Page 1

RFID System

V680 Series

User's Manual for Amplifiers, Antennas, and RF Tags

(EEPROM)

Amplifier and Antennas

V680-HA63A

V680-HS51

V680-HS52

V680-HS63

V680-HS65

V680-H01-V2

RF Tags

V680-D1KP52MT

V680-D1KP52M-BT01

V680-D1KP52M-BT11

V680-D1KP53M

V680-D1KP54T

V680-D1KP66T

V680-D1KP66MT

V680-D1KP66T-SP

V680-D1KP58HTN

Man. No.: Z262-E1-09A

Page 2

Introduction

Thank you for purchasing a V680-series RFID System. This manual describes the functions, performance,

and application methods needed for optimum use of the V680-series RFID System.

Please observe the following items when using the RFID System.

• Allow the RFID System to be installed and operated only by qualified specialist with a sufficient

knowledge of electrical systems.

• Read and understand this manual before attempting to use the RFID System and use the RFID System correctly.

• Keep this manual in a safe and accessible location so that it is available for re feren c e when re qu ired .

Page 3

Introduction

Section 1

Section 2

Section 3

Section 4

Section 5

READ AND UNDERSTAND THIS DOCUMENT

Product Overview

Specifications and Performance

Communications Specifications

Installation

Chemical Resistance

Introduction

Section 1 Section 2 Section 3 Section 4 Section 5

RFID System

V680-HA63A Amplifier

V680-HS51 Antenna

V680-HS52 Antenna

V680-HS63 Antenna

V680-HS65 Antenna

V680-H01-V2 Antenna

V680-D1KP52MT RF Tag

V680-D1KP52M-BT01 RF Tag

V680-D1KP52M-BT11 RF Tag

V680-D1KP53M RF Tag

V680-D1KP54T RF Tag

V680-D1KP66T RF Tag

V680-D1KP66MT RF Tag

V680-D1KP66T-SP RF Tag

V680-D1KP58HTN RF Tag

User's Manual

Page 4

Introduction

Introduction

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON representative if you have any qu estions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if specified)

from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN

ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS OMRON’S

ANALYSIS CO NFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT AR E NOT S AFETY RATED. THEY ARE NOT DESIGNED OR RATED FOR ENSURING SAFETY OF

PERSONS, AND SHOULD NOT BE RELIED UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES. Please refer to

separate catalogs for OMRON's safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of produc t s in th e customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents identifying ratings and limitations of use that apply to the products. This information by itself is not sufficient for a complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particu lar att ention must be given. This is not inten ded to be an exh austive list of all possible use s

of the products, nor is it intended to imply that the uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this document.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines, vehicles, safety

equipment, and installations subject to separate industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICA TION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM

AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLED FOR

THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DA TA

Performance data given in this document is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the

result of OMRON’s test conditions, and the users must corre late it to actual ap plication re quirement s. Actual per formance is subject to the OMRON Warranty

and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction changes are made. However,

some specifications of the product may be changed without any notice. When in doubt, special model numbers may be assigned to fix or establish key specifications for your application on your request. Please consult with your OMRO N representative at any time to confirm actual specifications of purchased

products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and i s believed t o be accurate; however, no responsibility is assumed for clerical, typographical ,

or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission. This document is protected by copyright and is intended solely for use in conjunction with the product. Please notify us before copying or reproducing this document in any m anner, for any other purpose. If copying or transmitting this

document to another, please copy or transmit it in its entirety.

RFID System

2

User's Manual

Page 5

Introduction

Precautions for Safe Use

Be sure to observe the following precautions to ensure saf e use of the Products.

1. Do not use the Products in environments with flammable, explosive, or corrosive gasses.

2. Do not attempt to disassemble, repair, or modify any Product.

3. Tighten mounting screws securely.

4. Do not allow water or pieces of wire to enter from openings in the case. Doing so may cause fire or

electric shock.

5. Turn OFF the Controller power supply before mounting or removing an Antenna or Amplifier.

6. Turn OFF the power supply to the Controller before changing settings.

Attach a Setting switch protection Cover after setting Switch.

7. If a n error is detected in an y Product , immediately stop op eration and turn OFF the power su pply. Consult

with an OMRON representative.

8. Dispose of the Products as industrial waste.

9. Observe all warnings and precautions given in the body of this manual .

10. Do not install the Products near equipment that generates a large amount of heat, such as a heater,

transformer, or high-capacity resistor.

11.Because a cable has a locking mechanism, make sure that it has been locked before using the cable.

12.Do not open the back cover of the V680-H01-V2 antenna.

13.Do not touch the product immediately after usage at high temper atures . Doing so may occasionally result

in burning.

14.When using a V680-D1KP58HTN, Make sure that the sp lit pi n is installed co rrectl y to prevent the product

from becoming detached.

Introduction

RFID System

User's Manual

3

Page 6

Introduction

Introduction

Precautions for Correct Use

Always observe the following precautions to prevent operation failures, malfunctions, and adverse effects on

performance and equipment.

1. Installation Environment

Do not use the Products in the following locations.

• Locations exposed to direct sunlight

• Locations exposed to corrosive gases, dust, metallic powder, or salts

• Locations not within the specified operating temperature range

• Locations subject to rapid changes in temperature or condensation

• Locations not within the specified humidity range

• Locations subject to direct vibration or shock outside the specified ranges

• Locations subject to spray of water, oil, or chemicals

• Locations subject to filled with steam

2. Installation

The Products communicate with RF Tags using the 13.56-MHz frequency band. Some motors, inverters, and switching po wer supplie s gener ate noise that can aff ect communications with th e RF Tags and

cause errors. If such de vices are located near t he RF Tags, always te st operat ion in adv ance to conf irm

whether the system will be affected.

• Observe the following precautions to minimize the effects of normal noise.

(1) Ground all metal objects in the vicinity of the Products to 100 Ω or less.

(2) Do not use the Products near high-voltage or high-current lines.

• Do not use non-waterproof Products in an environment where mist is present.

• Do not expose the Products to chemicals that adversely affect the Product materials.

• When mounting the Products, tighten the screws to the following torques.

Do not apply screw loctite and an y other organic solvent to any other parts than the screws.

The casing may get cracked.

V680-HS51: 6 N⋅m

V680-HS52: 40 N⋅m

V680-HS63: 1.2 N⋅m

V680-HS65: 1.2 N⋅m

V680-H01-V2: 1.2 N⋅m (Use the Mounting bracket of the attachment article.)

V680-D1KP52M-BT01: 24.5 N⋅m

V680-D1KP52M-BT11: 11 N⋅m

V680-D1KP66T/-D1KP66MT: 0.5 N⋅m

V680-D1KP66T-SP: 1.2 N⋅m

• Depending on the operating environment, the case surface may become fogged, but basic perfor-

mance will not be affected.

• Do not pull the Antenna connector over the power of 30 N.

The Antenna connector may be broken.

• If multiple Antennas are mounted near each other, communications performance may decrease due

to mutual interference. Refer to Installing Antennas on page 64 and check to make sure there is no

mutual interference.

• When Antenna(only V680-H01-V2) is used in the United States and Canada, the ferrite

core(ZCAT3035-1330) of the antenna's attachment is installed on controller's (V680-CA5D01-V@) DC

power cable.

• Transmission will not be possible if the front and back panels are mistakenly reversed and the Unit is

mounted to a metallic surface.

V680-D1KP66MT

• The transmission distance will be reduced when the Unit is not mounted to a metallic surface.

V680-D1KP66MT

RFID System

4

User's Manual

Page 7

Introduction

• The maximum communications distance can be obtained when the Antenna faces the RF tag directly.

When the Tag is installed at a tilt, the communications distance is reduced. Consider the effect of the

Tag at a tilt when installing the Tag.

• Provide the mounting distances between plural RF tags to prevent them from malfunctions due to

mutual interference.

• If the central axis of an antenna and RF tag shifts, a communications distance will fall.

3. Storage

Do not store the Products in the following locations.

• Locations exposed to direct sunlight

• Locations exposed to corrosive gases, dust, metallic powder, or salts

• Locations not within the specified storage temperature range

• Locations subject to rapid changes in temperature or condensation

• Locations not within the specified storage humidity range

• Locations subject to direct vibration or shock outside the specified ranges

• Locations subject to spray of water, oil, or chemicals

• Locations subject to filled with steam

Introduction

4. Cleaning

• Do not clean the Products with paint thinner or the equivalent. Paint thinner, benzene, acetone, and

kerosene or the equivalent will dissolve the resin materials and case coating.

5. Combination of the Amplifier

• With the amplifierV680-HA63A use only the RF tags of V680-D1KP52MT, V680-D1KP52M-BT01,

V680-D1KP52M-BT11, V680-D1KP53M, V680-D1KP54T, V680-D1KP66T, V680-D1KP66MT, V680D1KP66T-SP, or V680-D1KP58HTN. Do not use these RF T ags together with the V680-HA63B Amplifier.

6. Use at high temperatures (V680-D1KP58HTN)

• Data stored in memor y in the RF Tag may be lost due to the characteristics of EEPROM, if the accu-

mulated usage time of the RF Tag at a high temperature over 125°C exceeds 10 hours after writing

data to the RF Tag.

• Do not communicate between the Antenna and the RF Tag in an environment where the ambient

operating temperature is 85°C or higher.

An error in communications between the Antenna and the RF Tag may occur.

• Do not use the commands using UID (unique identification number for each RF Tag) when the RF tag

is used at a high temperature over 125°C. The UID may be lost due to the characteristics of

EEPROM.

•Do not use the READ ID command (command code: ID).

•Do not make the UID Addition Setting (command code: US).

•Communications specifications (FIFO trigger, FIFO repeat, multi-access trigger, multi-access repeat,

and selective) can not be used.

For Use at high temperatures, refer to RF T ags - Use at high temperatures (V680-D1KP58HTN) in Section 2 Specifica-

tions and Performance.

p.40

RFID System

User's Manual

5

Page 8

Introduction

Introduction

Meanings of Symbols

Meanings of Symbols

Indicates particularly important points related to a function, including precautions and application advice.

Indicates page numbers containing relevant information.

RFID System

6

User's Manual

Page 9

Introduction

Table of Contents

Introduction

Precautions for Safe Use 3

Precautions for Correct Use 4

Meanings of Symbols 6

Table of Contents 7

Section 1 Product Overview 9

Features 10

Product Configuration 11

Section 2 Specifications and Performance 13

Introduction

Antennas with Separate Amplifier 14

Antennas with Built-in Amplifier 21

Amplifier 26

RF Tags 29

Section 3 Communications Specifications 45

Communications Distances 46

Communication Time (Reference) 60

Section 4 Installation 63

Installing Antennas 64

Mounting Amplifiers 73

Installing RF Tags 75

Section 5 Chemical Resistance 95

Chemical Resistance of the Antennas 96

Chemical Resistance of RF Tags 97

Degree of Protection 101

Revision History 104

RFID System

User's Manual

7

Page 10

Introduction

Introduction

MEMO

RFID System

8

User's Manual

Page 11

Section 1 Product Overview

Features 10

Product Configuration 11

Section 1 Product Overview

RFID System

User's Manual

9

Page 12

Section 1

Product Overview

Features

Section 1 Features

The V680-series RFID System actively supports many different types of system, such as distributed-control

systems and many-product, small-lot production systems, with non-contact data communications using

electromagnetic induction.

Non-contact Data Communications

The V680 Series uses electromagnetic induction to enable non-contact, bi-directional data communications between Antennas and RF Tags.

EEPROM Memory

EEPROM (non-volatile memory) is used for RF Tag memory. No battery is required, so there is no

need to be concerned about battery service life.

CRC Used for Transmission Error Detection

A bi-directional 16-bit CRC (Cyclic Redundancy Chec k) ha s been a dd ed a s th e err or de te ct ion me th od

for wire transmissions between ID Controllers and Antennas, and for wireless transmissions between

Antennas and RF Tags. This method maintains superior communications reliability even where problems such as noise occur.

1,000byte of Memory

RF Tags have 1,000byte of memory. In addition to the ID data required on-site, data such as model

numbers and inspection information can be input.

100,000 Data Rewrites at Normal Temperatures

When the RF Tag is used at temperatures of up to 25°C, each block of EEPROM data can be rewritten

up to 100,000 times (in units of single block, 8-bytes).

Superior Environmental Resistance and High Reliability

Antennas and RF Tags now have greater environmental resistance and are not affected by vibration,

oil, or water.

10

RFID System

User's Manual

Page 13

Product Configuration

Section 1

Product Overview

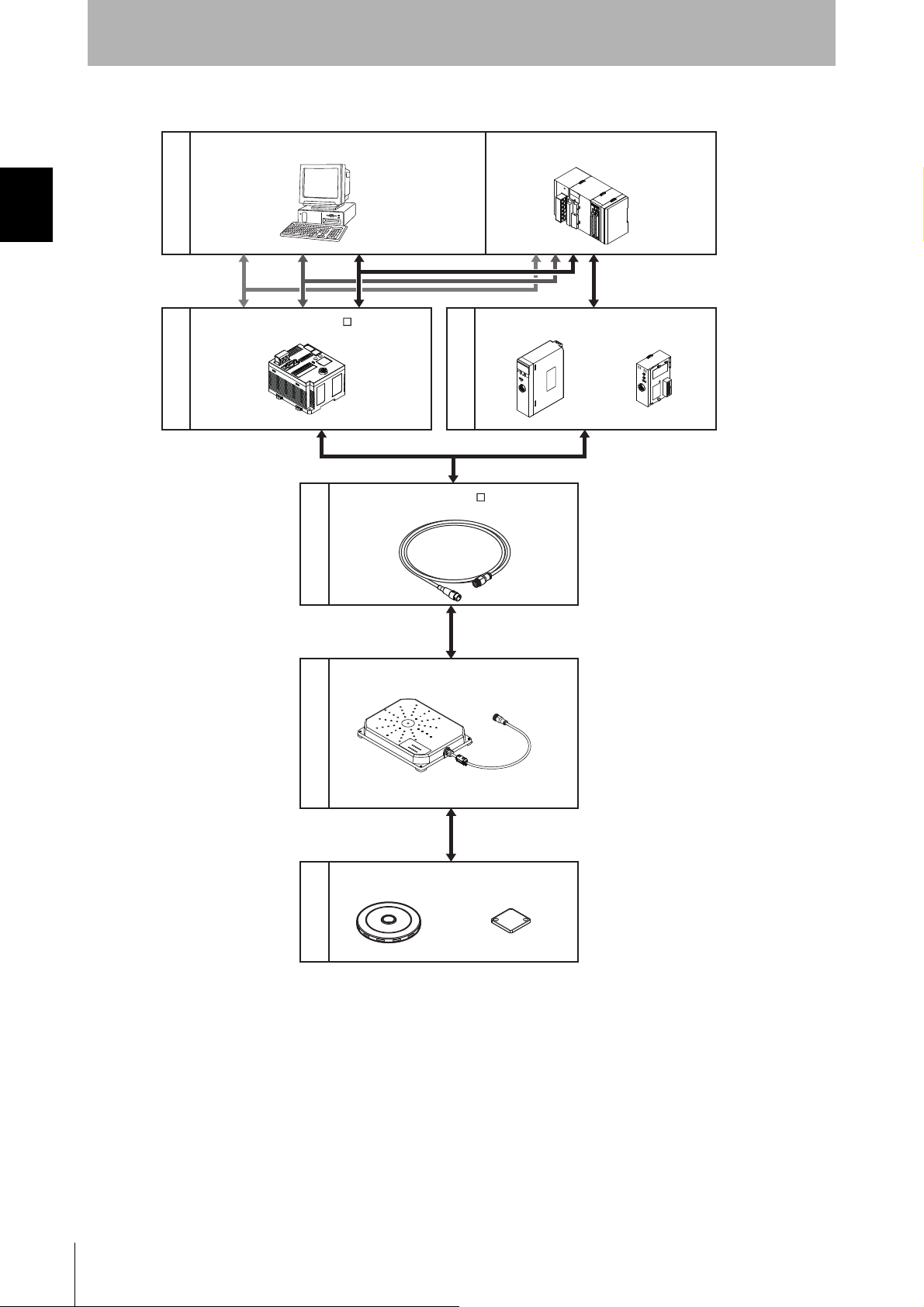

A V680-series RFID System consists of an ID Controller, one or more Amplifiers, one or two Antennas, and

RF Tags. Select the models suitable for the application.

Using Antennas with Separate Amplifiers

Host device

ID Controller

Personal computer Programmable Controller

RS-232C

RS-422 RS-485

V680-CA5D01-VV680-CA5D02-V CS1W-V680C11/12 CJ1W-V680C11/12

ID Sensor Units

V680-HA63A

(SYSMAC CS/CJ Series)

㪭

㪭

㪍

㪍

㪏㪇

㪏㪇

㪚

㪚

㪈

㪈

㪈

㪉

㪩

㪩

㪬

㪬

㪥

㪥

㪜

㪜

㪩

㪩

㪚

㪚

㪟

㪜㪘

㪛

㪜

㪜

㪈

㪩

㪩

㪧

㪧

㪫

㪫

㪆

㪆

㪥㪦㪩㪤㪆㪜㪩㪩

㪥㪦㪩㪤㪆㪜㪩㪩

㪜

㪜

㪩

㪩

㪩

㪩

㪟

㪟

㪟

㪜

㪘㪛

㪫

㪉

㪆

㪩

㪥㪦㪩㪤㪆㪜㪩㪩

㪫

㪫

㪜㪪

㪜

㪪

㪫

㪫

㪦

㪦

㪥

㪥

㪟

㪟

㪜

㪜

㪘㪛

㪘

㪛

㪈

㪈

㪛

㪟

㪚

㪜

㪉㪋

㪘

㪭

㪛

㪠㪥

㪉

㪧

㪬

㪫

㪂

㪄

Section 1 Product Configuration

Amplifiers

V680-HS51 V680-HS52 V680-HS63 V680-HS65

Antennas with Separate

Amplifier

V680-D1KP52MT V680-D1KP53M V680-D1KP66T-SPV680-D1KP54TV680-D1KP52MT-BT01/

-D1KP52MT-BT11

V680-D1KP66T/

-D1KP66MT

V680-D1KP58HTN

RF T ags

When embedding the V680-D1KP52MT and V680-D1KP53M into a metal surface, use the V680-HS51, V680-HS52 Antenna.

Transmission will not be possible if the V680-HS63 Antenna is used.

Use the V680-D1KP52MT, V680-D1KP52M-BT01, V680-D1KP52M-BT11, V680-D1KP53M, V680-D1KP54T, V680-D1KP66T,

V680-D1KP66MT, C680-D1KP66T-SP, and V680-D1KP58HTN RF Tags in combination with only the V680-HA63A Amplifier, Do

not use these RF Tags together with the V680-HA63B Amplifier.

RFID System

User's Manual

11

Page 14

Section 1 Product Configuration

RS-232C

CS1W-V680C11

V

6

8

0

C

1

1

R

U

N

E

R

C

T

/R

NORM/

ERR

E

R

P

E

R

H

T

E

S

T

O

N

H

E

A

D

1

CJ1W-V680C11

RS-422

RS-485

V680-H01-V2

* Always use the specified Cable to connect a

V680-H01-V2 Antenna. The V680-H01-V2

Antenna cannot be connected without using

the specified Cable.

Host device

Programmable Controller

(SYSMAC CS/CJ Series)

ID Controller

ID Sensor Units

Cable

Antennas with Built-in

Amplifier

RF T ags

V700-A40-W M

V680-CA5D01-V

Personal computer

V680-D1KP58HTN V680-D1KP66T

* When V680-H01-V2 is connected with

V680-CA1D/-CA2D, V680-D1KP66T cannot

be used.

Section 1

Product Overview

Using a V680-H01-V2 Antenna with Built-in Amplifier

12

RFID System

User's Manual

Page 15

Section 2 Specifications and Performance

Antennas with Separate Amplifier 14

Antennas with Built-in Amplifier 21

Amplifier 26

RF Tags 29

Section 2 Specifications and Performance

RFID System

User's Manual

13

Page 16

Section 2 Antennas with Separate Amplifier

Case material Brass

Communications

surface

ABS resin

Filling resin Epoxy resin

Cable PVC (black)

Section 2

Specifications and Performance

Antennas with Separate Amplifier

V680-HS51

General Specifications

Item Model V680-HS51

Ambient operating

temperature

Ambient storage

temperature

Ambient operating

humidity

Insulation resistance 20 MΩ min. (at 500 VDC) between connector terminals and case

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between connector terminals and case

Degree of protection IP67.(IEC60529)

Dielectric strength

Shock resistance

Dimensions M12 × 35 mm

Material ABS resin, brass, and epoxy resin filler

Weight Approx. 55 g

Cable length Standard lengths of 2 m

-10 to 60°C (with no icing)

-25 to 75°C (with no icing)

35% to 95% (with no condensation)

Oil resistance equivalent to IP67g according to the former JEM standard.

Note: The connectors are not waterproof.

10 to 2,000 Hz, 1.5-mm double amplitude, acceleration: 150 m/s

tions (up/down, left/right, and forward/backward) for 15 minutes each

2

1,000 m/s

, 3 times each in 6 directions (Total: 18 times)

2

, 10 sweeps in each of 3 axis direc-

Dimensions

• V680-HS51

12.5 dia.

Mounting Hole Dimensions

21 dia.

17

M12 × 1

9.6 dia.

(Unit : mm)

Toothed washer

Connector

(14.5 dia.)

Insulation cover

(16.8 dia.)

25

Ferrite core

26.2

50

Two lock nuts

12

7

24

33

35

Coaxial cable, 2.9 dia.,

standard length: 2 m

15

14

RFID System

User's Manual

Page 17

Specifications and Performance

Case material Brass

Communications

surface

ABS resin

Filling resin Epoxy resin

Cable PVC (gray)

V680-HS52

General Specifications

Item Model V680-HS52-W

(Standard cable, waterproof connector)

Ambient operating

temperature

Ambient storage

temperature

Ambient operating

humidity

Insulation resistance 20 MΩ min. (at 500 VDC) between connector terminals and case

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between connector terminals and case

Degree of protection IP67.(IEC60529)

Dielectric strength

Shock resistance

Dimensions M22 × 65 mm

Material ABS resin, brass, and epoxy resin filler

Weight Approx. 850 g (with 12.5 m cable)

Cable length Standard lengths of 2 and 12.5 m

-10 to 60°C (with no icing)

-25 to 75°C (with no icing)

35% to 95% (with no condensation)

Oil resistance equivalent to IP67g according to the

former JEM standard.

Note: The connector specifications are IP67 and

IP65.(IEC60529)

10 to 500 Hz, 1.5-mm double amplitude, acceleration: 100 m/s

(up/down, left/right, and forward/backward) for 8 minutes each

2

500 m/s

, 3 times each in 6 directions (Total: 18 times)

(Flexible cable, non-waterproof connector)

IP67.(IEC60529)

Oil resistance equivalent to IP67g according to the

former JEM standard.

Note: The connectors are not waterproof.

Section 2

V680-HS52-R

2

, 10 sweeps in each of 3 axis directions

Section 2 Antennas with Separate Amplifier

Dimensions

• V680-HS52-W

22.5 dia.

Mounting Hole Dimensions

Antenna

35 dia.

19.8 dia.

Two toothed washers

Two lock nuts

M22 × 1

16.5 dia.

Ferrite core

5030

37

Connector

16.5 dia.

14.5 dia.

Insulation cover

Operation indicator

730

47.6

50

57

65

Coaxial cable, 5.5 dia.,

standard length: 2 m

RFID System

User's Manual

15

Page 18

Section 2

Case material Brass

Communications

surface

ABS resin

Filling resin Epoxy resin

Cable PVC (black)

Specifications and Performance

• V680-HS52-R

Section 2 Antennas with Separate Amplifier

22.5 dia.

Mounting Hole Dimensions

Antenna

35 dia.

19.8 dia.

Two toothed washers

Two lock nuts

M22 × 1

16.5 dia.

Ferrite core

(39.5)

5030

Insulation cover

Connector

14.5 dia.

Insulation cover

16.5 dia.

Operation indicator

730

47.6

50

57

65

Coaxial cable, 5.3 dia.,

standard length: 2 m

16

RFID System

User's Manual

Page 19

V680-HS63

(Unit: mm)

23

5

5

Operation indicator

40

28±0.1

53

27 6

11

Note: Mounting Hole Dimensions

Coil center

Two, M4 or 4.5 dia. holes

37

5030

16.5 dia.

Coaxial cable, 5.5 dia.,

standard length: 2 m

Connector

Ferrite core

Insulation cover

16.5 dia.

14.5 dia.

Antenna

Case material ABS resin

Filling resin Epoxy resin

Cable PVC (gray)

General Specifications

Item Model V680-HS63-W

(Standard cable, waterproof connector)

Ambient operating

temperature

Ambient storage

temperature

Ambient operating

humidity

Insulation resistance 20 MΩ min. (at 500 VDC) between cable terminals and case

Dielectric strength 1,000 VAC, 50/60Hz for 1 min between cable terminals and case

Degree of protection IP67.(IEC60529)

Vibration resistance 10 to 500 Hz, 1.5-mm double amplitude, acceleration: 100 m/s

Shock resistance 500 m/s

Dimensions 40 × 53 × 23 mm

Material ABS resin case, epoxy resin filler

Weight Approx. 850 g (with 12.5 m cable)

Cable length Standard lengths of 2 and 12.5 m

-10 to 60°C (with no icing)

-25 to 75°C (with no icing)

35% to 95% (with no condensation)

IP67.(IEC60529)

Oil resistance equivalent to IP67g according to the

former JEM standard.

Note: The connector specifications are IP67 and

IP65.(IEC60529)

(up/down, left/right, and forward/backward) for 11 minutes each

2

, 3 times each in 6 directions (Total: 18 times)

Oil resistance equivalent to IP67g according to the

former JEM standard.

Note: The connectors are not waterproof.

Section 2

Specifications and Performance

V680-HS63-R

(Flexible cable, non-waterproof connector)

2

, 10 sweeps in each of 3 axis directions

Section 2 Antennas with Separate Amplifier

Dimensions

• V680-HS63-W

RFID System

User's Manual

17

Page 20

Section 2

Case material ABS resin

Filling resin Epoxy resin

Cable PVC (black)

Specifications and Performance

• V680-HS63-R

Antenna

Ferrite core

(39.5)

Connector

(Unit: mm)

Section 2 Antennas with Separate Amplifier

40

28±0.1

5

5

Operation indicator

23

Note: Mounting Hole Dimensions

Coil center

27 6

53

11

Two, M4 or 4.5 dia. holes

16.5 dia.

5030

Coaxial cable, 5.3 dia.,

standard length: 2 m

14.5 dia.

16.5 dia.

Insulation cover

18

RFID System

User's Manual

Page 21

Specifications and Performance

Operation indicator

30

20

11

(Unit: mm)

16.5 dia.

14.5 dia.

37

5030

16.5 dia.

Coaxial cable, 5.5 dia.,

standard length: 2 m

Connector

Ferrite core

Insulation cover

14

10

10

Bushing

50

25

100

90±0.25

50

100

90±0.2 5

4-4.5 dia.

(Mounting holes)

Case material ABS resin

Filling resin Epoxy resin

Cable PVC (gray)

V680-HS65

General Specifications

Item Model V680-HS65-W

(Standard cable, waterproof connector)

Ambient operating

temperature

Ambient storage

temperature

Ambient operating

humidity

Insulation resistance 20 MΩ min. (at 500 VDC) between connector terminals and case

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between connector terminals and case

Degree of protection IP67 (IEC60529)

Dielectric strength

Shock resistance

Dimensions 100 × 100 × 30 mm

Material ABS resin case, epoxy resin filler

Weight Approx. 1100 g (with 12.5 m cable)

Cable length Standard lengths of 2 and 12.5 m

−25 to 70°C (with no icing)

−40 to 85°C (with no icing)

35% to 95% (with no condensation)

Oil resistance equivalent to IP67g according to the

former JEM standard.

Note: The connector specifications are IP67 and

IP65 (IEC 60529).

10 to 500 Hz, 1.5-mm double amplitude, acceleration: 100 m/s

(up/down, left/right, and forward/backward) for 11 minutes each

2

500 m/s

, 3 times each in 6 directions (Total: 18 times)

(Flexible cable, non-waterproof connector)

IP67 (IEC60529)

Oil resistance equivalent to IP67g according to the

former JEM standard.

Note: The connectors are not waterproof.

Section 2

V680-HS65-R

2

, 10 sweeps in each of 3 axis directions

Section 2 Antennas with Separate Amplifier

Dimensions

• V680-HS65-W

RFID System

User's Manual

19

Page 22

Section 2 Antennas with Separate Amplifier

(39.5)

16.5 dia.

14.5 dia.

(Unit: mm)

5030

16.5 dia.

Coaxial cable, 5.3 dia.,

standard length: 2 m

Insulation cover

Connector

Ferrite core

Operation indicator

30

20

11

14

10

10

Bushing

50

25

100

90±0.25

50

100

90±0.2 5

4-4.5 dia.

(Mounting holes)

Case material ABS resin

Filling resin Epoxy resin

Cable PVC (black)

Section 2

Specifications and Performance

• V680-HS65-R

RFID System

20

User's Manual

Page 23

Antennas with Built-in Amplifier

V680-H01-V2

General Specifications

Item Model V680-H01-V2

Ambient operating

temperature

Ambient storage

temperature

Ambient operating

humidity

Insulation resistance 20 MΩ min. (at 100 VDC) between connector terminals and the rear plate

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between connector terminals and the rear plate

Degree of protection IP63.(IEC60529); Mounting direction: Communications surface facing up

Dielectric strength

Shock resistance

Cable length 0.5 m (use an relay cable to connect to the Controller up to 30.5 m)

LED indicators RUN, COMM, NORM, ERR, CNT-TYPE, TAG-TYPE, Error Code, Level

Weight Approx. 900 g

-10 to 55°C (with no icing)

-35 to 65°C (with no icing)

35% to 85% (with no condensation)

10 to 150 Hz, 0.35-mm single amplitude, acceleration: 50 m/s

(up/down, left/right, and forward/backward) for 8 minutes each

2

150 m/s

, 3 times each in 6 directions (Total: 18 times)

Section 2

Specifications and Performance

2

, 10 sweeps in each of 3 axis directions

Section 2 Antennas with Built-in Amplifier

Communications Specifications

Item Model V680-H01-V2

Communications method Electromagnetic induction

Operating frequency 13.56 MHz ± 7KHz

Modulation ASK

RFID System

User's Manual

21

Page 24

Section 2

Case material PC/ASA resin

Rear Panel Aluminum

Cable PVC

Specifications and Performance

Dimensions

MOUNTING SCREW HOLES

Senter of Coil

Section 2 Antennas with Built-in Amplifier

142.5

±0.2

235

65

(25-dia.)

50

Setting switch protection Cover

185±0.2

Four, M4 or 4.5-dia. holes

Twelve, Operation Indicator

Communications sufrace

200

185

Four, Mounting bracket

Vinyl Insulated Round Cord (5.8-dia.)

(41/0.16-dia.) 2 Cores (17/0.08-dia.) 8 Cores

Standard Length 0.5 m

Four, 5-dia. holes

(Mounting Holes)

6

30 38

142.5

235

250

7.5

(17)

(Unit : mm)

Connector

Ferrite Core

14 64.8

+50

500 0 (45)

20-dia.

(1)40

13.5

22

RFID System

User's Manual

Page 25

Operation Indicator

name Color Meaning

RUN Green Lit when the power is ON.

COMM Yellow Lit when a command is being sent.

NORM Green Lit when communications with a RF Tag are normal in Normal Communications

ERR Red Lit when an error occurs in communications with a RF Tag in Normal

CNT-TYPE Yellow Lit when in V680-CA1D/-CA2D Controller connection mode (SW1-1 setting: ON).

TAG-TYPE Yellow Lit when in V680-D@KF@@ RF Tag mode (SW1-2 setting: ON).

LV6/7D Yellow Maintenance Mode: Lit at distance or speed level 6.

LV5/7A Yellow Maintenance Mode: Lit at distance or speed level 5 or higher.

LV4/76 Yellow Maintenance Mode: Lit at distance or speed level 4 or higher.

LV3/72 Yellow Maintenance Mode: Lit at distance or speed level 3 or higher.

LV2/71 Yellow Maintenance Mode: Lit at distance or speed level 2 or higher.

LV1/70 Yellow Maintenance Mode: Lit at distance or speed level 1 or higher.

Section 2

Specifications and Performance

Mode.

Section 2 Antennas with Built-in Amplifier

Communications Mode.

Normal Communications Mode: Lit when a write protection error occurs.

Normal Communications Mode: Lit when an address error occurs.

Normal Communications Mode: Lit when a RF Tag memory error occurs.

Normal Communications Mode: Lit when a no RF Tag error occurs.

Normal Communications Mode: Lit when a verification error occurs.

Normal Communications Mode: Lit when a RF Tag communications error occurs.

The distance level will vary greatly depending on the surrounding environment. The setting position will serve as a

guide, but use RUN mode to conduct a sufficient number of tests in the actual operating environment.

Values of distance level 6 may not be displayed, but this will not affect the RUN mode performance and does not indicate a malfunction.

Differences between the V680-H01 and the V680-H01-V2

As shown in the following table, the V680-H01-V2 provides additional indicators.

Turn ON SW1-1(Antenna) when using the V680-CA1D/CA2D.

Only when the V680-D1KP58HTN is used, it is possible to set it.

display functions

RUN (POWER/COMM) OK OK OK

COMM (POWER/COMM) OK OK OK

NORM OK NO NO

ERR OK NO NO

CNT-TYPE OK OK NO

TAG-TYPE --- --- --LV6/7D OK NO NO

LV5/7A OK NO NO

LV4/76 OK NO NO

LV3/72 OK NO NO

LV2/71 OK NO NO

LV1/70 OK NO NO

SW1-1: OFF SW1-1: ON no switch

V680-H01-V2 V680-H01

RFID System

User's Manual

23

Page 26

Section 2

Note: Please attach a setting switch protection cover after setting switch.

Specifications and Performance

Setting Switch

Section 2 Antennas with Built-in Amplifier

Setting switch protection cover

Setting Function Default setting

SW1-1 Controller selection

OFF:V680-CA5D01-V@, CS1W-V680C11, or CJ1W-V680C11

ON: V680-CA1D/-CA2D

SW1-2 RF Tag selection

OFF:V680-D1KP@@ (EEPEOM RF Tags)

ON: V680-D@KF@@ (FRAM RF Tags)

SW1-3 Reserved by System (Always set this Switch to OFF.) --SW1-4 Reserved by System (Always set this Switch to OFF.) ---

Note: Only when the V680-D1KP58HTN is used, it is possible to connect it with the V680-CA1D/-CA2D.

When the V680-CA5D01-V@, CS1W-V680-C11 and CJ1W-V680C11 is used, set SW1-1 of the antenna to turning off.

See Note.

OFF

OFF

Set SW1-1 on the V680-H01-V2 Antenna and the Controller as shown in the following table.

When the V680-CA1D/-CA2D is used, set SW1-1 of the antenna to turning on.

When using it excluding the V680-CA1D/-CA2D, set SW1-1 of the antenna to turning off besides.

Antenna setting Controller setting

V680-H01-V2 V680-CA5D01-V@ CS1W-V680C11

CJ1W-V680C11

SW1-1: OFF SW4-8: OFF DM20000 + 100 × m+3=0000

SW1-1: ON SW4-8: ON

: Cannot be used.

: Can be used.(Controller setting not required.)

Note: The high-speed mode cannot be used by the controller's setting.

Differences between the V680-H01 and the V680-H01-V2

As shown in the following table, the V680-H01-V2 supports additional maintenance functions.

Turn ON SW1-1(Antenna) when using the V680-CA1D/CA2D.

Only when the V680-D1KP58HTN is used, it is possible to set it.

display functions

Communication Test Mode OK OK OK

Noise Level Measurement

Mode

Distance Level Measurement

Mode

Speed Level Measurement

Mode

Communications Success

Rate Measurement Mode

See Note.

DM20000 + 100 × m+3=0001

V680-H01-V2 V680-H01

SW1-1: OFF SW1-1: ON no switch

OK NO NO

OK NO NO

OK NO NO

OK NO NO

See Note. Å@See Note.

V680-CA1D

V680-CA2D

24

RFID System

User's Manual

Page 27

Section 2

Connector (Antenna end))

Connector (Controller end))

Connection label

Vinyl Insulated Round Cord

6 dia.

20 dia.

41.8

L1

±100

49

(Unit: mm)

15 dia.

Cable PVC

Specifications and Performance

Cables (V680-H01-V2 exclusive use)

Specifications

Item Model V700-A40-W

Number of conductors 10

Insulation resistance 5 MΩ min. (at 500 VDC) between terminals and sheath

Dielectric strength 500 VAC, 1 min

Dimensions

Item Model V700-A40-W 2M V700-A40-W 5M V700-A40-W 10M V700-A40-W 20M V700-A40-W 30M

Length (L1) Approx.2m Approx. 5 m Approx.10m Approx. 20 m Approx. 30 m

Weight Approx. 150 g Approx.360 g Approx. 700 g Approx.1,350 g Approx.2,000 g

L1 2,000 5,000 10,000 20,000 30,000

Section 2 Antennas with Built-in Amplifier

RFID System

User's Manual

25

Page 28

Section 2 Amplifier

Operation indicator

13.7 65 18

51

36

15 dia.

40

25

9.5 dia.

25

3.5

12.8 dia.

15 35.6

25

Round, vinyl-insulated cable (5.8 dia.), standard length: 5 m,

(41/0.16 dia) 2 conductors, (17/0.08 dia.) 8 conductors

Connector

Connector

Case material PC resin

Cable PVC

Section 2

Specifications and Performance

Amplifier

V680-HA63A

General Specifications

Item Model V680-HA63A

Ambient operating

temperature

Ambient storage

temperature

Ambient operating

humidity

Insulation resistance 20 MΩ min. (at 500 VDC) between cable terminals and case

Dielectric strength 1,000 VAC, 50/60 Hz for 1 minute between cable terminals and case.

Degree of protection IP67, IP65 (IEC 60529)

Dielectric strength

Shock resistance 500 m/s

Dimensions 25 × 40 × 65 mm (Not including protrusions.)

Materials PC

Weight Approx. 650 g (with 10 m cable)

Cable length Standard lengths of 5 and 10 m

Note: The maximum total cable extension is 50 m (including the Amplifier cable). A maximum of two extension cables can be

connected.

-10 to 55°C (with no icing)

-25 to 65°C (with no icing)

35% to 85% (with no condensation)

Note: Not including connector at Controller end.

(When V680-HS52-W, V680-HS63-W, and V680-HS65-W

is connected)

10 to 500 Hz, 1.5-mm double amplitude, acceleration:100 m/s

(up/down, left/right, and forward/backward) for 11 minutes each

2

, 3 times each in 6 directions (Total: 18 times)

IP40 (IEC 60529)

(When V680-HS51, V680-HS52-R, V680HS63-R, and V680-HS65-R is connected)

2

, 10 sweeps in each of 3 axis directions

Dimensions

26

RFID System

User's Manual

Page 29

Nomenclature

Section 2

Specifications and Performance

Antenna with Separate Amplifier connection port

RUN

COMM

NORM

ERR

LV6/7D

LV5/7A

LV4/76

LV3/72

Operation indicators

LV2/71

LV1/70

Controller connector

Antenna Connection Port

The Antenna connection port is connected a V680-series Antenna.

Controller Connector

The Controller connector is connected to Antenna connection port on the Controller.

Section 2 Amplifier

Operation Indicators (LEDs)

Name Color Meaning

RUN Green Lit when the power is ON.

COMM Yellow Lit when a command is being sent.

NORM Green Lit when communications with a RF Tag are normal in Normal Communications Mode.

ERR Red Lit when an error occurs in communications with a RF Tag in Normal Communications Mode.

LV6/7D Yellow

LV5/7A Yellow

LV4/76 Yellow

LV3/72 Yellow

LV2/71 Yellow

LV1/70 Yellow

The distance level will vary greatly depending on the surrounding environment. The setting position will serve as a

guide, but use RUN mode to conduct a sufficient number of tests in the actual operating environment.

Values of distance level 4 or above may not be displayed, but this will not affect the RUN mode performance and does

not indicate a malfunction.

Maintenance Mode: Lit at distance or speed level 6.

Normal Communications Mode: Lit when a write protection error occurs.

Maintenance Mode: Lit at distance or speed level 5 or higher.

Normal Communications Mode: Lit when an address error occurs.

Maintenance Mode: Lit at distance or speed level 4 or higher.

Normal Communications Mode: Lit when a RF Tag memory error occurs.

Maintenance Mode: Lit at distance or speed level 3 or higher.

Normal Communications Mode: Lit when a no RF Tag error occurs.

Maintenance Mode: Lit at distance or speed level 2 or higher.

Normal Communications Mode: Lit when a verification error occurs.

Maintenance Mode: Lit at distance or speed level 1 or higher.

Normal Communications Mode: Lit when a RF Tag communications error occurs.

RFID System

User's Manual

27

Page 30

Section 2 Amplifier

51 L1

±100

49

15.5 dia.

Connector (Controller end))

Connection label

Connector (Amplifier end)

6 dia.

15 dia.

(Unit: mm)

Cable PVC

Section 2

Specifications and Performance

Cables (V680-HA63 exc lusive use)

Specifications

Item Model V700-A43/V700-A44

Number of conductors 10

Insulation resistance 5 MΩ min. (at 500 VDC) between terminals and sheath

Dielectric strength 500 VAC, 1 min

Dimensions

Item Model V700-A43 V700-A44

Length (L1) Approx.10m Approx. 20 m

Weight Approx. 700 g Approx.1,350 g

28

RFID System

User's Manual

Page 31

RF Tags

8

0

−0.1

R0.2

5

0

−0.1

dia.

(Unit : mm)

Case material PPS resin

Filling resin Epoxy resin

Specifications and Dimensions

V680-D1KP52MT

• General Specifications

Item Model V680-D1KP52MT

Memory capacity 1,000 bytes (user area)

Memory type EEPROM

Data Retention 10 years after writing (85°C or less), 0.5 years after writing (85°C to 125°C)

Write Endurance 100,000 times per block (25°C)

Ambient operating

temperature when

communicating

Ambient storage

temperature (with data

retention)

Ambient operating

humidity

Degree of protection IP68 (IEC 60529)

Vibration resistance

Shock resistance 500 m/s

Dimensions 8 dia. × 5 mm

Materials Case: PPS resin, Filling resin: Epoxy resin

Weight Approx. 0.5 g

Metal countermeasures Yes

Specifications and Performance

Total data retention at high temperatures exceeding 125°C is 10 hours (See note.)

-25 to 85°C (with no icing)

-40 to 125°C (with no icing)

35% to 95%

Oil resistance equivalent to IP67g according to the former JEM standard.

10 to 2,000 Hz, 1.5-mm double amplitude, acceleration: 150 m/s

directions for 15 minutes each

2

, 3 times each in X, Y, and Z directions (Total: 18 times)

2

, 10 sweeps each in X, Y, and Z

Section 2

Section 2 RF Tags

Note: After string data at high temperatures, rewrite the data even if changes are not required, high temperatures

are those exceeding 125°

C up to 180°C.

• Dimensions

When embedding the V680-D1KP52MT into a metal surface, use the V680-HS51, V680-HS52 Antenna.

Transmission will not be possible if the V680-HS63 Antenna is used.

The side with the markings is the communications surface. Mount the RF Tag with this side facing the Antenna.

The ID code is written in the memor y of the R F Tag and may be affected by data retention characteristics at high temperatures. Take suitable precautions when using the READ ID command for RF Tags operating at high temperatures.

RFID System

User's Manual

29

Page 32

Section 2

Specifications and Performance

• RF Tag Heat Resistivity

• Storing RF Tags under high temperatures or heat cycle will adversely affect the performance of the

internal parts and the service life of the RF Tags.

• An LTPD of 10% was determined during the evaluation for RF Tags that reached the end of their life

after testing under the following test conditions.

Section 2 RF Tags

Heat cycle -10°C/+150°C, 30 minutes each for 1,000 cycles: Defective number 0/22 piece

-100°C/+180°C,30 minutes each for 200 cycles: Defectiv e number 0/22 piece

High temperatures +150°C, 1,000 hours: Defective number 0/22 piece

+180°C, 200 hours: Defective number 0/22 piece

LTPD: Lot tolerance percent defective

The lower limit of the malfunction rate for lots to be considered unacceptable during reliability testing.

30

RFID System

User's Manual

Page 33

Specifications and Performance

V680-D1KP52M-BT01

• General Specifications

Item Model V680-D1KP52M-BT01

Memory capacity 1,000 bytes (user area)

Memory type EEPROM

Data Retention 10 years after writing (85°C or less), 0.5 years after writing (85°C to 125°C)

Total data retention at high temperatures exceeding 125°C is 10 hours (See note.)

Write Endurance 100,000 times per block (25°C)

Ambient operating

temperature when

communicating

Ambient storage

temperature (with data

retention)

Ambient operating

humidity

Degree of protection IP68 (IEC 60529)

Vibration resistance

Shock resistance 500 m/s

Dimensions Hex Head: 17HEX × 9.5 mm, Screw: M10 × 10 mm

Materials Bolt: SUS303, Case(RF Tag): PPS resin, Filling resin(RF Tag): Epoxy resin

Weight Approx. 25 g

Metal countermeasures Yes

-25 to 85°C (with no icing)

-40 to 125°C (with no icing)

35% to 95%

Oil resistance equivalent to IP67g according to the former JEM standard.

10 to 2,000 Hz, 1.5-mm double amplitude, acceleration: 150 m/s

directions for 15 minutes each

2

, 3 times each in X, Y, and Z directions (Total: 18 times)

Section 2

2

, 10 sweeps each in X, Y, and Z

Section 2 RF Tags

• Dimensions

The side with the markings is the communications surface. Mount the RF Tag with this side facing the Antenna.

The ID code is written in the memor y of the R F Tag and may be affected by data retention characteristics at high temperatures. Take suitable precautions when using the READ ID command for RF Tags operating at high temperatures.

RF T ag

(19.6)

17

Bolt

15-30

8.4 dia.

M10-P1.5

C1.5

0.1 9.5 10

21.6

Bolt material SUS303

Case material (RF Tag) PPS resin

Filling resin (RF Tag) Epoxy resin

(Unit: mm)

RFID System

User's Manual

31

Page 34

Section 2 RF Tags

Section 2

Specifications and Performance

V680-D1KP52M-BT11

• General Specifications

Item Model V680-D1KP52M-BT11

Memory capacity 1,000 bytes (user area)

Memory type EEPROM

Data Retention 10 years after writing (85°C or less), 0.5 years after writing (85°C to 125°C)

Total data retention at high temperatures exceeding 125°C is 10 hours (See note.)

Write Endurance 100,000 times per block (25°C)

Ambient operating

temperature when

communicating

Ambient storage

temperature (with data

retention)

Ambient operating

humidity

Degree of protection IP68 (IEC 60529)

Vibration resistance

Shock resistance 500 m/s

Dimensions Hex Head: 13HEX × 7 mm, Screw: M8 × 10 mm

Materials Bolt: SUS303, Case(RF Tag): PPS resin, Filling resin(RF Tag): Epoxy resin

Weight Approx. 10 g

Metal countermeasures Yes

-25 to 85°C (with no icing)

-40 to 125°C (with no icing)

35% to 95%

Oil resistance equivalent to IP67g according to the former JEM standard.

10 to 2,000 Hz, 1.5-mm double amplitude, acceleration: 150 m/s

directions for 15 minutes each

2

, 3 times each in X, Y, and Z directions (Total: 18 times)

2

, 10 sweeps each in X, Y, and Z

• Dimensions

The side with the markings is the communications surface. Mount the RF Tag with this side facing the Antenna.

The ID code is written in the memor y of the R F Tag and may be affected by data retention characteristics at high temperatures. Take suitable precautions when using the READ ID command for RF Tags operating at high temperatures.

RF T ag

(15)

13

Bolt

15-30

6 dia.

M8-P1.25

C1.5

0.1 7 10

19.1

Bolt material SUS303

Case material (RF Tag) PPS resin

Filling resin (RF Tag) Epoxy resin

(Unit: mm)

32

RFID System

User's Manual

Page 35

Specifications and Performance

C0.5

6-R0.8

10 dia.

4.5

V680-D1KP53M

General Specifications

Item Model V680-D1KP53M

Memory capacity 1,000 bytes (user area)

Memory type EEPROM

Data Retention 10 years after writing (85°C or less), 0.5 years after writing (85 to 125°C)

Write Endurance 100,000 times per block (25°C)

Ambient operating

temperature when

communicating

Ambient storage

temperature (with data

retention)

Ambient operating

humidity

Degree of protection IP68 (IEC 60529)

Vibration resistance 10 to 2,000 Hz, 1.5-mm double amplitude, acceleration: 150 m/s

Shock resistance 500 m/s

Dimensions 10 dia. × 4.5 mm (DIN698373)

Materials Case: PPS resin, Filling resin: Epoxy resin

Weight Approx. 1.0 g

Metal countermeasures Yes

−25 to 85°C (with no icing)

−40 to 125°C (with no icing)

35% to 95%

Oil resistance equivalent to IP67g according to the former JEM standard.

directions for 15 minutes each

2

, 3 times each in X, Y, and Z directions (Total: 18 times)

Section 2

2

, 10 sweeps each in X, Y, and Z

Section 2 RF Tags

Dimensions

When embedding the V680-D1KP53M into a metal surface, use the V680-HS51, V680-HS52 Antenna.

Transmission will not be possible if the V680-HS63 Antenna is used.

The side with the markings is the communications surface. Mount the RF Tag with this side facing the Antenna.

Case material PPS resin

Filling resin Epoxy resin

RFID System

User's Manual

33

Page 36

Section 2 RF Tags

Case material PPS resin

1.1

2.7

±0.1

16 dia.

±0.1

20 dia.

±0.1

(Unit : mm)

Section 2

Specifications and Performance

V680-D1KP54T

• General Specifications

Item Model V680-D1KP52MT

Memory capacity 1,000 bytes (user area)

Memory type EEPROM

Data Retention 10 years after writing (85°C or less), 0.5 years after writing (85°C to 125°C)

Total data retention at high temperatures exceeding 125°C is 10 hours (See note.)

Write Endurance 100,000 times per block (25°C)

Ambient operating

temperature when

communicating

Ambient storage

temperature (with data

retention)

Ambient operating

humidity

Degree of protection IP67 (IEC 60529)

Vibration resistance

Shock resistance 500 m/s

Dimensions 20 dia. × 2.7 mm

Materials PPS resin

Weight Approx. 2.0 g

Metal countermeasures None

-25 to 85°C (with no icing)

-40 to 125°C (with no icing)

35% to 95%

Oil resistance equivalent to IP67g according to the former JEM standard.

10 to 2,000 Hz, 1.5-mm double amplitude, acceleration: 150 m/s

directions for 15 minutes each

2

, 3 times each in X, Y, and Z directions (Total: 18 times)

2

, 10 sweeps each in X, Y, and Z

Note: After string data at high temperatures, rewrite the data even if changes are not required, high temperatures

are those exceeding 125°

C up to 180°C.

Dimensions

V680-D1KP54T

The coin-shaped RF Tag has no directionality, so it can be faced in any direction.

The ID code is written in the memor y of the R F Tag and may be affected by data retention characteristics at high temperatures. Take suitable precautions when using the READ ID command for RF Tags operating at high temperatures.

34

RFID System

User's Manual

Page 37

V600-A86 Attachment

Material PPS resin

40

31

±0.2

T

w

o,

6

d

i

a

.

T

w

o

,

2

0

d

i

a

.

(

M

o

u

n

t

i

n

g

H

o

l

e

)

.

(Unit : mm)

24

18

22

22

5

8

3.5

1

Section 2

Specifications and Performance

Section 2 RF Tags

• RF Tag Heat Resistivity

• Storing RF Tags under high temperatures or heat cycle will adversely affect the performance of the

internal parts and the service life of the RF Tags.

• An LTPD of 10% was determined during the evaluation for RF Tags that reached the end of their life

after testing under the following test conditions.

Heat cycle -10°C/+150°C, 30 minutes each for 1,000 cycles: Defective number 0/22 piece

-100°C/+180°C,30 minutes each for 200 cycles: Defectiv e number 0/22 piece

High temperatures +150°C, 1,000 hours: Defective number 0/22 piece

+180°C, 200 hours: Defective number 0/22 piece

LTPD: Lot tolerance percent defective

The lower limit of the malfunction rate for lots to be considered unacceptable during reliability testing.

RFID System

User's Manual

35

Page 38

Section 2 RF Tags

V680-D1KP66MT V680-D1KP66T

MADE IN JAPAN

XXXXXX

V680-D1KP66MT

MADE IN JAPAN

XXXXXX

V680-D1KP66T

Section 2

Specifications and Performance

V680-D1KP66T/66MT

• General Specifications

Item Model V680-D1KP66T V680-D1KP66MT

Memory capacity 1,000 bytes (user area)

Memory type EEPROM

Data Retention 10 years after writing (85°C or less), 0.5 years after writing (85°C to 125°C)

Total data retention at high temperatures exceeding 125°C is 10 hours (See note.)

Write Endurance 100,000 times per block (25°C)

Ambient operating

temperature

Ambient storage

temperature

Ambient operating

humidity

Degree of protection IP68 (IEC 60529)

Vibration resistance

Shock resistance 500 m/s

Dimensions 34 × 34 × 3.5 mm

Materials Case: PPS resin

Weight Approx. 6 g Approx. 7.5 g

Metal countermeasures None Yes

-25 to 85°C (with no icing)

-40 to 125°C (with no icing)

35% to 95%

Oil resistance equivalent to IP67g according to the former JEM standard.

2

10 to 2,000 Hz, 1.5-mm double amplitude, acceleration: 150 m/s

directions for 15 minutes each

2

, 3 times each in X, Y, and Z directions (Total: 18 times)

,10 sweeps each in X, Y, and Z

Note: After string data at high temperatures, rewrite the data even if changes are not required, high temperatures

are those exceeding 125°

C up to 180°C.

The V680-D1KP66MT is designed to be mounted directly to metal. The V680-D1KP66T and V680D1KP66MT markings are shown in the f ollowing diagrams.

The side with the markings is the communications surface. Mount the RF Tag with this side facing the Antenna.

The ID code is written in the memor y of the R F Tag and may be affected by data retention characteristics at high temperatures. Take suitable precautions when using the READ ID command for RF Tags operating at high temperatures.

RFID System

36

User's Manual

Page 39

• Dimensions

25+0.2

25+0.2

25+0.2

25+0.2

3.5+0.1

Two, M3

Four, R3

Four, R4

32

32

34

34

Mounting Hole Dimensions

Two, 3.5 dia.

Two, 6 dia.

Case material PPS resin

25+0.2

25+0.2

25+0.2

25+0.2

16

4

10

3.5

3737343415

15

Two, M3

Two, 4 dia.

Four, R5.5

Case material PPS resin

V680-D1KP66T/66MT

V600-A86 Attachment

Section 2

Specifications and Performance

Section 2 RF Tags

• RF Tag Heat Resistivity

• Storing RF Tags under high temperatures or heat cycle will adversely affect the performance of the

internal parts and the service life of the RF Tags.

• An LTPD of 10% was determined during the evaluation for RF Tags that reached the end of their life

after testing under the following test conditions.

Heat cycle -10°C/+150°C, 30 minutes each for 1,000 cycles: Defective number 0/22 piece

-100°C/+180°C,30 minutes each for 200 cycles: Defectiv e number 0/22 piece

High temperatures +150°C, 1,000 hours: Defective number 0/22 piece

+180°C, 200 hours: Defective number 0/22 piece

LTPD: Lot tolerance percent defective

The lower limit of the malfunction rate for lots to be considered unacceptable during reliability testing.

RFID System

User's Manual

37

Page 40

Section 2 RF Tags

(Unit: mm)

Section 2

Specifications and Performance

V680-D1KP66T-SP

• General Specifications

Item Model V680-D1KP66T-SP

Memory capacity 1,000 bytes (user area)

Memory type EEPROM

Data Retention 10 years after writing (85°C or less)

Write Endurance 100,000 times per block (25°C)

Ambient operating

temperature when

communicating

Ambient operating

temperature when not

communicating

Ambient storage

temperature

Ambient operating

humidity

Degree of protection IP67

Vibration resistance

Shock resistance 500 m/s

Dimensions 95 × 36.5 × 6.5 mm (excluding protruding parts)

Materials External coatiog: Fluororesin (PFA)

Weight Approx. 20 g

Mounting method Two M5 screws

Metal countermeasures None

-25 to 70°C (with no icing)

-40 to110°C (with no icing)

-40 to 110°C (with no icing)

35% to 95%

10 to 2,000 Hz, 1.5-mm double amplitude, acceleration: 150 m/s

directions for 15 minutes each

2

, 3 times each in X, Y, and Z directions (Total: 18 times)

RF Tag body: PPS resin

2

,10 sweeps each in X, Y, and Z

• Dimensions

Four, R6

3436.5

6.5 2.5 max.

The side with the markings is the communications surface. Mount the RF Tag with this side facing the Antenna.

34

80±0.2

95

Two, 5.5 dia.

(Mounting hole)

1.3

Mounting Hole Dimensions

Two, M5

80±0.2

PFA resinCase material

38

RFID System

User's Manual

Page 41

Specifications and Performance

(Unit: mm)

Case material PPS resin

Mounting Hole Dimensions

20 dia.

M12

M12

4050

11.5

15

110

3.2 dia.

12 dia.

17

2

1

Nuts (M12):

Provided Parts

Split pin (3.2 × 20 mm):

(Unit: mm)

V680-D1KP58HTN

• General Specifications

Item Model V680-D1KP58HTN

Memory capacity 1,000 bytes (user area)

Memory type EEPROM

Data Retention 10 years after writing (85°C or less), 0.5 years after writing (85°C to 125°C)

Total data retention at high temperatures exceeding 125°C is 10 hours

Write Endurance 100,000 times per block (25°C)

Ambient operating

temperature

Ambient storage

temperature

Ambient operating

humidity

Degree of protection IP67 (IEC 60529)

Vibration resistance

Shock resistance 500 m/s

Materials Coatiog: PPS resin

Weight Approx. 70 g

-25 to 85°C (with no icing)

-40 to 250°C (with no icing)

(Data retention: -40 to 125°C)

35% to 95%

Oil resistance equivalent to IP67g according to the former JEM standard.

10 to 2,000 Hz, 1.5-mm double amplitude, acceleration: 150 m/s

directions for 15 minutes each

2

, 3 times each in X, Y, and Z directions (Total: 18 times)

Section 2

2

,10 sweeps each in X, Y, and Z

Section 2 RF Tags

• Dimensions

V680-D1KP58HTN

10±0.2

7.51.25

䋨60 dia.䋩

80 dia.

14 dia.

䋨5°䋩

V680-A80 (Attachment)

This Attachment is specifically designed to secure V680-D1KP58 H TN RF Tags to the workpiece.

Applicable RF Tag model: V680-D1KP58HTN

䋨1.25䋩

䋨5°䋩

18 dia.

Two, R1

RFID System

User's Manual

39

Page 42

Section 2 RF Tags

1 hour

at 2

5°

C

1 hour

at 25°C

3 hours

at 25°C

2 hours

at 25°C

1 hours

at 25°C

3 hours

at 25°C

㪘㪺㪺㫌㫄㫌㫃㪸㫋㪼㪻㩷㫋㫀㫄㪼䋺㩷㪈㩷㪿㫆㫌㫉

㪘㪺㪺㫌㫄㫌㫃㪸㫋㪼㪻㩷㫋㫀㫄㪼䋺㩷㪋㩷㪿㫆㫌㫉㫊

㪮㫉㫀㫋㫀㫅㪾㩷㪻㪸㫋㪸㩷㫋㫆㩷㫋㪿㪼㩷㪩㪝㩷㫋㪸㪾㩷

㫄㪼㫄㫆㫉㫐㩷㫀㫅㩷㫌㫊㪼㪅

Reset the data

retention time.

Leaving time other than high temperature environment

is not included in the cumulative time used.

*1.

*1. High temperatures are those exceeding 125°C up to 250°C.

Reset the data

retention time.

Fig. Concept of resetting the data retention time

1 hour at high

temperatures

*1.

3 hours at high

temperatures

2 hours at high

temperatures

*1. *1.

3 hours at high

temperatures

2 hours at high

temperatures

*1.

㪘㪺㪺㫌㫄㫌㫃㪸㫋㪼㪻㩷㫋㫀㫄㪼䋺㩷㪍㩷㪿㫆㫌㫉㫊

㪘㪺㪺㫌㫄㫌㫃㪸㫋㪼㪻㩷㫋㫀㫄㪼䋺㩷㪐㩷㪿㫆㫌㫉㫊

㪘㪺㪺㫌㫄㫌㫃㪸㫋㪼㪻㩷㫋㫀㫄㪼䋺㩷㪋㩷㪿㫆㫌㫉㫊

Section 2

Specifications and Performance

Use at high temperatures (V680-D1KP58HTN)

Data retention

• Data stored in memory in the RF Tag may be lost due to the characteristics of EEPROM, if the accumulated usage time of the RF Tag at a high temperature over 1 25

the RF Tag. Reset the data retention time before the accumulated usage time ex ceeds 10 hours.

• An error in communications between the Antenna and the RF Tag may occur in an environment where

the ambient operating temperature is 85

°

C or higher. Do not communicate between the Antenna and

the RF Tag in an environment where the ambient operating temperature is 85

• The UID (unique identification number for each RF Tag) may be lost due to the characteristics of

EEPROM when the RF tag is used at a high temperature over 125°C. Do not use the commands

using UID at a high temperature over 125°C.

•Do not use the READ ID command (command code: ID).

•Do not make the UID Addition Setting (command code: US).

•Communications specifications (FIFO trigger, FIFO repeat, multi-access trigger, multi-access repeat,

and selective) can not be used.

• Accumulated time

°

C exceeds 10 hours af te r writing data to

°

C or higher.

40

• Resetting the data retention time

<When using the RF Tag addresses 0010Hex to 0015Hex.>

1.Reading data from the RF tag addresses 0010Hex to 0015Hex.

Command : RDSTH100100006*[CR]

Reseponse : RD0010001122334455*[CR]

2.Read data written to the RF tag addresses 0010Hex to

0015Hex..

Command : WTSTH10010001122334455*[CR]

RFID System

User's Manual

Reseponse : WT0010*[CR]

Data retention is reset only data written to the RF tag address.

If you reset the data retention, writes the same data to all of the tag memory in use.

<RF tag memory>

Hex

0010

Hex

0011

Hex

0012

Hex

0013

Hex

0014

Hex

0015

Read data written to the RF

tag memory in use.

Hex

00

Hex

11

Hex

22

Hex

33

Hex

44

Hex

55

Reading data from the RF

tag memory in use.

<RF tag memory>

Hex

Hex

Hex

Hex

Hex

Hex

00

11

22

33

44

55

Hex

Hex

Hex

Hex

Hex

Hex

0010

0011

0012

0013

0014

0015

Page 43

Section 2

Specifications and Performance

Heat Resistance

Storing RF Tags under high temperatures or heat cycle will adversely affect the performance of the

internal parts and the service life of the RF Tags.

Correct operation has been confirmed through the OMRON in-house evaluation for RF Tags under the

following high-te mperature conditions.

1) 2,000 cycles, where 1 cycle is each 30-minute at Room temperature and 200°C

2) 250°C, 500 hours

The controller’s setting

Please set the latest ID controller to the CA1D mode and use it when the latest ID controller is used

together with the old model ID controller Model V680-CA1D/- CA2D.

Section 2 RF Tags

RF Tag

Controller

V680-CA1D/-CA2D only Not required Not required Not required

C680-CA1D/-CA2D and the latest

ID controller used together

The latest ID controller only Not required Not required Not required

Note: The latest ID controller:

V680-CA5D01-V2/-CA5D02-V2

V680-CH1D/CHUD/-CH1D-PSI

CS1W-V680C11/-V680C12

CJ1W-V680C11/-V680C12

V680-D1KP58HT only

Not required Set the latest ID controller to

V680-D1KP58HT and V680-

D1KP58HTN used together

the CA1D mode.

V680-D1KP58HTN only

Set the latest ID controller to

the CA1D mode.

RFID System

User's Manual

41

Page 44

Section 2

Specifications and Performance

Memory Map

Section 2 RF Tags

Address

Data

0000 H

0001 H

0002

0003 H

03E6

H

User area

H

03E7 H

1 byte

EEPROM is used as memory in the RF Tags.

The memory capacity availab l e to t he use r is 1, 000 bytes, including 0000H to 0003 H (t he Write Protection Setting Area).

The access to the memory is executed at every block.

1 block is 8 bytes (8 addresses).

The communication between RF Tag and the antenna of the V680 series is a block unit (8bytes).

There is a possibility to which data is mistaken with the block unit when the writing error occurs.

42

RFID System

User's Manual

Page 45

Section 2

Specifications and Performance

Write Protection Function

The write protection function prevents important data, such as product information, stored in memory

in a RF Tag from being inadvertently overwritten.

After important data has been written to memory, it can be write-protected using the following method.

The write protection function can be switched with SW4-7 (Write Protection Function Setting) of the V680-CA5D@@-V@

Controller or with word (Write Protection Function Setting) in the DM(m+2)CH Area words allocated to the C@1W-

V680C@@ ID Sensor Unit.

Refer to the V680 Series User’s Manual (Cat. No. Z249) for details.

Setting the Write Protection Function

Write protection is set in RF Tag addresses 0000H to 0003H.

The setting for the most significant bit of address 0000H specifies whether or not write protection is enabled.

Address Bit 7 6 5 4 3 2 1 0

H

0000

H Lower two digits of start address (00H to FFH)

0001

H Upper two digits of end address (00H to FFH)

0002

0003

H Lower two digits of end address (00H to FFH)

• Write-protect Bit (Most significant bit of address 0000H)

1: Write-protected (Yes)

0: Not write-protected (No)

YES/

Upper two digits of start address (00H to 7FH)

NO

Section 2 RF Tags

• Write Protection Setting Area

Start address: 0000

H to 7FFFH

End address: 0000H to FFFFH

RFID System

User's Manual

43

Page 46

Section 2 RF Tags

Section 2

Specifications and Performance

Write Protection Setting Examples

• Settings to write-protect addresses 0008H through 03E7H:

Address Bit 7 6 5 4 3 2 1 0

0000

H

H

0001

H

0002

0003

H

• Settings to not write-protect any addresses:

Address Bit 7 6 5 4 3 2 1 0

0000

H

0001

H

0002

H

0003

H

10000000

80

00001000

08

00000011

03

11100111

E7

00000000

00

00000000

00

00000000

00

00000000

00

The write protection function is a function of the V680-CA5D@@-V@ Controller and the C@1W-V680C@@ ID Sensor

Unit. It is not supported by reader/writer units from other manufacturers.

44

RFID System

User's Manual

Page 47

Section 3 Communications Specifications

Communications Distances 46

Communication Time (Reference) 60

Section 3 Communications Specifications

RFID System

User's Manual

45

Page 48

Section 3

V680-HS52

Metal

V680-HS63

V680-HS52

Non-metallic material

(Exmamples: Resin, plastic, wood, etc.)

Non-metallic material

Metal

V680-HS51 V680-HS51

V680-D1KP52MT

Metal

Non-metallic materialNon-metallic material

Metal

V680-D1KP52MT

Non-metallic material

(Exmamples: Resin, plastic, wood, etc.)

Non-metallic material

(Exmamples: Resin, plastic, wood, etc.)

Communications

distance

Communications

distance

Communications

distance

Communications

distance

Communications

distance

V680-D1KP52MT

V680-D1KP52MT

V680-D1KP52MT

Communications Specifications

Communications Distances

V680-D1KP52MT

Communications Distance Specifications (Guaranteed)

Amplifier Antenna RF Tag Communications distance

V680-HS51 V680-D1KP52MT

V680-HS51

V680-D1KP52MT

embedded in metal (steel)

Section 3 Communications Distances

V680-HA63A

When embedding the V680-D1KP52MT into a metal surface, use the V680-HS51, V680-HS52 Antenna.

Transmission will not be possible if the V680-HS63 Antenna is used.

V680-HS52 V680-D1KP52MT

V680-HS52

V680-HS63 V680-D1KP52MT

V680-D1KP52MT

embedded in metal (steel)

Read 0.5 to 6.5 mm (Axis offset: ±2 mm)

Write 0.5 to 6.0 mm (Axis offset: ±2 mm)

Read 0.5 to 3.5 mm (Axis offset: ±2 mm)

Write 0.5 to 3.0 mm (Axis offset: ±2 mm)

Read 0 to 9.0 mm (Axis offset: ±2 mm)

Write 0 to 8.5 mm (Axis offset: ±2 mm)

Read 0 to 4.5 mm (Axis offset: ±2 mm)

Write 0 to 4.0 mm (Axis offset: ±2 mm)

Read 0 to 12.0 mm (Axis offset: ±2 mm)

Write 0 to 9.5 mm (Axis offset: ±2 mm)

• Measurement Conditions

RFID System

46

User's Manual

Page 49

Section 3

20

30

10

Y

-40 -30 -20 -10 10 20 30 X0

20

30

10

Y

-40 -30 -20 -10 10 20 30 X0

20

30

10

Y

-40 -30 -20 -10 10 20 30 X0

20

30

10

Y

-40 -30 -20 -10 10 20 30 X0

20

30

10

Y

-40 -30 -20 -10 10 20 30 X0

Read

Write

(Embedded in Metal: Steel)

V680-HS51䋨Embedded in Metal䋩 and V680-D1KP52MT V680-HS51䋨Embedded in Metal䋩 and V680-D1KP52MT

(Embedded in Metal: Steel)

V680-HS52䋨Embedded in Non-Metal䋩 and V680-D1KP52MT V680-HS52䋨Embedded in Non-Metal䋩 and V680-D1KP52MT

V680-HS63䋨with Non-Metal on Back Surface䋩 and V680-D1KP52MT

Read

Write

Read

Write

Read

Write

Read

Write

Communications Specifications

Communications Area (Reference)

The communications areas given here are for reference only. For information on communications distances, refer

to p.46.

The communications area depends on the type of RF Tags used, the ambient temperature, surrounding metals,

and noise. Be sure to check carefully when installing the system.

Section 3 Communications Distances

RFID System

User's Manual

47

Page 50

Section 3

V680-HS51

V680-D1KP52M-BT01

Metallic material

V680-HS52

Non-metallic material

V680-D1KP52M-BT01

V680-HS51

V680-D1KP52M-BT11

Metallic material

V680-HS52

Non-metallic material

V680-D1KP52M-BT11

Metallic material/Non-metallic material

Metallic material/Non-metallic material

Metallic material/Non-metallic material

Metallic material/Non-metallic material

Communications

distance

Communications

distance

Communications

distance

Communications

distance

Communications Specifications

V680-D1KP52M-BT01/-D1KP52M-BT11

Communications Distance Specifications (Guaranteed)

Amplifier Antenna RF Tag Communications distance

V680-HS51 V680-D1KP52M-BT01/-D1KP52M-BT11

V680-HA63A

V680-HS52 V680-D1KP52M-BT01/-D1KP52M-BT11

Read 0.5 to 2.5 mm (Axis offset: ±2 mm)

Write 0.5 to 2.0 mm (Axis offset: ±2 mm)

Read 0 to 3.0 mm (Axis offset: ±2 mm)

Write 0 to 2.5 mm (Axis offset: ±2 mm)

Section 3 Communications Distances

• Measurement Conditions

Communications Area (Reference)

The communications areas given here are for reference only. For information on communications distances, refer

to p.46.

The communications area depends on the type of RF Tags used, the ambient temperature, surrounding metals,

and noise. Be sure to check carefully when installing the system.