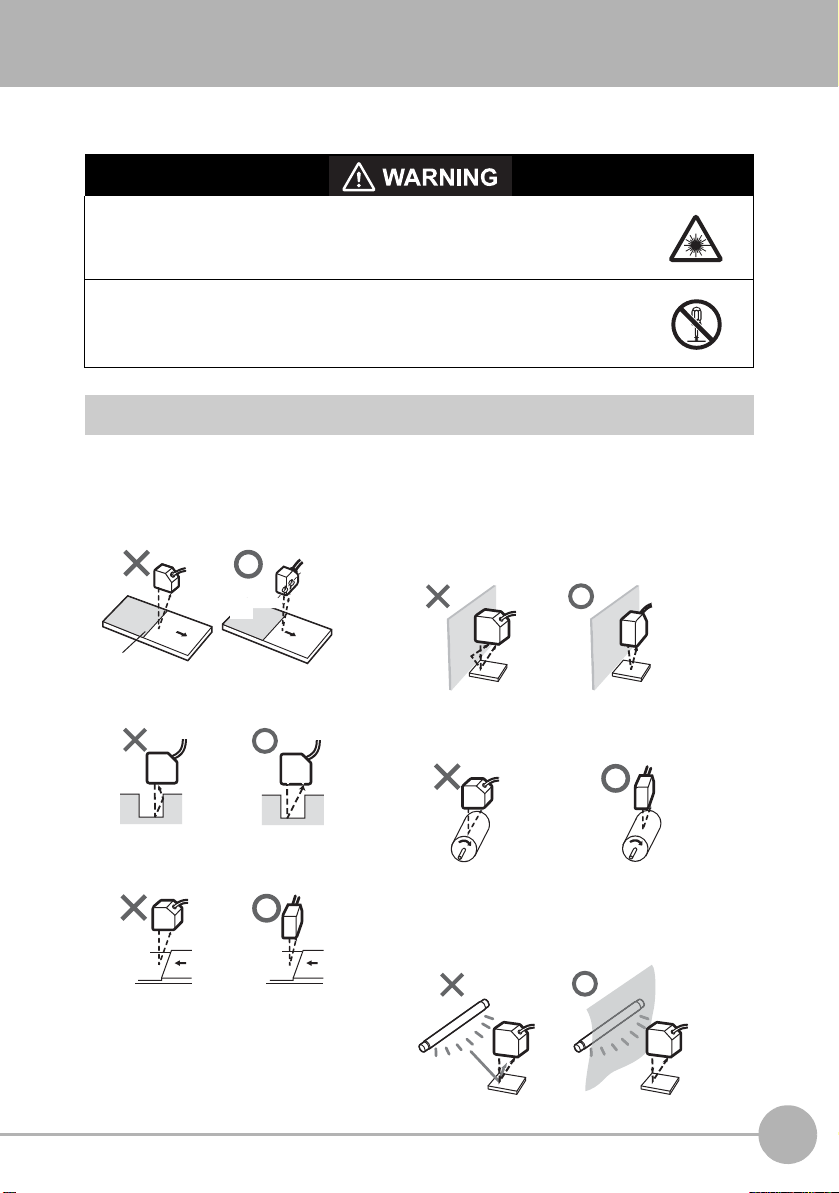

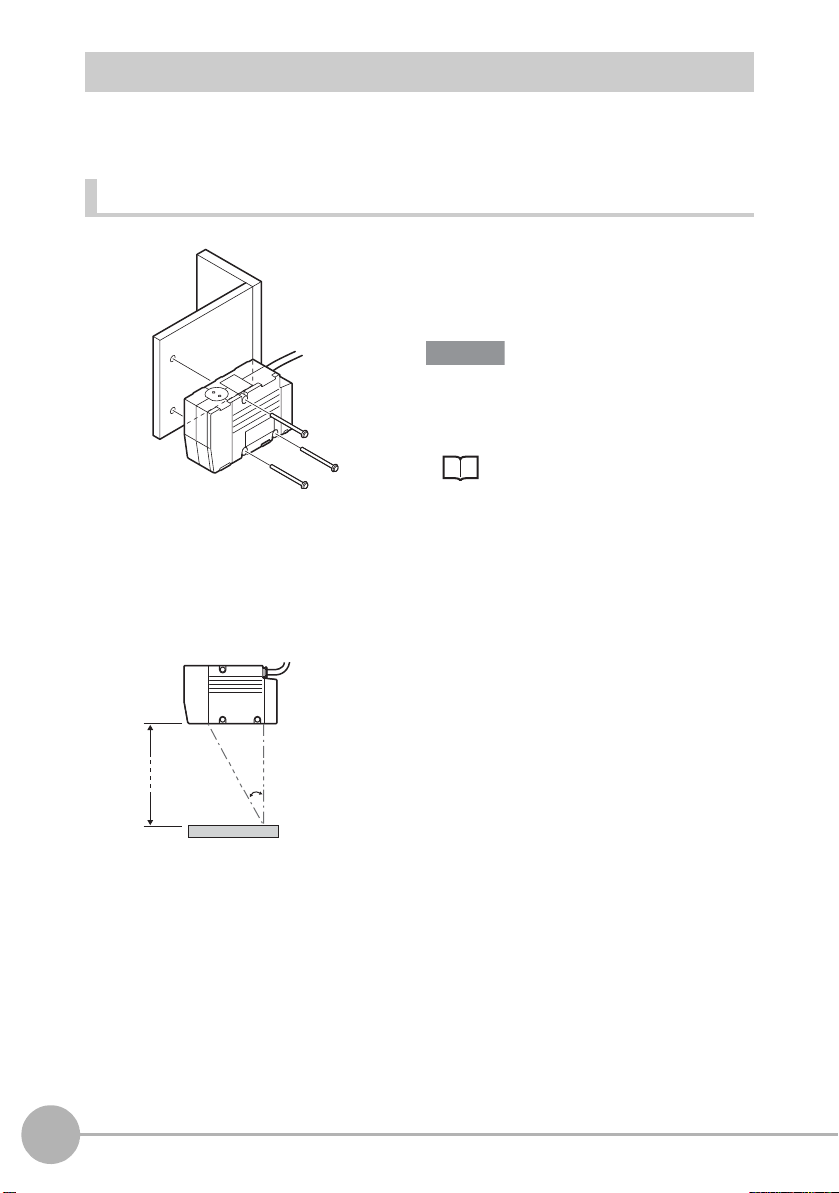

Installations to Suit Measur ement Target and Environment

Pay attention to the following points when mounting the Sensor Head to prevent

measurement precision from dropping.

Color/shiny surface boundary

Emission

axis

Boundary line

Narrow grooves or indentations

Reception

axis

Mounting near walls

Measurement errors can be reduced by installing the Sensor Head

with the line formed by the emission and reception axes parallel to

the wall, and painting the wall with non-reflective black paint.

Rotating objects

You can minimize the influence caused by vibration of the rotating object

and positional shifts by installing the Sensor Head with the line formed

by the emission and reception axes parallel to the axis of rotation.

1

BEFORE USE

Measuring stepped objects

ZG2 User’s Manual

Effect of peripheral lighting

Do not install the Sensor Head in a place where strong light hits the

laser emitter/receiver section of the Sensor. Also, if a measurement

target has a shiny surface, the light from the lighting will be reflected

and a malfunction may occur. In such as case, prevent reflection, for

example, by covering the light to stop reflection.

Mounting and Connecting Devices

27

Page 31

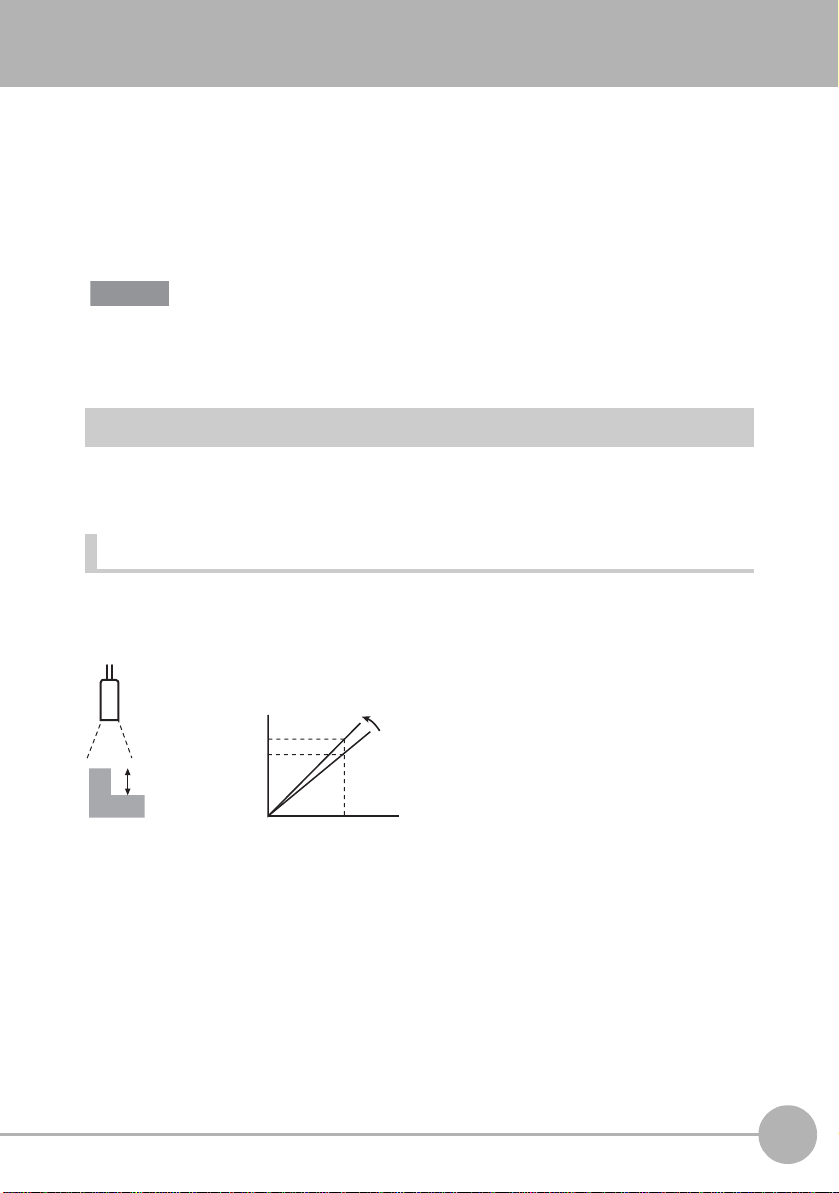

Mounting the ZG2-WDS70

Important

Mounting for diffuse reflection

measurement

Emission axis

Reception axis

210 mm

19°

Measurement target

Fix by mounting screws making sure that the distance between the Sensor Head and

measurement target is matched.

Mounting method

Fasten the Sensor Head onto the mounting

base with M4 screws.

Tightening torque: 1.2 N·m

For details on the positions of screw holes,

check the external dimensions in

“APPENDICES.”

External dimensions p.196

Mounting position

Mount the Sensor Head according to the following distances and angle.

28

Mounting and Connecting Devices

ZG2 User’s Manual

Page 32

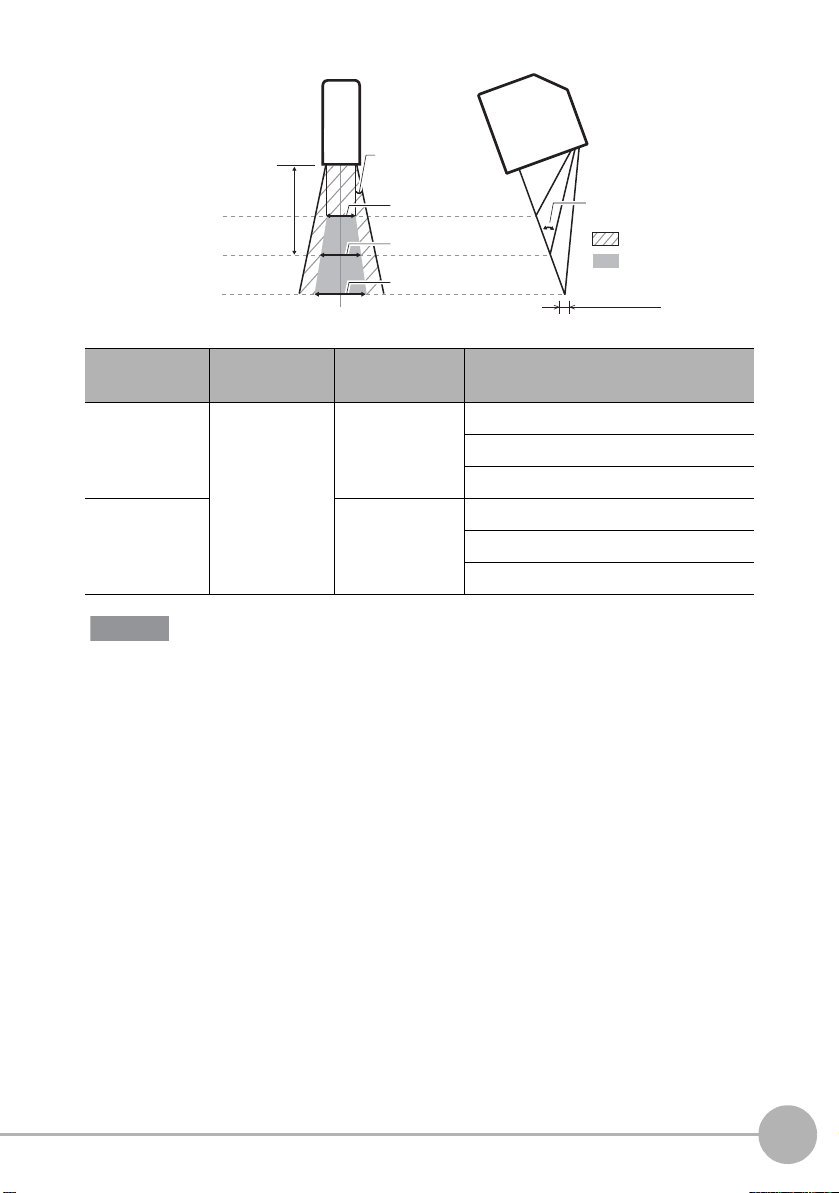

Measurement range

Important

Numerical values in the figure are for when the standard CCD mode is set. When the

CCD mode is changed, check the values in the table below.

<Mounting for diffuse reflection measurement>

1

BEFORE USE

Measurement center distance

NEAR end

CENTER

FAR end

210 mm

+30 mm

0 mm

-30 mm

CCD Mode Measurement

center distance

Standard

mode

Highresolution

mode

High-speed

mode

210mm ±30 mm NEAR end: 63mm 300 µm

Spread angle 10°

Measurement range (width)

63 mm

70 mm

79 mm

Measurement

range (height)

±48 mm NEAR end: 57mm 410 µm

±15 mm NEAR end: 66mm 210 µm

Measurement range

(width)

CENTER: 70mm 120 µm

FAR end: 79mm 300 µm

CENTER: 70mm 120 µm

FAR end: 83mm 410 µm

CENTER: 70mm 120 µm

FAR end: 74mm 210 µm

Angle of intersection 19°

: Irradiation range

: Measurement range

Beam diameter

Beam

diameter

The beam diameter and measurement range (width) between the NEAR/FAR ends are nominal

values, and are not to be used as guaranteed values.

ZG2 User’s Manual

Mounting and Connecting Devices

29

Page 33

Mounting the ZG2-WDS22

Important

Fix by mounting screws making sure that the distance between the Sensor Head and

measurement target is matched.

Mounting method

Fasten the Sensor Head onto the mounting

base with M4 screws.

Tightening torque: 1.2 N·m

For details on the positions of screw holes,

check the external dimensions in

“APPENDICES.”

External dimensions p.197

Mounting position

Mount the Sensor Head according to the following distances and angle.

30

12.5°

Emission axis Reception axis

100 mm

25°

Measurement target

Mounting for diffuse reflection

measurement

Emission axis Reception axis

94 mm

Measurement target

Mounting for regular reflection

measurement

Note

The default mounting state of the Sensor Head is for diffuse reflection measurement. To set

the Sensor Head for regular reflection measurement, change the Sensor Head mounting

setting.

Setting the Sensor Head Installation Status p.118

Mounting and Connecting Devices

ZG2 User’s Manual

Page 34

Measurement range

NEAR end

+12 mm

CENTER

0 mm

FAR end

-12 mm

Measurement center distance

100 mm

Spread angle 10°

Angle of intersection 25°

: Measurement range

: Irradiation range

20 mm

22 mm

24 mm

Measurement range (width)

Beam diameter

Important

Numerical values in the figure are for when the standard CCD mode is set. When the

CCD mode is changed, check the values in the table below.

<Mounting for diffuse reflection measurement>

1

BEFORE USE

CCD Mode Measurement

center distance

Standard mode/

high-resolution

mode

High-speed

mode

The beam diameter and measurement range (width) between the NEAR/FAR ends are nominal

values, and are not to be used as guaranteed values.

100mm ±12 mm NEAR end: 20mm 220 µm

Measurement

range (height)

±6 mm NEAR end: 21mm 140 µm

Measurement range

(width)

CENTER: 22mm 60 µm

FAR end: 24mm 220 µm

CENTER: 22mm 60 µm

FAR end: 23mm 140 µm

Beam

diameter

ZG2 User’s Manual

Mounting and Connecting Devices

31

Page 35

<Mounting for regular reflection measurement>

Important

Measurement center distance

94 mm

NEAR end

CENTER

FAR end

+10 mm

0 mm

-10 mm

CCD Mode Measurement

center distance

Standard mode/

94mm ±10 mm NEAR end: 20mm 220 µm

high-resolution

mode

Measurement range (width)

20 mm

22 mm

24 mm

Measurement

range (height)

Measurement range

(width)

CENTER: 22mm 60 µm

Angle of intersection 25°

: Irradiation range

: Measurement range

Beam diameter

Beam

diameter

FAR end: 24mm 220 µm

Spread angle 10°

High-speed

mode

±6 mm NEAR end: 21mm 140 µm

CENTER: 22mm 60 µm

FAR end: 23mm 140 µm

The beam diameter and measurement range (width) between the NEAR/FAR ends are nominal

values, and are not to be used as guaranteed values.

32

Mounting and Connecting Devices

ZG2 User’s Manual

Page 36

Mounting the ZG2-WDS8T

Important

Mounting for diffuse reflection

measurement

Emission axis Reception axis

50 mm

30°

Measurement target

Mounting for regular reflection

measurement

Emission axis Reception axis

44 mm

Measurement target

15°

Fix by mounting screws making sure that the distance between the Sensor Head and

measurement target is matched.

Mounting method

Fasten the Sensor Head onto the mounting

base with M4 screws.

Tightening torque: 1.2 N·m

For details on the positions of screw holes,

check the external dimensions in

“APPENDICES.”

External dimensions p.197

Mounting position

Mount the Sensor Head according to the following distances and angle.

1

BEFORE USE

Note

The default mounting state of the Sensor Head is for diffuse reflection measurement. To set

the Sensor Head for regular reflection measurement, change the Sensor Head mounting

setting.

Setting the Sensor Head Installation Status p.118

ZG2 User’s Manual

Mounting and Connecting Devices

33

Page 37

Measurement range

Important

Numerical values in the figure are for when the standard CCD mode is set. When the

CCD mode is changed, check the values in the table below.

<Mounting for diffuse reflection measurement>

Measurement center distance

50 mm

NEAR end

CENTER

FAR end

+3 mm

0 mm

-3 mm

CCD Mode Measurement

center distance

Standard mode/

50mm ±3 mm NEAR end: 7.9mm 120 µm

high-resolution

mode

Measurement range (width)

7.9 mm

8.0 mm

8.6 mm

Measurement

range (height)

Angle of intersection 30°

: Irradiation range

: Measurement range

Beam diameter

Measurement range

(width)

Beam

diameter

CENTER: 8.0mm 30 µm

FAR end: 8.6mm 120 µm

Spread angle 10°

High-speed

mode

±1.5 mm NEAR end: 7.7mm 110 µm

CENTER: 8.0mm 30 µm

FAR end: 8.3mm 110 µm

The beam diameter and measurement range (width) between the NEAR/FAR ends are nominal

values, and are not to be used as guaranteed values.

34

Mounting and Connecting Devices

ZG2 User’s Manual

Page 38

<Mounting for regular reflection measurement>

Important

Measurement center distance

NEAR end

CENTER

FAR end

44 mm

+2 mm

0 mm

-2 mm

Spread angle 10°

Measurement range (width)

7.9 mm

8.0 mm

8.6 mm

1

BEFORE USE

Angle of intersection 30°

: Irradiation range

: Measurement range

Beam diameter

CCD Mode Measurement

center distance

Standard mode/

high-resolution

mode

High-speed

mode

The beam diameter and measurement range (width) between the NEAR/FAR ends are nominal

values, and are not to be used as guaranteed values.

44mm ±2 mm NEAR end: 7.9mm 120 µm

Measurement

range (height)

±1 mm NEAR end: 7.9mm 105 µm

Measurement range

(width)

CENTER: 8.0mm 30 µm

FAR end: 8.6mm 120 µm

CENTER: 8.0mm 30 µm

FAR end: 8.1mm 105 µm

Beam

diameter

ZG2 User’s Manual

Mounting and Connecting Devices

35

Page 39

Mounting the ZG2-WDS3VT

Important

Reception axis

22.3 mm

Emission axis

Measurement target Measurement target

Mounting for

regular reflection measurement

Mounting for

diffuse reflection measurement

20°

Emission axis Reception axis

10.6 mm

40°

Note

Fix by mounting screws making sure that the distance between the Sensor Head and

measurement target is matched.

Mounting method

Fasten the Sensor Head onto the mounting

base with M4 screws.

Tightening torque: 1.2 N·m

For details on the positions of screw holes,

check the external dimensions in

“APPENDICES.”

External dimensions p.199

Mounting position

Mount the Sensor Head according to the following distances and angle.

The default mounting state of the Sensor Head is for regular reflection measurement. To set

the Sensor Head for diffuse reflection measurement, change the Sensor Head mounting

setting.

Setting the Sensor Head Installation Status p.118

36

Mounting and Connecting Devices

ZG2 User’s Manual

Page 40

Measurement range

2.9 mm

3.0 mm

3.1 mm

Measurement range

(width)

Angle of intersection 40°

: Measurement rang

: Irradiation range

Beam diameter

+0.5 mm

CENTER

FAR end

Measurement center distance

22.3 mm

NEAR end

0 mm

-0.5 mm

Important

Numerical values in the figure are for when the standard CCD mode is set. When the

CCD mode is changed, check the values in the table below.

<Mounting for regular reflection measurement>

1

BEFORE USE

CCD Mode Measurement

center distance

Standard mode/

high-resolution

mode

High-speed

mode

The beam diameter and measurement range (width) between the NEAR/FAR ends are nominal

values, and are not to be used as guaranteed values.

22.3mm ±0.5 mm NEAR end: 2.9mm 40 µm

Measurement

range (height)

±0.25 mm NEAR end: 2.95mm 33 µm

Measurement range

(width)

CENTER: 3.0mm 25 µm

FAR end: 3.1mm 40 µm

CENTER: 3.0mm 25 µm

FAR end: 3.05mm 33 µm

Beam

diameter

ZG2 User’s Manual

Mounting and Connecting Devices

37

Page 41

<Mounting for diffuse reflection measurement>

NEAR end

+0.4 mm

CENTER

0 mm

FAR end

-0.4 mm

Measurement center distance

10.6 mm

2.9 mm

3.0 mm

3.1 mm

Measurement range

(width)

Angle of intersectio

: Measuremen

: Irradiation ra

Beam diameter

Important

CCD Mode Measurement

center distance

Standard mode/

10.6mm ±0.4 mm NEAR end: 2.9mm 40 µm

high-resolution

mode

Measurement

range (height)

Measurement range

(width)

Beam

diameter

CENTER: 3.0mm 25 µm

FAR end: 3.1mm 40 µm

High-speed

mode

±0.2 mm NEAR end: 2.95mm 33 µm

CENTER: 3.0mm 25 µm

FAR end: 3.05mm 33 µm

The beam diameter and measurement range (width) between the NEAR/FAR ends are nominal

values, and are not to be used as guaranteed values.

38

Mounting and Connecting Devices

ZG2 User’s Manual

Page 42

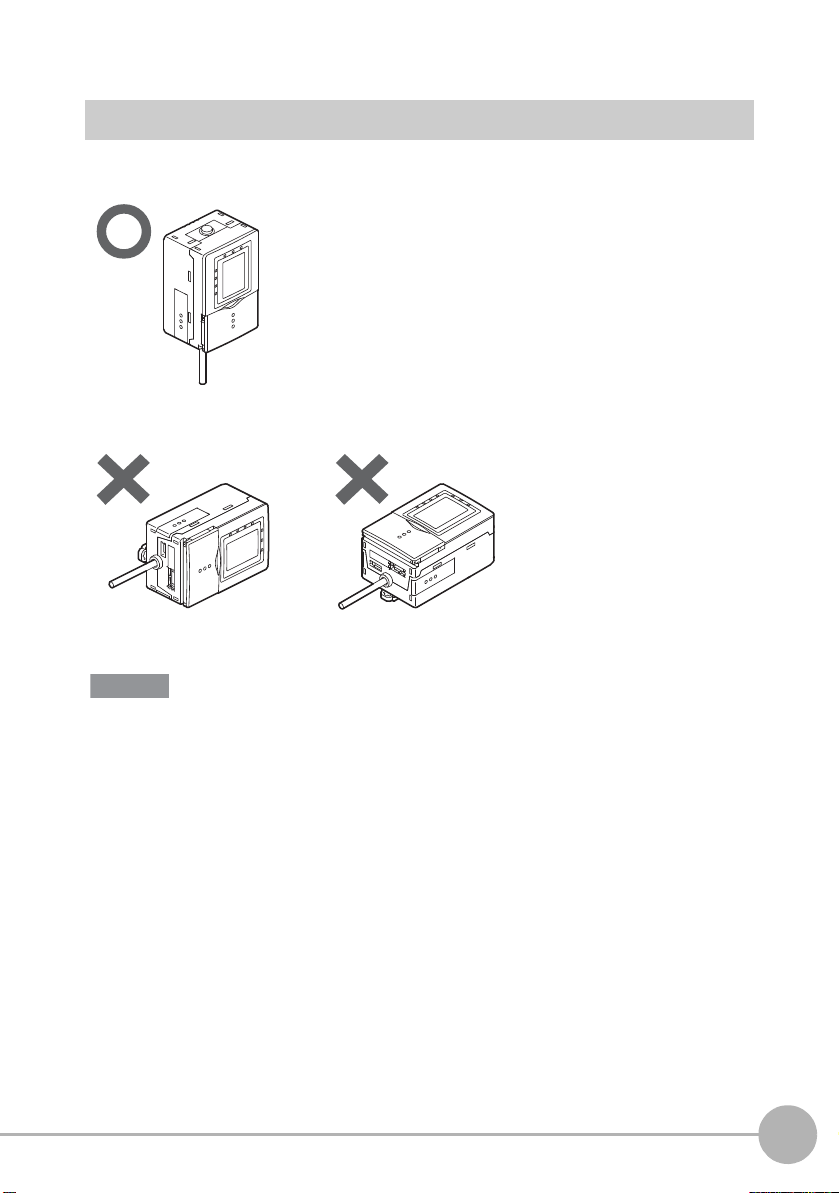

Mounting the Controller

Important

Cautions Regarding the Mounting Orientation

To improve heat radiation, install the Controller only in the orientation shown below.

Do not install the Controller in the following orientations:

1

BEFORE USE

• Do not block the ventilation holes at the top and bottom of the Controller body. Doing so will

cause heat to build up inside and result in a malfunction.

• When the temperature inside the control panel exceeds the ambient temperature of 50°C,

provide forced-air cooling or more space at surrounding areas, or improve air circulation to

lower the ambient temperature to 50°C or less.

ZG2 User’s Manual

Mounting and Connecting Devices

39

Page 43

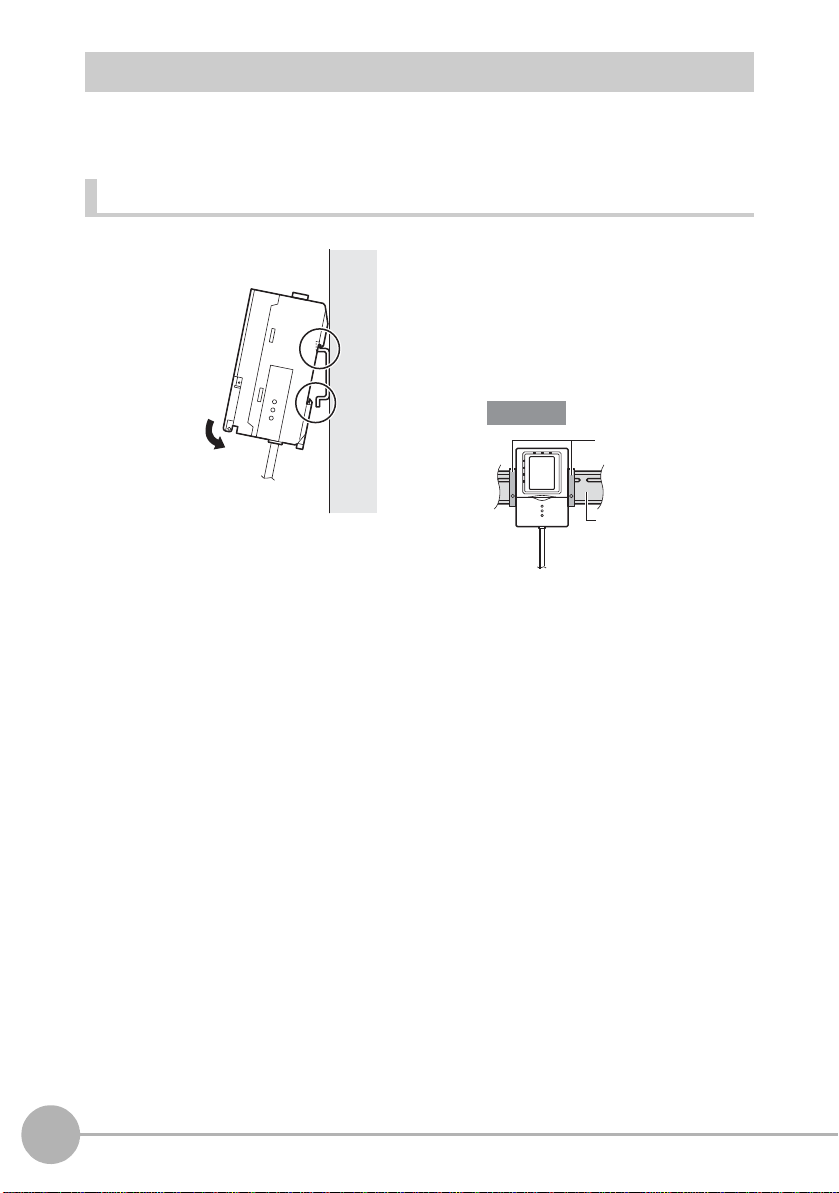

Mounting on a DIN Track

1

2

Important

DIN track (sold separately)

PFP-100N (1 m)

PFP-50N (0.5 m)

PFP-100N2 (1 m)

End plate

Mount Controllers on a DIN track correctly according to the number of Controllers to be

used.

When using only one Controller

1 Hook the connector end of the

Controller onto the DIN track.

2 Push the Controller down onto

the DIN track until the hook on the

I/O cable side is locked.

After mounting the Controller on the

DIN track, attach the end plates on

both sides of the Controller.

40

Mounting and Connecting Devices

ZG2 User’s Manual

Page 44

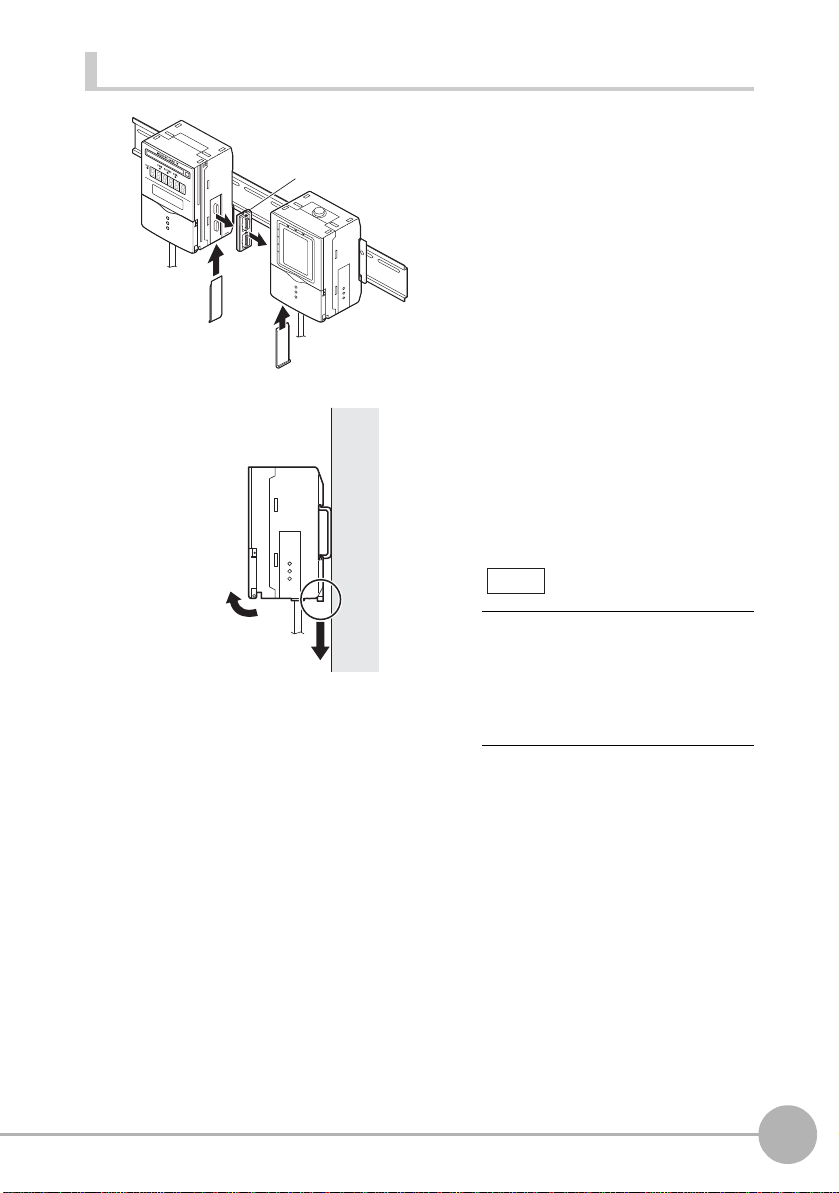

When gang-mounting devices

1

2

4

5

Controller

Link Unit

(sold separately)

Important

Indentation

The following explains how to mount Controllers when using a Data Storage Unit as well

or when gang-mounting two Controllers on the DIN track.

1 Hook the connector end of the

Controller onto the DIN track.

2 Push the Controller down onto

the DIN track until the hook on the

I/O cable side is locked.

3 Open the gang-mount cover.

Slide the cover downwards to

remove.

4 Insert the Controller Link Unit into

4

5

3

3

the connector on the unit on the

left side.

1

BEFORE USE

ZG2 User’s Manual

The connector must be inserted at the

correct orientation. Insert so that the

indentation on the Controller Link Unit

in the figure above matches the

connector protrusion on the unit on the

left side.

Mounting and Connecting Devices

41

Page 45

5 Slide the Controller on the right

Note

Important

DIN track (sold separately)

PFP-100N (1m)

PFP-50N (0.5m)

PFP-100N2 (1m)

End plate

1

2

side towards the Controller Link

Unit so that it fits into the

Controller Link Unit.

The mounting method is the same

even when two Controllers are gangmounted onto the Data Storage Unit.

Mount in the following order: Data

Storage Unit → 1st Controller → 2nd

Controller.

Attach the end plates on both sides of

the Controller.

Removing the Controller from the DIN track (when using only one Controller)

42

Mounting and Connecting Devices

1 Pull the hook on the I/O cable end

of the Controller downwards.

2 Lift up the Controller from the I/O

cable end, and remove it from the

DIN track.

ZG2 User’s Manual

Page 46

Removing Controllers from the DIN track (when gang-mounting devices)

1

2

3

3

Controller

Link Unit

(sold separately)

4

5

Note

1 Slide the Controller so that it is

removed from the connector on

the Controller Link Unit.

1

BEFORE USE

2 Remove the Controller Link Unit

2

1

from the connector on the Data

Storage Unit.

3 Attach the covers to the Data

3

3

Storage Unit and Controller g ang mount.

4 Pull the hook on the I/O cable end

of the Controller downwards.

5 Lift up the Controller from the I/O

cable end, and remove it from the

DIN track.

The removal method is the same

even when two Controllers are gangmounted onto the Data Storage Unit.

Remove in the following order: 2nd

Controller → 1st Contro ller → Data

Storage Unit.

ZG2 User’s Manual

Mounting and Connecting Devices

43

Page 47

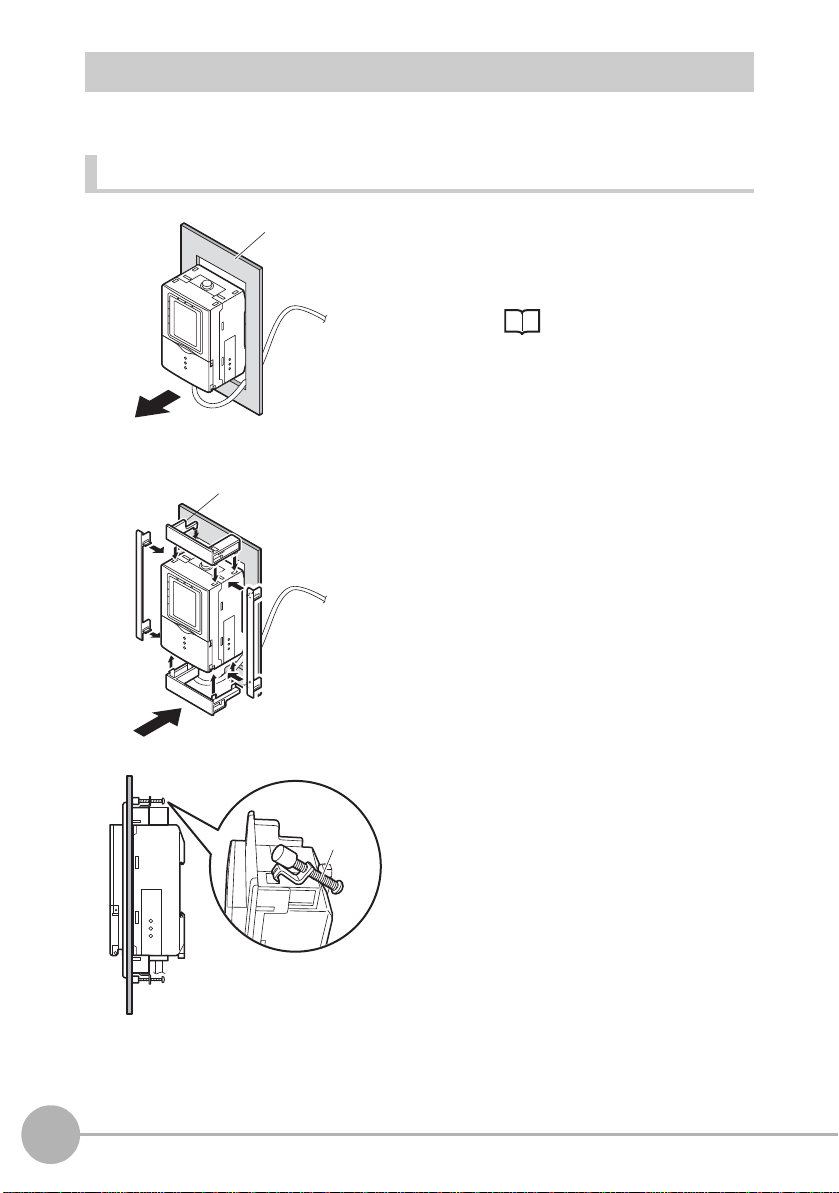

Mounting on a Panel

Panel

1

5

Mounting

bracket

Mount Controllers on a panel correctl y according to the number of Control lers t o be used.

When using only one Controller

1 Push out the Controller from the

rear of the panel towards the

front.

When mounting on a panel

p.206

Panel mount adapter

4

2 Install the short Panel Mount

2

Adapters on the four holes on the

Controller.

3 Install the long Panel Mount

Adapters on the two holes on the

Controller.

4 Install the Controller with Mount

3

Adapters attached onto the panel

from the front.

5 Hook the hooks of the mounting

fixture onto the two holes of the

short Mount Adapters and tighten

the screws.

6 Make sure that the Controller is

firmly fixed on the panel.

44

Mounting and Connecting Devices

ZG2 User’s Manual

Page 48

When gang-mounting devices

Important

H

L

D

O

N

Z

E

R

O

E

N

A

B

L

E

P

L

H

L

D

O

N

Z

E

R

O

E

N

A

B

L

E

P

L

H

L

D

O

N

Z

E

R

O

E

N

A

B

L

E

P

L

H

L

D

O

N

Z

E

R

O

E

N

A

B

L

E

P

L

2

Panel

H

L

D

O

N

Z

E

R

O

E

N

A

B

L

E

P

L

H

L

D

O

N

Z

E

R

O

E

N

A

B

L

E

P

L

H

L

D

O

N

Z

E

R

O

E

N

A

B

L

E

P

L

H

L

D

O

N

Z

E

R

O

E

N

A

B

L

E

P

L

3

Panel

mount

adapters

Panel mount

adapters

Important

1 Mount the Data Storage Unit and

Controllers onto the DIN track.

When gang-mounting

devices p.41

When mounting devices on a panel,

too, be sure to install the DIN track on

the rear side of the devices.

2 Push out the Data Storage Unit

and Controllers from the rear of

the panel towards the front.

3 Install the short Panel Mount

Adapters on the four holes on the

Data Storage Unit and

Controllers.

1

BEFORE USE

ZG2 User’s Manual

Install the short Panel Mount Adapters

on the gang-mounted Data Storage

Unit and all Controllers.

Mounting and Connecting Devices

45

Page 49

4 Install the long Panel Mount

H

LD ON ZERO

ENABLE

P

L

H

LD ON ZERO

ENABLE

P

L

H

LD ON

ZERO

ENABLE

P

L

H

LD ON

ZERO

ENABLE

P

L

4

Panel mount adapters

Panel mount adapters

Important

Panel

Important

Mounting

bracket

Important

Adapters on the two holes on the

short Panel Mount Adapter.

Attach the long Panel Mount Adapters

on only both sides of the gangmounted Data Storage Unit and

Controllers.

5 Install the Data Storage Unit and

Controllers with Mount Adapters

attached onto the panel from the

H

H

LD

LD

O

O

N

N

ZE

ZE

P

P

R

R

O

O

E

E

N

N

A

A

B

B

LE

LE

L

L

H

H

L

L

D

D

O

O

N

N

Z

Z

E

E

P

P

R

R

O

O

EN

EN

A

A

B

B

L

L

L

L

E

E

5

front.

Take care not to nip the I/O cable.

46

Mounting and Connecting Devices

6 Hook the hooks of the mounting

fixtures onto the two holes of the

short Mount Adapters and tighten

6

the screws.

Attach fixtures at two locations of each

of the gang-mounted Data Storage

Unit and all Controllers.

7 Make sure that the Data Storage

Unit and Controllers are firmly

fixed on the panel.

ZG2 User’s Manual

Page 50

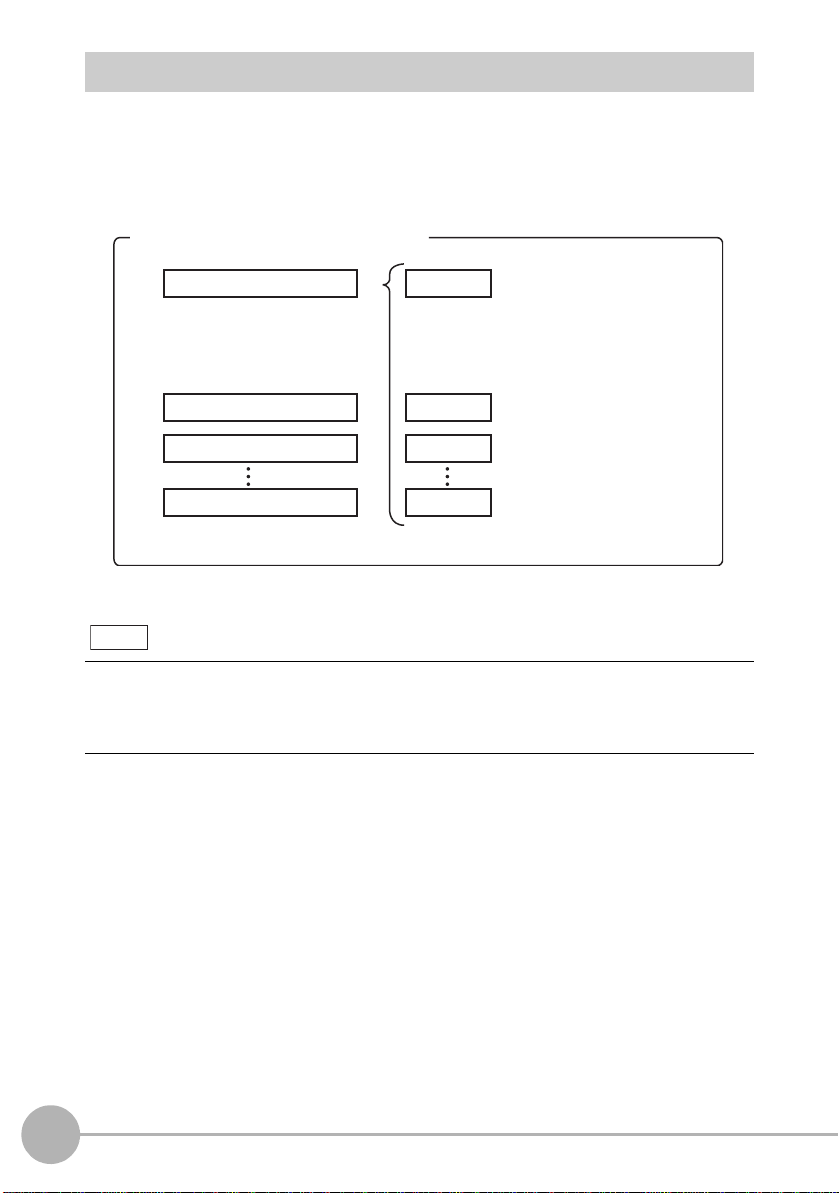

Combinations of Gang-mounted Controllers

Important

OUTPUT

RUN

OUTPUT

RUN

OUTPUT

RUN

LD ON ZERO ENABLE

OUTPUT

RUN

ZG2-WDCZG2-WDC

ZG2-WDC ZG2-WDCZG2-DSU

ZG2-WDCZG2-DSU

With the ZG2 series, one Data Storage Unit (ZG2-DSU) and up to two Controllers (ZG2WDC) can be gang-mounted. For details on the Data Storage Unit (ZG2-DSU), refer to

the ZG2-DSU User’s Manual.

• Supply power to all of the gang-mounted Controllers.

• The following three gang-mount combinations and arrangements are allowed. Note that

other combinations and arrangements will not result in proper operation.

1

BEFORE USE

ZG2 User’s Manual

Mounting and Connecting Devices

47

Page 51

CH number when Controllers are gang-mounted

Data Storage

Unit

CH0 CH1 CH2

Controller

(fixed)

Important

CH1 CH2

CH numbers are automatically assigned as follows when Controllers are gang-mounted.

To collect data from a Controller using the Data Storage Unit (ZG2-DSU_1), select the

CH number of the targeted Controller.

LD ON ZERO ENABLE

OUTPUT

RUN

• In the gang-mounted arrangement, the Data Storage Unit must be located at the leftmost

end viewed from the front.

• Even wh en the Data Storage Unit is not gang-mounted, the CH numbers of the Controllers

are CH1 and CH2 in this order from the left.

LD ON ZERO ENABLE

OUTPUT

RUN

48

Mounting and Connecting Devices

ZG2 User’s Manual

Page 52

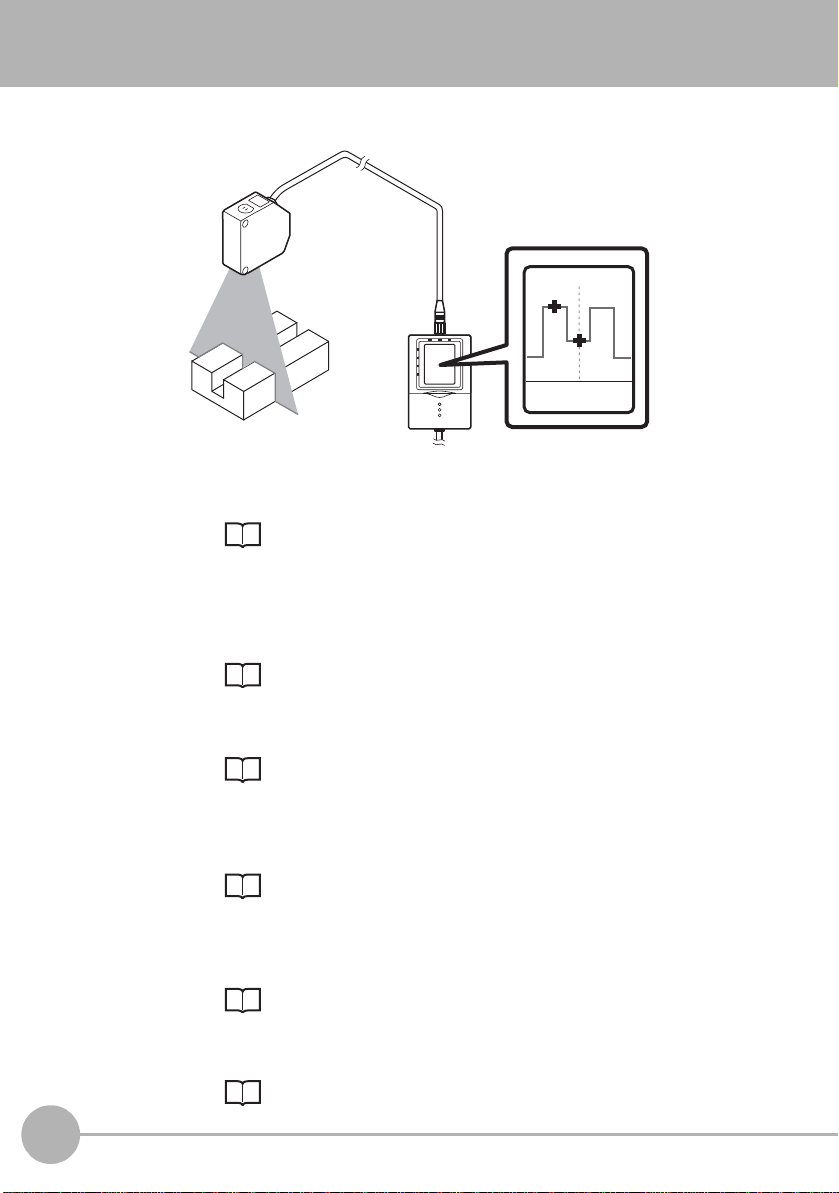

Connecting Devices

1

1

2

3

Important

Important

Ferrite coreFerrite core

Ferrite core

Before connecting/disconnecting the Sensor

Head, make sure that the Controller is turned

OFF. The Controller may break down if the

Sensor Head is connected or disconnected

while the power is ON.

1 Attach the ferrite cores (supplied)

to both ends of the Sensor cable.

2 Insert the Sensor Head connector

into the Controller until it locks in

place.

3 Connect the Controller’s I/O cable

and power supply.

If the Controller is turned ON without the Sensor Head connected, the Controller ’s screen will

remain dark and messages cannot be read. Before turning the Controller ON, connect the

Sensor Head.

Attaching the Ferrite Cores

Attach the ferrite cores (supplied) to both ends of the Sensor Head cable and to the

Controller’s I/O cable.

1

BEFORE USE

ZG2 User’s Manual

Mounting and Connecting Devices

49

Page 53

Connecting Cables

Important

1 Insert the Sensor Head’s

connector straight into the

Sensor Head connector on the

Controller.

Make sure that you hear the

connector snap firmly into place

when it is connected.

2 Fasten firmly with the fastening

screws (two screws, one each on

the left and right).

• Do not touch the terminals inside the connector.

• All settings on the Controller will be cleared if the Sensor Head is replaced with a different

type.

• Fasten the connector while making sure that it is not subjected to vibration or shock.

• Do not mount the Controller in such a way that a load is steadily applied on the connector, for

example, with tension applied to the cables.

50

When wiring, do not bend the cable for at least

10 mm from the edge of the connector.

At least 10 mm

Mounting and Connecting Devices

If the cable is bent in the first 10 mm away from

the edge of the connector, stress may adversely

affect measurements.

10 mm or less

ZG2 User’s Manual

Page 54

<Removing the cable>

ZG2-XC3CR: 3 m

ZG2-XC8CR: 8 m

ZG2-XC15CR: 15 m

ZG2-XC25CR: 25 m

Extension cable Cable for Sensor

(flexible cable): 0.5 m, 2 m

(Flexible cable)

Important

Loosen the fastening screws (two locations) to unlock the cable, and then draw out the

connector straight from the Sensor side.

Note

The cable connection between the Sensor Head and the Controller can be extended by using

the extension cable (sold separately). Attach the ferrite cores (supplied) to both ends of the

extension cable.

To extend the connection between the Sensor Head and the Controller

Connecting the Power Supply

1 Connect the power wire (brown)

and GND wire (blue) of the

Controller’s I/O cable to the 24

VDC (

±10%) power supply.

1

BEFORE USE

After turning the power supply ON, allow the product to stand for at least 30 minutes before

use. The circuits are still unstable just after the power supply is turned ON, so measurement

values may fluctuate gradually.

ZG2 User’s Manual

Note

The following power supply is

recommended:

• S8VS-03024 (24V DC, 1.3 A)

Be sure to connect the Controller to the

power supply in a 1:1 connection.

Mounting and Connecting Devices

51

Page 55

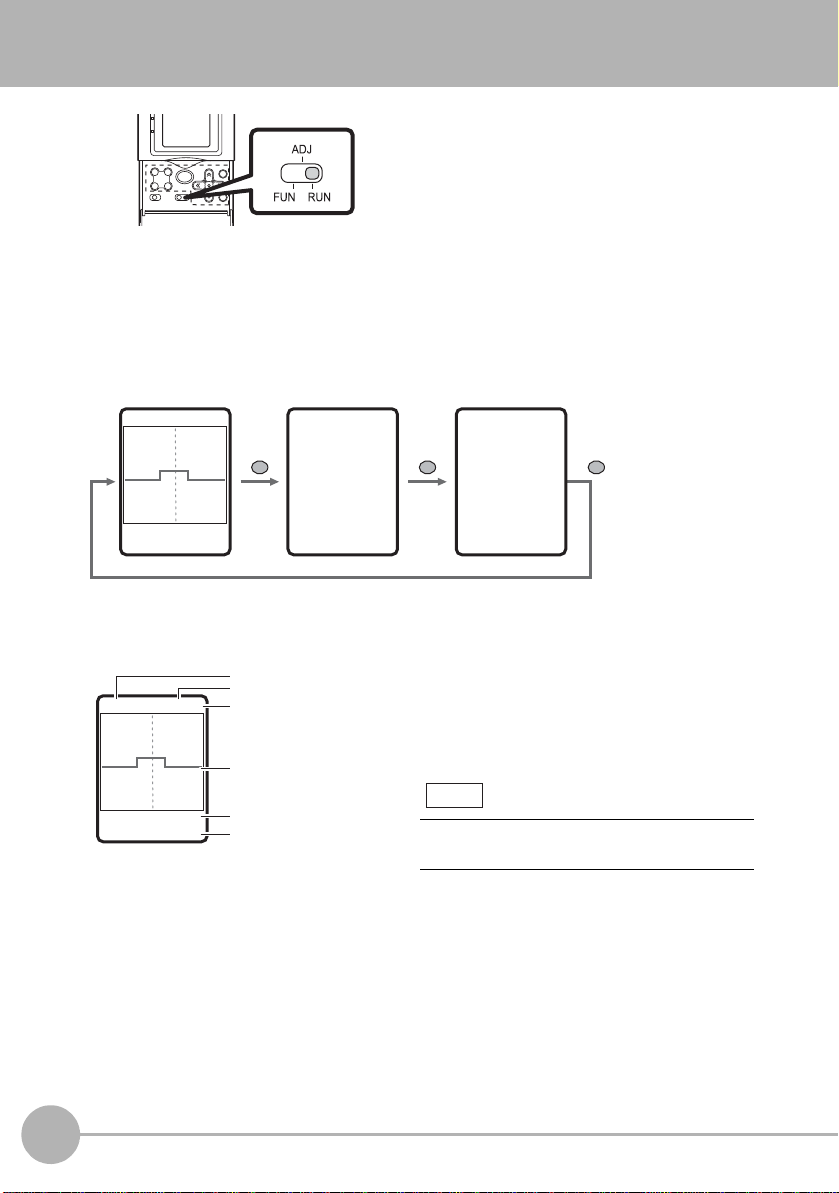

Overview of Settings and Measurement

ADJ mode

RUN mode

FUN mode

MEAS

FUN

Top Screen

Top Screen

109.052 10 mm

LV: 1-320

HEIGHT1 B01T1

Top Screen

Operation Modes

The ZG2-WDC has the following three

operation modes. Switch to the desired

mode before you start operation.

To switch the operation mode, use the mode

switch.

Mode Description

FUN mode This mode is for setting the measurement

conditions.

The easy-to-follow icon-based display

allows operations to be performed

intuitively.

52

ADJ mode This mode is for checking the

measurement state, and setting

threshold values and output conditions.

RUN mode This mode is used for performing actual

measurement. The measurement

information is displayed on the LCD

screen.

Overview of Settings and Measurement

HEIGHT1 B01T1

109.052 10 mm

LV: 1-320

ZG2 User’s Manual

Page 56

Tasks and Bank Data

(Task 1)

Height

Width

Step

(Task 2)

(Task 3)

(Task 4)

Crosssectional area

Bank 1

Setting for

product class A

Bank 2

For product class B

Bank 3

For product class C

Bank 4

For product class D

Multi-task Measurement

On the ZG2 series, up to eight measurements for a single profile can be processed

simultaneously. This function is called “multi-task measurement.”

Example:

Measurement is performed with “height,”

“width,” “step” and “cross-sectional area” set

to tasks 1 to 4, respectively. In other words,

this means that the total of tas ks 1 to 4 allow

you to judge the shape.

Data for Change of Device Setup

If you register bank data for each individual model, you can reduce the time required for

changing the device setup as all you need to do is to select different bank data to change

the measurement conditions.

1

BEFORE USE

ZG2 User’s Manual

Overview of Settings and Measurement

53

Page 57

Relationship between Tasks and Bank Data

You can register up to eight tasks to a single set of bank data. Up to 16 sets of bank data

can be set and saved on the ZG2 series, so you can prepare up to 128 measurement

patterns by combining bank data with task settings. Combinations of bank data and tasks

become the measurement and judgment condition settings.

Measurement/judgment conditions

Bank 1

• Profile registration information

• Setup information of image

adjustment function

•

Setup information of filter conditions

Bank 2

Bank 3

Bank 16

168x

Note

The maximum number of banks that can be saved on a Controller is 16. This can be

expanded up to 4096 banks (16 banks × 256 files) by gang-mounting the Data Storage Unit

(ZG2-DSU).

For details, refer to the ZG2-DSU User’s Manual.

Number of banks

Task 1

• Item registration information

• Custom setup information

• Scaling setup information

• Judgment threshold value information

Task 2

Task 3

Task 8

=128 measurement patterns

54

Overview of Settings and Measurement

ZG2 User’s Manual

Page 58

STD Menu and EXP Menu

Standard settings

Adjustment/

Custom setup

STD menu

EXP menu

Run in STD menu

Run in EXP menu

The Controller has two setup modes, the “STD menu” and the “EXP menu.” The features

of each of these menus are as follows.

<STD menu>

This menu is designed for ease of operation,

so its setting and adjustment ranges are

limited. Setting in this mode comprises only

three steps, so you can start measurement

immediately.

<EXP menu>

This menu allows you to set all adjustment

functions. You can use this menu to execute

advanced measurement processing, such

as measurement of image angle, calculation

of processing items and selection of

characteristic points.

Switching the menu

The STD and EXP menus are switched by

the menu switch on the front of the

Controller. The two menus cannot be

selected simultaneously during menu

operation as the menu is fixed by the menu

switch.

1

BEFORE USE

ZG2 User’s Manual

Overview of Settings and Measurement

55

Page 59

Initializing Controller Settings

Important

The settings of all banks and system settings are initialized regardless of the currently selected

bank No. To save the settings, back them up to a personal computer before performing

initialization.

• Receive System Data <SYSSAVE command> p.171

• Receive Bank Data <BANKSAVE command> p.169

1 Switch to the FUN mode.

The top screen is displayed.

FUN

SYS

SYS

1. SAVE

2.

INIT

3. SENSOR SET

4. CCD MODE

←→ P1/3

SYS/INIT

CLEAR

ALL DATA

YES

NO

2 Select [System].

3 Select [INIT].

4 Move to [YES] and press the SET

key.

56

Overview of Settings and Measurement

ZG2 User’s Manual

Page 60

BASIC OPERATIONS

Flow of Basic Setup 58

Starting Measurement 66

2

BASIC OPERATIONS

Page 61

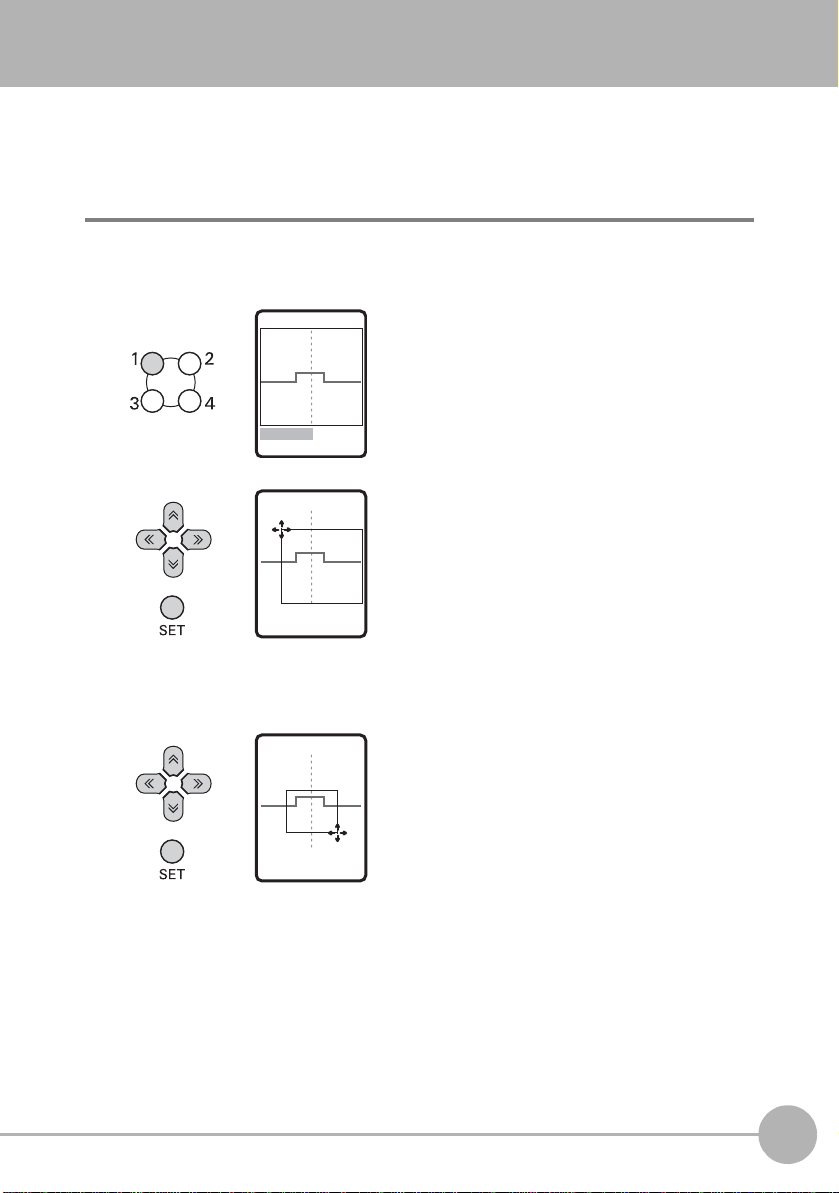

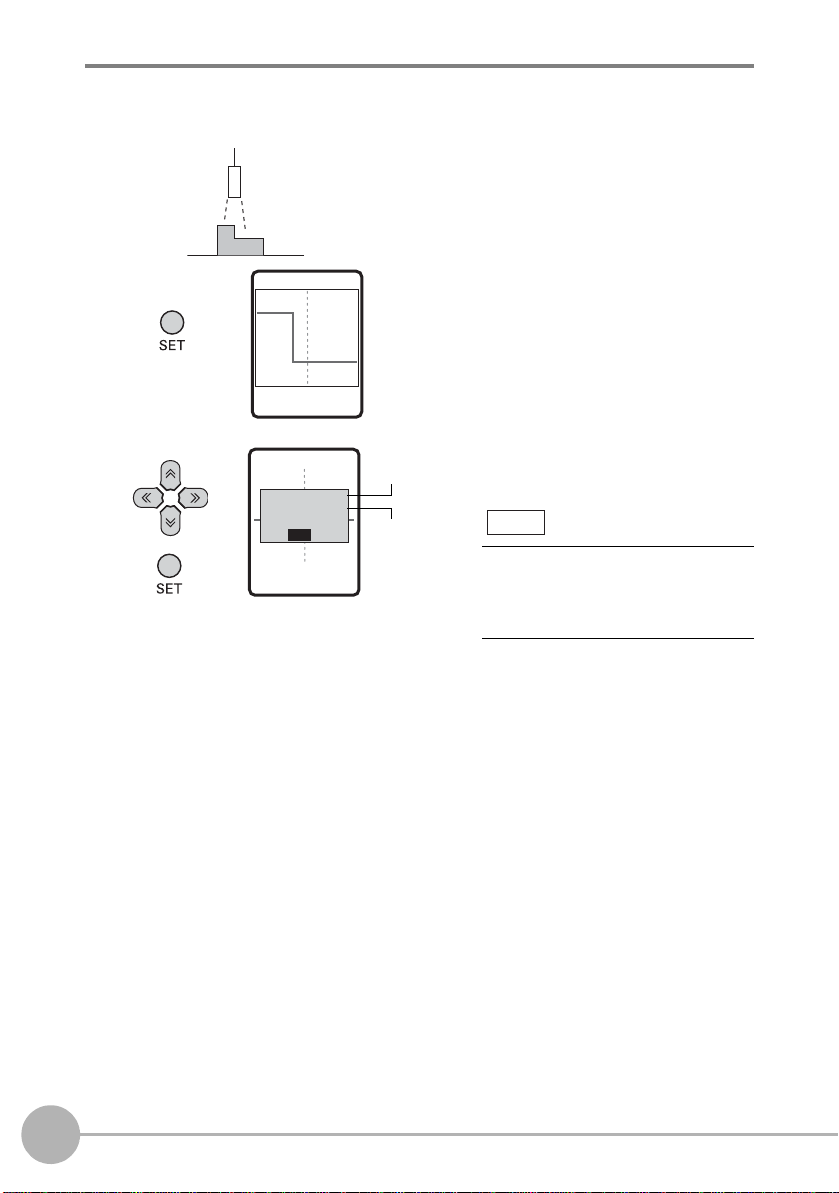

Flow of Basic Setup

0.00000 mm

LV:320

2PTS-2 B01T2

The following describes the flow of basic setup using, as an example, "2-pt step".

step 1

step 2

step 3

step 4

step 5

step 6

Displaying the reference target object

Display the target profile on the Controller's LCD monitor.

p.59

Stabilizing the shape profile (APS function)

Use the APS function to perform auto-tuning to obtain the optimum

settings to match the surface shape (e.g. color, shape and material)

of the measurement object.

p.60

Registering the profile of th e re fe re nc e target

Use this profile to set the measurement conditions.

p.61

Selecting measurement items

Select from height, step, width, and other items to suit your particular

measurement requirements.

p.62

Setting the measurement area

The optimum region can be automatically set by simply enclosing the

desired measurement area. This area can be fine-adjusted later on.

p.63

Adjusting the judgment threshold value

Perform a test measurement and determine the threshold values.

58

Flow of Basic Setup

p.64

ZG2 User’s Manual

Page 62

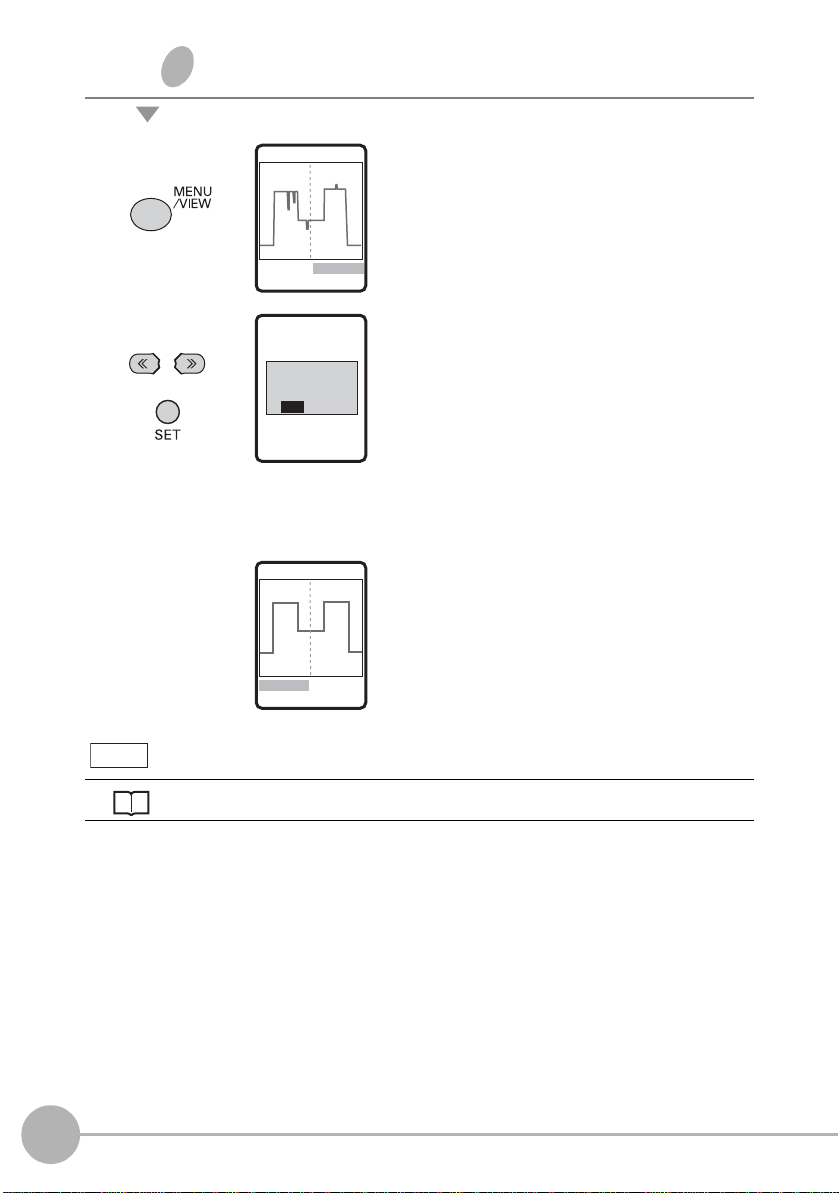

Displaying the reference target object

step 1

1 Switch to the STD menu.

Note

FUN

MEAS

MEAS

1TEACH 2IMAGE

Sensor Head mounting conditions

2 Switch to the FUN mode.

The top screen of the FUN mode is

displayed.

3 Select [MEAS].

4 Set the measurement object in

place.

The profile is displayed.

2

BASIC OPERATIONS

If necessary, change the Sensor Head installing settings (for diffuse reflection measurement

or for regular reflection measurement), or change the receiving status of the Sensor Head

CCD before setting the measurement conditions.

Setting the Sensor Head Installation Status p.118

Setting the CCD Mode p.121

ZG2 User’s Manual

Flow of Basic Setup

59

Page 63

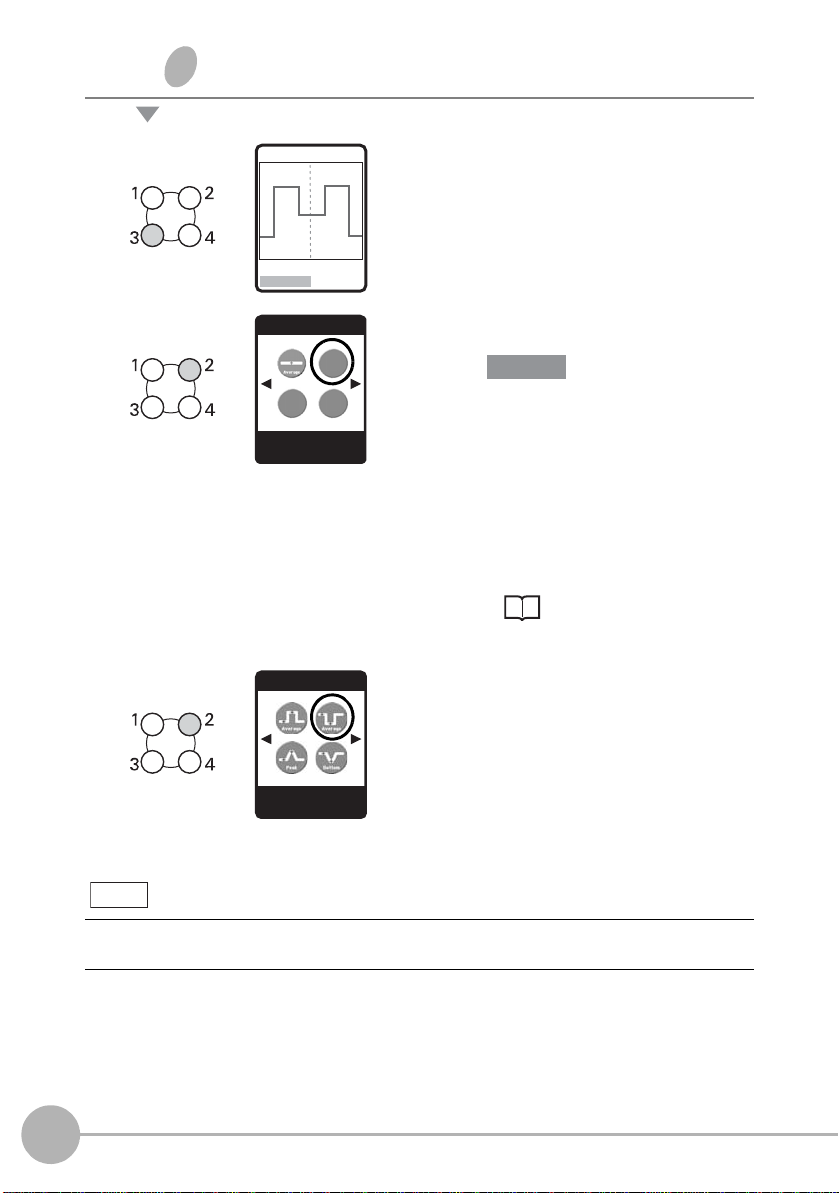

Stabilizing the shape profile (APS function)

step2

1TEACH 2IMAGE

MEAS

Note

1 Display the screen on the left and

press the MENU/VIEW key.

The confirmation message is

displayed.

MEAS

EXECUTE

FILTER SETTING

AUTOMATICALLY.

YES NO

MEAS

1TEACH 2IMAGE

2 Move to [YES] and press the SET

key.

The optimum profile acquisition

conditions are automatically set.

When profiles are not displayed as intended

Troubleshooting p.213

60

Flow of Basic Setup

ZG2 User’s Manual

Page 64

Registering the profile of the reference target

step3

1TEACH 2IMAGE

MEAS

1 Select [TEACH].

2

BASIC OPERATIONS

MEAS

TEACH

PROFILE

YES NO

1TEACH 2IMAGE

MEAS

1TEACH 2IMAGE