Page 1

Rev. 1.1

How to connect Omron NX-CSG320 + NX-SL5500

With

Omron GI-SMDxxxx CIP Safety IO block

Page 2

Rev. 1.1

Table of Contents

1. Application Devices and Device Configuration ..................................................................................... 1

1.1. Applicable Devices ........................................................................................................................ 1

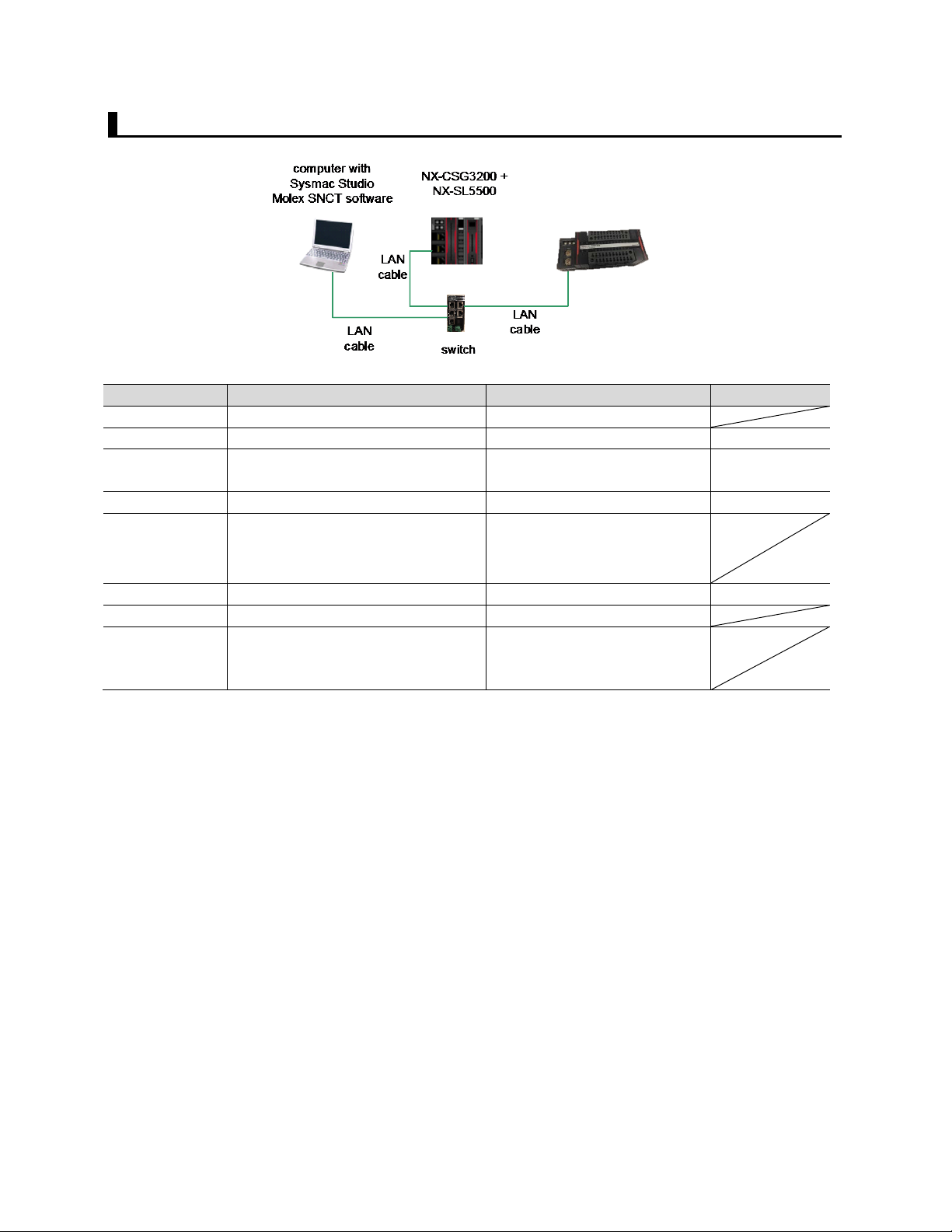

1.2. Device Configuration ..................................................................................................................... 2

2. EtherNet/IP Safety Connection Procedure ........................................................................................... 3

2.1. Safety Controller Setup ................................................................................................................. 3

2.1.1. Hardware configuration and IP address Settings .................................................................. 3

2.1.2. Starting Sysmac Studio and Going Online ............................................................................. 4

2.1.3. Creating a Safety Controller Unit Configuration ................................................................... 5

2.2. Network Setting with Sysmac Studio ............................................................................................ 6

2.2.1. Setting the Connections ........................................................................................................ 6

2.3. Transferring Program with Sysmac Studio .................................................................................. 11

2.3.1. Setting Global Variables ...................................................................................................... 11

2.3.2. Transferring the Safety Application Data ............................................................................ 12

2.3.3. Transferring the Safety Program ......................................................................................... 13

3. Acknowledgement .............................................................................................................................. 15

Page 3

Rev. 1.0

Manufacturer

Name

Model

OMRON

Ethernet switch

W4S1-0xx

OMRON

NX-series Safety CPU unit

NX-SL5xxx

OMRON

NX-series Communication Control unit

NX-CSGxxxx

OMRON

Omron Safety I/O block

GI-SMD1624

1. Application Devices and Device Configuration

1.1. Applicable Devices

The applicable devices are as follows:

1

Page 4

Rev. 1.0

Manufacturer

Name

Model

Version

OMRON

Ethernet switch

W4S1-05B

OMRON

NX-series Safety CPU unit

NX-SL5500

Ver. 1.3

OMRON

NX-series Communication Control

unit

NX-CSG3200

Ver. 1.01

OMRON

Sysmac Studio

SYSMAC-SE2xxx

Ver.1.25.1

OMRON

Compress CIP device file

OMRON

Safety I/O block

GI-SMD1624

1.0 - Personal computer (OS: Win 10)

-

-

LAN cable (STP (shielded, twisted-

or higher)

-

GI-SMD1624

1.2. Device Configuration

pair) cable of Ethernet category 5

CIP_Safety_XXXXX.zip

* XXXXX is a unique name for

each target device to be added

2

Page 5

Rev. 1.0

Precautions for Correct Use

Before setting up turn the power supply is OFF.

applicable.

1

Make sure Safety Controller is powered

OFF.

2

Connect Safety CPU Unit t o

3

Setting the IP address:

Set the rotary switch for port 1 and 2 to 00

2. EtherNet/IP Safety Connection Procedure

This section describes the procedures for connecting the Omron safety I/O block and the safety

controller via EtherNet/IP safety.

2.1. Safety Controller Setup

Set up the Safety Controller.

The Sysmac Studio is used for the Safety Controller setup, please install before proceeding.

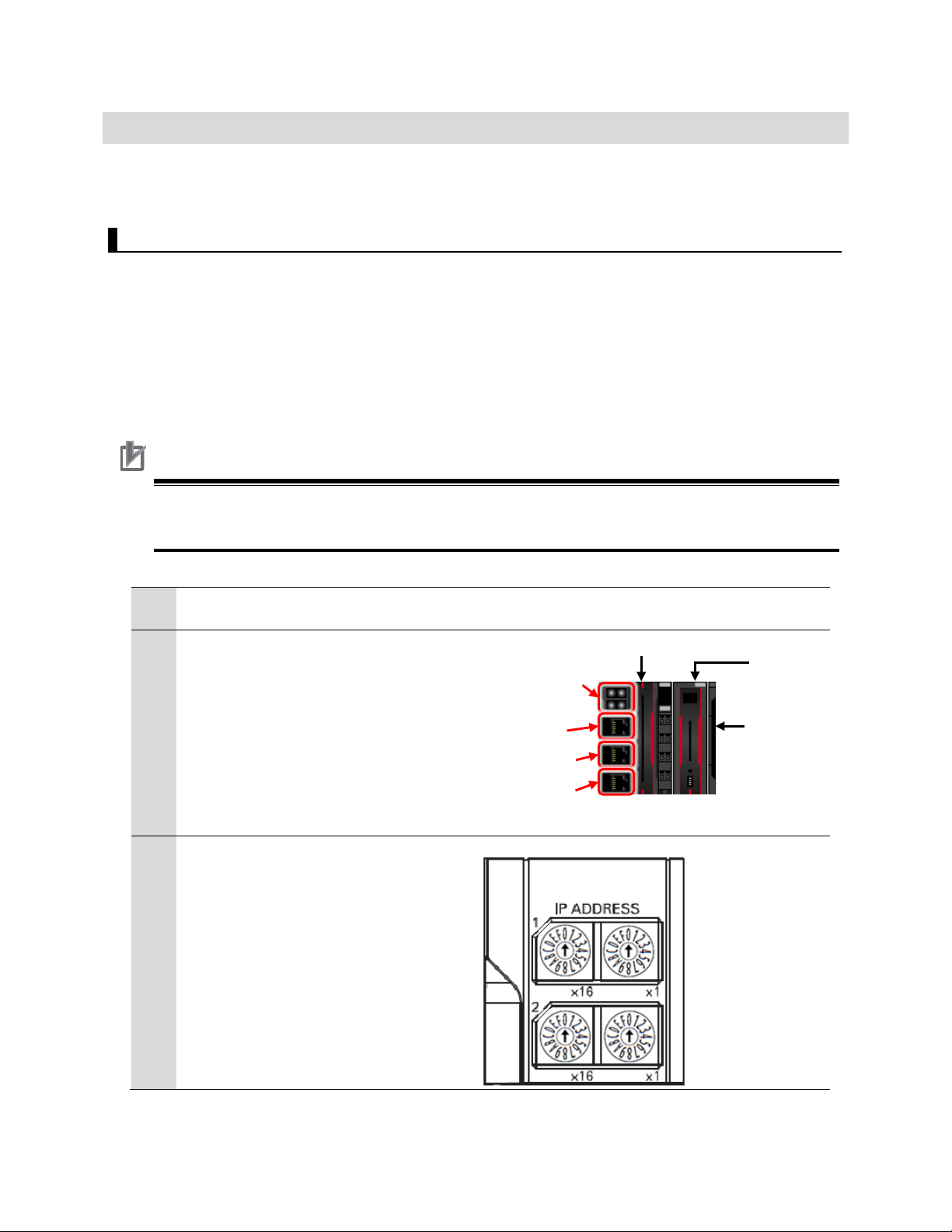

2.1.1. Hardware configuration and IP address Settings

Configure the hardware of the Safety Controller and set the IP address using the hardware

switches.

If it is ON, the settings described in the following steps and subsequent procedures may not be

Communication Control Unit.

1 is for port 1.

2 is for port 2A and 2B.

If the rotary switches are set to 00 then

the IP address for port 1 and 2 are set

using Sysmac Studio.

If the rotary switches are betw een 01

to FF (001 to 255 in decim al) t hen:

Port 1 default IP address =

192.168.1.xxx

Port 2A and 2B default IP addres s =

192.168.250.xxx

Communication Control Unit

Rotary switches

PORT1

PORT2A

PORT2B

Built-in EtherNet/IP

ports

Safety

CPU

Unit

End

Cover

3

Page 6

Rev. 1.0

1

Power up the Safety Controller and the

I/O block

2

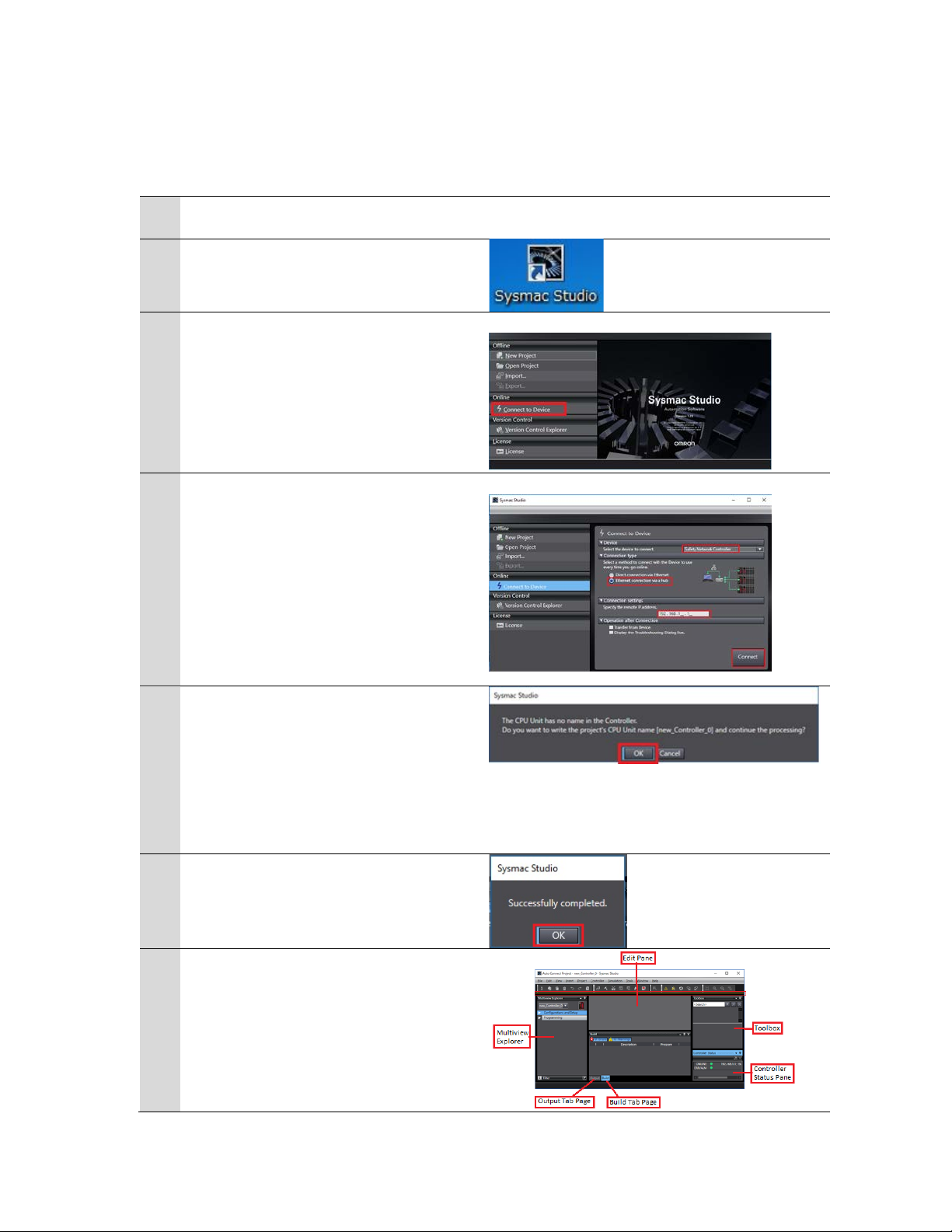

Launch Sysmac Studio

3

Form Sysmac Studio start page select

4

From the connect to device page:

5

If the dialog box on the right is

processing.

6

When the connection is successful select

7

The Auto Connect Project dialog box is

2.1.2. Starting Sysmac Studio and Going Online

Start Sysmac Studio and go online with the Safety Controller.

Connect to Device

• Select the device to connect = Safety

Network Controller

• Connection type = Ethernet

connection via a Hub

• Connection settings = 192.168.1.1

(this is the Safety network controller

port 1 IP address)

• Select Connect

displayed, select OK.

*The contents of the dialog box vary

depending on the status of Controller.

Check the contents and click on an

appropriate button to proceed with the

OK to finish.

displayed.

When an online connection is

established, ONLINE with a green dot is

displayed in the Controller Status pane.

4

Page 7

Rev. 1.0

1

Hardware configuration.

control unit

2

The comparison results are displayed.

3

Check that the configuration on Sysmac

4

Go offline with the Safety Controller.

2.1.3. Creating a Safety Controller Unit Configuration

Create and setup a unit configuration for the Safety Controller.

• From the Multiviewer Explorer

select Configurations and Setup ->

CPU/Expansion Racks

• Double click CPU Rack

• From the CPU/Expansion Racks tab

right click on Unit 0 (NX-CSG320).

• Select Compare and Merge with

Actual Unit Configuration.

This is how Sysmac Studio check to see

what is mounted to the communication

Select Apply Actual Unit Configuration.

Studio and actual unit configuration

match each other.

Select OK to finish.

Select from the top menu Controller ->

Offline

5

Page 8

Rev. 1.0

1

From the Multiview Explorer select

2

Select Configurations and Setup ->

3

The Safety Network Number Settings

4

From the Multiviewer Explorer double

2.2. Network Setting with Sysmac Studio

Set the EtherNet/IP safety connection.

2.2.1. Setting the Connections

Set connection between the Safety Controller and the Omron Safety I/O Block.

In the connection setting via the built-in EtherNet/IP port 2 of the Safety Controller, configure the

I/O block to use as a target device.

new_SafetyCPU0

Communications -> Safety ->

EtherNet/IP Safety Connection Settings.

Double click on Safety Network Number

Settings

tab page is displayed.

Click on to the right of Safety

Network Number (NX bus) to edit.

The Safety Network Number Setting

dialog box is display.

The safety network number (SNN)

default setting is Auto, if not, select

Auto to generate the SNN for the NX

bus.

Select OK to finish.

click on Connection Settings

(Originator).

6

Page 9

Rev. 1.0

5

The Connection Settings

Select OK to finish.

6

Select the GI module and

7

Select the GI module and

8

Give at least one input and

(Originator) tab page is

displayed.

Click on to the right of

Safety Network Number for

EtherNet/IP Port 1 to edit.

The Safety Network Number

Settings dialog box is display.

The safety network number

(SNN) default setting is Auto,

if not, select Auto to

generate the SNN for the

EtherNet/IP Port 1.

insert under the correct

Ethernet port.

insert under Ethernet port 1.

output a name

7

Page 10

Rev. 1.0

9

Set the GI nodes IP address

10

To program the GI

11

Set target node IP address –

Note: Use clear memory

function if below does not

seem to work. Changing IP

address is sometimes not

allowed if TUNID is set. Z400

section 6-4-3

Mode 0: 192.168.250.x x

set by x16 and x1

Mode 4: DHCP see manual

Z400

to match the I/O block rotary

set IP address

8

Page 11

Rev. 1.0

12

To program each input select

13

To program each output

13

Transfer program to Safety

CSG320 or NX102

I/O Configuration tab ->

Input.

select I/O Configuration tab

-> Output.

PLC (see section 2.4)

Transfer setting to NX-

9

Page 12

Rev. 1.0

14

Set GI TUNID

Z400 section 6-4-2

10

Page 13

Rev. 1.0

1

Click Go To I/O Map in the Connection

2

In the I/O Map click to expand.

3

To auto generate the variable names

variable names)

2.3. Transferring Program with Sysmac Studio

Transfer the Safety Network Controller and the Safety CPU program.

2.3.1. Setting Global Variables

Set global variables for the Safety Controller

Settings (Originator) Tab page.

Expand EtherNet/IP Port 1 (Originator)

right click on GI-SMD1624 and select

Create Device Variable.

*the auto generate variable name is the

instance name + the port description

(CIPOriginator_Instance_SI0)

To use user define variable names just enter the

variable name in the Variable column.

(Example: sensor and output are user define

11

Page 14

Rev. 1.0

1

From the Multiview Explorer, select

2

From Project -> Build Controller to check

3

From Controller -> Online to go online to

4

From Controller -> Synchronize.

5

During synchronization confirmation

Select Close.

2.3.2. Transferring the Safety Application Data

Transfer the safety application data to the Safety Network Contr oller (NX-CSGxxx)

new_Controller_0

for errors and compile the project

the safety network controller

The Synchronization Dialog Box is

displayed.

Check that the data to transfer (select

NX).

Select Transfer To Controller to

download the application.

and warning dialog boxes will be

displayed. Read and choose the option

accordingly.

Check the message “The

Synchronization process successfully

finished.” which indicate the

synchronization is completed.

12

Page 15

Rev. 1.0

1

From the Multiview Explorer, select

2

In the Offline mode create the safety

compile the project.

3

Select from the top menu Controller ->

displayed. Select OK.

4

Select from the top menu Controller ->

5

Select from the top menu Controller ->

2.3.3. Transferring the Safety Program

Transfer the safety progr am to t he s afety CPU unit.

new_SafetyCPU0.

program.

Select from the top menu Project ->

Build Controller to check for errors and

Online to go online to the safety

network controller.

The Monitoring warning dialog box is

Mode -> PROGRAM Mode.

The Mode change dialog box is

displayed. Select Yes.

Various dialog boxes will be displayed.

Read and choose the option accordingly.

Check the message in Controller Status

pane to show PROGRAM Mode.

Mode -> DEBUG Mode to begin

downloading the safety program.

The Mode change dialog box is

displayed. Select Yes.

Various dialog boxes will be displayed.

Read and choose the option accordingly.

Check the message in Controller Status

pane to show DEBUG mode (STOPPED).

13

Page 16

Rev. 1.0

6

Select from the top menu Controller ->

7

Select from the top menu Controller ->

Mode -> Safety Validation to validate

the safety program.

The Create boot application dialog box is

displayed. Select Yes.

The information dialog box is displayed.

Select OK.

The Safety Validation dialog box is

displayed. Select OK.

Mode -> RUN Mode.

The Mode change dialog box is

displayed. Select Yes.

Various dialog boxes will be displayed.

Read and choose the option accordingly.

Check the message in Controller Status

pane to show RUN Mode.

14

Page 17

Rev. 1.0

3. Acknowledgement

• EtherNet/IP is a trademark of ODVA, INC.

15

Loading...

Loading...