Cat. No. N138-E1-01

WT30

FA Wireless SS Terminal

Authorized Distributor:

Cat. No. N138-E1-01 Note: Specifications subject to change without notice

Printed in Japan

0105-?M (0105) (?)

Notice

(1) This manual may not be copied, reproduced, or reprinted, in whole or in part, without permission

from OMRON.

(2) The specifications listed within this manual may be revised without prior notice.

(3) The information in this manual was compiled with the utmost care. However, if you should find any

errors or inconsistencies, please contact the OMRON business office. Be sure to tell us the revi-

sion number of the manual in which you found the error.

Introduction

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

Thank you for purchasing this WT30 FA Wireless SS Terminal (also referred to as WT30 or WT30 Terminal in this manual).

The WT30 System consists of a Serial Master Station and I/O Slave Stations. The Serial Master Station is a wireless terminal that collects ON/OFF data using wireless communications and is connected

to a device with an RS-232C interface (e.g., a personal computer or PLC). I/O Slave Stations with I/O

terminals can also be connected to a DeviceNet-compatible WD30 Master.

Intended Audience

This manual is intended for the following readers.

• Persons in charge of introducing FA devices

• Persons who design FA systems

• Persons who install or connect FA devices

• Persons who manage working FA installations

Persons who use this product must have sufficient knowledge of electrical systems (i.e., an electrical

engineer or the equivalent).

i

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the product. Please consult your OMRON representative if you

have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for a period of one

year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER

OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL

SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF

PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS

BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which liability is

asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED,

STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR

INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT DESIGNED OR

RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED UPON AS A SAFETY COMPONENT

OR PROTECTIVE DEVICE FOR SUCH PURPOSES. Please refer to separate catalogs for OMRON's safety rated

products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of

products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents identifying ratings and

limitations of use that apply to the products. This information by itself is not sufficient for a complete determination of the

suitability of the products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an

exhaustive list of all possible uses of the products, nor is it intended to imply that the uses listed may be suitable for the

products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not

described in this document.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment,

amusement machines, vehicles, safety equipment, and installations subject to separate industry or government

regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

ii

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE

OMRON PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability and does not

constitute a warranty. It may represent the result of OMRON’s test conditions, and the users must correlate it to actual

application requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant

construction changes are made. However, some specifications of the product may be changed without any notice. When in

doubt, special model numbers may be assigned to fix or establish key specifications for your application on your request.

Please consult with your OMRON representative at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no responsibility is

assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product. Please notify us

before copying or reproducing this document in any manner, for any other purpose. If copying or transmitting this document

to another, please copy or transmit it in its entirety.

iii

Approved Standards

Conforming Wireless Standards:

Japan: ARIB STD-T66

USA: FCC part 15.247

Europe: EN 300 440-2

Conforming Safety Standards: UL508 (Listing)

Conforming EMC Standards: EN 301 489-3

Conforming EMF Standards: EN 50371

Applicable Countries

This product has been approved for wireless standards in the countries listed

below. This product cannot be used in any other countries.

Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland,

France, Germany, Greece, Hungry, Iceland, Ireland, Italy, Japan, Latvia,

Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland, UK, USA

Conformance to EN Standards

Use a DC power line less than 3 m to conform to EN standards. If a power line

of 3 m or longer is required, extend the length at the Switching Power Supply’s

primary side (i.e., the AC power line).

EN 60950-1

EN 301 489-17

Conformance to UL Standards

Always use a Class 2 power supply to conform to UL standards.

FCC Notice

This device complies with part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Caution

To ensure that the WLAN transmitter complies with current FCC regulations

limiting both maximum RF output power and human exposure to radio frequency radiation, a separation distance of at least 20 cm must be maintained

between the Unit’s antenna and the body of the user and any nearby persons

at all times and in all applications and uses.

Notice

Changes or modificatiaons not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

iv

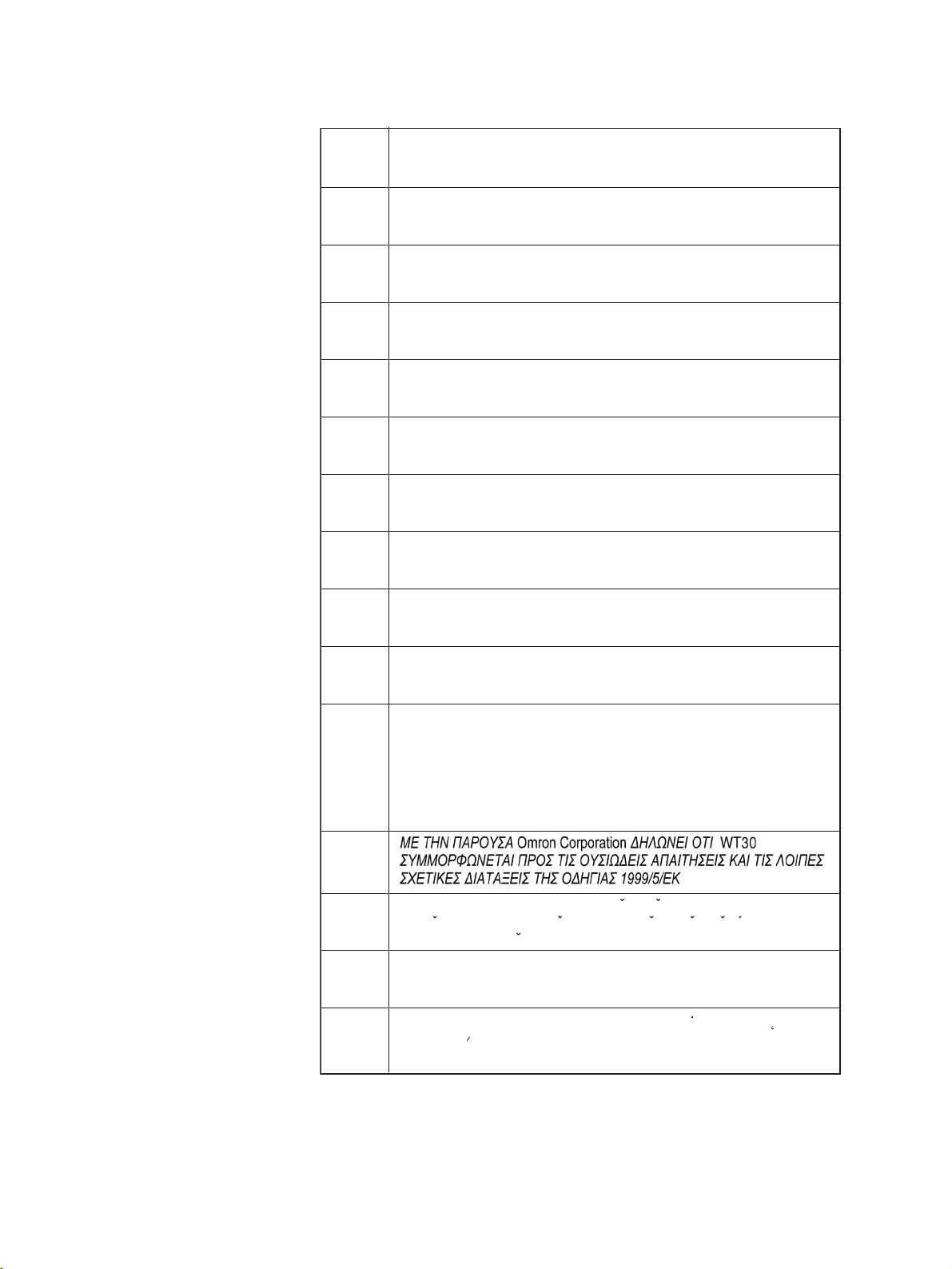

CE NOTICE

English Hereby, Omron Corporation, declares that this WT30 is in

compliance with the essential requirements and other relevant

provisions of Directive 1995/5/EC.

Finnish Omron Corporation vakuuttaa täten että WT30 tyyppinen laite

on direktiivin 1995/5/EY oleellisten vaatimusten ja sitä

koskevien direktiivin muiden ehtojen mukainen.

Dutch Bij deze verklaart Omron Corporation dat deze WT30 voldoet

aan de essentiële eisen en aan de overige relevante bepalingen

van Richtlijn 1995/5/EC.

Swedish Härmed intygar Omron Corporation att denna WT30 står I

överensstämmelse med de väsentliga egenskapskrav och övriga

relevanta bestämmelser som framgår av direktiv 1995/5/EG.

Danish Undertegnede Omron Corporation erklærer herved, at følgende

udstyr WT30 overholder de væsentlige krav og øvrige relevante

krav i direktiv 1995/5/EF

German Hiermit erklärt Omron Corporation die Übereinstimmung des

Gerätes WT30 mit den grundlegenden Anforderungen und den

anderen relevanten Festlegungen der Richtlinie 1995/5/EG.

Italian Con la presente Omron Corporation dichiara che questo WT30 è

conforme ai requisiti essenziali ed alle altre disposizioni

pertinenti stabilite dalla direttiva 1995/5/CE.

Spanish Por medio de la presente Omron Corporation declara que el

WT30 cumple con los requisitos esenciales y cualesquiera otras

disposiciones aplicables o exigibles de la Directiva 1995/5/CE

Portuguese

Norwegian

French Par la Présente Omron Corporation déclare que l'appareil WT30

Omron Corporation declara que este WT30 está conforme com

os requisitos essenciais e outras disposições da Directiva 1995/

5/CE.

Omron Corporation erklærer herved, at følgende utstyr WT30

overholder de vesentlige krav og øvrige relevante bestemmelser

i direktiv 1995/5/EF

est conforme aux exigences essentielles et aux autres

dispositions pertinentes de la directive 1995/5/CE.

La France étant le seul pays ayant une directive locale qui diffère

légèrement de la directive Européenne, ce produit ne peut être

utilisé en France.

Greek

Czech

Hungarian

Polish

Omron Corporation tímto prohlasuje, ze tento WT30 je ve

shode se základními pozadavky a dalsími príslusnymi

ustanoveními smernice 1999/5/ES.

Alulírott, Omron Corporation nyilatkozom, hogy a WT30

megfelel a vonatkozó alapvetõ követelményeknek és az 1999/5/

EC irányelv egyéb elõírásainak.

Niniejszym Omron Corporation deklaruje, ze dane urzadzenie

WT30 spelnia wymagania zasadnicze i inne stosowne

postanowienia Dyrektywy 1995/5/EC.

Overseas Use Export permission must be obtained from the Japanese government before

exporting (or providing to a non-resident) items or technology classified as

export-restricted under the Japanese Foreign Exchange and Foreign Trade

Control Law.

v

vi

Safety Precautions

O

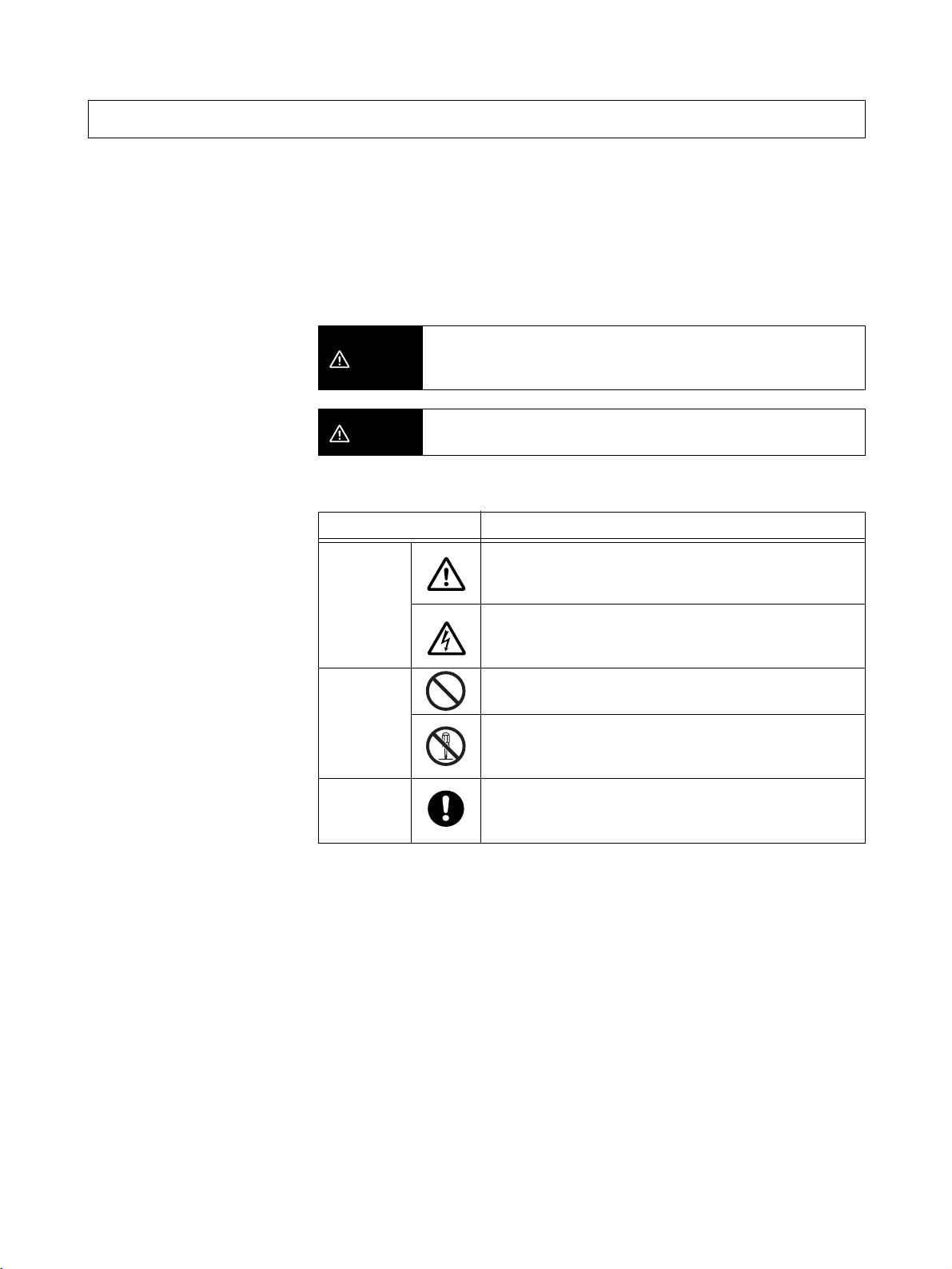

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required

to ensure safe usage of the product.

The safety precautions that are provided are extremely important to safety.

Always read and heed the information provided in all safety precautions.

The following notation is used.

WARNING

Indicates a potentially hazardous situation which, if not avoided,

will result in minor or moderate injury, or may result in serious injury

or death. Additionally there may be significant property damage.

Symbols

CAUTION

Symbol Meaning

Caution

Prohibition

Mandatory

Caution

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or in property damage.

General Caution

Indicates non-specific general cautions, warnings, and

dangers.

Electrical Shock Caution

Indicates possibility of electric shock under specific

conditions.

General Prohibition

Indicates non-specific, general prohibitions.

Disassembly Prohibition

Indicates prohibitions when there is a possibility of injury,

such as from electric shock, as the result of disassembly.

General Caution

Indicates non-specific, general cautions, warnings, and

dangers.

vii

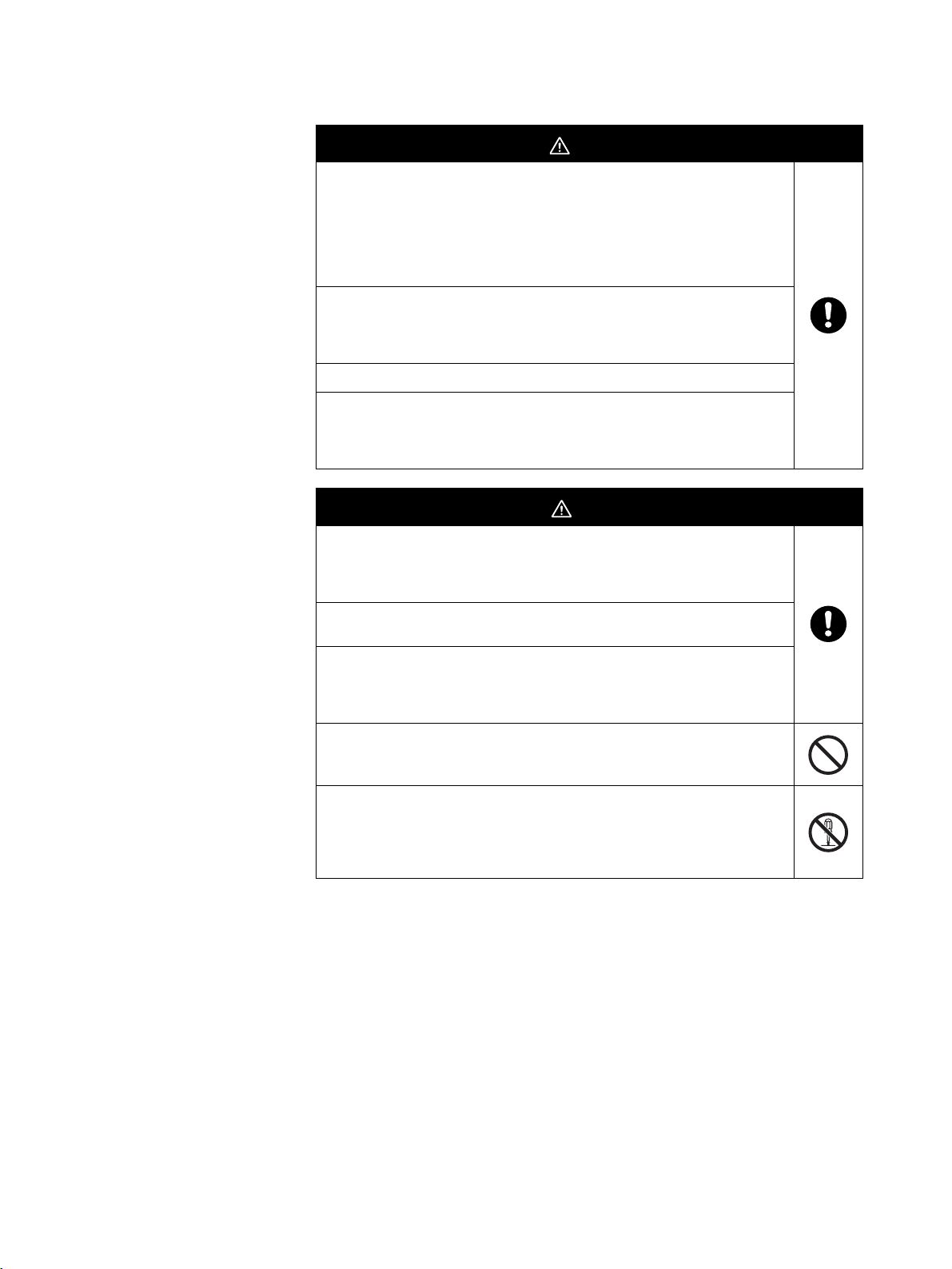

Precautions

WARNING

Always provide protective circuits in the network. Without protective

circuits, malfunctions may possibly result in accidents that cause serious

injury or significant property damage. Provide double or triple safety

measures in external control circuits, such as emergency stop circuits,

interlock circuits, or limit circuits, to ensure safety in the system if an

abnormality occurs due to malfunction of the product or another external

factor affecting the product's operation.

Design the system to ensure safety in the event of temporary

interruptions in communications due to interference with the

electromagnetic waves used for communications caused by the ambient

environment and application methods.

Do not use this product for real-time control.

Using the FA Wireless SS Terminal near a pacemaker or other medical

device may affect the operation of the medical device, possibly resulting

in serious injury. Never use the FA Wireless SS Terminal near

pacemakers or other medical devices.

CAUTION

Make sure that the direction and polarity (+/−) are correct when

connecting terminal blocks and connectors. Turning ON the power to I/O

circuits with the I/O cables connected in reverse, may result in a blown

output fuse.

Do not apply a voltage or connect a load to the outputs that exceeds the

maximum switching capacity.

Leave the dustproof label attached to the Unit when wiring. Be sure to

remove the label after the completion of wiring, however, to ensure

proper heat dissipation. Removing the label during wiring or leaving the

label attached after wiring may result in fire.

Do not allow pieces of metal, wire clippings, or fine metallic shavings or

filings from installation to enter the product. Doing so may occasionally

result in minor electric shock, fire, or malfunctions.

Do not attempt to disassemble, repair, or modify the product, or touch

the internal parts of the product. Doing so may occasionally result in

minor electric shock, fire, or malfunctions. In Japan, disassembly and

modification is also prohibited under Japan's Radio Law and may be

punishable by law.

viii

Precautions for Safe Use

Be sure to observe the following precautions to ensure safe use of the product.

1. Transport the product in the box in which the product was packaged, making sure the product is not subjected to excessive vibrations or shock, or

dropped.

2. Store the product within the specified environment. Allow the product to

warm up to room temperature for at least 3 hours after it has been stored

at

−10°C or lower.

3. Use the product within the specified temperature and humidity ranges.

4. Do not use the product in the following locations.

• Locations subject to extreme temperature changes resulting in condensation

• Locations subject to static electricity, excessive noise, or electric fields

• Locations where the product may come into contact with water, oil, or

chemicals

• Locations where corrosive gases or flammable gases are present

• Locations where large amounts of dust or dirt are present

• Locations subject to spatters, iron chips, or filings

5. Do not install the product outdoors (outside a control panel).

6. Use tape, cord, or other means to hold the product while adjusting the installation position to prevent the product from damage due to falling.

7. Do not install the product in areas where it will be subject to excessive external force, or in walkways.

8. Tighten the mounting screws to the specified torque of 0.5 to 0.6 N·m.

9. Provide sufficient space around the product for heat dissipation.

10. Do not install the product in walkways or locations subject to traffic when

installing the product outside a control panel.

11. Do not reverse the power supply connection or connect the product to an

AC power supply.

12. Use the correct power supply voltage.

13. Use AWG22 to AWG16 to connect wires for post terminals. For solid or

stranded wires, however, use AWG20 to AWG16 (0.52 to 1.5 mm

length of exposed wire is 10 mm.

14. Do not apply voltage to the inputs exceeding the rated voltage range.

15. Use communications cables (RS-232C cables) with a length of 15 m maximum and a load of 2,500 pF maximum.

2

). The

16. Do not lay communications cables (RS-232C cables) and antenna cables

near other high-voltage cables or power lines.

17. Use the specified cables for communications cables (RS-232C cables).

18. Be sure to perform communications tests to confirm operation after wiring

before using the product.

ix

19. Always set the product after it is installed or replaced. Set the product correctly according to the manual, and be sure to perform the tests provided

with the product (e.g., communications tests) before operating it.

20. When operating the product without checking serial numbers, check

whether an existing system is present, and design the system carefully to

prevent radio interference.

21. Do not apply excess vibrations or shock to this product. Do not drop this

product.

22. Make sure that wiring and switch settings are correct before starting operations.

23. Other wireless devices operating within the same frequency band may interfere with this product or be adversely affected by this product. Therefore,

be sure to perform the tests provided with the product (e.g., installation

tests) before operating it.

24. Make sure that the antenna is not disconnected during operation.

25. Do not use this product near other devices that may malfunction due to the

electromagnetic waves emitted by this product.

26. Turn OFF the power supply before performing any wiring or replacing devices.

27. Do not touch the product with wet hands.

m

Precautions for Correct Use

Always heed these precautions to prevent faulty operation, malfunction, or

adverse affect on the product's performance and functionality.

1. Communications performance will vary according to the operating environment. Always check operations before using the product.

2. Do not install the antenna in a location surrounded by metal, such as in a

control panel.

3. Install the antenna so that it is as far away as possible from and not parallel

to electric wires or metal plates.

4. Do not use this product in areas exposed to extremely high humidity, near

televisions or radios, near motors or drills that emit sparks, near strong

magnets, or near fluorescent lights.

5. Make sure that the terminal blocks, communications cables (RS-232C cables), and other items with locking devices are properly locked into place.

6. Do not pull or bend cables with force.

7. Do not change the mode selection switch during operation.

28. Dispose of the product as industrial waste.

x

m

Package Contents

• WT30 FA Wireless SS Terminal

• Instruction Sheet

• Terminal labels (I/O Slave Stations only)

• Non-slip feet (Serial Master Stations only)

xi

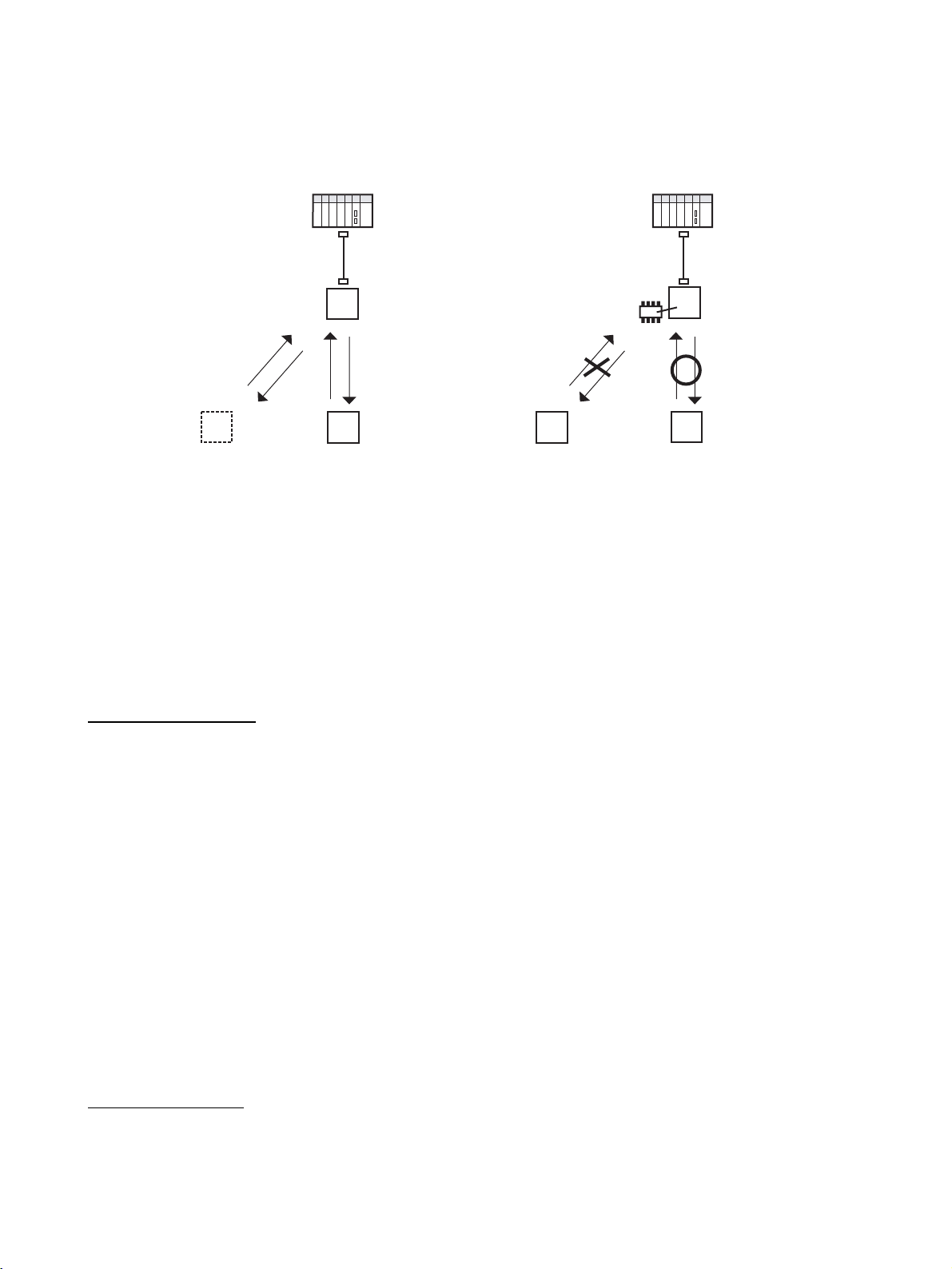

Application Guide

Select the required communications configuration and refer to the relevant

pages.

WT30 Basic

Communications

Configuration

The basic configuration uses 8 inputs and 8 outputs, or 16 inputs.

PLC

WT30-M01-FLK

Serial Master station

I/O Slave

station

I/O Slave

station

64 max.

WT30-S@@@

I/O Slave

station

Note Refer to Features . Select from either of two patterns of points for the input/

output terminals of the I/O Slave Station in a system configured using WT30.

A maximum of 16 input terminals per station can be used.

Extending the Communications Distance Using Relay Function

Using Relay Stations

Extending Communications Distance

Switching Communications Path

I/O Slave Station

PLC PLC

WT30-M01-FLK

Serial Master Station

Relay station

(I/O Slave Station)

I/O Slave Station

WT30-S@@@

I/O Slave Station

1. Communications are not possible.

Note Refer to 4-1 Relay Function on page 60. The communications distance can be

extended by using an I/O Slave Station as a Relay Station.

WT30-M01-FLK

Serial Master Station

2. Switch path.

I/O Slave Station

Relay station

(I/O Slave Station)

3. Perform communications

via relay station.

Relocation

WT30-S@@@

I/O Slave Station

xii

Communications between WT30 Terminals

Communications with Unregistered Slaves

(No Scan List Registration)

Nodes can be added,

changed, or moved.

I/O Slave Station

No. 2

Communications are performed with

specified I/O Slave Stations on the same

frequency channel within the signal range.

Scan list registration is not required, so I/O

Slave Stations can be added and replaced

using switch settings only. (See note 1.)

Communications with Registered Slaves

(Scan List Registration)

PLC PLC

Serial Master Station

Unregistered

I/O Slave Station

No. 1

I/O Slave Station

No. 2

Communications are performed only with those

I/O Slave Stations within the signal range with

the same frequency channel and that are

registered in the Serial Master Station. Select

whether to register the serial number of the I/O

Slave Station when registering it in the Serial

Master Station. (See note 2.)

Serial Master Station

EEPROM

Registered

I/O Slave Station

No. 1

I/O Slave Station

No. 1 is registered

in EEPROM.

Note 1. Refer to 3-4 Using Unregistered Communications Partners on page 42.

2. Refer to 3-5 Registering the Communications Partner on page 45.

Applied Functions

Communications Error

Output Control

Serial Number Check Perform communications with a specific I/O Slave Station registered in the

Replacing WT30

Terminal s

Installation Methods Refer to page 22.

Available Frequencies Refer to page 105.

I/O Terminal Details Refer to page 28.

Select the status of output terminals if errors occur during wireless communications.

Note Refer to 3-6-6 Output Control for Communications Errors on page 56 under 3-

6 Function Setting Switch.

Serial Master Station including the serial number (the serial number is the

product’s unique number).

Note Refer to 3-6-1 Scan List Registration on page 50 under 3-6 Function Setting

Switch.

Refer to page 73.

Useful Functions

Monitoring All Wireless

Channels Automatically

Refer to page 38.

xiii

Manual Outline

Outline of This Manual

Section 1 Introduction

This section explains the features of the WT30 Terminal, including the system configuration and the names and functions

of parts.

Section 2 Hardware Installation and Connection

This section provides information on connection methods and precautions related to installation.

Section 3 Basic Settings

This section describes the procedures for making the WT30 settings and also provides information on the basic system

configuration.

Section 4 Relay Function

This section provides information on the setting methods used to extend the communications distance.

Section 5 Troubleshooting and Maintenance

This section describes error processing, daily inspection, and troubleshooting and maintenance procedures needed to

keep the wireless network operating properly. We recommend reading through the error processing procedures before

operation so that operating errors can be identified and corrected more quickly.

Section 6 CompoWay/F

This section describes the CompoWay/F communications format and the variables that store the ON/OFF data and

received signal strength readings.

Appendices

The appendices provide information on the WT30 specifications and optional accessories. .

xiv

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Precautions for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Precautions for Correct Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Application Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Manual Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

SECTION 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Nomenclature and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 2

Hardware Installation and Connection . . . . . . . . . . . . . . . . 13

2-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-2 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-3 Wireless System Design Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SECTION 3

Basic Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-1 Scan List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-2 Monitoring Unused Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3-3 Setting Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3-4 Using Unregistered Communications Partners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-5 Registering the Communications Partner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3-6 Function Setting Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

SECTION 4

Relay Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4-1 Relay Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4-2 Setting Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4-3 Using Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

SECTION 5

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 67

5-1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5-2 Maintenance and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5-3 Replacing WT30 Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

SECTION 6

xv

TABLE OF CONTENTS

CompoWay/F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6-1 Frame Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6-2 List of Response Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6-3 Detailed Description of the Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6-4 Variable Area (Setting Range) List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6-5 Slave Station Entry Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6-6 Slave Station Input Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6-7 Slave Station Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6-8 Number of Communications Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6-9 Slave Station Route Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6-10 Slave Station Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6-11 Slave Station I/O Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6-12 Serial Number Registration Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6-13 CompoWay/F Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Appendices

Comparison between WT30 and WD30 . . . . . . . . . . 96

A

List of Supported Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

B

I/O Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

C

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

D

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

E

Frequency Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

xvi

SECTION 1

Introduction

This section describes the WT30 Terminal features, communications configuration, and part names and their functions.

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-1-3 Available Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2 Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-2-1 WT30 Terminals: Serial Master Stations . . . . . . . . . . . . . . . . . . . . . 6

1-2-2 WT30 Terminals: I/O Slave Stations . . . . . . . . . . . . . . . . . . . . . . . . 10

1

Fe at ur e s Section 1-1

1-1 Features

Information on systems using WT30 FA Wireless SS Terminals (also referred

to as WT30 or WT30 Terminals in this manual) is provided here.

1-1-1 Overview

The WT30 System consists of a Serial Master Station and I/O Slave Stations.

The Serial Master Station is a wireless terminal that collects ON/OFF data

using wireless communications and is connected to a device with an RS232C interface (e.g., a personal computer or PLC). I/O Slave Stations with I/O

terminals can also be connected to a DeviceNet-compatible WD30 Master.

Simple Relay Functions The relay functions enable an increase in the communications area. The

WT30 system supports a maximum of one relay stage using an I/O Slave Station as the Relay Station.

Install Multiple Sets in the

Same Area

Advantage of Full Range

of Channels

Easy Installation and

Settings

I/O Slave Stations with

Built-in I/O

High-level Security

Wireless Communications

Determine Operating

Status from the LED

Display

Path Switching Function Communications will continue via the Relay Station even if communications

Antennas (Optional) Three antenna types are available: Magnet-base Antennas, Flat Antennas,

Changing frequencies removes interference between different sets installed in

the same area. This enables you to construct a wireless system consisting of

up to 10 sets (depending on the installation environment).

Supporting up to 67 channels, you can construct multiple systems without

interference caused by intermodulation.

DIN Rail mounting makes installation easy. The system can be registered simply by setting the switches on the WT30 Terminal, so Support Software is not

required.

I/O Slave Stations are available in three types: With 16 inputs (DC inputs), 8

inputs/8 outputs (DC inputs/transistor outputs), or with different output terminal polarity.

Registering the I/O Slave Station data (serial number and I/O size) in the

Serial Master Station enables communications to be performed with specified

I/O Slave Stations only.

The LED display on the WT30 Terminal can be used to check the WT30's

error status, whether wireless communications are normal, and the received

signal strength.

with the Serial Master Station and I/O Slave Station are unstable, or if the I/O

Slave Station is removed.

and Pencil Antennas.

Compatible with Generalpurpose RS-232C

Interface

Supported in OMRON

Function Block Library for

SYSMAC CS/CJ-series

PLCs

2

A CompoWay/F command must be created to read (write) ON/OFF or other

data. By using the OMRON Function Block Library, PLC users can reduce the

amount of programming required.

The WT30 is supported the OMRON Function Block Library for SYSMAC CS/

CJ-series Programmable Controllers. The I/O Slave Station's input conditions,

output controls, and wireless communications status can be read simply via

the WT30-M01-FLK Serial Master Station connected to the PLC. Using the

OMRON Function Block Library eliminates the need to create communications programs for the WT30, reduces the load on system startup and maintenance, and improves software quality through programming standardization.

For details on the OMRON Function Block Library, refer to the OMRON FB

Library Start-Up Guide (Cat. No. R123).

Fe at ur e s Section 1-1

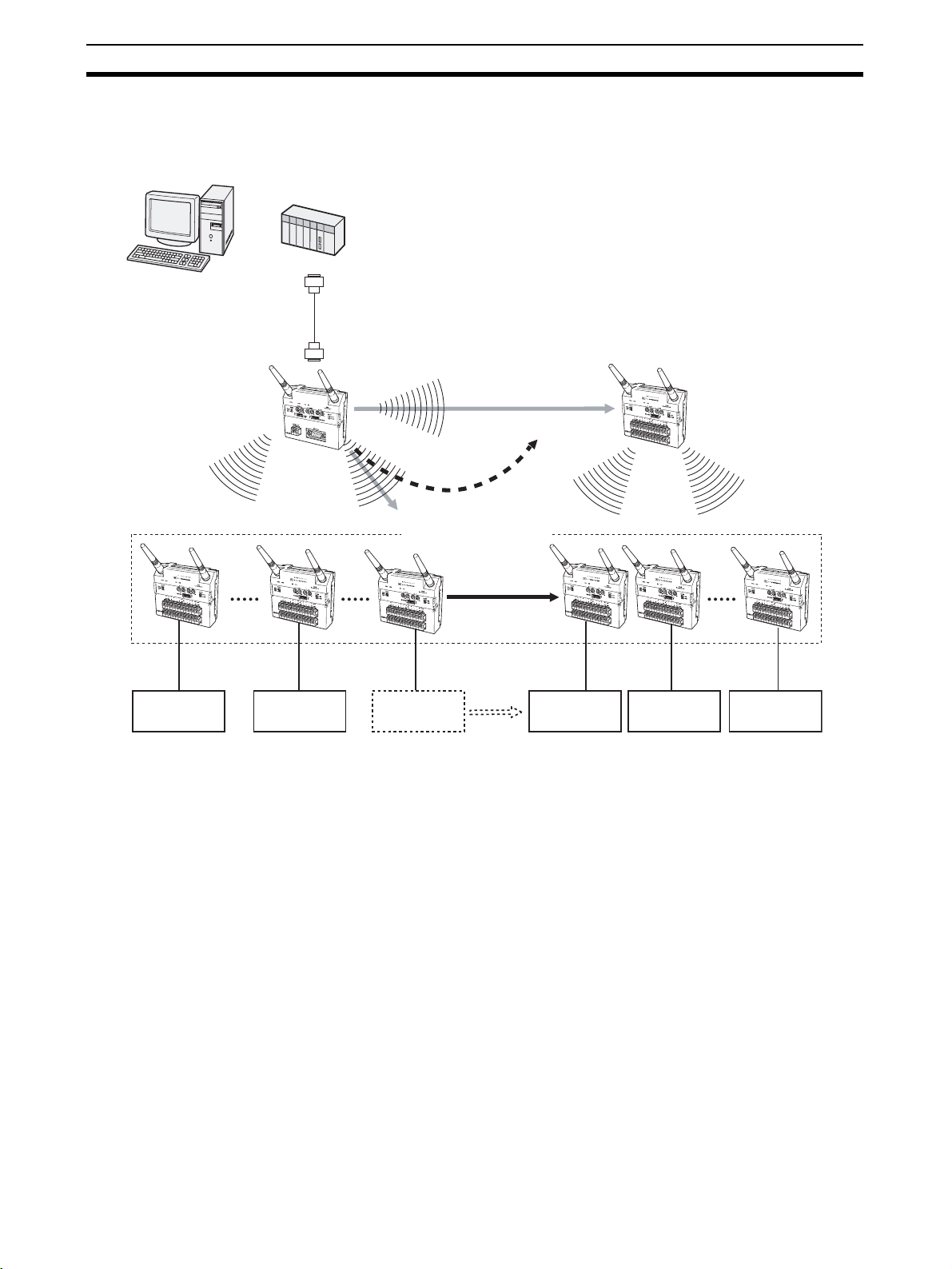

1-1-2 System Configuration

The Serial Master Station is connected to the PLC (Programmable Controller)

or personal computer to perform ON/OFF data communications with the I/O

Slave Stations. The I/O Slave Station can also be used as a Relay Station to

select the path and extend the communications area.

Basic Configuration

Personal computer

PLC

or

RS-232C cable

A

N

T

Serial Master Station

I/O Slave

Stations

1

A

N

T

2

W

T3

0-

M

01

F

L

K

A

N

T

1

A

N

T

2

W

T

3

0

-

S

I

D

1

6

A

N

T

1

A

N

T2

W

T3

0

-

S

I

D

1

6

64 max.

(total number of I/O

Slave Stations)

ON/OFF

data

ON/OFF

data

Device A Device B Device C

A

N

T

1

W

T

3

0

-

S

I

D

1

6

ON/OFF

data

A

N

T

2

3

Fe at ur e s Section 1-1

Relay Configuration The communications area can be extended by using a Relay Station, and the

communications path can also be switched when the WT30 Terminals are

moved due to layout changes.

Personal computer

PLC

or

RS-232C cable

The frequency channel is

Serial Master Station

A

N

T1

A

NT2

W

T

3

0

-

S

I

D

1

6

A

N

T1

A

NT

2

WT

3

0

M

0

1

F

L

K

always the same.

Relay station

(3) Perform communications

via the relay station.

(2) Switch the

path.

(1) Communications

are not possible.

64 max.

(total number of I/O

T1

A

N

T

2

W

T

3

0

-

S

I

D

1

6

A

NT

1

W

T

3

0

-

S

I

D

1

6

Relocation

AN

T

2

I/O Slave Station

AN

Slave Stations)

A

N

T1

W

T

3

0

-

S

I

D

1

6

A

N

T1

A

N

T

2

W

T

3

0

-

S

I

D

1

6

AN

T

1

A

NT

2

A

N

T

2

W

T

3

0

-

S

I

D

1

6

A

N

T

1

A

NT

2

W

T

30

-

S

I

D

1

6

ON/OFF data ON/OFF data ON/OFF data ON/OFF data ON/OFF data

Device A Device B Device C Device D Device E Device F

4

Fe at ur e s Section 1-1

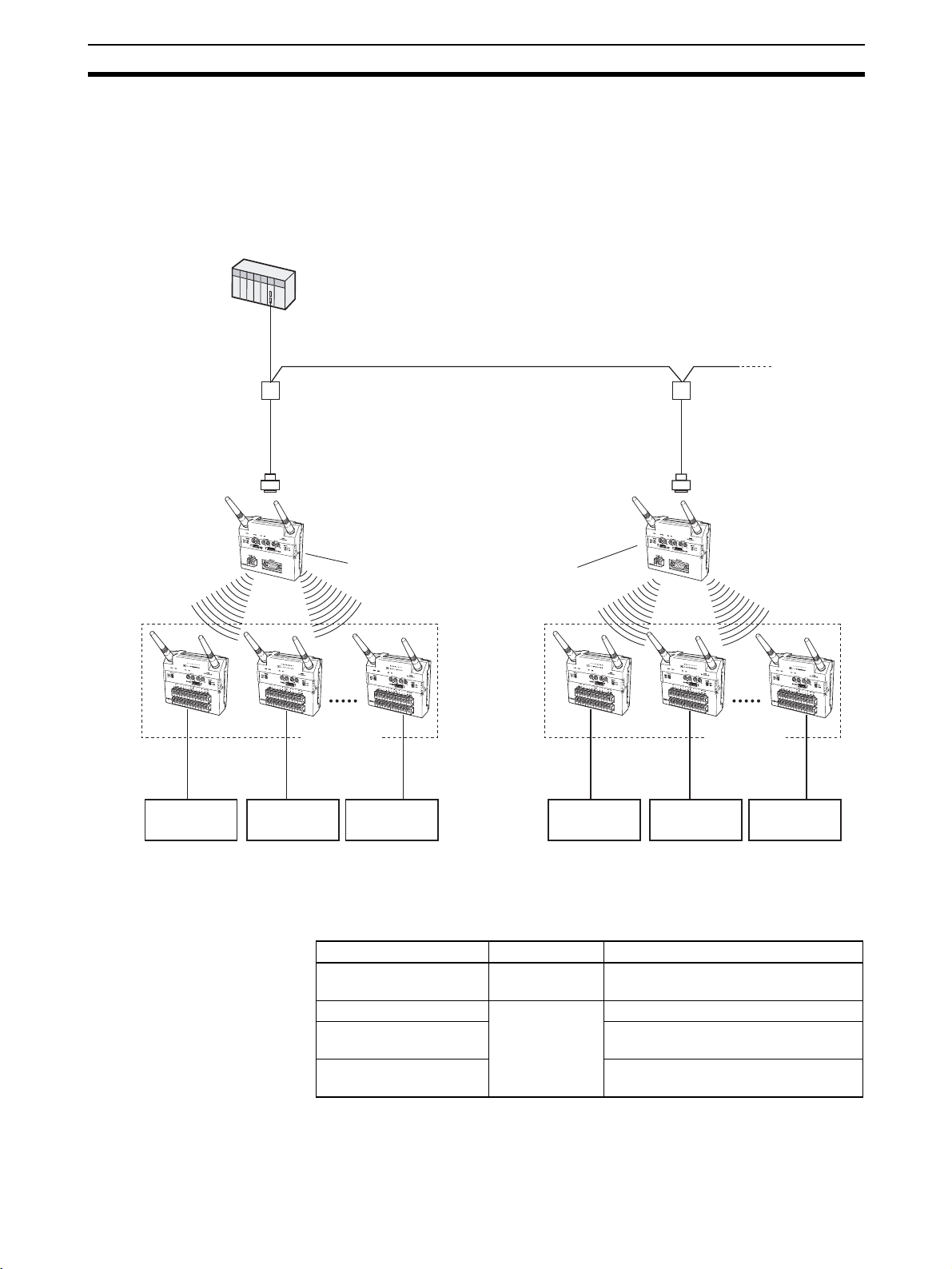

Connecting Multiple Serial

Master Stations

The K3SC RS-232C/RS-485 Interface Converter can be used to configure a

network requiring two or more Serial Master Stations (31 stations max.) or in

environments in which communications are not possible even when Relay

Stations are used in the system. Make sure that the Serial Master Stations are

each allocated unique unit numbers and frequency channels. For details on

wiring cables, refer to the operation manual provided with the K3SC Interface

Converter.

PLC

RS-485 cable

K3SC Interface Converter

RS-232C cable RS-232C cable

A

N

T

Serial Master Station Serial Master Station

I/O Slave

Stations

1

A

N

T

2

W

T

30-

M

01

F

L

K

A different frequency channel is set

for each Serial Master Station.

I/O Slave

Stations

K3SC Interface Converter

A

N

T

1

A

N

T

2

W

T

30

M

01

FL

K

31 max.

A

N

T

1

A

N

W

T

30-

S

I

D

1

6

A

N

T1

T

2

A

N

T

2

W

T

30

-

S

I

D

1

6

A

N

T

1

A

N

T2

W

T

3

0

-

S

I

D

1

6

64 max.

(total number of

I/O Slave Stations)

A

N

T1

A

W

T

30-

S

I

D

1

6

A

N

T

N

T

2

1

A

N

T

2

W

T

3

0

-

S

I

D

1

6

64 max.

(total number of I/O

Slave Stations)

ON/OFF data ON/OFF data ON/OFF data ON/OFF data ON/OFF data ON/OFF data

Device A Device B Device C Device D Device E Device F

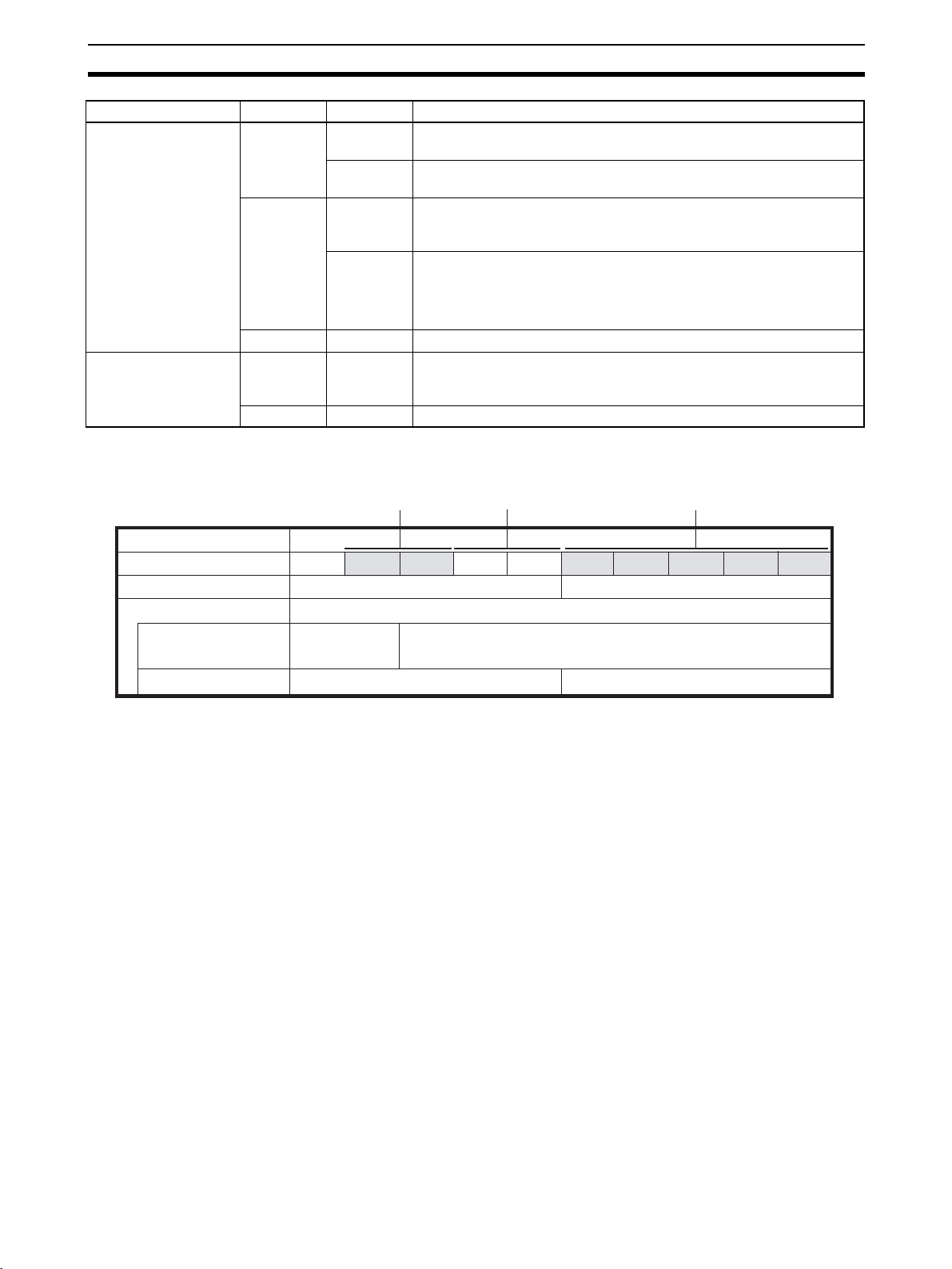

1-1-3 Available Models

The following models are available in the WT30 Series according to the polarity (NPN/PNP) of the terminals and number of I/O points.

WT30 Terminal model Type Specifications

WT30-M01-FLK Serial Master

Station

WT30-SID16 I/O Slave StaWT30-SMD16 8 DC inputs (NPN/PNP) + 8 transistor

tions

WT30-SMD16-1 8 DC inputs (NPN/PNP) + 8 transistor

Note The Antenna and Mounting Brackets are not included with the WT30 Termi-

nals.

RS-232C

16 DC inputs (NPN/PNP)

outputs (NPN)

outputs (PNP)

A

N

T1

A

N

T

2

W

T

3

0

-

S

I

D

1

6

5

Nomenclature and Functions Section 1-2

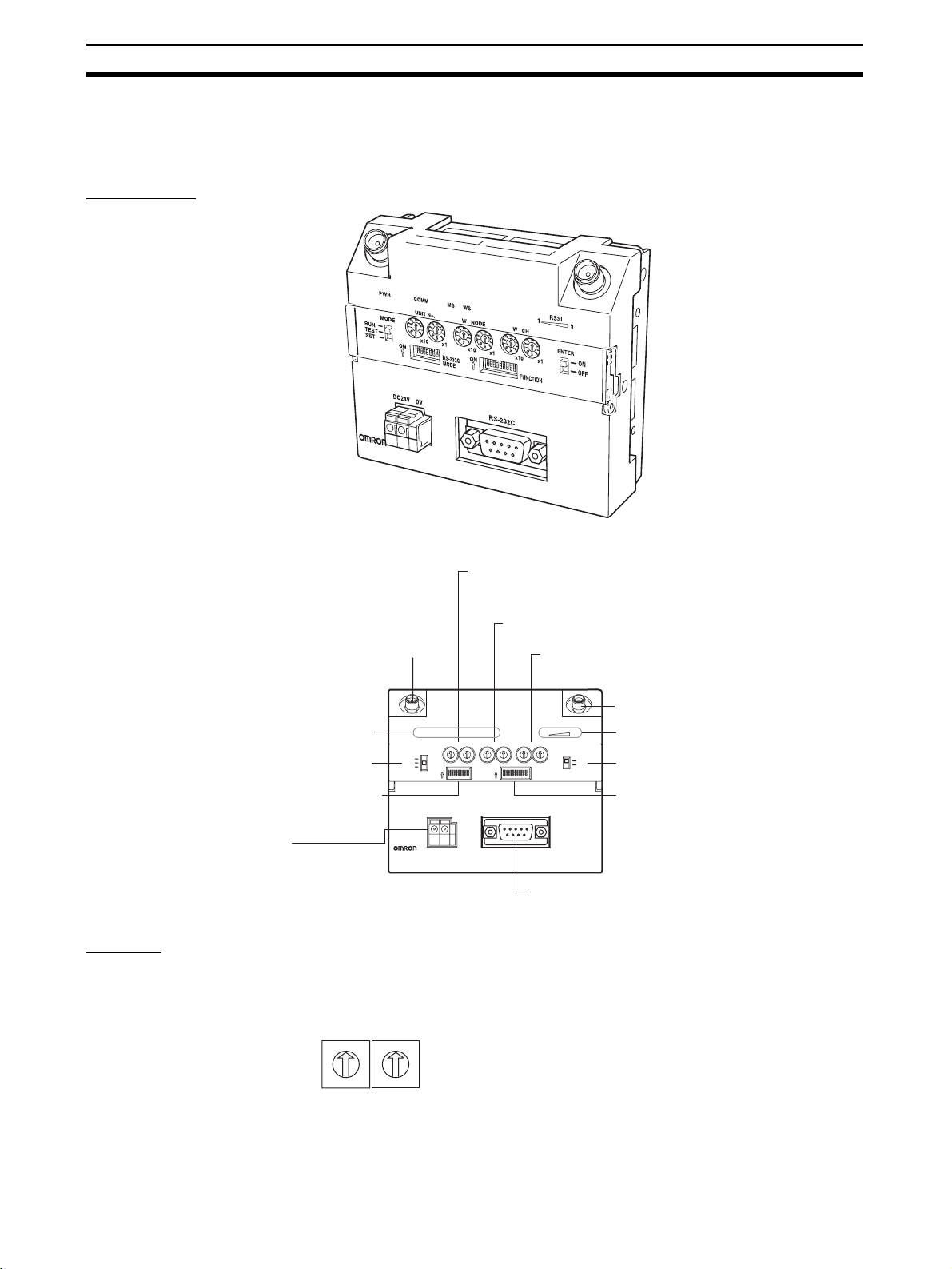

1-2 Nomenclature and Functions

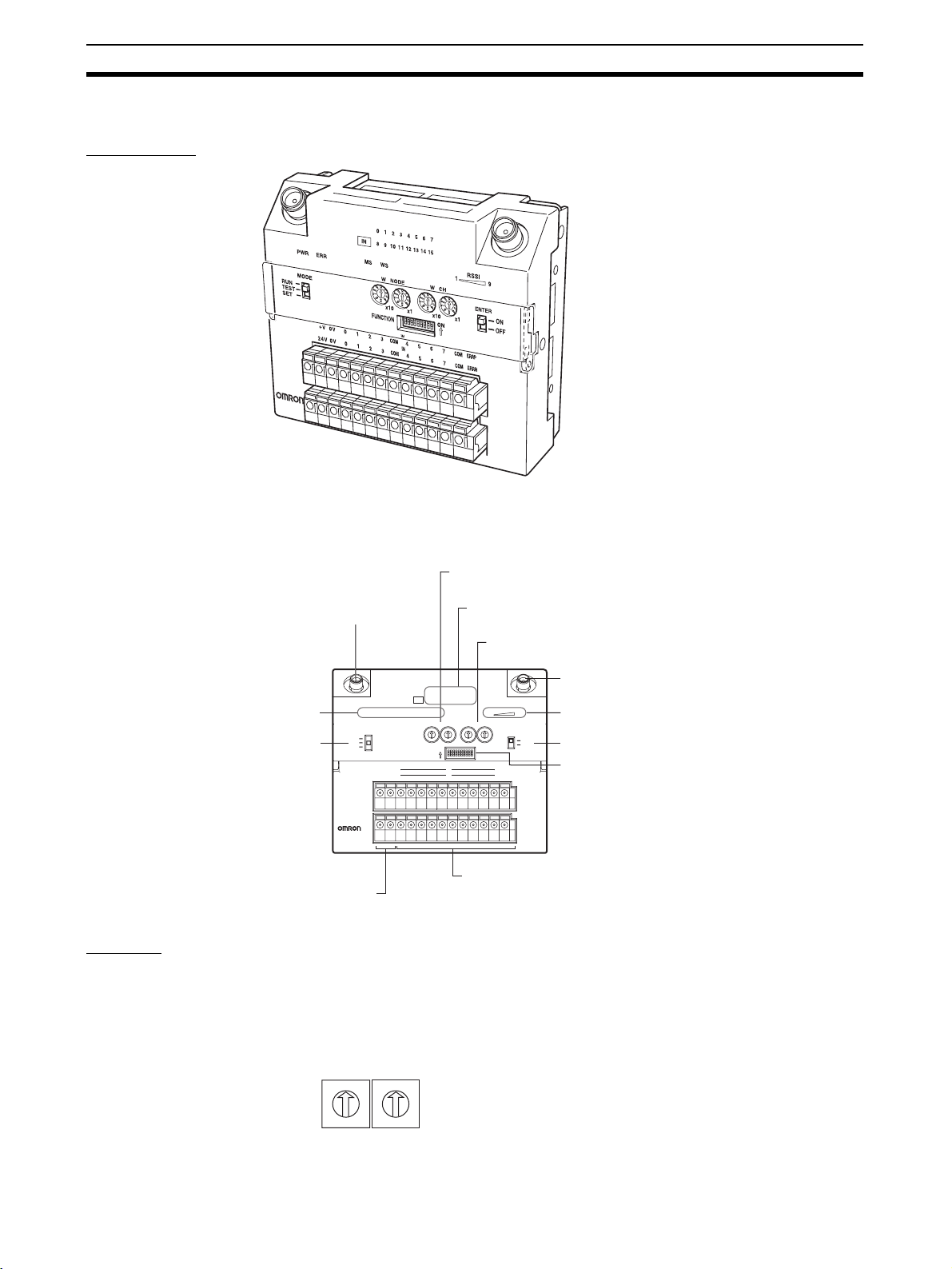

1-2-1 WT30 Terminals: Serial Master Stations

Appearance

ANT1

ANT2

WT30-M01-FLK

Unit No. switch

Set the unit number of the Serial Master Station.

This is used for Host Link communications.

Node setting switch (WNODE)

Antenna terminal (ANT1)

Set the number of connected I/O Slave Stations.

Channel setting switch (WCH)

Set the communications frequency.

Antenna terminal (ANT2)

Status indicators

Mode selection switch

Serial Communications

Setting Switch

Set the baud rate.

Power supply terminal

Supply power to the Unit.

ANT1

PWR

MODE

RUN

TEST

SET

ON

DC24V 0V

WT30-M01-FLK

COMM

MS WS

UNIT No.

W NODE W CH

0

0

0

1

9

2

8

3

7

4

6

5

O

N

123 4 5 6 7

0

1

1

1

9

9

9

2

2

2

8

8

8

3

3

3

7

7

7

4

4

4

6

6

6

5

5

5

x10 x1 x10 x1 x10 x1

8

RS-232C

MODE

O

N

ON

123 4 5 6 7 8 9

RS-232C

0

1

9

8

7

6

5

2

3

4

0

FUNCTION

0

1

9

2

8

3

7

4

6

5

ANT2

RSSI

19

ENTER

ON

OFF

Received signal

strength indicator

Special function switch

Function setting switch

Make the detailed settings

for RUN/TEST/SET mode.

RS-232C terminal

Connect the PLC, personal computer, etc.

Settings

Unit No. Switch Set the unit number for the Serial Master Station. The setting is read when the

power is turned ON. The default is 00.

UNIT No.

9

8

7

X10

0

6

0

1

5

1

9

2

4

2

8

3

3

7

4

6

5

X1

6

Nomenclature and Functions Section 1-2

Node Setting Switch

(WNODE)

Set the number of I/O Slave Stations connected to the Serial Master Station.

The setting is read when the power is turned ON. The default is 01.

W NODE

Channel Setting Switch

(WCH)

0

9

8

7

6

X10

Set the communications frequency. The setting is read when the power is

turned ON. For details on frequencies, refer to Appendix F Frequency Table

on page 105. The default is 02.

0

1

5

1

9

2

4

2

8

3

3

7

4

6

5

X1

W CH

0

9

8

7

6

X10

Mode Selection Switch Set the operation mode of the Serial Master Station (three positions).

RUN

TEST

SET

0

1

5

1

9

2

4

2

8

3

Setting range: 01 to 34, 51 to 83

3

7

(The channels 01/51 cannot be used for this product in China.)

4

6

5

X1

Switch setting Operation mode

RUN RUN mode

TEST TEST mode

SET SET mode

By switching the operating mode, a software reset is performed, and the set

value (setting switch setting) is read.

Special Function Switch Use this switch to end operation during scan list registration or as a trigger to

return to the factory settings.

ENTER

ON

OFF

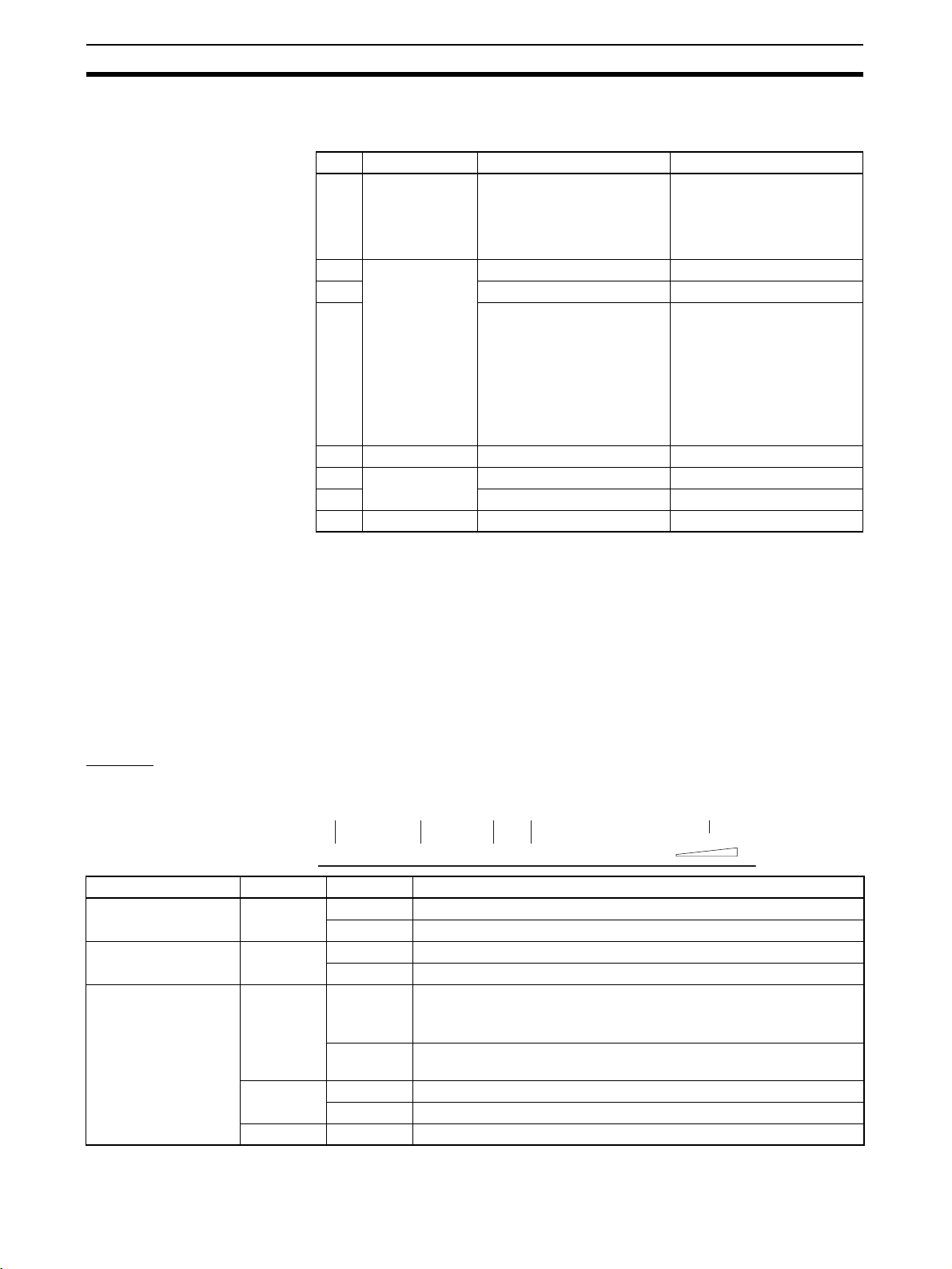

Function Setting Switch Make the detailed settings for RUN/TEST/SET mode.

No. Applicable

mode

1 RUN mode Holds I/O status data when a

2 Enable scan list Disable scan list

3 Relays used Relays not used

4 TEST mode Signal strength monitor dis-

5 All channels automatically

6 --- --7 SET mode Scan list recognition Nothing done

8 Registers specified I/O Slave Registers all I/O Slaves

9 Recognizes serial numbers

10 Not used. --- ---

ON functions OFF functions

Clears I/O status data when

communications error

occurs.

a communications error

occurs.

Signal strength monitor

abled

enabled

Specified channel selected

selected

automatically

Ignores serial numbers

(See note.)

7

Nomenclature and Functions Section 1-2

Note The serial number indicates the product’s unique number.

Serial Communications

Setting Switch

Note For example, if pin numbers 2, 3, and 4 are all ON, the total is 7, which corre-

Set the baud rate and other settings.

No. Function ON operation OFF operation

1 Communica-

tions setting

selection

2 Baud rate (bps)

(See note.)

32 0

Tot a l v al u e

44 0

= 0: 1,200

= 1: 2,400

= 2: 4,800

= 3: 9,600

= 4: 19,200

= 5: 38,400

= 6: 57,600

= 7: 115,200

5 Data length 8 bits 7 bits

6 Parity None Yes

7 Odd Even

8 Stop bits 1 bit 2 bits

Detailed settings (settings

for No. 2 to 8 used)

10

Default settings (baud rate:

9,600 bps; data length: 7

bits; parity: even; stop bits:

2) Settings for No. 2 to 8 are

ignored.

sponds to a baud rate of 115,200 bps.

Power Supply Terminal Supplies 24-VDC (allowable voltage range: 20.4 or 26.4 VDC) power to the

WT30 Terminal. The terminal construction uses a screwless terminal block

(Phoenix Contact: FFKDS/V1-5.08 or equivalent).

RS-232C Terminal The serial terminal construction uses D-sub, 9-pin (female) inch screws

(OMRON XM2F-0910-132 or equivalent)

Antenna Terminal Install an Antenna on both the right and left sides. Always use two Antennas.

Display

Status Indicators for Serial Master Station

(1) (2) (3) (4) (5)

RSSI

PWR COMM MS WS

Indicator Color Status Meaning (primary error)

(1) PWR Green Lit Power is being supplied.

Not lit Power is not being supplied.

(2) COMM Yellow Lit Serial communications in progress.

Not lit No serial communications.

(3) MS

(Module Status)

Red Lit A fatal error has occurred that cannot be recovered from, such as a

watchdog timer error, EEPROM, or hardware error.

Replace the WT30 Terminal.

Flashing A non-fatal error, illegal switch settings, or EEPROM checksum error

has occurred that can be recovered from by resetting the system.

Green Lit Communications are normal.

Flashing TEST mode or SET mode has been activated.

--- Not lit Power is not being supplied or the system is resetting.

1

9

8

Nomenclature and Functions Section 1-2

Indicator Color Status Meaning (primary error)

(4) WS

(Wireless Status)

(5) RSSI (See note 2.)

(Received Signal

Strength Indicator)

Red Lit A fatal wireless communications error or code sense error has

occurred.

Flashing A non-fatal wireless communications error or verification error (slave

station I/O size mismatch) has occurred, or the slave is not registered.

Green Lit RUN mode: Connection to wireless communications is completed or

remote I/O communications are in progress.

SET mode: Scan list creation completed.

Flashing RUN mode: There is no wireless communications connection or there

are no slaves participating in remote I/O communications.

TEST mode: The received signal strength is being monitored.

SET mode: Scan list is being created.

--- Not lit Wireless communications are not in progress.

Red/yellow/

green

0 to 9 lit Displays the received signal strength in 10 levels. The field strength is

determined by the number of indicators lit: weak for a small number

and strong for a large number.

Green Flashing Special function operation has completed.

Note (1) For details on troubleshooting, refer to 5-1 Troubleshooting on page 68.

(2) The RSSI can be used to confirm the operation status.

Red indicators Yellow indicators Green indicators

Field strength

Number of indicators lit

RUN mode

Test mode

Field strength monitor

test

Installation/confirmation test

Weak Medium Strong

01 23 45 6 7 89

Unstable communications range Stable communications range

Range in which

specified channel

can be used.

Unstable communications range Stable communications range

Range in which specified channel cannot be used.

The received signal strength is indicated using 10 levels. Check the communications status, referring to the field strength level.

9

Nomenclature and Functions Section 1-2

pply p

r

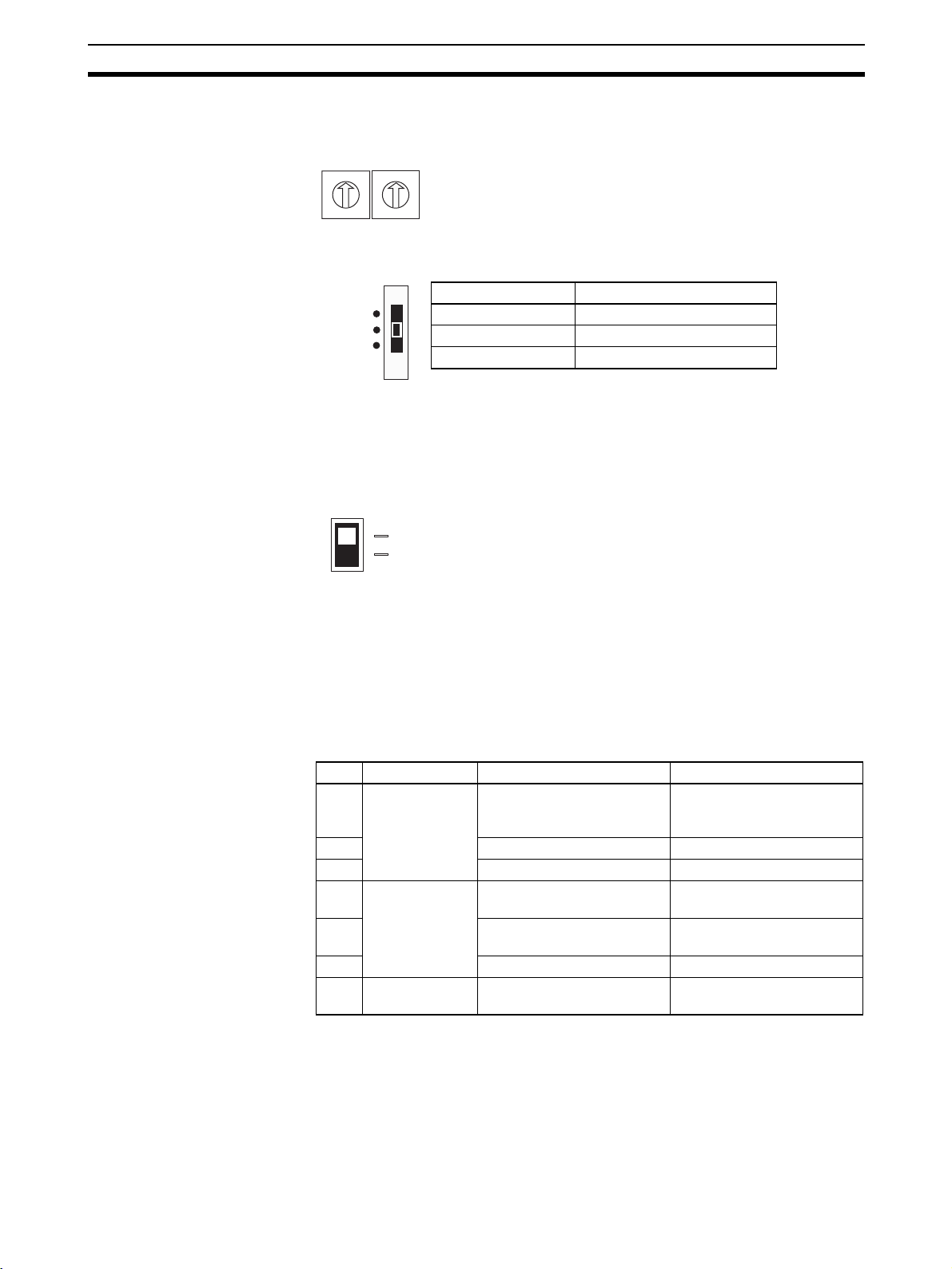

1-2-2 WT30 Terminals: I/O Slave Stations

Appearance

ANT1

ANT2

WT30SID16

(WT30-SID16)

Status indicators

Mode selection switch

Settings

Node Setting Switch

(WNODE)

Antenna terminal (ANT1)

ANT1

PWR E RR

MODE

RUN

TEST

SET

WT30SID16

Power supply terminal

Su

ower to the Unit.

Set the node number of the I/O Slave Station (64 max.). The setting is read

when the power is turned ON. After the power is turned ON, any changes to

the switch setting are ignored. The setting for WT30 Terminals used as Relay

Stations is always 99. The default is 01.

Node setting switch (WNODE)

Set the node number of the I/O Slave Station.

I/O terminal status indicators (0 to 7 or 8 to 15)

The contact status is displayed.

0 1 2 3 4 5 6 7

IN

8 9 10 1 1 12 1 3 14 1 5

WS

MS

W NODE W CH

0

0

0

0

1

9

8

7

6

5

O

123 4 5 6 7 8 9

IN

IN

1

1

9

9

2

2

2

8

8

3

3

3

4

4

4

7

7

6

6

5

5

N

0

FUNCTION

1

9

2

8

3

4

7

6

5

x10 x1 x10 x1

ON

V G 0 1 2 3 COM 4 5 67 COM ERRP

0V 8 9 1 0 11 COM 12 13 14 15 COM ERRN

DC24V

I/O terminals

Connect the contact signals.

Channel setting switch (WCH)

Set the communications frequency.

Antenna terminal (ANT2)

ANT2

RSSI

19

ENTER

Received signal strength indicato

ON

Special function switch

OFF

Function setting switch

Make the detailed settings

for RUN/TEST/SET mode.

10

W NODE

0

1

9

2

8

3

7

4

6

5

X10

0

1

9

2

8

3

7

4

6

5

X1

Nomenclature and Functions Section 1-2

Channel Setting Switch

(WCH)

Set the communications frequency. For details on frequencies, refer to Appendix F Frequency Table on page 105. The default is 02.

W CH

0

1

9

2

8

7

8

3

4

6

5

X10

Mode Selection Switch Set the operation mode of the Serial Slave Station (three positions).

RUN

TEST

SET

By switching the operating mode, a software reset is performed, and the set

value (setting switch setting) is read.

Special Function Switch Use this switch to clear the recorded signal strength or to return to the factory

settings.

ENTER

Setting range: 01 to 34, 51 to 83

0

1

9

2

(The channels 01/51 cannot be used for this product in China.)

3

7

4

6

5

X1

Switch setting Operation mode

RUN RUN mode

TEST TEST mode

SET SET mode

ON

OFF

Power Supply Terminals Supplies 24-VDC (allowable voltage range: 20.4 or 26.4 VDC) power to the

WT30 Terminal. The terminal construction uses a screwless terminal block

(Phoenix Contact: FFKDS/V1-5.08 or equivalent).

I/O Terminals Connect the I/O contact signals.

Antenna Terminal Install an antenna on both the right and left sides. Always use two antennas.

Function Setting Switch Make the detailed settings for I/O Slave Station operations in RUN mode,

TEST mode, and SET mode.

No. Mode ON functions OFF functions

1 RUN mode Holds I/O status data when a

communications error

occurs.

2 Input hold Normal mode

3 Input filter: 100 ms Input filter: 10 ms

4 TEST mode Signal strength monitor dis-

abled

5 All channels automatically

selected

6 Installation test function Nothing done.

7 to 10Not used. --- ---

Clears I/O status data when

a communications error

occurs.

Signal strength monitor

enabled

Specified channel selected

11

Loading...

Loading...