Page 1

Machine Automation Controller NJ-series

EtherCAT(R) Connection Guide

WAGO Kontakttechnik

GmbH & Co. KG

WAGO-I/O-SYSTEM Fieldbus Coupler

(750 Series)

P594-E1-01

Page 2

About Intellectual Property Rights and Trademarks

is registered trademark and patented technolo gy, licensed by Beckhoff Automation

Microsoft product screen shots repri nted with perm ission from Mic rosoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the USA and other countries.

EtherCAT(R)

GmbH, Germany.

Sysmac is a trademark or regi s tered trademark of OMRON Cor poration in Japan and other

countries for OMRON factory automation products.

Company names and prod uct names in this document ar e th e t ra dem arks or registered

trademarks of their respective companies.

Page 3

T a ble of Co ntent s

1. Related Manuals .......................................................................................... 1

2. T erms and Definitions ................................................................................. 2

3. Precautions .................................................................................................. 3

4. Overview ...................................................................................................... 4

5. Applicable Devices and Dev ice Configuration ........................................ 4

5.1. Applicable Devices .............................................................................. 4

5.2. Device Configuration ........................................................................... 5

6. EtherCAT Settings ....................................................................................... 7

6.1. EtherCAT Communications Param et er Settings ................................. 7

6.2. Allocation for PDO Communications ................................................... 7

7. EtherCAT Connection Procedur e .............................................................. 9

7.1. Work Flow ............................................................................................ 9

7.2. Setting Up the WAGO-I/O-SYSTE M Fieldbus Cou pler ..................... 10

7.3. Setting Up the Controller .................................................................... 11

7.4. Checking the EtherCAT Communications ......................................... 24

8. Initialization Method .................................................................................. 27

8.1. Initializing the Controller .................................................................... 27

9. Revision History ........................................................................................ 28

Page 4

1.Related Manuals

1

NJ301-[][][][]

100 Mbit/s, digital an d anal og signals (Manual)

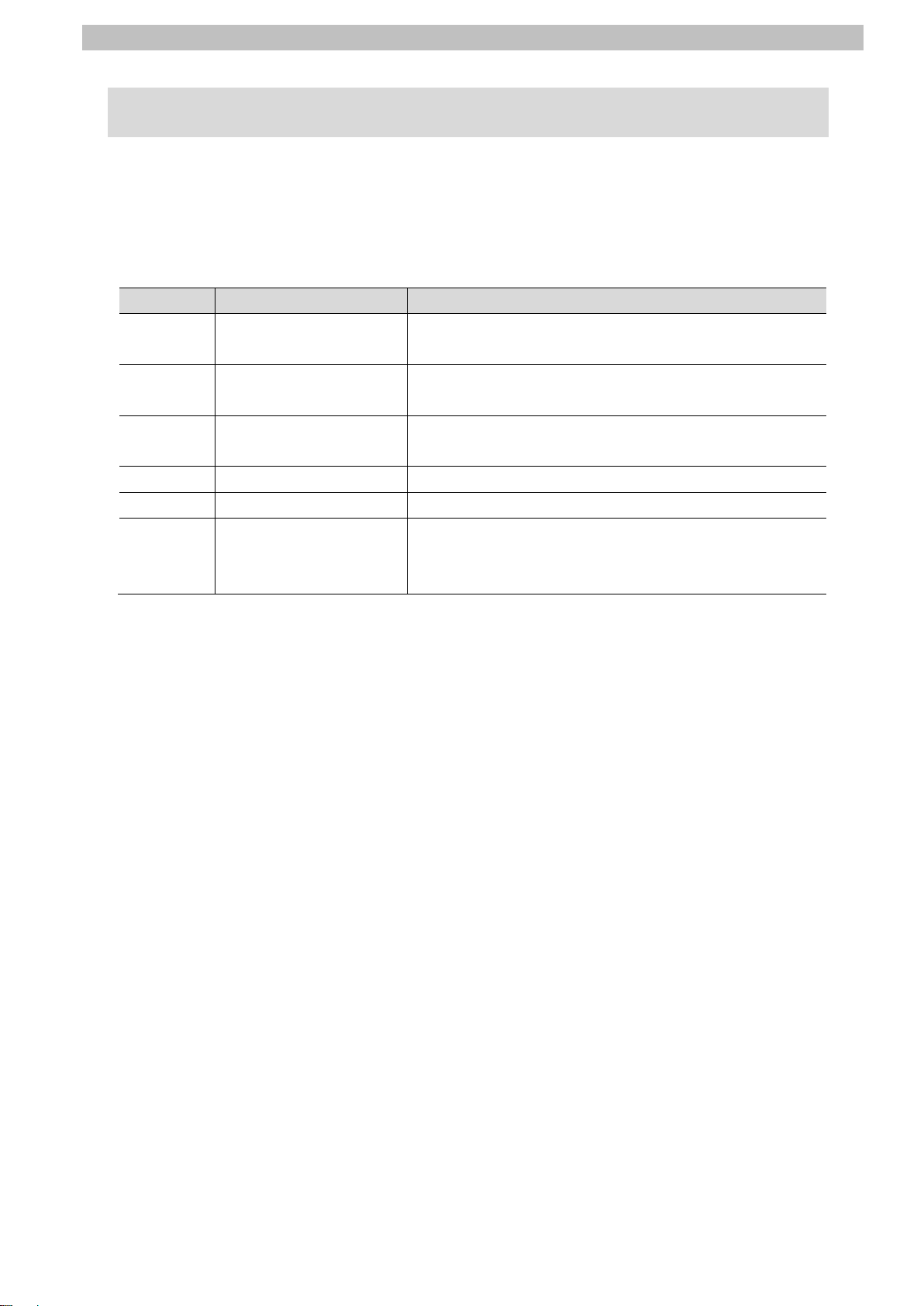

1. Related Manuals

The table below lists the manuals related to this document.

To ensure system safe ty, make sure to always read and h eed the information provided in all

Safety Precautions, Precautions for Safe Use, and Precaution for Correct Use of manuals for

each device which is used in the system.

Cat. No. Model Manual name

W500 NJ501-[][][][]

NJ301-[][][][]

W501 NJ501-[][][][]

NJ-series CPU Unit Hardware User's Manual

NJ-series CPU Unit Software User's Manual

W505 NJ501-[][][][]

NJ301-[][][][]

W504 SYSMAC-SE2[][][] Sysmac Studio Version 1 Operation Ma nual

750-354/000-001 EtherCAT(R) Fieldbus Coupler, ID Switch (Data Sheet)

750-354/000-001 WAGO-I/O-SYSTEM 750 Fieldbus Coupler EtherCAT

NJ-series CPU Unit Built-in EtherCAT Port User's

Manual

with ID Address Selection Switc h 750-354/000-001

(R)

Page 5

2

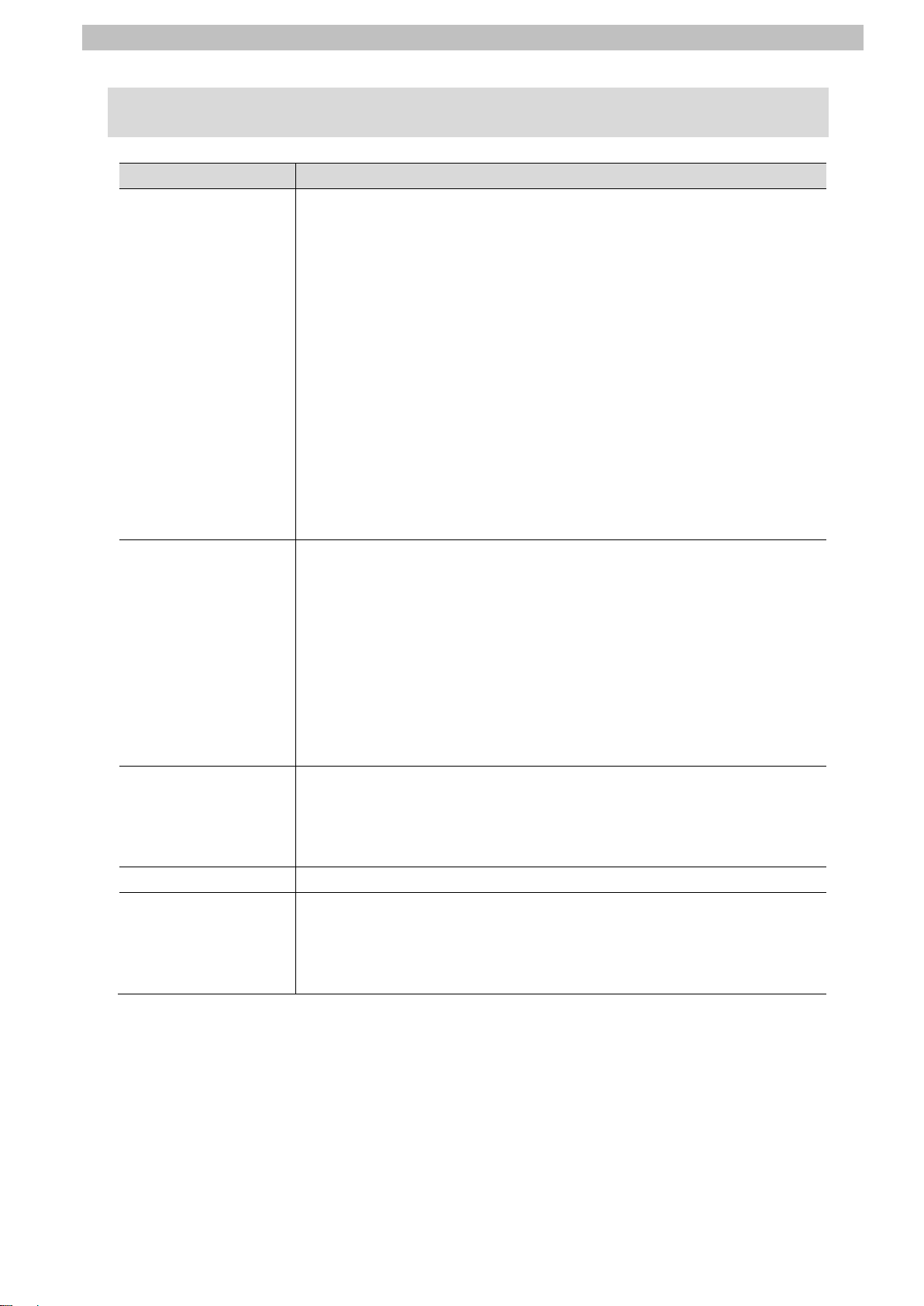

2. Terms and Definitions

EC_CoESDOWrite (Write CoE SDO) instruction.

Term Explanation and De fini tion

PDO communications

(Communications

using Process Data

Objects)

SDO

Communications

(Communications

using Service Data

Objects)

This method is used for cyclic data exchange between the master unit

and the slav e units.

PDO data (i.e., I/O data that is mapped to PDOs) that is allocated in

advance is refreshed per iodically each EtherCAT process data

communications cycle (i.e., the period of primary periodic task).

The NJ-series Machine Automati on Controller uses the PDO

communications for commands to refresh I/O data in a fixed control

period, including I/O data for EtherCAT Slave Units, and the position

control data for the Servomotors.

It is accessed from the NJ-series Machine Automation Controller in the

following ways.

・With device variables for EtherCAT slave I/O

・With Axis Variables for Servo Drive and encoder input slave to which

assigned as an axis

This method is used to read and write the specified slave unit data from

the master unit when required.

The NJ-series Machine Automati on Controller uses SDO

communications for commands to read and write data, such as for

parameter transfers, at specified times.

The NJ-series Machine Automation Controller can read/write the

specified slave data (parameters an d er ror information, etc.) w i th the

EC_CoESDORead (Read CoE SDO) instruction or the

2.Terms and Definitions

Slave unit There are various types of slaves such as Servo Drives that handle

position data and I/O te rmi nals that handle the bit signals.

The slave unit receives output data sent from the mast er , and sends

input data to the master.

Node address A node address is an address to ide nt i fy a unit connected to Ether C AT.

ESI file

(EtherCAT Slave

Information file)

The ESI files contain information unique to the EtherCAT slaves in XML

format.

Installing an ESI file enables the Sysmac Studio to allocate slave

process dat a and make other settings.

Page 6

3.Precautions

3

Indicates a potentially hazardous situation which, if not avoided,

damage.

Indicates a potential ly hazardous si tuation which, if not

damage.

Precautions for Safe Use

Precautions for Correct Use

Additional Inf or mation

Symbols

3. Precautions

(1) Understa nd the specifications of dev i ces which are used in the syst em. Allow some

margin for ratings and performance. Provide safety measures, such as installing safety

circuit in order to ensure safety and minimize risks of abnormal occurrence.

(2) To ensure system safety, always read and heed the information provided in all Safety

Precautions, Precautions for Safe Use, and Precaution for Correct Use of manuals for

each device used in the syst em.

(3) The user is encouraged to confirm the standards and regulations that the system must

conform to.

(4) It is prohibited to copy, to reproduce, and to distribute a part or the whole of this

document without the permission of OMRON Corporation.

(5) The information contained in this document is current as of April 2014. It is subject to

change without notice f or improvement.

The following notations are use d i n t his document .

will result in minor or moderate injury, or may result in serious

injury or death. Additionally there may be significant property

avoided, m ay result in min or or m oderate inju ry or propert y

Precauti ons on what to do and what not to do to ensure safe usage of the product.

Precauti ons on what to do and what not to do to ensure proper operation and performanc e.

Additional information to read as required.

This information is provided to increase underst anding or make operation easier.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in text.

This example shows a general precaution for something that you must do.

Page 7

4.Overview

4

Address Selection Switch

Precautions for Correct Use

Additional Inf or mation

4. Overview

This document describes the procedure for connecting WAGO-I/O-SYSTEM Fieldbus Coupler

(750-series) of WAGO Kontakttechnik GmbH & Co. KG (hereinafter referred to as WAGO) to

NJ-series Machine Automation Controller (hereinafter referred to as Controller) of OMRON

Corporation (hereinafter referred to as OMRON) via EtherCAT and provides the procedure for

checking their connection. Refer to Section 6 EtherCAT Settings and Section 7. EtherCAT

Connection Procedure to understand the setting method and key points to operate PDO

communications of EtherCAT.

5. Applicable Devic es and Device Configuration

5.1. Applicable Devices

The applicable devices are as follows:

Manufacturer Name Model

OMRON NJ-series CPU Unit NJ501-[][][][]

NJ301-[][][][]

WAGO WAGO-I/O-SYSTEM Fieldbus Coupler with ID

As applicable devices above, the devices with the models and versions listed in Section 5.2.

are actually used in this document to describe the procedure for connecting devices and

checking the connection.

You cannot use devices with versions lower than the versions listed in Section 5.2.

To use the above devices with versions not listed in Section 5.2 or versions higher than those

listed in Section 5.2, check the differences in the specifications by referring to the manuals

before operating the devices.

750-354/000-001

This document describes the procedure to establish the network connection. Except for the

connecti on procedure, i t does not provide information on operation, instal lation or wiring

method. It also does not describe the functionality or operation of the devices. R efer to the

manuals or contact the device manufacturer.

(WAGO http://www.wago.com )

This URL is the latest address at the time o f th i s do cument creation. Conta ct ea ch device

manufacturer for the latest information.

Page 8

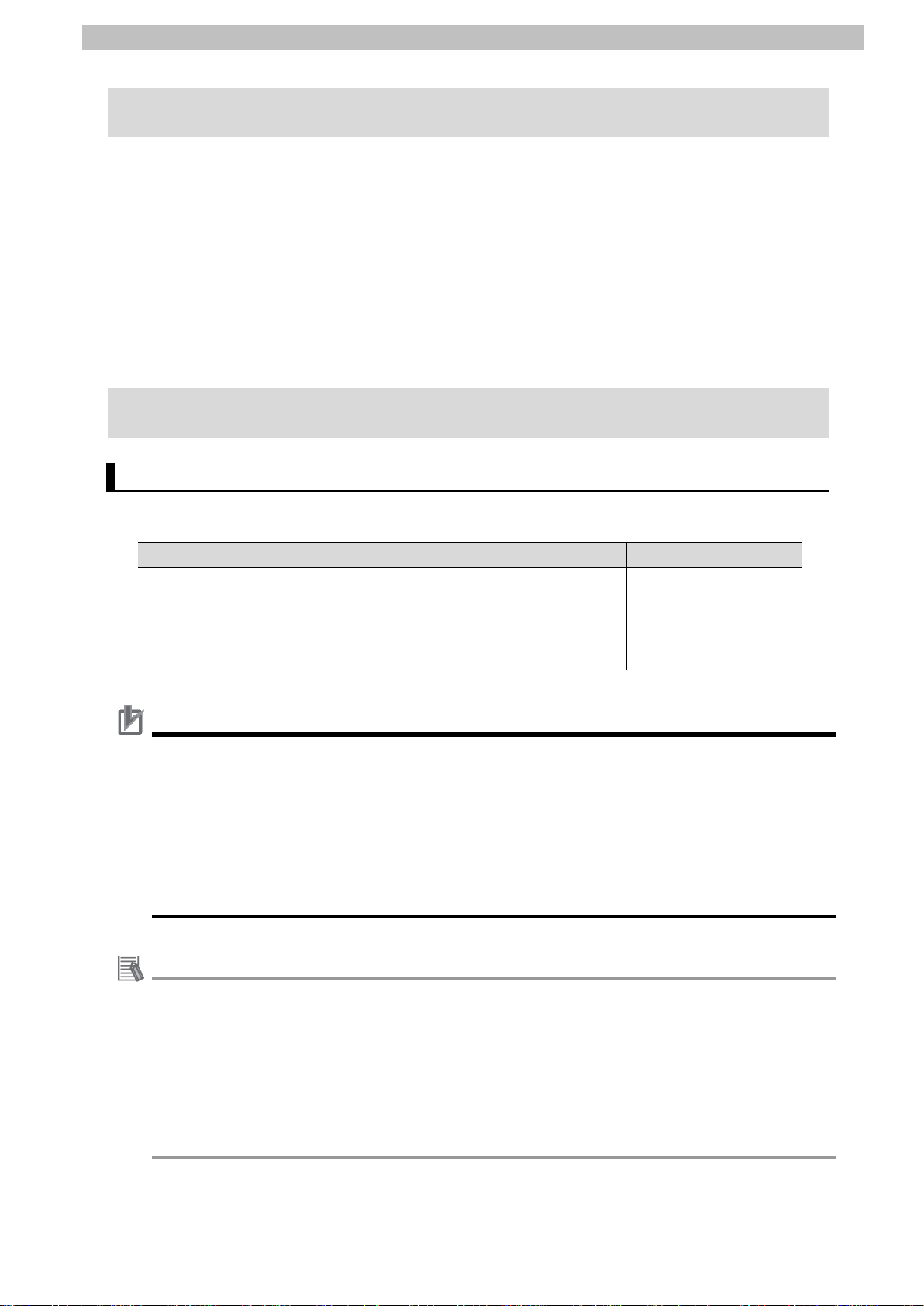

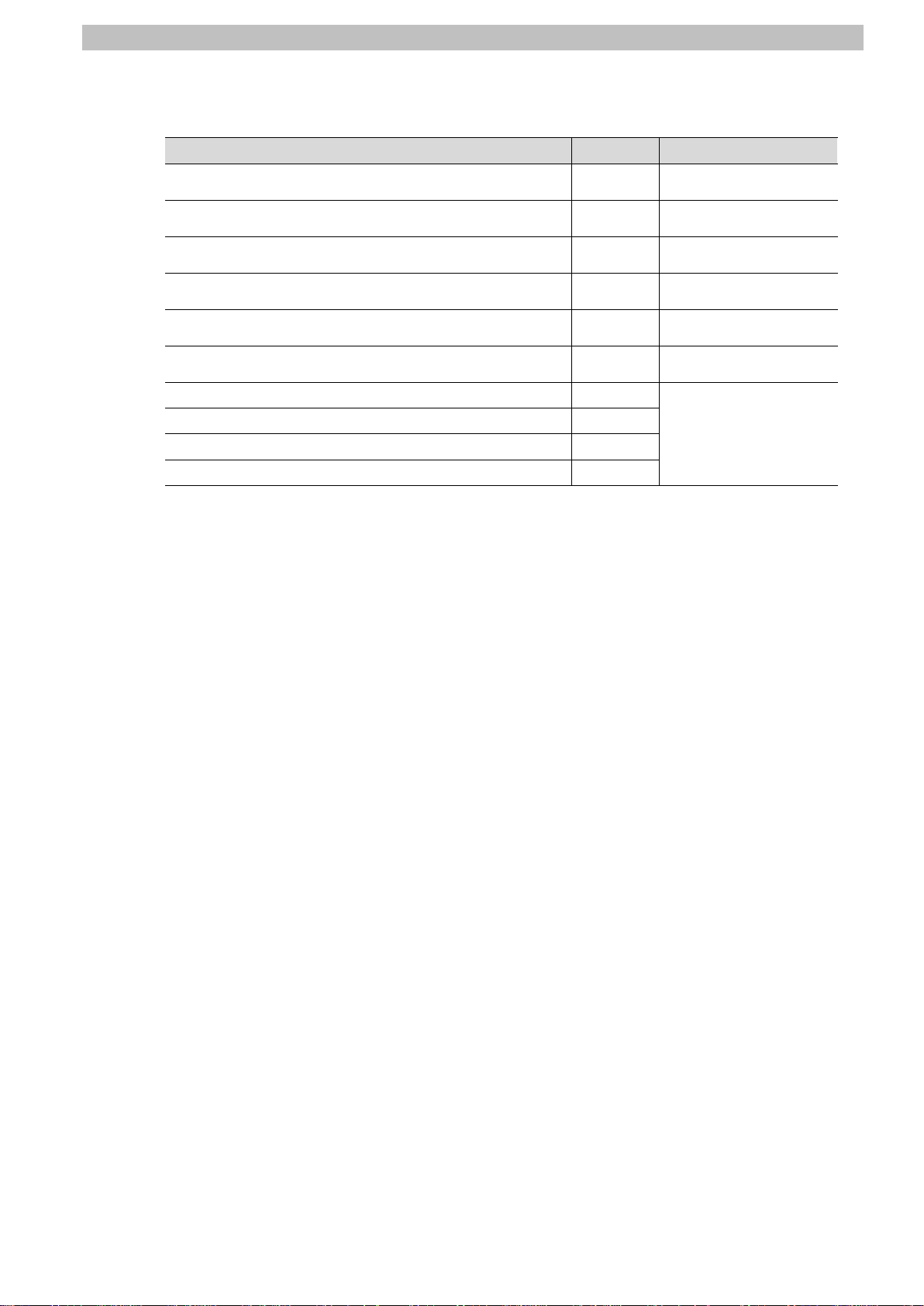

5.Applicable Devices and Dev i ce Configuration

5

Manufacturer

Name

Model

Version

OMRON

CPU Unit

(Built-in EtherCA T port)

NJ501-1500

Ver.1.07

OMRON

Power Supply Unit

NJ-PA3001

OMRON

Sysmac Studio

SYSMAC-SE2[][][]

Ver.1.08

Personal computer

(OS: Windows 7)

USB cable

(USB 2.0 type B connector)

-

OMRON

Ethernet cable (with industrial

Ethernet connector)

XS5W-T421-[]M[]-K

WAGO

WAGO-I/O-SYSTEM Fieldbus

Switch

750-354/000-001

Rev.

Power supply module

750-602

2-channel digital ou tpu t mo dule

750-501

4-channel digital input module

750-407

750-600

WAGO

ESI file

-

24 VDC power supply

-

Precautions for Correct Use

NJ501-1500

750-354/000-001+

Personal computer

24 VDC

24 VDC

power supply

5.2. Device Configuration

The hardware components to reproduce the connection procedure of this document are as

follows:

(Sysmac Studio installed,

OS: Windows 7)

(Built-in EtherCAT port)

Ethernet cable

750-602+750-501+

750-407+750-600

USB cable

power supply

-

-

Coupler with ID Address Selection

WAGO

WAGO

WAGO

WAGO End module

-

0x00010002

WAGO_750_354.xml

Prepare the ESI file shown in this section beforehand. The ESI file can be downloaded from

the WAGO website.

(WAGO

https://eshop.wago.com/JPBC/0_5StartPage.jsp?supplierAID=750-354%2F000-001&catalog

ID=WAGO01&zone=7)

Contact WAGO if the file is not available.

Page 9

5.Applicable Devices and Dev i ce Configuration

6

Precautions for Correct Use

Precautions for Correct Use

Additional Inf or mation

Additional Inf or mation

The connection line of EtherCAT communication cannot be shared with other Ethernet

networks.

Do not use devices for Ethernet such as a switching hub.

Use the cable (double shielding with aluminum tape and braiding) of Category 5 or higher,

and use the shielded connector of Category 5 or high er.

Connect the cable shield to the connector hood at both ends of the cable.

Update the S ysmac Studio to the version sp ec i fied in this s ection or hig her version using the

auto update function.

If a version not specified in this section is used, the procedures described in Section 7 and

subsequent sections may not be applic able. In that case, use the equivalent procedures

described in the Sysmac Studio Version 1 Operat io n M anual (Cat. No. W504).

For information on the specifications of the Ethernet cable and network wiring, refer to

Section 4 EtherCAT Network Wiring of the NJ-series CPU Unit Built-in Et herCAT Port User's

Manual (Cat. No. W505).

The system configuration in this document uses USB for the connection to the Controller.

For information on how to install a USB driver, refer to A-1 Driver Installation for Direct USB

Cable Connection of the Sysmac Studio V er s i on 1 Operation Manual (Cat. No. W504).

Page 10

6.EtherCAT Settings

7

Precautions for Correct Use

K-Bus Cycle Overrun

Flag Disable

Input Process Data Hold

Request

Output Process Data

Hold Request

Output Process Data

Clear Request

Diagnostics Control

Word

6. EtherCAT Settings

This section describes the specifications such as communication parameters and variables

that are set i n this document.

Hereinafter, the WAGO-I/O-SYSTEM Fieldbus Coupl er is referred t o as the "Destination

Device" or t he "Slave Unit" in some descr i ptions.

6.1. EtherCAT Communi cations Parameter Settings

The communications parameter required connecting the Controller and the Destination

Device via EtherCAT is given below.

WAGO-I/O-SYSTEM

Fieldbus Coupler

Node address 1

The Controller with the version described in this document cannot use the node address

setting with the rotary switches of the Destination Device. The node address for the

Destination Device can be set by Sysmac Studio.

6.2. Allocation for PDO Communications

The EtherCAT PDO communications data of the Destination Device are allocated to the

Controller's device variables. The device variables and the data types are shown below.

■ Output area (from Controller to Destination Device)

Device variable nam e Data type Meaning

E001_Output_K_Bus_Cycle_Overrun_Flag_Di_F200_01 BOOL

E001_Output_Input_Process_Data_Hold_Req_F200_02 BOOL

E001_Output_Output_Process_Data_Hold_Re_F200_03 BOOL

E001_Output_Output_Process_Data_Clear_R_F200_04 BOOL

E001_Output_Diagnostics_Control_Word_F200_05 UINT

M1_Output_s_Channel_1_Data_7000_01 BOOL

M1_Output_s_Channel_2_Data_7000_02 BOOL

M2_Output_s_Channel_1_Data_7000_01 BOOL

M2_Output_s_Channel_2_Data_7000_02 BOOL

Output of Digital Output

Module (Slot1)

Output of Digital Output

Module (Slot2)

Page 11

8

K-Bus Cycle Overrun

Flag

Input Process Data

Hold Acknowledge

Output Process Data

Hold Acknowledge

Output Process Data

Clear Acknowledge

Diagnostics History

Message Available

Diagnostics Status

Word

■ Input area (from Destination Device t o C ontroller)

Device variable nam e Data type Meaning

E001_Input_K_Bus_Cycle_Overrun_Flag_F100_01 BOOL

E001_Input_Input_Process_Data_Hold_Ack_F100_02 BOOL

E001_Input_Output_Process_Data_Hold_Ac_F100_03 BOOL

E001_Input_Output_Process_Data_Clear_A_F100_04 BOOL

E001_Input_New_Message_Available_10F3_04 BOOL

E001_Input_Diagnostics_Status_Word_F100_05 UINT

M3_Input_s_Channel_1_Data_6000_01 BOOL

M3_Input_s_Channel_2_Data_6000_02 BOOL

M3_Input_s_Channel_3_Data_6000_03 BOOL

M3_Input_s_Channel_4_Data_6000_04 BOOL

6.EtherCAT Settings

Input of Digital Input

Module (Slot3)

Page 12

7.EtherCAT Connection Procedure

9

7.2. Setting Up the WAGO-I/O-SYSTEM

Fieldbus Coupler

Set up the WAGO-I/O-SYSTEM Fieldbus Coupler.

↓

7.2.1. Hardware Settings

Set the hardware swi t ches o n th e

WAGO-I/O-SYSTEM Fieldbus Coupler.

↓

7.3. Setting Up the Controller

Set up the Controller.

↓

7.3.1. Starting the Sysmac Studio and

Installing the ESI File

Install the ESI file for the WAGO-I/O-SYSTEM

Fieldbus Coupler in the Sysmac Studio.

↓

7.3.2. Setting Up the EtherCAT

Network Configuration

Set up the EtherCAT network configuration.

↓

7.3.3. Setting the Device Variables

Set the device variables used for the EtherCAT

Slave Unit.

↓

7.3.4. Transferring the Projec t D ata

Transfer the project data from the Sysmac Studio to

the Controller.

↓

7.4. Checking the EtherCAT

Communications

Confirm that the PD O communications of EtherCAT

are performed normally.

↓

7.4.1. Checking the Connection Status

Check the connection status of the EtherCAT

network.

↓

7.4.2 Checking the Data that are Sent

and Receive d

Confirm that the correct data are sent and received.

7. EtherCAT Connection Procedure

This section describes the procedure for connecting the Controller to the WAGO-I/O-SYSTEM

Fieldbus Coupler via Et her CAT.

This document explains the procedures for setting up the Controller and the

WAGO-I/O-SYSTEM Fieldbus Coupler from the factory default setting.

For the initialization, refer to Section 8 Initialization Method.

7.1. Work Flow

Take the following steps to perform PDO communications of EtherCAT.

Page 13

7.EtherCAT Connection Procedure

10

following procedures.

4

Connect th e Ethernet cable to

5

Connect th e 24 VDC power

to the Field s upply.

Status LEDs

Fieldbus

Fieldbus connection

Digital output module

Fieldbus Coupler

Power supply module

Digital input module

Fieldbus connection

7.2. Setting Up the WAGO-I/O-SYSTEM Fieldbus Coupler

Set up the WAGO-I/O-SYSTEM Fieldbus Coupler.

7.2.1. Hardware Settings

Set the hardware swi t ches o n th e WAGO-I/O-SYSTEM Fieldbus Coupler.

Precautions for Correct Use

Make sure tha t t he power supply is OFF when you perform the set ting up.

Connect th e Power supply

1

module, Digi ta l in put module,

Digital output module, and End

module to the Fieldbus Coupler

so that the WAGO-I/O-SYSTEM

is created.

In this document, two sets of

2-channel dig i tal output modules

and one 4-c hannel digital input

module are c onnected as an I/O

Unit as shown on the right.

* If the power supply is turn ed

ON, settings may not be

applicable as described in the

System supply

Field supply

End module

Check the position of the

2

hardware switches on the front

panel of the

WAGO-I/O-SYSTEM Fieldbus

Coupler by referring to the right

figure.

Set all the Address Selection

3

Switches to OFF.

* The actual node address is set

by Sysmac Studio.

the Fieldbus connection (X1 IN).

supply to the System supply and

Address Selection

Switch

(X1 IN)

(X1 OUT)

Page 14

7.EtherCAT Connection Procedure

11

End Cover

Power Supply Unit

Ethernet

cable

CPU Unit

Controller

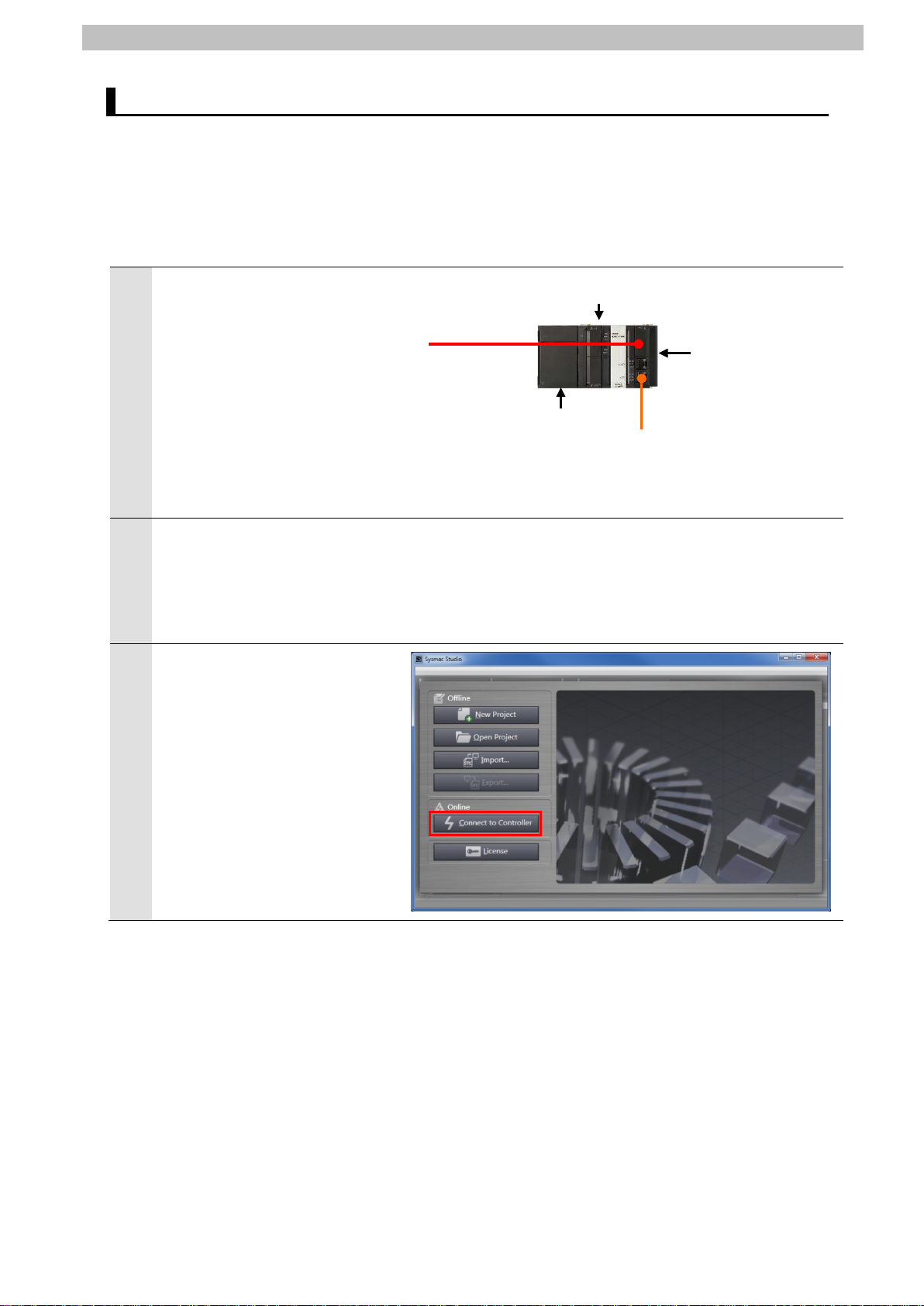

7.3. Setting Up the Controller

Set up the Controller.

7.3.1. Starting the Sysmac Studio and Installing the ESI File

Install the ESI file for the WAGO-I/O-SYSTEM Fieldb us Coupler in the Sysmac Studio.

Install the Sysmac Studio and USB driver in the Personal computer beforehand.

Connect the Ethernet cable to

1

the built-in EtherCAT port

(PORT2) of the Controller and

connect the USB cable t o the

peripher al ( U SB) port.

As shown in 5.2. Device

Configuration, connect the

Personal computer,

WAGO-I/O-SYSTEM Fieldbus

Coupler, and Controller.

Turn ON the power supply to the

2

Controller and the System

supply and the Field supply to

the WAGO-I/O-SYSTEM

Fieldbus Coupler.

Start the Sysmac Studio.

3

Click the Connect to Controller

Button.

* If a confirmation dialog for an

access right is displayed at

start, se lect to sta rt.

USB cable

Page 15

12

The Connect to Controller

Click the Connect Button.

proceed with the processi ng.

Additional Inf or mation

Status

Plane

Multiview

Explorer

Edit Pane

Toolbox

4

Dialog Box is displayed.

Select the Direct connect i on via

USB Option for Connection

type.

Uncheck both of the Upload the

project Check Box and the

Display the T r oubl esh ooting

Dialog Box Check Box of

Operation after Connection.

7.EtherCAT Connect i on Pr ocedure

A con firmation dialog box on the

5

right is displayed. Check t he

contents and click the OK

Button.

* The displayed dialog depends

on the status of the Controller

used. Check the contents and

click the Yes or OK Button to

A confirmation dialog box is

6

displayed. Check the contents

and click the OK Button.

The A ut o C onnect Project

7

Dialog Box is displayed online.

When an online connection is

established, a yellow bar is

displayed on the Pane.

The left pane is called Multiview

Explorer, the top right pane is

called Toolbox, the bottom r ight

pane is called Status Monitor

Plane, and the middle pane is

called Edit Pane.

Monitor

For details on online conn ect ions to a Controller, refer to Section 5 Online Connections to a

Controller of the Sysmac Studio Vers i on 1 O peration Manual (Cat. No. W504).

Page 16

13

10

Double-click EtherCAT under

8

Configurations and Setup in

the Multiview Explorer.

The EtherCAT Tab is displayed

9

on the Edit Pane.

Right-click Master and select

Display ESI Library.

7.EtherCAT Connect i on Pr ocedure

The ESI Library Dialog Box is

11

displayed. Click the this folder

link.

When the Explorer starts, close

the dialog box by clicking t he

Close Button.

The Explorer starts and a fo lder

12

is opened, allowing you to inst al l

the ESI file. Copy the prep ar ed

WAGO_750_354.xml to this

folder.

Page 17

14

Select Exit from the File Menu

Close

Precautions for Correct Use

13

to exit the Sysmac Studio.

A dialog box is displayed

confirming whether to save the

project. If you do not need to

save it, click the No Button.

* You need to restart the

Sysmac Studio after instal lin g

the ESI file.

7.EtherCAT Connect i on Pr ocedure

In the same way as steps 3 to

14

10, restart the Sysmac Studio

and display the ESI Librar y

Dialog Box.

Click the + Button of

WAGO_750_354 to confirm that

750-354/000-001

Rev:0x00010002(750-354/000001 EtherCAT fieldbus coupler)

device is displayed.

Confirm that an exclamation

mark (warning) is not disp l ayed.

Click the

Button

If an exclamation mark (war ning) is displayed for the ESI file, c heck the name of the ESI file

and obtain the ESI file wit h a cor r ect name. If an exclamation mark (warning) is displayed

even when the name of the ESI fil e is correct, the file may be corru pted. Contact the device

manufacturer.

Page 18

7.EtherCAT Connect i on Pr ocedure

15

7.3.2. Setting Up the EtherCAT Network Configuration

Set up the EtherCAT network configuration.

Confirm that a yellow bar is

1

displayed on the top of the Ed it

Pane which indicates an online

connection is established.

Right-click Master on the

2

EtherCAT Tab Page of the Edit

Pane, and select Wri t e Slave

Node Address.

* If the EtherCAT Tab Page is

not displayed on the Edit Pane,

display it by following step 8 of

7.3.1. Starting the Sysmac

Studio and Installing the ESI

File.

A screen is displayed stating

"Get information is being

executed".

The Slave Node Address W rit ing

3

Dialog Box is displayed.

The present value (setting node

address) and 750-354/000-001

Rev:0x00010002 are displayed

in the Actual network

configuration.

* If the present value of the node

address is 0, an error is

displayed.

Enter 1 in the Set value Fi eld for

4

a node address.

Page 19

16

Confirm that there is no error in

Close Button.

configuration

5

the set value and 1 is set.

Click the Write Button.

The Slave Node Address W rit ing

6

Dialog Box is displayed.

Click the Write Button.

Then, a screen is displayed

stating "Writing no de addresses

to slaves was successfully

completed".

Check the contents and c l ick the

7.EtherCAT Connect i on Pr ocedure

Cycle the power supply to t he

7

Slave Unit.

The EtherCAT Tab Page is

8

displayed again. Right-click

Master and select Compare

and Merge with Actual

Network Configuration.

A screen is displayed stating

"Get information is being

executed".

The Compare and Merge with

9

Actual Network Configur ation

Dialog Box is displayed.

Node address 1 and

750-354/000-001

Rev:0x00010002 are add ed t o

the Act ual network configuration

after the comparison.

Click the Apply actual network

Button.

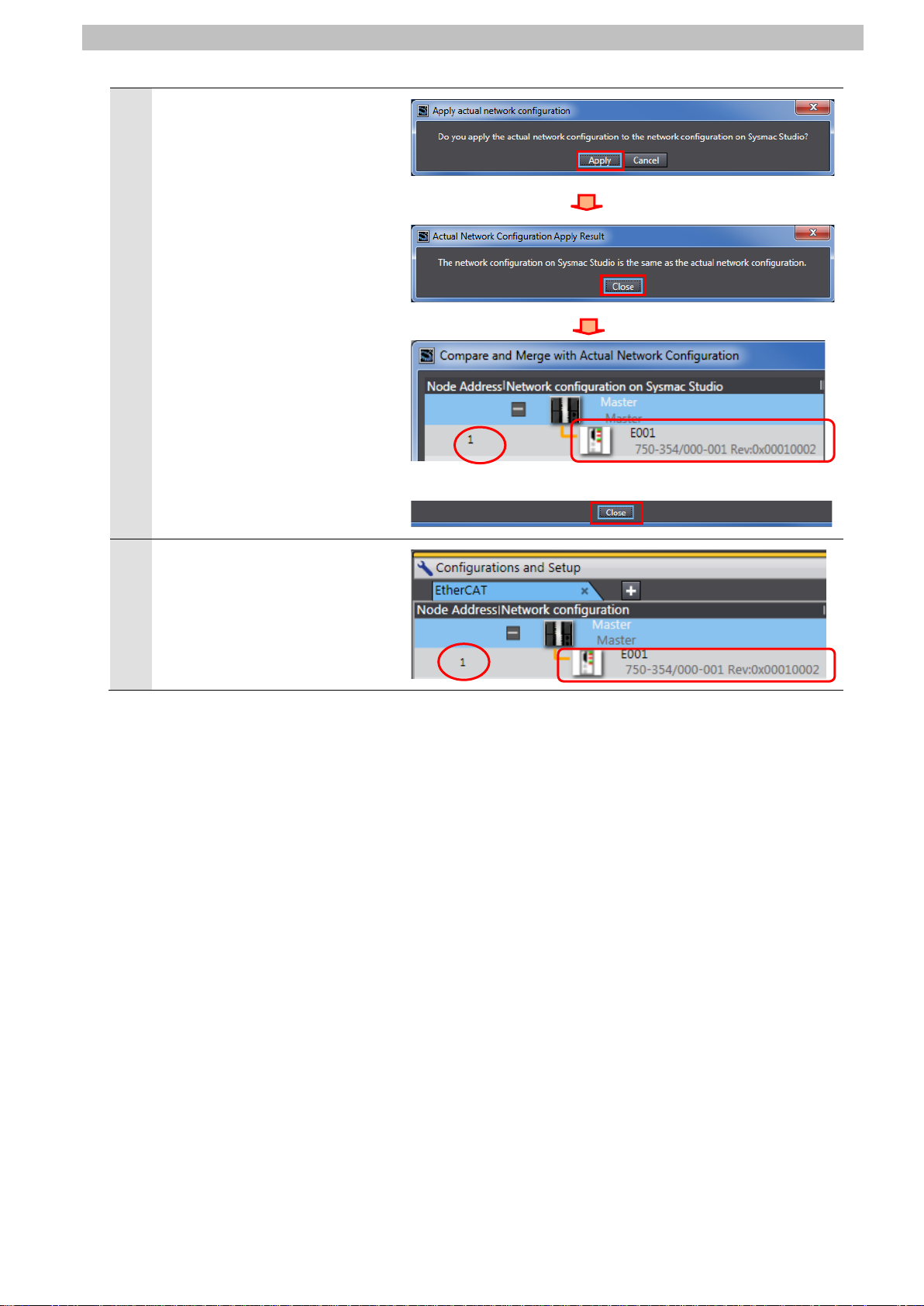

Page 20

17

A con firmation dialog box on the

10

right is displayed.

Check the contents and c l ick the

Apply Button.

A result confirmation dialog box

is displayed.

Click the Close Button.

Node address 1, E001 an d

750-354/000-001

Rev:0x00010002 are add ed t o

the Network configuratio n on

Sysmac Studio.

Confirm that the data abo ve are

added and click the Close

Button.

Node address 1, E001, and

11

750-354/000-001

Rev:0x00010002 are add ed t o

the EtherCAT Tab Page on the

Edit Pane.

7.EtherCAT Connect i on Pr ocedure

Page 21

18

7.3.3. Setting the Device Variables

Configuration Button.

Set the device variables us ed f or t he Et herCAT Slave Unit.

Select Offline from the

1

Controller Menu.

The yellow bar on the top of the

Edit Pane disappears.

Select 750-354/000-001

2

Rev:0x00010002 set in the

previous steps in the EtherCAT

Tab Page and confirm that

Device name is E001.

* Device name can be cha nged

as desired.

Click the Edit Module

7.EtherCAT Connect i on Pr ocedure

The Node1:

3

750-354/000-001(E0 01) Tab

Page is displayed.

Select each configured m odule

in order and confirm that Device

name is as follows:

・750-5xx / 750-15xx

(2b out)(M1) : M1

・750-5xx / 750-15xx

(2b out)(M2) : M2

・750-4xx / 750-14xx

(4b in)(M3) : M3

* Device name can be cha nged

as desired.

* The device name you s et is

used at the beginning of the

device variables.

Page 22

19

Double-click I/O Map under

4

Configurations and Setup in

the Multiview Explorer.

The I/O Map Tab is displayed on

5

the Edit Pane.

Confirm that Node1 is dis played

in the Position Column and the

Slave Unit is displayed.

* To manually set a variable

name for the Slave Unit, click a

column under the Variable

Column and enter a name.

7.EtherCAT Connect i on Pr ocedure

Right-click Node1 and select

6

Create Device Varia ble.

The variable names and

7

variable types are automa t ical ly

set.

Page 23

20

Additional Inf or mation

Additional Inf or mation

The device variables are named automatically from a com bination of the device names and

the port names.

The default device names ar e “ E" fo llowed by a serial number that star t s from 001.

For Slave Units with module configurations, the de fa ult device names start with an "M"

followed by a sequential n um ber st ar t ing from "1".

In this document, device var iab les are automatically named for a unit (a slave). Device

variables can also be manual ly nam ed for I/O ports.

7.EtherCAT Connect i on Pr ocedure

Page 24

7.EtherCAT Connect i on Pr ocedure

21

behave according to the sl ave sett ings. The ti me that communicat ions are c ut of f

Before you transfer the user pr ogr am, confirm that it will not adv er sely affect the

3

7.3.4. Transferring the Project Data

Transfer t he pr oject data from the Sysmac Stu dio t o the Controller.

Always confirm safety at the Des t in ation Device before you t r ansfer a user

program, configuration d ata, setup data, device variables, or values in memory

used for CJ-series Units from the Sysmac Studio.

The devices or machines may perform unexpected operation regardless of the

operating mode of the CPU U nit.

After you transfer the user pr ogr am, the CPU Unit restarts and co m m uni cat ions

with the EtherCAT slaves are cut off. During t hat period, the slave outputs

depends on the EtherCAT network configurat i on.

device.

Select Check All Programs

1

from the Project Menu.

The Build Tab Page is displayed

2

on the Edit Pane.

Confirm that "0 Errors" an d "0

Warnings" ar e di s played.

Select Rebuild Controller from

the Project Menu.

A con firmation dialog box on the

4

right is displayed. Confir m t hat

there is no problem and cl ick the

Yes Button.

Page 25

22

Confirm that "0 Errors" an d "0

5

Warnings" ar e di s played in the

Build Tab Page.

Select Online from the

6

Controller Menu.

Select Synchronization from

7

the Controller Menu.

7.EtherCAT Connect i on Pr ocedure

The Synchronization Dialog Box

8

is displayed.

Confirm that the data to transfer

(NJ501 in the right dialog) is

selected. Then, cli ck the

Transfer To Controller Button.

* After executing the Tr ansfer To

Controller, the Sysmac Studio

data is transferred to the

Controller and the data is

compared.

Page 26

23

A con firmation dialog box on the

9

right is displayed. Confir m t hat

there is no problem and cl ick the

Yes Button.

A screen stating "Synchronizing"

is displayed.

A con firmation dialog box on the

right is displayed. Confir m t hat

there is no problem and click the

No Button.

* Do not return it to RUN mode.

7.EtherCAT Connect i on Pr ocedure

Confirm that the synchron ized

10

data is displayed with the color

specified by "Synchronized"

and that a message is displayed

stating "The synchronizat ion

process successfully fini shed".

If there is no problem, click the

Close Button.

* A message stating "The

synchronization process

successfully finished" is

displayed if the Sysmac Studio

project data and the data in the

Controller match.

* If the synchronization fails,

check the wiring and repe at

from step 1.

Page 27

7.EtherCAT Connect i on Pr ocedure

24

Label

Name

Color

Status

Meaning

EtherCAT

NET RUN

EtherCAT communications are in progress

operation

EtherCAT

NET ERR

LINK/ACT

Activity

Data communications are in progress after

Flashes every time data is sent or received

Name

LED Status

Meaning

A connection from the EtherCATR connection to

via this interface.

RUN

(Green)

ERR

(Red)

7.4. Checking the EtherCAT Communications

Confirm that the PDO com m uni c at i ons of EtherCAT are performed normally.

7.4.1. Checking the Connection Status

Check the connection status of the EtherCAT network.

Confirm that the EtherC AT

1

communications are per fo r me d

normally by checking the LED

indicators on the Controlle r.

The LED indicators in nor ma l st at us

are as follows:

[NET RUN]: Lit green

[NET ERR]: Not lit

[LINK/ACT]: Flashing y el l ow

EtherCAT

RUN

ERROR

Link/

■

Green

■

Not lit There are no errors

Red

■

Flashing

Yellow

Lit

Inputs and outputs for I/O data are in

establishing link

Check the LED indicators on t he

2

WAGO-I/O-SYSTEM Fieldbus

Coupler.

The LED indicators in normal status

are as follows:

[L/A IN]: Flashing green

[RUN]: Lit green

[ERR]: Not lit

L/A IN

L/A OUT

Flashing

(Green)

ON The fieldbus coupler is in the OP state.

OFF The fieldbus node is ready for operation.

another EtherCATR participant was determined for

the respective interface. Data is being exchanged

Page 28

7.EtherCAT Connect i on Pr ocedure

25

Sufficiently confir m safety before y ou chang e the v alues of var iable s on a Watch

If you proceed to this section, ma ke sure to complete all the steps and place the

1

3

7.4.2. Checking the Data that are Sent and Received

Confirm that the correct d at a ar e s ent and received.

Tab Page when the Sysmac Studio is on lin e w ith the CPU Unit.

The devices that are conn ect ed t o out put units may operate regar dless of the

operating mode of the Contr oller.

The Destination Device wi ll run if you proceed to this section. Confirm safety

before operation. If you cannot confirm safety, do not proceed to this section

after completing until Section 7.4.1.

Destination Device in the safe state.

Select Watch Tab Page from the

View Menu.

The Watch1 Tab Page is displayed

2

in the lower section of the Edit

Pane.

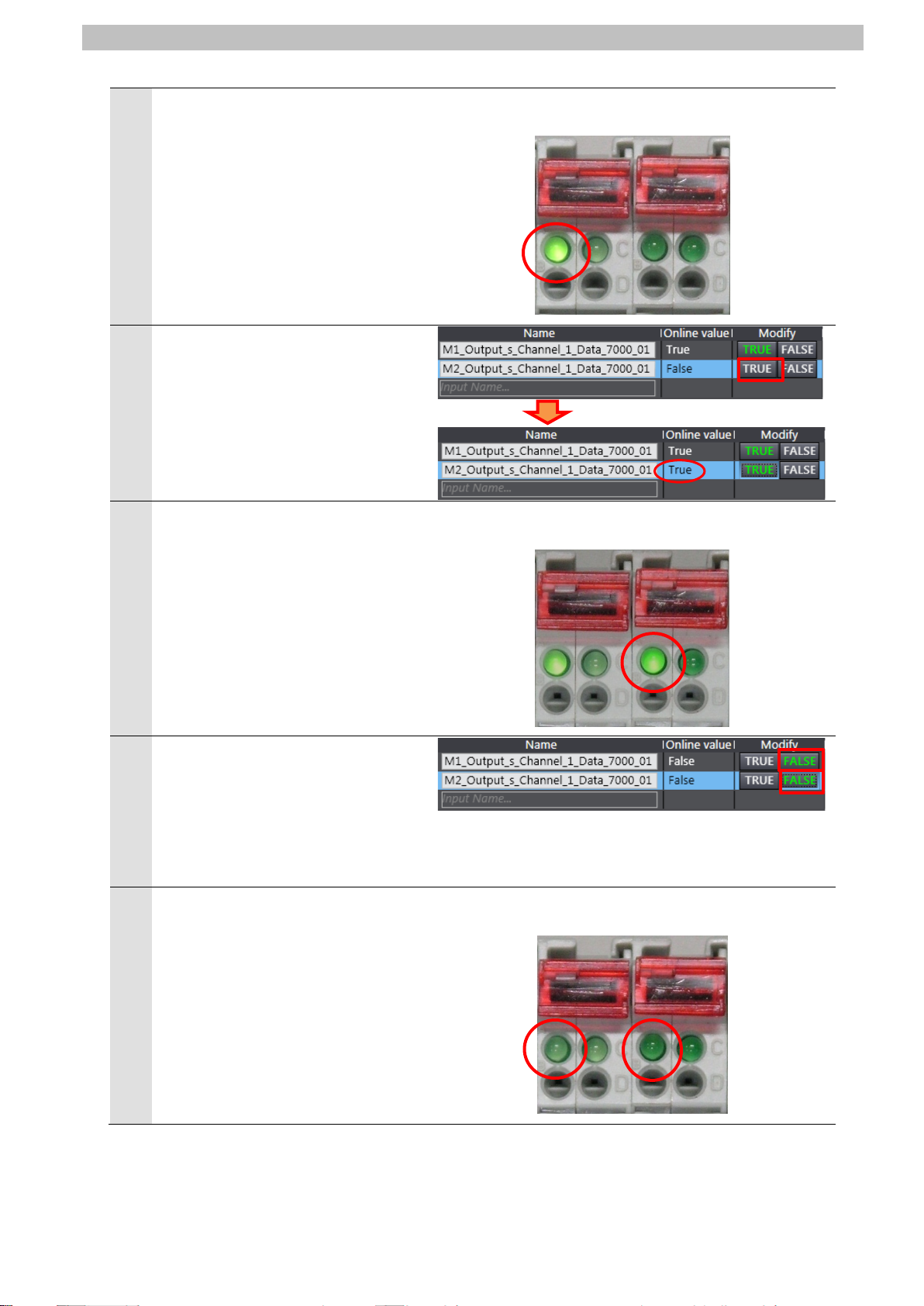

Enter the following names in the

Watch1 Tab Page f or m onitoring.

Click a column under the Name

Column to enter a new name.

M1_Output_s_Channel_1_Data_

7000_01

M2_Output_s_Channel_1_Data_

7000_01

Click TRUE in the Modify Column of

4

M1_Output_s_Channel_1_Data_70

00_01.

The Online value of

M1_Output_s_Channel_1_Data_70

00_01 changes to Tr ue.

Page 29

7.EtherCAT Connect i on Pr ocedure

26

Digital Output

Slot1(M1)

Digital Output

Slot2(M2)

Digital Output

Slot1(M1)

Digital Output

Slot2(M2)

Digital Output

Slot1(M1)

Digital Output

Slot2(M2)

Confirm that the bit corresponds to

5

the Digital Output Module Sl ot 1

(M1), which is connected to the

Fieldbus Coupler, is turned ON and

its LED indicator is lit.

In the same way, click TRUE in the

6

Modify Column of

M2_Output_s_Channel_1_Data_70

00_01.

The Online value changes to True.

Confirm that the bit corresponds to

7

the Digital Output Module Sl ot 2

(M2), which is connected to the

Fieldbus Coupler, is turned ON and

its LED indicator is lit.

Module

Module

Module

Module

Click FALSE in the Modify Columns

8

of

M1_Output_s_Channel_1_Data_70

00_01 and

M2_Output_s_Channel_1_Data_70

00_01.

Confirm that the bits corres pond to

9

Slot1 (M1) and Slot2 (M2) of the

Digital Output Modules are turned

OFF and their LED indicator s do not

light.

Module

Module

Page 30

8.Initialization Method

27

8. Initialization Method

This document explains the s et t ing procedure from the factory default setting.

Some settings may not be appl icable as described in this docu me nt unless you use the

devices with the factory d efault setting.

8.1. Initializing the Controller

To initialize the settings of the Control ler, select Clear All Memory from the Controller Menu of

the Sysmac Studio. The Clear All Memory Dialog Box is displ ayed. Check the contents a nd

click the OK Button.

Page 31

28

9. Revision History

code

Revision

01 Apr. 9, 2014 First edition

Date of revision Revision reaso n and revision page

9.Revision History

Page 32

2014

P594-E1-01

0414(-)

Loading...

Loading...