Page 1

AC Servo Driver

Manual No.

8U0108-E1-01

Manual No. 8U0108-E1-01

Page 2

ii

Copyright 2003 by YET, Yaskawa Eshed Technology Ltd.

XtraDrive User Manual

Catalog No.8U0108, Revision C

November 2003

All rights reserved. No part of this publication may be stored in a retrieval

system, or reproduced in any way, including but not limited to photocopy,

photography, magnetic or other recording, without the prior agreement and

written permission of the publisher. Program listings may be entered, stored and

executed in a computer system, but not reproduced for publication.

This guide is designed to provide information about the XtraDrive hardware.

Every effort has been made to make this guide complete and as accurate as

possible. However, no warranty of suitability, purpose or fitness is made or

implied. YET Ltd. is not liable or responsible to any person or entity for loss or

damage in connection with or stemming from the use of XtraDrive and/or the

information contained in this publication

YET Ltd. bears no responsibility for errors, which may appear in this

publication and retains the right to make changes to the products and the guide

without prior notice.

YET Ltd. ISRAEL YET US Inc.

13 Hamelacha St., 531 King St.,

Afeq Industrial Estate Unit 1

Rosh Ha’ayin 48091 Littleton, MA 01460

ISRAEL USA

Tel: +972-3-9004114 Tel: +1-866-YET-8080

Fax: +972-3-9030412 Fax: +1-978-952-6821

info@yetmotion.com USinfo@yetmotion.com

web site:

www.yetmotion.com

Page 3

iii

WARNING

YET manufactures component parts that can be used in a wide variety of industrial applications.

The selection and application of YET products remain the responsibility of the equipment designer

or end user. YET accepts no responsibility for the way its products are incorporated into the final

system design.

Under no circumstances should any YET product be incorporated into any product or design as the

exclusive or sole safety control. Without exception, all controls should be designed to detect faults

dynamically and fail safely under all circumstances. All products designed to incorporate a

component part manufactured by YET must be supplied to the end user with appropriate warnings

and instructions as to that part’s safe use and operation. Any warnings provided by YET must be

promptly provided to the end user.

YET offers an express warranty only as to the quality of its products in conforming to standards and

specifications published in YET’s manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED,

IS OFFERED. YET assumes no liability for any personal injury, property damage, losses, or claims

arising from misapplication of its products.

Page 4

iv

This page intentionally left blank.

Page 5

v

Safety Information

The following defines the symbols used in this manual to indicate varying

degrees of safety precautions and to identify the corresponding level of hazard

inherent to each. Failure to follow precautions provided in this manual can

result in serious, possibly even fatal, injury, and/or damage to the persons,

products, or related equipment and systems.

WARNING

• WARNING: Indicates a potentially hazardous situation, which, if not heeded, could result in

death or serious injury.

CAUTION

• CAUTION: Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

Page 6

vi

This page intentionally left blank.

Page 7

XtraDrive User Manual Table of Contents/Preface

vii

Table of Contents

1. Checking Product and Part Names .................................................................1-1

1.1. Checking the XtraDrive Series Products on Delivery................................... 1-2

1.1.1. Servo Amplifiers....................................................................................... 1-2

1.2. Product Part Names ........................................................................................ 1-3

1.2.1. Servo Amplifiers....................................................................................... 1-3

1.2.2. Model Numbers ........................................................................................ 1-4

2. Installation. ............................................................................…………………2-1

2.1. Servo Amplifiers ............................................................................................ 2-2

2.1.1. Storage Conditions.................................................................................... 2-2

2.1.2. Installation Site ......................................................................................... 2-2

2.1.3. Orientation................................................................................................. 2-3

2.1.4. Installation................................................................................................. 2-3

3. Wiring…… ........................................................................................................3-1

3.1. Connecting to Peripheral Devices.................................................................. 3-2

3.1.1. Single-Phase 200V Main Circuit Specifications ..................................... 3-3

3.1.2. Single-Phase 0.8kW 200V Main Circuit Specifications .........................3-4

3.1.3. Three-phase 200V Main Circuit Specifications....................................... 3-5

3.1.4. Three-Phase 400V Main Circuit Specifications ......................................3-6

3.2. XtraDrive Internal Block Diagrams............................................................... 3-7

3.2.1. Single-phase 30W to 800W, 200V Models ............................................. 3-7

3.2.2. Three-phase 1kW to 3kW, 200V Models ................................................ 3-8

3.2.3. Three-phase 0.5kW to 3.0kW, 400V Models.......................................... 3-9

3.3. Main Circuit Wiring ..................................................................................... 3-10

3.3.1. Names and Descriptions of Main Circuit Terminal............................... 3-11

3.3.2. Typical Main Circuit Wiring Example ..................................................3-12

3.3.3. Servo Amplifier Power Losses............................................................... 3-13

3.3.4. Wiring Main Circuit Terminal Blocks................................................... 3-14

3.4. I/O Signals .................................................................................................... 3-15

3.4.1. Example of Typical I/O Signal Connections .........................................3-15

3.4.2. List of CN1 Terminals............................................................................ 3-16

3.4.3. I/O Signal Names and Functions............................................................ 3-17

3.4.4. Interface Circuits..................................................................................... 3-19

3.5. Wiring Encoders (for SGMGH and SGMSH Motors Only) ...................... 3-23

3.5.1. Encoder Connections.............................................................................. 3-23

3.5.2. CN2 Encoder Connector Terminal Layout and Types.......................... 3-25

3.5.3. Encoder Cables Interconnections........................................................... 3-26

3.6. Examples of Standard Connections ............................................................. 3-28

4. Trial Operation .................................................................................................4-1

4.1. Two-Step Trial Operation .............................................................................. 4-2

4.1.1. Step 1: Trial Operation for Servomotor without Load ............................ 4-3

4.1.2. Step 2: Trial Operation with Servomotor Connected to Machine........... 4-9

4.2. Additional Setup Procedures in Trial Operation ......................................... 4-10

4.2.1. Servomotors with Brakes .......................................................................4-10

4.2.2. Position Control by Host Controller....................................................... 4-11

4.3. Minimum Parameters and Input Signals ..................................................... 4-12

4.3.1. Parameters............................................................................................... 4-12

4.3.2. Input Signals ........................................................................................... 4-12

Page 8

XtraDrive User Manual Table of Contents/Preface

viii

5. Parameter Settings and Functions ..................................................................5-1

5.1. Settings According to Device Characteristics ............................................... 5-4

5.1.1. Switching Servomotor Rotation Direction............................................... 5-4

5.1.2. Setting the Overtravel Limit Function .....................................................5-5

5.1.3. Limiting Torque........................................................................................ 5-8

5.2. Settings According to Host Controller......................................................... 5-12

5.2.1. Speed Reference .....................................................................................5-12

5.2.2. Position Reference ..................................................................................5-14

5.2.3. Using the Encoder Signal Output........................................................... 5-20

5.2.4. Sequence I/O Signals.............................................................................. 5-23

5.2.5. Using the Electronic Gear Function....................................................... 5-25

5.2.6. Contact Input Speed Control ..................................................................5-29

5.2.7. Using Torque Control............................................................................. 5-34

5.2.8. Torque Feed-Forward Function .............................................................5-40

5.2.9. Torque Limiting by Analog Voltage Reference ....................................5-42

5.2.10. Reference Pulse Inhibit Function (/INHIBIT)....................................... 5-44

5.3. Setting Up the Servo Amplifier ................................................................... 5-45

5.3.1. Parameters............................................................................................... 5-45

5.3.2. JOG Speed .............................................................................................. 5-46

5.3.3. Input Circuit Signal Allocation .............................................................. 5-46

5.3.4. Output Circuit Signal Allocation............................................................ 5-50

5.3.5. Control Mode Selection.......................................................................... 5-52

5.4. Setting Stop Functions ................................................................................. 5-54

5.4.1. Adjusting Offset...................................................................................... 5-54

5.4.2. Servo OFF Stop Mode Selection............................................................ 5-55

5.4.3. Using the Zero Clamp Function............................................................. 5-56

5.4.4. Using the Holding Brake........................................................................ 5-58

5.5. Forming a Protective Sequence ................................................................... 5-61

5.5.1. Using Servo Alarm and Alarm Code Outputs ....................................... 5-61

5.5.2. Using the Servo ON Input Signal (/S-ON) ............................................5-63

5.5.3. Using the Positioning Completed Output Signal (/COIN).................... 5-64

5.5.4. Speed Coincidence Output (/V-CMP) ...................................................5-65

5.5.5. Using the Running Output Signal (/TGON).......................................... 5-67

5.5.6. Using the Servo Ready Output Signal (/S-RDY) ..................................5-68

5.5.7. Using the Warning Output Signal (/WARN)......................................... 5-69

5.5.8. Handling Power Loss.............................................................................. 5-71

5.6. Selecting a Regenerative Resistor................................................................ 5-72

5.6.1. External Regenerative Resistor ..............................................................5-73

5.6.2. Calculating the Regenerative Power Capacity....................................... 5-74

5.7. Absolute Encoders........................................................................................ 5-78

5.7.1. Interface Circuit ...................................................................................... 5-79

5.7.2. Configuring an Absolute Encoder.......................................................... 5-80

5.7.3. Absolute Encoder Setup .........................................................................5-81

5.7.4. Absolute Encoder Reception Sequence .................................................5-84

5.8. AB Encoders................................................................................................. 5-89

5.9. Configuration of Serial Commands for AB Encoders ................................ 5-91

5.9.1. Position Control ......................................................................................5-91

5.9.1.1. Defining User Units for Motion Profiles ...............................................5-91

5.9.1.2. Position Units.......................................................................................... 5-91

5.9.1.3. Speed Units .............................................................................................5-92

Page 9

XtraDrive User Manual Table of Contents/Preface

ix

5.9.1.4. Acceleration Units ..................................................................................5-93

5.9.1.5. Setting Default Motion Profile Parameters............................................ 5-94

5.9.1.6. Profile Speed (Pn2A2, Pn2A3) ..............................................................5-95

5.9.1.7. Profile Acceleration (Pn2A4, Pn2A5).................................................... 5-95

5.9.1.8. Jerk Smoothing Time (Pn2A6) ..............................................................5-95

5.9.1.9. Quick Stop Deceleration (Pn2A8, Pn2A9) ............................................ 5-96

5.9.1.10. Motion End Window (Pn2C0) ...............................................................5-96

5.9.2. Torque Control........................................................................................ 5-96

5.9.2.1. Torque Slope (Pn2C1) ..............................................................5-96

5.9.3. Homing.................................................................................................... 5-97

5.9.4. Digital I/O ............................................................................................... 5-98

5.9.5. Auto Tuning............................................................................................ 5-99

5.10. Auto Running a User Program..................................................................... 5-99

6. Servo Adjustment..............................................................................................6-1

6.1. Selection of Control Mode............................................................................. 6-2

6.2. Analog Input or Contact Input Velocity Control........................................... 6-3

6.2.1. Principle and Block Diagram of the Velocity Control ............................6-3

6.2.2. Parameters of the Velocity Control.......................................................... 6-4

6.2.3. Setting the Input Gain............................................................................... 6-4

6.2.4. Adjusting Offset........................................................................................ 6-5

6.2.5. Using the Soft Start Function ...................................................................6-6

6.2.6. Load Inertia Setting................................................................................... 6-7

6.2.7. Adjusting Speed Loop Gain .....................................................................6-8

6.2.8. Setting the Torque Reference Filter Time Constant................................ 6-9

6.2.9. Notch Filter ............................................................................................... 6-9

6.2.10. Gain Setting Reference Values............................................................... 6-10

6.3. NCT Position Control................................................................................... 6-12

6.3.1. Load Inertia Setting................................................................................. 6-12

6.3.2. Position Control Block Diagram............................................................ 6-14

6.3.3. NCT Gain Parameters............................................................................. 6-15

6.3.4. OCA - Oscillation Canceling Algorithm ...............................................6-16

6.3.5. Additional Parameters Tuning................................................................ 6-17

6.3.6. Filters....................................................................................................... 6-17

6.3.7. Flexible System Parameters ...................................................................6-18

6.3.8. Gain Factor.............................................................................................. 6-19

6.3.9. Integral Clear Parameters .......................................................................6-19

6.3.10. Tuning Procedure for Position Control Parameters............................... 6-20

6.4. Analog Monitor ............................................................................................ 6-22

7. Using the Panel Operator.................................................................................7-1

7.1. Basic Operation .............................................................................................. 7-2

7.1.1. Panel Operator .......................................................................................... 7-2

7.1.2. Resetting Servo Alarms............................................................................ 7-3

7.1.3. Basic Mode Selection ...............................................................................7-3

7.1.4. Status Display Mode................................................................................. 7-4

7.1.5. Operation in Parameter Setting Mode...................................................... 7-6

7.1.6. Operation in Monitor Mode ................................................................... 7-11

7.2. Applied Operation ........................................................................................ 7-16

7.2.1. Operation in Alarm Traceback Mode ....................................................7-17

7.2.2. JOG Operation ........................................................................................7-18

7.2.3. Automatic Adjustment of Speed and Torque Reference Offset............ 7-20

Page 10

XtraDrive User Manual Table of Contents/Preface

x

7.2.4. Manual Adjustment of Speed and Torque Reference Offset ................7-22

7.2.5. Clearing Alarm Traceback Data............................................................. 7-25

7.2.6. Checking the Motor Model ....................................................................7-26

7.2.7. Checking the Software Version.............................................................. 7-27

7.2.8. Origin Search Mode................................................................................ 7-28

7.2.9. Initializing Parameter Settings................................................................ 7-30

7.2.10. Manual Zero Adjustment and Gain Adjustment of Analog Monitor Output

7-31

7.2.11. Adjusting the Motor Current Detection Offset ...................................... 7-34

7.2.12. Write Protection Setting .........................................................................7-36

7.2.13. Clearing the Option Unit Detection Alarm............................................ 7-37

8. Ratings, Specifications and Dimensional Drawings.......................................8-1

8.1. Ratings and Specifications ............................................................................. 8-2

8.2. Single-phase 200V XtraDrive and Motors Combinations ............................ 8-6

8.3. Three-phase 200V XtraDrive and Motor Combinations............................... 8-7

8.4. Three-phase 400V XtraDrive and Motors Combinations ............................. 8-8

8.5. Base-mounted Dimensional Drawings ........................................................ 8-10

8.5.1. XD-P3 to -02 (1-phase 200V, 30 to 200 W).......................................... 8-10

8.5.2. XD-04 (1-phase 200 V, 400 W)............................................................. 8-11

8.5.3. XD-08 (1-phase 200V, 0.75kW) and XD-10 (3-phase 200V, 1.0kW). 8-12

8.5.4. XD-05, 10, 15 (3-phase 400V, 0.5 to 1.5kW) ....................................... 8-13

8.5.5. XD-20, -30 (3-phase 200V,400V, 2.0 and 3.0 kW) .............................. 8-14

8.6. Rack-mounted Dimensional Drawings........................................................ 8-15

8.6.1. XD-P3 to -02 (1-phase 200V, 30 to 200 W).......................................... 8-15

8.6.2. XD-04 (1-phase 200 V, 400 W)............................................................. 8-16

8.6.3. XD-08 (1-phase 200V, 0.75kW) and XD-10 (3-phase 200V, 1.0kW). 8-17

8.6.4. XD-05, 10, 15 (3-phase 400V, 0.5 to 1.5kW) ....................................... 8-18

8.6.5. XD-20, -30 (3-phase 200V,400V, 2.0 and 3.0 kW) .............................. 8-19

9. Inspection, Maintenance, and Troubleshooting.............................................9-1

9.1. XtraDrive Inspection and Maintenance ......................................................... 9-2

9.1.1. Servomotor Inspection.............................................................................. 9-2

9.1.2. Servo Amplifier Inspection ......................................................................9-2

9.1.3. Replacing the Battery for the Absolute Encoder ..................................... 9-3

9.2. Troubleshooting.............................................................................................. 9-4

9.2.1. Troubleshooting Problems with Alarm Displays ....................................9-4

9.2.2. Troubleshooting Problems with No Alarm Display.............................. 9-25

9.2.3. Alarm Display Table............................................................................... 9-26

9.2.4. Warning Displays ...................................................................................9-28

Appendix A. Host Controller Connection Examples ......................................A-1

A.1. Connecting the GL-series MC20 Motion Module ........................................A-2

A.2. Connecting the CP-9200SH Servo Controller Module (SVA).....................A-3

A.3. Connecting the GL-series B2813 Positioning Module .................................A-4

A.4. Connecting OMRON's C500-NC222 Position Control Unit........................A-5

A.5. Connecting OMRON's C500-NC112 Position Control Unit........................A-6

A.6. Connecting MITSUBISHI's AD72 Positioning Unit ....................................A-7

A.7. Connecting MITSUBISHI's AD75 Positioning Unit ....................................A-8

Appendix B. Special Wiring ..............................................................................B-1

B.1. Wiring Precautions .........................................................................................B-2

B.2. Wiring for Noise Control ...............................................................................B-5

B.3. Using More Than One XtraDrive ..................................................................B-9

Page 11

XtraDrive User Manual Table of Contents/Preface

xi

B.4. Extending Encoder Cables...........................................................................B-10

B.5. 400V Power Supply Voltage .......................................................................B-12

B.6. Reactor for Harmonic Suppression..............................................................B-14

Appendix C. Specifications for Peripheral Devices.........................................C-1

C.1. Connector Terminal Block Converter Unit JUSP-TA50P............................C-2

C.2. External Regenerative Resistors ....................................................................C-4

C.3. DC Reactors for Power Supplies Designed for Minimum Harmonics........C-6

C.4. Brake Power Supplies ....................................................................................C-8

C.5. Surge Suppressor............................................................................................C-9

C.6. Magnetic Contactor........................................................................................C-9

C.7. Variable Resistor for Speed Setting...............................................................C-9

C.8. CN1 I/O Signal Connector.............................................................................C-9

C.9. Connecting Pulse A/B Encoder without C Pulse (Index Pulse) .................C-10

C.10. Absolute Encoder Battery ............................................................................C-11

C.11. Cables for Connecting PC to XtraDrive ......................................................C-12

C.11.1. RS-232 Communication Cable...............................................................C-12

C.11.2. Cable with RS-232 to RS-422 Active Adapter......................................C-14

C.12. Connecting Regenerative Resistors .............................................................C-15

C.13. Connecting Yaskawa Option Board ............................................................C-19

C.13.1. Attaching the Option Board ....................................................................C-19

C.13.2. Detaching the Option Board....................................................................C-19

Appendix D. List of Parameters........................................................................D-1

D.1. Parameters ......................................................................................................D-2

D.2. Switches..........................................................................................................D-7

D.3. Input Signal Selections.................................................................................D-11

D.3.1. Home Switches ........................................................................................D-12

D.3.2. Extended input signal selection...............................................................D-12

D.4. Output Signal Selections..............................................................................D-13

D.4.1. Extended Output Signal Selection..........................................................D-13

D.5. Auxiliary Functions......................................................................................D-14

D.6. Monitor Modes.............................................................................................D-14

Page 12

XtraDrive User Manual Table of Contents/Preface

xii

This page intentionally left blank.

Page 13

XtraDrive User Manual Table of Contents/Preface

xiii

Using This Manual

Intended Audience

This manual is intended for the following users.

• Those designing XtraDrive XD- Series servodrive systems.

• Those installing or wiring XtraDrive XD- Series servodrives.

• Those performing trial operation or adjustments of XtraDrive XD-

Series servodrives.

• Those maintaining or inspecting XtraDrive XD- Series

servodrives.

Description of Technical Terms

In this manual, the following terms are defined as follows:

• Servomotor = SGMAH/SGMPH/SGMGH/SGMSH or other

compatible servomotor.

• Servo Amplifier = XtraDrive Series XD- servo amplifier.

• Servodrive = A set including a servomotor and servo amplifier.

• Servo System = A servo control system that includes the

combination of a servodrive with a host computer and peripheral

devices.

Indication of Inverted Signals

In this manual, the names of inverted signals (ones that are valid when

low) are written with a forward slash (/) before the signal name, as

shown in the following equations:

• S–ON = /S–ON

• P–CON = /P–CON

Page 14

XtraDrive User Manual Table of Contents/Preface

xiv

Safety Precautions

The following precautions are for checking products upon delivery, installation,

wiring, operation, maintenance and inspections.

Checking Products upon Delivery

CAUTION

• Always use the servomotor and servo amplifier in one of the specified combinations.

Not doing so may cause fire or malfunction.

Installation

CAUTION

• Never use the products in an environment subject to water, corrosive gases, inflammable

gases, or combustibles.

Doing so may result in electric shock or fire.

Wiring

WARNING

• Connect the ground terminal to a class 3 ground (100. or less).

Improper grounding may result in electric shock or fire.

CAUTION

• Do not connect a three-phase power supply to the U, V, or W output terminals.

Doing so may result in injury or fire.

• Securely fasten the power supply terminal screws and motor output terminal screws.

Not doing so may result in fire.

Operation

CAUTION

• Never touch any rotating motor parts while the motor is running.

Doing so may result in injury.

Page 15

XtraDrive User Manual Table of Contents/Preface

xv

CAUTION

• Conduct trial operation on the servomotor alone with the motor shaft disconnected from

machine to avoid any unexpected accidents.

Not doing so may result in injury.

• Before starting operation with a machine connected, change the settings to match the

parameters of the machine.

Starting operation without matching the proper settings may cause the machine to run out of

control or malfunction.

• Before starting operation with a machine connected, make sure that an emergency stop

can be applied at any time.

Not doing so may result in injury.

• Do not touch the heat sinks during operation.

Not doing so may result in burns due to high temperatures.

Maintenance and Inspection

WARNING

• Do not remove the panel cover while the power is ON.

Doing so carries a risk of electric shock.

• Do not touch terminals for five minutes after the power has been turned OFF.

Residual voltage may cause electric shock.

• Never touch the inside of the servo amplifier.

Doing so may result in electric shock.

CAUTION

• Do not disassemble the servomotor.

Doing so may result in electric shock or injury

• Do not attempt to change wiring while the power is ON.

Doing so may result in electric shock or injury

Page 16

XtraDrive User Manual Table of Contents/Preface

xvi

General Precautions

NOTE THE FOLLOWING TO ENSURE

SAFE APPLICATION:

• The drawings presented in this manual are sometimes shown without covers or protective

guards. Always replace the cover or protective guard as specified first, and then operate the

products in accordance with the manual.

• The drawings presented in this manual are typical examples and may not match the product you

received.

• This manual is subject to change due to product improvement, specification modification, and

manual improvement. When this manual is revised, the manual code is updated, and the new

manual is published as a next edition. The edition number appears on the front and back covers.

• If the manual must be ordered due to loss or dama

g

e, inform your nearest YET representative or

one of the offices listed on the back of this manual.

• YET will not take responsibility for the results of unauthorized modifications of this product.

YET shall not be liable for any damages or troubles resulting from unauthorized modification.

Page 17

XtraDrive User Manual Chapter 1: Checking Product and Part Names

1-1

1. Checking Product and Part Names

This chapter describes the procedure for checking products upon delivery as

well as names for product parts.

1. Checking Product and Part Names.................................................................1-1

1.1. Checking the XtraDrive Series Products on Delivery ................................1-2

1.1.1. Servo Amplifiers.................................................................................1-2

1.2. Product Part Names.....................................................................................1-3

1.2.1. Servo Amplifiers.................................................................................1-3

1.2.2. Model Numbers ..................................................................................1-4

Page 18

XtraDrive User Manual Chapter 1: Checking Product and Part Names

1-2

1.1. Checking the XtraDrive Series Products on Delivery

The following procedure is suggested to check XtraDrive series products

upon delivery.

Use the following checklist when XtraDrive series products are delivered.

Initial Inspection Comments

Are the delivered products

the ones that were ordered?

Check the model numbers marked on

the nameplates of the servomotor and

servo amplifier. (Refer to the

descriptions of model numbers on

following pages)

Does the servomotor shaft

rotate smoothly?

The servomotor shaft is normal if it

can be turned smoothly by hand.

Servomotors with brakes, however,

cannot be turned manually.

Is there any damage? Check the overall appearance, and

check for damage or scratches that

may have occurred during shipping.

Are there any loose screws? Check screws for looseness using a

screwdriver.

If any of the above are faulty or incorrect, contact YET or an authorized

distributor.

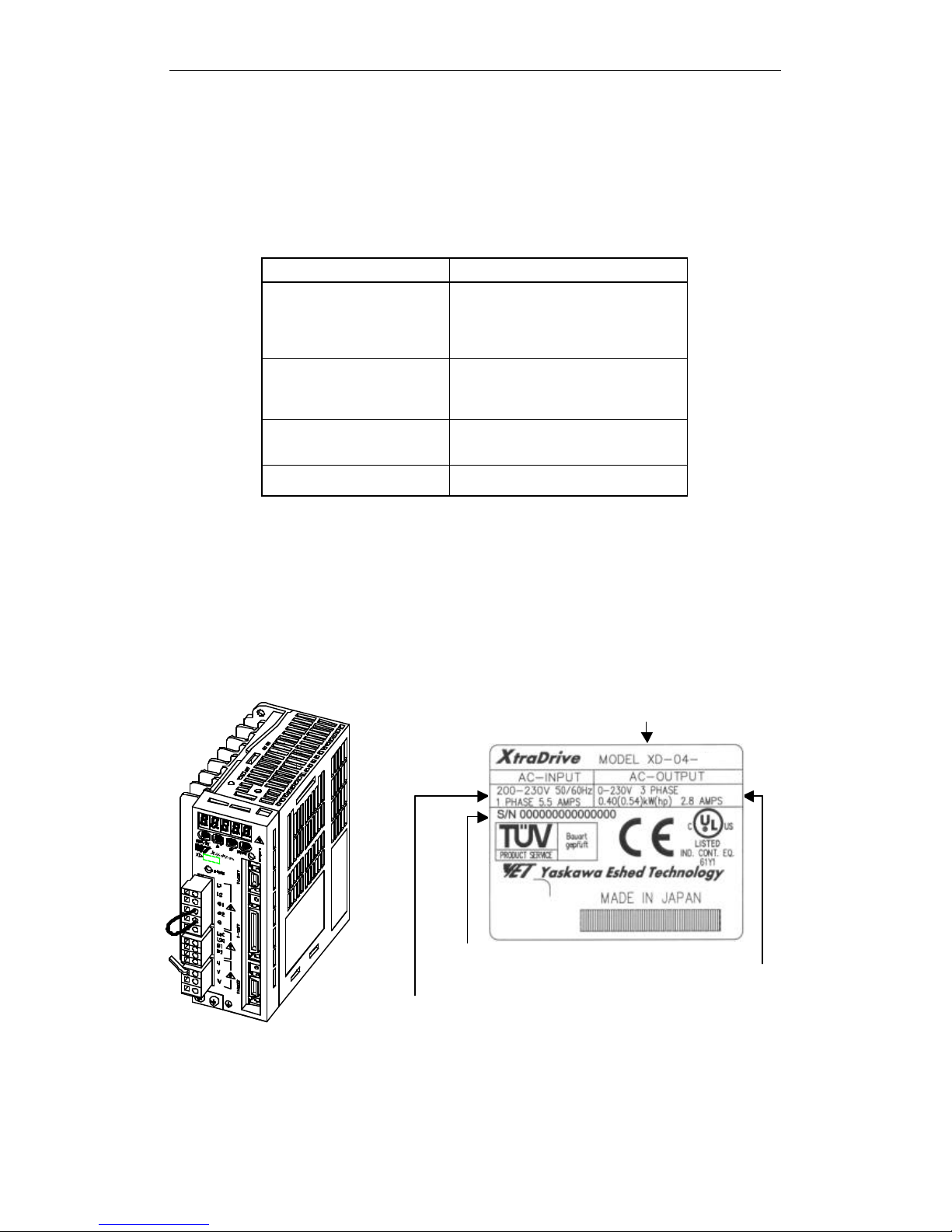

1.1.1. Servo Amplifiers

n External Appearance and Nameplate Examples

APPLICABLE POWER SUPPLY

SERIAL NUMBER

SERVOMOTOR OUTPUT

XtraDrive TYPE

MS

Page 19

XtraDrive User Manual Chapter 1: Checking Product and Part Names

1-3

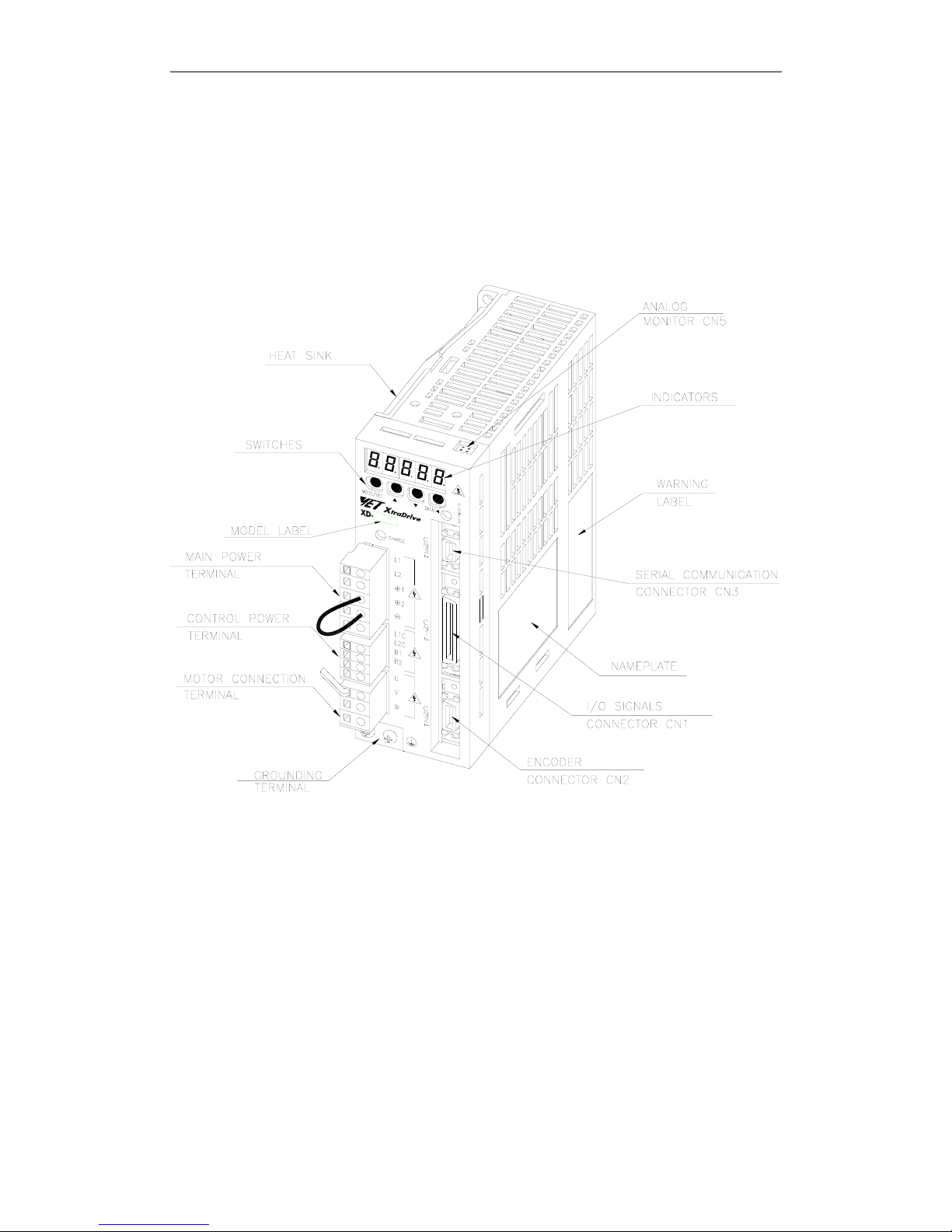

1.2. Product Part Names

This section describes product part names.

1.2.1. Servo Amplifiers

The figure below shows the part names for servo amplifiers.

Page 20

XtraDrive User Manual Chapter 1: Checking Product and Part Names

1-4

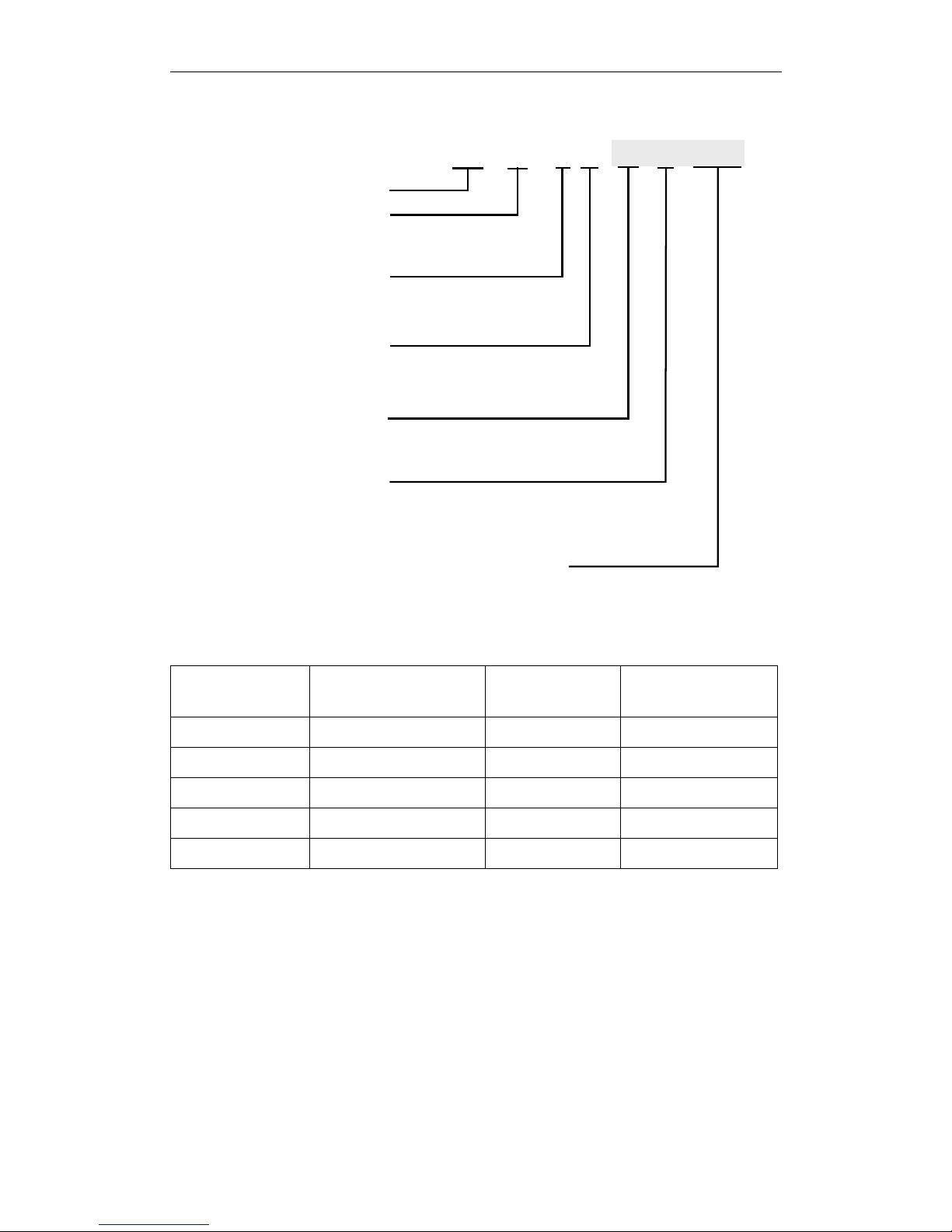

1.2.2. Model Numbers

XD - 01 - M S

XtraDrive Series

Max . A pplicabl e

Servomotor Power

(see table below)

Input V oltage:

M - 200VA C, or

T - 400VA C

Extended F unctional it y

By Option Boards:

S - no CN10 connect or, or

N - with CN10 c onnect or

Desi gn Version #

Bl ank, or 01-FF

(optional)

Bl ank, or

R - Rack m ounted, or

V - B oard coating

(optional)

Bl ank, or Y followed by 1 to 4 alphanum eric characters

to identify cus tomer applicat ions

(optional)

01 R Y999

Output Capacity

Code

Max. Applicable

Servomotor Power

(kW)

Output Capacity

Code

Max. Applicable

Servomotor Power

(kW)

P3 0.03 08 0.75

P5 0.05 10 1.0

01 0.10 15 1.5

02 0.20 20 2.0

04 0.40 30 3.0

Page 21

XtraDrive User Manual Chapter 2: Inst a lla t i o n

2-1

2. Installation

This chapter describes precautions for XtraDrive Series servomotor and servo

amplifier installation.

2.1. Servo Amplifiers.........................................................................................2-2

2.1.1. Storage Conditions..............................................................................2-2

2.1.2. Installation Site ...................................................................................2-2

2.1.3. Orientation ..........................................................................................2-3

2.1.4. Installation...........................................................................................2-3

Page 22

XtraDrive User Manual Chapter 2: Installation

2-2

2.1. Servo Amplifiers

The XtraDrive servo amplifiers are base-mounted. Incorrect installation will

cause problems. Follow the installation instructions below.

2.1.1. Storage Conditions

Store the servo amplifier within the following temperature range, as

long as it is stored with the power cable disconnected.

-20 to 85°C

2.1.2. Installation Site

The following precautions apply to the installation site.

Situation Installation Precaution

Installation in a Control Panel

Design the control panel size, unit layout, and cooling

method so the temperature around the servo amplifier does

not exceed 55°C.

Installation Near a Heating Unit

Minimize heat radiated from the heating unit as well as any

temperature rise caused by natural convection so the

temperature around the servo amplifier does not exceed

55°C.

Installation Near a Source of Vibration

Install a vibration isolator beneath the servo amplifier to

avoid subjecting it to vibration.

Installation at a Site Exposed to

Corrosive Gas

Corrosive gas does not have an immediate effect on the

servo amplifier, but will eventually cause electronic

components and contactor-related devices to malfunction.

Take appropriate action to avoid corrosive gas.

Other Situations

Do not install the servo amplifier in hot and humid locations

or locations subject to excessive dust or iron powder in the

air.

Page 23

XtraDrive User Manual Chapter 2: Installation

2-3

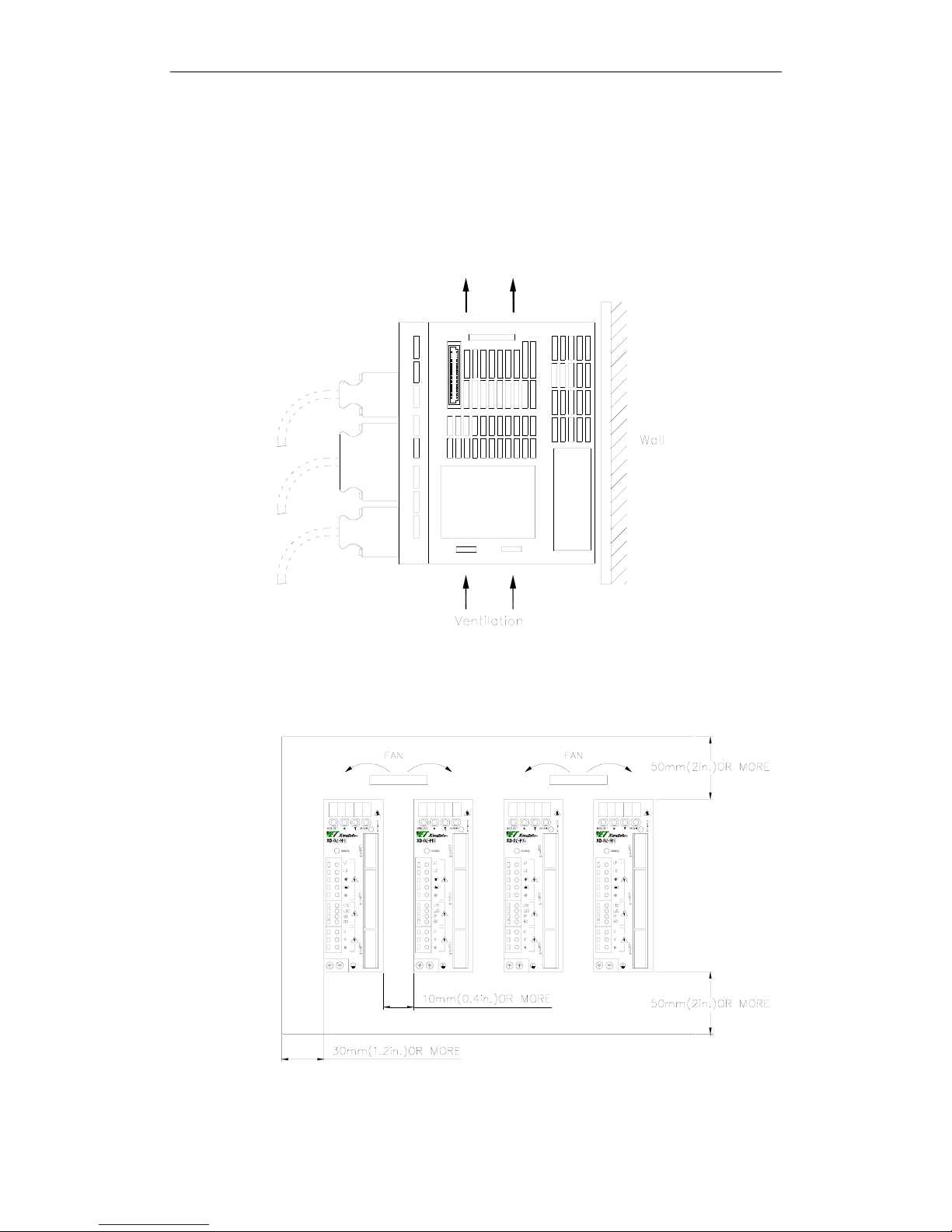

2.1.3. Orientation

Install the servo amplifier perpendicular to the wall as shown in the

figure. The servo amplifier must be oriented this way because it is

designed to be cooled by natural convection or by a cooling fan.

Secure the servo amplifier using the mounting holes. The number of

holes varies (from two to four) with the frame size of the servo

amplifier.

2.1.4. Installation

Follow the procedure below to install multiple servo amplifiers side by

side in a control panel.

Page 24

XtraDrive User Manual Chapter 2: Installation

2-4

Servo Amplifier Orientation

Install the servo amplifier perpendicular to the wall so the front panels’

connectors faces outward.

Cooling

As shown in the figure above, allow sufficient space around each servo

amplifier for cooling by cooling fans or natural convection.

Side-by-side Installation

When installing servo amplifiers side by side as shown in the figure

above, allow at least 0.39in (10mm) between and at least 1.97in

(50mm) above and below each servo amplifier. Install cooling fans

above the servo amplifiers to avoid excessive temperature rise and to

maintain even temperature inside the control panel.

Environmental Conditions in the Control Panel

• Ambient Temperature: 0 to 55°C

• Humidity: 90% RH or less

• Vibration: 0.5 G (4.9m/s

2

)

• Condensation and Freezing: None

• Ambient Temperature for Long-term Reliability: 45°C max.

Page 25

XtraDrive User Manual Chapter 3: Wiring

3-1

3. Wiring

This chapter describes the procedure used to connect XtraDrive Series products

to peripheral devices and gives typical examples of main circuit wiring as well

as I/O signal connections.

3.1. Connecting to Peripheral Devices...............................................................3-2

3.1.1. Single-Phase 200V Main Circuit Specifications.................................3-3

3.1.2. Single-Phase 0.8kW 200V Main Circuit Specifications.....................3-4

3.1.3. Three-phase 200V Main Circuit Specifications..................................3-5

3.1.4. Three-Phase 400V Main Circuit Specifications .................................3-6

3.2. XtraDrive Internal Block Diagrams............................................................3-7

3.2.1. Single-phase 30W to 800W, 200V Models ........................................3-7

3.2.2. Three-phase 1kW to 3kW, 200V Models ...........................................3-8

3.2.3. Three-phase 0.5kW to 3.0kW, 400V Models .....................................3-9

3.3. Main Circuit Wiring..................................................................................3-10

3.3.1. Names and Descriptions of Main Circuit Terminal..........................3-11

3.3.2. Typical Main Circuit Wiring Example.............................................3-12

3.3.3. Servo Amplifier Power Losses .........................................................3-13

3.3.4. Wiring Main Circuit Terminal Blocks..............................................3-14

3.4. I/O Signals ................................................................................................3-15

3.4.1. Example of Typical I/O Signal Connections ....................................3-15

3.4.2. List of CN1 Terminals......................................................................3-16

3.4.3. I/O Signal Names and Functions ......................................................3-17

3.4.4. Interface Circuits...............................................................................3-19

3.5. Wiring Encoders (for SGMGH and SGMSH Motors Only) ....................3-23

3.5.1. Encoder Connections ........................................................................3-23

3.5.2. CN2 Encoder Connector Terminal Layout and Types .....................3-25

3.5.3. Encoder Cables Interconnections......................................................3-26

3.6. Examples of Standard Connections ..........................................................3-28

Page 26

XtraDrive User Manual Chapter 3: Wiring

3-2

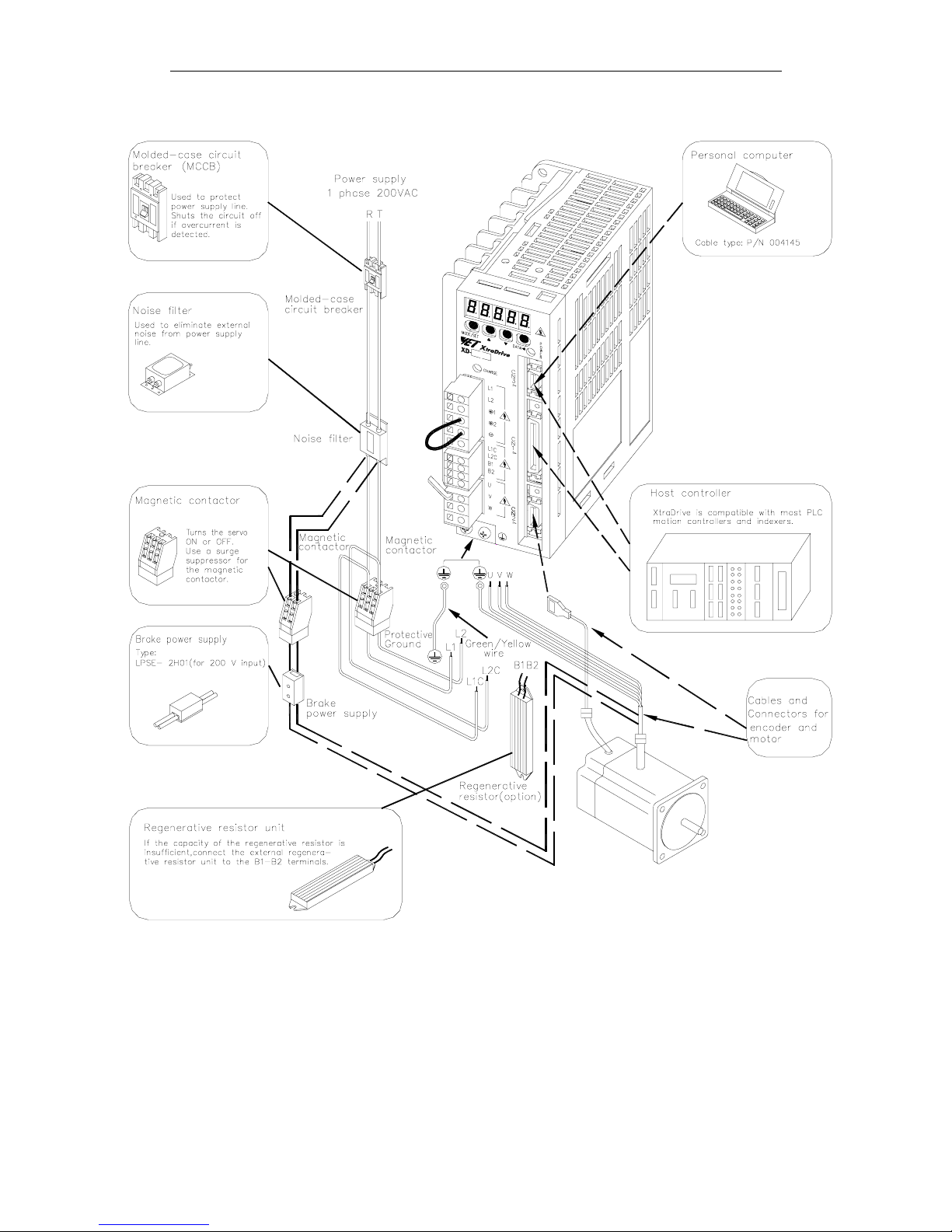

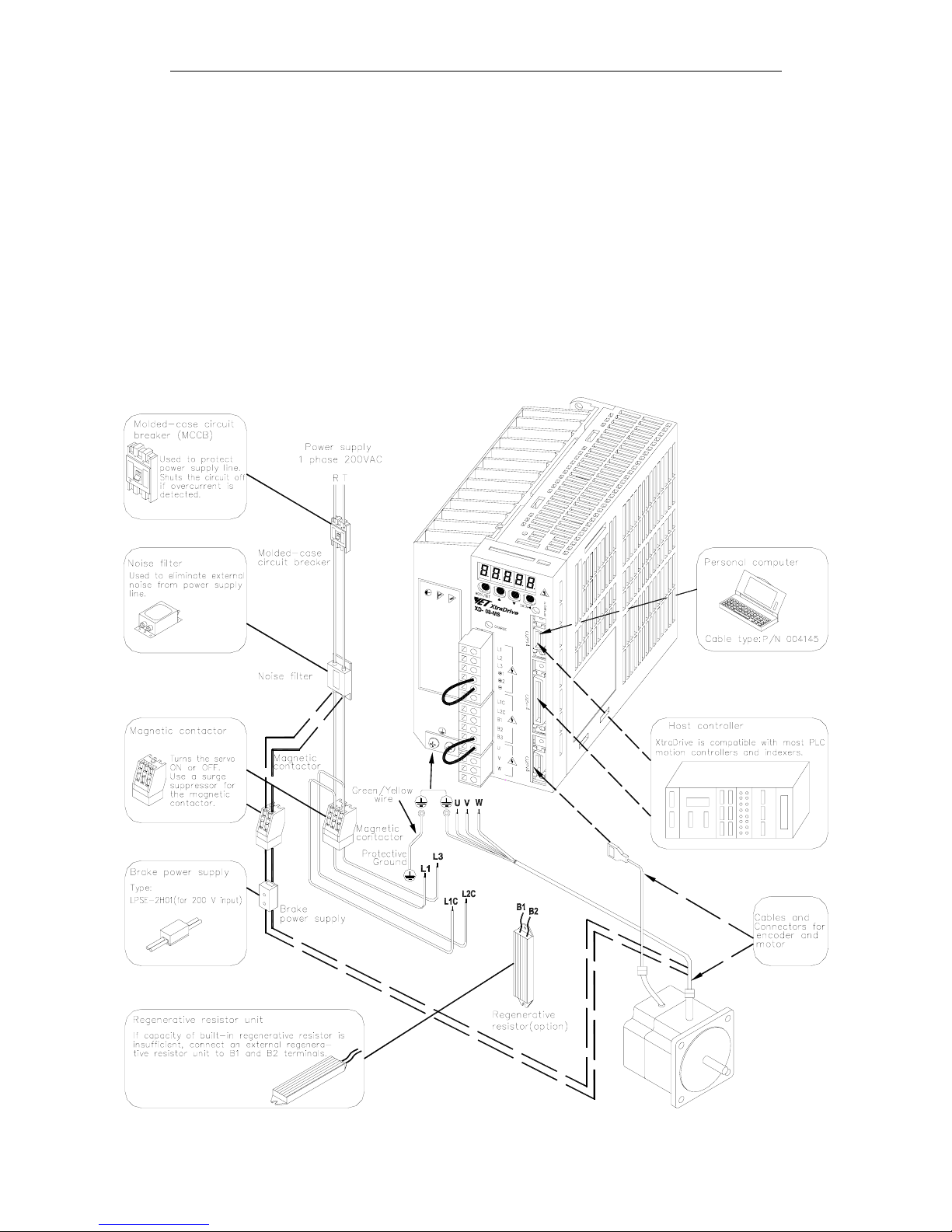

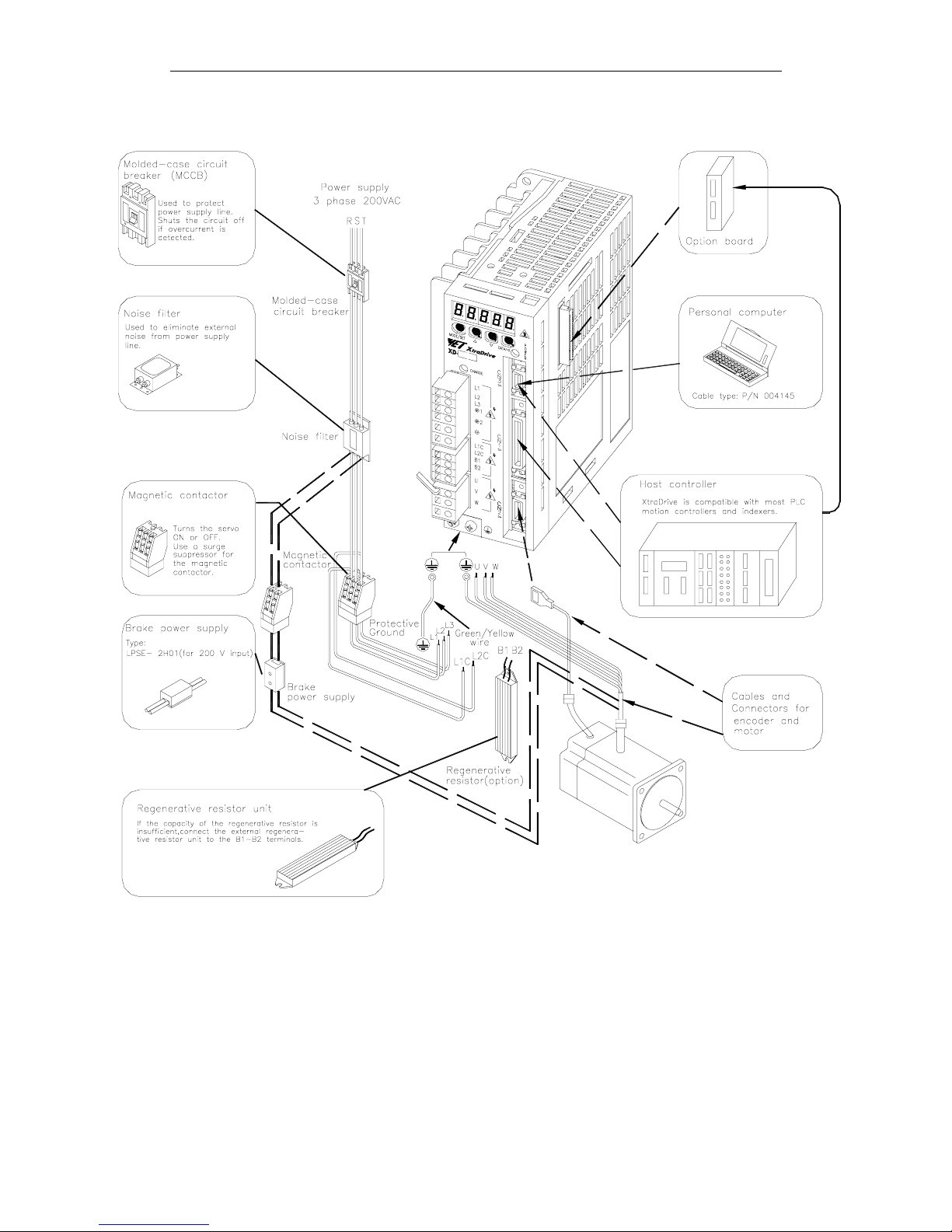

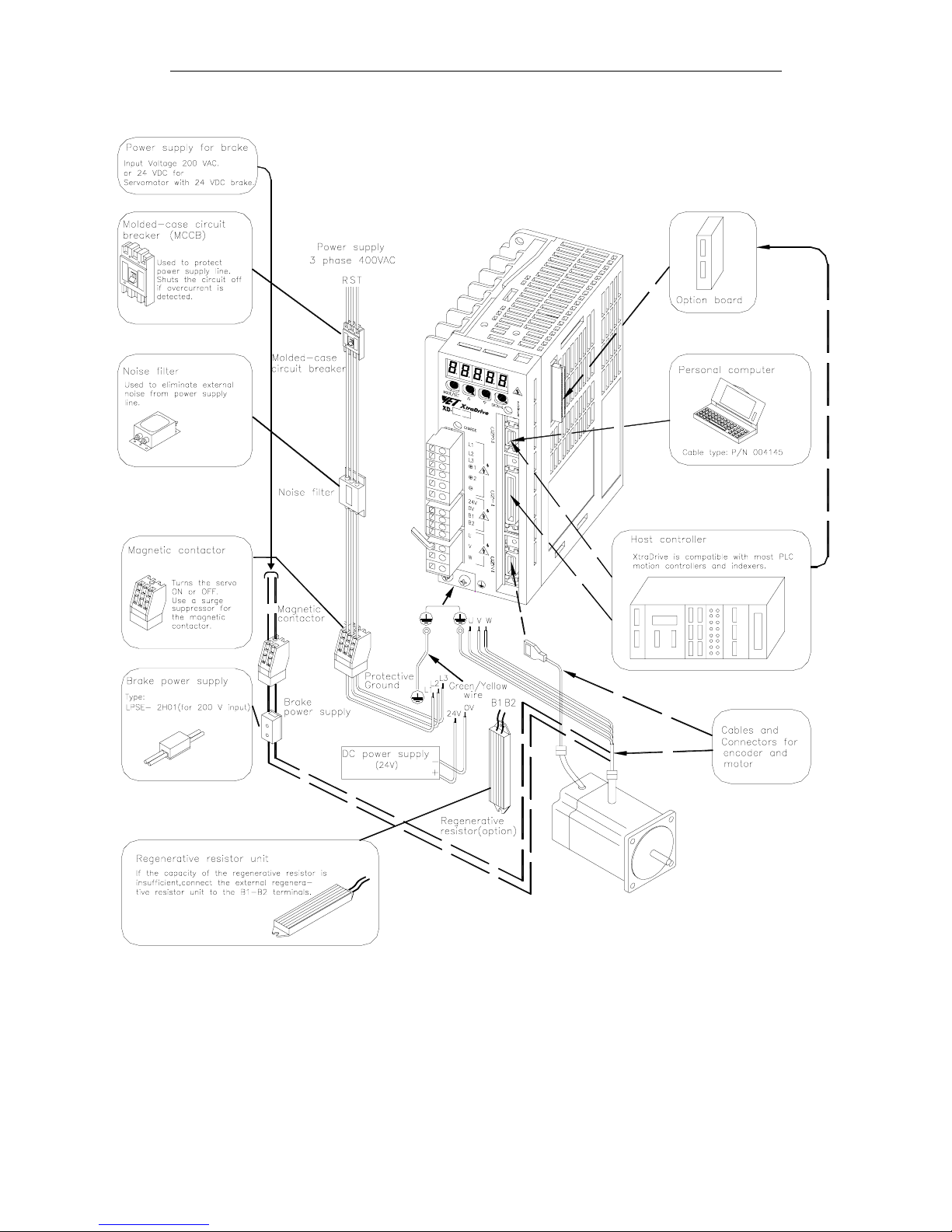

3.1. Connecting to Peripheral Devices

This section provides examples of standard XtraDrive Series product

connections to peripheral devices.

It also briefly explains how to connect each peripheral device.

Page 27

XtraDrive User Manual Chapter 3: Wiring

3-3

3.1.1. Single-Phase 200V Main Circuit Specifications

Page 28

XtraDrive User Manual Chapter 3: Wiring

3-4

3.1.2. Single-Phase 0.8kW 200V Main Circuit Specifications

XtraDrive XD-08-MS has been changed from three-phase specifications to single-

phase. Main circuit connection terminals (L1, L2, L3) remained.

These devices have terminal B3 and internal regenerative resistor. Observe the

following points.

1. Connect main power supply shown below to L1 and L3 terminals. Power supply is

single-phase, 220 to 230 VAC +10% to –15%, 50/60Hz. If power supply of 187V

(-15% of 220V) or less is used, alarm A.41 indicating voltage shortage, may occur

when accelerating to max speed with max torque of motor.

2. Short-circuit B2 and B3 terminals using the internal regenerative resistor. If

capacity of the regenerative resistor is insufficient, remove the lead between B2

and B3 terminals and connect an external regenerative resistor unit to B1 and B2

terminals.

Page 29

XtraDrive User Manual Chapter 3: Wiring

3-5

3.1.3. Three-phase 200V Main Circuit Specifications

Page 30

XtraDrive User Manual Chapter 3: Wiring

3-6

3.1.4. Three-Phase 400V Main Circuit Specifications

Page 31

XtraDrive User Manual Chapter 3: Wiring

3-7

3.2. XtraDrive Internal Block Diagrams

The following sections show internal block diagrams of the servo amplifiers.

3.2.1. Single-phase 30W to 800W, 200V M odels

Page 32

XtraDrive User Manual Chapter 3: Wiring

3-8

3.2.2. Three-phase 1kW to 3kW, 200V Models

Page 33

XtraDrive User Manual Chapter 3: Wiring

3-9

3.2.3. Three-phase 0.5kW to 3.0kW, 400V Models

Page 34

XtraDrive User Manual Chapter 3: Wiring

3-10

3.3. Main Circuit Wiring

This section shows typical examples of main circuit wiring for XtraDrive

Series servo products, functions of main circuit terminals, and the power ON

sequence.

Observe the following precautions when wiring.

CAUTION

•

Do not bundle or run power and signal line s together in the same duct. Keep power and

signal lines separated by at least 30cm (11.81 in).

Not doing so may cause a malfunction.

• Use twisted pair wires or multi-core shielded-pair wires for signal and encoder (PG)

feedback lines.

The maximum length is 3m (118.11 in) for reference input lines and is 20m (787.40 in) for PG

feedback lines.

• Do not touch the power terminals for 5 minutes after turning power OFF because high

voltage may still remain in the servo amplifier.

Make sure the charge indicator is out first before starting an inspection.

•

Avoid frequently turning power ON and OFF. Do not turn power ON or OFF more than

once per minute.

Since the servo amplifier has a capacitor in the power supply, a high charging current flows

for 0.2s when power is turned ON. Frequently turning power ON and OFF causes main power

devices like capacitors and fuses to deteriorate, resulting in unexpected problems.

Page 35

XtraDrive User Manual Chapter 3: Wiring

3-11

3.3.1. Names and Descriptions of Main Circuit Terminal

The following table gives the names and a description of main circuit

terminals.

Table

3.1: Main Circuit Names and Description

Terminal

Symbol

Name Description

L1, L2

30W to 1kW Single-phase 200 to 230V (+10%, -15%), 50/60Hz

1kW to 3kW Three-phase 200 to 230V (+10%, -15%), 50/60Hz

L1, L2, L3*

Main circuit AC input

terminal

2kW to 3.0kW 400V Three-phase 380 to 480V (+10%, -15%), 50/60Hz

U, V, W

Servomotor connection

terminal

Connects to the Servomotor.

Single-phase 200 to 230V (+10%, -15%), 50/60Hz

L1C, L2C

Three-phase 200 to 230V (+10%, -15%), 50/60Hz

24V, 0V

Control power input

terminal

30W to 3.0kW

24VDC (±15%) 400V units only

(2 places)

Ground terminal Connects to the power supply ground terminals and motor ground terminal.

30W to 400W

Normally not connected.

Connect an external regenerative resistor

(provided by customer) between B1 and B2 if the

regenerative capacity is insufficient.

Note: No B3 terminal.

B1, B2 or

B1, B2, B3

External regenerative

resistor terminal

800W to 3.0kW

Normally short B2 and B3 (for an internal

regenerative resistor).

Remove the wire between B2 and B3 and connect

an external regenerative resistor (provided by

customer) between B1 and B2 if the capacity of

the internal regenerative resistor is insufficient.

1, 2

DC reactor terminal

connection for power

supply harmonic wave

countermeasure

Normally short

1 and 2.

If a countermeasure against power supply harmonic waves is needed,

connect a DC reactor between

1 and 2.

The amplifier is delivered from the factory with these terminals shorted.

See 5.8.6 Reactor for Harmonic Suppression for details.

Main circuit Positive

terminal

Normally not connected.

Main circuit Negative

terminal

Normally not connected.

*XtraDrive XD-08 has single-phase, 200V power supply specifications. Connect the

following power supply between L1 and L3.

Single-phase 220 to 230 VAC

+10%, -15%

(50/60Hz)

When a power supply of 187V(-15% of 220V) or less is used, an alarm 41, indicating

voltage shortage, may occur when accelerating to max speed with max torque of motor.

Page 36

XtraDrive User Manual Chapter 3: Wiring

3-12

3.3.2. Typical Main Circuit Wiring Example

The following figure shows a typical example of main circuit wiring.

! Designing a Power ON Sequence

Note the following when designing the power ON sequence.

• Design the power ON sequence so that power is turned OFF when a

servo alarm signal is output. (See the circuit figure above.)

• Hold the power ON button for at least two seconds. The servo

amplifier will output a servo alarm signal for two seconds or less

when power is turned ON. This is required in order to initialize the

servo amplifier.

2.0 s max.

Power supply

Servo alarm (ALM)

output signal

Page 37

XtraDrive User Manual Chapter 3: Wiring

3-13

3.3.3. Servo Amplifier Power Losses

The following table shows servo amplifier power losses at the rated

output.

Table

3.2: Servo Amplifier Power Losses at Rated Output

Main

Circuit

Power

Supply

Maximum

Applicable

Servomotor

Capacity

[kW]

Servo Amplifier

Model

Output

Current

(Effective

Value) [A]

Main

Circuit

Power

Loss

[W]

Regenerative

Resistor

Power Loss

[W]

Control

Circuit

Power

Loss

[W]

Total

Power

Loss

[W]

0.10 XD-01-** 0.91 6.7 19.7

0.20 XD-02-** 2.1 13.3 26.3

0.40 XD-04-** 2.8 20

— 13

33

Single-

phase

200V

0.75 XD-08-** 4.4 47 12 15 74

1.0 XD-10-** 7.6 55 12 82

2.0 XD-20-** 18.5 120 163

Threephase

200V

3.0 XD-30-** 7.5 60

28

15

198

0.45 XD-05-** 1.9 19 48

1.0 XD-10-** 3.5 35 64

1.5 XD-15-** 5.4 53

14

82

2.0 XD-20-** 8.4 83 161

Threephase

400V

3.0 XD-30-** 11.9 118

28

15

243

Note: Regenerative resistor power losses are allowable losses. Take the following action if this value is

exceeded:

• Disconnect the internal regenerative resistor in the servo amplifier by removing the wire

between terminals B2 and B3.

•

Install an external regenerative resistor between terminals B1 and B2.

See 5.6 Selecting a Regenerative Resistor for more details on the resistors.

Page 38

XtraDrive User Manual Chapter 3: Wiring

3-14

3.3.4. Wiring Main Circuit Terminal Blocks

Observe the following precautions when wiring main circuit terminal

blocks.

CAUTION

•

Remove the terminal block from the servo amplifier prior to wiring.

•

Insert only one wire per terminal on the terminal block.

•

Make sure that the core wire is not electrically shorted to adjacent core wires.

•

Reconnect any wires that were accidentally pulled out.

Servo amplifiers with a capacity below 1.5kW will have connector-type

terminal blocks for main circuit terminals. Follow the procedure below when

connecting to the terminal block.

! Connection Procedure

• Strip the end of the wire, leaving the ends twisted together.

• Open the wire insert opening of the terminal block (plug) with a tool

using either of the two procedures shown in Fig. A and Fig. B on the

following page.

1. Fig. A: Use the provided lever to open the wire insert opening .

Fig. B: Using a commercially available 1/8in (3.0 to 3.5mm)

slotted screwdriver, press down firmly on the screwdriver insert

opening to release the wire insert slot.

2. Figs A and B: Insert the wire end into the opening and then

clamp it tightly by releasing either the lever or the screwdriver.

Page 39

XtraDrive User Manual Chapter 3: Wiring

3-15

3.4. I/O Signals

This section describes I/O signals for the XtraDrive servo amplifier.

3.4.1. Example of Typical I/O Signal Connections

Page 40

XtraDrive User Manual Chapter 3: Wiring

3-16

3.4.2. List of CN1 Terminals

The following diagram shows the layout and specifications of CN1

terminals.

Table

3.3: CN1 Terminal Layout

2 SG GND

4 SEN

SEN signal

input

6 SG GND

8 /PULS

Reference

pulse input

10 SG GND

12 /SIGN

Reference

symbol input

14 /CLR Clear input

16 TMON

Analog

Monitor Output

18 PL3

Open-collector

reference

power supply

20 /PCO

PG divided

output

C-phase

22 BAT (-) Battery (-)

24 — —

1 SG GND

3 PL1

Open-collector

reference

power supply

5 V-REF

Reference

speed input

7 PULS

Reference

pulse input

9 T-REF

Torque

reference input

11 SIGN

Reference sign

input

13 PL2

Open-collector

reference

power supply

15 CLR Clear input

17 VTG

Analog Monitor

Output

19 PCO

PG divided

output Cphase

21 BAT (+) Battery (+)

23 — —

25

/V-CMP+

(/COIN+)

Speed

coincidence

detection output

27 /TGON+

TGON signal

output

29 /SRDY+

Servo ready

output

31 ALM+

Servo alarm

output

33 PAO

PG divided

output Aphase

35 PBO

PG divided

output Bphase

37 AL01

Alarm code

output

39 AL03

Opencollector

output

41 P-CON

P operation

input

43 N-OT

Reverse

overtravel

input

45 /P-CL

Forward

current limit

ON input

47 +24V -IN

External

input power

supply

49 /PSO

S-phase

signal output

26

/V-CMP(/COIN-)

Speed coincidence detection

output

28 /TGON

TGON signal

output

30 /S-RDY

Servo ready

output

32 ALM

Servo alarm

output

34 /PAO

PG divided

output Aphase

36 /PBO

PG divided

output Bphase

38 AL02

Alarm code

output

40 /S-ON

Servo ON

input

42 P-OT

Forward

overtravel

input

44

/ALMRST Alarm reset

input

46 /N-CL

Reverse

current limit

ON input

48 PSO

S-phase

signal output

50 — —

Note: 1. Do not use unused terminals for relays.

2. Connect the shield of the I/O signal cable to the connector’s shell.

3. Connect to the FG (frame ground) at the servo amplifier-end connector.

! CN1 Specifications

Applicable Receptacle Kit (YET P/N: 4J4003)

XtraDrive Internal

Connector

Connector Case Manufacturer

10250-52A2JL or Equivalent

50-pin Right Angle Plug

MDR 10150-3000VE 50-pin 10350-52A0-008

Sumitomo 3M

Co.

Page 41

XtraDrive User Manual Chapter 3: Wiring

3-17

3.4.3. I/O Signal Names and Functions

The following section describes servo amplifier I/O signal names and

functions.

! Input Signals

Signal Name

Pin

No.

Function

Refer-

ence

/S-ON

40

Servo ON: Turns ON the servomotor when the gate block

in the inverter is released.

5.5.2

* Function selected via parameter.

5.2.1

5.2.7

Proportional

operation

reference

Switches the speed control loop from PI

(proportional/integral) to P (proportional)

control when ON.

5.2.1

Direction

reference

With internal reference speed selected:

Switches the direction of rotation.

5.2.6

Position Speed

Speed Torque

Control mode

switching

Torque

Speed

Enables

control mode

switching.

5.2.7

Zero-clamp

reference

Speed control with zero-clamp function:

reference speed is zero when ON.

5.4.3

Common

/P-CON

41

Reference

pulse block

Position control with reference pulse stop:

stops reference pulse input when ON.

5.2.10

P-OT

N-OT

42

43

Forward Run

prohibited

Reverse Run

prohibited

Overtravel prohibited: stops servomotor

when movable part travels beyond the

allowable range of motion.

5.1.2

* Function selected with a parameter.

—

Forward

current limit ON

Reverse

current limit ON

Current limit function used when ON.

5.1.3

/P-CL

/N-CL

45

46

Internal

speed

switching

With internal reference speed selected:

switches the internal speed settings.

5.2.6

/ALM

-RST

44 Alarm reset: Releases the servo alarm state.

5.5.1

+24V

IN

47

Control power supply input for sequence signals: users

must provide the +24V power supply.

5.2.4

SEN

4 (2) Initial data request signal when using an absolute encoder.

5.2.3

BAT+

BAT-

21

22

Connecting pins for the absolute encoder backup battery.

5.2.3

Speed

Referenc

e

V-REF 5 (6)

Speed reference input: ±2 to ±10V/rated motor speed

(Input gain can be modified with a parameter.)

5.2.1

Torque

Referenc

e

T-REF

9

(10)

Torque reference input: ±1 to ±10V/rated motor speed

(Input gain can be modified with a parameter.)

5.2.1

Position

Referenc

e

PULS

/PULS

SIGN

/SIGN

7

8

11

12

Corresponds

to reference

pulse input

Line-driver

Open-

collector

Input mode

•

Code + pulse string

•

CCW/CW pulse

•

Two-phase pulse (90° phase differential)

5.2.1

CLR

/CLR

15

14

Error counter clear: Clears the error counter during

position control.

5.2.1

PL1

PL2

PL3

3

13

18

+12V pull-up power supply when PULS, SIGN and CLR

reference signals is open-collector outputs (+12V power

supply is built into the servo amplifier).

5.2.1

Note: 1. The functions allocated to /S-ON, /P-CON. P-OT, N-OT, /ALM-RST, /P-CL, and /N-CL input

signals can be changed with parameters. (See 5.3.3 Input Circuit Signal Allocation.)

2. Pin numbers in parenthesis ( ) indicate signal grounds.

3. The voltage input range for speed and torque references is a maximum of ±12V.

Page 42

XtraDrive User Manual Chapter 3: Wiring

3-18

! Output Signals

Signal Name

Pin

No.

Function Reference

ALM+

ALM-

31

32

Servo alarm: Turns OFF when an error is detected. 5.5.1

/TGON+

/TGON-

27

28

Detection during servomotor rotation: detects

whether the servomotor is rotating at a speed higher

than the motor speed setting. Motor speed detection

can be set via parameter.

5.5.5

/S-RDY+

/S-RDY- 9 30

Servo ready: ON if there is no servo alarm when the

control/main circuit power supply is turned ON.

5.5.6

PAO

/PAO

PBO

/PBO

PCO

/PCO

33(1)

34

35

36

19

20

A phase

signal

B phase

signal

C phase

signal

Converted two-phase pulse (A and

B phase) encoder output signal

and origin pulse (C phase) signal:

RS-422 or the equivalent.

5.2.3

PSO

/PSO

48

49

S phase

signal

With an absolute encoder: outputs

serial data corresponding to the

number of revolutions (RS-422 or

equivalent).

ALO1

ALO2

ALO3

37

38

39(1)

Alarm code output: Outputs 3-bit alarm codes.

Open-collector: 30V and 20mA rating maximum.

5.5.1

TMON 16 Analog monitor signal

Common

VTG

17 Analog monitor signal

Speed

/V-CMP+

/V-CMP-

25

26

Speed coincidence (output in Speed Control Mode):

detects whether the motor speed is within the

setting range and if it matches the reference speed

value.

5.5.4

Position

/COIN+

/COIN-

25

26

Positioning completed (output in Position Control

Mode): turns ON when the number of error pulses

reaches the value set. The setting is the number of

error pulses set in reference units (input pulse units

defined by the electronic gear).

5.5.3

Not used.

23

24

50

These terminals are not used.

Do not connect relays to these terminals.

—

Note: 1. Pin numbers in parenthesis () indicate signal grounds.

2. The functions allocated to /TGON, /S-RDY, and /V-CMP (/COIN) can be changed via parameters.

Functions /CLT, /VCT, /BK, /WARN, and /NEAR signals can also be changed. (See 5.3.4 Output

Circuit Signal Allocation).

Page 43

XtraDrive User Manual Chapter 3: Wiring

3-19

3.4.4. Interface Circuits

This section shows examples of servo amplifier I/O signal connection to

the host controller.

! Interface for Reference Input Circuits

Analog Input Circuit

Analog signals are either speed or torque reference signals at the

impedance below.

• Speed reference input: About 14kΩ

• Torque reference input: About 14kΩ

The maximum allowable voltage for input signals is ±12V.

Reference Position Input Circuit

An output circuit for the reference pulse and error counter clear signal

at the host controller can be either line-driver or open-collector outputs.

These are shown below by type.

• Line-driver Output Example:

• Open-collector Output, Example 1: External power supply

Page 44

XtraDrive User Manual Chapter 3: Wiring

3-20

The following examples show how to select the pull-up resistor R1 so

the input current (I) falls between 7 and 15mA.

Application Examples

R1 =2.2kΩ with

V

CC

= 24V ±5%

R1 =1kΩ with

VCC = 12V ±5%

R1 =180Ω with

VCC = 5V ±5%

• Open-collector Output, Example 2: Using a servo amplifier with an

internal 12V power supply

This circuit uses the 12V power supply built into the servo

amplifier. The input is not isolated in this case.

! Sequence Input Circuit Interface

The sequence input circuit interface connects through a relay or opencollector transistor circuit. Select a low-current relay; otherwise a faulty

contact will result.

Page 45

XtraDrive User Manual Chapter 3: Wiring

3-21

! Output Circuit Interfaces

Any of the following three types of servo amplifier output circuits can

be used. Connect an input circuit at the host controller following one of

these types.

• Connecting to a Line-driver Output Circuit

Encoder serial data converted to two-phase (A and B phase) pulse

output signals (PAO, /PAO, PBO, /PBO), origin pulse signals (PCO,

/PCO) and S phase rotation signals (PCO, /PCO) are output via linedriver output circuits that normally comprise the position control

system at the host controller. Connect the line-driver output circuit

through a line receiver circuit at the host controller.

See 3.5 Wiring Encoders for connection circuit examples.

• Connecting to an Open-collector Output Circuit

Alarm code signals are output from open-collector transistor output

circuits.

Connect an open-collector output circuit through an optocoupler,

relay, or line receiver circuit.

Note: The maximum allowable voltage and current capacities for open-collector circuits are:

• Voltage: 30V

DC

• Current: 20mA

DC

Page 46

XtraDrive User Manual Chapter 3: Wiring

3-22

• Connecting an optocoupler output circuit

An optocoupler output circuits are used for servo alarm, servo ready,

and other sequence output signal circuits.

Connect an optocoupler output circuit through a relay or line

receiver circuit.

Note: The maximum allowable capacities for optocoupler output circuits are:

• Voltage: 30V

DC

• Current: 50mA

DC

• Connecting two XtraDrives (master-slave mode)

Connect output of “master” XtraDrive to “slave” XtraDrive’s input.

• Connecting an external load to XtraDrive’s output.

Maximum current: 50mA.

Page 47

XtraDrive User Manual Chapter 3: Wiring

3-23

3.5. Wiring Encoders (for SGMGH and SGMSH Motors Only)

The following sections describe the procedure for wiring a servo amplifier to

the encoder.

3.5.1. Encoder Connections

The following diagrams show the wiring of the encoder output from the

motor to CN2 of the servo amplifier, and PG output signals from CN1

to the controller. This applies to both incremental and absolute encoders

of SGMGH and SGMSH motors only.

Incremental Serial Encoders

Page 48

XtraDrive User Manual Chapter 3: Wiring

3-24

Absolute Serial Encoders

Incremental A/B+C Encoders

Page 49

XtraDrive User Manual Chapter 3: Wiring

3-25

3.5.2. CN2 Encoder Connector Terminal Layout and Types

The following tables describe CN2 connector terminal layout and types.

CN2 Connector Terminal Layout

1 PPG0V PG GND

3 PPG0V PG GND

5 PPG5V PG +5V

7 NC* -

9 /PS

Serial PG

/S-phase

2 PPG0V PG GND

4 PPG5V PG +5V

6 PPG5V PG +5V

8 PS

Serial PG

S-phase

10 SPG5V

Serial PG

+5V

11 SPG0V

Serial PG

GND

13 BAT-

Battery “ –“

input

15 /PC

PG

/C-phase

17 /PA

PG

/A-phase

19 /PB

PG

/B-phase

12 BAT+

Battery ”+”

input

14 PC

PG

C-phase

16 PA

PG

A-phase

18 PB

PG

B-phase

20 NC* -

Note: NC* – Leave contact open.

Optional: CN2 Connector with Commutation Sensors

Terminal Layout

1 PPG0V PG GND

3 PPG0V PG GND

5 PPG5V PG +5V

7 /UIN

U – Phase

Hall Effect

9 /VIN

V – Phase

Hall Effect

2 PPG0V PG GND

4 PPG5V PG +5V

6 PPG5V PG +5V

8 NC* -

10 SPG5V +5V

11 SPG0V GND

13 BAT-

Battery ” –“

input

15 /PC

PG

/C-phase

17 /PA

PG

/A-phase

19 /PB

PG

/B-phase

12 BAT+

Battery “+”

input

14 PC

PG

C-phase

16 PA

PG

A-phase

18 PB

PG

B-phase

20 /WIN

W – Phase

Hall Effect

Note: NC* – Leave contact open.

CN2 Connector Models

Applicable Plug (or Socket)

XtraDrive

Internal

Connector

Soldered Plug Case

Soldered Plug

(Servomotor

Side)

10220-52A2JL

20 PIN

MDR 10120-3000VE 20PIN

(YET P/N: 4J4001)

10320-52A0-008

(YET P/N:

4J0101)

54280-0600 6PIN

(YET P/N: 4J1521)

Note: The motor-end relay socket connects to the encoder connector for the SGMAH and SGMPH

servomotors.

Page 50

XtraDrive User Manual Chapter 3: Wiring

3-26

3.5.3. Encoder Cables Interconnections

This chapter shows interconnections for all standard encoder cables

available from YET (Refer to YET Part Number). For additional types

of encoders (like with communication sensors etc.) contact your YET

representative.

Absolute A/B Encoder Cable

For Yaskawa SGM motors. (P/N 004143)

PPG0V 1,2,3

PPG5V 4,5,6

FG Case

70V

8+5V

15 +3.6V

9FG

Cable Shield

14 0V

BAT+ 12

BAT- 13

P

P

- Twisted pair.

XtraDrive side

20-pin connect or

Motor side

15-pin connect or

P

P

P

PC 14

/PC 15

PA 16

/PA 17

PB 18

/PB 19

YELLOW/GR EEN

WHITE

YELLOW

WHITE/BLUE

BLUE

WHITE/GREEN

GREEN

WHITE

ORANGE

RED

BLACK

5C

6/C

1A

2/A

3B

4/B

Incremental A/B Encoder Cable

For Yaskawa SGM motors. (P/N 004144)

PPG0V 1,2,3

PPG5V 4,5,6

FG Case

70V

8+5V

9FG

Cable Shield

P

- Twisted pair.

XtraDrive side

20-pin connect or

Motor side

9-pin connect or

P

P

P

PC 14

/PC 15

PA 16

/PA 17

PB 18

/PB 19

YELLOW/GR EEN

WHITE

YELLOW

WHITE/BLUE

BLUE

WHITE/GREEN

GREEN

RED

BLACK

5C

6/C

1A

2/A

3B

4/B

Page 51

XtraDrive User Manual Chapter 3: Wiring

3-27

Absolute Serial Encoder Cable

For Yaskawa SGMAH motors. (P/N 004139)

SPG5V 10

SPG0V 11

12

FG Shield

1PG5V

2GND

3 PGBAT+

Shield FG

4 PGBAT-

5PS

6 /PS

/PS 9

PS 8

13

BAT+ 1

BAT- 2

P

P

P

- Twisted pair.

XtraDrive side

20-pin connect or

Motor side

6-pin connect or

Cable Shield

WHITE/BLUE

BLUE

WHITE/ORANGE

ORANGE

BLACK

RED

Battery

connector

Incremental Serial Encoder Cable

For Yaskawa SGMAH motors. (P/N 004140)

SPG5V 10

SPG0V 11

FG Shield

1PG5V

2GND

3 PGBAT+

Shield FG

4 PGBAT-

5PS

6 /PS

/PS 9

PS 8

BAT+ 12

BAT- 13

P

P

P

- Twisted pair.

XtraDrive side

20-pin connect or

Motor side

6-pin connect or

Cable Shield

WHITE/BLUE

BLUE

WHITE/ORANGE

ORANGE

BLACK

RED

Page 52

XtraDrive User Manual Chapter 3: Wiring

3-28

3.6. Examples of Standard Connections

The following diagrams show examples of standard servo amplifier

connections by specifications and type of control.

Note for single-phase power supply specifications:

XtraDrive XD-08** have changed from three-phase specifications to singlephase. Main circuit connection terminals (L1, L2, L3) remained.

These devices have terminal B3 and internal regenerative resistor. Observe

the following points.

1. Connect main power supply shown below to L1 and L3 terminals. Power

supply is single-phase, 220 to 230 VAC +10% to –15%, 50/60Hz. If

power supply of 187V (-15% of220V) or less is used, alarm A41

indicating voltage shortage, may occur when accelerating to max speed

with max torque of motor.

2. Short-circuit B2 and B3 terminals using the internal regenerative resistor.

If capacity of the regenerative resistor is insufficient, remove the lead

between B2 and B3 terminals and connect an external regenerative

resistor unit to B1 and B2 terminals.

Page 53

XtraDrive User Manual Chapter 3: Wiring

3-29

Position Control Mode

*1. P represents twisted-pair wires

*2. The time constant for the primary filter is 47us.

*3. Connect only with an absolute encoder.

*7. These circuits are SELV circuits, therefore are

separated from all other circuits by double and

reinforced insulator.

*4. Used only with an absolute encoder. *8. Use a double-insulated 24-VDC power supply.

*9. Optional – not available in all models. *5. Connect an external regenerative resistor

between terminals B1 and B2.(for XtraDrives with big

capacity)

*10. Resistors are different for each model.

*6. These circuits are hazardous, therefore are

separated by protecting separator.

*11. ∅ Represents contacts of CN1 connector

Page 54

XtraDrive User Manual Chapter 3: Wiring

3-30

Speed Control Mode

*1. P represents twisted-pair wires

*2. The time constant for the primary filter is 47us.

*3. Connect only with an absolute encoder.

*7. These circuits are SELV circuits, therefore are

separated from all other circuits by double and

reinforced insulator.

*4. Used only with an absolute encoder. *8. Use a double-insulated 24-VDC power supply.

*9. Optional – not available in all models. *5. Connect an external regenerative resistor

between terminals B1 and B2.(for XtraDrives with big

capacity)

*10. Resistors are different for each model.

*6. These circuits are hazardous, therefore are

separated by protecting separator.

*11. ∅ Represents contacts of CN1 connector

Page 55

XtraDrive User Manual Chapter 3: Wiring

3-31

Torque Control Mode

*1. P represents twisted-pair wires

*2. The time constant for the primary filter is 47us.

*3. Connect only with an absolute encoder.

*7. These circuits are SELV circuits, therefore are

separated from all other circuits by double and

reinforced insulator.

*4. Used only with an absolute encoder. *8. Use a double-insulated 24-VDC power supply.

*9. Optional – not available in all models. *5. Connect an external regenerative resistor

between terminals B1 and B2.(for XtraDrives with big

capacity)

*10. Resistors are different for each model.

*6. These circuits are hazardous, therefore are

separated by protecting separator.

*11. ∅ Represents contacts of CN1 connector

Page 56

XtraDrive User Manual Chapter 3: Wiring

3-32

This page intentionally left blank.

Page 57

XtraDrive User Manual Chapter 4: Trial Operation

4-1

4. Trial Operation

This chapter describes a two-step trial operation. Be sure to complete step 1

before proceeding to step 2.

4.1. Two-Step Trial Operation...........................................................................4-2

4.1.1. Step 1: Trial Operation for Servomotor without Load........................4-3

4.1.2. Step 2: Trial Operation with Servomotor Connected to Machine .....4-9

4.2. Additional Setup Procedures in Trial Operation.......................................4-10

4.2.1. Servomotors with Brakes..................................................................4-10

4.2.2. Position Control by Host Controller.................................................4-11

4.3. Minimum Parameters and Input Signals...................................................4-12

4.3.1. Parameters.........................................................................................4-12

4.3.2. Input Signals .....................................................................................4-12

Page 58

XtraDrive User Manual Chapter 4: Trial Operation

4-2

4.1. Two-Step Trial Operation

Make sure that all wiring is completed prior to starting trial operation.

For your own safety, perform the trial operation in the order given below

(step 1 and 2). See 4.1.1 Trial Operation for Servomotor without Load and

4.1.2 Trial Operation for Servomotor Connected to Mashine for more details

on the trial operation.

Step 1: Trial Operation for Servomotor without Load

M a ke sure the Se rv o moto r is wired p rop e rly a n d th e n tu rn th e

shaft prior to connecting the Servomotor to the equipment.

Step 2: Trial Operation with the Equipment and Servomotor Connected