Cat. No. Z910-E1-02

DeviceNet Safety

WS02-CFSC1-E

NE1A Logic Simulator

OPERATION MANUAL

DeviceNet Safety WS02-CFSC1-E NE1A Logic Simulator

Operation Manual

Revised June 2007

iv

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Notation in Operating Procedures

The following conventions are used in the manual in operating procedures.

Menu items are set in bold-italic text and menu levels are separated by hyphens.

Example: “Debug - Input Pulse” indicates selecting “Input Pulse” from the Debug Menu.

Tab, button, and key names are set in bold. Example: OK Button

Other on-screen text is set in bold when necessary for clarity.

Key combinations have been indicated with plus symbols.

Example: “Ctrl+M” indicates pressing the M Key while holding down the Ctrl Key.

v

Conditions for Software Application and Warranty

r

f

Application of and warranty for the NE1A Logic Simulator (hereafter “Software”) are bound by the following Conditions for Application and Warranty. After-sales service will be provided to the customer

based on the enclosed software user registration and upgrade form.

Conditions for Application and Warranty

1. Copyright

The copyright to the Software, including the contents of all enclosed storage media and manuals,

is the property of OMRON Corporation.

2. Copying and Modifying the Software

a. The Software may not be copied in part or whole for any purpose other than as a backup or for

modification as described in b, below.

b. The user may modify the Software to implement changes or improvements provided that the

user himself/herself makes these modifications and provided that the modifications are for application by the user himself/herself. OMRON, however, assumes no responsibility for the results of any modifications made by the used, including defects or damages of any nature.

3. Warranty and After-sales Service

a. If the Software fails to function normally in a manner for which OMRON is responsible, OMRON

will correct or replace the Software free of charge.

b. The warranty in a, above, is valid for one year from the date of purchase.

c. OMRON will provide to customers that return the user registration and upgrade form, informa-

tion on any bugs in the program that become known to OMRON and information on software

upgrades.

d. OMRON assumes no responsibility for the results of the application of the Software and as-

sumes no warranty other than that stated here.

4. Third-party Usage

Providing copies of the Software to any third party in any form or by any means is strictly prohibited.

Registered Trademarks

DeviceNet and DeviceNet Safety are registered trademarks of the ODVA. Windows is a registered

trademark of the Microsoft Corporation.

OMRON, 2007

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

vi

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

SECTION 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 The NE1A Logic Simulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 2

Basic Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2-1 Starting and Exiting the Logic Simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-2 NE1A Logic Simulator Window Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-3 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-4 Pop-up Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-5 Tool Bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-6 Status Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-7 Simulation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-8 Creating Logic Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2-9 Creating Simulation Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-10 Opening Simulation Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-11 Importing Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-12 Debugging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-13 Using the Watch Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

2-14 Saving Simulation Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-15 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-16 Help Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SECTION 3

Debugging with the Logic Window . . . . . . . . . . . . . . . . . . . . 29

3-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3-2 Starting and Stopping the Logic Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-3 Modifying Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-4 Setting Initial Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-5 Setting the Cycle Time Base Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-6 Feedback Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-7 Monitoring a User-defined Function Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-8 Zooming In and Out of the Logic Window Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

vii

TABLE OF CONTENTS

SECTION 4

Debugging with the Timing Chart Window . . . . . . . . . . . . . 41

4-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4-2 Timing Chart Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4-3 Adding to the Timing Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4-4 Inputs to the Timing Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-5 Starting and Stopping the Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4-6 Importing/Exporting Timing Chart Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4-7 Printing the Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4-8 Timing Chart Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4-9 Breakpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4-10 I/O Breakpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4-11 Zooming In and Out of the Timing Chart Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

SECTION 5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5-1 Operating Errors and Countermeasures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Appendix

A Shortcut Key List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

viii

About this Manual:

This manual describes the installation and operation of the Logic Simulator and includes the sections

described below. The NE1A Logic Simulator is a software package that runs on Windows and is used

to simulate and verify the operation of programs for NE1A Safety Network Controllers.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the NE1A Logic Simulator. Please use this manual together with the

DeviceNet Safety System Configuration Manual (Cat. No. Z905) and the Network Configurator Operation Manual (Cat. No. W382). Be sure to read the precautions provided in the following section.

Precautions provides general precautions for using the NE1A Logic Simulator.

Section 1 provides an overview of the NE1A Logic Simulator, including features and system require-

ments.

Section 2 describes the basic operation of the NE1A Logic Simulator.

Section 3 describes how to debug programs for the NE1A Logic Simulator using the Logic Window.

Section 4 describes how to debug programs for the NE1A Logic Simulator using the Timing Chart

Window.

Section 5 describes troubleshooting problems that can occur based on error messages displayed by

the NE1A Logic Simulator.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

x

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

xiv

PRECAUTIONS

This section provides general precautions for using the NE1A Logic Simulator.

The information contained in this section is important for the safe and reliable application of the NE1A Logic

Simulator. You must read this section and understand the information contained before attempting to set up or

operate the NE1A Logic Simulator.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

xv

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems

• Personnel in charge of designing FA systems

• Personnel in charge of managing FA systems and facilities

• Personnel qualified, authorized, and responsible for maintaining safety in

equipment design, installation, operation, maintenance, and disposal

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for installing and operating the NE1A Logic

Simulator. Be sure to read this manual before attempting to use the Simulator

and keep this manual close at hand for reference during operation.

3 Safety Precautions

!WARNING The NE1A Logic Simulator simulates the safety logic of an NE1A Controller.

Operation and timing, however, vary somewhat from that of the NE1A Controller. After debugging safety logic on the NE1A Logic Controller, always debug

the safety logic directly on the NE1A Controller to verify operation. Debugging

only on the NE1A Logic Simulator may result in unexpected operation, possibly causing accidents.

xvi

SECTION 1

Overview

This section provides an overview of the NE1A Logic Simulator, including features and system requirements.

1-1 The NE1A Logic Simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1

The NE1A Logic Simulator Section 1-1

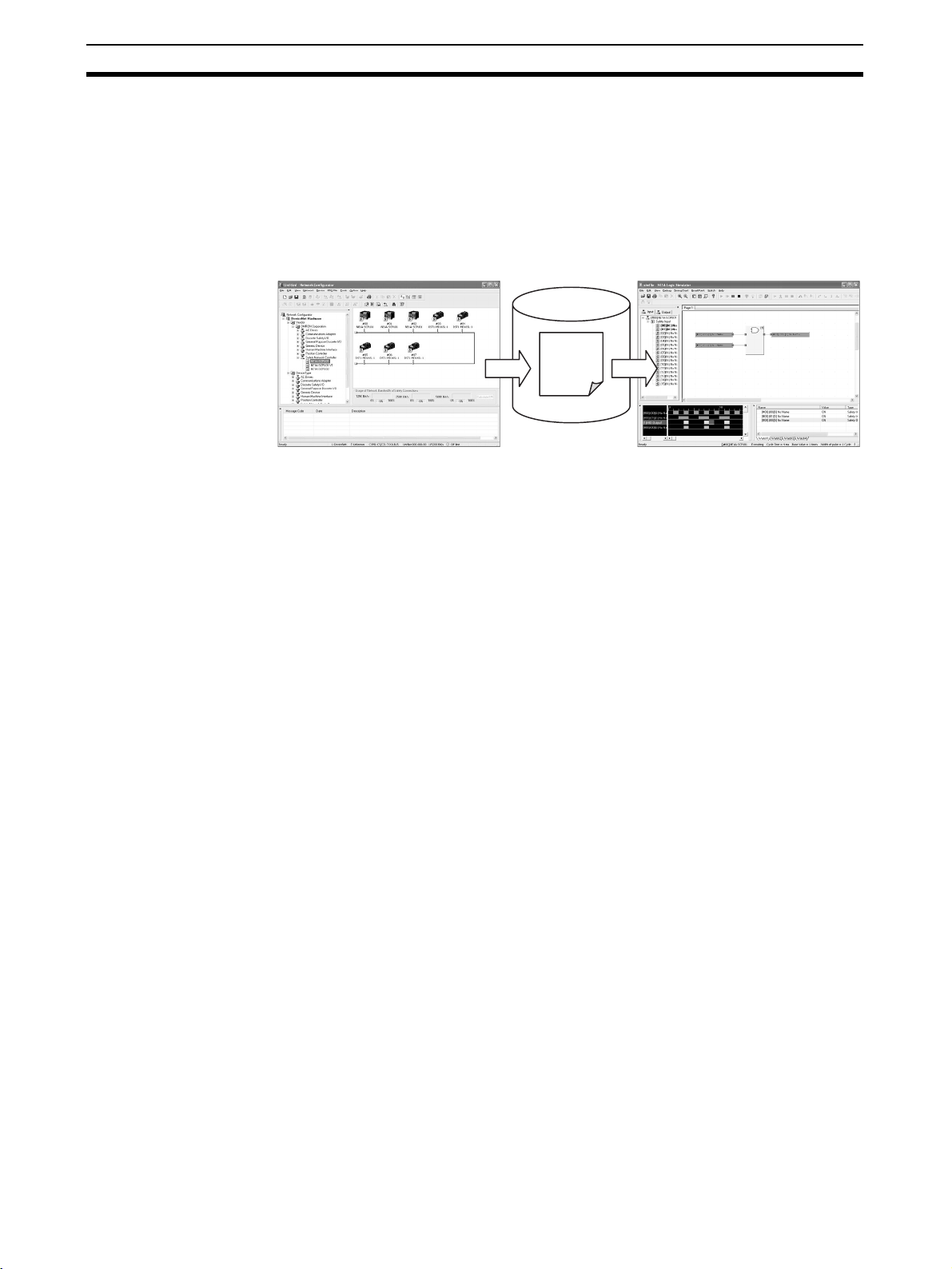

1-1 The NE1A Logic Simulator

The NE1A Logic Simulator provides an offline debugging environment on a

computer by simulating the safety logic operation of an NE1A-series Safety

Network Controller using only software. The NE1A Logic Simulator operates

on Windows 2000 or XP. Logic programs created with the Network Configurator (WS02-CFSC1-E) are loaded as files, and then the virtual safety logic

engine is started.

Hard Disk

*.smr

File

Network Configurator

Note (1) When a logic program that has been created with the Network Configu-

rator is exported from the Network Configurator, a simulation file (*.smr

file) will be created.

The simulation file will be loaded into the NE1A Logic Simulator and simulation will begin.

(2) Safety logic programs can be simulated only for one NE1A-series Con-

troller at a time. Multiple Controllers connected to the same network cannot be linked for simulations.

NE1A Logic Simulator

2

Fe at ur e s Section 1-2

1-2 Features

When using the NE1A Logic Simulator, the following features can be used to

reduce the debug work.

• Input tags can be modified on a screen similar to the logic editor on the

Network Configurator. Corresponding outputs can be verified.

• The Timing Chart Window can be used to run simulations.

• There is a Watch Window, which can be used to monitor registered tags.

3

System Requirements Section 1-3

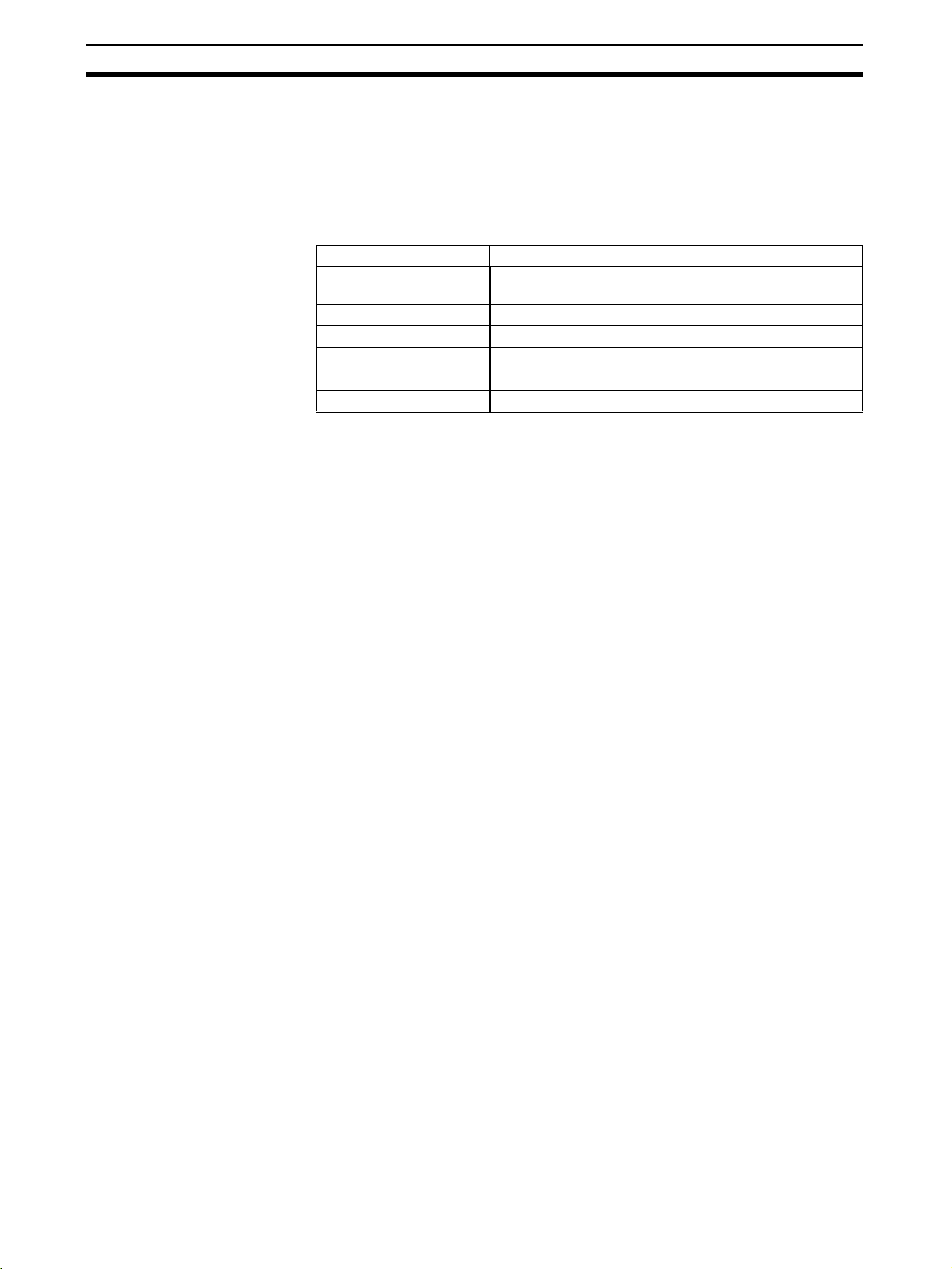

1-3 System Requirements

The NE1A Logic Simulator is compatible with the NE1A-series Network

Safety Controllers.

The following system requirements must be satisfied in order to use the NE1A

Logic Simulator.

Item Specification

Operating system Microsoft Windows 2000

Microsoft Windows XP

Computer hardware IBM PC/AT or compatible with Pentium 300 MHz or better

Memory (RAM) 256 MB min. (512 MB min. recommended)

Hard-disk space 40 MB available space

Display High-definition display, S-VGA (800 × 600) or better

Disk drive CD-ROM drive

Note The specified amount of RAM required relates to the capacity of the program

created by the Network Configurator. If the computer does not contain sufficient RAM, it may slow the performance of the NE1A Logic Simulator.

4

This section describes the basic operation of the NE1A Logic Simulator.

2-1 Starting and Exiting the Logic Simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1-1 Starting the Logic Simulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1-2 Exiting the Logic Simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-2 NE1A Logic Simulator Window Configuration . . . . . . . . . . . . . . . . . . . . . . . 7

2-3 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-4 Pop-up Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-5 Tool Bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-5-1 General Tool Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-5-2 Debug Tool Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-5-3 Timing Chart Tool Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-5-4 Watch Tool Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-6 Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-7 Simulation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-8 Creating Logic Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-9 Creating Simulation Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-10 Opening Simulation Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-11 Importing Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-12 Debugging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-12-1 Debugging with the Logic Window . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-12-2 Debugging with the Timing Chart Window . . . . . . . . . . . . . . . . . . . 21

2-13 Using the Watch Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-13-1 What Is the Watch Window? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-13-2 Displaying/Hiding the Watch Window. . . . . . . . . . . . . . . . . . . . . . . 22

2-13-3 Adding Tags to the Watch Window . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-13-4 Deleting from the Watch Window . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-13-5 Modifying Tag Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-13-6 Moving Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-14 Saving Simulation Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-15 Versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-16 Help Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SECTION 2

Basic Operation

5

Starting and Exiting the Logic Simulator Section 2-1

2-1 Starting and Exiting the Logic Simulator

This section describes how to start and how to exit the NE1A Logic Simulator.

2-1-1 Starting the Logic Simulator

Use the following procedure to start the NE1A Logic Simulator.

1,2,3... 1. Select Start - All Program - OMRON Network Configurator for De-

viceNet Safety - NE1A Logic Simulator.

The NE1A Logic Simulator will start and the following main window will be

displayed.

2-1-2 Exiting the Logic Simulator

Use the following procedure to exit the NE1A Logic Simulator.

1,2,3... 1. Select File - Exit from the main window.

The NE1A Logic Simulator will be closed.

6

NE1A Logic Simulator Window Configuration Section 2-2

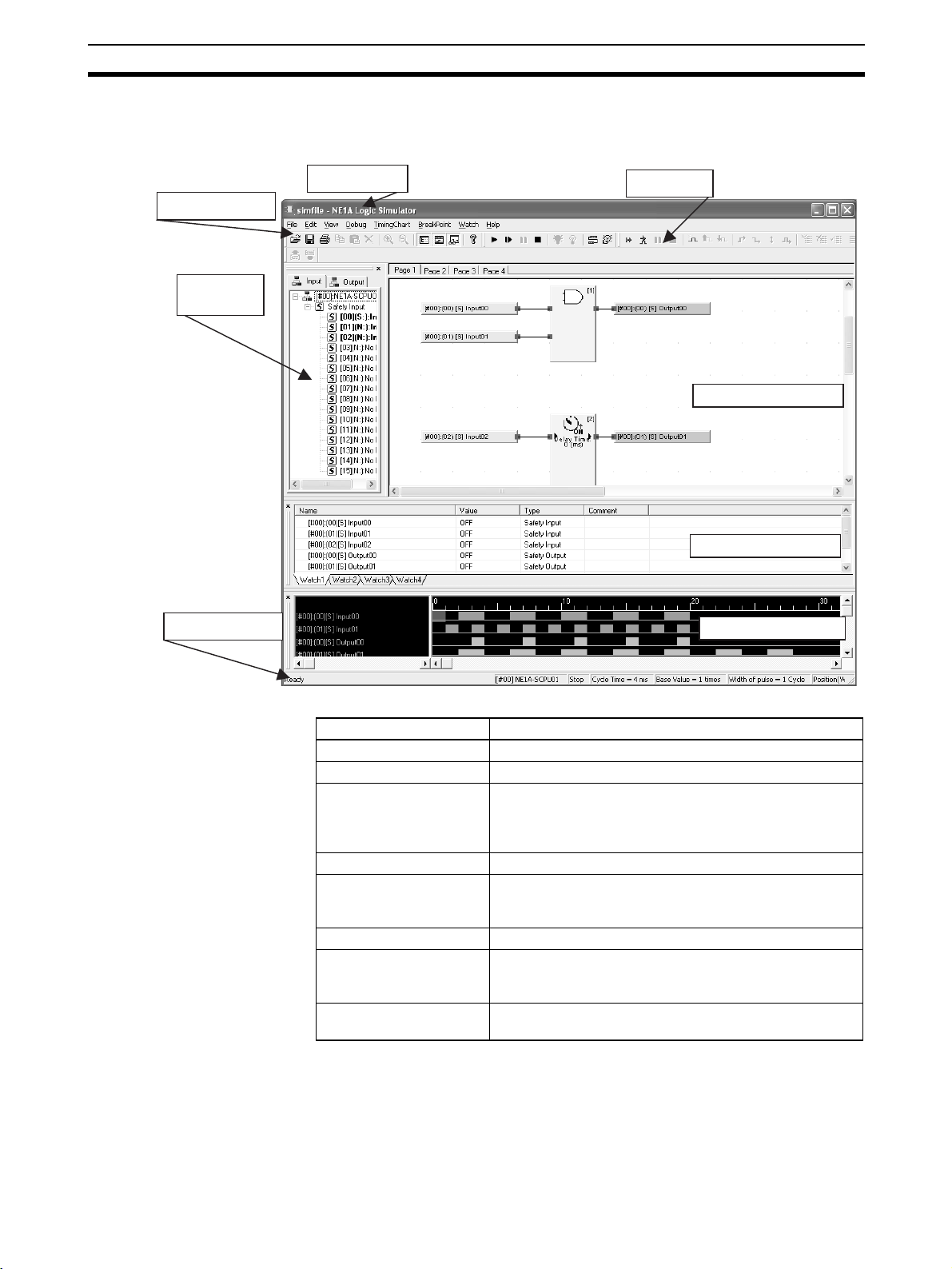

2-2 NE1A Logic Simulator Window Configuration

This section describes the various parts of the NE1A Logic Simulator Window.

Main Menu

Tag List

Window

Status Bar

Title Bar

Tool Bars

Logic Window

Watch Window

Timing Chart Window

Item Function

Title Bar Displays the file name.

Main Menu Used to select menu items.

Tool Bars Used to select functions by clicking icons.The desired tool

Logic Window Displays the logic program.

Tag List Window Displays the tag list.Tags can be set or reset. They can

Timing Chart Window Used to create timing charts and monitor debugging.

Watch Window Used to monitor and set tags.Tags that have been added

Status Bar Displays information such as the device ID, device com-

bars can be displayed by selecting View - Tool Bar. The

position of a tool bar can be changed by dragging it as a

group.

also be selected and added to the Timing Chart Window

or to the Watch Window.

to the Watch Window can be monitored, and their values

can be modified.

ment, debug status, and cycle time.

7

Menus Section 2-3

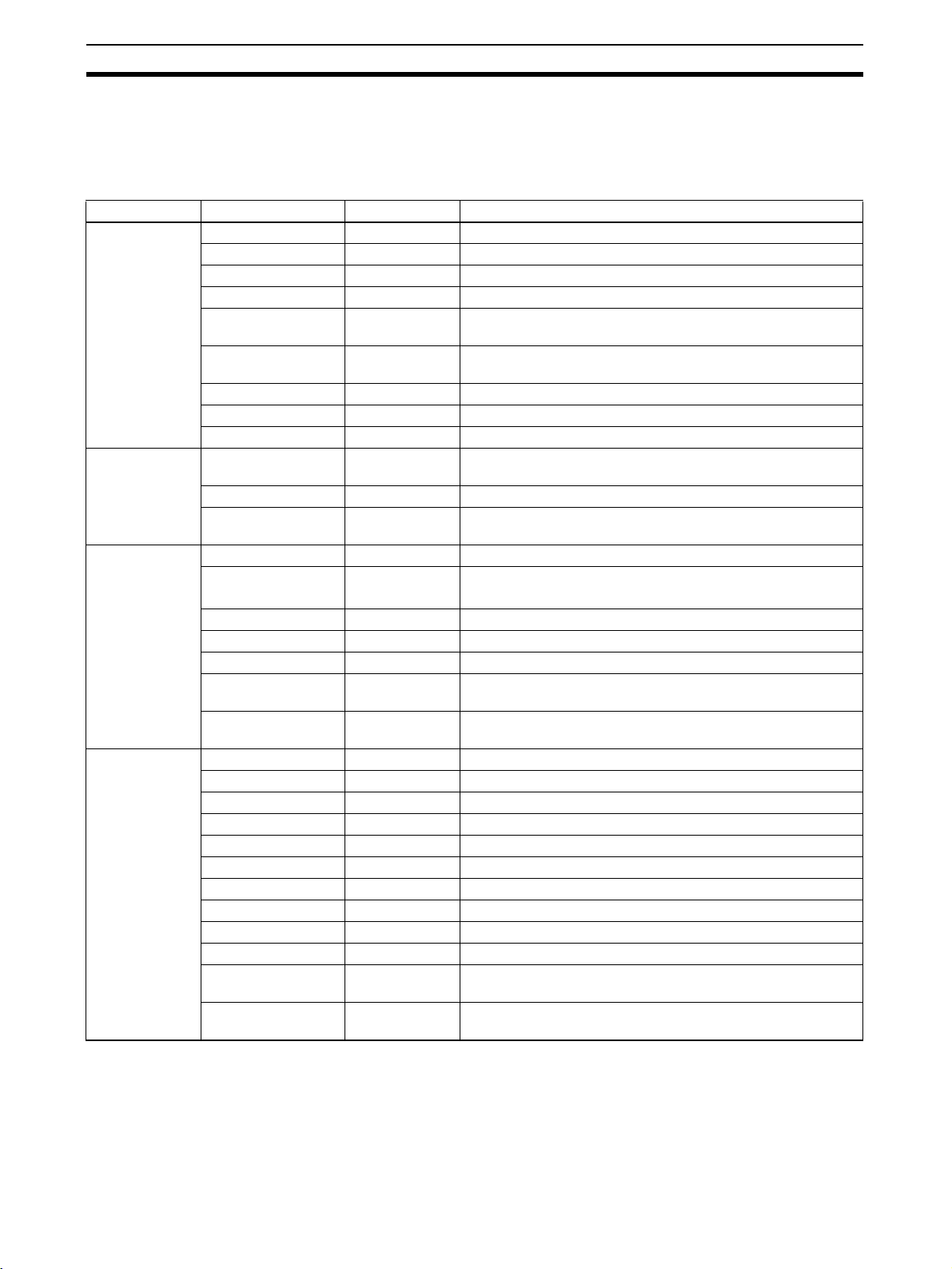

2-3 Menus

Menu items and shortcut keys for the NE1A Logic Simulator are listed in the

following table.

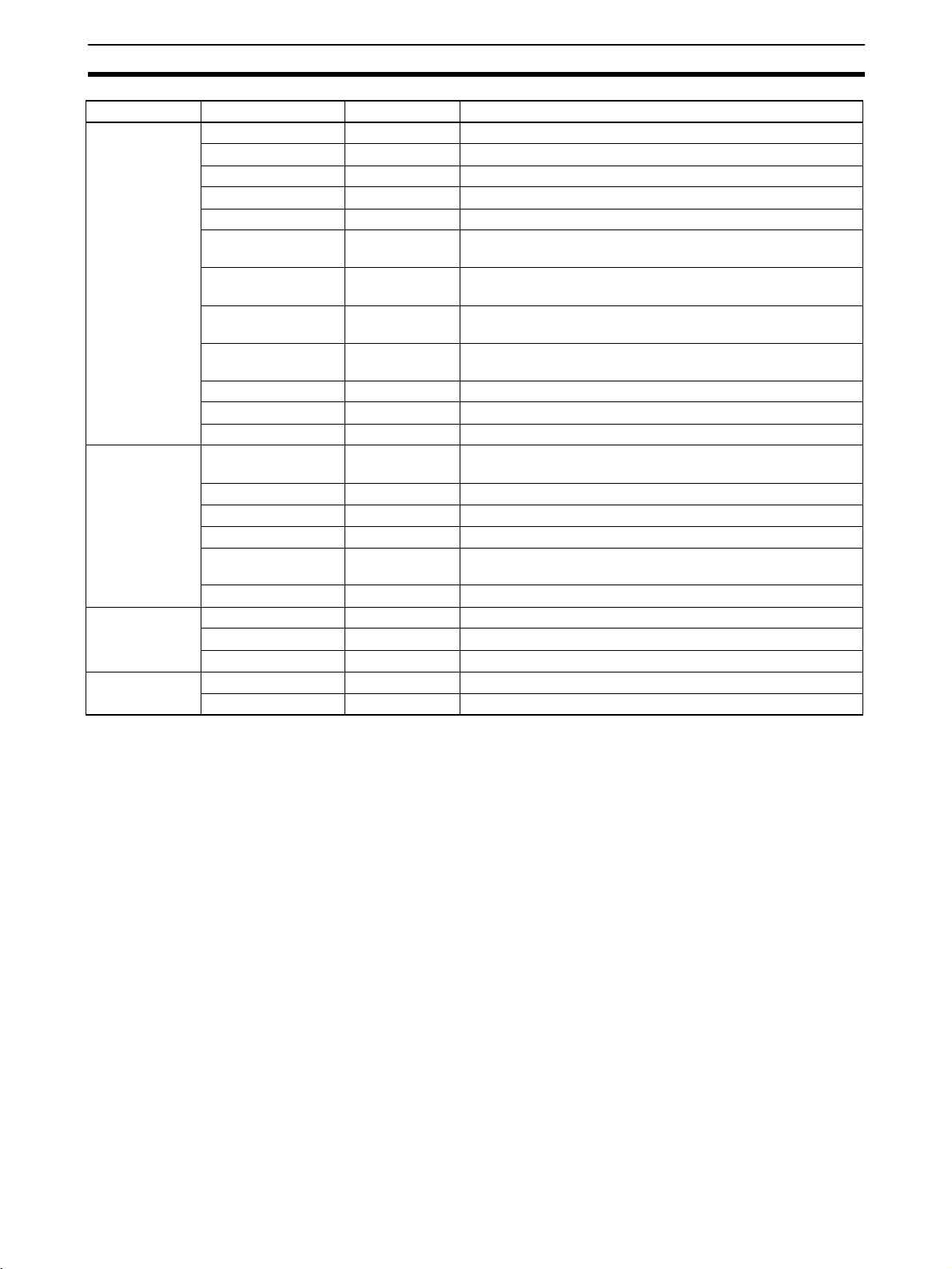

Main menu Item Shortcut key Function

File Open Ctrl+O Opens an existing file.

Save Ctrl+S Overwrites the current working file.

Save As Saves the current working file with a new name.

Import Program Reads in program data from a file.

Import Timing Chart

Data

Export Timing Chart

Data

Print Timing Chart Ctrl+P Prints the timing chart.

Recent Displays recently used files.

Exit Closes the application and saves the file.

Edit Copy Ctrl+C Copies the selected area of the timing chart and saves it to the

Paste Ctrl+V Pastes the contents of the clipboard onto the timing chart.

Delete Del Deletes the selected tags in the Timing Chart Window or

View Tool Bars Displays/Hides the tool bars.

Windows Displays/Hides windows.

Reads in timing chart data from a file.

Writes timing chart data to a file.

clipboard.

Watch Window.

Status Bar Displays/Hides the status bar.

Next Pane F6 Switches to the next pane.

Previous Pane Shift+F6 Switches to the previous pane.

Zoom In Enlarges the display in the Logic Window or the Timing Chart

Window.

Zoom Out Reduces the display in the Logic Window or the Timing Chart

Window.

Debug Start F5 Starts debugging in the Logic Window.

Execute 1 Cycle F10 Executes the logic program for one cycle.

Pause Ctrl+F5 Pauses the logic program.

Stop Shift+F5 Stops and resets the logic program.

Set Ctrl+J Turns ON the selected tags.

Reset Ctrl+K Turns OFF the selected tags.

Reverse Ctrl+R Reverses the selected tags.

Input Pulse Applies a specified pulse input to the selected tag.

Set Initial Values Sets the initial values of tags.

Feedback Settings Makes feedback settings.

Set Cycle Time Base

Val ue

Monitor Function

Block

Sets the cycle time base value for executing the logic program.

Used to monitor user-defined function blocks.

8

Menus Section 2-3

Main menu Item Shortcut key Function

Timing Chart Execute F7 Executes timing chart simulation.

Execute 1 Pulse F8 Executes timing chart simulation for one pulse.

Pause Ctrl+F7 Pauses timing chart simulation.

Stop Shift+F7 Stops and resets timing chart simulation.

Add Tag Insert Adds tags from the tag list to the Timing Chart Window.

ON S Turns ON the selected section of the waveform in the timing

OFF R Turns OFF the selected section of the waveform in the timing

Reverse Space Reverses the selected section of the waveform in the timing

Make Pulses Applies the specified pulses to the selected section of the tim-

Move Up Moves the selected tags in the timing chart upwards.

Move Down Moves the selected tags in the timing chart downwards.

Options Sets the timing chart options.

Breakpoints Register/Unregister F9 Registers/Unregisters a breakpoint at a specified position in

Delete All Shift+F9 Deletes all breakpoints in the timing chart.

Enable Enables the selected breakpoint.

Disable Disables the selected breakpoint.

Display Breakpoint

List

I/O Breakpoint Sets an I/O breakpoint.

Watch Add Tag Ctrl+Insert Adds tags to the Watch Window.

Move Up Moves the selected tags upwards.

Move Down Moves the selected tags downwards.

Help Topics F1 Displays the help file.

About Displays NE1A Logic Simulator version information.

chart.

chart.

chart.

ing chart.

the timing chart.

Displays a list of breakpoints.

9

Pop-up Menus Section 2-4

2-4 Pop-up Menus

Menu options that appear when you right-click on a window are listed.

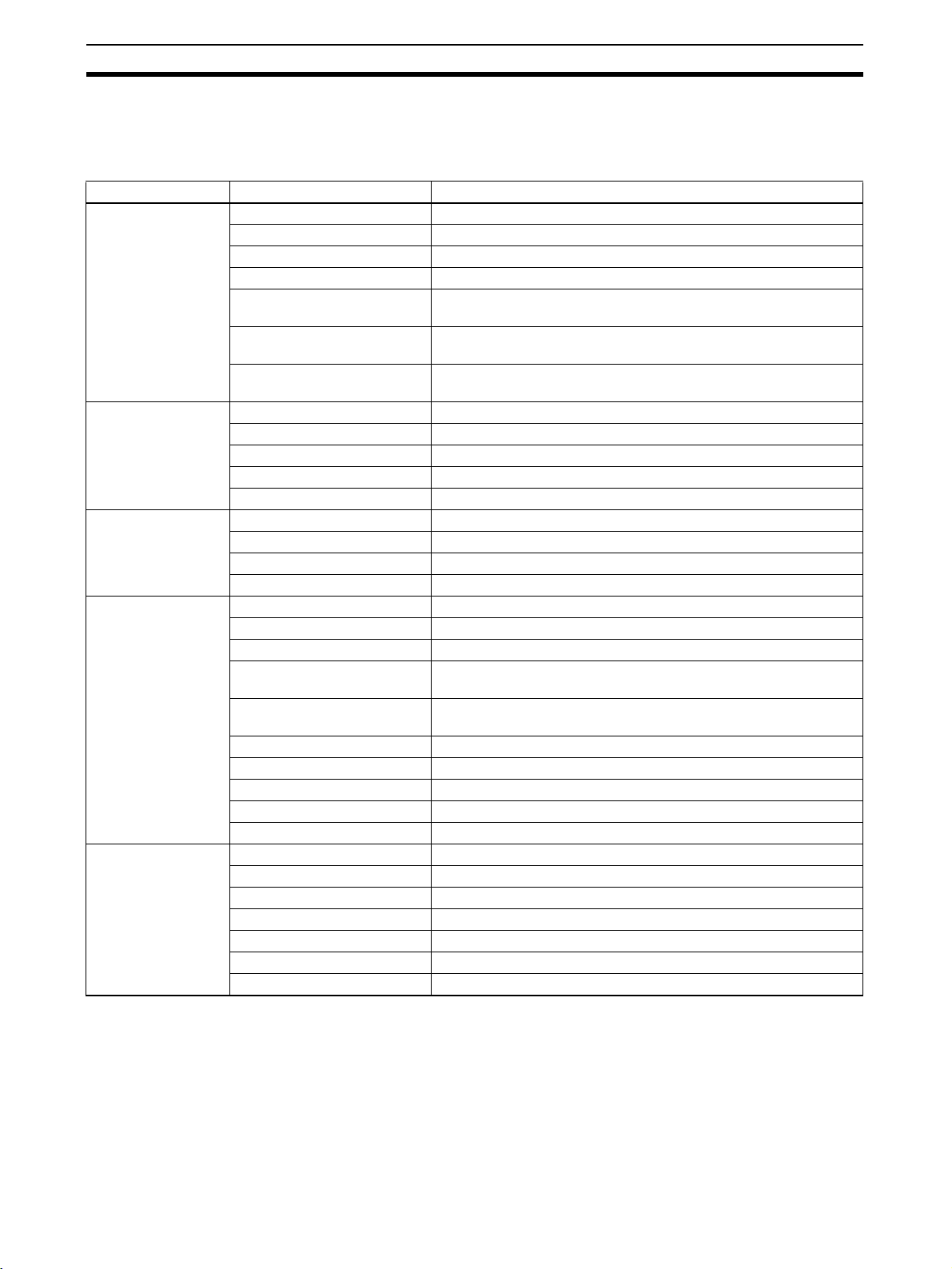

Window Menu item Function

Logic Window Set Turns ON the selected tags.

Reset Turns OFF the selected tags.

Reverse Reverses the selected tags.

Input Pulse Applies a specified pulse input to the selected tag.

Add to Timing Chart Adds the selected tag, jump address, or function block to the Tim-

Add to Watch Adds the selected tag, jump address, or function block to the

Monitor Function Block Monitors the internal functions of the selected user-defined func-

Tag List Window Set Turns ON the selected tags.

Reset Turns OFF the selected tags.

Reverse Reverses the selected tags.

Add to Timing Chart Adds the selected tags to the Timing Chart Window.

Add to Watch Adds the selected tags to the Watch Window.

Timing Chart Window (Tag Part)

Timing Chart (Chart

Part)

Watch Window Set Turns ON the selected tags.

Add Tag Adds tags from the tag list to the Timing Chart Window.

Delete Deletes the selected tags from the Timing Chart Window.

Move Up Moves the selected tags in the timing chart upwards.

Move Down Moves the selected tags in the timing chart downwards.

ON Turns ON the selected section of the timing chart waveform.

OFF Turns OFF the selected section of the timing chart waveform.

Reverse Reverses the selected section of the waveform in the timing chart.

Make Pulses Applies the specified pulses to the selected section of the timing

Copy Copies the selected area of the timing chart and saves it to the

Paste Pastes the contents of the clipboard onto the timing chart.

Breakpoints Registers/Unregisters breakpoints.

I/O Breakpoint Sets, enables, or disables an I/O breakpoint.

Import Timing Chart Data Reads in the timing chart data from a file.

Export Timing Chart Data Writes the timing chart data to a file.

Reset Turns OFF the selected tags.

Reverse Reverses the selected tags.

Input Pulse Applies a specified pulse input to the selected tag.

Delete Deletes the selected tags in the Watch Window.

Move Up Moves the selected tags upwards.

Move Down Moves the selected tags downwards.

ing Chart Window.

Watch Window.

tion block.

chart.

clipboard.

10

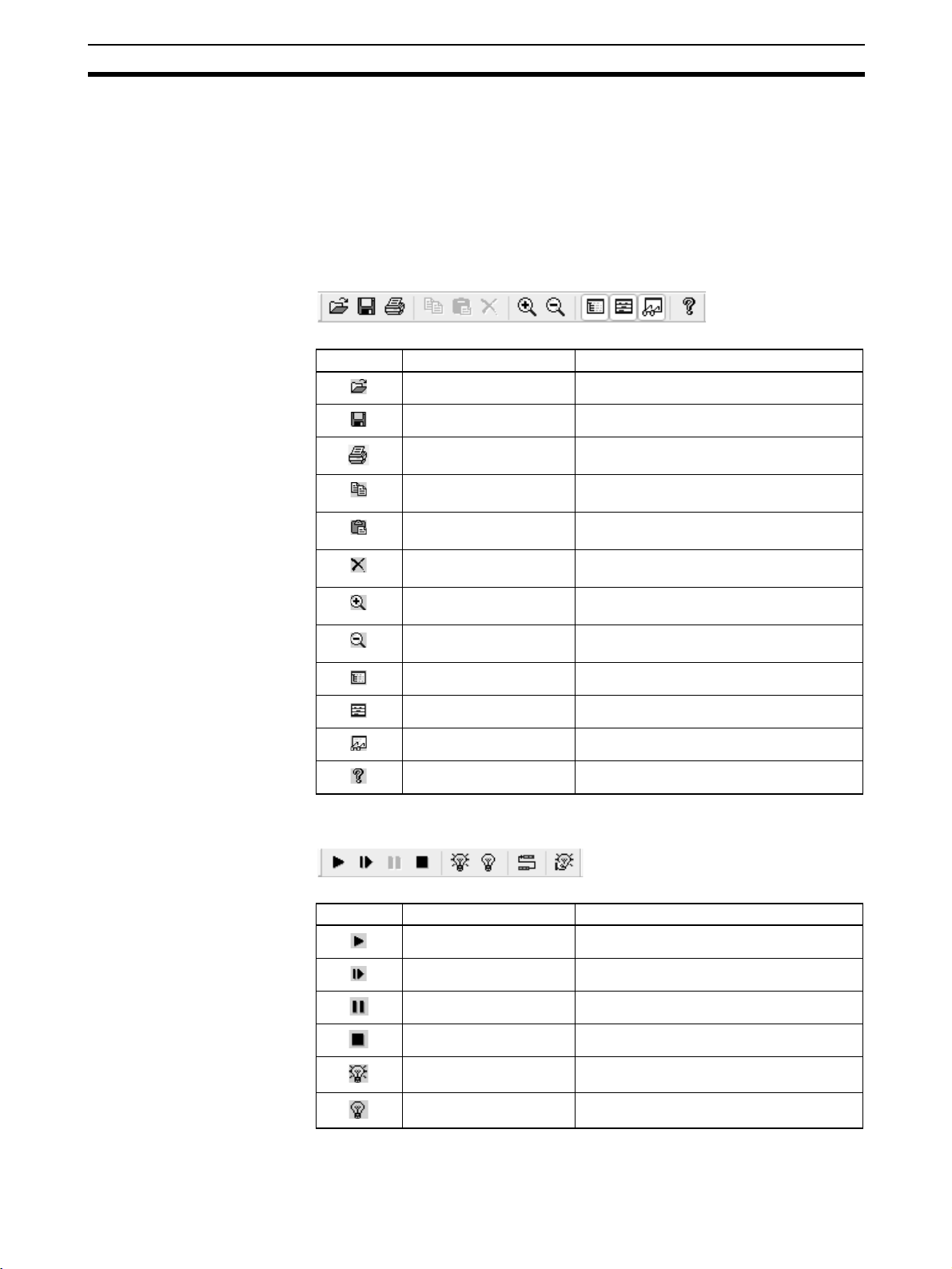

Tool Bars Section 2-5

2-5 Tool Bars

This section describes the functions of the tool bars in the NE1A Logic Simulator.

There are four tool bars in the NE1A Logic Simulator as described below.

Each tool bar can be displayed or hidden by selecting View - Tool Bars fol-

lowed by the name of the tool bar.

2-5-1 General Tool Bar

Icon Function Description

Open File Opens an existing file.

Save File Overwrites the current working file.

Print Timing Chart Prints the timing chart.

Copy Copies the selected area of the timing chart

and saves it to the clipboard.

Paste Pastes the contents of the clipboard onto

the timing chart.

Delete Tag Deletes tags in the Timing Chart Window or

Zoom In Enlarges the display on the Logic Window

Zoom Out Reduces the display on the Logic Window

Tag List Window Displays/Hides the Tag List Window.

Watch Window.

or the Timing Chart Window.

or the Timing Chart Window.

2-5-2 Debug Tool Bar

Timing Chart Window Displays/Hides the Timing Chart Window.

Watch Window Displays/Hides the Watch Window.

Topics Displays the help file.

Icon Function Description

Start Starts debugging in the Logic Window.

Execute 1 Cycle Executes the logic program for one cycle.

Pause Pauses the logic program.

Stop Stops and resets the logic program.

Set Turns ON the selected tags.

Reset Turns OFF the selected tags.

11

Tool Bars Section 2-5

Icon Function Description

Feedback Settings Makes feedback settings.

Set Initial Values Sets the initial values of input tags.

2-5-3 Timing Chart Tool Bar

Icon Function Description

Start Executes timing chart simulation.

Execute 1 Pulse Executes timing chart simulation for one

Pause Pauses timing chart simulation.

Stop Stops and resets timing chart simulation.

Add Tag Adds tags from the tag list to the Timing

Move Up Moves the selected tags in the timing chart

Move Down Moves the selected tags in the timing chart

ON Turns ON the selected section of the wave-

OFF Turns OFF the selected section of the wave-

Reverse Reverses the selected section of the wave-

Make Pulses Applies the specified pulses to the selected

Register/Unregister Registers/Unregisters a breakpoint at a

Delete All Deletes all breakpoints in the timing chart.

Enable Enables the selected breakpoint.

pulse

Chart Window.

upwards.

downwards.

form in the timing chart.

form in the timing chart.

form in the timing chart.

section of the timing chart.

specified position in the timing chart.

12

Disable Disables the selected breakpoints.

Display Breakpoint List Displays a list of the breakpoints.

I/O Breakpoint Sets an I/O breakpoint.

Enable Enables the I/O breakpoint.

Disable Disables the I/O breakpoint.

Tool Bars Section 2-5

2-5-4 Watch Tool Bar

Icon Function Description

Move Up Moves the selected tags in the Watch Win-

Move Down Moves the selected tags in the Watch Win-

dow upwards.

dow downwards.

13

Status Bar Section 2-6

2-6 Status Bar

The following information is displayed in the Status Bar.

Debug Status

ID + Device comment

ID + Device comment Displays the device ID and device comment that have been

Debug Status Displays the debug status: Run, Pause, or Stop

Cycle Time Displays the device cycle time.

Cycle Time Base Value Displays the cycle time base value.

Pulse Width Displays the multiplier of the time width of one pulse in the

Cursor Position Displays the cursor position on the timing chart. The time of

Cycle Time Base Value

Cycle Time

Item Description

set by the Network Configurator.

timing chart against the device cycle time.

the selected section of the pulse is shown in the brackets.

When a timing chart simulation is running, the current execution point will be displayed.

Pulse

Cursor Position

(Selected Pulse Width)

14

Simulation Procedure Section 2-7

2-7 Simulation Procedure

Use the following procedure to simulate execution of a safety logic program.

1. Create a Logic Program

Create a logic program using the logic editor in the Network Configurator.

….Refer to DeviceNet Safety System Configuration Manual (Cat. No. Z905).

2. Create a Simulation File

Create a simulation file (.smr) using the Network Configurator.

….Refer to 2-9 Creating Simulation Files.

3. Read in the File

Open the simulation file (.smr) in the NE1A Logic Simulator or import the program.

….Refer to 2-10 Opening Simulation Files or 2-11 Importing Programs.

4. Execute the Simulation

Execute the simulation in the NE1A Logic Simulator.

….Refer to SECTION 3 Debugging with the Logic Window and SECTION 4 Debugging with the

Timing Chart Window.

15

Creating Logic Programs Section 2-8

2-8 Creating Logic Programs

Logic Programs must be created with the Network Configurator.

For information on creating logic programs using the Network Configurator,

refer to Section 6 Programming the Safety Network Controller in the

DeviceNet Safety System Configuration Manual (Cat. No. Z905).

16

Creating Simulation Files Section 2-9

2-9 Creating Simulation Files

New simulation files (*.smr file) are created with the Network Configurator.

Use the following procedure to create a simulation file.

1,2,3... 1. Select the icon for the device which has the program that you want to sim-

ulate and select Device - Create Simulator File. Alternatively, right-click

on the device icon and select Create Simulator File from the pop-up

menu.

2. The Create Simulator File Dialog Box will be displayed as shown below.

Specify the save location, enter the file name, and then click the Save Button to create a simulation file (*.smr File) in the specified location.

17

Opening Simulation Files Section 2-10

2-10 Opening Simulation Files

Use the following procedure to load the simulation file (*.smr file) to run a simulation.

1,2,3... 1. Select File - Open.

The following dialog box will be displayed.

2. Select the simulation file and click the Open Button.

If there is a password setting on the program in the opened simulation file,

the following Confirm Password Dialog Box will be displayed.

3. Enter the password and click the OK Button.

Note If there is no password setting, the Confirm Password Dialog Box

will not be displayed.

The simulation file (*.smr file) will be loaded and displayed on the screen.

Note To set the password, select the Enable Password Option on the Program Tab

Page of the Edit Device Parameter Dialog Box in the Network Configurator.

18

Importing Programs Section 2-11

2-11 Importing Programs

To load programs from other simulation files, use the program import function.

The program import function only loads the program part of the file; information in the Timing Chart Window and Watch Window will not be changed.

1,2,3... 1. Select File - Import Program.

The following dialog box will be displayed.

2. Select a Simulation File and click the Open Button.

If there is a password setting on the program in the imported simulation file,

the following Confirm Password Dialog Box will be displayed.

3. Enter the Password and click the OK button.

Note If there is no password setting, the Confirm Password Dialog Box

will not be displayed.

The program part of the simulation file will be loaded and the logic program

will be displayed on the screen.

Note (1) After importing the program, if the tags and function blocks used in the

Timing Chart Window and Watch Window are not used within the imported program, their names will appears as “???”. Check these tags to see

if they are required. If they are not required, delete them. The original

names can be displayed again by importing the original program.

(2) To correct a program from a file that is being used in a simulation, edit the

program with the Network Configurator and then create a new simulation

file. Save the new file with a different name to that of the file being used

in the simulation, then import the program from that file. Files can be overwritten while the Logic Simulator is being used but any data other than

the program (i.e., information on the Timing Chart Window and Watch

Window) will all be deleted.

19

Importing Programs Section 2-11

(3) To set the password, select the Enable Password Option on the Program

Tab Page of the Edit Device Parameter Dialog Box in the Network Configurator.

20

Debugging Section 2-12

2-12 Debugging

There are the following two methods for debugging using the NE1A Logic

Simulator.

2-12-1 Debugging with the Logic Window

The Logic Window displays the logic program. It is the similar to the Online

Monitor of the logic editor in the Network Configurator. Input tags can be modified using the Logic Window, Tag List Window, or Watch Window. The corresponding outputs can then be verified. A graphical interface allows for easyto-understand verification, and is suited for verifying simple logic.

Refer to SECTION 3 Debugging with the Logic Window for details.

2-12-2 Debugging with the Timing Chart Window

The user can enter input tag values over time and execute a simulation for

them. By executing the simulation, an output result timing chart can be

obtained that is suited for debugging when the input values change in short

periods of time.

Refer to SECTION 4 Debugging with the Timing Chart Window for details.

21

Using the Watch Window Section 2-13

2-13 Using the Watch Window

This section describes how to use the Watch Window.

2-13-1 What Is the Watch Window?

The Watch Window can list in one window many tags and function block outputs that are located on different pages. Input tag values can be modified from

this window when debugging with the Logic Window,

In the Watch Window there are four tab pages, from Watch 1 to Watch 4. You

can group tags and function block outputs that you want to view together on a

tab page for easy viewing.

The items that are displayed in the Watch Window are listed below.

Item Content

Name Displays tag name or function block output name.

Value Displays tag value or function block output value as either ON

Type Displays tag or function block output type.

Comment Displays the function block name for a function block output

or OFF.

2-13-2 Displaying/Hiding the Watch Window

To display the Watch Window, select View - Windows - Watch from the System Menus. Alternatively, click the Icon on the General Tool Bar

To hide the Watch Window, follow the same steps as displaying the window.

Select View - Windows - Watch. Alternatively, click the Icon on the General Tool Bar or click the Close Button in the Watch Window.

2-13-3 Adding Tags to the Watch Window

Tags can be added to the Watch Window in the following ways.

Note A maximum of 100 tags that can be added to one tab page of the Watch Win-

dow. The same tag can be added more than once.

Adding from a Tag

List

1,2,3... 1. Click a Watch Window Tab (Watch 1 to Watch 4) to select it.

22

Using the Watch Window Section 2-13

2. Select Watch - Add Tag.

The Add Tags to Watch Window Dialog Box will be displayed.

Adding from a Tag

List Window

1,2,3... 1. Click a Watch Window Tab (Watch 1 to Watch 4) to select it.

3. Select the tag to be added to the Watch Window and click the OK Button.

More than on tag can be added at the same time by holding down the Ctrl

Key or Shift Key while selecting the tags.

The selected tags will be added to the Watch Widow as shown below.

Note The names of the Watch Window tabs cannot be changed.

2. Right-click the tag in the Tag List Window to be added to the Watch Window and select Add to Watch.

23

Using the Watch Window Section 2-13

The selected tag will be added to the Watch Window.

Adding from the

Logic Window

1,2,3... 1. Click a Watch Window Tab (Watch 1 to Watch 4) to select it.

2. In the Logic Window, select the tag or function block that you want to add

to the Watch Window. To select more than one tag or function blocks, hold

down the Shift Key while clicking on the tags.

3. Right-click and select Add to Watch.

The selected tags or function blocks will be added to the Watch Window.

2-13-4 Deleting from the Watch Window

Tags can be deleted from the Watch Window in using the following procedure.

24

1,2,3... 1. Select the tag to be deleted from the Watch Window.

2. Select Edit - Delete. Alternatively, right-click and select Delete from the

pop-up menu.

Using the Watch Window Section 2-13

2-13-5 Modifying Tag Values

When the Logic Window is used for debugging, input tags that have been

added to the Watch Window can be set, reset, or reversed.

Note Output tag values or function block output values cannot be modified.

1,2,3... 1. Select a tag from the Watch Window to modify its value. More than one tag

can be selected by holding down the Ctrl Key or the Shift Key while selecting the tags.

2. Select Debug and then Set, Reset, or Reverse. Alternatively, right-click

and select Set, Reset, or Reverse from the pop-up menu.

2-13-6 Moving Tags

Tags that have been added to the Watch Window can be moved up or down.

1,2,3... 1. Select a tag to be moved from the Watch Window. More than one tag can

be selected by pressing the Ctrl Key or the Shift Key while selecting tags.

2. Select Watch - Move Up (or Move Down). Alternatively, right-click and select Move Up (or Move Down) from the pop-up menu.

25

Saving Simulation Files Section 2-14

2-14 Saving Simulation Files

You can save a simulation file (*.smr) by overwriting an existing file or as a

new file with a different name. Saving a file will save the logic program, timing

chart data, and registered watch data in a single file.

Overwriting Simulation

Files

1,2,3... 1. Select File - Save.

The simulation file will be overwritten.

Saving the File with a

Different Name

1,2,3... 1. Select File - Save As.

The following dialog box will be displayed.

2. Change the file name and click the Save Button.

The simulation file will be saved with a different name.

26

Ve r s io n s Section 2-15

2-15 Versions

You can check the version of the NE1A Logic Simulator using the following

procedure.

1,2,3... 1. Select Help - About.

The NE1A Logic Simulator Dialog Box will be displayed.

27

Help Display Section 2-16

2-16 Help Display

This section describes how to display the NE1A Logic Simulator Help.

1,2,3... 1. Select Help - Topics.

The Help Menu will be displayed.

28

SECTION 3

Debugging with the Logic Window

This section describes how to debug programs for the NE1A Logic Simulator using the Logic Window.

3-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3-2 Starting and Stopping the Logic Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-2-1 Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-2-2 Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-2-3 Pausing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-2-4 Executing One Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-3 Modifying Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-3-1 Setting, Resetting, and Reversing . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-3-2 Inputting Pulses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-4 Setting Initial Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-5 Setting the Cycle Time Base Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-6 Feedback Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-7 Monitoring a User-defined Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-8 Zooming In and Out of the Logic Window Display . . . . . . . . . . . . . . . . . . . . 39

29

Overview Section 3-1

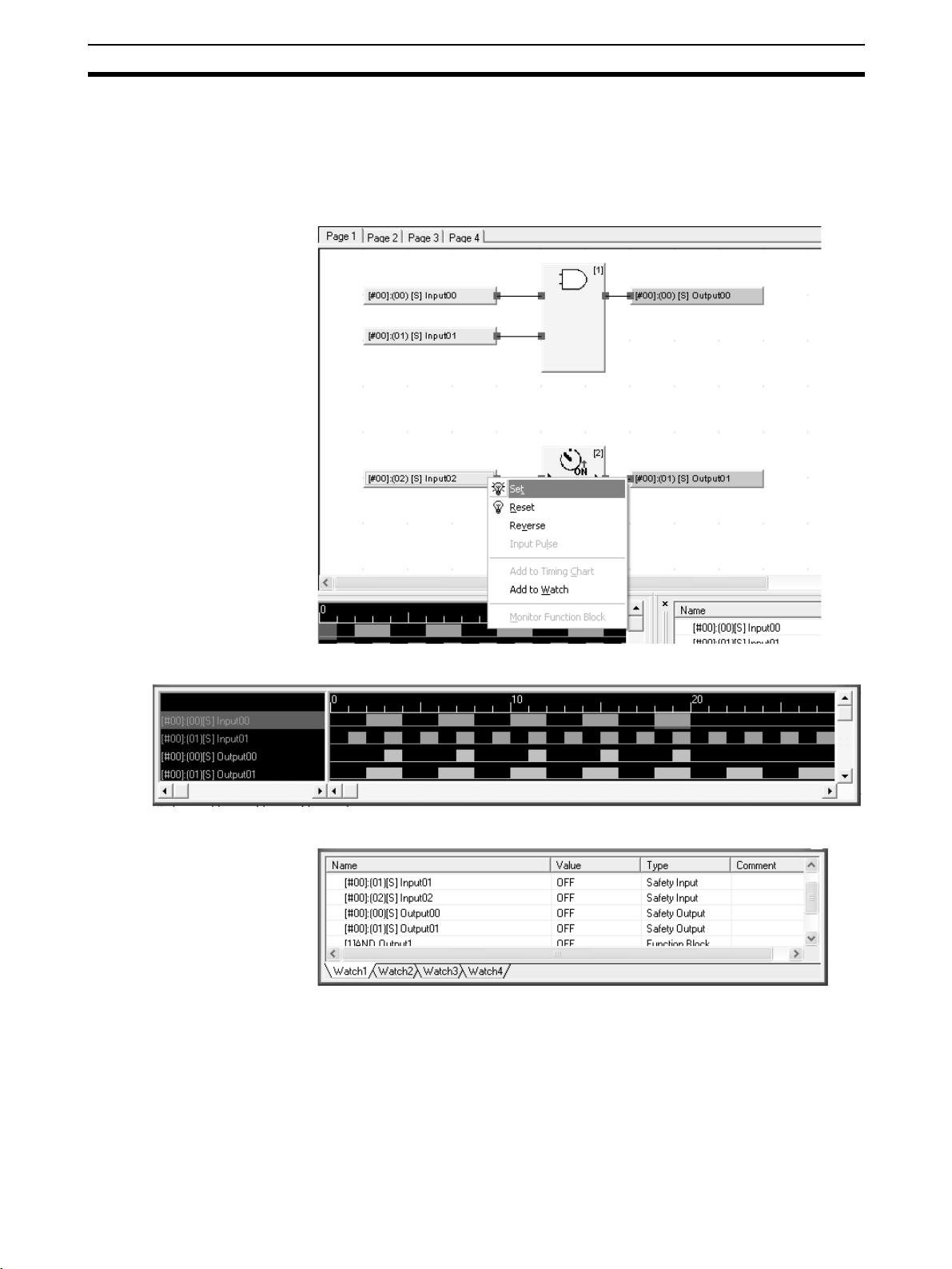

3-1 Overview

This section describes how to debug using the Logic Window.

The Logic Window displays the Logic Program. Input tags can be modified

using the Logic Window, Tag List Window, or the Watch Window. The corresponding outputs can then be verified. Similar to the Online Monitor Screen

for the Logic Editor of the Network Configurator, tags that are ON and lines

that are connected are displayed in dark green.

Note The Timing Chart Window and the Logic Window cannot be used for debug-

ging simultaneously.

A program simulation using an AND function block is shown as an example

below.

Input 1 is ON and input 2 is OFF. Therefore the output (output 1) of the AND

function block is OFF.

Note Tags that are ON and lines that are connected are displayed in dark

green.

Now, input 2 is modified by right-clicking it and selecting Set from the pop-up

menu.

As shown below, input 1 and input 2 turn ON and the AND function block output (output 1) turns ON.

30

Starting and Stopping the Logic Program Section 3-2

3-2 Starting and Stopping the Logic Program

This section describes how to start and stop a logic program.

3-2-1 Starting

To start a logic program when it is stopped or paused, select Debug - Start.

Alternatively, click the Icon on the tool bar.

The logic program will begin execution. Input tags can be modified and the

corresponding outputs verified while in this state.

3-2-2 Stopping

To stop a logic program when it is being executed or when it is paused, select

Debug - Stop. Alternatively, click the Icon on the tool bar.

The logic program will stop. When the program is stopped, it will be reset and

all input and output tags will return to their initial values.

3-2-3 Pausing

To pause execution of a logic program while it is being executed, select

Debug - Pause. Alternatively, click the Icon on the tool bar.

Execution of the logic program will pause.

3-2-4 Executing One Cycle

To execute one cycle of the logic program when it is stopped or paused, select

Debug - 1 Cycle Execute. Alternatively, click the Icon on the tool bar.

The logic program will be executed for one cycle and then pause.

31

Modifying Input Tags Section 3-3

3-3 Modifying Input Tags

This section describes how to modify input tags.

3-3-1 Setting, Resetting, and Reversing

Set, reset, and reverse functions can be applied in the Logic Window, Tag List

Window, or Watch Window. Set turns ON a value, Reset turns OFF a value,

and Reverse turns OFF a value if it's ON and turns ON a value if it's OFF.

Modifying Tags from

the Logic Window

Modifying Tags from

the Tag List Window

Modifying Tags from

the Watch Window

Note Tags that have been selected in a window can be set or reset by clicking the

Select an input tag in the Logic Window and select Set, Reset, or Reverse

from the Debug Menu. These functions can be applied also by right-clicking

and selecting menu items from the pop-up menu or selecting icons from the

tool bar.

More than one tag can be selected and modified at once. To select more than

one tag, hold down the Shift Key while selecting tags with the mouse in the

Logic Window, or make a block selection by dragging the mouse.

Select an input tag in the Tag List Window and select Set, Reset, or Reverse

from the Debug Menu. These functions can be applied also by right-clicking

and selecting a menu item from the pop-up menu or selecting icons from the

tool bar. More than one tag can be selected and applied at once. To select

more than one tag, hold down the Shift Key while selecting tags with the

mouse in the Tag List Window.

Select an input tag in the Watch Window and select Set, Reset, or Reverse

from the Debug Menu. These functions can be applied also by right-clicking

and selecting a menu item from the pop-up menu or selecting icons from the

tool bar. More than one tag can be selected and applied at once. To select

more than one tag, hold down the Ctrl Key or Shift Key while selecting tags

with the mouse from the Watch Window.

Set () or Reset ( ) Icon in the Debug Tool Bar.

3-3-2 Inputting Pulses

A pulse input can be applied to an input tag. Use the following procedure to

apply a pulse input.

1,2,3... 1. Select an input tag in the Logic Window.

2. Select Debug - Input Pulse. (Alternatively, right-click on the input tag and

32

select Input Pulse from the pop-up menu.)

The following dialog box will be displayed.

Modifying Input Tags Section 3-3

3. Enter the OFF and ON times and click the OK Button. The time settings for

both the OFF and ON times must be between 100 and 10,000 ms. The

time setting specified here is the program time. Simulation with the Logic

Simulator will be executed based on the time set here, multiplied by the cycle time base value.

The shape of the input pulse is shown below.

ON

OFF

Present

value

OFF time

Click the OK

ON time

33

Setting Initial Values Section 3-4

3-4 Setting Initial Values

The initial values of input tags can be entered when debugging with the Logic

Window. Use the following procedure to set the initial values of input tags.

1,2,3... 1. Select Debug - Set Initial Value.

The following dialog box will be displayed.

2. Select an input tag to set the initial value for debugging. To select more

than one tag, hold down the Shift Key or the Ctrl Key while selecting tags

with the mouse.

3. Click the buttons on the right of the Input Tag List to set the initial values

and then click the OK Button.

Functions of the buttons are given below.

Button Function

ON/OFF Turns ON to OFF, and OFF to ON.

All ON Turns ON all tags.

All OFF Turns OFF all tags.

Current Value Sets the tag to its present value.

When the OK Button is clicked and the dialog box is closed, the settings

will be reflected in the program.

Note The tags in the Input Tag List can be set to ON or OFF by double-clicking

them.

34

Setting the Cycle Time Base Value Section 3-5

3-5 Setting the Cycle Time Base Value

The cycle time base value is a multiplier applied to the actual device cycle

time. When the cycle time base value is 1, the simulator runs based on the

same cycle time as the actual device. If the value is larger than 1, the simulation can be made slower than the actual device, so that delay times and discrepancy times can be checked. For example, if the delay function block is set

to 300 ms and the cycle time base value is set to 10, the delay in the logic

simulator will be 3 seconds.

Use the following procedure to set the cycle time base value. The setting cannot be changed if debug is being executed or paused.

1,2,3... 1. Select Debug - Cycle Time Base Value.

The following dialog box will be displayed.

2. Set the Cycle Time Base Value between 1 and 1,000, and then click the

OK Button.

The product of the cycle time and the cycle base value (ms) will become

one cycle of the debug process.

Note The cycle time is determined by the Network Configurator based on

the program size and other factors. It is only displayed for reference

in this window and cannot be modified.

Note (1) If the cycle time base value is set to a small value and the CPU perfor-

mance of the computer is low, CPU utilization will become high. When

this happens, it may create a time error in the input pulse or feedback settings. This may interfere with correct operation of the program. If this occurs, increase the cycle time base value to reduce the error.

(2) The cycle time base value set here does not affect debugging using the

Timing Chart Window.

35

Feedback Settings Section 3-6

3-6 Feedback Settings

If the EDM input (monitored input) is changed while the program is being executed when using EDM function blocks, the EDM feedback signal will not

change and will trigger a feedback error. Use the feedback settings to link the

reverse output signal to the EDM feedback signal in the EDM function block to

avoid feedback errors.

Note Feedback settings operate based on the Windows timer, which has error. The

error becomes larger particularly when the load on Windows is high. If this

happens, feedback error may occur even if feedback settings have been

made. To avoid feedback errors, make the cycle time base setting larger than

the current value.

Use the following procedure to set the feedback settings.

1,2,3... 1. Select Debug - Feedback Settings.

The Feedback Dialog Box will be displayed.

36

Item Description

Input Tag Specifies the input tag to be used in the feedback settings.

Output Tag Specifies the output tag that is linked to the input tag.

Delay Specifies the delay time between 50 and 1000 ms.

Condition Sets whether the value is reversed or not. Select the cell when

the reverse of the output tag is to be assigned to the input tag.

Feedback Settings Section 3-6

2. Select or assign the input tag, output tag, delay time, and condition in the

feedback settings, and then click the Add Button.

The feedback settings will be added to the registered list as shown below.

• To correct feedback settings that have already been registered, select the

desired setting from the Registered List Area, change the contents, and

then click the Add Button again.

• To delete registered feedback settings, select the desired setting from the

Registered List Area and click the Delete Button.

Note A maximum of 200 feedback settings can be registered.

37

Monitoring a User-defined Function Block Section 3-7

3-7 Monitoring a User-defined Function Block

This section describes how to monitor the contents of a user-defined function

block.

1,2,3... 1. Right-click a user-defined function block in the Logic Window and select

Monitor Function Block from the pop-up menu.

The User-defined Function Block Window will be opened as shown below.

The contents of the selected user-defined function block will be displayed.

38

The User-defined Function Block Window has the following functions.

Main menu Menu item Function

File Exit Exits the user-defined function block

monitor and closes the window.

View Tool Bar Displays/hides the tool bar.

Zoom In Enlarges the display.

Zoom Out Reduces the display.

Note (1) Input tags cannot be modified directly from the User-defined Function

Block Window. Go to the Logic Window, Tag List Window, or the Watch

Window to modify them.

(2) If the user-defined function block file does not exist, it cannot be moni-

tored. Import the function block using the logic editor in the Network Configurator.

Zooming In and Out of the Logic Window Display Section 3-8

3-8 Zooming In and Out of the Logic Window Display

Use the following procedure to zoom in and out of the display in the Logic

Window.

1,2,3... 1. Click in the Logic Window (or press F6/Shift + F6) to move to the Logic

Window.

2. Select View - Zoom In or View - Zoom Out.

This will zoom in or out of the display in the Logic Window.

This function can only be used in the Logic Window.

Note Pressing the Ctrl Key while moving the mouse wheel up or down will also

zoom in and out of the display in the Logic Window.

39

Zooming In and Out of the Logic Window Display Section 3-8

40

SECTION 4

Debugging with the Timing Chart Window

This section describes how to debug programs for the NE1A Logic Simulator using the Timing Chart Window.

4-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4-2 Timing Chart Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4-3 Adding to the Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-3-1 Adding from the Tag List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-3-2 Adding from the Tag List Window. . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-3-3 Adding from the Logic Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-4 Inputs to the Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-4-1 Basic Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-4-2 Pulse Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-4-3 Copying and Pasting in the Timing Chart. . . . . . . . . . . . . . . . . . . . . 45

4-4-4 Editing the Timing Chart with a Text Editor . . . . . . . . . . . . . . . . . . 46

4-5 Starting and Stopping the Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4-6 Importing/Exporting Timing Chart Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4-6-1 Importing Timing Chart Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4-6-2 Exporting Timing Chart Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4-7 Printing the Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4-8 Timing Chart Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4-8-1 Displaying the Timing Chart Options Dialog Box . . . . . . . . . . . . . . 51

4-8-2 Setting Tab Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4-8-3 View Tab Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4-8-4 Print Tab Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4-9 Breakpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4-9-1 Adding Breakpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4-9-2 Deleting Breakpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4-9-3 Enabling/Disabling Breakpoints. . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4-9-4 Breakpoint List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4-10 I/O Breakpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4-10-1 I/O Breakpoint Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4-10-2 Enabling/Disabling the I/O Breakpoint . . . . . . . . . . . . . . . . . . . . . . 57

4-11 Zooming In and Out of the Timing Chart Display . . . . . . . . . . . . . . . . . . . . . 58

41

Overview Section 4-1

4-1 Overview

This section describes how to debug a program using the Timing Chart Window.

The debugging process starts with assigning input values to tags in the timing

chart, executing the logic program, then displaying the output results.

Pulses can be specified in terms of the device cycle time when using the Timing Chart Window. This makes it possible to run simulations for inputs that

fluctuate quickly, which is not possible when debugging with the logic window.

Note Debugging cannot be performed simultaneously using both the Timing Chart

Window and the Logic Window.

42

Timing Chart Window Section 4-2

4-2 Timing Chart Window

This section describes the various parts of the Timing Chart Window.

The tags and function block outputs are displayed on the left of the window.

The corresponding chart is displayed on the right.

Input Tag, Output Tag, or

Function Block Output

Pulse Scale

Cursor

Chart

43

Adding to the Timing Chart Section 4-3

4-3 Adding to the Timing Chart

Use the following procedure to add a tag or a function block output to the timing chart. A maximum of 1,000 tags can be added to a timing chart.

4-3-1 Adding from the Tag List

1,2,3... 1. Select Timing Chart - Add Tag.

2. Select the tag to be added to the timing chart and click the OK Button. The

tag will be added to the timing chart.

More than one tag can be added at the same time by holding down the Ctrl

Key or Shift Key while selecting the tags.

4-3-2 Adding from the Tag List Window

1,2,3... 1. In the Tag List Window, select the tag to be added to the timing chart.

2. Right-click and select Add to Timing Chart from the pop-up menu.

The tag will be added to the timing chart.

4-3-3 Adding from the Logic Window

1,2,3... 1. Select an input tag, output tag, jump address, or function block from the

logic window to be added to the timing chart. More than one item can be

selected by holding down the Shift Key while selecting the items.

2. Right-click and select Add to Timing Chart from the pop-up menu.

The tags will be added to the timing chart.

44

Inputs to the Timing Chart Section 4-4

4-4 Inputs to the Timing Chart

This section explains how to apply inputs to the tags that have been added to

the timing chart. The output tags, jump address, and function blocks cannot

be changed.

4-4-1 Basic Input

Use the following procedure to turn the input tags to ON or OFF or to reverse the tag

status.

1,2,3... 1. Move the cursor to the area where you want to apply an input to the timing

chart. An area can be selected.

2. Select ON, OFF, or Reverse from the Timing Chart Menu.

4-4-2 Pulse Setting

A specified pulse can be assigned using the following procedure.

1,2,3... 1. Select the area on the timing chart where you want to apply the set pulses.

2. Select Timing Chart - Make Pulses. Alternatively, right-click in the selected area and select Make Pulses from the pop-up menu.

The following dialog box will be displayed.

3. Set the number of pulses and the start pulse, and then click the OK Button.

The specified pulses will be applied to the selected area.

4-4-3 Copying and Pasting in the Timing Chart

1,2,3... 1. Select the area on the timing chart to be copied.

2. Select Edit - Copy. Alternatively, right-click and select Copy from the pop-

up menu.

3. Move the cursor to where you want to paste and select Edit - Paste. Alternatively, right-click and select Paste from the pop-up menu.

45

Inputs to the Timing Chart Section 4-4

4-4-4 Editing the Timing Chart with a Text Editor

The timing chart can be edited with a text editor by using the copy and paste

functions.

1,2,3... 1. Select the area of the timing chart that you want to edit.

2. Select Edit - Copy.

The contents will be copied to the clipboard.

3. Start a text editor and paste the content of the clipboard in it. The data will

be displayed in 0s and 1s as shown below.

4. After the text has been edited, copy the text in the text editor to the clipboard.

5. Go to the timing chart and select Edit - Paste.

Note When using a text editor to edit the timing chart, do not delete the first line

'NE1ASimulatorTimingChart'. If this line is missing, or characters other than 0

and 1 are entered, the data cannot be pasted.

46

Starting and Stopping the Timing Chart Section 4-5

4-5 Starting and Stopping the Timing Chart

This section describes how to start and stop timing chart simulations.

To start timing chart simulations, the logic program must be stopped.

When the timing chart simulation is being executed, the input tags and output

tags that are displayed in the logic window will not be updated. The display will

be updated when the simulation is paused.

The display in the Watch Window will be updated regardless of whether the

timing chart simulation is executing or has stopped.

Starting the Timing Chart

1,2,3... 1. Select Timing Chart - Execute 1 Pulse, or click the Icon on the Timing

Chart Tool Bar.

The timing chart simulation will be started.

Pulse Execute on the

Timing Chart

1,2,3... 1. Select Timing Chart - Execute 1 Pulse, or click the Icon on the Timing

Chart Tool Bar.

The timing chart simulation will be executed for one pulse.

When it has finished, simulation will be paused.

Stopping the Timing Chart

1,2,3... 1. Select Timing Chart - Stop, or click the Icon on the Timing Chart Tool

Pausing the Timing Chart

1,2,3... 1. Select Timing Chart - Pause, or click the Icon on the Timing Chart

Note Breakpoints and an I/O breakpoint can be set in the timing chart. Refer to 4-9

Bar.

The timing chart simulation will be stopped.

When the timing chart simulation is stopped, the input tags displayed in the

Logic Window and Watch Window will be set to their initial values.

Tool Bar.

The timing chart simulation will be paused.

Breakpoints and 4-10 I/O Breakpoint on for details on setting breakpoints.

47

Importing/Exporting Timing Chart Data Section 4-6

4-6 Importing/Exporting Timing Chart Data

Data in the Timing Chart Window can be saved to a file or read in from a file.

The file extension is *.tcd.

4-6-1 Importing Timing Chart Data

1,2,3... 1. Select File - Import Timing Chart Data.

The following dialog box will be displayed.

2. Select a timing chart data file (*.tcd) and click the Open Button.

The timing chart data will be read in and displayed on the timing chart.

Note Importing a file will overwrite the data that is currently being dis-

played on the timing chart. If you need to save the data currently in

the timing chart, export it before importing a file.

4-6-2 Exporting Timing Chart Data

1,2,3... 1. Select File - Export Timing Chart Data.

The following dialog box will be displayed.

48

2. Specify the save location and the filename (*.tcd) of the timing chart data,

and then click the Save Button.

The timing chart data file will be saved.

Importing/Exporting Timing Chart Data Section 4-6

Note The breakpoint information described in 4-9 Breakpoints and 4-10 I/O Break-

point will not be included in the timing chart data export file.

49

Printing the Timing Chart Section 4-7

4-7 Printing the Timing Chart

The timing chart can be printed.

1,2,3... 1. Select File - Print Timing Chart.

The standard Windows Print Dialog Box will be displayed.

2. Set the printing properties as required, and click the OK Button.

The timing chart will be printed.

Note The contents that is printed can be specified on the Print Tab Page of the Tim-

ing Chart Option Dialog Box. Refer to 4-8-4 Print Tab Page for details on set-

tings.

50

Timing Chart Options Section 4-8

4-8 Timing Chart Options

This section describes the timing chart option settings. The timing chart

option settings can be changed in the Timing Chart Options Dialog Box.

4-8-1 Displaying the Timing Chart Options Dialog Box

1,2,3... 1. Select Timing Chart - Options.

The Timing Chart Options Dialog Box will be displayed.

4-8-2 Setting Tab Page

The pulses used in the timing chart can be set up on the Configuration Tab

Page.

1,2,3... 1. Click the Configuration Tab in the Timing Chart Options Dialog Box.

51

Timing Chart Options Section 4-8

The pulse configuration consists of the following items.

Parameter/button Description

Number of Pulses Specifies the number of pulses that are used in the timing

Pulse Width Specifies the width of one pulse as a multiple of the device

Pulse Time Displays the time of one pulse. (Cycle time (ms) × Pulse width

Initialize Button Returns the number of pulses and pulse width to their initial

2. Modify the pulse settings and click the OK Button.

Note If a value smaller than the current number of pulse is entered, the following

dialog box will be displayed.

chart. The number of pulses can be set to between 10 and

1,000. (The initial value is 100.)

cycle time. The pulse width can set to between 1 and 100