Page 1

Cat. No. Z291-E1-0

FZ3

Xpectia Series

Vision Sensor

Processing Items List

USERS MANUAL

Page 2

Introduction

Thank you for purchasing the FZ3 Series.

This manual provides information regarding functions, performance and operating methods that

are required for using the FZ3 Series.

When using the FZ3 Series, be sure to observe the following:

• The FZ3 Series must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the

product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

Page 3

Contents

1. Input image

Camera Image Input ………………………………………………………………………………………12

Settings Flow (Camera Image Input) …………………………………………………………………12

Camera Selection (Camera Image Input) ……………………………………………………………13

Camera Settings (Camera Image Input) ………………………………………………………………14

Screen Adjustment Settings (Camera Image Input) …………………………………………………18

White Balance (Camera Image Input) …………………………………………………………………23

Calibration (Camera Image Input)………………………………………………………………………24

Additional Explanation (Camera Image Input) ………………………………………………………31

Camera Image Input HDR+ ………………………………………………………………………………32

Settings Flow (Camera Image Input HDR+) …………………………………………………………32

HDR Settings (Camera Image Input HDR+) …………………………………………………………33

Bright Adjust Setting (Camera Image Input HDR+) …………………………………………………36

Camera Switching …………………………………………………………………………………………38

Camera Selection (Camera Switching) ………………………………………………………………38

Additional Explanation (Camera Switching) …………………………………………………………38

Measurement Image Switching ……………………………………………………………………………40

Parameter Settings (Measurement Image Switching) ………………………………………………40

2. Measurement

Search ………………………………………………………………………………………………………42

Settings Flow (Search) …………………………………………………………………………………42

Model Registration (Search) ……………………………………………………………………………43

Region Setting (Search) …………………………………………………………………………………46

Detection Point (Search)…………………………………………………………………………………47

Reference Position (Search) ……………………………………………………………………………47

Measurement Parameters (Search) ……………………………………………………………………48

Output Parameters (Search) ……………………………………………………………………………50

Key Points for Test Measurement and Adjustment (Search) ………………………………………50

Measurement Results for Which Output Is Possible (Search) ………………………………………52

Flexible Search………………………………………………………………………………………………53

Settings Flow (Flexible Search)…………………………………………………………………………53

Model Registration (Flexible Search) …………………………………………………………………54

Region Setting (Flexible Search) ………………………………………………………………………57

Measurement Parameters (Flexible Search) …………………………………………………………57

Output Parameters (Flexible Search) …………………………………………………………………59

Key Points for Test Measurement and Adjustment (Flexible Search)………………………………59

Measurement Results for Which Output Is Possible (Flexible Search) ……………………………61

Sensitive Search ……………………………………………………………………………………………62

Settings Flow (Sensitive Search) ………………………………………………………………………62

Model Registration (Sensitive Search)…………………………………………………………………63

Region Setting (Sensitive Search) ……………………………………………………………………66

Detection Point (Sensitive Search) ……………………………………………………………………67

Reference Position (Sensitive Search)…………………………………………………………………67

Measurement Parameters (Sensitive Search) ………………………………………………………68

Output Parameters (Sensitive Search)…………………………………………………………………69

………………………………………………………………………………………………11

……………………………………………………………………………………………41

FZ3 Processing Items List Manual

1

Page 4

Key Points for Test Measurement and Adjustment (Sensitive Search) ……………………………70

Measurement Results for Which Output Is Possible (Sensitive Search) …………………………72

ECM Search …………………………………………………………………………………………………73

Settings Flow (ECM Search) ……………………………………………………………………………73

Model Registration (ECM Search) ……………………………………………………………………74

Error Model Registration (ECM Search) ………………………………………………………………78

Region Setting (ECM Search) …………………………………………………………………………78

Detection Point (ECM Search) …………………………………………………………………………78

Reference Position (ECM Search) ……………………………………………………………………79

Measurement Parameters (ECM Search) ……………………………………………………………80

Output Parameters (ECM Search) ……………………………………………………………………81

Key Points for Test Measurement and Adjustment (ECM Search) …………………………………82

When Using Measurement Results Externally (ECM Search) ………………………………………83

EC Circle Search ……………………………………………………………………………………………84

Settings Flow (EC Circle Search) ………………………………………………………………………84

Circle Setting (EC Circle Search) ………………………………………………………………………85

Region Setting (EC Circle Search) ……………………………………………………………………86

Reference Position (EC Circle Search) ………………………………………………………………87

Color Specification (EC Circle Search)…………………………………………………………………88

Measurement Parameters (EC Circle Search) ………………………………………………………89

Output Parameters (EC Circle Search) ………………………………………………………………91

Key Points for Test Measurement and Adjustment (EC Circle Search) ……………………………92

Measurement Results for Which Output Is Possible (EC Circle Search) …………………………93

Shape Search+ ……………………………………………………………………………………………94

Settings Flow (Shape Search+)…………………………………………………………………………95

Model Registration (Shape Search+) …………………………………………………………………95

Region Setting (Shape Search+) ………………………………………………………………………97

Detection Point (Shape Search+) ………………………………………………………………………97

Reference Position (Shape Search+) …………………………………………………………………98

Measurement Parameters (Shape Search+) …………………………………………………………99

Output Parameters (Shape Search+)…………………………………………………………………100

Key Points for Test Measurement and Adjustment (Shape Search+) ……………………………101

Measurement Results for Which Output Is Possible (Shape Search+) …………………………102

Classification ………………………………………………………………………………………………104

Settings Flow (Classification) …………………………………………………………………………104

Model Registration (Classification) ……………………………………………………………………105

Region Setting (Classification) ………………………………………………………………………109

Measurement Parameters (Classification) …………………………………………………………110

Output Parameters (Classification)……………………………………………………………………111

Key Points for Test Measurement and Adjustment (Classification) ………………………………111

Measurement Results for Which Output Is Possible (Classification)………………………………113

Edge Position ………………………………………………………………………………………………114

Settings Flow (Edge Position) …………………………………………………………………………114

Region Setting (Edge Position) ………………………………………………………………………115

Edge Color Specification - For Color Cameras Only (Edge Position) ……………………………117

Reference Position (Edge Position) …………………………………………………………………118

Measurement Parameters (Edge Position) …………………………………………………………119

Output Parameters (Edge Position) …………………………………………………………………122

Key Points for Test Measurement and Adjustment (Edge Position) ………………………………123

2

FZ3 Processing Items List Manual

Page 5

Measurement Results for Which Output Is Possible (Edge Position) ……………………………123

Edge Pitch …………………………………………………………………………………………………124

Settings Flow (Edge Pitch) ……………………………………………………………………………124

Region Setting (Edge Pitch)……………………………………………………………………………125

Edge Color Specification - For Color Cameras Only (Edge Pitch)…………………………………126

Measurement Parameters (Edge Pitch)………………………………………………………………127

Output Parameters (Edge Pitch)………………………………………………………………………129

Key Points for Test Measurement and Adjustment (Edge Pitch) …………………………………130

Measurement Results for Which Output Is Possible (Edge Pitch)…………………………………131

Scan Edge Position ………………………………………………………………………………………132

Settings Flow (Scan Edge Position) …………………………………………………………………132

Region Setting (Scan Edge Position)…………………………………………………………………133

Edge Color Specification - For Color Cameras Only (Scan Edge Position) ………………………135

Reference Position (Scan Edge Position) ……………………………………………………………136

Measurement Parameters (Scan Edge Position)……………………………………………………137

Judgment Conditions (Scan Edge Position) …………………………………………………………140

Output Parameters (Scan Edge Position) ……………………………………………………………142

Key Points for Test Measurement and Adjustment (Scan Edge Position) ………………………143

Measurement Results for Which Output Is Possible (Scan Edge Position) ………………………144

Scan Edge Width …………………………………………………………………………………………145

Settings Flow (Scan Edge Width) ……………………………………………………………………145

Region Setting (Scan Edge Width)……………………………………………………………………146

Edge Color Specification - For Color Cameras Only (Scan Edge Width) …………………………148

Measurement Parameters (Scan Edge Width)………………………………………………………149

Judgement Conditions (Scan Edge Width) …………………………………………………………151

Output Parameters (Scan Edge Width) ………………………………………………………………152

Key Points for Test Measurement and Adjustment (Scan Edge Width) …………………………153

Measurement Results for Which Output Is Possible (Scan Edge Width) …………………………153

Color Data …………………………………………………………………………………………………154

Settings Flow (Color Data) ……………………………………………………………………………154

Region Setting (Color Data)……………………………………………………………………………155

Measurement Parameters (Color Data)………………………………………………………………156

Output Parameters (Color Data) ………………………………………………………………………158

Key Points for Test Measurement and Adjustment (Color Data) …………………………………158

Measurement Results for Which Output Is Possible (Color Data)…………………………………159

Gravity and Area …………………………………………………………………………………………160

Settings Flow (Gravity and Area) ……………………………………………………………………160

Color Specification (Gravity and Area) ………………………………………………………………162

Binarization (Gravity and Area) ………………………………………………………………………164

Region Setting (Gravity and Area) ……………………………………………………………………165

Reference Position (Gravity and Area) ………………………………………………………………166

Measurement Parameters (Gravity and Area) ………………………………………………………167

Output Parameters (Gravity and Area) ………………………………………………………………169

Key Points for Test Measurement and Adjustment (Gravity and Area) …………………………170

Measurement Results for Which Output Is Possible (Gravity and Area) …………………………170

Labeling ……………………………………………………………………………………………………172

Settings Flow (Labeling) ………………………………………………………………………………172

Color Specification (Labeling) …………………………………………………………………………173

Binarization (Labeling) …………………………………………………………………………………176

FZ3 Processing Items List Manual

3

Page 6

Region Setting (Labeling)………………………………………………………………………………177

Reference Position (Labeling) …………………………………………………………………………178

Measurement Parameters (Labeling)…………………………………………………………………179

Judgement Conditions (Labeling) ……………………………………………………………………182

Output Parameters (Labeling) …………………………………………………………………………183

Key Points for Test Measurement and Adjustment (Labeling) ……………………………………184

Measurement Results for Which Output Is Possible (Labeling)……………………………………184

Label Data …………………………………………………………………………………………………186

Settings Flow (Label Data) ……………………………………………………………………………187

Setting (Label Data) ……………………………………………………………………………………187

Output Parameters (Label Data)………………………………………………………………………188

Test Measurement (Label Data) ………………………………………………………………………189

Measurement Results for Which Output Is Possible (Label Data)…………………………………189

Labeling+ …………………………………………………………………………………………………190

Settings Flow (Labeling+)………………………………………………………………………………190

Color Specification (Labeling+) ………………………………………………………………………192

Binarization (Labeling+) ………………………………………………………………………………194

Region Setting (Labeling+) ……………………………………………………………………………196

Reference Position (Labeling+) ………………………………………………………………………197

Extraction Conditions (Labeling+) ……………………………………………………………………198

Measurement Parameters (Labeling+) ………………………………………………………………200

Judgement Conditions (Labeling+)……………………………………………………………………204

Output Parameters (Labeling+) ………………………………………………………………………205

Key Points for Test Measurement and Adjustment (Labeling+)……………………………………206

Measurement Results for Which Output Is Possible (Labeling+) …………………………………207

Defect ………………………………………………………………………………………………………209

Settings Flow (Defect) …………………………………………………………………………………209

Region Setting (Defect) ………………………………………………………………………………210

Measurement Parameters (Defect) …………………………………………………………………211

Output Parameters (Defect)……………………………………………………………………………215

Key Points for Test Measurement and Adjustment (Defect) ………………………………………215

Measurement Results for Which Output Is Possible (Defect)………………………………………216

Precise Defect ……………………………………………………………………………………………217

Settings Flow (Precise Defect) ………………………………………………………………………217

Region Setting (Precise Defect) ………………………………………………………………………218

Measurement Parameters (Precise Defect) …………………………………………………………219

Output Parameters (Precise Defect) …………………………………………………………………223

Key Points for Test Measurement and Adjustment (Precise Defect) ……………………………223

Measurement Results for Which Output Is Possible (Precise Defect) ……………………………224

Fine Matching………………………………………………………………………………………………225

Settings Flow (Fine Matching)…………………………………………………………………………225

Model Registration (Fine Matching) …………………………………………………………………227

Difference Image Display (Fine Matching)……………………………………………………………228

Measurement Parameters (Fine Matching) …………………………………………………………230

Output Parameters (Fine Matching) …………………………………………………………………233

Key Points for Test Measurement and Adjustment (Fine Matching) ………………………………234

Measurement Results for Which Output Is Possible (Fine Matching) ……………………………235

Character Inspection………………………………………………………………………………………236

Settings Flow (Character Inspection) …………………………………………………………………236

4

FZ3 Processing Items List Manual

Page 7

Dictionary Parameters (Character Inspection) ………………………………………………………237

Region Setting (Character Inspection) ………………………………………………………………238

Measurement Parameters (Character Inspection) …………………………………………………238

Output Parameters (Character Inspection) …………………………………………………………240

Key Points for Test Measurement and Adjustment (Character Inspection) ………………………241

Measurement Results for Which Output Is Possible (Character Inspection) ……………………242

Date Verification …………………………………………………………………………………………244

Settings Flow (Date Verification)………………………………………………………………………244

Verification Parameters (Date Verification) …………………………………………………………245

Date Parameters (Date Verification) …………………………………………………………………247

Code Parameters (Date Verification) …………………………………………………………………248

Output Parameters (Date Verification) ………………………………………………………………251

Test Measurement (Date Verification) ………………………………………………………………252

Measurement Results for Which Output Is Possible (Date Verification) …………………………252

Model Dictionary …………………………………………………………………………………………253

Settings Flow (Model Dictionary) ……………………………………………………………………253

Model Registration (Model Dictionary) ………………………………………………………………254

Measurement Parameters (Model Dictionary) ………………………………………………………257

Model Automatic Registration (Model Dictionary) …………………………………………………258

Key Points for Test Measurement and Adjustment (Model Dictionary)……………………………260

Measurement Results for Which Output Is Possible (Model Dictionary) …………………………260

Barcode+……………………………………………………………………………………………………261

Settings Flow (Barcode+)………………………………………………………………………………261

Region Setting (Barcode+) ……………………………………………………………………………262

Measurement Parameters (Barcodes+)………………………………………………………………262

Results Settings (Barcode+) …………………………………………………………………………265

Output Parameters (Barcode+) ………………………………………………………………………265

Key Points for Test Measurement and Adjustment (Barcode+)……………………………………266

Measurement Results for Which Output Is Possible (Barcodes+)…………………………………266

2D Code+ …………………………………………………………………………………………………268

Settings Flow (2D Code+) ……………………………………………………………………………268

Region Setting (2D Code+) ……………………………………………………………………………269

Measurement Parameters (2D Code+) ………………………………………………………………269

Results Settings (2D Code+) …………………………………………………………………………271

Output Parameters (2D Code+) ………………………………………………………………………271

Key Points for Test Measurement and Adjustment (2D Code+) …………………………………272

Measurement Results for Which Output Is Possible (2D Codes+) ………………………………273

Circle Angle ………………………………………………………………………………………………275

Settings Flow (Circle Angle)……………………………………………………………………………276

Region Setting (Circle Angle) …………………………………………………………………………277

Output Parameters (Circle Angle) ……………………………………………………………………279

Key Points for Test Measurement and Adjustment (Circle Angle)…………………………………279

Measurement Results for Which Output Is Possible (Circle Angle) ………………………………280

3. Compensate image

Position Compensation……………………………………………………………………………………282

Region Compensation (Position Compensation) ……………………………………………………283

Scroll Method (Position Compensation)………………………………………………………………283

Measurement Results for Which Output Is Possible (Position Compensation) …………………285

FZ3 Processing Items List Manual

…………………………………………………………………………………281

5

Page 8

Trapezoidal Correction+ …………………………………………………………………………………286

Conversion Method (Trapezoidal Correction+)………………………………………………………286

Region Setting (Trapezoidal Correction+) ……………………………………………………………292

Key Points for Test Measurement and Adjustment (Trapezoidal Correction+) …………………293

Measurement Results for Which Output Is Possible (Trapezoidal Correction+) …………………293

Filtering ……………………………………………………………………………………………………294

Filtering Parameters (Filtering) ………………………………………………………………………294

Region Setting (Filtering) ………………………………………………………………………………298

Background Suppression …………………………………………………………………………………299

Filter Setting (Background Suppression) ……………………………………………………………299

Region Setting (Background Suppression) …………………………………………………………301

Measurement Results for Which Output Is Possible (Background Suppression) ………………301

Color Gray Filter……………………………………………………………………………………………302

Filter Setting (Color Gray Filter) ………………………………………………………………………302

Extract Color Filter…………………………………………………………………………………………306

Color Specification (Extract Color Filter) ……………………………………………………………306

Region Setting (Extract Color Filter) …………………………………………………………………309

Output Image (Extract Color Filter)……………………………………………………………………309

Measurement Results for Which Output Is Possible (Extract Color Filter) ………………………310

Anti Color Shading…………………………………………………………………………………………311

Filter Setting (Anti Color Shading) ……………………………………………………………………311

Region Setting (Anti Color Shading) …………………………………………………………………313

Key Points for Test Measurement and Adjustment (Anti Color Shading) …………………………313

Measurement Results for Which Output Is Possible (Anti Color Shading) ………………………313

Stripes Removal Filter+ …………………………………………………………………………………314

Filter Setting (Stripes Removal Filter+) ………………………………………………………………314

Region Setting (Stripes Removal Filter+) ……………………………………………………………316

Halation Cut+ ………………………………………………………………………………………………317

Filter Setting (Halation Cut+) …………………………………………………………………………317

Measurement Results for Which Output Is Possible (Halation Cut+) ……………………………319

Panorama+ …………………………………………………………………………………………………320

Camera Placement (Panorama+) ……………………………………………………………………322

Image Combination (Panorama+) ……………………………………………………………………324

Measurement Results for Which Output Is Possible (Panorama+) ………………………………325

Polar Transformation ……………………………………………………………………………………326

Region Setting (Polar Transformation) ………………………………………………………………326

Measurement Results for Which Output Is Possible (Polar Transformation) ……………………328

4. Support Inspection and Measurement

Calculation …………………………………………………………………………………………………330

Settings (Calculation) …………………………………………………………………………………330

Output Parameters (Calculation)………………………………………………………………………332

Layout of Setting Expression Window ………………………………………………………………333

Expression Usage Examples …………………………………………………………………………336

Key Points for Test Measurement and Adjustment (Calculation) …………………………………339

Measurement Results for Which Output Is Possible (Calculation) ………………………………340

Line Regression……………………………………………………………………………………………341

Function Selection (Line Regression) ………………………………………………………………342

Line 0 (Line Regression) ………………………………………………………………………………342

6

………………………………………………………329

FZ3 Processing Items List Manual

Page 9

Line 1 (Line Regression) ………………………………………………………………………………344

Point (Line Regression) ………………………………………………………………………………344

Key Points for Test Measurement and Adjustment (Line Regression) ……………………………344

Measurement Results for Which Output Is Possible (Line Regression) …………………………345

Circle Regression …………………………………………………………………………………………346

Parameter Settings (Circle Regression) ……………………………………………………………346

Key Points for Test Measurement and Adjustment (Circle Regression) …………………………348

Measurement Results for Which Output Is Possible (Circle Regression)…………………………348

Calibration+ ………………………………………………………………………………………………349

Calibration (Calibration+) ………………………………………………………………………………349

Measurement Results for Which Output Is Possible (Calibration+) ………………………………353

Set Unit Data ………………………………………………………………………………………………354

Parameter Settings (Set Unit Data) …………………………………………………………………354

Measurement Results for Which Output Is Possible (Set Unit Data) ……………………………355

Get Unit Data ………………………………………………………………………………………………356

Parameter Settings (Get Unit Data) …………………………………………………………………356

Measurement Results for Which Output Is Possible (Get Unit Data) ……………………………357

Set Unit Figure ……………………………………………………………………………………………358

Parameter Settings (Set Unit Figure) …………………………………………………………………358

Key Points for Test Measurement and Adjustment (Set Unit Figure) ……………………………362

Measurement Results for Which Output Is Possible (Set Unit Figure) ……………………………362

Get Unit Figure ……………………………………………………………………………………………363

Parameter Settings (Get Unit Figure)…………………………………………………………………363

Key Points for Test Measurement and Adjustment (Get Unit Figure) ……………………………363

Measurement Results for Which Output Is Possible (Get Unit Figure) ……………………………364

Trend Monitor………………………………………………………………………………………………366

Measurement Value (Trend Monitor) …………………………………………………………………367

Display Range (Trend Monitor) ………………………………………………………………………367

Judgement Conditions (Trend Monitor) ………………………………………………………………370

Measurement History Display (Trend Monitor) ………………………………………………………371

Data Save (Trend Monitor) ……………………………………………………………………………374

Output Parameters (Trend Monitor) …………………………………………………………………375

Key Points for Test Measurement and Adjustment (Trend Monitor) ………………………………376

Measurement Results for Which Output Is Possible (Trend Monitor) ……………………………376

Image Logging ……………………………………………………………………………………………378

Logging Conditions (Image Logging) …………………………………………………………………378

Save Destination (Image Logging) ……………………………………………………………………379

Key Points for Test Measurement and Adjustment (Image Logging) ……………………………380

Measurement Results for Which Output Is Possible (Image Logging) ……………………………380

Data Logging ………………………………………………………………………………………………381

Settings (Data Logging) ………………………………………………………………………………381

Output Format (Data Logging)…………………………………………………………………………382

Additional Explanation (Data Logging) ………………………………………………………………384

Measurement Results for Which Output Is Possible (Data Logging) ……………………………385

Elapsed Time ………………………………………………………………………………………………386

Measurement Results for Which Output Is Possible (Elapsed Time) ……………………………387

Wait …………………………………………………………………………………………………………388

Settings (Wait) …………………………………………………………………………………………388

Focus ………………………………………………………………………………………………………389

FZ3 Processing Items List Manual

7

Page 10

Measurement Parameters (Focus)……………………………………………………………………389

Region Setting (Focus)…………………………………………………………………………………390

Output Parameters (Focus) ……………………………………………………………………………391

Key Points for Test Measurement and Adjustment (Focus) ………………………………………391

Iris …………………………………………………………………………………………………………392

Measurement Parameters (Iris) ………………………………………………………………………392

Region Setting (Iris) ……………………………………………………………………………………394

Output Parameter (Iris)…………………………………………………………………………………395

Key Points for Test Measurement and Adjustment (Iris)……………………………………………395

5. Branch

Conditional Branch ………………………………………………………………………………………398

Conditional Branch ……………………………………………………………………………………399

Conditional Branch Settings Examples ………………………………………………………………400

Measurement Results for Which Output Is Possible (Conditional Branch) ………………………402

End …………………………………………………………………………………………………………403

DI Branch …………………………………………………………………………………………………405

Settings (DI Branch) ……………………………………………………………………………………405

Measurement Results for Which Output Is Possible (DI Branch) …………………………………406

6. Output result

Data Output ………………………………………………………………………………………………410

Settings (Data Output) …………………………………………………………………………………410

Output Format (Data Output) …………………………………………………………………………411

Key Points for Test Measurement and Adjustment (Data Output)…………………………………414

Measurement Results for Which Output Is Possible (Data Output) ………………………………414

Parallel Data Output ………………………………………………………………………………………415

Settings (Parallel Data Output) ………………………………………………………………………415

Output Format (Parallel Data Output) ………………………………………………………………416

Measurement Results for Which Output Is Possible (Parallel Data Output) ……………………417

Parallel Judgement Output ………………………………………………………………………………418

Settings (Parallel Judgement Output) ………………………………………………………………418

Output Parameters (Parallel Judgement Output)……………………………………………………419

Measurement Results for Which Output Is Possible (Parallel Judgement Output)………………420

……………………………………………………………………………………………………397

……………………………………………………………………………………………409

7. Display result

Result Display ……………………………………………………………………………………………422

Result Display …………………………………………………………………………………………423

Display Image File…………………………………………………………………………………………427

Select Image (Display Image File) ……………………………………………………………………427

Key Points for Test Measurement and Adjustment (Display Image File) …………………………428

Display Last NG Image ……………………………………………………………………………………429

NG Error Judgement (Display Last NG Image)………………………………………………………429

Image Saving (Display Last NG Image)………………………………………………………………431

Data Saving (Display Last NG Image) ………………………………………………………………432

Output Parameters (Display Last NG Image) ………………………………………………………432

Key Points for Test Measurement and Adjustment (Display Last NG Image) ……………………433

Measurement Results for Which Output Is Possible (Display Last NG Image) …………………433

8

……………………………………………………………………………………………421

FZ3 Processing Items List Manual

Page 11

Index

……………………………………………………………………………………………………………435

FZ3 Processing Items List Manual

9

Page 12

How This Manual Is Organized

This manual includes two manuals: the "User's Manual", which describes basic operations and settings

for vision sensors, and the "Processing Item List Manual", which describes the setting options for each

processing item.

Conventions Used in This Manual

Symbols

The symbols used in this manual have the following meanings.

Indicates relevant operational precautions that must be followed.

Indicates operation-related suggestions from OMRON.

Use of Quotation Marks and Brackets

In this manual, menus and other items are indicated as follows.

[ ] Menu Indicates the menu names or processing items shown in the menu bar.

" " Item name Indicates the item names displayed on the screen.

Version Upgrade Information (at Oct.1 2009)

The newly added functions are described here.

Revision history : FZ3-9 /H9 series (V3.0)

Newly added

function

Special function

corresponding to

FZ3-9 /H9

series

Operation modes, NG analyser, focus, iris and other functions

have been added.

※ The correspondence software is different in FZ3-3 /H3

/7 /H7 series.

The latest software is Ver2.1.

Description of newly added functions Reference in manual

Reference: "User's Manual",

"Description of M odel-specific

Functions" (p.21)

10

FZ3 Processing Items List Manual

Page 13

Input image

This chapter describes how to load images from cameras.

Reference: Camera Image Input (p.12)

Reference: Camera Image Input HDR+ (p.32)

Reference: Camera Switching (p.38)

Reference: Measurement Image Switching (p.40)

1

Input image

FZ3 Processing Items List Manual

11

Page 14

1

Input image

Camera Image Input

Set the conditions for loading images from the camera and for storing images of the measured

objects.This processing item must be used when measuring.

Used in the Following Case

Important

●

When using an intelligent camera FZ-SLCx or an auto-focus camera FZ-SZCx, camera image input and camera

image input HDR+ cannot be used together.

●

[Camera Image Input] is preset for Unit 0.Do not set any processing item other than camera image input

(camera image input HDR+) for Unit 0.

●

When switching from a color camera to a monochrome or switching to a camera with a different resolution,

reconfigure the settings in the following units.

●

If a camera is connected other than the one for the previous settings, the camera settings are returned to their

initial settings.

●

It is also possible to set multiple camera image input items to the flow and shoot images at different shutter

speeds. However, in this case, if the images are logged, only the last camera image input is logged.

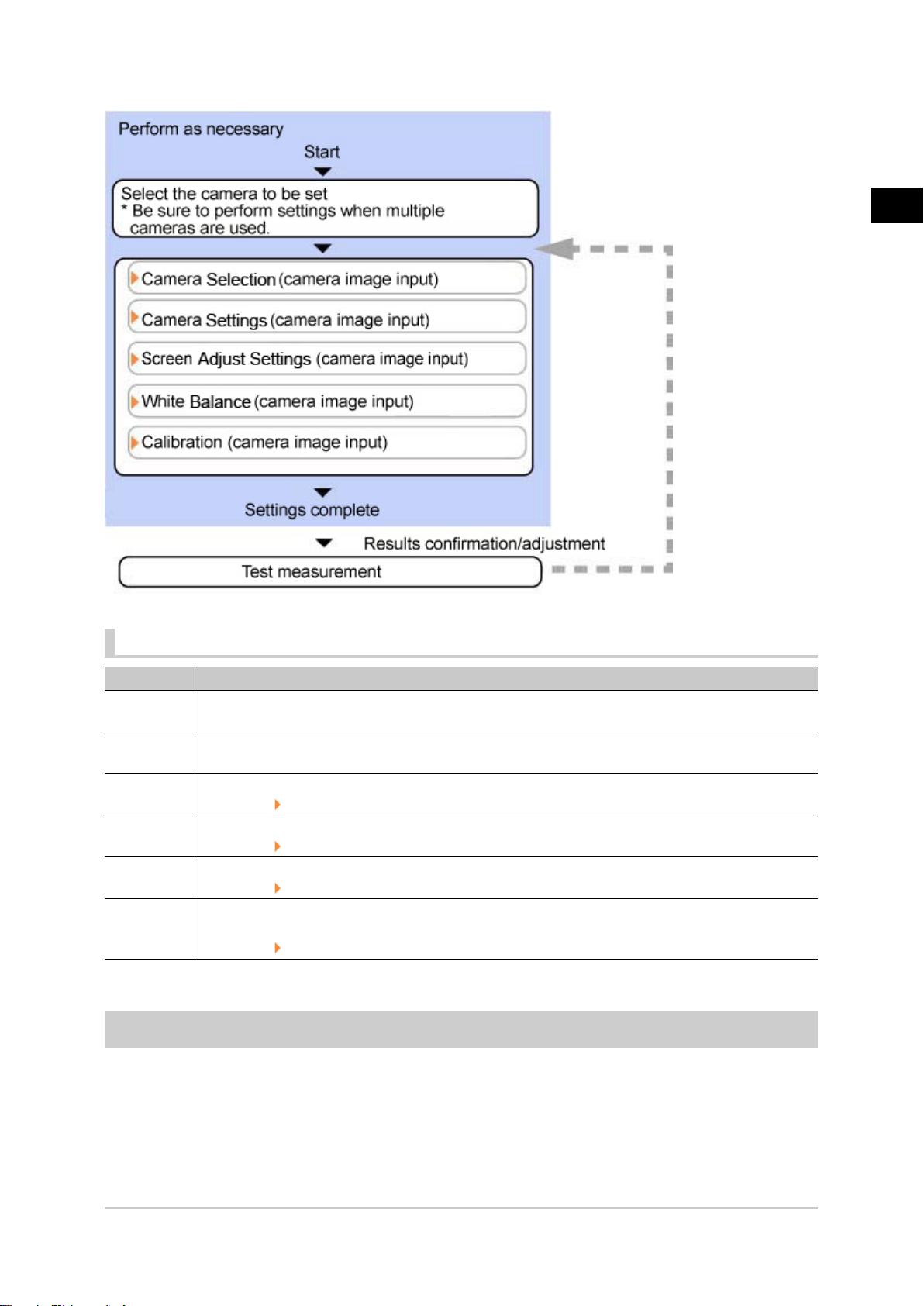

Settings Flow (Camera Image Input)

To set camera image input, follow the steps below.

12 Camera Image Input

FZ3 Processing Items List Manual

Page 15

Camera Image Input Item List

1

Input image

Item Description

Camera 0 to

3

Select

camera

Camera

setting

Screen

adjust

White

balance

Calibration

Select the camera to be set.

When multiple cameras are connected, select the camera to use for measurement.

Specify the camera settings such as the shutter speed or electronic flash.

Reference: Camera Settings (Camera Image Input) (p.14)

Adjust the lighting and the lens.

Reference: Screen Adjust Settings (Camera Image Input) (p.18)

When using a color camera, adjust the white balance.

Reference: White Balance (Camera Image Input) (p.23)

Set when measurements (camera coordinate measurement values) are to be output using actual

dimensions. Select the calibration setting method and generate the calibration parameters.

Reference: Calibration (Camera Image Input) (p.24)

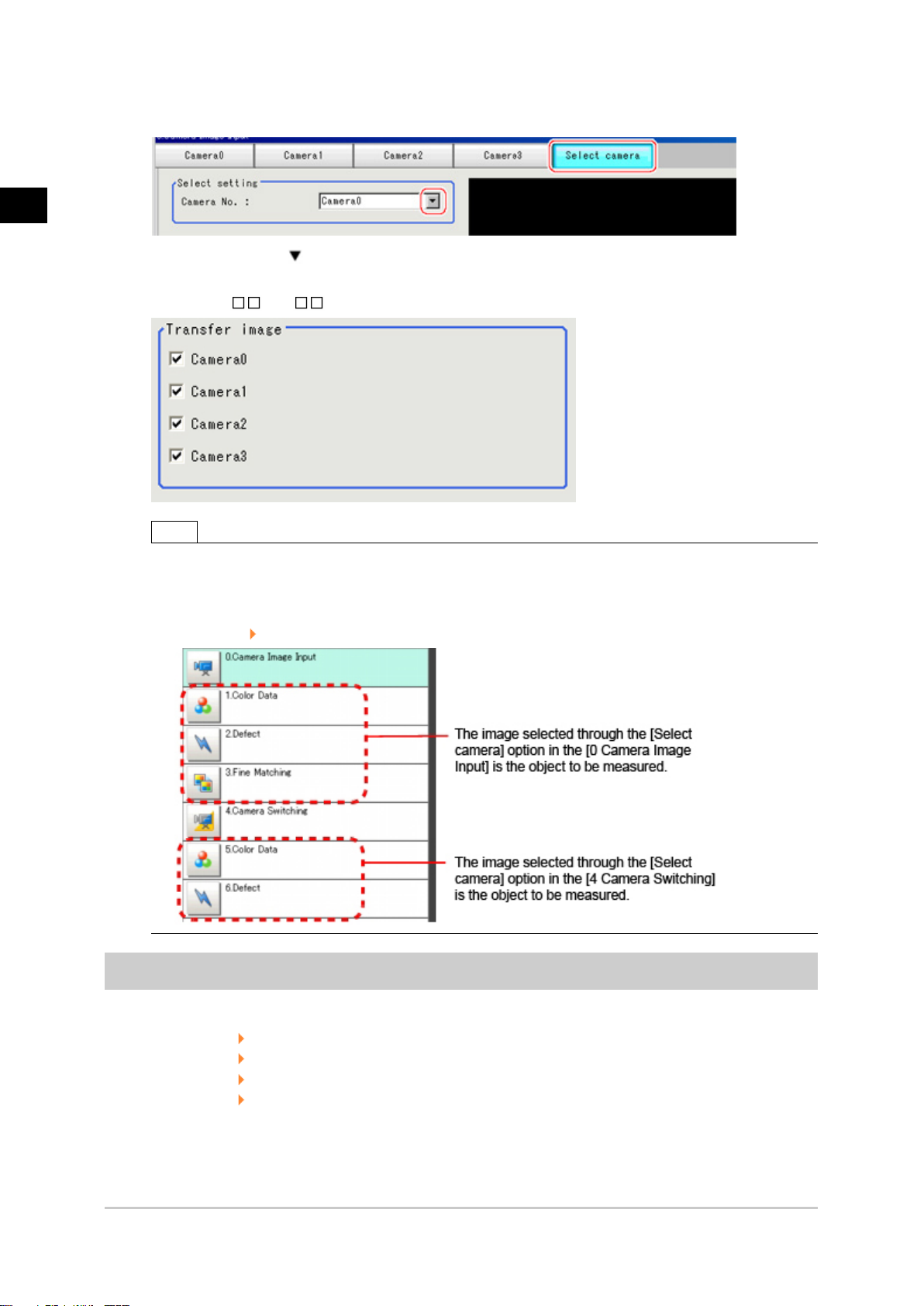

Camera Selection (Camera Image Input)

When multiple cameras are connected, select the camera to use for measurement.

FZ3 Processing Items List Manual

Camera Image Input 13

Page 16

1

Input image

In the item tab area, tap [Select camera].

1.

Tap [Camera No.] [ ] and select the camera number.

2.

If multiple cameras are connected, whether or not to capture images from each camera can be

3.

set. (FZ3-9 /H9 only)

Note

●

The image from the camera selected in [Select camera] will be the object to be measured in the

following units.

If you need to switch the camera during the process, insert a [Camera Switching] unit in the scene and

switch the image.

Reference: Camera Switching (p.38)

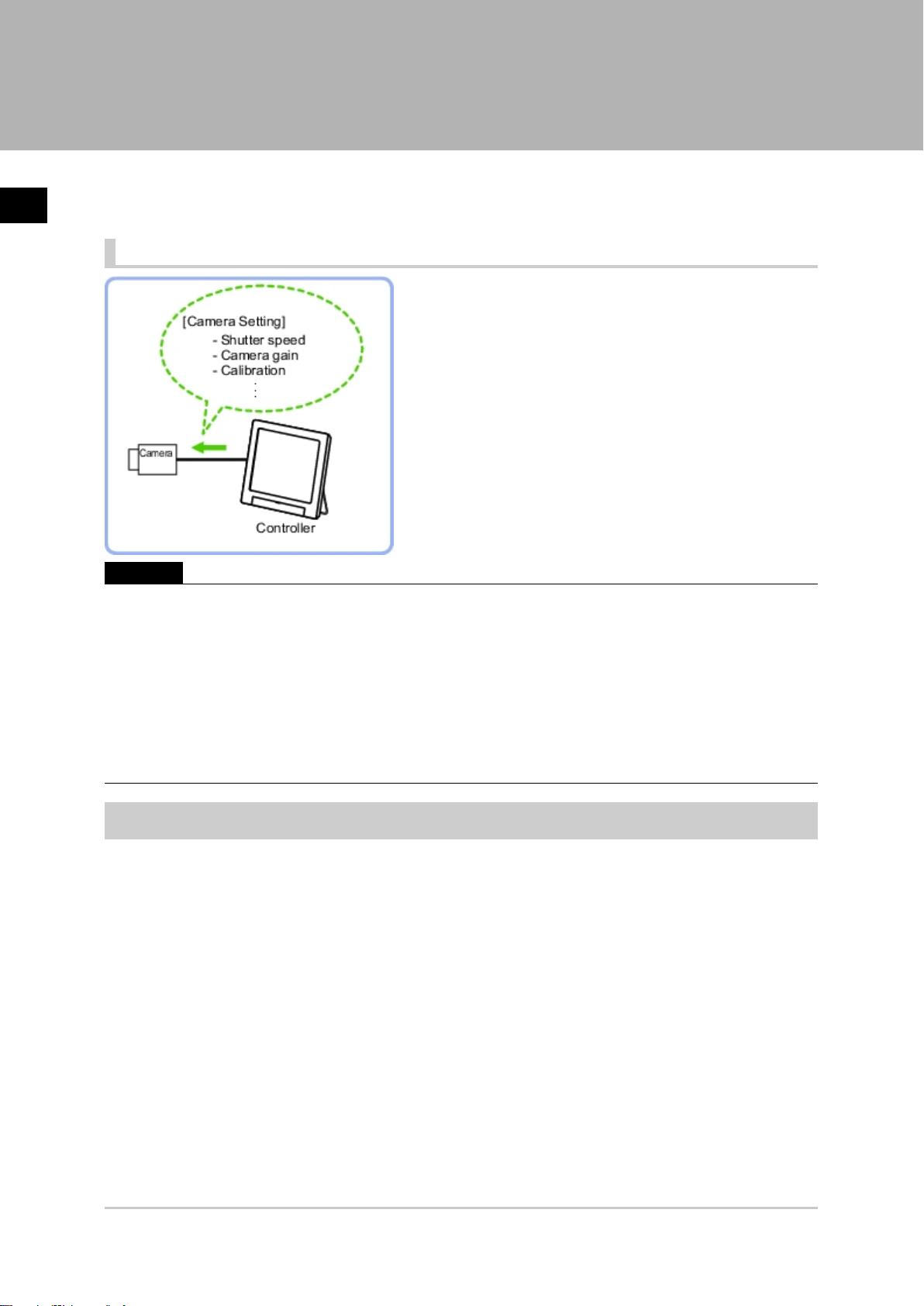

Camera Settings (Camera Image Input)

Set the following photographing conditions for each camera.

●

Reference: Camera Settings (p.15)

●

Reference: Frame/Field - for Monochrome Cameras Only (p.16)

●

Reference: Number of lines to be read (p.17)

●

Reference: Electronic Flash Setting (p.18)

14 Camera Image Input

FZ3 Processing Items List Manual

Page 17

Note

●

The displayed items differ depending on the camera type and lighting mode. Perform the following procedure as

necessary in accordance with the use environment.

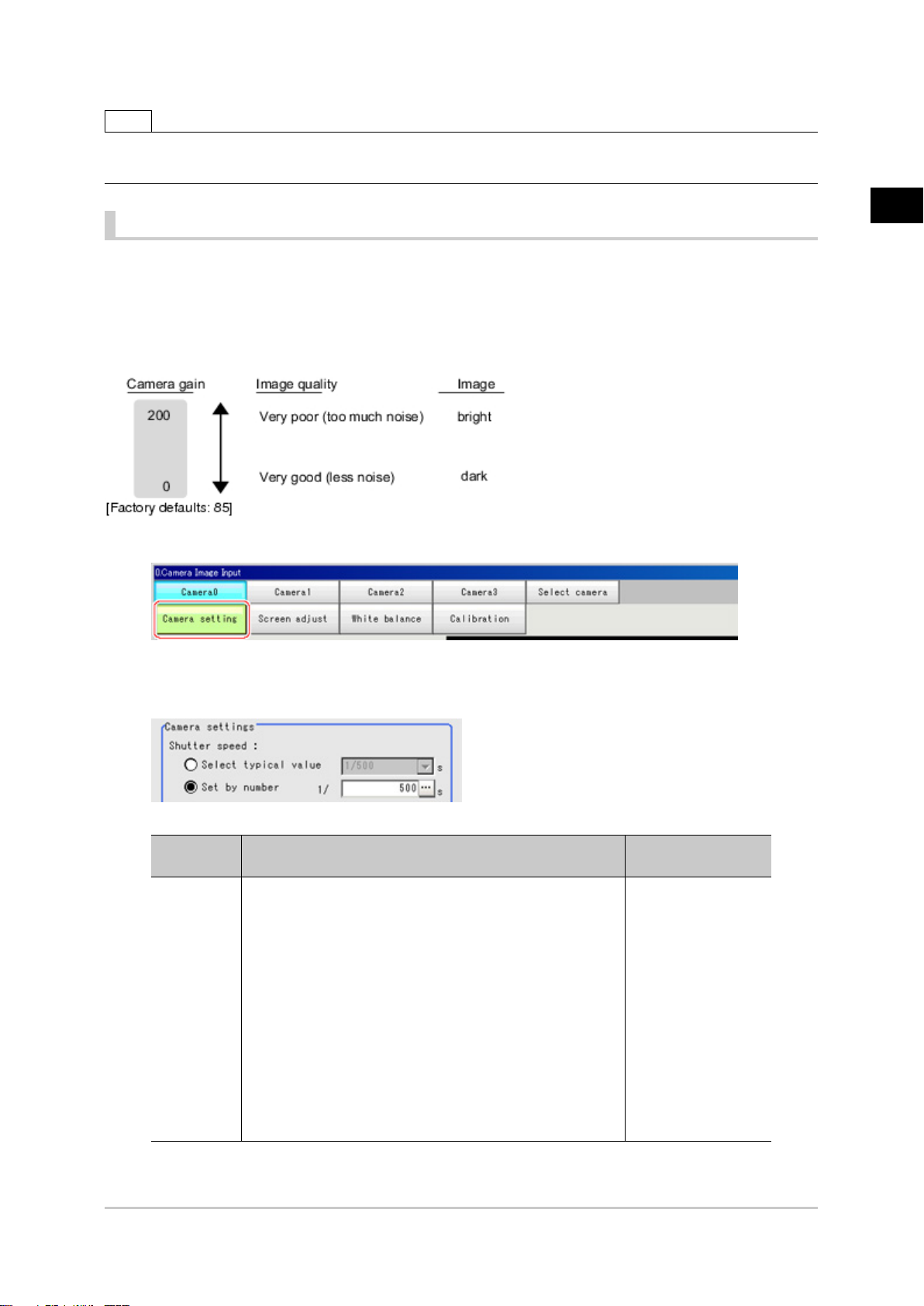

Camera Settings

Adjust the settings related to camera shutter speed and camera gain.

Select the shutter speed appropriate to the speed of the measurement object. Choose a faster shutter

speed if the measurement object is moving quickly and the image is blurred.

Adjust the camera gain when images cannot be brightened through the shutter speed, lens aperture, or

lighting conditions. Usually, the factory default value can be used.

In the Item Tab area, tap [Camera setting].

1.

1

Input image

In the "Camera settings" area, specify the shutter speed.

2.

The setting methods are to select from the options offered or to set the value directly.

Item

Shutter

speed

Typical value

●

[1/120]

(For FZ-SFx, FZ-SPx, FZ-SC2M/FZ-S2M, FZ-SC5M/

FZ-S5M)

●

1/200

●

[1/500]

(for FZ-Sx, FZ-SLC, FZ-SZC)

●

1/1000

●

1/2000

●

1/4000

●

1/8000

●

1/20000

●

Set by number

1/10 to 1/50000

Set value

[Factory default]

Description

Option values for the

shutter speed differ

depending on the

camera type.

FZ3 Processing Items List Manual

Camera Image Input 15

Page 18

1

Input image

Specify the camera gain while checking the image.

3.

Set value

[Factory default]

Description

Adjust the camera gain when the shutter speed, the

lens aperture, and lighting conditions cannot be

used to brighten the image. Usually, the factory

default value can be used.

Gain

Item

0 to 230

[50]

(For FZ-SFx, FZ-SPx,

FZ-SC2M/FZ-S2M, FZ-SC5M/

FZ-S5M)

[85]

(for FZ-Sx, FZ-SLC, FZ-SZC)

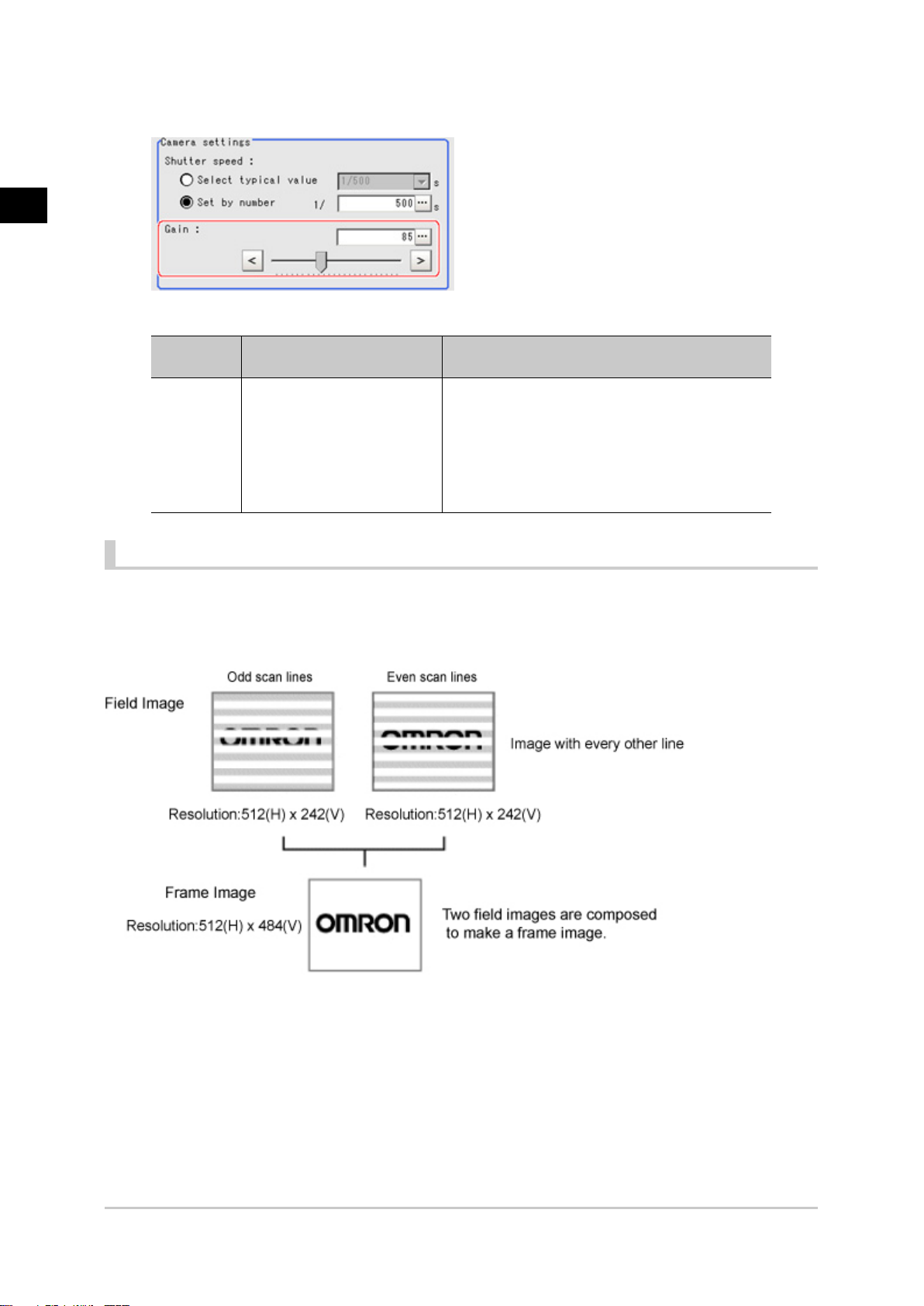

Frame/Field - for Monochrome Cameras Only

There are two methods to transfer one image from a camera to the controller: frame read and field read.

Frame read is to read all of the scanned lines of the image. The result is called a frame image. Field read

is used to read half of the interlaced scanned lines of the image. The result is called the field image.

Here, select the unit to be treated as one image.

In the Item Tab area, tap [Camera setting].

1.

In the "Frame/Field" area, select either "Frame" or "Field".

2.

16 Camera Image Input

FZ3 Processing Items List Manual

Page 19

Set value

Item

[Factory

Description

default]

[Frame] Measurements are done in frame units.

Measurements are done in field units. Select "Field" when you prefer

Frame/Field

Field

shorter image input time rather than higher accuracy.

Processing becomes faster since each image is scanned skipping

one scan line per two consecutive lines, but the measurement

precision is decreased because the vertical image resolution is lower.

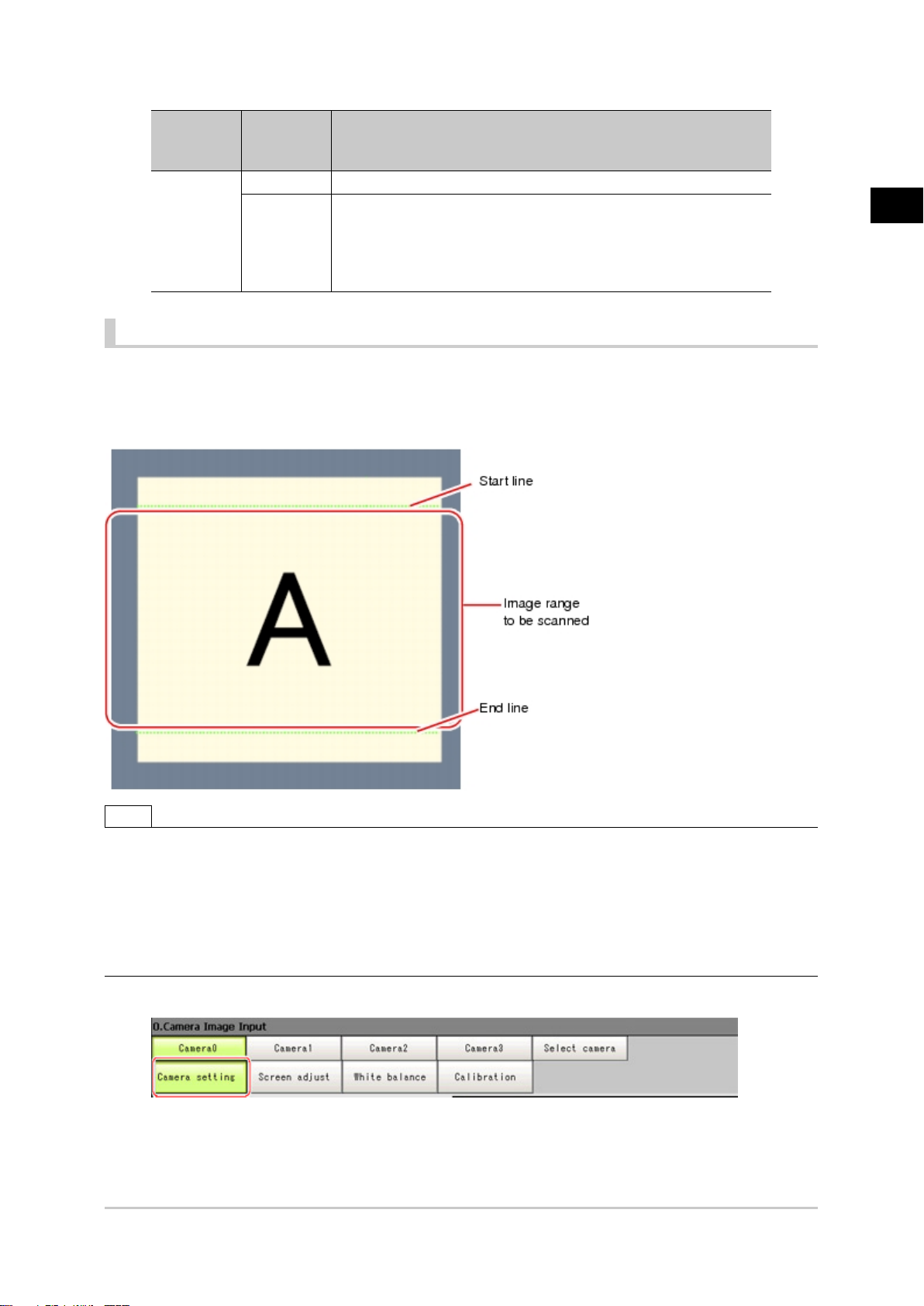

Number of lines to be read

By narrowing the image range to be loaded, the image scan time can be shortened.

Set the range taking the offset of the measurement object into consideration.

The part of the image narrowed down by the start line and the end line will be displayed in the Image

Display area of the processing item setting window or the Main screen.

1

Input image

Note

About minimum number of lines

●

The minimum number of lines (minimum number of lines between start and end lines) is 12 lines.

●

For 5 megapixel cameras, the end line is fixed to 1799.

About coordinate values

●

The coordinate values displayed as the measurement results are the values of the display position on the

monitor.

●

The coordinate values do not vary according to the settings for "Number of lines to be read".

In the Item Tab area, tap [Camera setting].

1.

FZ3 Processing Items List Manual

Camera Image Input 17

Page 20

1

Input image

Set the start/end line in the "Number of lines to be read" area.

2.

Electronic Flash Setting

This function is set when an electronic flash is used.This sets the output conditions for the signal for

synchronizing the measurement and the electronic flash timing.

In the Item Tab area, tap [Camera setting].

1.

In the "Electronic flash setting" area, specify each item.

2.

Item

S T E P

-S T G O UT

delay

STGOUT

width

Set value

[Factory default]

[0] to 511

(1 count 30μs)

1 to 63

[3]

(1 count 30μs)

Description

Set the waiting time from the time the STEP signal is input

until the electronic flash trigger output signal comes ON.

Delay Time=Count x 30μs + 90μs

Set the output time for the electronic flash trigger signal.

Select the pulse polarity of the electronic flash trigger.

Positive polarity: Flashes synchronized with the timing of the

STGOUT

polarity

●

[Positive]

●

Negative

electronic flash trigger output signal changing from OFF to

ON.

Negative: Flashes when the strobe trigger output signal

changes from ON to OFF.

Screen Adjustment Settings (Camera Image Input)

Set the lighting and lens conditions for each camera.

●

Reference: Lighting Control (p.19)

●

Reference: Line Bright (p.21)

●

Reference: Lens Adjustment Setting (p.21)

●

Reference: Common Setting for All Cameras (p.22)

18 Camera Image Input

FZ3 Processing Items List Manual

Page 21

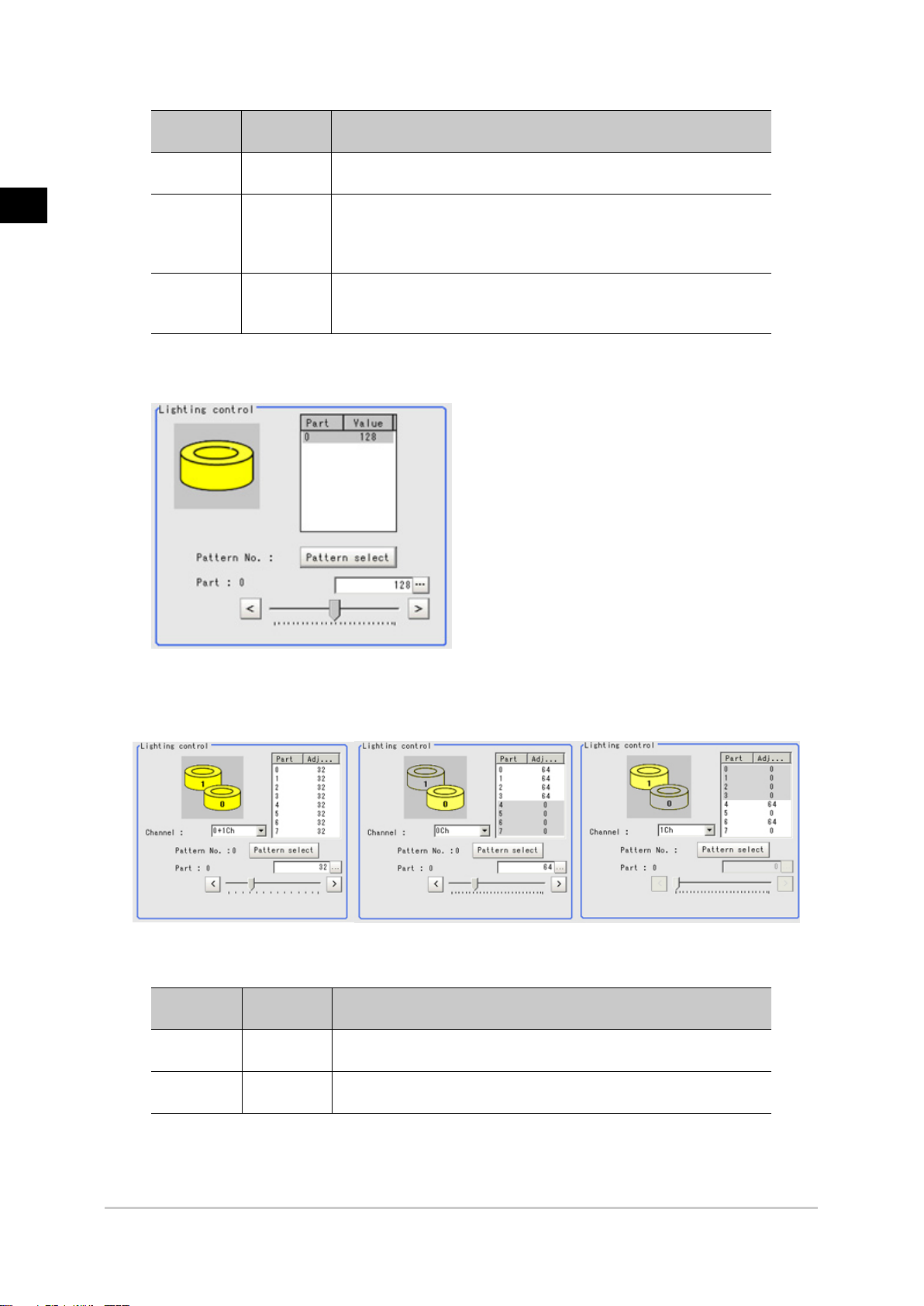

Lighting Control

When a camera with a lighting function is connected, the light volume of the lighting can be adjusted

from the controller. Brightness can be adjusted automatically or one of the preset patterns can be

selected.

A lighting lamp image is displayed as a guide illustration.

Note

●

When one scene contains 2 or more camera image input units, lighting control can be performed only for the

first camera image input unit.

In the item tab area, tap [Screen adjust].

1.

1

Input image

In the "Lighting control" area, specify the brightness.

2.

The image display contents depend on the connected camera.

When an intelligent camera is connected

Important

●

When model FZ-SLC15 is connected, only parts 0 to 3 are active. Changing parts 4 to 7 will not affect

the light volume of lighting.

FZ3 Processing Items List Manual

Camera Image Input 19

Page 22

1

Input image

Item

Pattern

select

Turn -

Brightness

at each part

Setting

value

Pattern 0 to

16

0 to 255 x 8

ch

[0]

Description

Can be selected from a preset lighting pattern.

After the camera is installed, if the orientation of the camera does not

match the orientation of the lighting parts, tap [Turn] under the lighting

diagram. The lighting diagram rotates 90 degrees clockwise each time

you tap [Turn].

The light volume at each part can be adjusted to one of 256 levels. 0

indicates the lighting is OFF. The larger the number, the higher the

brightness.

MG-WAVE or electronic flash controller (FZ-LTA100) is connected:

Electronic flash controller FZ-LTA200 is connected:

CH0 to CH7 are used: CH0 to CH3 are used: CH4 to CH7 are used:

Item

Pattern

select

Brightness at

each part

Setting

value

Pattern 0 to

2

0 to 255

[0]

Description

Can be selected from a preset lighting pattern.

The light volume can be adjusted to one of 256 levels. 0 indicates the

lighting is OFF. The larger the number, the higher the brightness.

Other cameras are used:

20 Camera Image Input

FZ3 Processing Items List Manual

Page 23

The light volume cannot be adjusted.

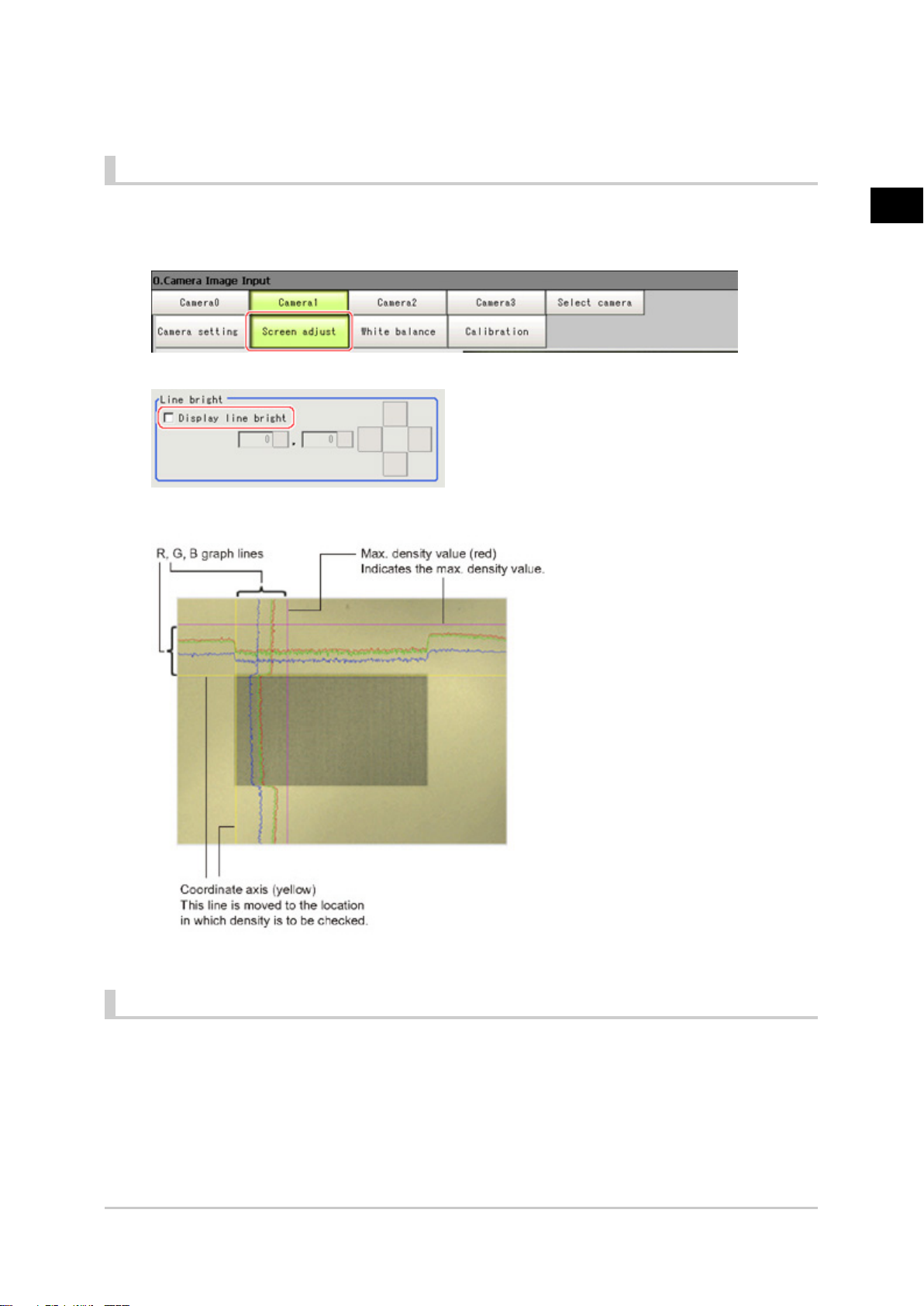

Line Bright

The graph showing the gray distribution for 1 line in the image is called the "Line bright". You can display

the line brights for R, G and B for any horizontal or vertical line.

In the item tab area, tap [Screen adjust].

1.

Place a check at "Display line bright".

2.

Move the line to the position whose density distribution you want to see.

3.

1

Input image

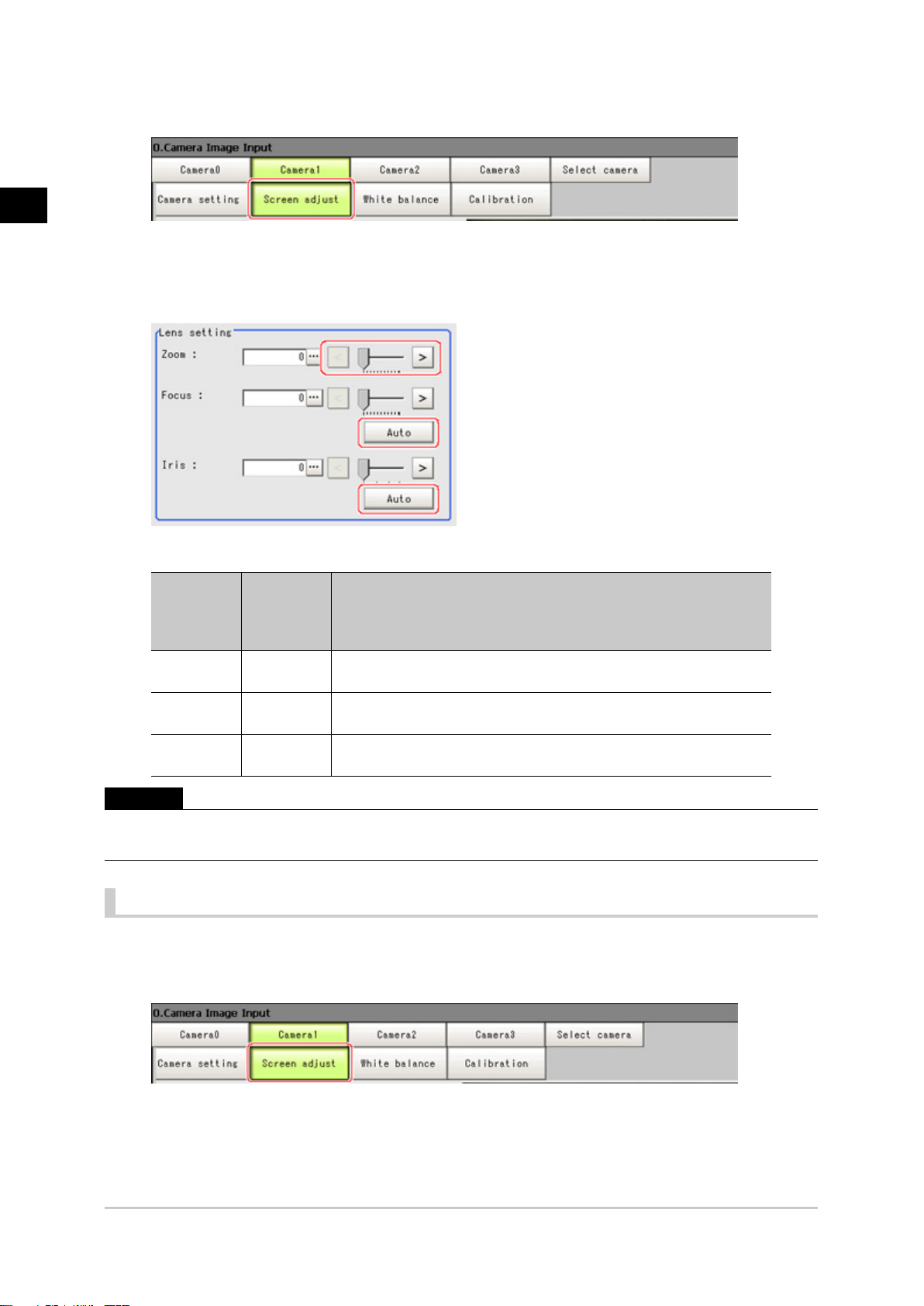

Lens Adjustment Setting

This function is only displayed when an intelligent camera or an auto-focus camera is connected.

Make lens adjustments such as the focus and zoom. The optimum value can be set automatically for the

focus and iris.

FZ3 Processing Items List Manual

Camera Image Input 21

Page 24

1

Input image

In the item tab area, tap [Screen adjust].

1.

Specify the "Zoom" size while checking the image.

2.

Tap [Auto] at "Focus" and "Iris".

3.

The focus and iris optimized for the zoomed image are set automatically.

Setting

Item

Zoom [0] to 1023

Focus [0] to 1023

Iris [0] to 31

Important

●

Auto focus and auto iris can only be used when setting with this screen open. They cannot be used during

running.

value

[Factory

default]

Description

Displays the image zoomed in and out. Depending on the focus

setting value, it may not be possible to set a large zoom value.

Adjust the focus. When [Auto] is clicked, the optimum focus for the

current image is set automatically.

Adjust the light volume that passes through the lens. When [Auto] is

clicked, the optimum iris for the current image is set automatically.

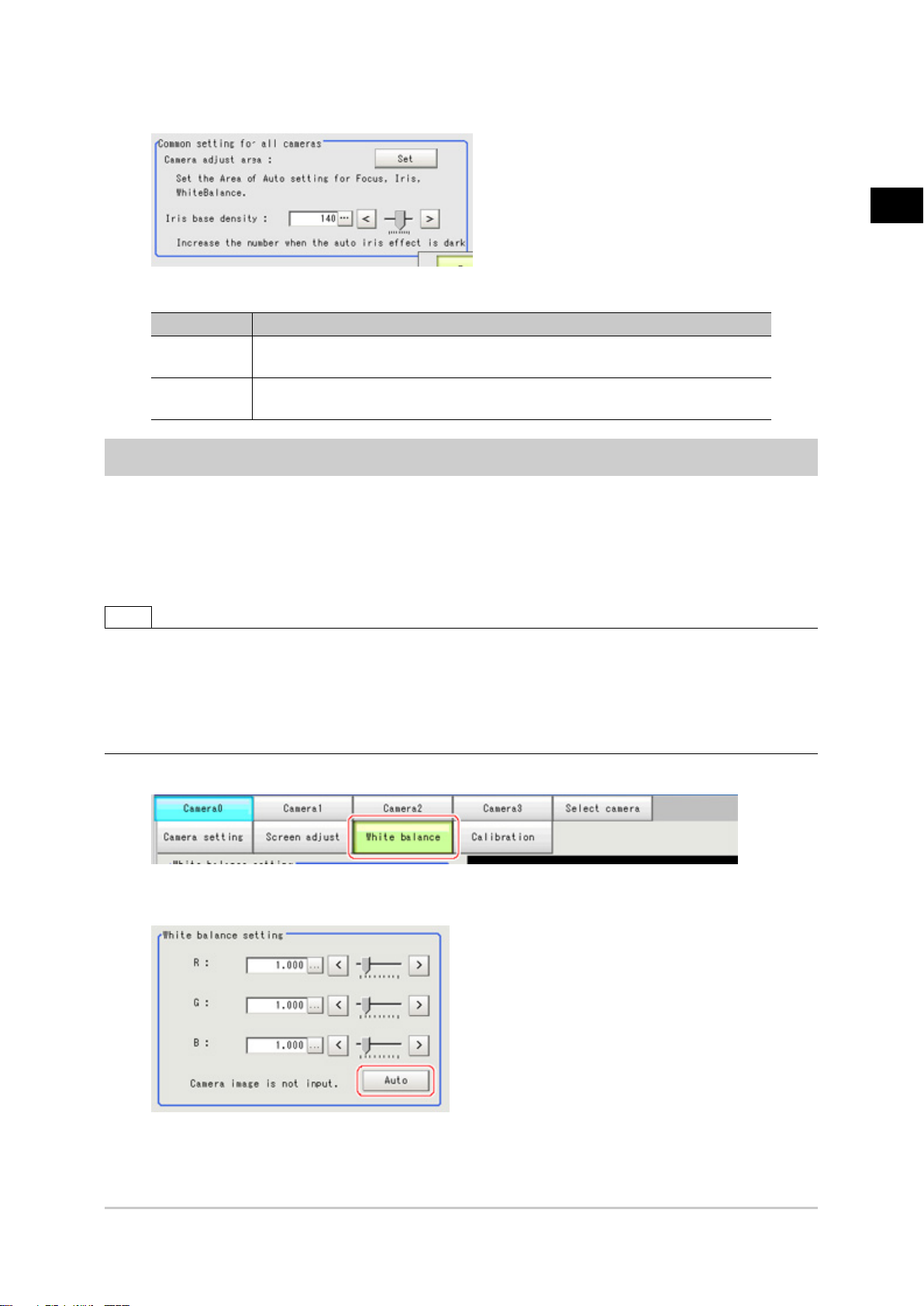

Common Setting for All Cameras

This function is only displayed when an intelligent camera or an auto-focus camera is connected. This

sets the conditions for automatically setting the focus, iris, and white balance.

In the item tab area, tap [Screen adjust].

1.

In the "Common setting for all cameras" area, set up "Camera adjust area" and "Iris base

2.

22 Camera Image Input

FZ3 Processing Items List Manual

Page 25

density".

Item Description

Camera adjust

area

Iris base

density

This sets the region for judging whether or not the state is appropriate when

automatically setting the focus, iris, and white balance.

Increase the number when the auto iris effect is dark.

White Balance (Camera Image Input)

Set the white balance to make white objects look white by calibrating the color of images loaded from

cameras.

By adjusting the white balance, the appropriate white color can be reproduced under any lighting

conditions

Appropriate values can also be set automatically.

1

Input image

Note

●

Perform the white balance setting only when a color camera is used.

●

In the following cases, make sure to perform white balance.

●

When a new system is installed

●

When the camera or lighting is changed

Since measurement results may vary with changes of the white balance setting, be sure to verify the operation

after it has changed.

In the Item Tab area, tap [White balance].

1.

Shoot a white piece of paper or cloth.

2.

Tap [Auto].

3.

FZ3 Processing Items List Manual

Camera Image Input 23

Page 26

1

Input image

Note

●

When the "Too bright" or "Too dark" message is displayed, adjust the iris, shutter speed, gain and/or

lighting conditions until "Automatic adjustment is possible" is displayed.

Adjust the "R", "G" and "B" values as necessary.

4.

Item

White

balance

setting

●

R

●

G

●

B

0.001 to 7.999 (R, G, and B)

For FZ-SC

[R=1.183]

[G=1.000]

[B=1.323]

For FZ-SC2M

[R=1.394]

[G=1.000]

[B=1.222]

For FZ-SFC, FZ-SPC

[R=1.145]

[G=1.000]

[B=1.1889]

For FZ-SC5M

[R=1.351]

[G=1.000]

[B=2.314]

Set value

[Factory default]

Description

Adjust the white balance.

Whiteness increases when the

value of "R", "G", and "B" is

increased.

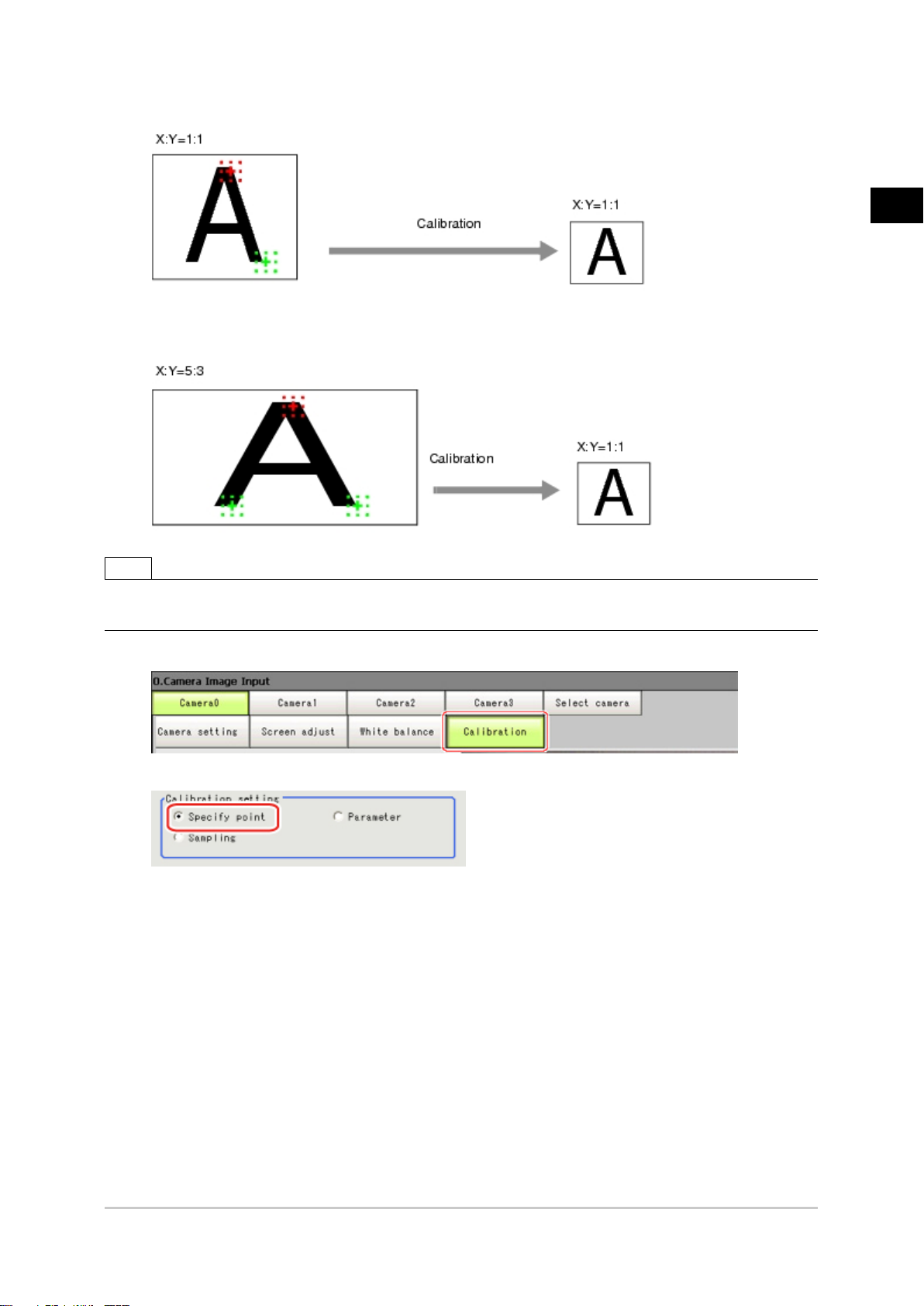

Calibration (Camera Image Input)

By setting the calibration, the measurement result can be converted and output as actual dimensions.

The calibration method is selected here.

There are three calibration methods, point, sampling, and parameter.

●

Reference: Specifying Points and Setting (Point Specification) (p.24)

●

Reference: Setting calibration through sampling measurement (sampling) (p.26)

●

Reference: Inputting and setting values (Value Setting) (p.29)

●

Reference: View Calibration Parameters (p.30)

Calibration

Reference: See "User's Manual", "Terminology Explanations" (p.309)

Note

●

In order to output measurement results in actual dimensions, set [Calibration] to "ON" in [Output parameter] for

each processing unit. If [Calibration] is "OFF" (factory default), measurement results are output as camera image

coordinate values.

Specifying Points and Setting (Point Specification)

This is a method for performing calibration by specifying arbitrary points (in pixels).

Calibration parameters are calculated automatically when actual coordinates of specified locations are

entered. Up to 3 points can be specified.

●

When magnification is the same in the X and Y directions

Specify only 2 points.

24 Camera Image Input

FZ3 Processing Items List Manual

Page 27

●

When magnification is not the same in the X and Y directions

Specify 3 points.

Note

●

When 2 points are specified, the coordinate system is set to the left-hand system (forward in the clockwise

direction). Specify 3 points to perform calibration including the coordinate system.

In the Item Tab area, tap [Calibration].

1.

1

Input image

In the "Calibration setting" area, select "Specify point".

2.

Tap the first point on the screen.

3.

Input the actual coordinates for the specified point.

4.

The actual coordinate input window is displayed.

FZ3 Processing Items List Manual

Camera Image Input 25

Page 28

1

Input image

Actual coordinate

Point X, Y 0 to 9999.9999 [Point you tapped in the window]

Actual X, Y -99999.9999 to 99999.9999 [0]

Set the 2nd and 3rd points in the same way.

5.

Tap [Generate calibration parameters].

6.

The calibration parameters will be generated.

Set value

[Factory default]

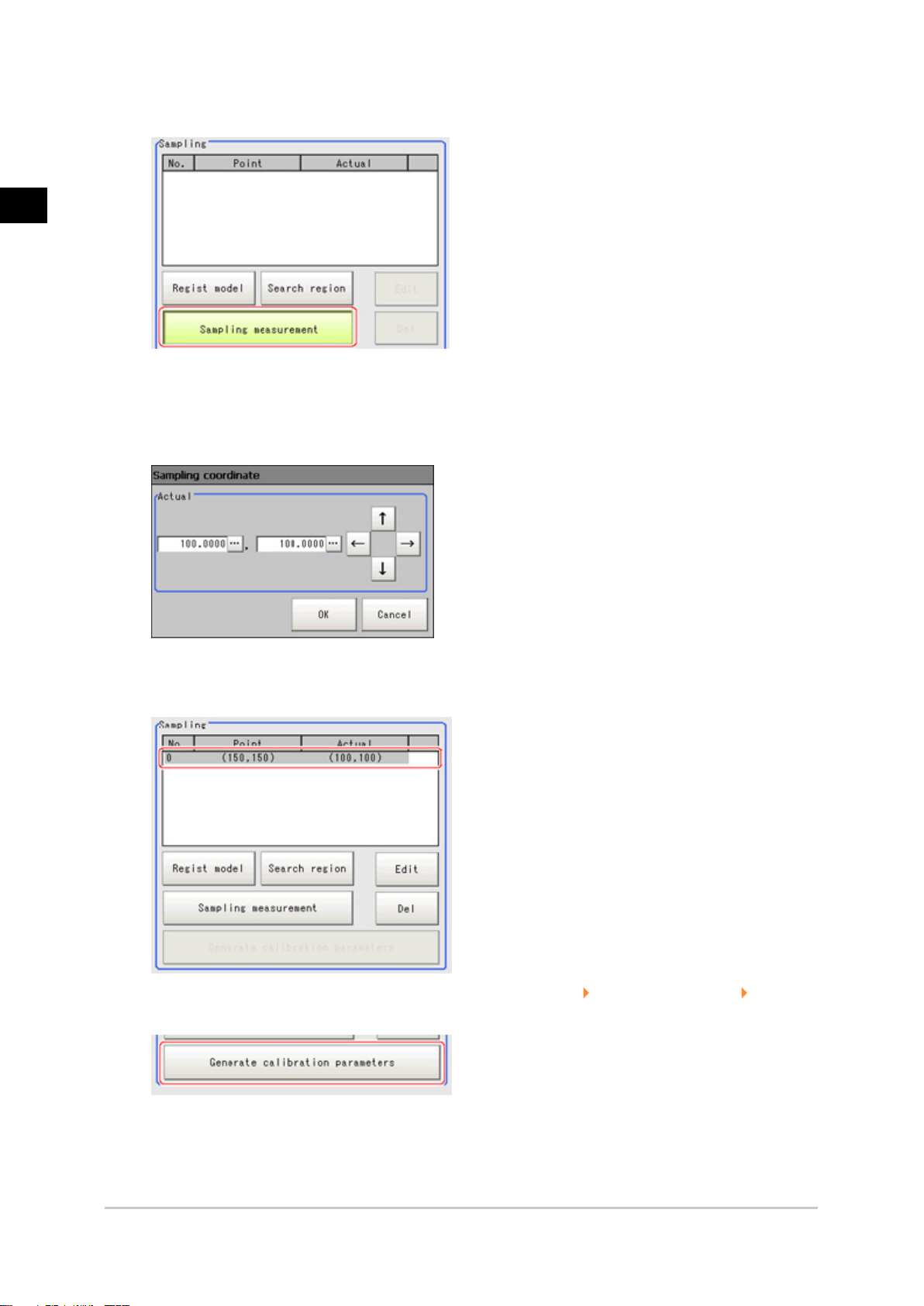

Setting Calibration through Sampling Measurement (Sampling)

This is a method for setting calibration based on measurement results.

Calibration parameters are calculated automatically when a registered model is searched and the actual

coordinates for that position entered.

In the Item Tab area, tap [Calibration].

1.

In the "Calibration setting" area, select "Sampling" .

2.

26 Camera Image Input

FZ3 Processing Items List Manual

Page 29

In the "Sampling" area, tap [Regist model].

3.

Use the Drawing tools to register the model.

4.

1

Input image

Adjust the search region as necessary.

5.

The default value setting is for the entire screen.

FZ3 Processing Items List Manual

Camera Image Input 27

Page 30

1

Input image

Tap [Sampling measurement].

6.

Measurement is performed.

The search result (cross-shaped cursor) is displayed in the Image Display area, and the

Sampling Coordinate window is displayed.

In the Sampling Coordinate window, enter the X and Y values.

7.

Tap [OK].

8.

Point coordinates and actual coordinates are registered in the "Sampling" area.

Move the object to be measured and repeat the Steps Reference: 3(p.27) to Reference: 8(p.28) .

9.

Tap [Generate calibration parameters].

10.

The calibration parameters will be generated.

28 Camera Image Input

FZ3 Processing Items List Manual

Page 31

Inputting and Setting Values (Value Setting)

Enter calibration data directly with numerical values.

In the Item Tab area, tap [Calibration].

1.

In the "Calibration setting" area, select "Parameter".

2.

In the "Parameter" area, specify values for the "Coordinate", "Origin" and "Magnification".

3.

1

Input image

Item

Coordinate

FZ3 Processing Items List Manual

Set value

[Factory default]

[Lefthand],

Righthand

Description

Left-hand type: Clockwise is forward when specifying the

coordinates.

Right-hand type: Counter-clockwise is forward when specifying

the coordinates.

Camera Image Input 29

Page 32

1

Input image

Origin

Select where the origin of the actual coordinates will be.

[Upperleft],

Lowerleft, Center

Magnificati

Tap [Generate calibration parameters].

4.

0.00001 to

on

9.99999

The calibration parameters will be generated.

View Calibration Parameters

View the set calibration data.

In the Item Tab area, tap [Calibration].

1.

In the "Calibration parameter" area, confirm the calibration data.

2.

Specify the ratio of 1 pixel to the actual dimensions.

Item Set value Description

A Calculation value

B Calculation value

C Calculation value

D Calculation value

E Calculation value

F Calculation value

30 Camera Image Input

These are calibration conversion values. Camera coordinates are

converted to actual coordinates based on these values. The

conversion formulas for actual coordinates are as follows:

●

(X, Y): Measurement point (camera coordinates), Unit: pix

●

(X', Y'): Conversion point (actual coordinates)

X'=A x X + B x Y + C

Y'=D x X + E x Y + F

FZ3 Processing Items List Manual

Page 33

Field of view Calculation value This is an actual dimension in the X direction.

Additional Explanation (Camera Image Input)

Position Compensation and Camera Image Input

When creating a scene, if a [Camera Image Input] unit is positioned after a [Position Compensation]

processing unit, that [Position Compensation] unit will be cancelled, which will cause a new image to be

read.

1

Input image

FZ3 Processing Items List Manual

Camera Image Input 31

Page 34

1

Input image

Camera Image Input HDR+

This is a processing item for just FZ3-H series high grade controllers.

You can acquire a wide dynamic lens image by combining images photographed consecutively at

different shutter speeds.

With objects that generate halation, images with low-contrast, and environments with fluctuation in the

lighting, this processing item is an effective substitute for camera image input.

Used in the Following Case

●

To acquire stable images of objects for which halation occurs easily

●

To measure images with low-contrast stably

Use high-contrast mode.

Important

●

When using an intelligent camera FZ-SLCx or an auto-focus camera FZ-SZCx, camera image input and camera

image input HDR+ cannot be used together.

Settings Flow (Camera Image Input HDR+)

To set camera image input HDR+, follow the steps below.

32 Camera Image Input HDR+

FZ3 Processing Items List Manual

Page 35

Camera Image Input HDR+ Item List

Item name Description

Camera

setting

HDR setting

Bright adjust

Screen

adjust

White

balance

Calibration

Specify the camera settings such as the electronic flash.

The setting method is the same as for [Camera Image Input].Please check it.

Reference: Camera Settings (Camera Image Input) (p.14)

Carry out the image combination and photography settings.

Reference: HDR Settings (Camera Image Input HDR+) (p.33)

Specify the brightness follow-up adjustment setting.

Reference: Bright Adjust Setting (Camera Image Input HDR+) (p.36)

Adjust the lighting and the lens.

The setting method is the same as for [Camera Image Input].Please check it.However, the iris

cannot be adjusted.

Reference: Screen Adjust Settings (Camera Image Input) (p.18)

When using a color camera, adjust the white balance.

The setting method is the same as for [Camera Image Input].Please check it.

Reference: White Balance (Camera Image Input) (p.23)

Set when measurements (camera coordinate measurement values) are to be output using actual

dimensions. Select the calibration setting method and generate the calibration parameters.

The setting method is the same as for [Camera Image Input].Please check it.

Reference: Calibration (Camera Image Input) (p.24)

1

Input image

HDR Settings (Camera Image Input HDR+)

Specify the image combination method etc.

In the Item Tab area, tap [HDR setting].

1.

In the "Mode select" area, specify the mode.

2.

When you select the mode in the "Mode select" area and specify the measurement region on the

FZ3 Processing Items List Manual

Camera Image Input HDR+ 33

Page 36

1

Input image

image, the parameters are set automatically.To finely adjust the parameters, refer to the next

items.

Set value

Item

Mode select

In the "Image input setting" area, set the items.

3.

[Factory

default]

[ HDR mode]

High

contrast

mode

Description

Generate images with stable brightness by shooting multiple images

with different shutter times based on the specified brightness range.

This is used to improve the contrast within an image.Specify the

average brightness and brightness range, fix the shutter time, shoot

multiple images, and generate images with good contrast.

HDR

Item

Minimum

brightness

Maximum

brightness

Input

number

setting

34 Camera Image Input HDR+

Set value

[Factory default]

0 to 20

[8]

0 to 20

[14]

●

[Unchecked]

●

Checked

2 to 16

[6]

Description

This item sets the minimum brightness for combining images.

This item sets the maximum brightness for combining images.

Place a check to set the number of shots manually.

Setting a high shot count provides images with low

noise.However, more processing time is required.

Setting a low shot count shortens the processing time.However,

the image is more easily affected by noise.

FZ3 Processing Items List Manual

Page 37

High contrast mode

1

Input image

Item

Average

Width

Input

number set

In the "Output setting" area, set the combination method.

4.

Item

Type of

image

combination

Set value

[Factory default]

1.00 to 20.00

[11.00]

0.01 to 1.00

[1.00]

●

[Unchecked]

●

Checked

2 to 16

[6]

Set value

[Factory

default]

[Normal] Select the combination method.

Color

Linear

Specify the average brightness for images shot.

Specify the brightness range for images shot.

Place a check to set the number of shots manually.

Setting a high shot count provides images with low

noise.However, more processing time is required.

Setting a low shot count shortens the processing time.However,

the image is more easily affected by noise.

Normal: Standard combination method. This compensates the

brightness so that dark sections on the combination image do not

become all black.

Color: This is suitable for inspecting labeling and the Gravity and

Area.This compensates the saturation when there is little hue

information in the combined image.

Linear: This is suitable for fine matching and defect inspection.In

order to output the actual brightness of the workpiece, no

compensation is performed.

The processing speed is Color (slow) - Normal - Linear (fast).

Description

Description

The current shot count and image combination time for the settings are displayed.

FZ3 Processing Items List Manual

Camera Image Input HDR+ 35

Page 38

1

Input image

Bright Adjust Setting (Camera Image Input HDR+)

This sets how far to track the brightness of the loaded images.

In the Item Tab area, tap [Brightness adjustment].

1.

Set each item in the "Bright adjust setting" area.

2.

Set value

Item

Brightness

adjustment

Minimum

Adjustment

range

Maximum

Adjustment

range

Adjust bright

ave.

[Factory

default]

[Unchecked]

Checked

0.00 to 20.00

[6.00]

0.00 to 20.00

[16.00]

0.00 to 20.00

[11.00]

Description

If a check is placed at "Brightness adjustment", the image is output

with its brightness automatically compensated.This makes it possible

to obtain images with stable brightness even if the lighting conditions

fluctuate, for example due to interfering light.

Specify the follow-up brightness minimum value.

Specify the follow-up brightness maximum value.

Specify the target for brightness follow-up.Tapping the [Set current

bright] button updates this value.

When a check is placed at "Brightness adjustment", the Brightness Adjustment range is

displayed with blue lines in the "Histogram" area.

Change the "Adjust bright ave." and brightness adjust area.

36 Camera Image Input HDR+

FZ3 Processing Items List Manual

Page 39

1

Input image

FZ3 Processing Items List Manual

Camera Image Input HDR+ 37

Page 40

1

Input image

Camera Switching

Used in the Following Case

●

When switching to images on cameras other than that has been set to [Camera Image Input]

during scene processing

Important

●

When switching from a monochrome camera to color camera, reconfigure the settings in the following units.

●

Camera switching cannot be used with camera image input HDR+.

Camera Selection (Camera Switching)

Select the cameras used for measurement.

1.

Tap [OK].

2.

The settings are finalized.

Additional Explanation (Camera Switching)

When creating a scene, [Position Compensation] will be disabled if [Camera Switching] is positioned

after a [Position Compensation] unit, and this will restore the image of the measurement object to its

former state before the position compensation was applied.

38 Camera Switching

FZ3 Processing Items List Manual

Page 41

1

Input image

FZ3 Processing Items List Manual

Camera Switching 39

Page 42

1

Input image

Measurement Image Switching

This sets the output image for the specified image conversion related processing items as the input

image for the processing items set in the flow from this processing item onward.

This is primarily used to return converted images back to their originals and to increase the images that

can be selected as conversion targets for image conversion related processing items by placing before

the image conversion related processing items.

Used in the Following Case

●

To return a converted image to its original

Parameter Settings (Measurement Image Switching)

Specify the processing unit outputting the images to display.

Select the target unit in the "Target" area.

1.

Note

●

If <Nothing> is left selected, the measurement image switching measurement result is NG.

Be sure to set something other than <Nothing>.

●

Only an image conversion related unit prior to this unit can be selected.

Tap [OK].

2.

The settings are finalized.

40 Measurement Image Switching

FZ3 Processing Items List Manual

Page 43

Measurement

This chapter describes how to set up the processing items

that execute measurement.In addition, key points for

adjustment addressing unstable measurement results and

shortening measurement time will also be introduced.

Reference: Search (p.42)

Reference: Flexible Search (p.53)

Reference: Sensitive Search (p.62)

Reference: ECM Search (p.73)

Reference: EC Circle Search (p.84)

Reference: Shape Search+ (p.94)

Reference: Classification (p.104)

Reference: Edge Position (p.114)

2

Measurement

Reference: Edge Pitch (p.124)

Reference: Scan Edge Position (p.132)

Reference: Scan Edge Width (p.145)

Reference: Color Data (p.154)

Reference: Gravity and Area (p.160)

Reference: Labeling (p.172)

Reference: Label Data (p.186)

Reference: Labeling+ (p.190)

Reference: Defect (p.209)

Reference: Precise Defect (p.217)

Reference: Fine Matching (p.225)

Reference: Character Inspection (p.236)

Reference: Date Verification (p.244)

Reference: Model Dictionary (p.253)

Reference: Barcode+ (p.261)

Reference: 2D Code+ (p.268)

FZ3 Processing Items List Manual

Reference: Circle Angle (p.275)

41

Page 44

Search

Register the feature sections of the measurement object as an image pattern (model), then find the most

similar part to these models from the input images to detect the position.

The correlation value showing the degree of similarity, measurement object position, and inclination can

be output.

2

Measurement

Used in the Following Case

●

When identifying the shape of measurement objects (for detecting defects or foreign matter)

Note

●

Search processing basic concepts

Reference: "User's Manual", "Search Processing Mechanism" (p.300)

Settings Flow (Search)

Set up searches according to the following flow.

42 Search

FZ3 Processing Items List Manual

Page 45

List of Search Items

Item name Description

This item registers the pattern characteristic of the measurement image as a model.

Model

register

Region

setting

Detection

point

Ref. position

Measurement

Output

parameter

Model parameter values can be changed as needed to address unstable measurement results or to

increase the processing speed.Normally, the factory default value will be used.

Reference: Model Registration (Search) (p.43)

This item is used to set up the measurement area.

Instead of measuring the entire input image, narrowing the measurement area shortens the

processing time.

Reference: Region Setting (Search) (p.46)

This item can be changed if necessary.Specify a position in the model that should be used as the

detection coordinates during measurement. Usually, the central position of the set model is

registered as the detection coordinates.

Reference: Detection Point (Search) (p.47)

This item can be changed if necessary.Specify the reference position within the camera's field of

view.

Reference: Reference Position (Search) (p.47)

This item specifies the judgement condition for measurement results.Specify the criteria to judge the

measurement result if the X and Y coordinates and the correlation with the model are OK.

Reference: Measurement Parameters (Search) (p.48)

This item can be changed if necessary.Normally, the factory default value will be used.

Use the output parameter to specify how to handle the coordinates.

Reference: Output Parameters (Search) (p.50)

2

Measurement

Model Registration (Search)

Register the parts to measure as the model.

The position at the time of registration is also registered in the model information.Place the

measurement object in the correct position when registering a model.

In the Item Tab area, tap [Model register].

1.

When setting a new model, you do not have to tap [Model register].

FZ3 Processing Items List Manual

Search 43

Page 46

Use the drawing tools to specify the model registration range.

2.

2

Measurement

Note

To save the entire image used for model registration, place a check at the "Save registered

3.

model" option.

Note

●

If you save the registered model image, you can re-register the model with the same image after model

parameters are adjusted.Note that the scene data size increases when a registered model image is

saved.

Tap [OK].

4.

The model is registered.

●

When a model is registered, the central coordinates of the model are registered as the detection point.A

detection point is a point output as a measurement value. If multiple figures are combined, the central

coordinates of the circumscribed rectangle are registered.

Changing Model Parameters

Model parameter values can be changed as needed to address unstable measurement results or to

increase the processing speed.Normally, the factory default value will be used.

After changing a setting, re-register the model.

In the "Model parameter" area, select the search mode, then specify a value for each item for

1.

44 Search

FZ3 Processing Items List Manual

Page 47

that mode.

Setting item

Search

mode

Set value

[factory

default]

[CR]

PT

2

Measurement

Description

Search for normalizing the brightness.This method can provide stable

measurement when there is fluctuation in the overall brightness and

when the image has low contrast.

Measures the degree of matching with the model profile.This method

can measure at higher speed when the rotation angle has a wide

range.

It is available only when a 0.3 megapixel color camera is connected.

When CR is selected

Setting item

Rotation

Angle range [-180 to 180]

Skipping angle

Smart mode

Stability

Prec.

Set value

[factory

default]

Checked

[Unchecked]

1 to 30

[5]

[Checked]

Unchecked

1 to 15

[The default

value

depend on

the

connected

camera.9 or

12]

1 to 3

[2]

Description

When the measurement object is

rotating, place a check at "Rotation" and

specify how many degrees the model

created rotates each time and through

what range of angles.A smaller skipping

angle increases stability, but slows down

the processing. The normal direction is

clockwise.

Checking the "Smart mode" option

enables a high-speed rotation

search.However, the stability may be

lowered when the model shape aspect

ratio is large or when the NOT mask is

used.

Specify which is to have priority,

measurement stability or speed.

If lowering stability does not speed up

processing, it is likely that many

candidates have been detected.In this

case, specify a larger value for

"Candidate LV" or "Stab."

Specify which is to have priority,

measurement positional precision or

speed.

FZ3 Processing Items List Manual

Search 45

Page 48

2

Measurement

If you save the model registration image, it is easy to re-register the model after model parameters are

changed.

Disp model/Input

image

Re-register

Delete Deletes models.

When PT is selected

Set value

Setting item

Angle range [-180 to 180]

Stability

[factory

default]

1 to 5

[3]

This item specifies the rotation angle range for searching.The normal

direction is clockwise.

If lowering stability does not speed up processing, it is likely that many

candidates have been detected.In this case, specify a larger value for

"Candidate LV" or "Stab."

Displaying/Re-Registering/Deleting a Model

Item Description

The model image display and input image display are switched.

When model parameters are modified, display the original model image and re-register the

model.

Description

Region Setting (Search)

Use a rectangle to specify the area where the model is searched.

Instead of measuring the entire input image, narrowing the measurement area shortens the processing

time.

In the Item Tab area, tap [Region setting].

1.

Tap [Edit].

2.

The figure setting area is displayed.

Specify the area in which to search for the model.

3.

The rectangle covering the entire screen is set. Adjust the size and position of the rectangle.

Tap [OK].

4.

The area to measure is registered.

46 Search

FZ3 Processing Items List Manual

Page 49

Detection Point (Search)

Specify a position in the model that should be used as the detection coordinates during

measurement.Usually, the central position of the set model is registered as the detection point. This

function is used to change to any desired position.

Note

●

After changing the detection coordinates to another position, re-registering the model will change it back to the

central coordinates of the model.

In the Item Tab area, tap [Detection point].

1.

In the Image Display area, the current detection point is displayed with a crosshair cursor.

Tap the position to be set as the detection point.

2.

Note

●

Displaying the image enlarged makes this tapping easier.

Reference: "Using the Zoom Function" in the "User's Manual" (p.317)

2

Measurement

If necessary, finely adjust with numeric input and the arrow buttons.

3.

Reference Position (Search)

When the model is set, this position is automatically set at the same time as the reference position.This

item can be used to change the reference position to any desired position. This is handy for measuring

the positional deviation from a certain position.

In the Item Tab area, tap [Ref. position].

1.

In the Image Display area, the current reference position will be displayed as the crosshair

cursor.

FZ3 Processing Items List Manual

Search 47

Page 50

2

Measurement

Tap the position to be set as the reference position.

2.

Note

●

Displaying the image enlarged makes this tapping easier.

Reference: "Using the Zoom Function" in the "User's Manual" (p.317)

If necessary, finely adjust with numeric input and the arrow buttons.

3.

To remeasure on the displayed image and set the reference position, tap [Measure ref.].

Measurement Parameters (Search)

Specify the search measurement conditions and the judgement conditions for the measurement results.

In the Item Tab area, tap [Measurement].

1.

In the "Measurement condition" area, specify a value for each item.

2.

Setting item

Sub-pixel

48 Search

Set value

[factory default]

●

Checked

●

[Unchecked]

Description

When a check is placed at sub-pixel, the position information can

be measured in units of sub-pixels.However, this requires more

processing time.

FZ3 Processing Items List Manual

Page 51

CandidateLV0 to 100

[70]

When executing a multi search

Specify the threshold value with which to detect candidate points

in a rough search.Specify a smaller value when model search

results are unreliable.

Setting item

Multiple

output

Detail LV

0 to 100

[75]

Sort

condition

Search No.

When the setting has been changed, tap [Measurement] in the Detail area to verify whether

3.

0 to 31

[0]

Set value

[factory default]

●

Checked

●

[Unchecked]

●

Corr. ascending

●

[Corr. descending]

●

X ascending

●

X descending

●

Y ascending

●

Y descending

Description

Select to execute a multi search.

Specify the threshold value with which to detect candidate

points in a detail search.

Specify the conditions by which the search number is

re-assigned.

When sorting referencing the X and Y coordinates, the

upper left is the origin.

Input the search number for outputting the data.

measurements can be made correctly.

Set up the judgement condition.

4.

2

Measurement

Note

●

The values beside each item are measurement results of the displayed image.Take these values into

consideration to determine the upper and lower limits.

Setting item Set value Description

Count 0 to 32 Specify the number of detections that are judged to be OK.

-99999.9999

Measure X

Measure Y

FZ3 Processing Items List Manual

to

99999.9999

-99999.9999

to

99999.9999

Specify the range of X-axis shifting that is judged to be OK.

Specify the range of Y-axis shifting that is judged to be OK.

Search 49

Page 52

Measure

angle

-180 to 180 Specify the range of angles that are judged to be OK.

Correlation 0 to 100

Specify the range of correlation values that are judged to be

OK.However, when the correlation value of the measurement result is

0, the judgement result will be NG regardless of the lower limit setting.

2

Measurement

Specify how to treat the coordinates to be output to the external device as measurement results.This

item can be changed if necessary.Normally, the factory default value will be used.

Important

Output Parameters (Search)

●

After setting up the measurement parameters, changing the output parameters will cause measurement results

to vary accordingly.If the output parameters have been changed, re-specify the measurement, too.

Tap [Output parameter] in the Item Tab area.

1.

Specify each of the following items.

2.

Set value

Setting item

[factory

Description

default]

●

Output

Coordinates

scroll]

●

scroll

[After

Before

As measurement results, select whether to output coordinate values

to external devices before or after the position deflection correction is

applied.

Select whether to reflect the calibration in the values output to the

Calibration

●

[OFF]

ON

external device as measurement results.

ON: Output the coordinates converted into actual dimensions.

●

OFF: Output the camera coordinate values.

Reflect to

overall

judgement

●

●

[ON]

OFF

Enables choosing whether or not the judgement results of this

processing unit is reflected in the scene overall judgement.

Key Points for Test Measurement and Adjustment (Search)

The following content is displayed in the "Detail result" area as text.

Important

●

Executing test measurements will also update the measurement results and the figures in the image.

50 Search